Method for smelting nickel-containing molten iron by use of laterite ore

A technology of laterite ore and nickel-iron water, which is applied in the field of laterite ore smelting nickel-containing iron water, can solve the problems of insufficient competitiveness, high power consumption of the electric furnace method, and loss of competitiveness, so as to avoid dust, overcome poor feeding, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

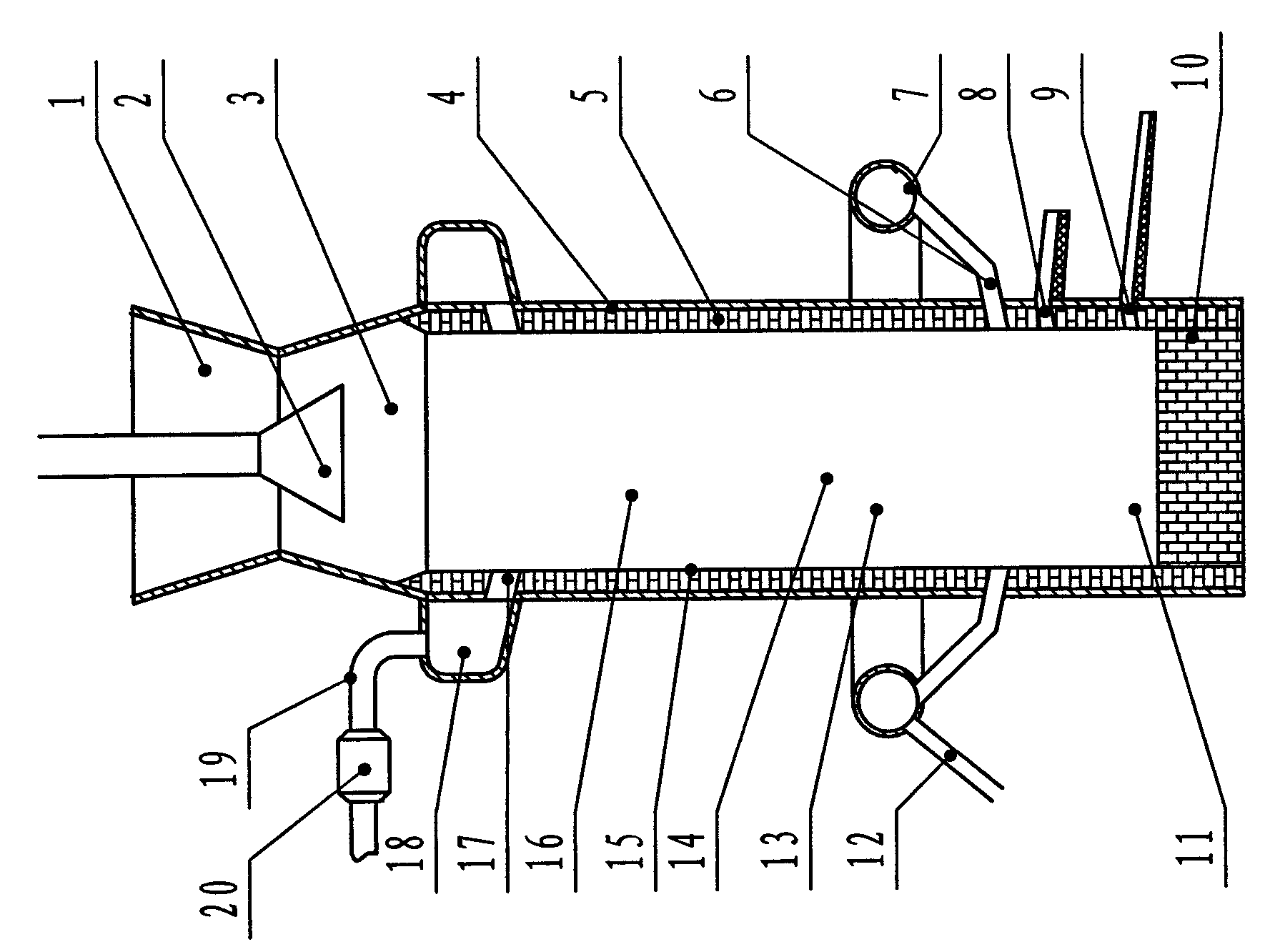

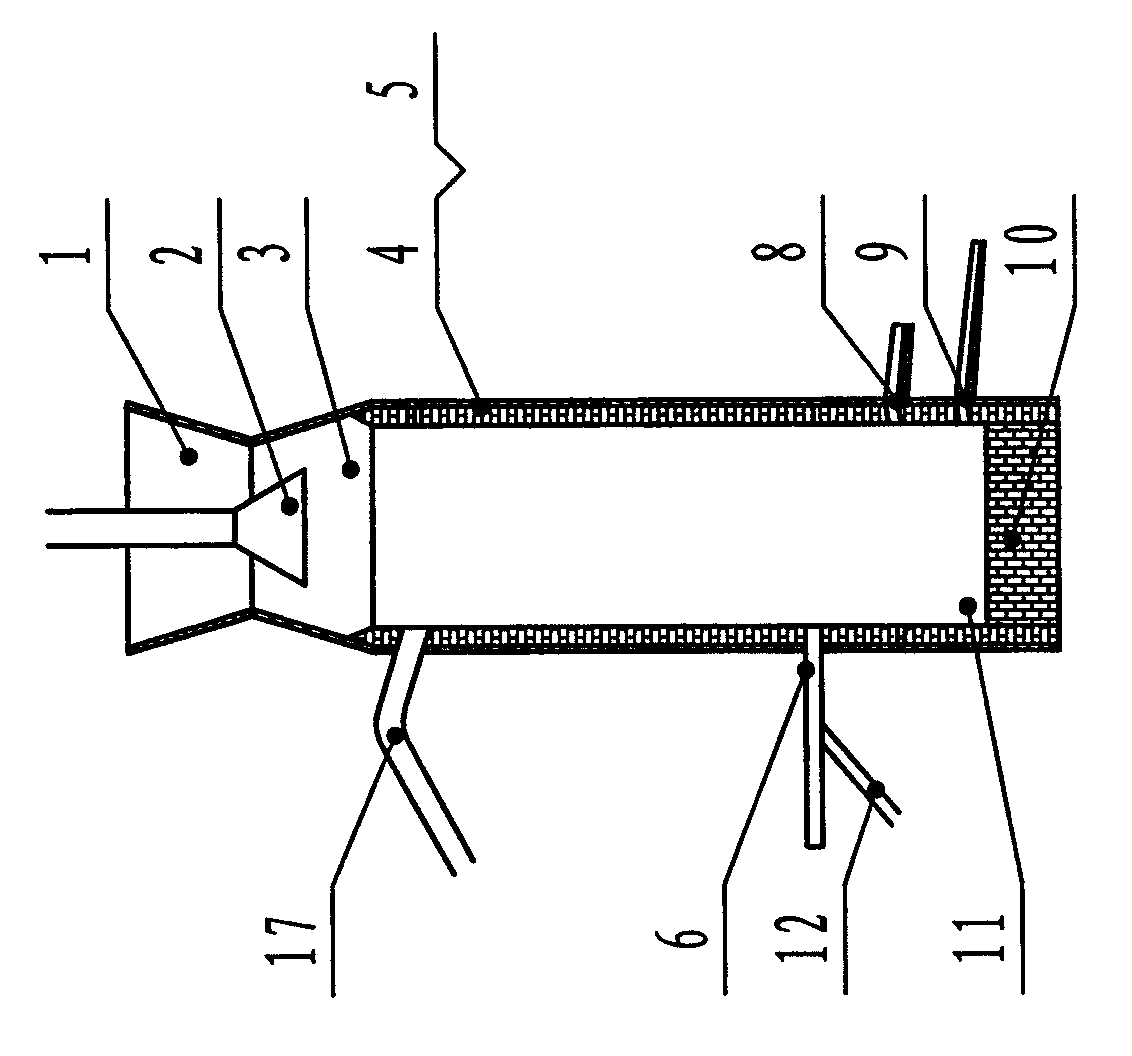

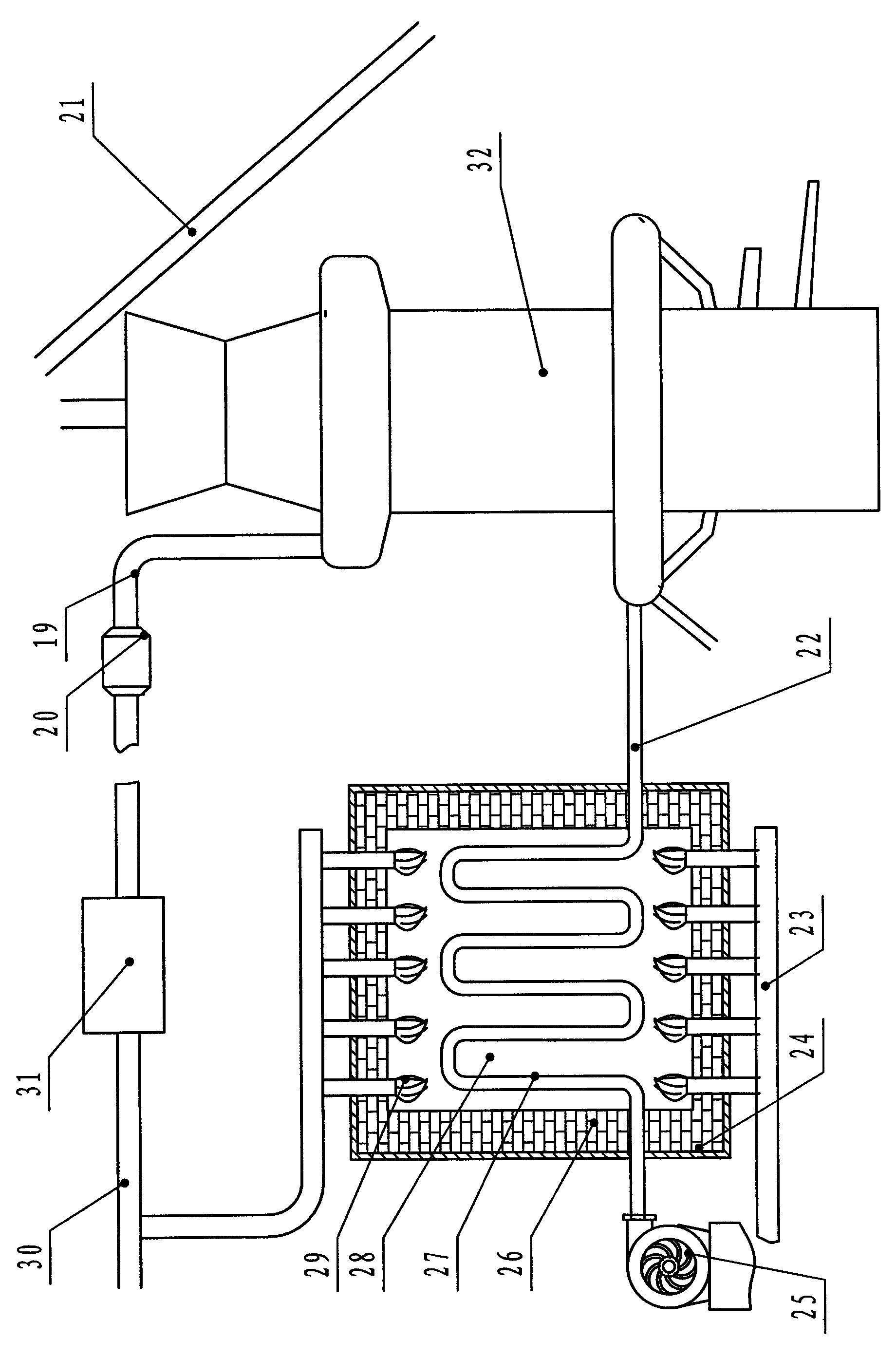

[0064] This embodiment uses the figure 2 The new small shaft furnace described, the furnace capacity of the new shaft furnace test furnace of this embodiment is 4m 3 , about 1m in diameter, 4m in height, one tap outlet 9, one air outlet 6, no sealing facilities for charging, gravity dust collector, no fine dust removal facilities, and a set of heat exchanger 21 built with refractory materials, see the structure image 3 . Manual feeding, manual weighing. Hot air temperature: 530~660℃, the furnace body is sprayed and cooled. A small cast iron trolley and eight molds are set in front of the furnace, which can cast about 300kg of cast iron at a time. The hole diameter of the tap hole 9 is 20mm. The slag outlet 8 has no cooling jacket.

