Patents

Literature

199results about How to "Reduce exhaust heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

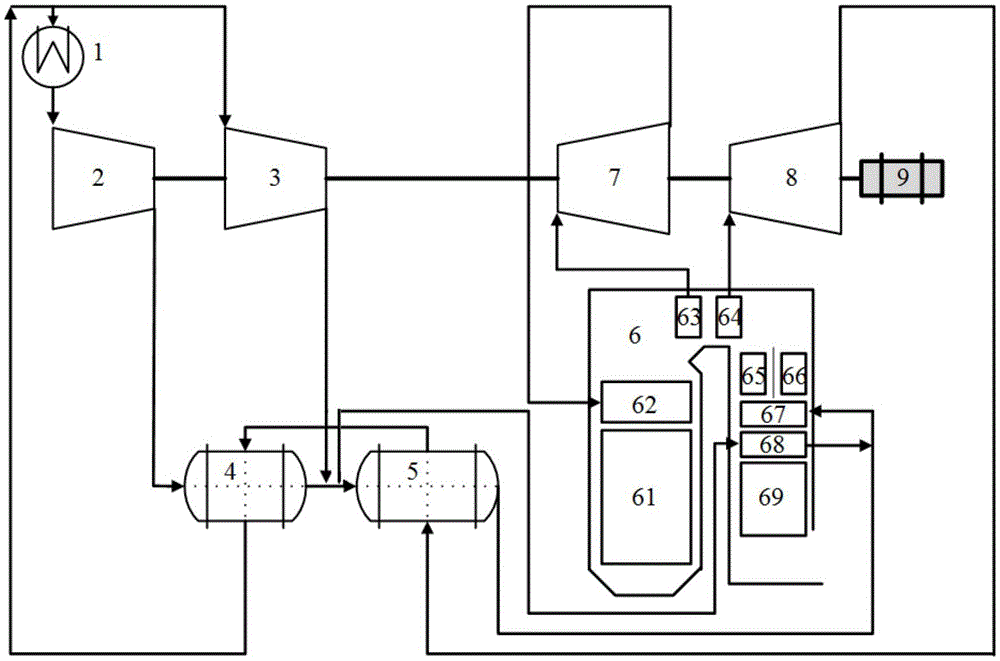

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

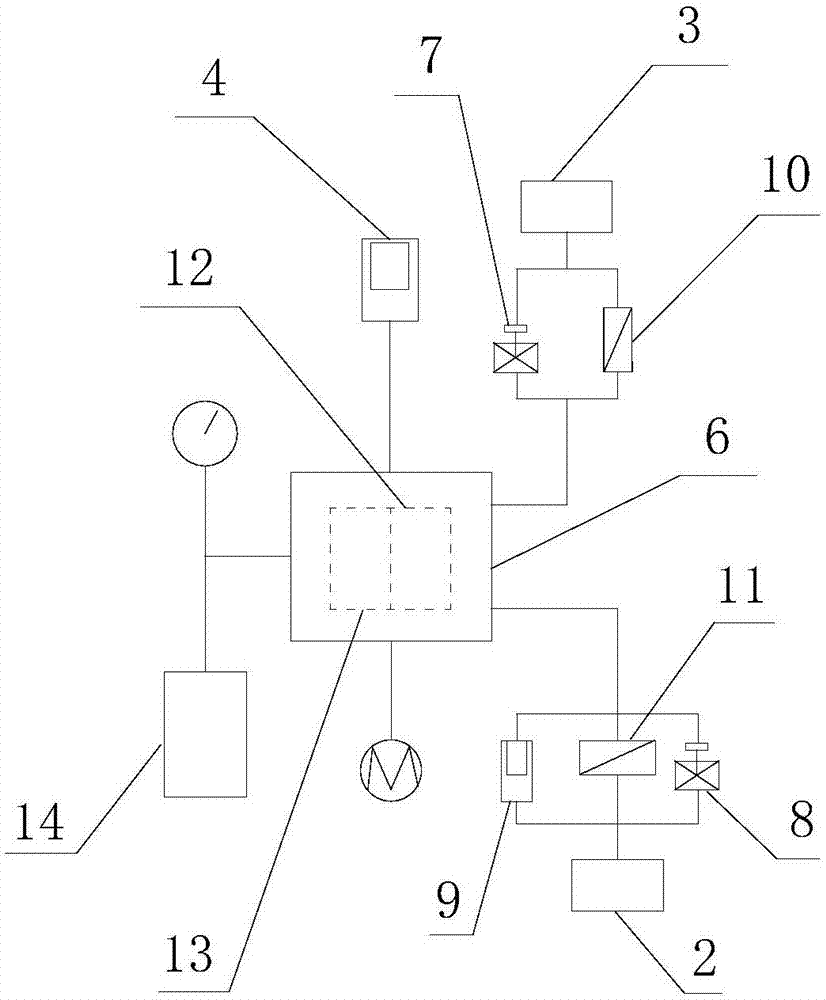

Device and method for detecting sulfur trioxide in flue gas on line

ActiveCN103472061ARealize online measurementTake convenienceMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesGas phaseEngineering

The invention discloses a device and a method for detecting sulfur trioxide (SO3) in flue gas on line. The device comprises a flue gas collecting unit, a gas liquid separator, a gas phase detection unit, a first solution tank, a liquid phase detection unit and a digital control unit, wherein the gas liquid separator is used for condensing SO3 in the flue gas from a flue gas sampling unit into sulfuric acid liquid drops and separating the sulfuric acid liquid dropsfrom gas phase; the gas phase detection unit is used for measuring the flow of the gas phase from the gas liquid separator; the first solution tank is used for providing an absorption liquid to the gas liquid separator and mixing the absorption liquid with the sulfuric acid liquid drops to form mixed liquid; the liquid phase detection unit is used for measuring the mass of the transformed SO3 in the mixed liquid from the gas liquid separator; and the digital control unit is used for calculating the SO3 concentration of the flue gas according to the detection results of the gas phase detection unit and the liquid phase detection unit. According to the device and the method, on-line measurement of the SO3 of the flue gas is realized, the SO3 of the flue gas is sampled and the SO3 content is analyzed, so that a coal-fired power plant can take corresponding measures conveniently, the SO3 content of the flue gas is controlled, the corrosion to a flue and equipment is reduced, and the heat loss due to exhaust smoke of a boiler is reduced to the maximum degree.

Owner:ZHEJIANG UNIV

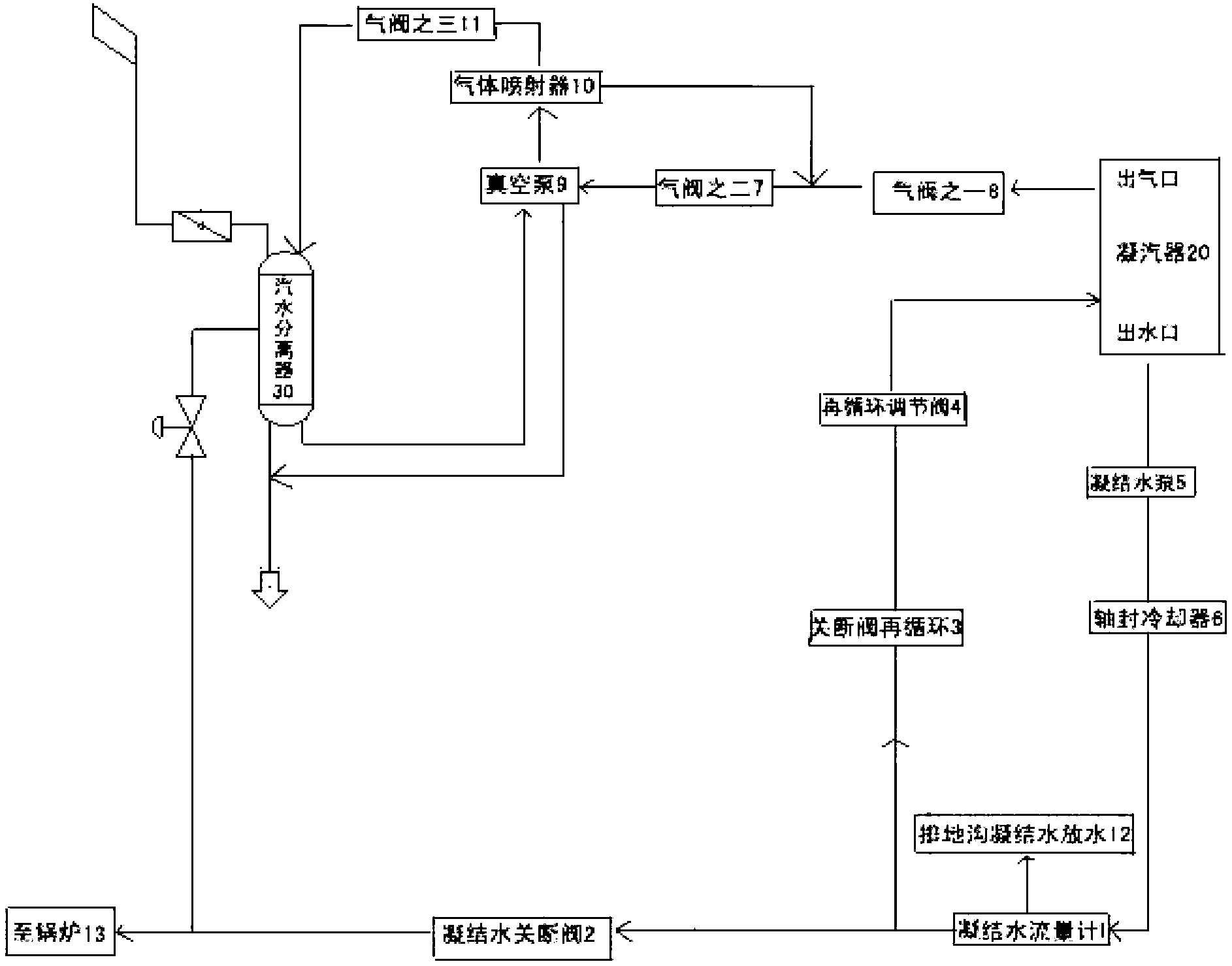

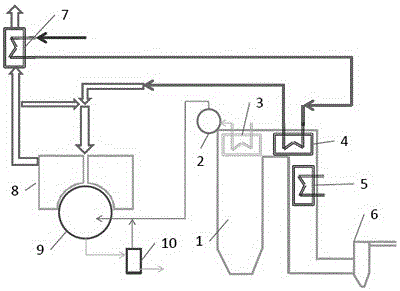

Quick start method and system of combined cycle unit

InactiveCN102997215ASimple structureImprove operating economyBoiler controlOperation modeEngineering

The invention relates to a quick start method and system of a combined cycle unit, which mainly detect and control the PH value of the condensed water by controlling the dissolved oxygen in the water and steam of a thermodynamic system and controlling the dissolved oxygen corrosion according to the relationship among temperature, pressure and content of dissolved oxygen of water and steam, by setting the content of dissolved oxygen in the condensed water to be less than or equal to 50microgram / L and by setting the content of dissolved oxygen in the water feed to be less than or equal to 15microgram / L, and adopts the combined deoxygenization manners of condenser vacuum deoxygenization and chemical dosing deoxygenization, and optimized operation mode and maintenance mode to ensure that the oxygen content in the condensed water in the combined cycle unit reaches the standard so as to avoid oxide etch of the metal due to that the oxygen content in the condensed water of the unit is excessive. The quick start system used for the combined cycle unit comprises a condenser; the water outlet of the condenser is connected with the input end of a condensed water flow meter through a condensed water pump and a shaft-sealing cooler; one loop of the outlet end of the condensed water flow meter is communicated with a boiler of the combined cycle unit through a condensed water cut-off valve, and the other loop is connected with a water return port of the condenser through a recycle cut-off valve and a recycle control valve; and a steam outlet of the condenser is connected with a vacuum pump through an air valve. The quick start method and system have the advantages that the overall structure of the thermodynamic system is simplified and the reliability and the economical efficiency of the system are improved.

Owner:SHENZHEN GUANGQIAN ELECTRIC POWER

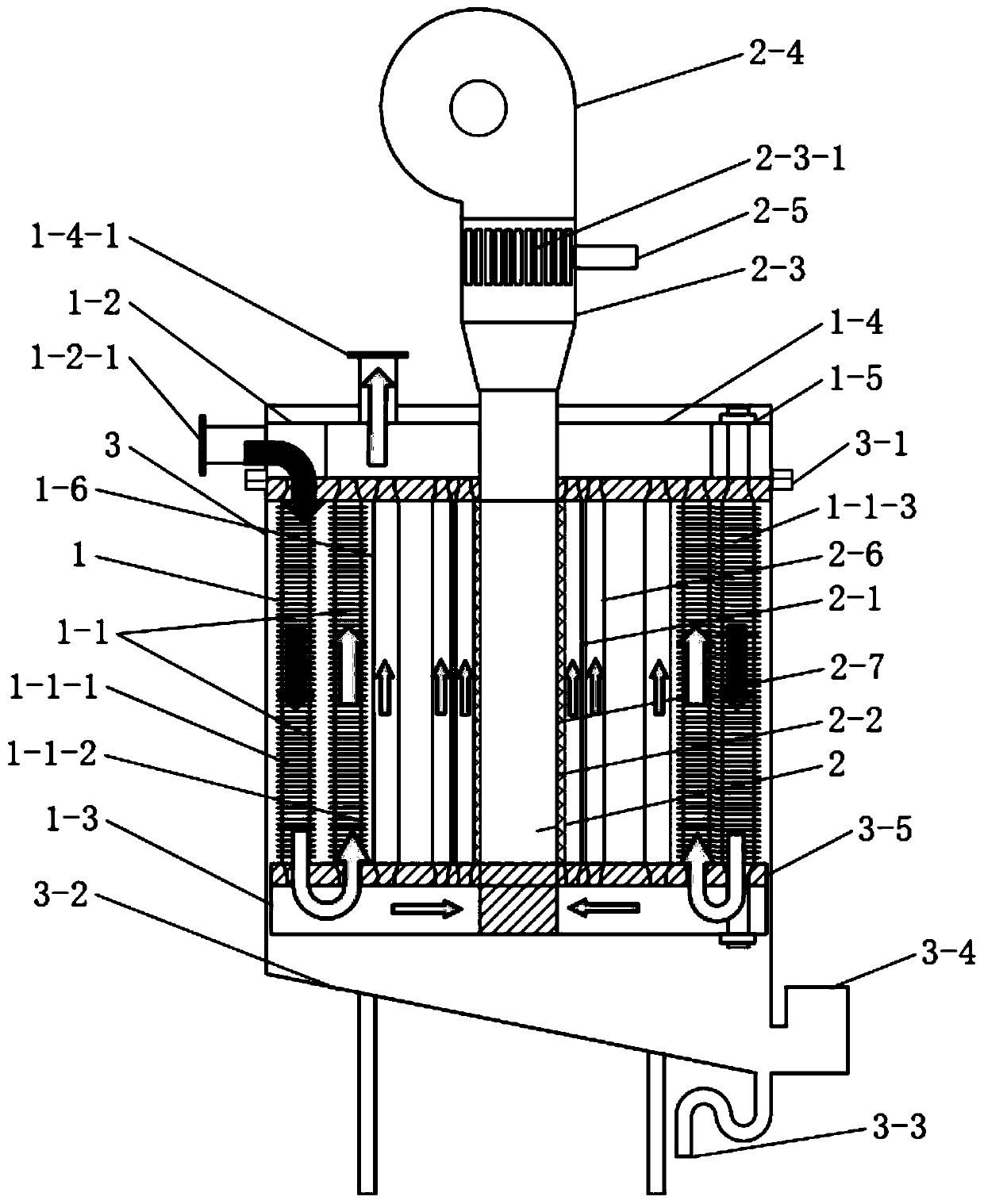

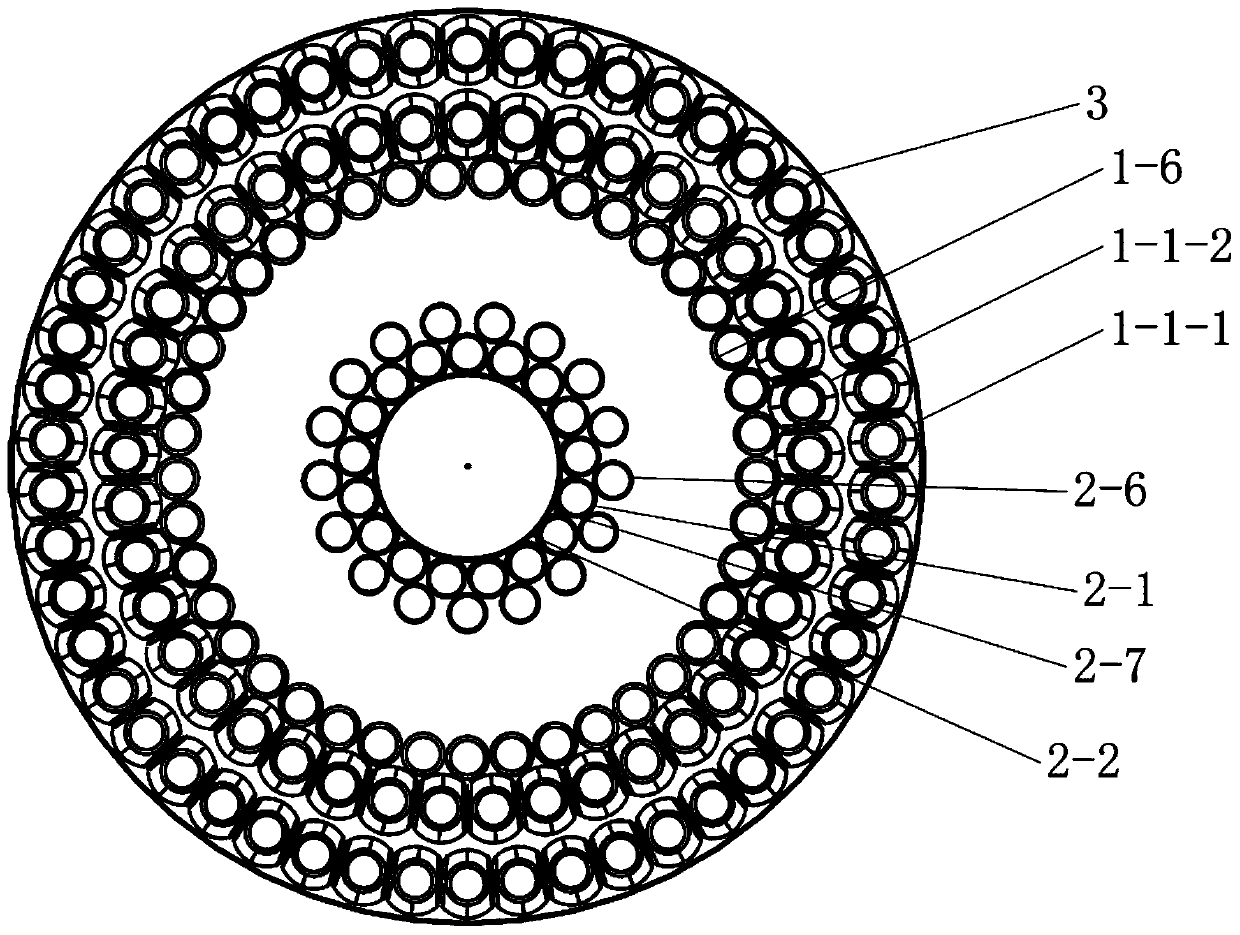

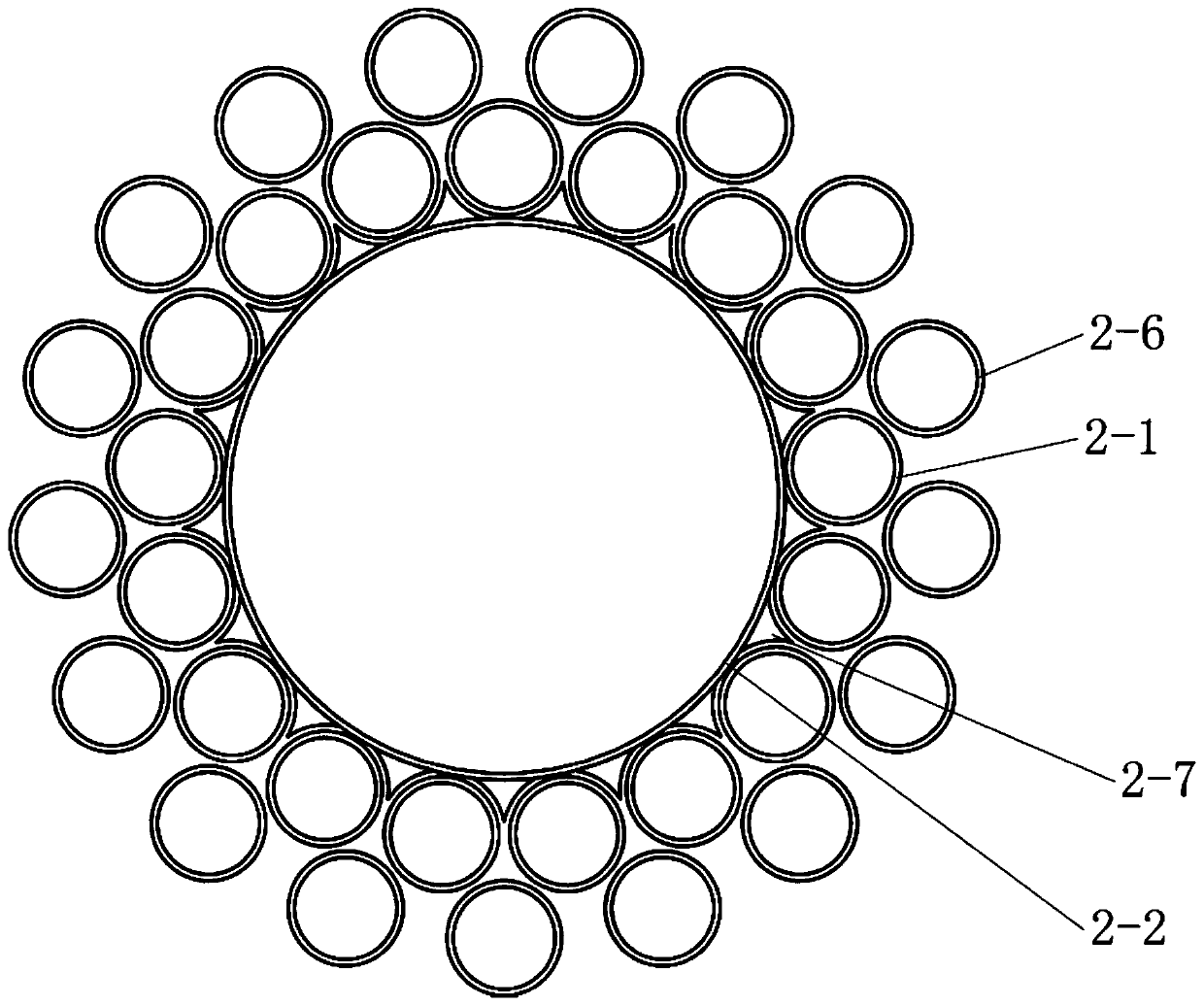

High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

PendingCN111141028AFully absorb radiation heat transferEnhanced radiation heat transferAir heatersGaseous fuel burnerCombustorAir blower

The invention provides a high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler comprises a combustor and a heat exchanger, wherein the full-premixed combustor mounted in the center of a boiler top plate consists of a booster fan, a premixing chamber and a water-cooling combustion head; a flame stabilizing pipe and an anti-tempering column of the water-cooling combustion head can realize high-adjustment-ratio water-cooling premixed combustion; the heat exchanger consists of a lap of water-cooling wall and one or more laps of fins uniformly arranged in the peripheral direction by bent edge folding fin pipes; an air blower feedsair into the premixing chamber for fully mixing with gas to enter an inner cavity of a hole plate of the combustion head; the air flows out from a fire hole, and is sprayed out from narrow gaps amongthe water-cooling pipes distributed in the peripheral direction; after the air flows out from the flame stabilizing pipe, the air is ignited to uniformly combust in the peripheral direction and the axial direction, and radiates and releases heat to an inner pipe ring; smoke flushes base pipes and fins of inner and outer ring fin pipes in sequence to reinforce heat exchange; and the smoke downwards flows into a dew bearing disc through gaps between a housing and an outer layer fin pipe, and is exhausted into atmosphere from a smoke outlet. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler is high in combustion load adjustment ratio, compact in heat exchange, low in nitrogen emission and high in heat efficiency.

