High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

A premixed combustion, condensing boiler technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of the commercial gas stainless steel coil condensing water heater with large volume, complicated coil process, and expensive molds. Elimination of flashback hazards, compact combustion chamber, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

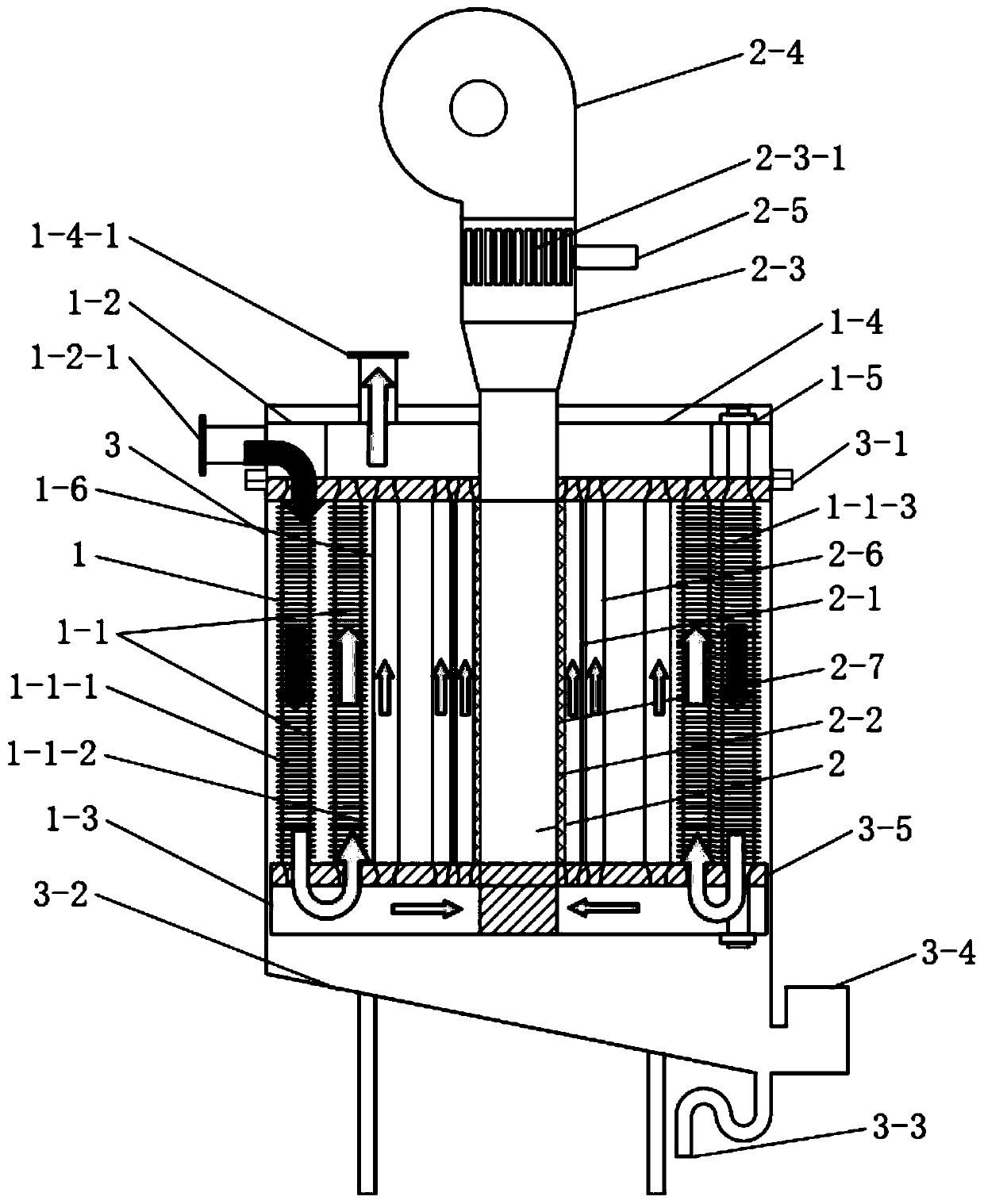

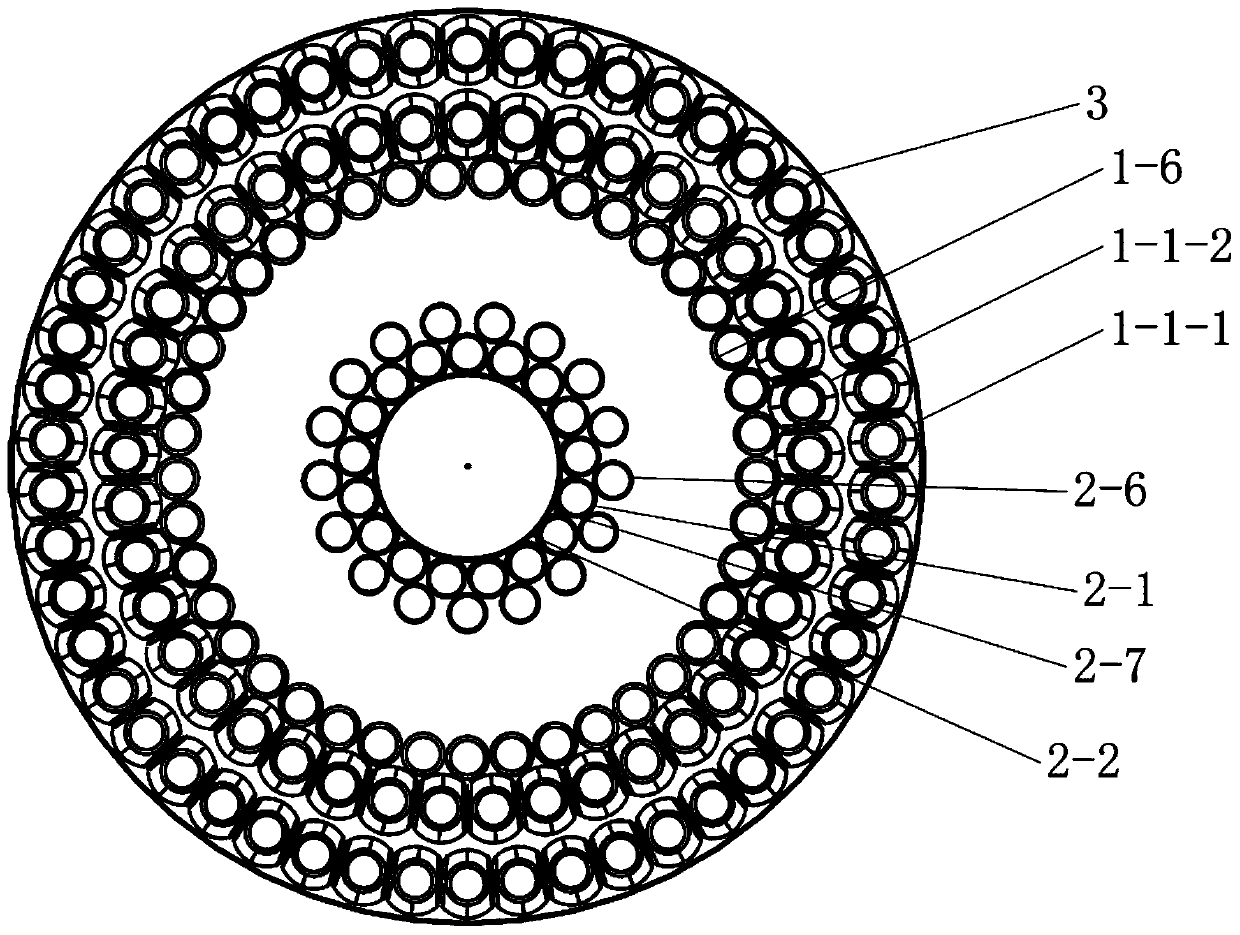

