Patents

Literature

401results about How to "Reduce desulfurization cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

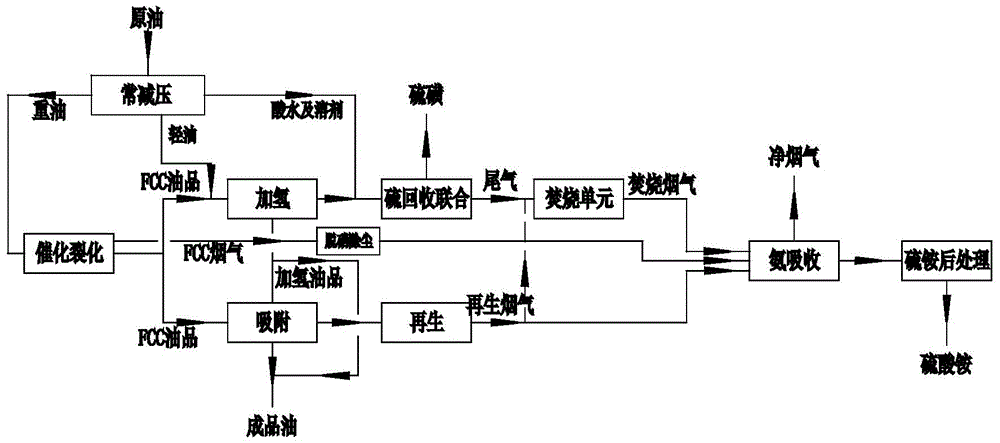

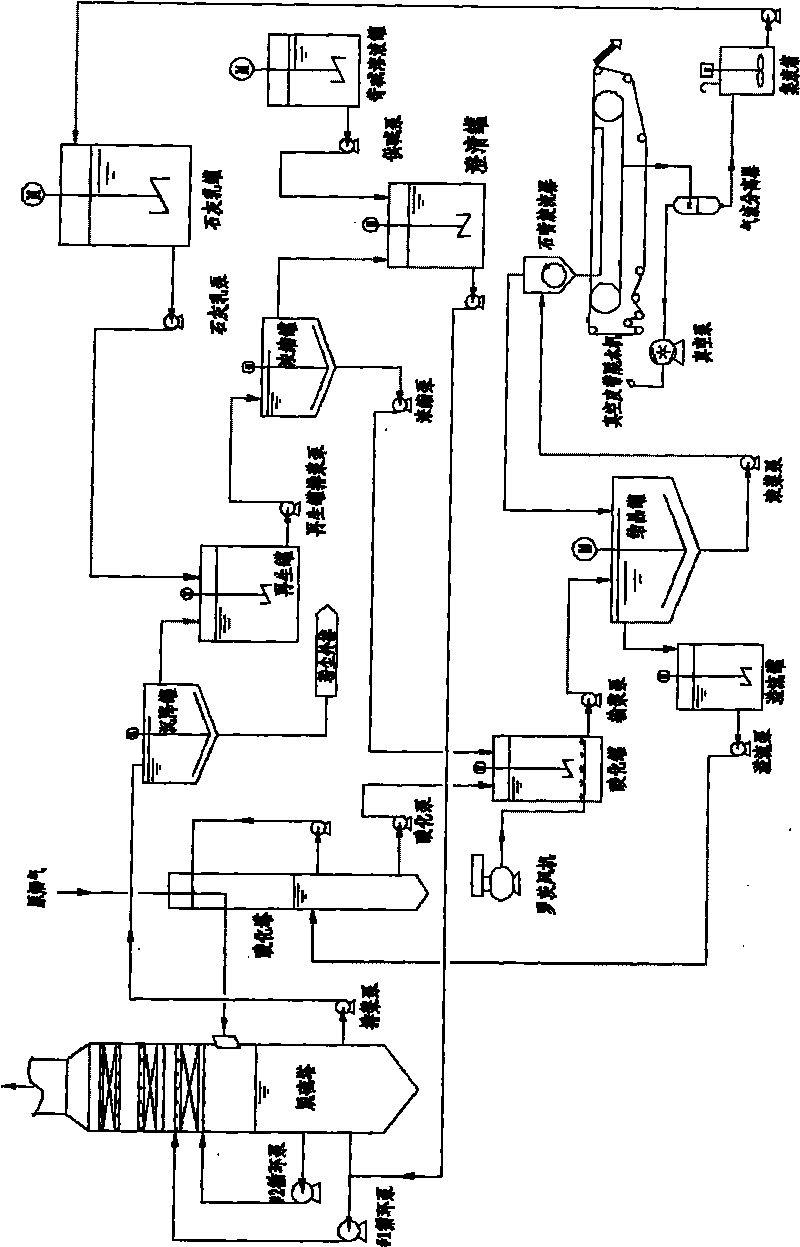

Integrated ammonia-process desulfurization method of various acidic gases in oil refining device

ActiveCN105126573ASimple processLess investmentDispersed particle separationSulfur preparation/purificationPtru catalystFlue gas

An integrated ammonia-process desulfurization method of various acidic gases in an oil refining device includes the following steps: (1) preparing heavy oil, light oil, acidic liquid and solvents through an atmospheric and vacuum distillation unit from crude oil, and feeding the heavy oil into a catalytic cracking device, the light oil into a hydrogenation device, and the acidic liquid and the solvents into a sulfur recovery combined device; (2) mixing a part of FCC oil, which is produced through the catalytic cracking device, with the light oil and feeding the mixed oil into the hydrogenation device to produce hydrogenated oil, the acidic liquid and solvents, wherein a part of the hydrogenated oil is fed into an adsorption device while the other part of the hydrogenated oil is stored and marketed as product oil; (3) feeding the acidic liquid and solvents and the acidic liquid and solvents prepared from the atmospheric and vacuum distillation unit into the sulfur recovery combined device to produce sulfur, and feeding the tail gas into an incineration unit for incineration to obtain incinerated flue gas; (4) feeding a part of the FCC oil which is produced in the catalytic cracking device into the adsorption device, performing adsorption desulfurization, and feeding an adsorption catalyst into a regenerative device to regenerate the adsorption catalyst in an oxidizing manner to obtain regenerated flue gas; and (5) feeding the FCC flue gas, the incinerated flue gas and the regenerated flue gas into an ammonia absorption device to perform absorption desulfurization and discharging cleaned flue gas after the flue gas meets standard.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

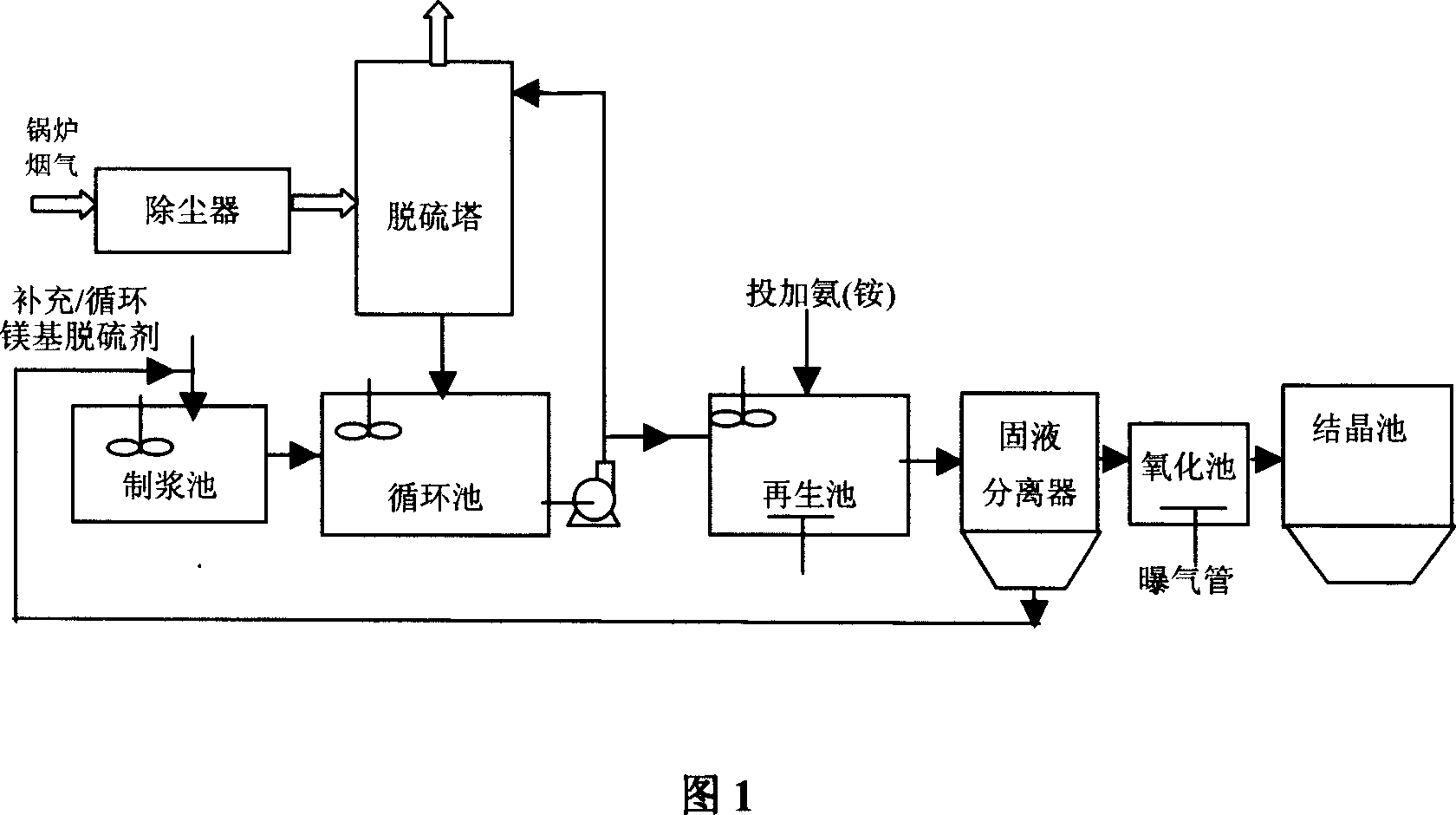

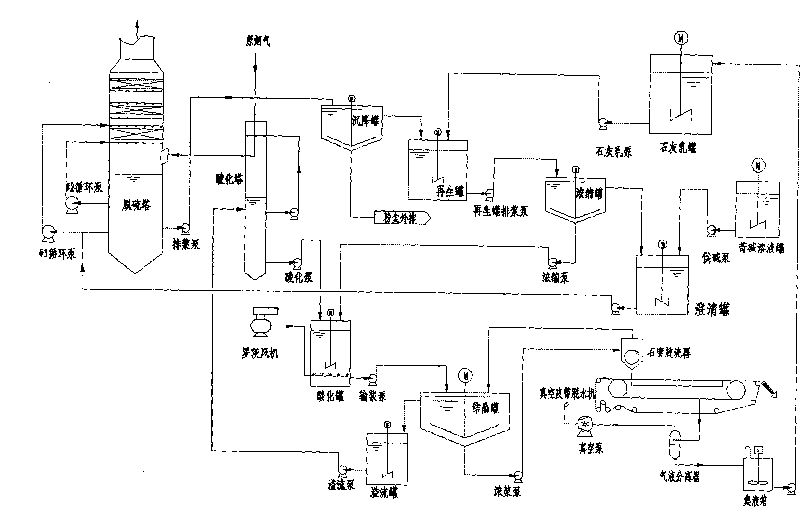

Method for using magnesium compound and ammonia to circulate regeneration flue gas desulfurization

InactiveCN101053742AReduce desulfurization costThere is no secondary pollution problemDispersed particle separationMagnesium sulfiteCarbonate

The invention relates to a cyclic regeneration flue gas desulfurization method using magnesium compounds and ammonia. Firstly, the magnesium compounds and ammonia which is used as desulfurizer is made to be seriflux after mixed with water, and then is send to recycling tank and then to the thionizer using seriflux pump to absorb the sulfur dioxide therein via the contact with flue gas to get the purpose of desulfurization purification of the flue gas. Part of the desulfurization solution is drawn off and regenerated using ammonia or ammonium salt when the PH of the seriflux after absorbing the SO2 is low than 6.2. Regeneration uses the method of direct regeneration or oxydizing regeneration, and the precipitate such as magnesium sulphites, magnesium hydroxide or magnesium carbonate get after regeneration can be periodic duty. After concentrating crystallization, the ammiaonia sulfate of liquid phase can get the ammonium sulphate crystals, and is also made to be a composite Crystals of ammonium sulphate and magnesium sulfate. The invention reduces the desulfurization cost without secondary pollution at the precondition for ensuring the effect desulfurization of flue gas.