Owner:XI AN JIAOTONG UNIV +1

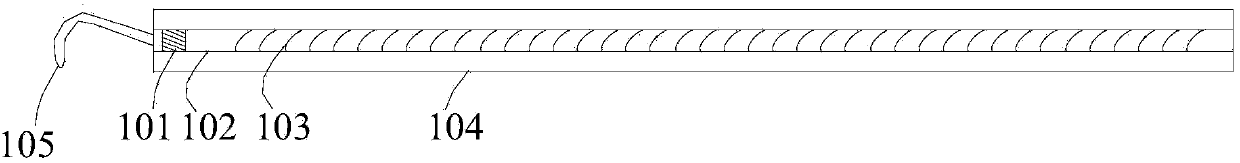

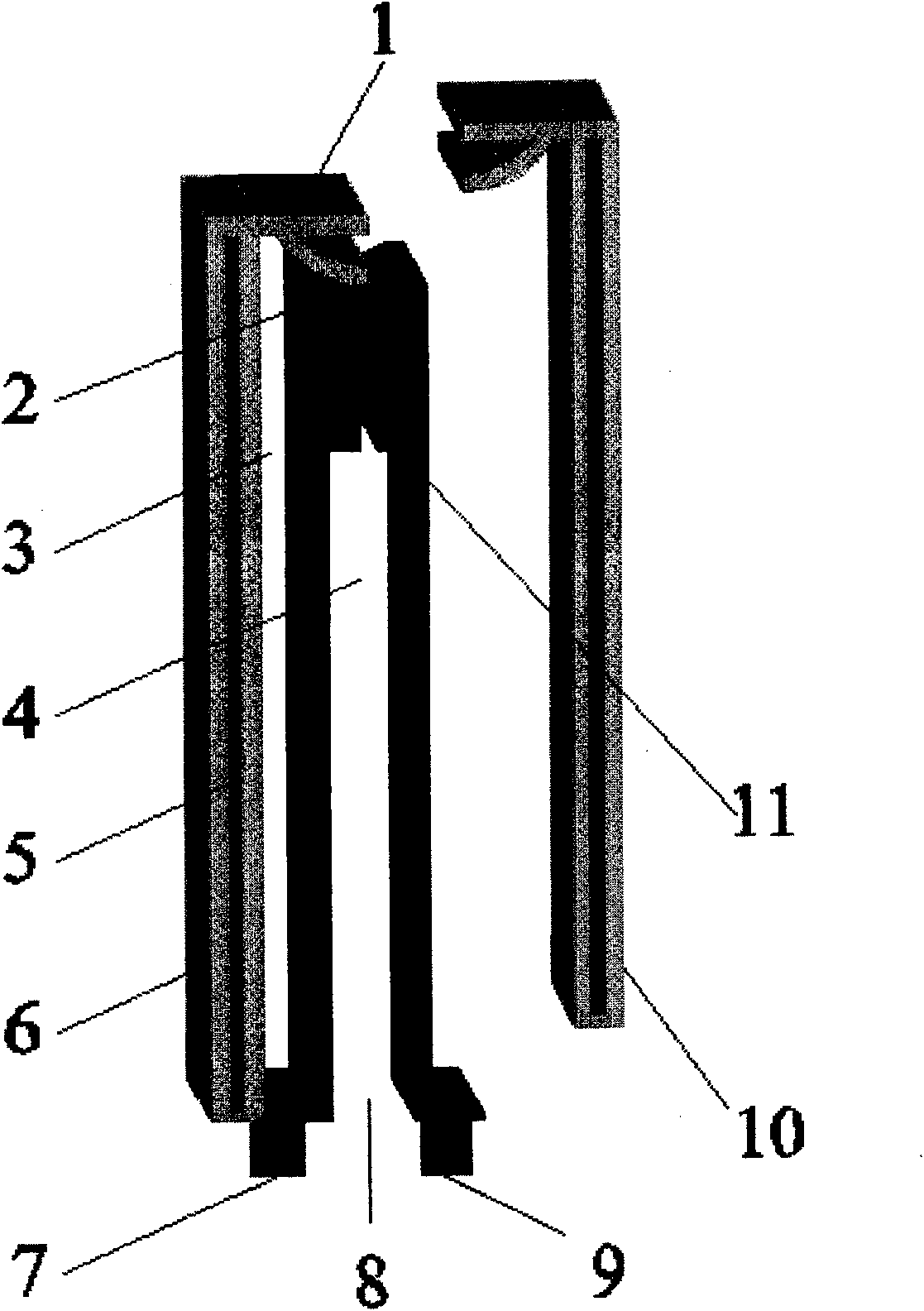

Micro parallel plate burner with preheating channel

InactiveCN101539293AImprove temperature distributionIncrease enthalpyGaseous fuel burnerCombustion chamberHydrogen

The invention belongs to the field of micro-power electromechanical systems (MEMS), particularly relates to a micro parallel plate burner with a preheating channel. The micro parallel plate burner with a preheating channel consists of a parallel plate burning chamber, a preheating channel and a quartz shade, which are arranged from inside to outside, wherein the upper half section of the parallel plate burner is an oxy-hydrogen premixing zone; and the quartz shade is double-layered and internally vacuumized. Fuels and oxidant can be preheated before being mixed by the preheating channel, thereby more stable burning is realized; and the double-layered vacuumized quartz shade not only can make most of photons generated on the radiation surface of the burner pass through, but also play a heat insulation role, so that the whole transformation efficiency and the working performance of micro thermophotovoltaic systems are greatly improved.

Owner:JIANGSU UNIV

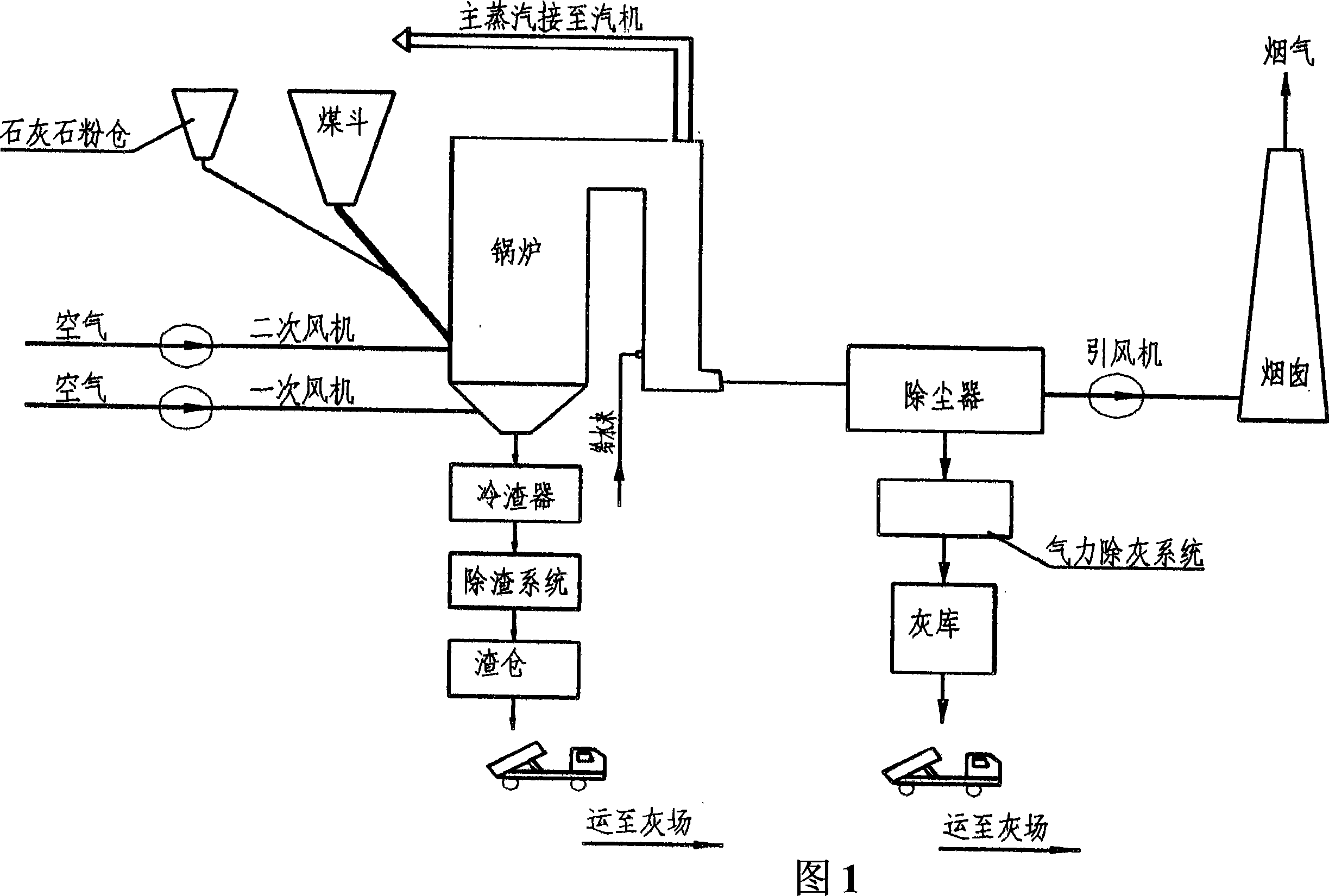

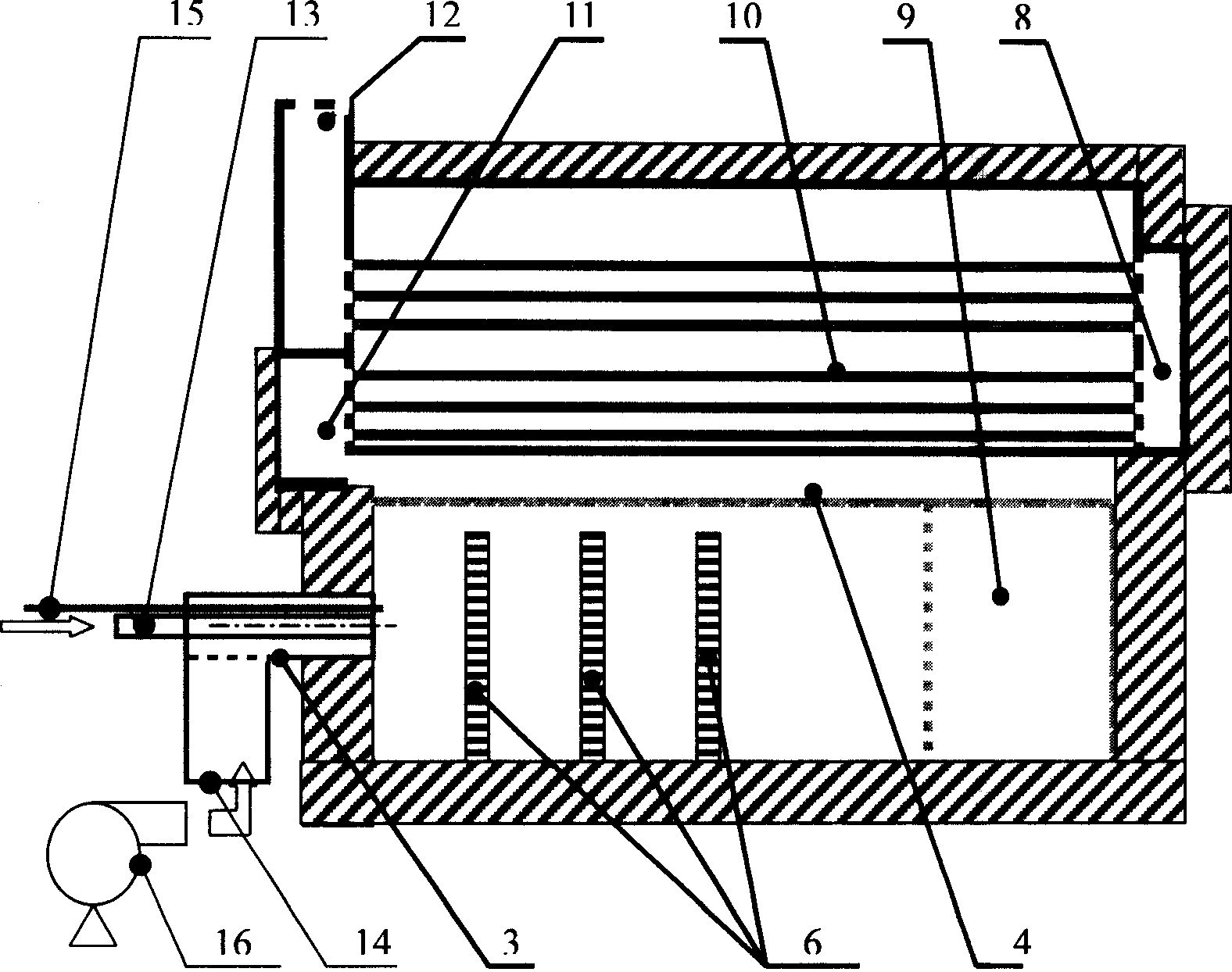

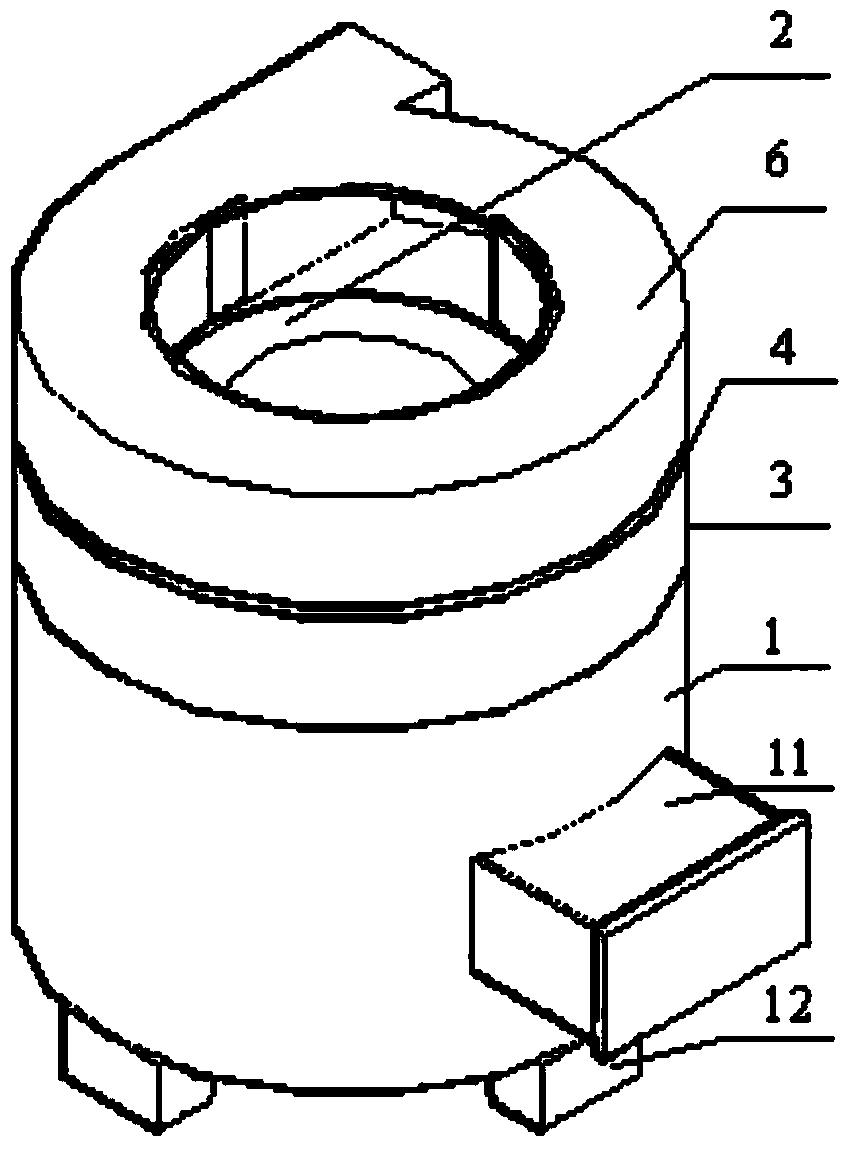

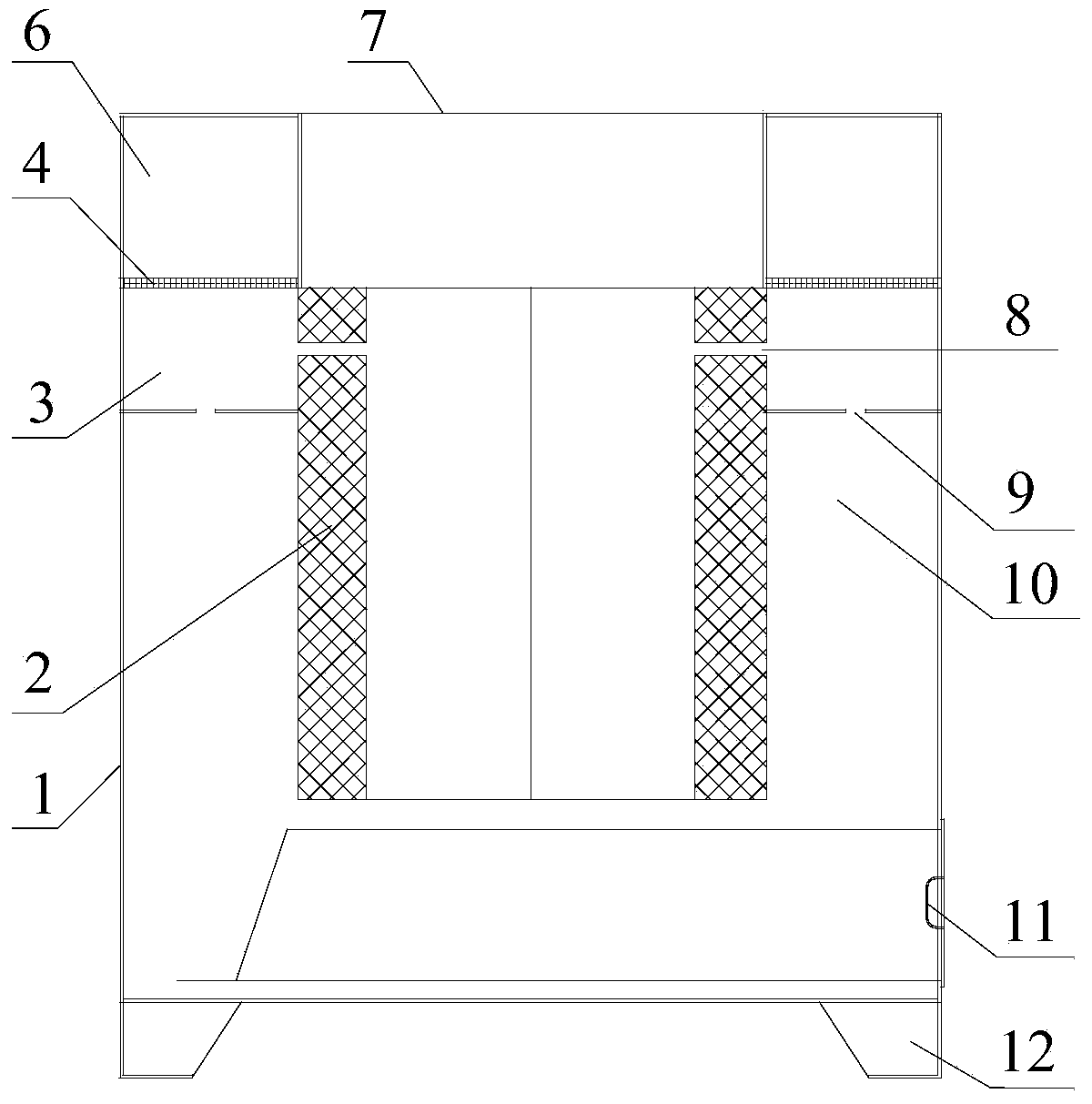

300MW circulating fluidized bed boiler island

InactiveCN101162087ASuppress generationReduce exhaust heat lossFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses a 300MW circulating fluidized bed boiler island device; the boiler of the invention adopts the circulating fluidized bed profile, limestone powders are added in the boiler and combusted at the temperature of 840 DEG C to 950 DEG C; the boiler comprises a separator, a material return system, a first-level raw coal crushing system, a second-level raw coal crushing system, a first-level coal feeder, a second-level coal feeder, an air-water combined fluidized type cold slag apparatus, a mechanical dry type slag removing system, a deoxidizing chamber and a coal bunker, wherein an outlet of the second-level coal feeder is provided with a helical type dispenser; the deoxidizing chamber and the coal bunker adopt the combination single frame arrangement, the deoxidizing chamber is provided with a built-in deaerator; the invention has the advantages of high efficiency, environmental protection, cleanliness, smooth slag removal, safety, reliability and high efficiency and energy save of the equipment; moreover, the coal feeding system is not blocked, all environmental protection emitting values of the boiler operation reach or exceed the National Environmental Protection Emission Standard, the main workshop arrangement of the invention is optimized, compact and reasonable, which meets the requirements of the production operation and the maintenance and the whole project is low in investment.

