Patents

Literature

61results about How to "High utilization rate of waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

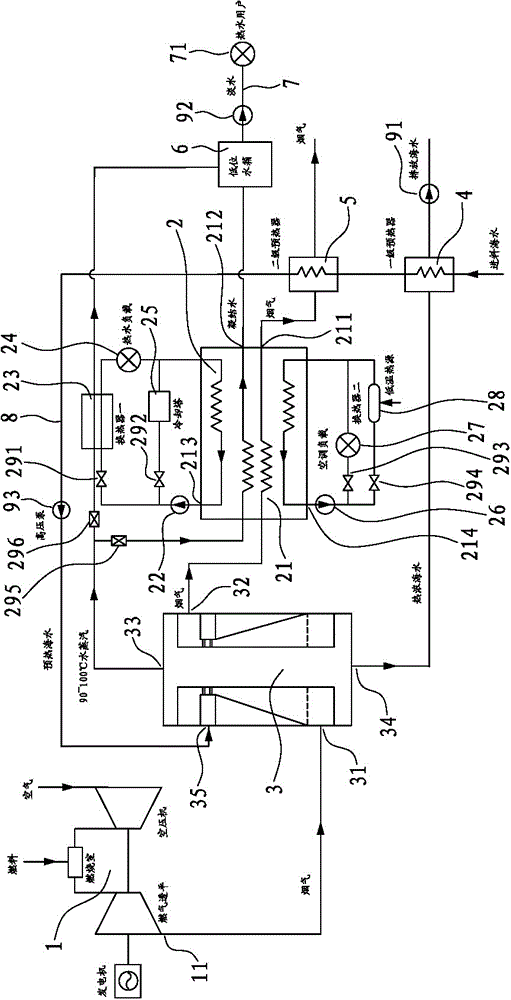

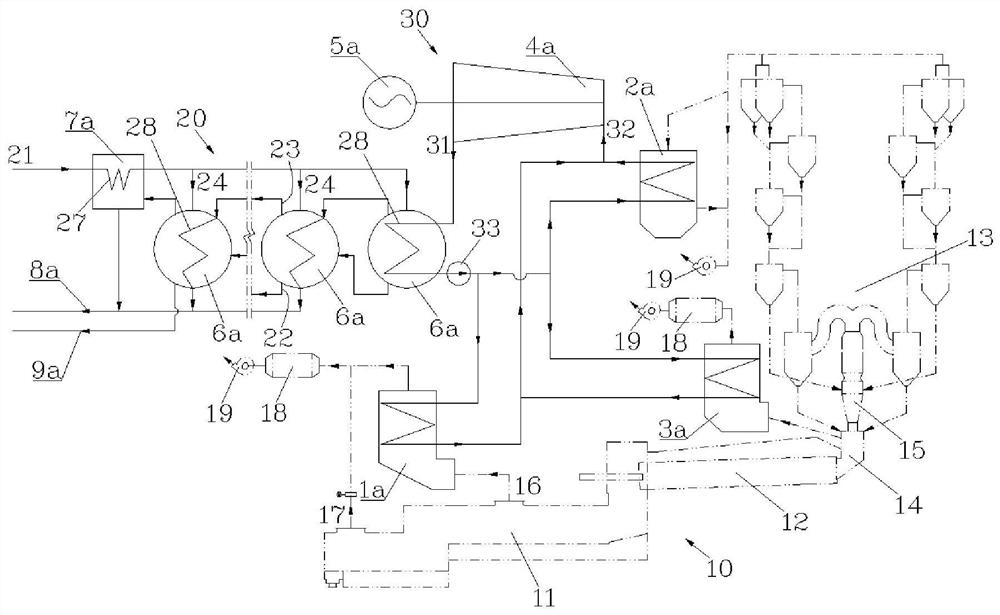

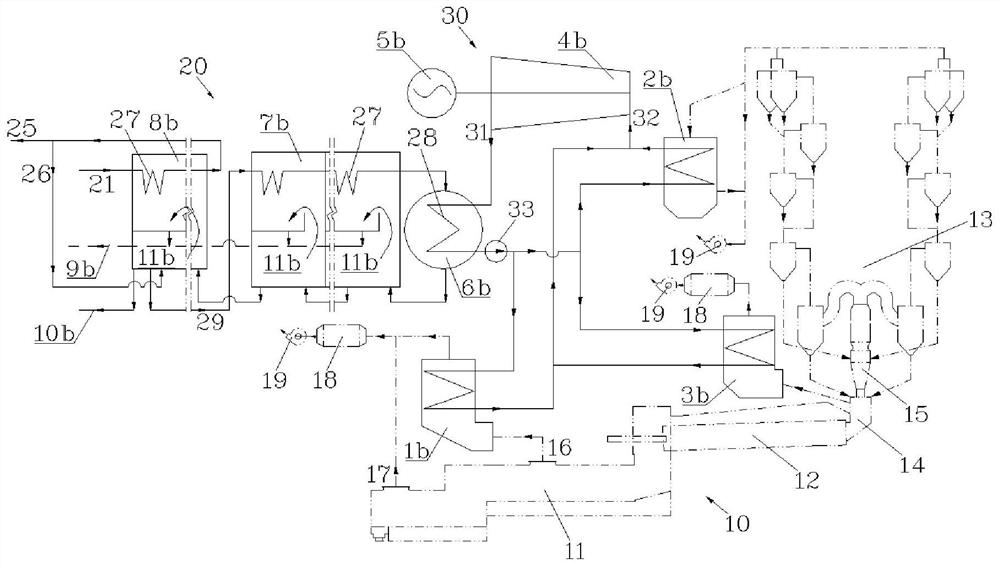

Combined cycle thermoelectric conversion system utilizing multi-grade waste heat of internal combustion engine

ActiveCN103352772ARealize comprehensive utilizationImprove fuel economyInternal combustion piston enginesEngine componentsOrganic Rankine cycleExhaust gas recirculation

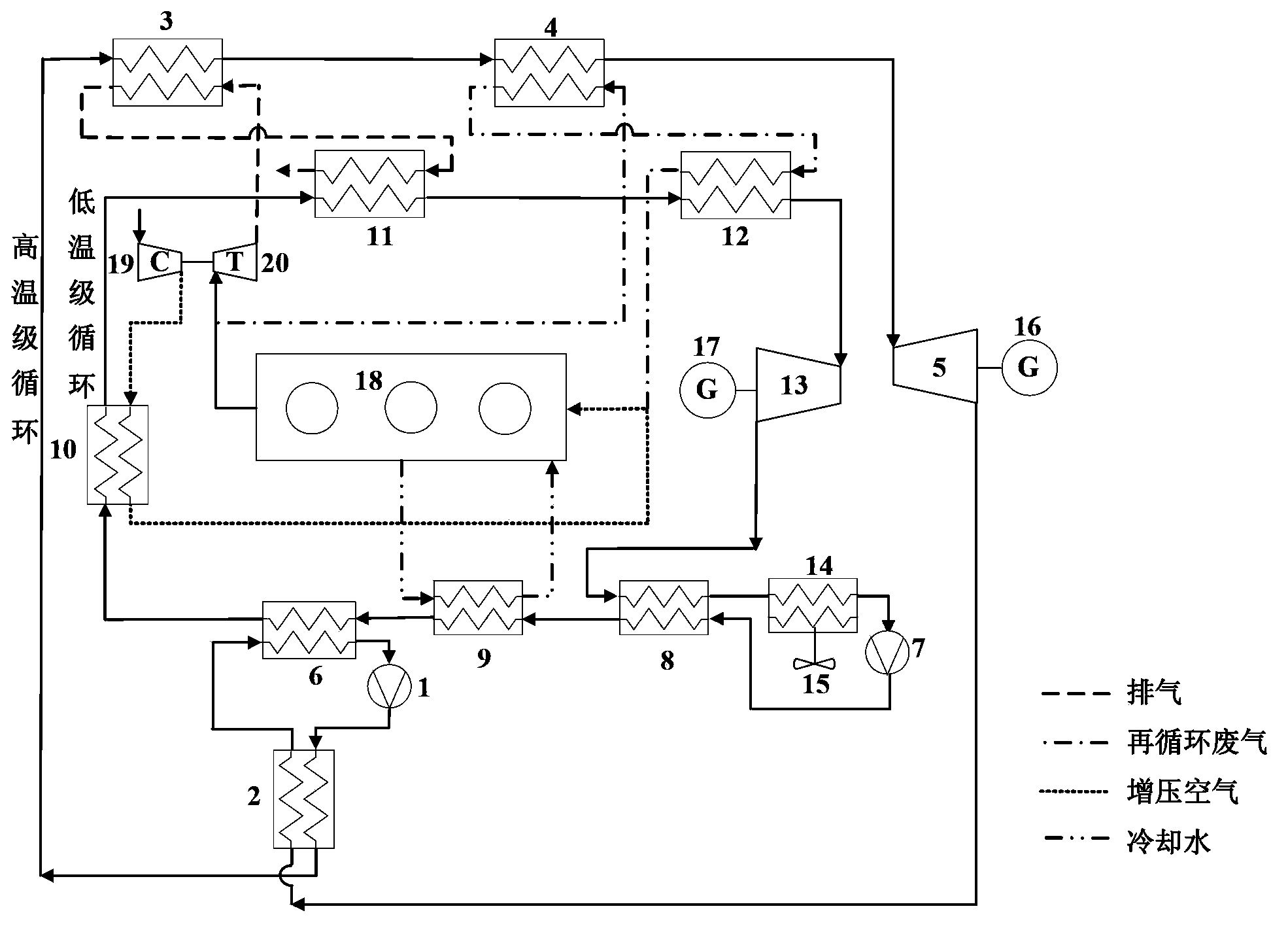

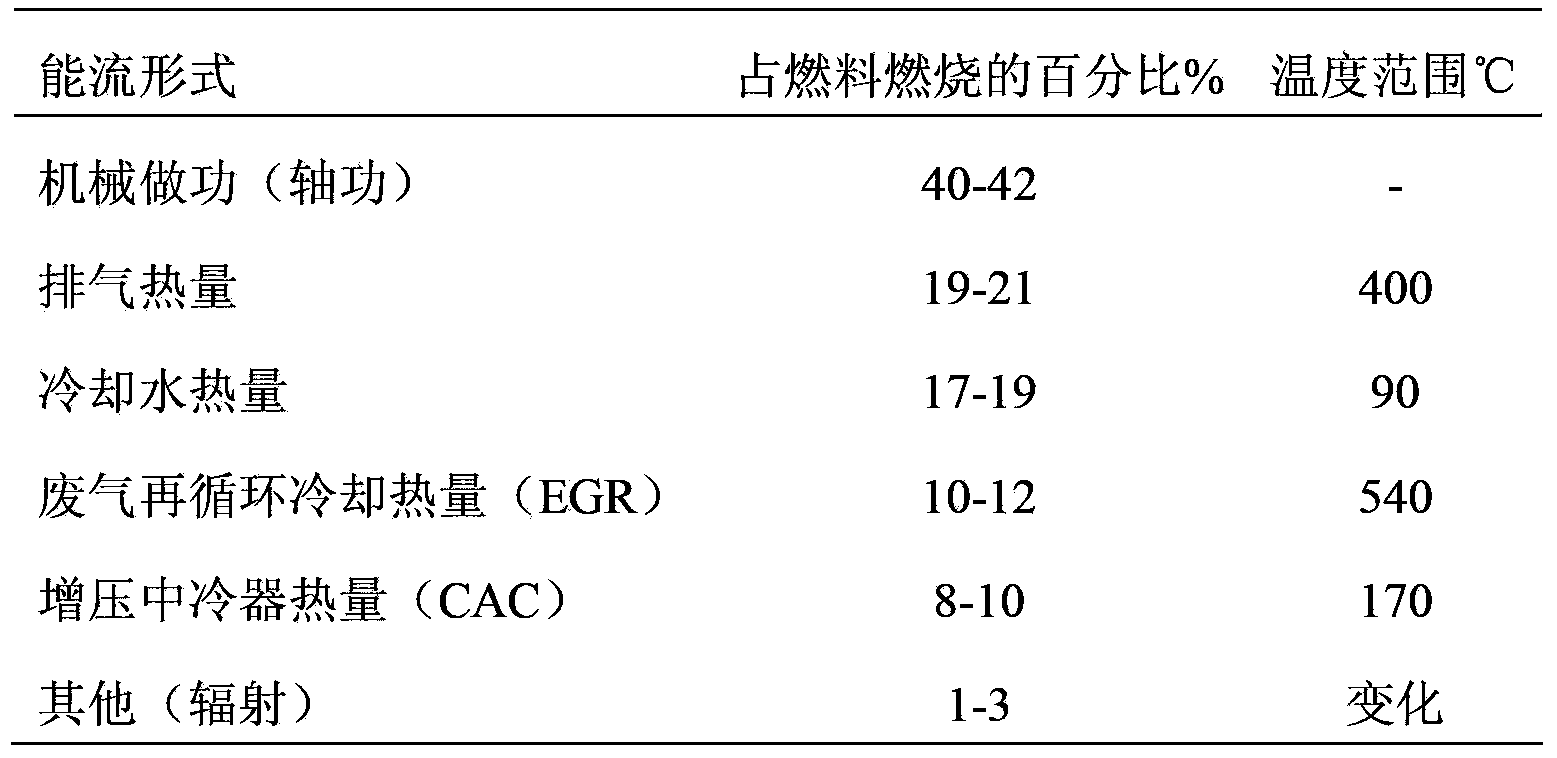

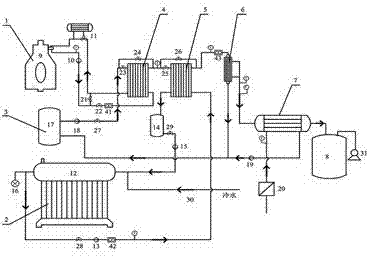

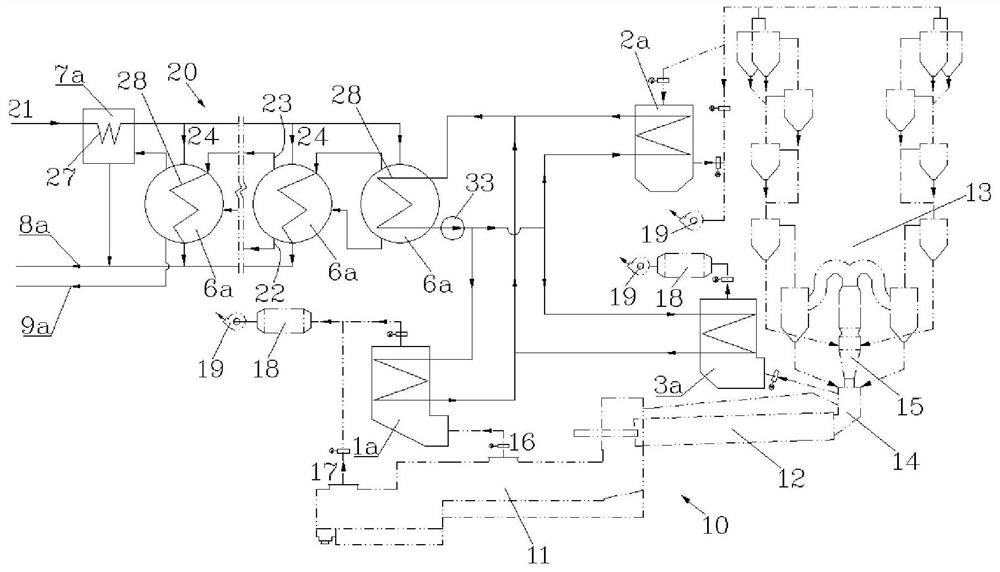

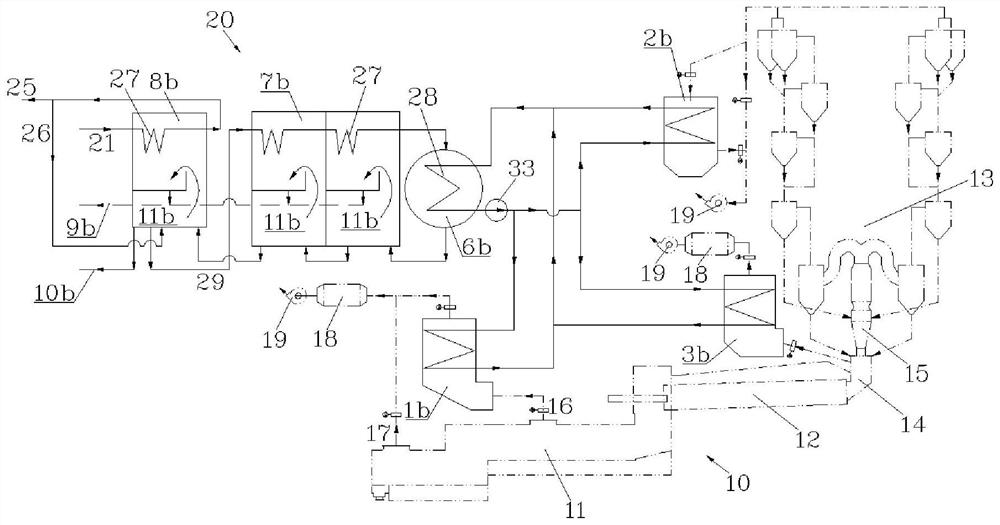

The invention provides a combined cycle thermoelectric conversion system utilizing multi-grade waste heat of an internal combustion engine. According to the system, combined organic Rankine cycle is formed by high-temperature grade cycle and low-temperature grade cycle, heat is supplied by exhaust waste heat of the internal combustion engine, supercharged and mid-cooling waste heat, exhaust gas recirculation waste heat and cooling water waste heat, a cooling quantity is provided by cold wind, and the system comprises a high-temperature grade working medium pump, a high-temperature grade heat regenerator, a high-temperature grade exhaust heater, a high-temperature grade EGR (exhaust gas recirculation) heater, a high-temperature grade expansion engine, a high-temperature grade condenser, a low-temperature grade working medium pump, a low-temperature grade heat regenerator, a low-temperature grade cooling water heater, a low-temperature grade supercharged air heater, a low-temperature grade exhaust heater, a low-temperature grade EGR heater, a low-temperature grade expansion engine, a low-temperature grade condenser, a low-temperature grade condenser fan and a power generator. According to the combined cycle thermoelectric conversion system utilizing multi-grade waste heat of the internal combustion engine, comprehensive and efficient utilization of multi-grade waste heat of the internal combustion engine can be achieved, further, irreversible loss is smaller when both the high temperature and the low temperature adopt supercritical expanding cycle, and the integral efficiency of the internal combustion engine can be effectively improved.