Owner:SHANGHAI JIAO TONG UNIV

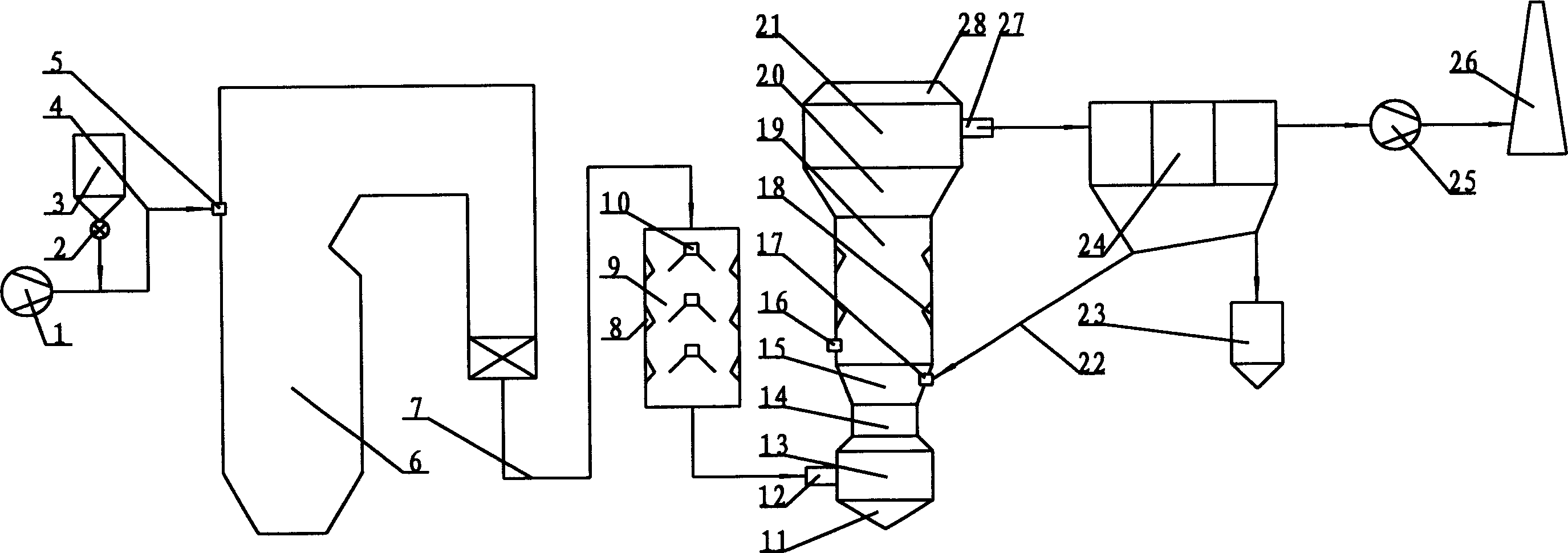

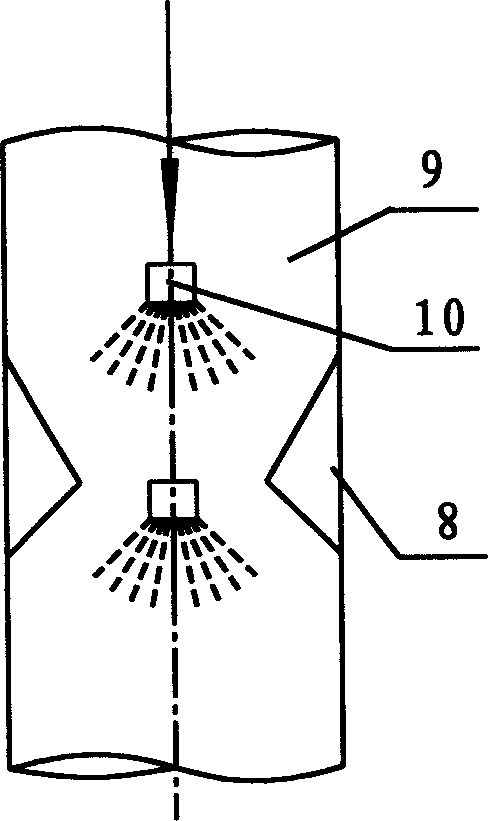

Multiple reaction integrated process for desulfuizing from fume by dry method and its system

ActiveCN1537668AImprove surface activityReduce desulfurization costDispersed particle separationPartial oxidationCalcium sulfite

A multiple reactions integrated process for desulfurizing from the fume by dry method includes such steps as spraying limestone powder in high-temp combustion box from its top to decompose calcium carbonate into calcium oxide and CO2, absorbing SO2 from fume by partial calcium oxide to generate calcium sulfate, spraying water to activate calcium oxide to transform partial calcium oxide to calcium hydroxide and absorb SO2 from fume to generate calcium sulfite, and using the residual calcium hydroxide and calcium oxide to desulfurize the fume in desulfurizing tower. Its system is composed of limestone powder sprayer, moistening flue, desulfurizing tower, external electric duster, draught blower and chimney.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Absorption catalyst for desulfurization of smoke gas and preparation method thereof

InactiveCN101181684AExtend your lifeSimple processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsLiquid wasteSulfur

The invention relates to an absorption catalyst used in flue gas desulfurization and a preparation method thereof. Gamma- Al2O3 is adopted as a carrier, and cupric oxide and cerium oxide are loaded on the surface of the catalyst, wherein, weight of the cupric oxide is 2.5 to 15.0 percent of the mass of Gamma- Al2O3, and the weight of the cerium oxide is 2.5 to 15.0 percent of the mass of Gamma- Al2O3. Ce is added as catalyst accelerato to modify CuO / Gamma- Al2O3 catalyst, thus the service life of the absorption catalyst of the invention is prolonged. The absorption catalyst can be circularly used, thus desulfurization cost is lowered. After the absorption desulfurization process is conducted with the absorption catalyst, and concentrated SO2 is analyzed, then sulfur can be obtained after reduction; secondary pollution, waste water and waste liquid are not produced, thus the aim of environmentally protection is fully realized. Co which originally exists in fume is utilized by the absorption catalyst of the invention to reduce SO2, thus production cost is reduced, and the aim of changing waste into valuable is realized; the preparation method of the invention is an environmental friendly technology, therefore an efficient approach of flue gas desulfurization is opened up.

Owner:SHANGHAI UNIV

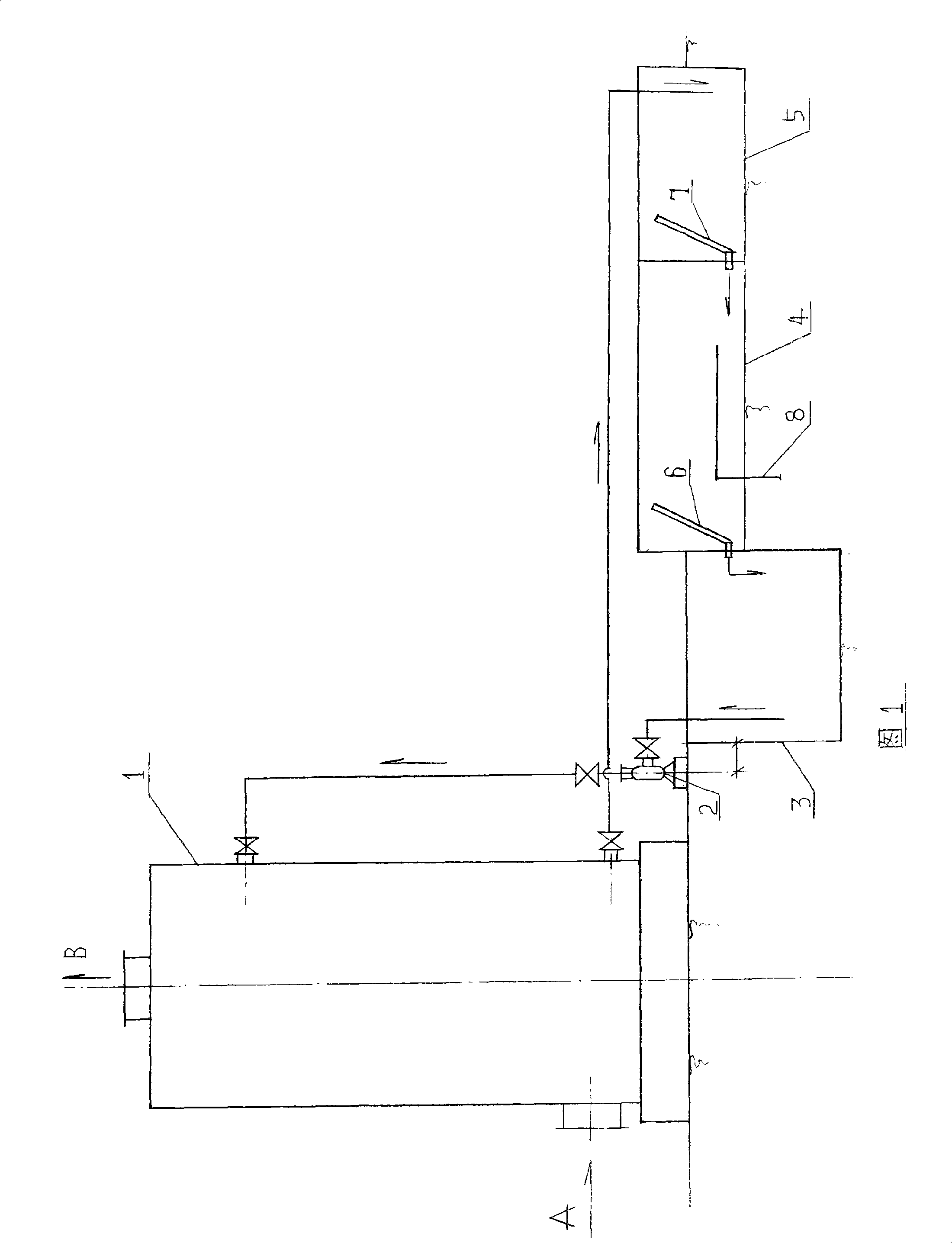

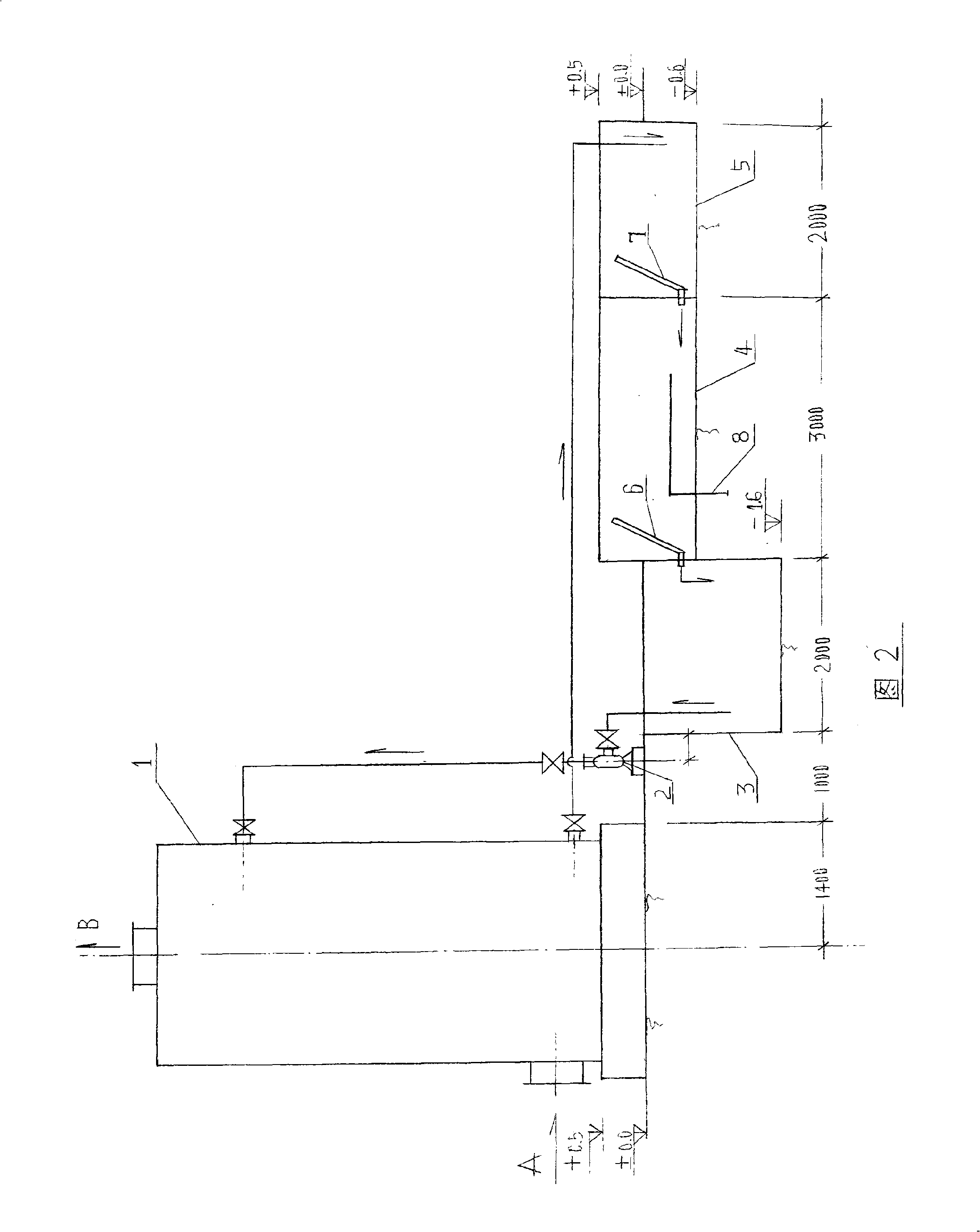

Process for desulphurizing and dedusting catalytic cracking regenerated smoke

ActiveCN101716454AHigh purityReduce consumptionDispersed particle separationHigh concentrationSlurry

The invention relates to a process for desulphurizing and dedusting catalytic cracking regenerated smoke, which comprises the following steps of: (1) leading smoke to enter a desulphurizing tower and leading effluent desulphurized pulp to enter a precipitating tank; (2) leading the precipitated pulp to enter a regenerating tank to finish the regeneration of sodium alkali and generating sediments of NaOH and CaSO3; (3) leading the regenerated pulp to enter a concentrating tank to obtain high-concentration and high-purity alkali liquid and the high-purity CaSO3 sediment; and (4) leading the CaSO3 sediment to perform the processes of acidification, oxidation, crystallization and dehydration to obtain solid gypsum with high purity and low water content. The smoke is in full contact with the alkali liquid by adopting an efficient pneumatic desulphurizing technology, and the desulphurizing efficiency is beyond 98 percent; the dedusting efficiency is high and is beyond 90 percent for micro dust with the grain diameter of 1-5 microns by the method; the utilization ratio of the lime milk pulp is high, and the utilization ratio of Ca(OH)2 is approximately 100 percent; in addition, the invention combines the desulphurizing tower and a chimney and effectively reduces the building cost and the occupation area.