Owner:ENERGY CHINA YNPD

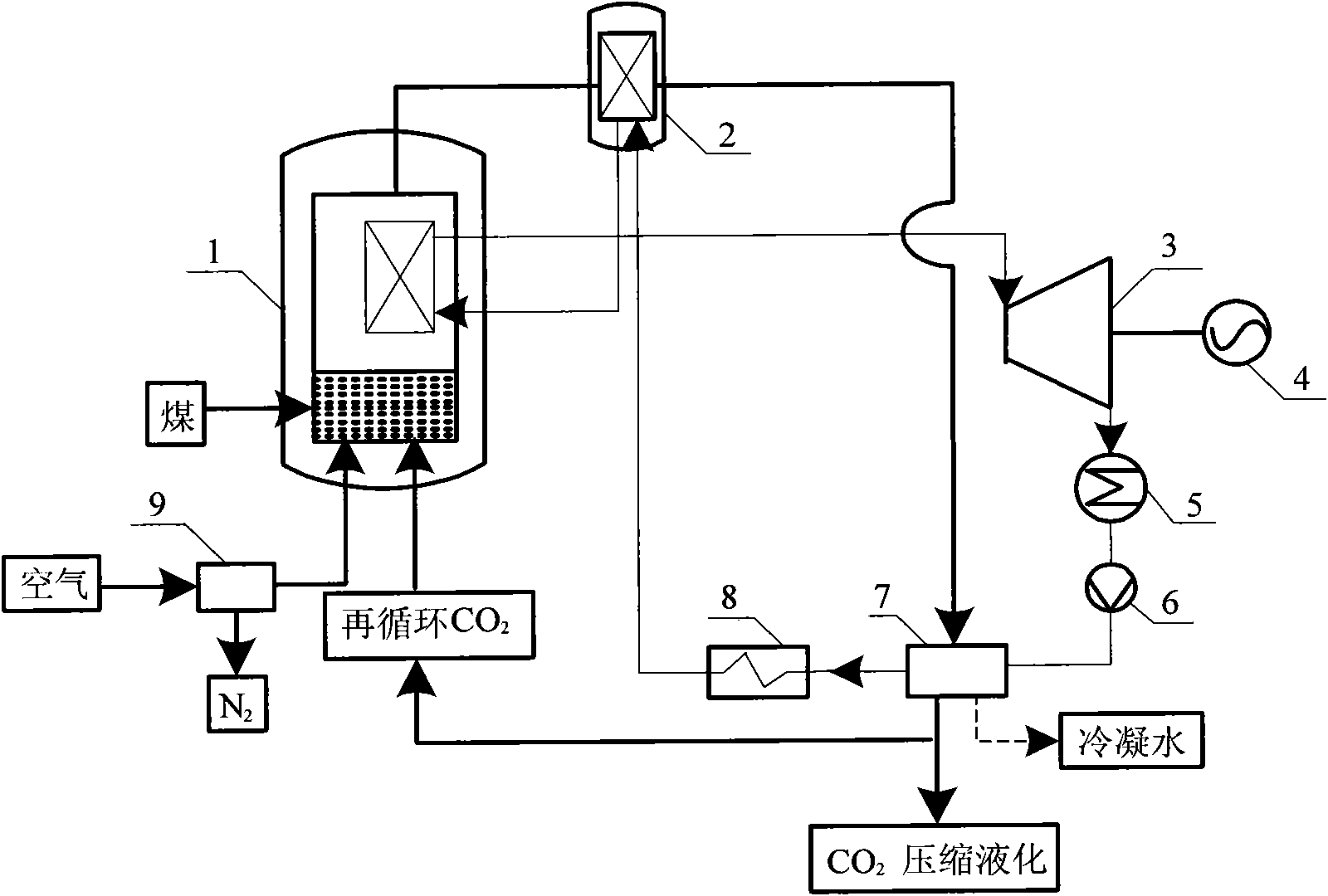

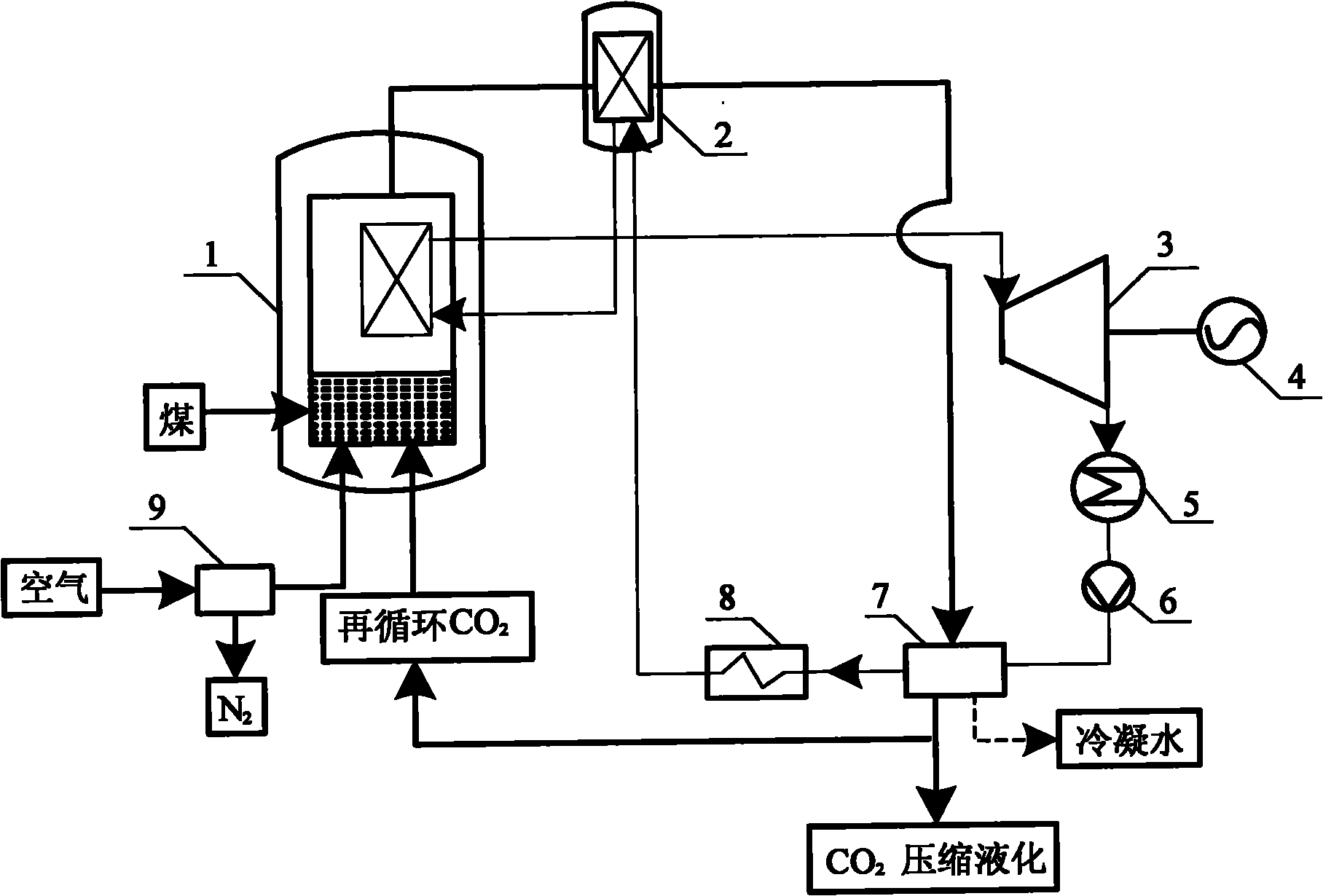

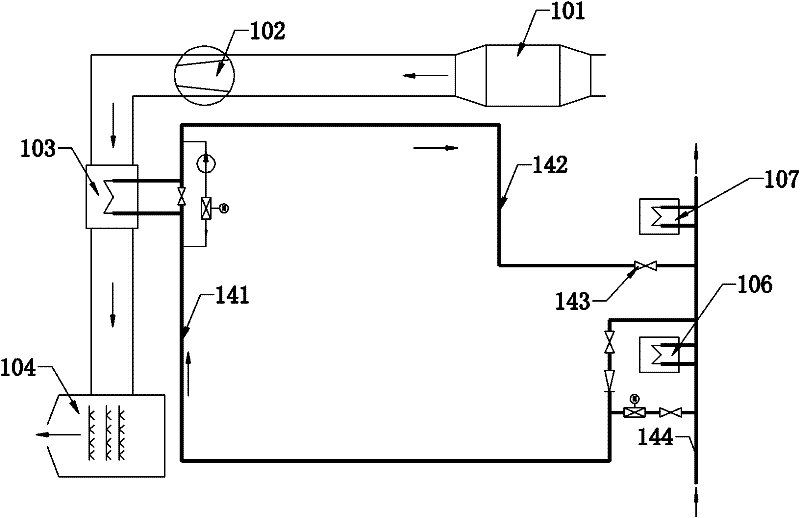

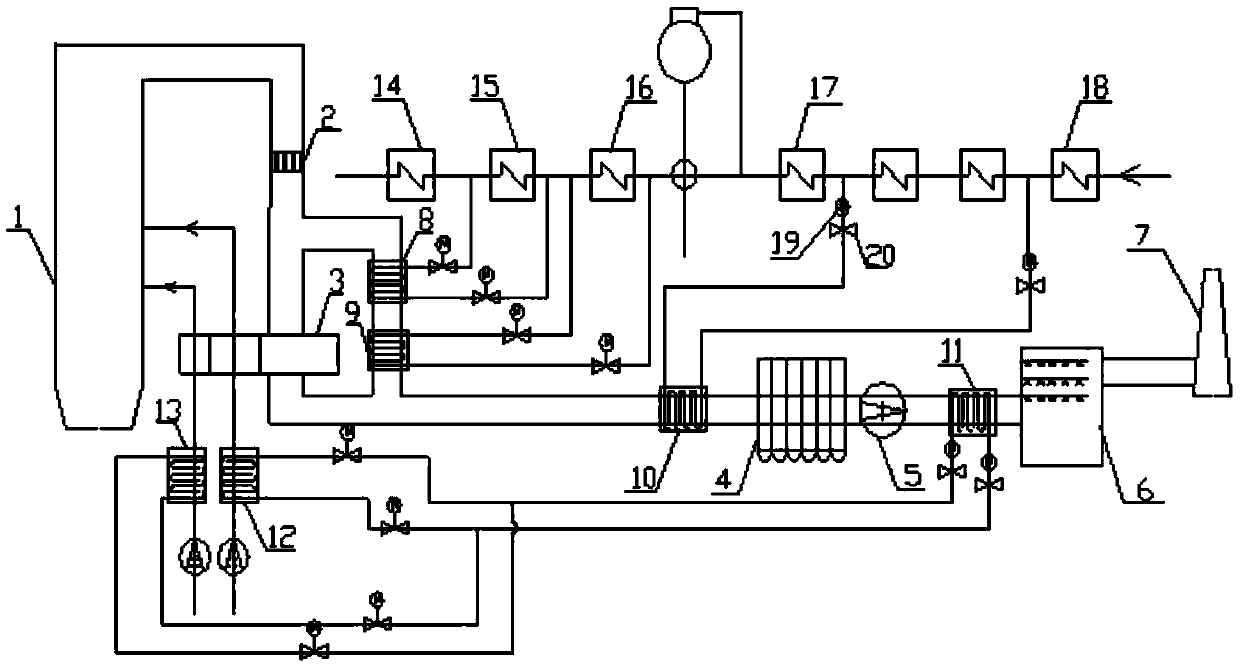

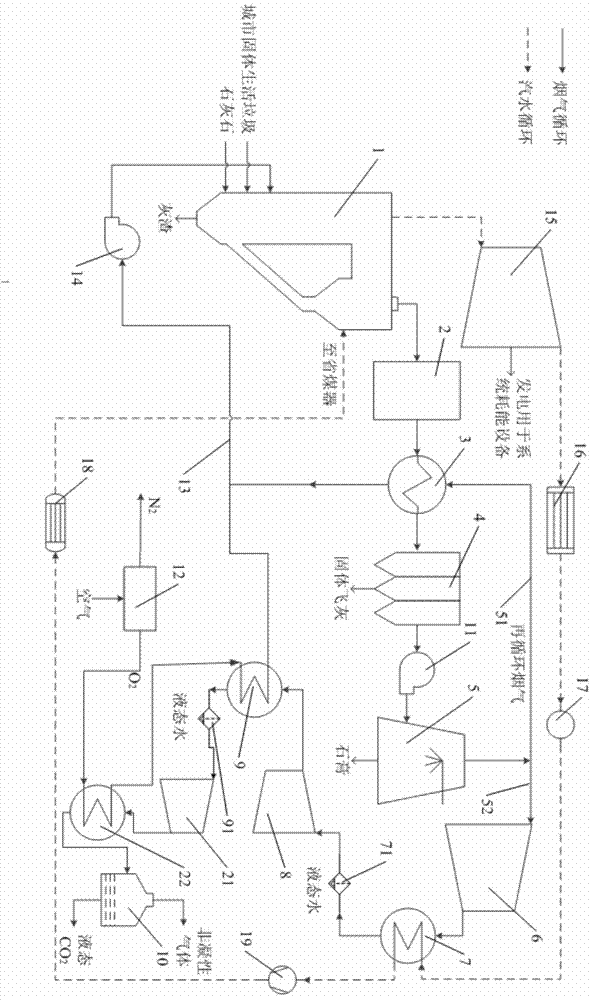

Reclaiming system for condensation heat of flue gas during pressurized oxy-coal combustion

InactiveCN101858592ASimplify the dehydration processGreat effortFeed water supplySteam engine plantsWater vaporHigh pressure

The invention discloses a reclaiming system for condensation heat of flue gas during pressurized oxy-coal combustion, and belongs to the field of energy technology application and CO2 capture. In the technology, by utilizing the characteristic that the condensation temperature of flue gas moisture under high pressure is improved to about 200 DEG C, the condensation heat of the flue gas moisture heats condensation water of a steam turbine, the condensation process is performed in a high-pressure flue gas condenser, the flue gas generated during pressurized oxy-coal combustion enters the high-pressure flue gas condenser, steam in the flue gas is cooled and releases latent heat of vaporization to heat the condensation water of the steam turbine, and the discharged flue gas is continuously compressed and liquefied to fulfill the aim of capturing CO2. Through the technology, the condensation heat of the flue gas moisture is fully utilized, the smoke discharge loss is reduced, the output of the steam turbine is improved, the energy consumption for capturing the CO2 is reduced, and the thermal economy of the pressurized oxygen enriched combustion generating system is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

