Patents

Literature

121 results about "Condensing boiler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensing boilers are water heaters fueled by gas or oil. They achieve high efficiency (typically greater than 90% on the higher heating value) by condensing water vapour in the exhaust gases and so recovering its latent heat of vaporisation, which would otherwise have been wasted. This condensed vapour leaves the system in liquid form, via a drain. In many countries, the use of condensing boilers is compulsory or encouraged with financial incentives.

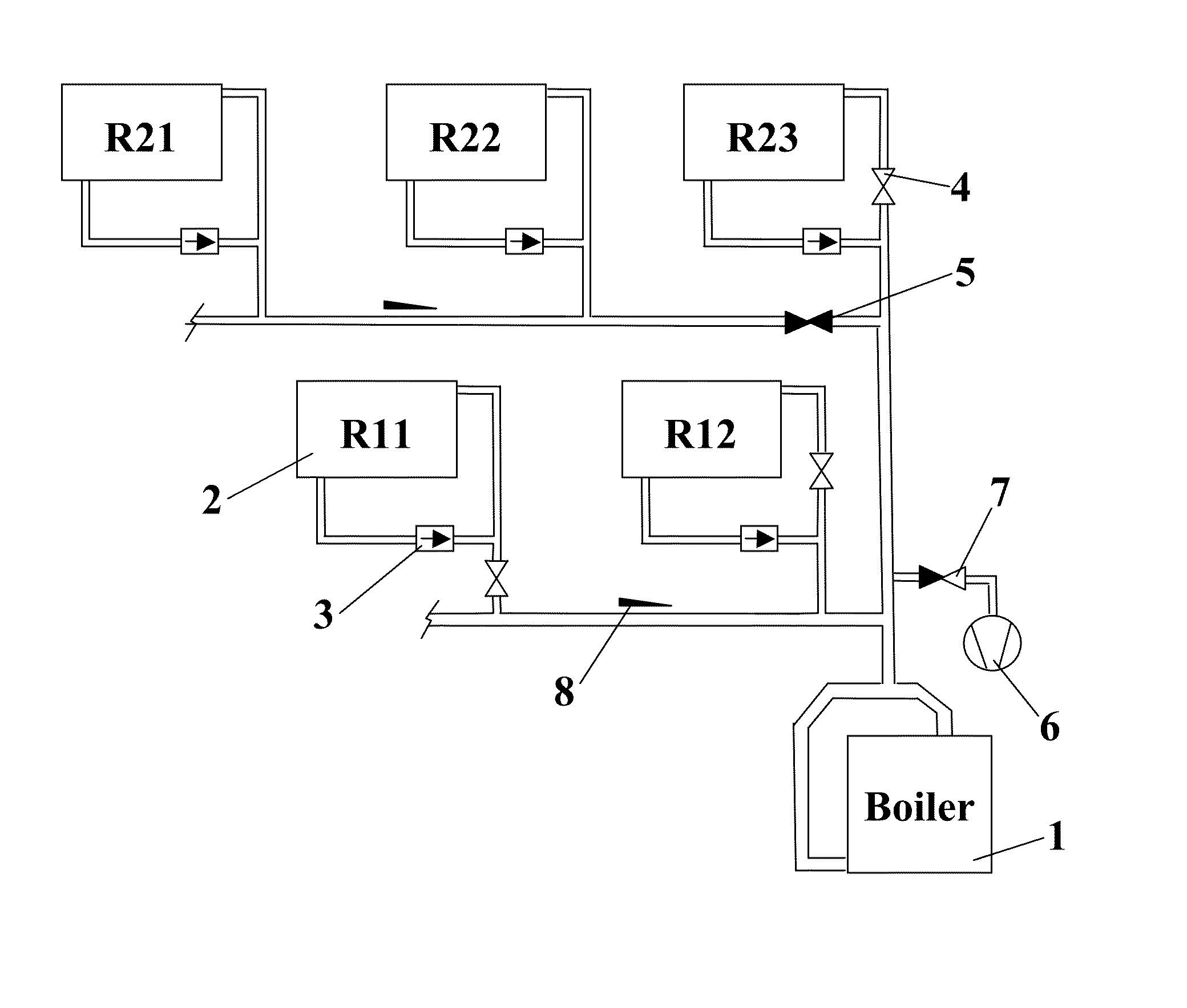

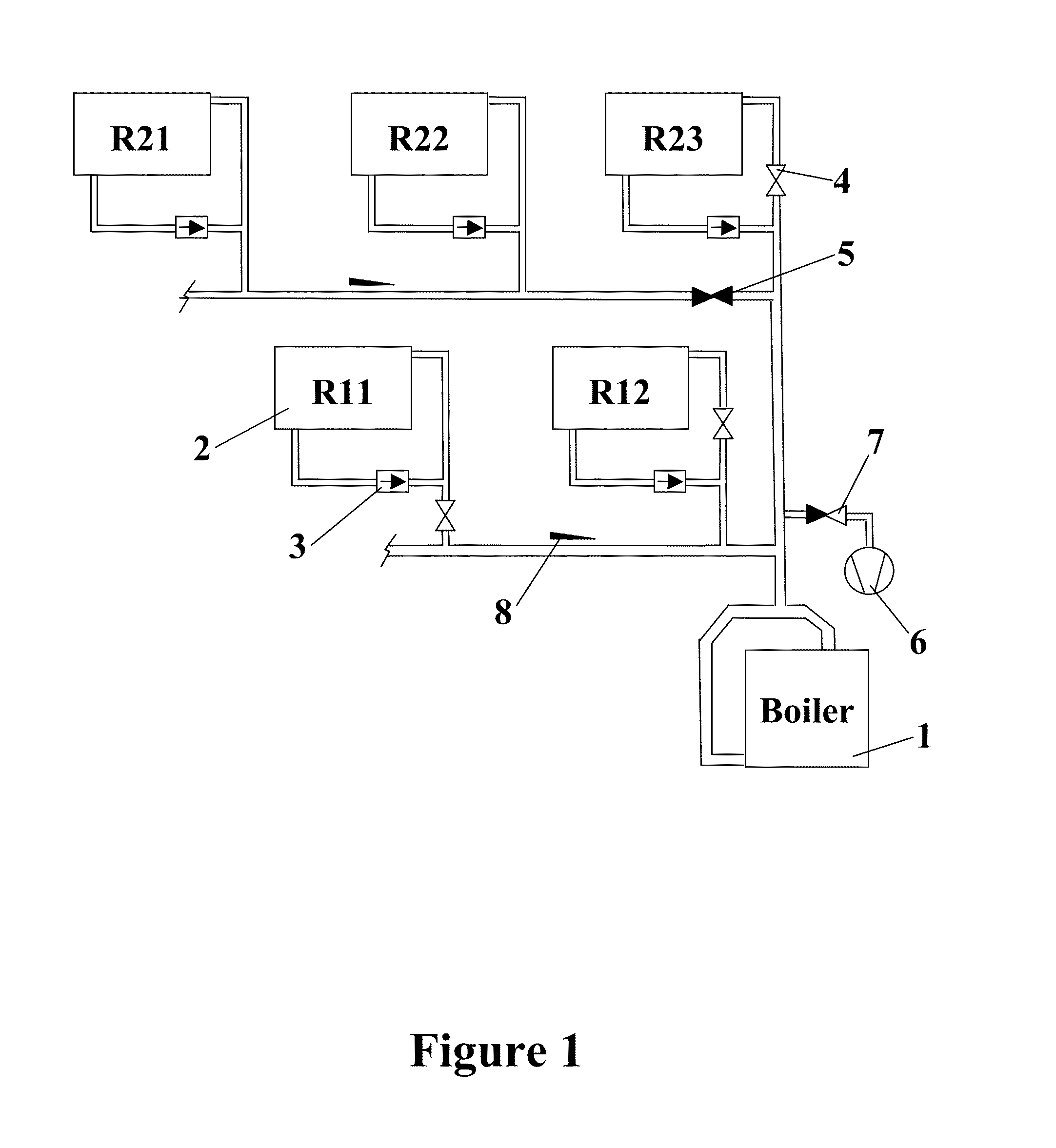

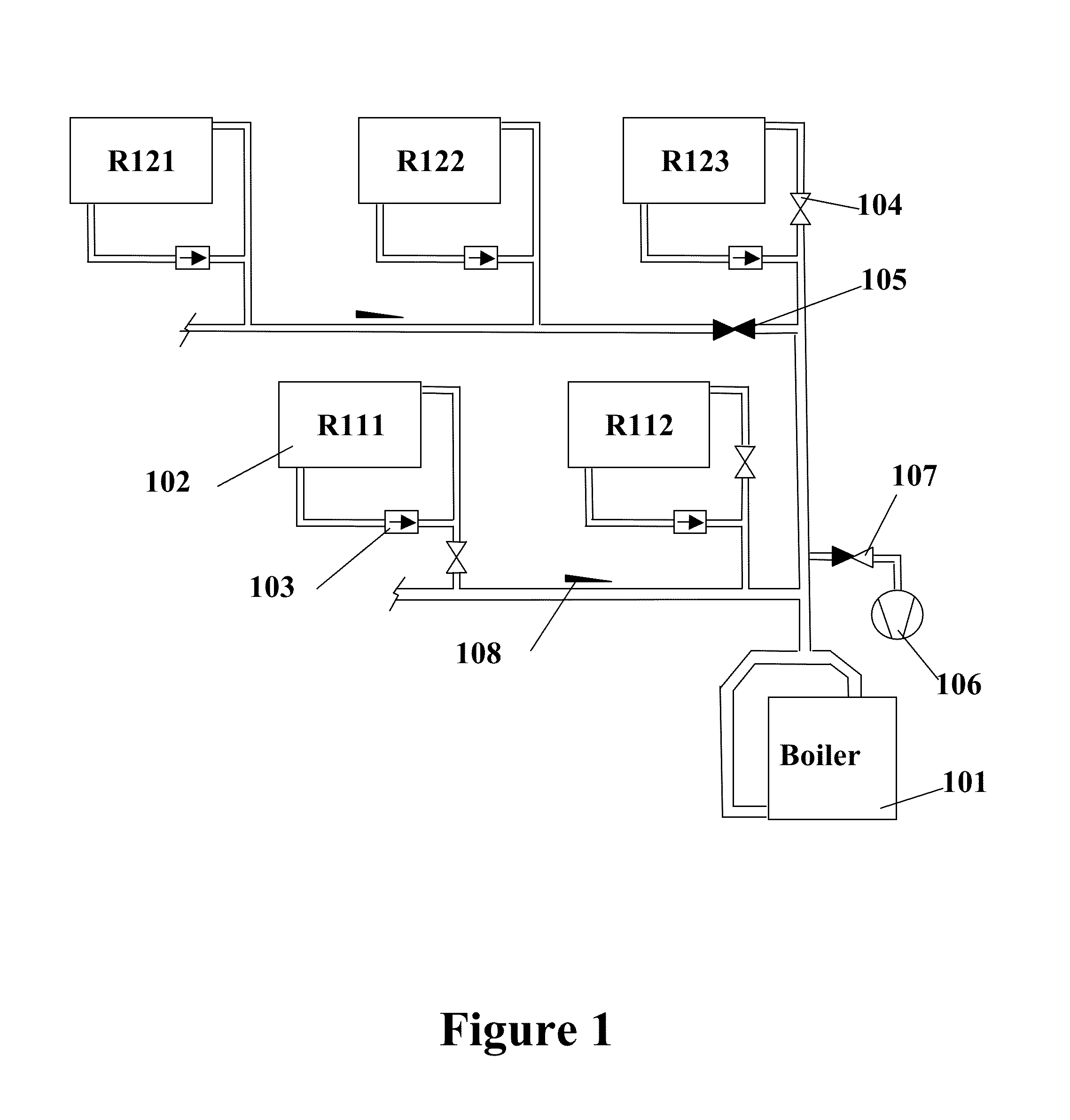

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

ActiveUS20100006042A1Maintaining overall heating plant efficiencyImprove efficiencyBoiler controlSteam generation plantsBoiler plantIndependent group

