Patents

Literature

996 results about "Steel mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steel mill or steelworks is an industrial plant for the manufacture of steel. It may be an integrated steel works carrying out all steps of steelmaking from smelting iron ore to rolled product, but may also describe plants where steel semi-finished casting products (blooms, ingots, slabs, billets) are made, from molten pig iron or from scrap.

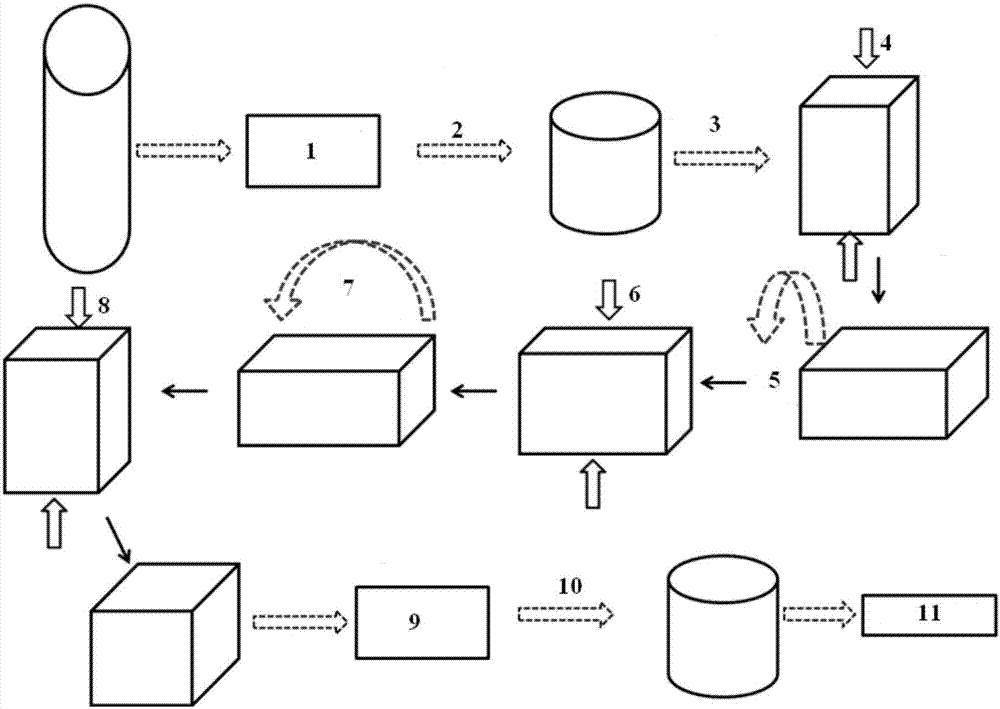

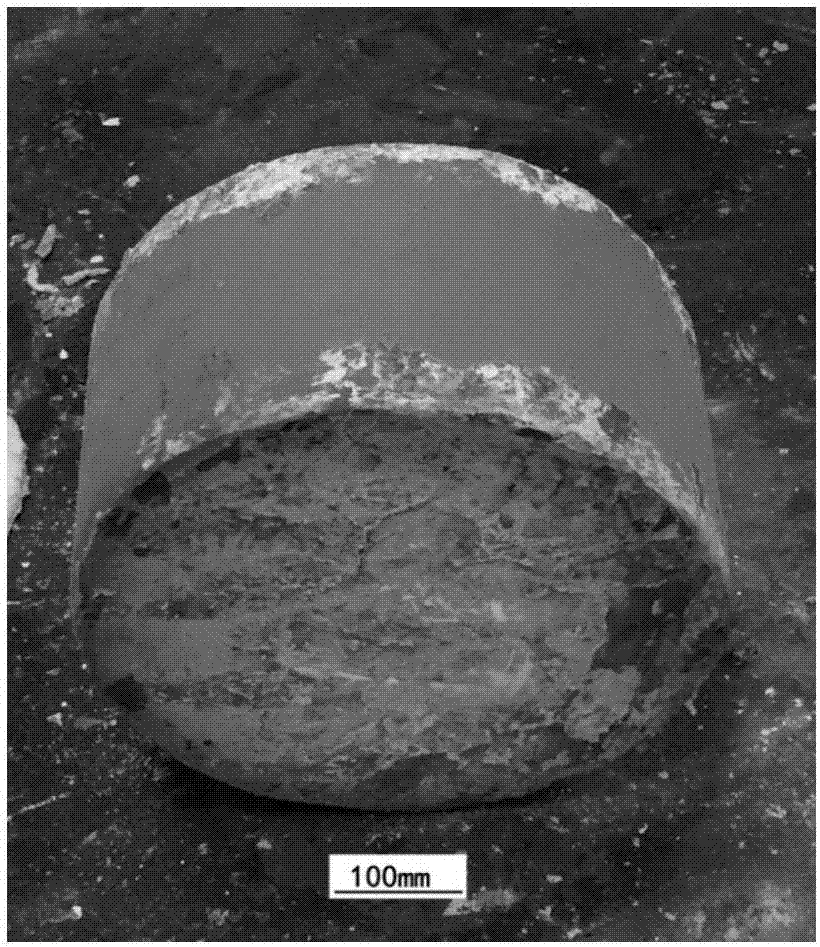

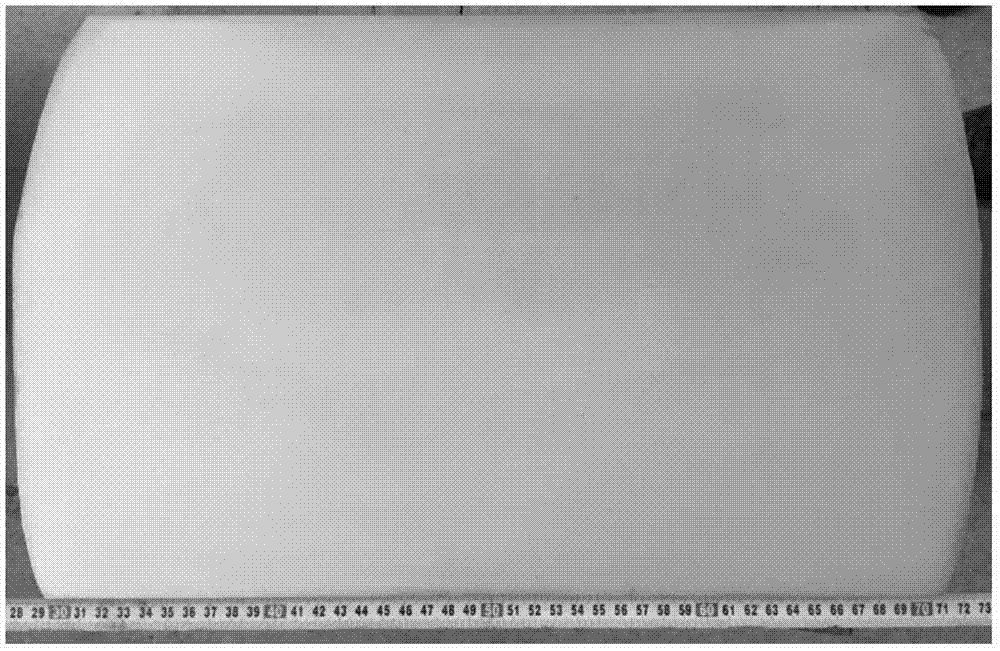

Multidirectional forging method for high-alloyed high-temperature alloy sheared billet/biscuit

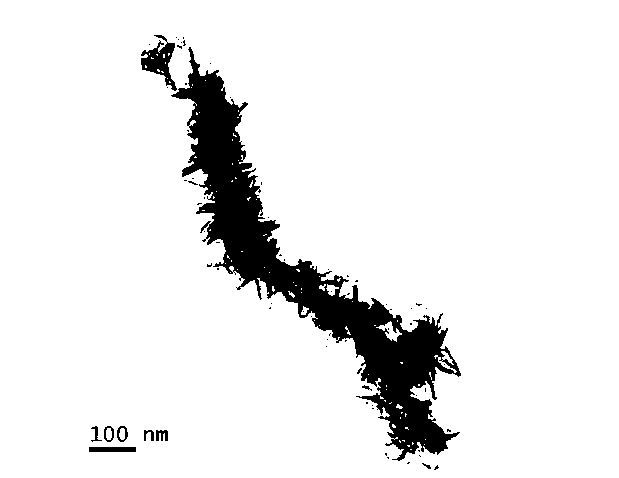

ActiveCN106862447AAccurately measure uniformityGuaranteed uniformityMetal-working apparatusFine structureUltra fine

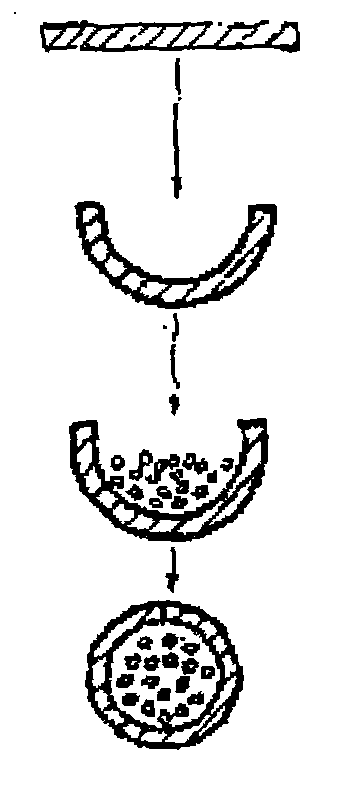

The invention relates to a forging method, in particular to a multidirectional forging method for obtaining a high-alloyed high-temperature alloy sheared billet / biscuit with the uniform and fine structure. The multidirectional forging method includes the following steps that (1) high-temperature homogenizing treatment is conducted on a low-segregation and high-purity controlled directional solidification ingot blank; (2) the controlled directional solidification ingot blank is subjected to upsetting and cogging; (3) the upset blank is forged into a cuboid blank; (4) multidirectional forging is conducted on the cuboid blank; (5) the blank subjected to multidirectional forging for multiple cycles is subjected to finishing, so that a shear billet / biscuit of the required size is obtained; and (6) the obtained shear billet / biscuit is subjected to physical and chemical testing. The multidirectional forging method is not only suitable for preparation of uniform and ultra-fine-grain high-alloyed nickel-based high-temperature alloy sheared billets for aviation, spaceflight and vessels, but also can be popularized to a steel mill to product high-speed steel and hot-working die steel, and the prepared ultra-fine-grain shear billets have the characteristic of uniform structure.

Owner:CENT IRON & STEEL RES INST

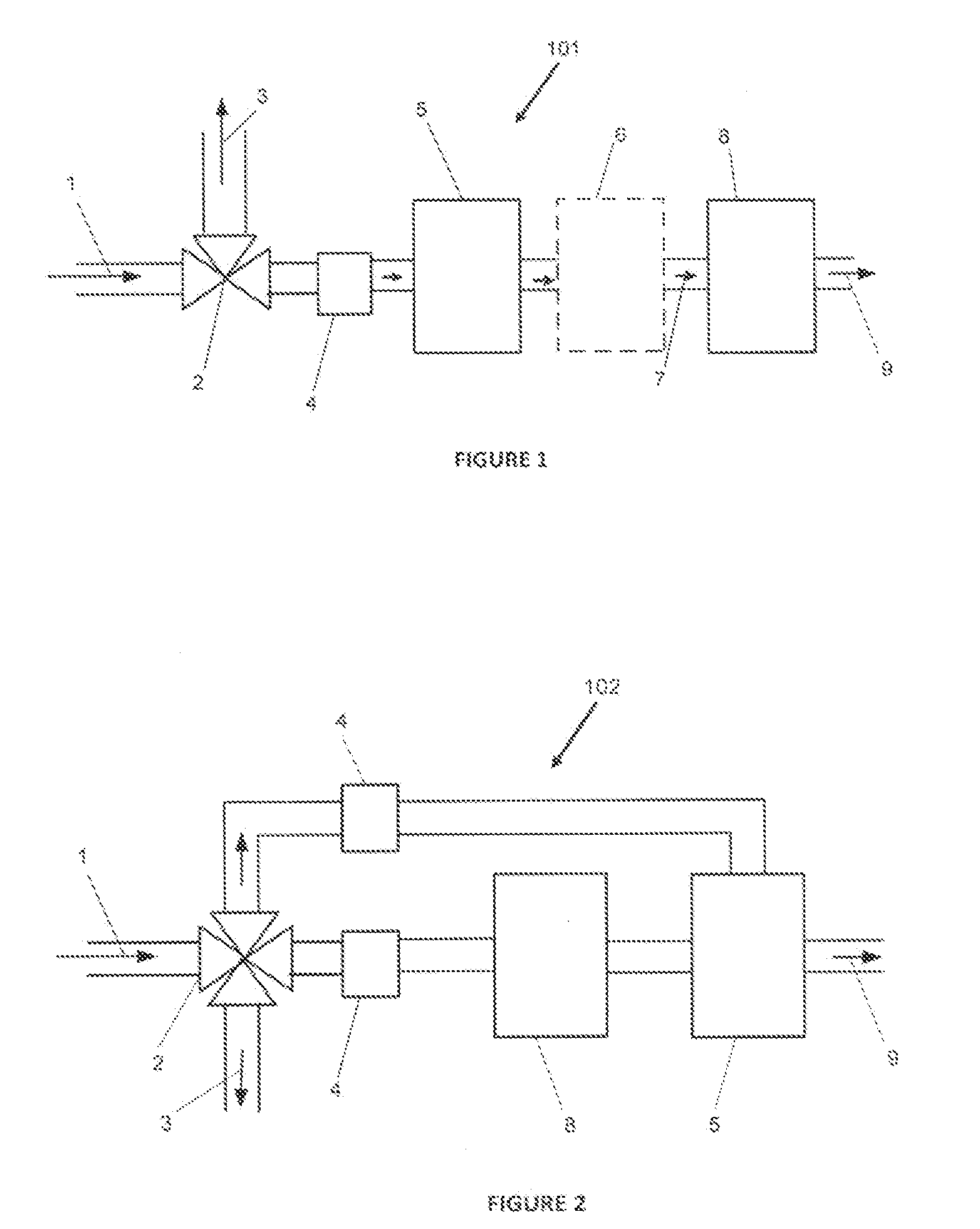

Carbon capture in fermentation

ActiveUS20100323417A1Improve processing efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismAlcohol

The invention relates to methods of capturing carbon by microbial fermentation of a gaseous substrate comprising CO. The methods of the invention include converting CO to one or more products including alcohols and / or acids and optionally capturing CO2 to improve overall carbon capture. In certain aspects, the invention relates to processes for producing alcohols, particularly ethanol, from industrial waste streams, particularly steel mill off-gas.

Owner:LANZATECH NZ INC

Steel mill continuous annealing galvanized sheet chromium-free compound passivator and preparation method thereof

InactiveCN103834938AImprove corrosion resistanceExcellent coating adhesion performanceAnti-corrosive paintsMetallic material coating processesChromium freeEnvironmental resistance

The invention discloses a steel mill continuous annealing galvanized sheet chromium-free compound passivator which comprises the following raw materials in percentage by weight: 5-20 percent by weight of a main film-forming agent, 0.1-5 percent by weight of a coupling agent, 0.1-0.5 percent by weight of inorganic complex film-forming agent, 0.1-4 percent by weight of silicate, 0.1-0.4 percent of an emulsifying agent, 0.1-0.2 percent of a dispersing agent, 0.1-0.4 percent of a corrosion inhibitor, 0.1-0.3 percent of a protective colloid, 0.1-1 percent of a nanometer sealing agent, 0.1-0.4 percent of phosphate and the balance of water. The steel mill continuous annealing galvanized sheet chromium-free compound passivator disclosed by the invention is uniform in appearance, stabilizes a liquid, has an expiration date of above 90 days, is nontoxic and environment-friendly, and accords with the ROHS (Restriction Of Hazardous Substances) requirement. The steel mill continuous annealing galvanized sheet chromium-free compound passivator is simple in preparation process; a passivated film is uniform in appearance and has certain glossness. A galvanized sheet passivated by using the passivator has the advantages that the corrosion resistance is remarkably improved, the neutral salt mist SST (Sea Surface Temperature) resistant time reaches above 72 hours, the white rust area is less than 5 percent, the blackening resistance delta E is less than 5, the yellowing resistance delta E is less than 3, the alkaline resistance delta E is less than 3, the interlamination resistance R is less than 3 omega / cm, and the conductivity is less than 1 m Omega.