[0065] The steps of this embodiment are as follows:

[0066] (1) Mixing

[0067] The mass ratio of the raw materials constituting the laterite ore mixture is:

[0068] Laterite 78.5 Cement 10 Bentonite 1.5 In addition, the mixture maintai...

Embodiment 2

[0099] The difference between this embodiment and the first embodiment has three points: the raw materials used during the step (1) mixing are different, add pulverized coal in the mixing, and mix the materials according to the following proportions

[0100] (1) Mixing

[0101] The mass ratio of the raw materials constituting the laterite ore mixture is:

[0102] Laterite 69 Cement 10 Bentonite 1 Pulverized Coal 10

[0103] In addition, the mixture maintains 10 parts of water;

[0104] All the above-mentioned raw materials are processed into powders with less than 200 mesh accounting for more than 60%. After the materials are mixed according to the above mass fraction, they are put into the mixer and mixed evenly.

[0105] In addition, the composition of the molten iron in step (5) is different from that of Embodiment 1, and the composition mass percentage of the nickel-containing molten iron of the present embodiment is:

[0106] C: 4.5% Si: 0.85% Mn: 1.30% Ni: 2.15%

[...

Embodiment 3

[0113] The main difference between this embodiment and the first embodiment is that the raw materials used in (1) mixing are different. In this embodiment, stainless steel dust is also added to the laterite mixture, and the laterite mixture is prepared according to the following mass fractions Ratio mix:

[0114] Laterite 40 Stainless Steel Dust 39 Cement 11

[0115] Bentonite 1.5 The water distribution is 8 parts.

[0116] All the raw materials required for the above-mentioned briquetting are processed into powder with less than 200 mesh accounting for more than 60%. After the materials are mixed according to the above mass fraction, they are put into the mixer and mixed evenly.

[0117] The mass percentage of the composition of the briquetting ball is shown in Table 2

[0118] Table 2

[0119] Fe 2 O 3

FeO

SiO 2

AI 2 O 3

CaO

MgO

P

Cr 2 O 3

NiO

C

46.88

6.09

6.57

3.0

8.21

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com