Owner:AEROSPACE ENVIRONMENTAL ENG

Desulfurizing method using soda waste liquid and calcium carbide waste residue

InactiveCN101306304AHigh desulfurization rateQuick responseDispersed particle separationLiquid wasteSlag

The invention discloses a method for removing SO2 by utilizing soda ash waste liquid and carbide waste slag. CaCl2 in the soda ash waste liquid is utilized to react with the SO2 in flue gas, white CaSO3 settlement is generated, HCl is released and dissolved in water to form hydrochloric acid with very low concentration; Ca(OH)2 in the carbide waste slag is used for neutralizing HCl and generating CaCl2 and water, and CaCl2 is recycled. The desulphurization process mainly consumes Ca(OH)2 in the carbide waste slag. If no local soda ash waste liquid, calcium chloride dehydrate (CaCl2*2HO) produced by the soda ash waste liquid can be purchased for preparing CaCl2 solution. The carbide waste slag can be replaced by lime. The process is characterized by one high, two low and three points of environmental protection. The process firstly has high desulphurization rate, secondly has low fixed-asset investment and low running costs and thirdly utilizes the waste liquid and the waste slag to reduce the environmental pollution. Compared with all prior desulphurization processes, the process has great advantages.

Owner:康仁

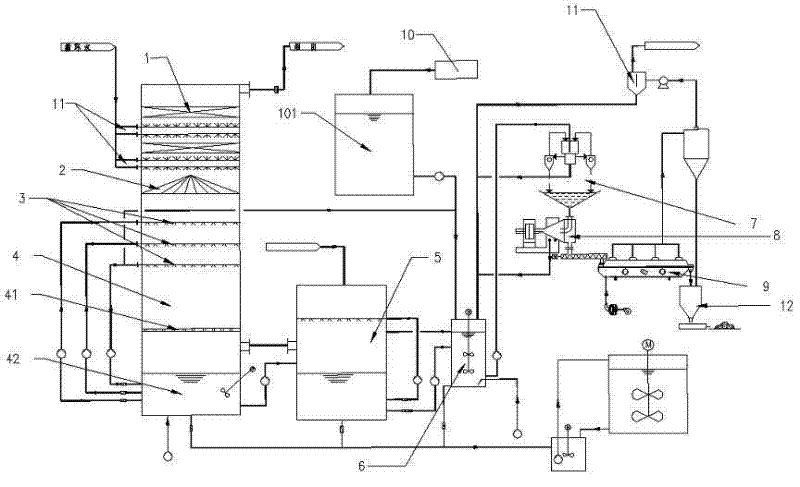

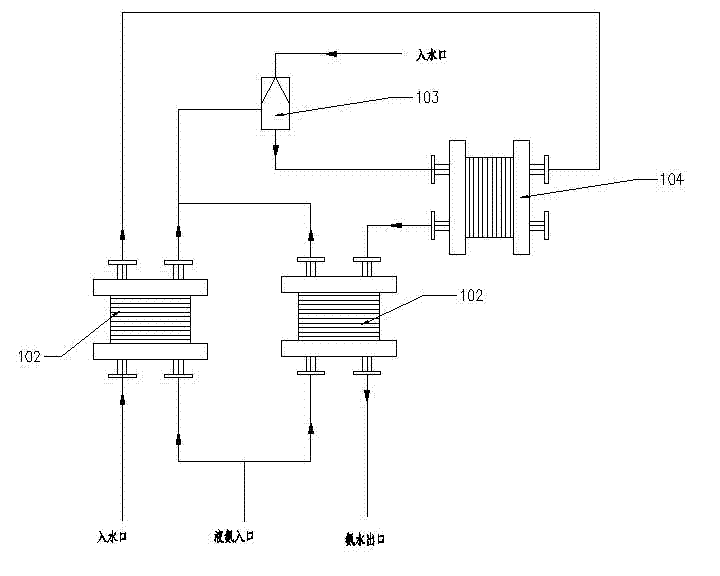

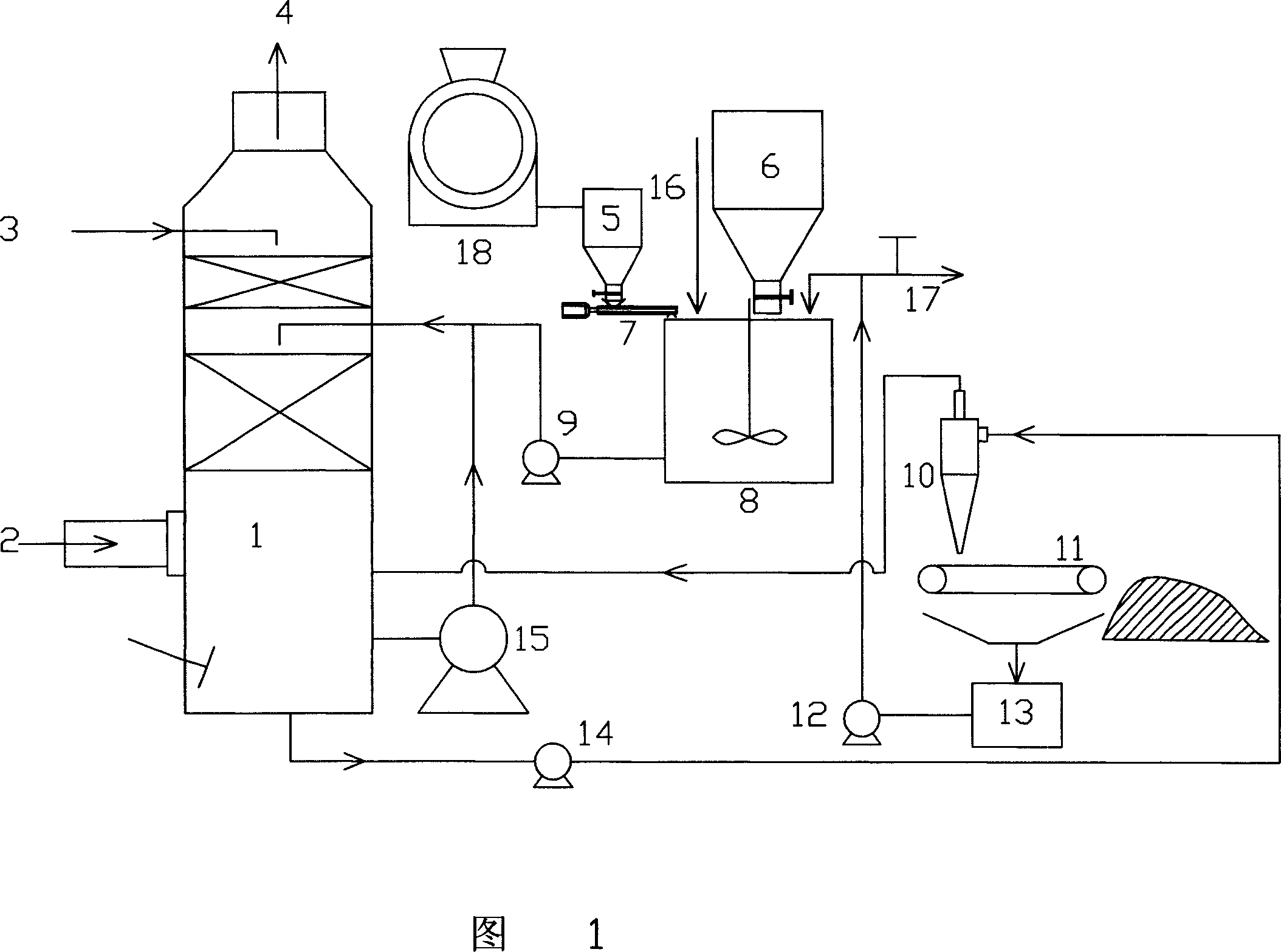

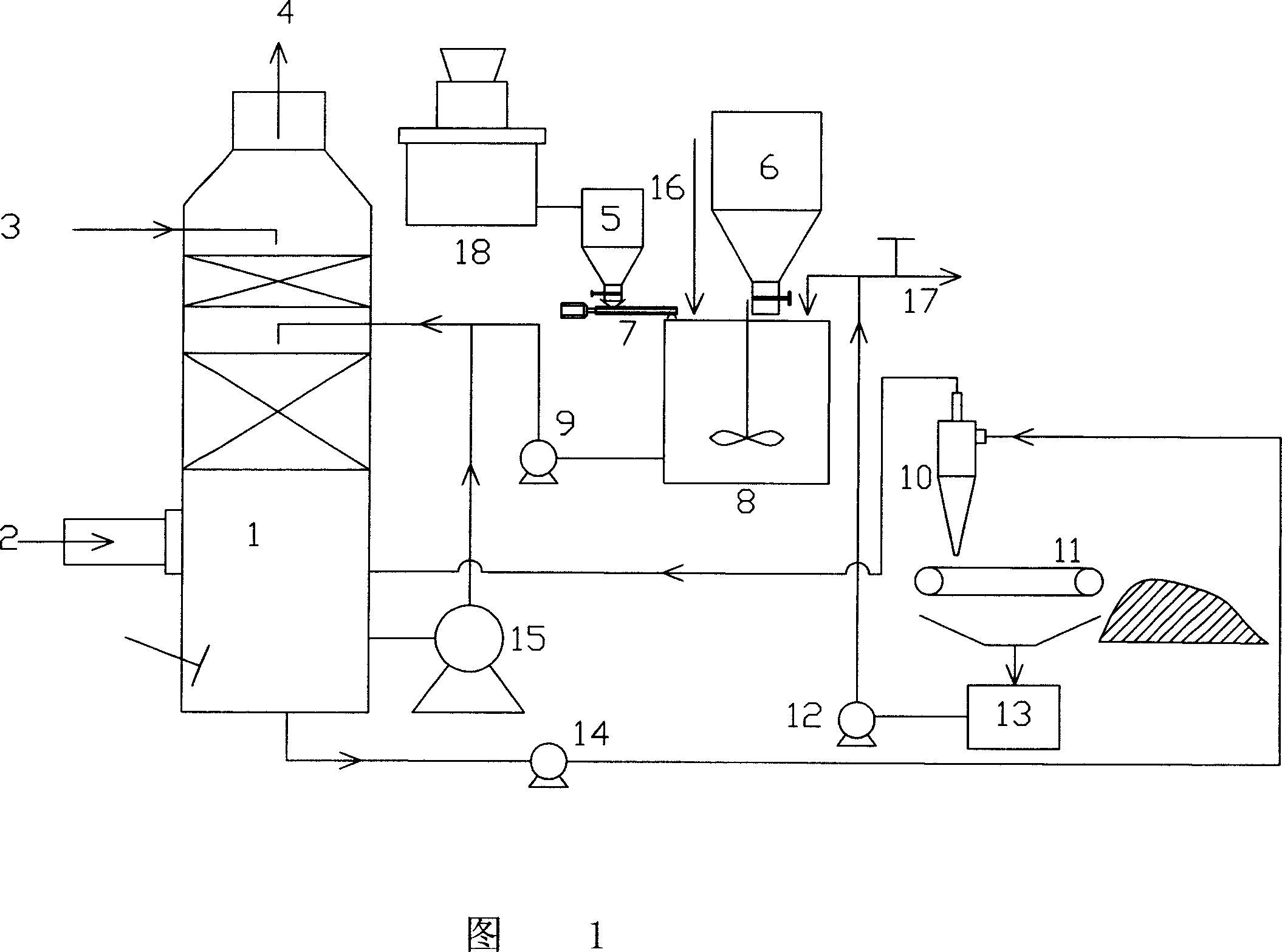

Double-oxidation ammonia desulfurization process and device

InactiveCN102228777AReduce usageIncrease profitDispersed particle separationAmmonium sulfatesWater storage tankFlue gas

The invention discloses a double-oxidation ammonia desulfurization process and a double-oxidation ammonia desulfurization device. The device comprises an ammonia water preparation device, an absorption tower, a pre-scrubber, a buffer oxidation tank, a cyclone, a centrifugal machine, a drying bed, a tail gas scrubber, a packaging machine and an ammonia water storage tank. Sulfur dioxide is removedfrom flue gas by liquid ammonia, and ammonium sulfate crystals with the purity of over 99 percent are obtained; and the invention has the advantages that: the cost of the conventional ammonia desulfurization is reduced, the absorption efficiency is improved, the desulfurization efficiency is over 95 percent, the yield is improved, the ammonium sulfate crystals with the purity of over 99 percent are obtained, the waste is changed into treasure, economic benefit is increased, the ammonium sulfate yield is over 96 percent, and the ammonia escape volume is reduced and is less than 8mg / m<3>.

Owner:潍坊恒安散热器集团有限公司

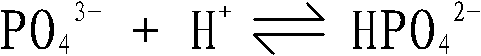

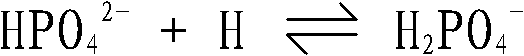

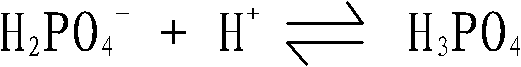

Desulfurization agent

InactiveCN103084050AImprove desulfurization efficiencyImprove solubilityDispersed particle separationSolubilityCalcium biphosphate

The invention discloses a desulfurization agent, which comprises organic calcium carboxylates and calcium phosphate, and concretely comprises the following components, by mass, 15-20% of calcium formate, 10-16% of EDTA calcium disodium, 10-16% of calcium lactate, 0-10% of calcium phytate, 25-30% of calcium citrate, 0-10% of calcium gluconate, 10-20% of calcium oxalate, and 1-10% of calcium phosphate. According to the desulfurization agent, combination of the organic calcium carboxylates and the calcium phosphate is adopted, solubility in the solution is high, calcium ions can be ionized quickly, a desulfurization reaction speed is rapid, and desulfurization efficiency is high.

