Gear tilting type coaxial machine

A coaxial machine and gear technology, applied in the field of single-person aircraft, can solve the problems of high requirements for take-off and landing sites, complex structures of traditional helicopters, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

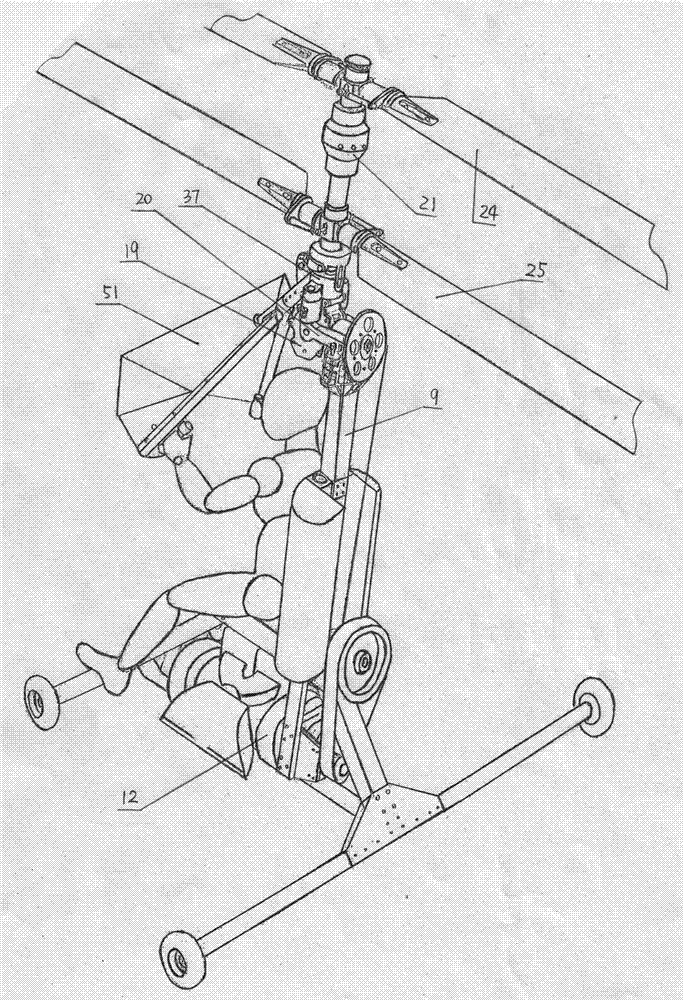

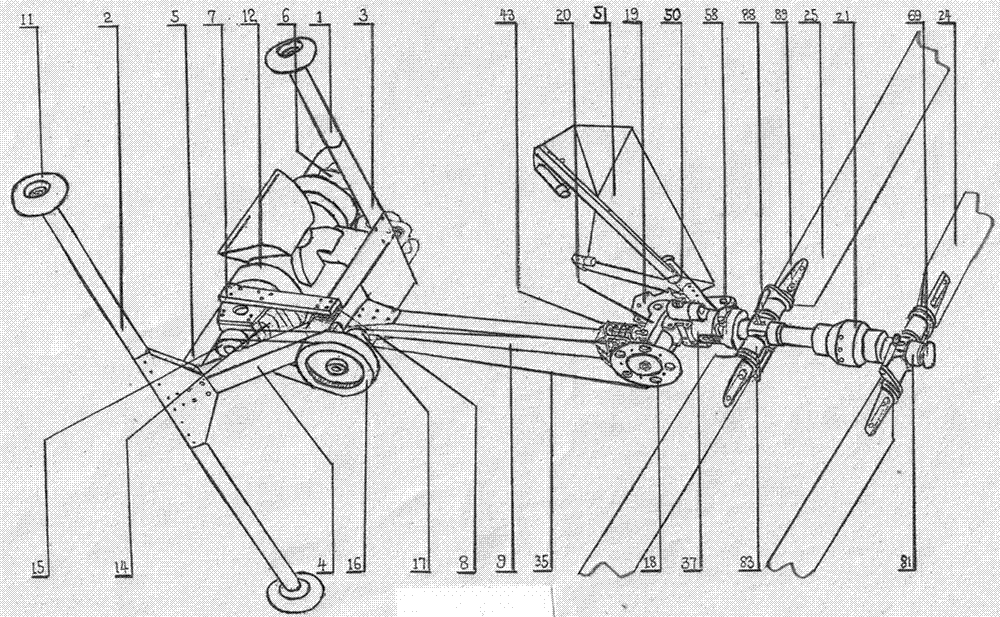

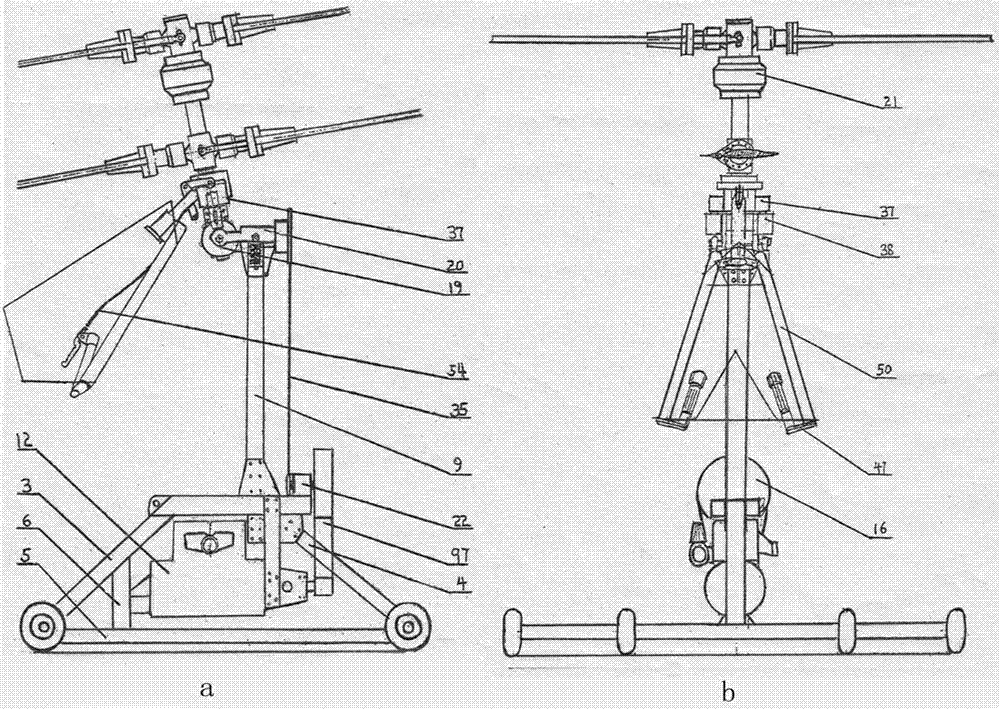

[0038] Embodiment one: see figure 1 , figure 2 , image 3 -a, image 3 -b, Figure 4 , Figure 5 , the gear tilting coaxial machine of the present invention fixes the engine 12 and the deceleration mechanism on the fuselage, and the engine 12 is connected to the tilting conversion gear mechanism fixed at the upper end of the column 9 of the fuselage through the deceleration mechanism, and the tilting conversion gear mechanism includes Tilt conversion gearbox 19 and a tilt conversion support arm 20, the power input bevel gear of the rotor tilt conversion gear mechanism is arranged on both sides of the fuselage column 9 through the bearing seat 26, and the tilt conversion support arm 20 is arranged on the power input Between the two bearing seats 26 of the small bevel gear, the tilting steering gear box 19 connects the fuselage and the tilting control rod base 37 at the lower part of the rotor shaft, and the tilting steering gear box 19 passes through the rotor shaft pitch ...

Embodiment 2

[0039] Embodiment 2: The gear tilting coaxial machine of this embodiment is different from Embodiment 1 in that it further discloses a rotor tilting steering gear mechanism.

