Patents

Literature

44results about How to "Improve fuel combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

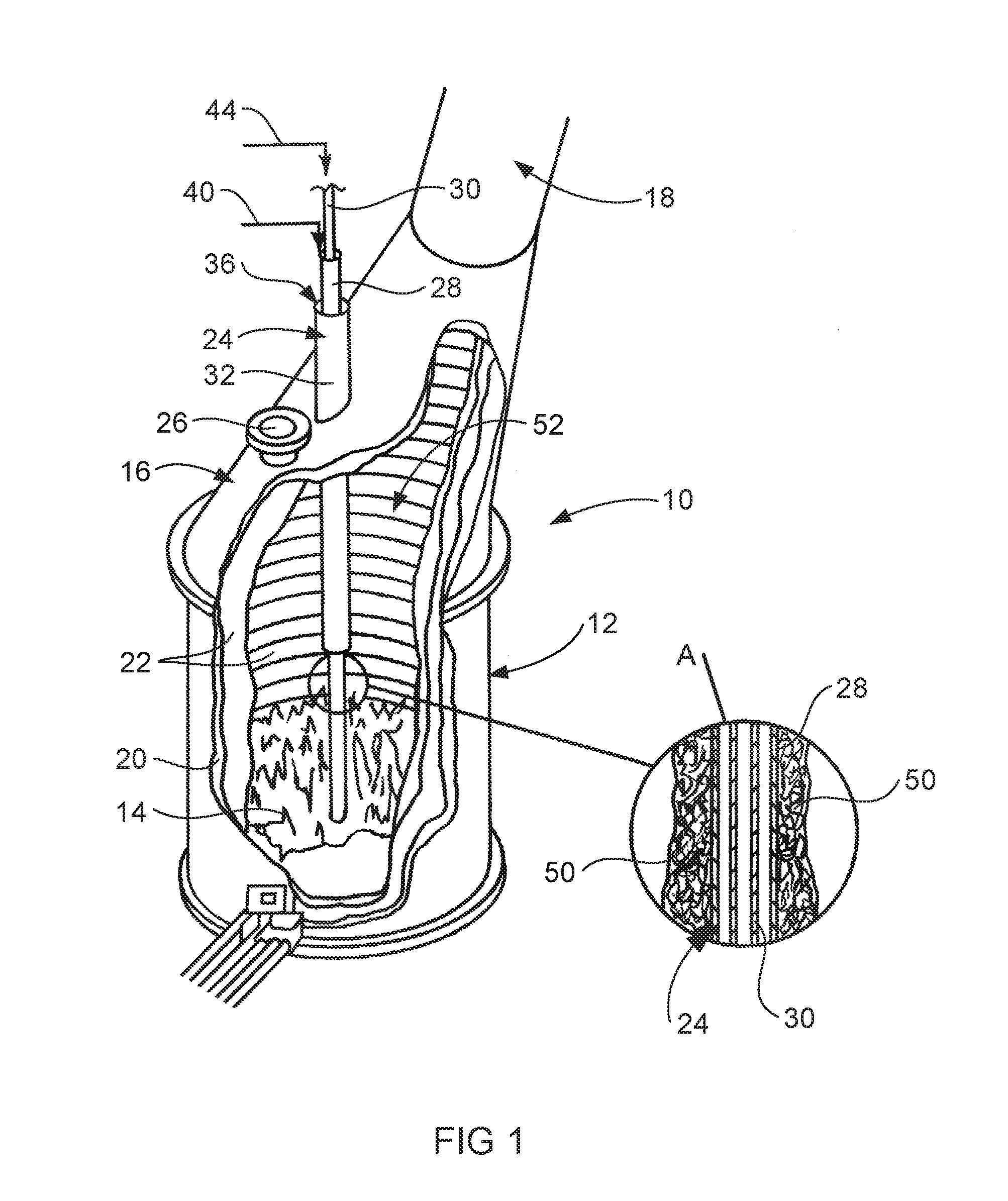

Apparatus and Methods For Providing Uniformly Volume Distributed Combustion of Fuel

InactiveUS20100285413A1Promote oxidationSufficient distance of travelIndirect carbon-dioxide mitigationIncinerator apparatusCombustorCombustion chamber

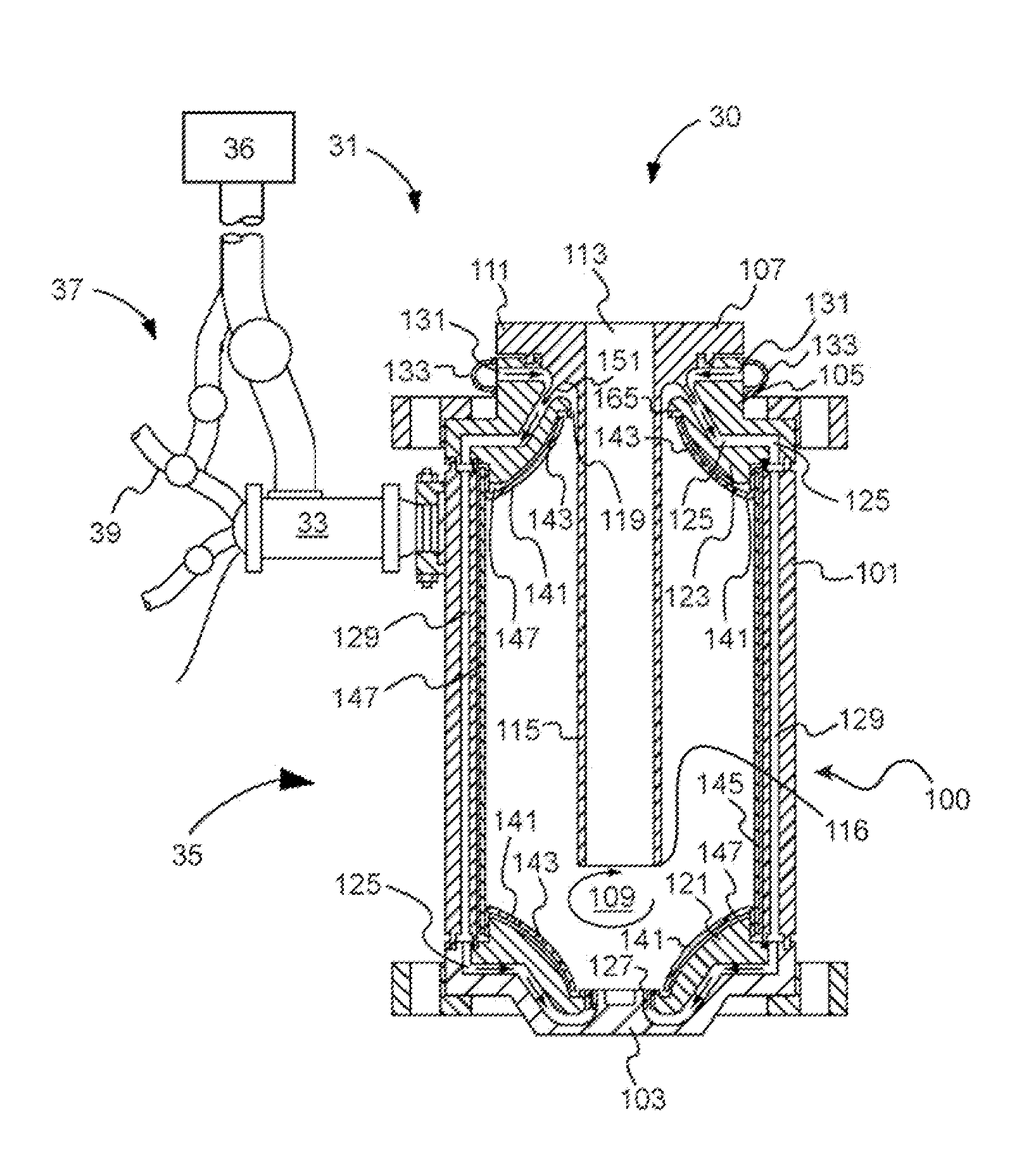

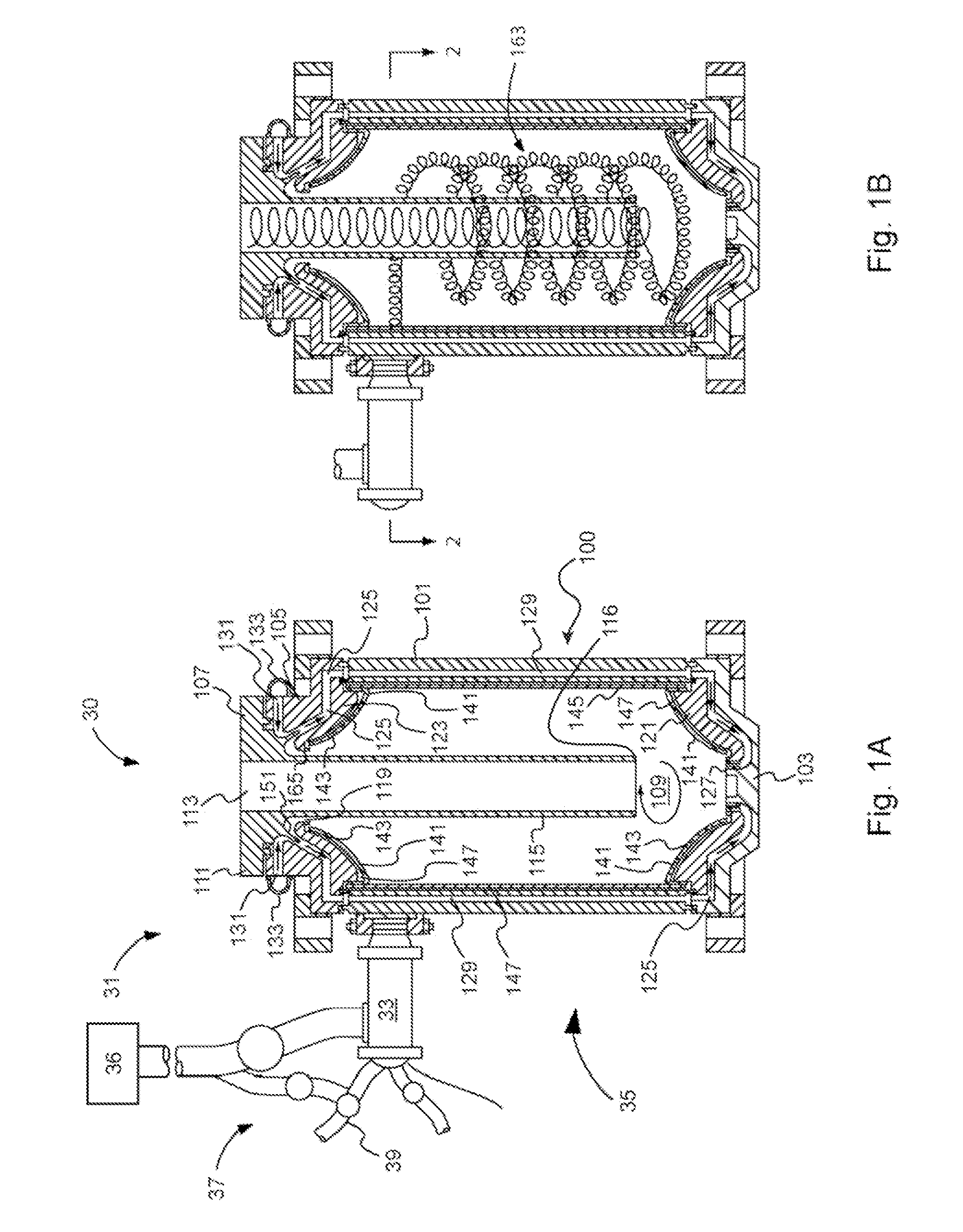

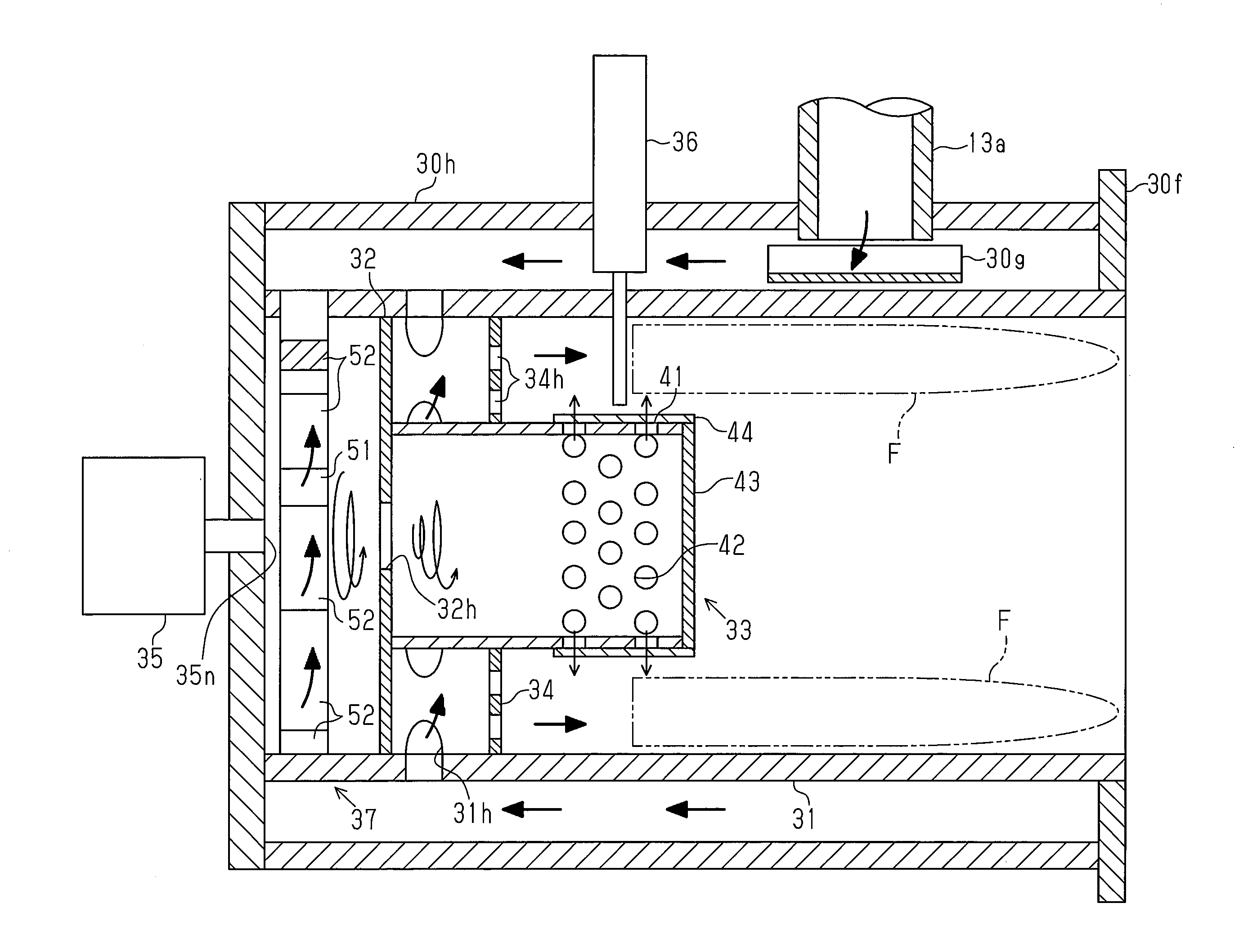

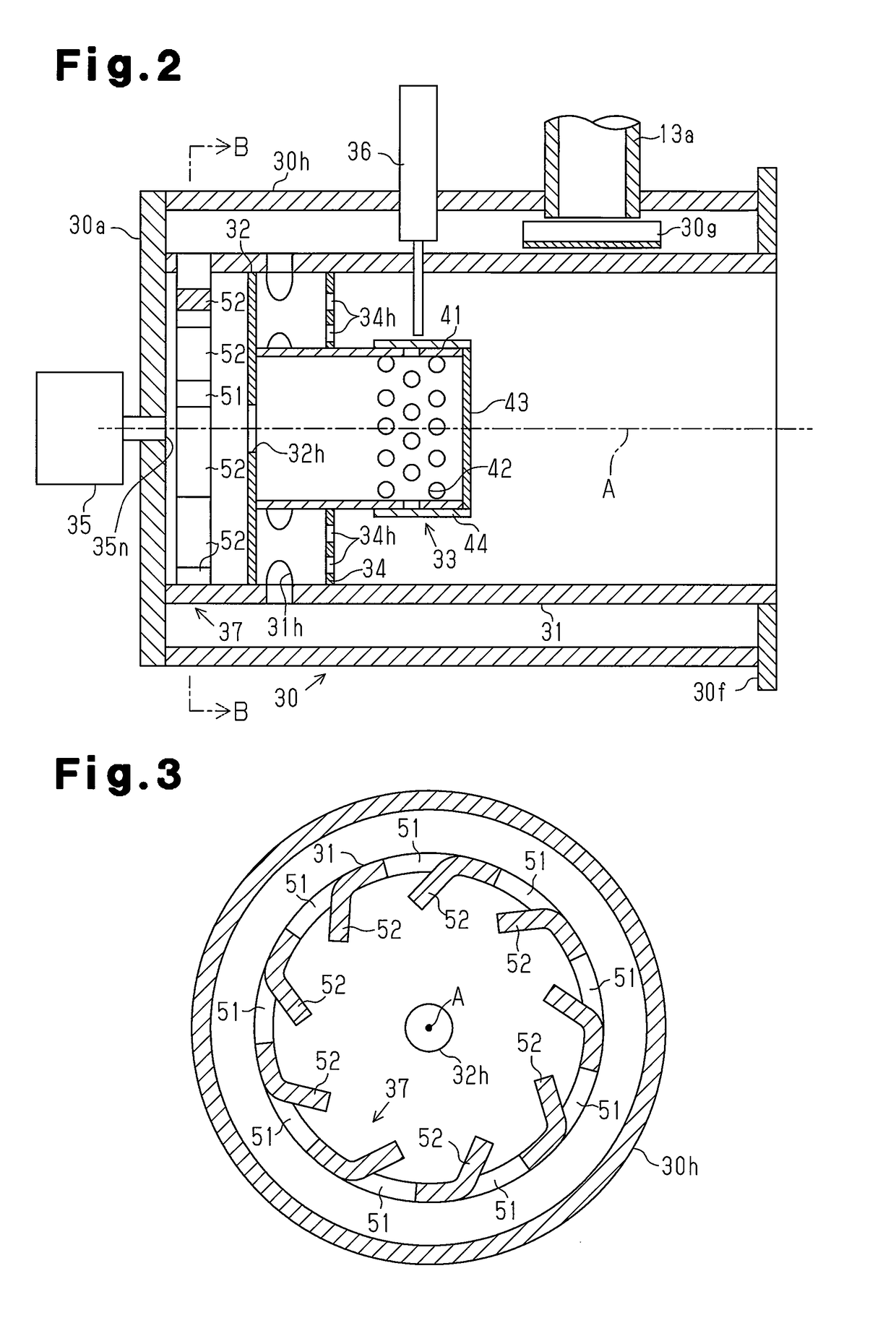

A combustor apparatus and method for the combustion of viscous fuels are provided. The combustor apparatus can include a precombustion chamber particularly adapted to heat and at least partially combust a heavy primary fuel, and a main combustion chamber adapted to combust the primary fuel uniformly through the main combustion chamber (in flameless mode). The precombustion chamber can include at least one air injection inlet port positioned to induce a first stage vortex in the main body portion of the housing of the precombustion chamber. Further, the precombustion chamber can be interfaced with a main combustion chamber to induce a second stage vortex within the main combustion chamber. The main combustion chamber can have an extended axial length in order to accommodate heavier fuels that require additional time to sufficiently combust (oxidize) within the combustion chamber.

Owner:GENERAL VORTEX ENERGY

Fuel activator using multiple infrared wavengths

ActiveUS20090120416A1Promote combustionImprove performanceCombustion-air/fuel-air treatmentMachines/enginesCombustionMicrometer

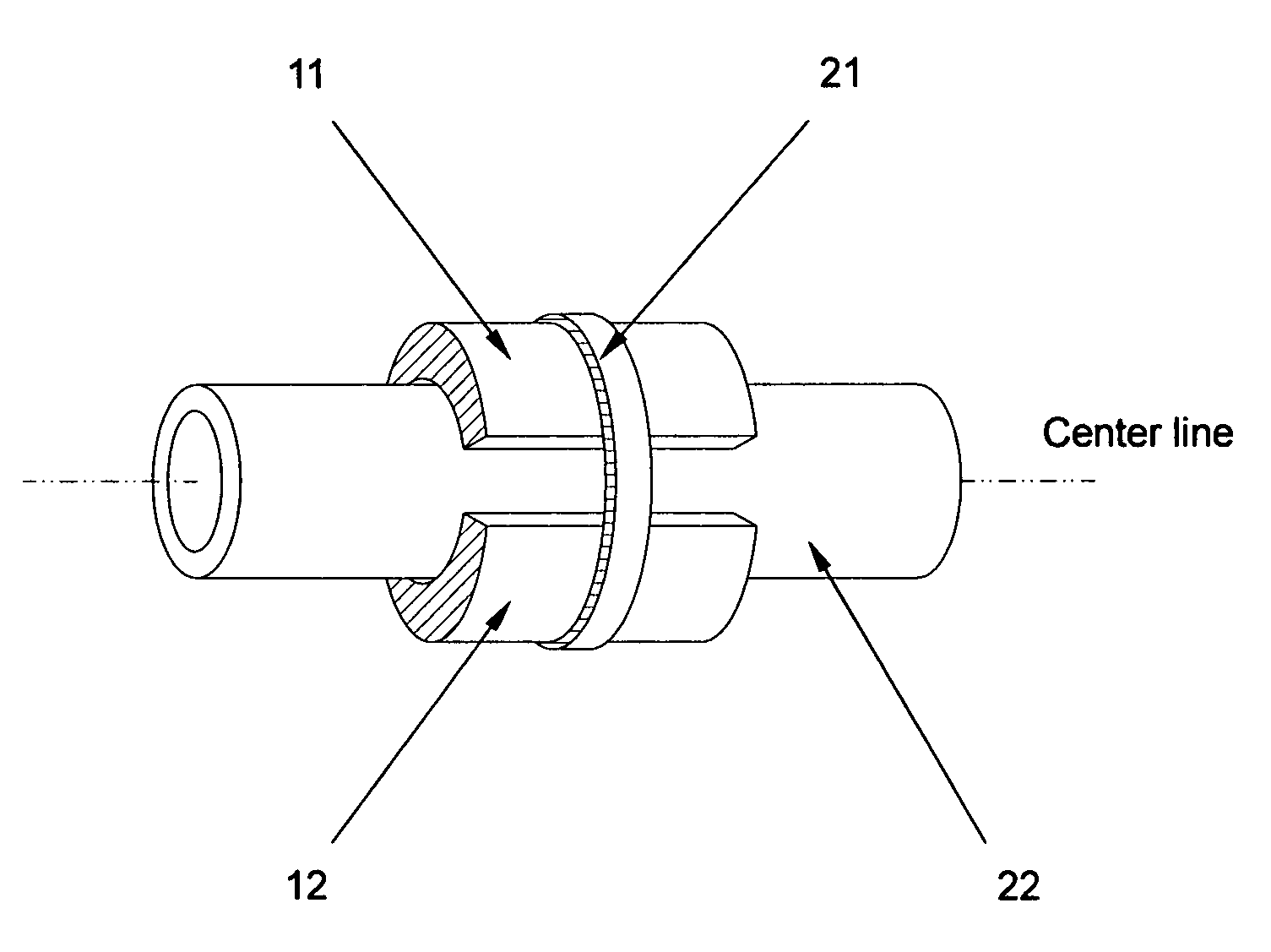

This invention relates to a fuel activating device and method consisting of at least two separate infrared-emitting bodies, each infrared-emitting body being engineered to have specific peak wavelength and spectral luminance in 3-20 um (micrometer) wavelength range, that provides an effective means for enhancing combustion of hydrocarbon fuels in internal combustion engines, resulting in better engine performance with increased power, improved fuel economy, and reduced emissions.