Owner:SNTO TECH GRP

Resource utilization method of half-dry desulfurized fly ash

ActiveCN104096707AFull realization of resource valueImprove conversion rateCalcium/strontium/barium carbonatesSolid waste disposalResource utilizationSlurry

The invention discloses a resource utilization method of half-dry desulfurized fly ash. The resource utilization method comprises the following steps: (1) the half-dry desulfurized fly ash is oxidized to fully convert CaSO3 into CaSO4; (2) water is added to prepare the oxidized desulfurized fly ash to desulfurized fly ash slurry; and then, CO2 is filled in the desulfurized fly ash slurry, so that the CO2 is fully reacted with Ca(OH)2 in the desulfurized fly ash slurry to generate CaSO3, wherein the CO2 is filled by 1.2-1.5: 1 of the mol ratio of the CO2 to the Ca(OH)2; (3) NH4HCO3 is added by 1.2-1.5: 1 of the ratio of the NH4HCO3 to calcium in the obtained slurry, and the pH is adjusted within 7-9, so that sulfur-contained calcium is fully converted to calcium carbonate precipitate; and (4) the slurry obtained in the step (3) is prepared to a calcium oxide and ammonium sulfate solid. The method fully uses the characteristics of high calcium and high sulfur in the half-dry desulfurized fly ash to convert the desulfurized fly ash into ammonium sulfate and calcium carbonate, so that the conversion rates of a calcium element and a sulfur element respectively reach above 95%, and the resource value of the desulfurized fly ash is fully realized.

Owner:武汉钢铁有限公司

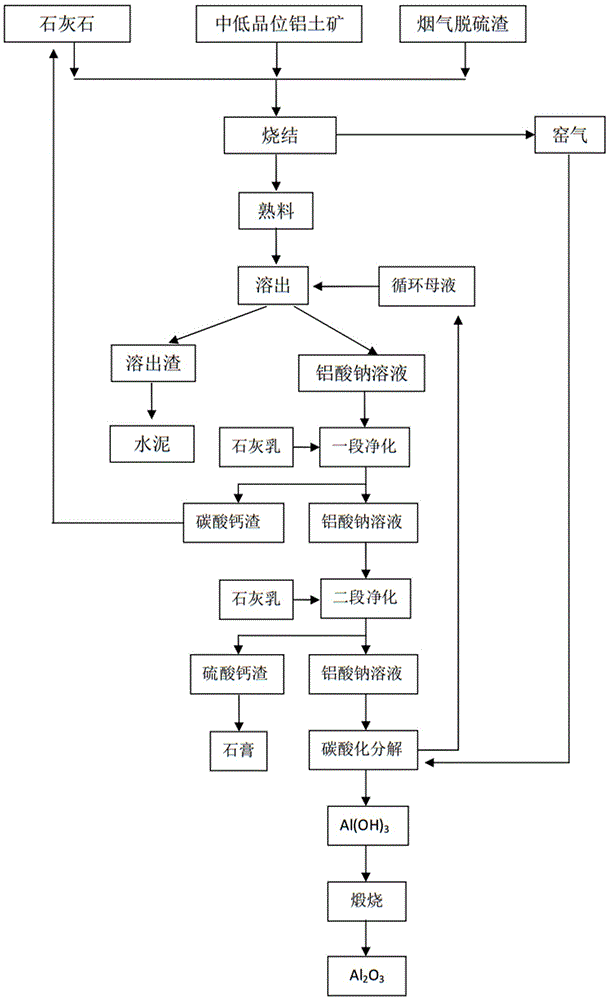

Method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime

ActiveCN105540628AAvoid the effect of dissolution rateAvoid corrosionAluminium oxides/hydroxidesSocial benefitsSlag

The invention relates to the technical field of aluminum oxide, and in particular relates to a method for producing aluminum oxide through sintering sulfur-containing monohydrallite and lime. According to the method, through properly adding a small amount of flue gas desulfurization slag and the lime into sulfur-containing monohydrallite for sintering, the aluminum oxide is produced, enabling aluminum element and sulphur element in a raw material to form a 4Cao.3Al2O3.SO3 phase, and by enabling silicon element to form a gamma-2CaO.SiO2 phase, and then adopting a low-temperature dissolution technology to perform aluminum oxide production, the deleterious effect of the sulphur element is reduced, the aluminum oxide dissolution performance of clinker is improved, and better market application value and social benefit are realized.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

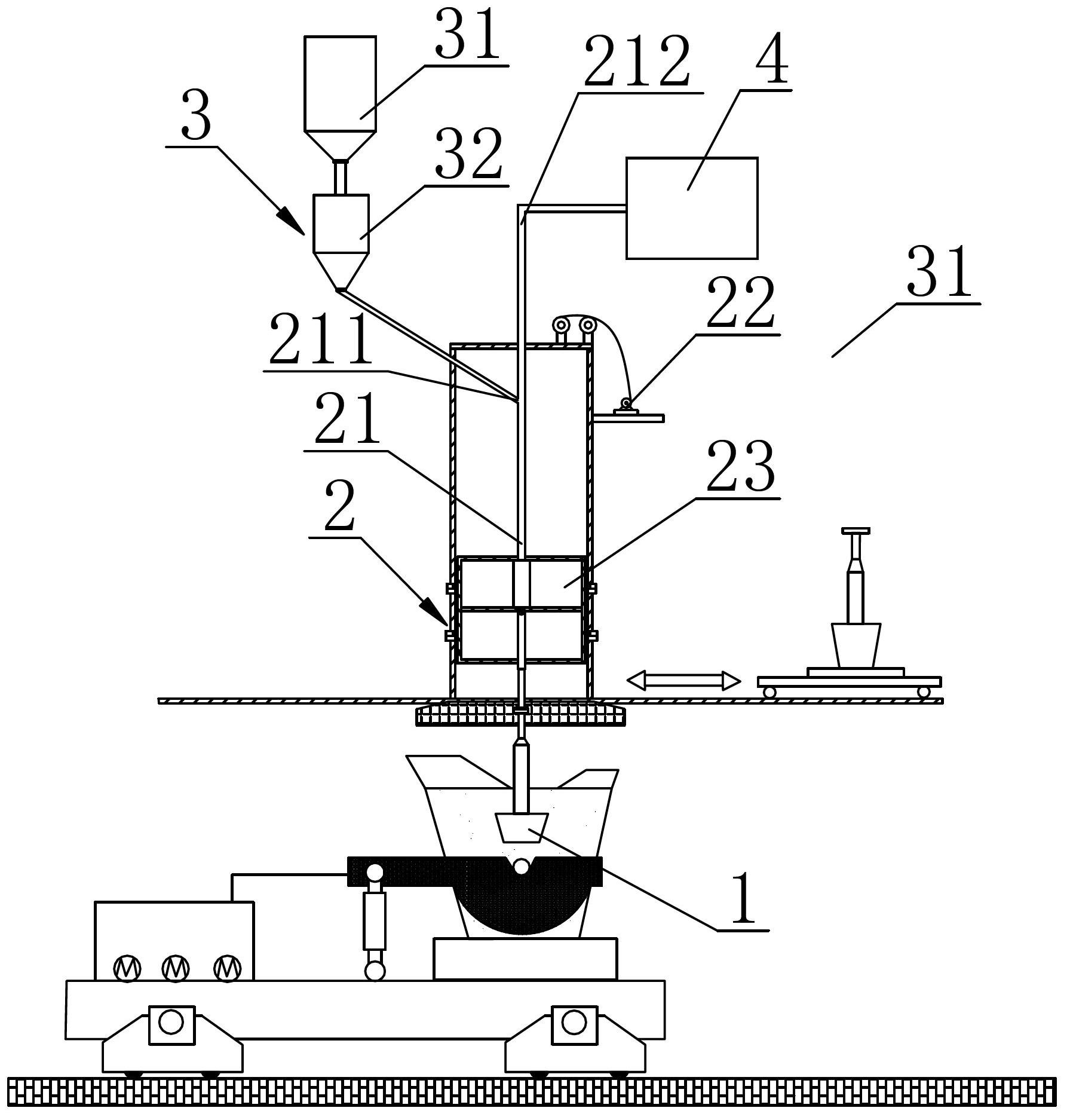

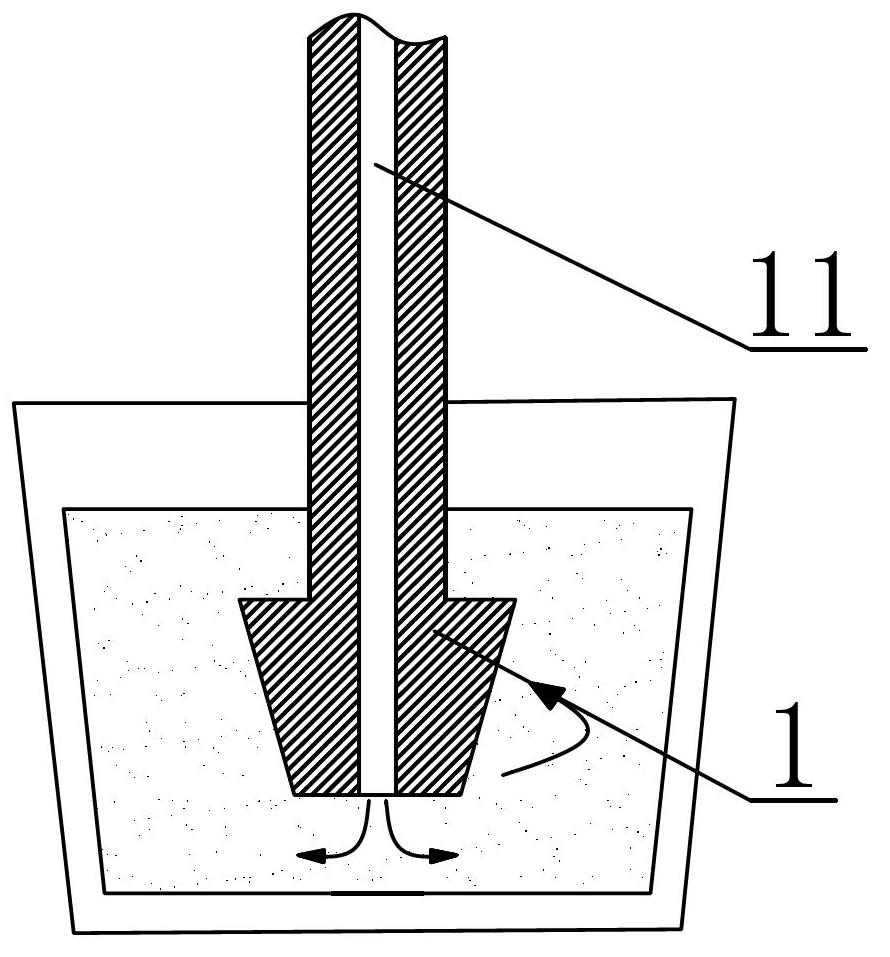

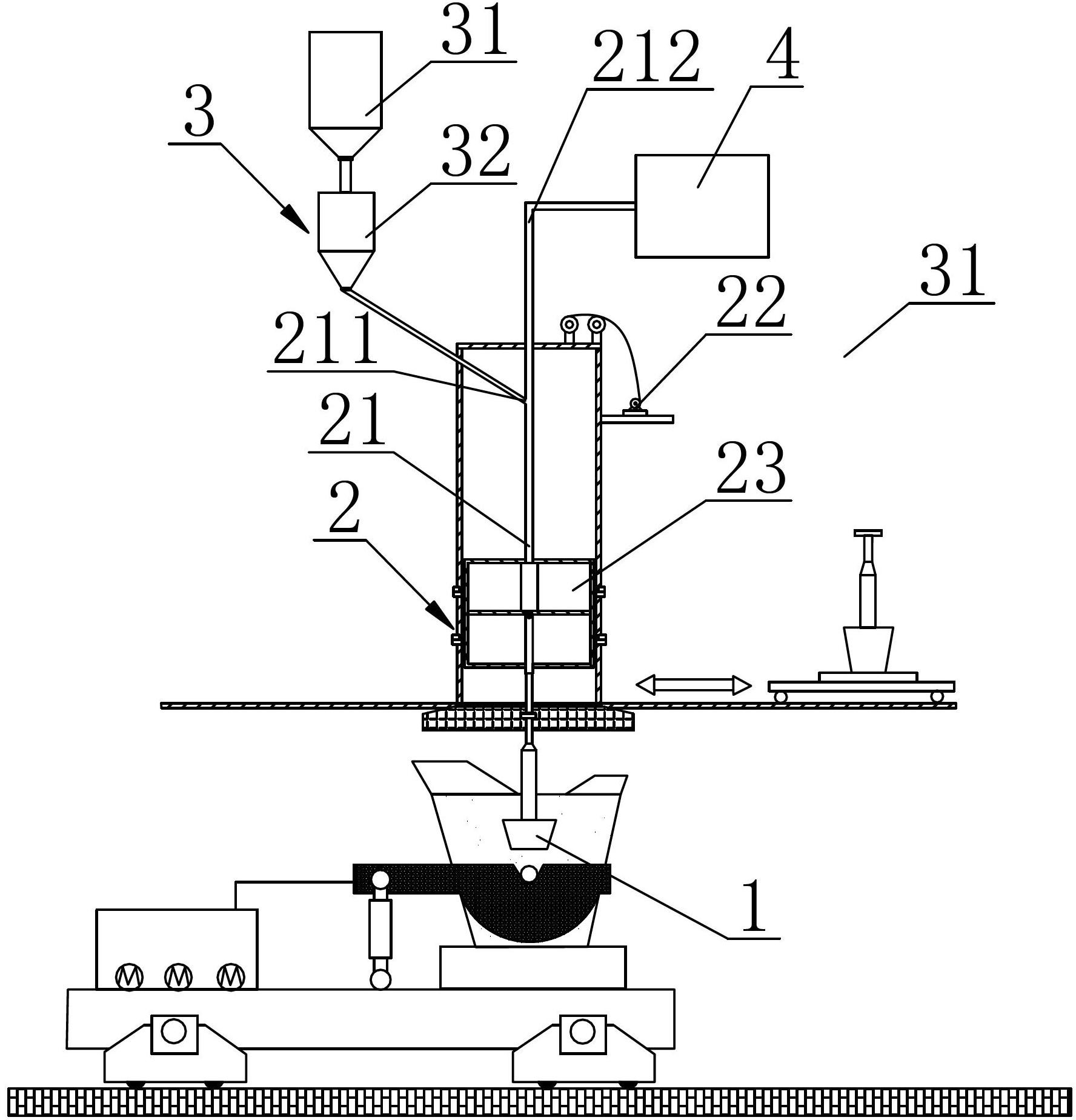

KR (knotted reactor) powder spraying, stirring and desulfurizing device and method

