Desulfurizing method using soda waste liquid and calcium carbide waste residue

A technology of calcium carbide waste residue and waste liquid, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of huge investment and high operating costs, and achieve the effect of low investment, low operating costs and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

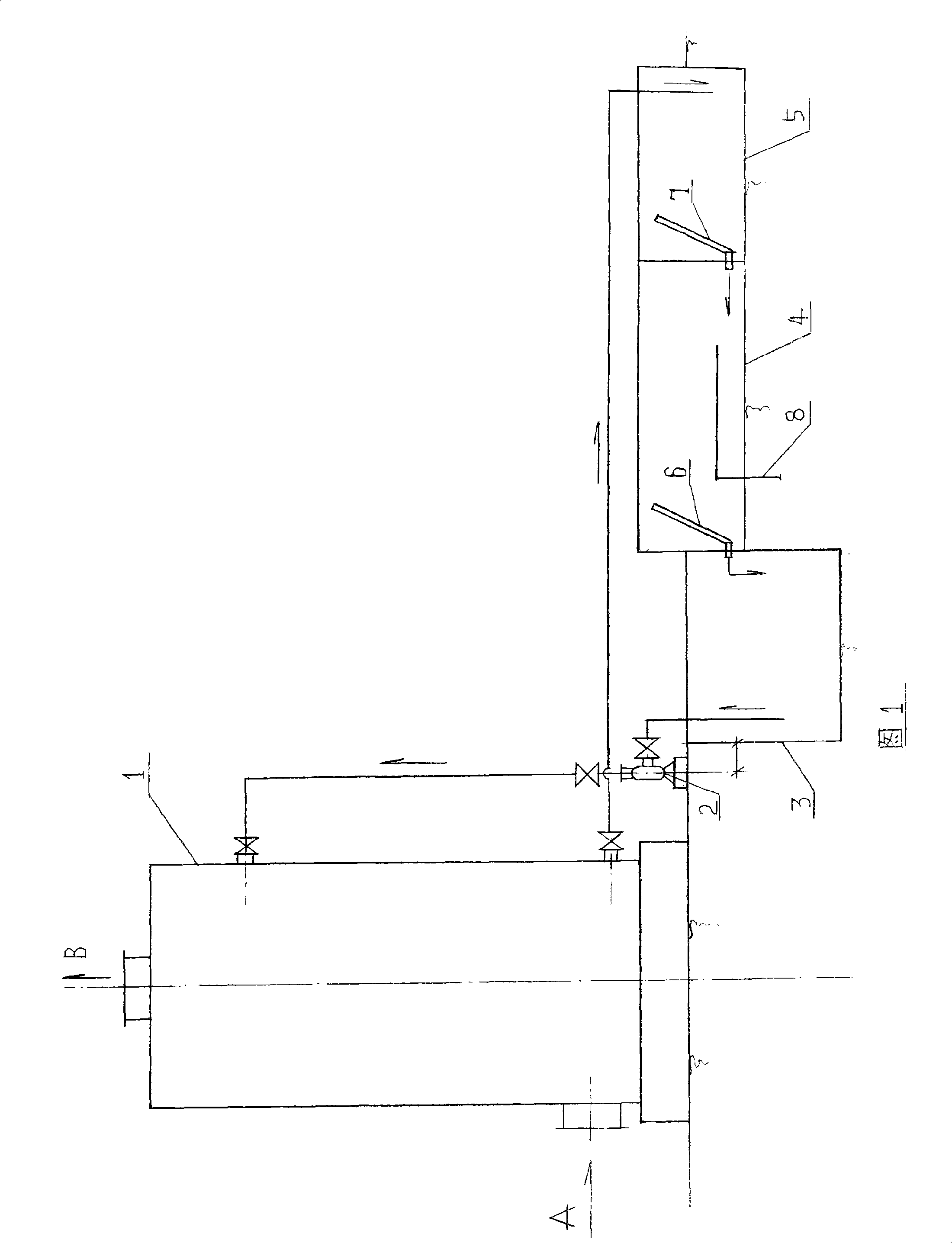

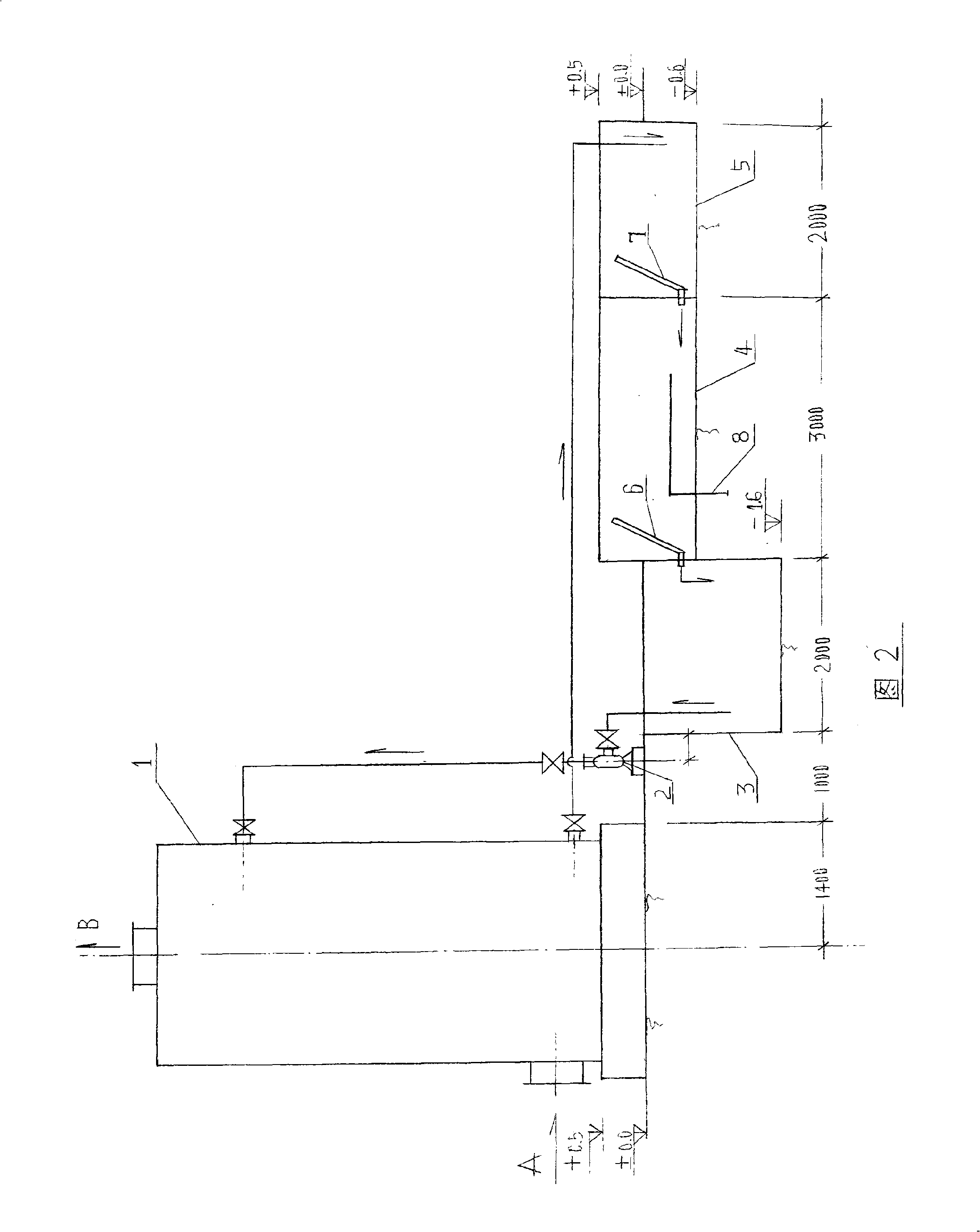

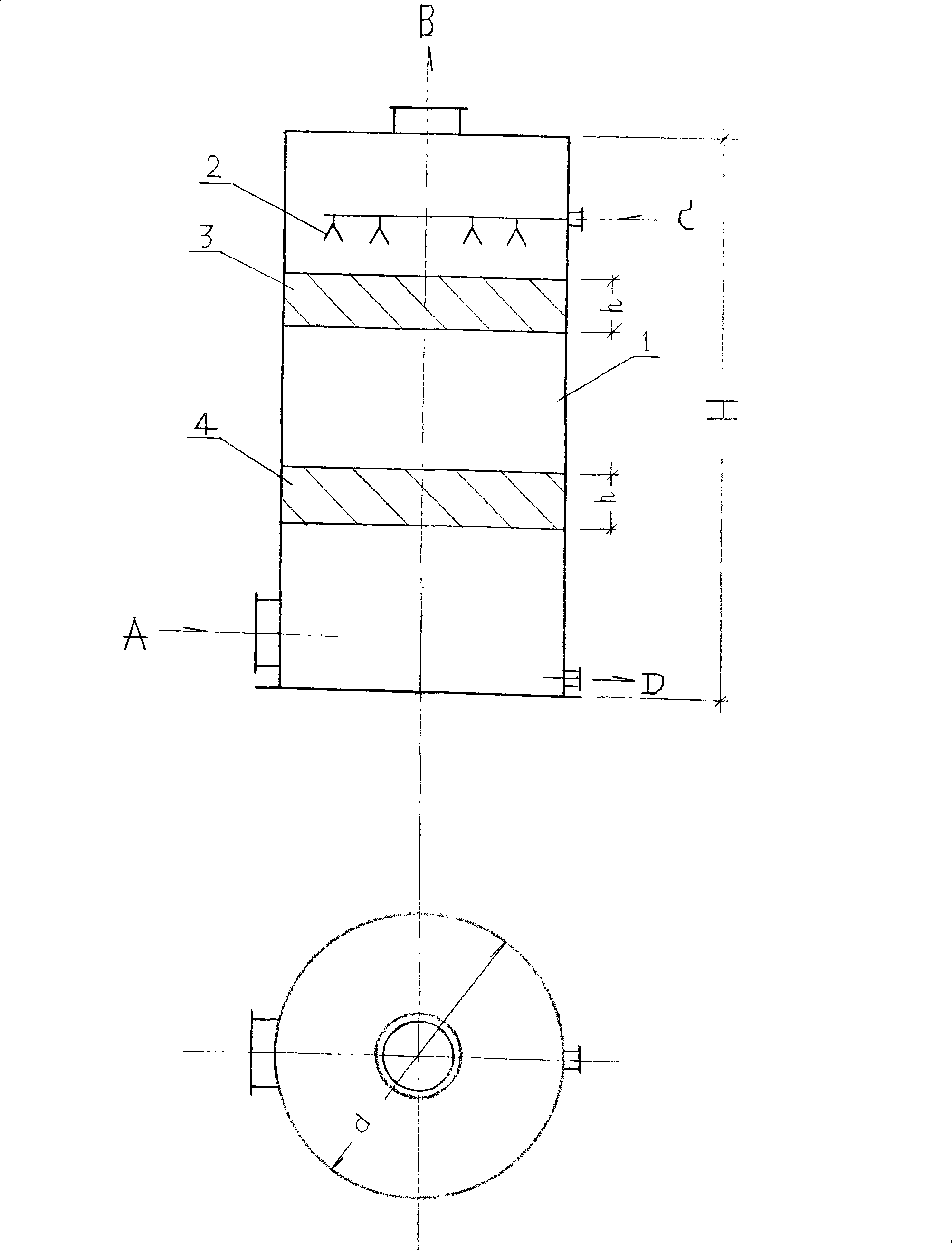

[0031] First, a desulfurization tower is fabricated according to the structure shown in Fig. 3 . Tower height H=5m, diameter d=2.5m, packing layer height h=0.5m. The filler is ceramic ring, PVC ball or iron filings.

[0032] Fix the desulfurization tower according to the arrangement in Figure 2.

[0033] According to the arrangement in Figure 2, the circulation tank (2m×2m×1.6m), the clarification tank (3m×3m×1.1m) and the neutralization tank (2m×2m×1.1m) are made of concrete.

[0034] The pump and piping are installed according to Figure 2.

[0035] The prepared 15% CaCl 2 The solution is put into the circulation tank (3), and the prepared milk of lime is put into the neutralization tank (5).

[0036] Start the centrifugal pump to circulate the CaCl in the pool 2 The solution is sent to the desulfurization tower, and after 5-10 minutes of operation, the flue gas inlet is opened, and the flue gas enters the desulfurization tower from A, and the desulfurization work begins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com