Owner:NORTHEASTERN UNIV

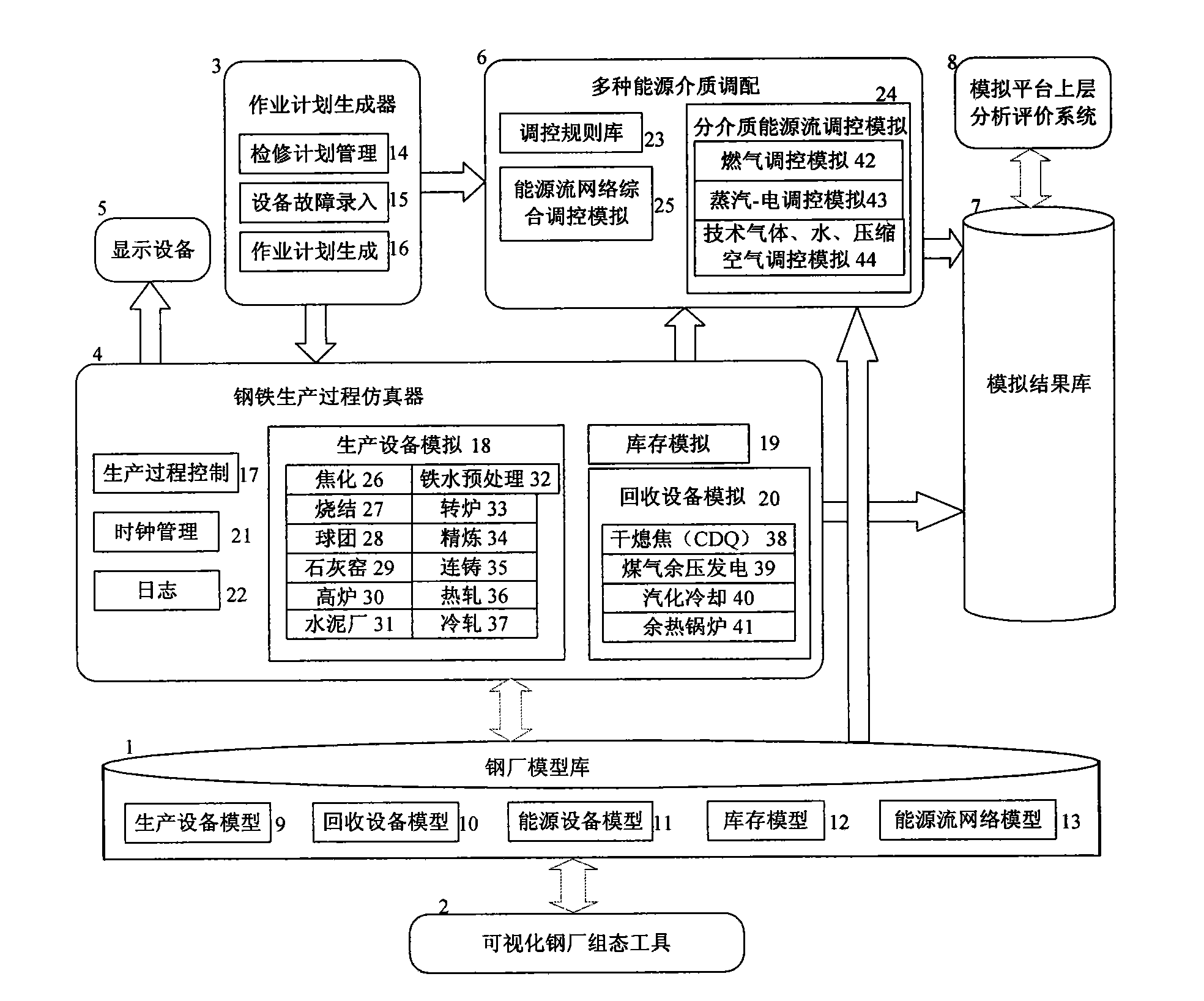

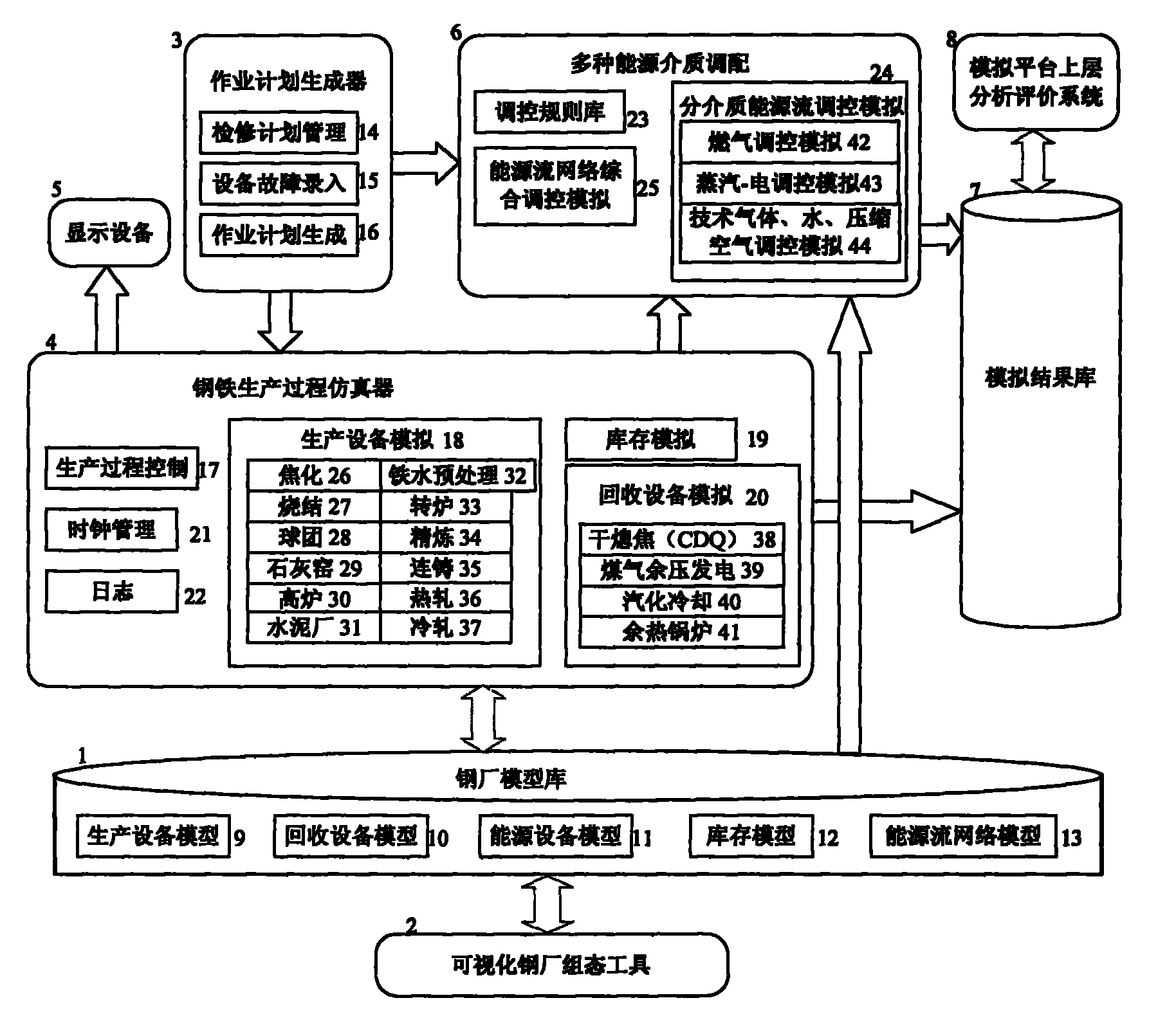

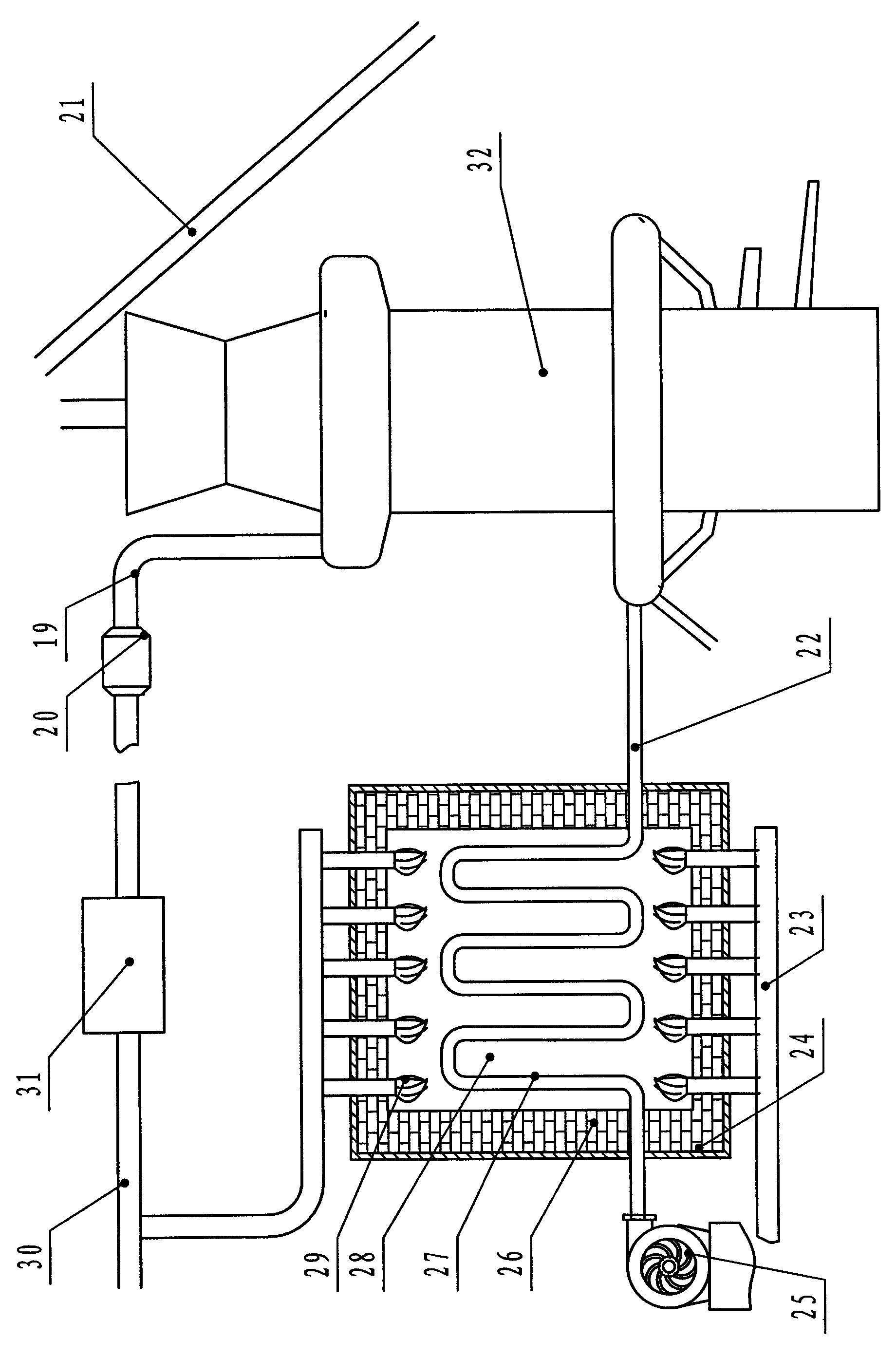

Computer-based iron and steel enterprise energy simulation platform

InactiveCN101980262AConsumption responseConvenient researchTechnology managementResourcesEvaluation systemSteel mill

The invention discloses a computer-based iron and steel enterprise energy simulation platform and belongs to the technical field of metallurgical energy simulation. The energy simulation platform comprises a steel mill model library, a visual steel mill configuration tool, an iron and steel production process simulator, display equipment, various energy medium mixers, a simulated result library and a simulation platform upper analysis and evaluation system, wherein the visual steel mill configuration tool is connected with the steel mill model library; the iron and steel production process simulator is connected with the steel mill model library and an operation plan generator, stimulates the production process and outputs results to the various energy medium mixers and the display equipment; and the simulated result library saves the simulated and regulated result and provides input for the simulation platform upper analysis and evaluation system. The computer-based iron and steel enterprise energy simulation platform has the advantages that: a transaction sign in an equipment model can analyze and evaluate the iron and steel enterprise energy situation under different conditions; a recovery plant independently constructs a model, and the research on a recovery scheme and efficiency is facilitated; and the tightly coupled energy medium forms three subsystems according to the correlation degree, and the solving is facilitated by a hierarchical coordination method.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND +1

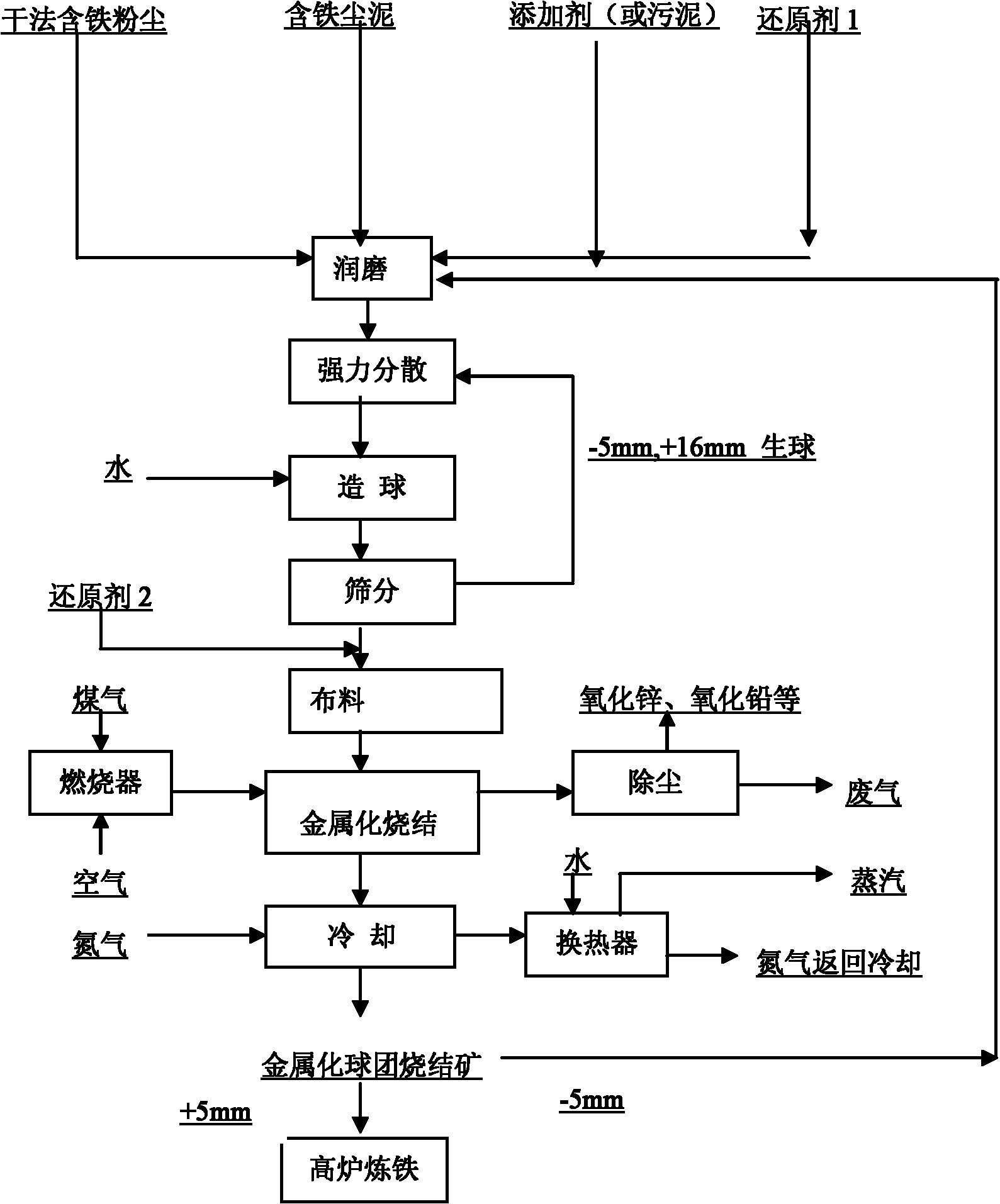

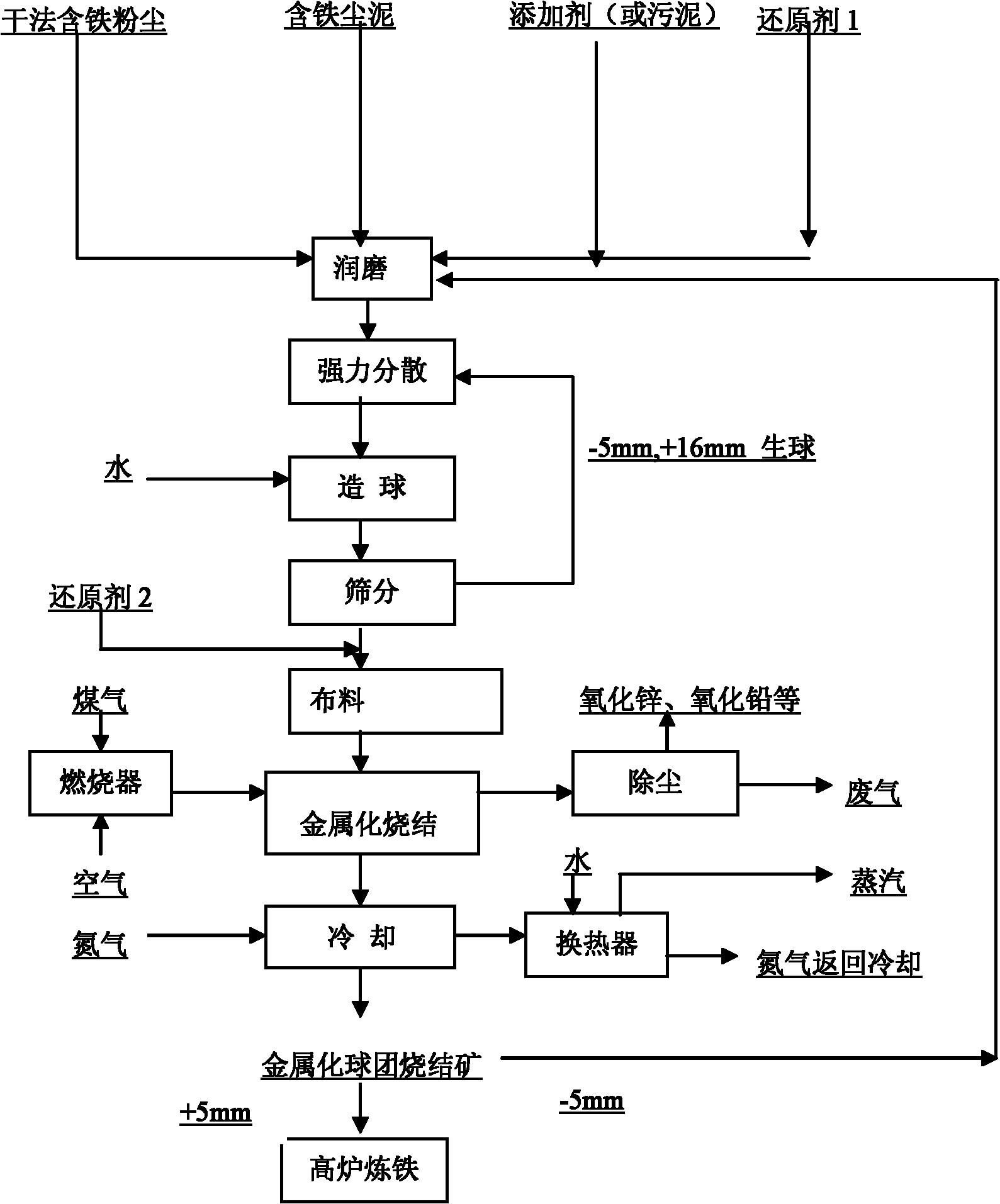

Comprehensive utilization process of zinc-containing iron dust

ActiveCN102534199ASimple processAdvanced technical indicatorsProcess efficiency improvementSludgeNitrogen gas

The invention relates to a comprehensive utilization process of zinc-containing iron dust. The process comprises the steps of: uniformly mixing iron-containing dust mud, iron-containing dust, carbon-containing sludge, pyrite residue, first reducing coal and an additive, and carrying out moist grinding, pelletizing and screening to obtain qualified raw pellets; and then uniformly mixing the raw pellets with second reducing coal, carrying out downdraught drying and reduction roasting on a pellet sinter roasting machine to finish sintering of metallized pellets, carrying out nitrogen cooling to room temperature, and discharging to obtain the metallized pellet sintered ore. According to the invention, the process method is simple and convenient for operation; aiming at the characteristics of the zinc-containing iron dust in steel mill, high-efficiency utilization of iron, zinc, carbon and other valuable elements is realized by pelletizing and metallized roasting, and at the same time, harmful elements are removed and secondary pollution is eliminated; at the same time of removing the harmful elements, the zinc-containing iron dust is prepared into metallized pellet sintered blocks, and iron has high grade and low content of zinc, sulfur and other harmful elements, and can be used as a high-quality raw material to be directly entered into a blast furnace for smelting, therefore, the comprehensive utilization process plays an effect of reducing coke and increasing yield on the blast furnace and has significant economic benefits.

Owner:CENT SOUTH UNIV +1

Tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and preparation method thereof

The invention relates to a tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and a preparation method thereof. The technical scheme is as follows: mixing 50-80wt% of the waste magnesia carbon bricks, 10-40wt% of fused magnesia or sintered magnesia fine powder, 3-8wt% of binding agent and 0.5-5wt% of additive, evenly stirring, carrying out vibration moulding, baking under the temperature of 200-400 DEG C, and demoulding to obtain the tundish dry type vibration material, wherein the MgO content in the waste magnesia carbon bricks are no less than 70wt%. The invention has the characteristics of simple process, low cost and energy conservation, is environmental friendly, and is convenient in construction. As for the tundish dry type vibration material, the main chemical components are MgO and C, the main crystalline phases are periclase and graphite, the continuous casting rate is high, the metallurgical effect is favorable, and the disassembly is easy after use. The tundish dry type vibration material is mainly applicable to continuous casting of tundish linings. The invention provides a new way for recycling the waste magnesia carbon bricks of a steel mill, and has important significances on energy conservation, consumption reduction and environment protection.