InactiveCN102676741AThe desulfurization cycle is shortenedReduced desulfurization working timeGranularityEngineering

The invention relates to a KR (knotted reactor) powder spraying, stirring and desulfurizing device. The KR powder spraying, stirring and desulfurizing device comprises a stirring head and a driving device for controlling the stirring head to act, wherein the driving device comprises a connecting rod linked with the stirring head, a lifting device for driving the connecting rod to move up and down and a stirring motor for driving the connecting rod to rotate. The KR powder spraying, stirring and desulfurizing device is characterized by further comprising a feeding system and a high-pressure gas source, wherein a through hole for introducing high-pressure inert gas and desulfurizing agents is formed on the stirring head, and an inlet of the through hole is communicated with a desulfurizing agent outlet and a high-pressure gas source outlet of the feeding system. The invention further relates to a method for desulfurizing molten iron by using the KR powder spraying, stirring and desulfurizing device. By using the device, efficient, fast and precise desulfurization can be realized, and the effects of reducing the requirements for granularity of desulfurizing agents, reducing the temperature drop and reducing the loss of the stirring head can be achieved.

Owner:ZENITH STEEL GROUP CORP

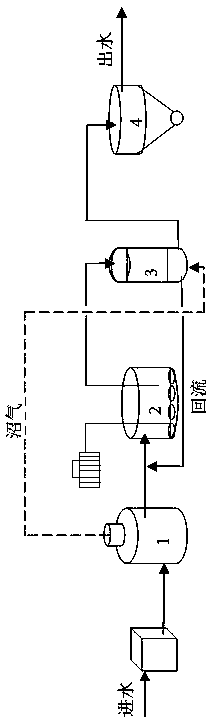

Method of promoting removal of total nitrogen from wastewater through short-cut denitrification

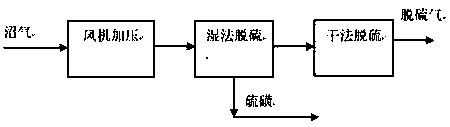

ActiveCN108946944AHigh removal rateRealize denitrificationGas treatmentWater contaminantsSulfurEmission standard

The invention discloses a method of promoting removal of total nitrogen from wastewater through short-cut denitrification. High ammonia-nitrogen wastewater enters a pretreatment unit, so that organicmatters are removed, and biogas is produced; then yielding water enters a short-cut nitrification-anaerobic ammonia oxidation denitrification unit, so that ammonia nitrogen and most total nitrogen areremoved; yielding water enters a sulfur reduction short-cut denitrification unit, and the biogas is introduced, so that nitrate nitrogen is transformed into nitrite nitrogen; partial yielding water of the sulfur reduction short-cut denitrification unit reflows to the short-cut nitrification-anaerobic ammonia oxidation denitrification unit, and suffers anaerobic ammonia oxidation reaction so as tofurther remove the total nitrogen; the remaining yielding water enters an aftertreatment unit, and suffers advanced treatment in the aftertreatment unit; and after yielding water of the aftertreatment unit reaches the emission standards, the water is discharged. The method has the advantages that the total nitrogen removal rate of anaerobic digestion yielding water is high; the wastewater denitrification and the biogas desulfurization are realized at the same time; the complete autotrophic denitrification is realized; the biogas biological desulfurization does not require oxygenation; and thewhole wastewater denitrification and biogas desulfurization system has low operating cost.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Preparation method and application of multifunctional desulfurizer for hydrolyzing, absorbing and deoxidizing organic sulfur

ActiveCN107497440AGood dispersionHigh and low temperature hydrolysis conversion and absorptionGas treatmentHeterogenous catalyst chemical elementsActivated carbonAluminium isopropoxide

The invention provides a preparation method of a multifunctional desulfurizer for hydrolyzing, absorbing and deoxidizing organic sulfur. The preparation method comprises the steps as follows: adding activated carbon to a mixed solution of Zn(NO3)2, Fe(NO3)3 and first active aid soluble salt, performing ultrasonic equivalent-volume impregnation and microwave roasting to obtain first semi-finished catalyst powder, adding an acetic acid aqueous solution to an isopropanol solution of aluminum isopropoxide and tetrabutyl titanate, and performing microwave roasting to obtain Al2O3-TiO2 composite carrier powder; adding an Al2O3-TiO2 composite carrier to a second aid soluble salt solution, performing ultrasonic equivalent-volume impregnation and microwave roasting to obtain second semi-finished catalyst powder, evenly mixing the first semi-finished catalyst powder, the second semi-finished catalyst powder, a binder, a the pore forming agent and water, and performing extrusion forming, drying and microwave roasting to obtain the multifunctional desulfurizer. The multifunctional desulfurizer has the advantages of efficiently hydrolyzing, converting, absorbing and deoxidizing the organic sulfur.

Owner:江苏天东新材料科技有限公司

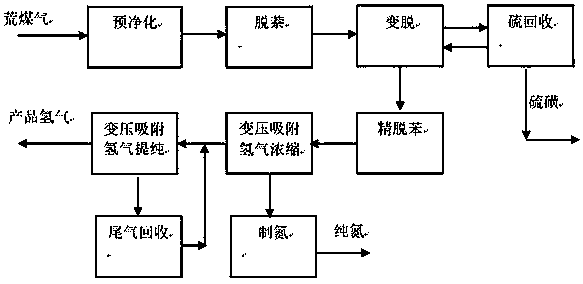

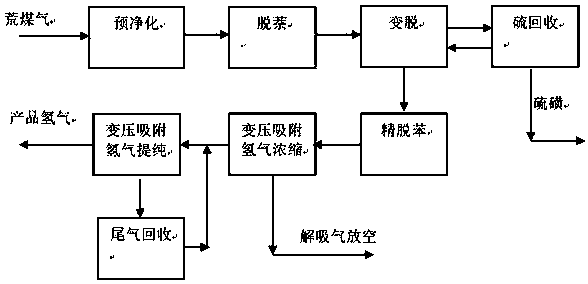

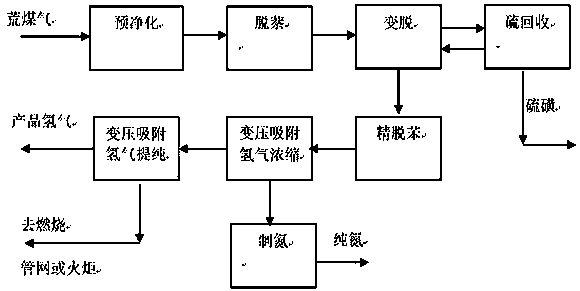

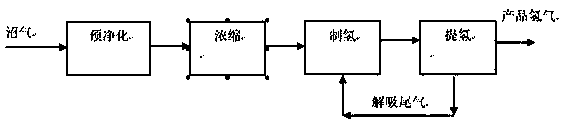

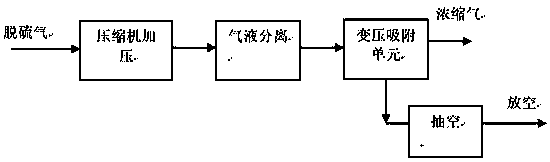

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

Cracking C5 desulfurization agent composition

ActiveCN103320157AImprove the total sulfur removal rateReduce productionRefining with metal saltsEconomic benefitsChemical products

The invention relates to a cracking C5 desulfurization agent composition. The cracking C5 desulfurization agent composition comprises the following components in percentage by weight: 10-98% of first component, 0.1-85% of second component and 0.01-0.5% of third component. The cracking C5 desulfurization agent composition disclosed by the invention has the beneficial effects that on the premise of ensuring the quality of a product, by introducing the desulfurization agent composition, the total sulfur removal rate of the C5 can be greatly improved, the total sulfur content in the product and the desulfurization cost can be reduced, the output of desulfurization reaction products is little, and the desulfurization reaction products can be used as other chemical products, so that the cracking C5 desulfurization agent composition has secondary utilization values and obvious economic benefits and environment-friendly benefits.