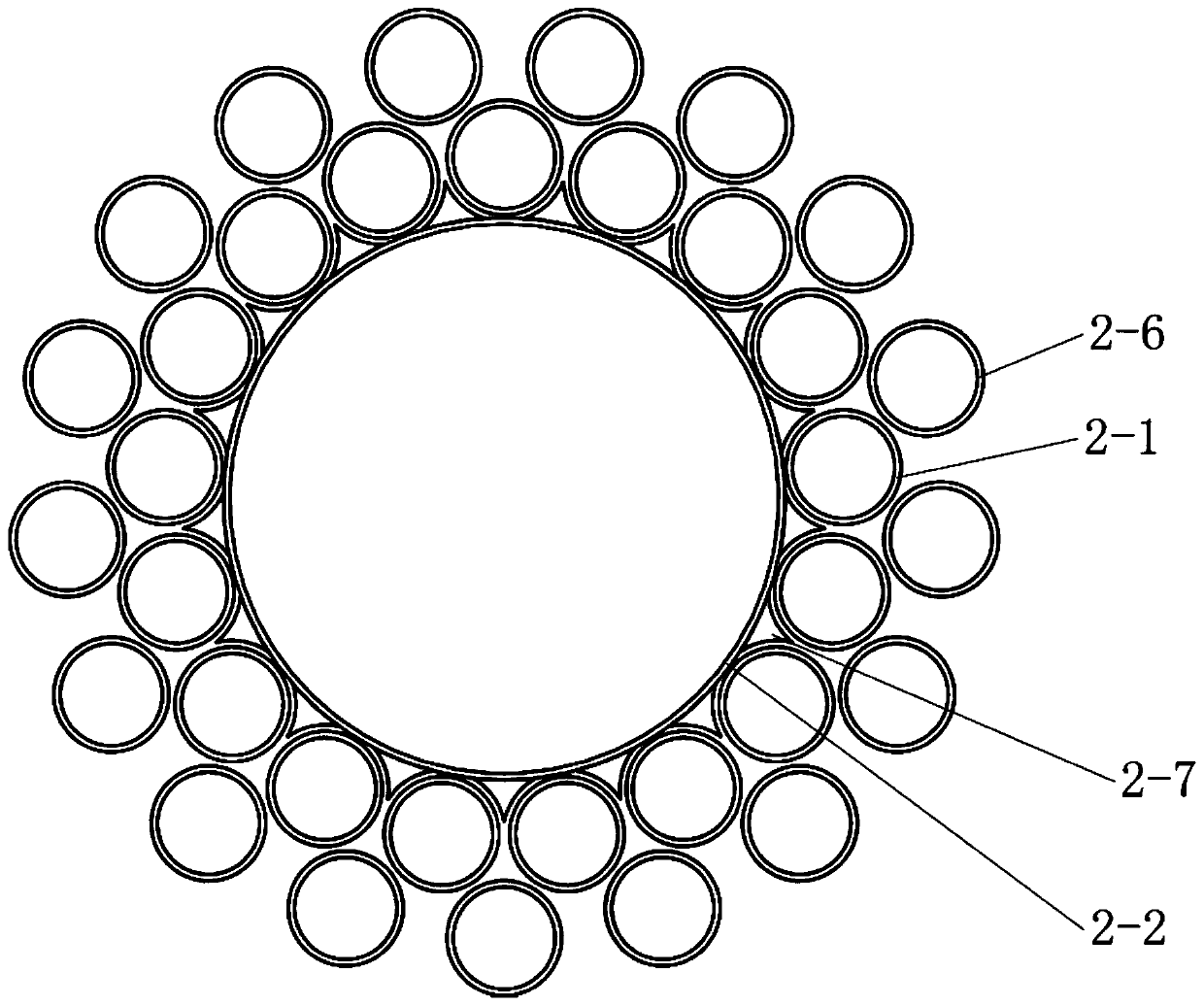

[0044] Such as figure 1 with figure 2 As shown, the present invention is a gas-fired condensing boiler with a large adjustment ratio, water-cooled premixed combustion, and high-intensity heat exchange. One or more circles of ring-shaped finned tubes 1-1 are arranged outside the wall tubes 1-6, and the water-cooled wall tubes 1-6 surround the radiation heat exchange space in the furnace of the gas condensing boiler, and the radiation heat exchange in the furnace Inside the space is the fully premixed burner head 2 composed of orifice plate 2-2, anti-tempering column 2-7, water cooling tube 2-1 and flame stabilizing tube 2-6; the fully premixed burner is installed on the shell 3, The head 2 of the fully premixed burner goes deep into the radiation heat exchange space in the furnace for combustion and heat release; the air enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com