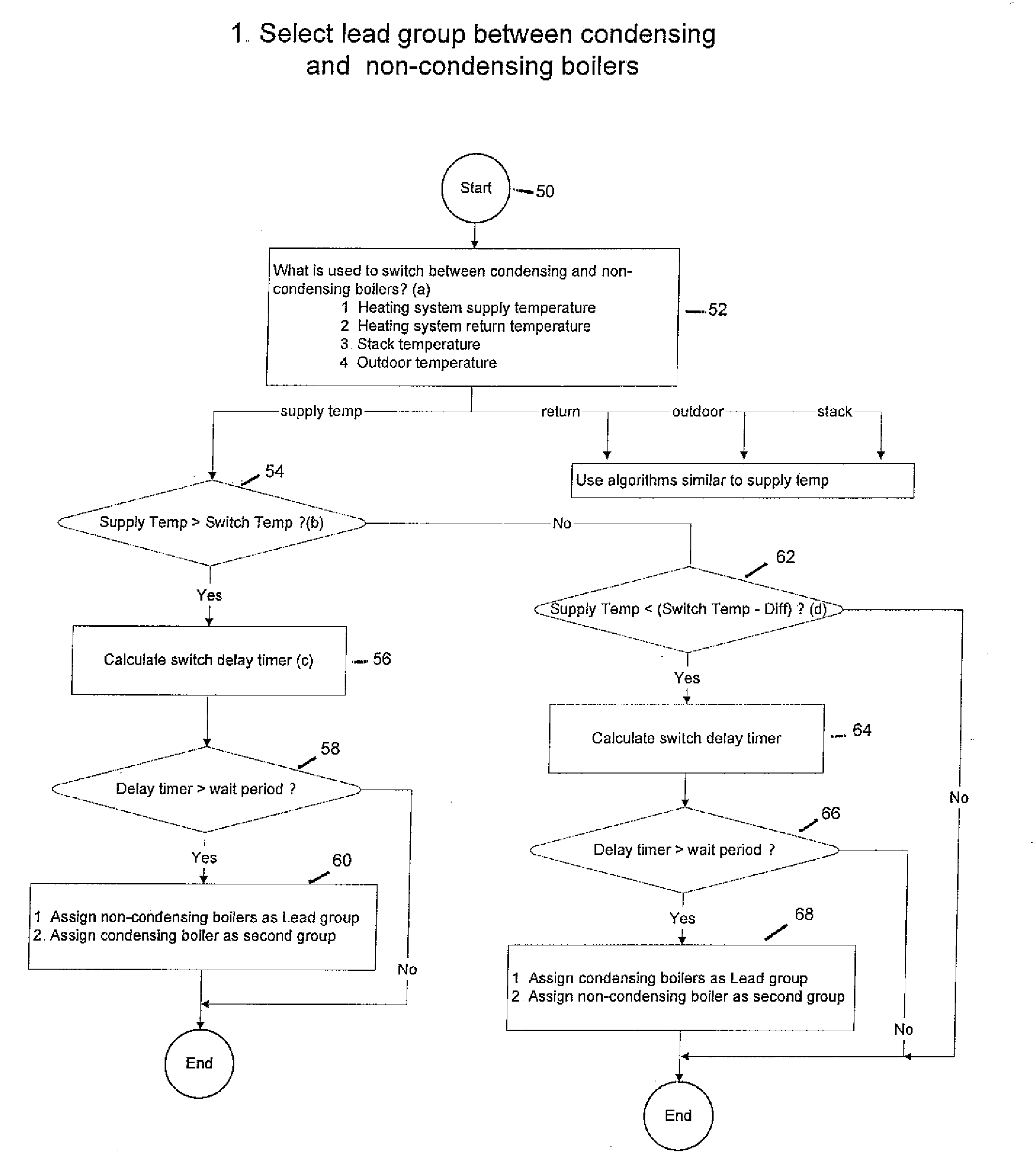

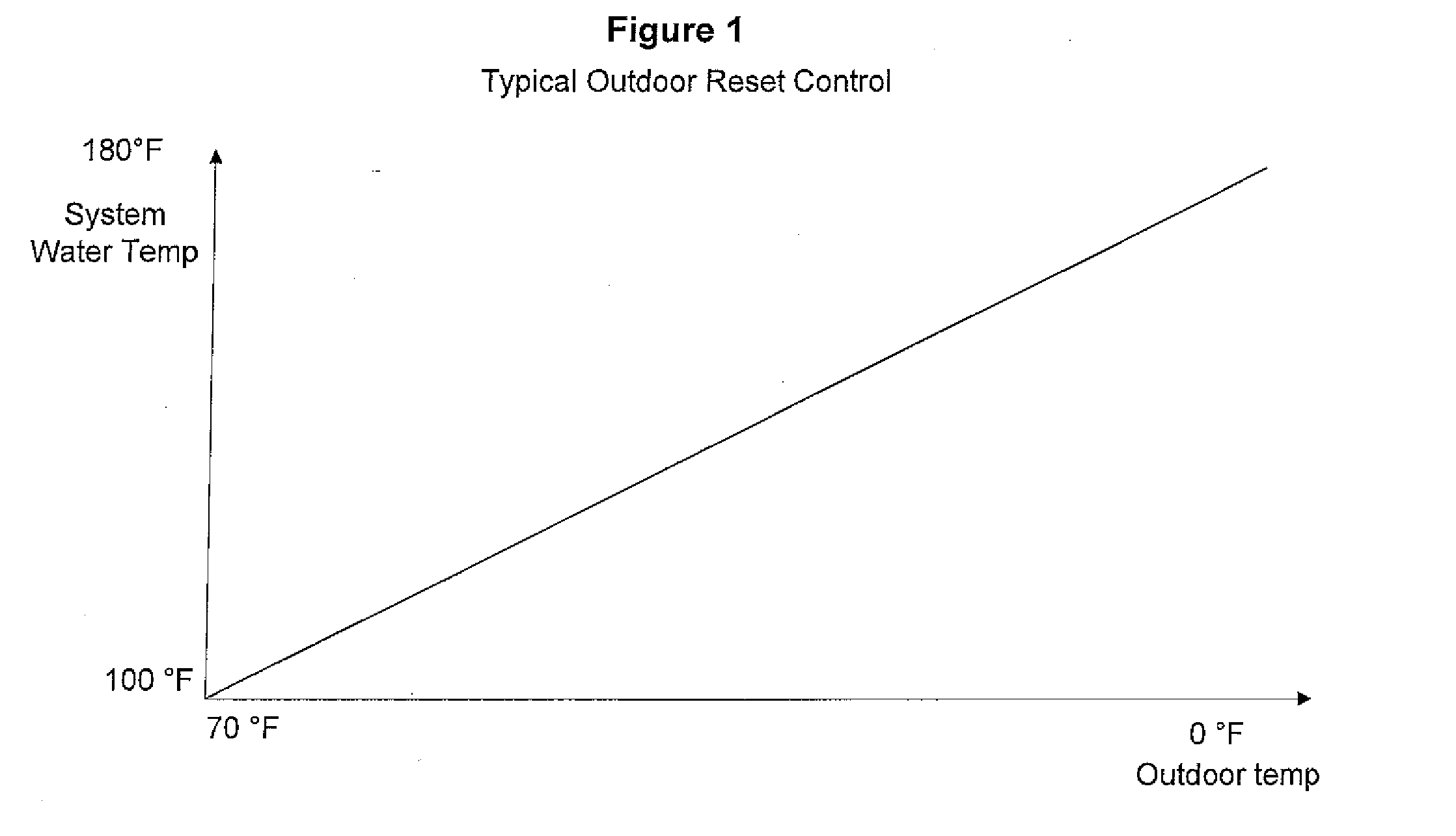

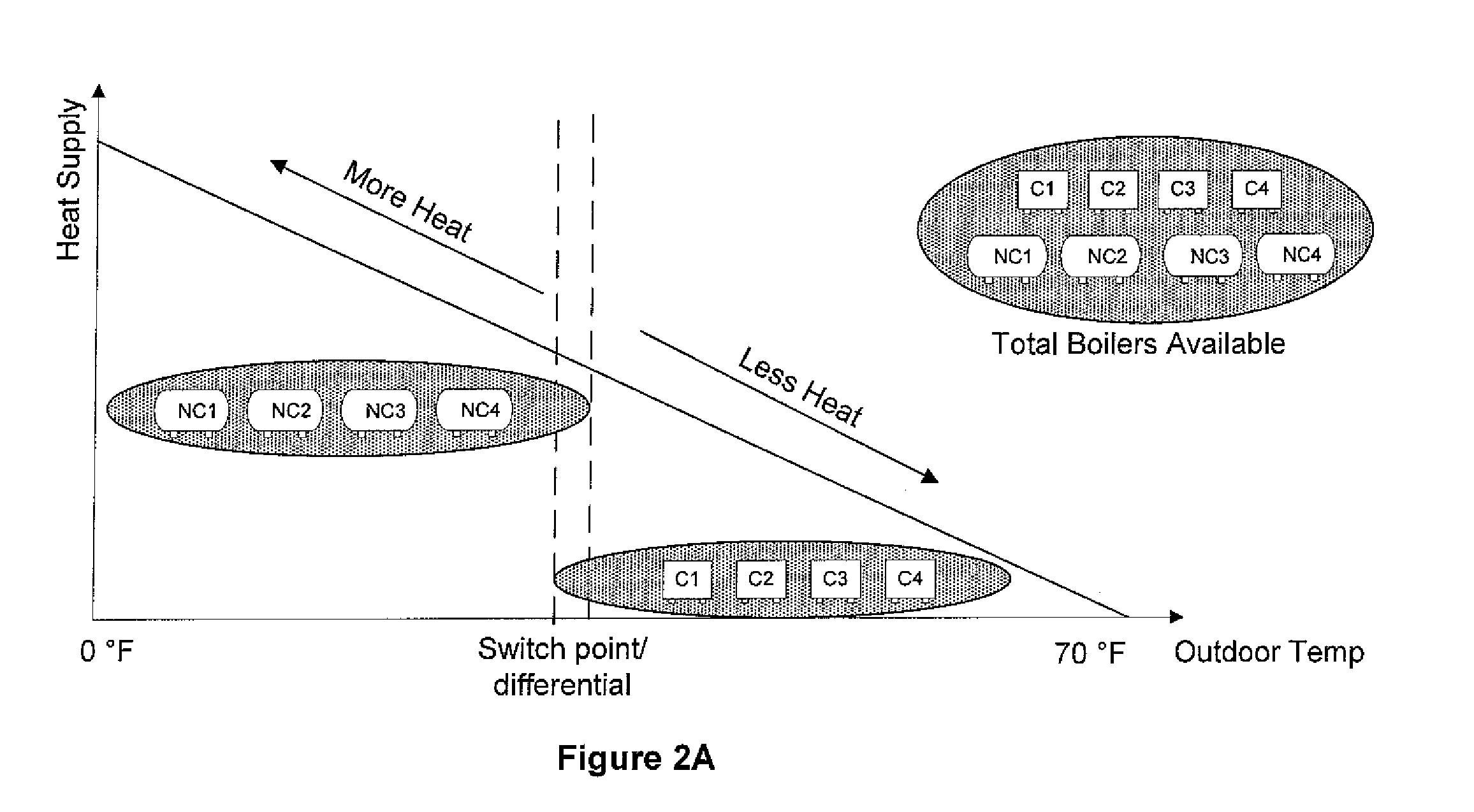

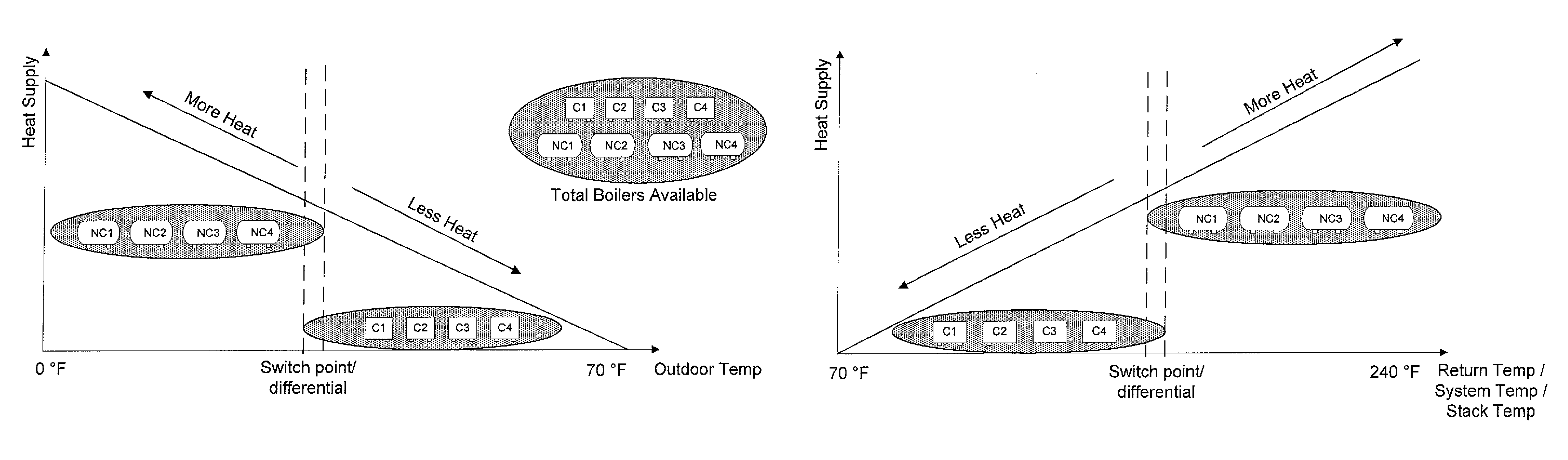

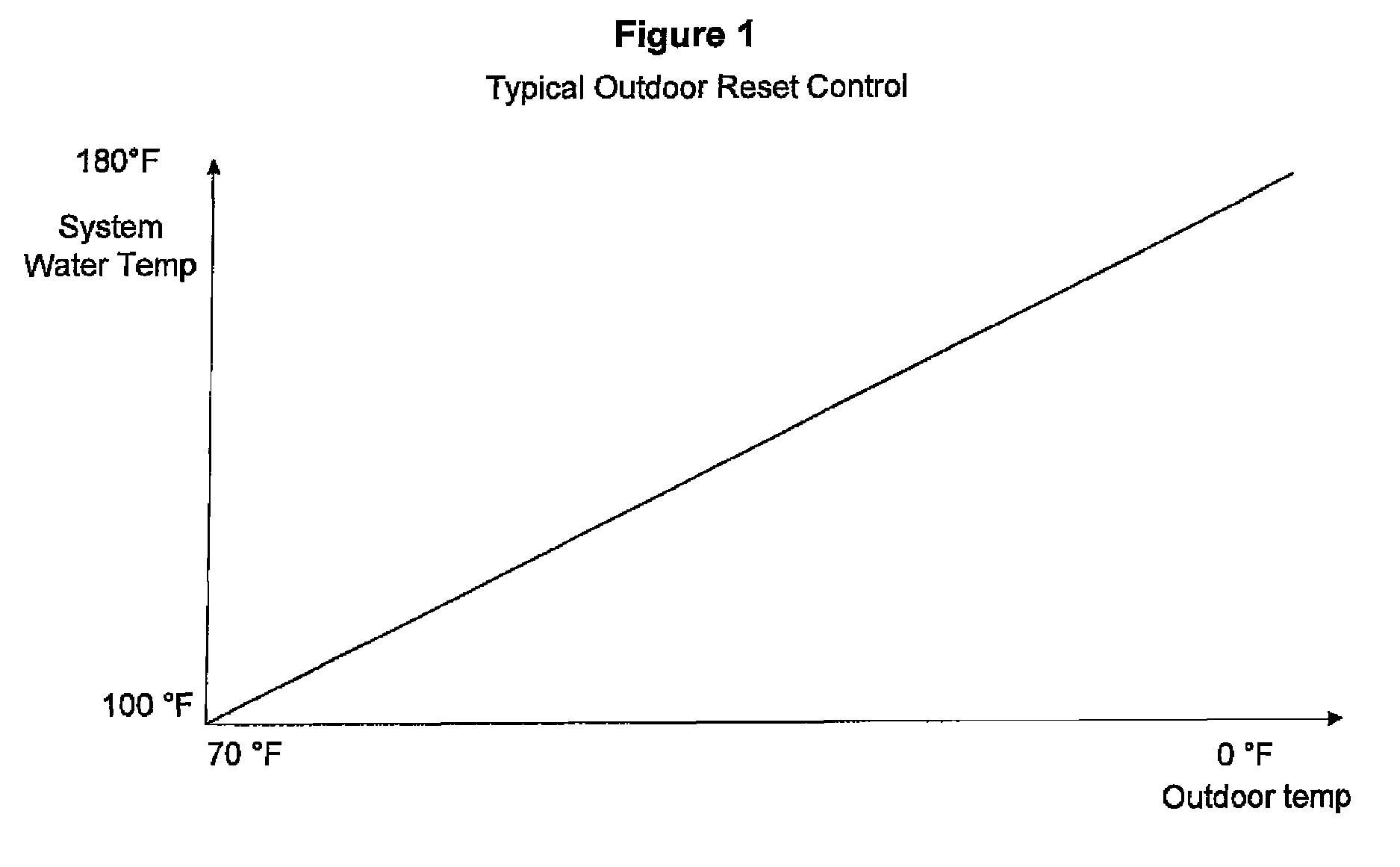

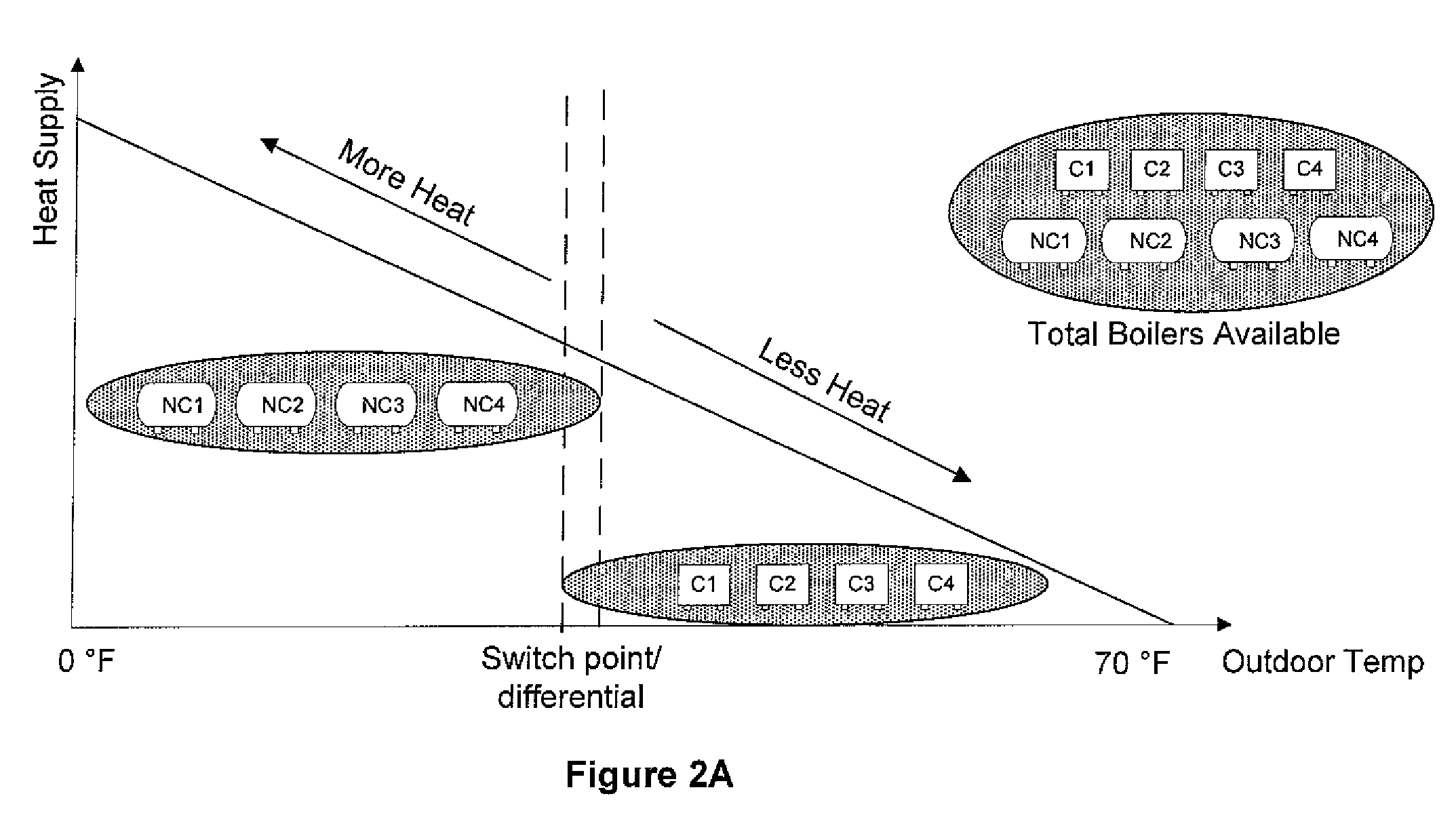

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

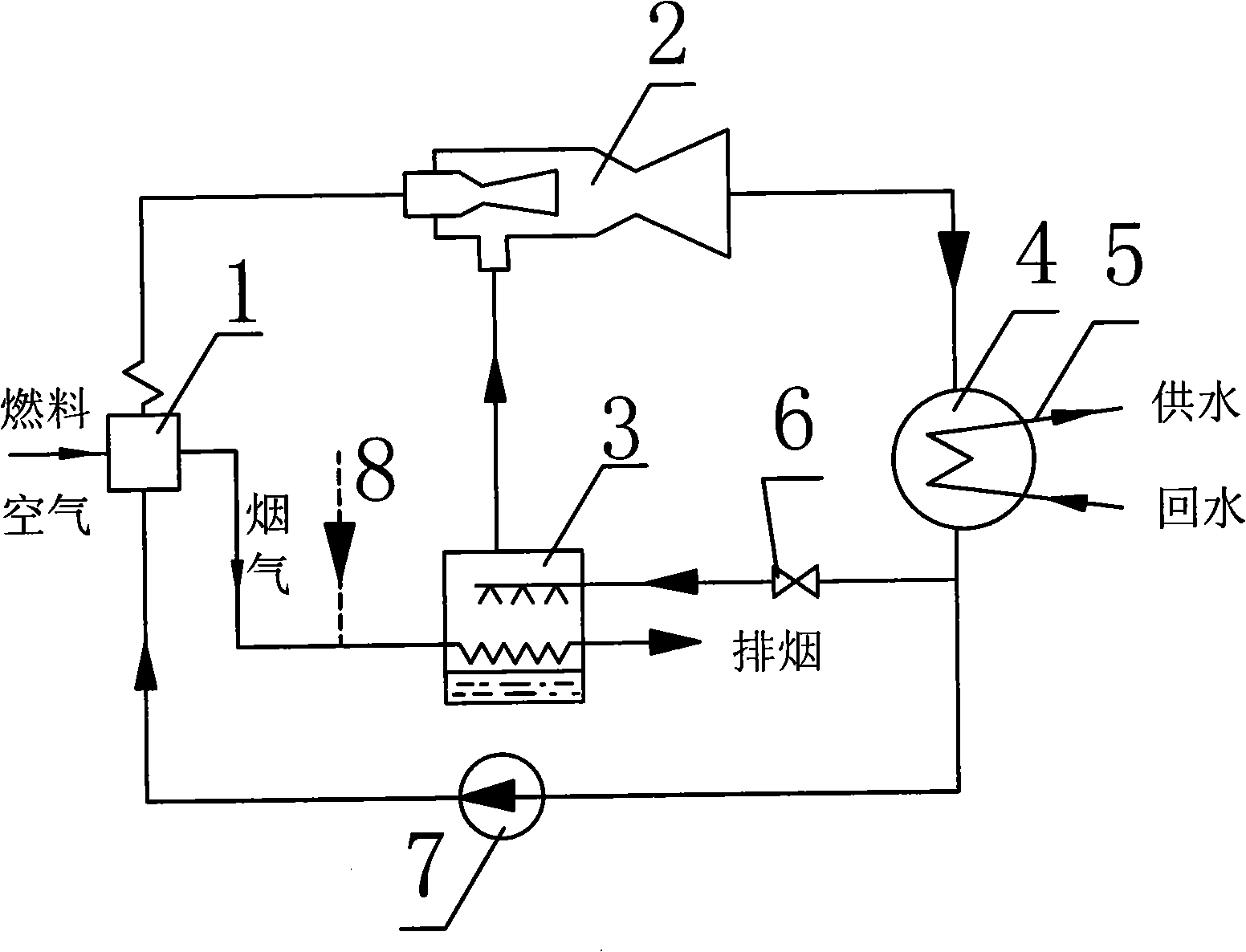

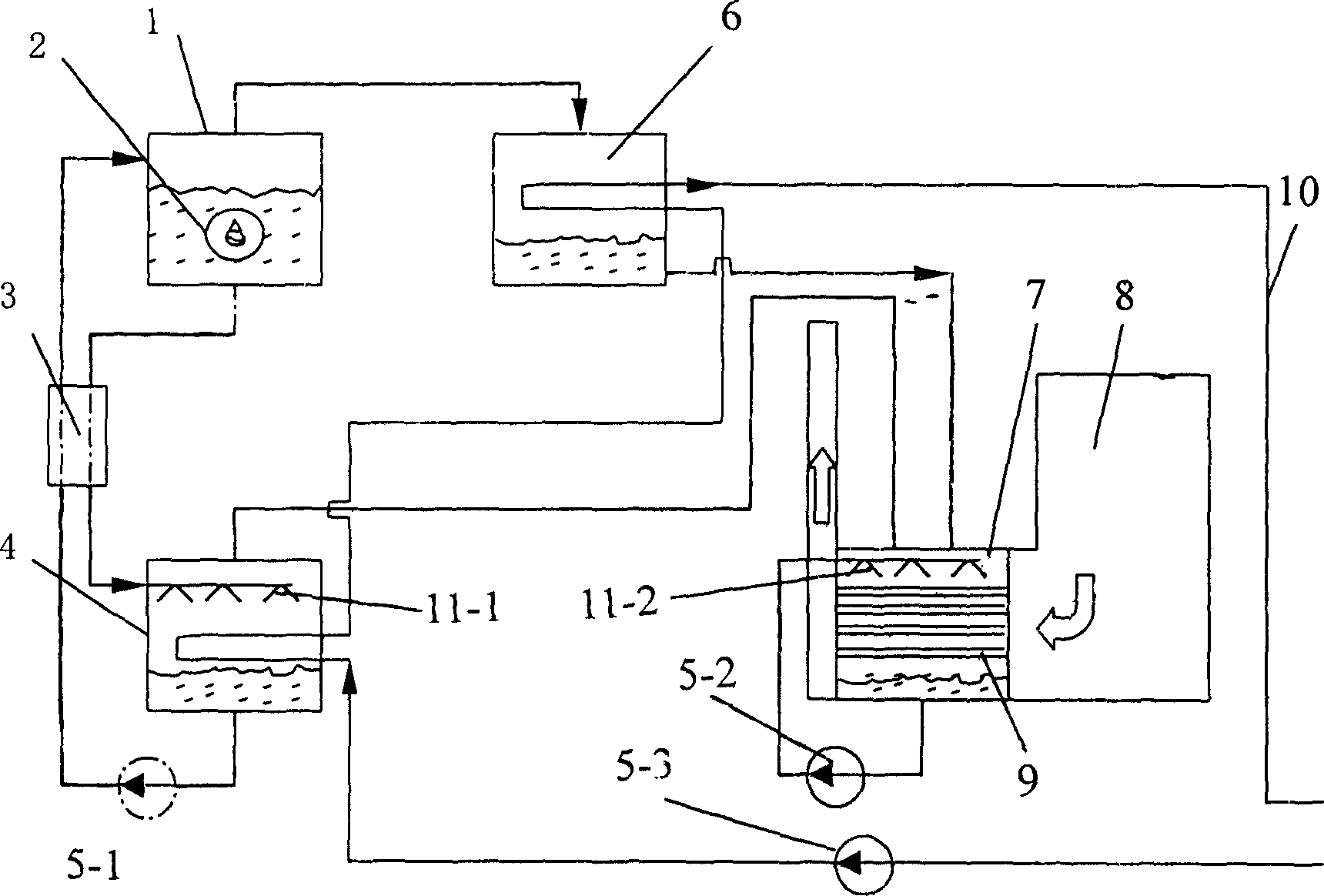

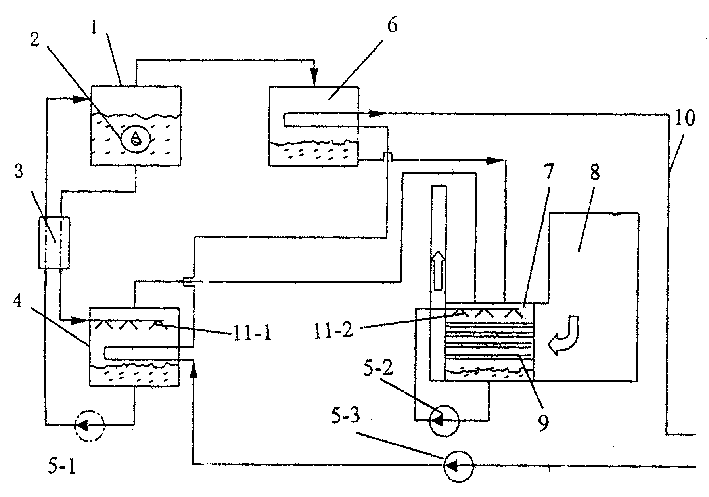

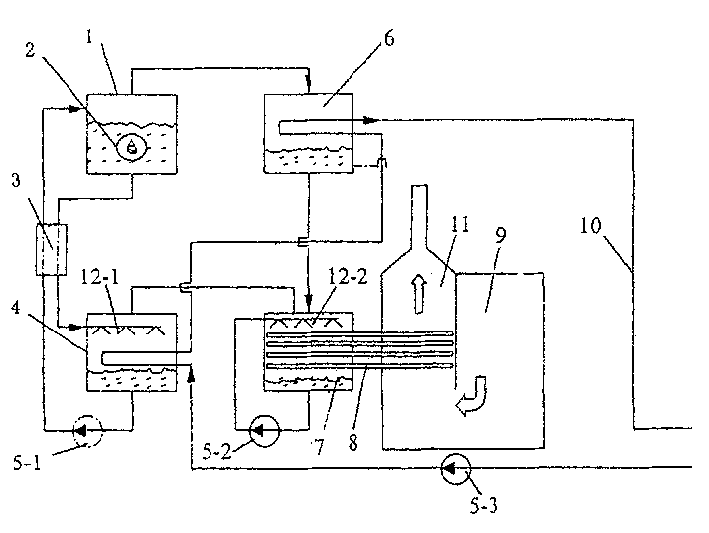

Heat supply device capable of recovering aqueous vapour in fuel gas, fuel oil boiler flue gas

InactiveCN1414288AImprove efficiencyEmission reductionHeat pumpsFeed water supplyFlue gasAbsorption heat pump

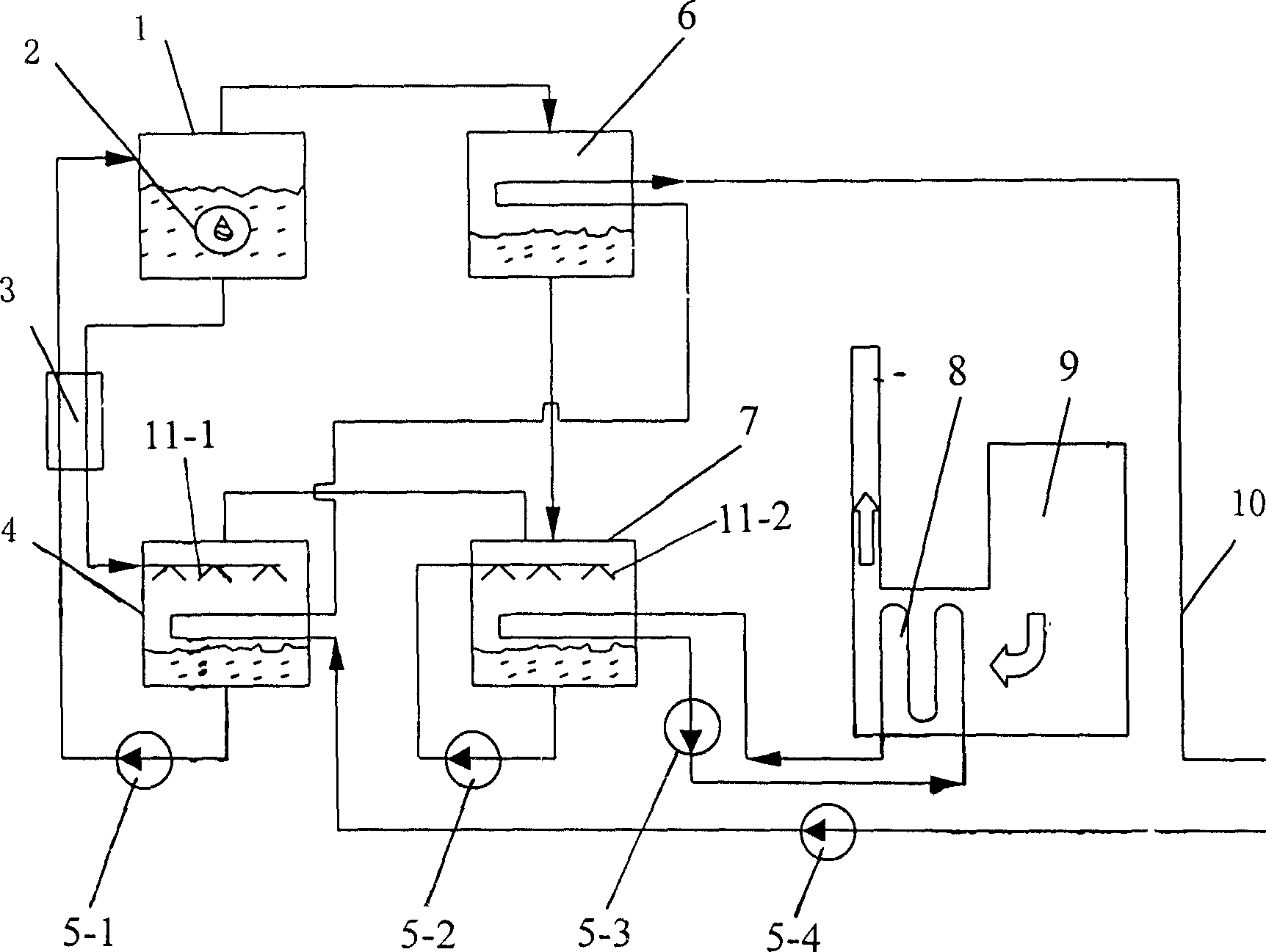

The present invention discloses heat supply device for recovering latent heat of aqueous vapour in flue gas of fuel oil and fuel gas boiler fume, it includes boiler, condensation heat exchanger, heatsupply pipe and absorption heat pump composed of generator, solution exchanger, absorber, evaporator, condenser and connecting pipe; a part of the said condensation exchanger is set up in gas flue ofthe said boiler and its extended part is set up in the evaporator of absorption heat pump, the said heat supply pipe passes through the condense and the absorber of the said absorption heat pump.

Owner:TSINGHUA TONGFANG CO LTD

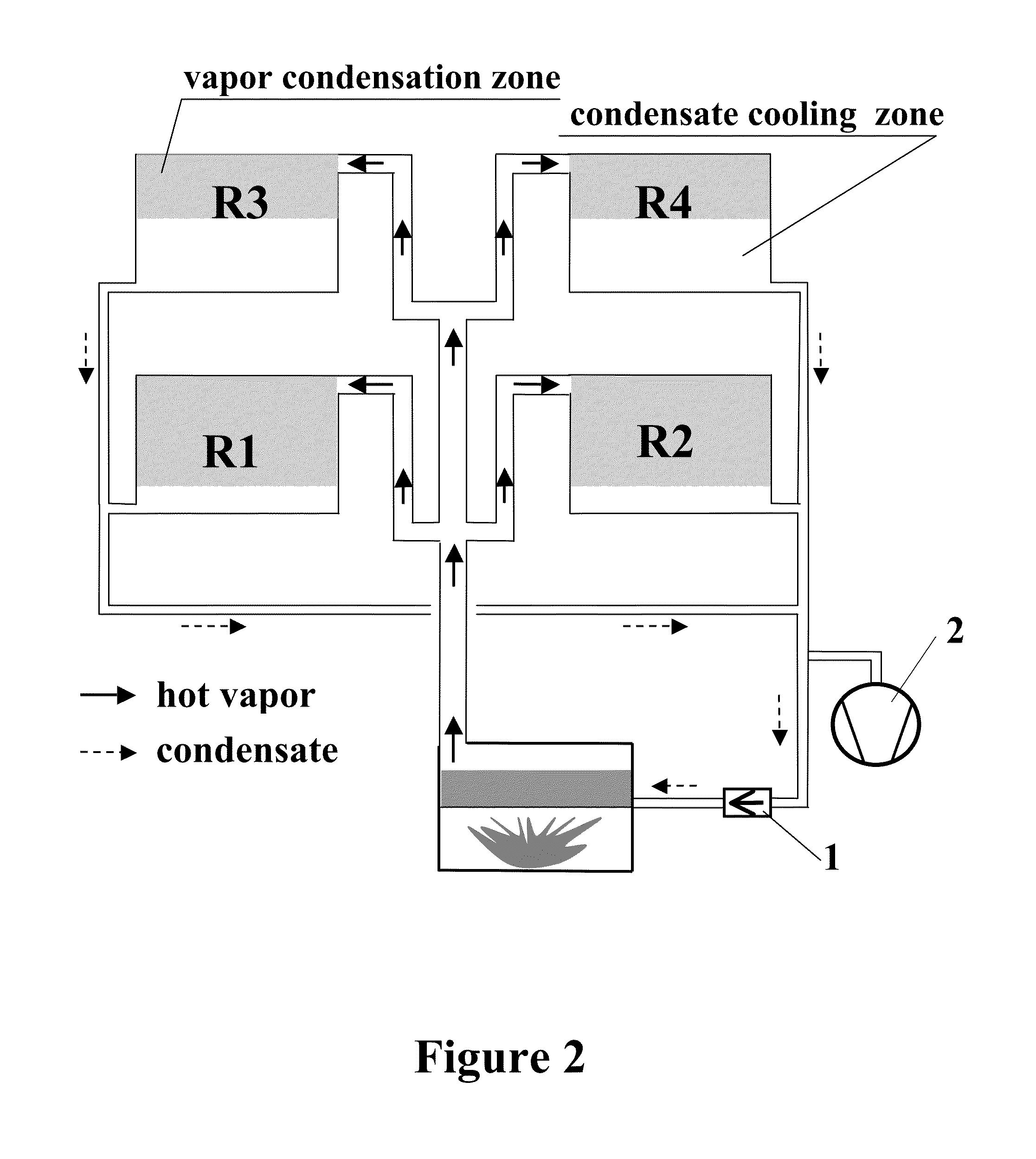

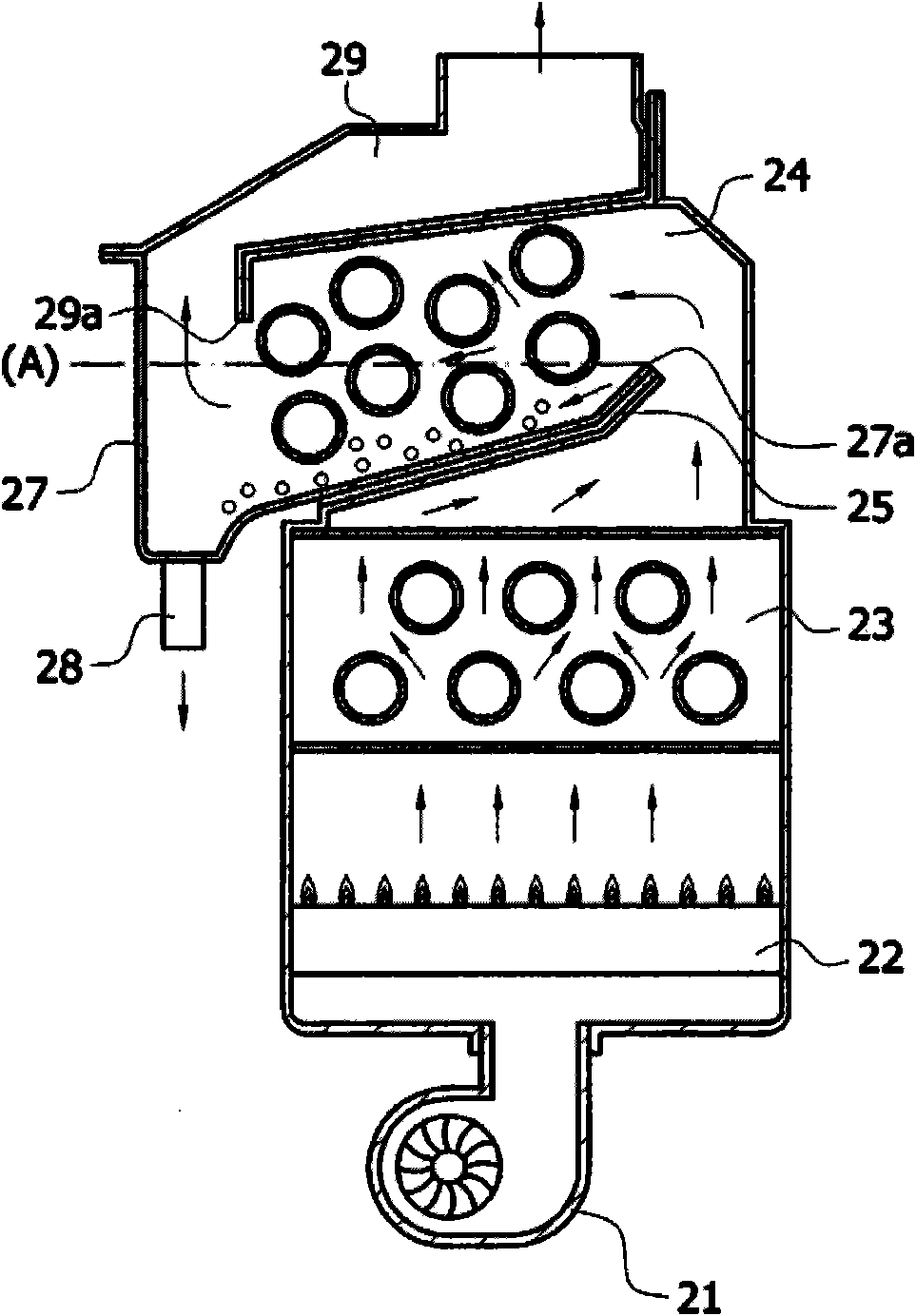

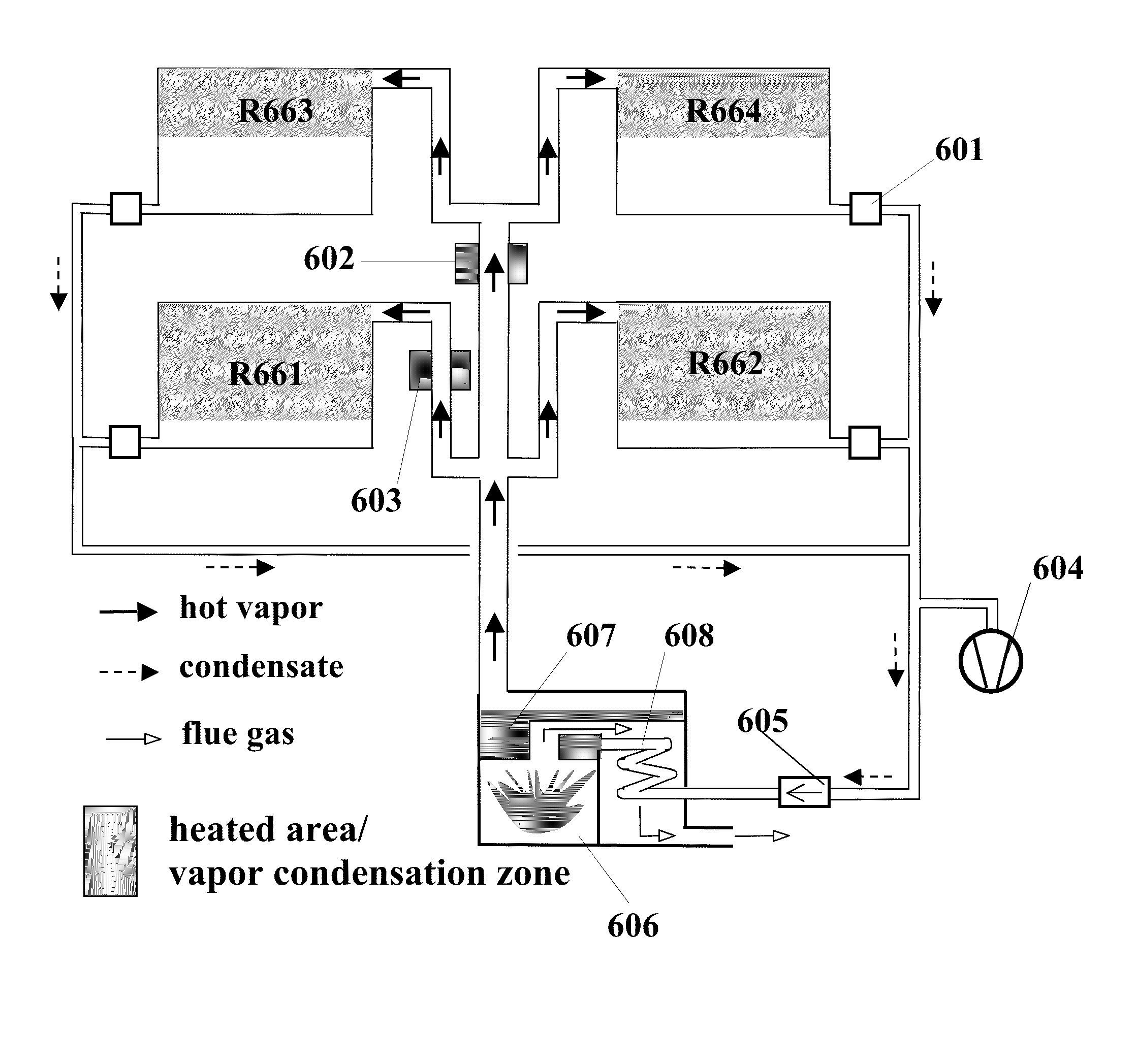

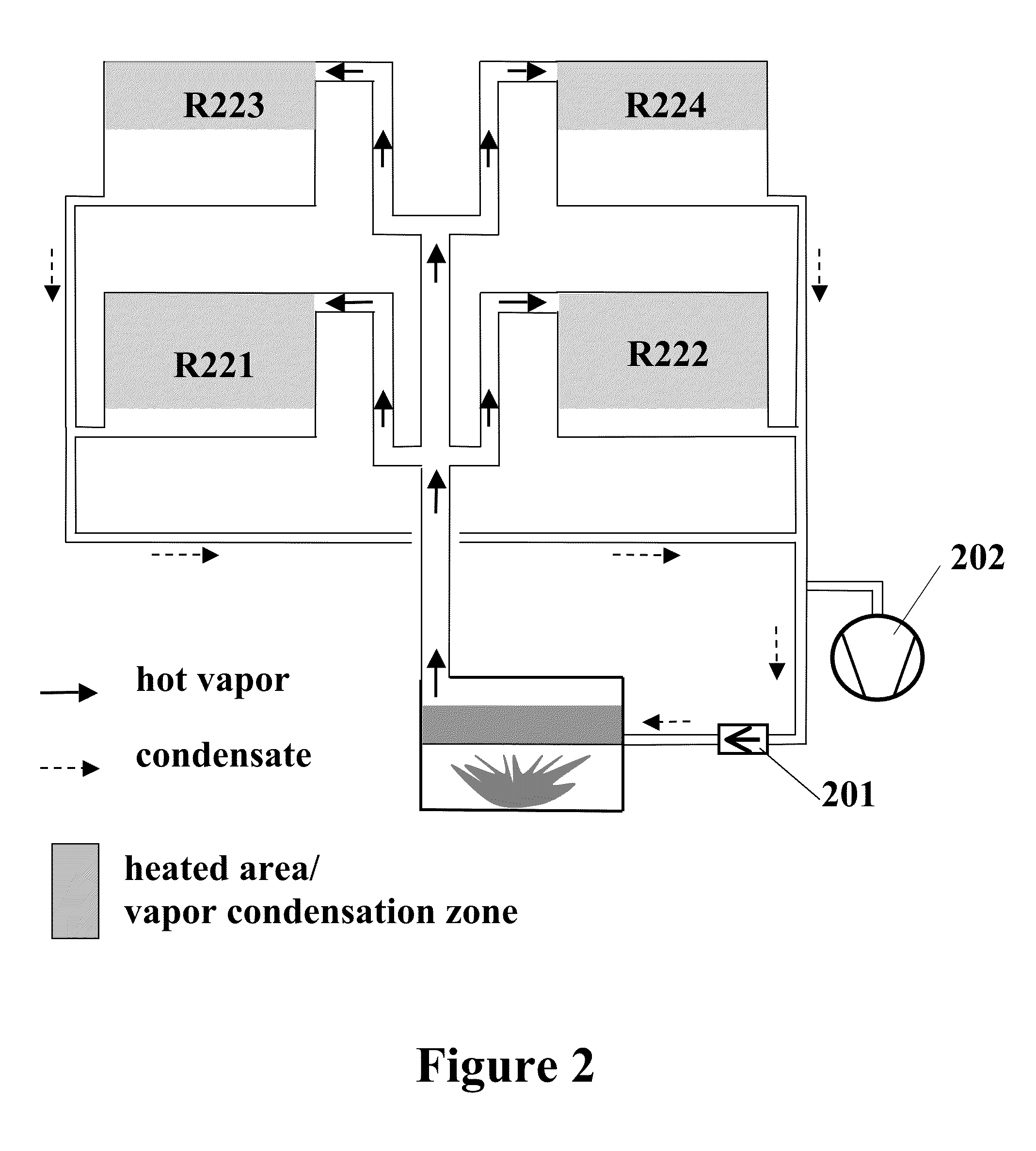

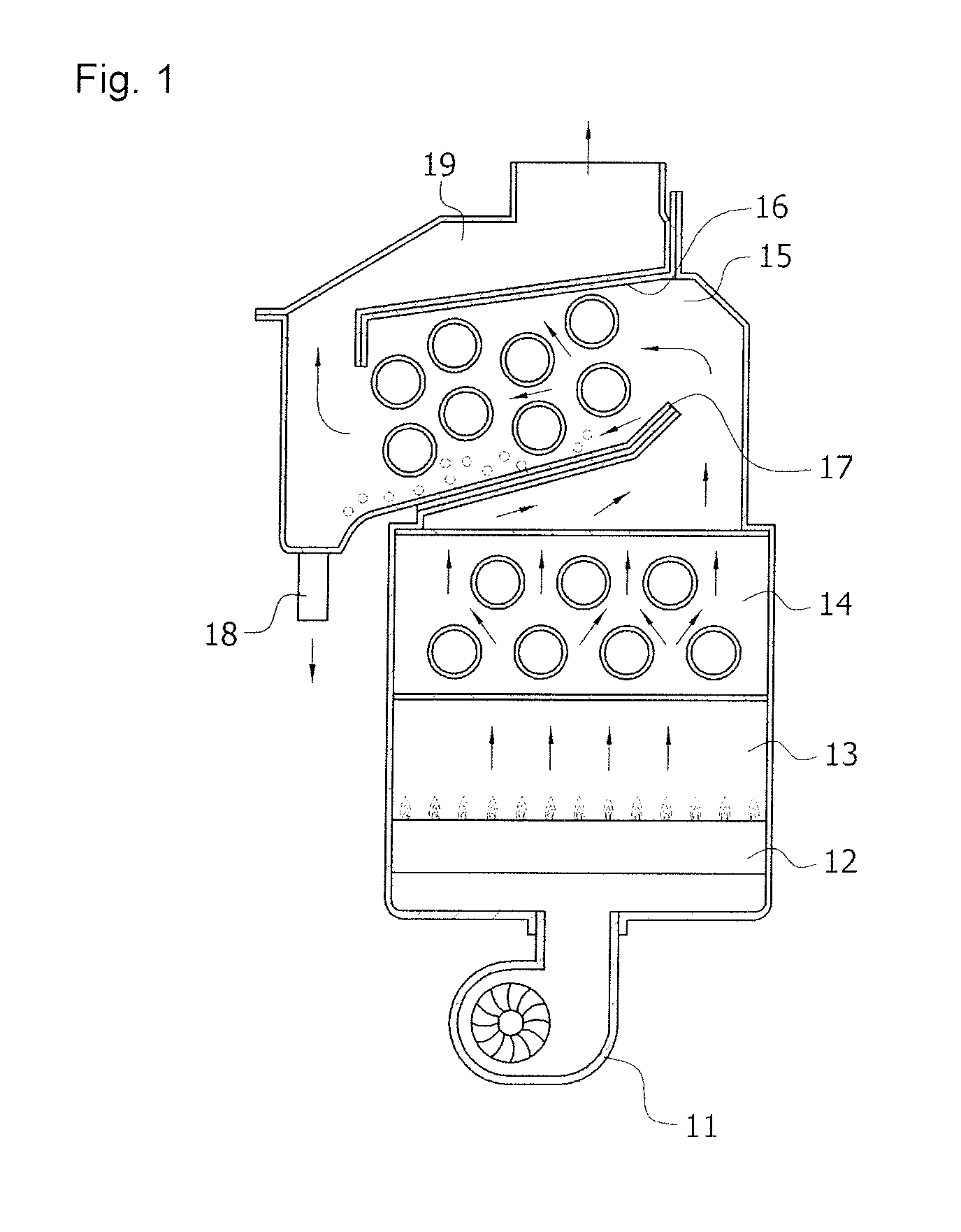

Vapor vacuum heating systems and integration with condensing vacuum boilers

ActiveUS20140034743A1Prevent backflowCentral heating componentsSteam useProcess engineeringSteam trap

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, first presented is a novel system and method for a vapor vacuum system having low temperature condensate return which can operate without steam traps in both single-pipe and dual-pipe configurations. Secondly is disclosed systems and methods for integrating the disclosed vapor vacuum system with a condensing boiler. Thirdly is presented several systems and method of operating radiators having low temperature condensate return with the disclosed vapor vacuum system. Finally is presented condensing vacuum boiler designs that can be utilized with the disclosed vapor vacuum system. Also presented are embodiments having naturally-induced vacuum and utilizing district heat as well as combined heat and power. All innovations presented herein make vapor vacuum steam more efficient and economical for industrial, commercial, and home applications.