Owner:NINGBO ZHONGYI PETROCHEM TECH

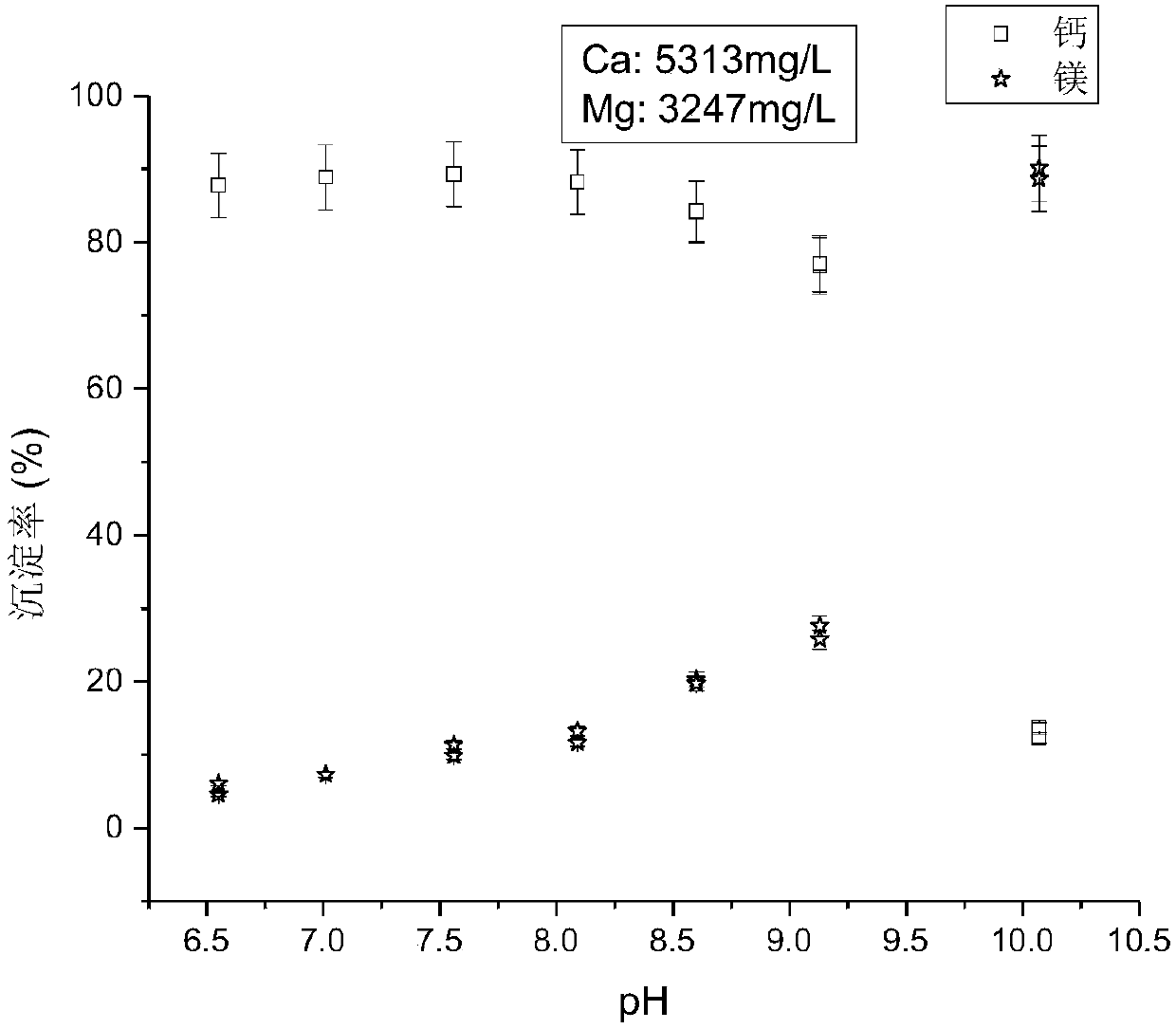

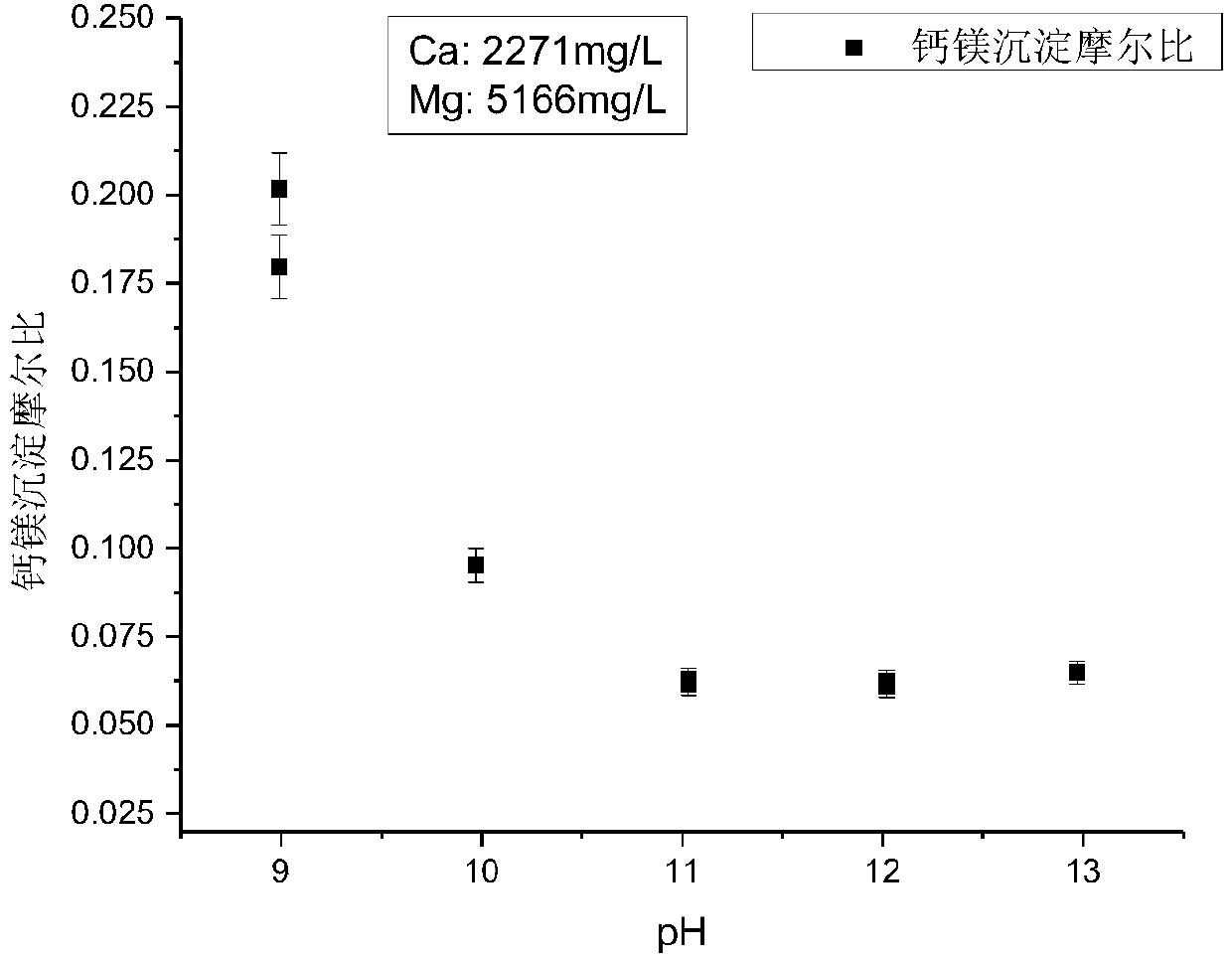

Device and method for recycling calcium magnesium in desulfurization waste water by using carbonization method

InactiveCN107619137AReduce adverse effectsIncrease the reuse ratioCalcium/strontium/barium carbonatesMultistage water/sewage treatmentCarbonizationWastewater

The invention discloses a device and a method for recycling calcium magnesium in desulfurization waste water by using a carbonization method. By adopting the device and the method, desulfurization waste water is simply pretreated to remove heavy metals, CO2 is introduced to reduce the pH value of wastewater, CaCO3 in the wastewater is separated and fed back to a desulfurization tower for continuous utilization, alkali is put into a clear liquid to sediment most Mg, and Mg(OH)2 in sediment is recycled. The device has the advantages that most hardness of wastewater is removed, calcium and magnesium are recycled, and certain economic benefits are made for power plants.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

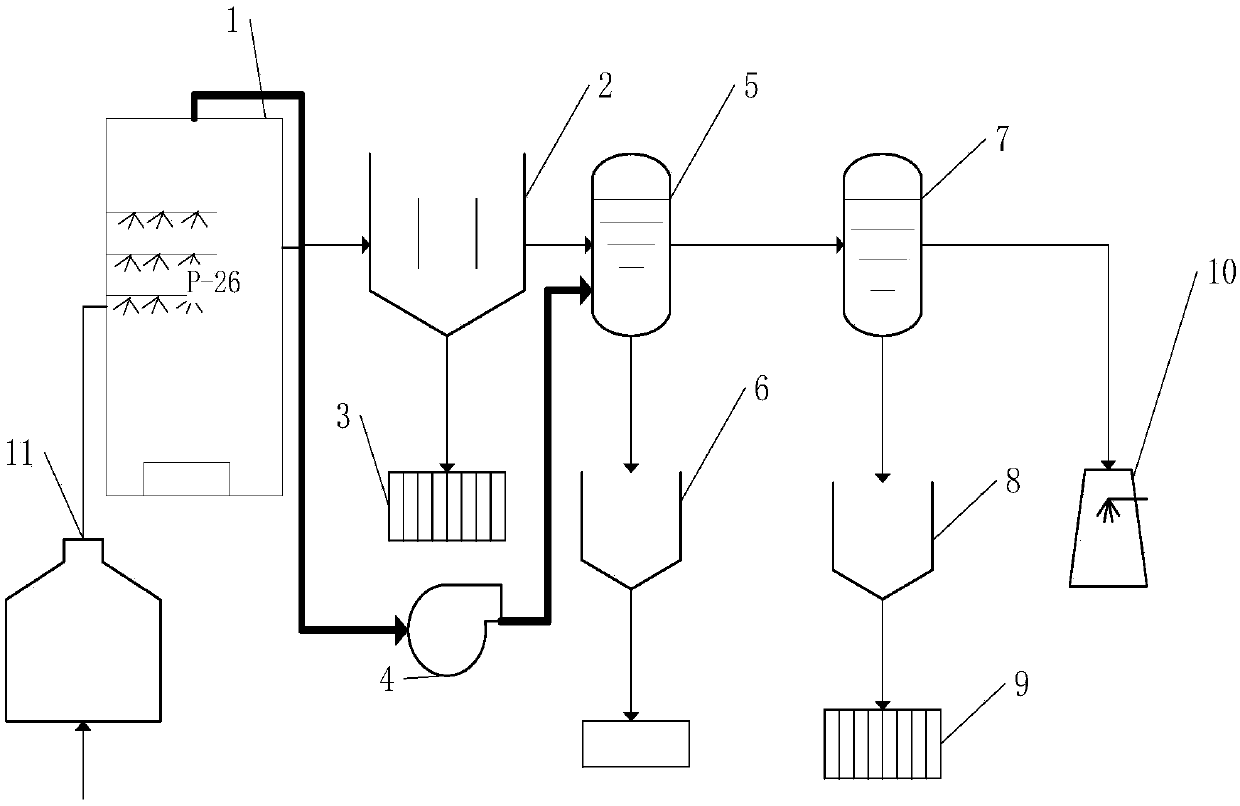

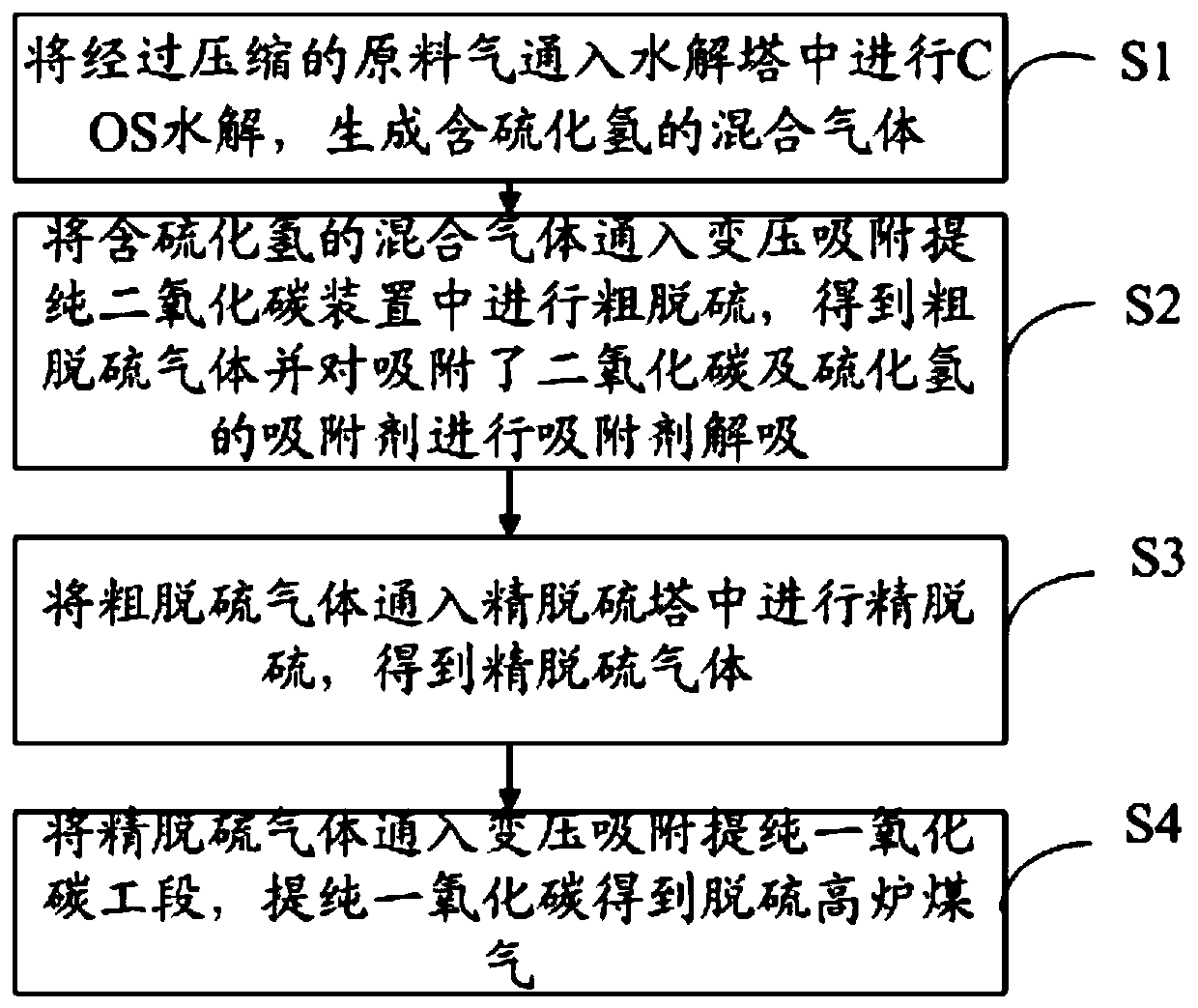

Blast furnace gas desulfurization method and system

InactiveCN110218590AExtended service lifeReduce desulfurization costGas purification with selectively adsorptive solidsGas contaminants removalChemistryCarbon dioxide

