Dry soil fine grinding and screening device for analyzing soil in contaminated area

A polluted area, fine pulverization technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of poor pulverization effect, no screening device, affecting analysis results, etc., to improve the pulverization effect and improve the effect. , the effect of reducing work stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

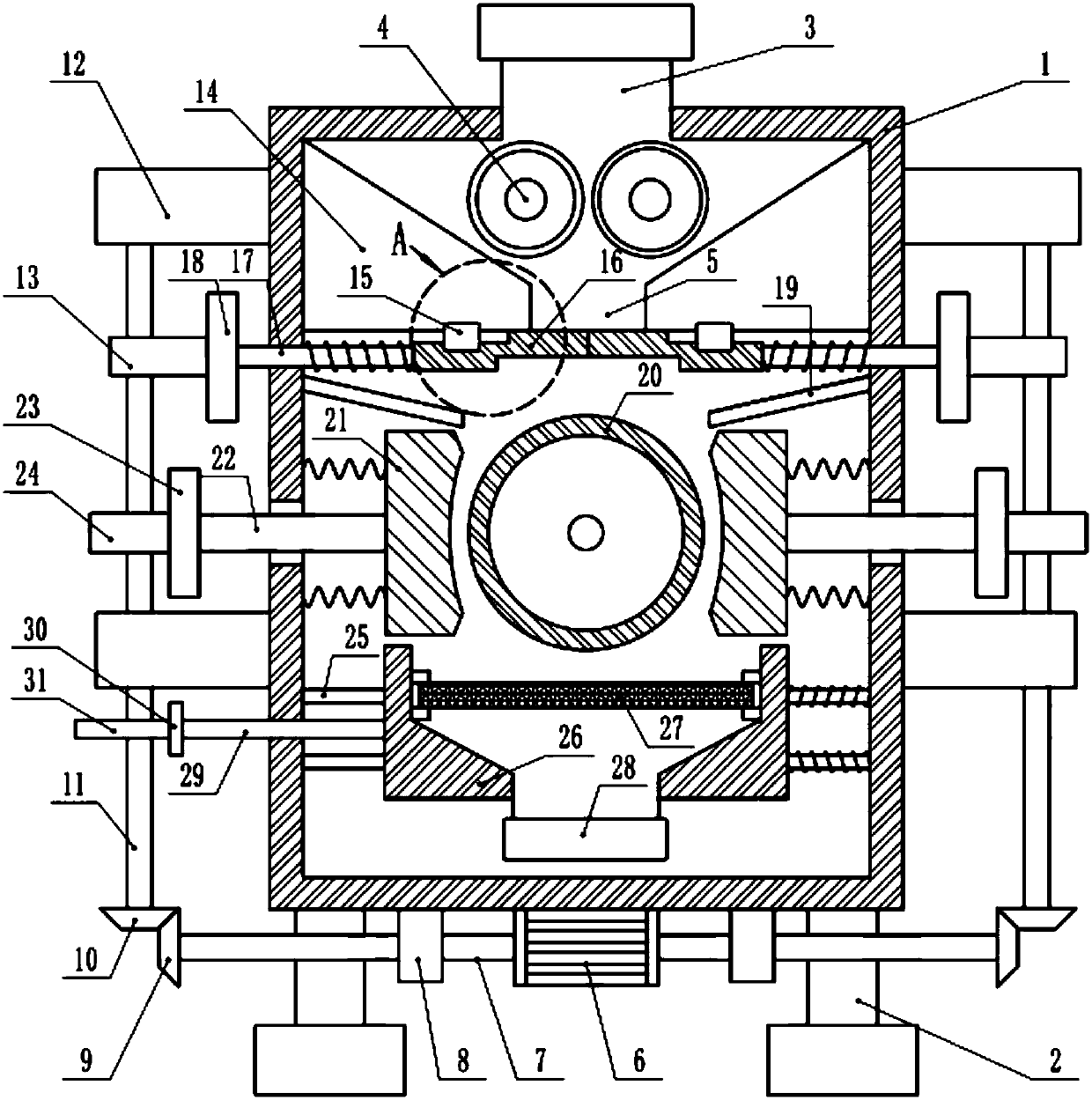

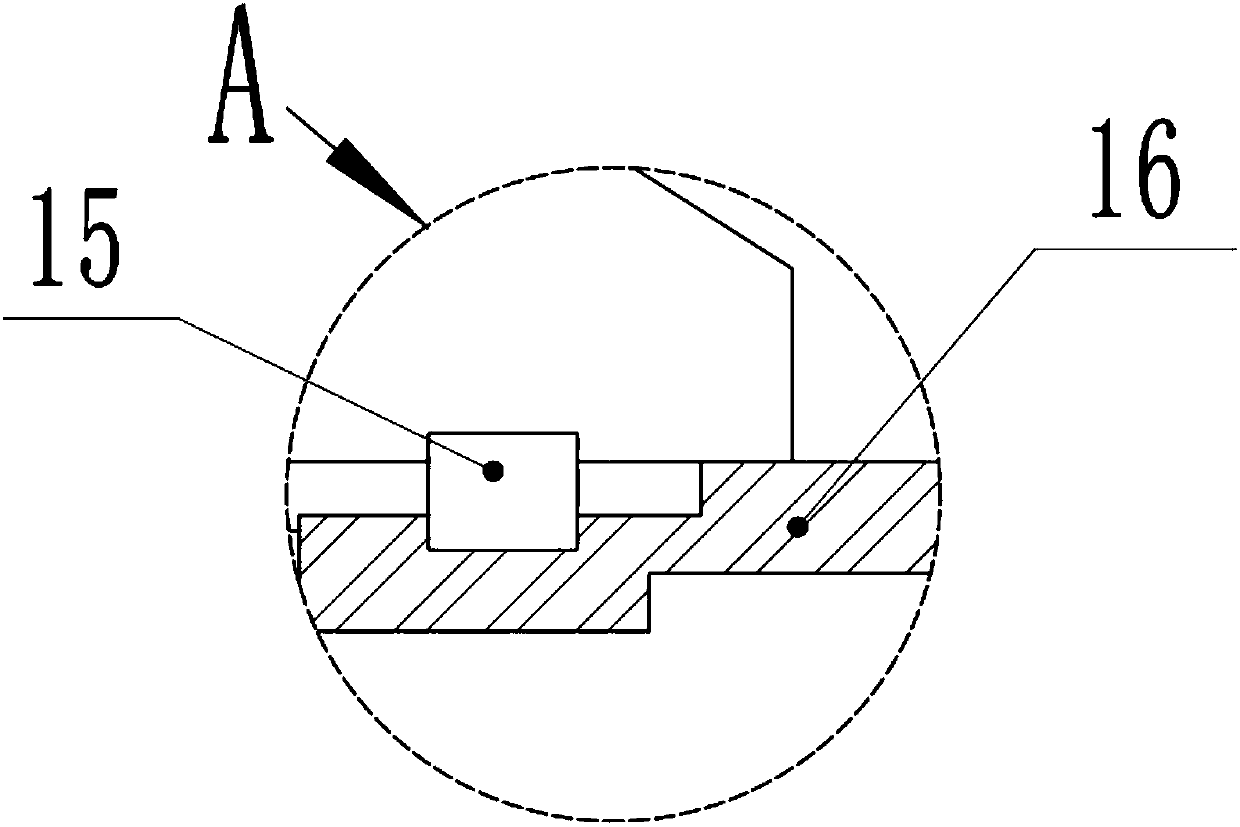

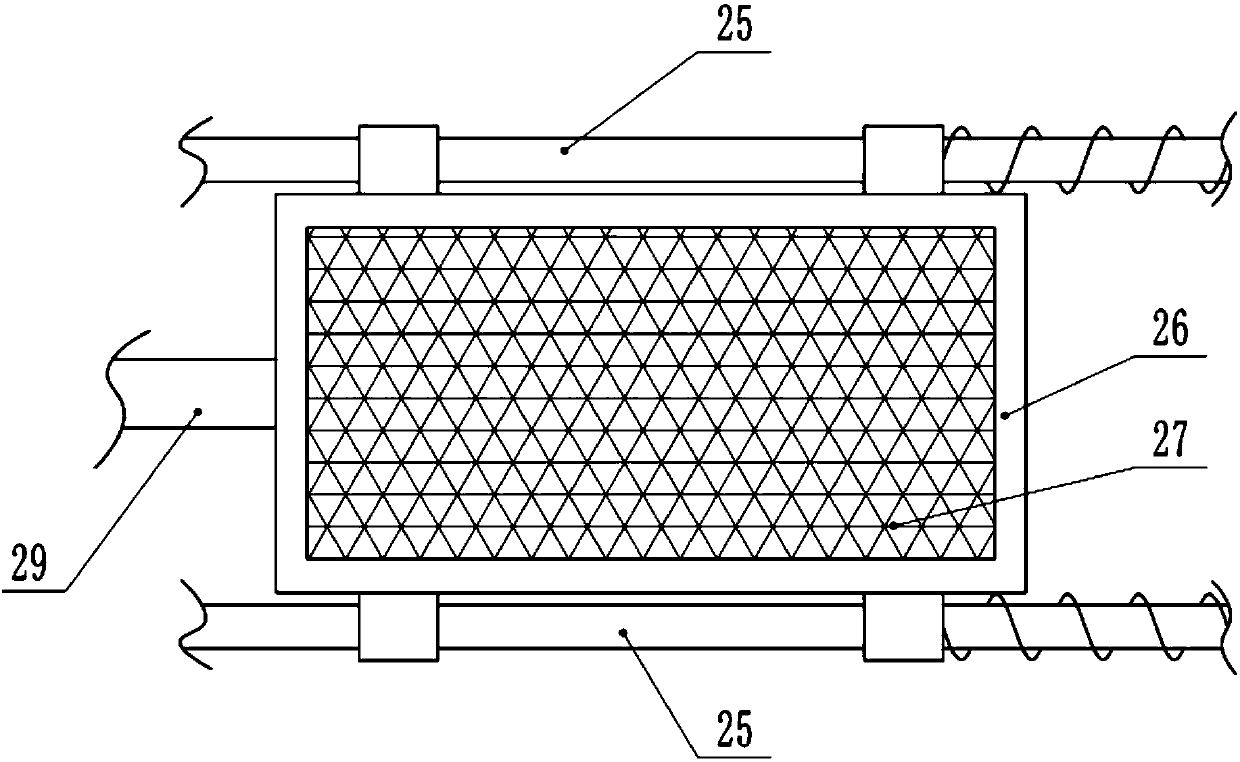

[0020] see Figure 1-3 , a dry soil fine crushing and screening device for soil analysis in a polluted area, comprising a device cabinet 1, a preliminary crushing roller 4, a biaxial motor 6, a first cam 13, a sealing partition 16, a fine crushing roller 20 and a screening box 26 The lower side of the device chassis 1 is welded with at least two sets of legs 2, and the center position of the upper side of the device chassis 1 is provided with a feed port 3, the feed port 3 is circular and a sealing cover is installed on the feed port 3, the described There are two sets of preliminary crushing rollers 4 installed inside the device cabinet 1. The preliminary crushing rollers 4 are located below the feed port 3. The preliminary crushing rollers 4 are driven by an external drive device (not shown in the figure). Between the two groups of preliminary cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com