High-efficiency condensation-type flue gas waste heat recycling device

A flue gas waste heat and recovery device technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of not fully utilizing the heat exchange efficiency of the water pipe group, limiting the recovery and utilization rate of flue gas waste heat, and the effective recovery of the recovery device. Space reduction and other issues, to achieve the effect of ensuring long-term maintenance-free use, improving air uniformity, and increasing recycling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

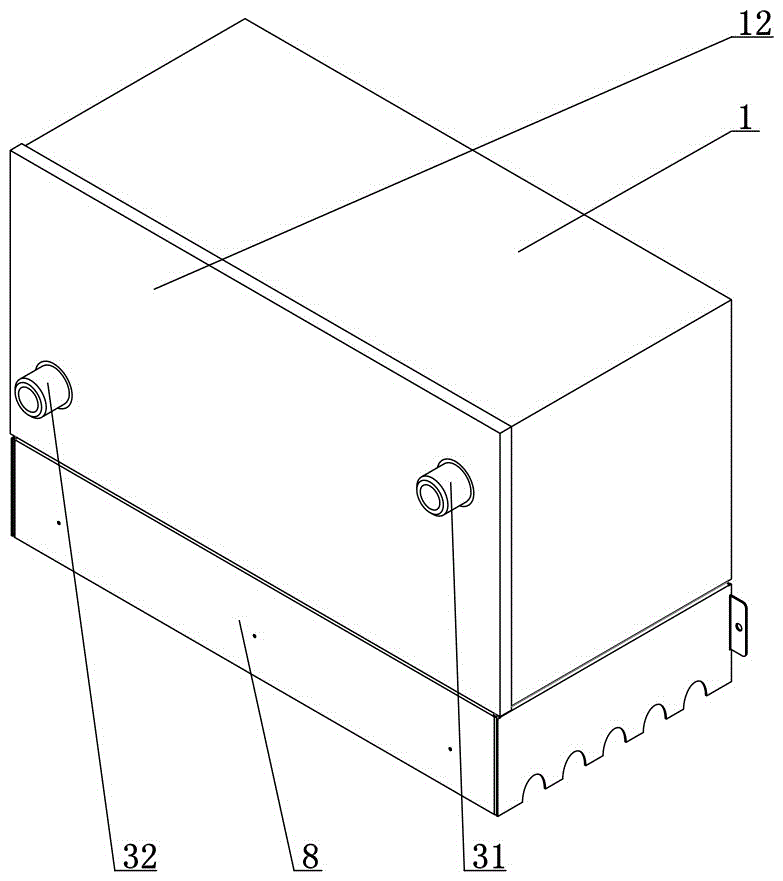

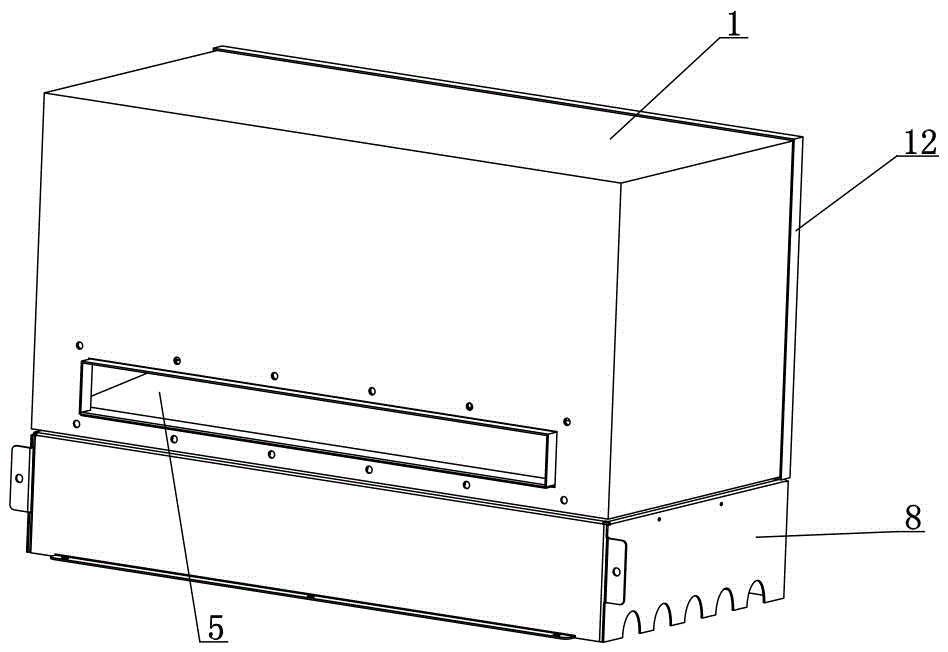

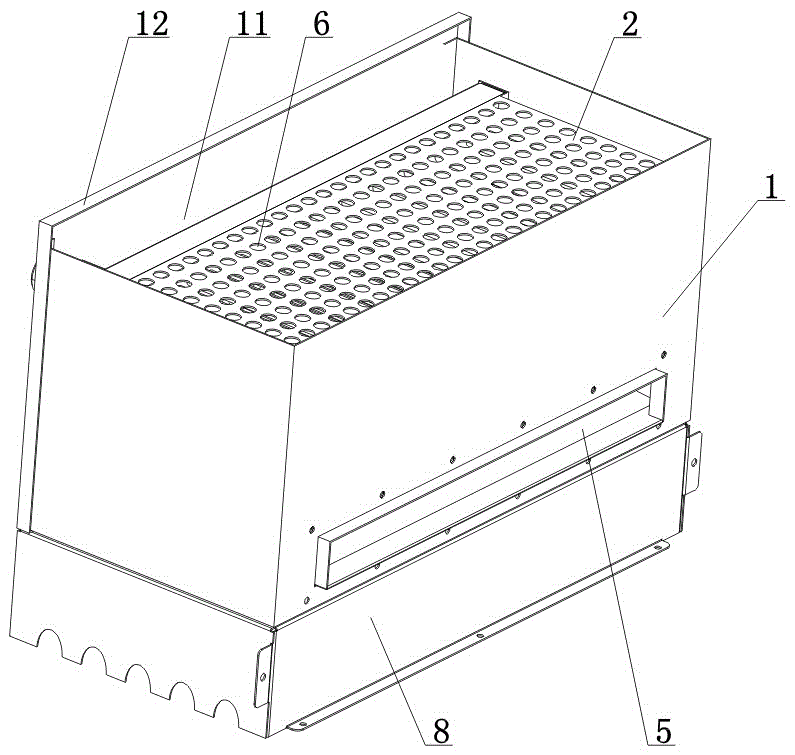

[0026] According to attached figure 1 to attach Figure 5 As shown, the high-efficiency condensing flue gas waste heat recovery device of the present invention includes the condensing box including the outer shell 1 with the condensing cavity 11, the condensing inner shell 2 with the condensing inner cavity 21, and the condensed water pipe with the function of equal resistance flow equalization Group 3. The condensing inner shell 2 is installed on the condensing chamber 11 , and the condensing water tube group 3 is installed on the condensing inner chamber 21 . The bottom of the condensing shell 1 is provided with a smoke inlet 4, the bottom of the condensing shell 1 is provided with a smoke collection chamber 8, and the cavity 81 of the smoke collection chamber communicates with the smoke inlet 4, that is, the collection chamber 4 at the bottom of the recovery devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com