Owner:TIANJIN UNIV

High-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method

PendingCN111850194AImprove pulverization rateImprove processing efficiencyExhaust gas handlingRecycling and recovery technologiesSlagDust control

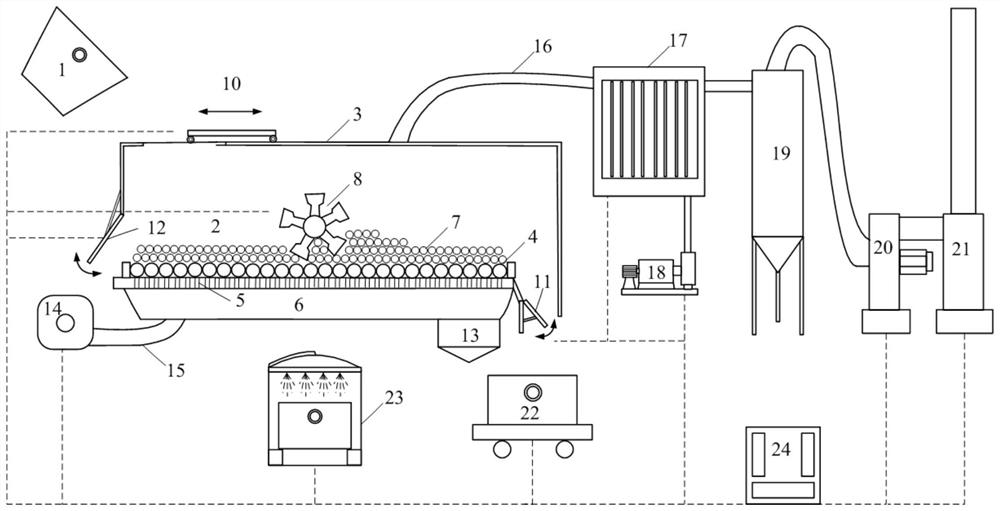

The invention relates to a high-temperature steel slag bottom blowing air cooling crushing waste heat recovery device and method. A crushing bed is adopted as a high-temperature steel slag treatment carrier, a crusher is adopted for efficiently crushing steel slag, meanwhile, cold air is introduced into a bottom blowing air cooling box to solidify and cool the high-temperature steel slag, and meanwhile, the crusher rotates at a certain speed, moves forwards and backwards and rotates to crush the steel slag. A heat exchanger and a generator are adopted for cooling the high-temperature steel slag to generate high-temperature waste heat for recovery and power generation. The crushing capacity is high, the steel slag treatment efficiency is greatly improved, and meanwhile, waste heat recoveryand power generation can be realized by adopting air cooling heat exchange. Efficient crushing and waste heat recovery of the high-temperature steel slag are realized, a steel slag water cooling system device is omitted, a simple dry dust removal mode is adopted to replace a wet flue gas treatment system caused by a previous water cooling process, the advantages of being high in automation degree,small in space occupation, good in leakproofness, low in system investment, capable of achieving ultra-clean emission and the like are achieved, and the comprehensive economic benefits of steel slagtreatment are improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Titanium dioxide production process calcining tail gas processing method

ActiveCN105561721AHigh utilization rate of waste heat recoveryReduce consumptionCombination devicesGas treatmentProduction lineUtilization rate

The present invention discloses a titanium dioxide production process calcining tail gas processing method comprising the following steps: 1) dust removal; 2) preliminary heat exchange, to be more specific, calcining tail gas after the dust removal is discharged into a waste heat boiler system for heat exchange with process water, and the calcining tail gas is preliminarily calcined; 3) further heat exchange, to be more specific, the preliminarily-calcined calcining tail gas enters a venturi system and further cooled by spraying with spent sulfuric acid; and 4) desulfurization. According to the titanium dioxide production process calcining tail gas processing method, waste heat boiler system with high heat recovery utilization rate is used, and by step-by-step heat exchange, heat can be efficiently recovered from the calcining tail gas, and can be used for other processes in a titanium dioxide production line, energy and water consumption can be greatly saved, and by the desulfurization, desulfurization rate of the calcining tail gas is significantly increased.

Owner:SHANGHAI TITANOS IND

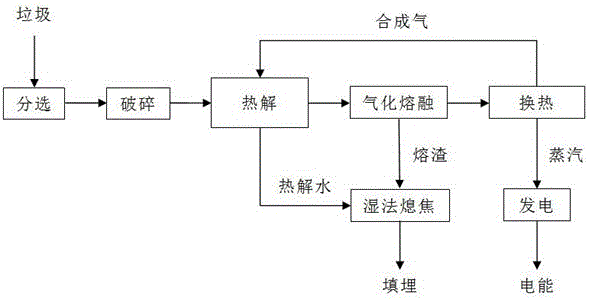

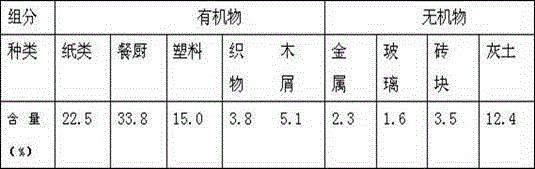

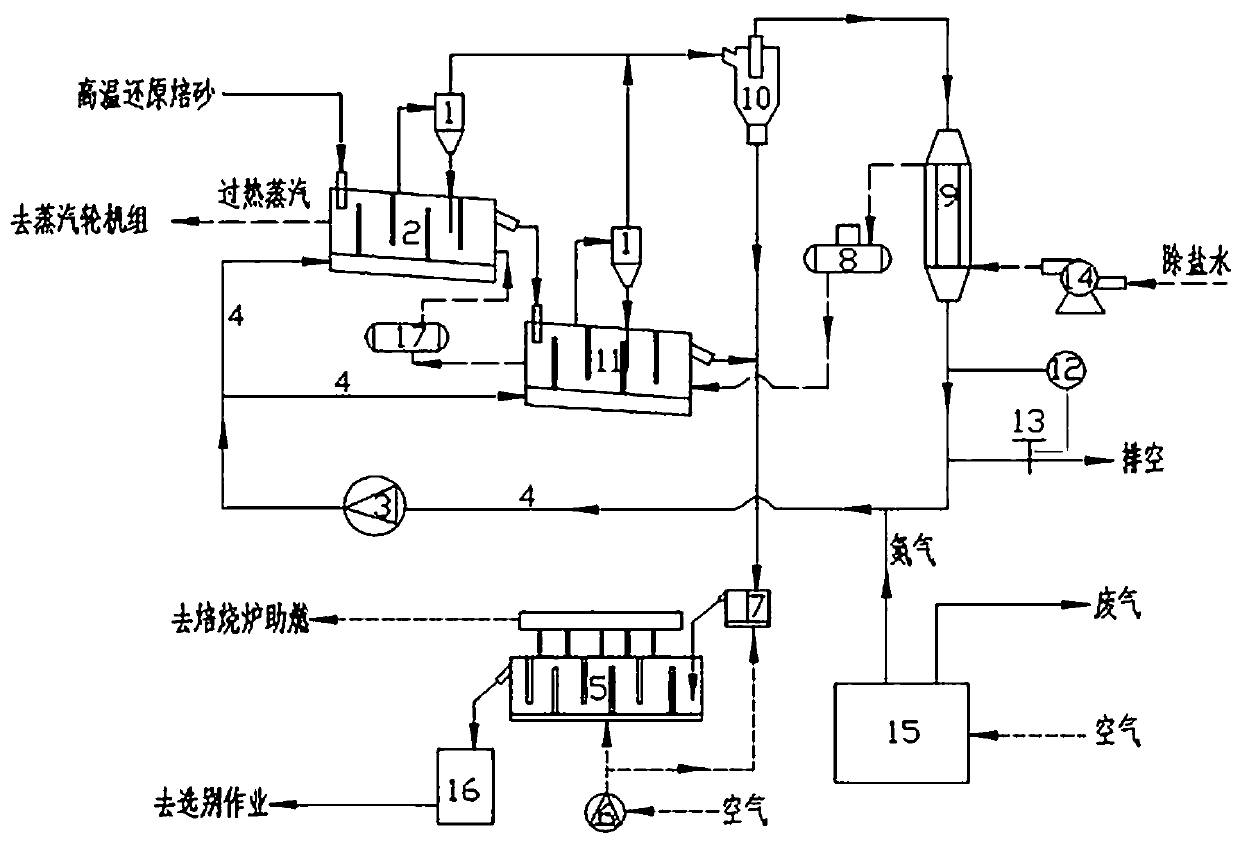

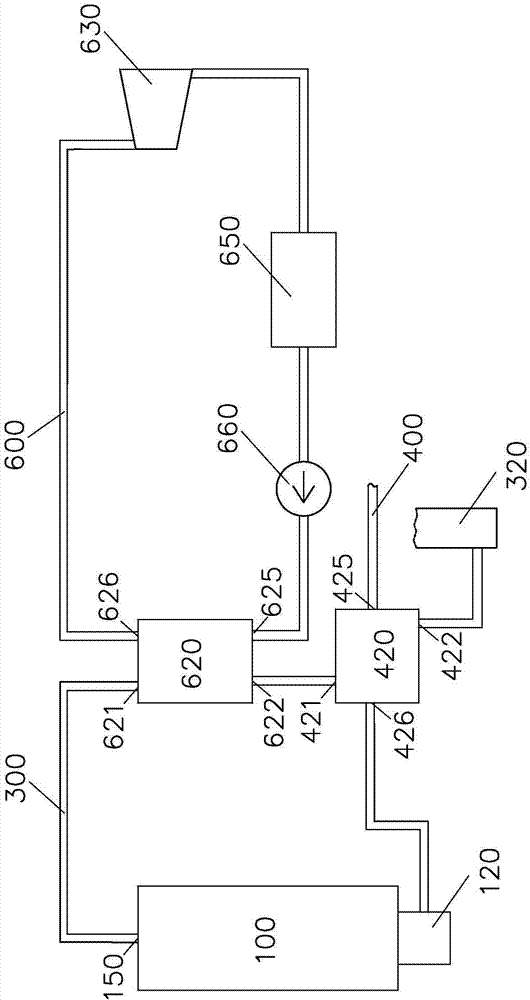

System and method for waste pyrolysis, gasification and fusion

ActiveCN106500107AHigh yieldHigh calorific valueIncinerator apparatusCombined combustion mitigationSlagQuenching

The invention provides a system and method for waste pyrolysis, gasification and fusion. The system comprises a sorting device, a crushing device, a heat storage type rotating bed used for performing drying and pyrolysis treatment on waste so as to obtain pyrolytic water, pyrolytic oil and gas mixtures and pyrolytic carbon, a gasification and fusion reaction chamber used for making pyrolytic oil and hydrocarbon gas subjected to gasification and recombination under the high-temperature gasification effect of a plasma torch so as to obtain synthesized gas comprising CO and H2 and fusing the pyrolytic carbon into glass state slag, a heat exchange device, a power generation device and a coke quenching device. The heat storage type rotating bed is adopted to perform pyrolysis on pretreated waste raw materials; the gasification and fusion reaction chamber is used for gasifying the pyrolytic oil and gas mixtures, water obtained through drying serves as water for coke quenching of the pyrolytic carbon, and the obtained synthesized gas is high in yield and heat value and is used as fuel gas of a heat storage type radiant pipe; and steam obtained by performing heat exchange treatment on the synthesized gas can be used for power generation selling, and the 'harmless, reduction and recycling' treatment of waste is achieved.

Owner:SHENWU TECH GRP CO LTD

Thermal power plant energy storage method and device with waste heat recovery

ActiveCN110631400AReduce surface temperatureEvenly heatedHeat storage plantsEngineeringElectromagnetic valve

The invention discloses a thermal power plant energy storage method and device with waste heat recovery. The thermal power plant energy storage device with waste heat recovery comprises a conveying pipe, a heating tank and a heat storage tank; a recovery pipe, a low-temperature pipe and a high-temperature pipe is fixedly connected to the bottom end of the conveying pipe through a four-way connector; a first electromagnetic valve is fixedly connected to the interior of the recovery pipe; a second electromagnetic valve is fixedly connected to the interior of the low-temperature pipe; and a thirdelectromagnetic valve is fixedly connected to the interior of the high-temperature pipe. The invention relates to the technical field of waste heat recovery. For the thermal power plant energy storage method and device with waste heat recovery, waste heat gases with different temperatures have different recycling modes, waste heat with different temperatures can be classified and utilized, and working pressure of the energy storage device with waste heat recovery is weakened; by combining a heating water tank device with a heat storage and release device, the waste heat recovery utilization rate is remarkably increased, the practicability of the device is improved, a phase change heat storage material is more uniformly heated, the utilization rate of the heat storage material is increased, and the heat storage efficiency is improved.

Owner:华电呼图壁能源有限公司热电厂

System for desalting vacuum membrane distilled seawater by utilizing solar energy and after heat of diesel engine cylinder sleeve cooling water via cascade coupling

ActiveCN104291406AReduce lossesReduce wasteGeneral water supply conservationSeawater treatmentCollection systemWorking temperature

The invention discloses a system for desalting vacuum membrane distilled seawater by utilizing solar energy and after heat of diesel engine cylinder sleeve cooling water via cascade coupling. The system comprises a diesel engine cylinder sleeve cooling water circulation system, a solar energy hot water circulation system, a feed liquid circulation system, a heat exchanger I, a heat exchanger II, a membrane assembly, a condensation system and a vacuum collection system. After being preheated by a condenser, the seawater enters into a water supply pool and further undergoes cascade heating with the diesel engine cylinder sleeve cooling water and the solar energy hot water in sequence through the heat exchangers I and II to ensure that the temperature of fed seawater achieves the working temperature of the membrane assembly; and a fresh water steam outlet of the membrane assembly is connected with the vacuum collection system through the condensation system. The system has the advantages of being high in utilization rate of the after heat of the diesel engine cylinder sleeve cooling water, high in utilization rate of device energy and suitable for different working conditions, saving the manufacture cost of the fresh water and improving the yield of the fresh water.

