Unequal-radius tandem three-rotor helicopter

A three-rotor, tandem technology, applied in the direction of rotorcraft, fuselage, motor vehicles, etc., can solve the problems of poor handling characteristics, poor heading stability, and heavy control burden on two rotors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

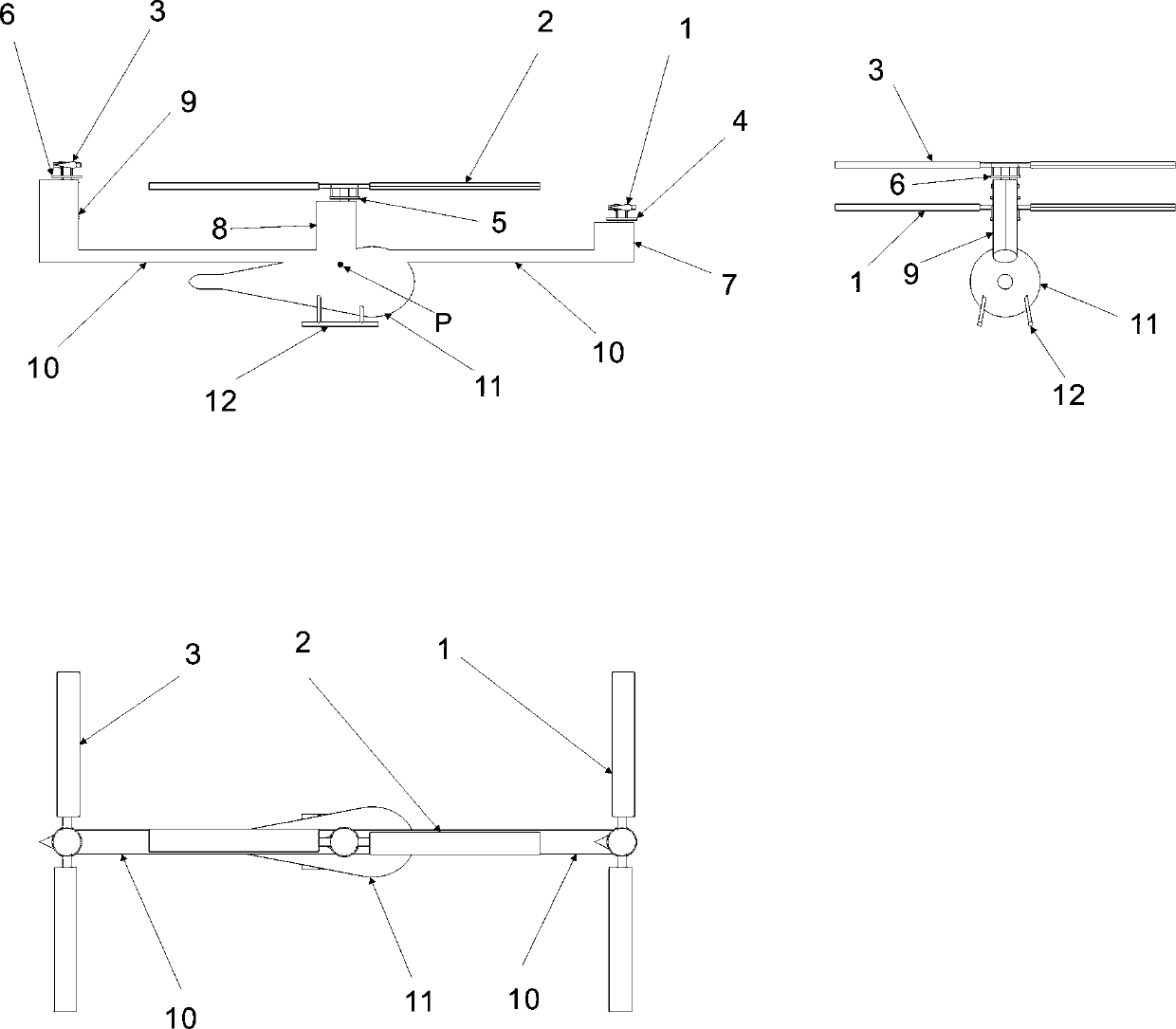

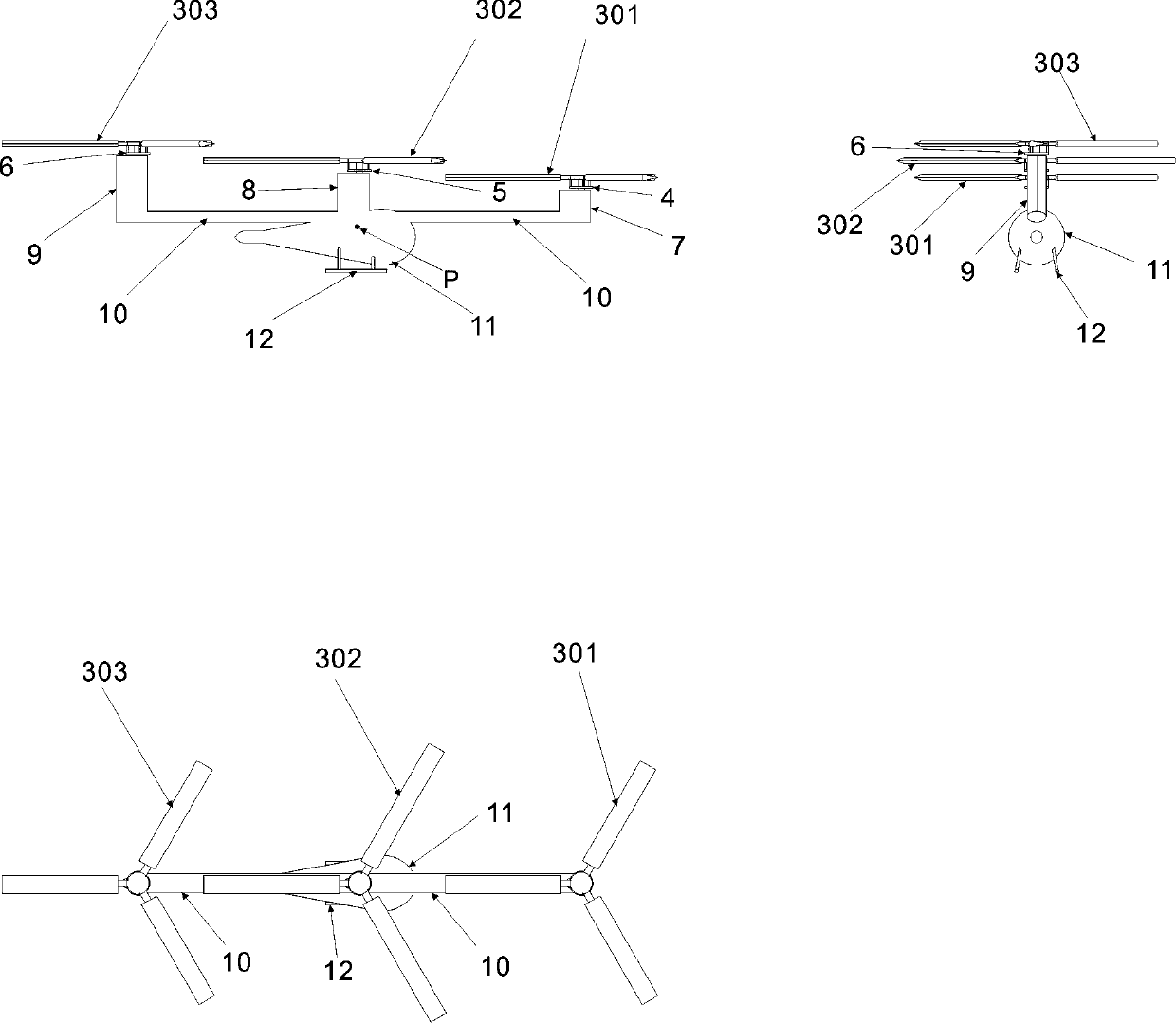

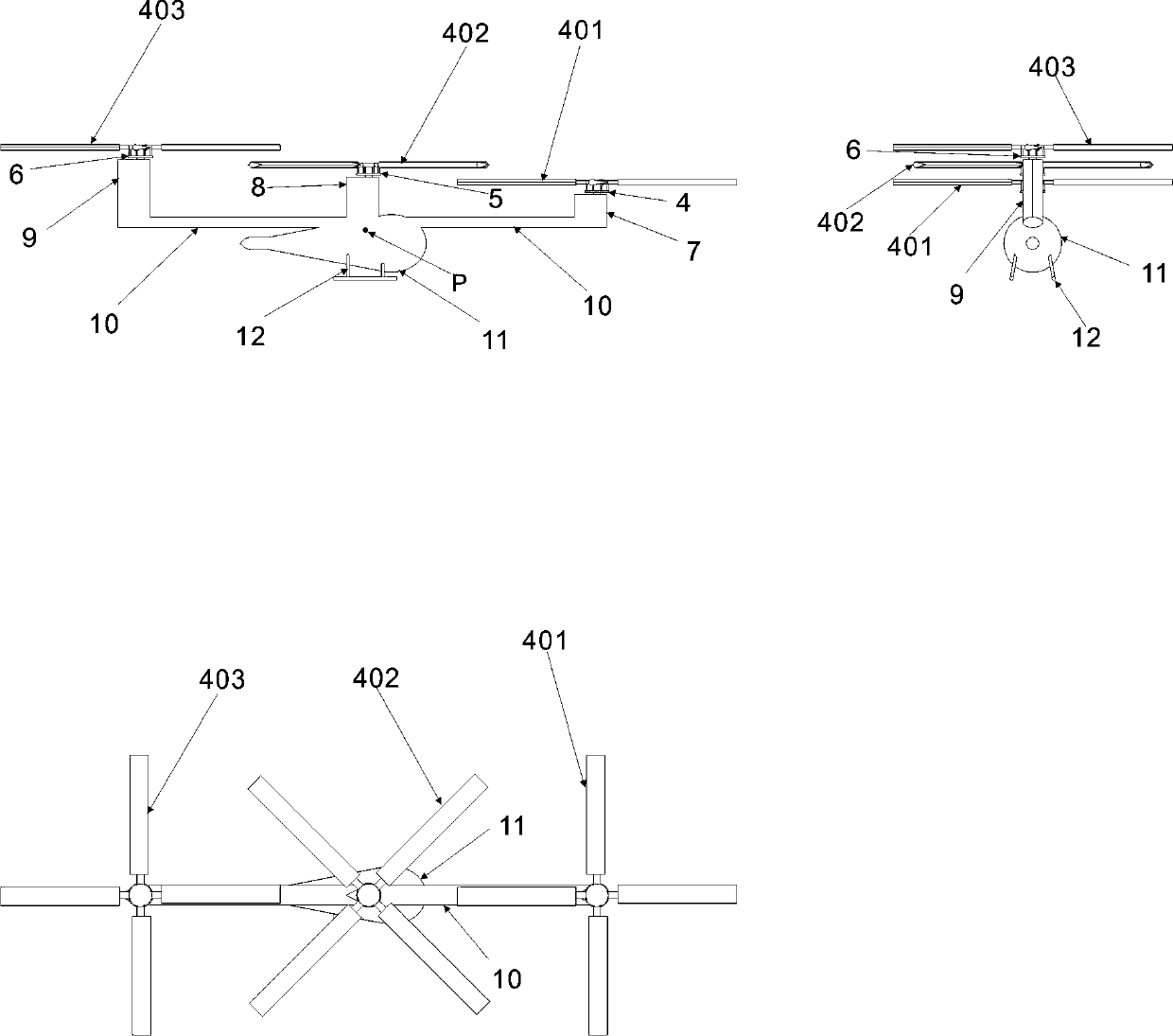

[0064] figure 1 In the shown embodiment, a longitudinal beam is arranged on the top of the fuselage (11), hereinafter referred to as the longitudinal beam (10), and the first small tower (7) is arranged on the cantilever at the front end of the longitudinal beam (10). The tower (7) plays the role of the vertical tail. The first rotor (1) consisting of two blades is set on the first small tower (7). The center of the longitudinal beam (10) is above the center of gravity (P). The top of the fuselage (11) above the center of gravity (P) is provided with a second small tower (8), and the second small tower (8) of the airfoil acts as a vertical empennage. The second rotor (2) formed by the blades, the third small tower (9) is arranged on the cantilever at the rear end of the longitudinal beam (10), and the third small tower (9) of the airfoil acts as a vertical tail. The tower (9) is provided with the third rotor (3) consisting of two blades.

[0065] Set the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com