Structure of vertical take-off and landing rotor aircraft

A vertical take-off and landing, aircraft technology, applied in the aviation field, can solve the problems of complex aerodynamics, low hovering efficiency, low forward flying speed, etc., and achieve uniform aerodynamic load distribution, improved hovering efficiency, and large internal space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

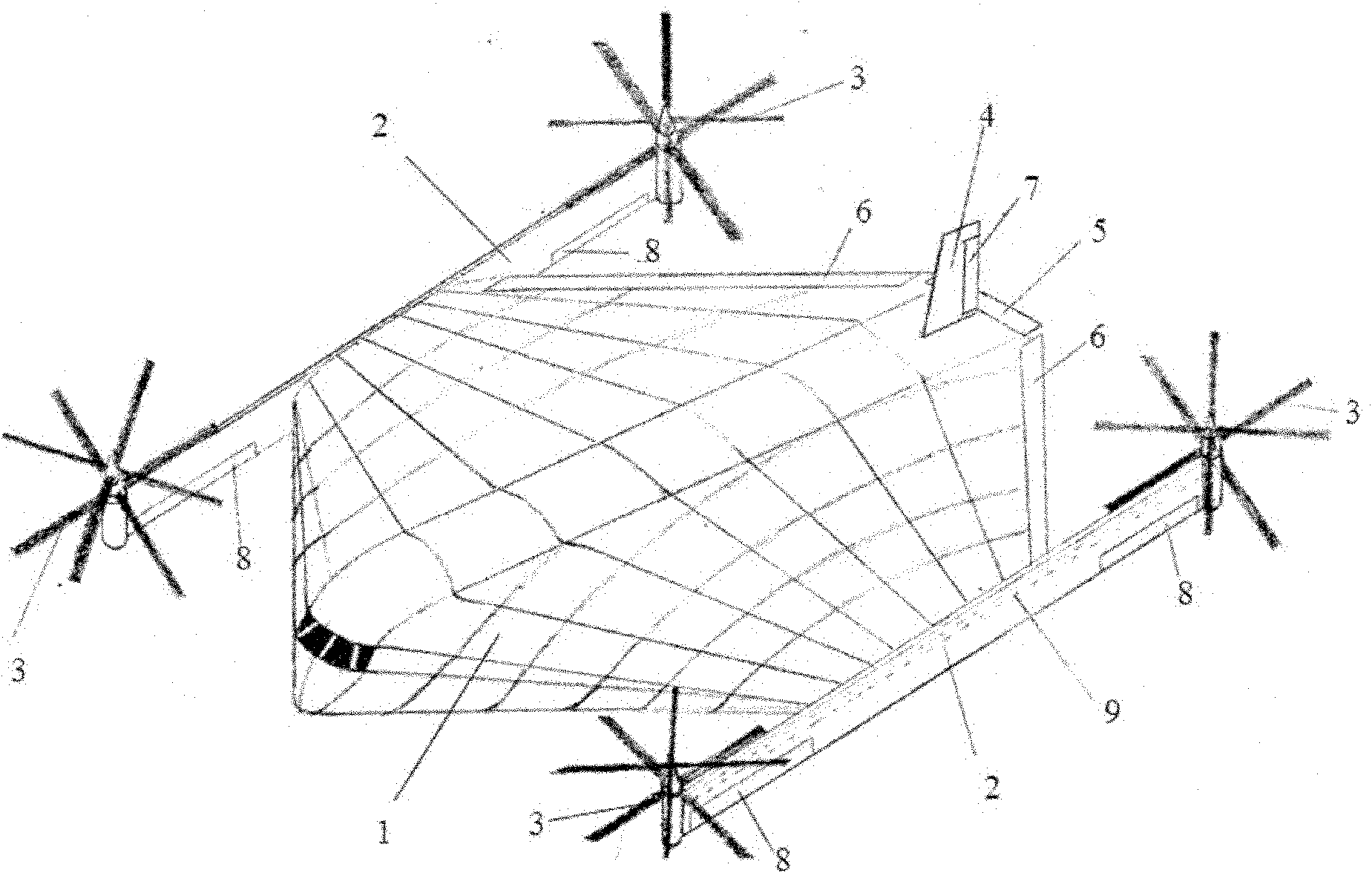

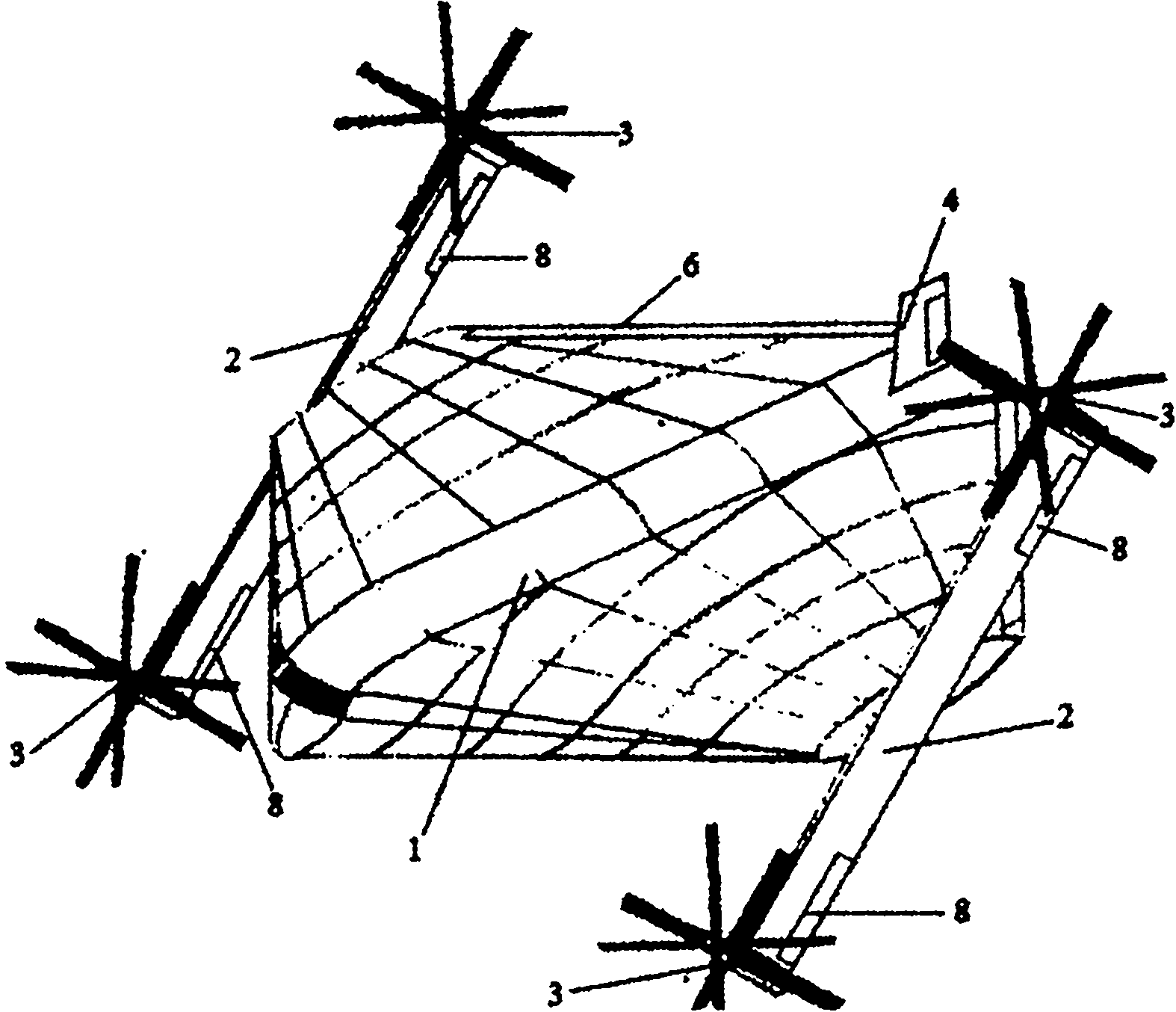