Owner:JIMEI UNIV

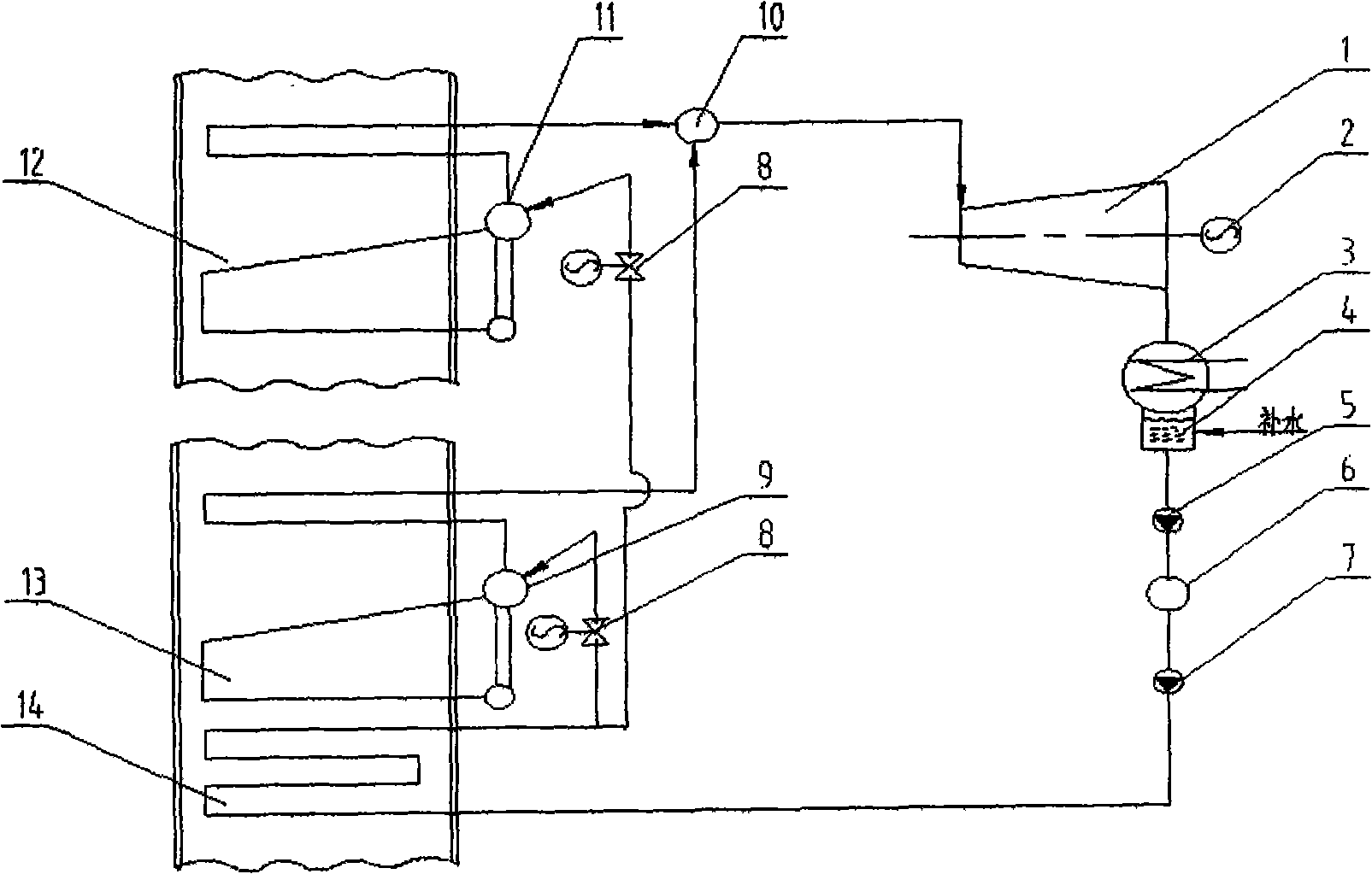

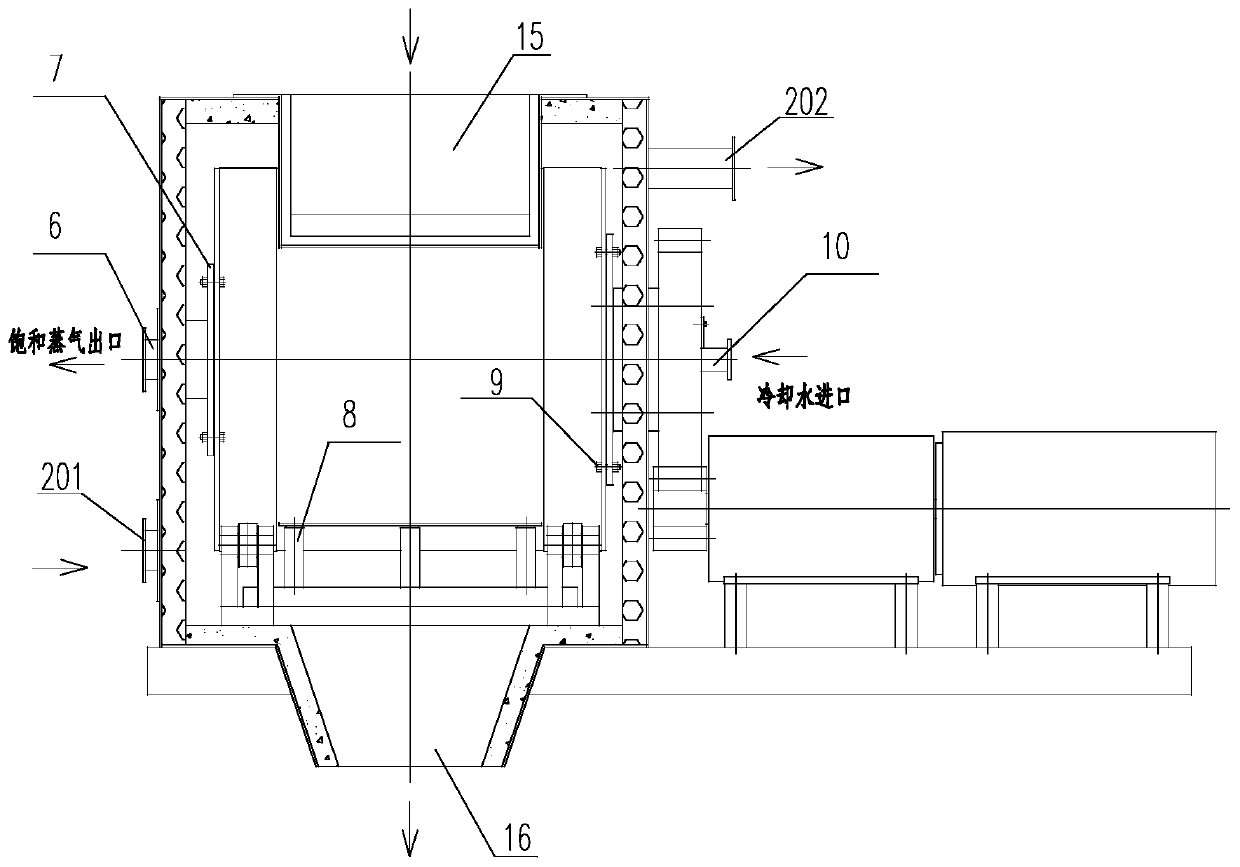

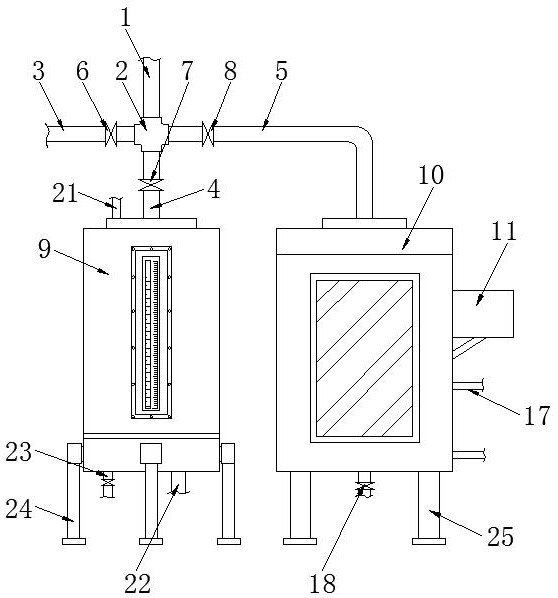

After heat power station heat system for performing vacuum deoxidization using steam turbine condenser

InactiveCN101275738ASimplify thermal systemLess investmentLiquid degasificationIncreasing energy efficiencyDeoxidizationHeating power

A waste heat power station thermodynamic system processing the vacuum deoxygenation with a steam turbine condensator is a vacuum deoxygenatiom system using the chemical deionization water inside a condensator (2) connected with a stream filling and condensing steam turbine (1) for entering an AQC waste heat boiler (13) and a SP waste heat boiler (12) for water supply, which can markedly raise the waste heat utilance. The condensed water of 41-36 degrees can enter the water heating zone of the water heat boiler, heat the condensed water higher than 170 degrees, and reduce the discharging temperature of the waste gas to 100 degrees or so, which reasonably increases the recovery waste heat utilance.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

High-temperature reduced calcine cooling protection waste heat recycling system and method

PendingCN109813124AReduce heat consumptionReduce flow rateIncreasing energy efficiencyHandling discharged materialDeaeratorNitrogen gas

The invention discloses a reduced calcine cooling protection waste heat recycling system and method. The system comprises a first-stage fluidized bed heat exchanger and a second-stage fluidized bed heat exchanger which communicate in sequence and communicate with a nitrogen pipe network through a nitrogen pressurization fan, the first-stage fluidized bed heat exchanger and the second-stage fluidized bed heat exchanger sequentially communicate with a first-stage dust remover, a second-stage dust remover and a third-stage heat exchanger, the third-stage heat exchanger communicates with the first-stage fluidized bed heat exchanger and the second-stage fluidized bed heat exchanger through the nitrogen pressurization fan, an oxygen analyzer is arranged on a pipeline between the third-stage heatexchanger and the nitrogen pressurization fan the three-stage heat exchanger communicates with a boiler deaerator, a discharge outlet of the second-stage fluidized bed heat exchanger communicates with a feed inlet of a fluidized bed preheater through a material sealing valve, and the material sealing valve and an air inlet of the fluidized bed preheater communicate with an air outlet of an air pressurization fan. The problems that high-temperature reduced calcine calcination concentrate quality is poor and calcination energy consumption is high are solved, and the system can be widely appliedto mineral resources such as high-temperature powdered iron ore and manganese ore which are prone to oxidizing reaction after being subjected to reducing calcination.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

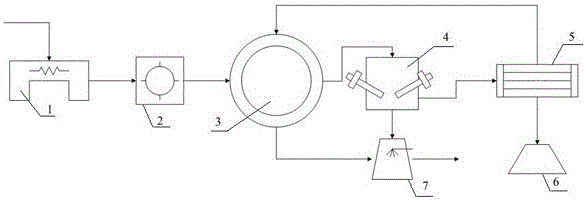

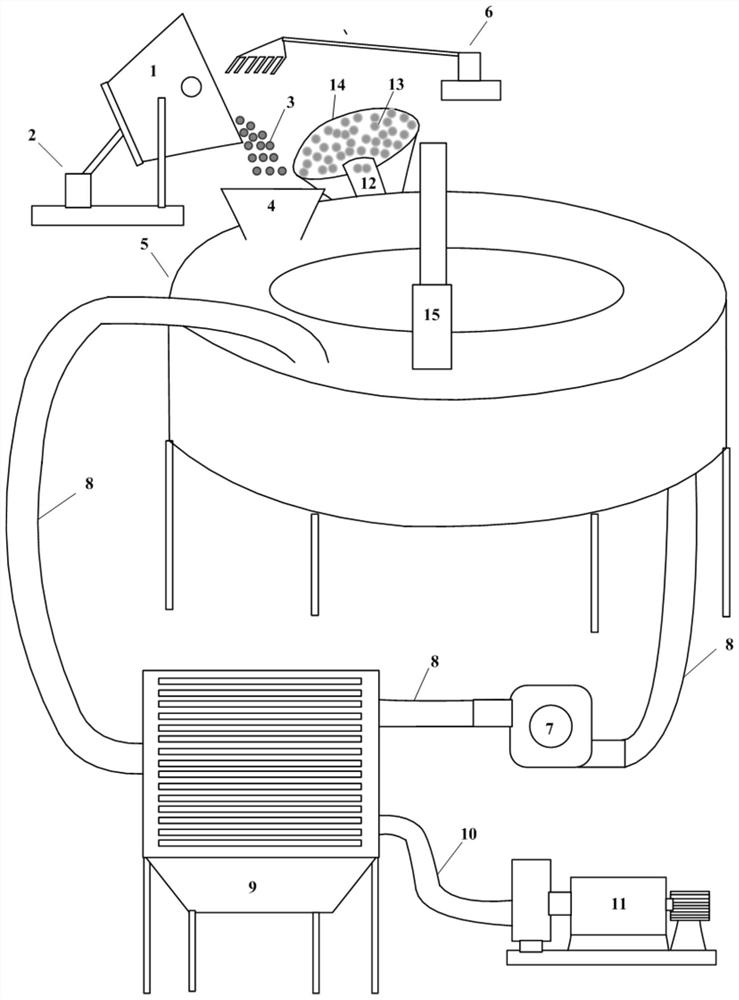

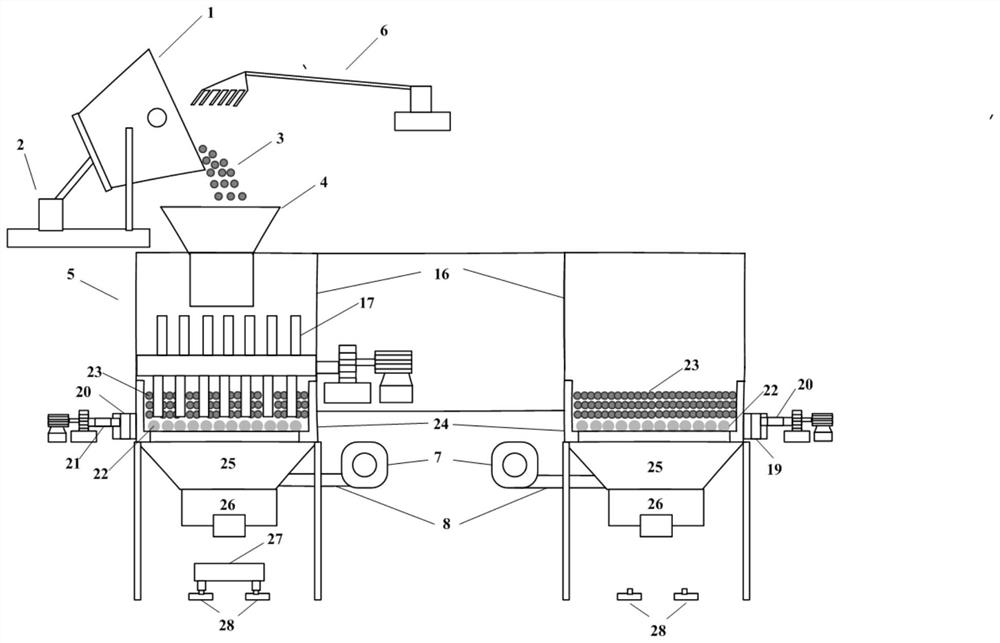

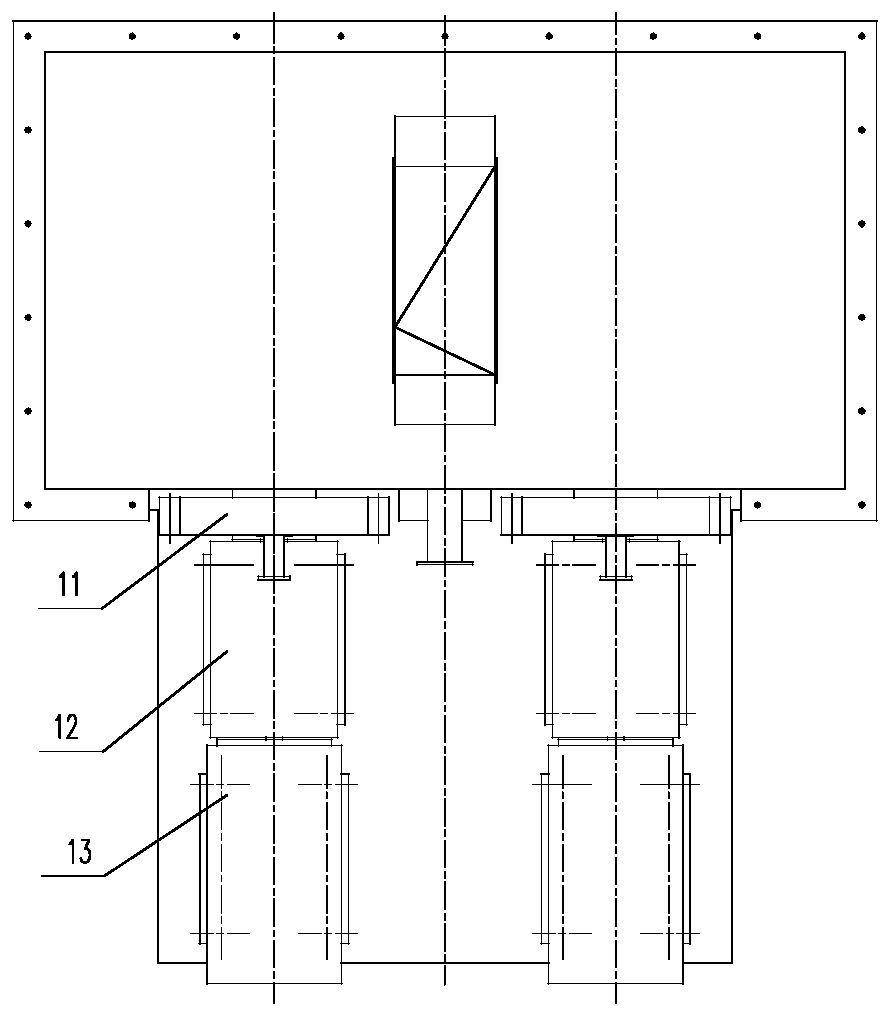

High-temperature steel slag rotating bed crushing waste heat recovery device and method

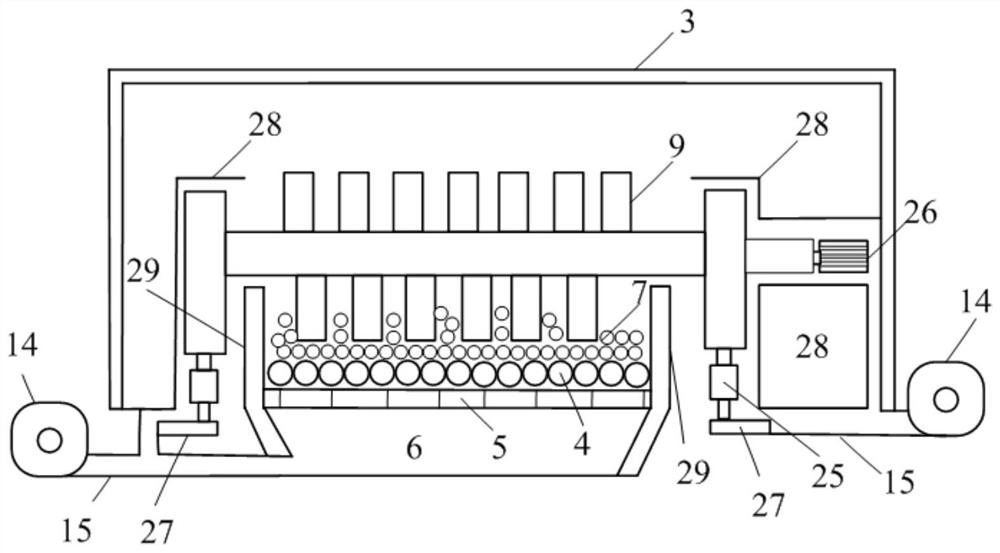

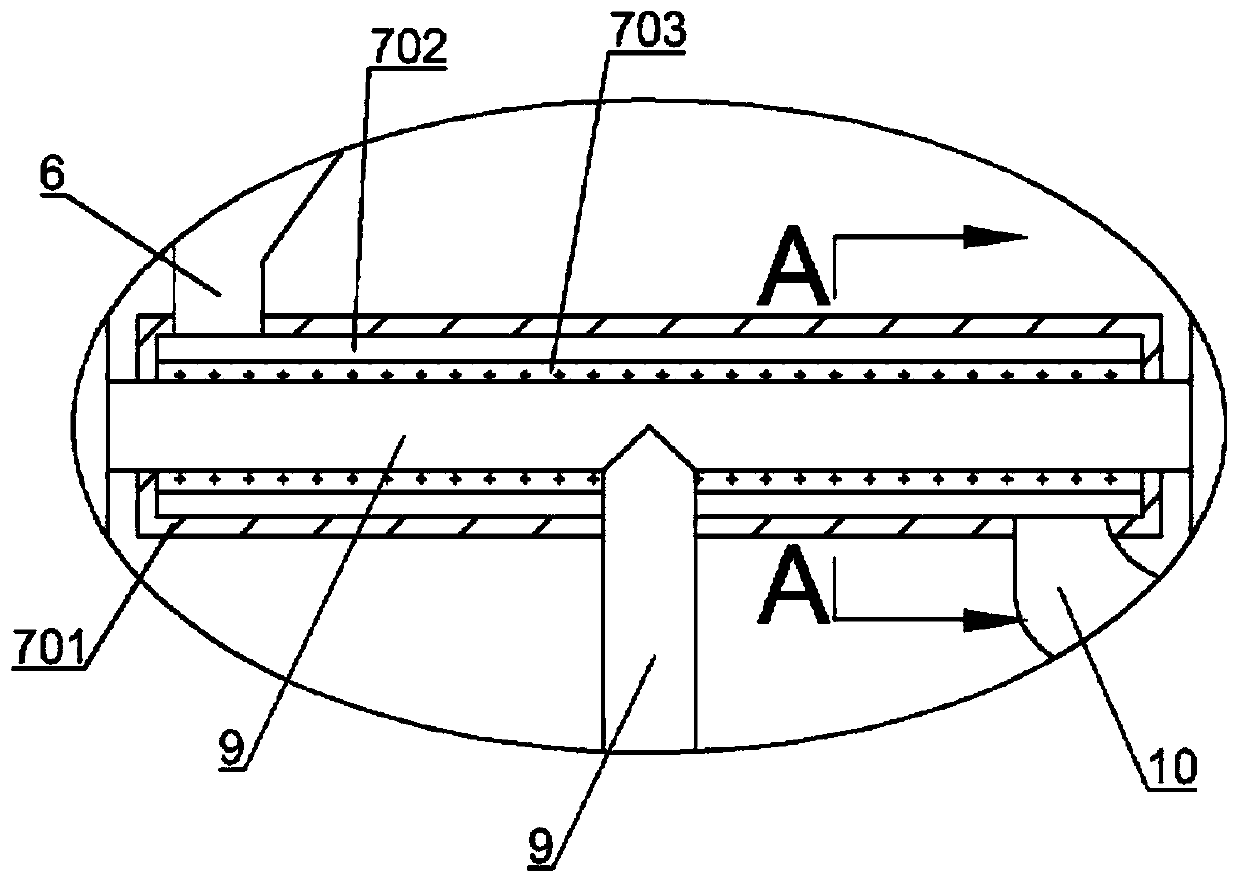

PendingCN113061673AImprove processing efficiencyImprove crushing effectRecycling and recovery technologiesProcess efficiency improvementLiquid slagDust control