Owner:ZHADANOVSKY IGOR

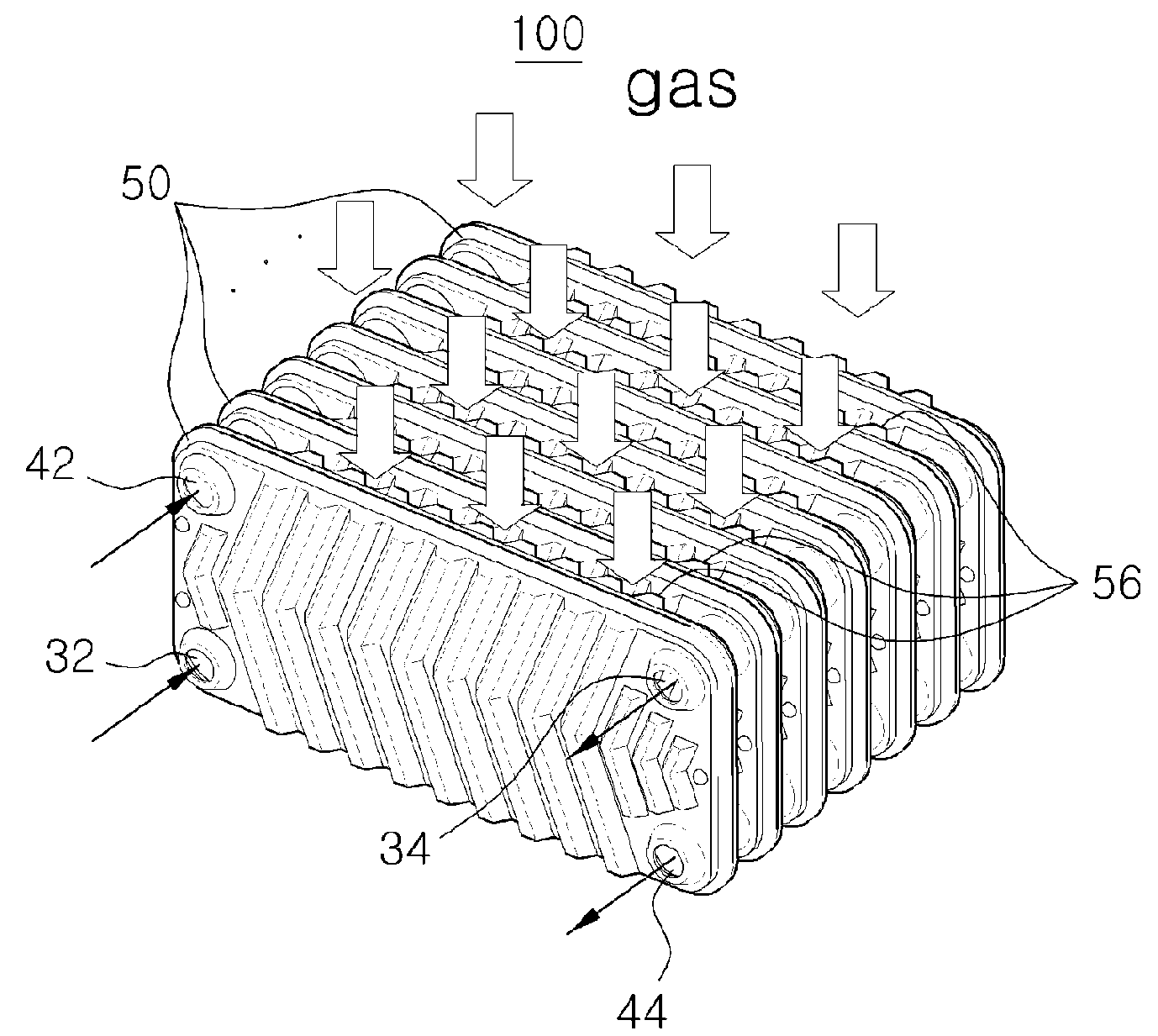

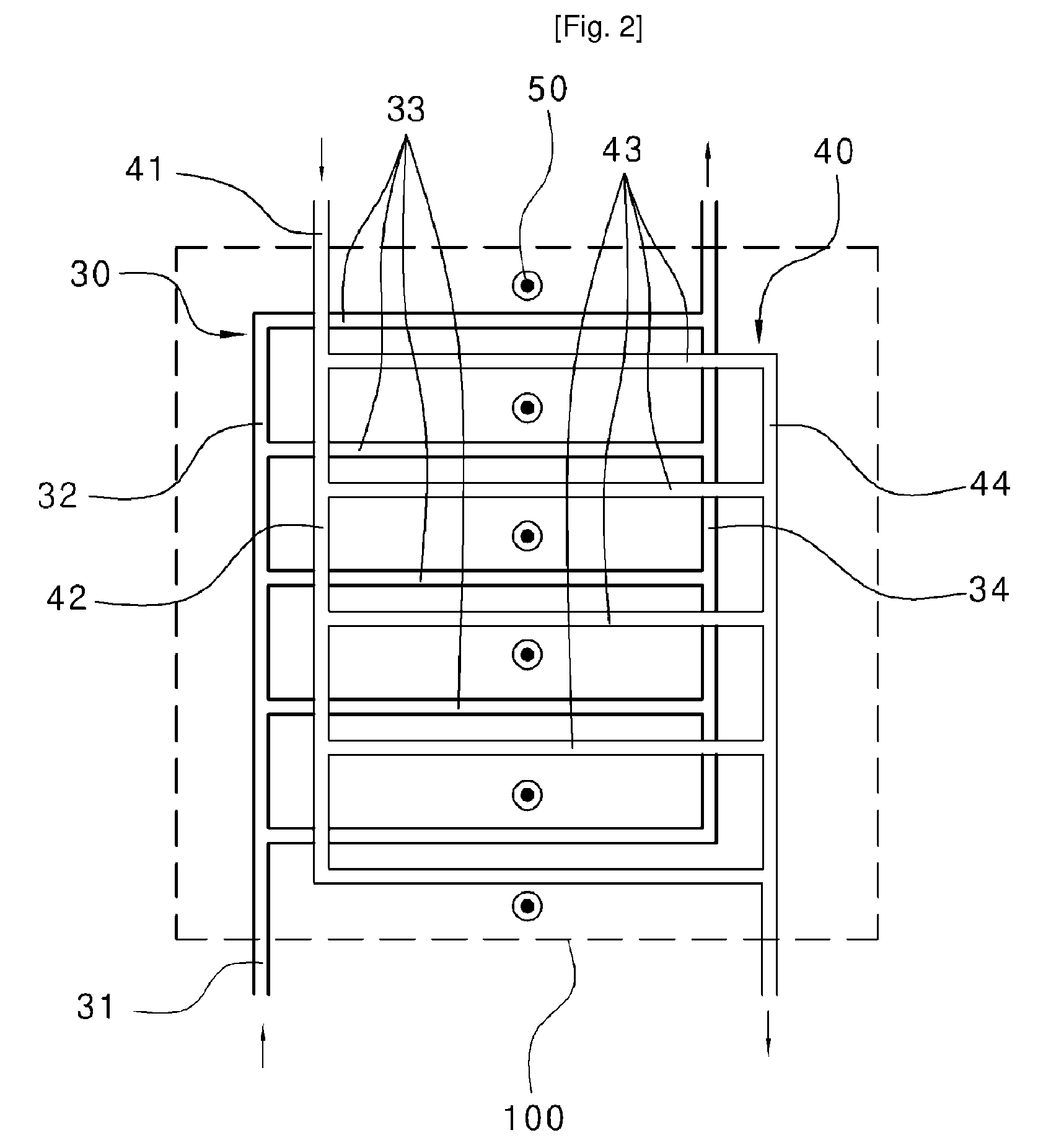

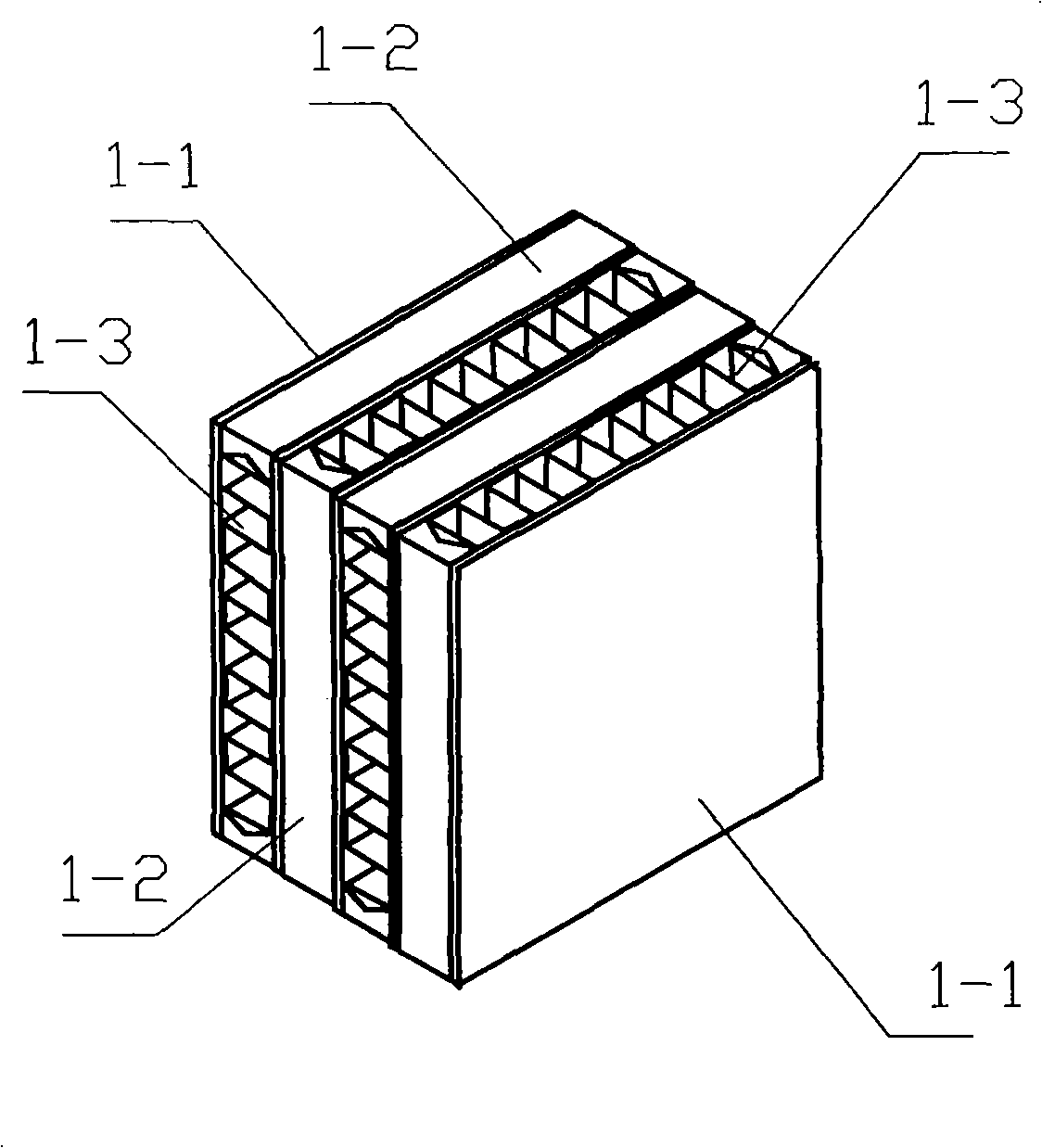

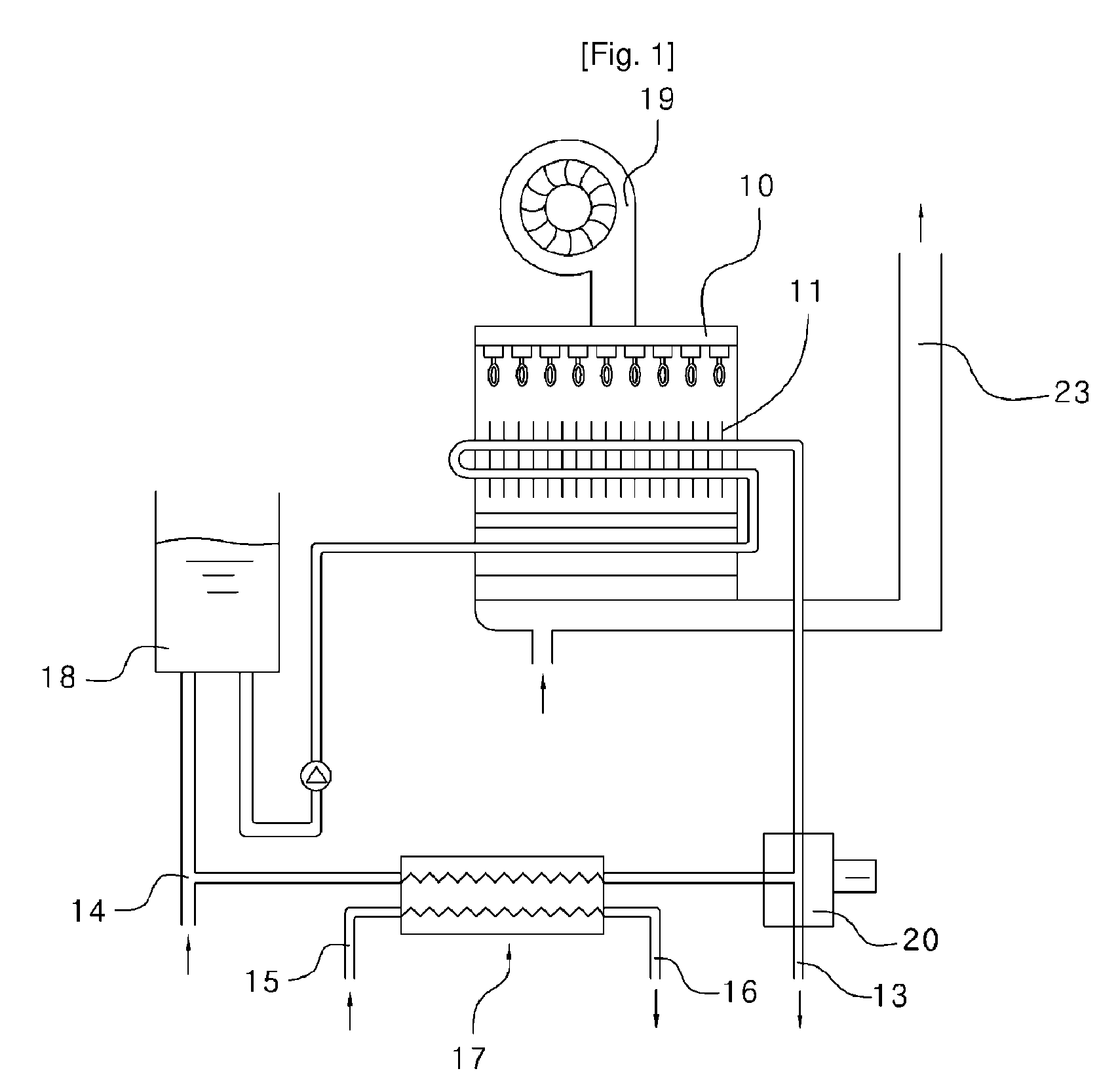

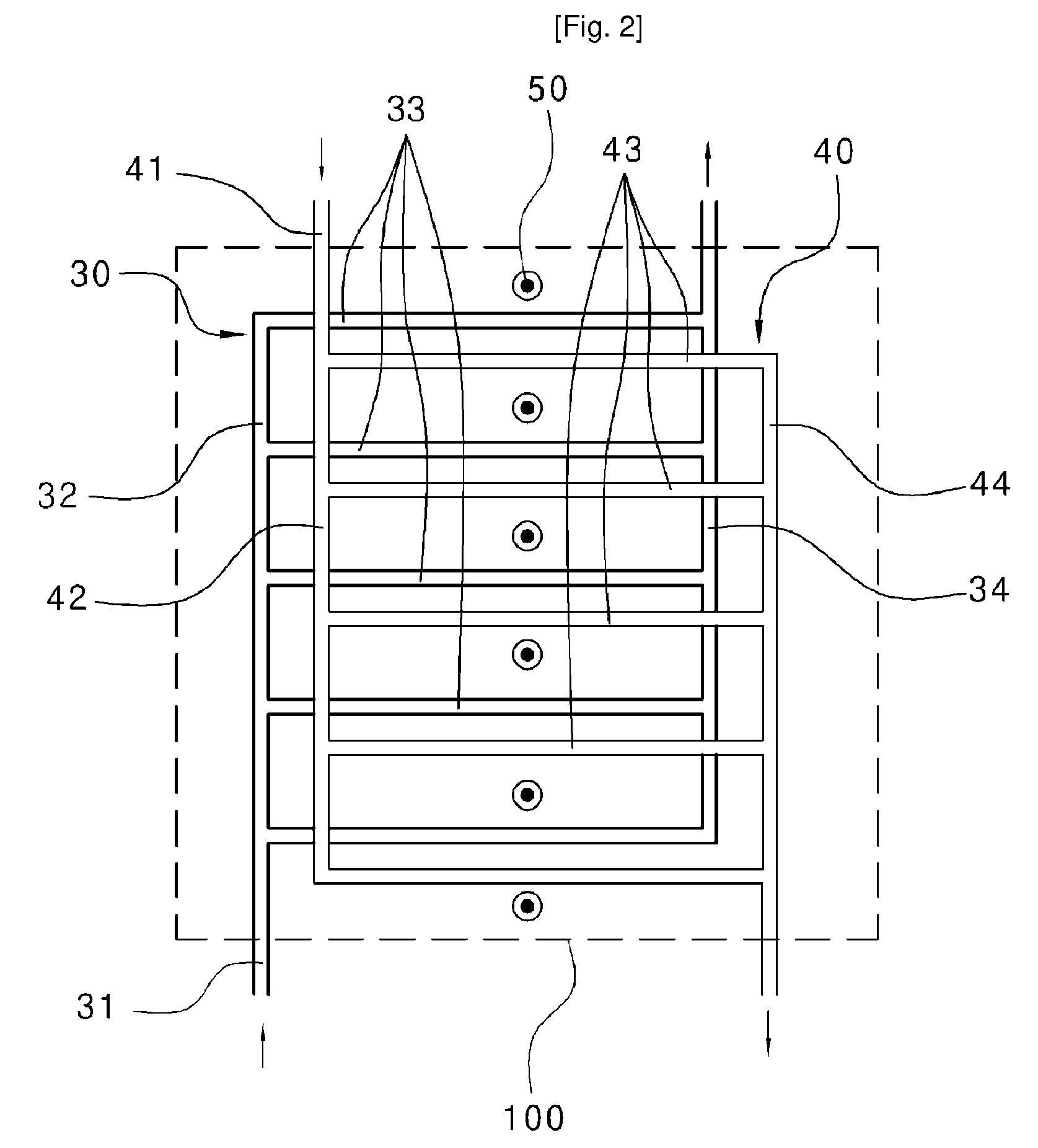

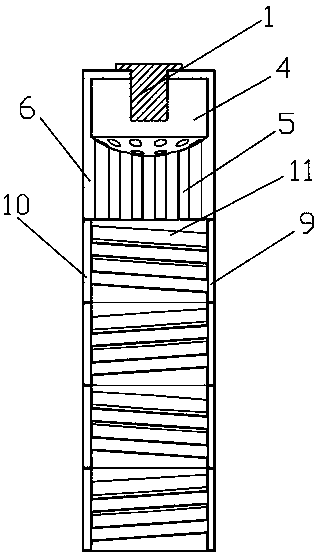

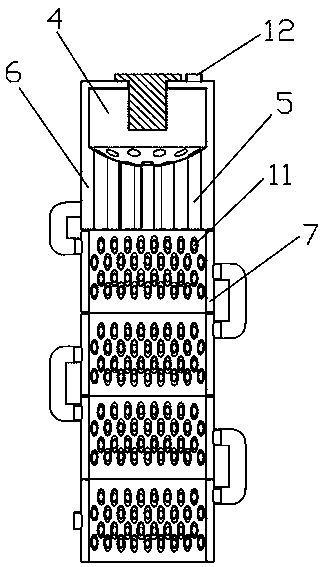

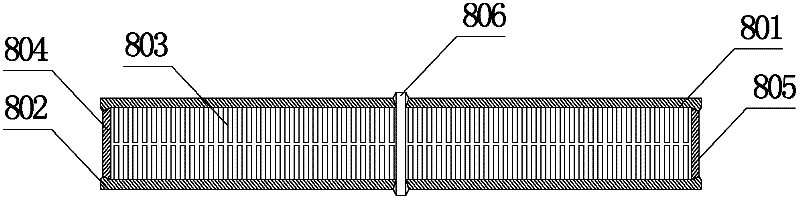

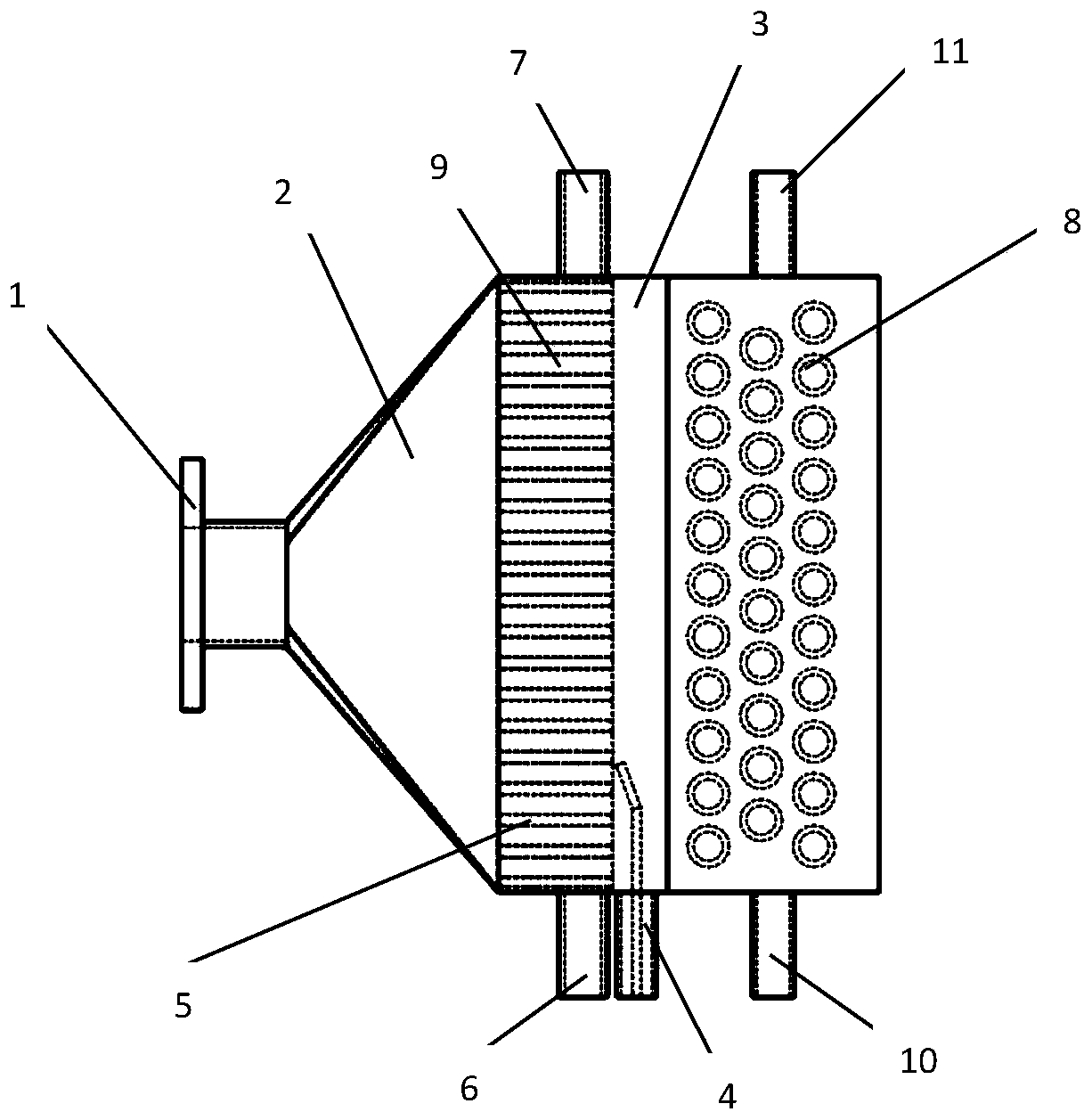

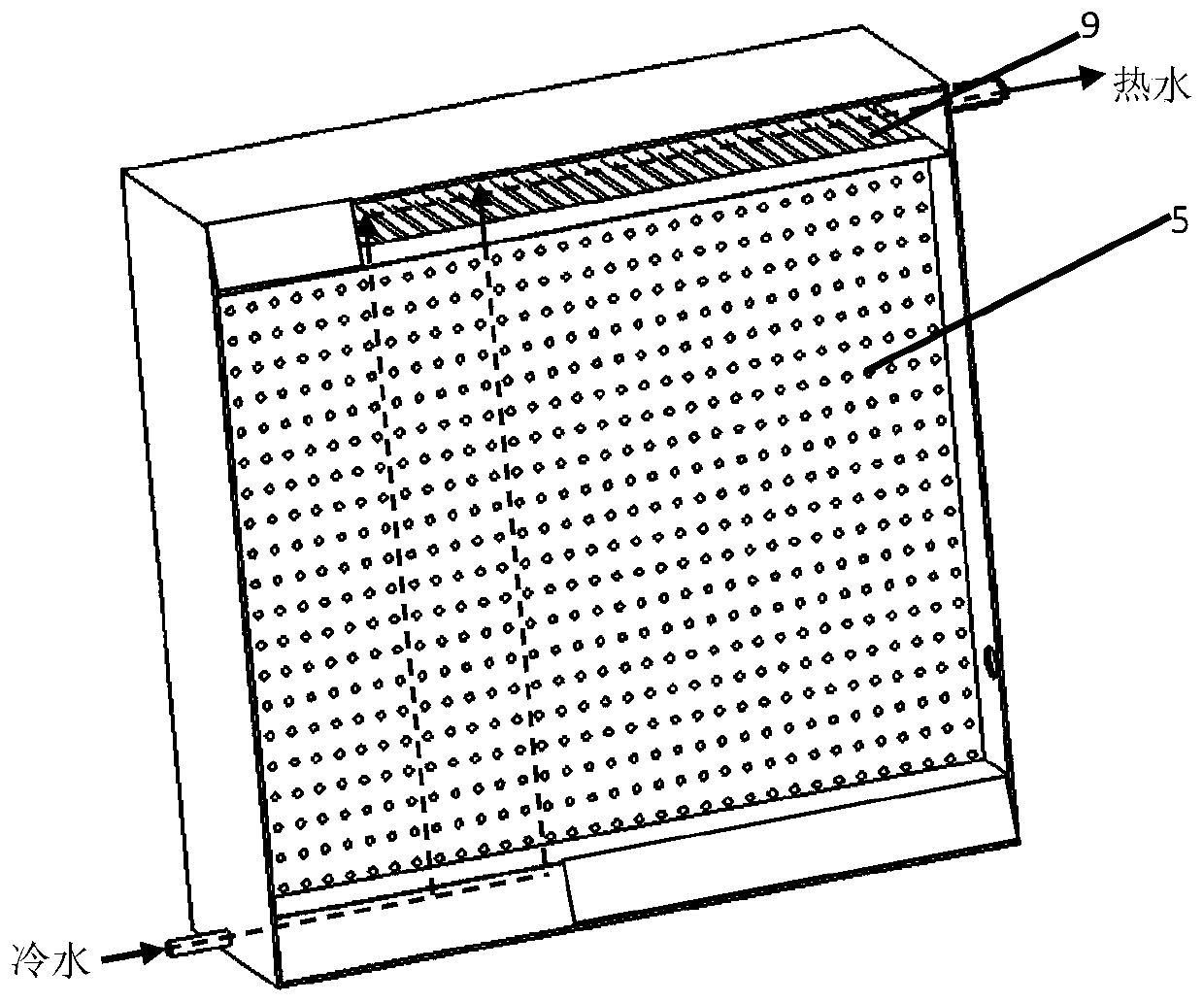

Heat Exchanger of Condensing Boiler for Heating and Hot-Water Supply

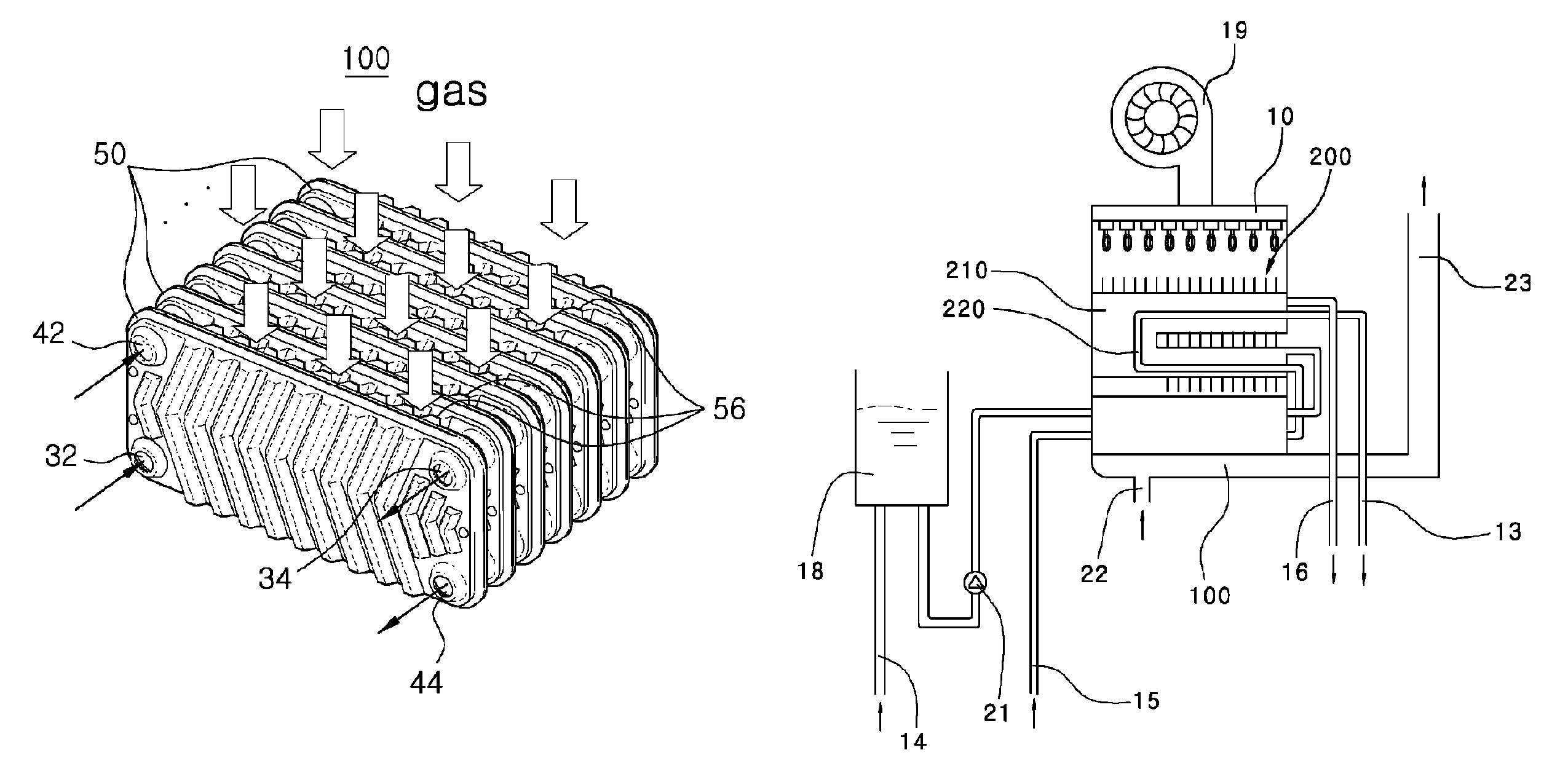

ActiveUS20090133861A1Simple structureLower the volumeMechanical apparatusBoiler water tubesEngineeringLatent heat

Disclosed is a heat exchanger for a condensing boiler supplying both heating water and hot water, which can use a double pipe as a sensible heat exchanger, instead of the use of an indirect heat exchanger. The heat exchanger includes: a sensible heat exchanger; and a latent heat exchanger made by connecting a plurality of unit heat exchangers to define exhaust gas pathway, each unit heat exchanger being manufactured in such a manner that three plates having a convexo-concave shape are stacked on one another to define a heating water pathway and a hot water pathway to be adjacent to each other in order to increase a heat transfer area.