Owner:WUHAN UNIV OF SCI & TECH

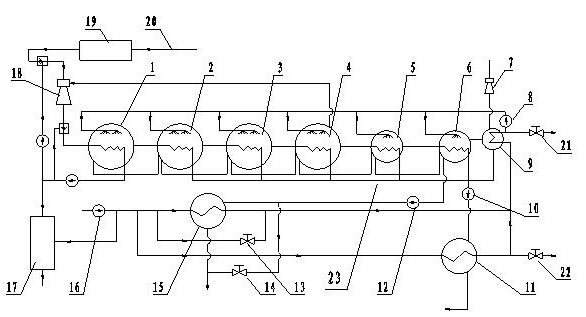

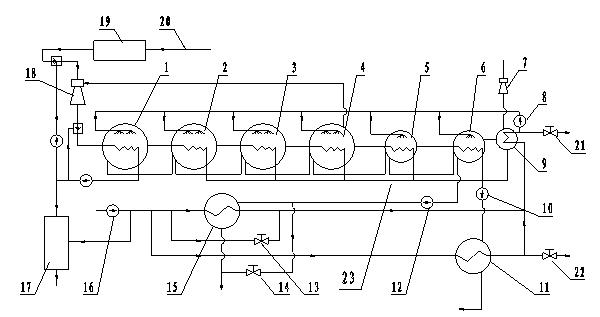

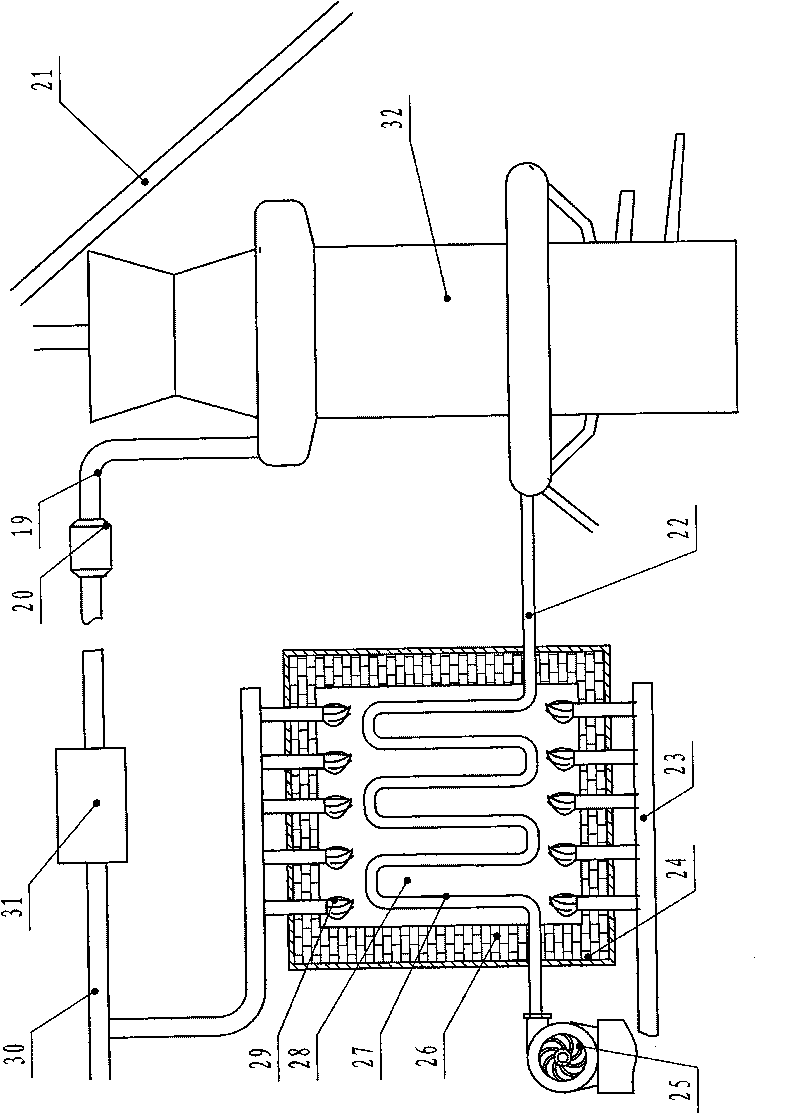

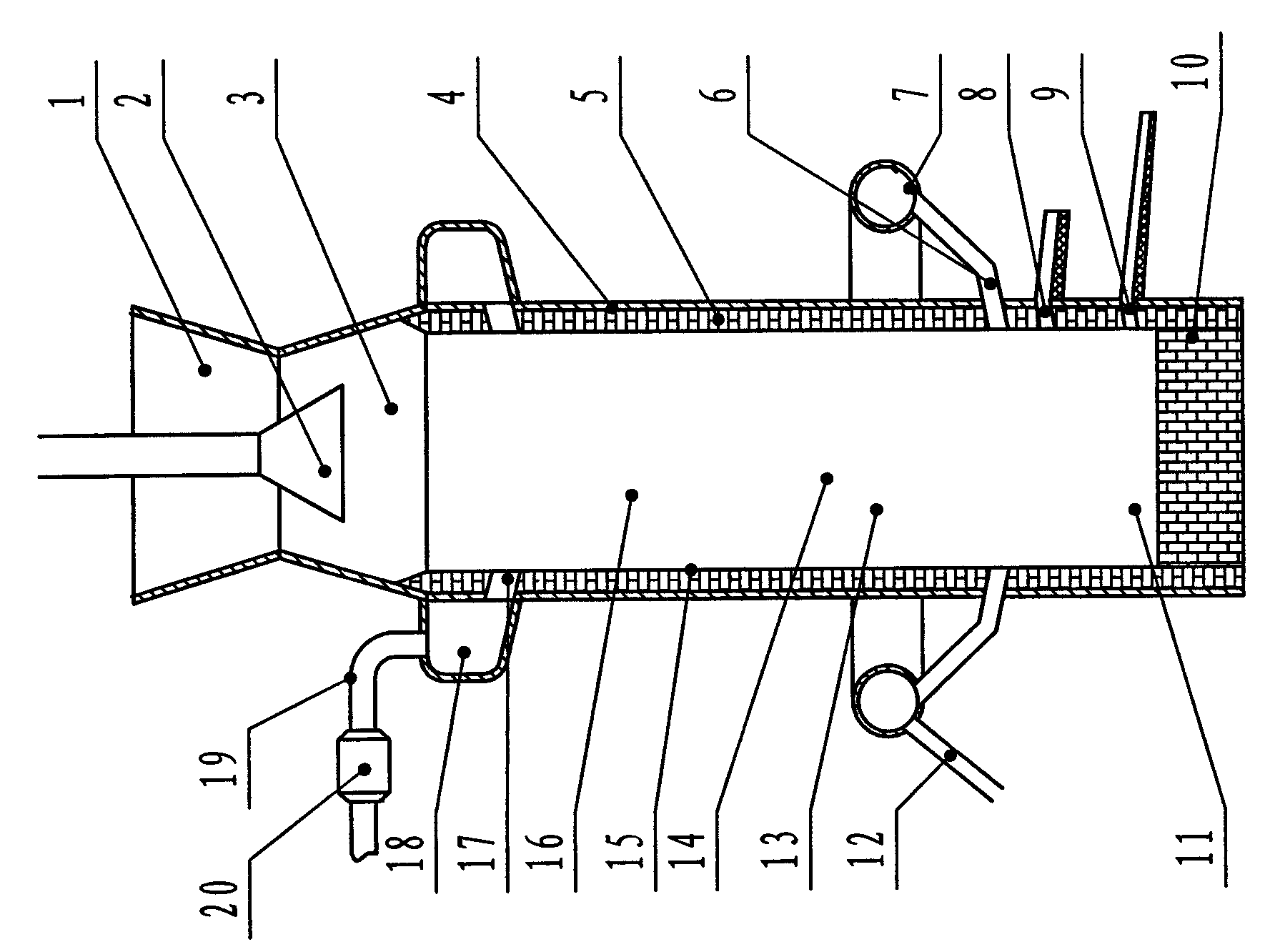

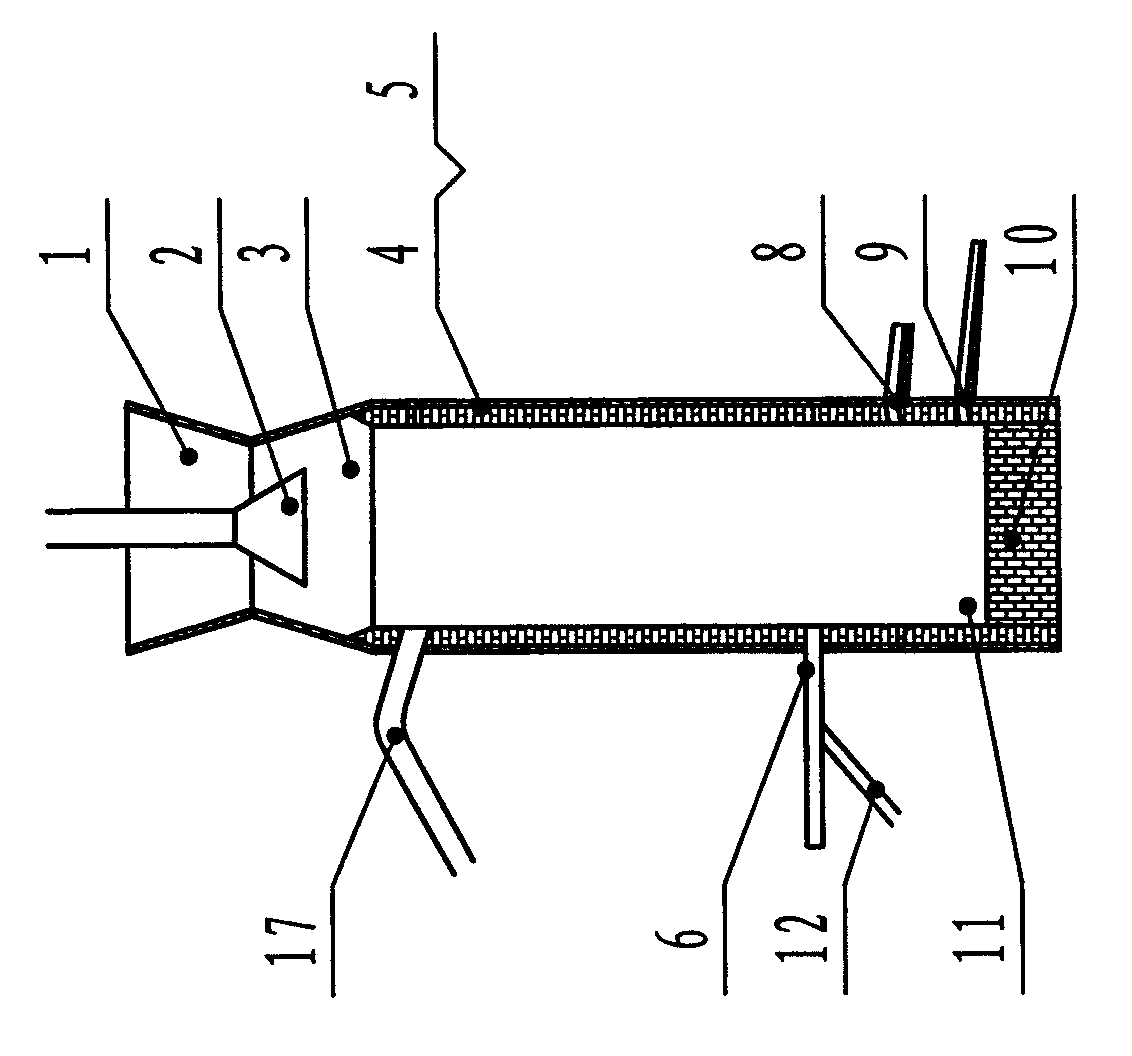

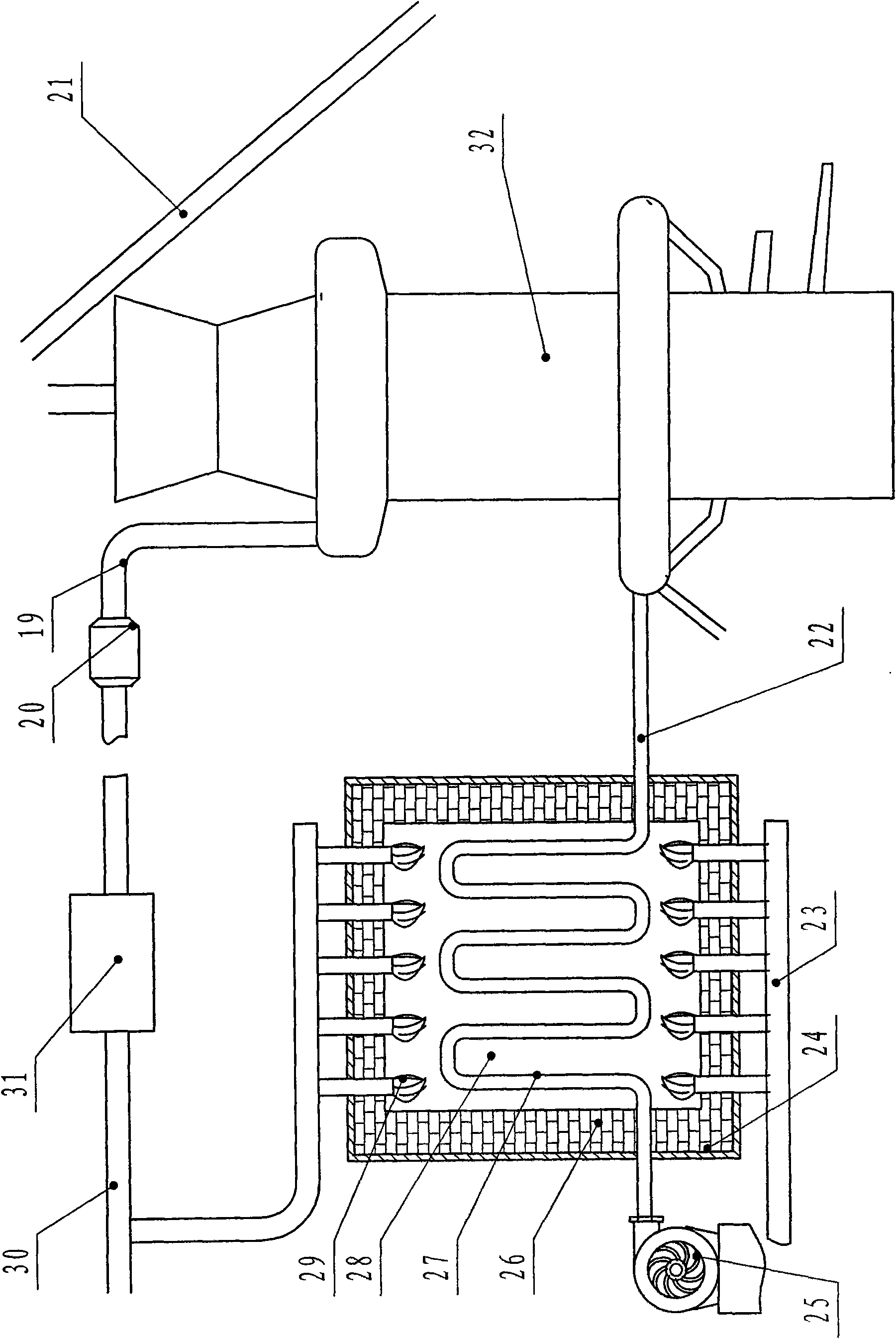

Energy-saving low-temperature multiple-effect seawater desalting device

ActiveCN101948148ALow running costReduce pollutionGeneral water supply conservationSeawater treatmentSteelmakingEngineering

The invention discloses an energy-saving low-temperature multiple-effect seawater desalting device, which is used for solving the problems of high operation cost and unstable operation of a desalting device. The energy-saving low-temperature multiple-effect seawater desalting device comprises a steam ejector, evaporators and a condenser, wherein multiple effect evaporators are connected in series; after improvement, the heat source of the device consists of a steel mill off-gas pipeline and a waste heat boiler; the waste heat boiler converts steel mill waste heat off-gas into saturated steam and overheat steam; the saturated steam and overheat steam are introduced into the first effect evaporator through the steam ejector; and the outlet of the last effect evaporator is connected with the condenser. The energy-saving low-temperature multiple-effect seawater desalting device has the advantages that: a, the waste heat boiler is introduced, the steel mill off-gas is fully utilized, the energy is saved, the operating cost of the device is reduced, and the pollution of the steelmaking off-gas on the environment is reduced; and b, the heat of finished water and strong brine is fully utilized, the temperature of the seawater at the inlet and outlet of the condenser is kept stable through intelligent pipeline control despite of the change of the temperature of seawater, and the equipment has the stable and optimized running state.

Owner:HEBEI HONGRUN NUCLEAR EQUIP SCI & TECH CO LTD

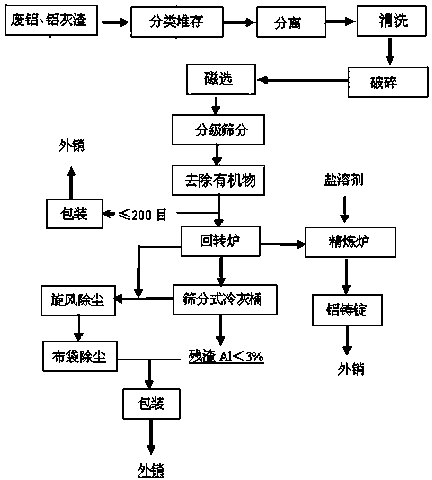

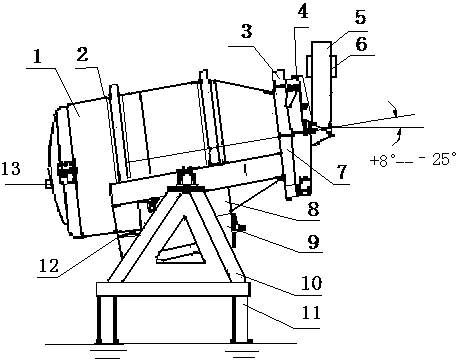

Production method of recycled aluminum

The invention relates to a production method of recycled aluminum. The production method comprises the steps: classifying and stacking waste aluminum or aluminum ash slag, then separating, wherein the separation is to remove dirt by washing and crushing; removing steel by a magnetic separation method, then crushing the initially purified aluminum, sieving to obtain a mixed aluminum powder, then putting into a rotary furnace for a combustion reaction, so as to decompose the aluminum slag or the waste aluminum into aluminum liquid and aluminum ash; putting the aluminum liquid in a refining furnace for further smelting, to obtain aluminum liquid with relatively high purity, outpouring to form aluminum ingots, wherein the pure aluminum content can reach 99.99%; and merging the aluminum ash unloaded from the rotary furnace with aluminum ash obtained by treating flue gas through a cyclone dust extractor, wherein the content of aluminum in the residues is 1-3%, then packaging, and providing the packaged product as a smelting additive for a steel mill.