[0040] Such as Figure 5 , Figure 6 -a, Figure 6 -b, Figure 7 As shown, the power input small bevel gear 27 axis of the rotor pitch conversion gear mechanism traverses through the power input small bevel gear bearing seats 26 on both sides of the column and the tilt conversion support arm 20 sandwiched in the middle, and the power is input to the tilt conversion The two reversing large bevel gears 28 horizontally opposed in the center of the gearbox 19, through the reversing of the large bevel gears 28, the power input on the small bevel gear 27 is transmitted to the normal state and the input power of the small bevel gear 27 The axis is on the small power output bevel gear 29 at an angle of about 90 degrees upward, and then transmitted to the rotor shaft 31 through the rotor shaft spline sleeve 30...

Embodiment 3

[0044] Embodiment 3: The gear tilting coaxial machine of this embodiment is different from Embodiment 1 or Embodiment 2 in that it adopts Figure 9 The pitch variable mechanism shown: the pitch variable control mechanism includes the built-in pitch variable mechanism of the rotor shaft and the external pitch variable mechanism. The built-in variable pitch mechanism of the rotor shaft consists of a left-hand handle 49, a small handle 52, a variable pitch cable 54, a variable pitch disc support rod 55, a variable pitch disc support rod bushing 56, a tilting control rod base 37, and a variable pitch disc support rod Screw shaft 57, variable distance disk inner sleeve 59, variable distance disk outer cover 58, variable distance pin shaft 60, variable distance disk bearing 61, variable distance disk inner sleeve snap ring 62, variable pitch disk outer jacket snap ring 63, Disc spring 64, rotor reversing gear box 21, rotor shaft spline sleeve 30, rotor shaft 31, upper rotor pitch-va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com