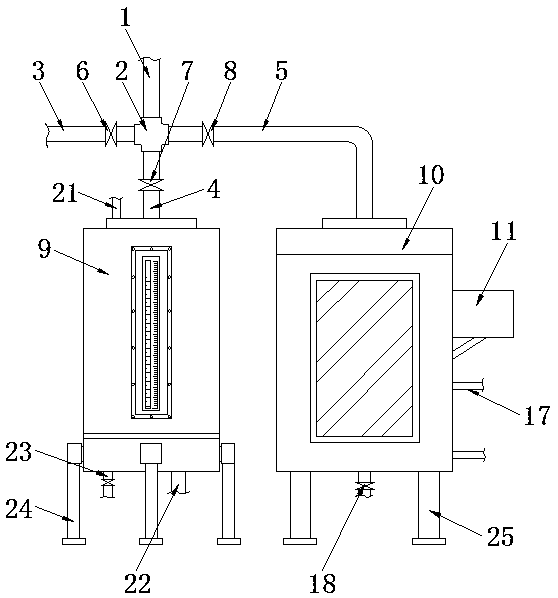

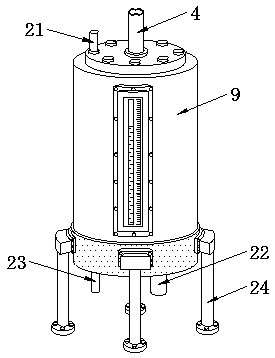

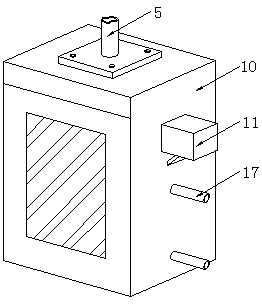

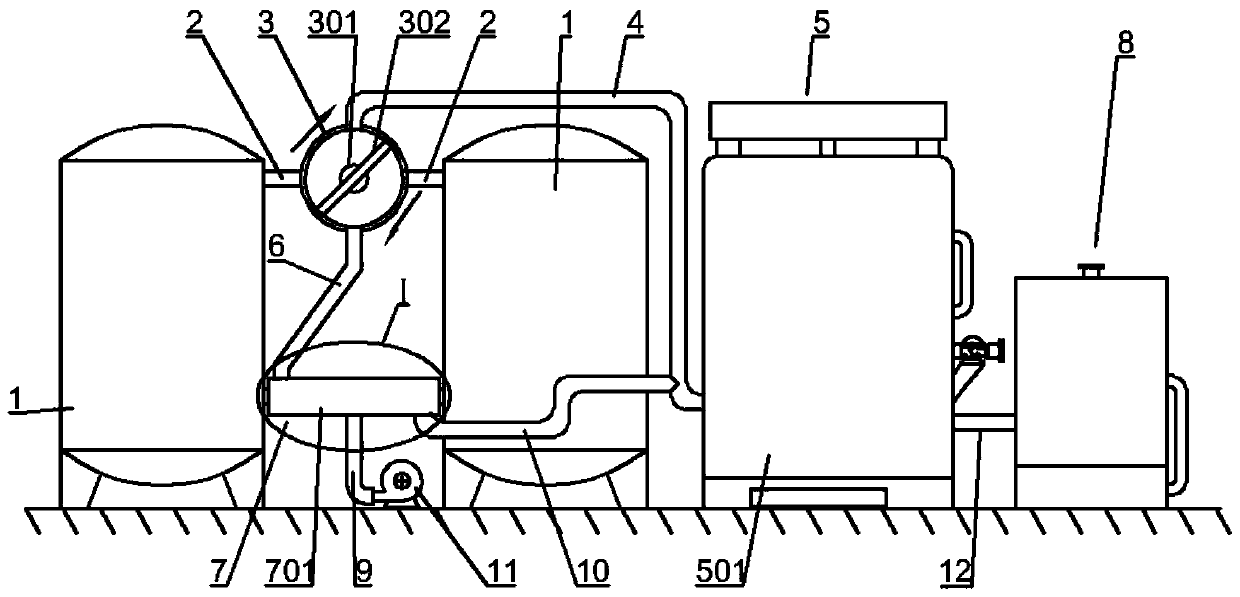

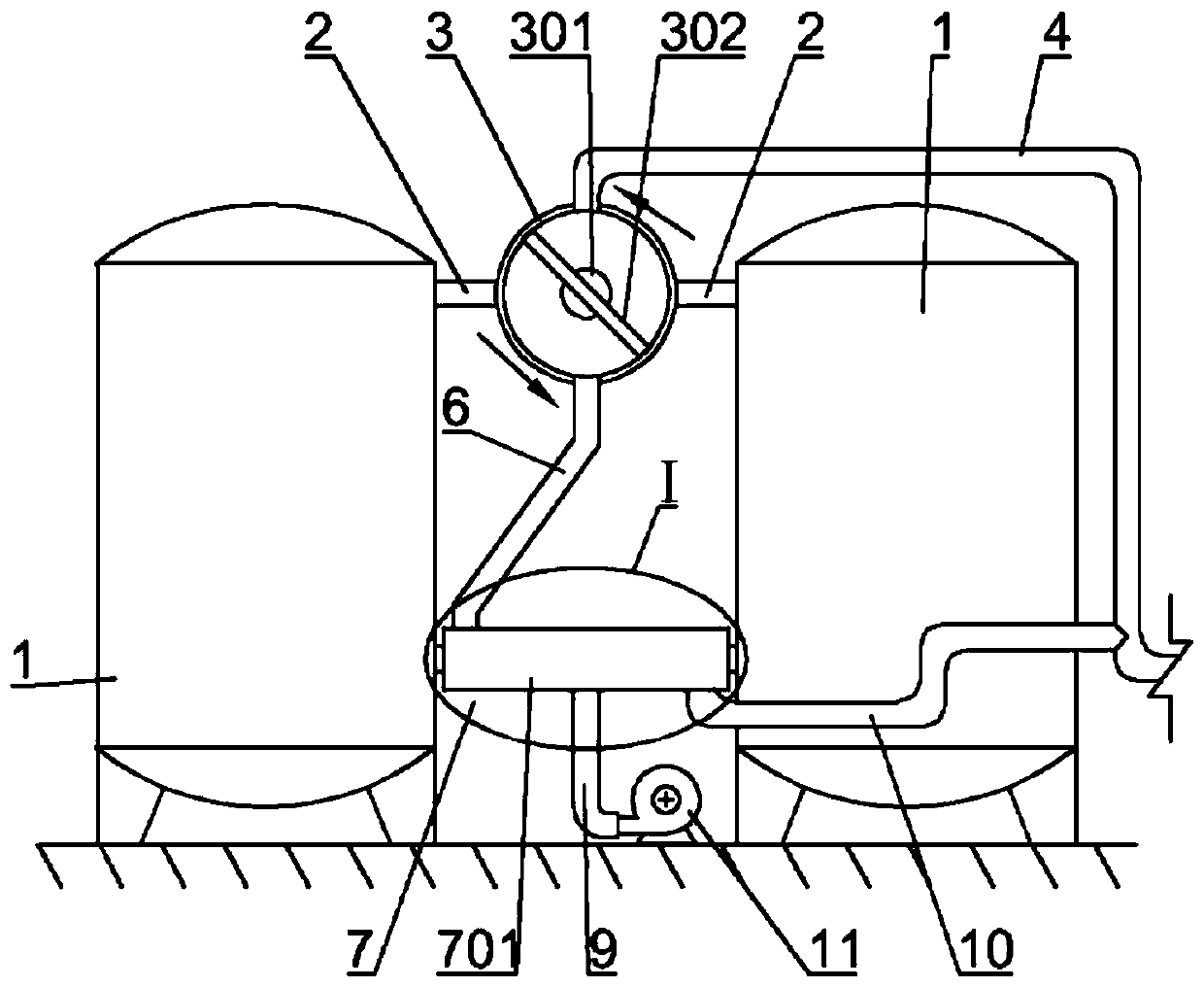

The invention provides a high-temperature steel slag rotating bed crushing waste heat recovery device and method. The high-temperature steel slag rotating bed crushing waste heat recovery device comprises a liquid slag tank (1), a slag pouring machine (2), a rotating bed (5), a slag pulling machine (6), a circulating fan (7), an air pipe (8), a heat exchanger (9), a steam pipe (10), a power generator (11) and a solid slag tank (14), wherein the liquid slag tank (1) is arranged on the slag pouring machine (2) in a pouring mode, and the slag pulling machine (6) is arranged above the rotating bed (5); and the circulating fan (7) is connected with the rotating bed (5) and the heat exchanger (9) through the air pipe (8), the heat exchanger (9) is connected with the power generator (11) through the steam pipe (10), the rotating bed (5) is rotationally arranged between the slag pouring machine (2) and the circulating fan (7), and steel slag is cooled and discharged through the rotating bed (5). The device and method greatly solve the problem about discharge in the steel slag treatment process, greatly reduce the investment of public and auxiliary facilities such as water and dust removal, effectively reduce the steel slag production and operation cost, and improve the system income.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

High-efficiency condensation-type flue gas waste heat recycling device

InactiveCN105823218ALarge internal spaceIncrease the number ofAir heatersSustainable buildingsWater dischargeFlue gas

The invention provides a high-efficiency condensation-type flue gas waste heat recycling device. The device comprises a condensation outer shell, a condensation inner shell and a condensate pipe unit, wherein the condensation outer shell comprises a condensation chamber; the condensation inner shell comprises a condensation inner chamber; the condensate pipe unit comprises a water charging pipe and a water discharging pipe which are distributed diagonally; the condensation inner shell is mounted on the condensation chamber; the condensate pipe unit is mounted on the condensation inner chamber; a flue gas inlet is formed in the bottom surface of the condensation outer shell; a flue gas exhausting passage communicating with the condensation inner chamber is arranged on the bottom of the condensation outer shell; through holes communicating with the condensation chamber and the condensation inner chamber correspondingly are formed in the upper wall surface of the condensation inner shell; the flue gas inlet, the condensation chamber, the through holes, the condensation inner chamber and the flue gas exhausting passage form a flue gas waste heat recycling flow path which is used for heat exchange with the condensate pipe unit, so that the flowing resistance of the flue gas in the condensation inner chamber is equal, the condensate pipe unit is heated uniformly, sensible heat in high-temperature exhausted flue gas of a gas module and latent heat released by condensation of water steam can be fully absorbed, and thus returning water inside the condensate pipe unit can be effectively preheated, the flue gas heat energy recycle rate is increased, the thermal efficiency of the gas module is improved, and the using effect of the product is improved.

Owner:ZHONGSHAN PRIMA IND

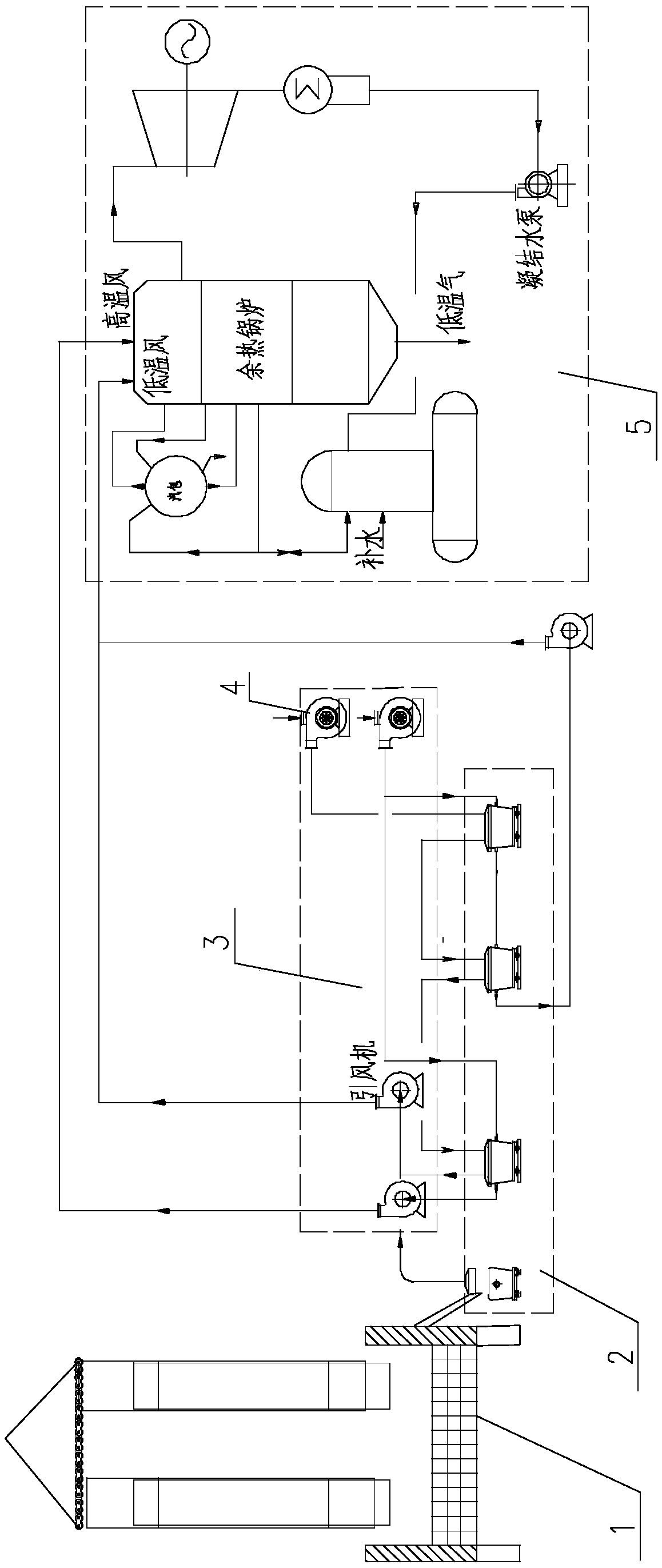

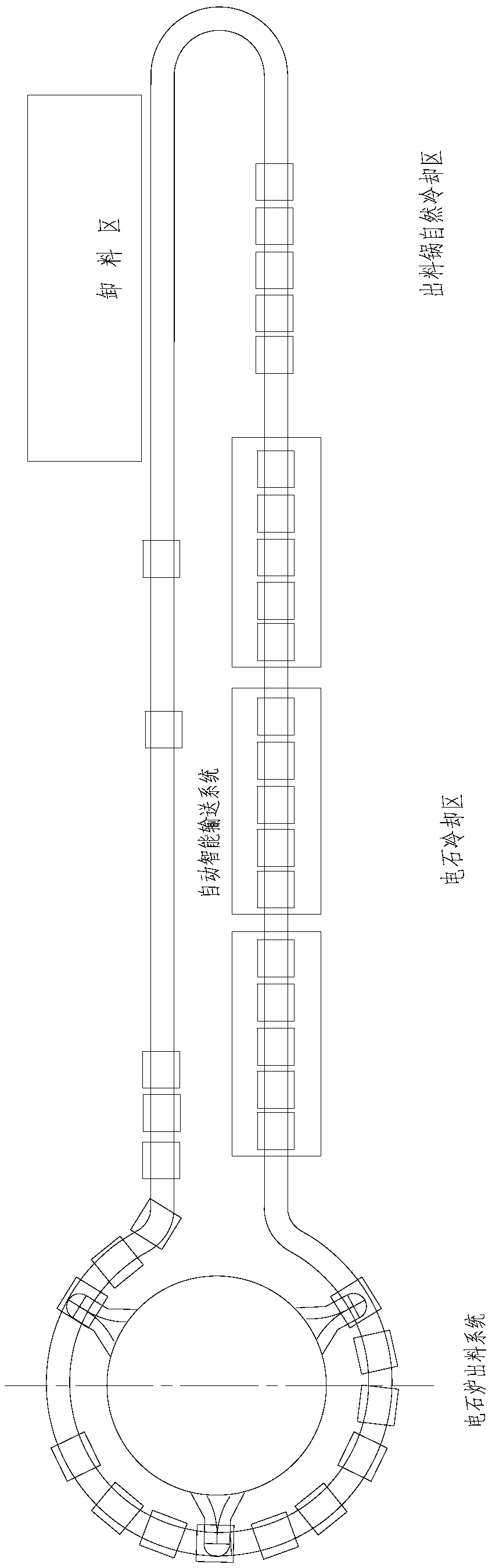

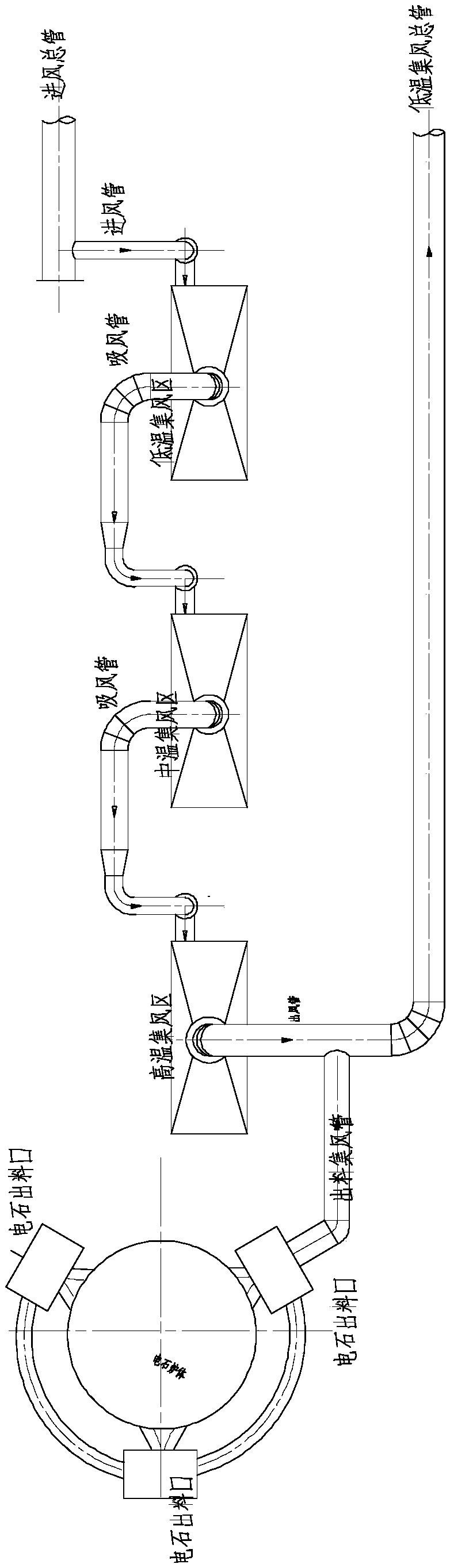

Calcium carbide waste heat recycling and utilizing system

ActiveCN109579550AImprove the environmentSimple structureEnergy inputCalcium carbideAir volumeFully automatic

The invention discloses a calcium carbide waste heat recycling and utilizing system. The calcium carbide waste heat recycling and utilizing system comprises a calcium carbide pot, a waste heat boiler,a fully-automatic intelligent conveying system, a smoke air system and a PLC control system, wherein hot air which flows through a cooling channel of the calcium carbide pot to heat up is fed into the waste heat boiler by the smoke gas system to subject to waste heat recycling; the PLC control system controls the fully-automatic intelligent conveying system to work; the system is simple in equipment structure, is high in degree of automation, recycles waste heat in a calcium carbide furnace outlet liquid and calcium carbide cooling process, and is high in waste heat recovery rate; the coolingflue is connected end to end to form a sealed cooling space, so that amount of leaked air is effectively reduced, and the waste heat recovery rate is increased; and cooling air and smoke gas are adopted as a heat exchange medium, so that a production process is safe and reliable.