Owner:ALNAN ALUMINIUM CO LTD

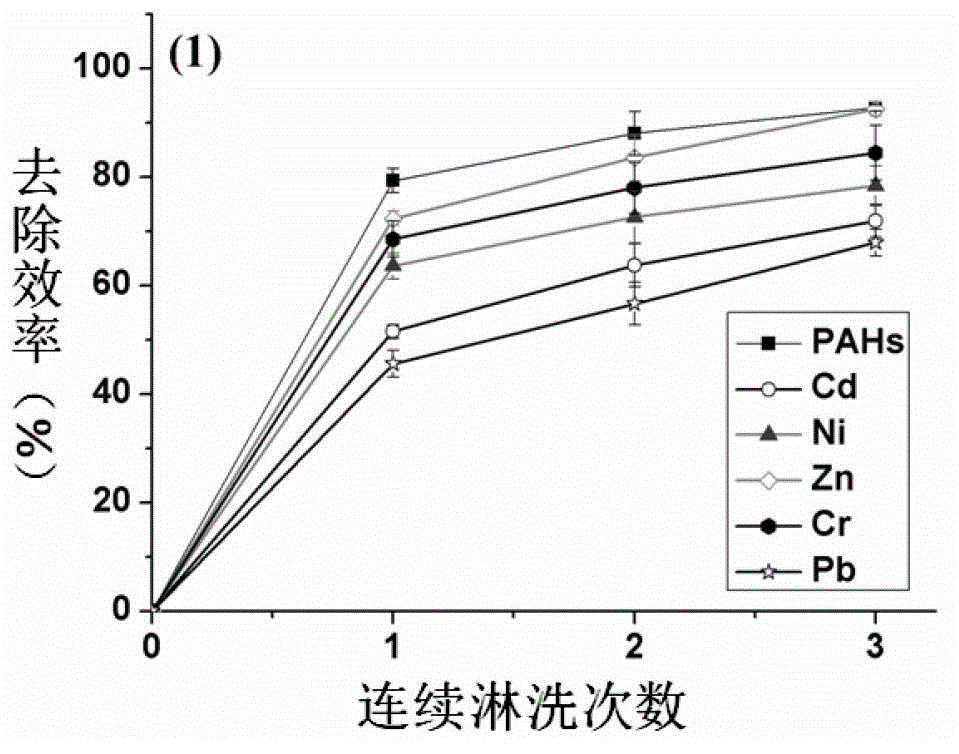

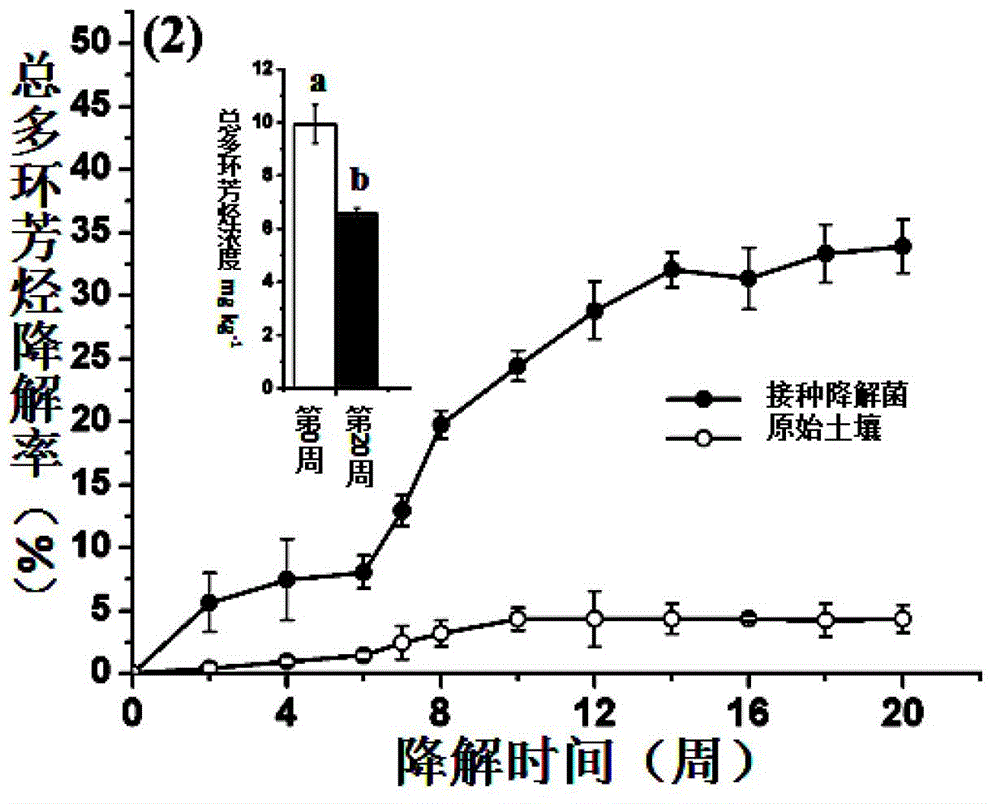

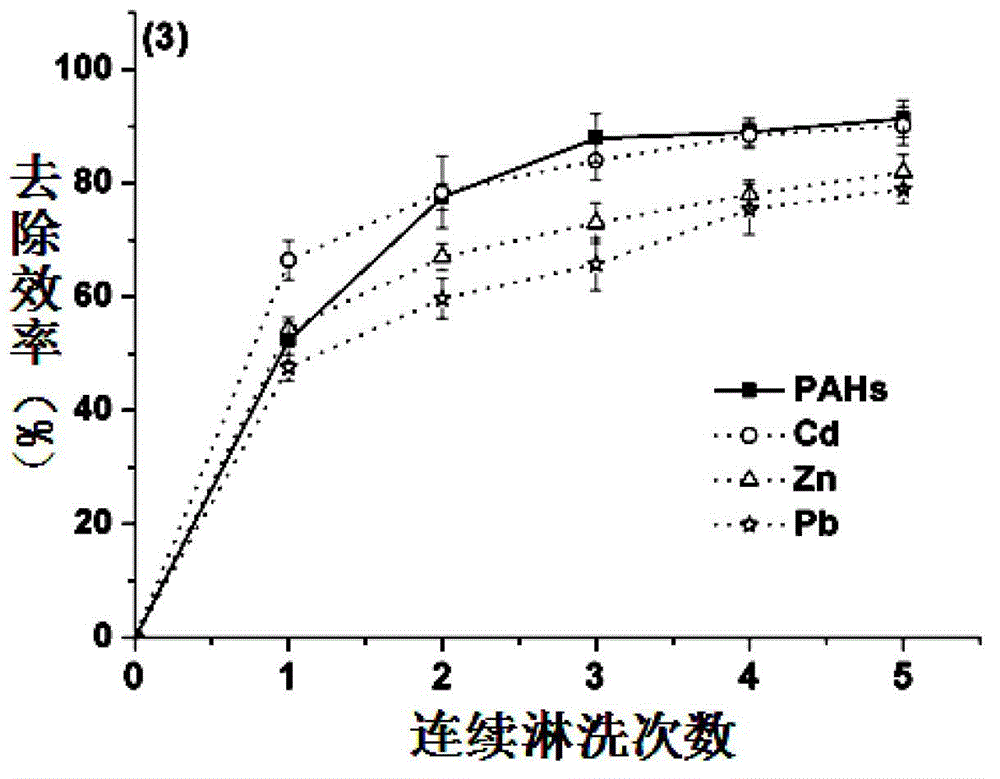

Chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil

InactiveCN102941225ANo secondary pollutionImprove environmental friendlinessContaminated soil reclamationCyclodextrinCoking plant

Disclosed is a chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil. The method comprises steps of (1), preparing soil particles and air drying and grinding contaminated site soil; (2), setting a restoration system, adding methyl beta cyclodextrin leacheate to a blender; (3), adjusting the reaction temperature to be 50+ / -2 DEG C; (4), adjusting an ultrasonic emission device to 35kHz for ultrasound of 30 minutes; (5) conducting continuous leaching, and repeating the continuous leaching for 3 times; and (6) conducting depth restoration of degrading bacteria, and inoculating polycyclic aromatic hydrocarbons degrading bacteria to soil which is subjected to continuous leaching restoration, adjusting the N / P to be 10:1 and conducting degradation for 90-140 days continuously. By the aid of the method, the restoration of the polycyclic aromatic hydrocarbons and heavy metal contaminated site soil generated by enterprises such as transferred coking plants, steel mills and power plants has wide application prospects.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