Owner:ALDI FAR IR PROD INC

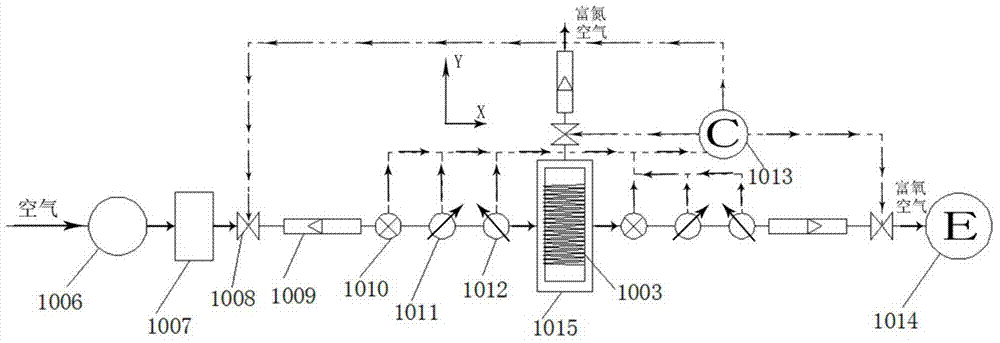

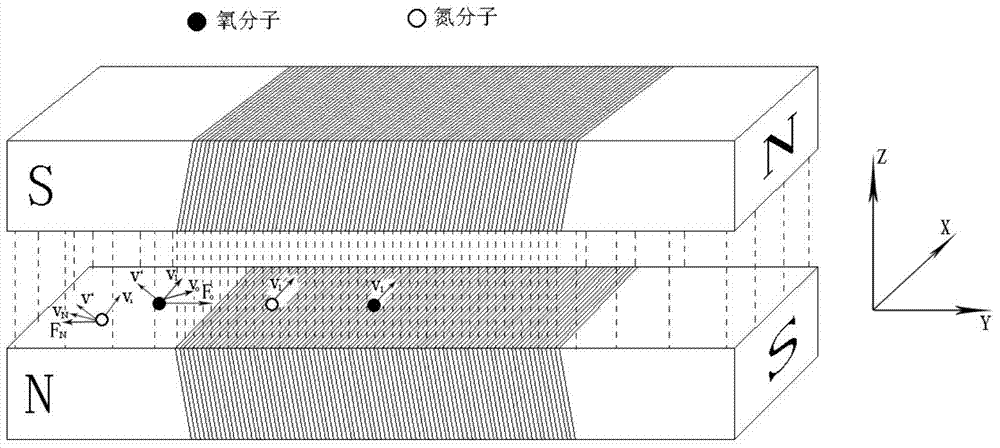

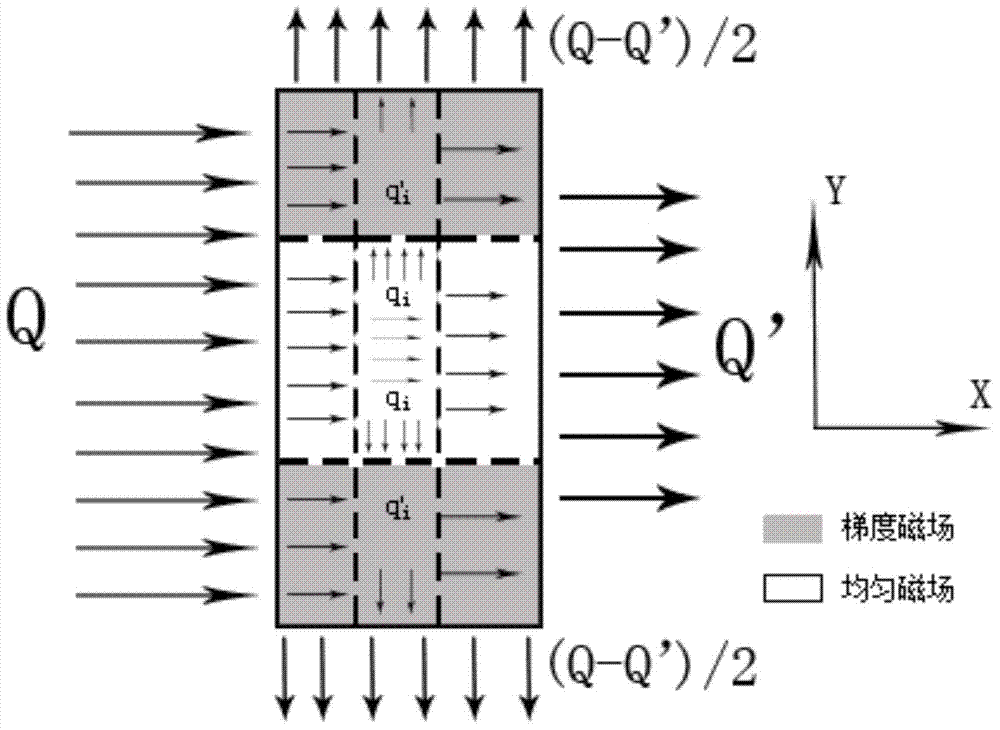

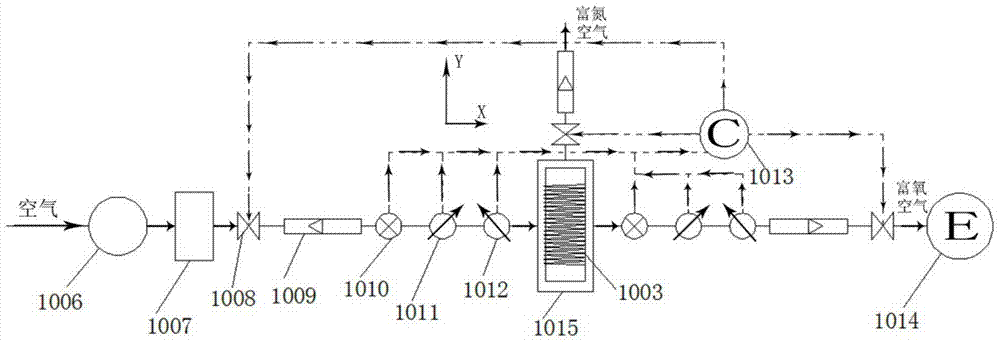

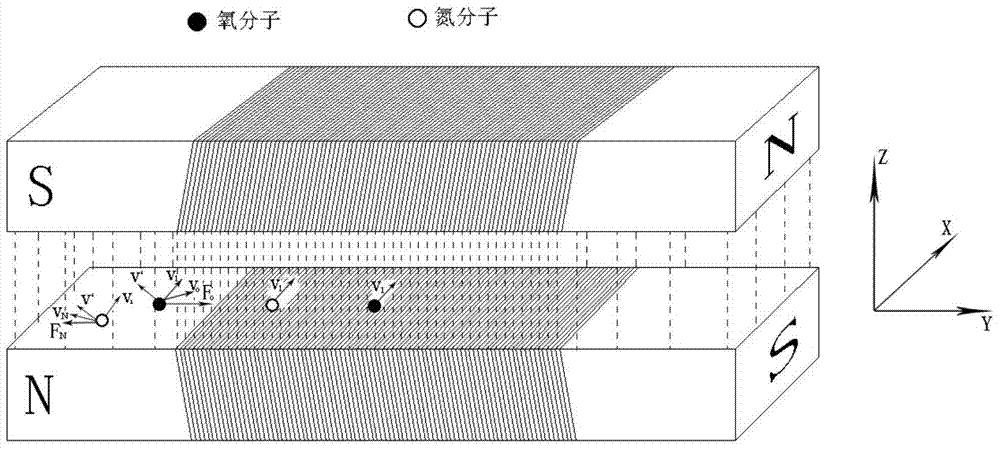

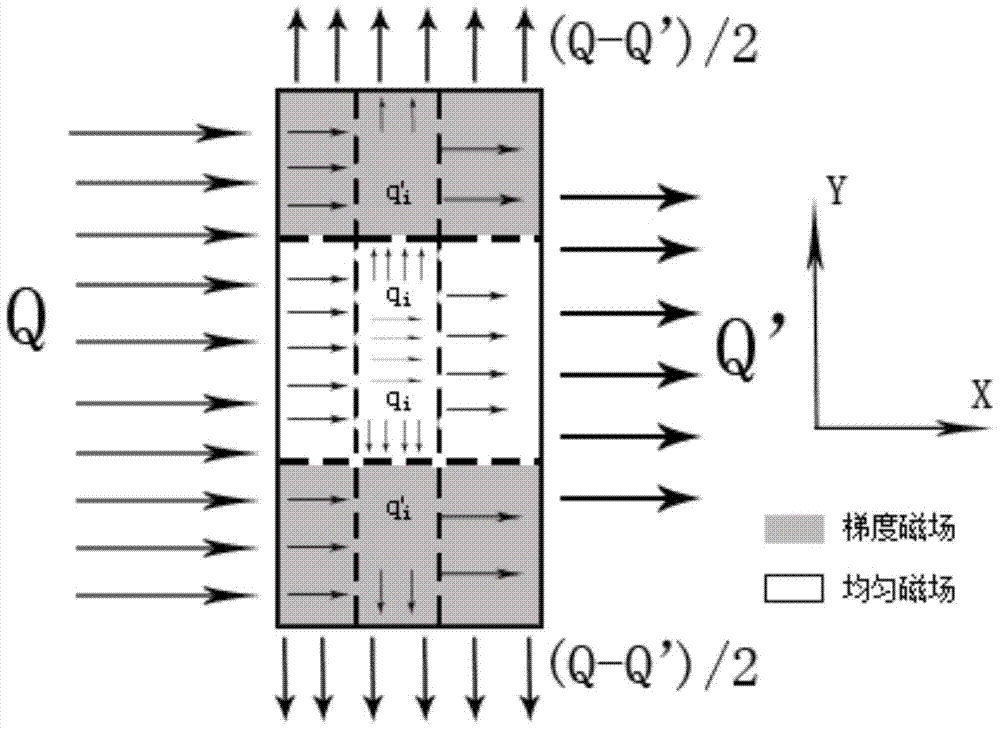

Electromagnetic type automobile nitrogen and oxygen separation device

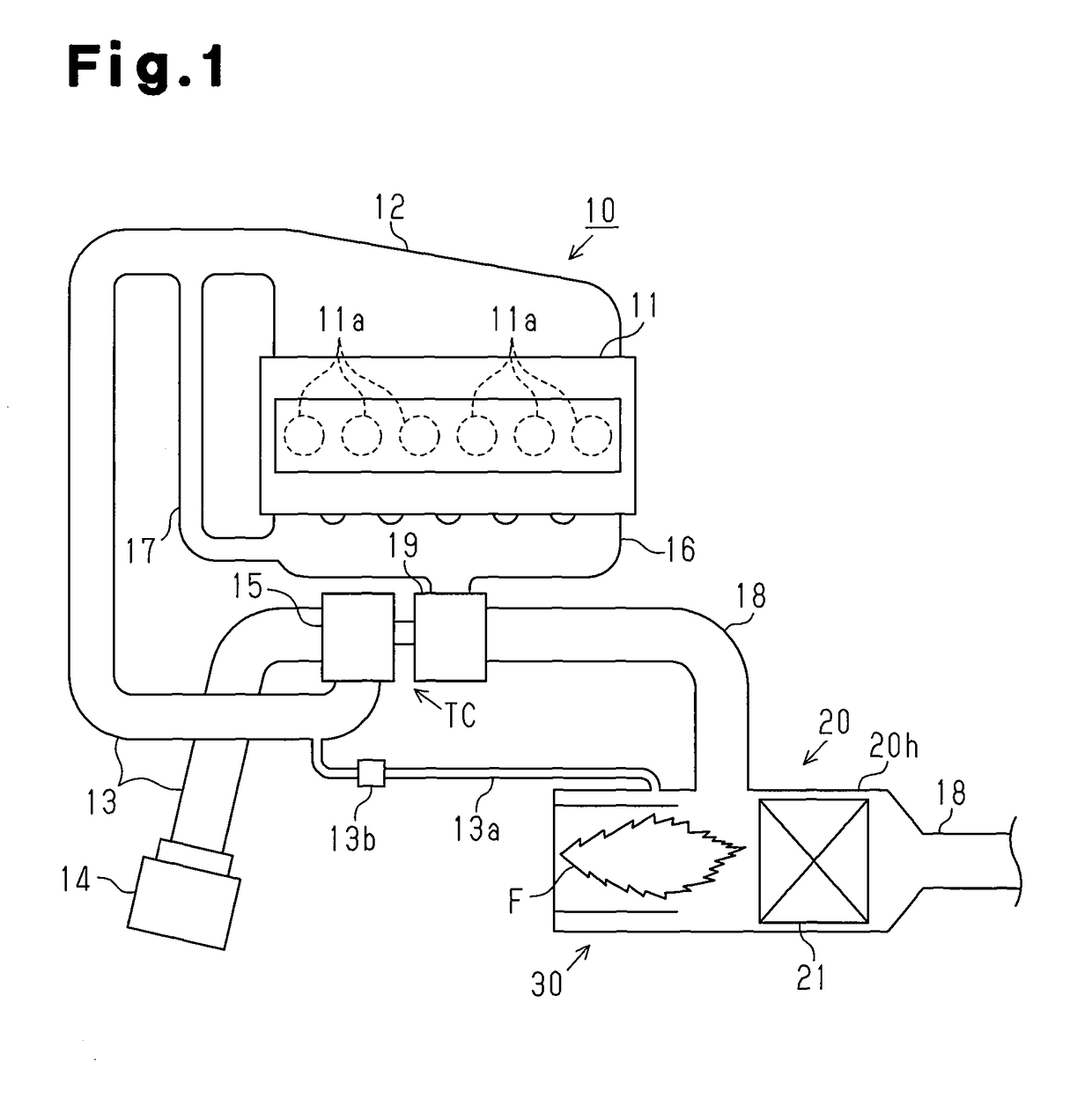

InactiveCN104727991AControl oxygen concentrationControllable oxygen concentrationNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerNitrogen

The invention discloses an electromagnetic type automobile nitrogen and oxygen separation device. The electromagnetic type automobile nitrogen and oxygen separation device comprises a turbocharger and a nitrogen and oxygen separator. A magnetic field generating device is arranged in the nitrogen and oxygen separator, the magnetic field generating device generates a gradient magnetic field so as to intercept oxygen in the air which flows past the gradient magnetic field, nitrogen and oxygen are separated, and the nitrogen and oxygen separator enables separated oxygen-enriched air to be provided for an automobile engine and enables the oxygen-enriched air to be exhausted. The particle movement law in the electromagnetism theory is used by the device, the characteristic that the magnetic field intensity of an electromagnet is far higher than that of a permanent magnet is fully utilized, and the defects that an existing oxygen production device is large in size and cannot be arranged easily and the oxygen concentration increment is low when the permanent magnet is adopted are greatly overcome. The electromagnetic type automobile nitrogen and oxygen separation device is simple in structure, low in manufacturing cost and processing difficulty, simple in technology, easy to manufacture, capable of achieving mass production easily and capable of achieving the vehicle-mounted purpose easily.

Owner:JILIN UNIV

Preparation method of tourmalinite fuel oil activator

ActiveCN103980964AStrong NMR propertiesImprove conductivityLiquid carbonaceous fuelsWater useCombustion

The invention discloses a preparation method of a tourmalinite fuel oil activator. The tourmalinite fuel oil activator comprises tourmalinite nano-powder as a main functional component. The preparation method comprises the following steps of compounding the tourmalinite nano-powder and spinel ferrite, mixing the compound and an additive according to a mass ratio of the tourmalinite nano-powder, the spinel ferrite to the additive of 87-93: 5-9: 2-4, carrying out sintering to obtain a solid mixture, and adding water and a surfactant into the mixture, wherein the amount of the used mixture is 1-5% the total amount of the solid-liquid mixture, a water use ratio is in a range of 5-98% and a surfactant use ratio is in a range of 2-30%. The tourmalinite fuel oil activator obtained by the preparation method can improve fuel oil quality, promote full combustion of fuel oil, improve combustion efficiency, save fuel oil, improve fuel oil atomization quality, and realize full combustion of fuel oil thereby reducing discharge of harmful gas so that energy saving and emission reduction are realized.

