A high-efficiency atomizing burner for industrial furnaces based on high-viscosity biomass fuel

A biomass fuel oil and industrial furnace kiln technology, applied in the fields of energy and environment, can solve the problems of burner nozzle outlet sintering, affecting production efficiency, carbon deposition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

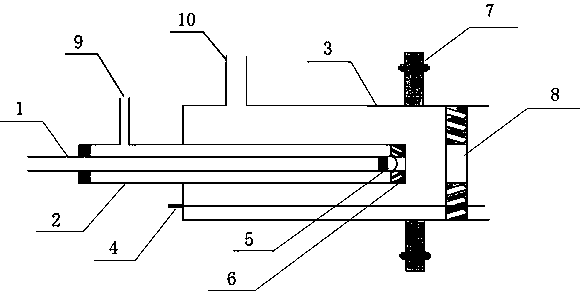

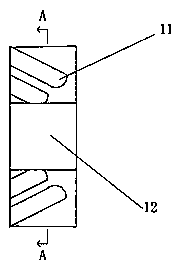

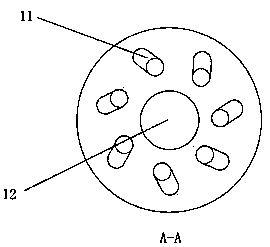

[0023] Such as Figures 1 to 3 As shown, the high-efficiency atomizing burner for industrial furnaces based on high-viscosity biomass fuel oil includes a fuel oil channel 1, a high-pressure nitrogen channel 2, a high-pressure oxygen channel 3, an electronic ignition needle 4, a fuel nozzle 5, and a first-stage nitrogen atomizing rotor. Flow sheet 6, mounting flange 7, secondary oxygen atomization swirl sheet 8, nitrogen inlet 9 and oxygen inlet 10, fuel channel 1, high-pressure nitrogen channel 2, high-pressure oxygen channel 3 are concentric, three layers from inside to outside In the cavity, the fuel channel 1 is provided with a fuel inlet at one end and a fuel nozzle 5 at the other end, a nitrogen inlet 9 at the top of one end of the high-pressure nitrogen channel 2, and a first-stage nitrogen atomizing swirl plate 6 at the other end of the high-pressure nitrogen channel 2 , the top of one end of the high-pressure oxygen channel 3 is provided with an oxygen inlet 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com