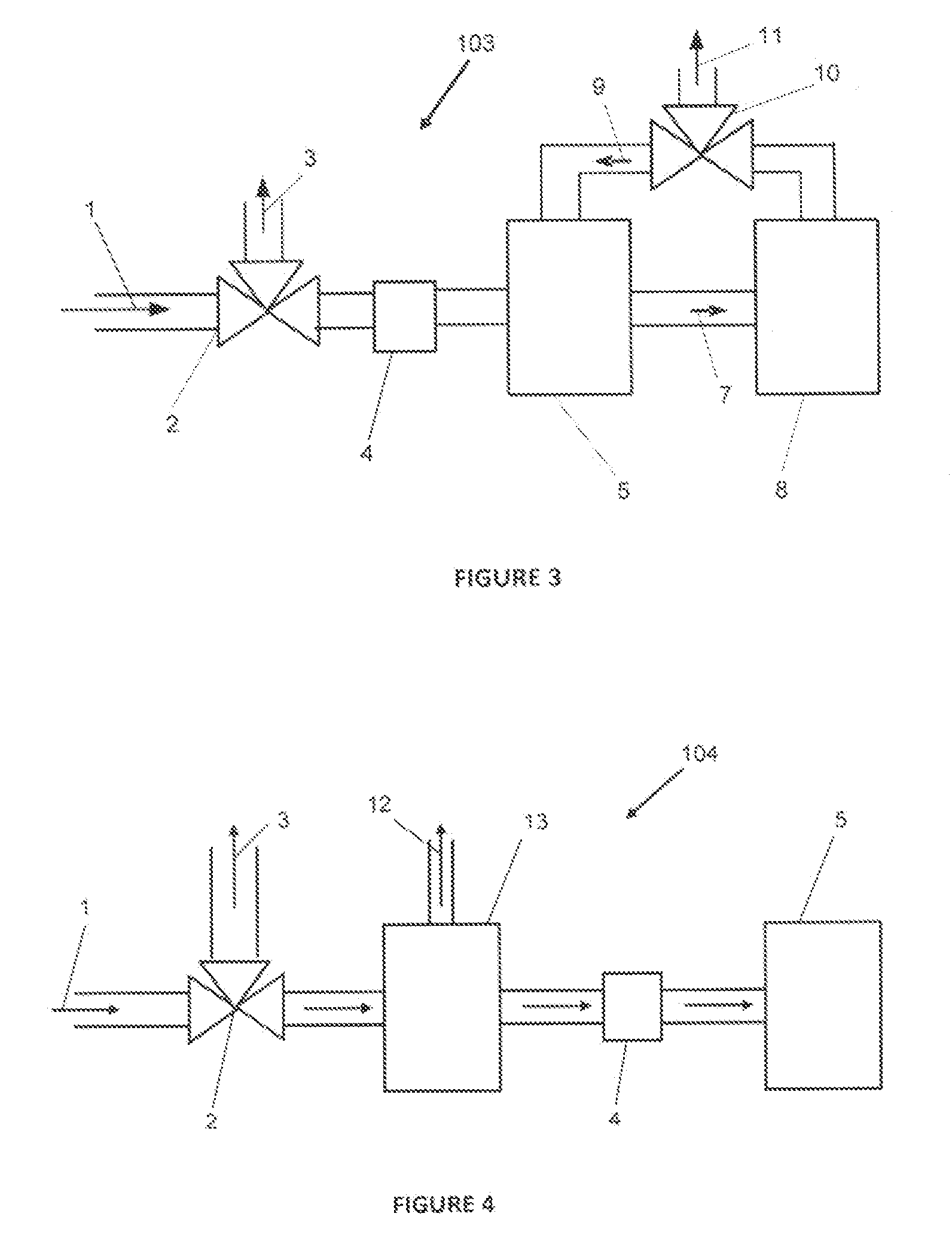

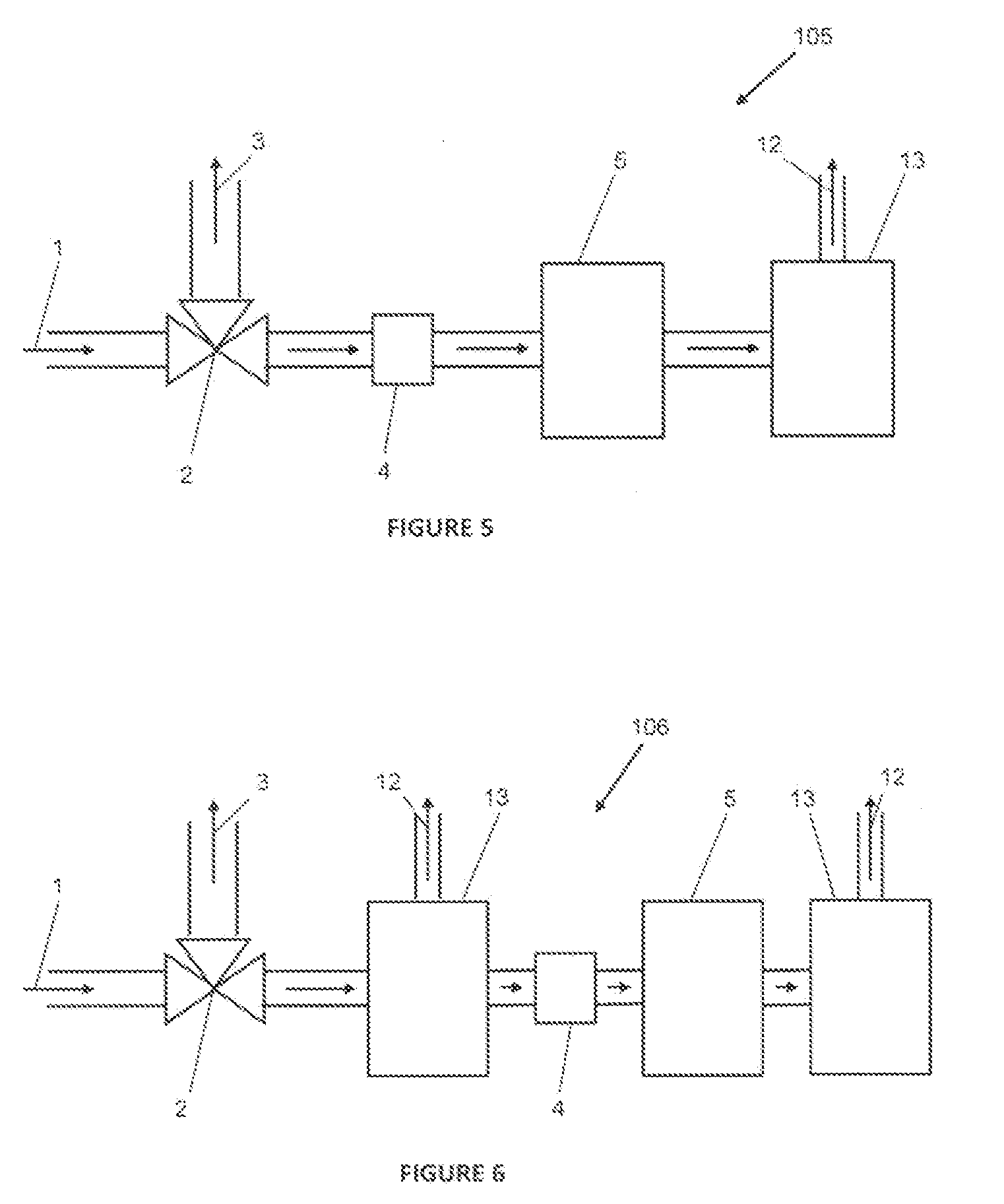

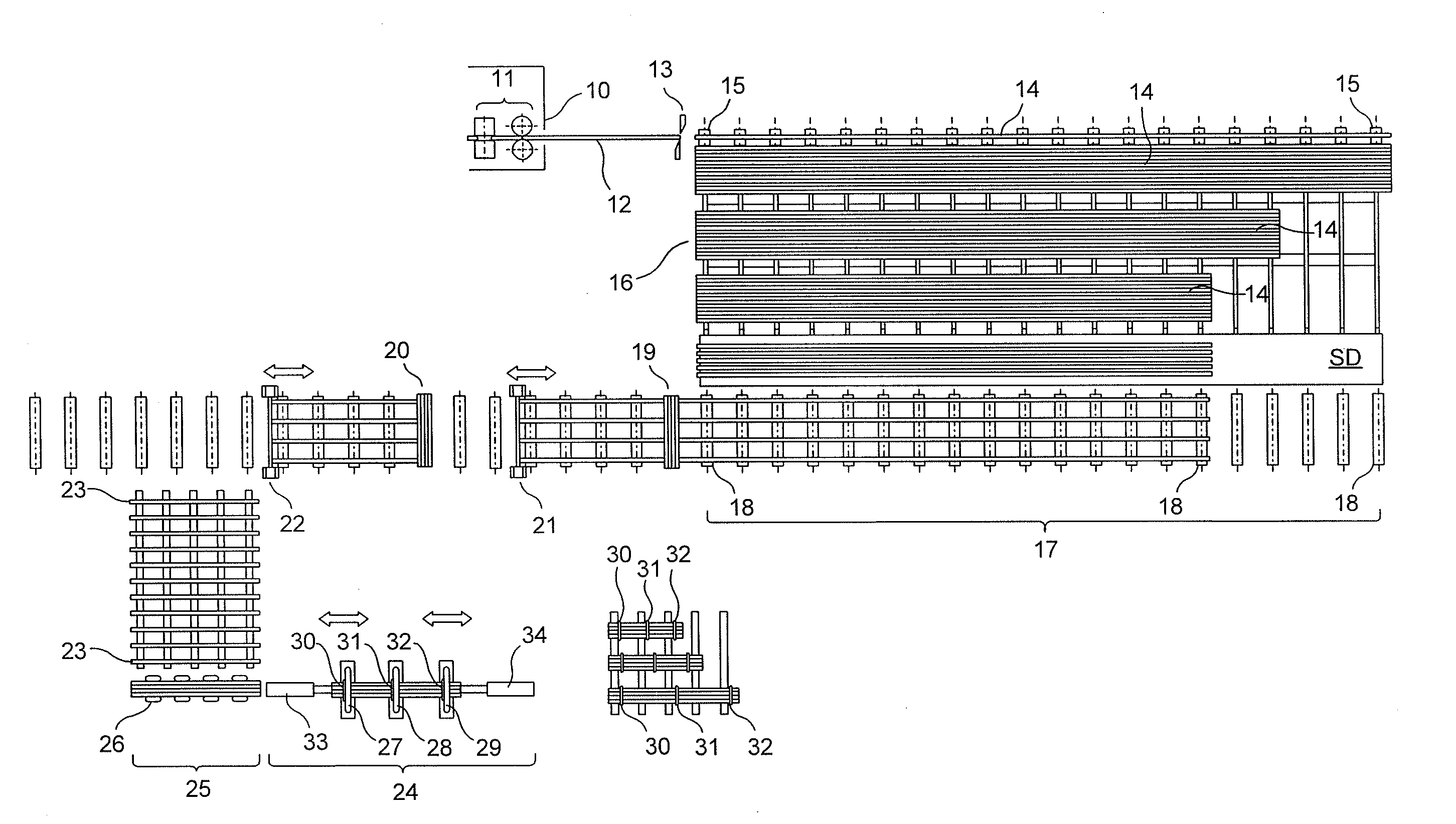

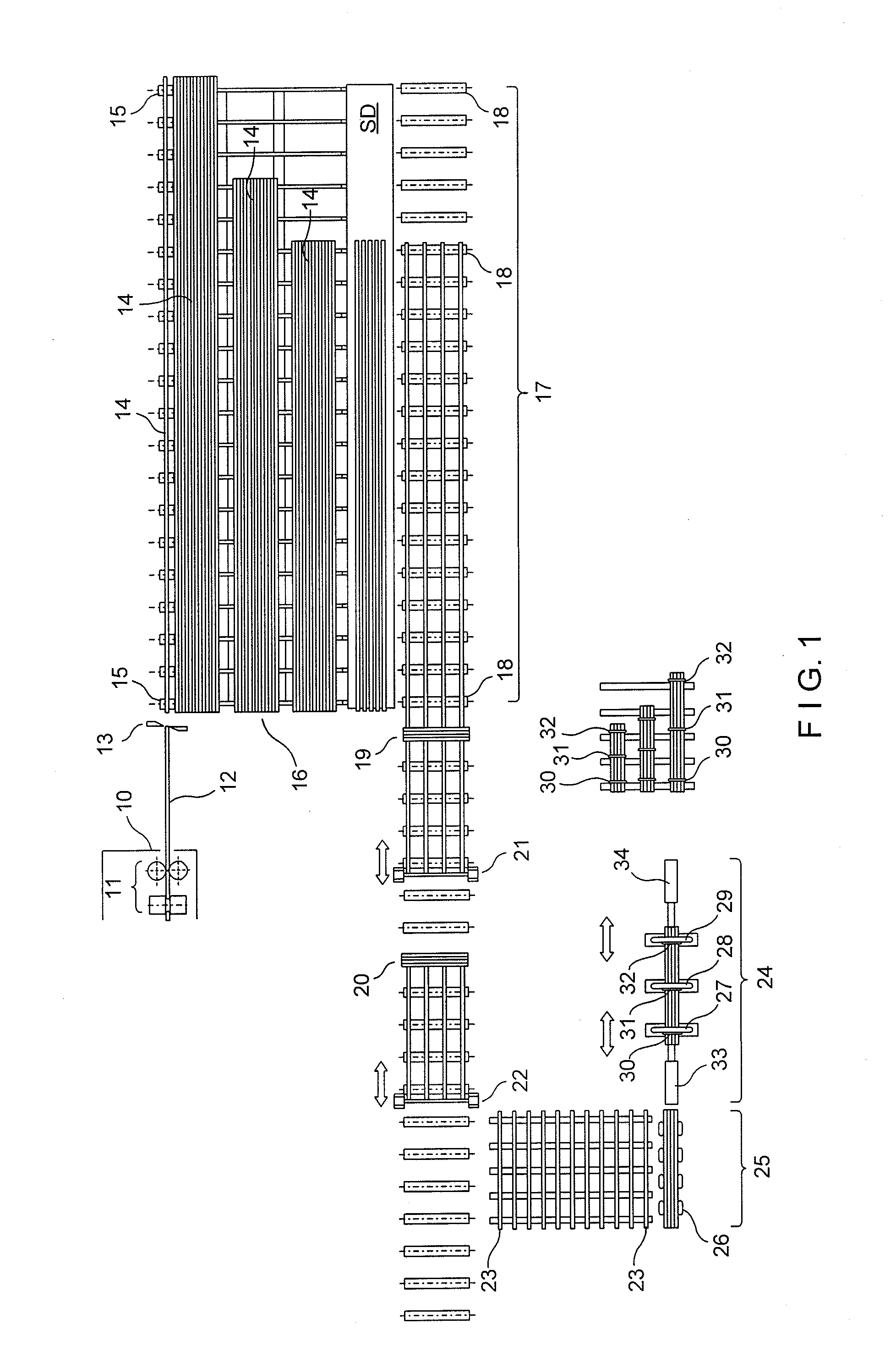

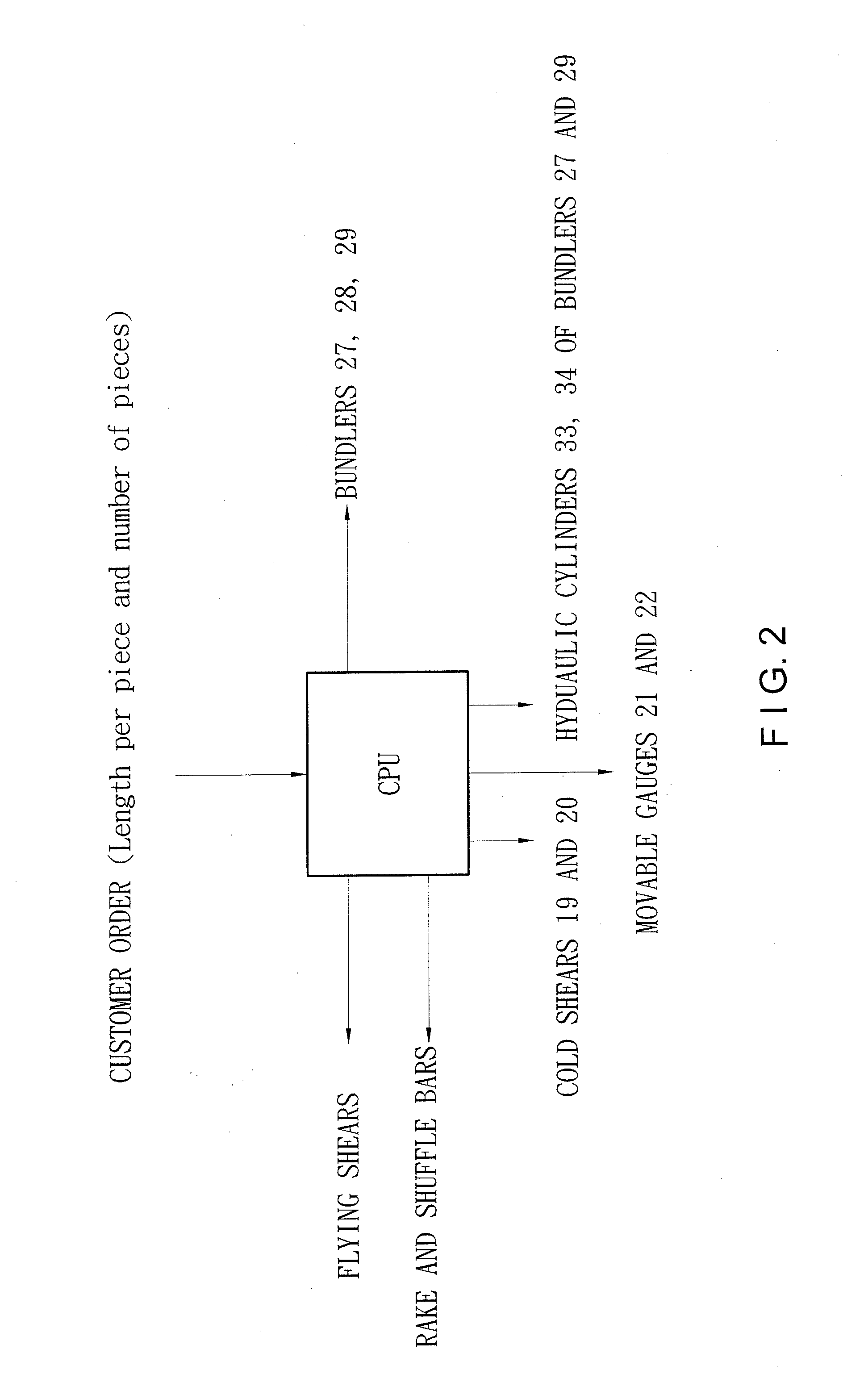

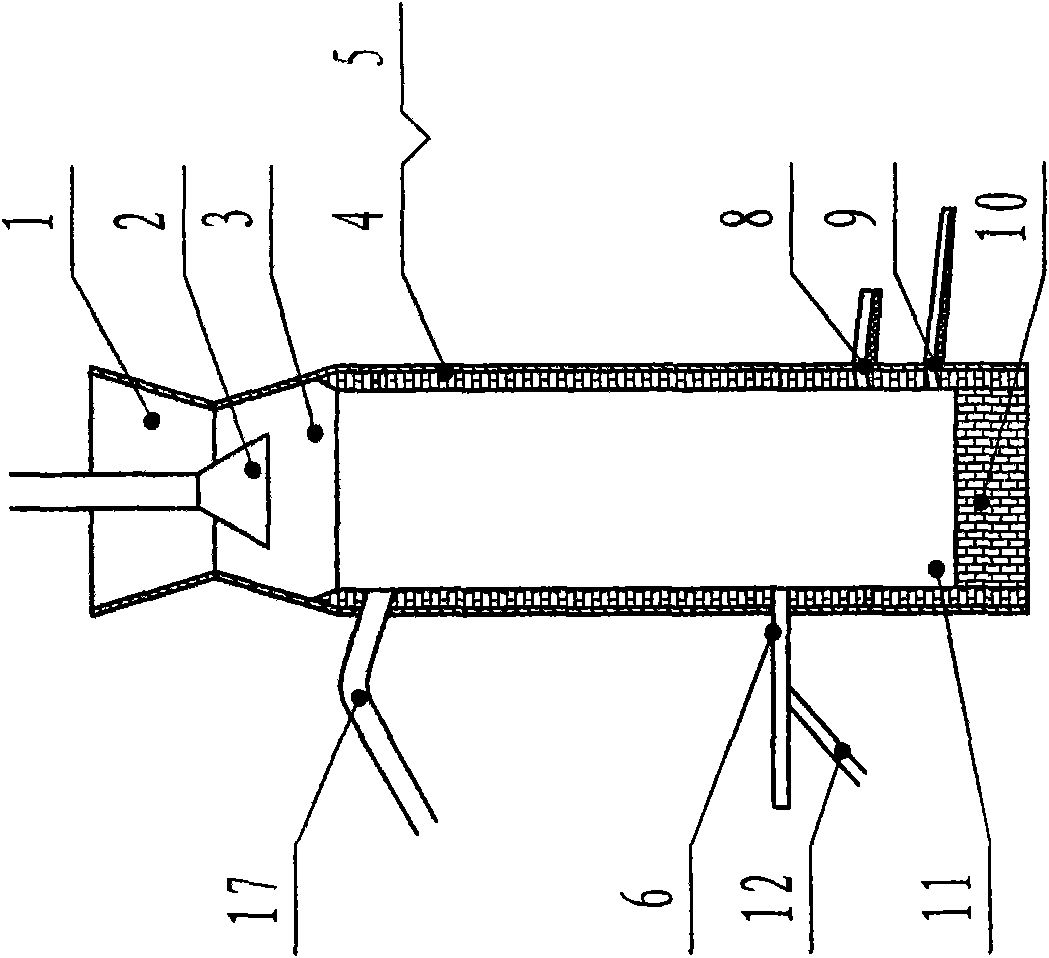

Method and apparatus for producing cut to length bars in a steel mill

A method and apparatus for producing steel bars that are cut to length in response to a customer order. The method includes producing a continuous length of steel bar from a rolling mill, cutting the continuous length of steel bar into successive segments, each representing a multiple of the length of the bar of the customer order, cutting the segments in in-line cold shears first into two times the length of the bar of the customer order and then in half into lengths equal to the length of the bar of the customer order while maintaining the production of the continuous length of steel bar produced by the rolling mill, and bundling the bars of the length of the customer order for discharge from the mill.

Owner:PONG DAVID TENG

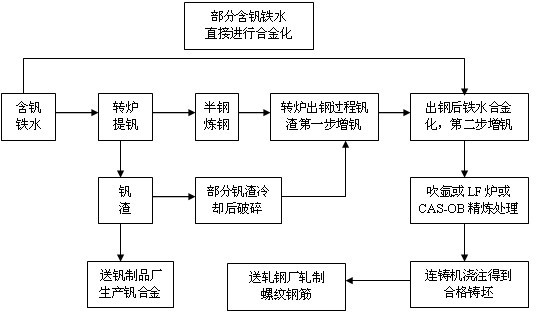

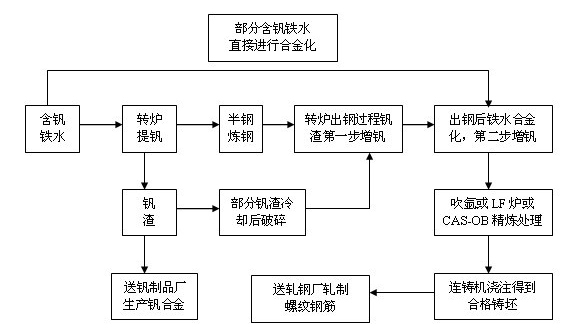

Smelting technology of III grade hot-rolled ribbed bars

InactiveCN102304604AHigh strengthMeet the seismic requirementsManufacturing convertersSlagShock resistance

The invention relates to a smelting technology of III grade hot-rolled ribbed bars. The invention belongs to the technical field of steel smelting. The technical scheme of the invention is that: vanadium-containing molten iron is adopted as a raw material; a vanadium increasing process in a bar production procedure is divided into two steps that: first, during a steel producing procedure, vanadium slag extracted from the vanadium-containing molten iron is added, and vanadium elements are reduced and added into molten steel, such that first-step vanadium increasing is carried out; second, when steel is discharged from a converter, vanadium-containing molten iron is directly poured into the ladle, such that second-step vanadium increasing is carried out. During the process, the vanadium elements in the vanadium-containing molten iron are directly converted into the vanadium elements in the vanadium-containing molten steel. The vanadium alloyed raw materials (the vanadium slag and the vanadium-containing molten iron) are internal materials sourced from a steel refinery. With the composite vanadium increasing method, a problem of high cost in the production process of the III grade hot-rolled ribbed bars is solved. The produced ribbed bars satisfy both the performance requirement and the shock resistance requirement. With the method, direct and highly efficient utilization of rare resources is realized, the technology process is reduced, the production efficiency is improved, and the production cost is reduced.

Owner:HEBEI IRON AND STEEL

Method for smelting stainless steel mother liquid by using chromium mineral powder and laterite as raw materials

ActiveCN101701312AReduced sintering processAvoid pollutionBlast furnace detailsShaft furnaceSlagIngot

The invention relates to a method for smelting stainless steel mother liquid by using chromium mineral powder and laterite as raw materials, which comprises the sequential steps of mixing, briquetting, proportioning, burning and smelting to obtain chromium-containing molten iron, wherein (1) mixing: uniformly mixing chromium mineral powder, laterite, coal powder or coke powder and composite binder; (2) briquetting: putting the mixture into a briquetting machine for briquetting, and then, drying or curing the briquettes to the specified strength; (3) proportioning: adding the dried or cured briquettes into a reduction accelerator and a slag preparing agent, and proportioning the briquettes, the reduction accelerator and the slag preparing agent; (4) smelting: adding the proportioned raw materials into a small blast furnace or new vertical furnace with an iron opening and an air opening from a furnace opening, and adding coke for smelting; and (5) tapping and transmitting the smelted chromium-bearing molten iron (i.e. stainless steel mother liquid) into steel works, or casting the smelted chromium-containing molten iron into iron ingots. The method for smelting stainless steel mother liquid by using chromium mineral powder and laterite as raw materials has lower production cost and reduces the environment pollution.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

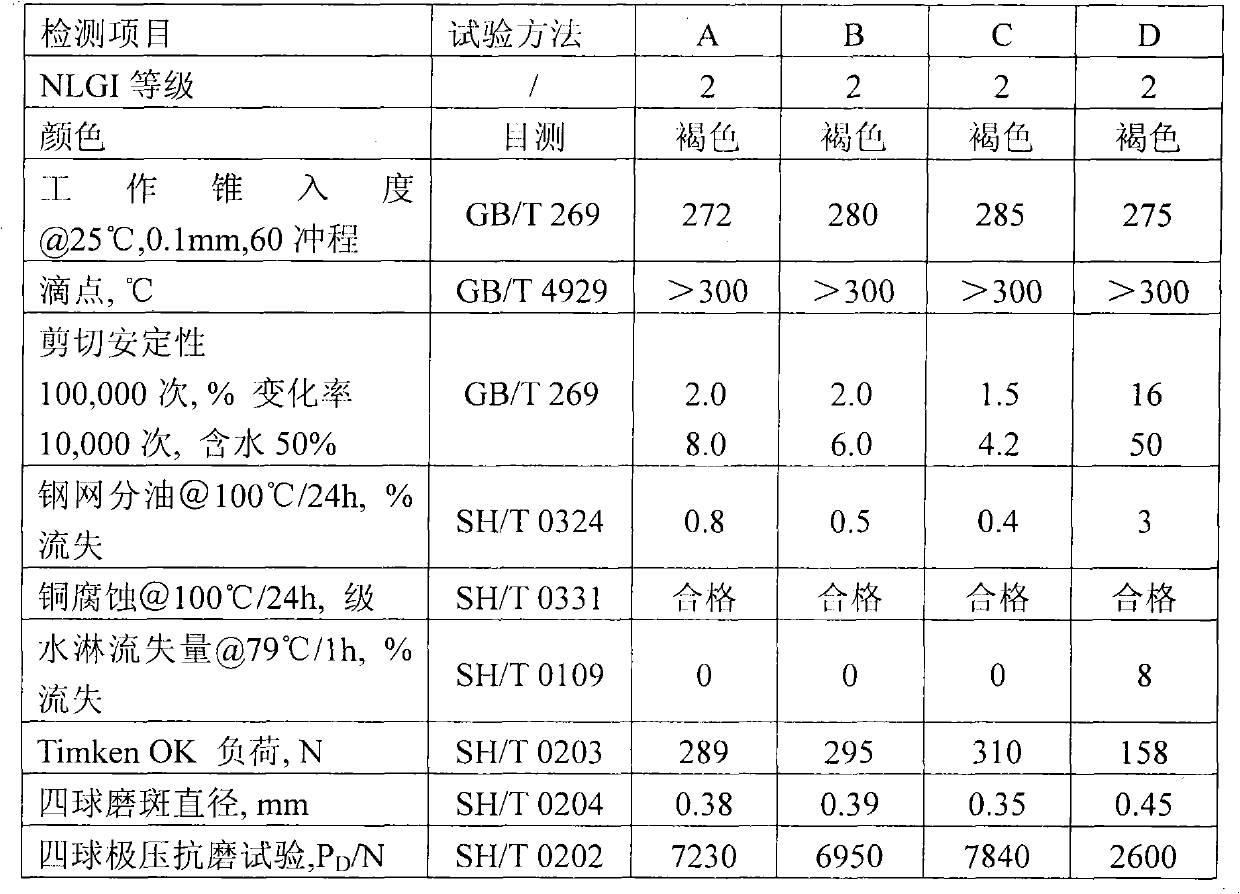

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

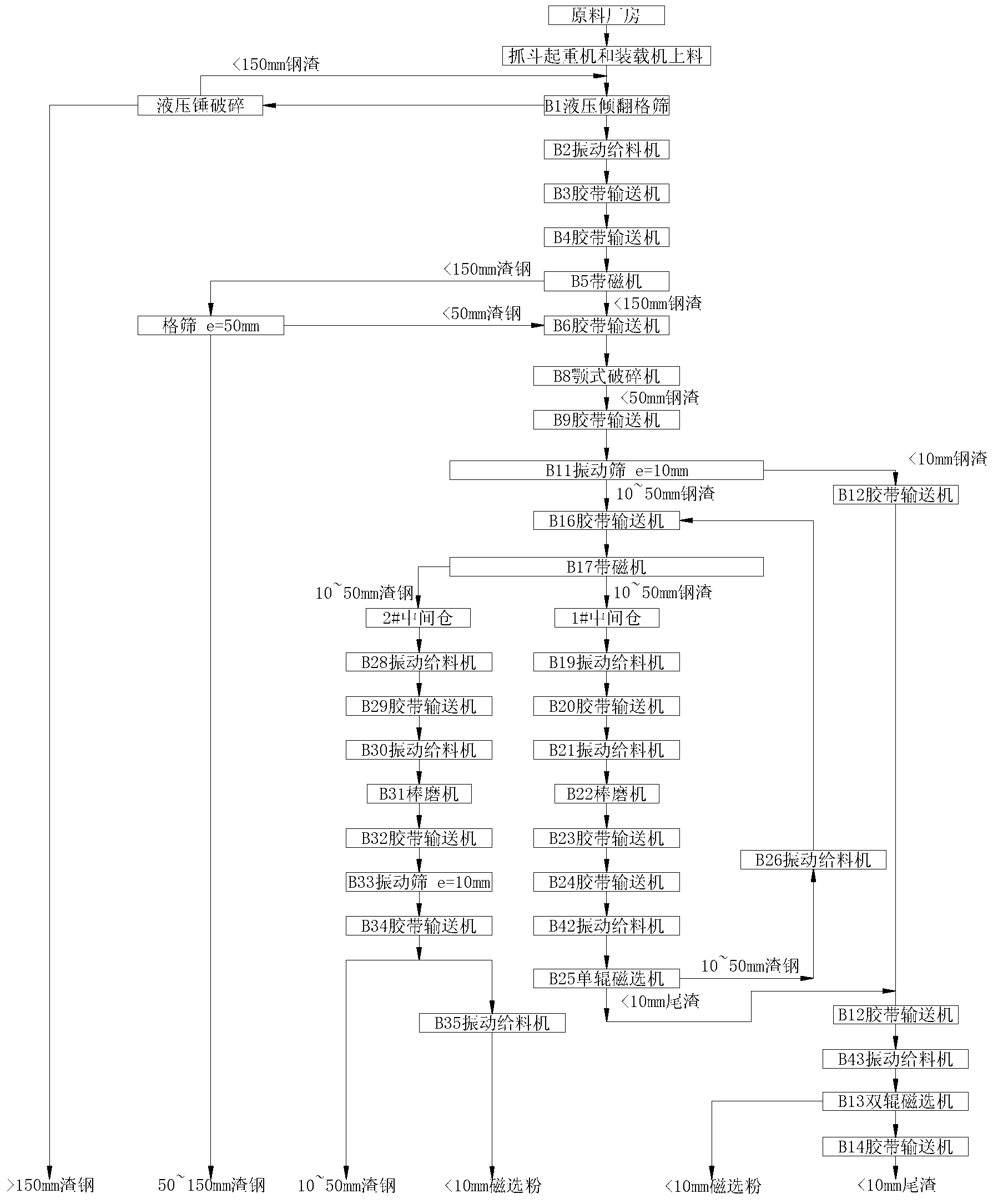

Steel slag treating technology

ActiveCN103290153AIncrease added valueFor subsequent useRecycling and recovery technologiesSteelmakingClosed loop

The invention relates to a steel slag treating technology which can be used for treating steel slag after which is stabilized by adopting a hot and stuffy method. According to the technology, the steel slag is treated by the procedures of screening, crushing, magnetic separation, purification and the like through utilizing the mode of combining an open loop and a closed loop circulation to obtain five high-value-added high-quality products, namely first-type bulk slag steel with the grade of more than or equal to 80% and particle size of 150mm, a second-type bulk slag steel with the grade of more than or equal to 80% and particle size of 50-150mm, slag steel with grade of more than or equal to 85% and particle size of 10-50mm, magnetic separation powder with grade of more than or equal to 42% and particle size of 10mm, and metal iron content (2% of tailings with the particle size of 10mm), wherein the first-type bulk slag steel and the second-type bulk slag steel and the slag steel with the grade of more than or equal to 85% can be returned for steelmaking, the magnetic separation powder can be used for sintering, and the tailings can be used for producing steel slag micropowder as high-activity admixture of cement and concrete and the like. Through the technology, the zero emission of the steel slag can be realized, the defects that the steel slag stored occupies a large area and pollutes the environment can be solved, and the economic benefits of a steel mill can be increased.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Process for producing fly ash steamed brick by using sintering machine desulfuration ash

InactiveCN101559618ASolve the problem of resource utilizationFast oxidative conversionSolid waste managementMixing operation control apparatusBreaking strengthBrick

The invention relates to a process for producing a fly ash steamed brick by using sintering machine desulfuration ash. The fly ash steamed brick comprises the following raw materials in portion by weight: 20 to 80 portions of fly ash, 5 to 25 portions of desulfuration ash, 0.1 to 10 portions of lime, 0.1 to 4 portions of gypsum, 5 to 50 portions of aggregate, and 0 to 1.5 portions of composite assistant. A product is prepared by the processes of adding water and stirring, pressing and molding, keeping standing and steam curing. The process is used for producing the fly ash steamed brick by using the sintering machine desulfuration ash of a steel mill to totally or partially replace the lime and the gypsum, solves the problem of resource utilization of the sintering machine desulfuration ash of the steel mill; and the fly ash steamed brick produced by the sintering machine desulfuration ash has following performance test results: the breaking strength of the steamed brick is 2.5 to 4.0 MPa, the compressive strength is 10 to 20 MPa, the frost resisting property is qualified, and the carbonization coefficient is 0.80 to 0.95.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminium-magnesia carbon brick and preparation method thereof

The invention provides an aluminium-magnesia carbon brick and a preparation method thereof, belonging to the field of refractory materials. The raw materials of the aluminium-magnesia carbon brick include 30-80 parts of waste aluminium-magnesia carbon brick grains, 3-40 parts of special grade bauxite chamotte, 3-10 parts of magnesia, 3-10 parts of magnesia-alumina spinel, 5-8 parts of graphite, 3-15 parts of micro powder additives and 2.2-3.5 parts of organic bonds by weight. The preparation method is characterized by sorting, hydrating, drying and grinding the waste aluminium-magnesia carbonbricks from the steel mills and then mulling the waste aluminium-magnesia carbon brick grains with other raw materials, forming and carrying out heat treatment to prepare the aluminium-magnesia carbon brick. The energy-saving and environment-friendly aluminium-magnesia carbon brick prepared by the invention has high compression strength, low porosity, good resistance to molten steel corrosion andservice life reaching or exceeding the service lives of the traditional aluminium-magnesia carbon bricks. In the invention, the waste aluminium-magnesia carbon bricks are rationally utilized and consumption of the mineral resources is reduced.

