Steel slag treating technology

A technology for processing steel slag, which is applied in the field of steel slag processing and processing, can solve the problems of unfavorable subsequent use of products, large floor space, and substandard pollution, etc., and achieve favorable follow-up use, small floor space, and advanced and reasonable equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

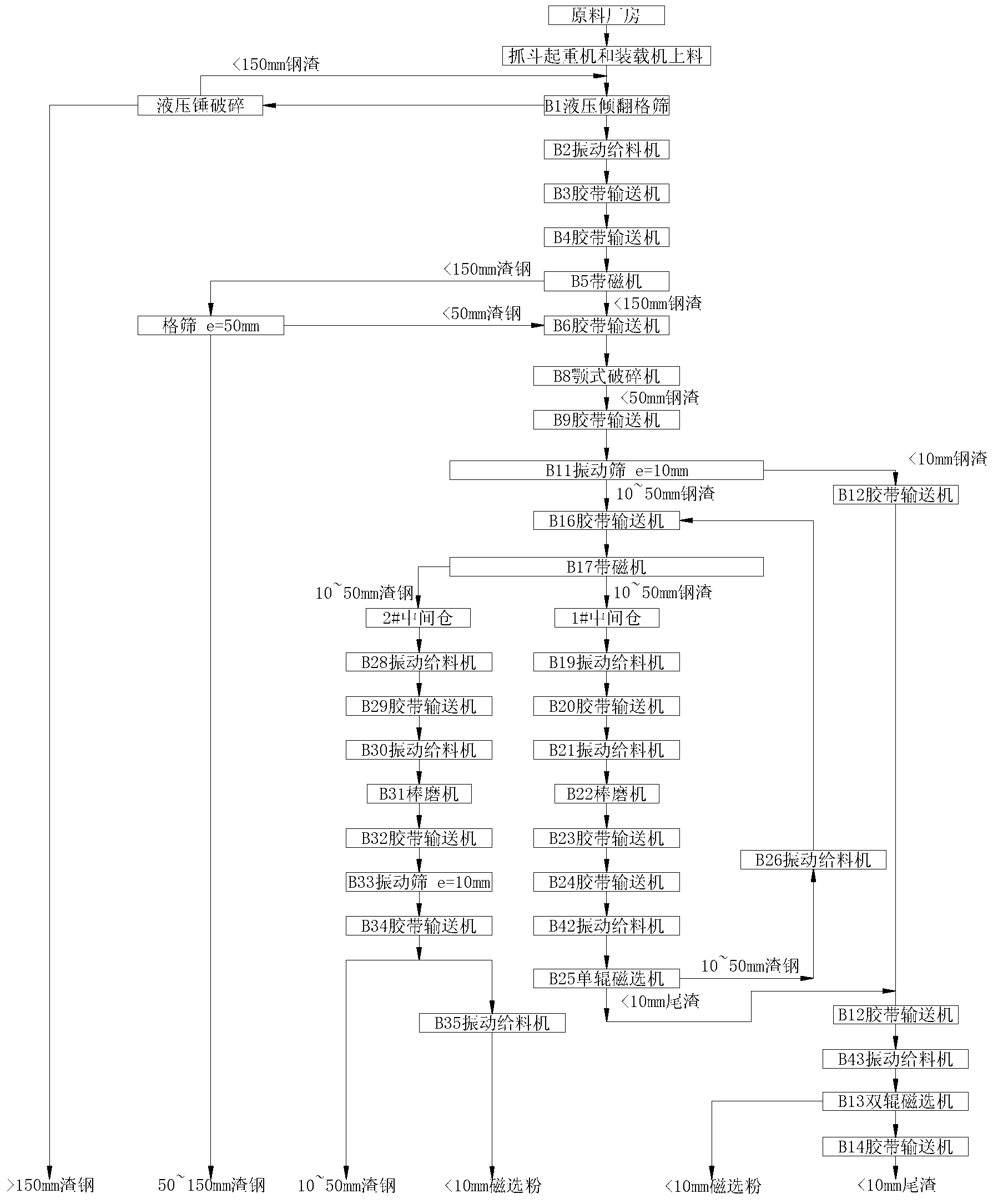

[0040] Now take the 400,000 tons / year steel slag processing and treatment production line of a steel factory as an example to illustrate this process:

[0041] The stuffy steel slag is stored in the raw material workshop, which can be stored for about 4 days. The aged steel slag is loaded to the B1 hydraulic tilting grid sieve (150mm×150mm) by the grab crane and wheel loader. Into the silo, the screened material is the bulk material produced when the steelmaking is running out of steel or hot stuffy treatment is abnormal, the steelmaking running steel is > 150mm slag steel, returned to steelmaking for use, and the big chunks produced when the hot stuffy treatment is abnormal The steel slag is broken by the hydraulic breaker and then returned to the B1 hydraulic tilting grid. The underscreen material enters the B3 belt conveyor through the B2 vibrating feeder under the silo, and then transfers to the B4 belt conveyor. The B5 belt magnetic machine is suspended above the B4 belt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com