Owner:丘寿勇 +1

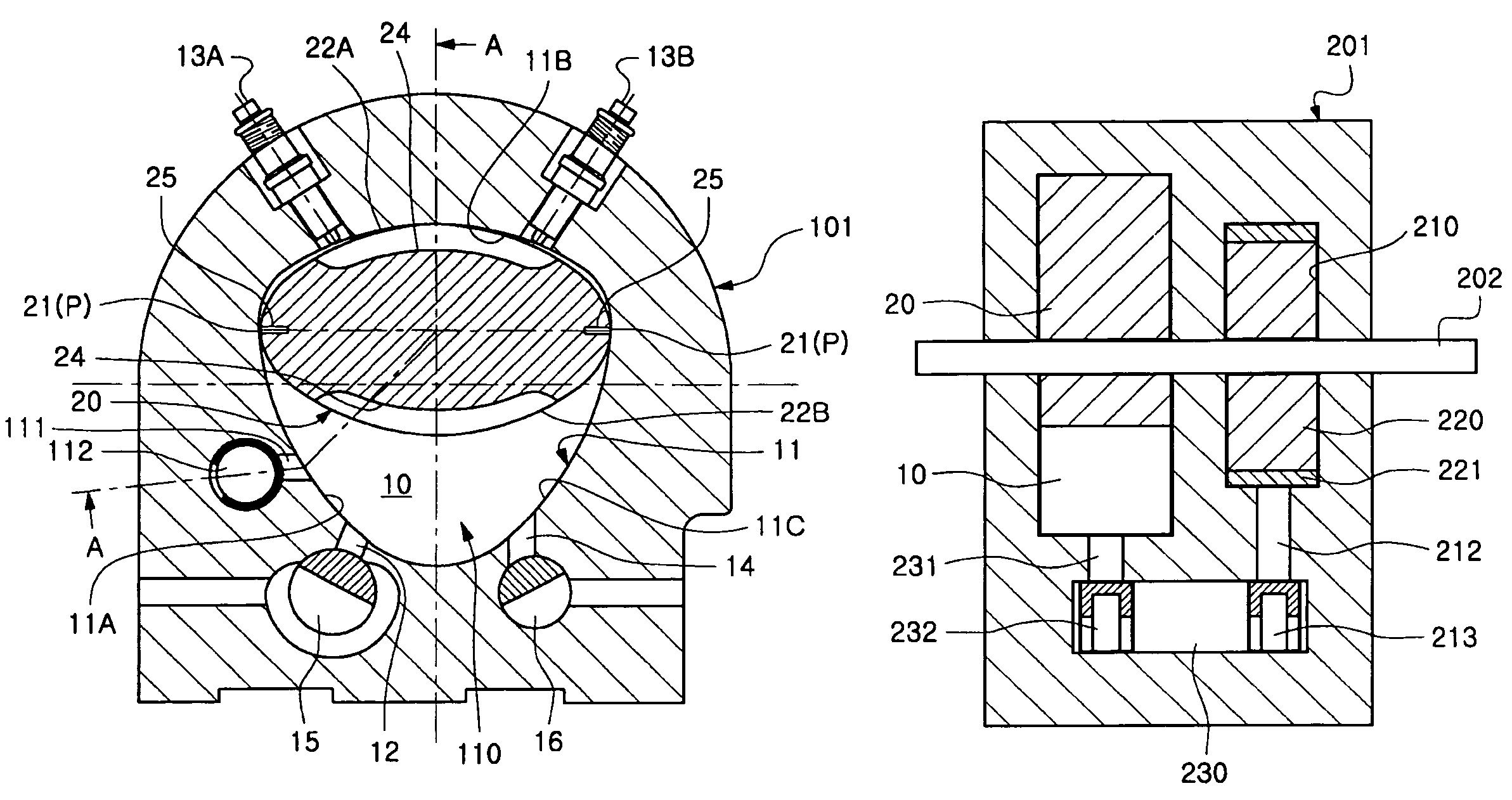

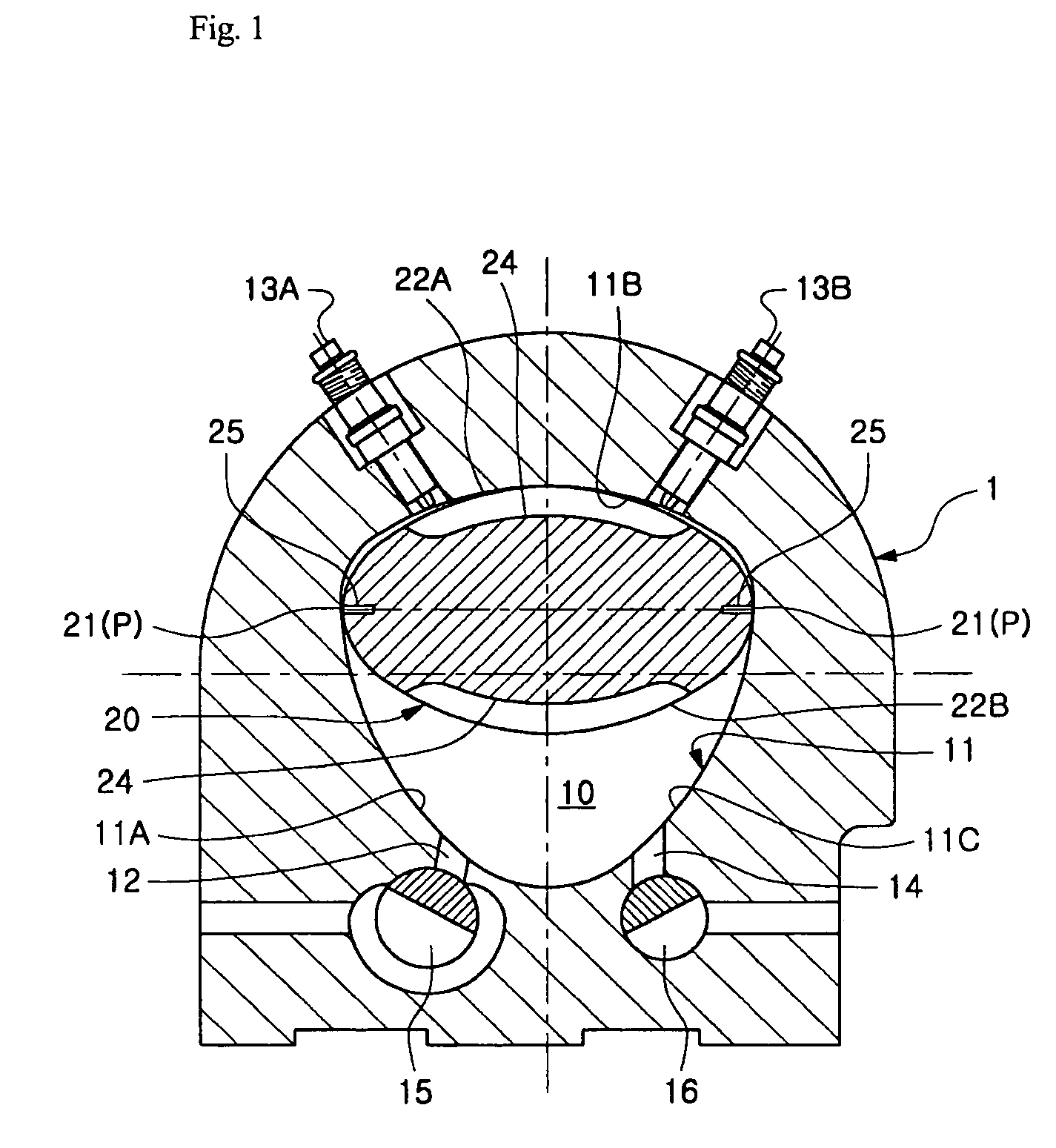

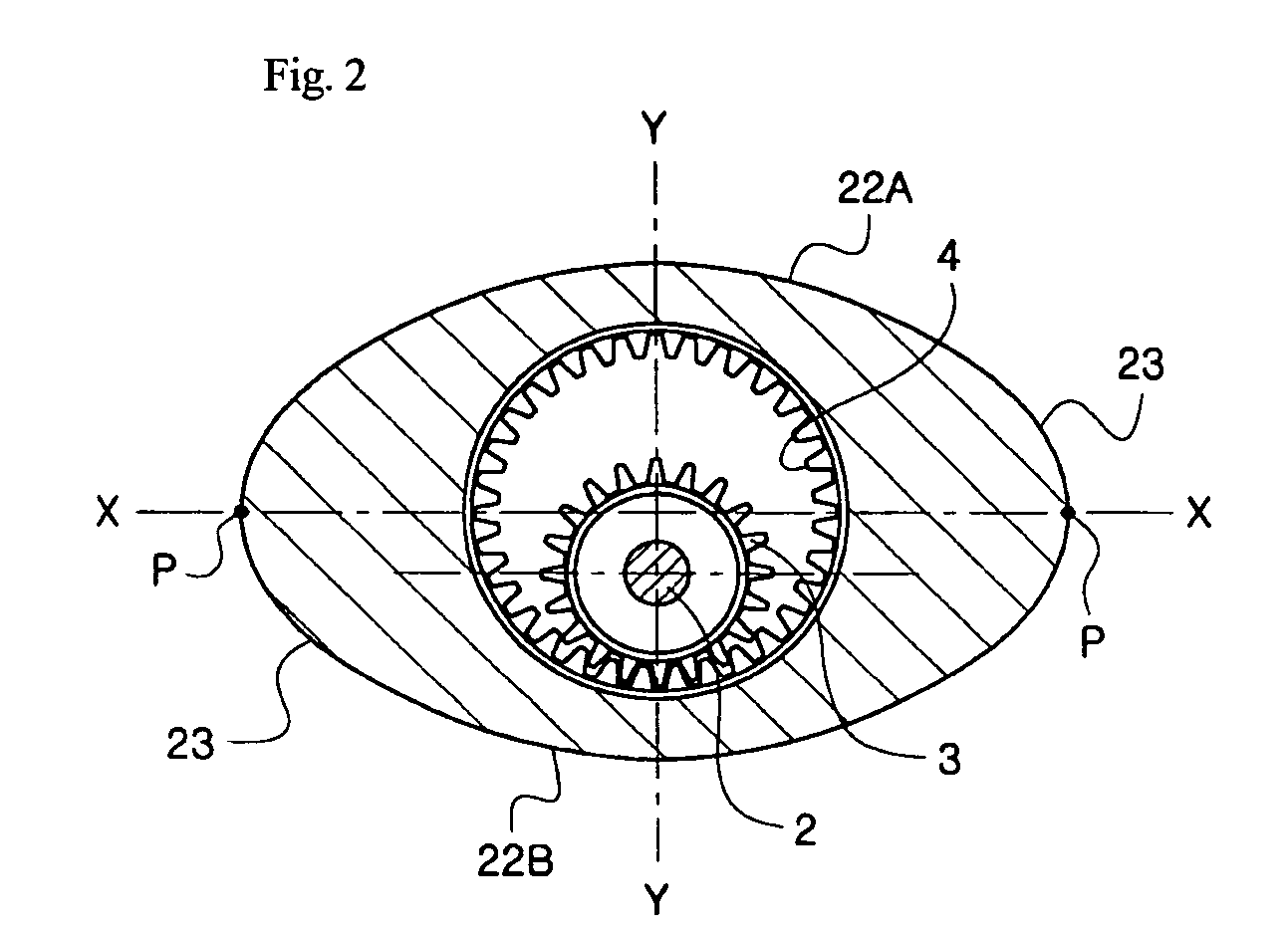

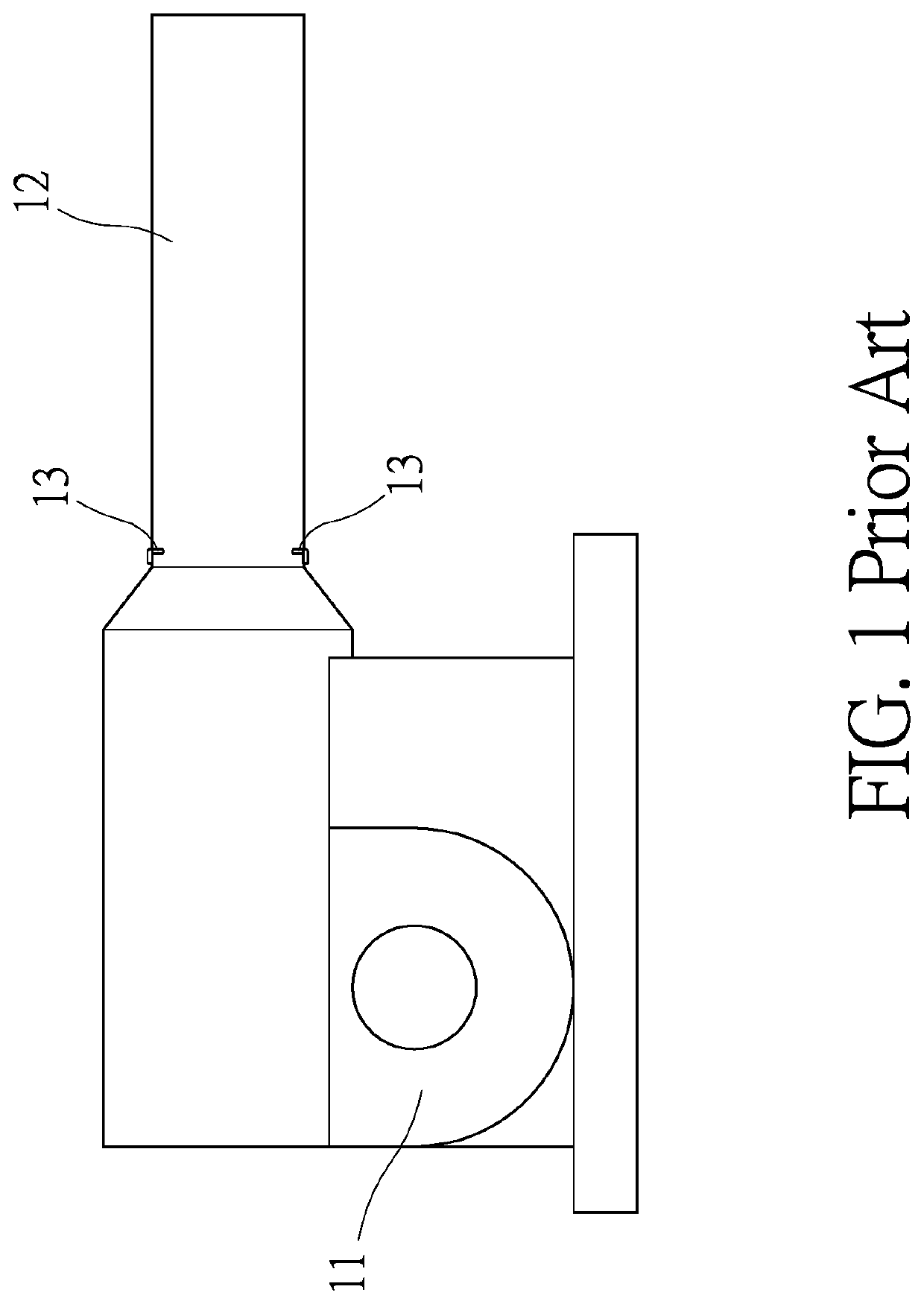

Rotary engine

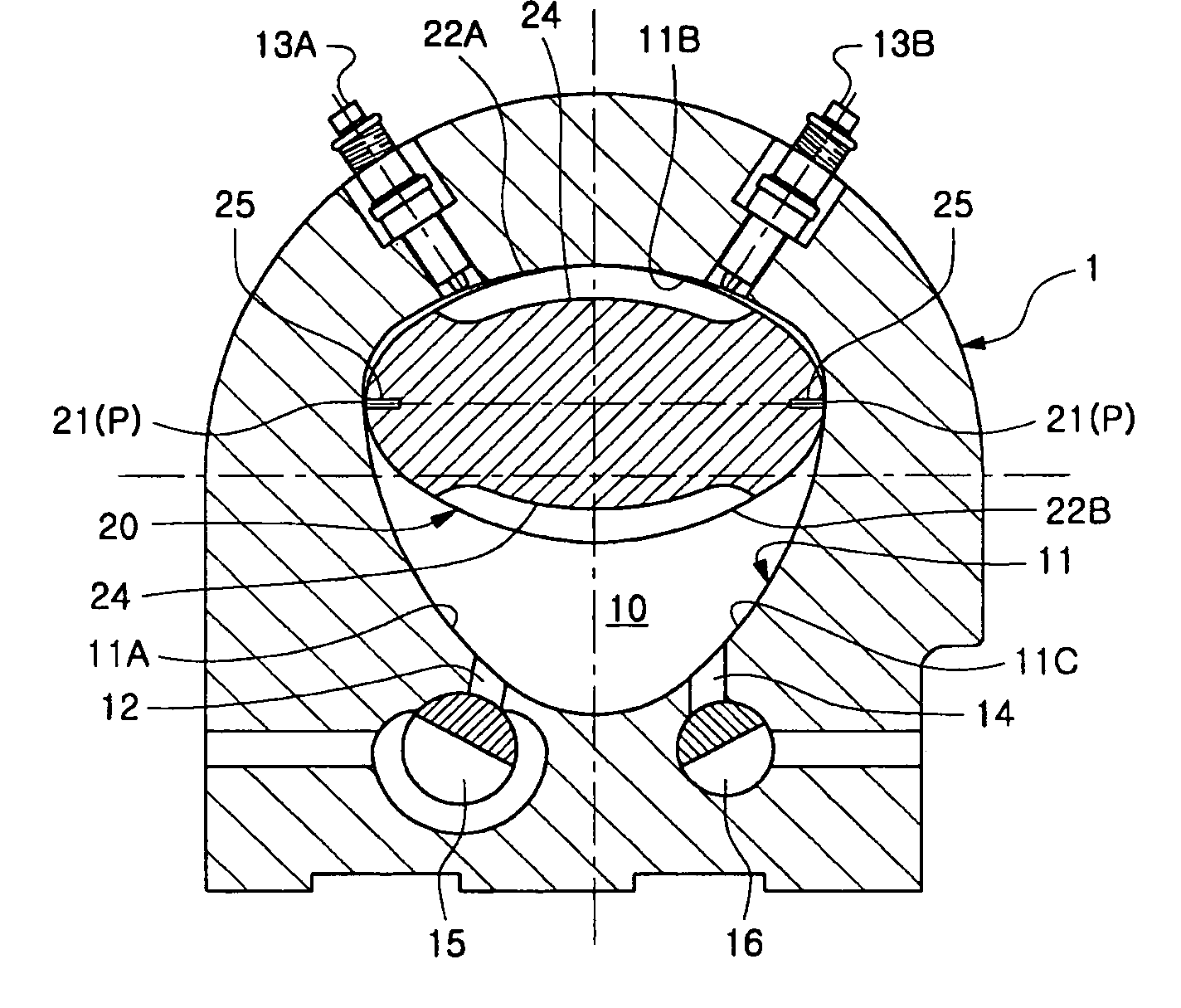

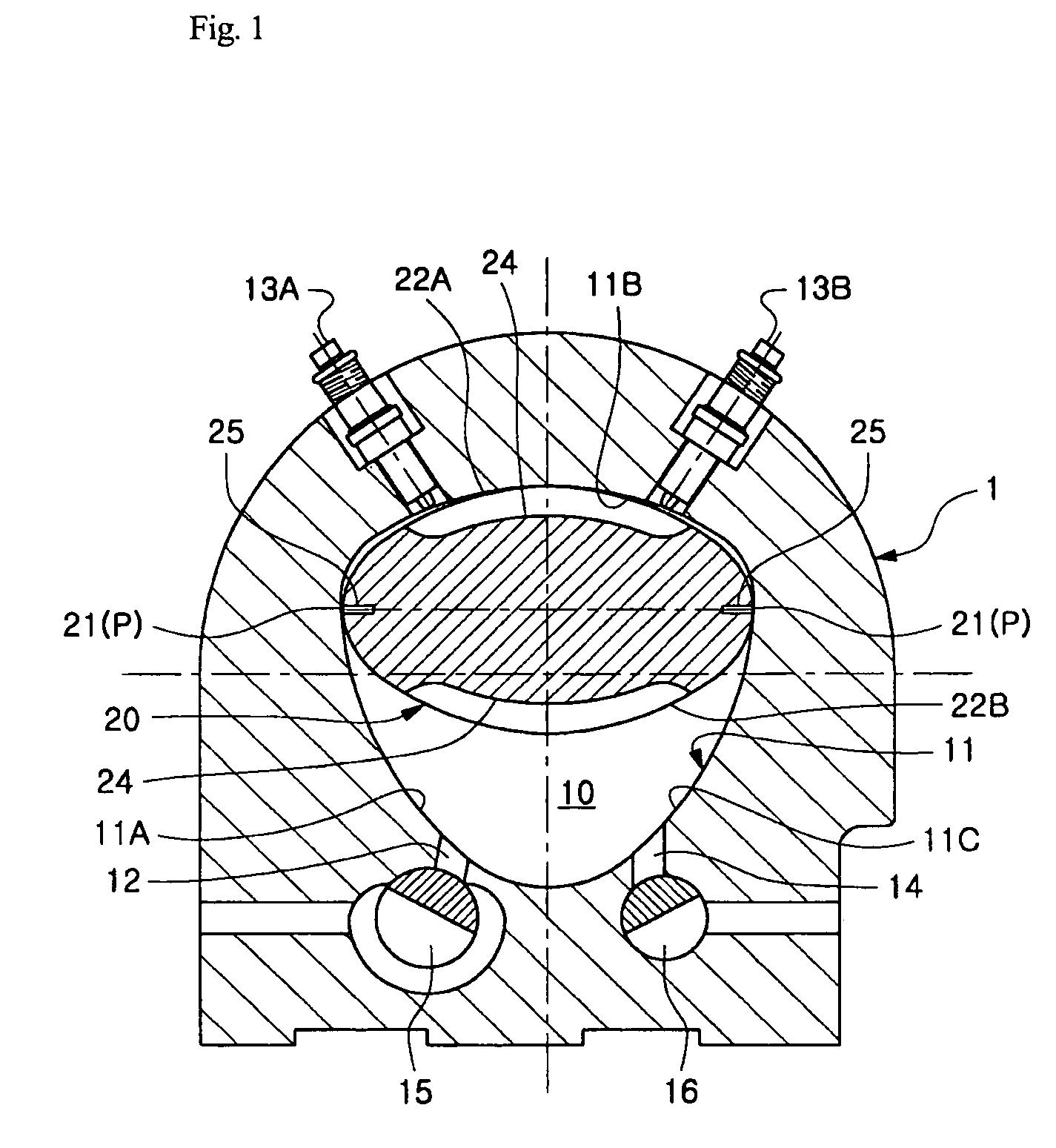

ActiveUS7434563B2Improve sealingImprove fuel combustion efficiencyInternal combustion piston enginesEngine of arcuate-engagement typeCombustionRotary engine

The rotary engine includes a cylinder body having a cylinder chamber, an intake port, an exhaust port, and a spark plug, and a rotor which is received in the cylinder chamber to eccentrically rotate while coming into contact at seal faces thereof with an inner circumferential contact wall of the cylinder chamber to thereby implement intake, compression, expansion, and exhaust strokes. The rotor has an elliptical outer contour, and the inner circumferential contact wall of the cylinder chamber coincides with a specific curve, which is described by opposite apexes of the elliptical rotor in a direction of a major axis, when the rotor eccentrically rotates. The intake port and exhaust port are provided with opening / closing valves, respectively. Sealing performance between the cylinder chamber and the rotor may achieve an enhancement in the efficiency of fuel combustion and engine output and prevent waste of fuel.