Owner:史晓云 +2

System for heating batch by utilizing secondary waste heat of float glass furnace

ActiveCN101625112AReduce the temperatureReduce dust contentGlass furnace apparatusDrying gas arrangementsScrew conveyorHeating system

The invention relates to the technical field of waste heat utilization of a float glass furnace, aiming at solving the technical problems which are present during the operation of waste heat generation systems of the traditional float glass furnaces, such as low recovery rate of waste heat, severe environmental pollution caused by emission of smoke containing a large amount of dust, unstable system operation and the like. A smoke outlet of the float glass furnace of the invention is communicated with a smoke inlet of a waste heat boiler; a smoke outlet of the waste heat boiler is communicated with an inlet of a waste heat draft fan; an outlet of the waste heat draft fan is communicated with an inlet of a rotary dryer through a flue, a charging hole is arranged above the inlet of the rotary dryer, an outlet of the rotary dryer is provided with a downward material outlet end and an upward flue respectively; the upward flue is communicated with a helical conveyor above which a dust collector is arranged; a discharge hole of the helical conveyor and a material outlet end of the rotary dryer are connected with a kiln head feeding bin, and a smoke outlet of the helical conveyor is communicated with a system draft fan and a chimney. The invention is suitable for the waste heat utilization of the float glass furnace.

Owner:成都南玻玻璃有限公司

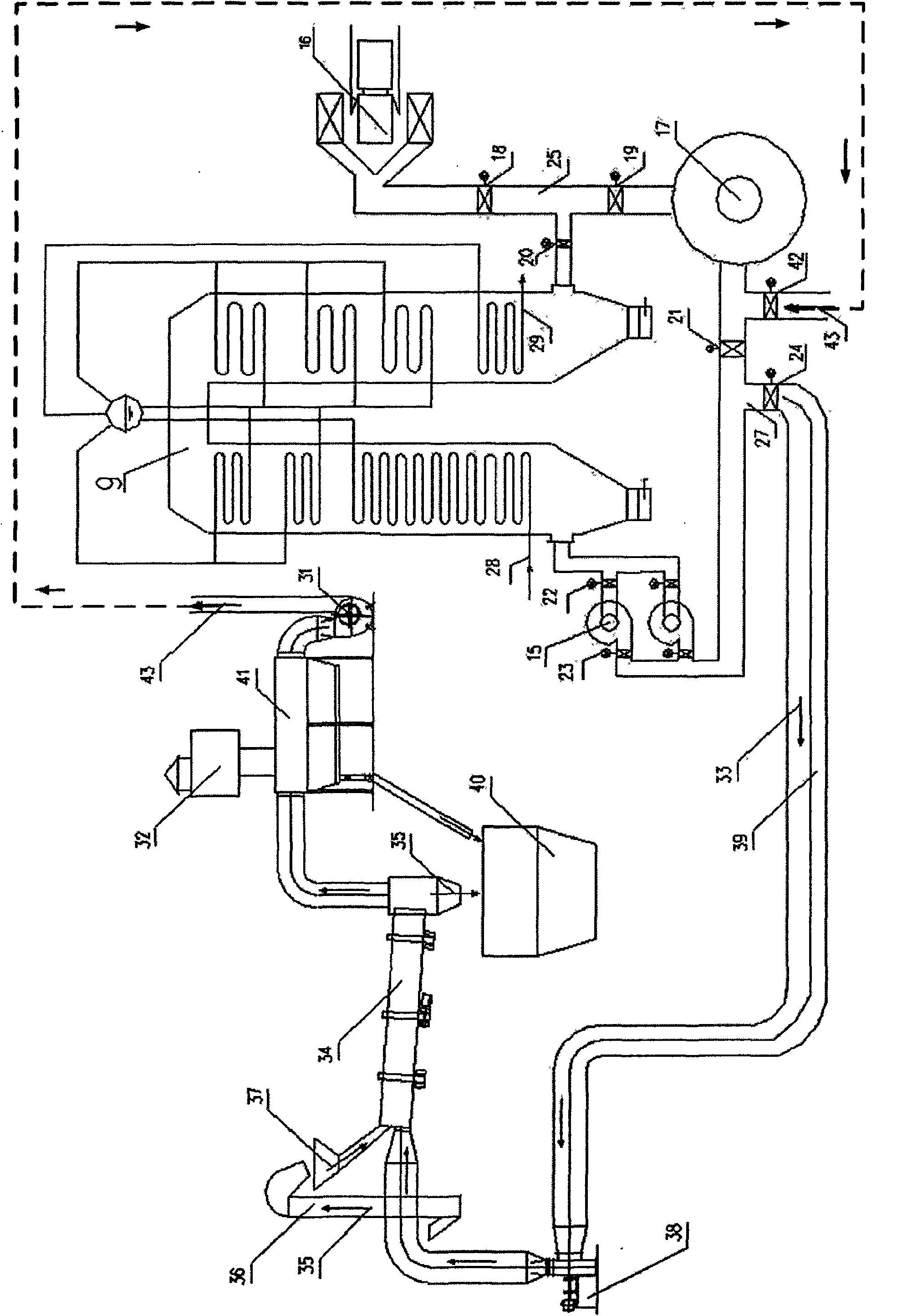

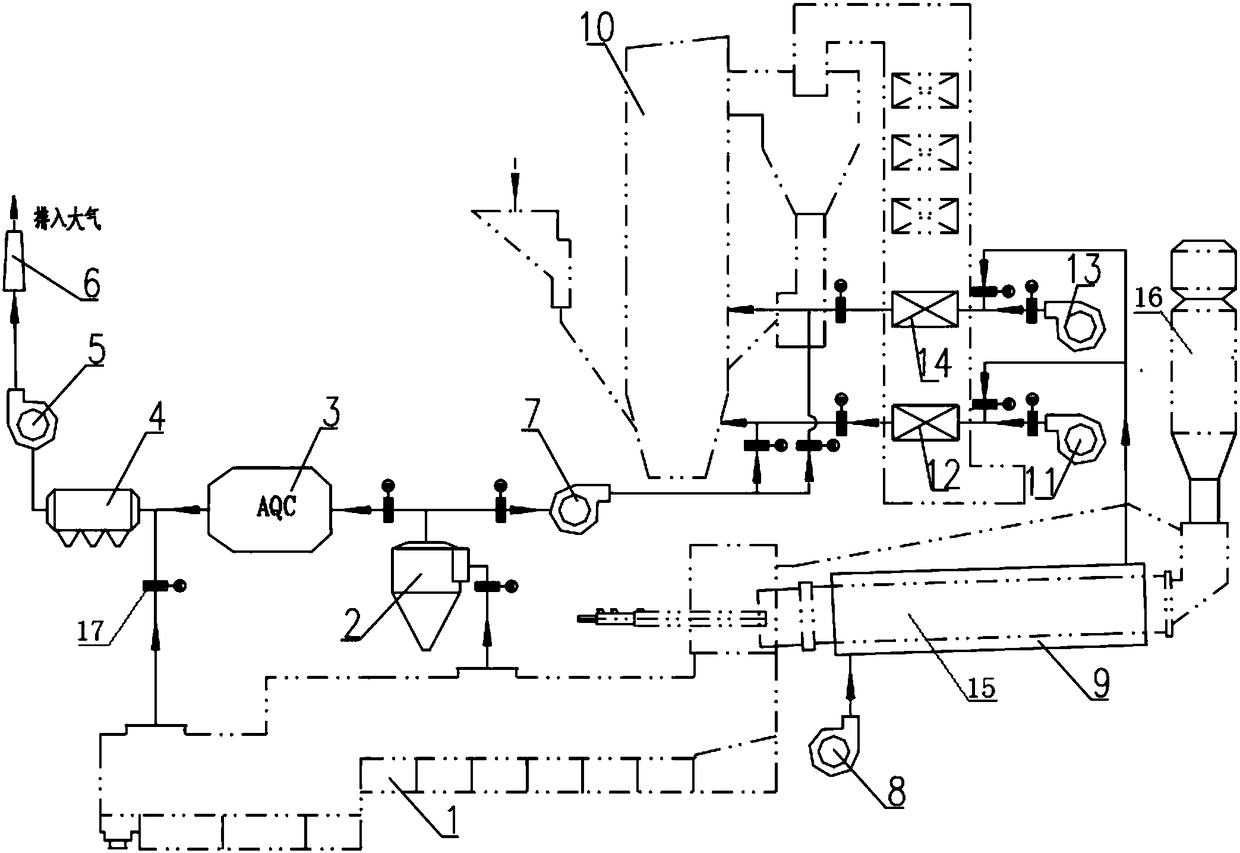

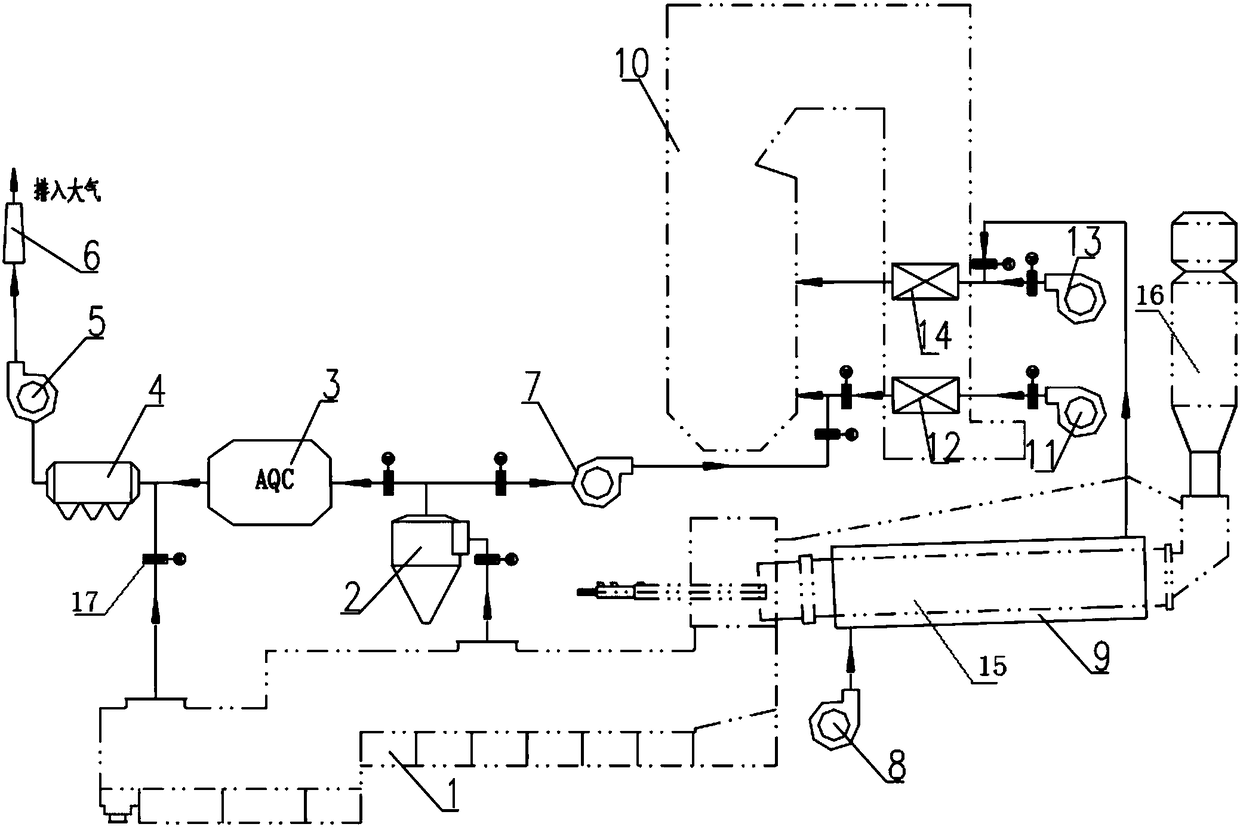

Self-provided power station boiler and cement kiln waste heat recovery coupling system

PendingCN108278905AImprove power generation efficiencyImprove production and operation efficiencyCombustion processIncreasing energy efficiencyAir preheaterPower station

The invention discloses a self-provided power station boiler and cement kiln waste heat recovery coupling system, and belongs to the technical field of cement production waste heat recovery and boilers. The self-provided power station boiler and cement kiln waste heat recovery coupling system comprises a kiln head waste heat recovery system, a rotary kiln waste heat recovery system and a power station boiler system; the kiln head waste heat recovery system comprises a grate cooler, a first dust removal device, a waste heat boiler, a second dust removal device, an induced draft device, a pressurizing air device and a connecting pipeline; the rotary kiln waste heat recovery system comprises an air supply device, an air heating device and a connecting pipeline; and the power station boiler system comprises a boiler, a primary air pipeline, a primary air preheater, a secondary air pipeline and a secondary air preheater. According to the self-provided power station boiler and cement kiln waste heat recovery coupling system, the overall power generation efficiency of a project for power generation can be effectively improved, the energy waste existing in the cement industry can be reduced, and the multiple purposes of effectively improving the overall power generation efficiency of the project for power generation, improving the operation efficiency of cement production and reducingthe operation energy consumption can be achieved.

Owner:成都建筑材料工业设计研究院有限公司

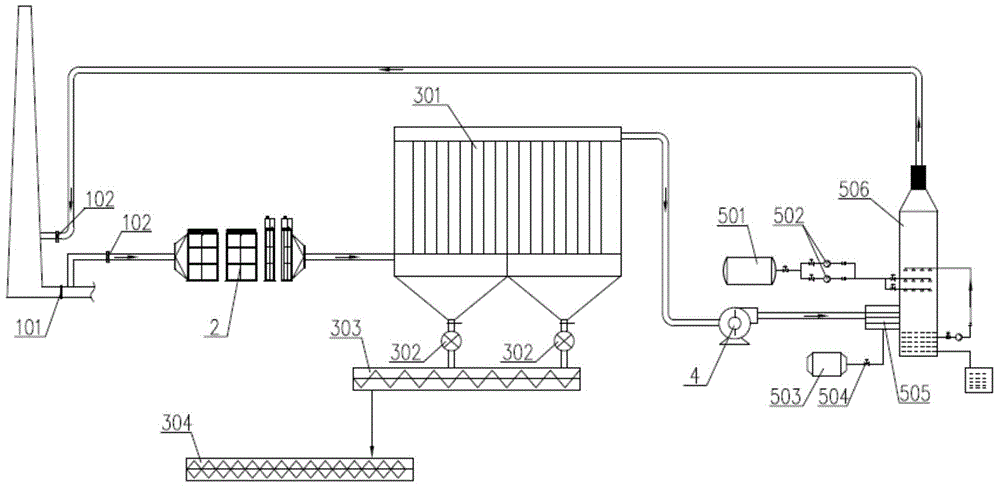

Energy saving and emission reduction comprehensive purifying treatment technology of coke oven flue gas

ActiveCN105233645AImprove efficiencyHigh utilization rate of waste heat recoveryDispersed particle separationFlue gasCoke oven

The invention relates to an energy saving and emission reduction comprehensive purifying treatment technology of coke oven flue gas, and belongs to the technical field of metallurgy coking industry energy saving and emission reduction. An apparatus for enforcing the technology comprises a coke oven flue gas leading-out regulating valve, an induced draught fan, a waste heat recovery system, a flue gas dedusting system and a coke oven flue gas low temperature oxidation absorption system. The technology comprises the following steps: the coke oven flue gas goes through the leading-out regulating valve and the induced draught fan and enters the waste heat recovery utilization system to recovery waste heat of the flue gas and make the temperature of the flue gas decrease to below 150DEG C from 320DEG C, the cooled flue gas enters the flue gas dedusting system to reduce the dust particle content to below 30mg / Nm<3> from 150mg / Nm<3>, and the dedusted flue gas enters the low temperature oxidation absorption system to carry out desulphurization and denitration purifying treatment in order to reduce the SO2 and NOX content of the flue gas with the integral desulphurization and denitration efficiency being 85% or above in order to realize the coke oven flue gas energy saving and emission reduction comprehensive treatment purposes. The technology has the advantages of high coke oven flue gas waste heat recycling efficiency and good comprehensive purification effect.

Owner:BEIJING SHOUGANG INT ENG TECH

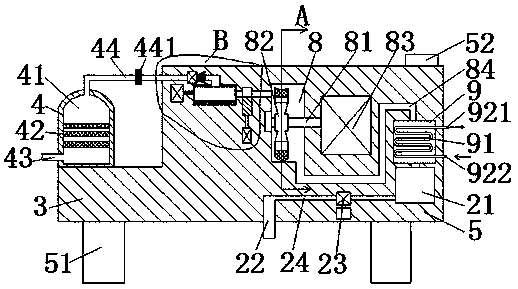

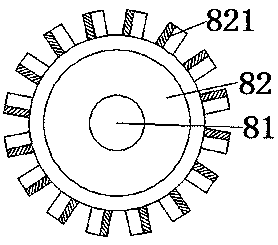

Equipment suitable for high-temperature molten material cooling and waste heat recycling

PendingCN109827441AUniform thicknessReduce crushing processIncreasing energy efficiencyHandling discharged materialEngineeringPhase change

The invention discloses equipment suitable for high-temperature molten material cooling and waste heat recycling. A molten material is fed into the middle of a roller pair from a feed inlet and is carried over along with the rotation of the two rollers so as to form a liquid film; cooling water enters a shell water-cooled wall through a water supply pipeline and absorbs sensible heat of the high-temperature molten material so as to enter the rollers through a pipeline and be sprayed to the inner wall surfaces of the cooling rollers through a nozzle group of a cooling spraying system; the cooling water absorbs heat of the inner walls of the rollers so as to be phase-changed into steam; solidification heat of the high-temperature molten material is absorbed; the steam is discharged through asteam discharge device; the sensible heat and the solidification heat of the high-temperature molten material during the cooling process are recycled through the water-cooled wall and the cooling water fed into the rollers, so that the waste heat recycling utilization ratio is high; and the high-temperature material can be quickly cooled through heat absorption for two times, so that the heat exchange efficiency is high, and the working efficiency is high.