Owner:ZHENGZHOU DONGFANG SANLI REFRACTORY MATERIALS

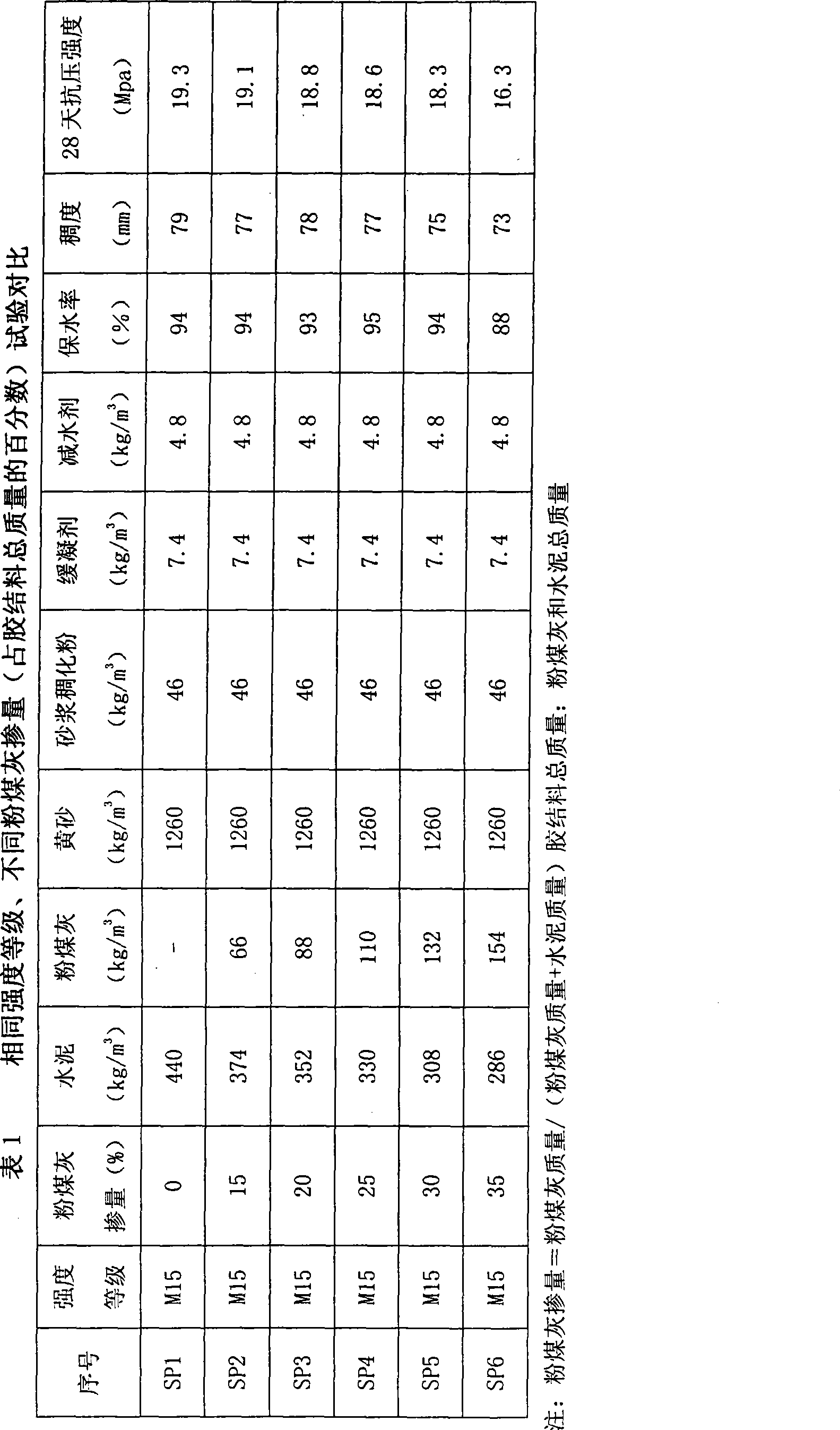

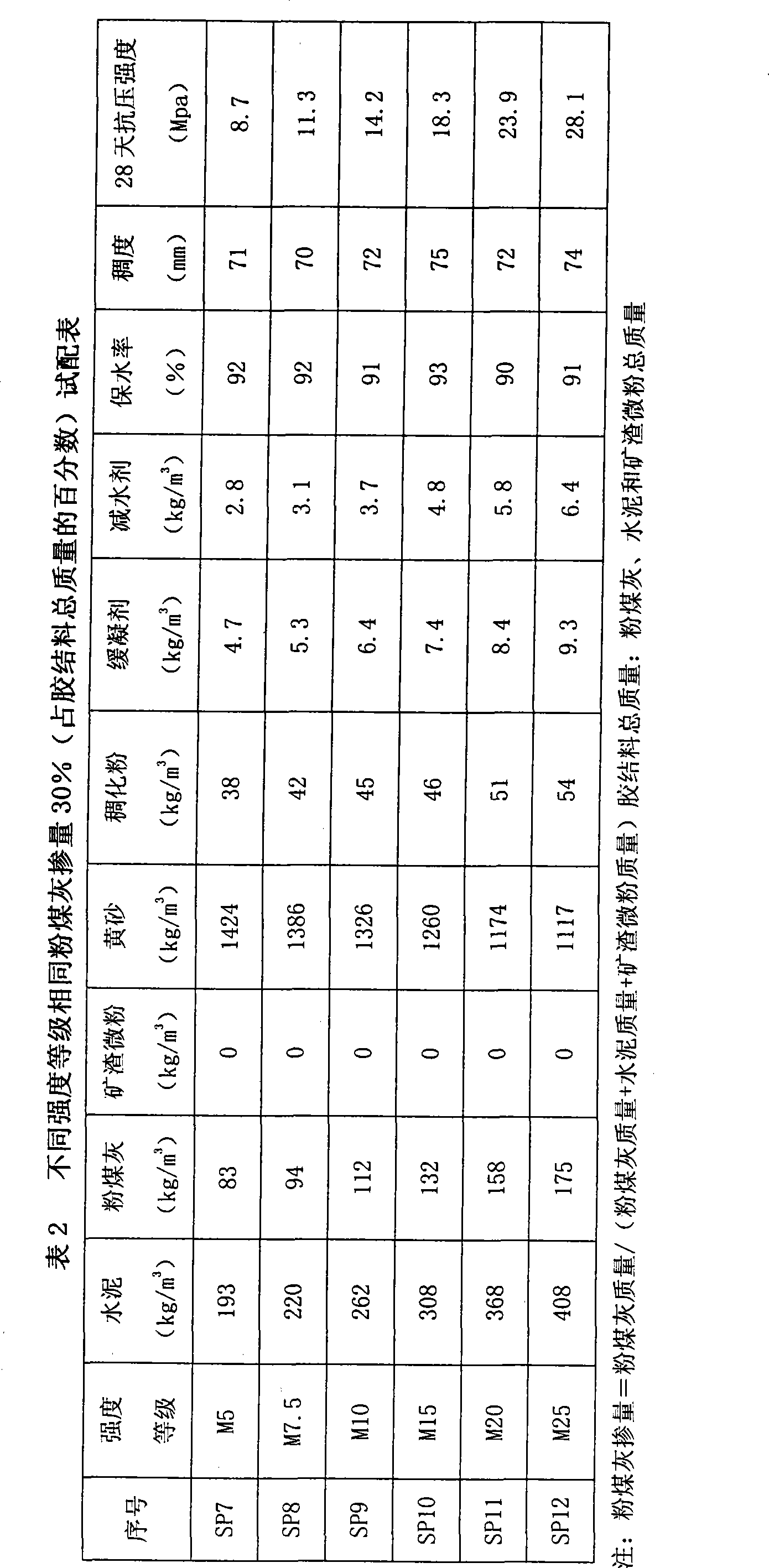

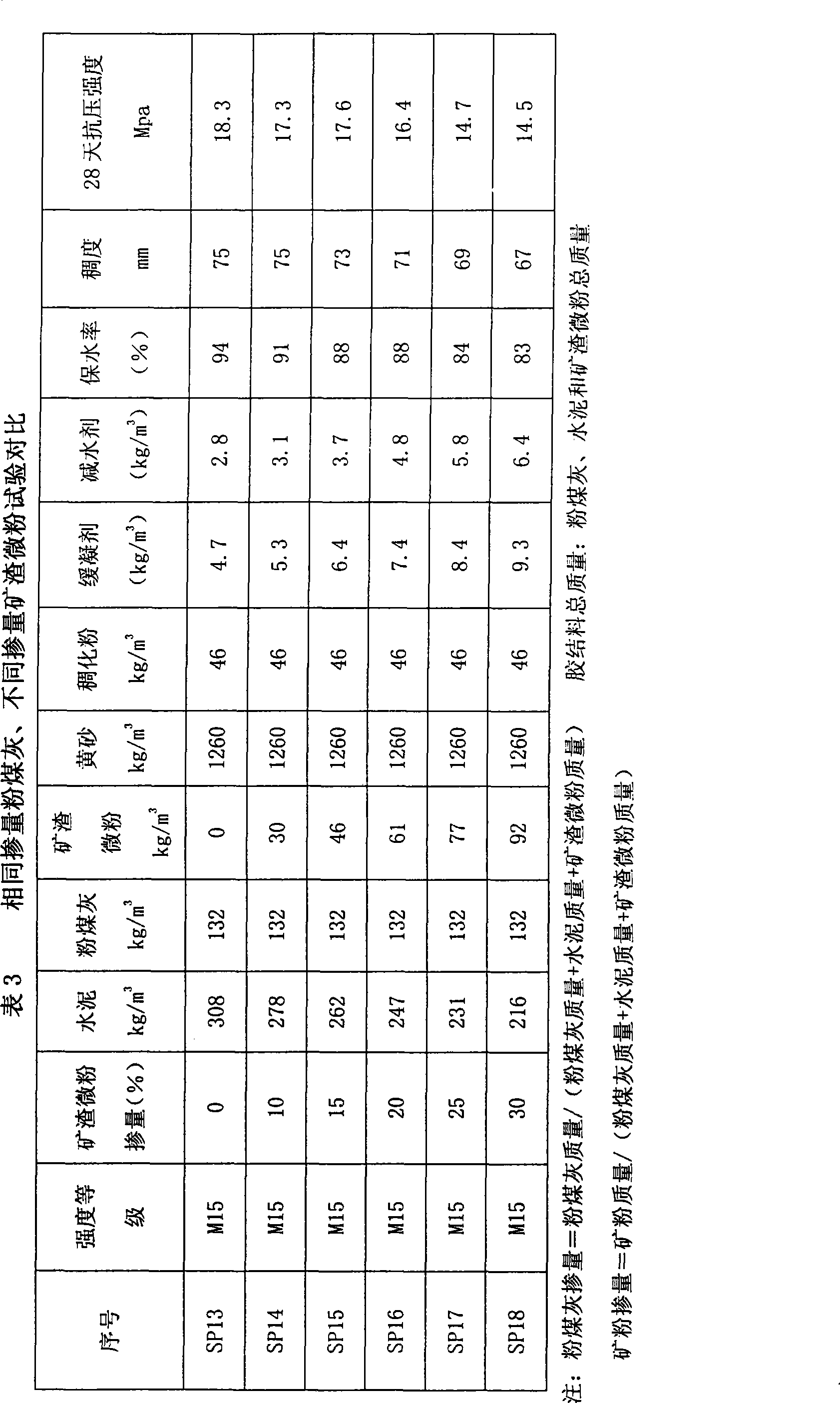

Wet mixture mortar capable of pumping

InactiveCN101423364ASolve the consistency (80mm~110mm)Solve water retentionSolid waste managementSlagSteel mill

The invention relates to pumping wet mixture mortar, which is characterized in that the pumping wet mixture mortar mainly comprises cement, fly ash, slag micropowder, yellow sand, mortar thickening powder, a mortar retarder, a mortar water reducer and cellulose ether. The application of the pumping wet mixture mortar has the advantages of saving energy and improving efficiency, protecting environment and reducing emission, fully utilizing waste such as fly ash, slag and the like from steel mills and power plants, benefiting the nation and people, simultaneously improving working efficiency, lowering labor cost, reducing labor intensity of a worker and saving machine expense.

Owner:JIANGSU PROVINCIAL CONSTR GRP CO LTD +1

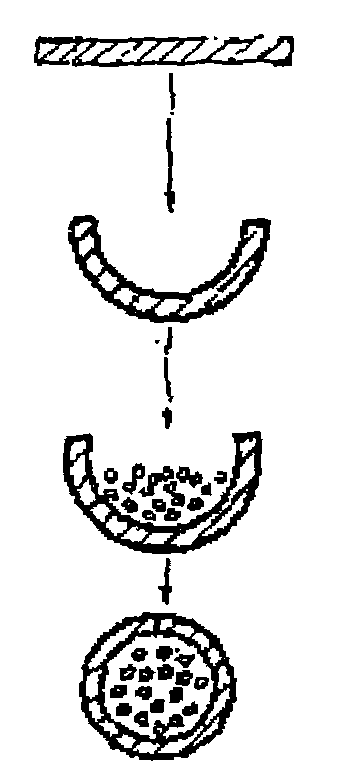

High-hardness self-protecting cold roll build-up welding flux-cored wire

The invention discloses a high-hardness self-protecting cold roll build-up welding flux-cored wire, and belongs to the field of welding in material processing. The flux-cored wire is mainly applied to build-up welding repair of cold rolls of steel mills. The flux-cored wire is characterized in that: the outer surface of the powder cored wire is an H08A cold rolling steel strip; and the powder of the powder cored wire comprises the following components in percentage by mass: 25 to 45 percent of high carbon ferrochrome, 5 to 15 percent of chromium metal, 4 to 8 percent of ferromolybdenum, 5 to 10 percent of manganese metal, 4 to 8 percent of No.75 silicon iron, 4 to 10 percent of aluminum magnesium alloy, 6 to 12 percent of ferrocolumbium, 4 to 10 percent of ferrotungsten, 4 to 12 percent of nickel powder and 4 to 18 percent of iron powder. A coating prepared by build-up welding has high hardness (Rockwell hardness (HRC): 55 to 60) and excellent abrasion resistance; and a self-protecting build-up welding mode is adopted, namely a protective gas source and a flux are not needed in the build-up welding process, and slag knocking is not needed in the build-up welding process, so automatic production is easy to realize.

Owner:BEIJING SURYEE SCI & TECH

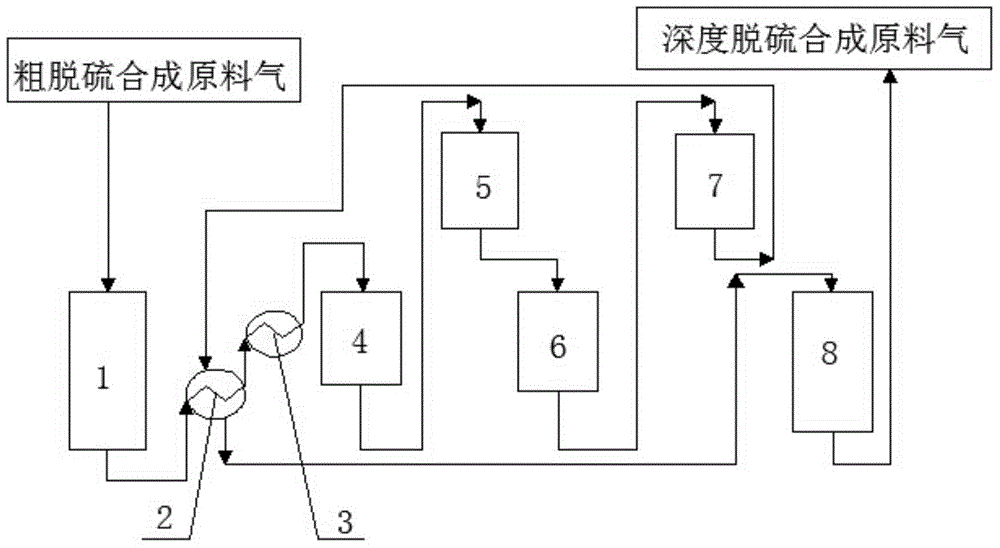

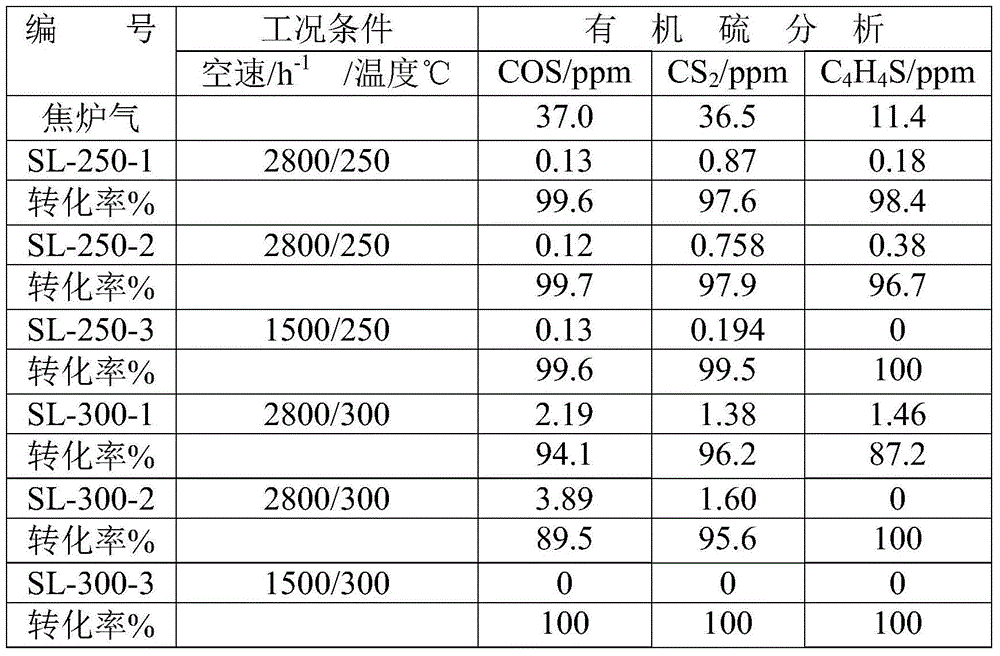

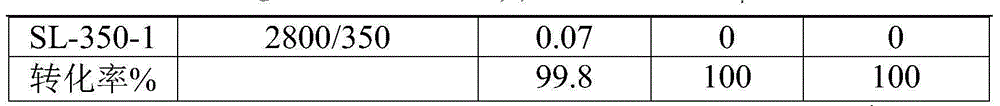

Synthetic raw material gas deep fine desulfurization process and fine desulfurization device

InactiveCN104437032AReduce energy consumptionExtend your lifeDispersed particle separationPetroleumMaterials science

The invention discloses a deep desulfurization method for preparing a synthetic raw material gas by taking a coal-based natural gas, a petroleum refining gas, a coke oven gas, a steel mill converter gas and the like as raw materials. The method comprises the step of enabling the raw material gas which is treated by rough desulfurization and contains hundreds of parts per million (ppm) of H2S and hundreds of ppm of organic sulfur (including COS, CS2, sulfur alcohol, sulfur ether, thiophene and the like) to pass through a plurality of stages of titanium-based molybdenum-cobalt catalysts, a plurality of stages of zinc oxide desulfurizing agents and a stage of multifunctional fine desulfurizing agent to enable the total sulfur to be less than or equal to 0.01ppm. Compared with the existing desulfurization accuracy (0.1ppm), the desulfurization accuracy of the deep desulfurization method enables the degree of purification to be increased by one order of magnitude and enables the service life of a methyl alcohol catalyst to be doubled. The invention also discloses a medium-temperature fine desulfurization device used by the synthetic raw material gas deep fine desulfurization method. For the industrial community, after the method and the device are used, the starting and stopping times of the device can be reduced, the raw material and the power consumption are reduced, the yield of the device is increased, and an effective measure capable of saving energy, reducing emission and increasing yield can be provided.