Owner:CHAE ON SOON

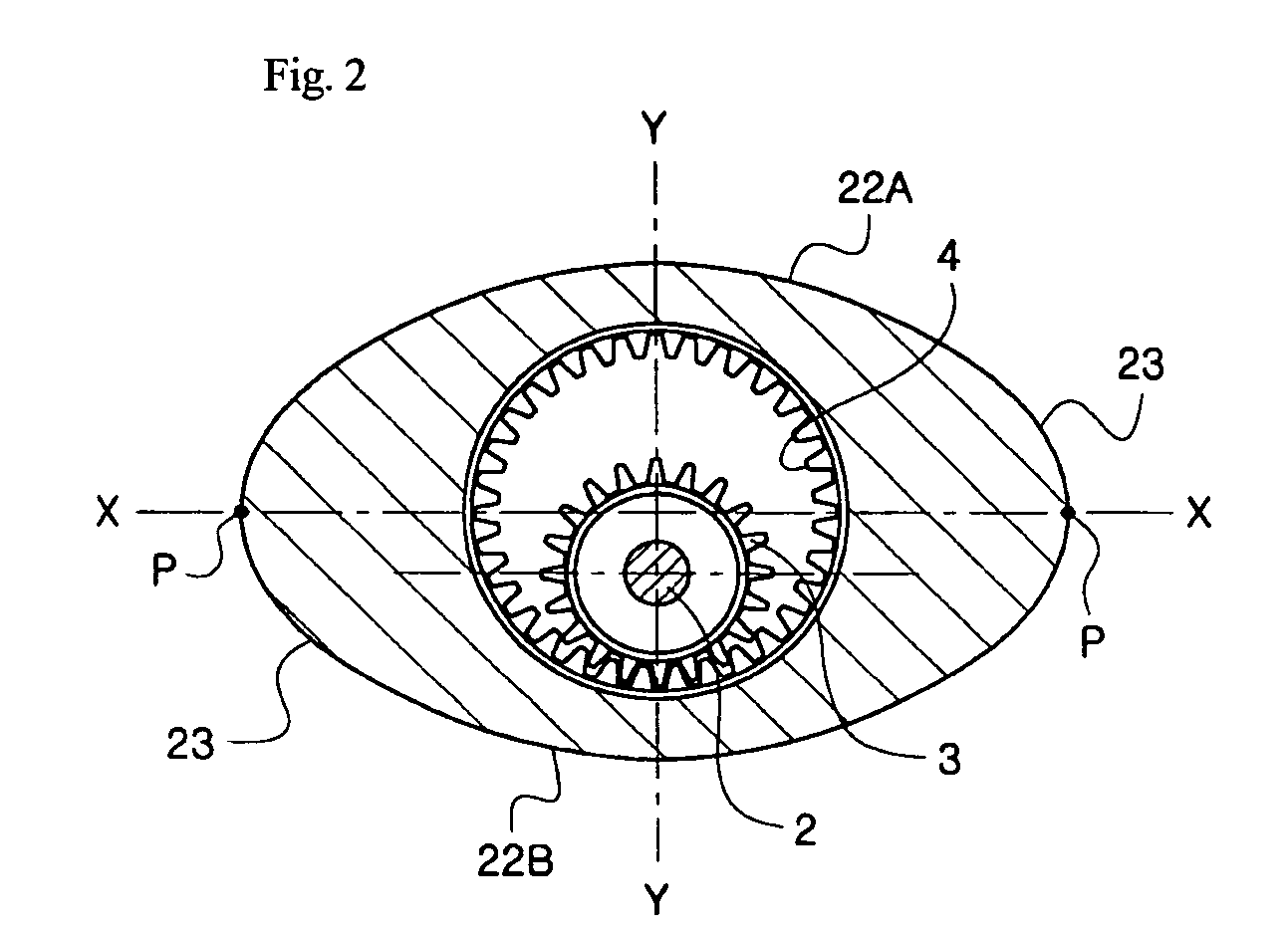

Burner

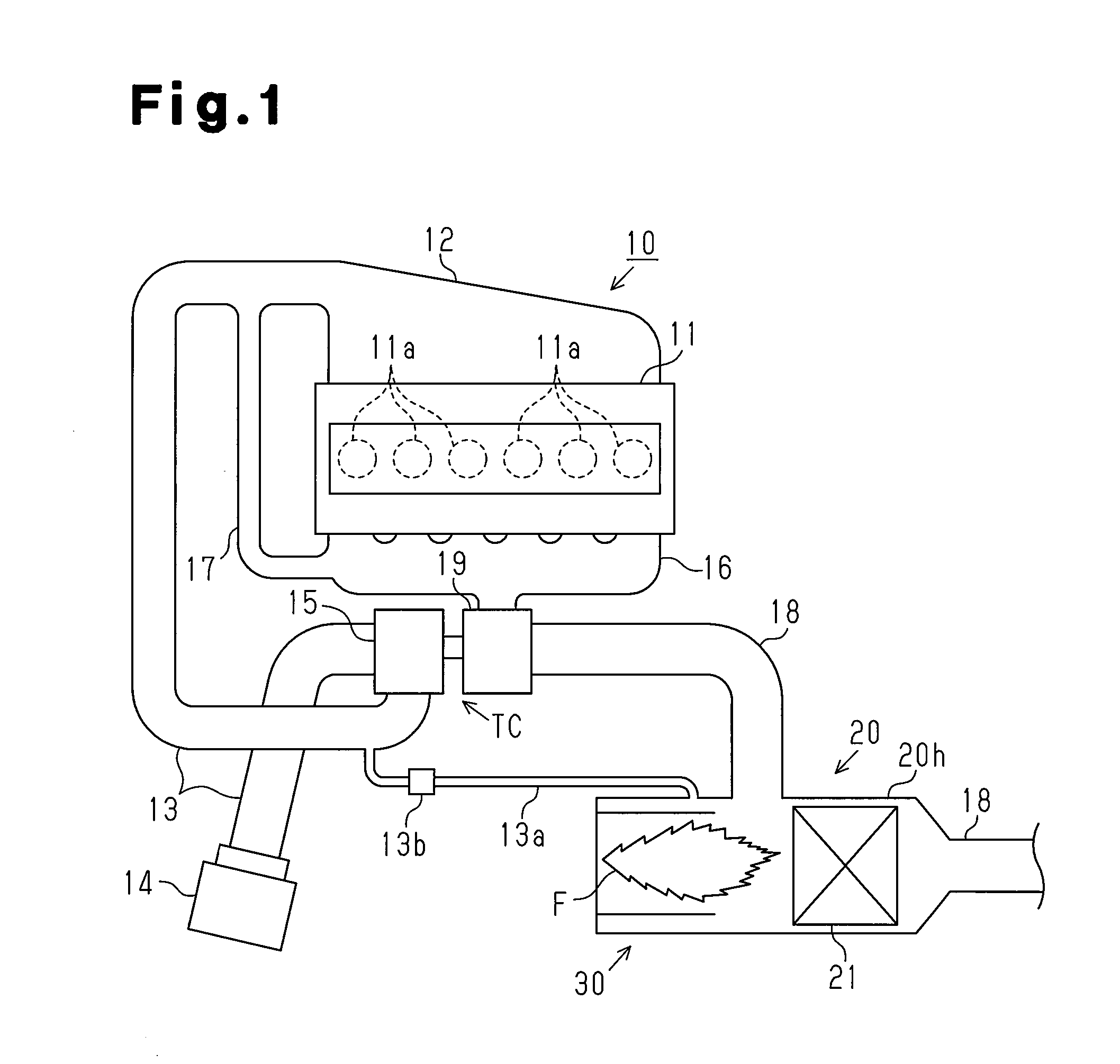

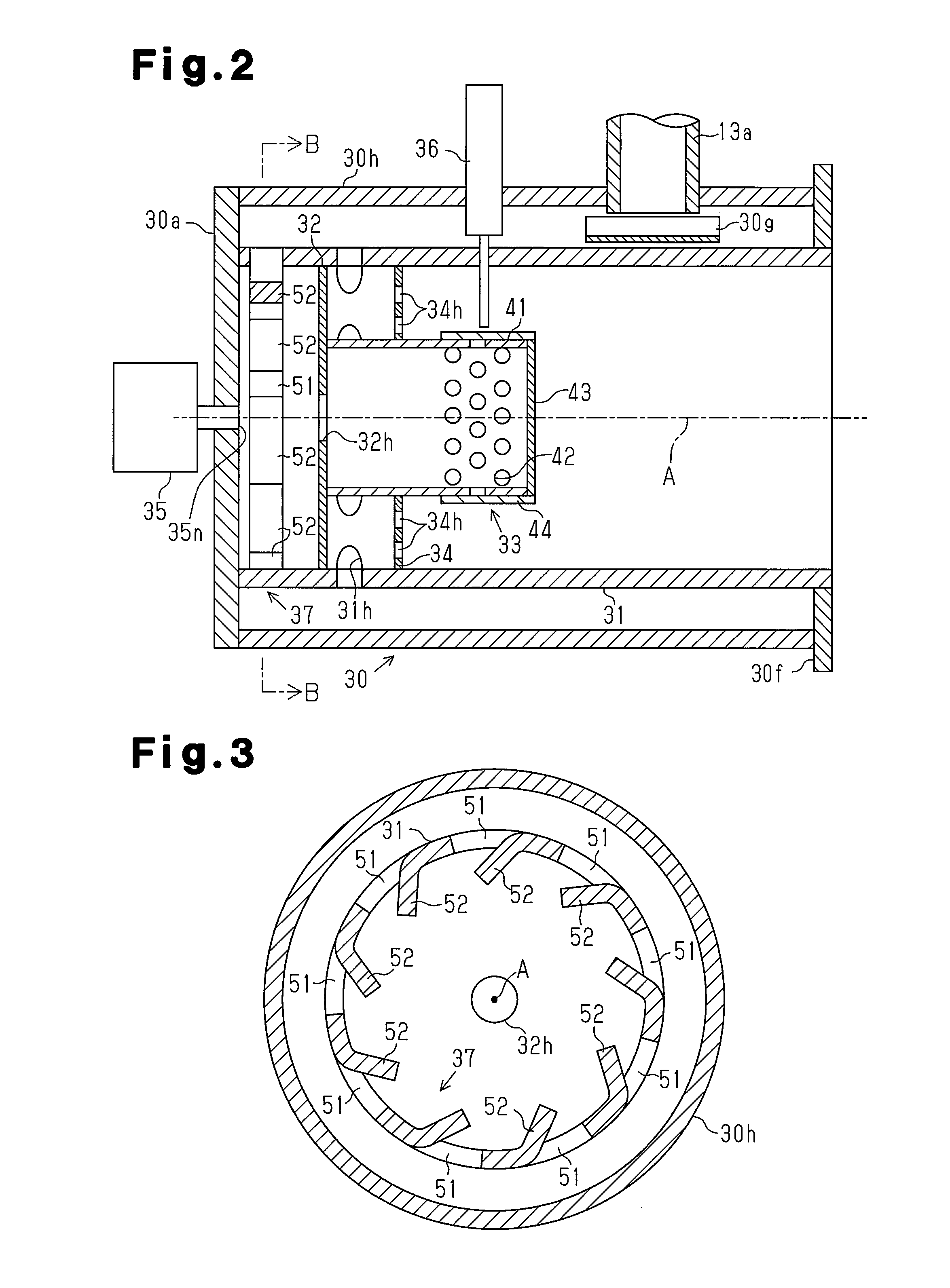

InactiveUS20150204223A1Improve mixing efficiencyReduce in quantityInternal combustion piston enginesFlow mixersCombustorEngineering

A burner includes a tubular inner tube portion and a tubular outer tube portion. The inner tube portion mixes fuel with air. The outer tube portion surrounds the inner tube portion. A peripheral wall of the inner tube portion has a gaseous mixture outflow hole. The gaseous mixture outflow hole causes a clearance between an inner peripheral surface of the outer tube portion and an outer peripheral surface of the inner tube portion to communicate with an interior of the inner tube portion. A peripheral wall of the outer tube portion has an air supplying hole. The air supplying hole further supplies air to the clearance.

Owner:HINO MOTORS LTD

Fuel additive and preparation method thereof

The invention discloses a fuel additive. The fuel additive is prepared from the following raw materials in parts by weight: 50 to 80 parts of tourmaline nanometer powder, 2 to 5 parts of graphite nanometer powder, 5 to 10 parts of magnesium powder, 30 to 50 parts of diisopropyl ether, 10 to 20 parts of biological oil, 5 to 10 parts of dispersant, 5 to 30 parts of water and 0.1 to 0.2 part of ferrocene. The preparation method of the fuel additive comprises the step of uniformly mixing all of the raw materials at normal temperature and pressure. By using the fuel additive, the fuel quality can be improved, fuel is promoted to fully burn, the burning efficiency is improved, and the fuel is saved; the atomization quality of the fuel can be increased, so that the fuel fully burns, the emission of noxious gas is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:丘濠玮 +2

Fuel additive and preparation method thereof

The invention discloses a fuel additive. The fuel additive is prepared from the following raw materials in parts by weight: 50 to 80 parts of tourmaline nanometer powder, 10 to 20 parts of alcohol, 30 to 50 parts of diisopropyl ether, 10 to 20 parts of biological oil, 5 to 10 parts of antioxidant, 5 to 10 parts of dispersant and 5 to 30 parts of water. The preparation method of the fuel additive comprises the step of uniformly mixing all of the raw materials at normal temperature and pressure. By using the fuel additive, the fuel quality can be improved, fuel is promoted to fully burn, the burning efficiency is improved, and the fuel is saved; the atomization quality of the fuel can be increased, so that the fuel fully burns, the emission of noxious gas is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:丘濠玮

Rotary engine

ActiveUS20060065233A1Improve sealingImprove fuel combustion efficiencyInternal combustion piston enginesEngine of arcuate-engagement typeCombustionRotary engine

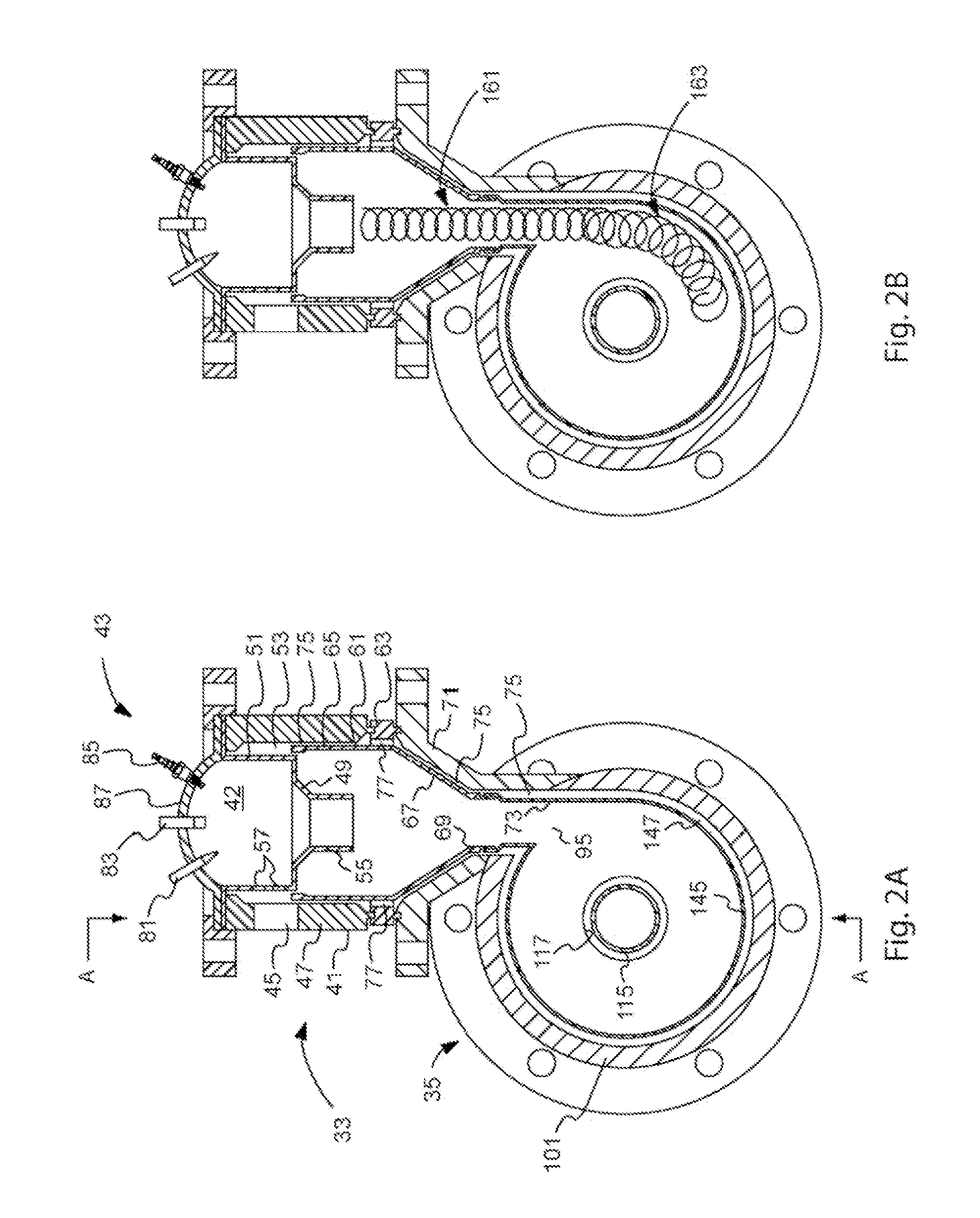

Disclosed is a rotary engine which can improve sealing performance between a cylinder chamber and a rotor, achieve an enhancement in the efficiency of fuel combustion and engine output, prevent waste of fuel and air pollution due to the discharge of uncombusted gas, and achieve a further enhancement in the efficiency of fuel combustion and engine output by supercharging the uncombusted gas into the cylinder chamber in which an intake stroke is implemented. The rotary engine comprises a cylinder body having the cylinder chamber, an intake port, an exhaust port, and a spark plug, and a rotor which is received in the cylinder chamber to eccentrically rotate while coming into contact at seal faces thereof with an inner circumferential contact wall of the cylinder chamber to thereby implement intake, compression, expansion, and exhaust strokes. The rotor has an elliptical outer contour, and the inner circumferential contact wall of the cylinder chamber coincides with a specific curve, which is described by opposite apexes of the elliptical rotor in a direction of a major axis, when the rotor eccentrically rotates. The intake port and exhaust port are provided with opening / closing valves, respectively. The rotary engine further comprises supercharging means to introduce leaked uncombusted gas into the cylinder chamber.