Owner:史晓云 +1

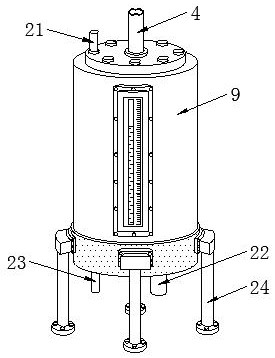

Steam waste heat recovery device

InactiveCN108343942AHigh utilization rate of waste heat recoverySimple structureMachines/enginesSteam superheatersEngineeringWaste heat

The invention discloses a steam waste heat recovery device which comprises a recovery machine body and a heating table fixedly arranged at the left end of the recovery machine body, wherein a heatingcylinder is arranged at the top of the heating table; a heating cavity is formed in the heating cylinder; a heating net is arranged in the heating cavity; a steam inlet pipe extending leftwards is arranged at the bottom of the inner wall of the left end of the heating cavity in a penetrating manner; a reheating steam outlet pipe is arranged at the top of the heating cavity in a penetrating manner;a reheating steam inlet pipe is arranged in the recovery machine body; the extending tail end of the left end of the reheating steam inlet pipe penetrates through and stretches out of the end face ofthe left end of the recovery machine body and communicates with the reheating steam outlet pipe; and a connecting sleeve for sealing connection is arranged at the connecting part of the reheating steam inlet pipe and the reheating steam outlet pipe. The steam waste heat recovery device is simple in structure and convenient to operate and accommodate and improves the steam waste heat recovery efficiency and effect.

Owner:王炜杰

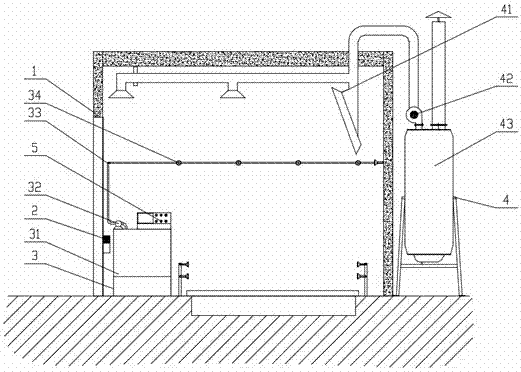

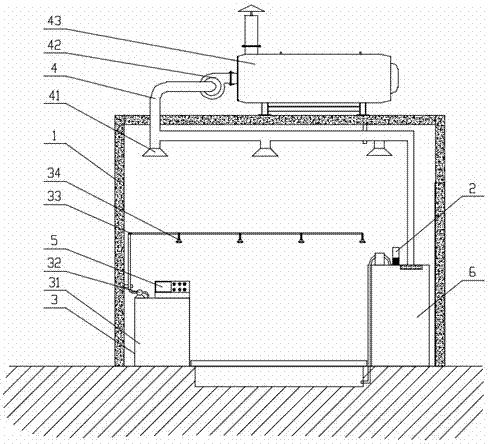

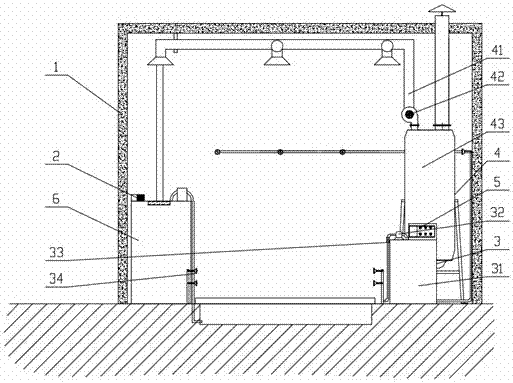

Sanitary epidemic prevention device for garbage station

PendingCN107284935AEliminate transmissionInhibition of decayRefuse receptaclesRefuse cleaningPathogenic microorganismEnvironmental engineering

The invention relates to a sanitary epidemic prevention device for a garbage station. The sanitary epidemic prevention device for the garbage station comprises a monitoring inductor, an epidemic prevention disinfecting device, a foreign odor purifying device and an electric control device. The monitoring sensor is mounted in the gas station; the epidemic prevention disinfecting device comprises a disinfecting liquid box body, a liquid pump, a distributing valve and a spray mechanism. The spray mechanism is mounted on the inner wall of the garbage station and / or around a garbage pit / bin; the spray mechanism communicates with the outlet of the liquid pump through a distributing valve, the inlet of the liquid pump communicates with the disinfecting liquid box body, and the foreign odor purifying device is connected to the garbage station. The device provided by the invention has the advantages of being simple and compact in structure, convenient to operate, automatic to control, reliable to operate and the like. By means of the device provided by the invention, the environmental problem of the garbage station and the periphery can be thoroughly solved, propagation of pathogenic microorganisms, mosquitoes and flies and malodorous gas in a residential quarter is eliminated, decay of organic matters is inhibited, and more organic matter resources and energy sources are stored for follow-up incineration power generation treatment of household garbage. Meanwhile, underground water or urban sewer lines can be prevented from being polluted by landfill leachate.