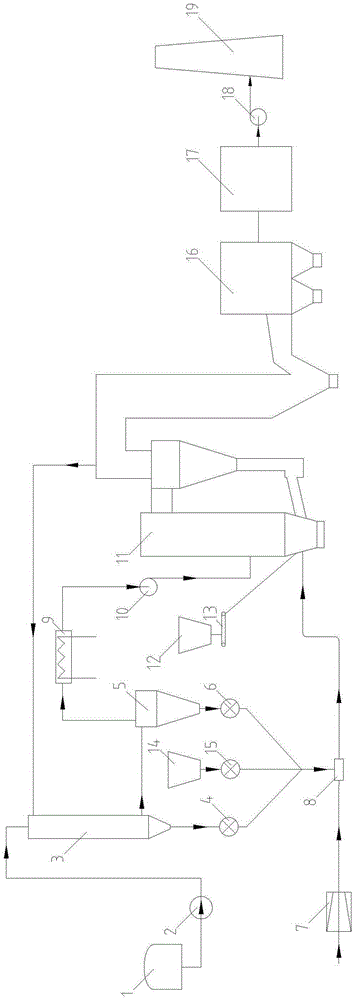

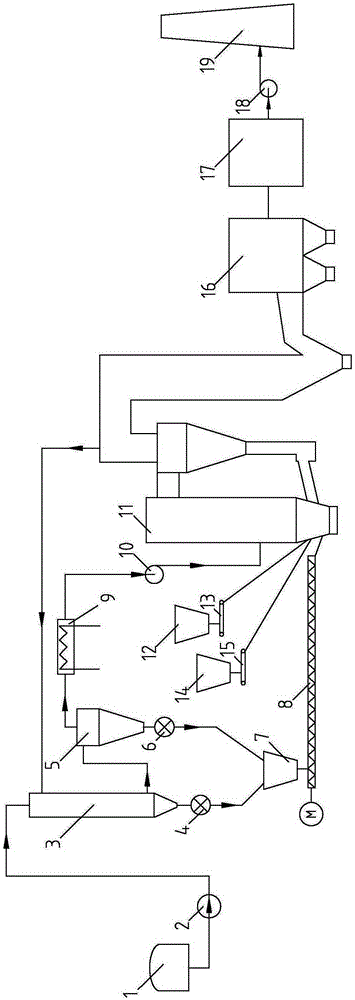

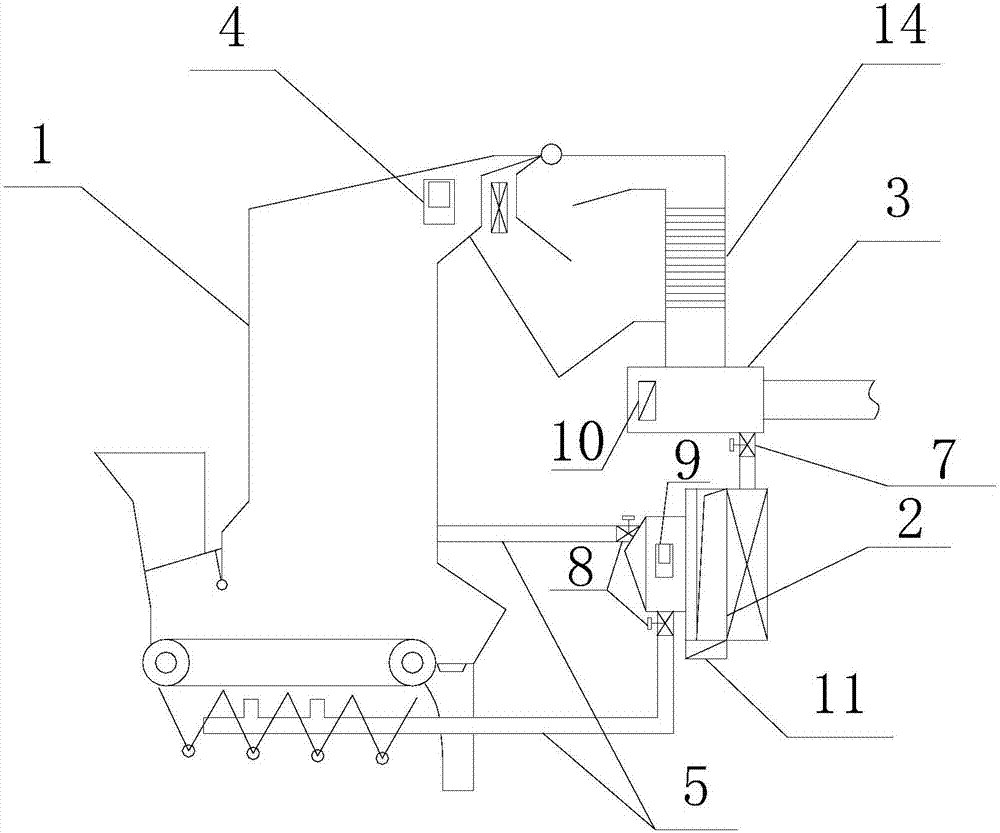

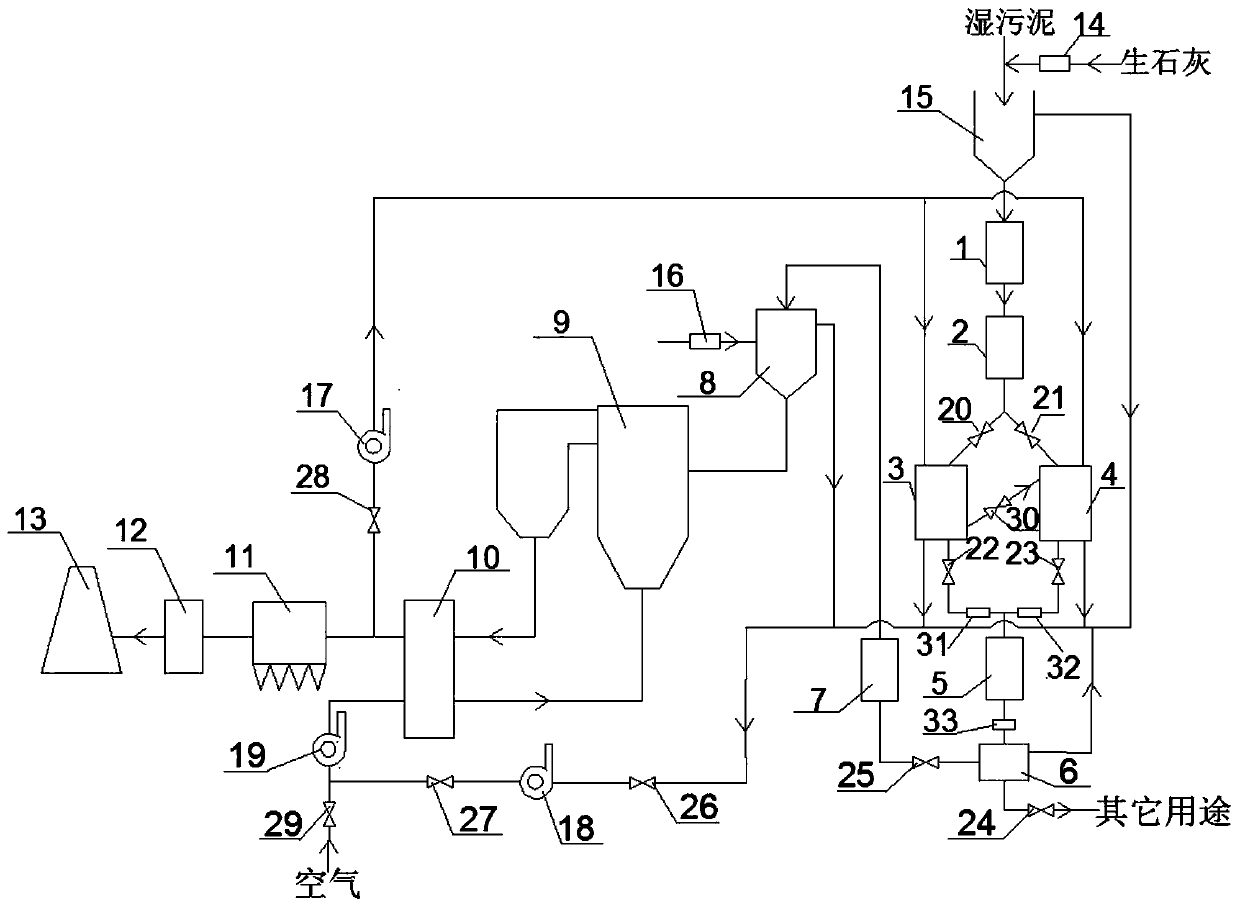

Coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying

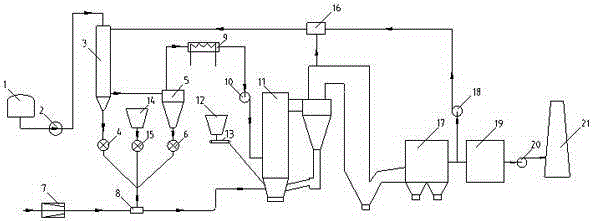

ActiveCN105276603AIncrease speedEasy to handleSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeRotary feeder

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and pneumatic conveying. A sludge storage bin is connected with a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with a cyclone separator outlet flue of a circulating fluidized bed boiler. A first outlet of the spray drying pipe is connected with a first rotary feeder, and a second outlet of the spray drying pipe is connected with a cyclone separator. An exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and an exhaust gas fan, and a discharging opening of the cyclone separator is connected with a second rotary feeder. A limestone bin is connected with a third rotary feeder. An outlet of the first rotary feeder, an outlet of the second rotary feeder and an outlet of the third rotary feeder are connected with a feeding opening of a jet feeding device, an air inlet of the jet feeding device is connected with a Roots fan, and an outlet of the jet feeding device is connected with the circulating fluidized bed boiler. The functions of sludge drying and conveying, dry tail gas waste heat utilization, sludge and coal co-combustion, pollutant control and the like can be achieved, bad smell and dust diffusion can be avoided, and the coal-sludge co-combustion system has the beneficial effects of being simple, environment-friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

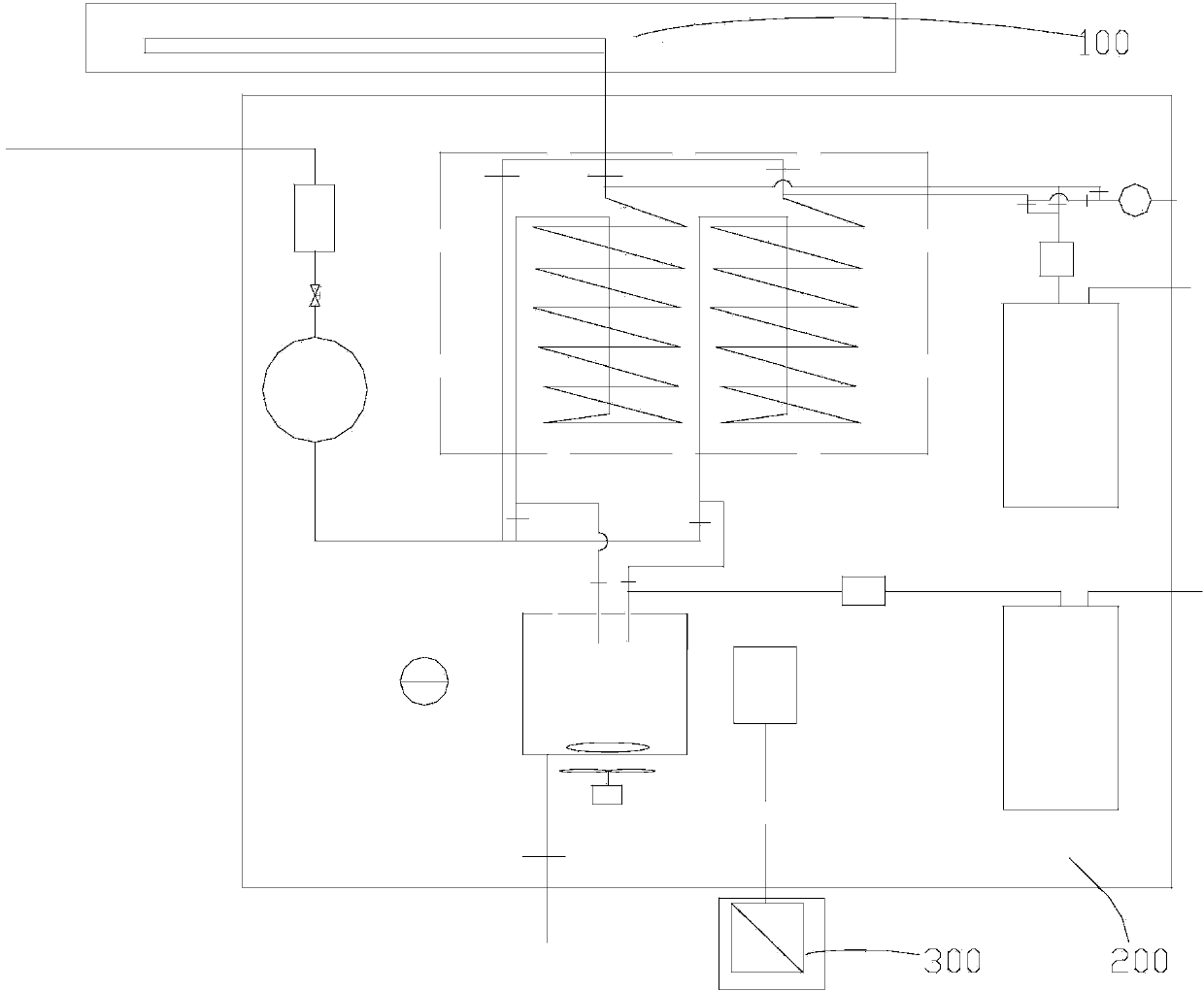

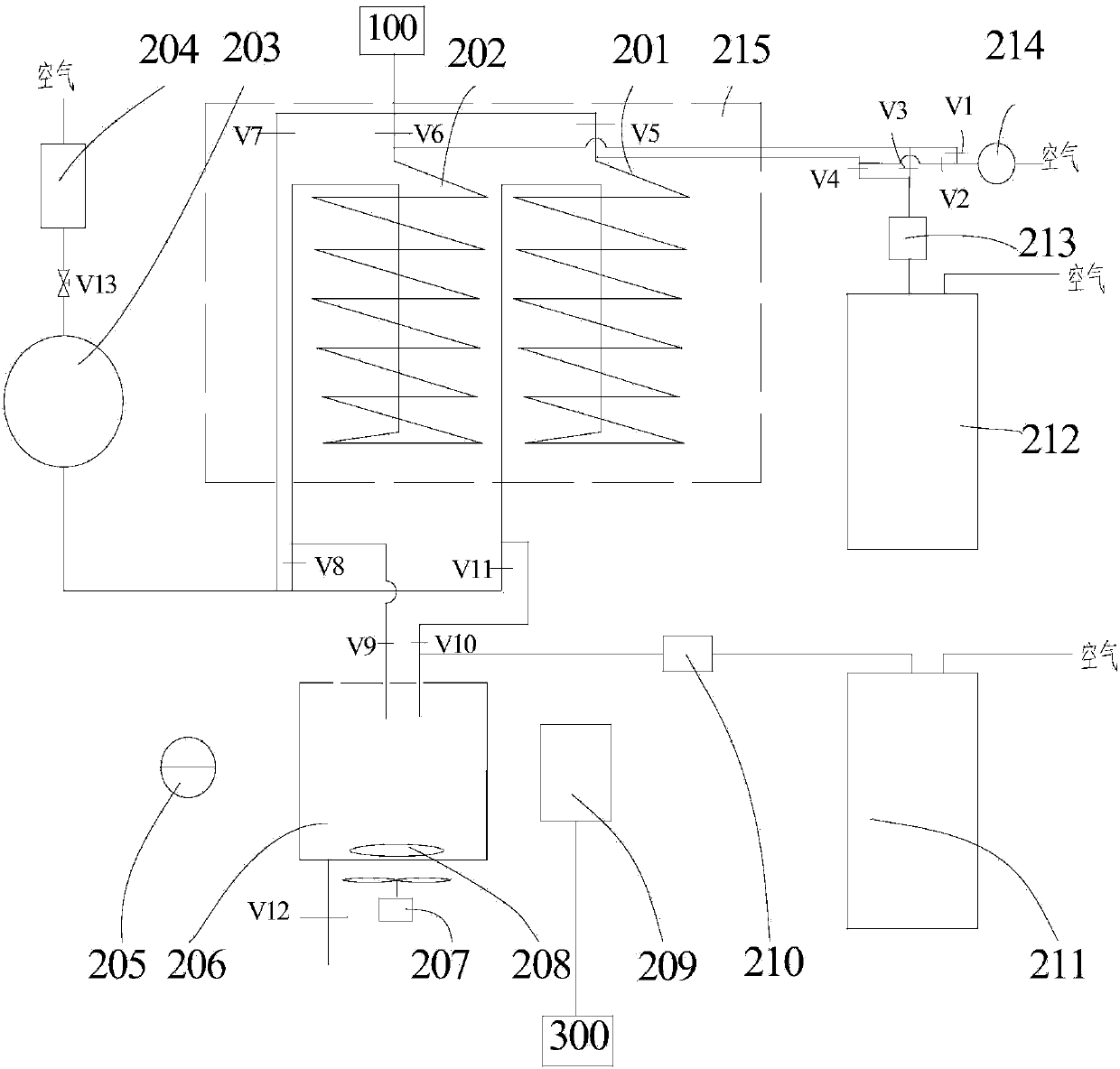

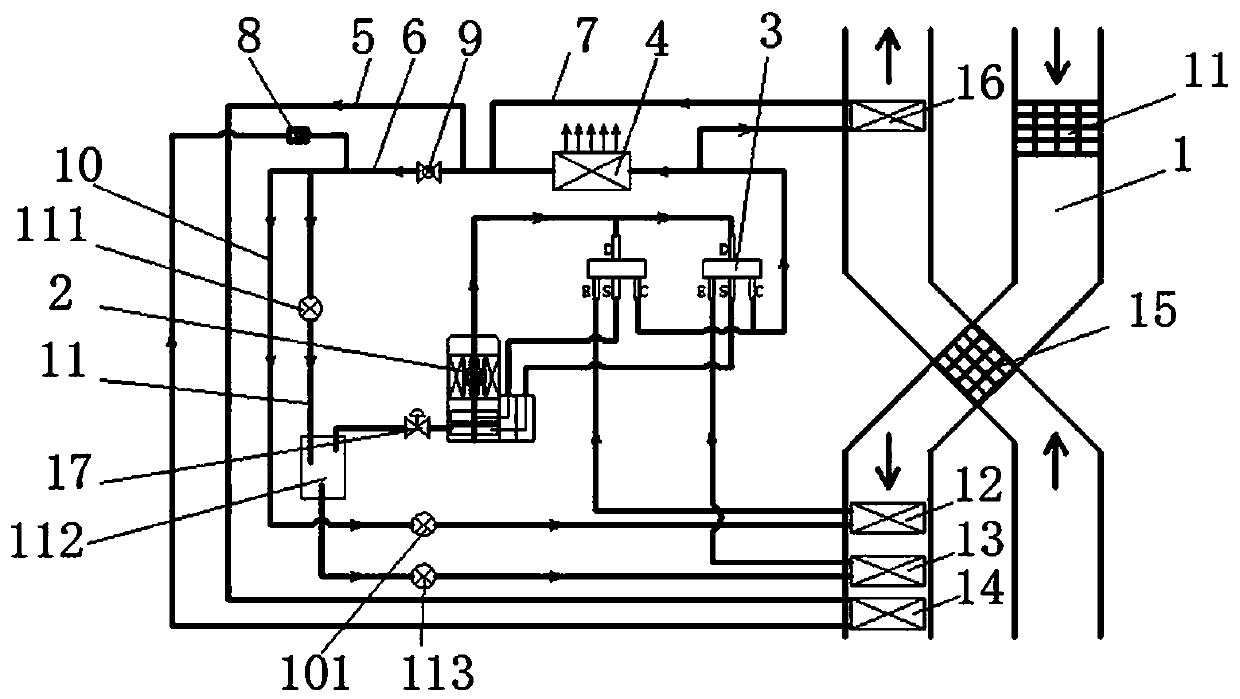

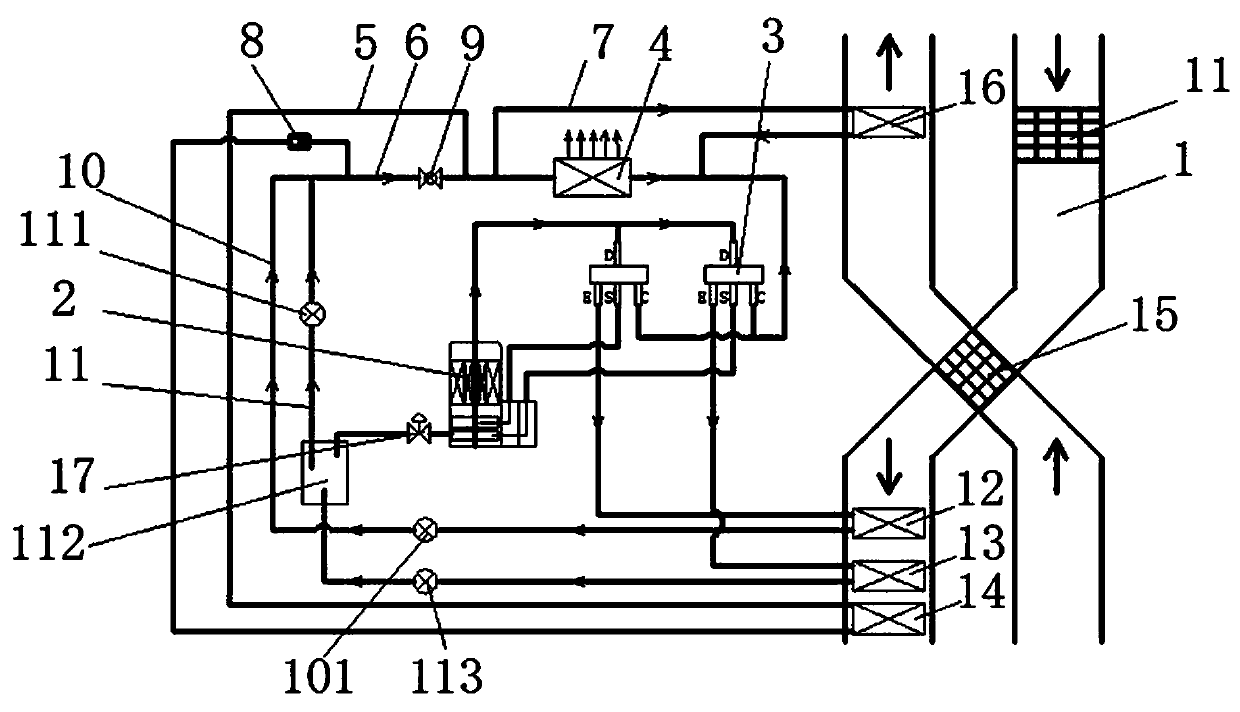

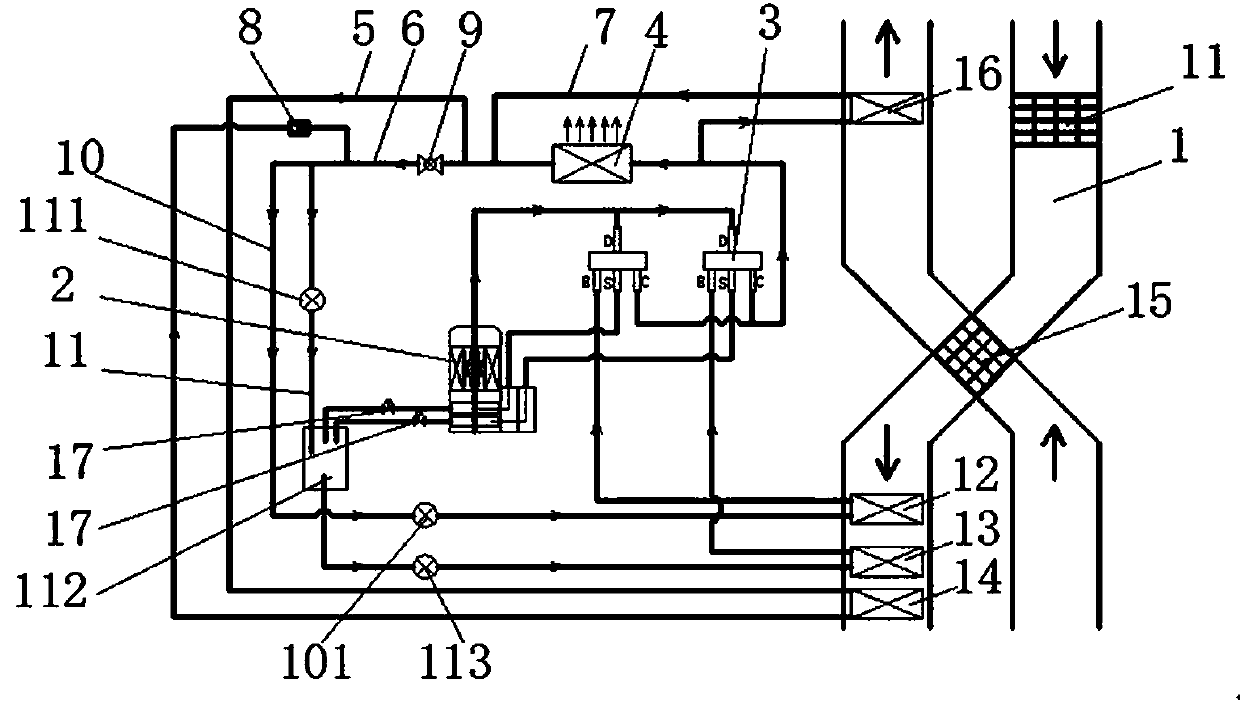

Fresh air dehumidification air conditioner system

PendingCN108679747AReduce heat lossLow energy efficiencyMechanical apparatusFluid circulation arrangementFresh airEngineering

The invention discloses a fresh air dehumidification air conditioner system. The fresh air dehumidification air conditioner system comprises an air conditioner device and a fresh air device. Multipleheat exchangers are sequentially arranged in a pipeline of the fresh air device, the air conditioner device adopts a double-temperature enthalpy-increasing compressor and a step cooling technology tosolve the problems that the evaporation temperature is too low due to the large difference of the inlet air temperature and the outlet air temperature of an evaporator and the system energy efficiencyis low. By the adoption of the fresh air dehumidification air conditioner system, the high-efficiency operation of the fresh air dehumidification air conditioner is realized, it is ensured that the air outlet temperature and the moisture content satisfy the requirements, and meanwhile the condensation problem, caused by the excessively low temperature of an air-drying ball, of the air outlet is avoided.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Smoke exhaust system for realizing energy conservation by using coal-fired boiler flue-gas waste heat recovery and water conservation by using wet desulphurization

InactiveCN102213438AReduce exhaust heat lossReduce the temperatureCombustion processIndirect carbon-dioxide mitigationEvaporationEngineering

The invention provides a smoke exhaust system for realizing energy conservation by using coal-fired boiler flue-gas waste heat recovery and water conservation by using wet desulphurization, wherein a secondary flue-gas heat exchanger is arranged between a dust collector and an induced draft fan, a cooling pipe of the secondary flue-gas heat exchanger is connected with a condensation water outlet pipe; a condensation water inlet pipe is provided with a boiler air heater, an auxiliary heater and a variable frequency boosted water pump which are connected in sequence from left to right, a startup bypass pipeline is arranged between the right side of the variable frequency boosted water pump and the far right end of the condensation water outlet pipe, a valve is arranged on the startup bypass pipeline and a check valve is arranged on the lower side of the valve. The smoke exhaust system for realizing energy conservation by using coal-fired boiler flue-gas waste heat recovery and water conservation by using wet desulphurization provided by the invention reduces the heat losses of smoke exhaust of the boiler, and the condensation water (or closed circulating water), instead of an auxiliary steam, is used to heat the boiler air heater, thus realizing energy conservation; meanwhile, as the temperature of smoke exhaust of the boiler decreases, the temperature of the smoke entering a desulphurization tower can be decreased, and the consumption of water evaporation in the desulphurization tower can be reduced.

