Down feather and wool mixing expanding sleeping bag, manufacturing method and using method

A sleeping bag and velvet cotton technology, which is applied in the field of sleeping bags, can solve the problems of feather clumping and loss, inability to rest well, discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

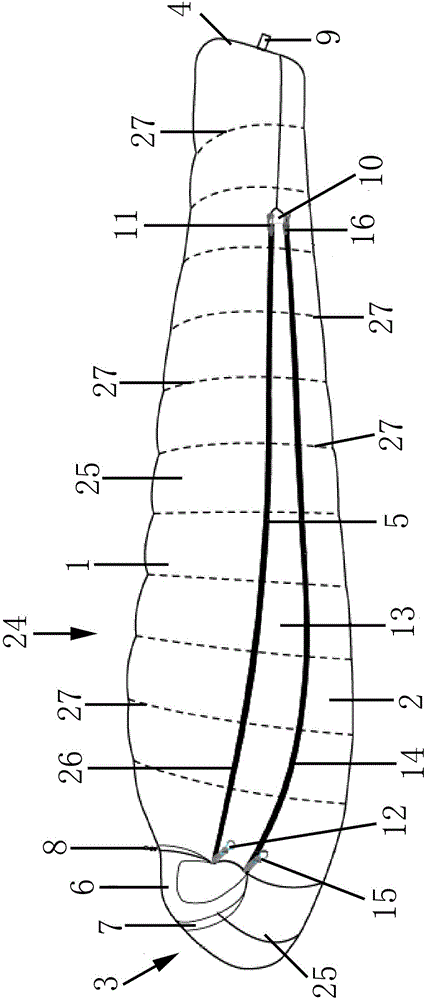

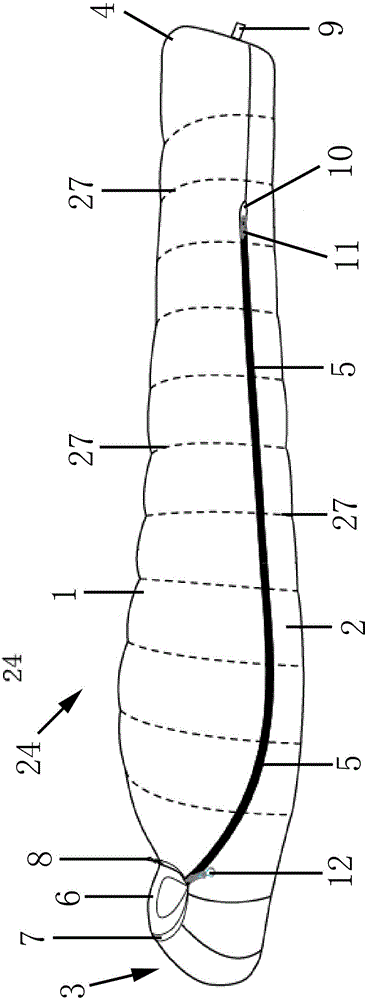

[0053] The overall sleeping body (24) is composed of the upper sleeping piece (1), the lower sleeping piece (2), the night cap (3), the bottom barrel (4), the sleeping triangle piece (10), the hanging ear (9), and the placket (28), sleeping bag expansion piece (13), placket zipper (5), sleeping top piece (1), sleeping bottom piece (2), placket (28), nightcap (3) and bottom bucket (4 ) constitute a sleeping body (24), and the top portion of the sleeping body (24) is fixedly provided with a nightcap (3), and the nightcap (3) coincides with the head of the human body, and the nightcap (3) protects the head from being warm, and the sleeping body ( The bottom end of 24) is fixedly equipped with a bottom bucket (4), the bottom bucket (4) keeps the warmth of the feet, and the upper part of the sleeping body (24) is fixedly equipped with a sleeping body piece (1), covering the upper part of the human body to keep the warmth of the human body , the lower part of the sleeping body (24) ...

Embodiment 2

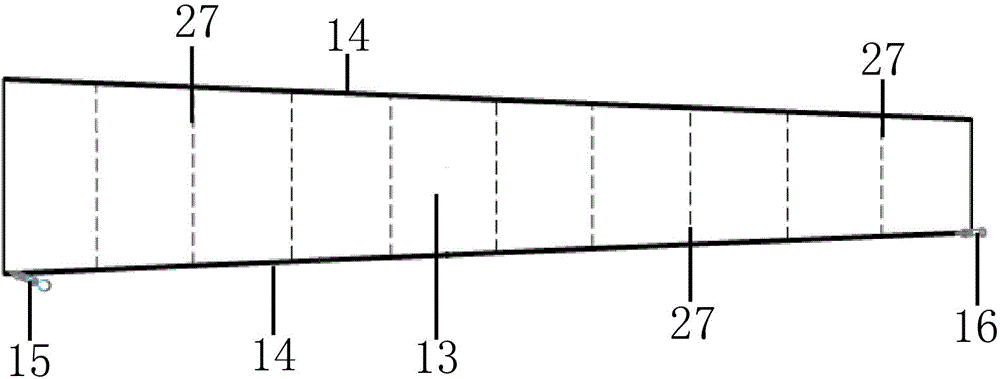

[0058] The sleeping bag expansion sheet (13) is strip-shaped as a whole, and the upper end of the sleeping bag expansion sheet (13) is wide and the lower end is narrow. The lining (22) constitutes an independent space filled with down, and the down filling material (21) is filled in the independent space filled with down, which is made by stitching with quilting stitches (27), and expansion pieces are set on both sides of the sleeping bag expansion piece (13) Zipper (14), expansion piece slide fastener (14) is provided with expansion piece zipper upper slider (15) and expansion piece zipper lower head (16), sleeping body triangular piece (10) overall triangular shape, sleeping body triangle piece (10 ) is arranged on the inner side of the fly zipper (5), the two sides of the narrow end of the sleeping triangle (10) are fixedly connected with the inner side of the bottom end of the fly (26), and the width of the sleeping triangle (10) The end coincides with the narrow end of th...

Embodiment 3

[0060] Make the sleeping bag fabric (25) and the sleeping bag lining (17) according to the design requirements of the sleeping bag (1) to make the sleeping bag fabric (25) and the sleeping bag lining (17) Merge and make the sleeping body piece (1), the sleeping bag fabric (25) faces outwards, the pile lining (22) is arranged between the sleeping bag fabric (25) and the sleeping bag lining (17), and the sleeping bag lining (17) Inwardly, between the sleeping bag fabric (25) of the sleeping body piece (1) and the sleeping bag lining (17), eider down is poured into to form the down filler (21) in the sleeping body piece (1).

[0061] Make the sleeping bag fabric (25) and the sleeping bag lining (17) into the sleeping body lower piece (2) according to the design requirements of the sleeping bag lower piece (2), and fill the cotton batting between the sleeping bag fabric (25) and the sleeping bag lining (17) To form the cotton filling material (23), the sleeping bag fabric (25), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com