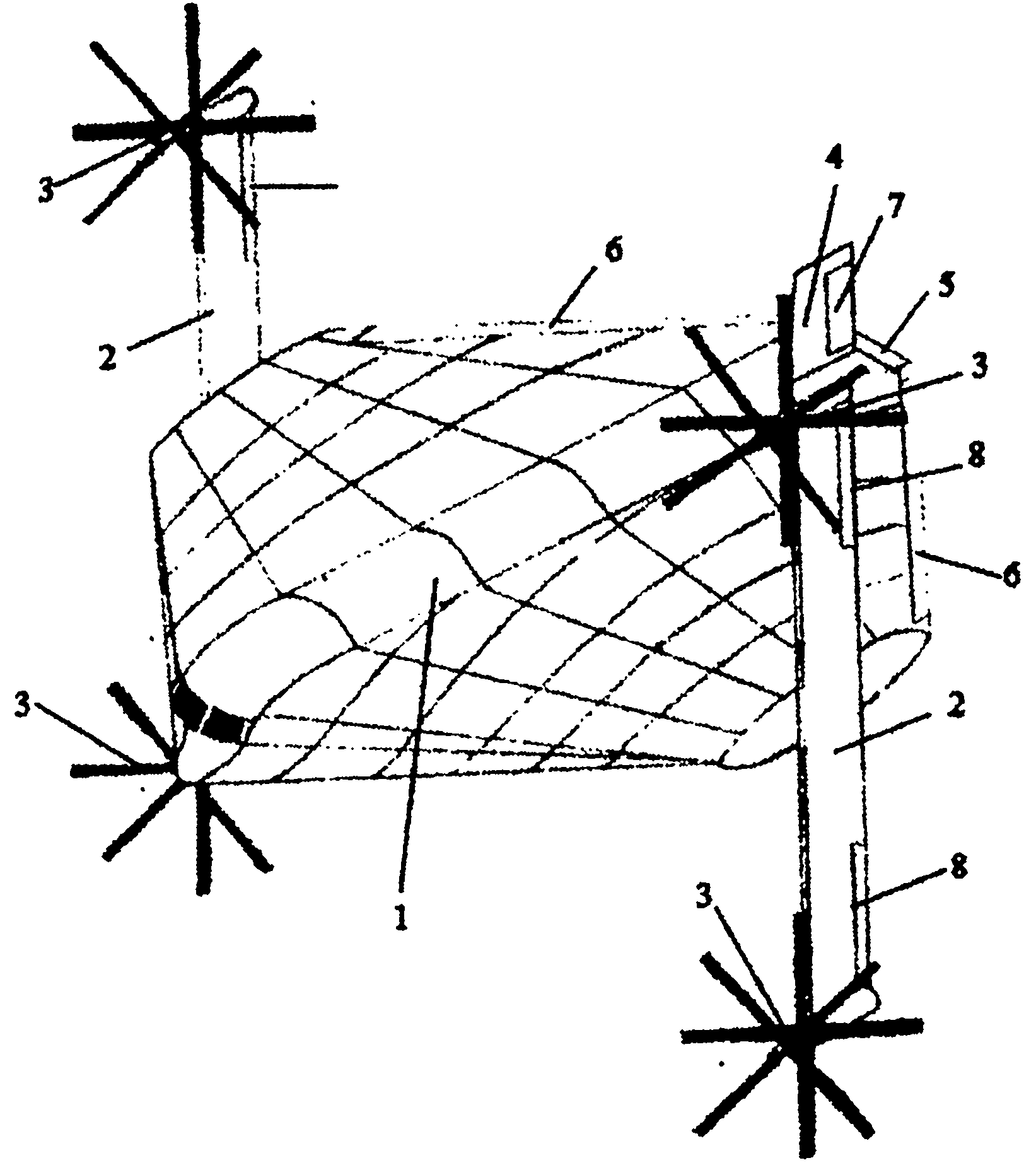

[0020] see figure 1 , figure 2 or image 3 , the vertical take-off and landing rotorcraft structure of the present invention includes a flying-wing fuselage 1 and wings 2 connected to the flying-wing fuselage 1 . Wherein at the rear portion of flying-wing type fuselage 1, be provided with vertical empennage 4, horizontal empennage 5 and flap 6, respectively be provided with an auxiliary wing 2 at the both sides of flying-wing type fuselage 1, as shown in the figure, this aircraft The wing 2 is flat and long, and is connected with the flying wing type fuselage 2 by a tilting mechanism at the middle part of the wing 2 . Both ends of the wing 2 are respectively provided with a rotor system 3 , and a vertically downward rudder 8 is arranged below the rotor system 3 at both ends of the wing 2 .

[0021] figure 1 It is a structural schematic diagram of a preferred embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com