Owner:华润电力投资有限公司

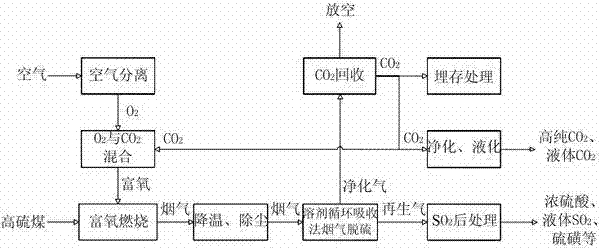

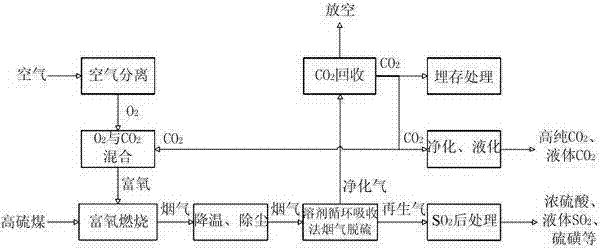

Oxygen-enriched combustion of high-sulfur coal and comprehensive flue gas treatment process

InactiveCN102261647AImprove heat transfer performanceIncrease oxygen contentCarbon compoundsChemical industryChemical industryFlue gas

The invention relates to the oxygen-enriched combustion of high-sulfur coal and the comprehensive treatment process of flue gas. Through the integration and application of various technologies such as oxygen-enriched combustion technology and solvent circulation absorption method flue gas desulfurization technology, a high thermal efficiency, low energy consumption, and low Pollution, good economic characteristics, and taking into account flue gas desulfurization, decarbonization, dust removal treatment and SO2 pollutants, CO2 pollutants recovery and utilization of high-sulfur coal oxygen-enriched combustion and flue gas comprehensive treatment process, so as to provide a clean environment for high-sulfur coal A feasible way has been found. The technical content of the invention can be widely used in the combustion and utilization of high-sulfur coal by coal-fired furnaces in thermal power, chemical industry, building materials and other industries and the comprehensive treatment of SO2 and CO2 in the flue gas.

Owner:成都华西工业气体有限公司

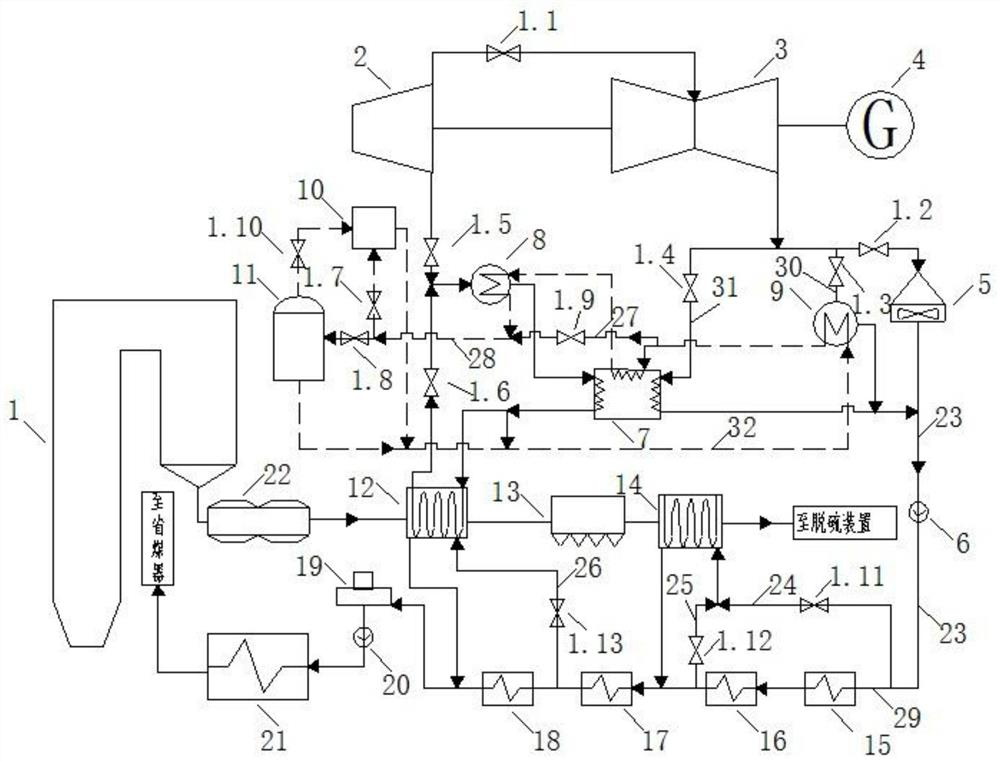

System capable of utilizing smoke waste heat in gradient mode for assisting in removing SO3 and improving dust removing efficiency

InactiveCN105371291AImprove dust removal efficiencyReduce SO3 concentrationLighting and heating apparatusCombustion technology mitigationFlueElectricity

The invention relates to a system capable of utilizing smoke waste heat in a gradient mode for assisting in removing SO3 and improving dust removing efficiency. The system comprises a boiler, a denitration device, an air preheater, an electric dust remover, an induced draft fan, a desulfurizing absorption tower, a chimney, low-pressure heaters, high-pressure heaters, heat exchangers, regulating valves and flow pumps, wherein the denitration device, the air preheater, the electric dust remover, the induced draft fan, the desulfurizing absorption tower and the chimney are connected with a flue at the tail of the boiler in sequence; the low-pressure heaters, the high-pressure heaters and the heat exchangers are arranged on bypasses; the regulating valves and the flow pumps are arranged on pipes and used for controlling flow; the air preheater is connected with the first bypass in parallel, the second bypass is arranged between the air preheater and the electric dust remover, and the third bypass is arranged between the induced draft fan and the desulfurizing absorption tower. The system follows the energy gradient utilization principle, smoke of the boiler is divided to three parts for waste heat utilization, and the smoke waste heat is deeply recycled; besides, the specific resistance of dust in the smoke can be changed, the electric dust removing efficiency can be improved, and the SO3 concentration in the smoke can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

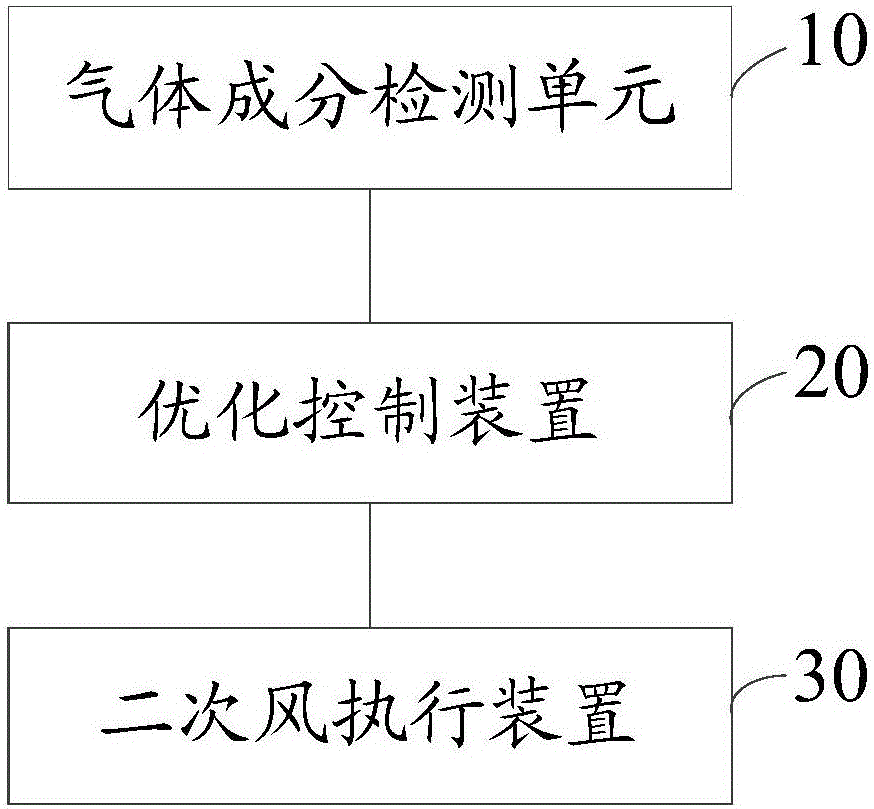

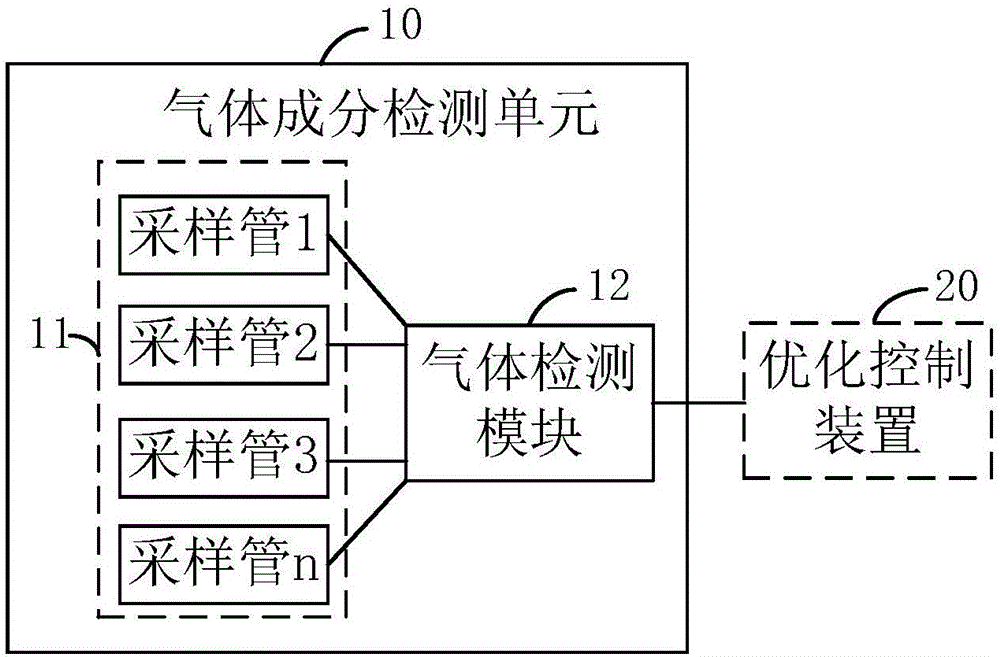

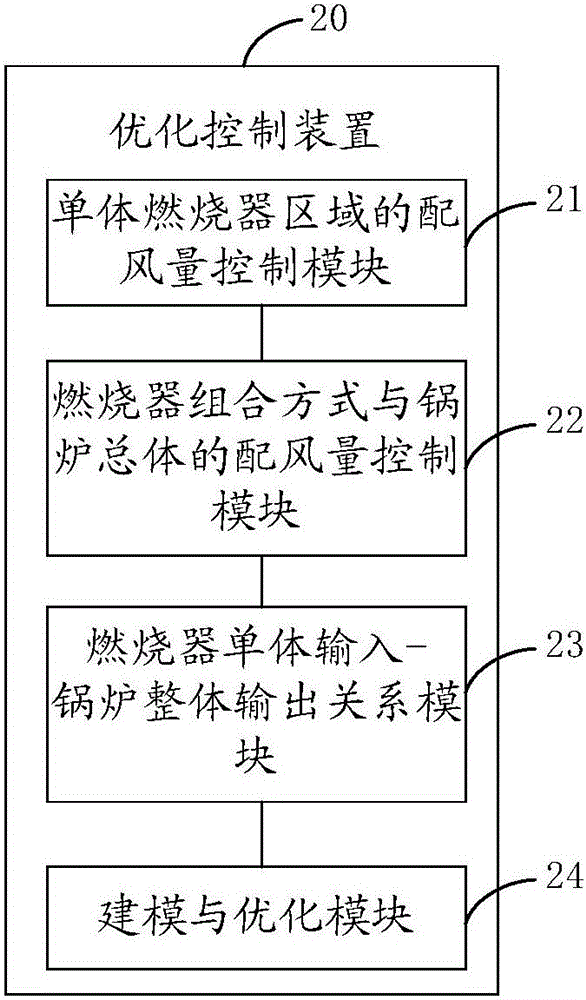

Control system for optimized combustion of combustor

ActiveCN106247396AReduce reducing atmosphereAchieve combustion optimization controlNon-combustible gases/liquids supplyCombustion regulationAir volumeCombustor

The application discloses a control system for optimized combustion of a combustor. The system comprises a gas component detection unit, an optimized control device and a secondary air executing device, wherein the gas component detection unit is used for detecting smoke component numerical values of a region where the combustor is and of a region of a rear flue of a boiler and sending the detection result to the optimized control device; the optimized control device is connected to the gas component detection unit for receiving the smoke component numerical values detected by the gas component detection unit and generating a control command according to the smoke component numerical values; the secondary air executing device is connected to the optimized control device for receiving the control command sent by the optimized control device and controlling a second air baffle plate executing mechanism according to the control command. According to the technical scheme disclosed by the invention, operation under a relatively low excessive air coefficient is guaranteed by controlling the air supply amount of the combustor, so that the burnout efficiency of fuels is effectively improved, the reducing atmosphere of the boiler is reduced and coking and corroding phenomena are improved while the heat loss due to exhaust gas is reduced, and the combustion process is safe, efficient and low in pollution.

Owner:河北思路科技有限公司

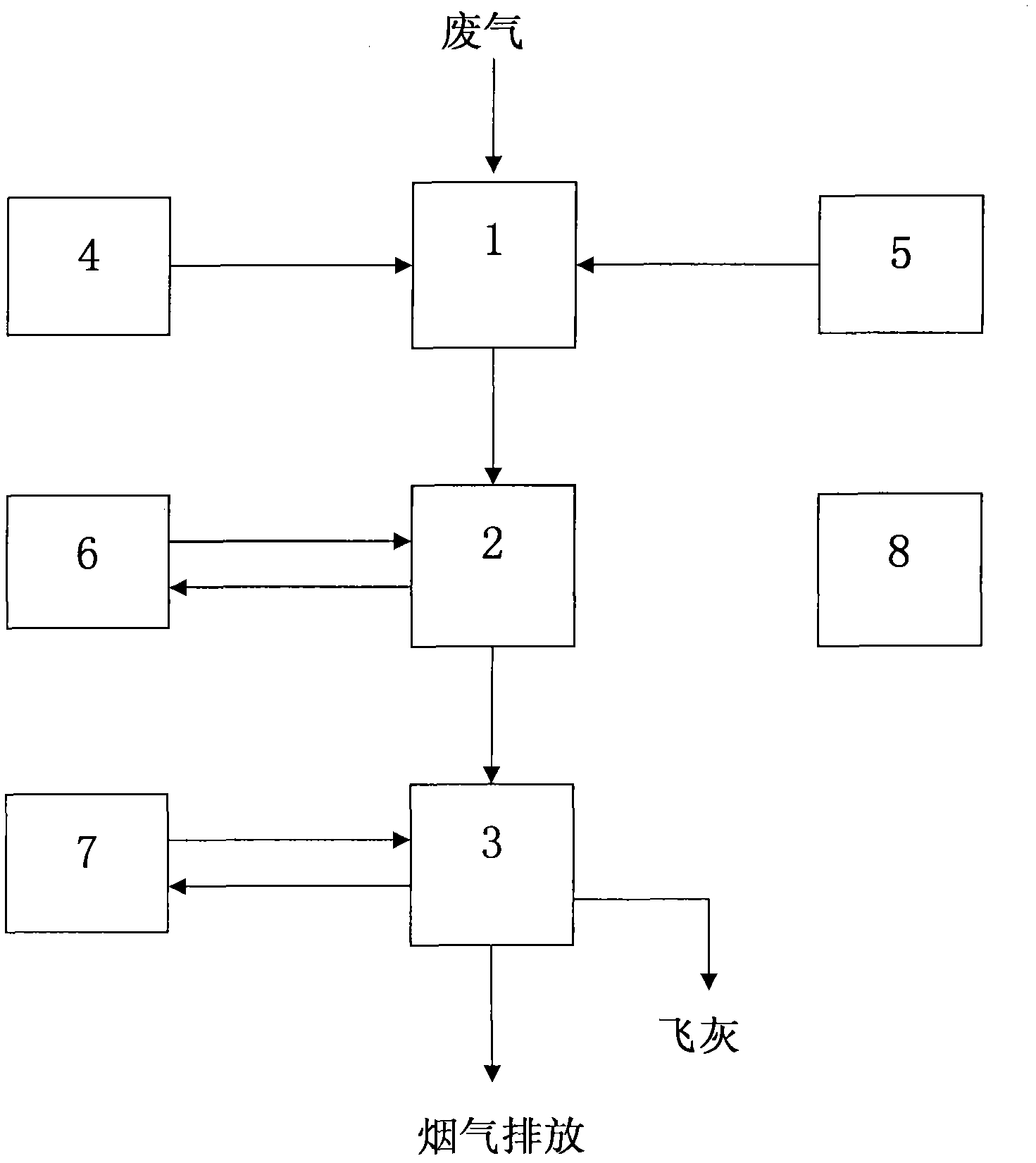

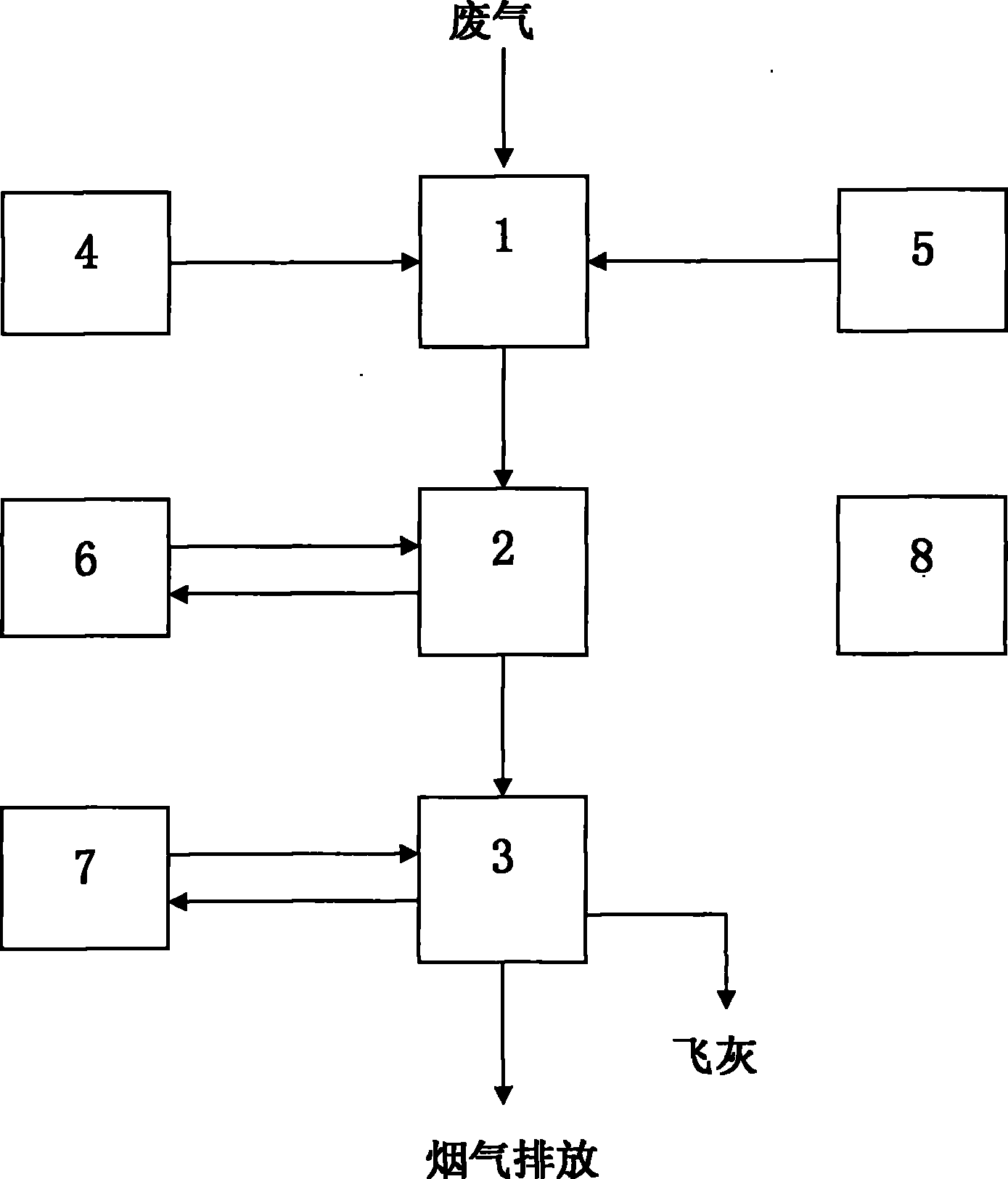

Low energy consumption system for purifying and incinerating harmful gases

InactiveCN102519049ALow costSolve not all burnIndirect carbon-dioxide mitigationIncinerator apparatusCombustorSorbent