Owner:KYUNGDONG NAVIEN

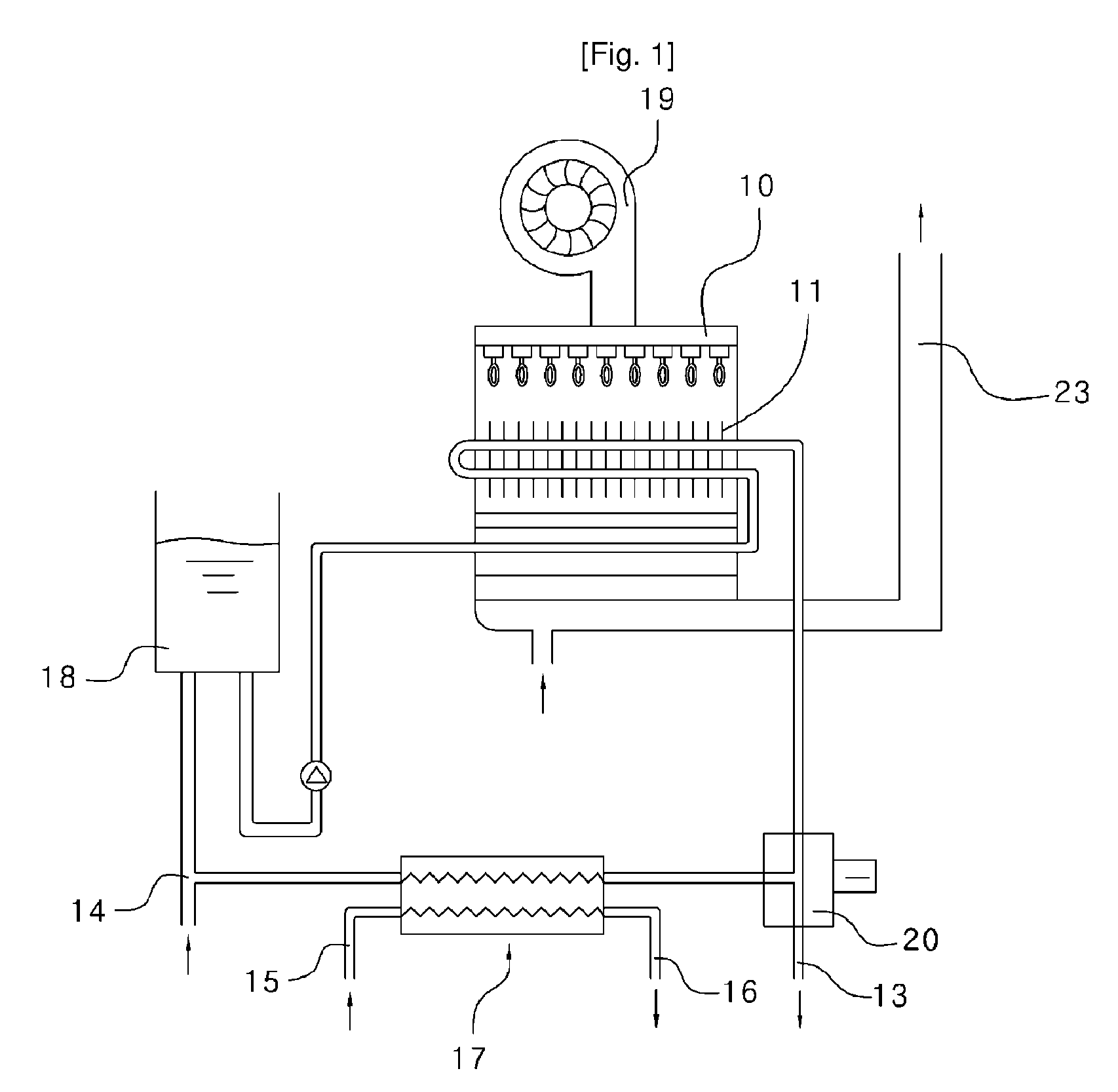

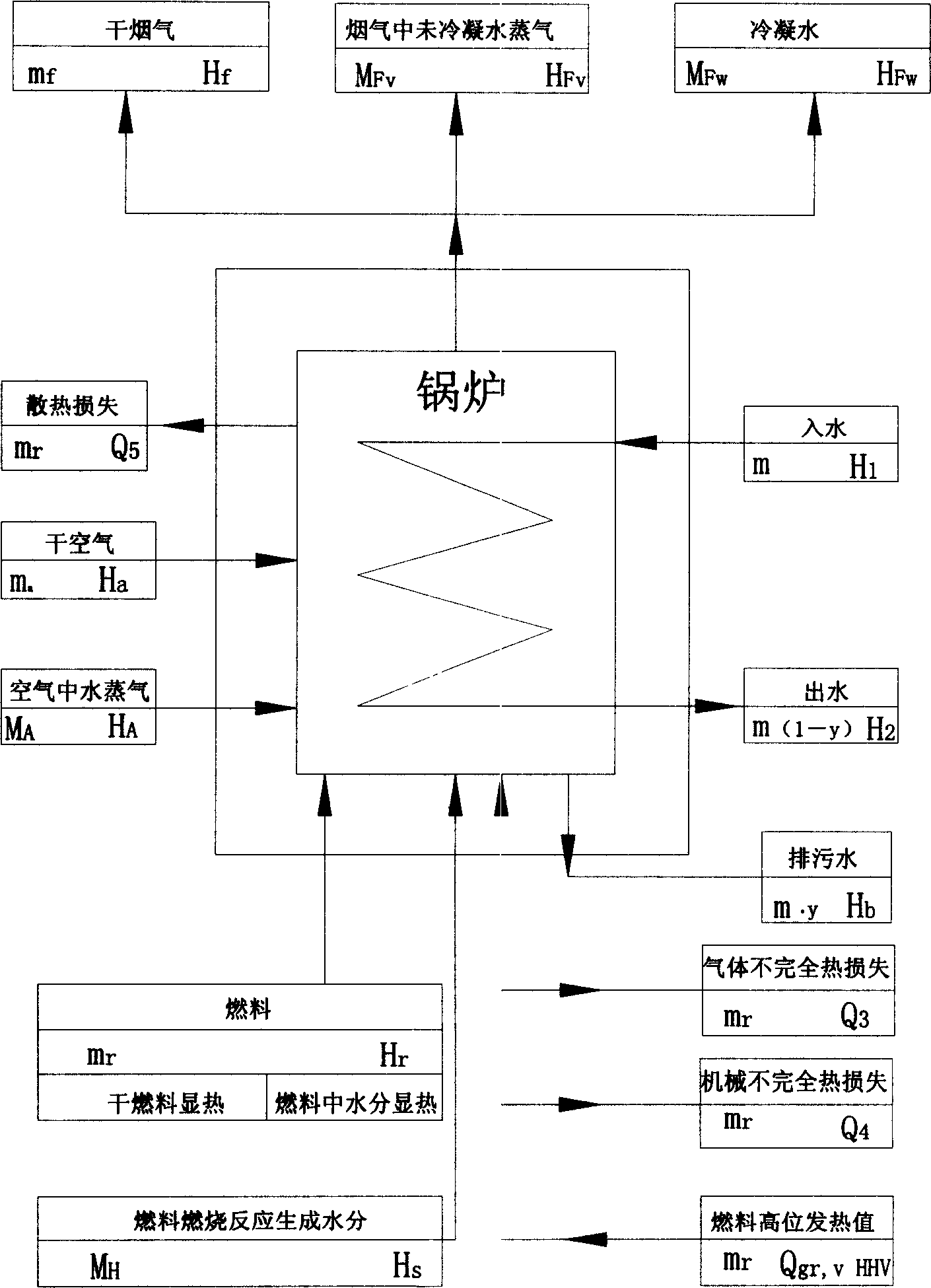

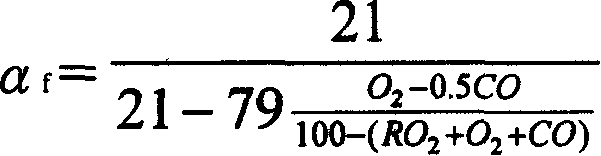

Fuel oil condensing boiler reverse-balancing heat efficient measuring method

InactiveCN1584572AHigh thermal efficiencyClear conceptMaterial thermal conductivityMaterial heat developmentAtmospheric airFuel oil

A method for measuring anti-balance heat efficiency of boiler in fuel oil condensing type includes selecting datum and reference temperature; analysing fuel composition; measuring fuel heating value, air pressure and air relative humidity, volume content of composition in smoke, temperature of smoke fuel, consumption and condensed water in smoke; selecting method for calculating heat efficiency and utilizing model to operate out boiler heat efficiency.

Owner:XI AN JIAOTONG UNIV

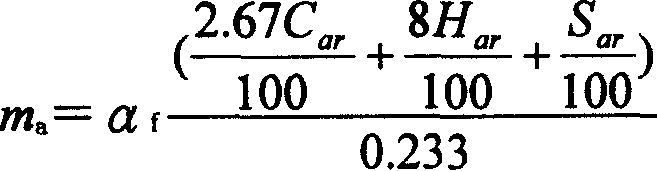

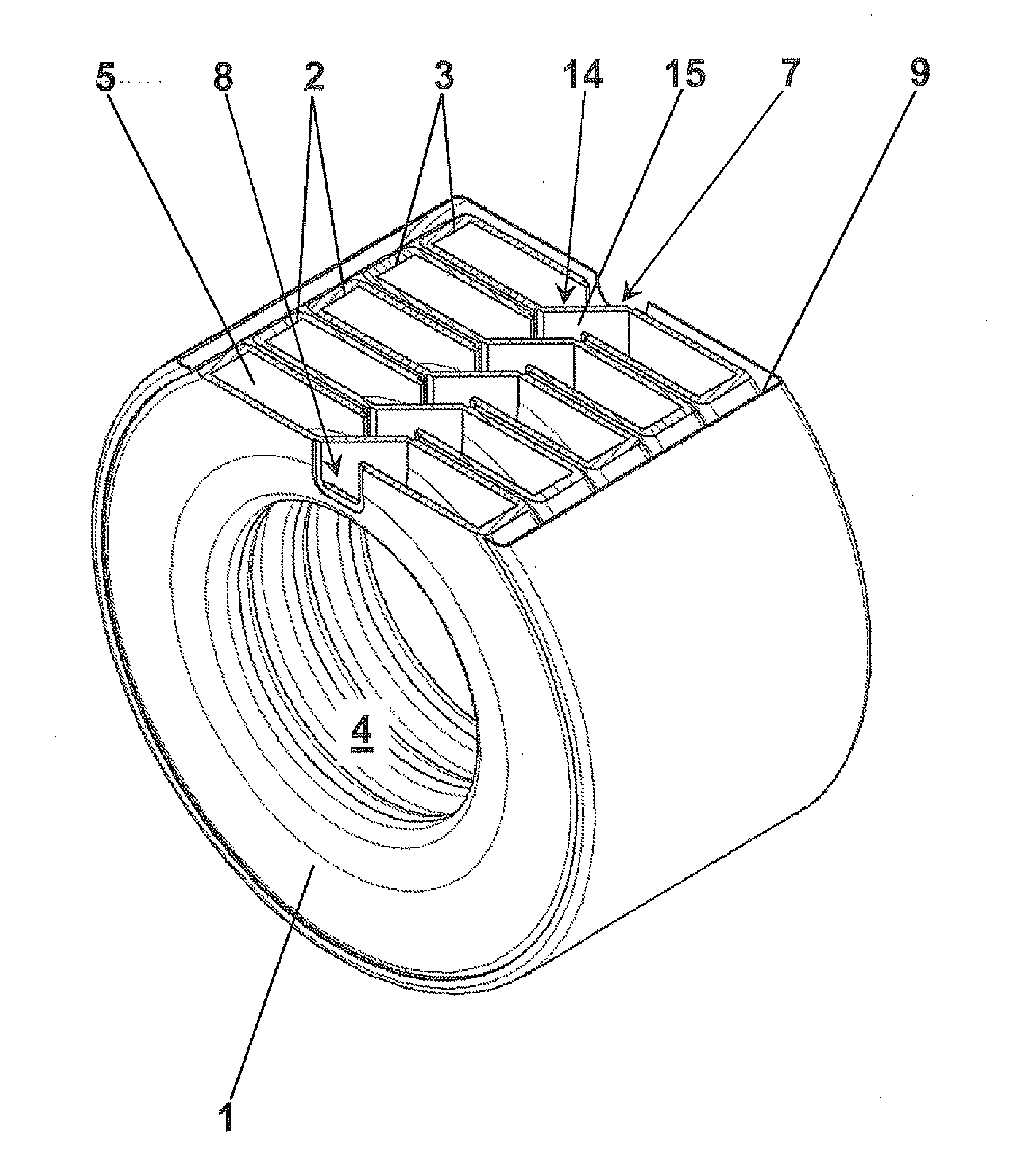

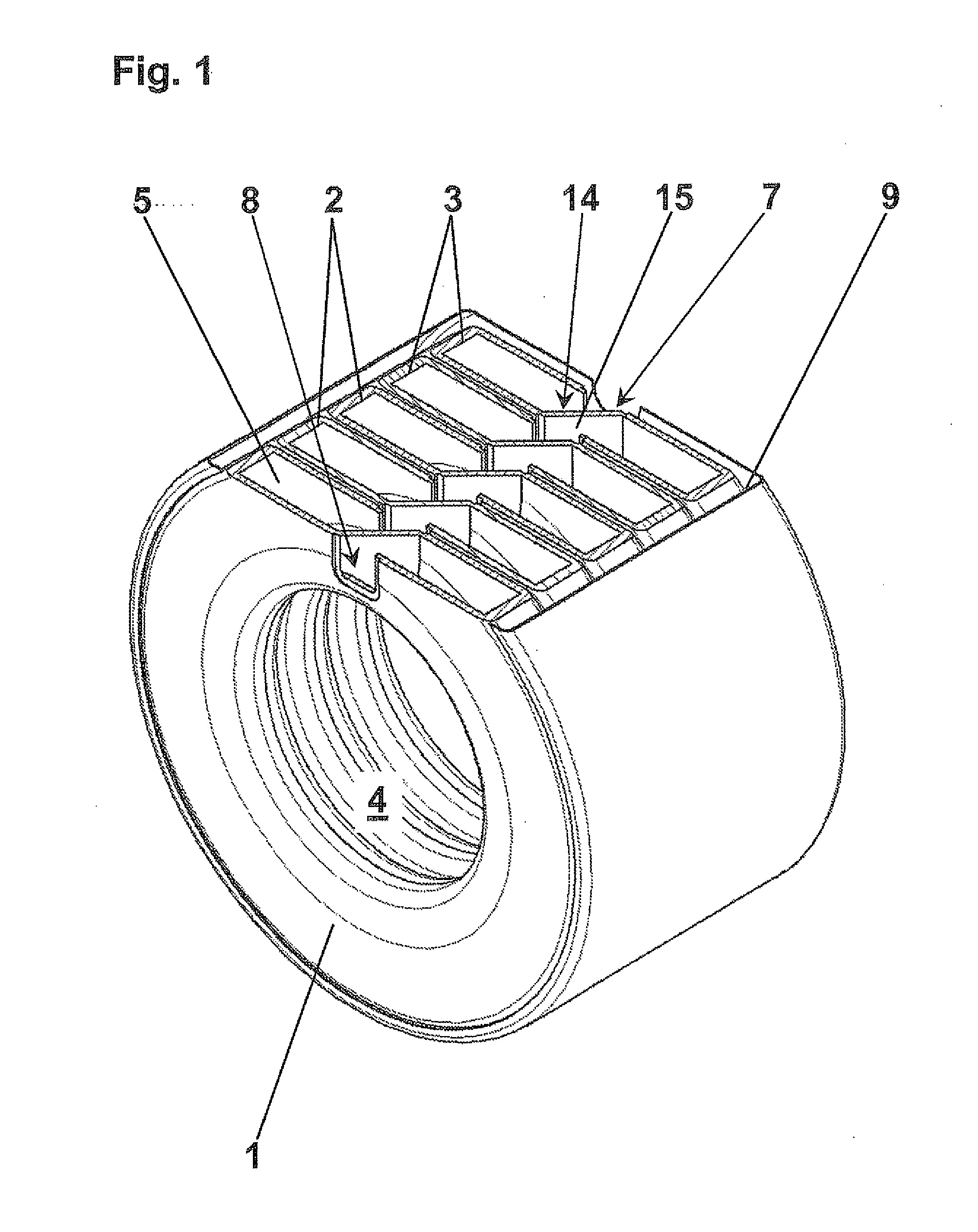

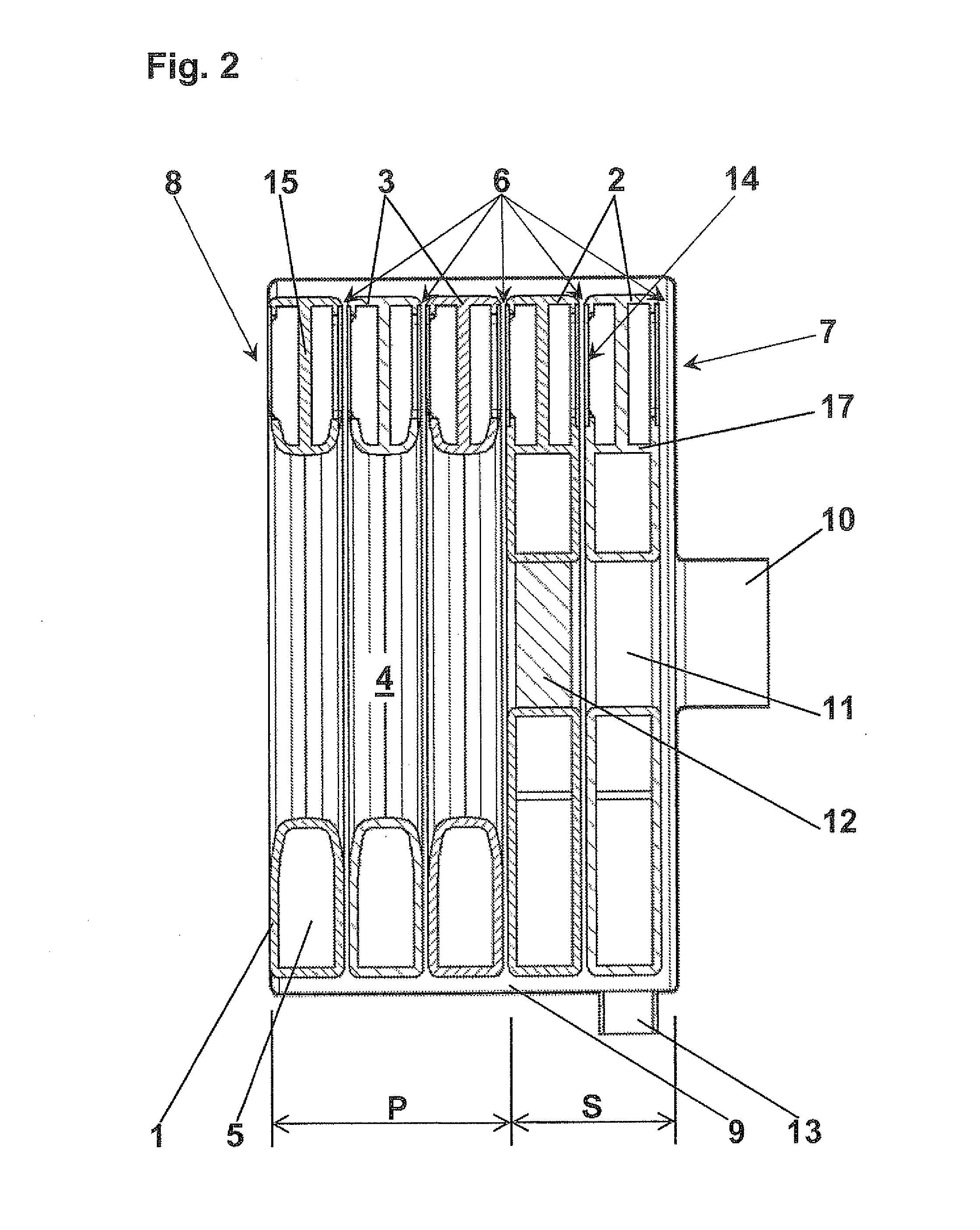

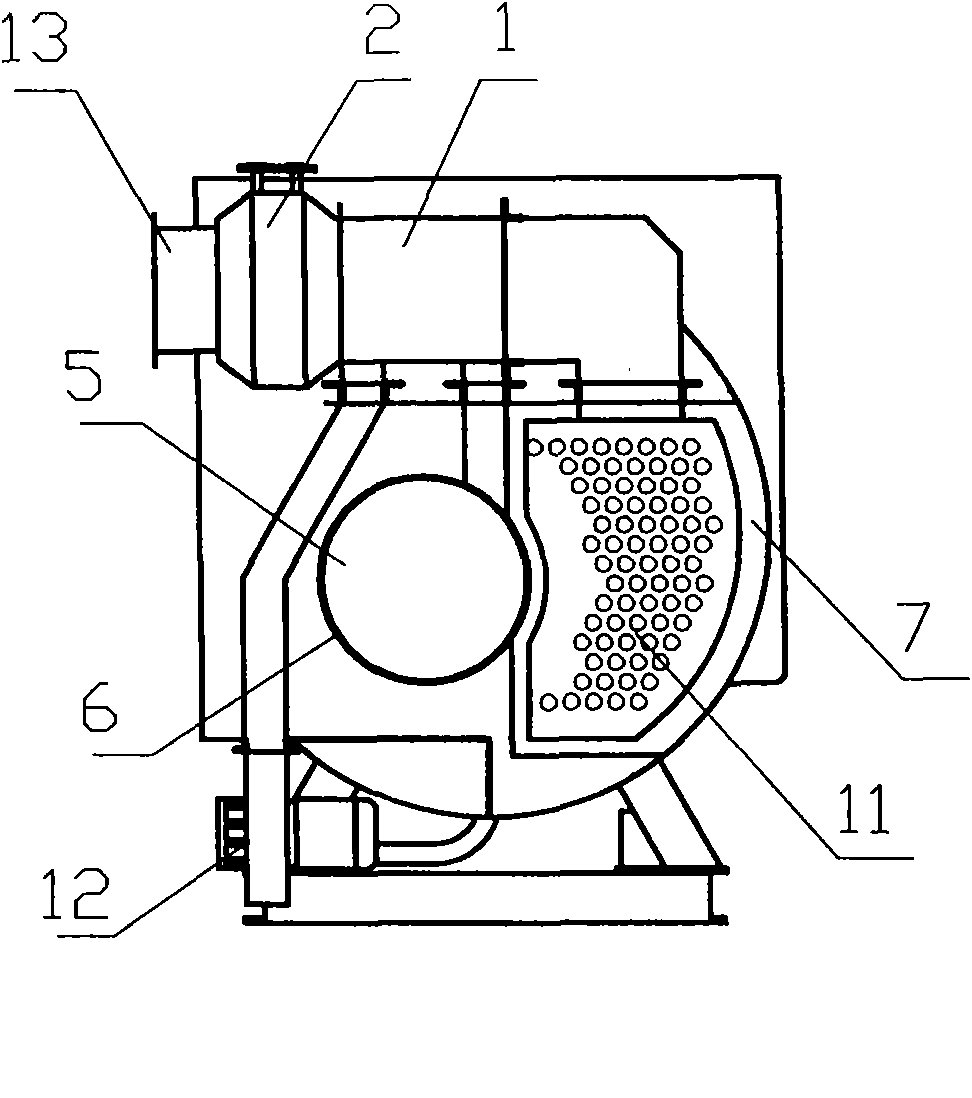

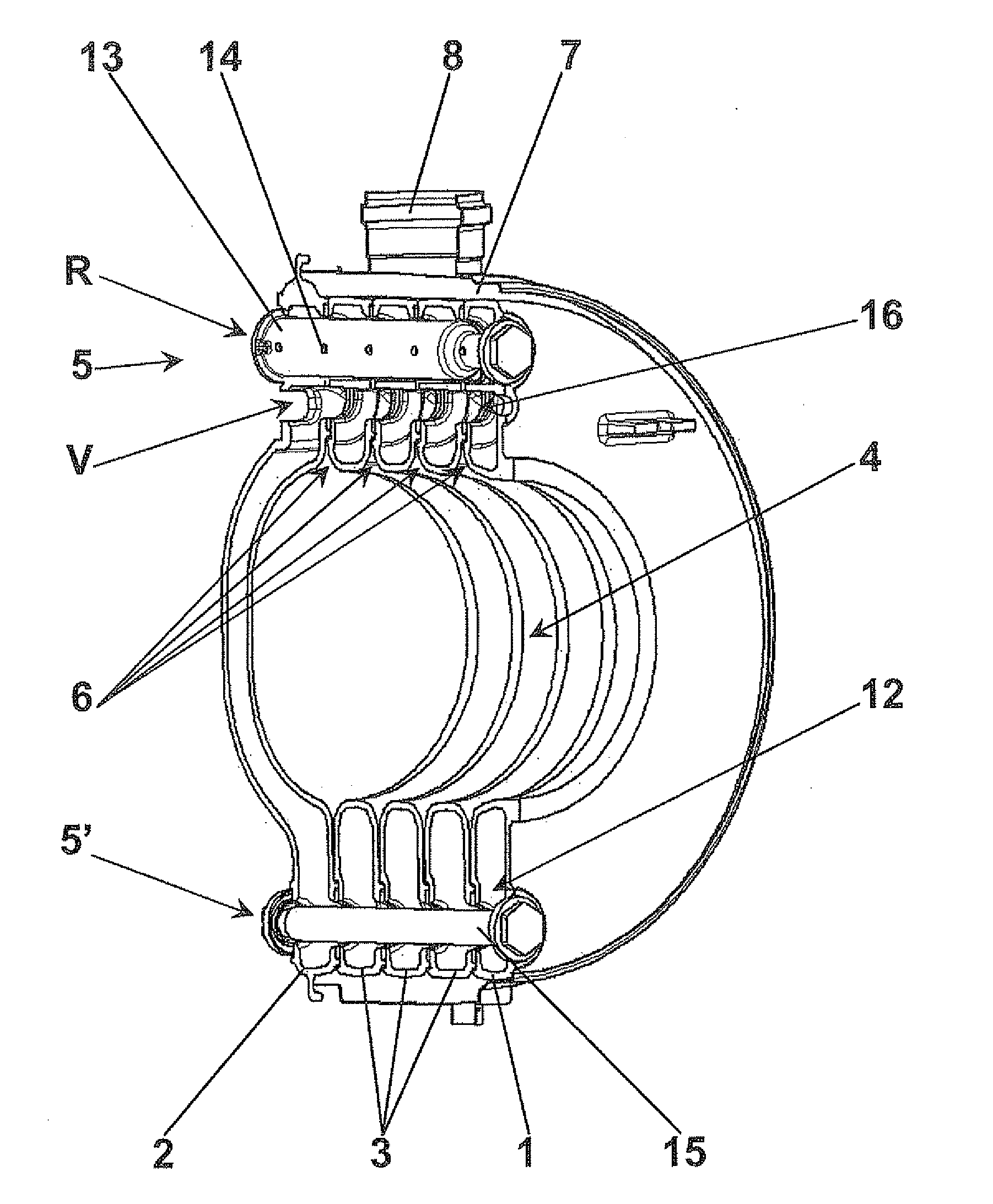

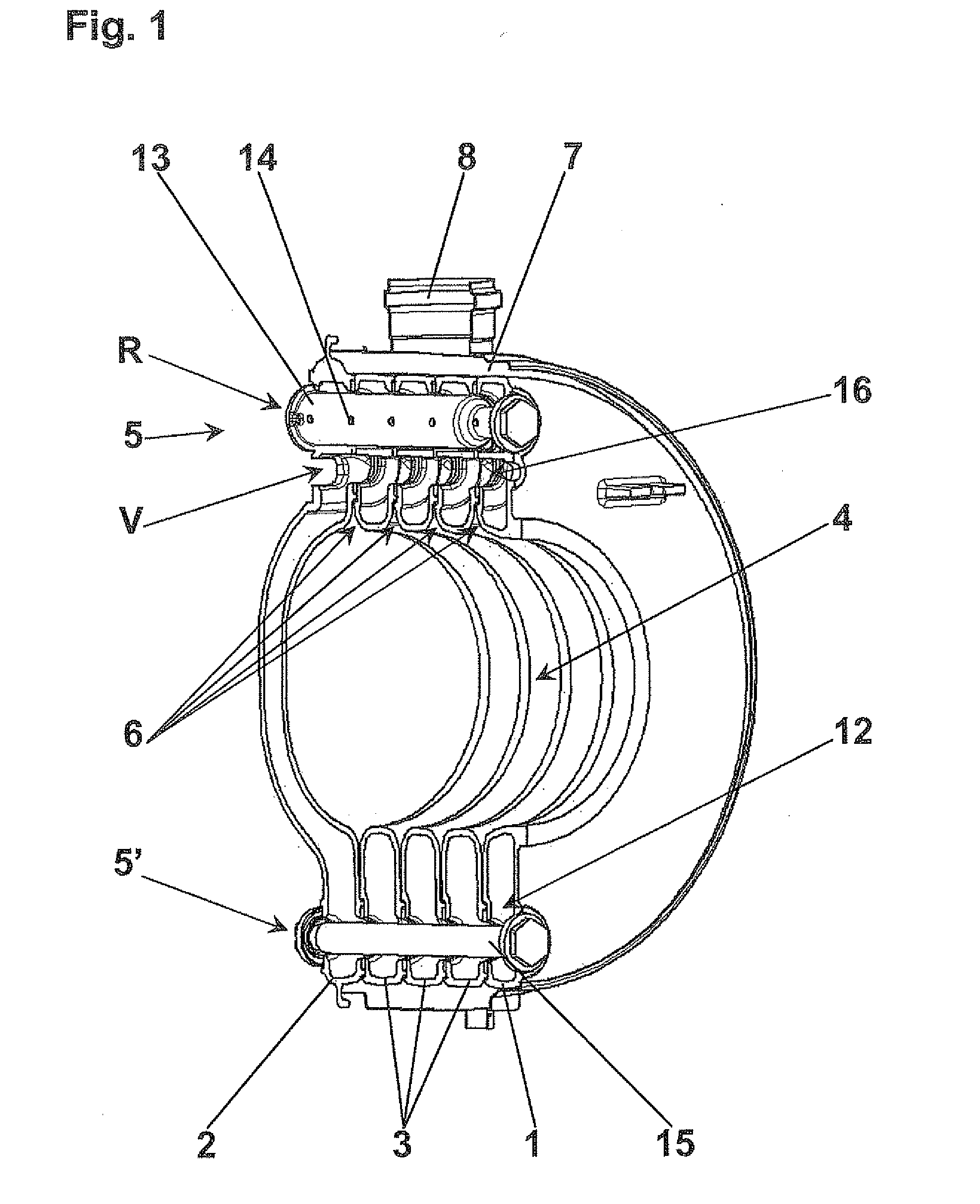

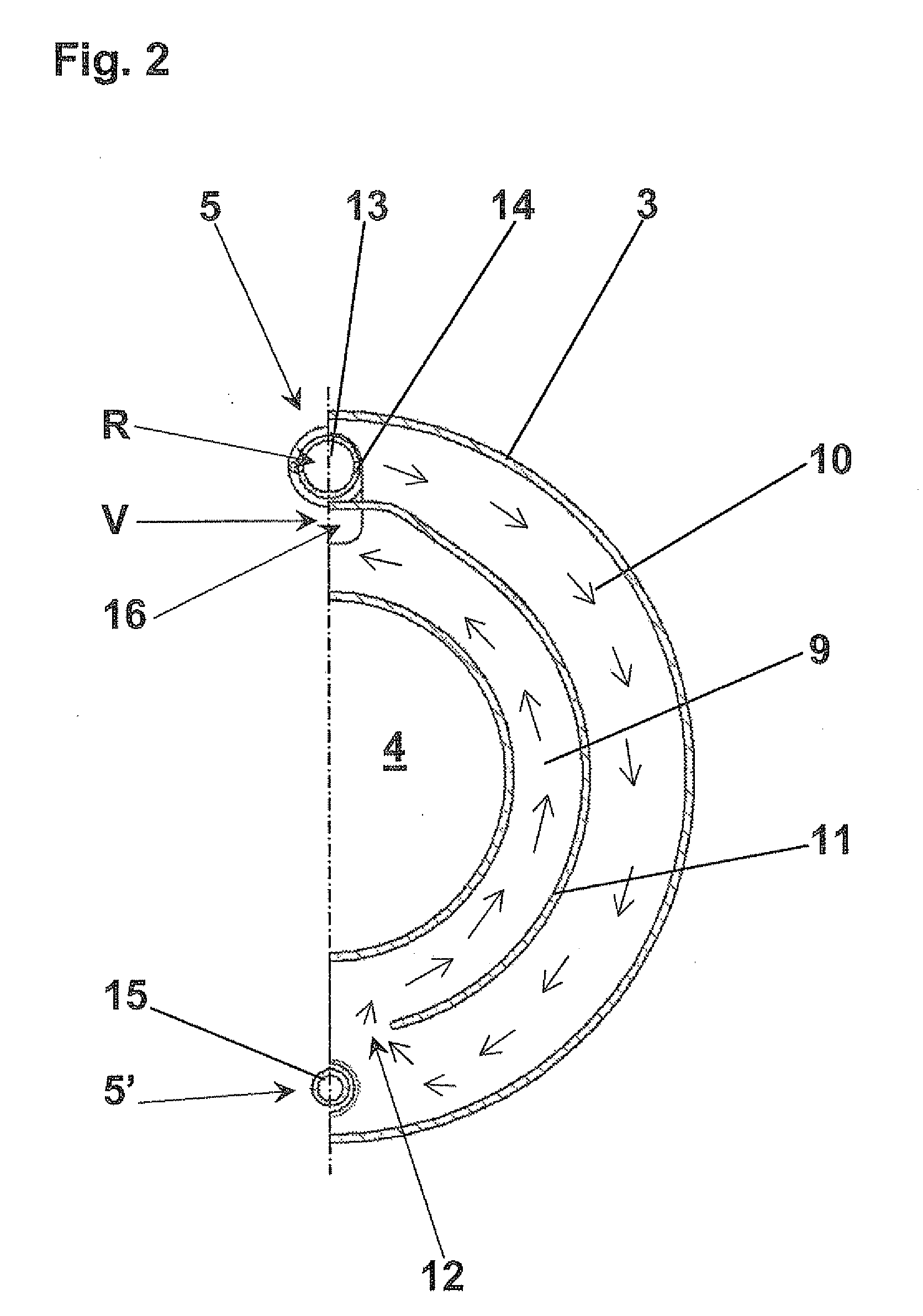

Sectional Boiler

InactiveUS20120055421A1Improve applicabilityPositive material propertiesEnergy efficient heating/coolingFurnace-tube steam boilersCombustion chamberMechanical engineering

A sectional boiler is described as made of cast iron or aluminum, in particular a condensing boiler, having essential annular sections, a front section, at least one rear section and at least one center section being provided, which form a combustion chamber having an essentially surrounding heat exchanger made of a sectional block, whose annular water chambers are connected to one another and which has gap-like heating gas flues, which extend between two adjacent sections with a mutually adapted geometry approximately radially and empty into an exhaust gas collection chamber, and having a return port and a feed port. The present system is based on the objective of optimizing a sectional boiler made of cast iron or aluminum as a condensing boiler particularly with respect to compactness and robustness. The present system provides that the return port and the feed port are located on opposite sides of the sectional block, the flow passes through the water chambers of the sections in series starting from the return port, and the individual sections are respectively provided hydraulically with overflow openings in only one place on the periphery and are connected by these on at least one side with an adjacent section.