Owner:CHAE ON SOON

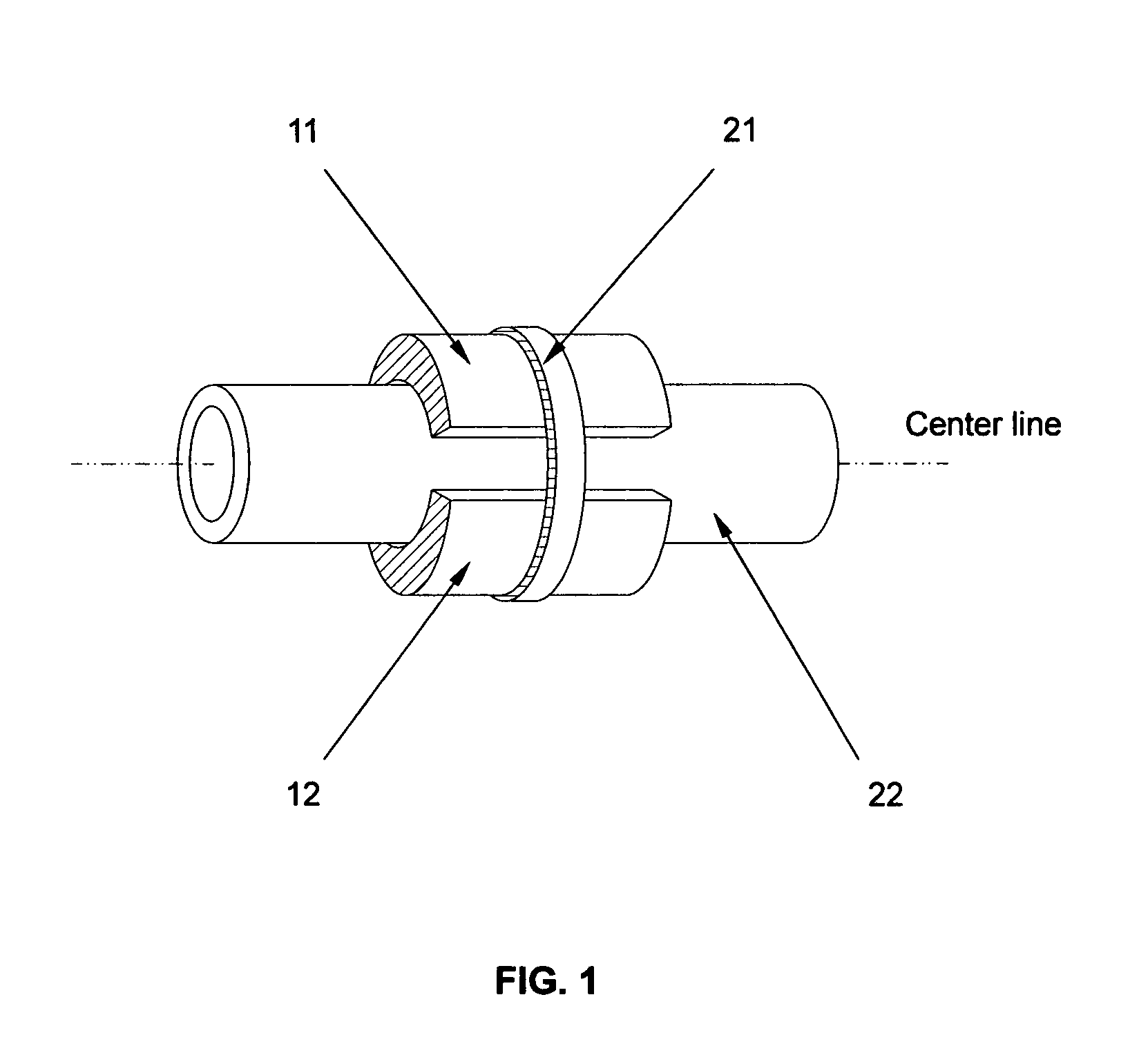

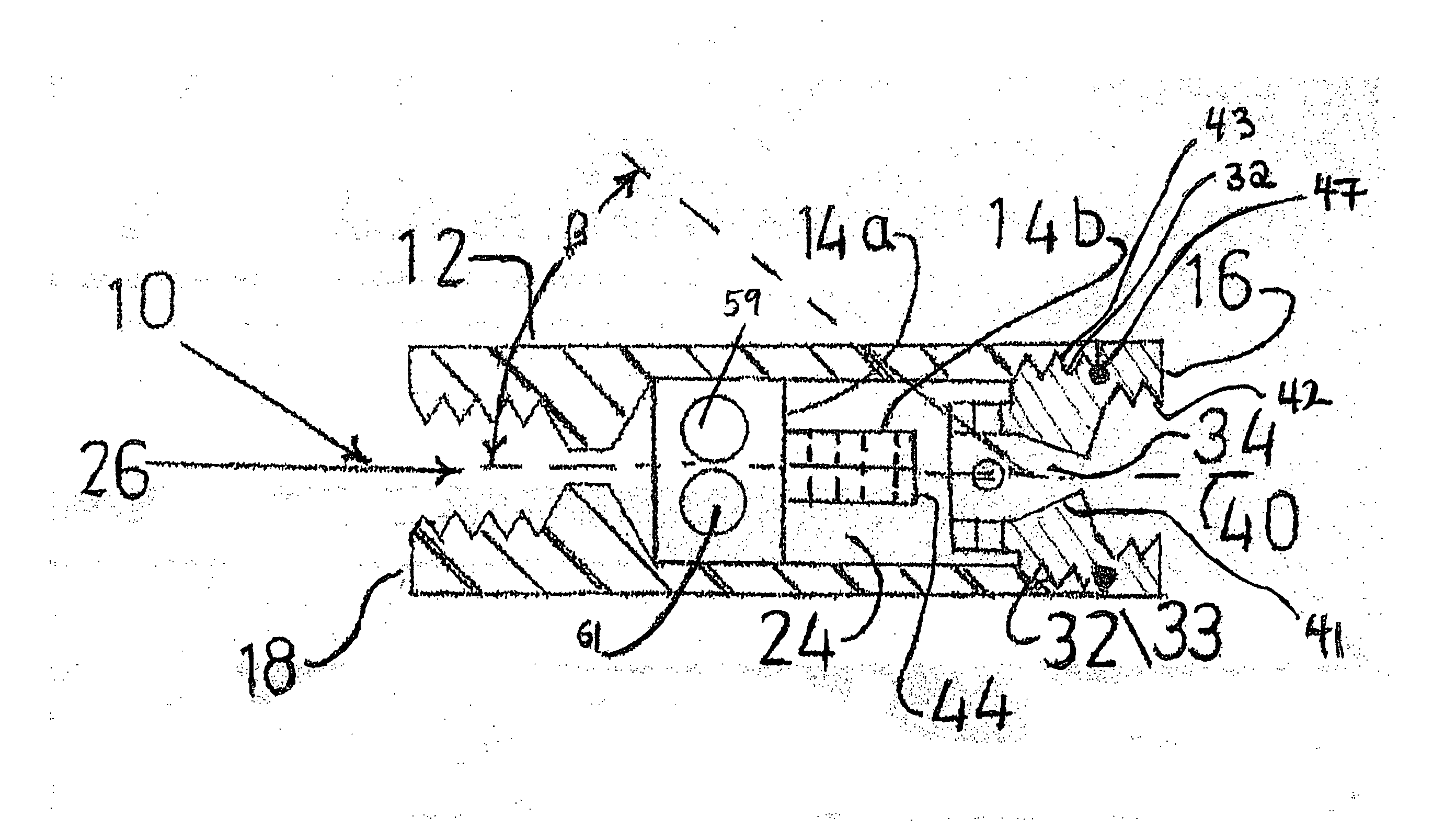

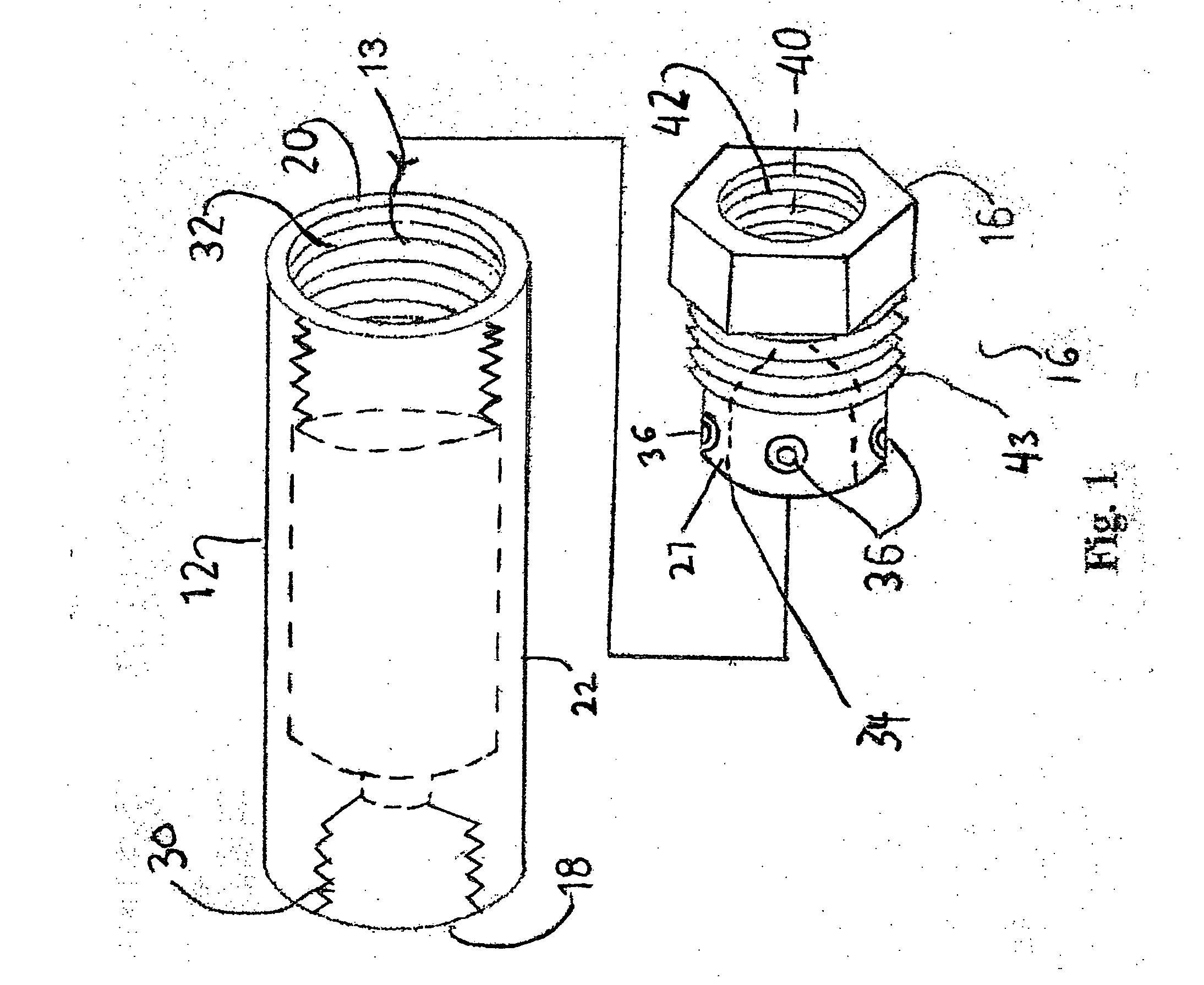

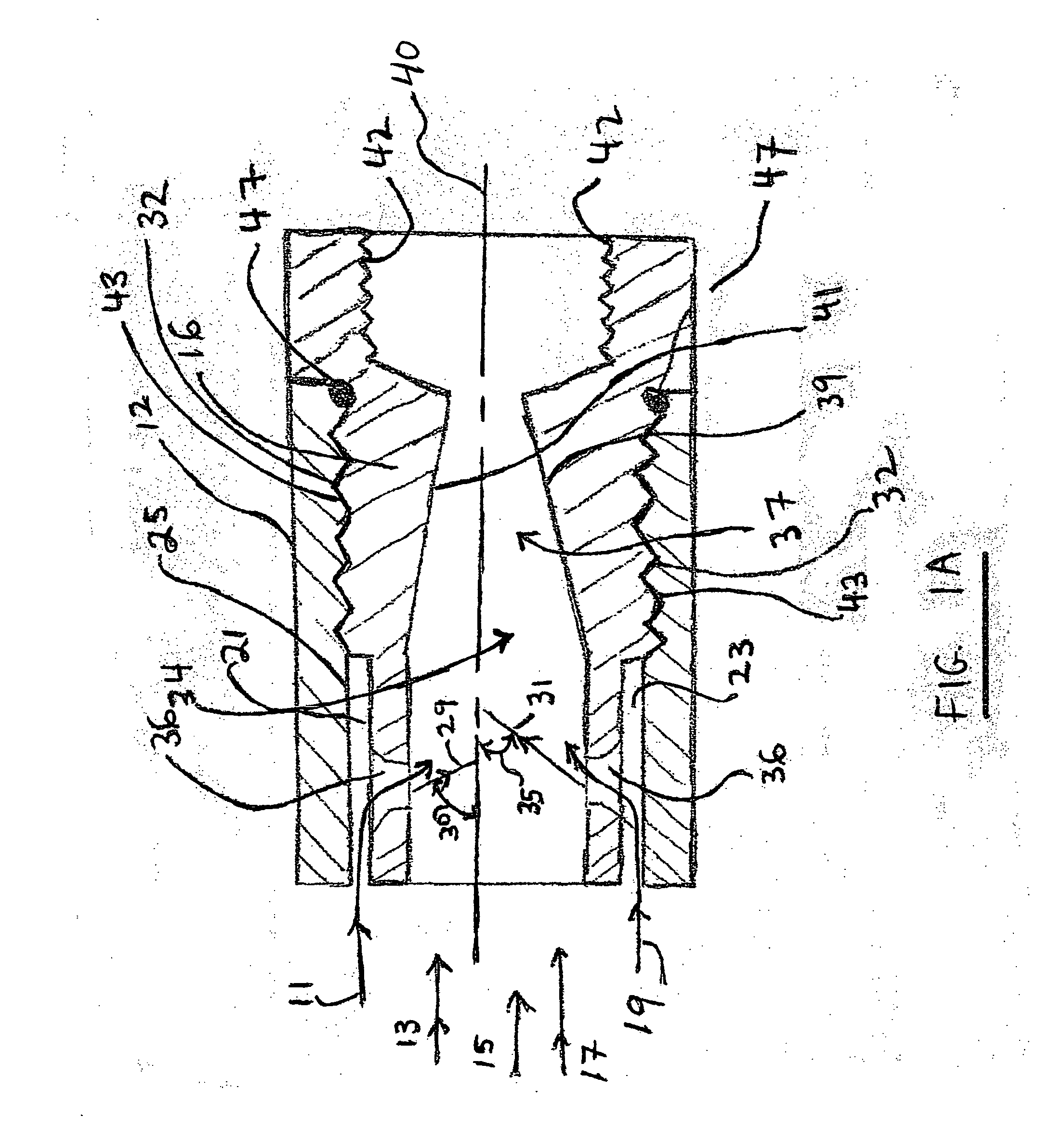

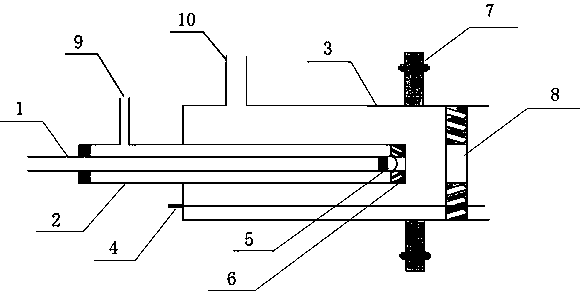

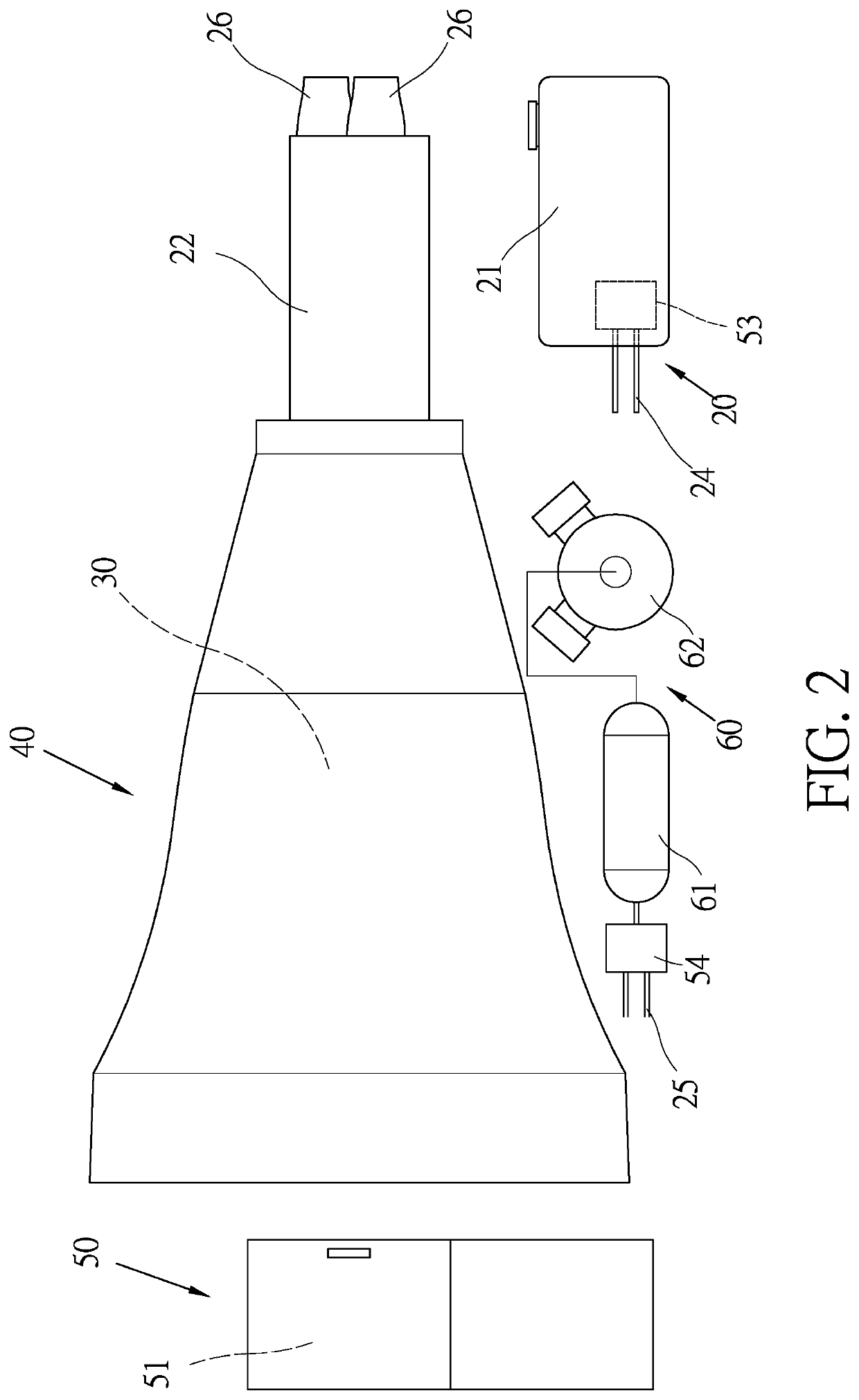

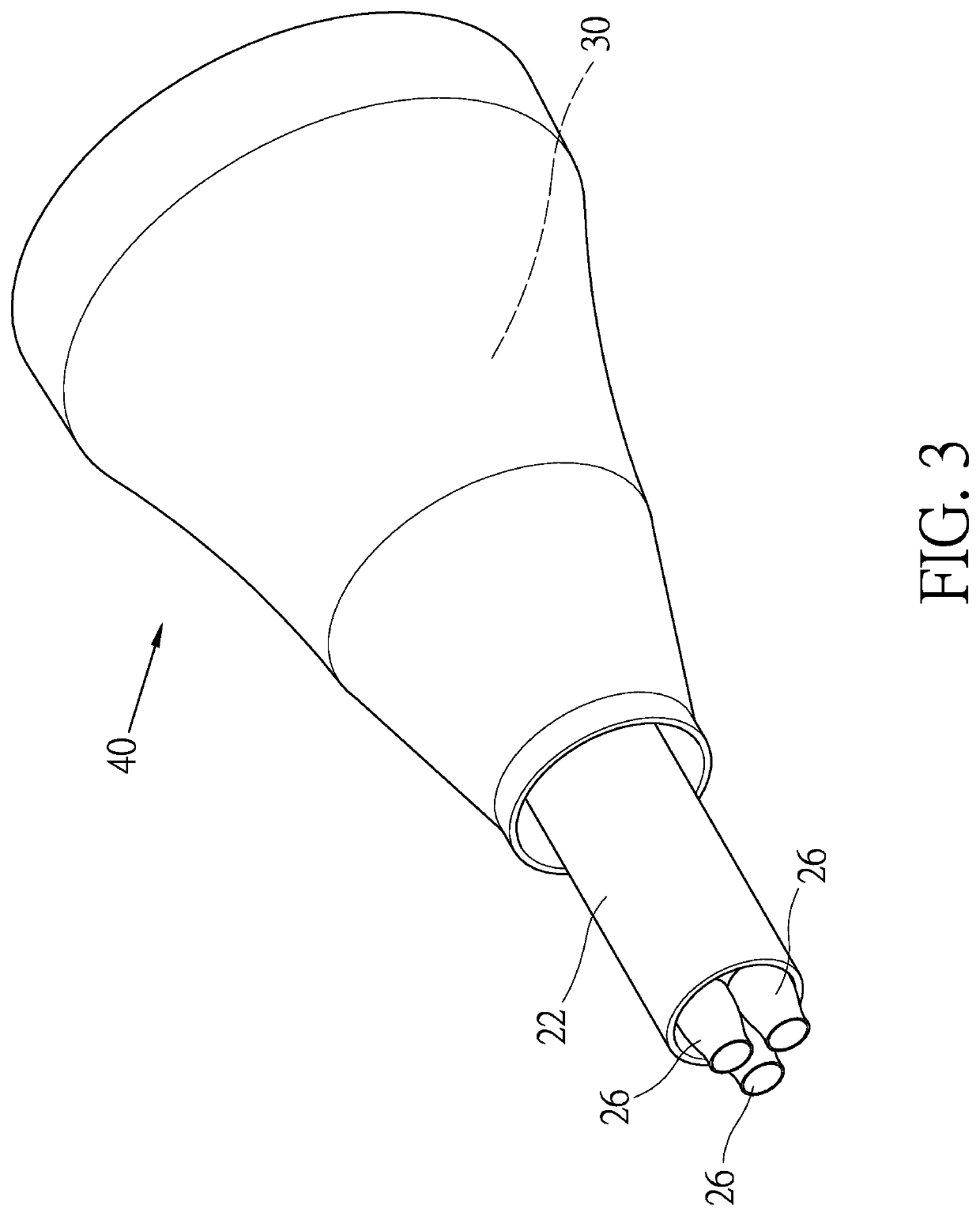

Efficient dispersion device

InactiveUS20070079799A1Improve fuel combustion efficiencyReduce pollutant emissionsCombustion-air/fuel-air treatmentCombustion enginesEngineeringMechanical engineering

A fuel conditioning device for increasing fuel burning efficiency and reducing pollutant emissions. The device contains: a hollow housing with an interior wall with a first surface roughness, a flow diverter disposed in an intermediate portion of such hollow housing, and a compound venturi disposed in said hollow housing downstream of such flow diverter. The compound venturi contains a multiplicity of radial venturis and a descending conical section disposed downstream from said radial venturis. The descending conical section is defined by a wall whose interior surface has a second surface roughness that is no greater than 0.1 times as great as said first surface roughness.

Owner:ATLANTA ATTACHMENT

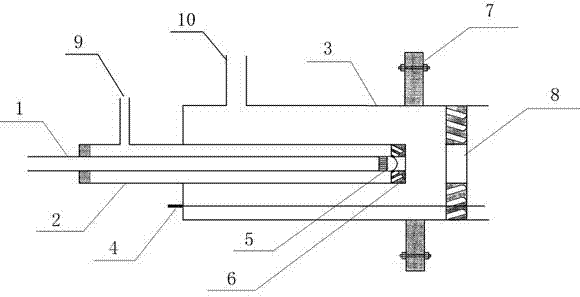

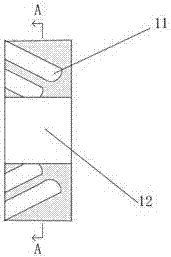

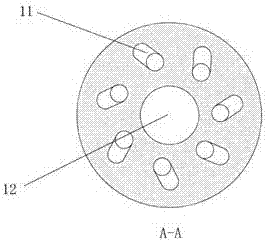

Industrial furnace high-efficiency atomizer burner based on high-viscosity biomass fuel

ActiveCN107477574AOvercome sinteringOvercome the problem of carbon depositionBurnersHigh pressure oxygenEngineering

The invention relates to an industrial furnace high-efficiency atomizer burner based on high-viscosity biomass fuel, and belongs to the technical field of energy and environments. In the industrial furnace high-efficiency atomizer burner, a fuel channel, a high-pressure nitrogen channel and a high-pressure oxygen channel are three layers of cavities which are concentric from inside to outside, one end of the fuel channel is provided with a fuel inlet, the other end of the fuel channel is provided with a fuel nozzle, the top of one end of the high-pressure nitrogen channel is provided with a nitrogen inlet, and the end part of the other end of the high-pressure nitrogen channel is provided with a first-grade nitrogen atomizing converging-diverging plate; and the top of one end of the high-pressure oxygen channel is provided with an oxygen inlet, the other end of the high-pressure oxygen channel is provided with a second-grade oxygen atomizing converging-diverging plate, a mounting flange connected with an industrial furnace is arranged on the high-pressure oxygen channel, and the high-pressure oxygen channel is provided with an electronic spark electrode penetrating through the high-pressure oxygen channel. According to the industrial furnace high-efficiency atomizer burner based on the high-viscosity biomass fuel, waste nitrogen after oxygen generating is utilized to serve as an auxiliary atomizing gas medium, after first-grade atomizing is conducted by utilizing the nitrogen, a non-burning isolation area which is about 5 cm is formed, it is ensured that a fuel pocket cannot burn at an outlet of the nozzle, and therefore the problems that nozzle outlet sintering and carbon depositing are solved.

