Synthetic raw material gas deep fine desulfurization process and fine desulfurization device

A raw material gas and fine desulfurization technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as irremovable, and achieve the effects of reducing cost and energy consumption, low reaction temperature, and large space velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

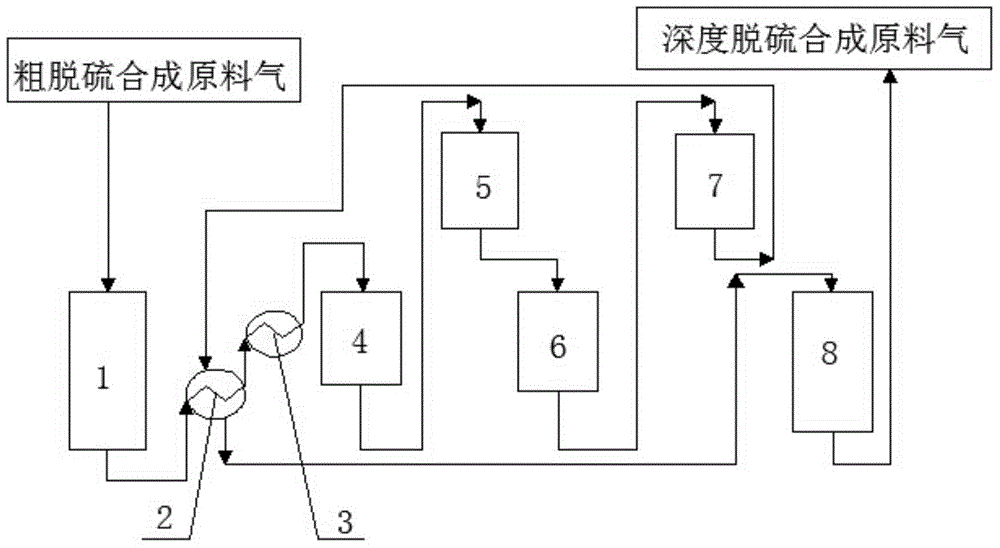

[0017] A device for deep fine desulfurization process of synthetic feed gas, such as figure 1 Shown: including iron oxide coarse desulfurizer 1, gas-gas heat exchanger 2, start-up heater 3, primary hydrogenation reactor 4, primary zinc oxide desulfurizer 5, secondary hydrogenation reactor 6, secondary Zinc oxide desulfurizer 7 and multi-functional fine desulfurizer 8, iron oxide coarse desulfurizer 1 are connected with gas-gas heat exchanger 2, start-up heater 3, primary hydrogenation reactor 4, and primary zinc oxide desulfurizer through pipelines 5. The secondary hydrogenation reactor 6 and the secondary zinc oxide desulfurizer 7 are connected, and the outlet of the secondary zinc oxide desulfurizer 7 is connected to another inlet at the top of the gas-gas heat exchanger 2 through a pipeline. Another outlet at the bottom of the gas-gas heat exchanger 2 is connected to the inlet of the multifunctional fine desulfurizer 8 through a pipeline.

[0018] According to the amount o...

Embodiment 2

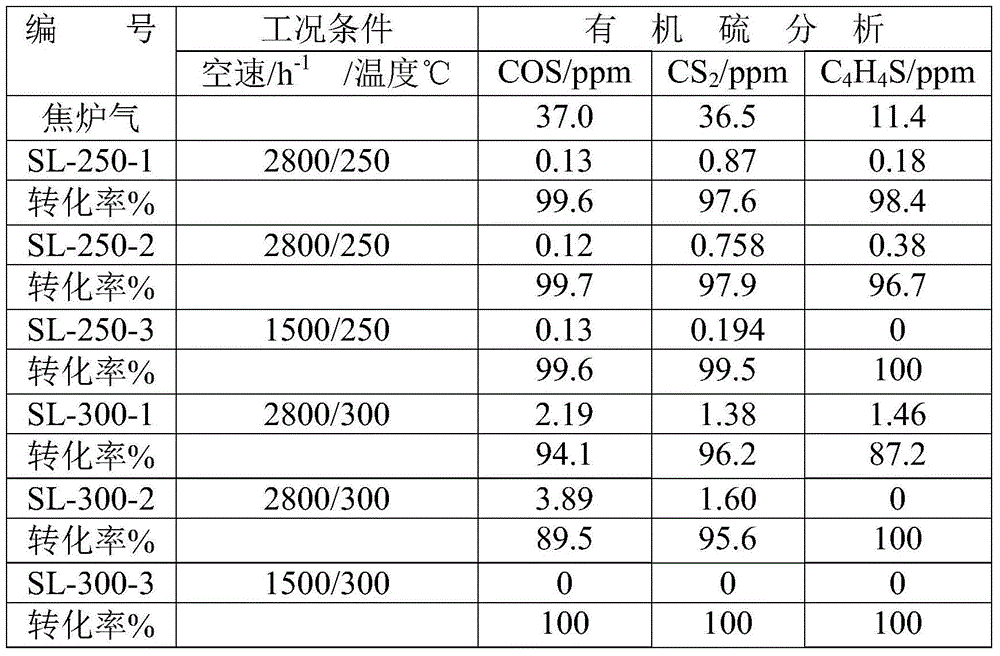

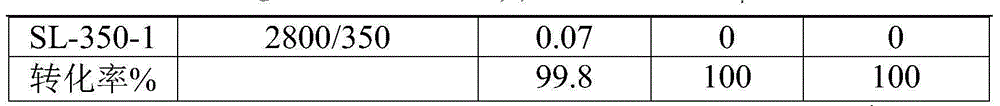

[0020] Now take the desulfurization of coke oven gas as an example to describe the technical process in the present invention in detail. Coke oven gas is a gas source that contains a lot of organic sulfur and has a complex composition in the synthetic raw material gas. It also contains O 2 , CO, CO 2 Components, atmosphere effect is very obvious. The coke oven gas after rough desulfurization passes through iron oxide rough desulfurization reactor 1, and the H in the gas 2 The S content is reduced to 2 , RSH, RSR, C 4 h 4 S, etc.) hydrogenation into H 2 S, after leaving the primary hydrogenation reactor 4, coke oven gas enters the primary zinc oxide desulfurizer 5 equipped with zinc oxide desulfurizer to convert H 2 S is removed to ≤0.03ppm, and then enters the secondary hydrogenation reactor 6, allowing the remaining organic sulfur to undergo hydrogenation conversion reaction again, and the raw material gas after the reaction enters the secondary zinc oxide desulfurizer 7...

Embodiment 3

[0027] Taking water gas desulfurization as an example, the technical process in the present invention is described in detail. The water gas after crude desulfurization passes through iron oxide crude desulfurization reactor 1, and the H in the gas 2 The S content is reduced to 2 , RSH, RSR, C 4 h 4 S, etc.) hydrogenation into H2 S, after leaving the primary hydrogenation reactor 4, the water gas enters the primary zinc oxide desulfurizer 5 equipped with a zinc oxide desulfurizer to convert H 2 S is removed to ≤0.03ppm, and then enters the secondary hydrogenation reactor 6, allowing the remaining organic sulfur to undergo hydrogenation conversion reaction again, and the raw material gas after the reaction enters the secondary zinc oxide desulfurizer 7, and the organic sulfur and H 2 S off to trace. After the secondary hydrogenation reaction and secondary zinc oxide desulfurization, the water gas passes through the gas-gas heat exchanger 2 for heat exchange, and after the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com