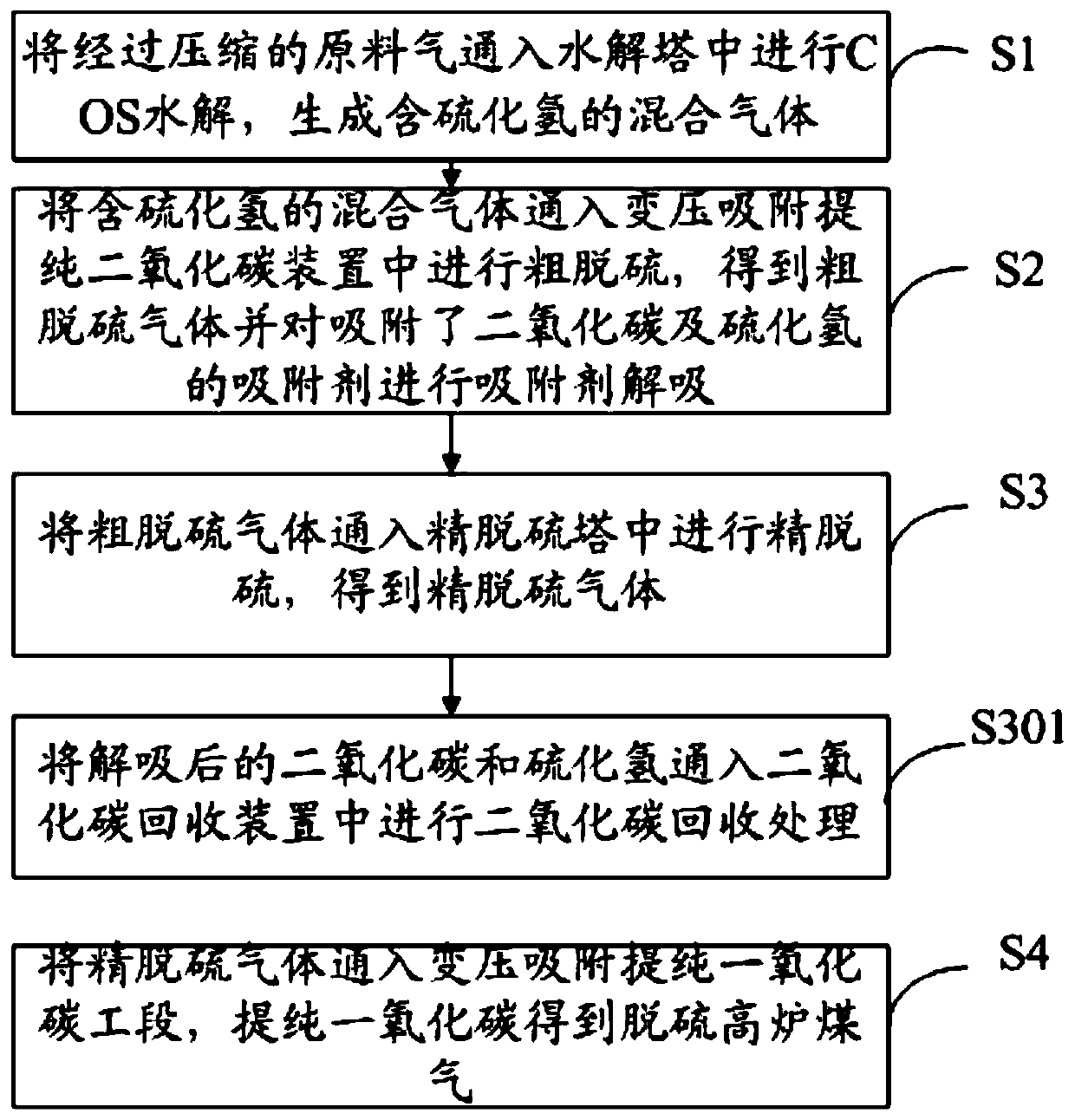

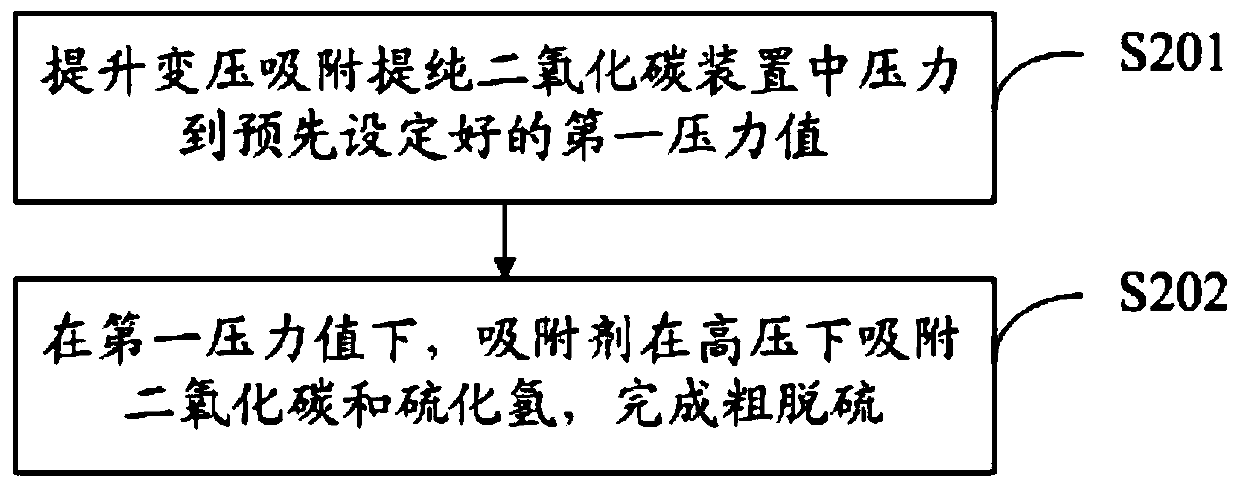

The invention is applicable to the technical field of energy conservation and provides a blast furnace gas desulfurization method and system. The blast furnace gas desulfurization method comprises thefollowing steps: S1, introducing a compressed raw material gas into a hydrolysis tower for COS (carbon oxysulfide) hydrolysis so as to generate a mixed gas with hydrogen sulfide; S2, introducing themixed gas with the hydrogen sulfide into a pressure swing adsorption purification carbon dioxide device for crude desulfurization so as to obtain a crude desulfurization gas, and carrying out desorption on an adsorbent which adsorbs carbon dioxide and hydrogen sulfide; S3, introducing the crude desulfurization gas into a refined desulfurization tower for refined desulfurization so as to obtain a refined desulfurization gas; and S4, introducing the refined desulfurization gas into a carbon monoxide pressure swing adsorption purification section, and purifying carbon monoxide, so as to obtain adesulfurization blast furnace gas. As no elemental sulfur is generated after the raw material gas is hydrolyzed, and the adsorbent adsorbs no elemental sulfur, the carbon dioxide and the hydrogen sulfide can be desorbed from the adsorbent, the adsorbent can be regenerated, the service life of the adsorbent can be prolonged, and the desulfurization cost of the blast furnace gas can be lowered.

Owner:湖南衡钢百达先锋能源科技有限公司

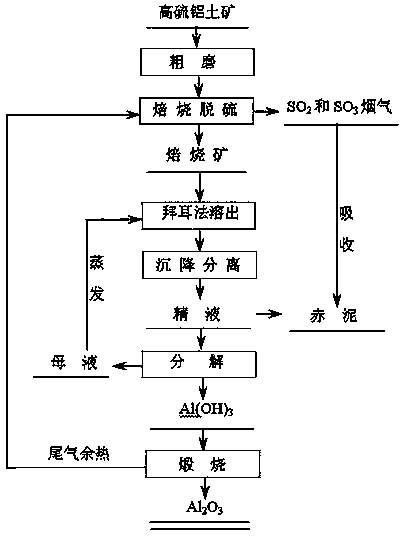

Method for producing alumina by use of high sulfur bauxite

InactiveCN103833056APromote dissolutionReduce energy consumptionAluminium oxides/hydroxidesEnergy consumptionMaterials science

The invention discloses a method for producing alumina by use of high sulfur bauxite, and the method comprises the following steps: carrying out coarse grinding on crushed high sulfur bauxite, roasting the crushed high sulfur bauxite to enable the sulfur content of the ore to be smaller than 0.7%, and then, directly entering an alumina production flow by use of a Bayer process. After the pre-roasting treatment, the leaching performance of the ore is perfected, a better leaching effect can be obtained without fine grinding, and the energy consumption in a fine grinding process of the ore is reduced, so that the method is beneficial to equipment selection in the roasting process and suitable for treating the high sulfur bauxite. The ore in the invention is roasted at a rough particle size, thus helping the overflow of the generated SO2 (or SO3) gas and ensuring a good roasting desulfurization effect; in addition, by adopting the method disclosed by the invention, the energy consumption in the fine grinding process of the ore is reduced, the over burning and dust pollution problems caused by superfine particle size are avoided, the cyclic utilization of energy source is achieved and the desulfurization cost is reduced.

Owner:GUIZHOU UNIV

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

Fume desulfurizing process with enhancement lime method

ActiveCN1923339AIncrease profitImproves pH buffering capacityDispersed particle separationSulfurSlurry

The invention relates to a method for desulfurising smoke, especially a strengthen limestone smoke desulfurising method. Wherein, it comprises adding limestone and additive into reactor, to be mixed and reacted with water to generate adsorption slurry; inputting slurry into adsorption tower; the sulfur smoke enters into tower to react with slurry; the purified smoke is discharge outside the tower; the slurry with sulfur dioxide will be discharged at the bottom of tower to be recycled. The invention can improve desulfurising efficiency at 5-10% and improve the absorber utilization at 1-10%.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Alkaline magnesium oxysulfate cement and preparation method thereof

The invention relates to alkaline magnesium oxysulfate cement and a preparation method thereof. The alkaline magnesium oxysulfate cement is prepared from magnesium oxide, magnesium sulfate heptah, coal ash, core additives and water, wherein the core additives include a first core additive and a second core additive, and the first core additive is inorganic acid, and the second core additive is organic acid. The preparation method includes the steps: (1) dissolving the magnesium sulfate heptah in the water to prepare magnesium sulfate heptah solution; (2) weighing raw materials according to ratio; (3) adding the first core additive into the magnesium sulfate heptah solution; (4) sequentially adding the second core additive and the coal ash into the magnesium oxide, uniformly stirring the raw materials, adding the mixture into the magnesium sulfate heptah solution obtained in the step (3), and uniformly stirring the mixture and the solution to form cement paste. The completely hydrated alkaline magnesium oxysulfate cement is prepared, the hydrated phase of the magnesium oxysulfate cement is improved by leading in the core additives, a novel insoluble crystal whisker hydrated phase is generated, and further the strength, the flexibility and the water resistance of the novel insoluble crystal whisker hydrated phase are obviously superior to those of the magnesium oxysulfate cement.

Owner:内蒙古中鼎工正环保有限公司

Method for producing hydrogen from biogas biomass

Owner:SICHUAN TECHAIRS

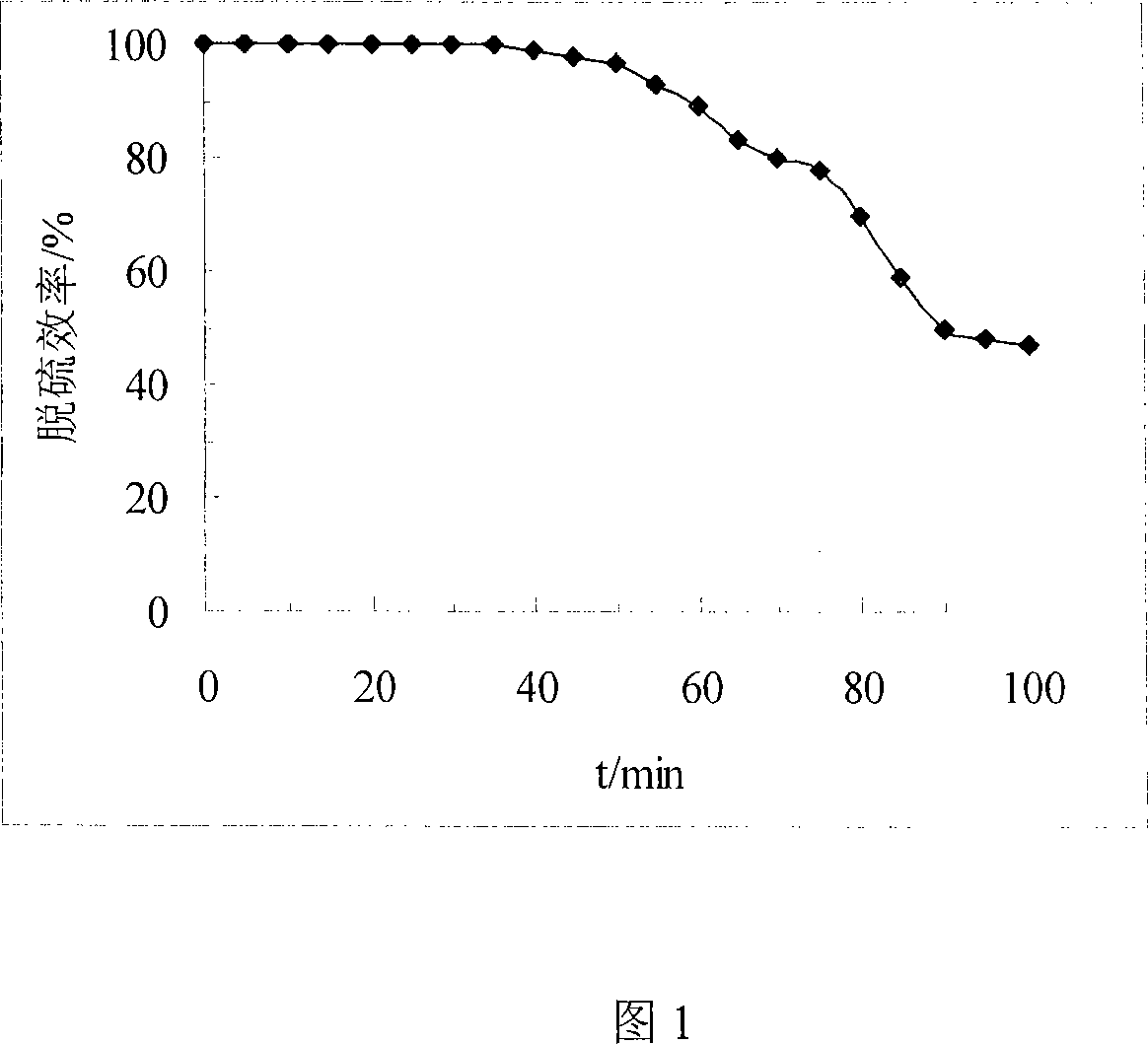

Regeneration method of CaO/Al2O3 desulfurizing agent

InactiveCN1460555ASimple regeneration methodEasy to operateDispersed particle separationCatalyst regeneration/reactivationSulfurSpace velocity

The regeneration method of CuO / Al2O3 desulfurizer is that the CuO / gamma-Al2O3 desulfurizer for absorbing sulfur can be reduced and regenerated in the atmosphere containing ammonia gas, its regeneration temp. is 350-500 deg.C, space velocity is 500-3000 hr (-1) and regeneration time is 30-90 min. Its regeneration process is simple, its secondary desulfurizing activity is stable, the SO2 produced in the course of regeneration can be combined with unreacted NH3 under the condition of low temp. to form solid ammonium sulfate salt.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Fiber-reinforced composite refractory castable for molten iron desulphurization lance and preparation method of fiber-reinforced composite refractory castable

The invention relates to a fiber-reinforced composite refractory castable for a molten iron desulphurization lance and a preparation method of the fiber-reinforced composite refractory castable. According to the technical scheme, the method comprises the steps of dispersing the following raw materials in parts by weight: 1-4 parts of mullite powder, 3-5 parts of kyanite, 5-8 parts of fused dense corundum powder, 5-8 parts of alpha-Al2O3 micro powder, 4-7 parts of silica powder, 1-4 parts of silicon carbide powder and 5-7 parts of pure aluminum silicate cement and an additive into a flat container and mixing evenly by using a rake; adding the following raw materials in parts by weight: 10-15 parts of first-level bauxite chamotte, 30-38 parts of natural fused mullite, 20-25 parts of andalusite and 1-2 parts of high-purity fused mullite particles; and pouring the mixed materials into a stirrer for stirring to obtain the fiber-reinforced composite refractory castable for the molten iron desulphurization lance. The fiber-reinforced composite refractory castable is low in cost and wide in raw material source, the obtained product is good in mechanical property and thermal shock resistance, the service life of the molten iron desulphurization lance can be prolonged, and the desulphurization cost can be reduced.