Owner:KUNMING UNIV OF SCI & TECH

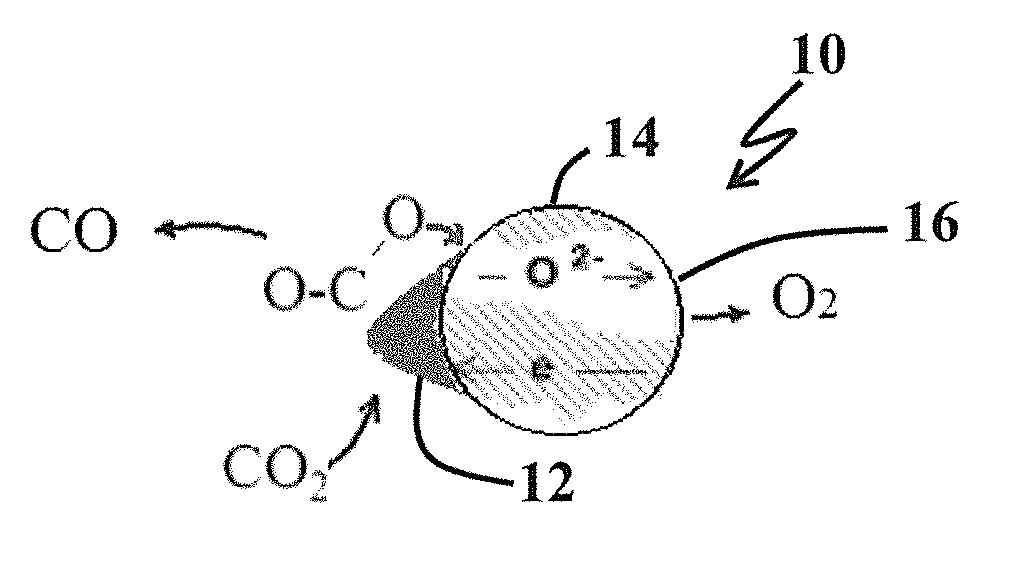

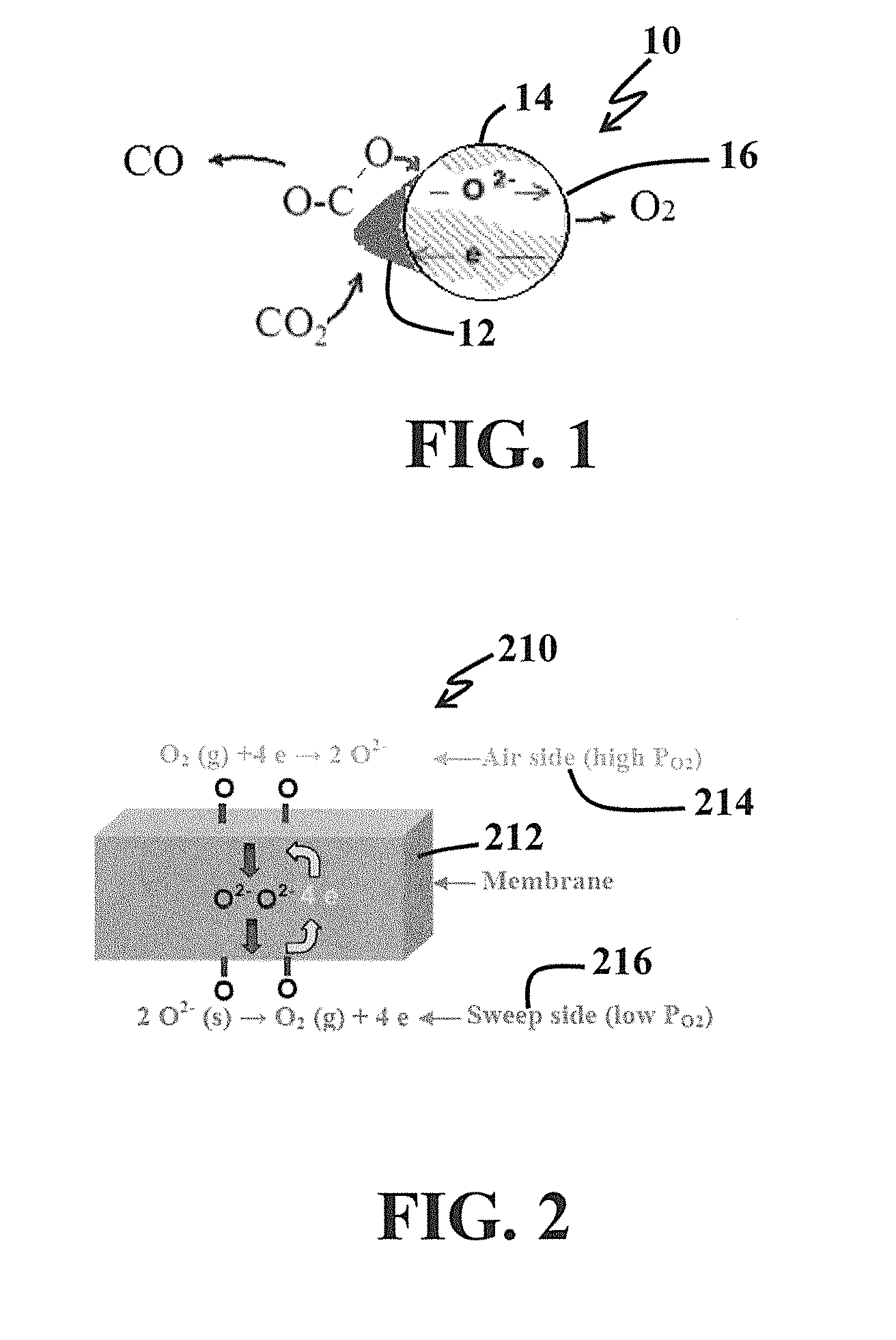

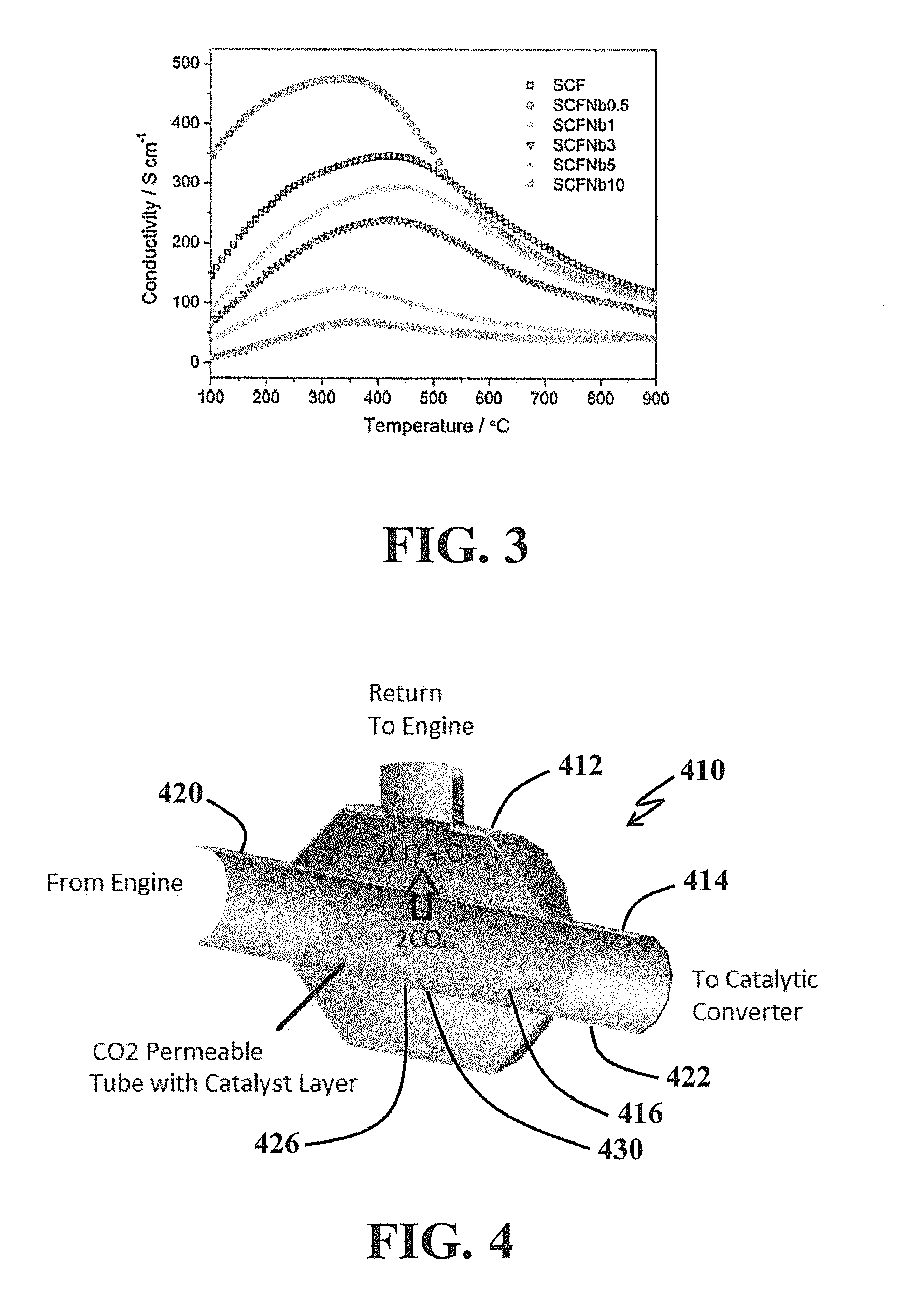

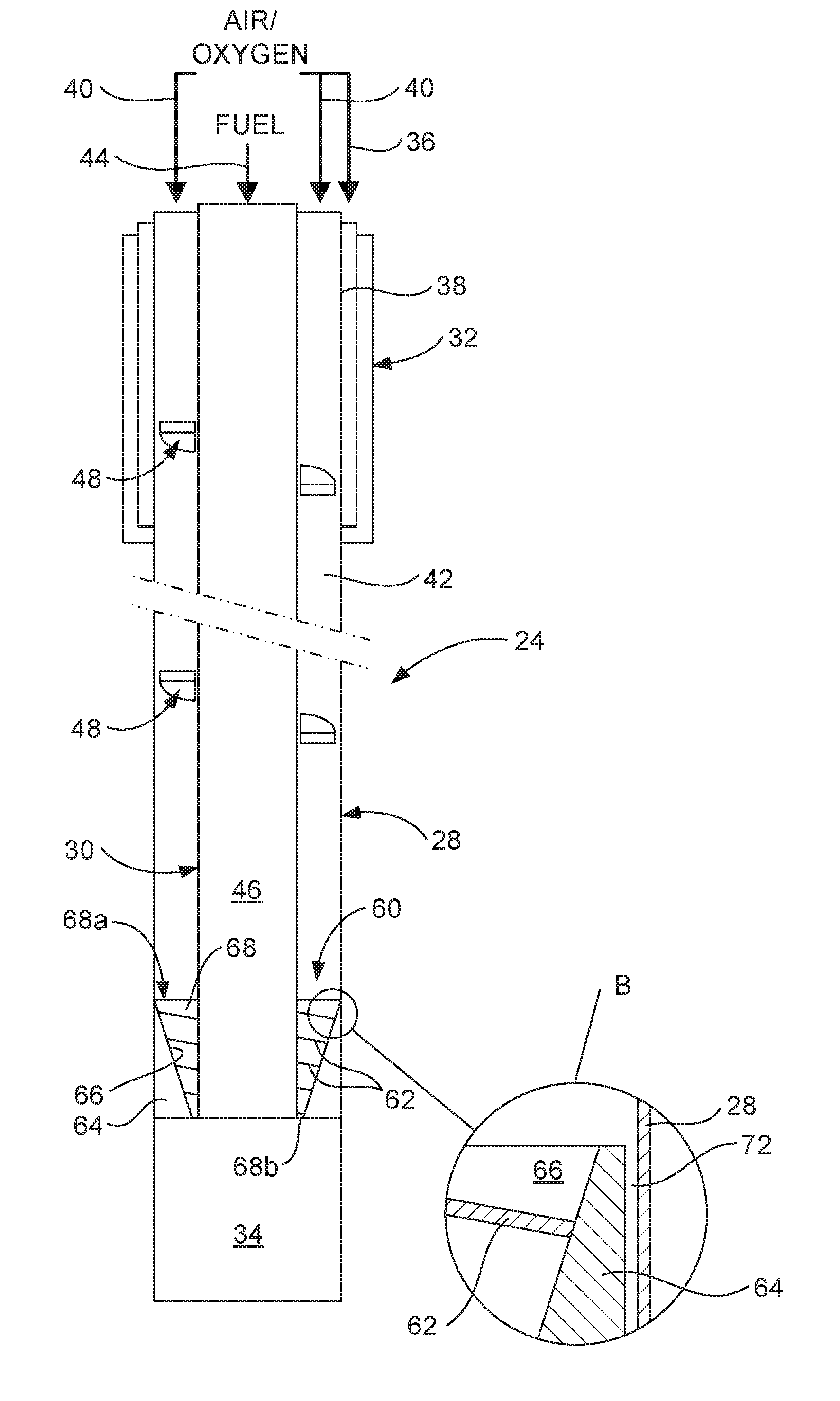

Carbon dioxide decomposition

ActiveUS9364791B1Improve fuel combustion efficiencyIncrease oxygen contentProductsOxygen/ozone/oxide/hydroxidePorous mediumDecomposition

Carbon monoxide and oxygen gas can be produced from carbon dioxide by introducing a supply of CO2-containing gas to a CO2 permeable porous media. The CO2 permeates through the media to separate the CO2 from other species in the CO2-containing gas supply. An oxygen-deficient ferrite material, disposed on a surface of the CO2 permeable porous media, contacts with the separated CO2 at decomposition reaction conditions to produce CO and O2. Corresponding devices for treating exhaust gases from a CO2 exhaust gas-producing apparatus are also provided.

Owner:GAS TECH INST

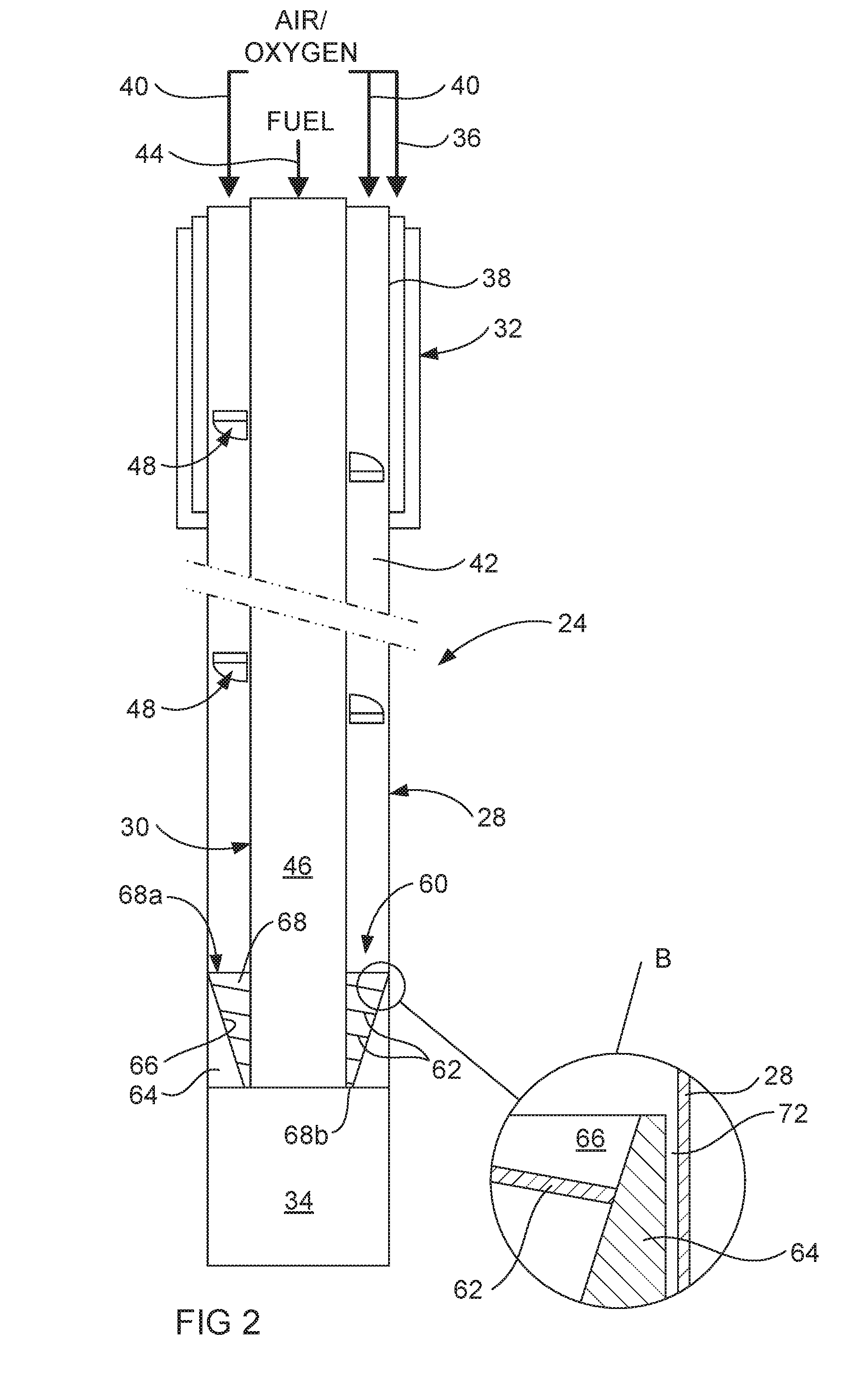

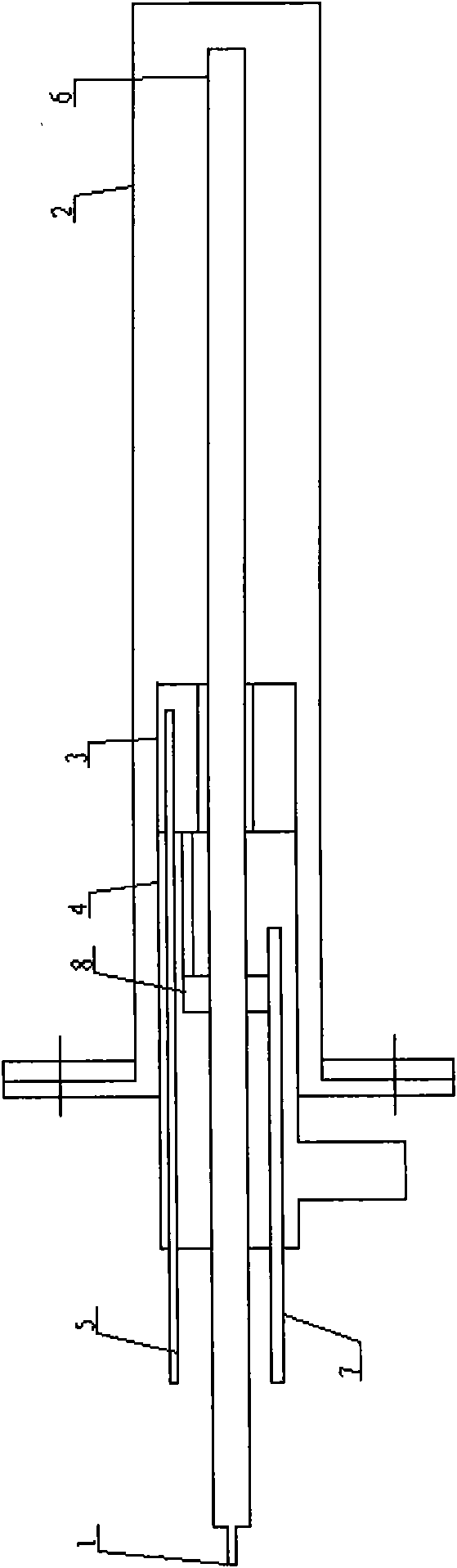

Top submerged injection lance for enhanced submerged combustion

ActiveUS20160265848A1Strong combustionEasy maintenanceCharge manipulationManufacturing convertersCombustionEngineering

A lance for top submerged lancing injection in a pyro-metallurgical operation, wherein the lance has at least two substantially concentric pipes, with an annular passage for oxygen-containing gas defined between an outermost one of the pipes and a next adjacent pipe and a further passage for fuel defined within an innermost one of the pipes; the outermost pipe has a lower part of its length, from a submergible lower outlet end of the lance, by which the outermost pipe extends beyond an outlet end of the or each other pipe to define between the outlet end of the outermost pipe and the outlet end of the or each other pipe a chamber with which the passage for oxygen-containing gas communicates; and the lance further includes a defined gas flow-modifying device that is disposed in a lower end section of the passage for oxygen-containing gas.

Owner:METSO OUTOTEC (FINLAND) OY

Preparation method of fuel oil activator

The invention discloses a preparation method of a fuel oil activator. According to the preparation method, rare earth waste is doped with nanosized TiO2, and the rare earth waste-doped nanosized TiO2 is compounded with tourmaline nano-powder and spinel ferrite so as to prepare a solid mixture; and then, water, a dispersant and a surfactant are added into the solid mixture to form solid-liquid mixed slurry. Mass ratio of rare earth waste to nanosized TiO2 to tourmaline nano-powder to spinel ferrite is 2-5: 1-3: 60-80: 5-9. Addition amount of water is 10-90% of the amount of the mixed slurry. Addition amount of the dispersant is 2-10% of the amount of the mixed slurry. Addition amount of the surfactant is 5-28% of the amount of the mixed slurry. The prepared fuel oil activator can improve oil quality, promote sufficient burning of fuel oil, raise burning efficiency and save fuel oil. By the use of the fuel oil activator, atomization quality can be raised, and fuel oil can be sufficiently burnt so as to reduce emission of harmful gases. Thus, the purpose of energy conservation and emission reduction is achieved.

Owner:广西运通燃料科技有限公司

Fuel oil activator and preparation method thereof

The invention discloses a fuel oil activator. According to the invention, graphene is doped with nanosized TiO2, and the graphene-doped nanosized TiO2 is compounded with tourmaline nano-powder and spinel ferrite so as to prepare a solid mixture; and then, water, a dispersant and a surfactant are added into the solid mixture to form solid-liquid mixed slurry. Mass ratio of graphene to nanosized TiO2 to tourmaline nano-powder to spinel ferrite is 2-10: 1-3: 63-78: 6-8. Addition amount of water is 12-88% of the amount of the mixed slurry. Addition amount of the dispersant is 3-7% of the amount of the mixed slurry. Addition amount of the surfactant is 7-25% of the amount of the mixed slurry. The prepared fuel oil activator can improve oil quality, promote sufficient burning of fuel oil, raise burning efficiency and save fuel oil. By the use of the fuel oil activator, atomization quality can be raised, and fuel oil can be sufficiently burnt so as to reduce emission of harmful gases. Thus, the purpose of energy conservation and emission reduction is achieved.

Owner:丘濠玮 +2

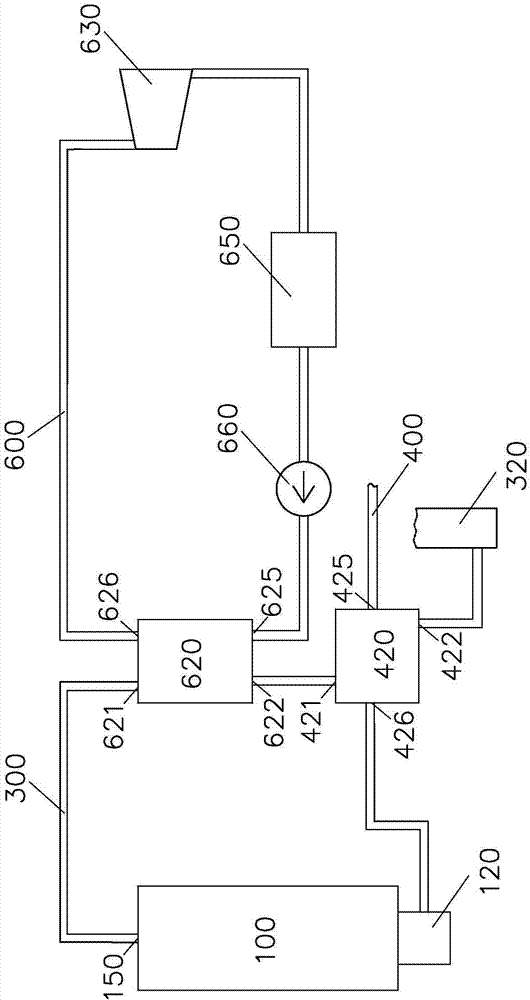

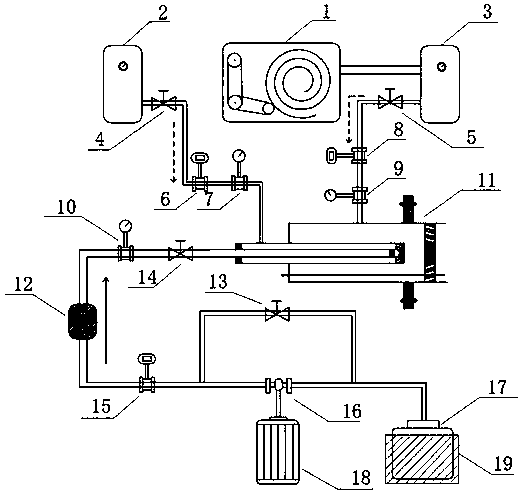

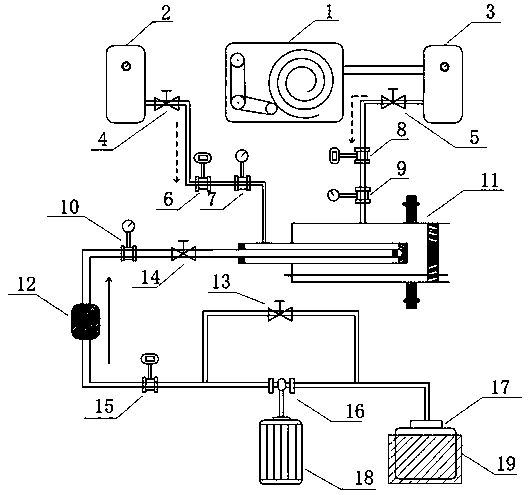

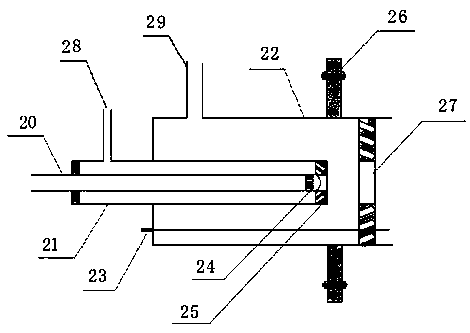

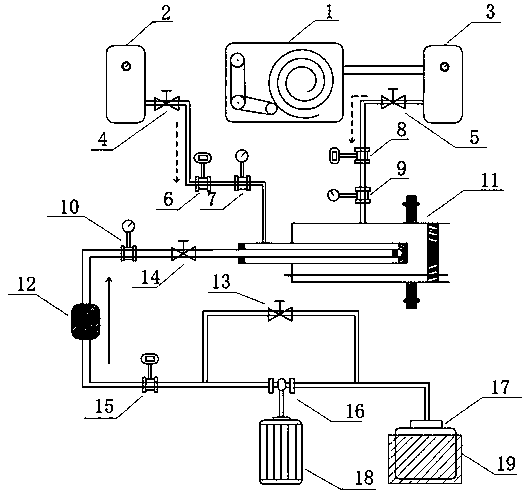

Heat-conducting oil boiler waste heat power generation system

InactiveCN104501198AImprove fuel combustion efficiencyImprove flue gas waste heat recovery rateCombustion processStorage heatersCombustionFlue gas

The invention discloses a heat-conducting oil boiler waste heat power generation system. The heat-conducting oil boiler waste heat power generation system comprises a furnace body, a spray nozzle, a flue gas pipe and an air pipe, wherein a furnace hearth for heating heat-conducting oil is arranged inside the furnace body; the spray nozzle is arranged in the end wall of one side of the furnace body and is used for spraying fuel and combustion air into the furnace hearth for combusting and releasing heat; the flue gas pipe is connected to the end wall of the other side of the furnace body and is used for discharging flue gas from a flue gas outlet of the furnace body to a chimney; the air pipe is connected to the spray nozzle and is used for conveying the combustion air to the spray nozzle; the heat-conducting oil boiler waste heat power generation system further comprises a water steam circulating power generation circuit; the water steam circulating power generation circuit comprises a steam generator arranged inside the flue gas pipe, and a steam turbine connected with the steam generator through a pipeline.