Owner:ROBERT BOSCH GMBH

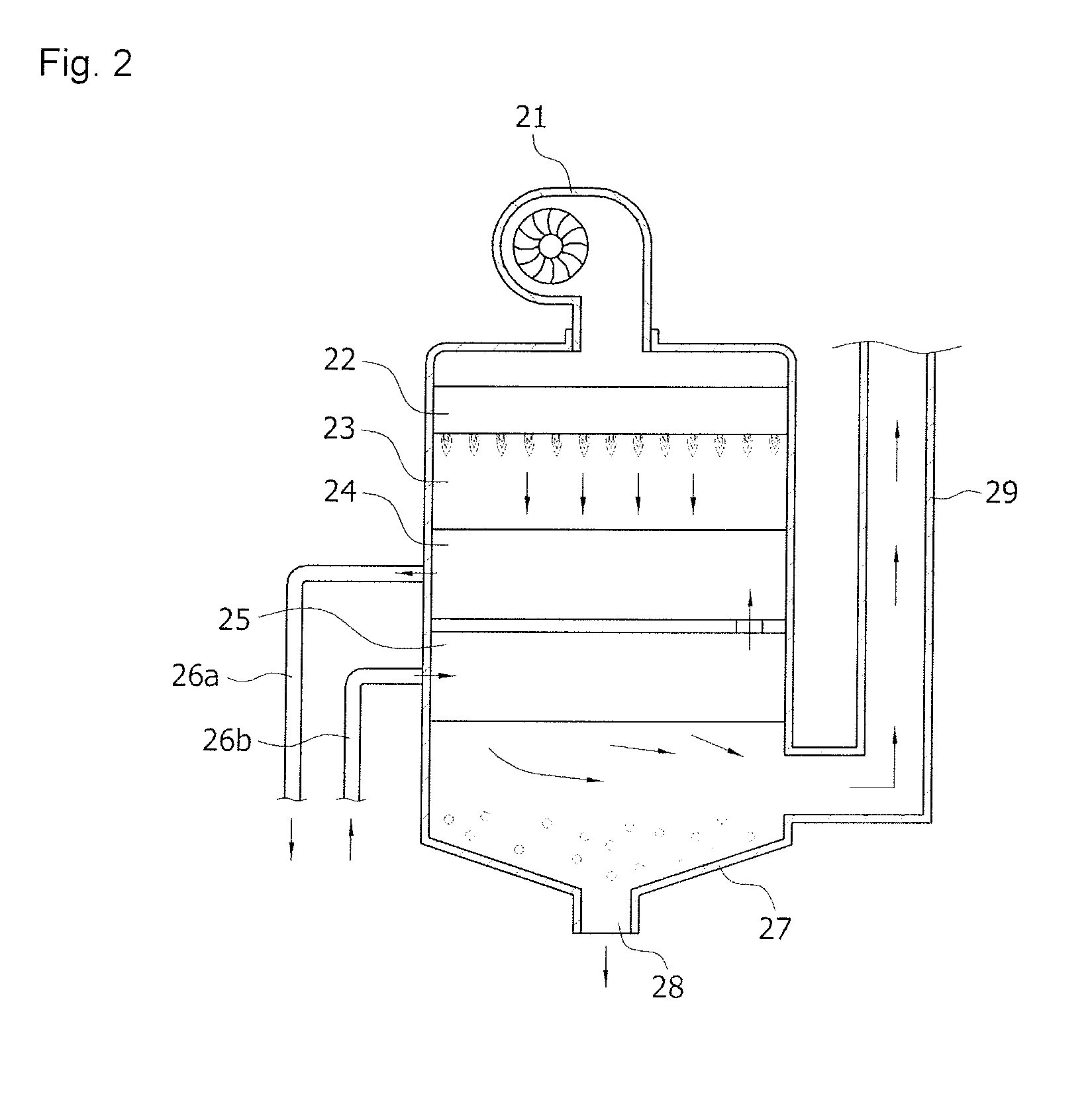

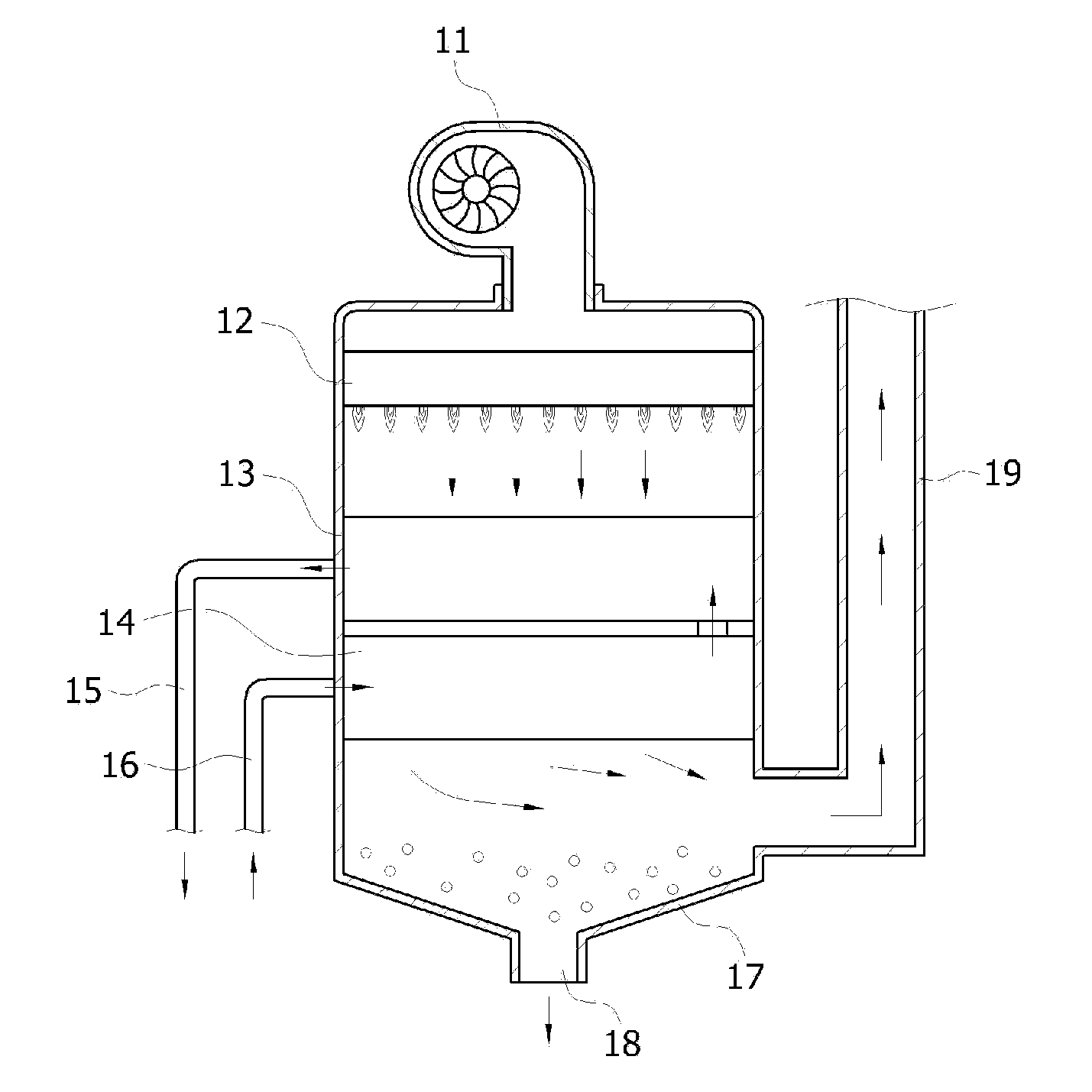

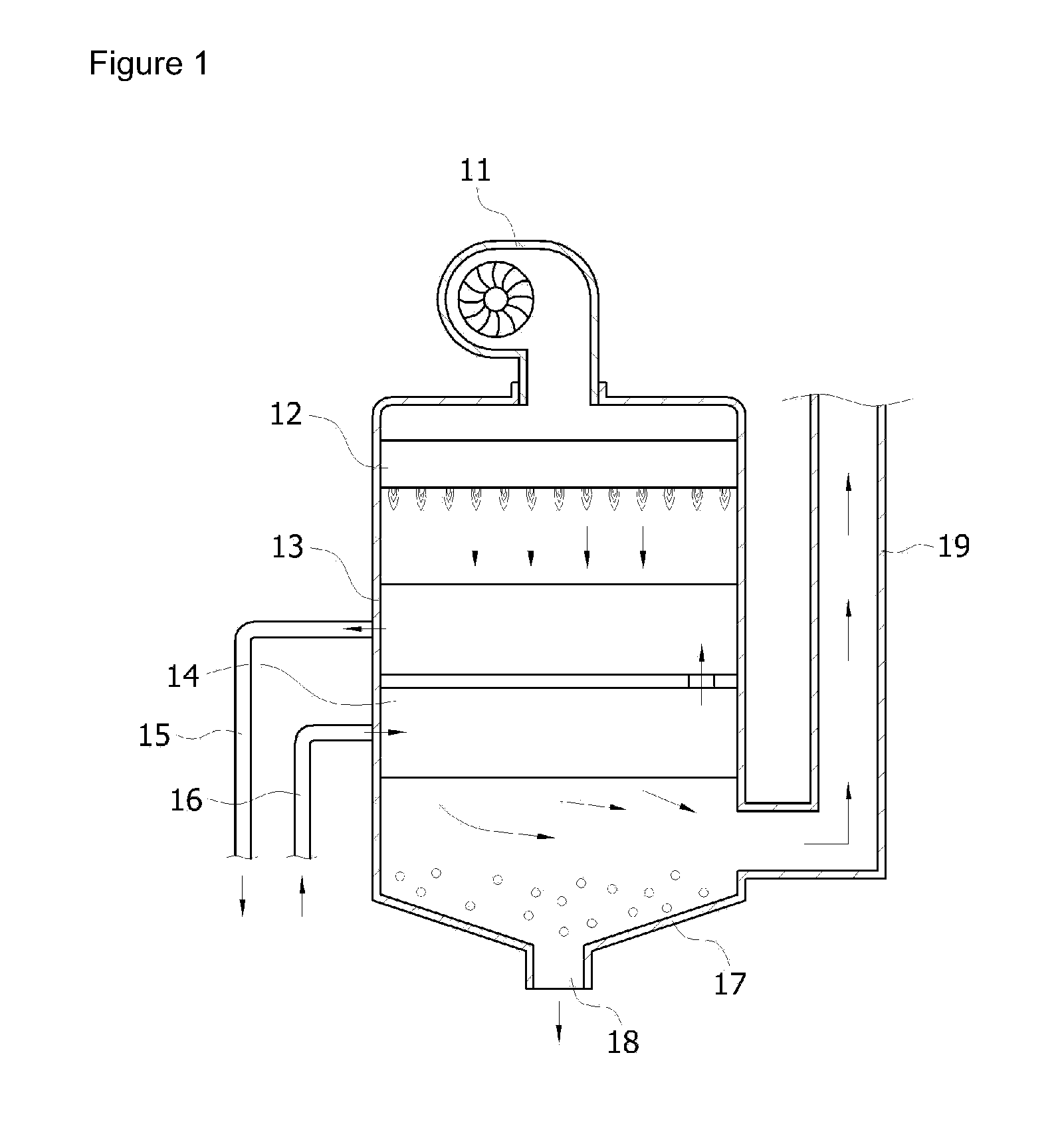

Heat exchanger of upward combustion type condensing boiler

InactiveCN101903711ASmall sizeMaximize latent heat recovery efficiencyMechanical apparatusEnergy efficient heating/coolingCombustorWater vapor

Owner:KYUNGDONG NAVIEN

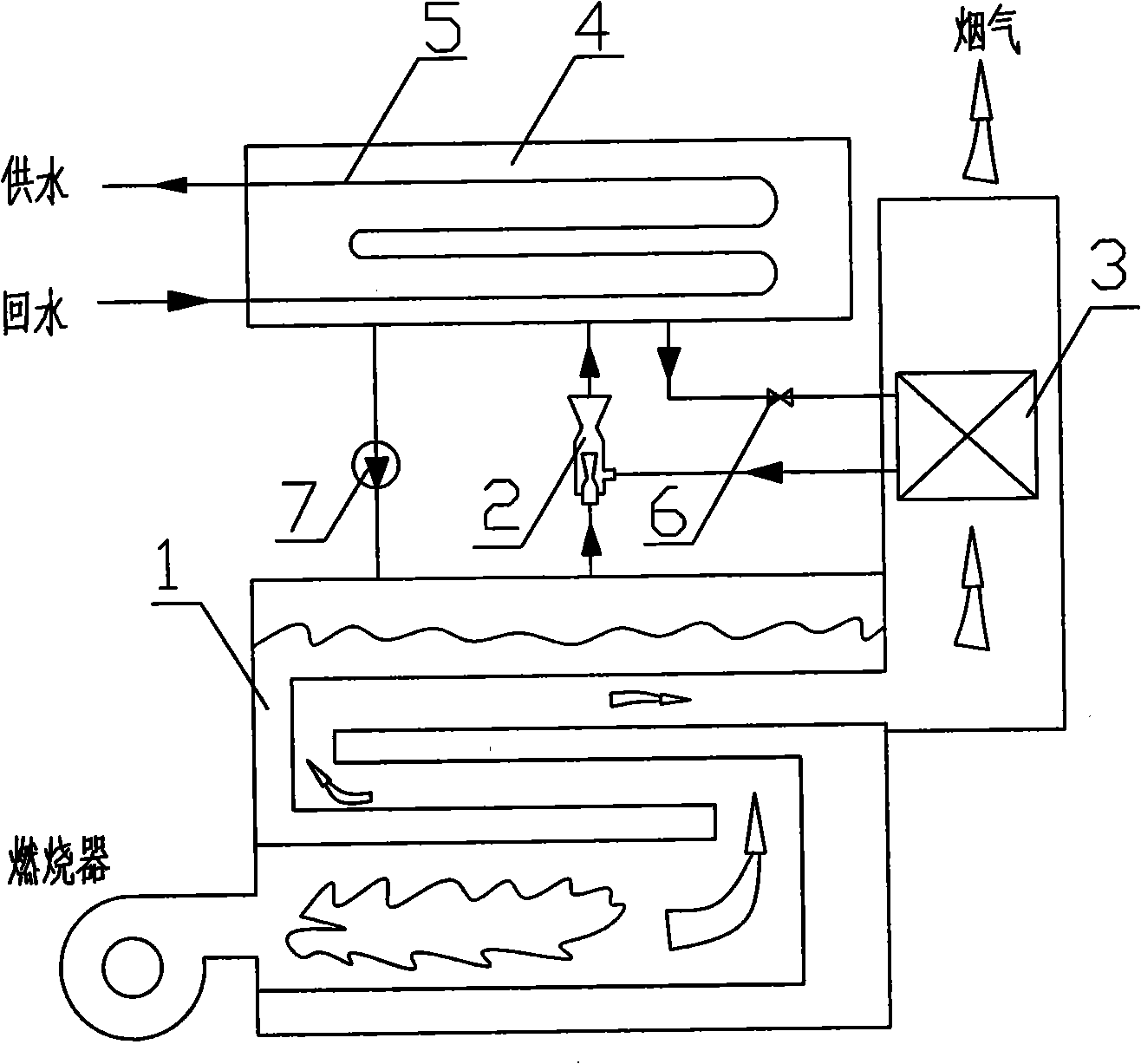

Ultra low temperature smoke-discharging heat supply boiler

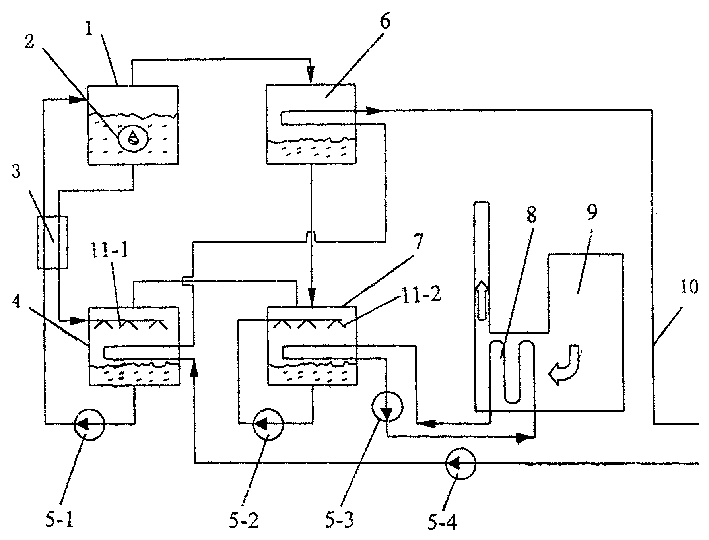

InactiveCN101255983AImprove efficiencyEmission reductionHeat recovery systemsWaste gas energyFuel oilEngineering

The invention discloses an ultra low temperature fume-discharging heat-supplying boiler, comprising a steam generating segment, a steam induction device, a low temperature fume heat energy recovering device, a condenser section, a heat exchange tube set, a throttling valve, a circulating working medium and a circulating booster pump. The heat exchange tube set is disposed in the condenser section, and the low temperature fume heat energy recovering device is disposed in a fume channel at the tail of the boiler. The invention solves the problem that the condensing boiler in prior art is difficult to be popularized in heat supply field since the condensing residue heat grade thereof is too low. The inventive boiler can recover residual heat of gas, fuel oil and coal-fired boilers, and also can be used for reconstructing boiler from steam heat supply to hot water supply comprising other fuels.