Owner:长沙紫宸科技开发有限公司

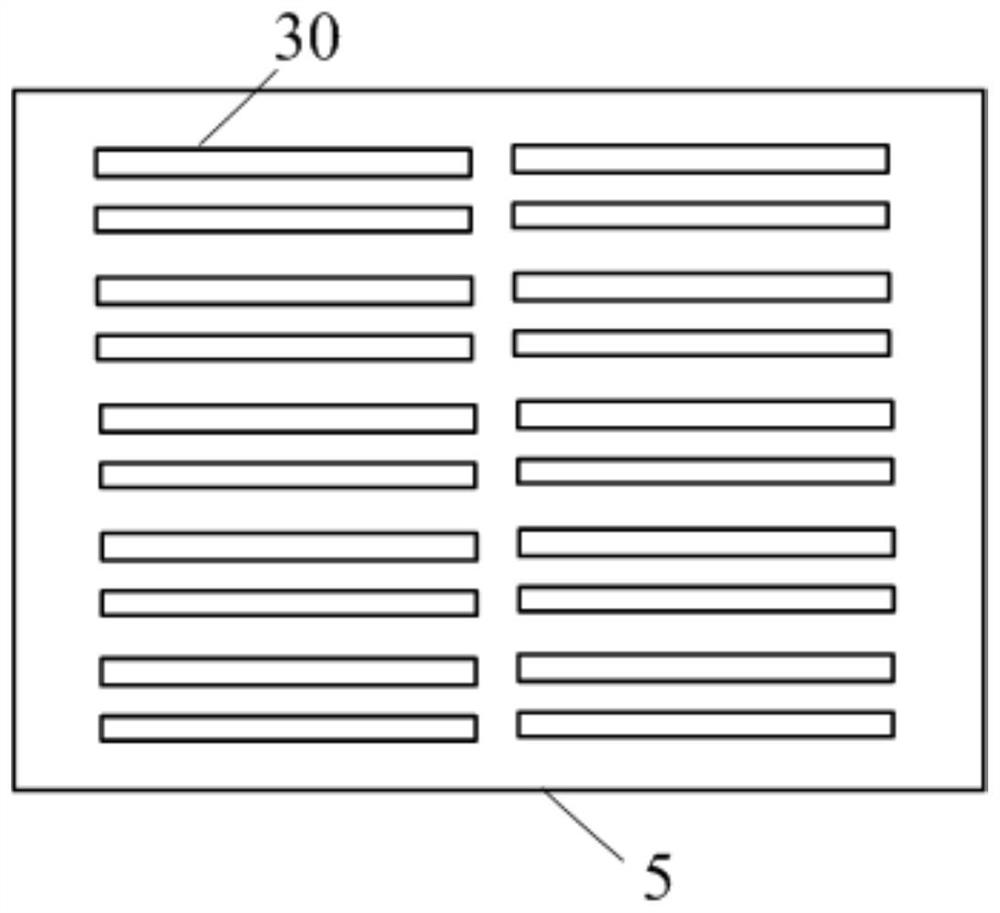

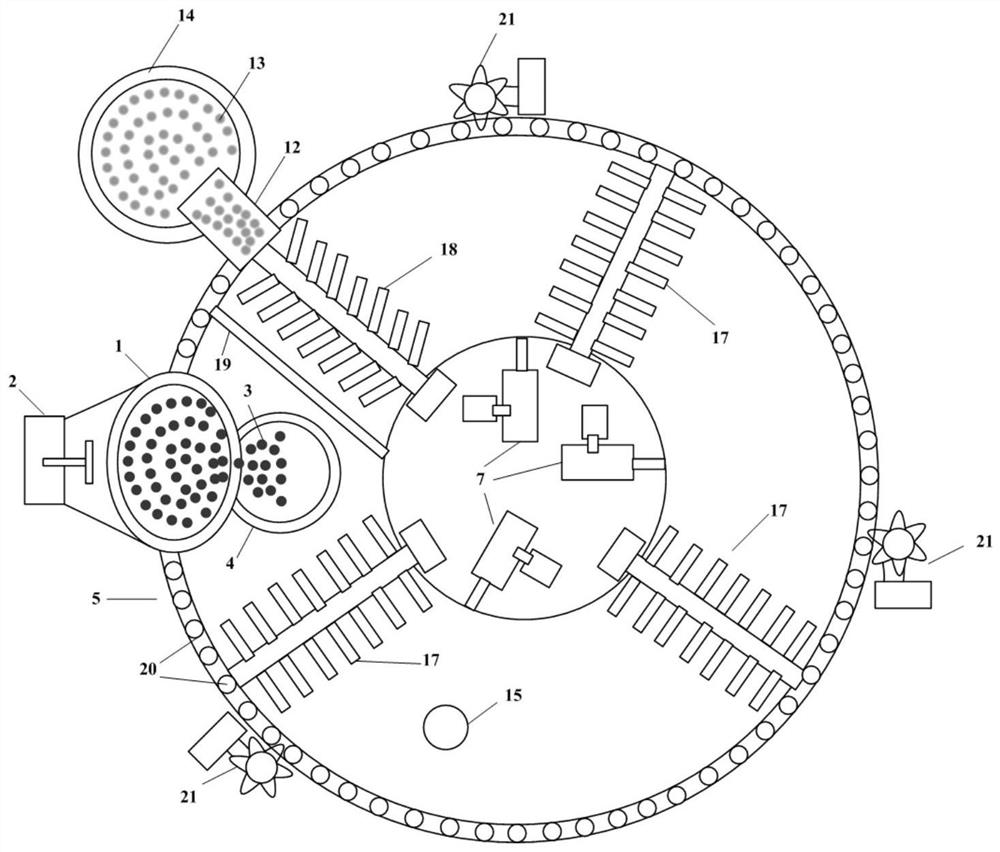

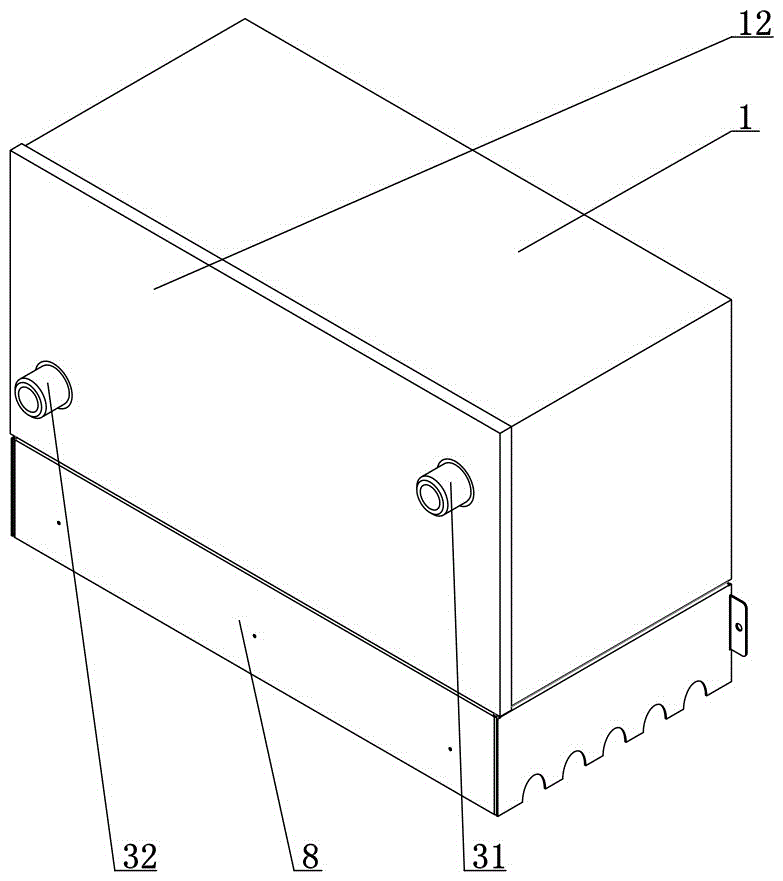

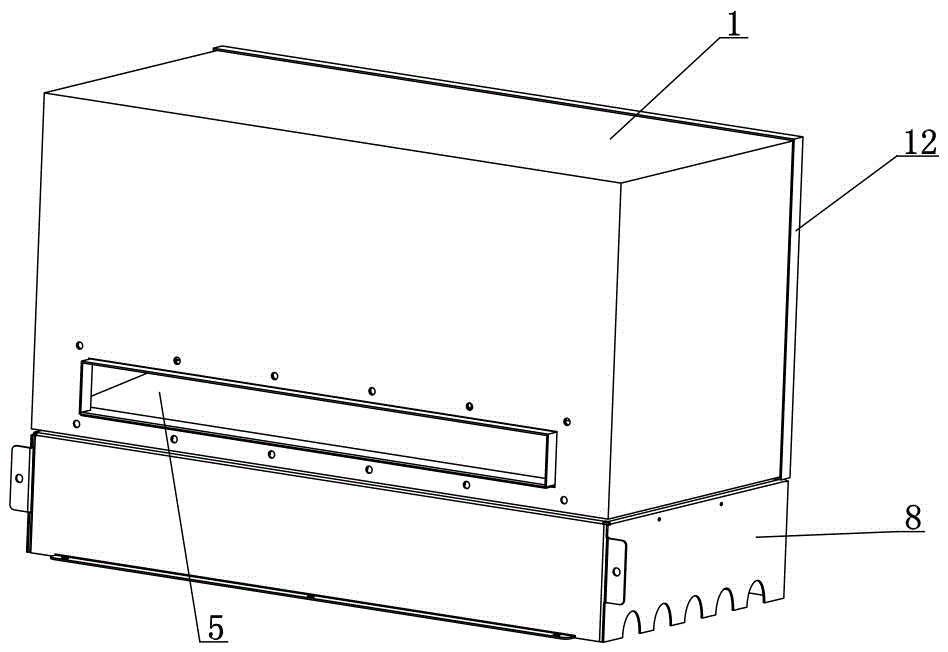

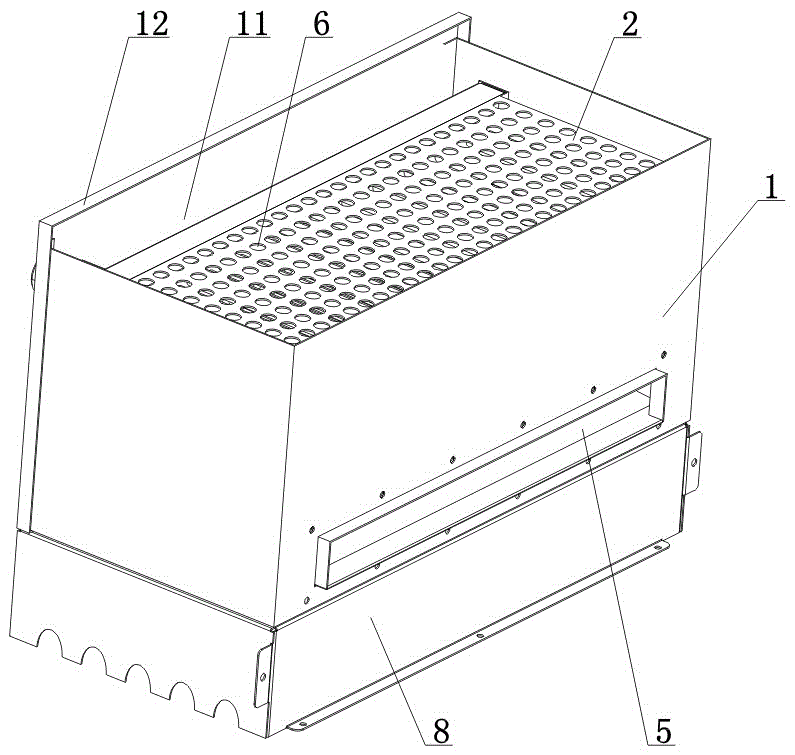

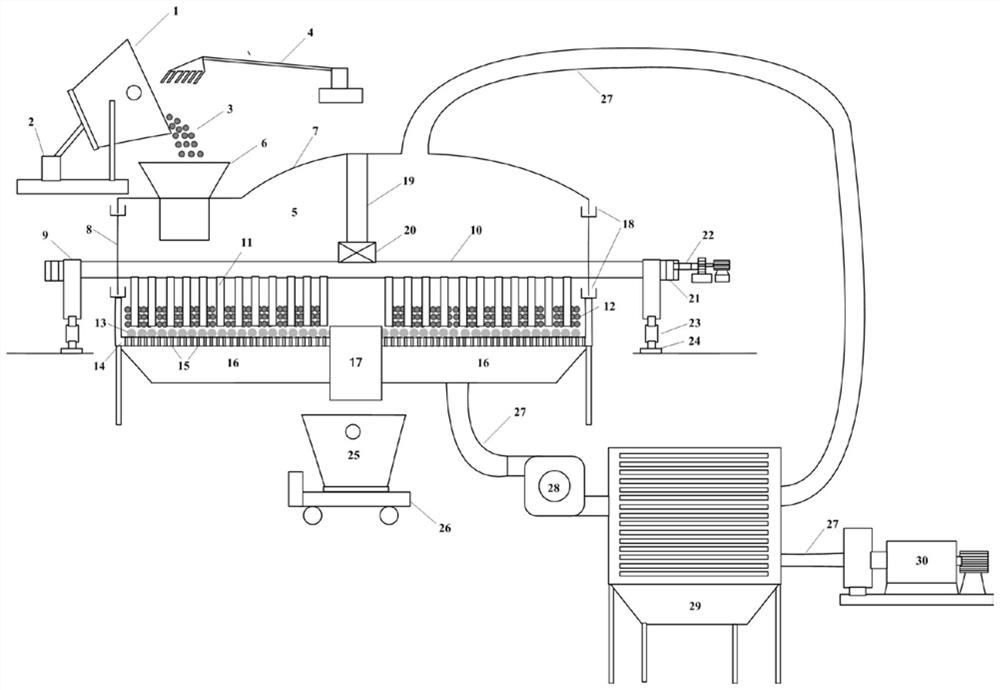

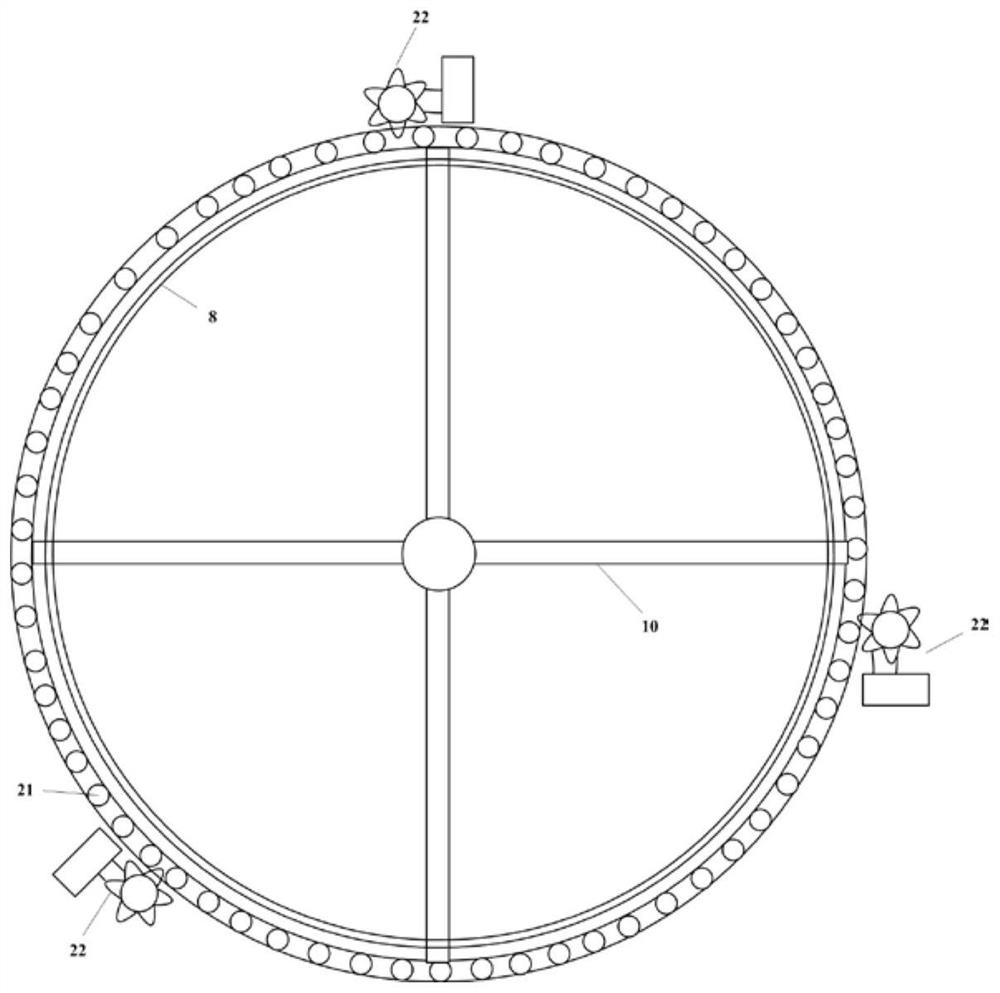

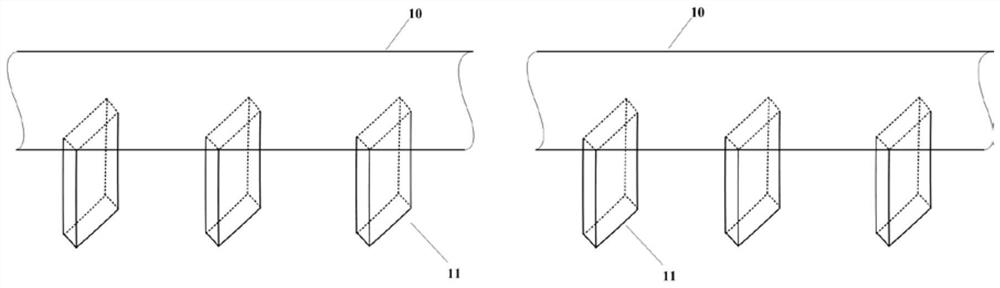

High-temperature steel slag disc crushing waste heat recovery device and method

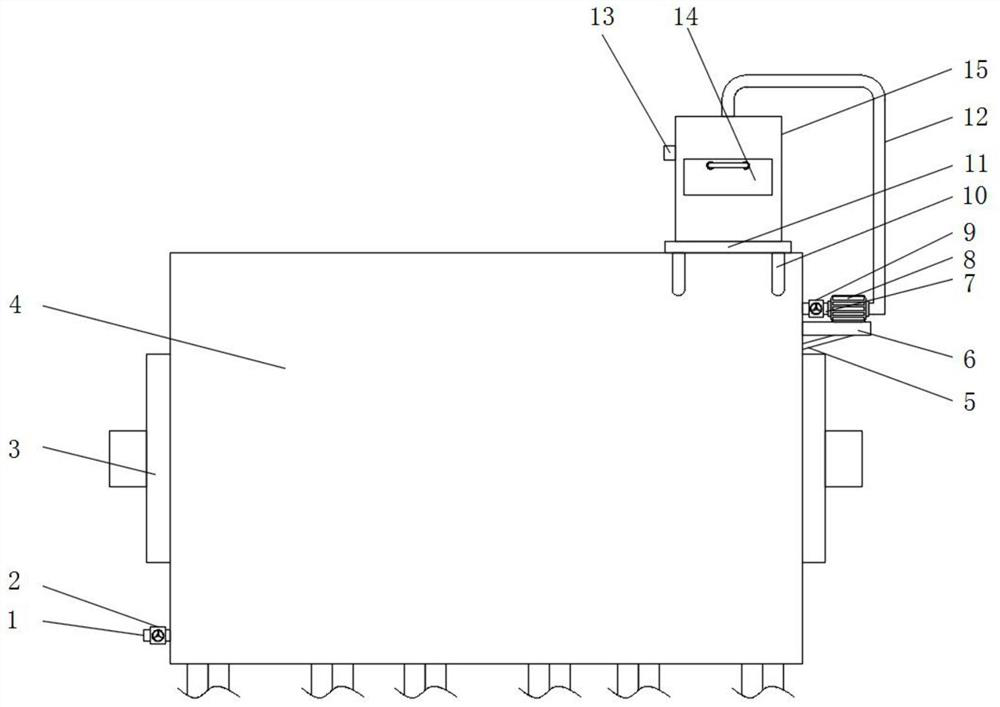

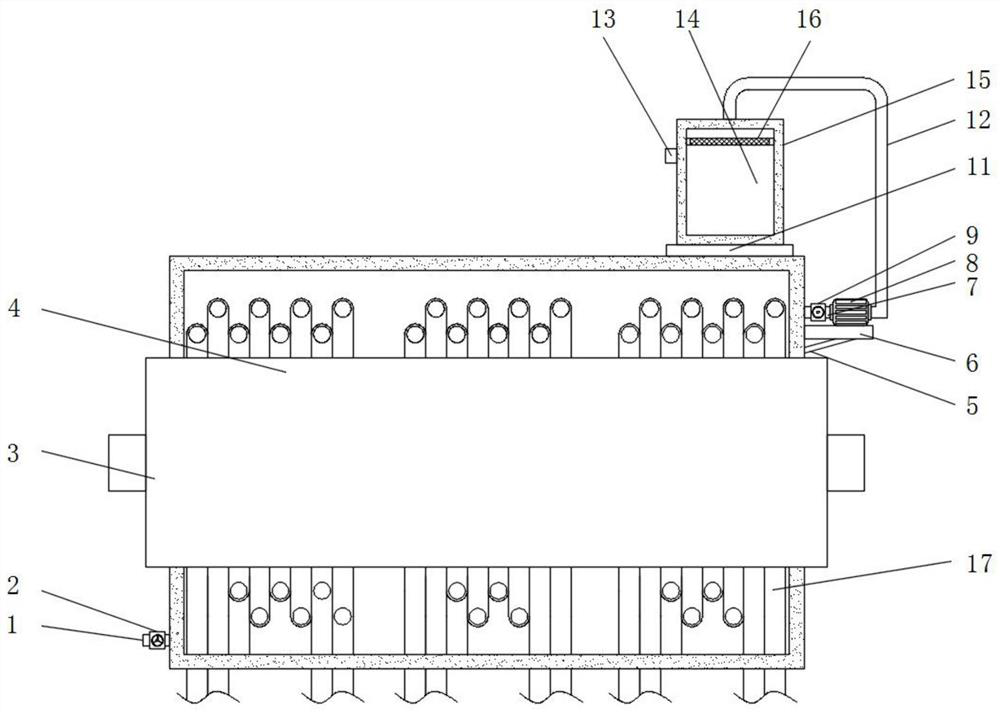

PendingCN112958246AImprove processing efficiencyEfficient crushingRecycling and recovery technologiesProcess efficiency improvementCircular discLiquid slag

The invention discloses a high-temperature steel slag disc crushing waste heat recovery device. The high-temperature steel slag disc crushing waste heat recovery device comprises a liquid slag tank 1, a slag pouring machine 2, high-temperature slag 3, a slag pulling machine 4, a disc crushing bed 5, a crusher 9, a track 24, a solid slag tank 25, a slag receiving vehicle 26, a pipeline 27, a draught fan 28, a heat exchanger 29 and a generator 30, the liquid slag tank 1 is arranged on the slag pouring machine 2, the high-temperature slag 3 is arranged in the liquid slag tank 1, the slag pulling machine 4 is arranged on the side part of the slag pouring machine 2, the disc crushing bed 5 is arranged below the slag pouring machine 2, the crusher 9 penetrates through the disc crushing bed 5 and is arranged above the track 24, a slag pushing part of the crusher 9 is arranged in the disc crushing bed 5, the slag pushing part drives a high-temperature steel slag layer to move from an inlet of the disc crushing bed 5 to an outlet of the disc crushing bed 5, the solid slag tank 25 is arranged below the disc crushing bed 5 and is fixed to the slag receiving vehicle 26, and the disc crushing bed 5, the draught fan 28, the heat exchanger 29 and the generator 30 are connected through the pipeline 27.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

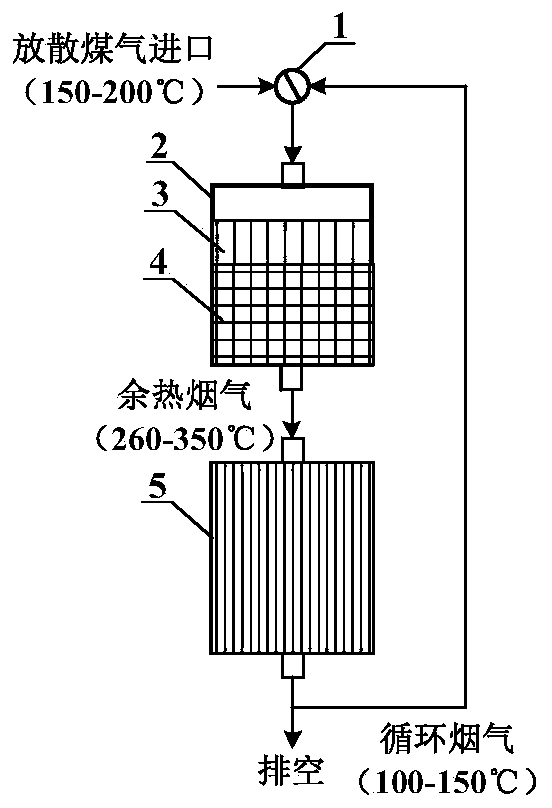

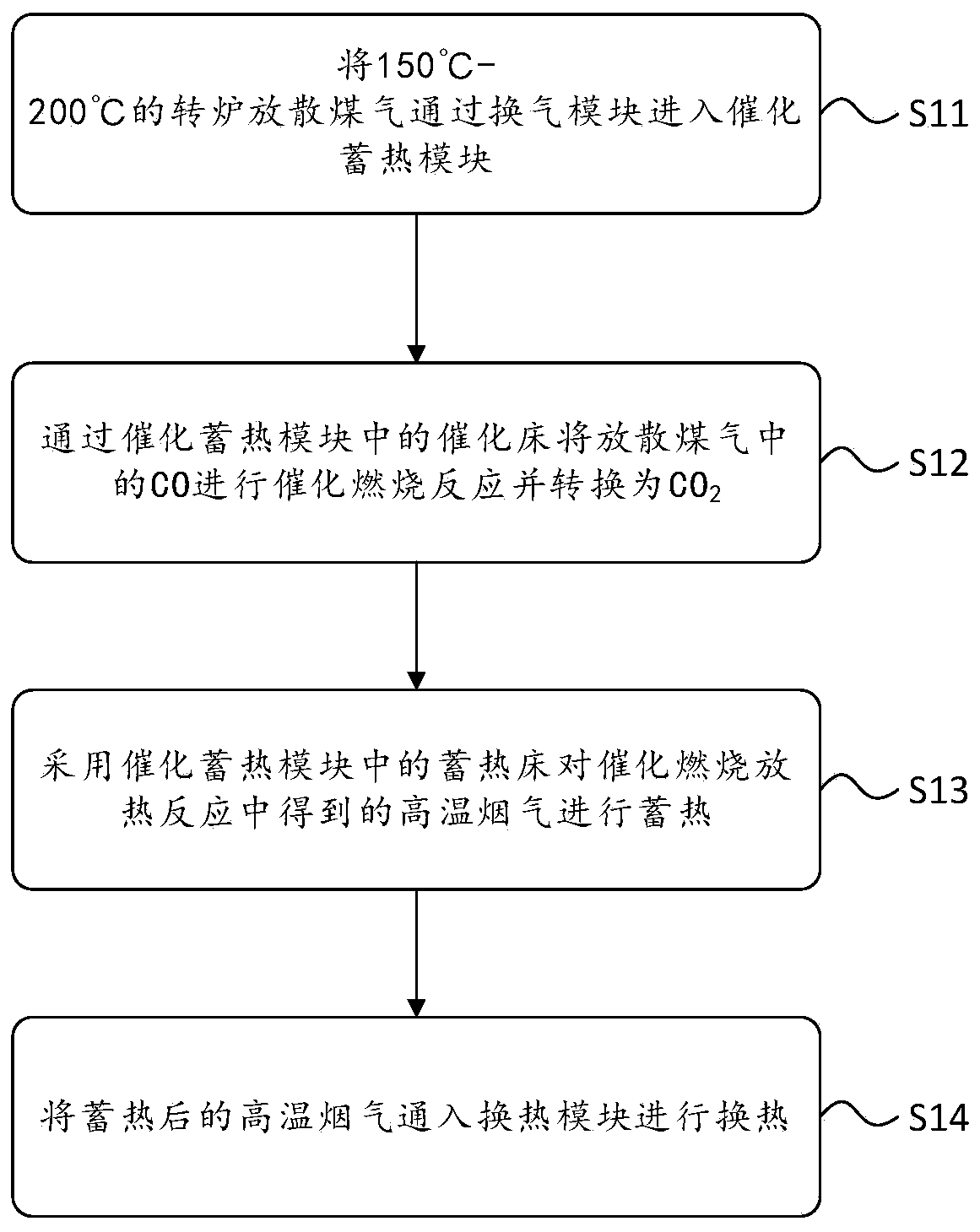

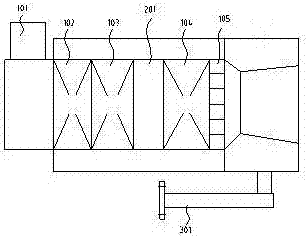

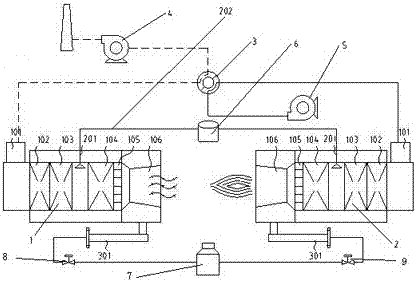

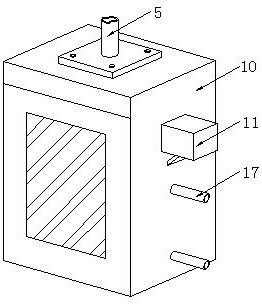

Converter-diffused coal gas catalyzing and heat-storage integration and heat-exchanging system, and method

InactiveCN111578298ALow running costHigh catalytic efficiencyIncinerator apparatusProcess engineeringCatalytic combustion

The embodiments of the invention relate to a converter-diffused coal gas catalyzing and heat-storage integration and heat-exchanging system, and a method. The converter-diffused coal gas catalyzing and heat-storage integration and heat-exchanging system comprises a ventilation module, a catalyzing and heat-storage module and a heat-exchanging module which are arranged on a pipeline in sequence; the ventilation module is connected with the catalyzing and heat-storage module and introduces diffused coal gas into the catalyzing and heat-storage module to enable the diffused coal gas to be subjected to a catalytic combustion exothermic reaction in the catalyzing and heat-storage module so as to convert CO in the diffused coal gas into CO2, and meanwhile heat storage is conducted on high-temperature smoke obtained in the catalytic combustion exothermic reaction; and the catalyzing and heat-storage module is connected with the heat-exchanging module, and the high-temperature smoke is introduced into the heat-exchanging module for heat exchanging. The method has the characteristics of low operation cost, high catalytic efficiency, high waste heat recycling rate, easy and safe operation and the like; and by adopting the method to treat the diffused coal gas, the national or regional emission standard can be met, meanwhile heat is recycled in a heat-storage mode, the waste heat utilization quality is improved, and energy conservation and emission reduction are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

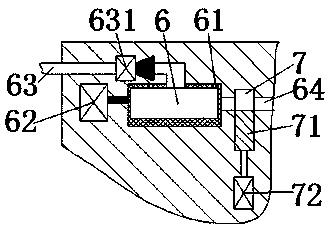

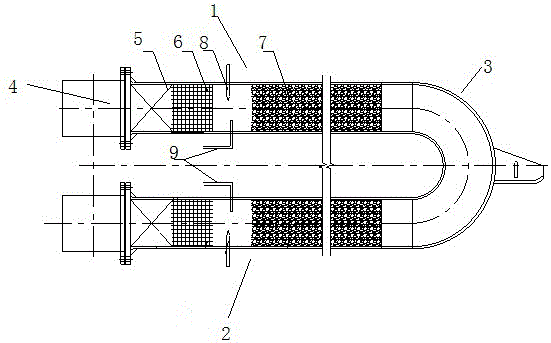

Single heat accumulating type denitration burner

PendingCN107883387ASimple denitrification systemCompact structureIncinerator apparatusStops deviceFlue gas

The invention provides a single regenerative denitrification burner, comprising: an air distribution port, a low temperature honeycomb heat storage chamber, a denitrification honeycomb heat storage chamber, a high temperature honeycomb heat storage chamber, an empty coal mixing chamber, corundum block bricks and a combustion air device , not only integrates the denitrification function into the regenerative burner, but also eliminates the need for the traditional regenerative burner to set up an ammonia zone and ammonia injection AIG device for denitrification treatment, simplifies the structure of the device, and can be adapted to specific sites with limited space Moreover, it can effectively reduce the content of nitrogen oxides in the flue gas produced by traditional regenerative burners, and the denitrification efficiency can reach about 75%. In addition, the device can effectively reduce the exhaust gas temperature and improve the utilization rate of flue gas waste heat recovery , has a series of advantages such as simple structure, convenient operation, low operating cost, high efficiency and energy saving, environmental protection, high heat storage and denitrification efficiency.