The invention discloses a low energy consumption system for purifying and incinerating harmful gases. The low energy consumption system consists of main body units such as a waste gas purifying and incinerating unit, a waste heat recovering unit and a flue gas treating body unit as well as auxiliary equipment such as fuel equipment, combustion-supporting air equipment, heat exchange medium equipment and harmful gas adsorbent equipment. According to the low energy consumption system, due to the adoption of various latest energy-saving combustion technologies and energy-saving emission-reducing measures, the optimization is carried out from the whole, the problems that energy consumption of a DTO (Direct-Fired thermal Oxidizer) of a conventional chamber type waste gas incinerator is over high, RTO (Regenerative Thermal Oxidizing Furnace) waste gas of a reversed heat accumulation type waste gas incinerator is not completely combusted, a heat accumulator is blocked by dust-containing waste gas and the like are solved and various harmful waste gases can be continuously purified and incinerated at low cost. Due to the adoption of a brand-new heat accumulation incineration mode, the low energy consumption system has the characteristics that the heat accumulator is easy to clean for avoiding blocking, the harmful waste gases are completely incinerated and discharged after reaching the standard, the energy-saving effect is remarkable and the like. In addition, due to the adoption of measures of selecting an oxygen-enriched combustor, matching with oxygen-enriched and combustion-supporting air supply equipment, providing hot air for incineration to support combustion and the like, the consumption of auxiliary fuel can be effectively reduced, the incineration treatment expenses are reduced and the popularization and the application are facilitated.

Owner:朱海生

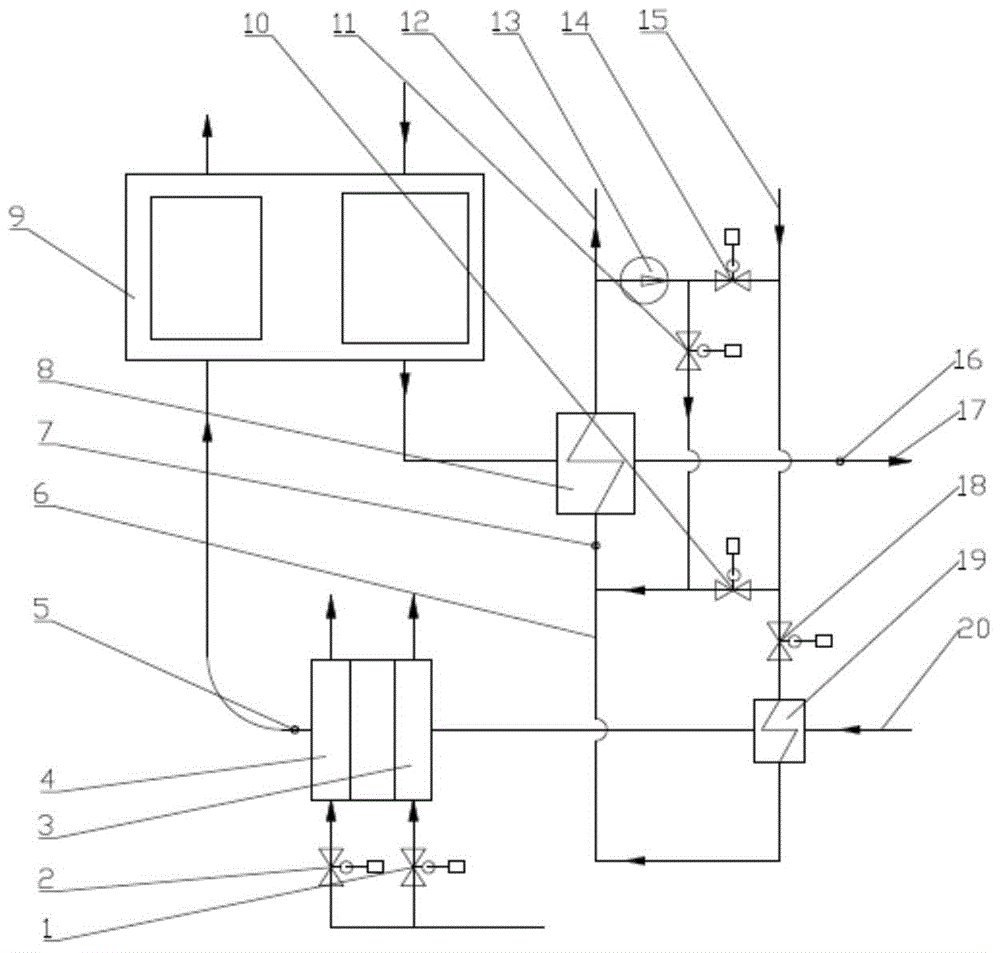

Air preheating and flue gas waste heat utilizing system and method

InactiveCN104807035ASolve the existing disadvantagesRaise the inlet air temperatureFeed water supplyCombustion processAir preheaterFlue gas

The invention particularly aims to the technical field of boiler air preheating. A disclosed air preheating and flue gas waste heat utilizing system comprises a flue gas channel (17), an air channel (20), an air preheater (9), a condensed water flue heat exchanger (8) and a condensed water air channel heat exchanger (19), and further comprises a condensed water feeding main pipe (15) and a condensed water returning main pipe (12); the flue gas channel (17) and the air channel (20) are connected with the air preheater (9); the condensed water flue heat exchanger (8) is arranged on the flue gas channel (17) at the back of the air preheater (9) in a flue gas flowing direction; the condensed water air channel heat exchanger (19) is arranged on the air channel (20) at the front of the air preheater (9) in an air flowing direction. According to the air preheating and flue gas waste heat utilizing system, flue gas discharge and heat exchange can be automatically adjusted according to change of operation conditions; on the premise of ensuring the safety of a heated surface and the regular operation of the system, the maximization of the heat circulation efficiency and the system economical efficiency is ensured.

Owner:郝江平

Coal-sludge co-combustion system based on high-temperature smoke drying and circulating fluidized bed boiler

The invention relates to a coal-sludge co-combustion system based on high-temperature smoke drying and a circulating fluidized bed boiler. A discharging outlet of a sludge storage bin is connected with a feeding inlet of a spray drying pipe through a screw pump. An air inlet of the spray drying pipe is connected with an outlet flue of a cyclone separator of the circulating fluidized bed boiler. An outlet I of the spray drying pipe is connected with a dry sludge bin through a rotary feeder I, and an outlet of the dry sludge bin is connected with the circulating fluidized bed boiler through a spiral conveyer so that dry sludge in the dry sludge bin can be fed into a dense-phase zone of the circulating fluidized bed boiler through the spiral conveyer to be combusted; an outlet II of the spray drying pipe is connected with the cyclone separator, an unloading opening of the cyclone separator is connected with the dry sludge bin through a rotary feeder II, and an exhaust opening of the cyclone separator is connected with the circulating fluidized bed boiler through a cooling condenser and a vent fan. The coal-sludge co-combustion system integrates the functions of sludge drying, combustion and pollutant control, and has the characteristics of being concise, environmentally friendly and efficient.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Denitration of non-selective catalytic reducing smoke

InactiveCN1817415ALow running costInexpensive flue gas denitrification processDispersed particle separationCoalEngineering

A non-selective catalytic reduction process for denitrating fume without spraying reducer includes such steps as controlling the excessive air coefficient of burner in boiler to 0.75-0.85, spraying burn-off air in it, regulating said excessive air coefficient to 1.05-1.15, spraying fine coal powder in it to obtain CO, H2 and hydrocarbon gas used as reducer, non-selective catalytic reduction reaction between NSCR catalyst and NOx in fume in the catalytic reactor, burning the residual CO gas under the action of oxidizing catalyst, and recovering its energy in preheater.

Owner:孙克勤 +3

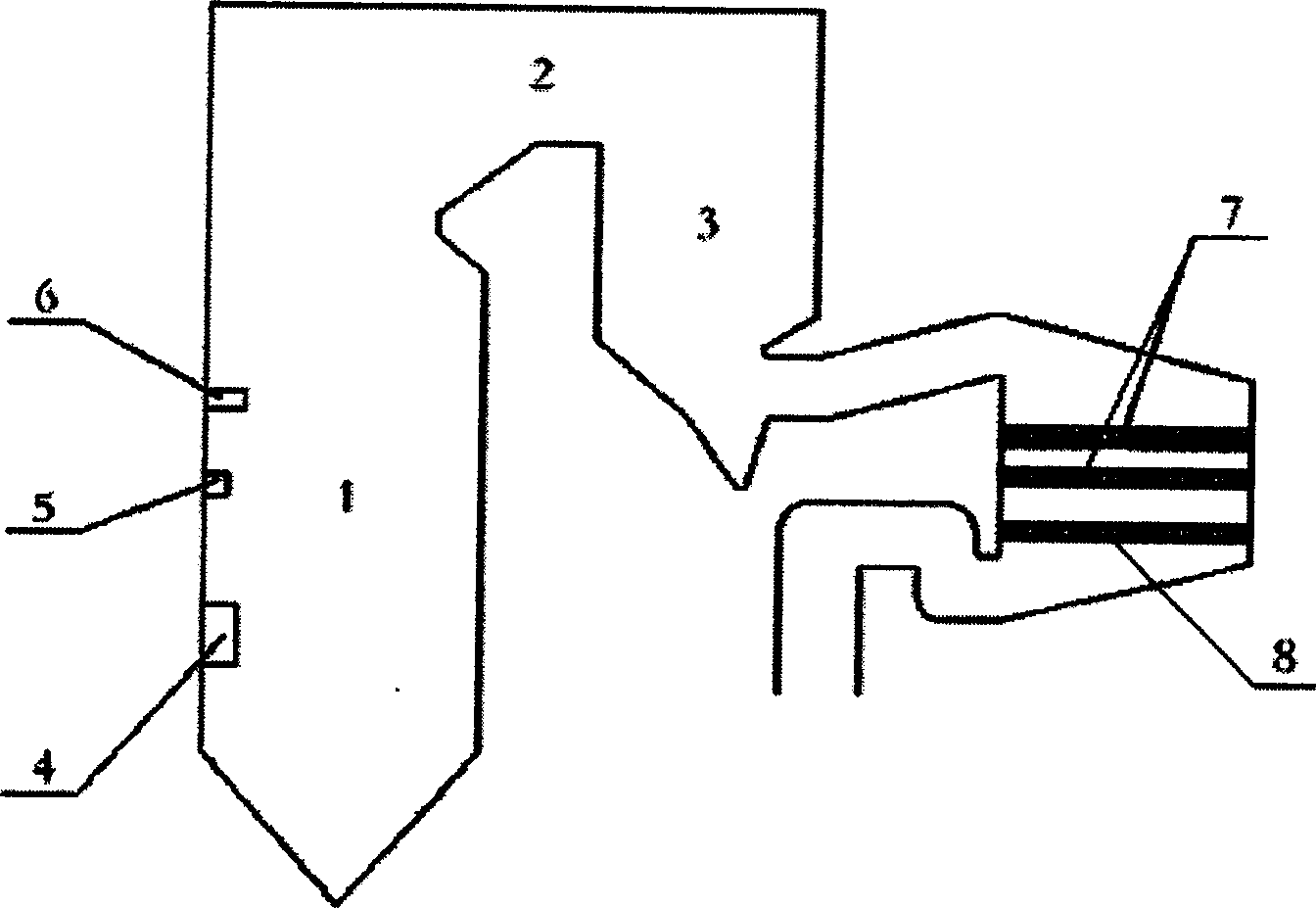

Smoke recirculator for boiler

InactiveCN105588135AReduce emission concentrationLower combustion temperatureIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyEngineeringOxygen

The invention relates to the technical field of boiler burning, in particular to a smoke recirculator for a boiler. According to a conventional smoke recirculator, auxiliary equipment is needed, a system is complicated, the investment is large, and it is quite difficult to stably lowering the oxygen concentration to the degree which is low enough in the true sense on most occasions. According to the smoke recirculator for the boiler, recirculating smoke and air are mixed, so that the burning temperature is decreased, the oxygen concentration is lowered, the smoke heat exchange coefficient is increased, and the overall efficiency of the boiler is improved; by arranging a smoke and air mixing chamber and optimizing the structure of a flue system, a complicated flue structure is simpler and more reasonable, and the stability and safety of the whole system are improved.

Owner:TAIJUNE BOILER IND KUSN

Boiler using gas or fuel oil

InactiveCN1862090AHigh thermal efficiencyOvercome uniformity issuesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberFuel oil

There is disclosed a gas-firing or oil-burning boiler, in which, a combustion stirring reactor and a combustion chamber connected with a liquid or gaseous fuel feeding device are mounted in the hearth. The hearth bed is used as the boiler bed and the side wall of the hearth is connected with the boiler bed. The surface of the hearth side wall is made of materials capable of resisting the temperature not below 1500 deg. c. The fuel feeding device is connected with the combustion chamber through the front boiler wall and at the exhaust nozzle is disposed an igniter. When the temp. on the wall surface of the combustion chamber is not below 850 deg. c. the boiler can realize non-flame burning in the boiler.