Owner:XI AN JIAOTONG UNIV

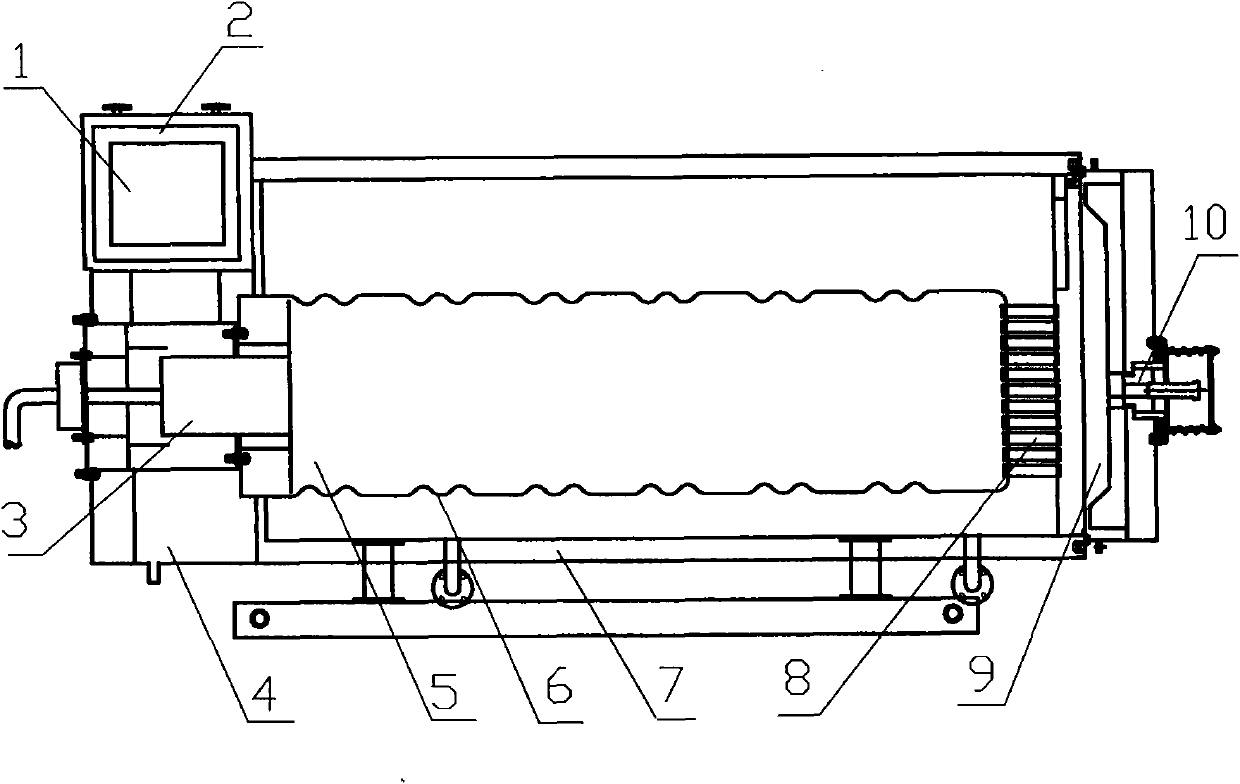

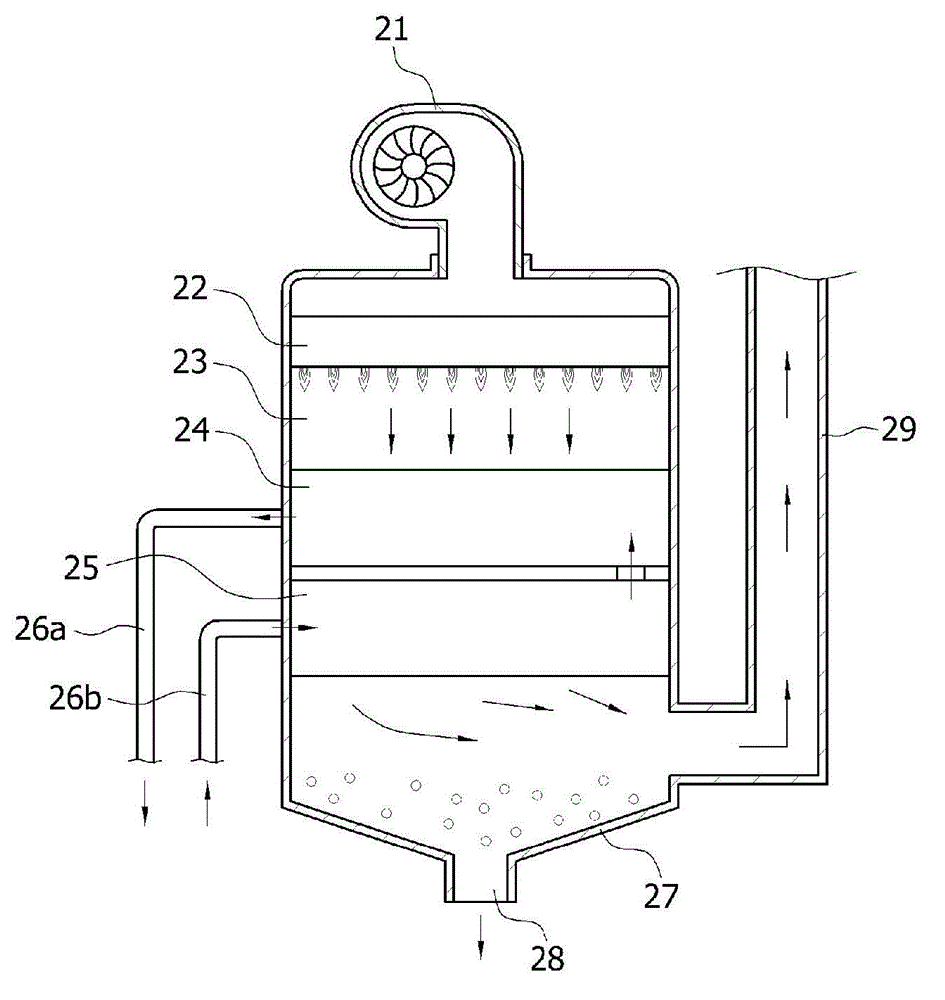

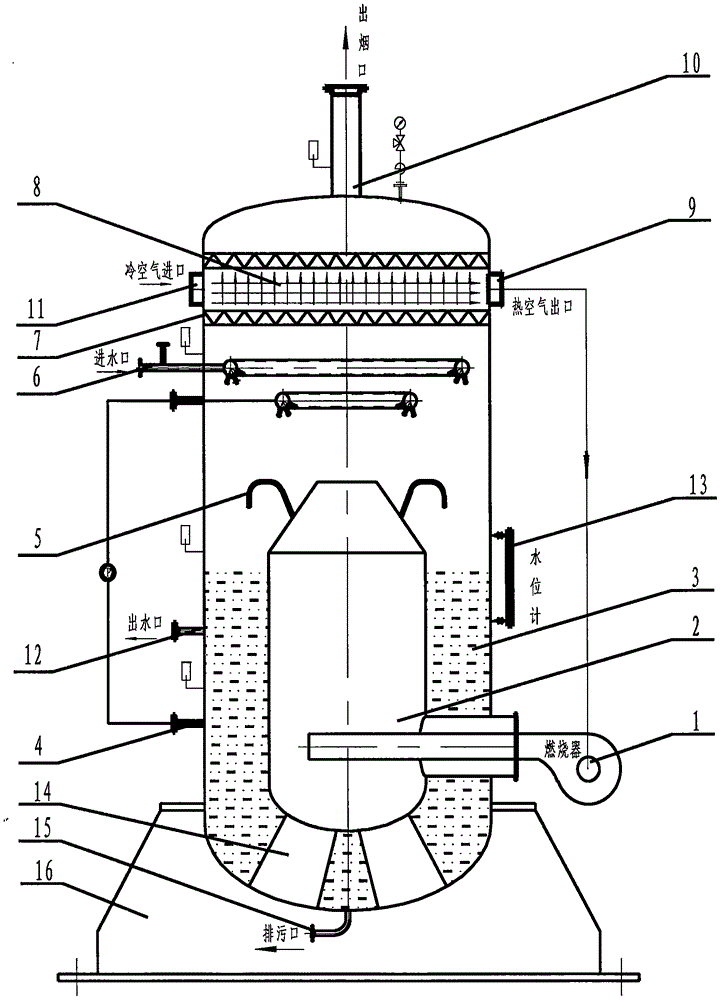

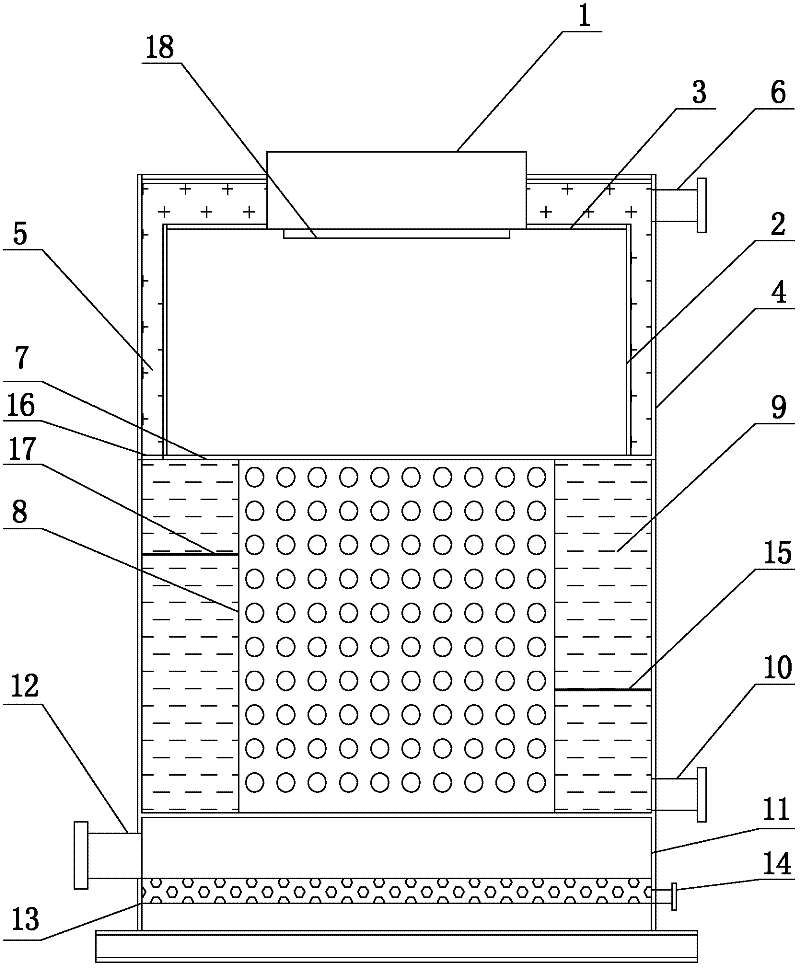

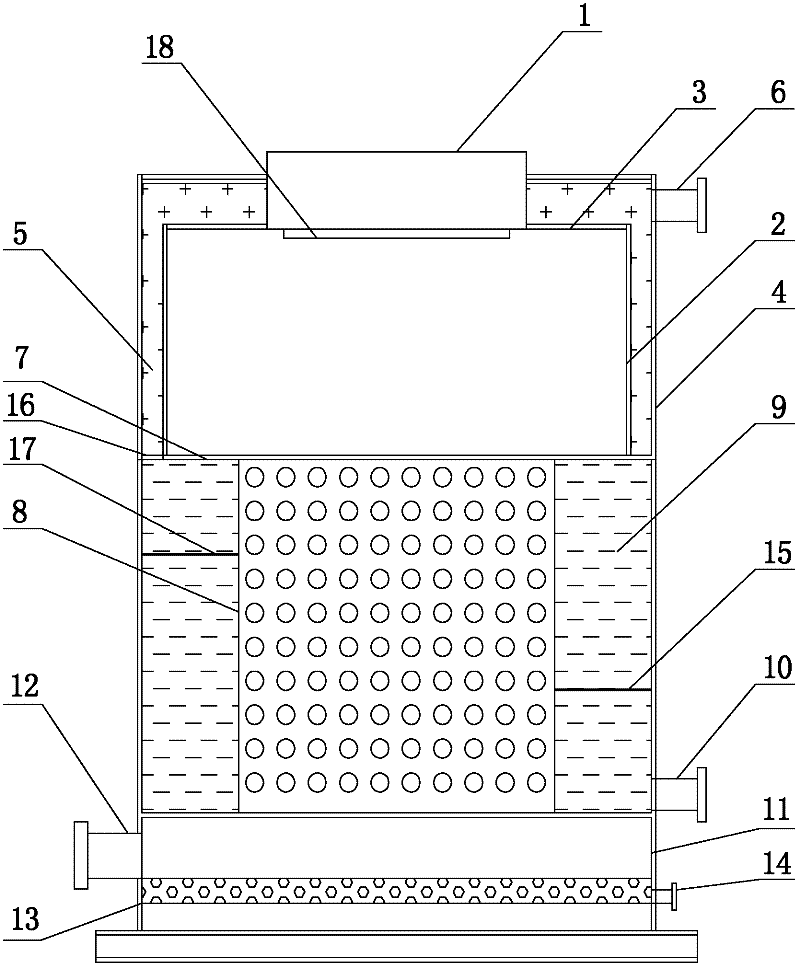

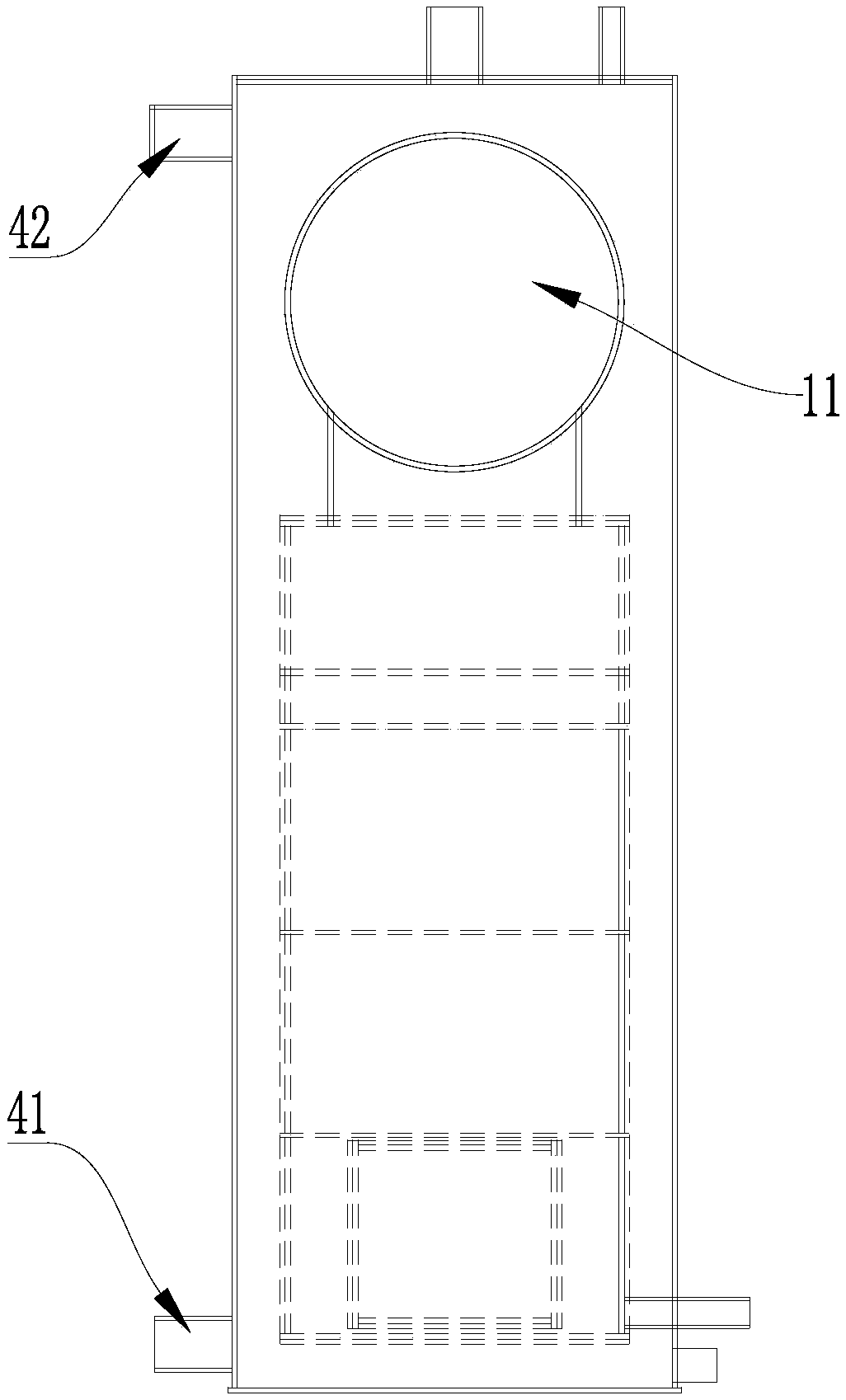

Integrated flue gas condensing waste heat recovery boiler

InactiveCN101793434AImprove recycling effectCompact structureCombustion processEnergy efficient heating/coolingAir preheaterSteam condensation

The invention relates to an integrated flue gas condensing waste heat recovery boiler, and belongs to the field of heating equipment, in particular to an oil-fired and gas-fired two-return-stroke shell type hot water or steam condensing boiler. The technical scheme of the invention is as follows: an air inlet of a plate-fin type air pre-heater is connected with a blower, and an air outlet is connected with the air inlet of a burner; a flame hole of the burner is connected with the left end of a hearth, and the shell of the hearth is of a corrugated flue; the right end of the corrugated flue is of a corrugated flue top, and the corrugated flue top is communicated with the front wall of a back smoke box by a convection tube bank; the back smoke box is communicated with a convection heating surface, and the convection heating surface is communicated with a front smoke box; the front smoke box is communicated with a flue gas inlet of the air pre-heater, and the flue gas outlet of the air pre-heater is communicated with a flue gas inlet of a condenser; and the flue gas outlet of the condenser is communicated with a smoke exhaust port, and the parts and the boil shell form an integrated structure. The invention has the advantages: the air pre-heater, the flue gas condenser and the boiler are integratively designed, so that the whole structure of the boiler is more compact, the corrosion-resistant ability is strong, the equipment is safer, the use is stable and reliable, and the service life is longer.

Owner:ANYANG FANGKUAI BOILER

Vapor vacuum heating systems and integration with condensing vacuum boilers

ActiveUS8702013B2Prevent backflowHeat recovery systemsCentral heating componentsCogenerationProcess engineering

In order to solve the numerous problems with existing steam, vacuum, and hot water heating systems, first presented is a novel system and method for a vapor vacuum system having low temperature condensate return which can operate without steam traps in both single-pipe and dual-pipe configurations. Secondly is disclosed systems and methods for integrating the disclosed vapor vacuum system with a condensing boiler. Thirdly is presented several systems and method of operating radiators having low temperature condensate return with the disclosed vapor vacuum system. Finally is presented condensing vacuum boiler designs that can be utilized with the disclosed vapor vacuum system. Also presented are embodiments having naturally-induced vacuum and utilizing district heat as well as combined heat and power. All innovations presented herein make vapor vacuum steam more efficient and economical for industrial, commercial, and home applications.

Owner:ZHADANOVSKY IGOR

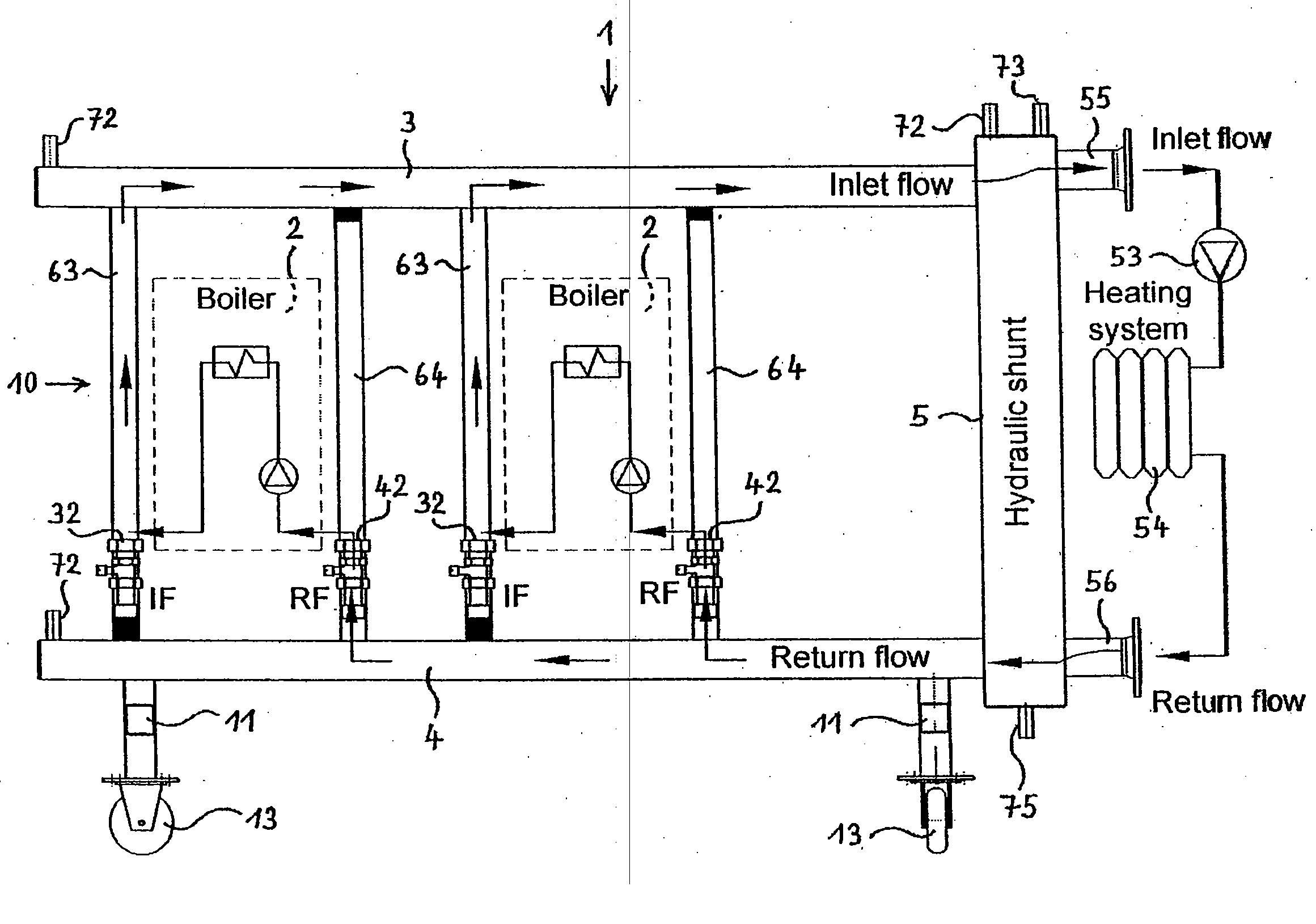

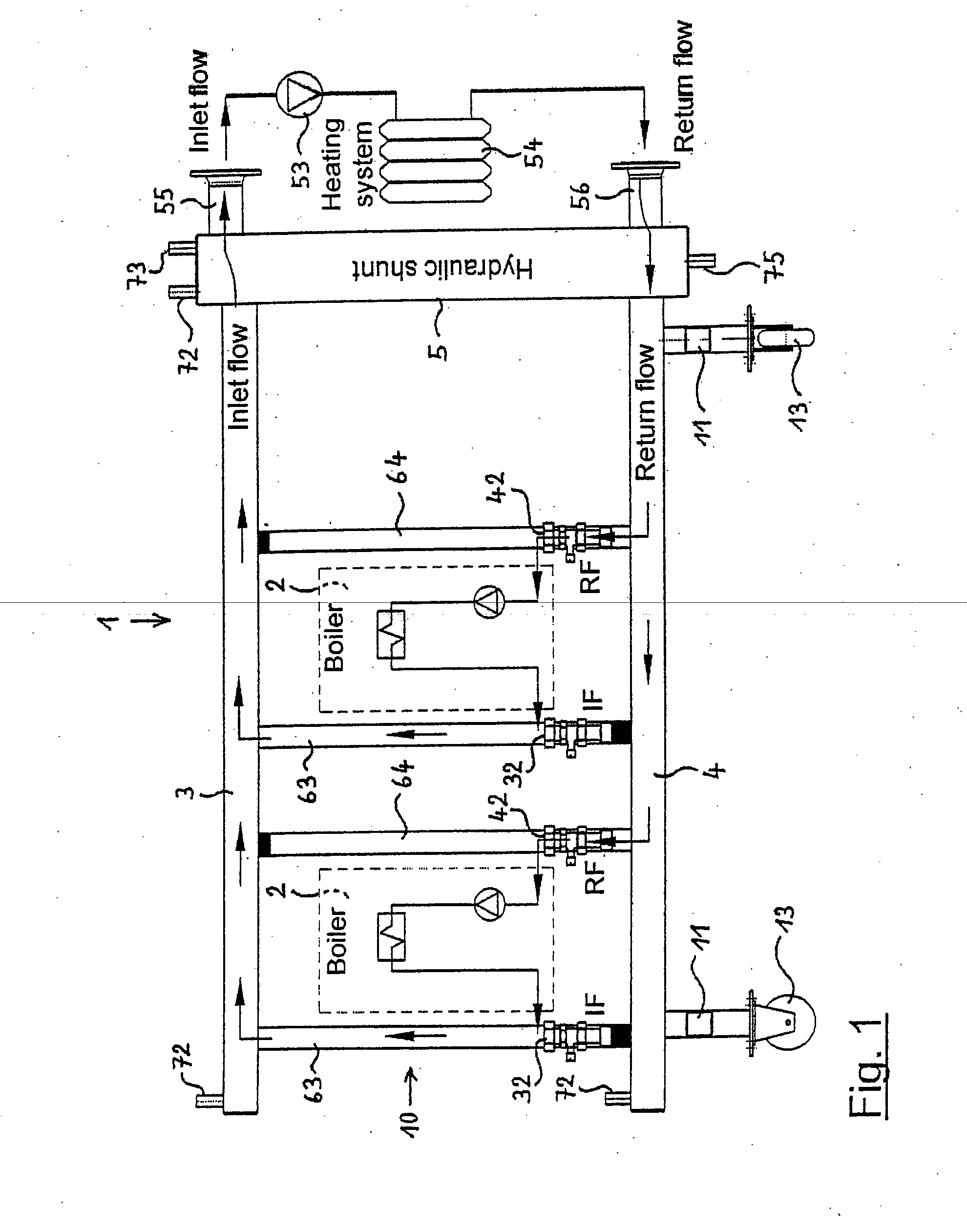

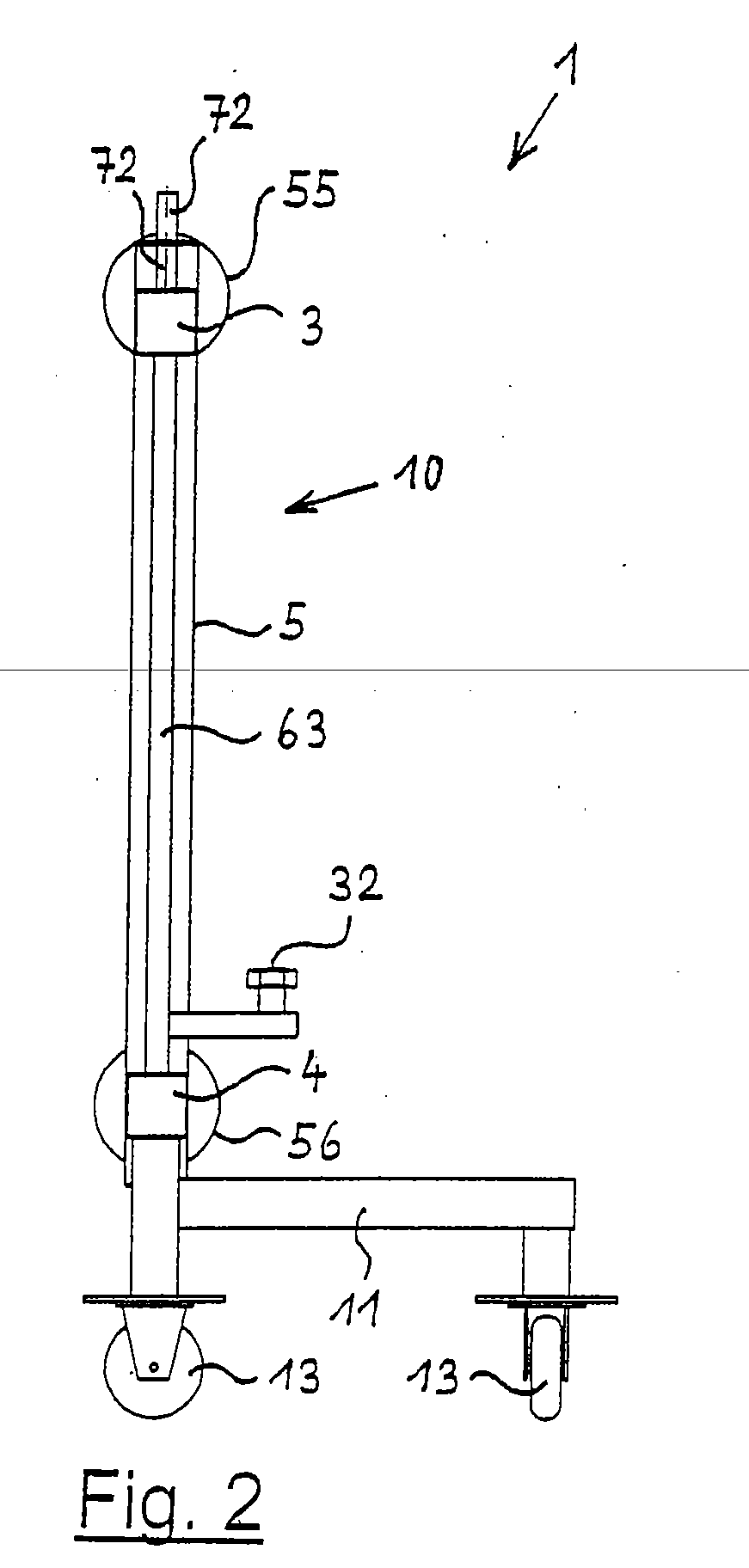

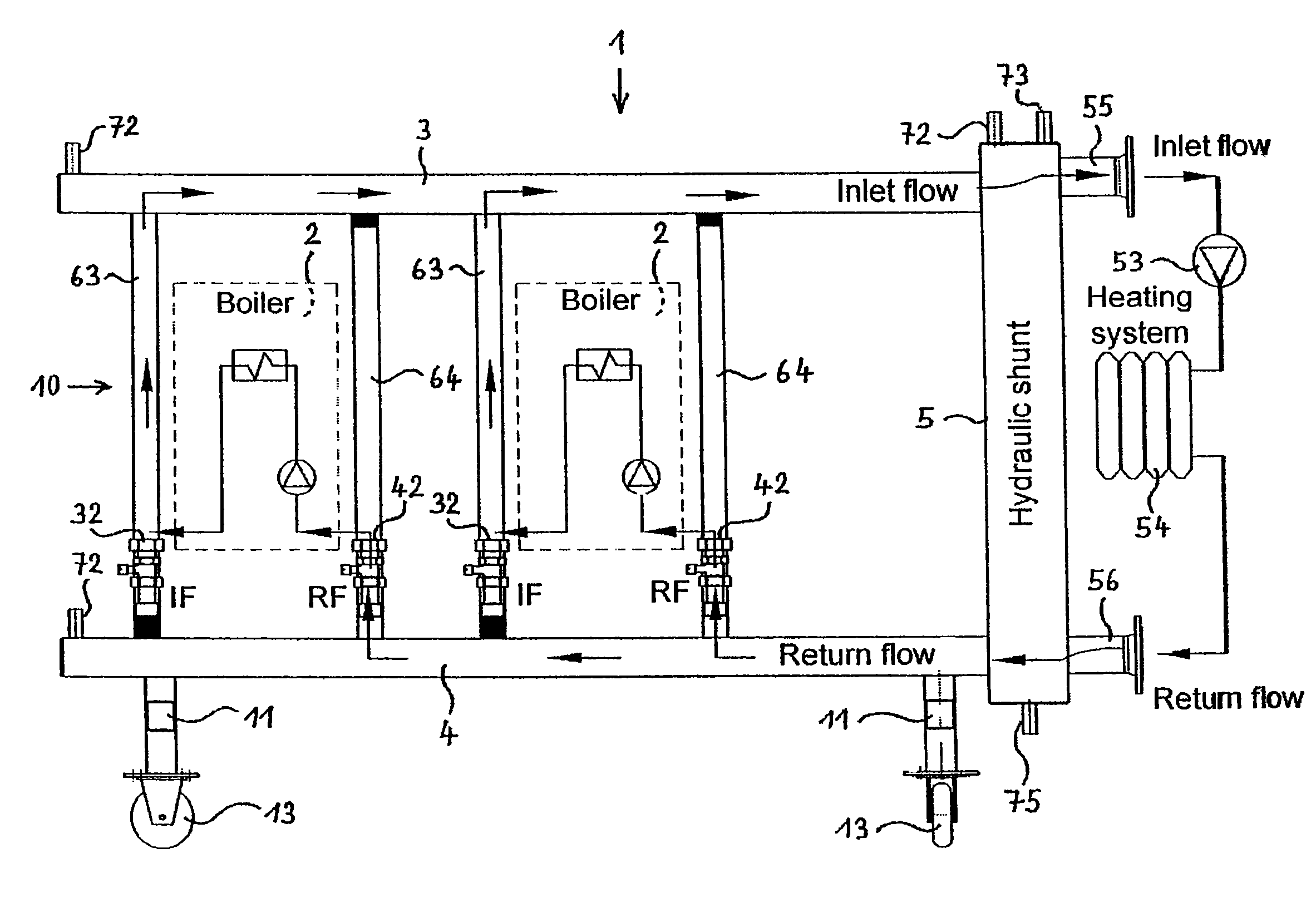

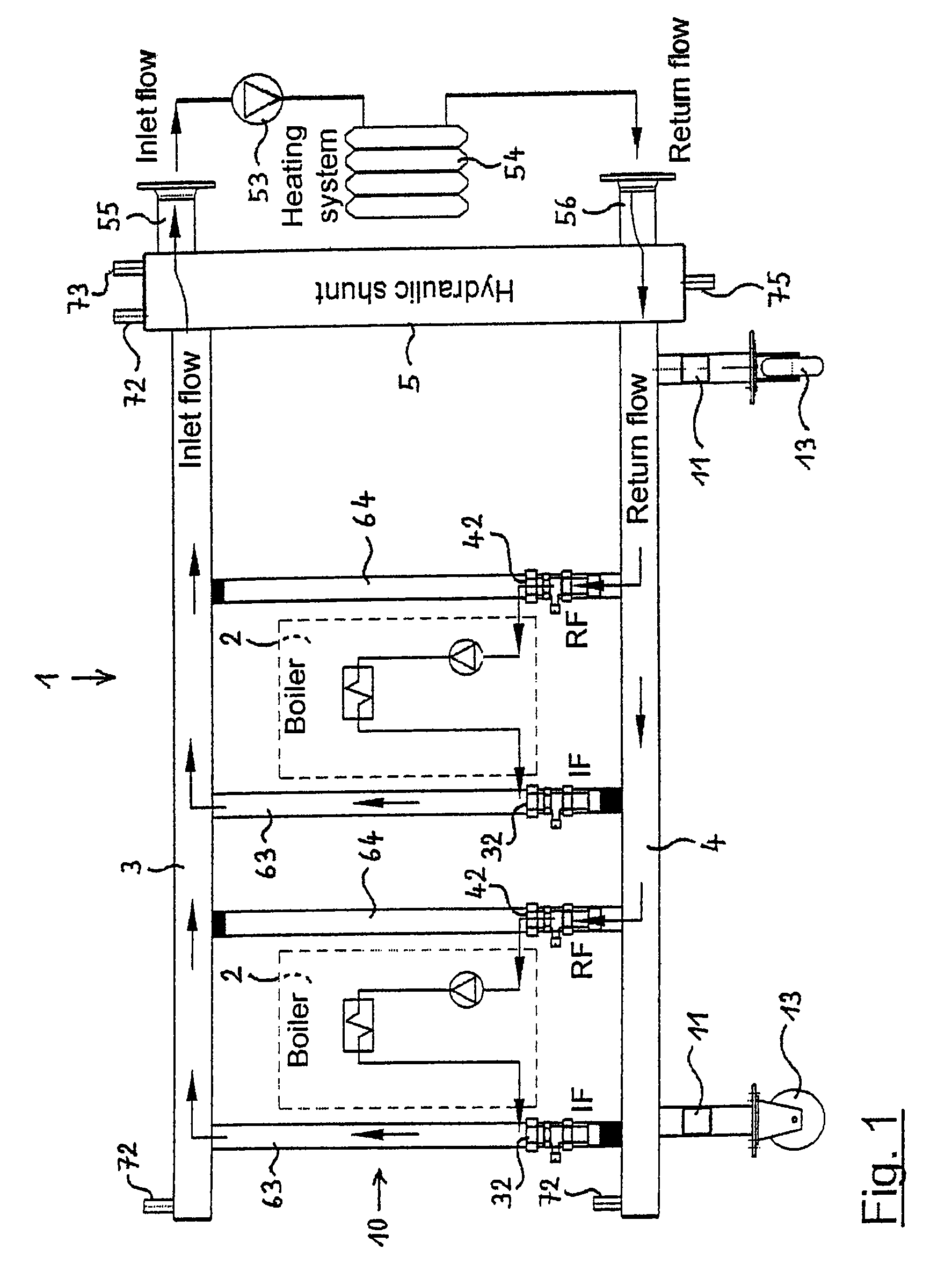

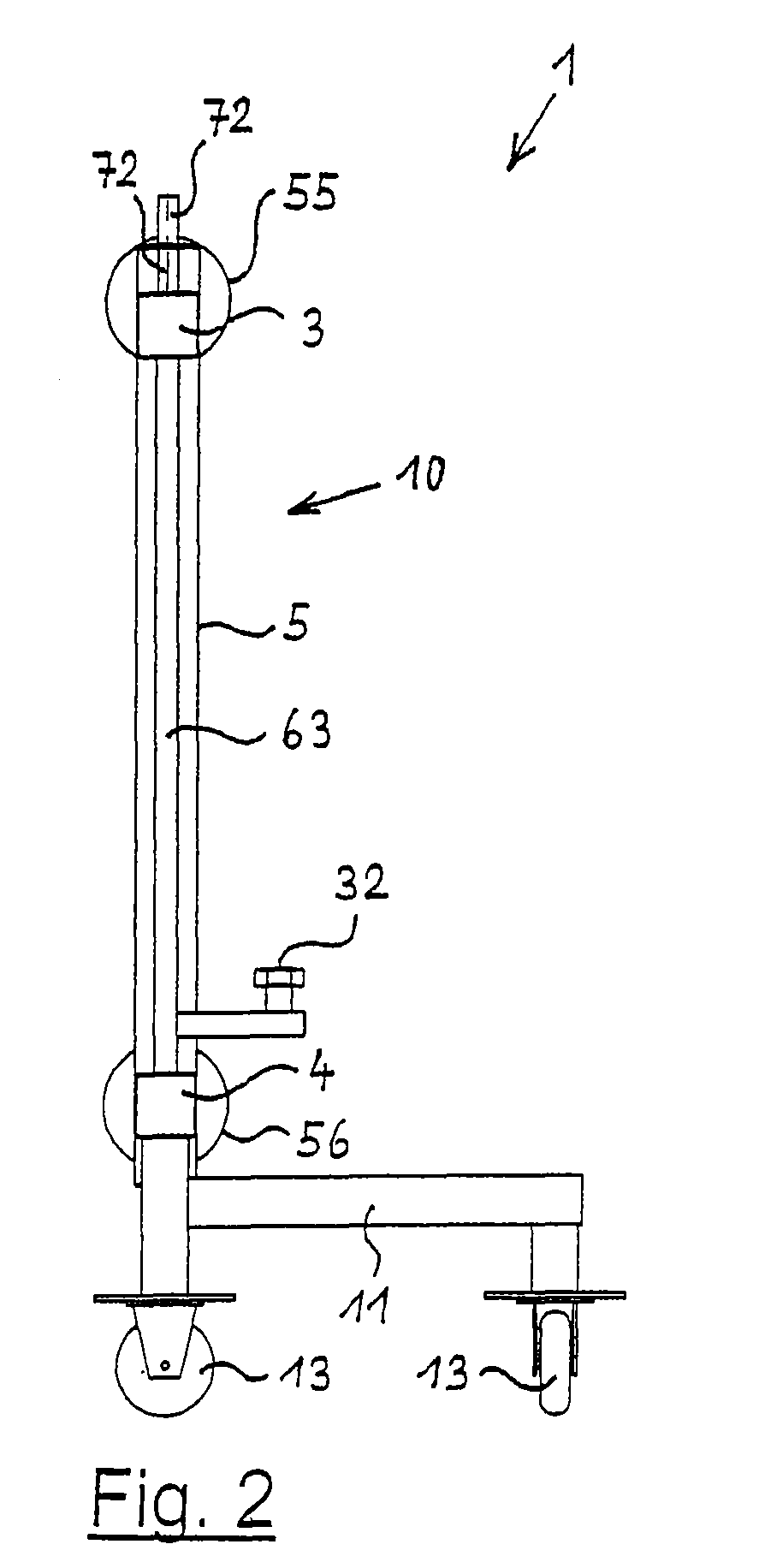

Cascade unit for a heating system with two or more heating boilers

ActiveUS20070144458A1Lower assembly costsExtensive and thus cost-saving prefabricationFluid heatersHeating fuelEngineeringInlet flow

The invention relates to a cascade unit for a heating system with two or more heating boilers, in particular condensing boilers, with a hydraulic shunt which is connected on the one hand with the inlet flows and return flows of all heating boilers and on the other hand with at least one heating circuit inlet flow and heating circuit return flow each, with the cascade unit furthermore comprising one each of the essentially horizontally extending boiler inlet flow header and boiler return flow manifold, the header and the manifold being connected with the hydraulic shunt, and the header and the manifold each being designed with prepared connecting nozzles fittingly placed for a group of two or more heating boilers the connection of the heating boiler inlet flows and the heating boiler return flows. The cascade unit forms at least one self-supporting support frame on which at least one of the heating boilers is mountable.