Owner:SHENWU TECH GRP CO LTD

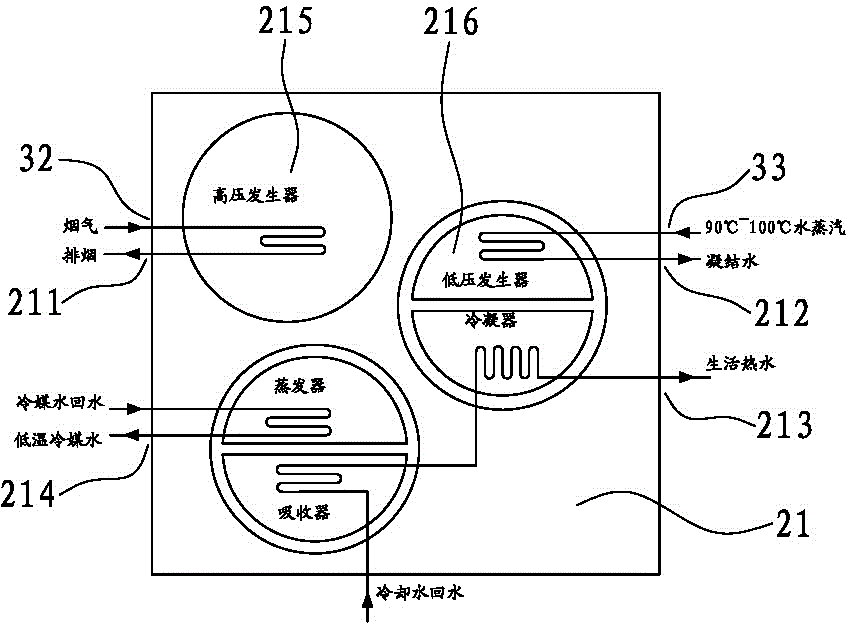

Cooling, heating, water supplying and power supplying combined system with flue gas heat gradient utilization function coupled with seawater desalination technology

ActiveCN103115457BHigh utilization rate of waste heat recoveryLower exhaust gas temperatureGeneral water supply conservationSeawater treatmentThermal energyLithium bromide

Owner:JIMEI UNIV

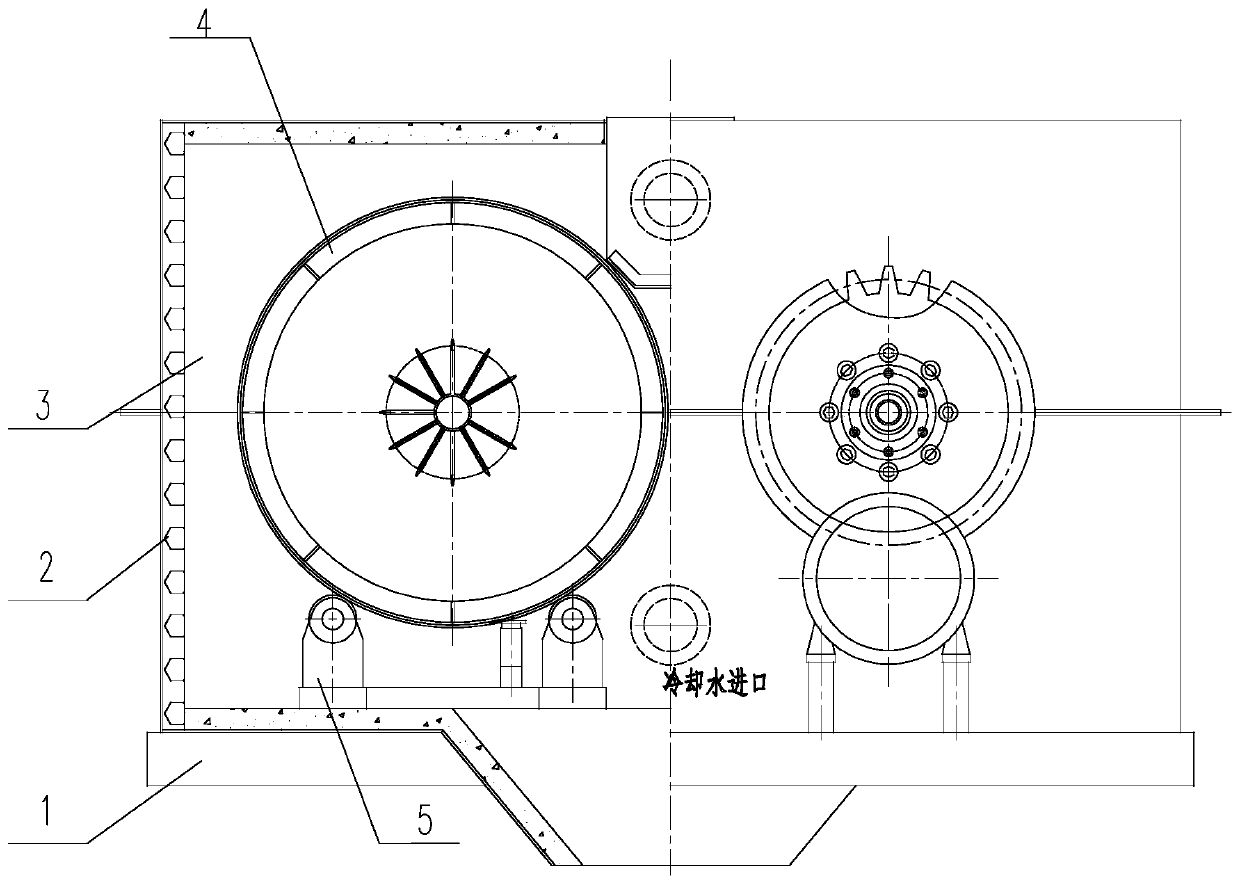

Total heat recovery system for molten blast furnace slag

ActiveCN102618674AHigh utilization rate of waste heat recoveryReduce consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure

The invention discloses a total heat recovery system for molten blast furnace slag, which solves the problem that waste heat of blast furnace slag is low in utilization rate in the prior art. Molten blast furnace slag can be poured into a high-pressure steam tank filled with water, water generates a great deal of steam upon high heat, the blast furnace slag is broken into particles, and the generated steam is recycled through a high-pressure steam tank. Devices include a slag feeding hopper, a conveying and storage passage and the high-pressure steam tank for recycling steam. The conveying and storage passage is provided with an insulating device and a heating device, and the upper end and the lower end of the conveying and storage passage are connected with the slag feeding hopper and the high-pressure steam tank respectively. The upper portion of the high-pressure steam tank is provided with a water injection hole and a steam outlet, and the lower portion of the high-pressure steam tank is provided with a slagging device. The system fully utilizes total heat (sensible heat and latent heat) of the blast furnace slag, and the efficiency of recycling waste heat of the blast furnace slag is improved.

Owner:HEBEI GOLD BANGZI BOILER

System and method for realizing combination of cement production, seawater desalination and power generation in coastal area

ActiveCN111924922ASolve the problem of domestic production waterRealize hydropower cogenerationGeneral water supply conservationSeawater treatmentSeawaterBoiler (power generation)

The invention relates to the field of energy recycling, aims to solve the problems of fresh water and electric energy shortage and low energy utilization rate in remote coastal areas, and provides a system and method for realizing combination of cement production, seawater desalination and power generation in coastal area. The method comprises the steps that waste heat of a cement system exchangesheat through an AQC boiler, an SP boiler and a BP boiler to drive a working medium to do work on a power generation system, and dead steam of a steam turbine enters the sea water desalination systemto be used for sea water desalination. The device has the beneficial effects that the device is very suitable for remote coastal areas, cement production, power generation and sea water desalination can be organically combined, the energy utilization rate is high, and fresh water, cement and electric energy can be produced at the same time.

Owner:成都建筑材料工业设计研究院有限公司

Heat-conducting oil boiler waste heat power generation system

InactiveCN104501198AImprove fuel combustion efficiencyImprove flue gas waste heat recovery rateCombustion processStorage heatersCombustionFlue gas

The invention discloses a heat-conducting oil boiler waste heat power generation system. The heat-conducting oil boiler waste heat power generation system comprises a furnace body, a spray nozzle, a flue gas pipe and an air pipe, wherein a furnace hearth for heating heat-conducting oil is arranged inside the furnace body; the spray nozzle is arranged in the end wall of one side of the furnace body and is used for spraying fuel and combustion air into the furnace hearth for combusting and releasing heat; the flue gas pipe is connected to the end wall of the other side of the furnace body and is used for discharging flue gas from a flue gas outlet of the furnace body to a chimney; the air pipe is connected to the spray nozzle and is used for conveying the combustion air to the spray nozzle; the heat-conducting oil boiler waste heat power generation system further comprises a water steam circulating power generation circuit; the water steam circulating power generation circuit comprises a steam generator arranged inside the flue gas pipe, and a steam turbine connected with the steam generator through a pipeline.

Owner:陈翔

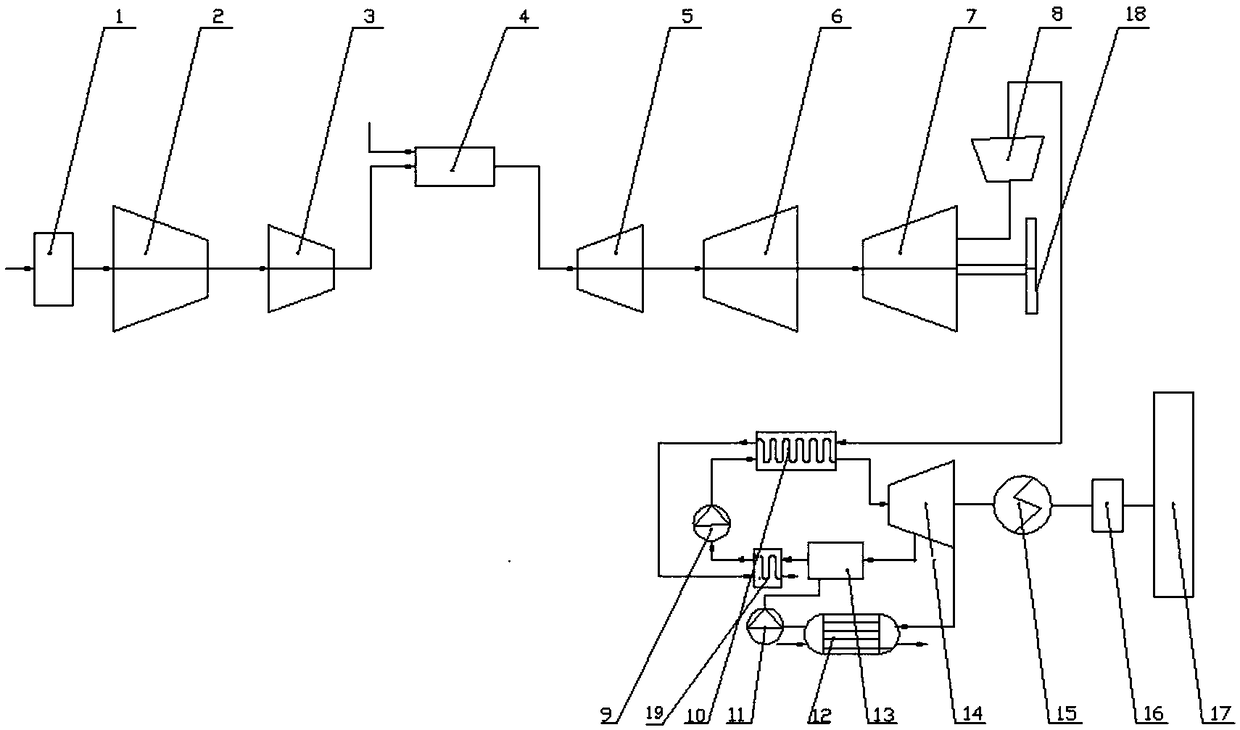

Efficient waste-heat-recycle power generation device for gas turbine and control method

InactiveCN109236493AReduce heat transfer areaSave metal materialInternal combustion piston enginesEngine componentsProcess engineeringHigh pressure

The invention relates to an efficient waste-heat-recycle power generation device for a gas turbine and a control method. A fuel gas output port of a power turbine is communicated with a fuel gas inputport of a heat exchanger; a working medium input port of the heat exchanger is communicated with an output port of a first working medium pump, a working medium output port of the heat exchanger is communicated with a working medium input port of a turbine, and a working medium output port of the turbine is communicated with a working medium input port of a condenser; a working medium output portof the condenser is communicated with an input port of a second working medium pump, an output port of the second working medium pump is communicated with a working medium input port of a heat regenerator, and a working medium input port of the heat regenerator is communicated with an input port of the first working medium pump; the turbine is provided with an air exhaust port and communicated with the working medium input port of the heat regenerator through an air exhaust pipe, the air exhaust pipe is provided with a valve, and a pressure detection device is arranged on the turbine; the turbine drives a power generator for power generation. According to the device, waste gas of the gas turbine is used for heating a working medium to high-temperature and high-pressure gas, the gas entersthe turbine for working, the power generator is driven to generate power, and waste heat in the waste gas is recycled.

Owner:AECC AVIATION POWER CO LTD

Coastal area cement production and seawater desalination combined implementation system and method

InactiveCN111924921AImprove economic efficiencyImprove energy efficiencyLiquid degasificationGeneral water supply conservationSeawaterEnergy recycling

The invention relates to the field of energy recycling, aims to solve the problems of fresh water shortage and low energy utilization rate in remote coastal areas, and provides a coastal area cement production and seawater desalination combined implementation system and method. The coastal area cement production and sea water desalination combined implementation method is characterized in that waste heat of a cement system is used for sea water desalination through heat exchange of an AQC boiler, an SP boiler and a BP boiler. The device has the beneficial effects that the device is very suitable for remote coastal areas, cement production and seawater desalination can be organically combined, the energy utilization rate is high, and fresh water and cement can be produced at the same time.

Owner:成都建筑材料工业设计研究院有限公司

Heat storage smoke recovery device

ActiveCN109724425AStable absorptionHigh utilization rate of waste heat recoveryIncreasing energy efficiencySteam generation using hot heat carriersRefluxFour-way valve

The invention discloses a heat storage smoke recovery device, and relates to the technical field of smoke recovery. The heat storage smoke recovery device comprises a four-way valve; four branch pipesof the four-way valve communicate with smoke discharge pipes of two furnace bodies, a high-heat smoke pipe and a low-heat smoke pipe; the high-heat smoke pipe communicates with a first afterheat recovery device; the low-heat smoke pipe communicates with a second afterheat recovery device; the second afterheat recovery device sleeves a three-way pipe; the second afterheat recovery device communicates with the first afterheat recovery device through a smoke reflux pipe; and when a valve blade is positioned in a position A, the smoke discharge pipe on one side communicates with the high-heat smoke pipe, and the smoke discharge pipe on the other side communicates with the low-heat smoke pipe. The heat storage smoke recovery device is simple in structure and low in transformation cost of traditional equipment, facilitates popularization, and can continuously use high-temperature smoke to achieve high afterheat recycling rate; and air in the three-way pipe is continuously heated by low-temperature smoke generated during tapping of a furnace body, so that the afterheat recovery efficiency is further improved.

Owner:四会市国耀铝业有限公司

Waste heat recovery device of industrial kiln

InactiveCN112781386AHigh utilization rate of waste heat recoveryFast coolingIncreasing energy efficiencyWaste heat treatmentClimatic warmingProcess engineering

The invention discloses a waste heat recovery device of an industrial kiln, and relates to the technical field of industrial kiln equipment. The device specifically comprises a kiln body. When the device is used, a heat insulation box, a heat preservation coating outside the heat insulation box and a heat absorption pipe are arranged, in a using process of the kiln body, heat dissipated by the kiln body through surface radiation can be effectively recycled, a waste heat recovery rate of the kiln body is increased, the cost is saved, the situation that the heat is directly scattered into the atmosphere to cause climate warming is prevented, environmental protection is facilitated, after firing is completed, a first control valve and a second control valve are opened, a fan is started, and the fan introduces external airflow into the heat insulation box via an air conveying pipe and then introduces the external airflow out of the heat insulation box via an air outlet pipe, so that the cooling speed of the kiln body can be increased, collection of fired objects in the kiln body and next-time material distribution of the kiln body are facilitated, and the production efficiency of the kiln body is improved.

Owner:HUBEI XISHUI KEMEI MACHINERY

Energy storage method and device for thermal power plant with waste heat recovery

ActiveCN110631400BReduce work stressHigh utilization rate of waste heat recoveryHeat storage plantsProcess engineeringHeat storage material

The invention discloses a thermal power plant energy storage method and device with waste heat recovery. The thermal power plant energy storage device with waste heat recovery comprises a conveying pipe, a heating tank and a heat storage tank; a recovery pipe, a low-temperature pipe and a high-temperature pipe is fixedly connected to the bottom end of the conveying pipe through a four-way connector; a first electromagnetic valve is fixedly connected to the interior of the recovery pipe; a second electromagnetic valve is fixedly connected to the interior of the low-temperature pipe; and a thirdelectromagnetic valve is fixedly connected to the interior of the high-temperature pipe. The invention relates to the technical field of waste heat recovery. For the thermal power plant energy storage method and device with waste heat recovery, waste heat gases with different temperatures have different recycling modes, waste heat with different temperatures can be classified and utilized, and working pressure of the energy storage device with waste heat recovery is weakened; by combining a heating water tank device with a heat storage and release device, the waste heat recovery utilization rate is remarkably increased, the practicability of the device is improved, a phase change heat storage material is more uniformly heated, the utilization rate of the heat storage material is increased, and the heat storage efficiency is improved.

Owner:华电呼图壁能源有限公司

Multifunctional radiant tube combustion device

PendingCN106705043AEmission reductionHigh utilization rate of waste heat recoveryIndirect carbon-dioxide mitigationGaseous fuel burnerPorous mediumEngineering

The invention belongs to the field of combustion equipment and particularly relates to a multifunctional radiant tube combustion device, comprising a side A combustion radiant tube, a side B combustion radiant tube and a transitional radiant tube, wherein two ends of the transitional radiant tube are connected to one ends of the side A combustion radiant tube and the side B combustion radiant tube respectively, and the other end of the side A combustion radiant tube is sequentially provided with an air / fuel gas mixed gas inlet or a smoke outlet, a low-temperature heat accumulator, a denitration catalyst area and a porous medium layer area. The multifunctional radiant tube combustion device has the advantages that smoke discharge temperature can be decreased effectively, smoke waste heat recycling rate is increased, energy-saving effect is significant, smoke denitration measures are applied to the radiant tube combustion device, denitration and energy conservation are integrated, nitrogen oxide emission from smoke is reduced effectively, the system is more environmentally friendly, and comprehensive input cost is lowered.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com