Owner:UNIV OF SCI & TECH OF CHINA

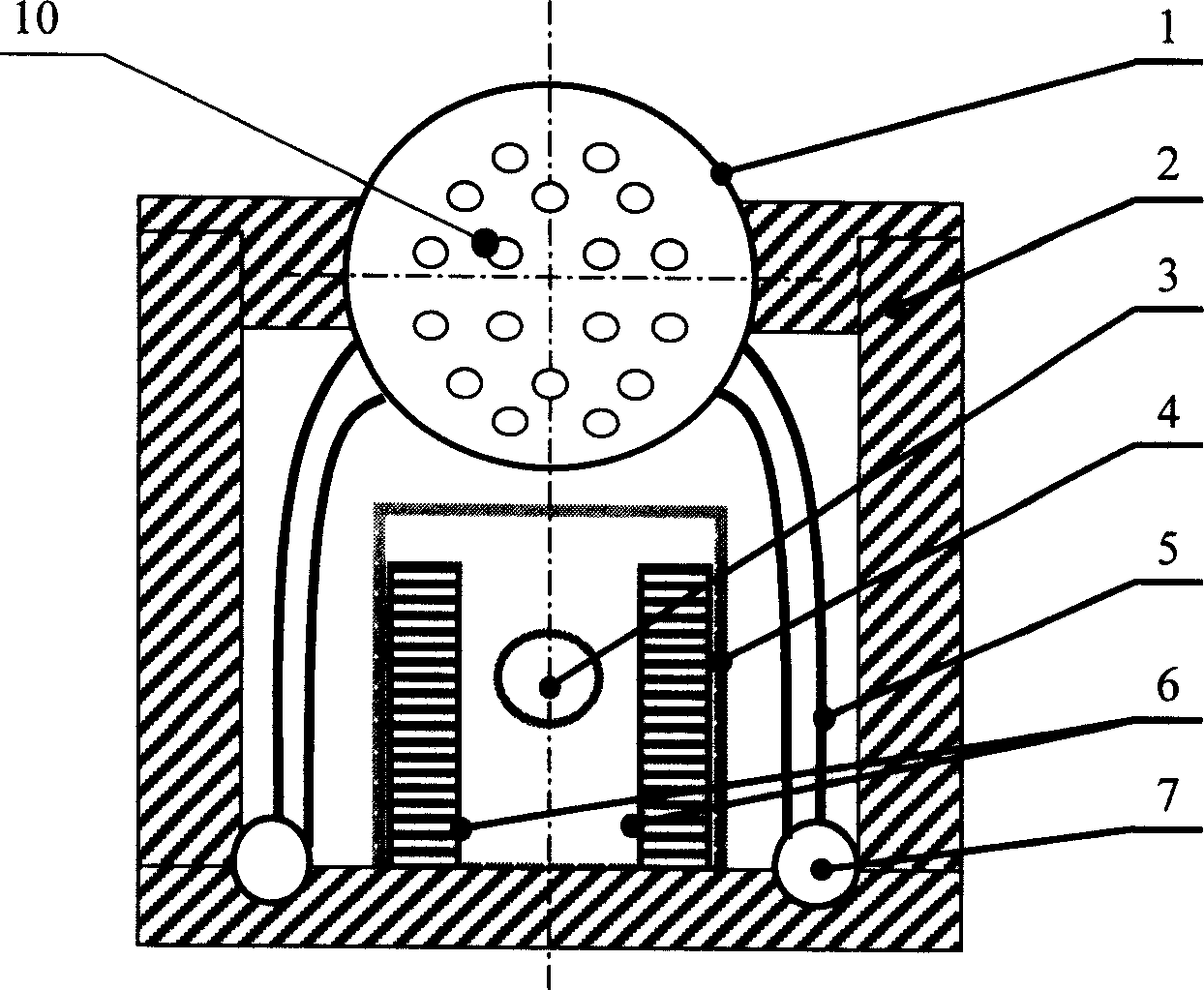

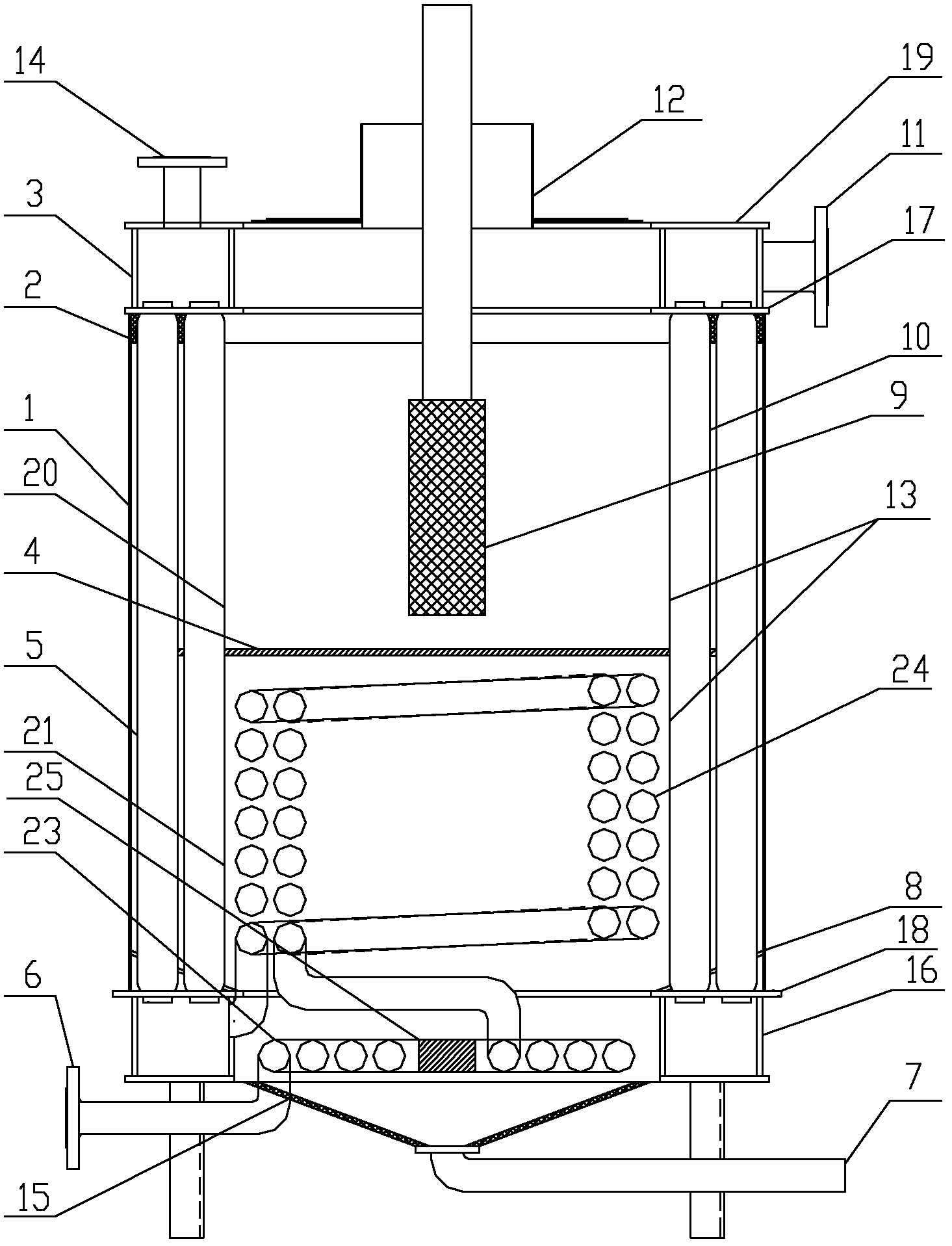

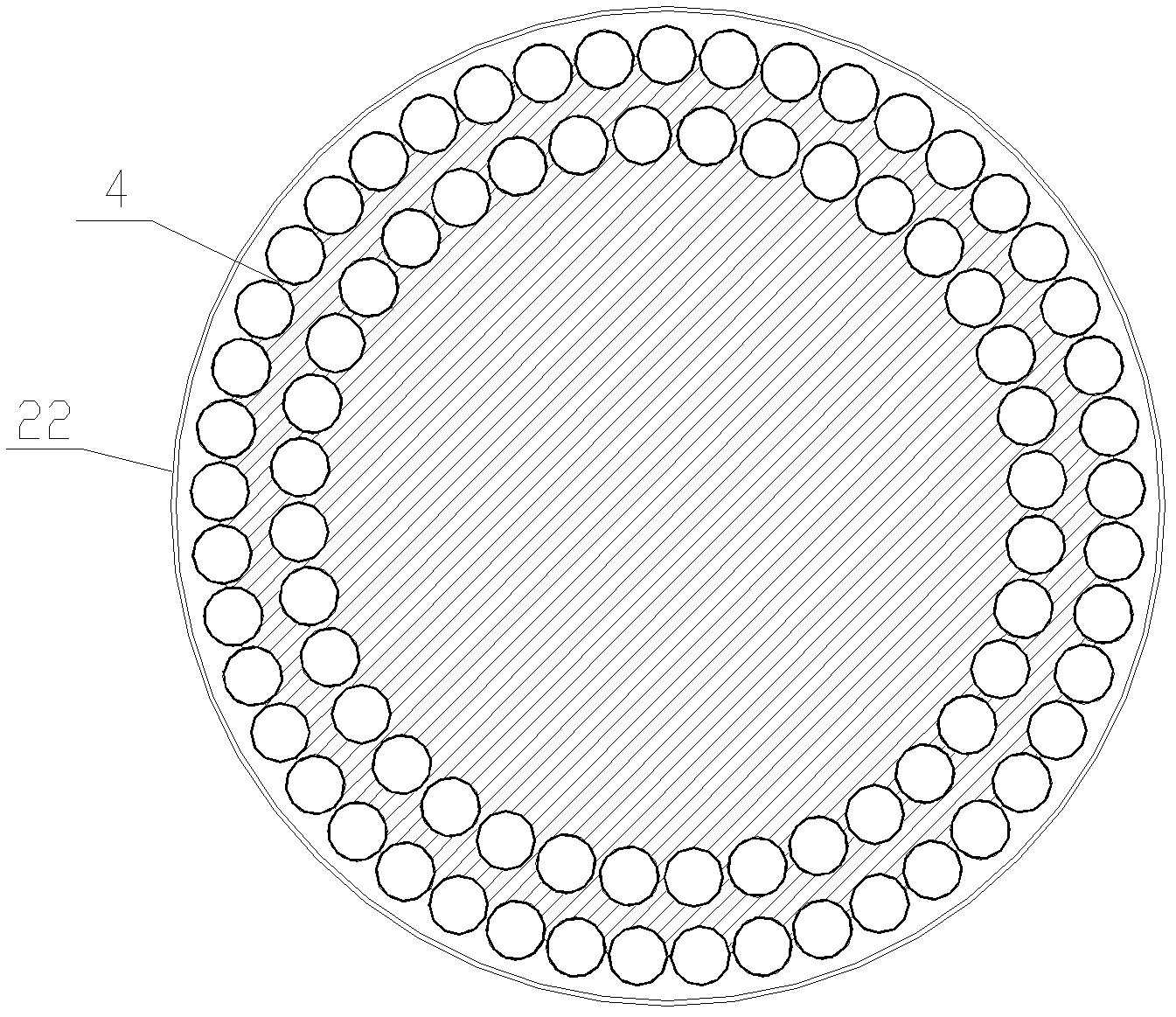

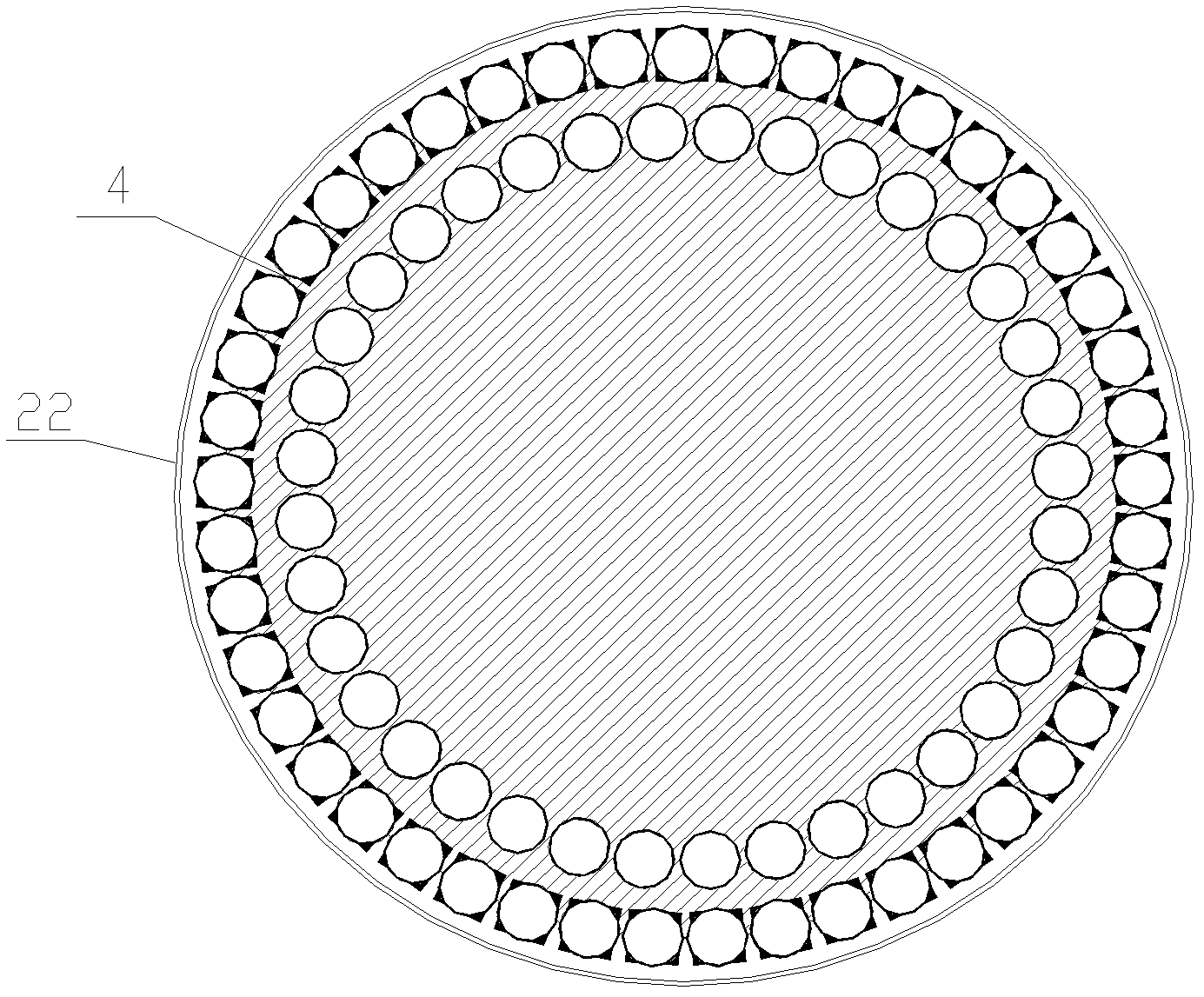

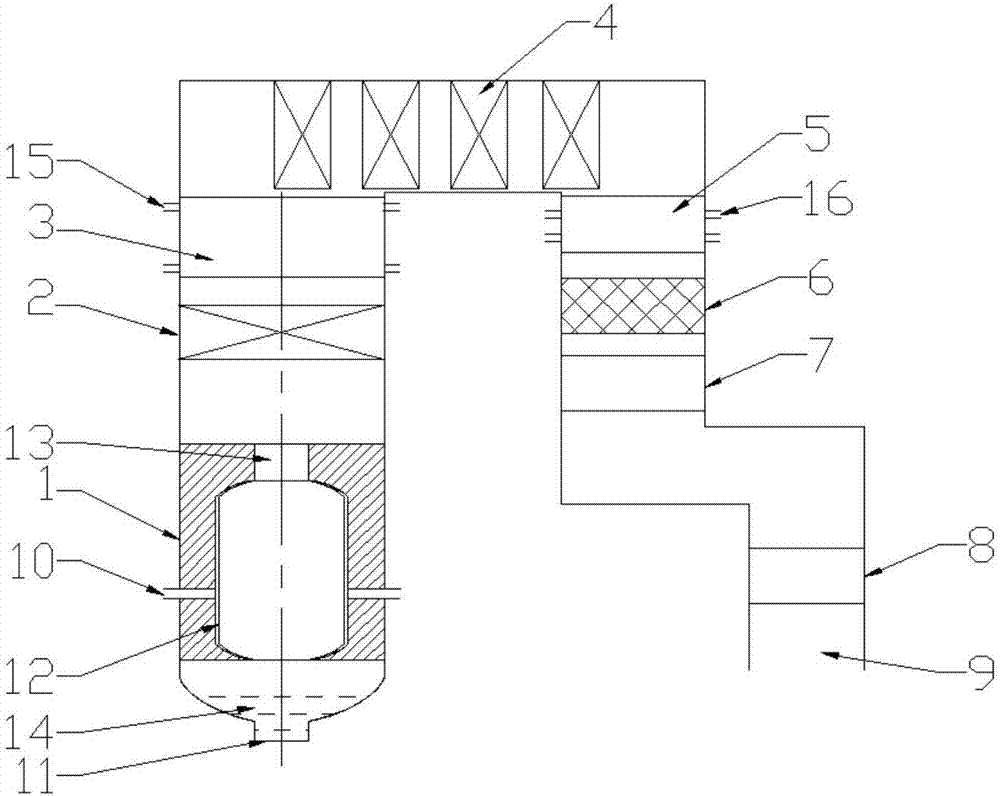

Through-flow type narrow-clearance integral condensation hot-water boiler

InactiveCN102635945ALow investment costAvoid uneven temperature distributionAir heatersSustainable buildingsCombustorEngineering

A through-flow type narrow-clearance integral condensation hot-water boiler comprises a shell. An annular water outlet header is arranged on the upper portion of the shell, an annular water feeding header is arranged on the lower portion of the shell, a deep condensation heat exchange tube bundle and a V-shaped condensation collecting device with a condensate neutralizing treatment device are arranged below the annular water feeding header, an all-premixing metal fiber combustor is arranged on a top plate of a boiler, a metal fiber head of the all-premixing metal fiber combustor penetrates into a radiation heat exchange space so as to realize the characteristic of high radiation heat exchange capacity of the metal fiber head, the annular water outlet header is communicated with the annular water feeding header via inner and outer circles of annular water cooling walls consisting of a plurality of vertical water tubes, a clearance with the size of 1-2mm is reserved between each two adjacent vertical water tubes and is used as a smoke circulation channel, smoke realizes convection heat exchange and condensation heat exchange when flowing among the vertical water tubes, heat is transmitted to working medium water in the vertical water tubes, the deep condensation heat exchange tube bundle deeply cools the smoke, and efficiency of the boiler is improved. In addition, the through-flow type narrow-clearance integral condensation hot-water boiler is simple in structure and convenient in manufacture, and can effectively avoid the harm that tubes are easy to be exploded due to uneven heat load distribution of a traditional through-flow boiler.

Owner:XI AN JIAOTONG UNIV

Coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation

The invention relates to a coal-sludge multi-fuel combustion system based on two-medium flue gas drying and pneumatic transportation. A sludge storage cabin is connected with a spraying drying pipe; the spraying drying pipe is connected with a mixing chamber; one path of an inlet of the mixing chamber is connected with an outlet flue of a cyclone separator, and the other path is connected with an outlet of a dust remover through a cold smoke draught fan; a spraying drying pipe outlet I is connected with a rotary feeder I; a spraying drying pipe outlet II is connected with the cyclone separator; an exhausting hole of the cyclone separator is connected with a circulating fluidized bed boiler through a cooling condenser and an exhausting steam draught fan; an unloading hole of the cyclone separator is connected with a rotary feeder II; a limestone cabin is connected with a rotary feeder III; the rotary feeder I, the rotary feeder II and the rotary feeder III are connected with the circulating fluidized bed boiler through a spraying feeder; and a gas inlet of the spraying feeder is connected with a Roots draught fan. With the adoption of the coal-sludge multi-fuel combustion system, functions of sludge desiccation and transportation, residual heat utilization of dry tail gas, multi-fuel combustion of sludge and coal, control of pollutants and the like can be realized, and the diffusion of stench and dust is facilitated; and the system has the characteristics of simplicity, environmental friendliness and high efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Low-odor type reed pulp black liquor combustion boiler and combustion method thereof

ActiveCN102734808ASolve the pollution of the environmentIncreased combustion air temperatureIncinerator apparatusAir preheaterBoiler furnace

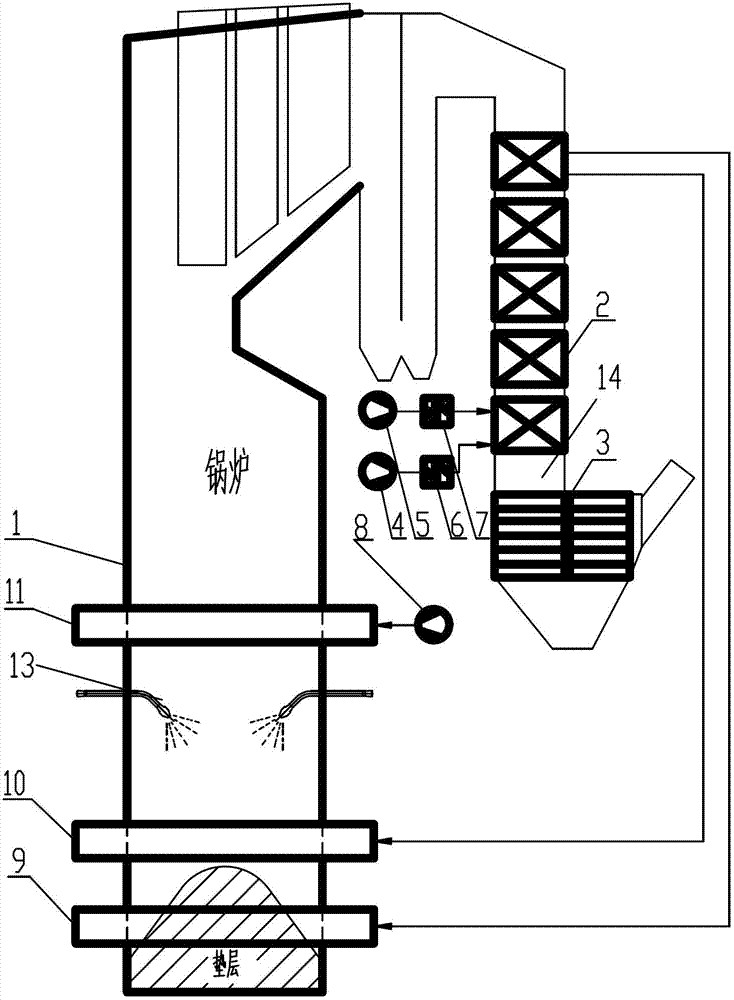

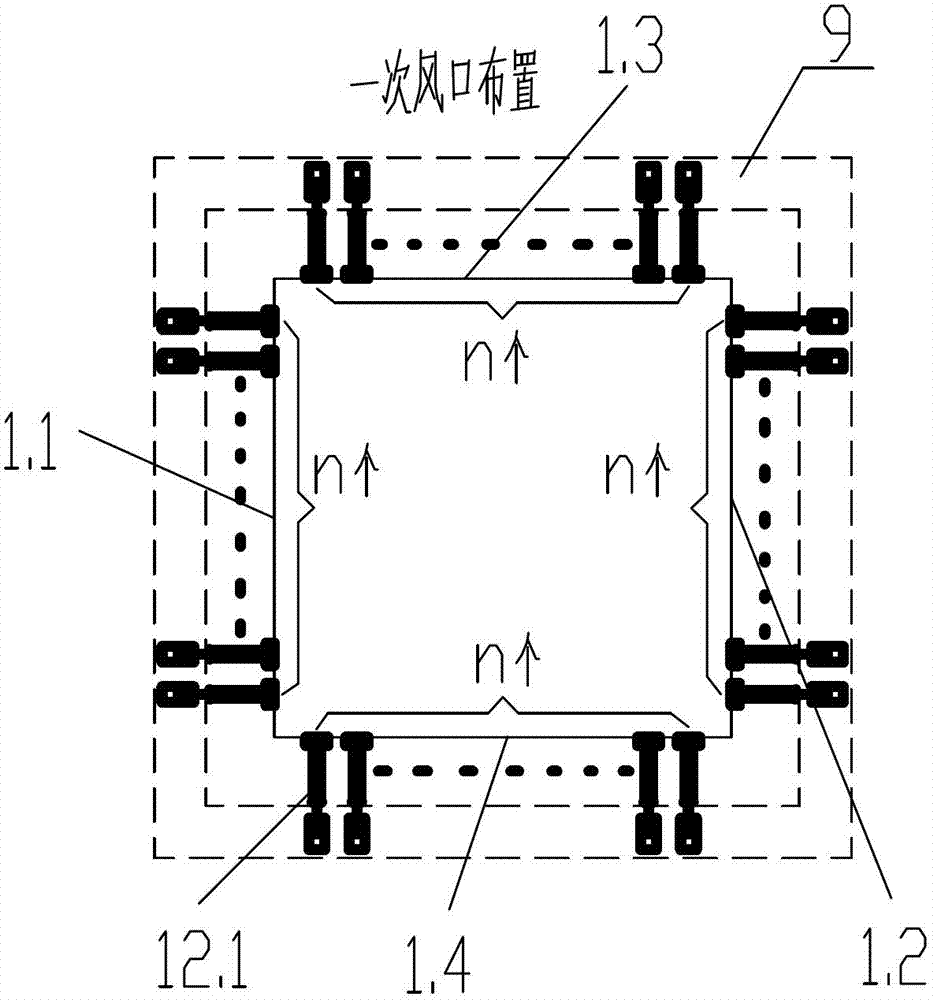

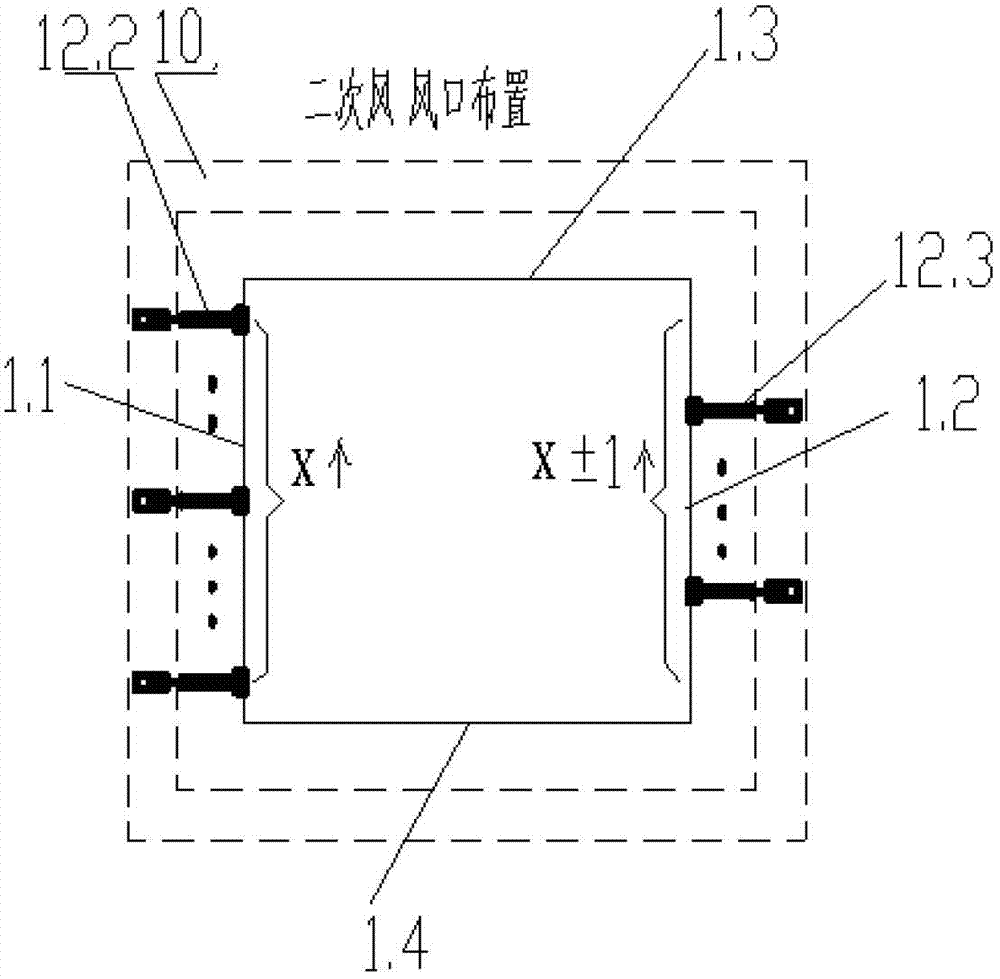

The invention discloses a low-odor type reed pulp black liquor combustion boiler and a combustion method thereof. The low-odor type reed pulp black liquor combustion boiler comprises a boiler body structure, an air supply structure in a hearth of the boiler body structure comprises a primary air supply duct, a secondary air supply duct and a tertiary air supply duct which are sequentially arranged from bottom to top; air outlets of the primary air supply duct is arranged on the front wall, the rear wall, the left side wall and the right side wall of the hearth; air outlets of the secondary air supply duct is arranged on the front wall and the rear wall of the hearth; air outlets of the tertiary air supply duct is arranged on the front wall and the rear wall of the hearth; and air inlet sections of the primary air supply duct and the secondary air supply duct are connected with an air preheater. Secondary air is fed in from the front wall and the rear wall alternatively, thus being beneficial to full mixing of air and smoke as well as black liquor particles, disturbing rising smoke, improving the turbulivity, enhancing the combustion, enabling the smoke to be uniformly distributed in the hearth, and improving the consistency of temperature field equal-altitude sections.