Owner:SANLONG CATALYST

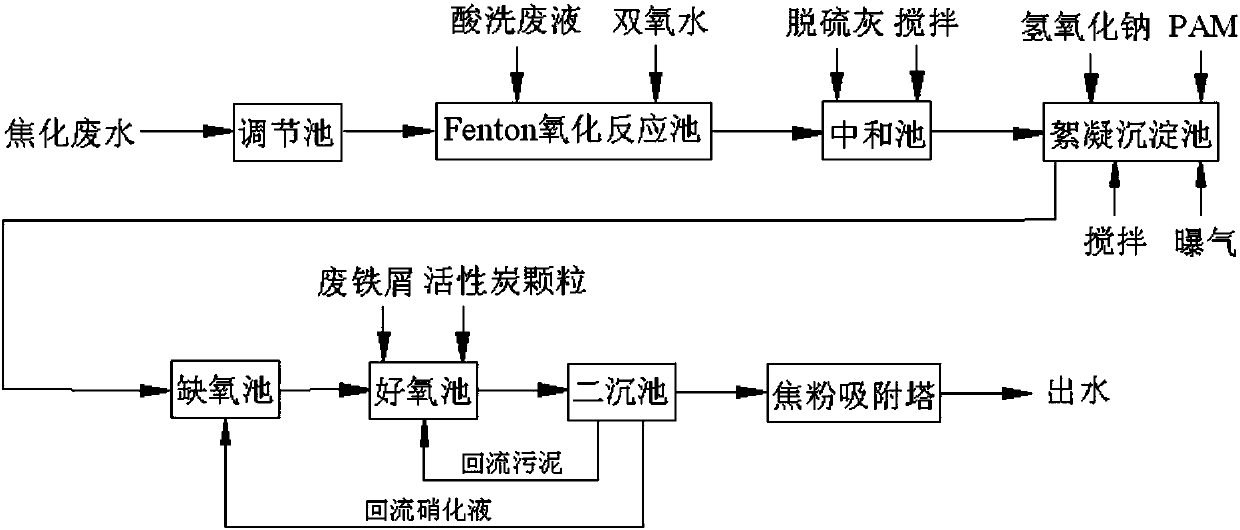

Low-cost treatment method for coking wastewater

ActiveCN107555701ALow running costReduce processing operating costsWaste water treatment from quariesMultistage water/sewage treatmentLiquid wasteWater quality

The invention discloses a method for treating coking wastewater by adopting a Fenton oxidation tank, a neutralization tank and a flocculation and sedimentation tank for pretreatment, adopting an anoxic tank and an aerobic tank for biochemical treatment and adopting modified coke powder adsorption for deep treatment. At a pretreatment stage, a metallurgical acid pickling waste liquid is added intoa Fenton oxidation reaction tank, so that waste acid resources and Fe<2+> in the acid pickling waste liquid are sufficiently utilized, and the acid pickling waste liquid from steel mills is recycled to the maximum extent; desulfurized ash is added into the neutralization tank, and part of additionally added alkaline liquid is replaced by sufficiently utilizing the alkalinity of the desulfurized ash, so that the operation cost of a process is reduced; and dry quenching coke powder for deep treatment is a byproduct produced in a coking process, and when the dry quenching coke powder is applied to the field of wastewater treatment, not only is the wastewater treatment cost reduced, the quality of the final effluent improved, but also the aim of treating wastes by utilizing wastes is achieved.

Owner:ANGANG STEEL CO LTD

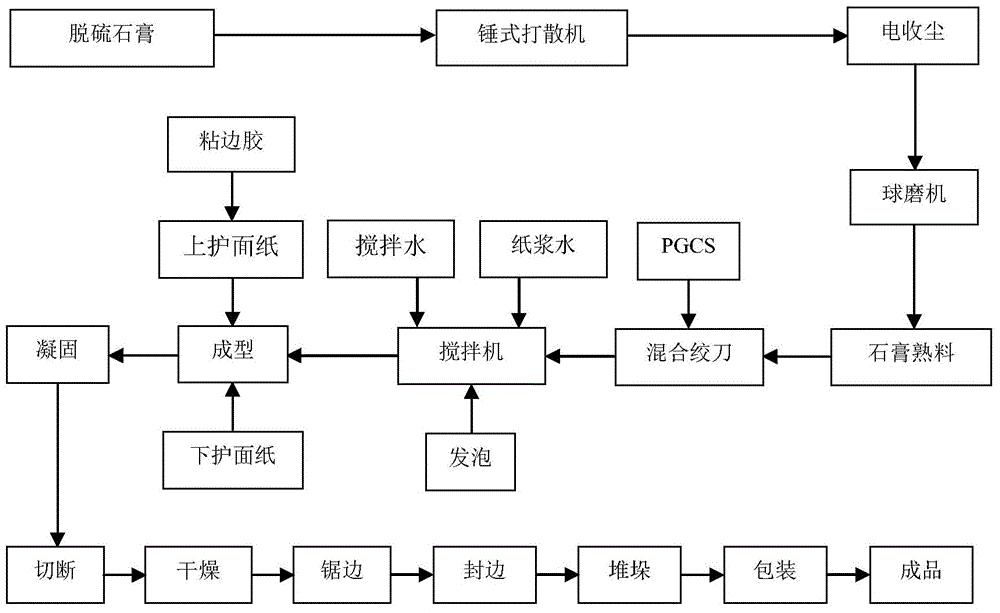

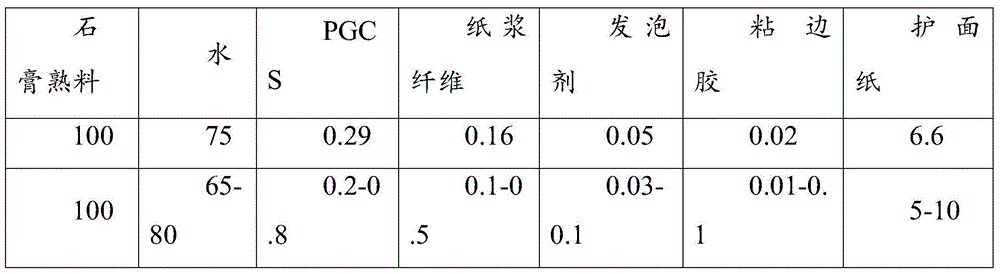

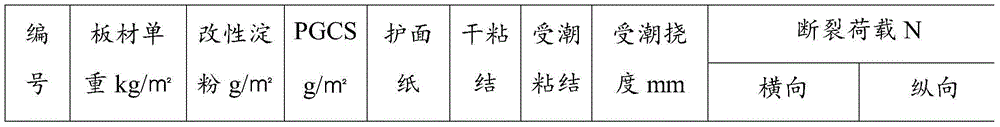

Preparation method of paper-surface gypsum board

InactiveCN104973882AImprove bonding qualityAchieve self-consumptionCeramicwareSlurryToxic industrial waste

The invention discloses a preparation method of a paper-surface gypsum board. The method comprises the following steps: after being metered, gypsum clinker and PGCS are fully mixed, and then the mixture enters a mixer; paper pulp, mixing cement and foam respectively enter the mixer; the above dry and wet materials are fully stirred in the mixer to prepare uniform slurry, the slurry is continuously poured between two layers of covering paper, and a wet gypsum board is prepared by extrusion molding; and the wet gypsum board undergoes solidification, cutting, drying, final trimming, edge banding, stacking and packaging so as to prepare the paper-surface gypsum board finished product. According to the invention, bonding quality and strength of the board are enhanced; raw materials can be saved, energy consumption is reduced, and production cost is decreased; and dependence of bonding quality of the covering paper on operation and drying system is reduced. The scheme of drying the paper-surface gypsum board by the use of waste heat from a power plant or a steel mill is feasible. Energy conservation and emission reduction as well as automatic disposal of industrial waste residues are realized. In addition, the aggregate resources conservation purpose of ''low energy, low pollution and high return'' is achieved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Furnace roller and manufacturing method thereof

The invention relates to a high-temperature furnace roller for steel mill cold-rolled steel sheet continuous annealing line, continuous hot galvanizing line and silicon steel production line, especially to a JSSTDG-04-01 furnace roller and manufacturing method thereof. The product is composed of furnace roller base made of heat-resisting cast steel and detonation-sprayed metal-ceramic oxide coating on the surface of the furnace roller; the chemical composition of the ceramic in the coating is Al2O3, whose content is 10% to 30%; the content of the high-temperature alloy in the coating is 70% to 90%. The manufacturing steps include: cleaning the roller surface, preheating, sandblasting, spraying, polish-grinding, heat processing, dynamic balancing, testing and packaging. The high-temperature strength, accumulated-burl-resistant property and wear-resistant property of the product are tested to be superior.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Preparation method of manganese dioxide nanosheet/CNT (carbon nano tube) denitration catalyst with core-shell structure

ActiveCN103071484AImprove low temperature denitrification performanceEasy to makeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbon nanotube

The invention relates to a preparation method of a manganese dioxide nanosheet / CNT denitration catalyst with a core-shell structure, and belongs to the field of environmental-friendly catalytic materials. A backflow method is used for preparing the catalyst; manganese dioxide nanosheets are prepared and coats a CNT evenly; and ammonia gas can be taken as a reducing agent at a certain temperature to convert nitric oxide into nitrogen and water through selective catalytic reduction. The preparation method is simple, and good in low-temperature activity; the prepared catalyst has an excellent desorption effect on nitric oxide in smoke; and the synthetic catalyst can be used for processing nitric oxide in smoke discharge by coal-fired power plants, garbage incinerators, steel mills and the like.

Owner:SHANGHAI UNIV

Method for smelting nickel-containing molten iron by use of laterite ore

The invention provides a method for smelting nickel-containing molten iron by use of laterite ore. The method sequentially comprises the following: (1) a step of mixing materials, which is to mix laterite ore, bentonite and flux as main raw materials well with water; (2) a step of briquetting, which is to put mixture into a briquetting machine for briquetting and then dry or maintain briquettes to prescriptive strength; (3) a step of proportioning, which is to add coke to the dried or maintained briquettes; (4) a step of smelting, which is to feed and smelt the proportioned raw materials in a small-sized blast furnace or a novel shaft furnace with an iron port and a blast tuyere from a furnace mouth; and (5) a step of discharging molten iron, which is to send the smelted nickel-containing molten iron to steel works or cast iron ingots into the nickel-containing molten iron. The method for smelting nickel-containing molten iron by use of laterite ore has the advantages of lower production cost for smelting nickel-containing molten iron and less environmental pollution.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