Owner:COMFORT SINUSVERTEILER

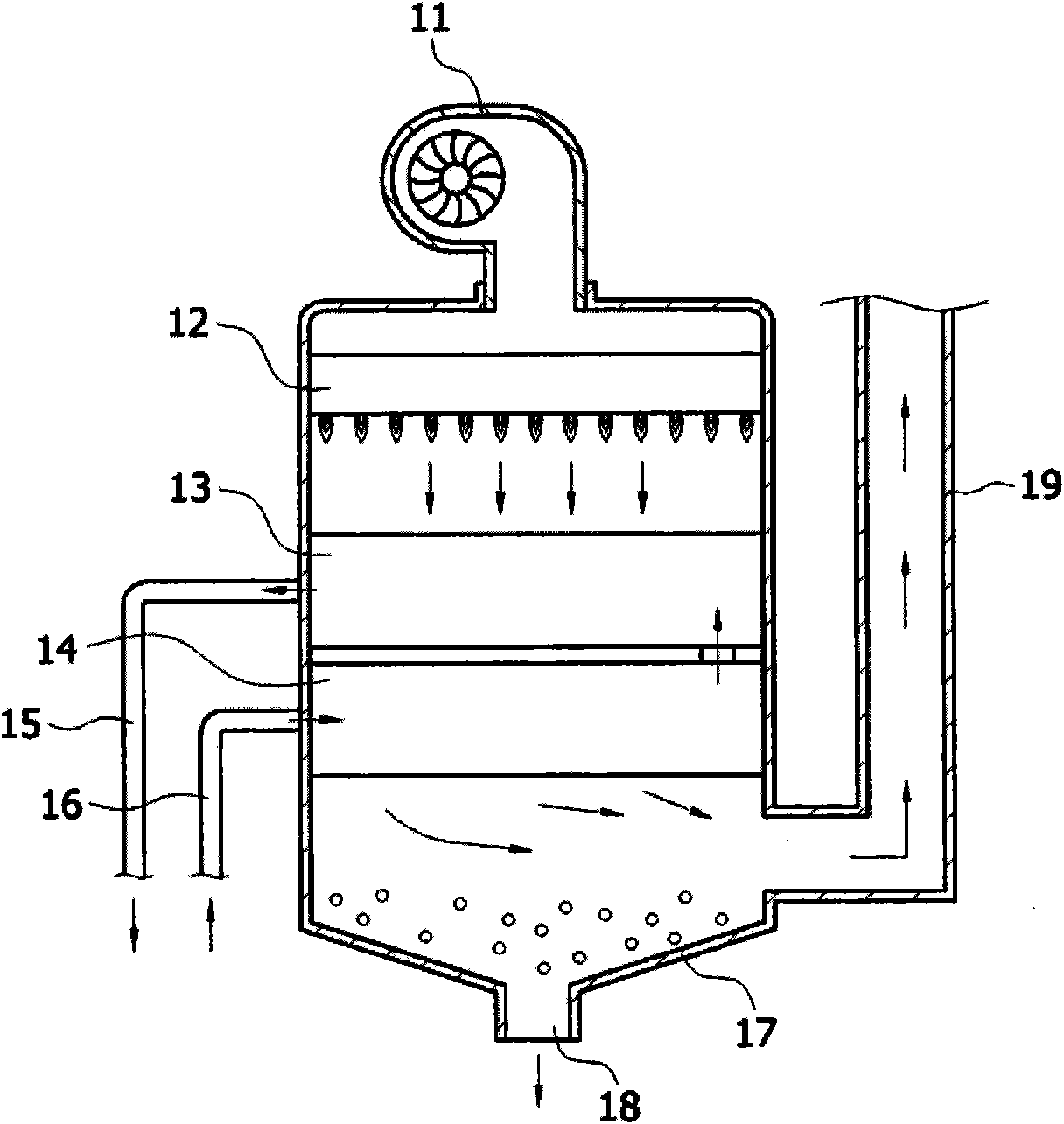

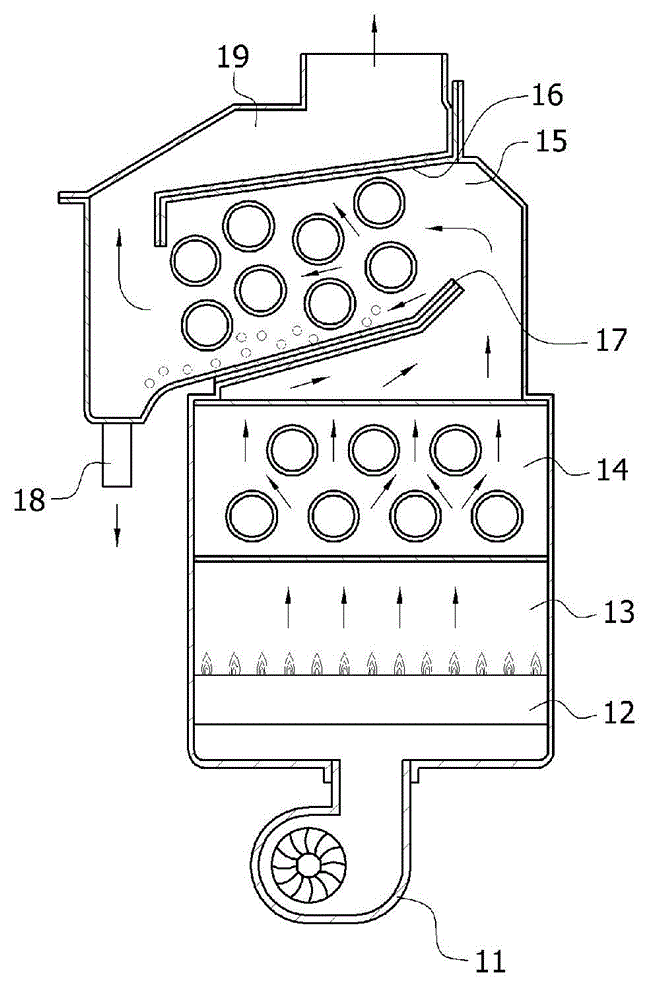

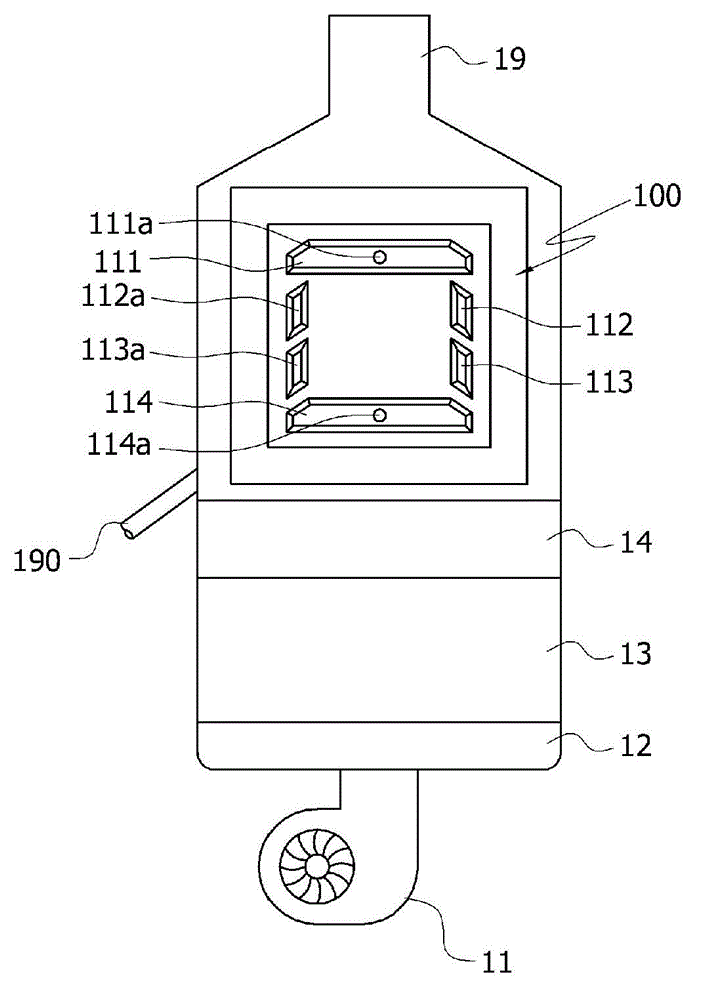

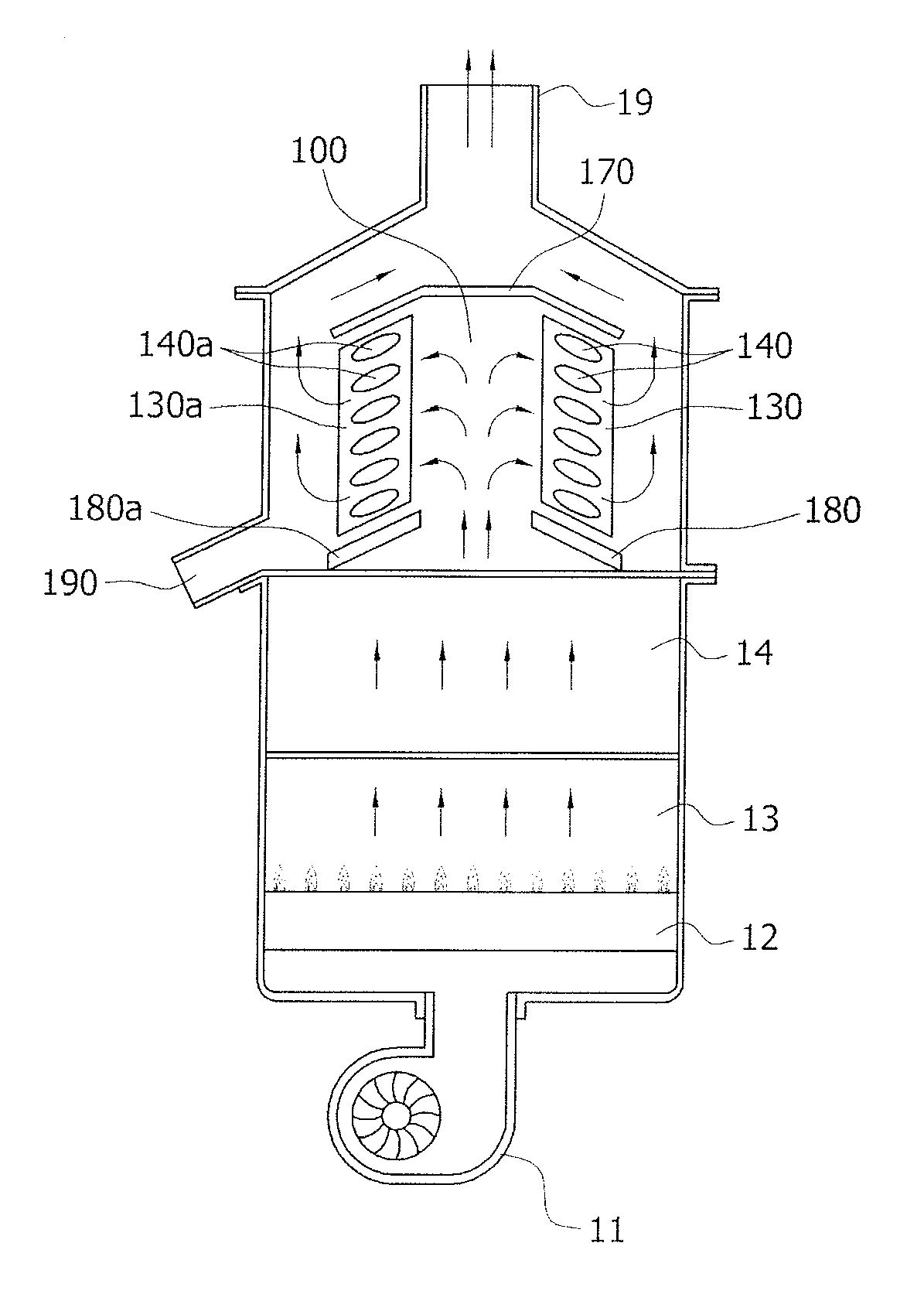

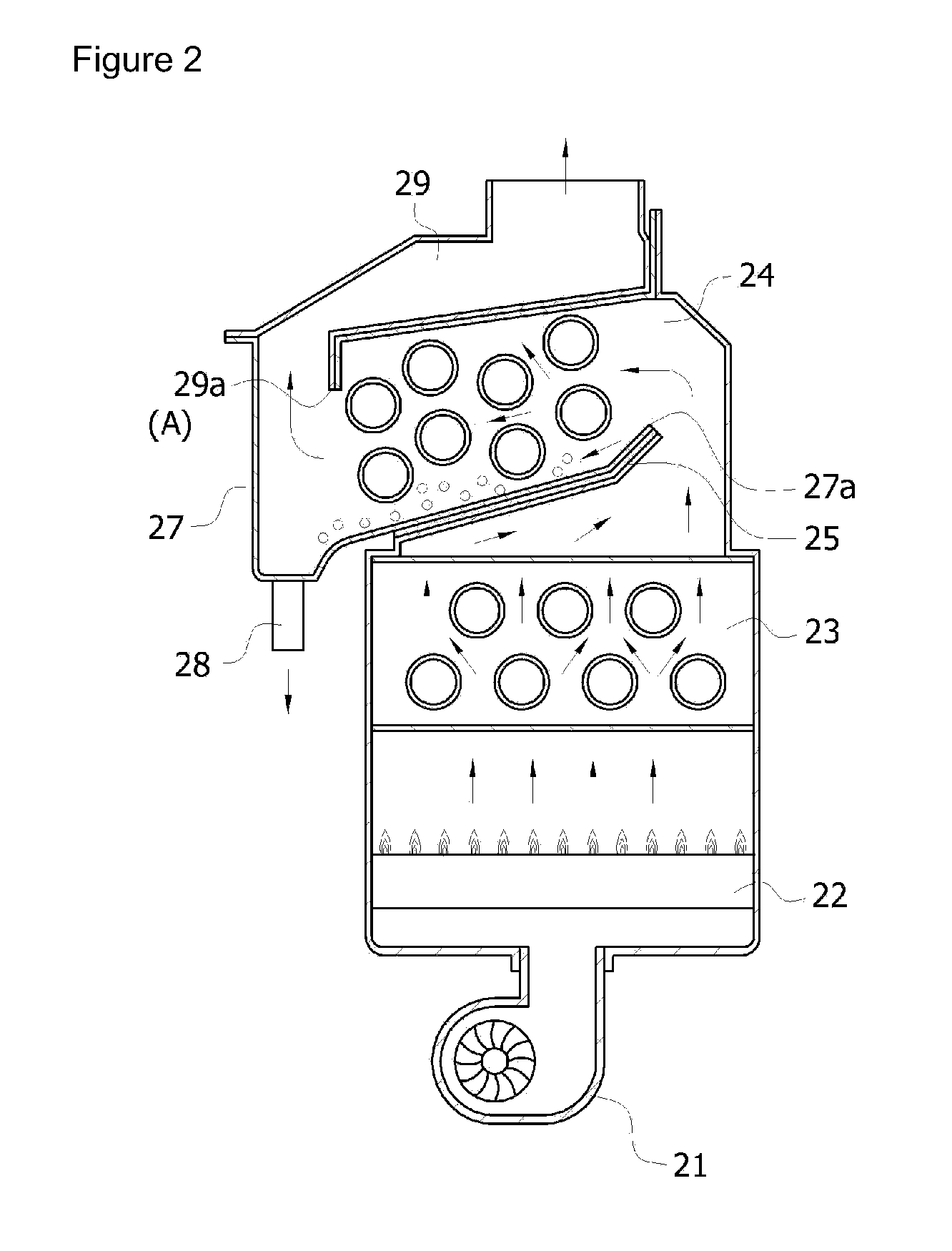

Latent heat exchanger in condensing boiler

InactiveCN103069225AReduced exhaust resistanceSmooth dischargeRecuperative heat exchangersEnergy efficient heating/coolingCombustorAcute angle

The present invention aims to provide a latent heat exchanger in a condensing boiler, which has no limit in the usage of a burner, comprises an upward combustion condensing boiler with a simple installation structure, reduces the exhaust resistance of a combustion product, and allows seamless discharging of condensed water generated from the latent heat exchanger so as to enhance the efficiency of latent heat recovery. To this end, the condensing boiler of the present invention comprises: a sensible heat exchanger for absorbing combusted sensible heat from the burner; the latent heat exchanger for absorbing the latent heat in water vapors in the combustion product that has been heat-exchanged in the sensible heat exchanger; an exhaust hood for discharging the combustion product that has passed through the latent heat exchanger; and a condensed water outlet port for discharging the condensed water generated from the latent heat exchanger, wherein the combustion product combusted in the burner is passed through the sensible heat exchanger, perpendicularly raised to the latent heat exchanger, descended in a slanted manner on the outer side, creating an acute angle with a horizontal surface, for heat-exchanging in the latent heat exchanger, and then perpendicularly raised and discharged from the exhaust hood.

Owner:KYUNGDONG NAVIEN

Latent heat exchanger in condensing boiler

InactiveUS20130125838A1Reduce exhaust resistanceSmooth dischargeRecuperative heat exchangersEnergy efficient heating/coolingCombustorAcute angle

A latent heat exchanger of a condensing boiler, in which the condensing boiler includes a sensible heat exchanger absorbing combustion sensible heat generated by a burner, a latent heat exchanger absorbing latent heat of water vapor contained in a combustion product heat-exchanged by the sensible heat exchanger, an exhaust hood discharging the combustion product flowing through the latent heat exchanger, and a condensed water outlet discharging condensed water generated from the latent heat exchanger. In the latent heat exchanger the combustion product burnt by the burner flows through the sensible heat exchanger, is vertically raised toward the latent heat exchanger, is slantingly lowered in an outward direction at an acute angle from a horizontal plane, is heat-exchanged by the latent heat exchanger, is vertically raised, and is discharged to the exhaust hood.

Owner:KYUNGDONG NAVIEN

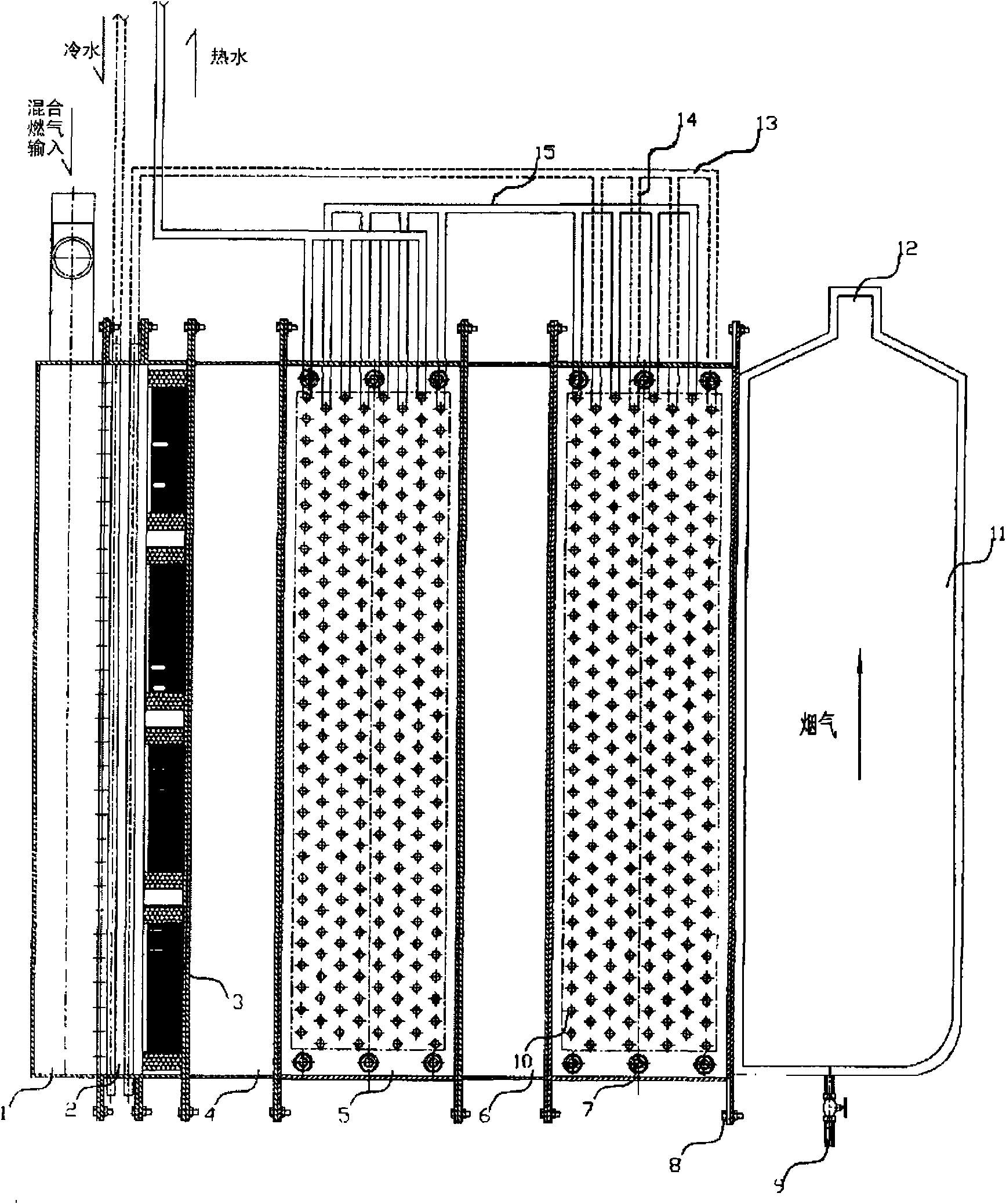

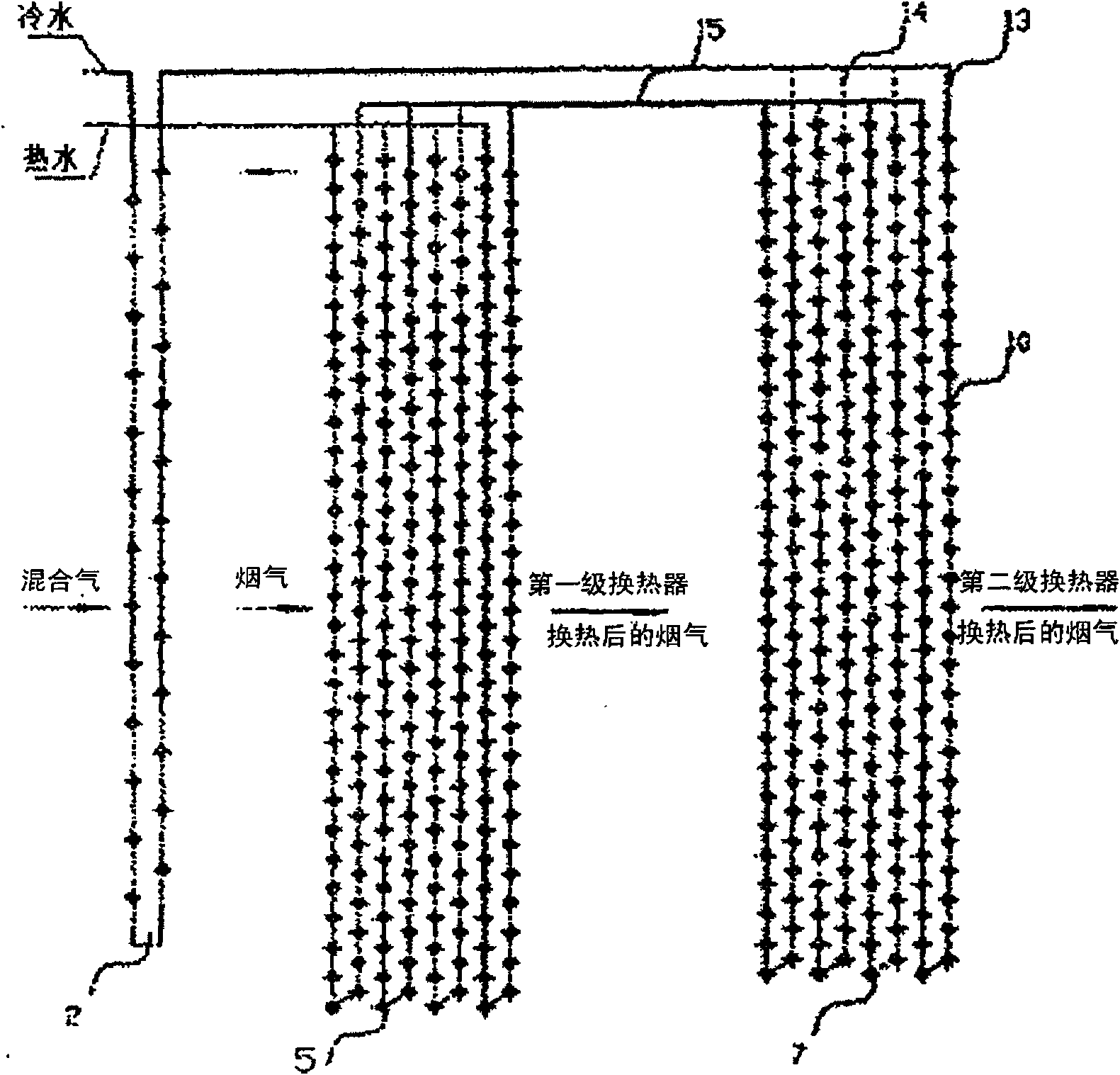

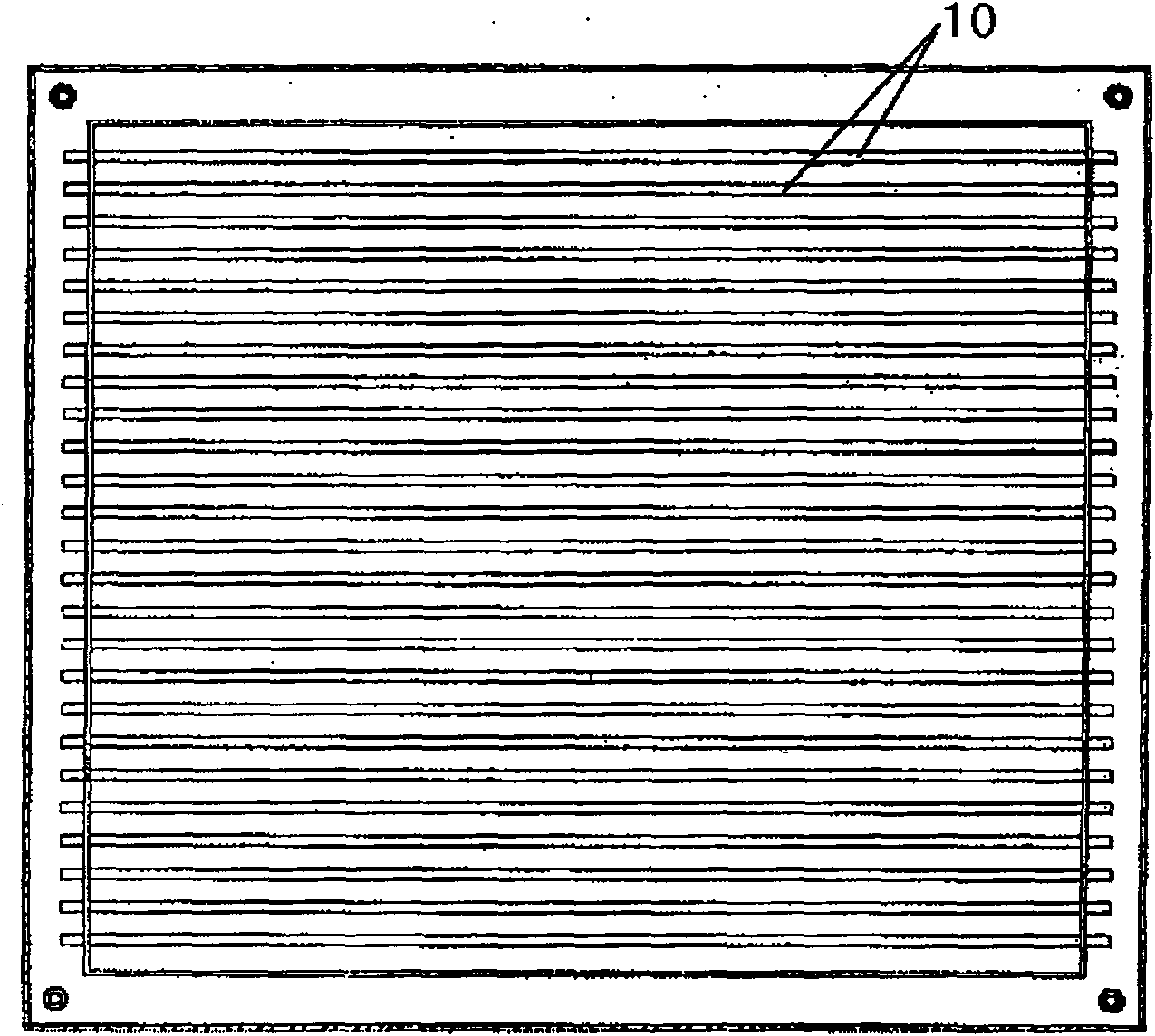

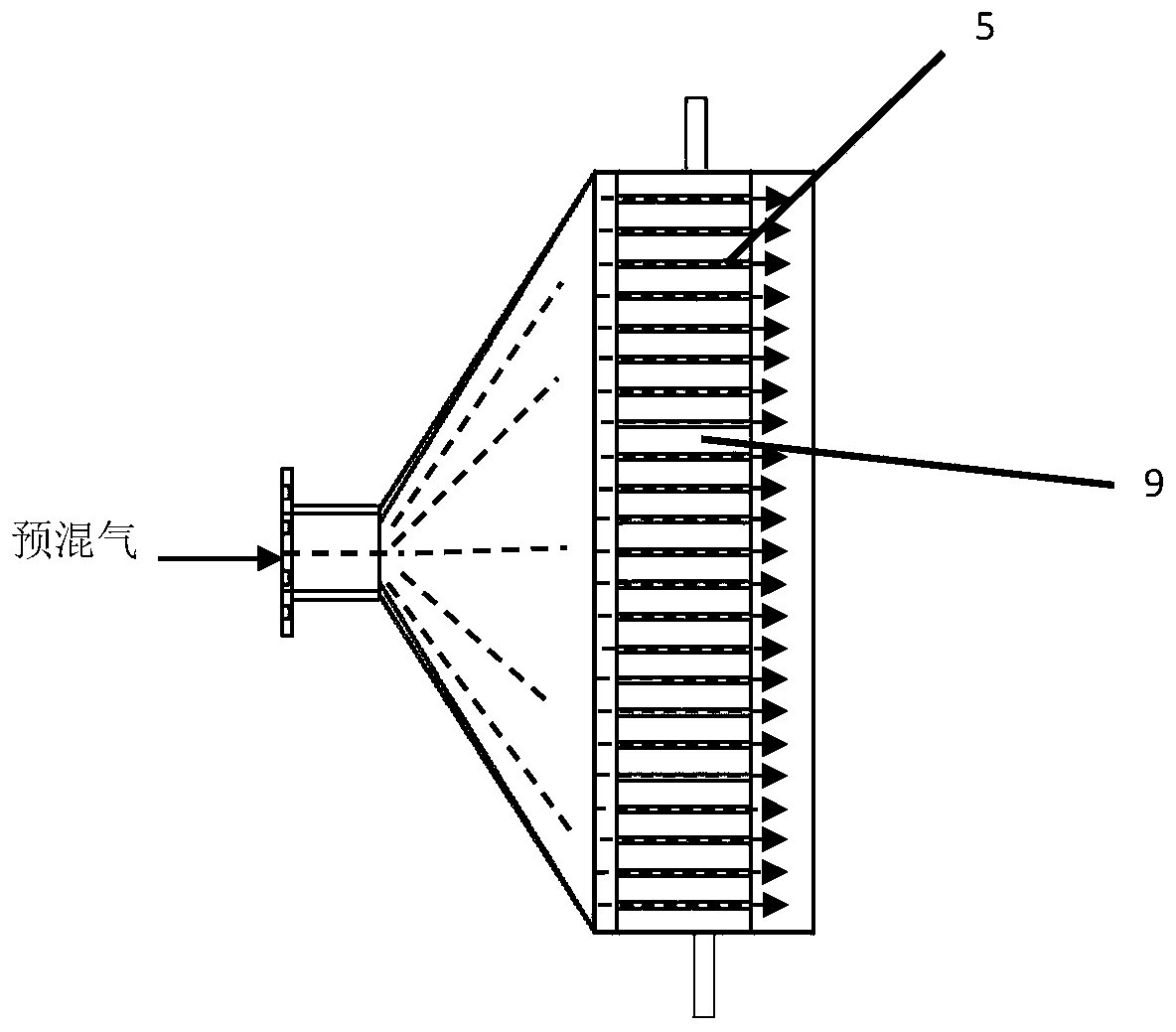

Flameless catalytic combustion condensing boiler with near zero pollutant discharge

InactiveCN101586807AAvoid ignitionSolve the key technical problems of continuous and stable operationIndirect carbon-dioxide mitigationCombustion using catalytic materialCombustorPalladium catalyst

The present invention discloses a flameless catalytic combustion condensing boiler which belongs to the range of environment friendly heating device and has near zero pollutant discharge. The catalytic combustion condensing boiler is composed of a combustor chamber, a combustor cooling device, a catalyst loading container, a first-stage heat exchanger, a second-stage condensing heat exchanger and a smoke extractor. The honeycomb support in the catalyst loading container is plated with platinum or palladium catalyst, and the honeycomb support is prepared by the iolite material. The invention obtains the no-flame combustion on the cross section of honeycomb support and obtains the high-degree mixing and the high-degree uniformity of the flow velocity. The cooling device in the combustor effectively prevent the ignition of the mixed gas in the combustor chamber, which is caused by the high-temperature radiation. A cross discharge structure is adopted through a heat exchanger in the combustor, the second-stage condensing heat exchanger and the one-stage condensing heat exchanger for effectively utilizing the energy. The flameless catalytic combustion condensing boiler of the invention has the advantages of simple structure, small volume, high operation and control degree, stable combustion, facilitated heat exchange and facilitated maintenance.

Owner:北京建筑工程学院

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

Heat exchanger of condensing boiler for heating and hot-water supply

ActiveUS8220529B2Simple structureLower the volumeMechanical apparatusBoiler water tubesEngineeringLatent heat

Disclosed is a heat exchanger for a condensing boiler supplying both heating water and hot water, which can use a double pipe as a sensible heat exchanger, instead of the use of an indirect heat exchanger. The heat exchanger includes: a sensible heat exchanger; and a latent heat exchanger made by connecting a plurality of unit heat exchangers to define exhaust gas pathway, each unit heat exchanger being manufactured in such a manner that three plates having a convexo-concave shape are stacked on one another to define a heating water pathway and a hot water pathway to be adjacent to each other in order to increase a heat transfer area.