Owner:陈翔

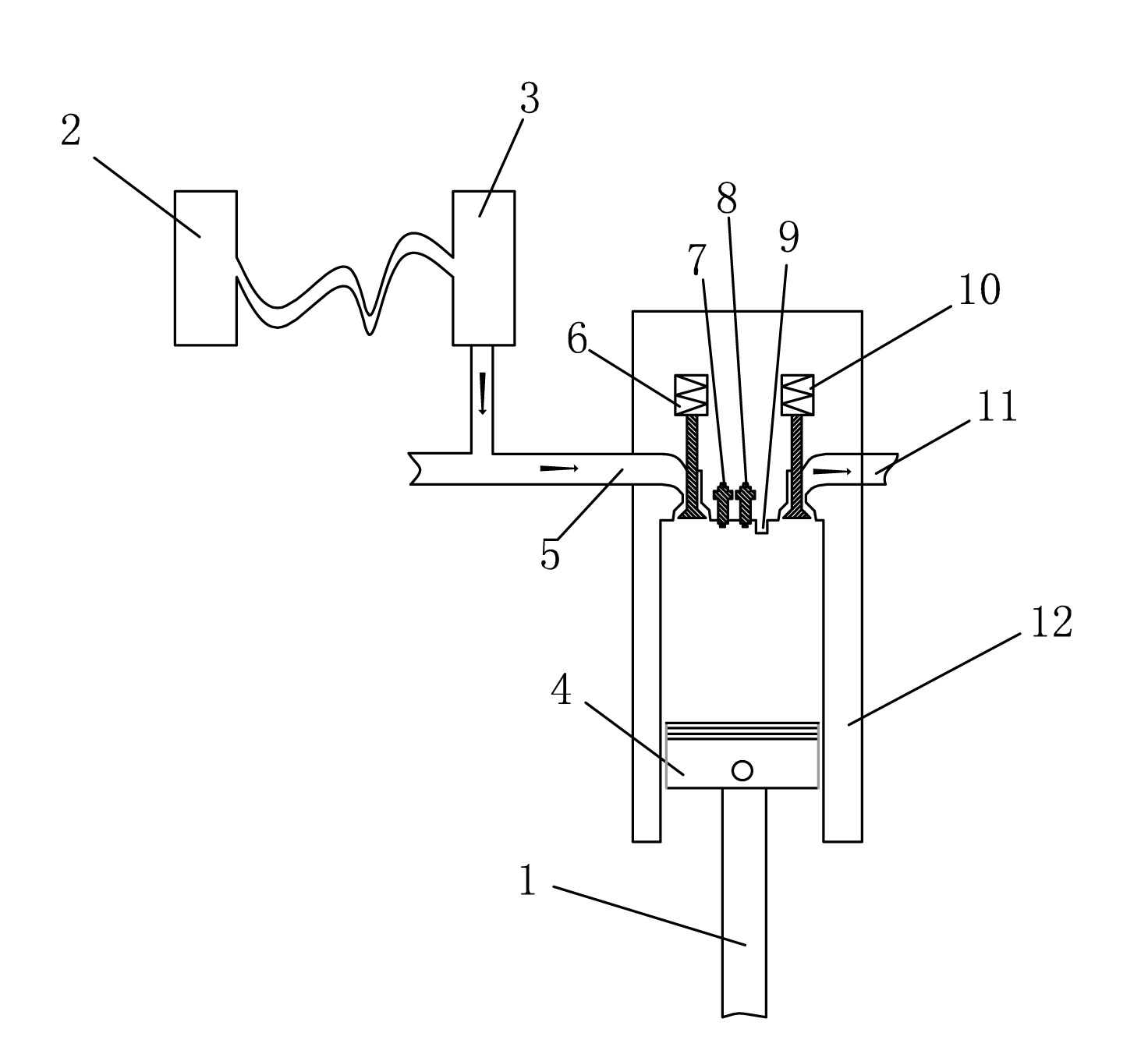

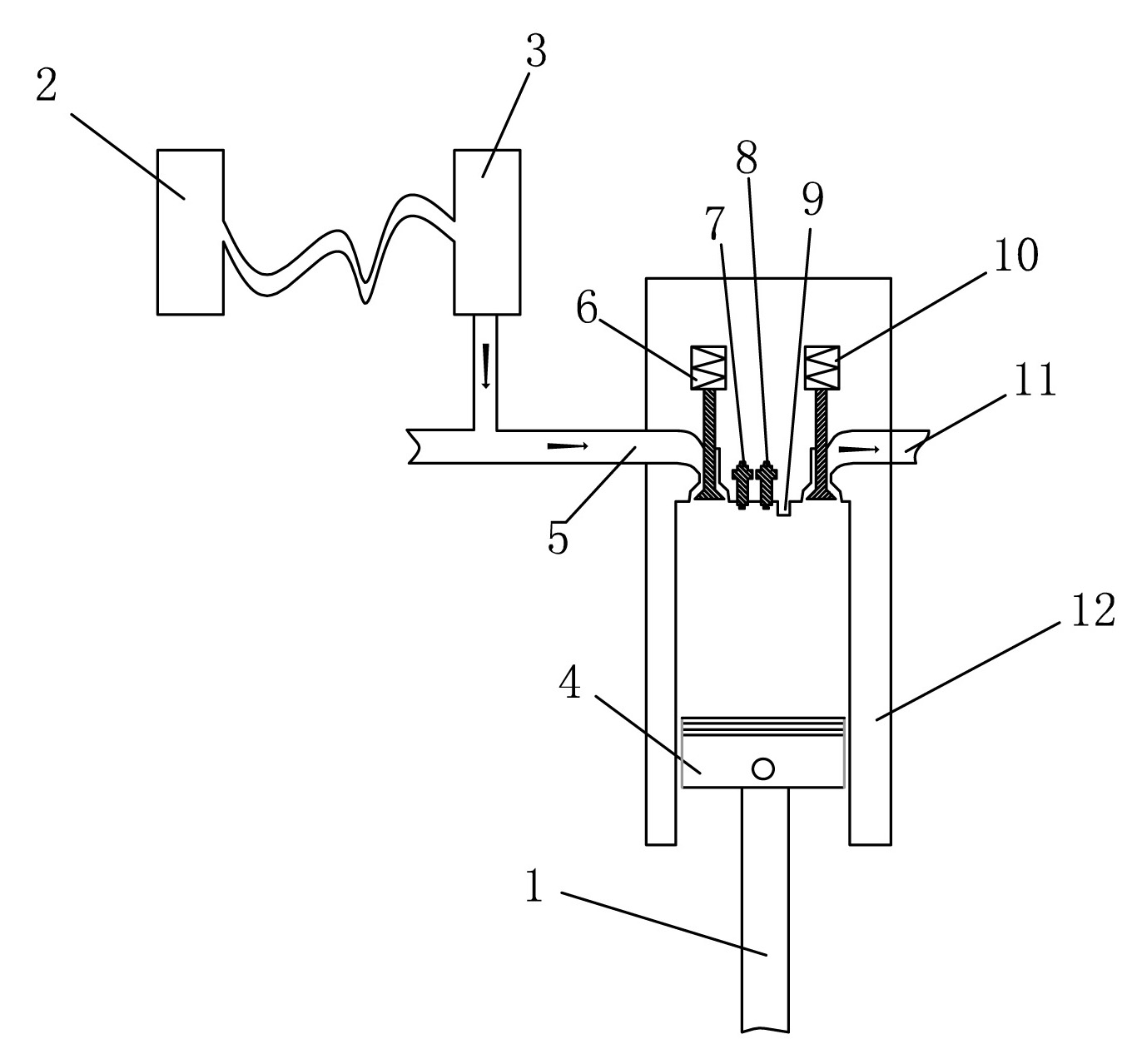

Six-stroke engine

InactiveCN102022188AImprove fuel combustion efficiencyIncrease output powerInternal combustion piston enginesPistonIn vehicle

The invention discloses a six-stroke engine comprising a piston cylinder which is positioned in an engine case. A piston connecting rod, a piston, an air inlet passage, a first electric control air valve, an oil nozzle, an igniter, an isolating wall, a second electric control air valve and an exhaust channel are arranged in the piston cylinder, wherein the piston is connected with the piston connecting rod; the air inlet passage, the first electric control air valve, the oil nozzle, the igniter, the second electric control air valve and the exhaust channel are controlled by a vehicle-mounted computer; and the air inlet passage is connected with an air compressor. The six-stroke engine has the advantages of energy saving, high utilization rate and large power output.

Owner:陈伟明

An electromagnetic vehicle nitrogen and oxygen separation device

InactiveCN104727991BControl oxygen concentrationControllable oxygen concentrationInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerNitrogen

The invention discloses an electromagnetic type automobile nitrogen and oxygen separation device. The electromagnetic type automobile nitrogen and oxygen separation device comprises a turbocharger and a nitrogen and oxygen separator. A magnetic field generating device is arranged in the nitrogen and oxygen separator, the magnetic field generating device generates a gradient magnetic field so as to intercept oxygen in the air which flows past the gradient magnetic field, nitrogen and oxygen are separated, and the nitrogen and oxygen separator enables separated oxygen-enriched air to be provided for an automobile engine and enables the oxygen-enriched air to be exhausted. The particle movement law in the electromagnetism theory is used by the device, the characteristic that the magnetic field intensity of an electromagnet is far higher than that of a permanent magnet is fully utilized, and the defects that an existing oxygen production device is large in size and cannot be arranged easily and the oxygen concentration increment is low when the permanent magnet is adopted are greatly overcome. The electromagnetic type automobile nitrogen and oxygen separation device is simple in structure, low in manufacturing cost and processing difficulty, simple in technology, easy to manufacture, capable of achieving mass production easily and capable of achieving the vehicle-mounted purpose easily.

Owner:JILIN UNIV

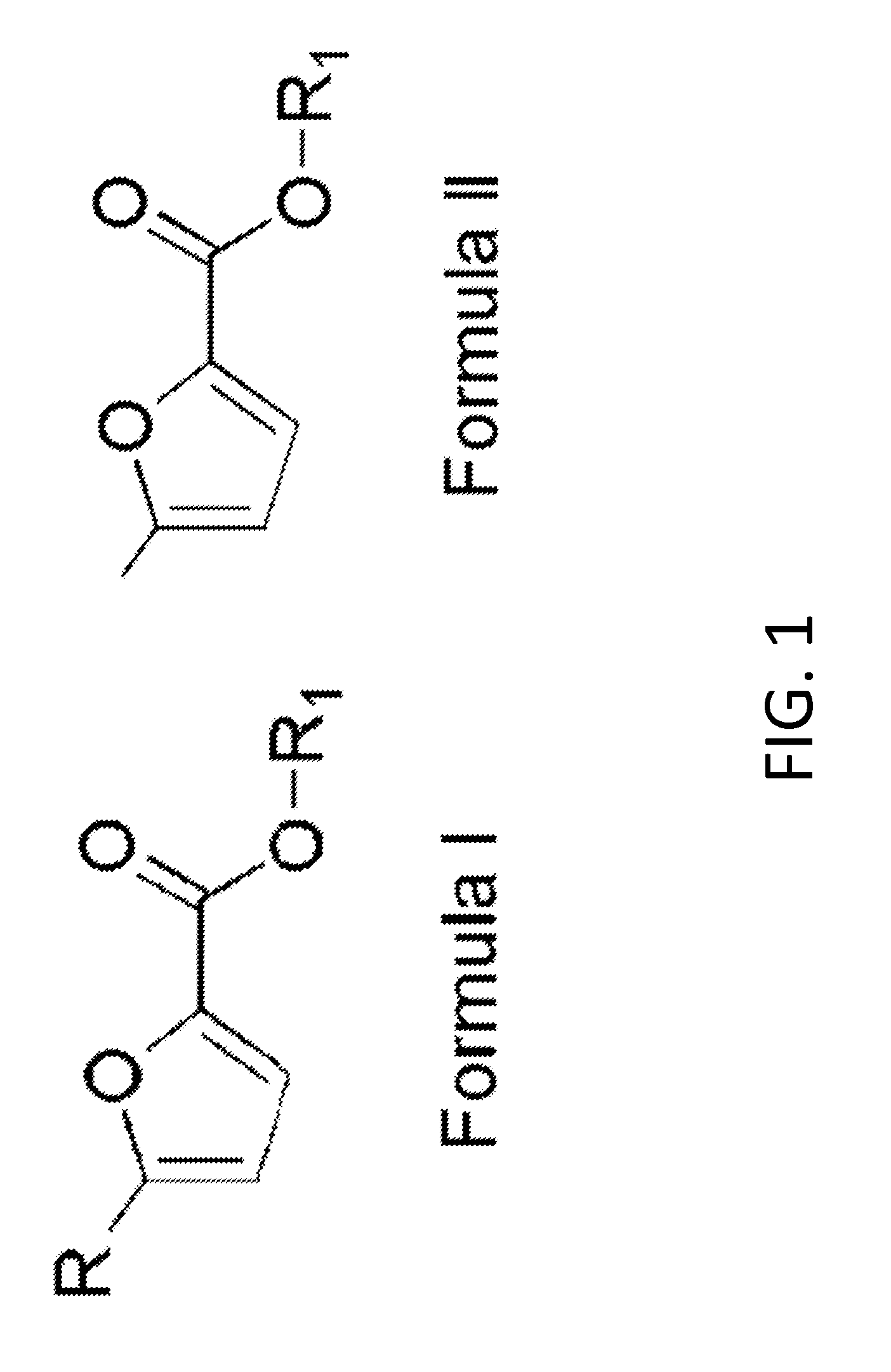

Fuels and fuel additives comprising ester derivatives of 5-methyl-2-furoic acid

InactiveUS20150047251A1Improve fuel combustion efficiencyReduce pressureLiquid carbonaceous fuelsFuel additivesCombustionGasoline

Ester derivatives of furoic acids and in particular of 5-methyl-2-furoic acid can be used as fuel as fuel additives. Such esters can be used to displace crude oil products such as gasoline, diesel, jet fuel, etc. As fuel additives, such esters had been shown to improve the performance of spark ignition internal combustion engines, compression ignition internal combustion engines. In addition, testing shows indications that said molecule will improve the performance of air breathing engines as well.

Owner:XF TECH INC

Apparatus for automatic control of exhaust pressure of an internal combustion engine

InactiveUS20110126532A1Increase exhaust pressureReduce exhaustExhaust apparatusSilencing apparatusRotational axisCombustion

The present invention relates to an apparatus for automatic control of the exhaust pressure of an internal combustion engine. The apparatus includes: a body having an inlet and an outlet for exhaust gas; a pressure control plate, which is a thin plate placed between the inlet and outlet inside the body, designed to rotate along a vertical direction with respect to the ground, within a particular range of angles; a rotational shaft, which is a bar coupled to one side of the pressure control plate that allows it to have a substantial vertical-rotation movement; first and second side elements, attached on both sides of the body's exterior and affixed to the protruding part of the rotational shaft extending outward through the holes on both sides; a controlling pendulum coupled to the first side element for setting the initial gradient of the pressure control plate; and a pendulum blade, coupled to a lower portion of the controlling pendulum, which moves in vertical rotation within a particular range of angles by means of air resistance generated during the operation of a vehicle and which, interlocked with the vertical rotational movement, causes the pressure control plate to move in vertical rotation also.

Owner:JANG KEUN JIN

Burner

InactiveUS9765662B2Improve fuel combustion efficiencyImprove mixing efficiencyBurnersInternal combustion piston enginesCombustorEngineering

Owner:HINO MOTORS LTD

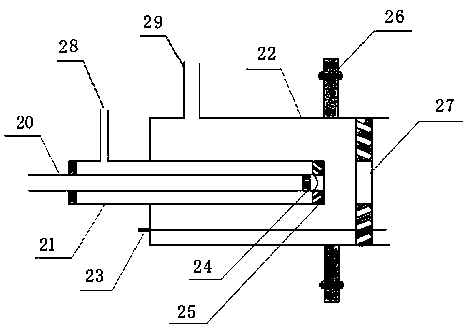

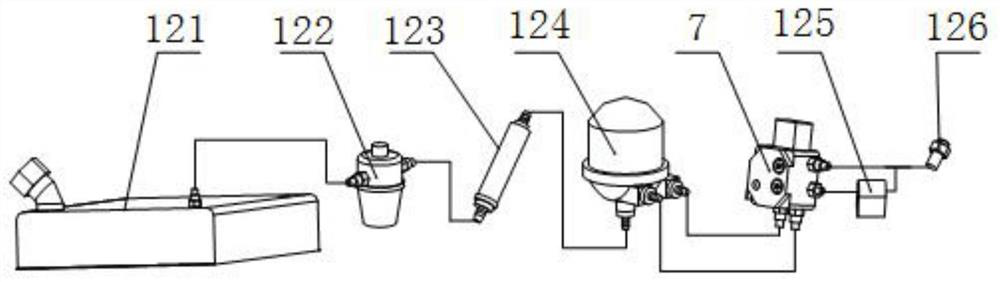

Industrial furnace efficient atomization combustion system and method based on high-viscosity biomass fuel oil

ActiveCN107620957AOvercome sinteringOvercome the problem of carbon depositionBurnersFuel oilNitric oxide

The invention relates to an industrial furnace efficient atomization combustion system and method based on high-viscosity biomass fuel oil, and belongs to the technical field of energy and environment. Waste nitrogen obtained after oxygen making is utilized to serve as an auxiliary atomized gaseous medium, after first-grade atomization is conducted by utilizing the nitrogen, a non-combustion isolation area which is about 5 cm is formed, and the problems of sintering and carbon depositing of an outlet of a nozzle are solved. Meanwhile, because the leading-in amount of the atomized nitrogen is adjusted according to the actual production needs, it is ensured that the yield of nitric oxide is within an artificially controllable and adjustable range, and it is ensured that flue gas emission canreach the standard. According to the industrial furnace efficient atomization combustion system and method based on the high-viscosity biomass fuel oil, the biomass fuel oil can be efficiently applied to industrial furnace combustion, the waste nitrogen obtained after oxygen making can further be reused, the effects of energy conservation, emission reduction and environmental protection are achieved, and meanwhile the problems of sintering and carbon depositing of the nozzle are further solved.

Owner:KUNMING UNIV OF SCI & TECH

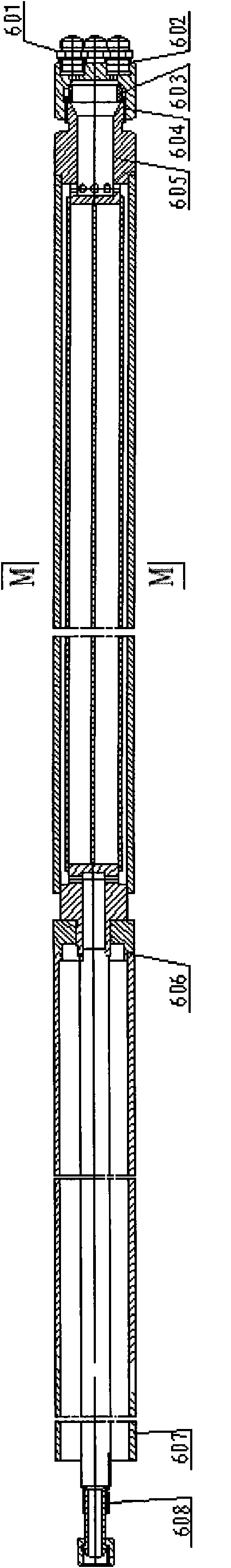

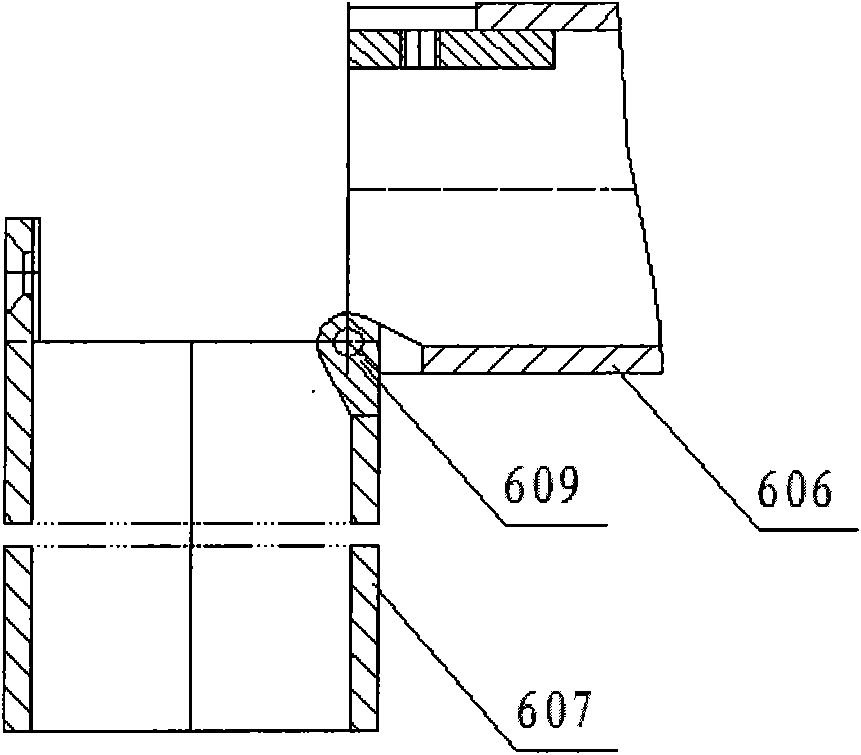

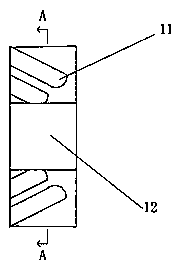

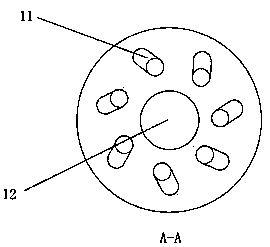

Gasification oil gun

The invention relates to a gasification oil gun, which comprises an oil gun head and a gun rod. The gun rod of the gasification oil gun (6) comprises an inner tube (611) and an outer tube (612), the outer tube (612) is sleeved outside the inner tube (611), and the inner tube (611) and the outer tube (612) are supported by a support component. By adopting the gasification oil gun, the further gasification and combustion of oil can be realized, the higher oil combustion efficiency can be achieved, the energy can be saved, and the environment can be protected.

Owner:YANTAI LONGYUAN POWER TECH

A high-efficiency atomizing burner for industrial furnaces based on high-viscosity biomass fuel

ActiveCN107477574BGuarantee atomization qualityRaise the combustion temperatureBurnersHigh pressure oxygenFuel oil

The invention relates to an industrial furnace high-efficiency atomizer burner based on high-viscosity biomass fuel, and belongs to the technical field of energy and environments. In the industrial furnace high-efficiency atomizer burner, a fuel channel, a high-pressure nitrogen channel and a high-pressure oxygen channel are three layers of cavities which are concentric from inside to outside, one end of the fuel channel is provided with a fuel inlet, the other end of the fuel channel is provided with a fuel nozzle, the top of one end of the high-pressure nitrogen channel is provided with a nitrogen inlet, and the end part of the other end of the high-pressure nitrogen channel is provided with a first-grade nitrogen atomizing converging-diverging plate; and the top of one end of the high-pressure oxygen channel is provided with an oxygen inlet, the other end of the high-pressure oxygen channel is provided with a second-grade oxygen atomizing converging-diverging plate, a mounting flange connected with an industrial furnace is arranged on the high-pressure oxygen channel, and the high-pressure oxygen channel is provided with an electronic spark electrode penetrating through the high-pressure oxygen channel. According to the industrial furnace high-efficiency atomizer burner based on the high-viscosity biomass fuel, waste nitrogen after oxygen generating is utilized to serve as an auxiliary atomizing gas medium, after first-grade atomizing is conducted by utilizing the nitrogen, a non-burning isolation area which is about 5 cm is formed, it is ensured that a fuel pocket cannot burn at an outlet of the nozzle, and therefore the problems that nozzle outlet sintering and carbon depositing are solved.

Owner:KUNMING UNIV OF SCI & TECH

A high-efficiency atomization combustion system and method for an industrial furnace

ActiveCN107620957BGuarantee atomization qualityRaise the combustion temperatureBurnersNitric oxideFuel oil

Owner:KUNMING UNIV OF SCI & TECH

A kind of fuel additive and preparation method thereof

The invention discloses a fuel additive. The fuel additive is prepared from the following raw materials in parts by weight: 50 to 80 parts of tourmaline nanometer powder, 2 to 5 parts of graphite nanometer powder, 5 to 10 parts of magnesium powder, 30 to 50 parts of diisopropyl ether, 10 to 20 parts of biological oil, 5 to 10 parts of dispersant, 5 to 30 parts of water and 0.1 to 0.2 part of ferrocene. The preparation method of the fuel additive comprises the step of uniformly mixing all of the raw materials at normal temperature and pressure. By using the fuel additive, the fuel quality can be improved, fuel is promoted to fully burn, the burning efficiency is improved, and the fuel is saved; the atomization quality of the fuel can be increased, so that the fuel fully burns, the emission of noxious gas is reduced, and the purposes of energy conservation and emission reduction are achieved.