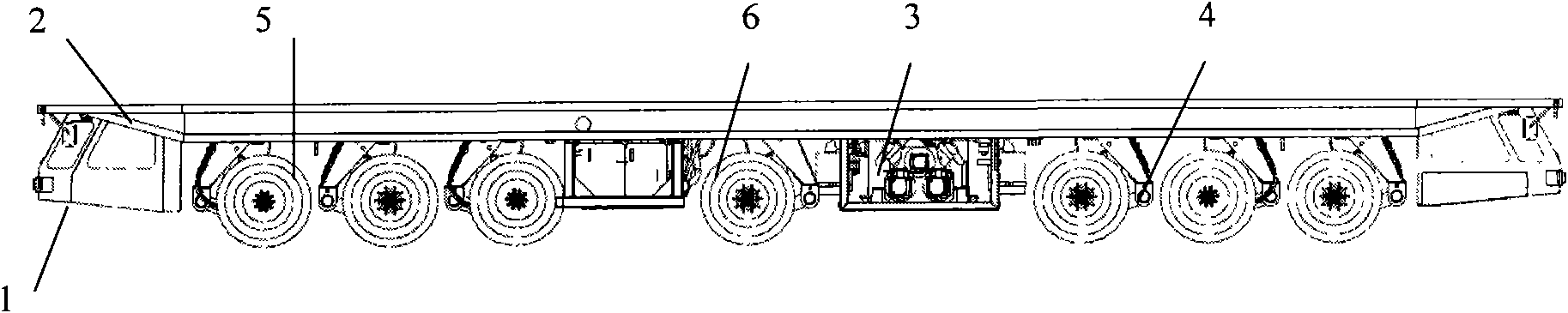

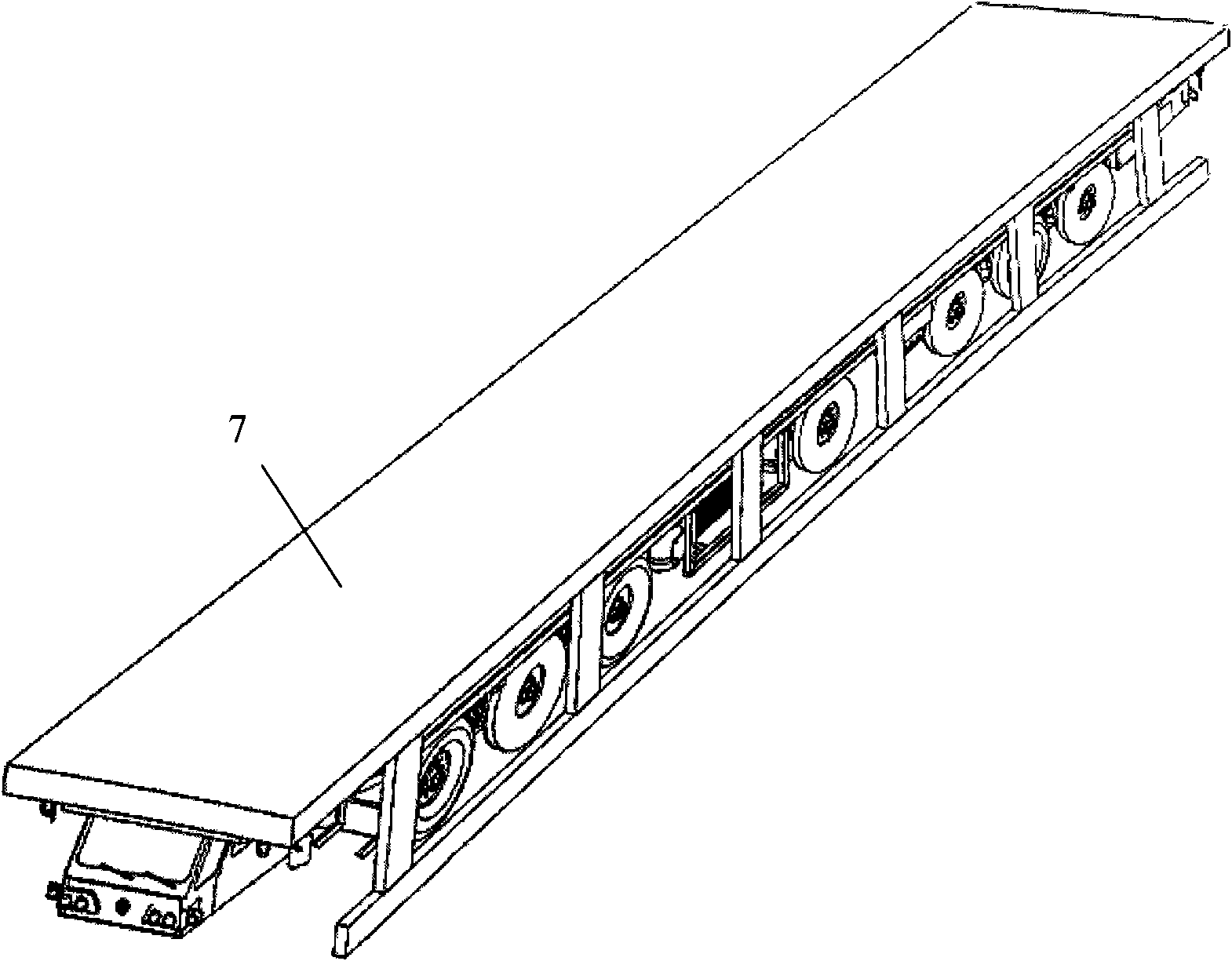

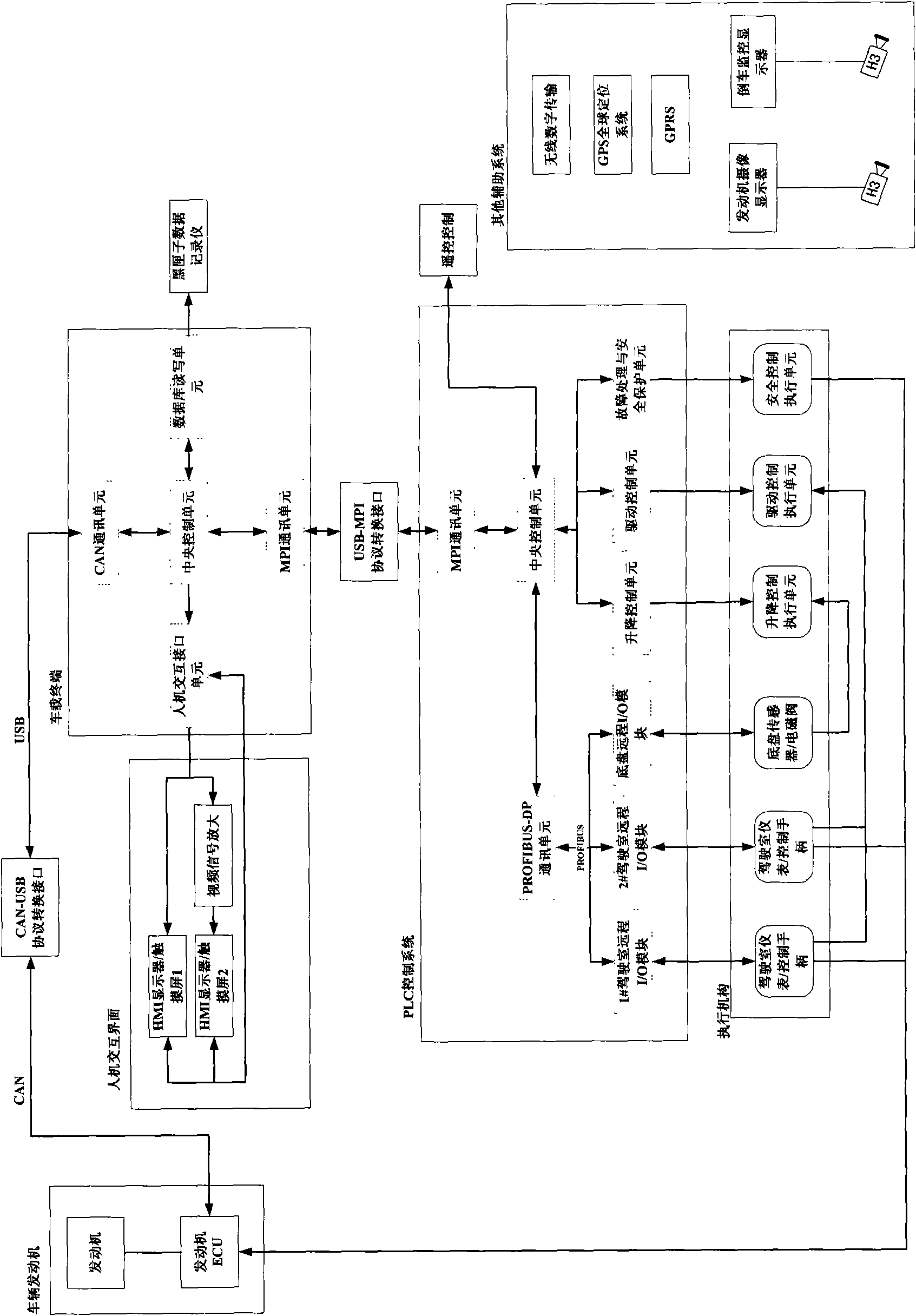

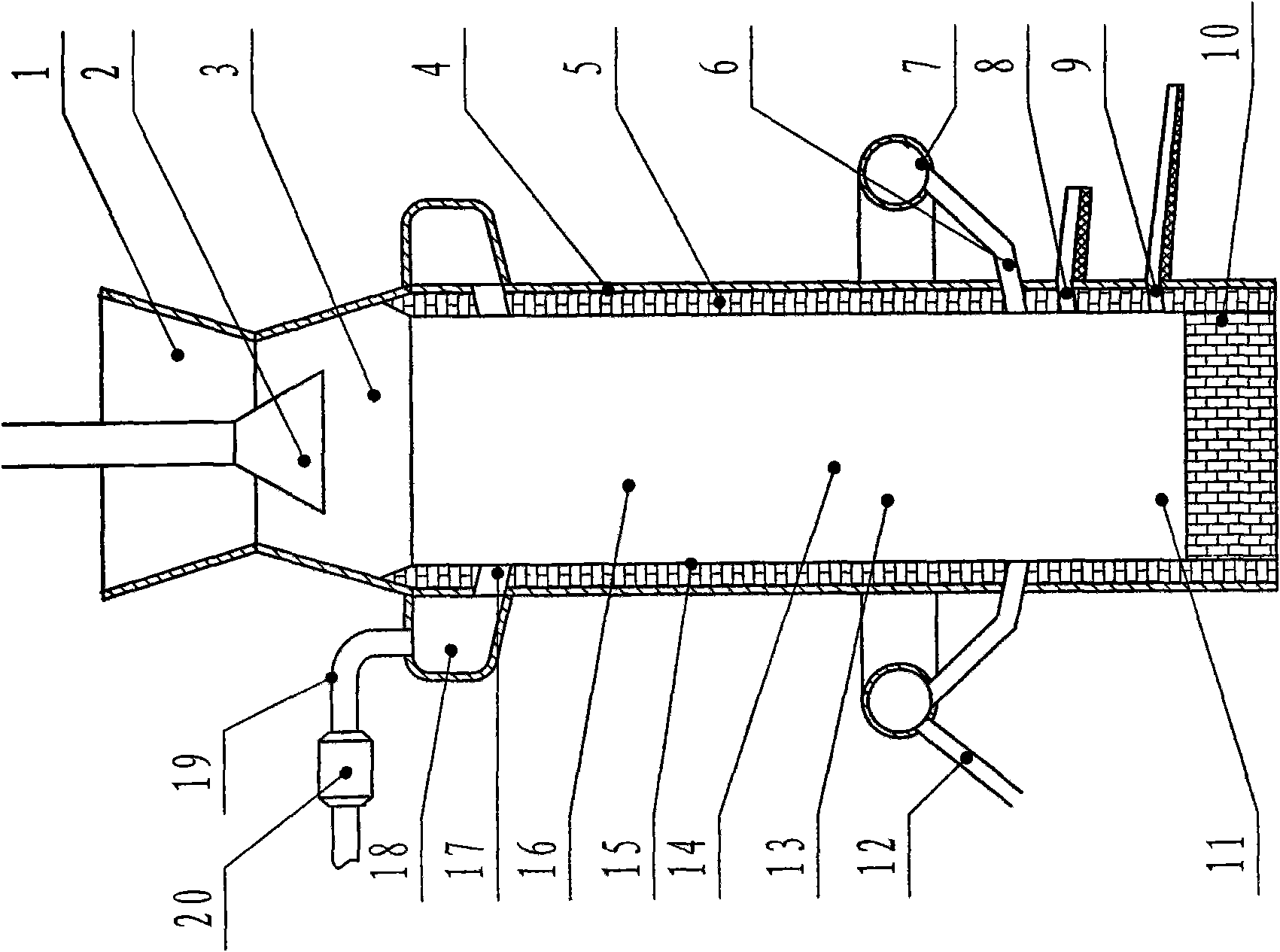

Power-driven lift platform carrier vehicle for steel mill

ActiveCN101767549AReduce data trafficImprove reliabilityRegistering/indicating working of vehiclesEngine controllersVehicle frameLogistics management

The invention provides a power-driven lift platform carrier vehicle for a steel mill, comprising an engine, a carriage, a hydraulic system with an oil cylinder, at least one cab, an engine control unit, a vehicle-mounted terminal system, a PLC control system and related executive mechanisms; and in the process, data is transmitted by respectively using CAN, MIPI and USB protocol to finish the control of a finished vehicle. The invention has the advantages of having higher driving speed, satisfying logistics operation efficiency in the steel mill, being capable of continuous operation in full load working condition, having compact installation structure of the parts and conforming to the requirement of road boundary line.

Owner:BAOSHAN IRON & STEEL CO LTD +2

Method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material

ActiveCN101654738AMeet production needsLow process costBlast furnace detailsShaft furnaceSodium BentoniteSlag

The invention relates to a method for smelting chromated-nickel-containing molten iron by stainless steel dedusting ash and iron scale companion material, which comprises the steps of mixing, briquetting, dosing, smelting and producing the molten iron; wherein (1) mixing: evenly mixing the dedusting ash, bentonite, cement, solvent, iron scale or scrap iron and water; (2) briquetting: putting the mixed material into a briquetting machine to be briquetted; (3) dosing: 60-80 parts by weight of block mass, 30-50 parts by weight of coke and 3-12 parts by weight of solvent; or 60-80 parts by weightof block mass, 30-50 parts by weight of coke, 3-12 parts by weight of solvent and 6-20 parts by weight of slag-metal; (4) smelting: adding the prepared raw materials into a novel shaft furnace or a minitype blast furnace provided with a single iron notch and a single air inlet to be smelted; and (5) producing the molten iron: sending the smelted molten iron into steel plants or casting into iron ingots. Or in step (3), 6-20 parts by weight of slag-metal can be added into the material. The smelting method is low in production cost and high in content of chromium and nickel of the product.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

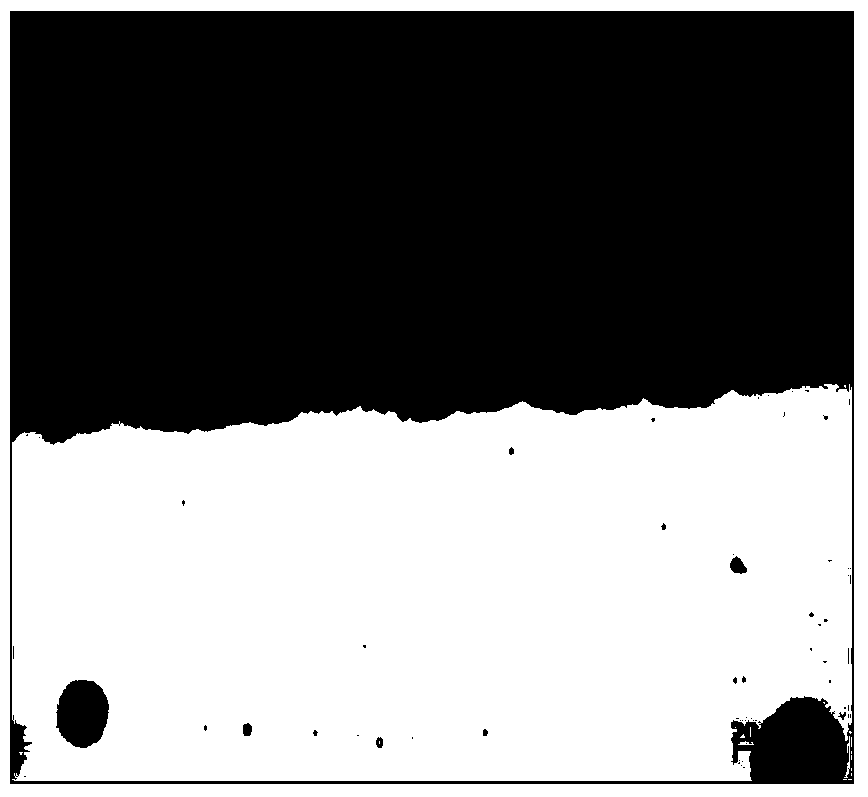

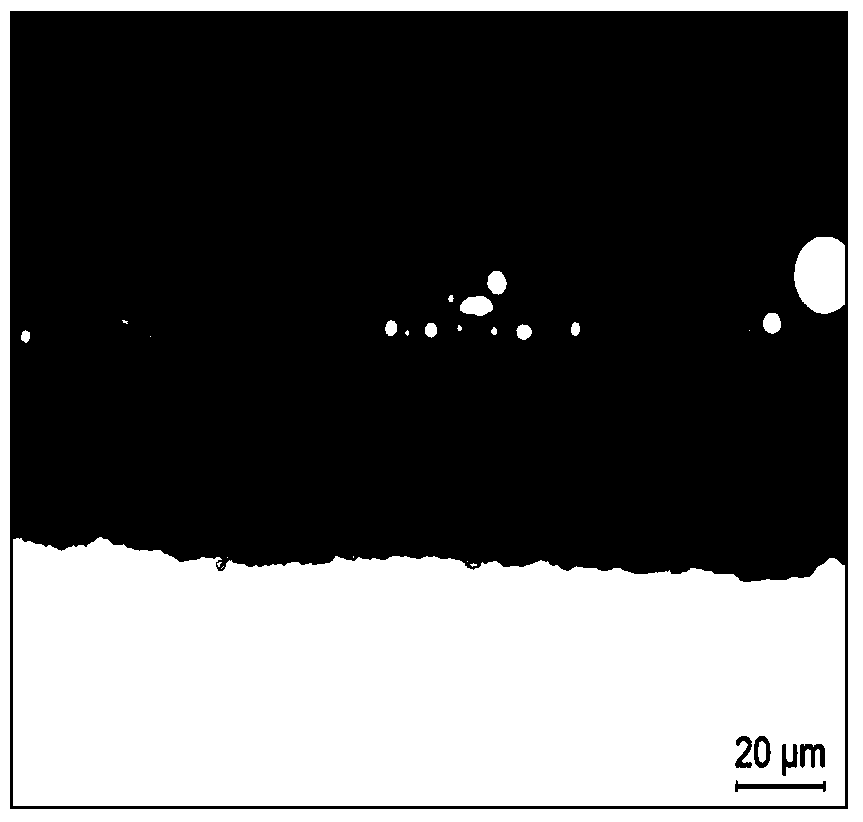

Oxide scale control method for improving corrosion resistance of hot rolled medium plate

ActiveCN103962386AImprove corrosion resistanceReduce contentTemperature control deviceWork treatment devicesScale structureMechanical property

The invention provides an oxide scale control method for improving the corrosion resistance of a hot rolled medium plate and belongs to the technical field of metallurgy. The control method comprises the steps that smelting molten steel is made into a plate billet in a continuous casting mode, and the plate billet is heated, subjected to heat preservation and then roughly descaled, wherein the rough descaling pressure is larger than or equal to 16 MPa, and the rough descaling time is 4-10 seconds; the plate billet is subjected to rough rolling and then finish rolling, and finish descaling is conducted before an odd number of secondary finish rolling stages, wherein the finish descaling pressure is larger than or equal to 16 MPa, and the finish descaling time is 4-10 seconds; after being subjected to finish rolling, the plate billet is placed onto a cooling bed and cooled to the room temperature at the speed of 10-25 DEG C per second. According to the control method, a hot rolling process adjustment scheme is proposed according to an oxide scale structure of the hot rolled medium plate; the cooling speed of the plate billet on the cooling bed is controlled, the oxide scale structure is controlled reasonably by controlling the eutectoid reaction degree of FeO, and therefore the corrosion resistance of the surface of the hot rolled medium plate is improved; since existing equipment and process conditions in a steel mill are utilized, investment cost and production cost are not increased, and the corrosion resistance of the hot rolled medium plate is improved on the basis of guaranteeing the mechanical properties of the hot rolled medium plate.

Owner:NORTHEASTERN UNIV

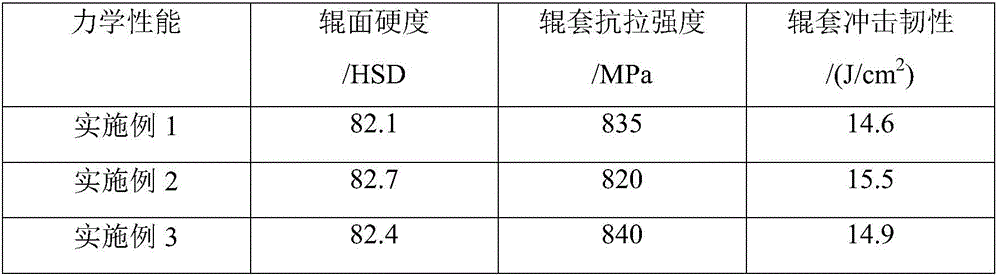

Wear-resistant high-vanadium-nitrogen high-speed steel section steel roll and manufacturing method thereof

ActiveCN105779861AReduce manufacturing costHigh hardnessProcess efficiency improvementWear resistantFerrochrome

The invention relates to a wear-resistant high-vanadium-nitrogen high-speed steel section steel roll and a manufacturing method thereof and belongs to the technical field of steel rolling. The wear-resistant high-vanadium-nitrogen high-speed steel section steel roll is compounded by hot charging a high-vanadium-nitrogen high-speed steel roll sleeve and a medium carbon steel roll shaft, wherein the high-vanadium-nitrogen high-speed steel roll sleeve is prepared from the following components in percentage by mass: 20-24 percent of M2 high-speed steel (also called W6Mo5Cr4V2 high-speed steel) scraps, 4.5-4.8 percent of vanadium-nitrogen alloy, 1.8-2.2 percent of ferrocolumbium, 55-59 percent of Q235 steel scraps, 10-12 percent of carbon ferrochrome, 1.2-1.4 percent of electrolytic nickel, 0.30-0.45 percent of ferrotitanium and 1.2-1.4 percent of metal aluminum burdens and is prepared by the following steps of smelting the components by an electric furnace, pouring on a centrifuge to form a roll sleeve, annealing, rough machining, quenching, tempering and finish machining. The high-vanadium-nitrogen high-speed steel roll sleeve is compounded with the medium carbon steel roll shaft together in a hot charging manner, and a compound is used on a section steel mill and is excellent in wear resistance.

Owner:枣庄瑞兴机械制造有限公司

High-temperature grease and preparation method thereof

The invention relates to a high-temperature grease and a preparation method thereof, which are widely applied to equipment bearings of production lines in steel mills and steel works. The high-temperature grease contains the following components in weight parts: 45 to 81.5 parts of high-viscosity mineral oil, 4 to 10 parts of polyurea, 10 to 30 parts of high-base number calcium petrolem sulfonate, 1 to 3 parts of transforming agent, 1 to 3 parts of anti-rust agent, 1 to 3 parts of extreme-pressure additive, 0.5 to 1 part of antioxidant, and 1 to 5 parts of thickening agent. The high-viscosity mineral oil is 150BS. The high-temperature grease has higher dropping point, does not turn thin or has lower thinning degree after meeting water; the antirust performance is as good as the new grease after meeting water; and the extreme-pressure performance thereof is reduced by a lower degree or does not reduce after meeting water.

Owner:辽宁海华科技股份有限公司

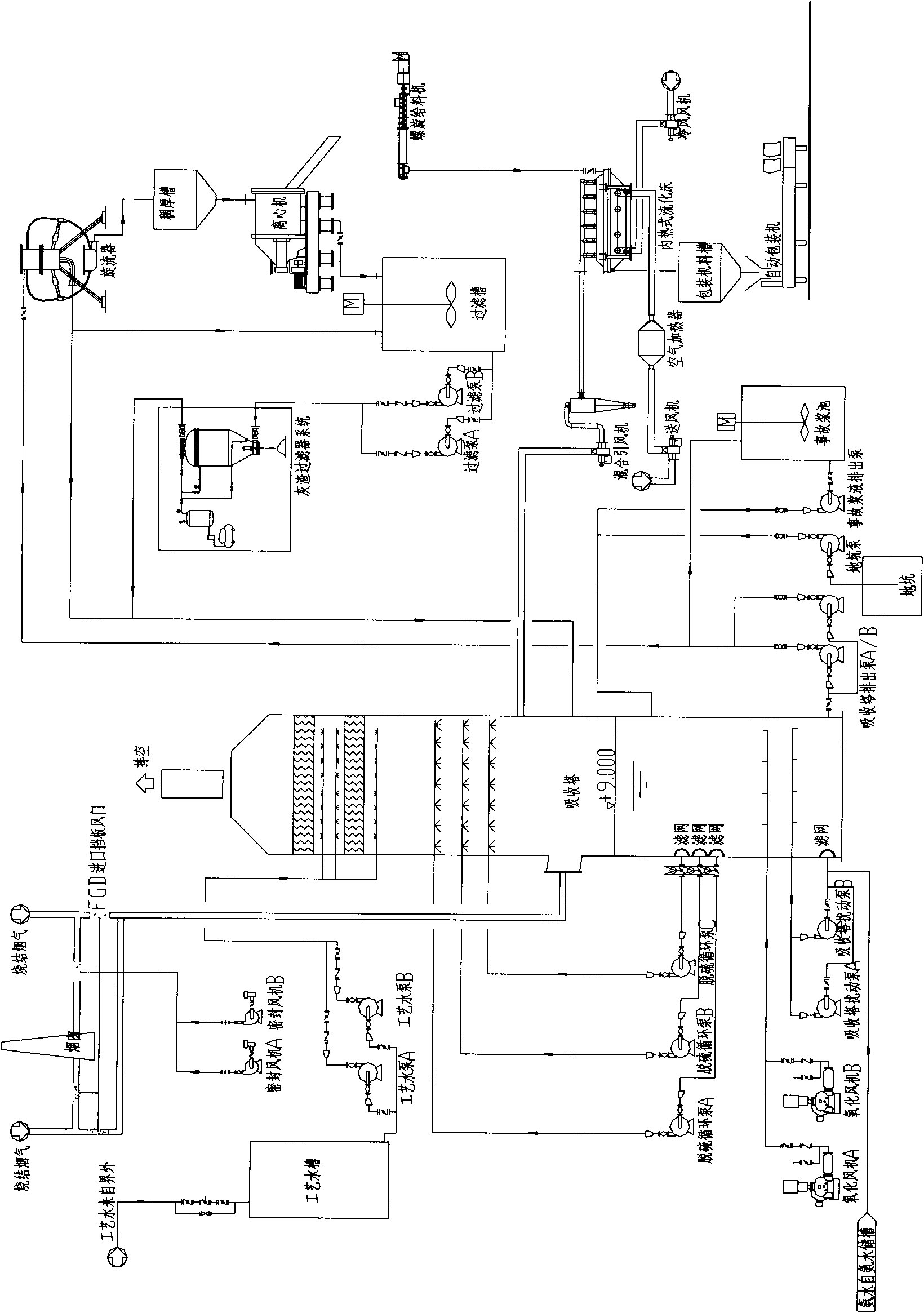

Flue gas desulfurization process suitable for sintering machine of steel mill

InactiveCN101862583AHigh desulfurization rateLow running costDispersed particle separationProcess engineeringSteel mill

The invention discloses process technology suitable for removing a sulfur dioxide byproduct, namely, ammonium sulfate chemical fertilizer in flue gas produced by a sintering machine of a steel mill and suitable for the characteristics of large sintering flue gas amount, large flue temperature fluctuation, high moisture content, high dust content and the like. The process comprises the following steps of: allowing sintering flue gas to enter from the middle of an absorption tower, wherein the flue gas is reversely contacted with absorption liquid; removing sulfur dioxide from the flue gas in a contacting process; exhausting the flue gas through a chimney on the top of the tower after the flue gas flows through a demister on the top of the tower; introducing compressed air and ammonia water into the absorption liquid, wherein ammonium sulfate in solution is saturated and 5 percent of crystal is separated out along with continuous absorbing and oxidizing processes; and rotating, filtering and drying ammonium sulfate crystal-containing suspension to obtain a finished product. Since the absorption, oxidation and condensation of the sintering flue gas are completed in the absorption tower at the same time, the process has the characteristics of refined flow, high desulfurization efficiency and high byproduct quality.

Owner:高翀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com