Owner:WUHAN UNIV OF SCI & TECH

Fume desulfurizing process with enhancement limestone method

ActiveCN1923338AIncrease profitImproves pH buffering capacityDispersed particle separationSulfurSlurry

The invention relates to a method for desulfurising smoke, especially a strengthen limestone smoke desulfurising method. Wherein, it comprises adding limestone and additive into reactor, to be mixed and reacted with water to generate adsorption slurry; inputting slurry into adsorption tower; the sulfur smoke enters into tower to react with slurry; the purified smoke is discharge outside the tower; the slurry with sulfur dioxide will be discharged at the bottom of tower to be recycled. The invention can improve desulfurising efficiency at 5-10% and improve the absorber utilization at 1-10%.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Efficient composite desulfurizer

The invention discloses a high-efficiency compound desulfurizing agent, relating to the ladle desulphurization accessory field. In the existing ladle desulphurization, the uniserial desulfurizing agent is uniformly adopted, with narrower function, and non-agreeable desulphurization effect. Aiming at the condition that small and medium-sized steel mills do not have liquid iron pretreatment systems or desulphurization stations, and do not have powder spraying desulphurization devices, the desulfurizing agent of the invention adopts ingredient with multi-components, namely, the compound desulfurizing agent consisting of limestone, calcined soda, fluorite, calcium carbide, magnesium powder and caustic-calcined magnesite, with the weight proportion of 40 to 50, 10 to 20, 5 to 15, 10 to 20, 4 to 6 and 5 to 15 sequentially. The desulfurizing agent has the following advantages that: 1. the integral desulphurization capability is strong, and the sulfur content can be reduced to 20ppm; 2. sulfur substance can be contained, and resulfurization phenomenon can not be generated; 3. the desulfurizing agent can be directly poured, and equipment and investment are not needed to be increased; and 4. the desulphurization speed is high.

Owner:西峡县福盈冶金材料有限公司

Molten iron desulphurization method

The invention relates to a molten iron desulphurization method which comprises the following steps: adding a KR desulfurizer into an iron ladle, pouring molten iron into the iron ladle, stirring to carry out a desulphurization reaction between the KR desulfurizer and molten iron; and blowing granulated magnesium to the iron ladle so as to conduct desulphurization. The KR desulfurizer has advantages of low granularity, large reaction area and good average molten iron desulphurization effect. With the addition of the KR desulfurizer, CaO content of iron slag is effectively increased, alkalinity of iron slag is raised, iron slag is modified, and it is beneficial to adsorption of granulated magnesium desulphurization products and removal of desulphurization slag. According to the molten iron desulphurized by a two-step method, first-hit yield of desulphurization by blowing granulated magnesium is raised, and molten iron resulfurization in a converter is minimized. Thus, desulphurization cost during the whole molten iron desulphurization process is reduced.

Owner:BEIJING SHOUGANG CO LTD

Low-cost high-activity catalytic type desulphurization active coke and preparation method thereof

ActiveCN104028218AImprove desulfurization effectReduce usageOther chemical processesDispersed particle separationPyrolusiteWater vapor

The invention provides a low-cost high-activity catalytic type desulphurization active coke. The low-cost high-activity catalytic type desulphurization active coke is a material which is activated, extruded and formed by mainly components comprising carbonization soft coal and pyrolusite; the percentage of weight of manganese is not less than 1.6%; the saturated sulphur capacity of the desulphurization active coke is 140-181mg / g; the specific surface area is 319-363m<2> / g; the iodine value is 344-393mg / g. The preparation method of the low-cost high-activity catalytic type desulphurization active coke comprises the following steps: firstly carbonizing smoke, crushing the pyrolusite and the soft coal carbonization material into powder, adding the soft pyrolusite powder into the soft coal carbonization material powder and uniformly mixing, then adding water to mix till the material is free of powder aggregate, adding coal tar, fully kneading and then extruding, forming and drying, causing the dried material to be subjected to activation reaction under the conditions with N2 protection and water vapor, finally cooling the material along with a furnace to room temperature under the N2 protection to obtain the low-cost high-activity catalytic type desulphurization active coke. By virtue of the low-cost high-activity catalytic type desulphurization active coke, the problems of low desulfuration capacity, regeneration frequency, large use amount and high operation cost of the currently-used desulfuration active coke can be solved.

Owner:SICHUAN UNIV

MgO-based desulfurizer based on self-propagating and preparation thereof

The invention relates to a MgO base desulfurizer based on self-propagation and a method for preparing the same. The invention is characterized in that: the MgO base desulfurizer is a particle in a spherical shape or other shapes and consists of MgO, carbonaceous reducing agent, self-propagating exothermic agent, reaction promoter, PH value modifying agent and caking agent; the MgO, the carbonaceous reducing agent, the self-propagating exothermic agent, the reaction promoter and the PH value modifying agent are respectively dried for 4 to 20 hours at a temperature of between 120 and 200 DEG C in a drying box, then grinded by a ball mill into powder with a granularity of less than 200 meshes; the material powder is mixed according to the proportion, added with the caking agent, then pressed into particles in a spherical shape or other shapes by a pressure of 20 MPa; and the particles are dried and prepared into the MgO base desulfurizer. The MgO base desulfurizer is used for desulphurization and has the advantages of less slagging amount, low desulphurization cost, high utilization rate of desulfurizer, high desulphurization rate, no obvious temperature reduction in the desulphurization process, no need of specialized desulphurization equipment, simple convenient, etc.

Owner:NORTHEASTERN UNIV

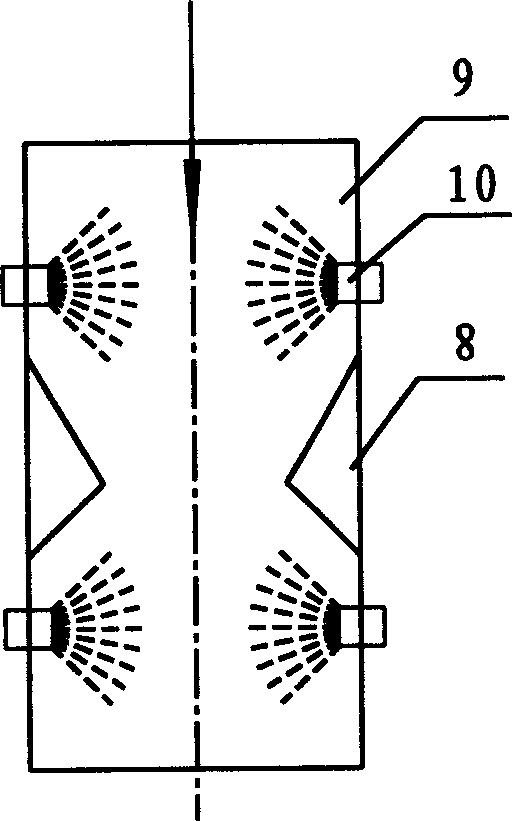

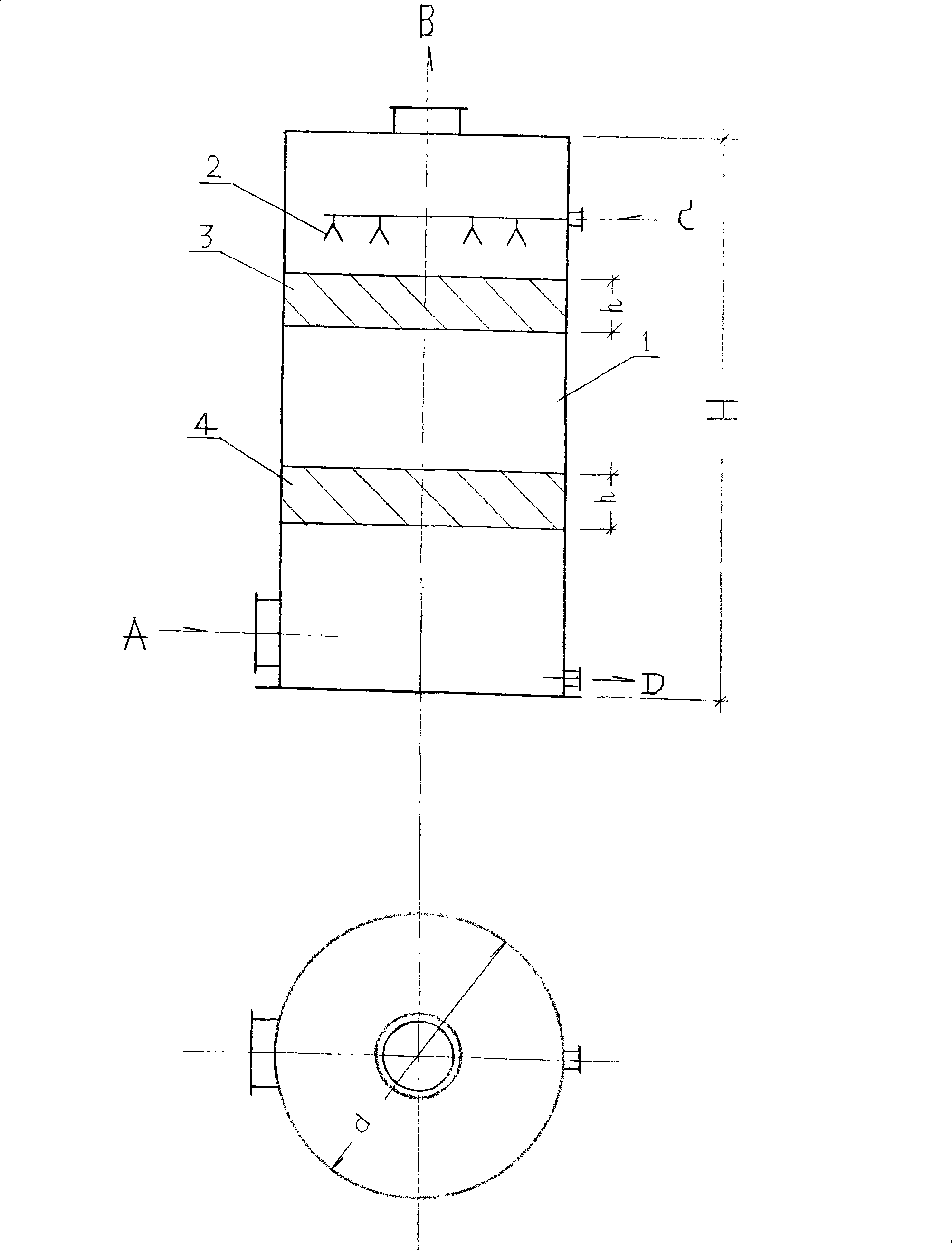

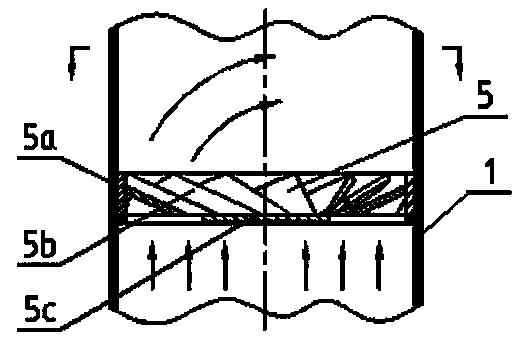

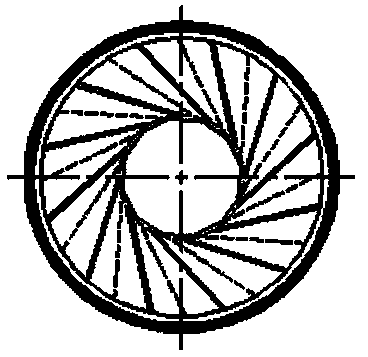

Wet-process flue gas desulfurization tower

InactiveCN103357264AFully contactedImprove desulfurization effectDispersed particle separationSlurryCorrosion

The invention provides a wet-process flue gas desulfurization tower to well solve the technical problems of poor desulphurization effect, unreliable equipment operation caused by nozzles obstructed by foreign materials such as fouling fragments and the like, poor spray removal effect after flue gas washing and desulphurization which are all caused by poor slurry atomization effect of a present industrial kiln and boiler flue gas spraying washing type desulfurization tower. According to the invention, desulphurization efficiency and operational reliability are raised by improving the desulphurized slurry atomization effect and nozzle passageways; due to improvement of the nozzles, pressure requirements on desulphurized slurries are low, nozzle blocking probability is reduced, and removal rate of sulfur dioxide is raised; and a routine cyclone dehydrator structure is improved, rising cyclone diameter of flue gas is increased, the flue gas dehydration and demisting effect after washing is raised, and corrosion and dirt deposition of downstream flues and equipment are decreased. The wet-process flue gas desulfurization tower provided by the invention has characteristics of high desulphurization efficiency, good spray removal effect, simple structure, high operation reliability and the like, can be adopted to effectively reduce investment and operation costs, and is suitable for a wet flue gas desulphurization technology.

Owner:NANNING COLLEGE FOR VOCATIONAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com