Owner:WUHAN WUGUO ENERGY ENG CO LTD

Harmless disposal system for refuse and method for refuse disposal by harmless disposal system

InactiveCN104501176AAvoid corrosionLow costSolidificationLiquefactionHigh concentrationChemical products

The invention relates to a harmless disposal system for refuse and a method for refuse disposal by the harmless disposal system. The refuse is subjected to combustion disposal by a circulating fluidized bed combustion technology, and O2 / CO2 mixed gas formed by mixing of high-concentration oxygen with recycled flue gas is adopted to substitute for air to participate in solid refuse combustion during refuse combustion. A relatively high-temperature combustion condition can be achieved in oxygen-enriched and oxygen-enriched combustion environments, and generation of dioxin and dioxin precursors is inhibited. After flue gas is subjected to denitration, dust removal and desulfurization, one part of the flue gas forms the recycled flue gas after being preheated by a gas-to-gas heat exchanger; after the other part of the flue gas is subjected to multi-stage compression and multi-stage cooling and water therein is recycled, high-purity liquid-state CO2 is formed to serves as chemical products or be used for oil well oil displacing or geological storage. The harmless disposal system adopting refuse combustion does not discharge gaseous pollutants any longer, so that the problem of secondary pollution caused by refuse combustion is solved thoroughly, and harmless disposal with near-zero emission of gaseous pollutants caused by refuse combustion is realized truly.

Owner:BEIJING JIAOTONG UNIV

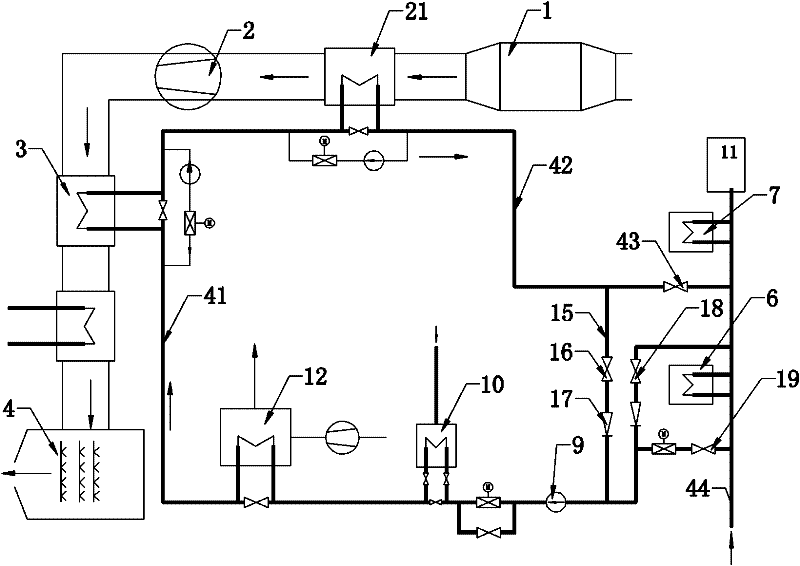

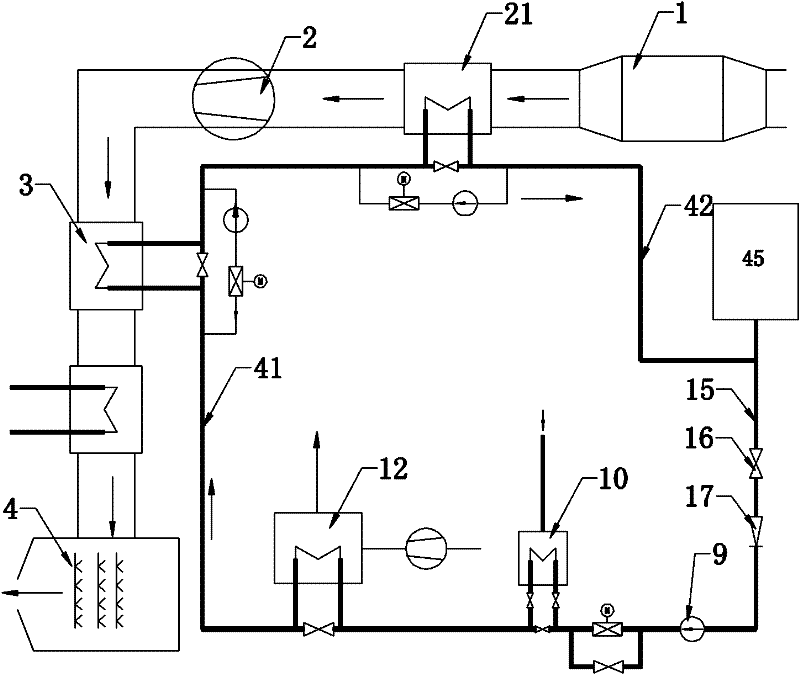

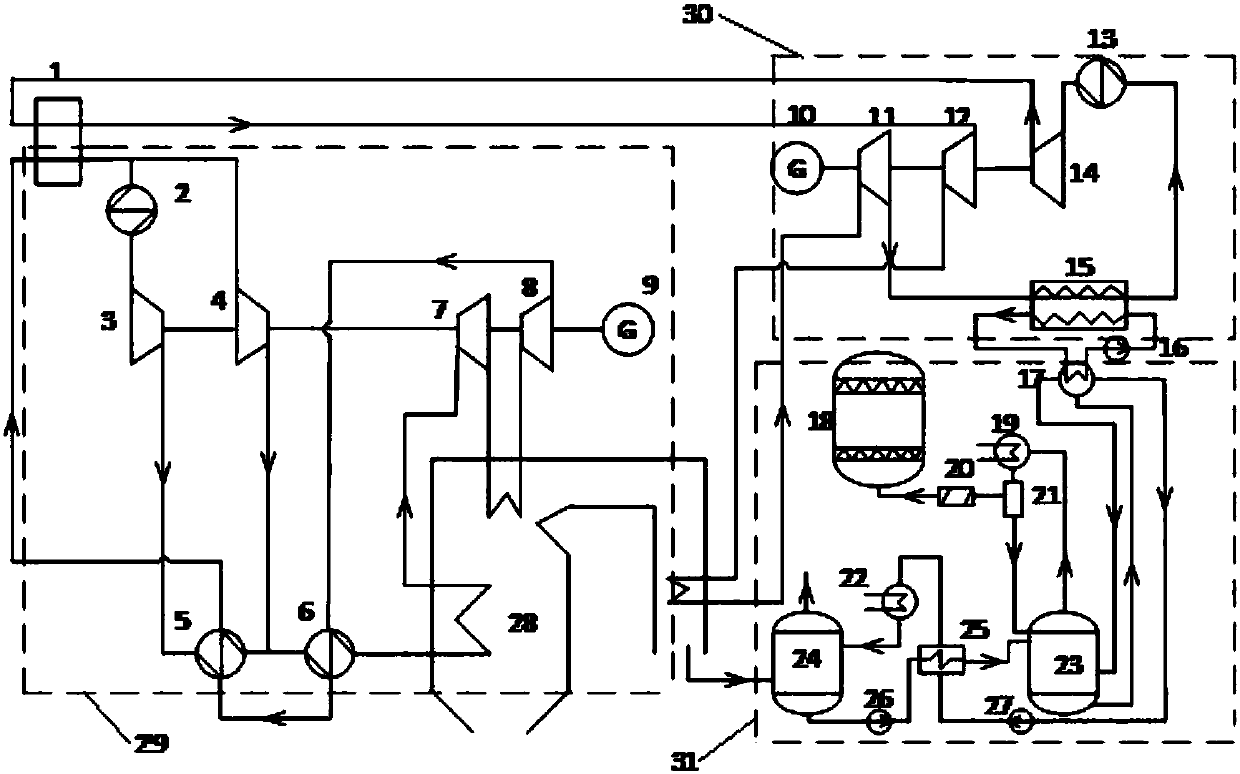

Integrated carbon capture carbon dioxide double-Brayton-cycle power generation system

PendingCN107859539AReduce waste heat lossReduce exhaust heat lossCombustion technology mitigationSteam engine plantsReboilerCarbon dioxide

The invention relates to an integrated carbon capture carbon dioxide double-Brayton-cycle power generation system. The integrated carbon capture carbon dioxide double-Brayton-cycle power generation system comprises a main cycle, a bottom cycle and a carbon capture system. The main cycle comprises a waste heat exchanger, a precooler, a main compressor, a recompressor, a low-temperature regenerator,a high-temperature regenerator, a high-pressure CO2 turbine, a low-pressure CO2 turbine, a main cycle power generator and a boiler which are connected through a main cycle working medium pipeline. The bottom cycle comprises a CO2 turbine, a second compressor, a second precooler, a first compressor, a bottom cycle power generator and a water-CO2 heat exchanger which are connected through a bottomcycle working medium pipeline. The carbon capture system comprises a reboiler, a storage tank, an overhead condenser, a compressor, a steam-water separator, a condenser, a regeneration tower, an absorption tower, a rich-lean liquor exchanger, a rich liquor pump and a lean liquor pump. Through the integration of the whole system, the waste heat utilization rate of a main cycle power generation system is increased, the source problem of a cycle working medium of a supercritical CO2 Brayton-cycle power generation system and the application problem of captured carbon dioxide are solved, and the CO2 emission reduction cost of power plants is lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method

ActiveCN107975782AEfficient emissionsReduce pollutionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberSlag

The invention discloses a slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method. The slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system comprises a lean-oxygen combustion chamber and a carbon monoxide catalytic oxidation device. A cavity is contained in the lean-oxygen combustion chamber. The upper end of the lean-oxygen combustion chamber is provided with a smoke outlet. A secondary combustion chamber is arranged on the downstream side of the smoke outlet of the lean-oxygen combustion chamber. A smoke inlet of the secondary combustion chamber communicates with the smoke outlet of the lean-oxygen combustion chamber. An air supplementation chamber is arranged on the downstream side of the smoke outlet of the secondary combustion chamber. A smoke inlet of the air supplementation chamber communicates with a smoke outlet of the secondary combustion chamber. The downstream side of the smoke outlet of the air supplementation chamber is provided with the carbon monoxide catalytic oxidation device. The smoke inlet of the carbon monoxide catalytic oxidation device communicates with a smoke outlet of the air supplementation chamber. According to the slag lean-oxygen combustion catalytic oxidation type staged combustion boiler system and method, through staged combustion of coal, high efficiency and low emission of NOx can be achieved, and atmospheric pollution is lowered; a SCR denitration device is not arranged, so that the catalyst optimum temperature limitation problem, the ammonia injection mixing evenness problem, the catalyst waste treatment problem and other serious problems in the denitration process can be avoided.

Owner:XI AN JIAOTONG UNIV

Machine-boiler coupled heat supply waste heat utilization system

PendingCN111623402AGood effectSolve the problem of waste, which is not conducive to energy conservation and environmental protectionEmission preventionSteam useElectrolysisBoiler (power generation)

The invention provides a machine-boiler coupled heat supply waste heat utilization system. The system comprises a boiler smoke waste heat reuse system, a steam turbine power generating system, a condensate water reheating system and a heating system. The boiler smoke waste heat reuse system comprises smoke-water heat exchangers. The steam turbine power generating system comprises an intermediate-pressure cylinder and a low-pressure cylinder communicating with the intermediate-pressure cylinder. The intermediate-pressure cylinder and the low-pressure cylinder further communicate with the heating system. The condensate water reheating system is used for reheating condensate water obtained after heat of steam used as a heat network circulating water heat source is released and / or condensate water obtained after condensation of a condensation device. The heating system is used for supplying heat to a user side. By means of the system, boiler waste heat and low-grade energy for steam turbine power generation are fully used for heating, and waste of low-grade and high-grade heat energy is reduced; a heat storage tank is arranged, the heat energy can be stored in the power generating high-load period, and the effect of thermoelectric decoupling is achieved; and the temperature of exhaust temperature of a boiler is reduced, the amount of water used for smoke desulfuration is reduced, and the system achieves energy saving and environmental protection and has good economic benefits.

Owner:GUODIAN LONGYUAN POWER TECH ENG

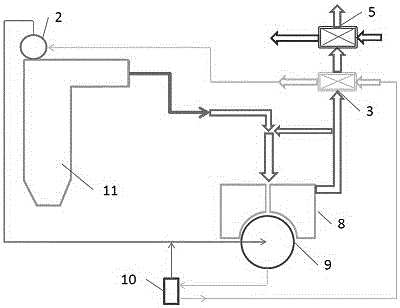

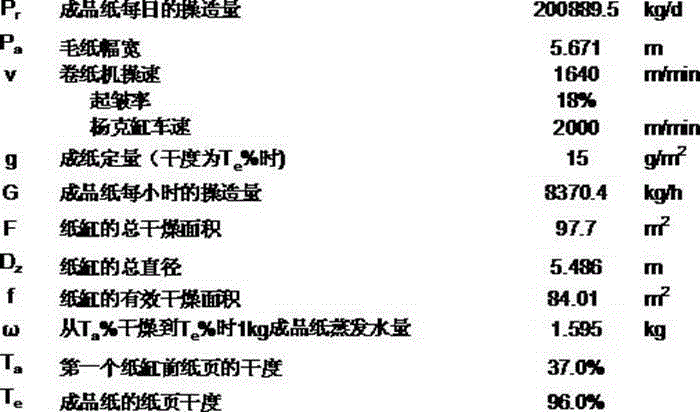

Paper drying energy comprehensive utilization system for steam and hot air combined supply boiler

ActiveCN105066657ALess investmentImprove utilization efficiencyDrying gas arrangementsCombustion technology mitigationProcess engineeringFuel oil

The invention provides a paper drying energy comprehensive utilization system for a steam and hot air combined supply boiler and relates to the field of paper making. The system comprises a hot air supply device, a steam supply device, a hot air utilization device and a steam utilization device. The hot air supply device is connected with the hot air utilization device through a hot air pipeline. The steam supply device is connected with the steam utilization device through a steam pipeline. The hot air supply device and the steam supply device are the same equipment. Steam generated by the steam and hot air combined supply boiler flows to the steam pipeline communicated with the steam utilization device. The steam and hot air combined supply boiler is adopted for generating steam used by the steam utilization device and generating high-temperature hot air used by the hot air utilization device. The steam and hot air combined supply boiler burns clean gas or fuel oil, so that the dust content of smoke is low. Hot air acquired after heat exchange is conveyed to a hot air utilization system. The temperature of the hot air generated by the steam and hot air combined supply boiler is not lower than 300 DEG C.

Owner:上海纸风节能环保科技有限公司

Radiating heating furnace with annular flue

ActiveCN103629702ASmall temperature fluctuationsTake advantage ofDomestic stoves or rangesLighting and heating apparatusElectricityInlet channel

The invention discloses a radiating heating furnace with an annular flue. The radiating heating furnace comprises a furnace body, an air supply channel with an air inlet is arranged on the upper portion of the furnace body, a plurality of primary air inlet holes are formed in the bottom of the air supply channel, a plurality of secondary air inlet holes are formed in the inner wall of the air supply channel, a primary air inlet channel is formed between the outer wall of a hearth and the inner wall of the furnace body, the primary air inlet holes are communicated with the bottom of the hearth through the primary air inlet channel, the secondary air inlet holes are directly communicated with the hearth, the annular flue is arranged on the upper portion of the air supply channel, the flue is communicated with the hearth through a smoke inlet, a plurality of thermoelectricity modules generating electricity through temperature difference are arranged between the flue and the air supply channel, and an air blower powered by the thermoelectricity modules is arranged on the air inlet. The radiating heating furnace with the annular flue has the good combustion and heating effects in high-altitude regions, and is suitable for being used in the high-altitude regions. According to the radiating heating furnace with the annular flue, when smoke passes through the secondary air inlet holes, unburned smoke is combusted again, the hearth and smoke temperature rises, the radiating efficiency of the annular flue is improved, the heating efficiency is high, and the using and maintenance cost is low.

Owner:中国人民解放军32181部队

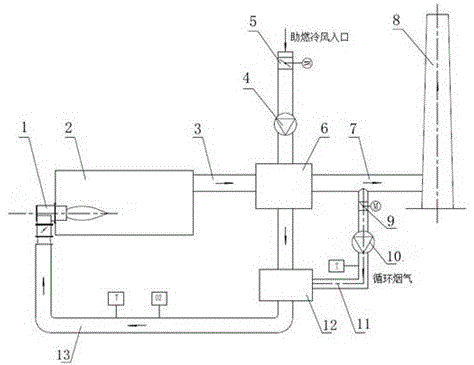

Control system for flue gas oxygen content of layer combustion boiler based on flue gas recirculation

ActiveCN107166428AReduce the intensity of manual operationImprove accuracyAir supply regulationSolid fuel combustionControl systemFlue gas

The invention provides a control system for the flue gas oxygen content of a layer combustion boiler based on flue gas recirculation. The control system is mainly composed of the layer combustion boiler, a blower, a flue gas recirculation fan, a zirconium oxide analyzer, an air pipe, a DCS system (or a PLC system) and the like, and can be widely applied to the field of combustion control and combustion optimization of layer combustion boilers. The control system adopts conventional equipment, performance is reliable and stable, stable operation of the boiler under the very low load (the 30% rated load) can be achieved, ash accumulating of the heating surface of the tail of the boiler is reduced, the initial discharge concentration of boiler nitrogen and oxygen compounds can be reduced by 15-20%, and the heat efficiency of the boiler under the low load is improved by 5% or more.

Owner:廊坊市华源盛世热力有限公司

Thermal power plant flue gas recirculation and sludge drying coupled on-line mixed-burning system

PendingCN110790475AReduce loadRelieve pressureSludge treatment by de-watering/drying/thickeningIncinerator apparatusScrew conveyorProcess engineering

The invention provides a thermal power plant flue gas recirculation and sludge drying coupled on-line mixed-burning system, and belongs to the field of boiler flue gas waste heat utilization and sludge drying in order to solve the problems that in a current system, odorous gas leaks, flue gas carries toxic and harmful organic matter, consequently, environmental pollution is caused, and up-to-standard discharge of dust and sulfur is affected, system operation is not flexible enough, boiler NOx emission exceeds the standard during the low load. After a quick lime weighing conveyor in a sludge drying system mixes wet sludge with quick lime, a mixture is conveyed into one or two drying machines through a first screw conveyor and a sludge strip cutting machine, 120-150 DEG C high-temperature flue gas from a circulating fluidized bed power generation system enters the drying machines to be dried, dried sludge is conveyed into a blending bin through a dried sludge weighing conveyor to be mixed with pulverized coal and then enters a boiler for burning, flue gas from the drying machines serves as boiler primary air for recirculation to be delivered back to a hearth, the circulating fluidized bed power generation system is combined with the sludge drying system, and after the wet sludge is dried through flue gas waste heat, the dried sludge is taken as fuel for burning power generation.

Owner:山西平朔煤矸石发电有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com