Owner:丘濠玮 +2

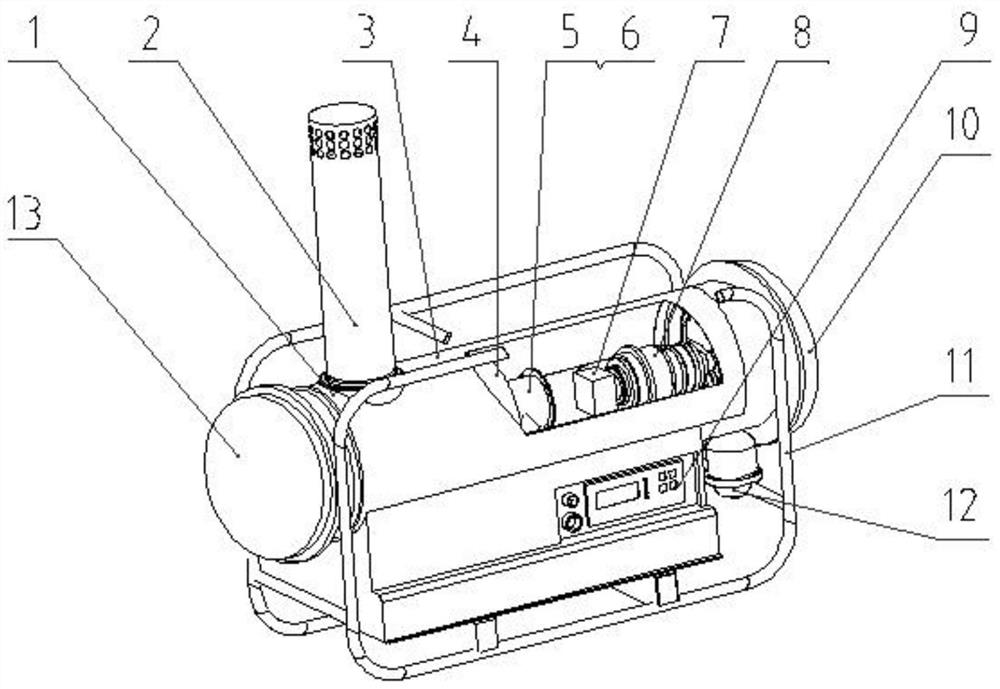

Three-proofing type fan heater

PendingCN113188251AImprove fuel combustion efficiencyNo frequent startup noiseAir heatersOil supplyEnvironmental geology

The invention relates to a three-proofing type fan heater. The three-proofing type fan heater comprises a shell, wherein an air return port and an air supply port are respectively formed in two ends of the shell; a combustion heat exchanger, a combustion system, a heat exchange fan and an oil pump are arranged in the shell; an oil supply system and a combustion fan are arranged outside the shell; the combustion heat exchanger is connected with the combustion system; the oil pump is respectively connected with the heat exchange fan and the oil supply system; the oil supply system and the combustion fan are respectively connected with the combustion system; and a chimney communicated with the combustion heat exchanger is arranged on the shell. The three-proofing type fan heater has the advantages of capability of realizing precise temperature control, high fuel combustion efficiency, no frequent starting noise, energy conservation, environmental protection and reliable equipment work.

Owner:SHAANXI ZIZHU ELECTRON

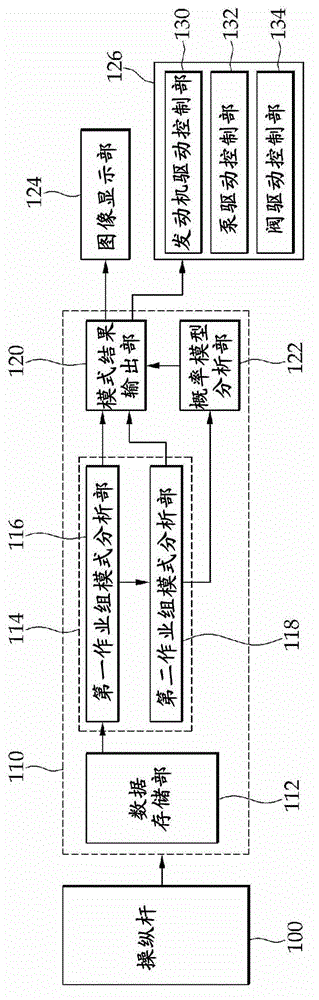

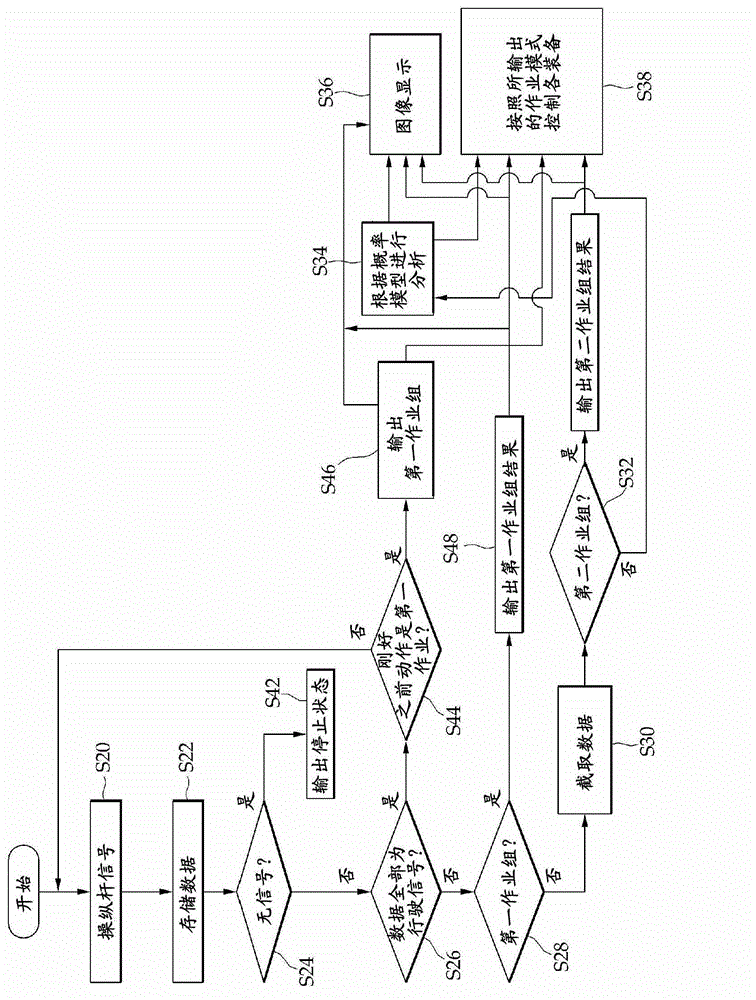

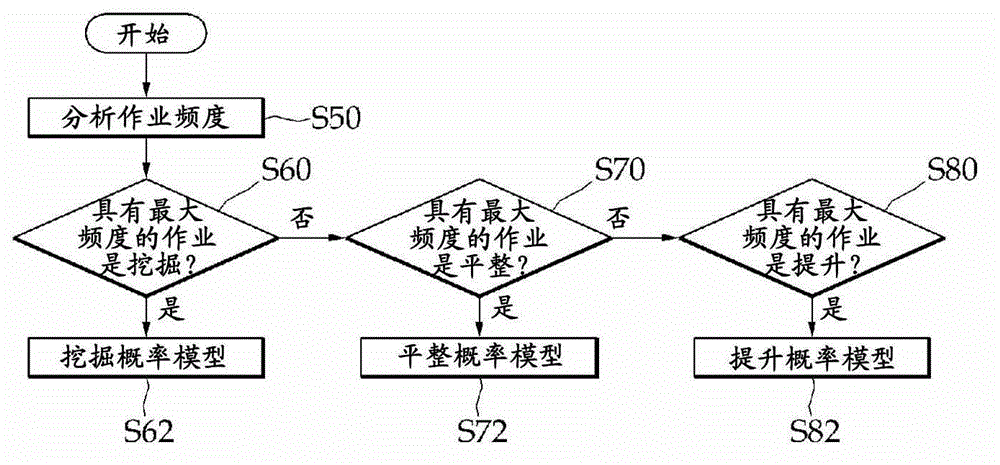

Apparatus and method for controlling construction machinery

ActiveCN103069083AImprove fuel combustion efficiencyReduce consumptionElectric controllersSoil-shifting machines/dredgersPattern recognitionProbit

The present invention relates to an apparatus and method for controlling construction machinery. According to the present invention, a task pattern controlling apparatus comprises a task pattern recognition apparatus for analyzing tasks being performed by construction machinery and a drive controlling apparatus for controlling individual equipment of the construction machinery to fit the task pattern analyzed by the task pattern recognition apparatus. The task pattern recognition apparatus comprises: a data accumulation unit for receiving an input of a manipulation signal from an operator and accumulating data; a task pattern analysis unit for analyzing data on the accumulated manipulation signal and determining a current task pattern; a probability model analysis unit for using a probability model to determine data that could not be determined by the task pattern analysis unit; and a pattern result output unit for outputting tasks, determined by the task pattern analysis unit and the probability model analysis unit, to the drive controlling apparatus.

Owner:DOOSAN INFRACORE CO LTD

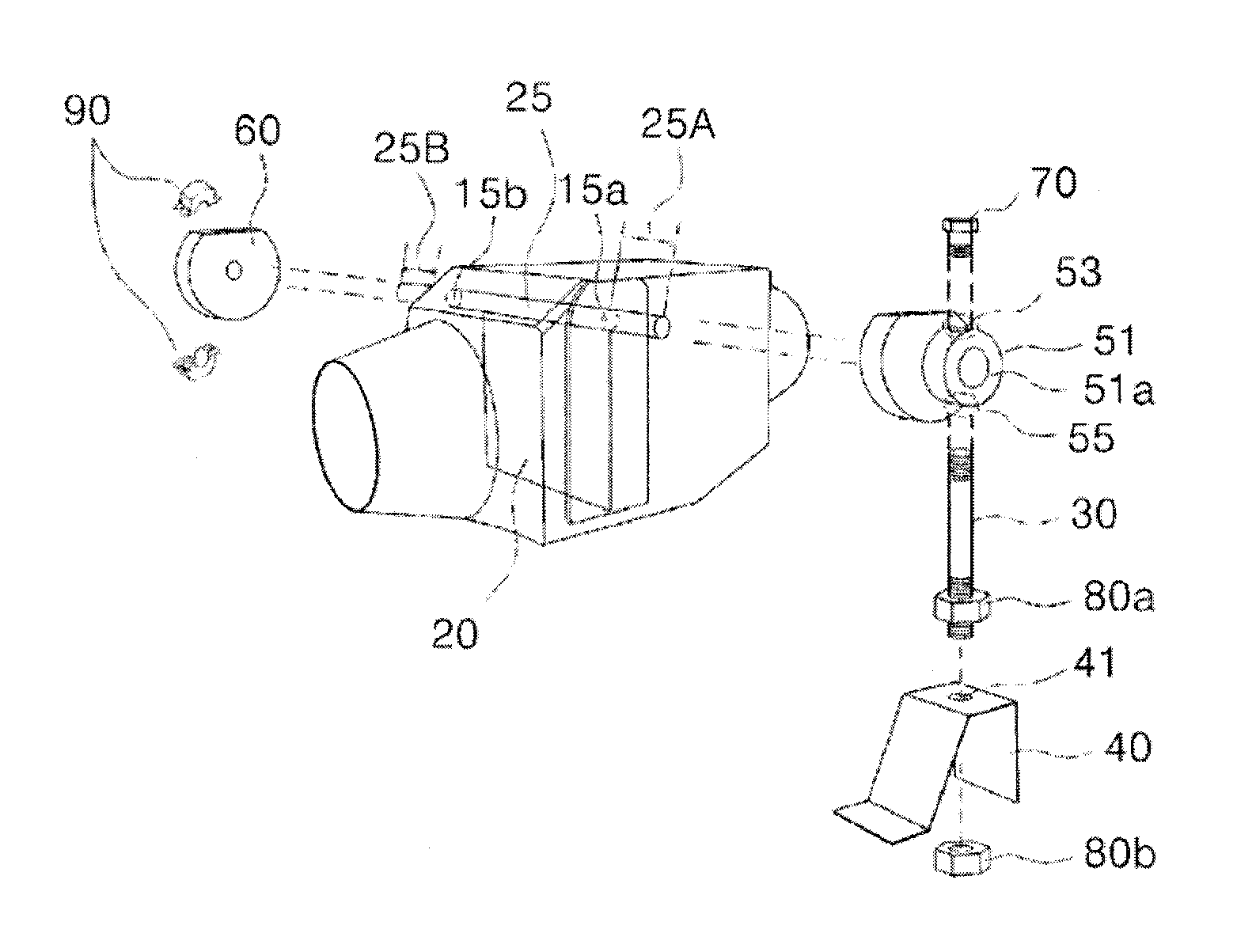

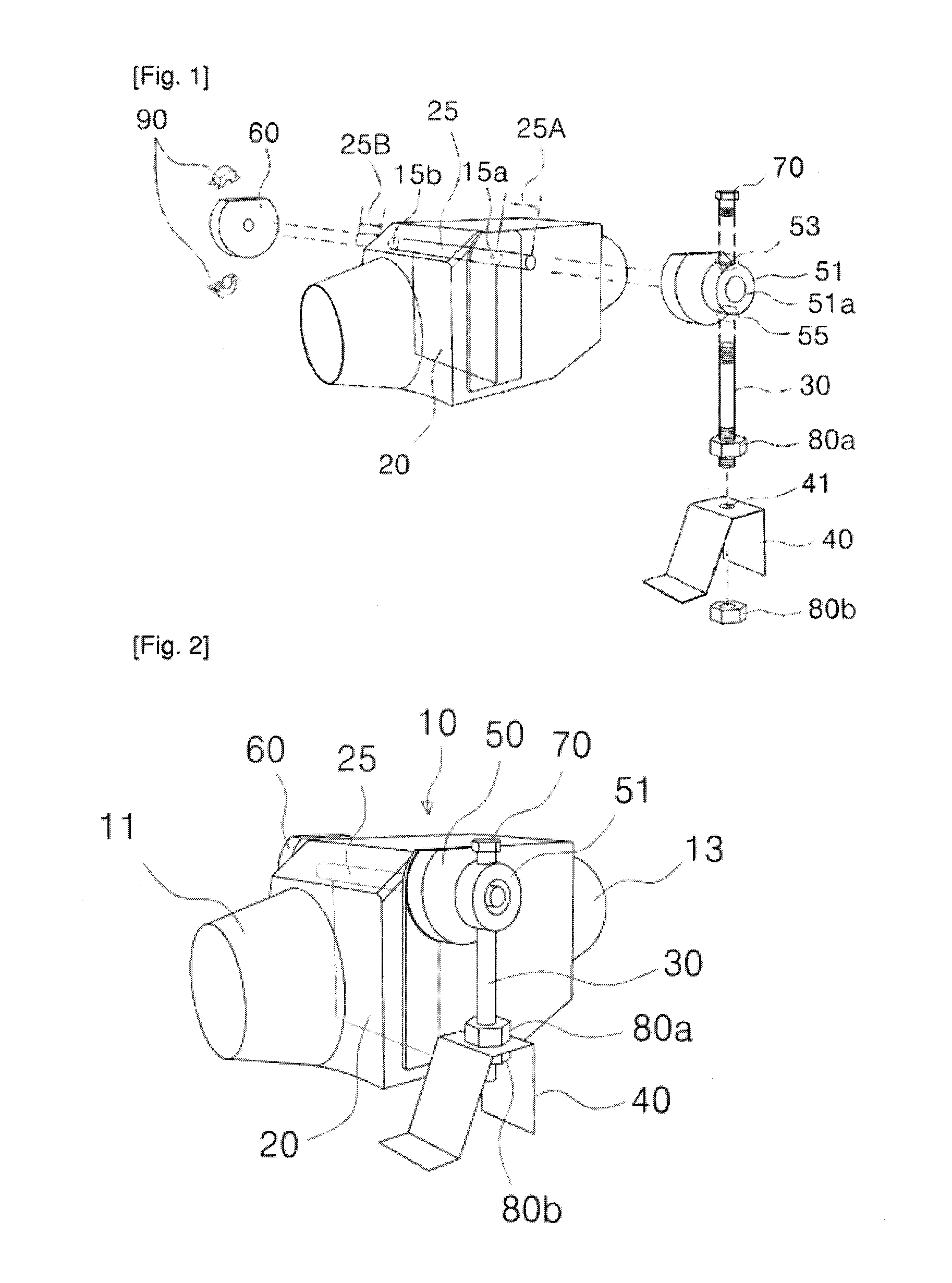

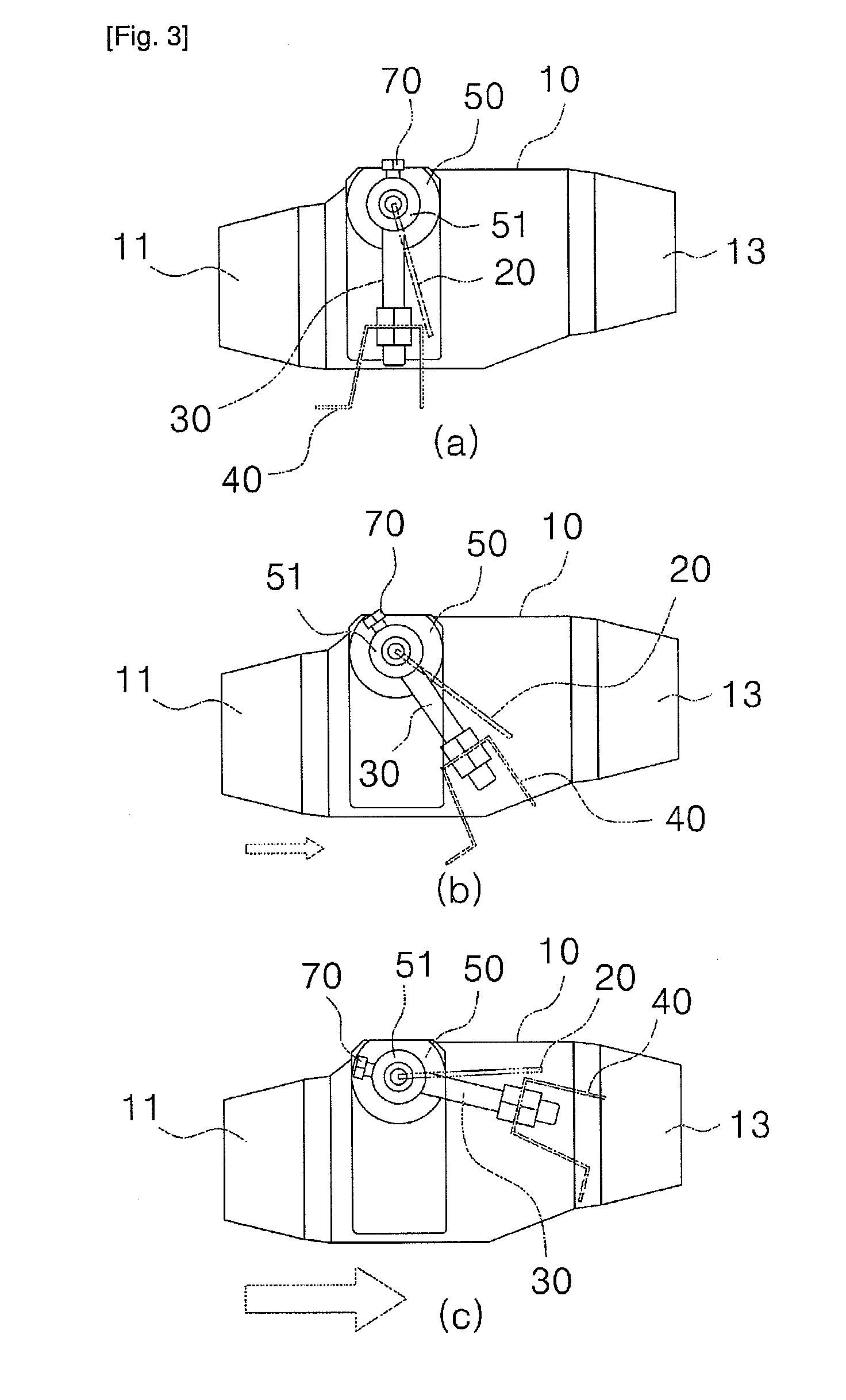

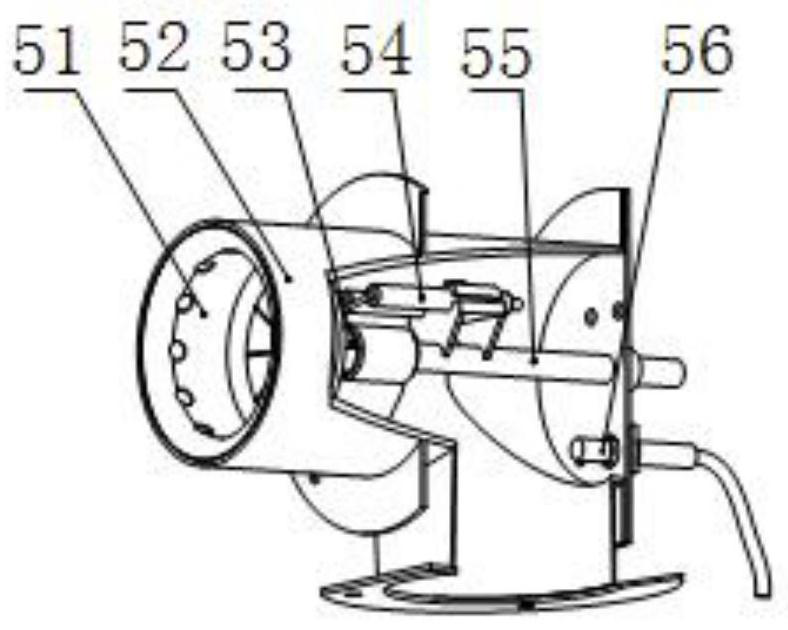

Jet burner

ActiveUS10760786B2Improve fuel combustion efficiencyExtension of timeBurner ignition devicsGaseous fuel burnerCombustorCombustion chamber

A jet burner of the present disclosure basically includes a burner unit and an air blower disposed at a rear end of a burning chamber of the burner unit, wherein the burner unit is installed with a fuel bucket for storing fuel and the burning chamber having a tubular shape. Interior of the burning chamber is installed with a least one nozzle, at least one fuel pipe coupled to the fuel bucket is installed at each the nozzle, a front end of the burning chamber is installed with at least one jet pipe, and a pipe diameter of each the jet pipe is less than an inner diameter of the burning chamber. Under the reaction of the jet pipe, the burning stay time of the fuel in the interior of the burning chamber is increased, as to achieve the objective of increasing the fuel burning efficiency.

Owner:PURE METHANOL ENERGY TECH CO LTD

A kind of preparation method of fuel oil activator

The invention discloses a preparation method of a fuel activator, which comprises doping nano-TiO2 with rare earth waste slag, compounding it with tourmaline nano-powder and spinel ferrite to obtain a solid mixture, and then adding water, dispersant, surface active agent to form a solid-liquid mixed slurry; the mass ratio of the rare earth waste residue, nano-TiO2, tourmaline mineral powder, and spinel ferrite is 2~5:1~3:60~80:5~9; The input amount is 10-90% of the mixed slurry; the input amount of the dispersant is 2-10% of the mixed slurry; the input amount of the surfactant is 5-28% of the mixed slurry. The fuel activator prepared by the invention can improve oil quality, promote full combustion of fuel, improve combustion efficiency, and save fuel; can improve its atomization quality, enable full combustion of fuel and reduce harmful gas emissions, thereby achieving the purpose of energy saving and emission reduction.

Owner:广西运通燃料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com