Owner:KYUNGDONG NAVIEN

Heat exchanger of upward combustion type condensing boiler

InactiveUS20110114300A1Maximize latent heat recovery efficiencySafely stoppedMechanical apparatusEnergy efficient heating/coolingExhaust fumesEngineering

Owner:VARIAN SEMICON EQUIP ASSOC INC +1

Condensing boiler

InactiveCN105757983AImprove thermal efficiencyHigh thermal efficiencyAir heatersSustainable buildingsCombustion chamberCombustor

The invention provides a condensing boiler which comprises a combustor, a combustion chamber, a condensing heat exchange barrel, an inner circulating system and an outer circulating system. The combustion chamber is disposed in the condensing heat exchange barrel, a connecting pipeline on the side wall of the combustion chamber penetrates out of the condensing heat exchange barrel and is used for being connected with the combustor, a top barrel wall of the combustion chamber is connected with a smoke diversion elbow, a smoke outgoing port of the smoke diversion elbow is formed downwards, and a boiler inner circulating spray device, a water feeding spray device and an air preheating system are arranged above the smoke diversion elbow. The inner circulating system is characterized in that boiler water is circulated into the inner circulating spray device above the combustion chamber in a forced manner, inner circulation of the boiler water is enhanced, and heat is absorbed better. Through a special arrangement mode of the combustor, the smoke diversion elbow, the spray devices, a demisting and preheating device and the inner and outer circulating systems, so that the condensing boiler is more convenient and quicker to mount, direct contact of high-temperature smoke with boiler feed water for heat exchange can be efficiently realized, the temperature of discharged smoke can be lowered fully, and heat efficiency of the boiler can be improved fully.

Owner:徐进廷 +2

Cascade unit for a heating system with two or more heating boilers

ActiveUS7806346B2Lower assembly costsExtensive and thus cost-saving prefabricationBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringInlet flow

A cascade unit for a heating system with two or more heating boilers, in particular condensing boilers, with a hydraulic shunt which is connected on the one hand with the inlet flows and return flows of all heating boilers and on the other hand with at least one heating circuit inlet flow and heating circuit return flow each, with the cascade unit furthermore comprising one each of the essentially horizontally extending boiler inlet flow header and boiler return flow manifold, the header and the manifold being connected with the hydraulic shunt, and the header and the manifold each being designed with prepared connecting nozzles fittingly placed for a group of two or more heating boilers for the connection of the heating boiler inlet flows and the heating boiler return flows. The cascade unit forms at least one self-supporting support frame on which at least one of the heating boilers is mountable.

Owner:COMFORT SINUSVERTEILER

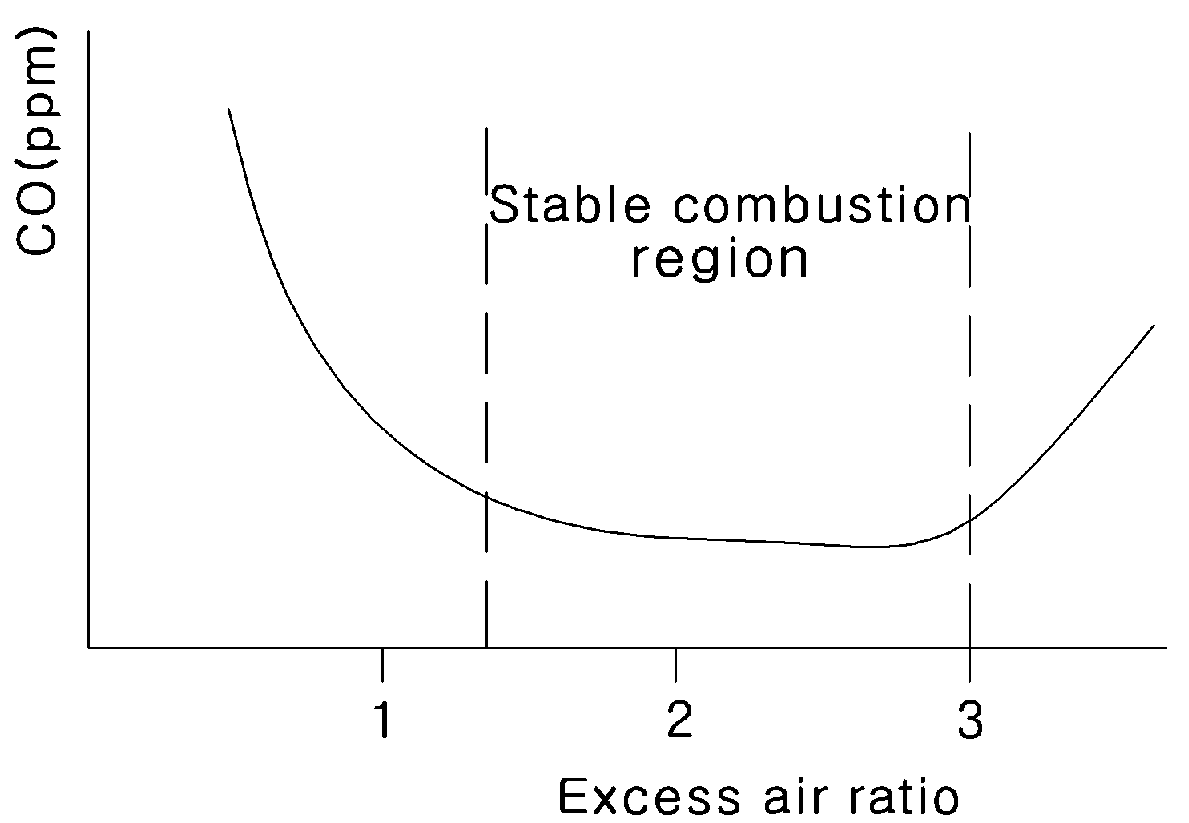

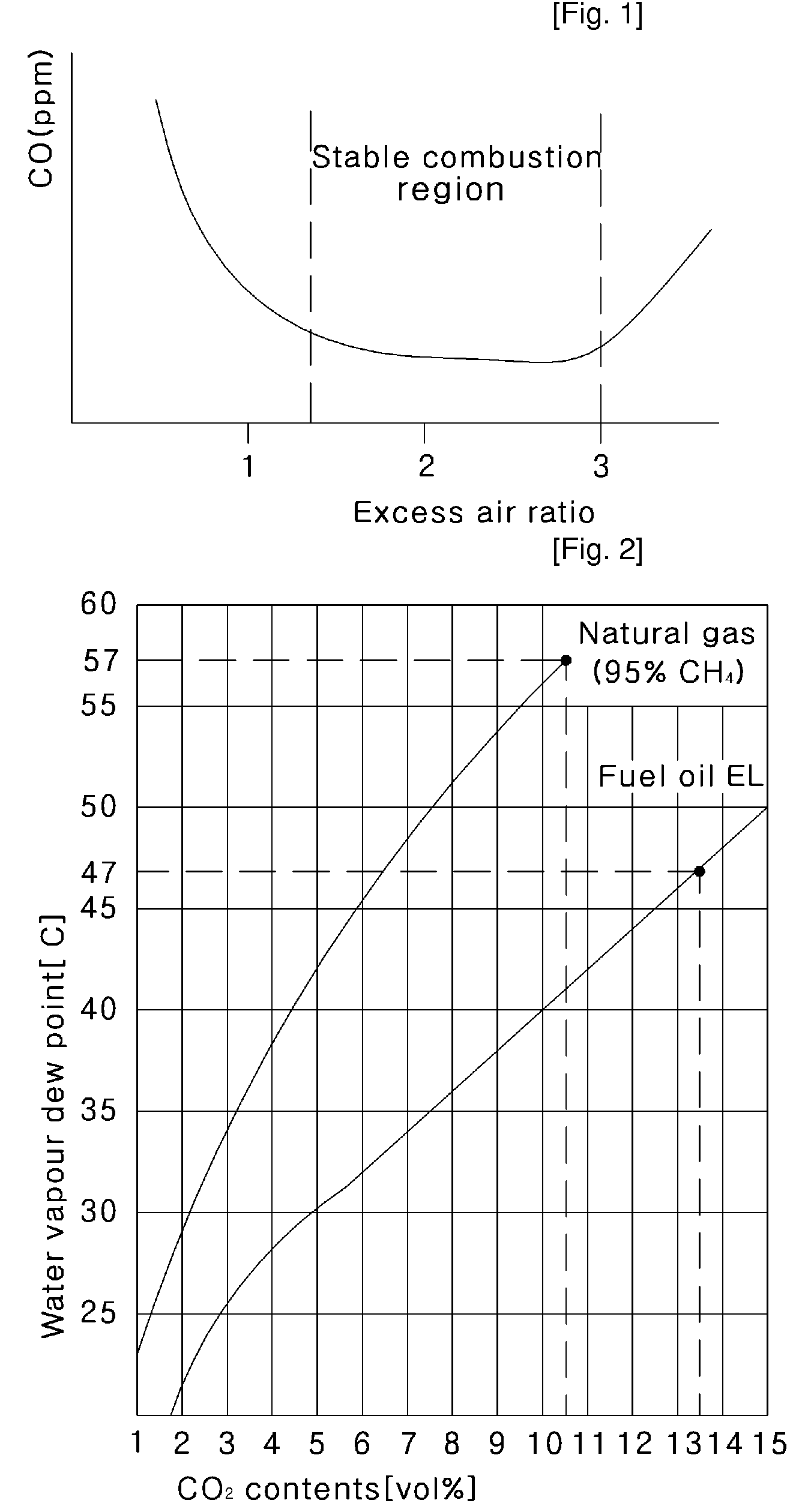

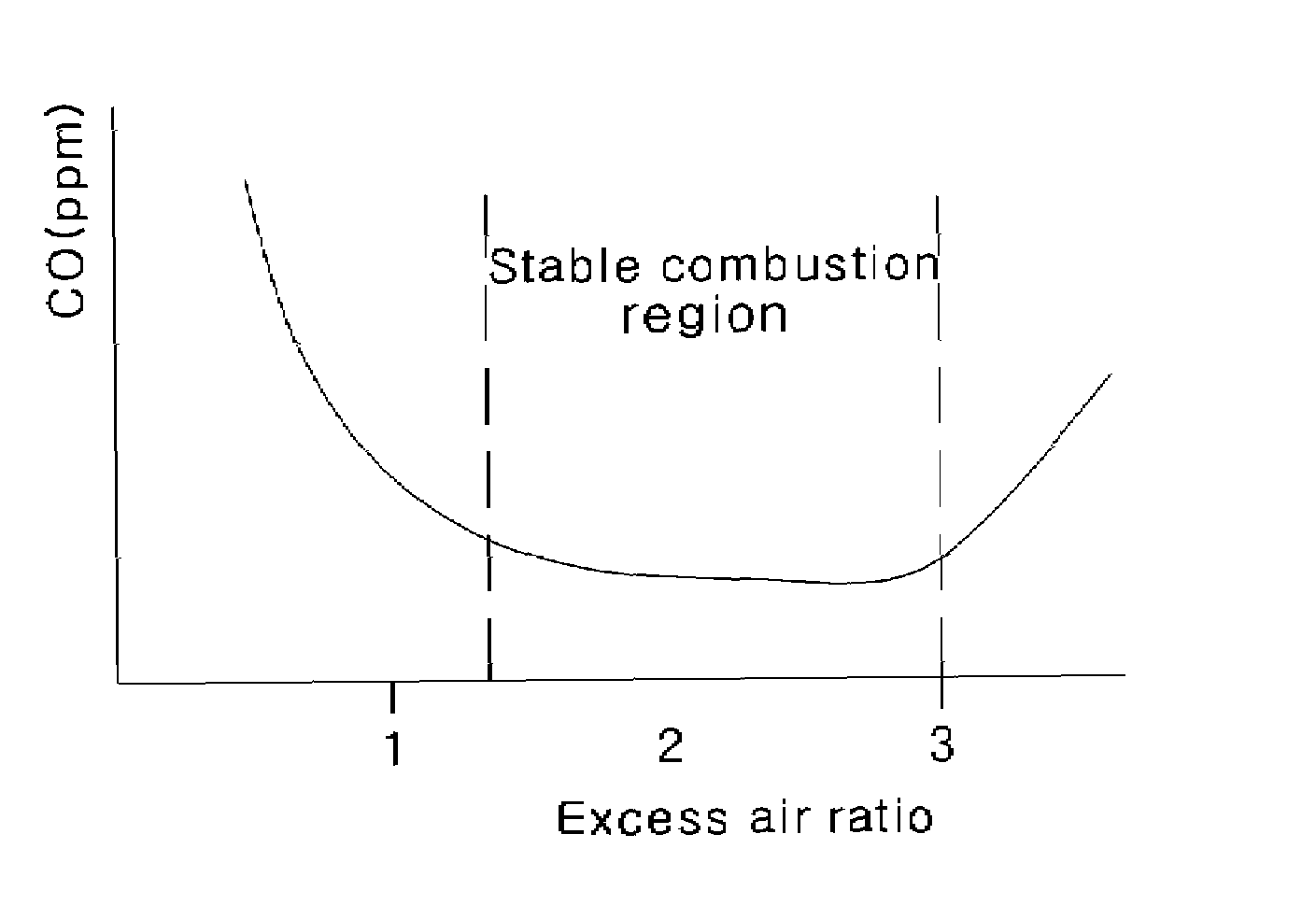

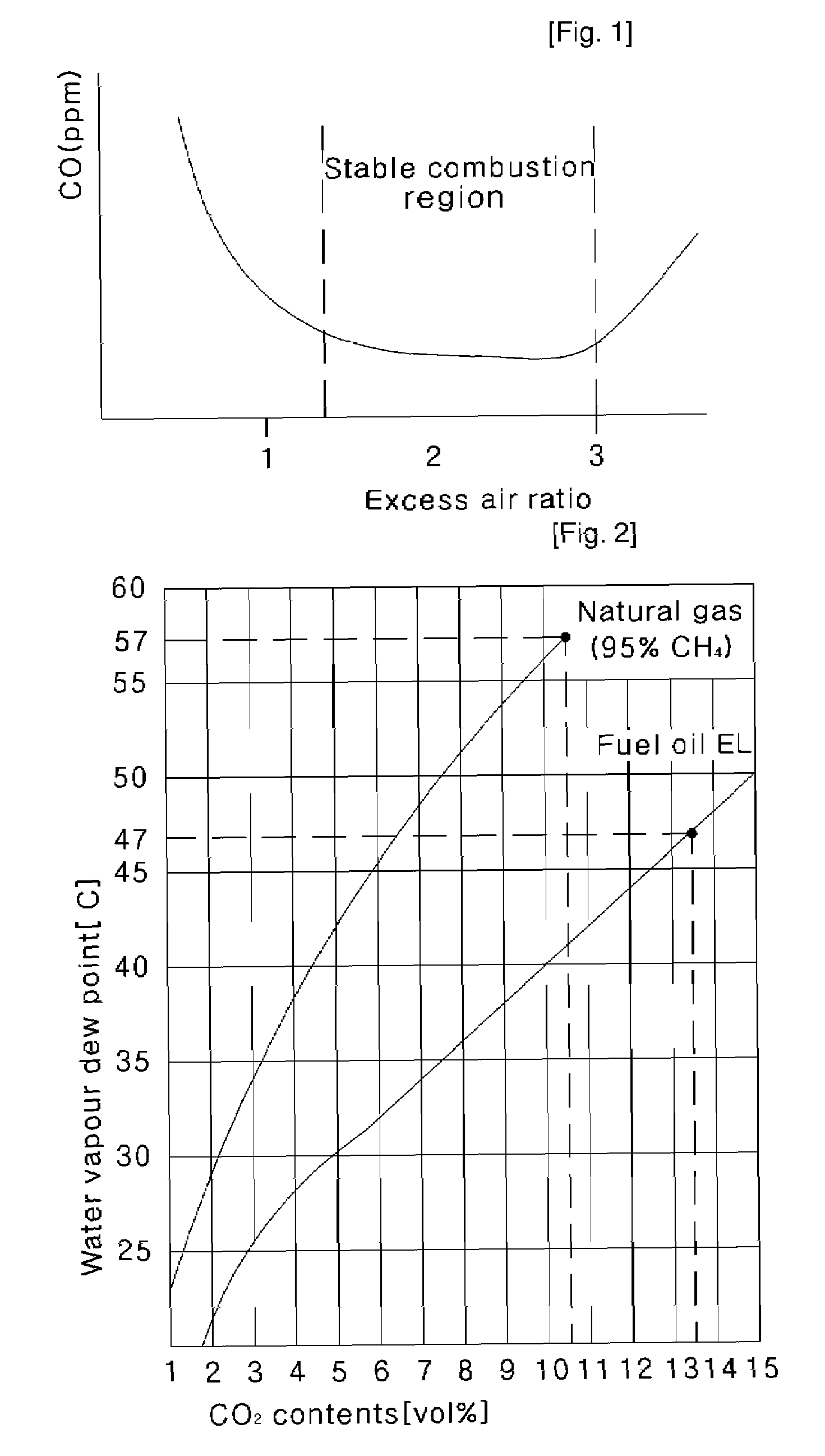

Method for Maximum Efficiency of Non-Condensing Boiler

InactiveUS20090120382A1Increased durabilityEasy to assembleFluid heatersFuel supply regulationLower limitCombustor

Provided is a method for operating a non-condensing boiler at maximum non-condensation efficiency, and more particularly a method for operating a non-condensing boiler, capable of supplying an appropriate amount of excess air for combustion of a burner, avoiding damaging a heat exchanger due to the condensed water generated at the heat exchanger, and effectively improving the heat efficiency. The method comprises the steps of: sensing a temperature of exchange water introduced into a heat exchanger and a temperature of supply water discharged from the heat exchanger and calculating an average temperature from the two temperatures to obtain a maximum concentration of CO using information stored in a controller; calculating a ratio of excess air (λ) from the maximum concentration of CO using a combustion equation chosen depending on a fuel used; checking from a combustion characteristic curve whether or not the excess air ratio (λ) is within a stable combustion region; when the excess air ratio (λ) is within the stable combustion region, setting this excess air ratio to the control target value, and when the excess air ratio (λ) is less than a lower limit of the stable combustion region, setting a minimum excess air ratio of the stable combustion region to the control target value; calculating a target value of air flow suitable for the current consumption amount of fuel based on the set excess air ratio; and performing feedback control with respect to the air flow target value and a value input from an air flow sensor. With this configuration, no condensation takes place during operation of the non-condensing boiler, so that the boiler can have increased durability, be easily assembled at inexpensive production costs, be made compact, and obtain maximum heat efficiency under a non-condensation condition.

Owner:KYUNGDONG NAVIEN

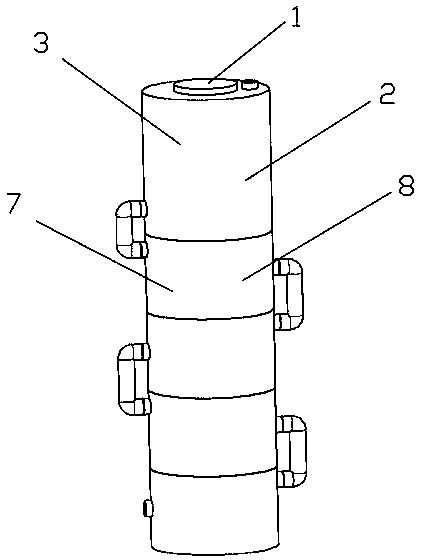

Full-premixing condensation boiler

PendingCN111059759AIncrease contact timeImprove heat transfer efficiencyMechanical apparatusAir heatersCombustorCombustion chamber

The invention discloses a full-premixing condensation boiler. The boiler comprises a combustor and a heat exchanger, the heat exchanger comprises a heat exchanger shell, a combustor mounting block isarranged in the heat exchanger shell, a combustion chamber is formed in the combustor mounting block, a plurality of heat exchange tubes are arranged between the bottom of the combustor mounting blockand the inner bottom surface of the heat exchanger shell in a connection mode, a heat exchange chamber is formed by the heat exchange tubes and a gap between the combustor mounting block and the interior of the heat exchanger shell, a condenser is arranged at the bottom of the heat exchanger shell, the condenser comprises a cylinder body, the cylinder body penetrates up and down to form a condensation channel, one end of each heat exchange tube communicates with the combustion chamber in the combustor mounting block, and the other end communicates with the condensation channel, a water inletcavity and a water outlet cavity are formed in an interlayer between the outer side wall of the cylinder body and the inner side wall formed by the condensation channel, a plurality of condensation pipes transversely arranged in the condensation channel are arranged between the water inlet cavity and the water outlet cavity in a connection mode, and the two ends of each condensation pipe communicate with the water inlet cavity and the water outlet cavity respectively. The boiler can greatly improve the heat efficiency.

Owner:喀什翰明燃气设备有限公司

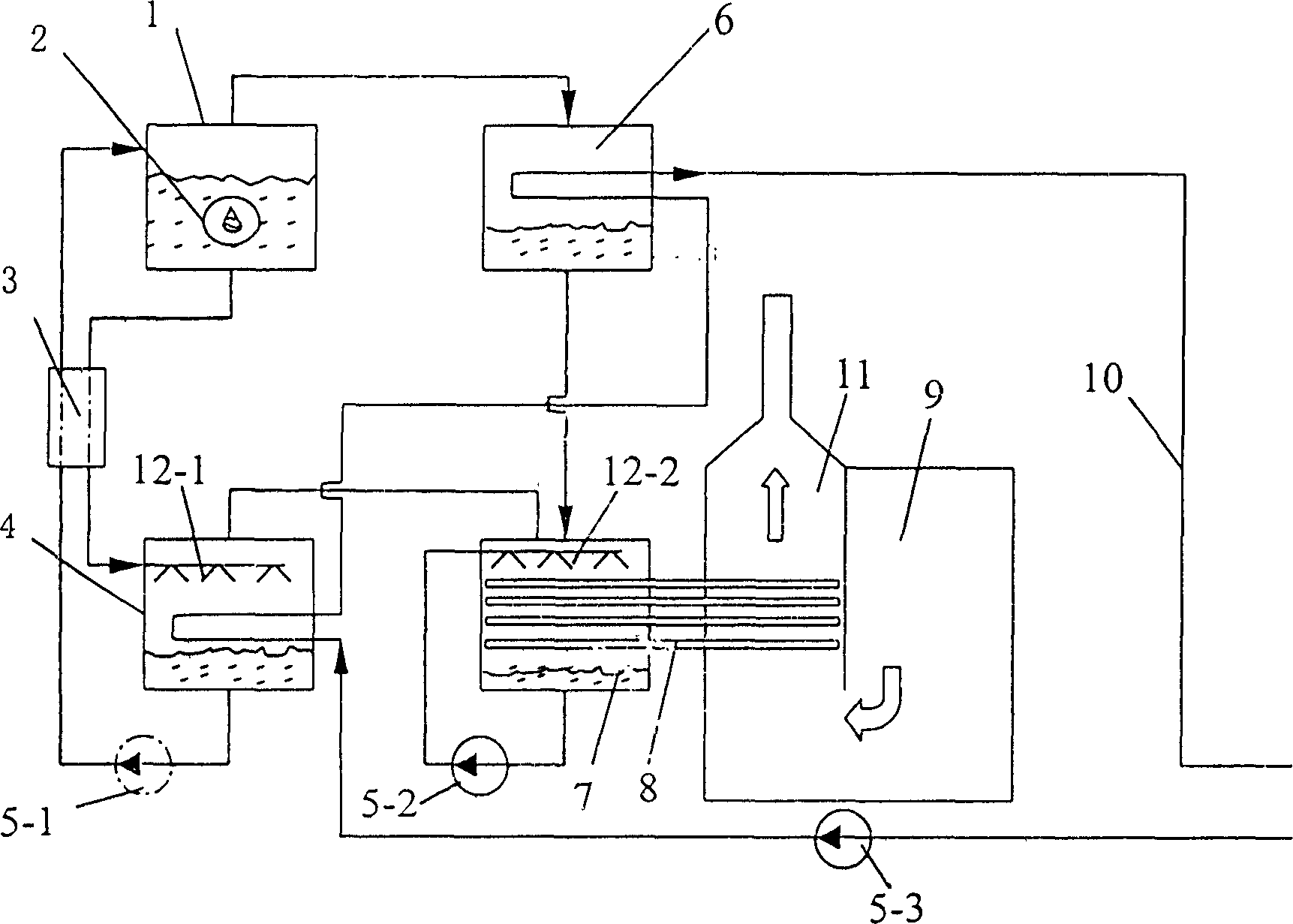

Heat supply device capable of recovering aqueous vapour latent heat in fuel gas, fuel oil boiler flue gas

InactiveCN1414287AImprove efficiencyEmission reductionHeat pumpsFeed water supplyFlue gasEngineering

The present invention discloses a heat supply device for recovering the aqueous vapour latent heat in fuel gas and fuel oil boiler flue gas, it includes boiler, heat supply pipe and absorption type heat pump which is composed of generator, solution exhcanger, absorber, evaporator, condensor and connecting pipe; the said evaporator is equipped in the flue duct of boiler, the heat supply pipe passes through the condenser and the absorber of absorption type heat pump.

Owner:TSINGHUA TONGFANG CO LTD

Sectional boiler

InactiveUS20120055420A1Improve applicabilityImprove compactnessEnergy efficient heating/coolingFurnace-tube steam boilersCombustion chamberMechanical engineering

A sectional boiler is described as being made of cast iron or aluminum, in particular a condensing boiler, having essentially annular sections, a front section, a cover-shaped rear section and at least one center section being provided, which form a combustion chamber having an essentially surrounding heat exchanger made of a sectional block, whose annular water chambers are connected to one another via at least one hub and which has gap-like heating gas flues, having a return port and a feed port in the upper area and at least two armature rods for holding the sectional block together. The present system is based on the objective of optimizing a sectional boiler made of cast iron or aluminum particularly with respect to compactness and robustness. In the present system, as heating gas flues the heat exchanger respectively has annular gaps between two adjacent sections having a mutually adapted geometry, which respectively run from the combustion chamber approximately radially outward and open into an exhaust gas collection chamber on the outside of the sections, and the individual sections are respectively divided on the heating water side into at least two flow channels.

Owner:ROBERT BOSCH GMBH

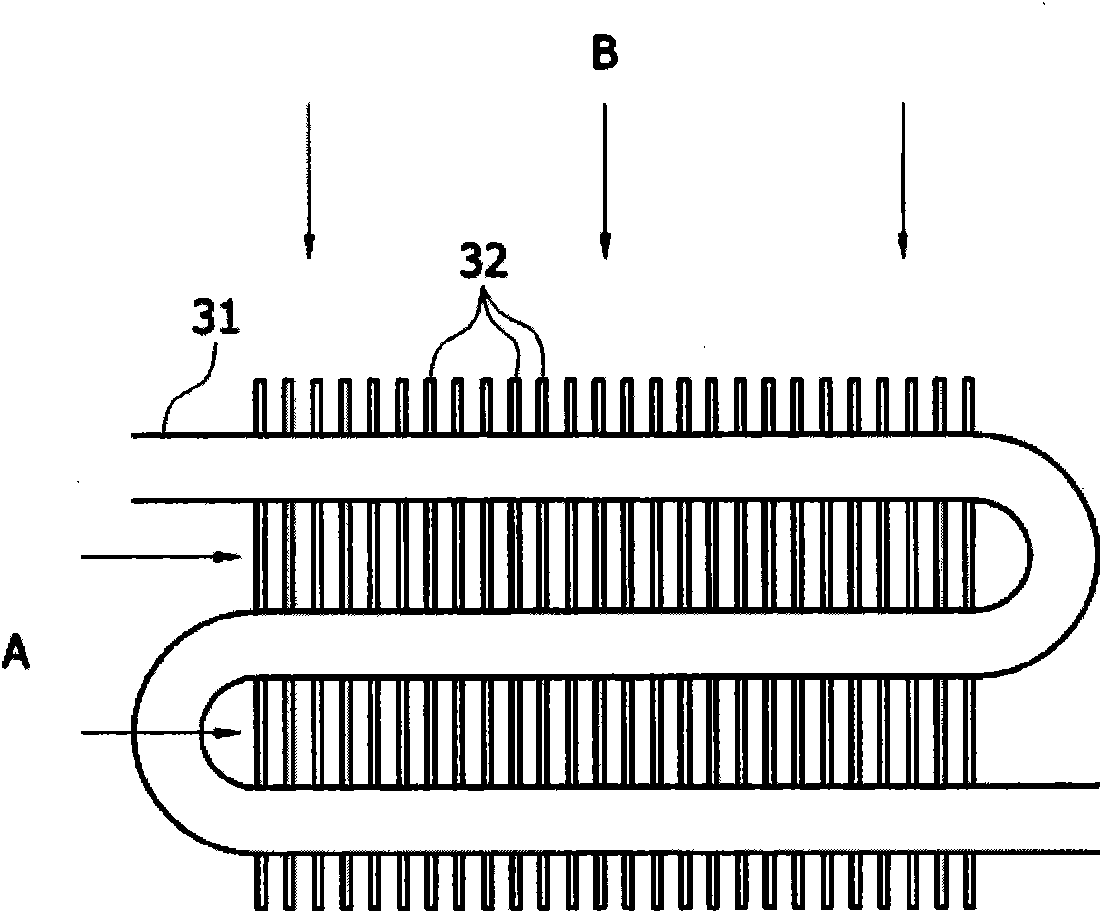

Integral condensing boiler

ActiveCN102331085ACompact structureEfficient and environmentally friendly structureEnergy efficient heating/coolingAir heatersThermal energyBoiler furnace

The invention provides an integral condensing boiler. In the integral condensing boiler, a fully-premixed flameless burner fueled by oil gas fuels is used for radiant heat exchange in a boiler furnace, a platefin type heat transfer component is used for entire convection and condensation heat transfer and a flue gas mainstream temperature zone is directly inserted by welding a pin or a cast boss, thus effectively reducing the temperature gradient from the glue gas mainstream to a wall surface, continuously damaging a flowing boundary layer of the wall surface and a flue gas center and strengthening the heat convection; furthermore, condensation heat transfer can expand from the wall surface to the whole surface of the pin or the cast boss so that the condensation heat transfer area can be effectively enlarged; meanwhile, condensation heat transfer of water vapor in the flue gas can be strengthened, thus the whole convection and condensation heat transfer coefficients of the condensing boiler can be greatly improved; the condensation liquid can absorb partial harmful gases in the flue gas, such as CO2, NOx, SOx, and the like, thus pollutant emission can be effectively reduced. The boiler has a simple structure and high entire convection and condensation heat transfer coefficients and can be used for improving the conversion efficiency of thermal energy to the greatest extent.

Owner:XI AN JIAOTONG UNIV

Heating apparatus utilizing aqueous vapour latent heat in fuel gas, fuel oil boiler exhaust gas

InactiveCN1414320AEmission reductionImprove protectionEnergy efficient heating/coolingAir heatersFlue gasFuel oil

The present invention discloses a heat supply device using aqueous vapour latent heat in fuel gas and fuel oil boile flue gas, it includes boiler, heat pipe, heat supply pipe and absorption type heatpump composed of generator, solution exchanger, absorber, evaporator, condensor and connecting pipe: one end of the said heat pipe is set in gas duct of boiler, the other end of set in the evaporator, the said heat supply pipe passes through condensor and absorber of the said absorption type heat pump.

Owner:TSINGHUA TONGFANG CO LTD

Method for maximum efficiency of non-condensing boiler

InactiveUS7628122B2Increased durabilityEasy to assembleFluid heatersFuel supply regulationLower limitCombustor

Provided is a method for operating a non-condensing boiler at maximum non-condensation efficiency, and more particularly a method for operating a non-condensing boiler, capable of supplying an appropriate amount of excess air for combustion of a burner, avoiding damaging a heat exchanger due to the condensed water generated at the heat exchanger, and effectively improving the heat efficiency. The method comprises the steps of: sensing a temperature of exchange water introduced into a heat exchanger and a temperature of supply water discharged from the heat exchanger and calculating an average temperature from the two temperatures to obtain a maximum concentration of CO using information stored in a controller; calculating a ratio of excess air (λ) from the maximum concentration of CO using a combustion equation chosen depending on a fuel used; checking from a combustion characteristic curve whether or not the excess air ratio (λ) is within a stable combustion region; when the excess air ratio (λ) is within the stable combustion region, setting this excess air ratio to the control target value, and when the excess air ratio (λ) is less than a lower limit of the stable combustion region, setting a minimum excess air ratio of the stable combustion region to the control target value; calculating a target value of air flow suitable for the current consumption amount of fuel based on the set excess air ratio; and performing feedback control with respect to the air flow target value and a value input from an air flow sensor. With this configuration, no condensation takes place during operation of the non-condensing boiler, so that the boiler can have increased durability, be easily assembled at inexpensive production costs, be made compact, and obtain maximum heat efficiency under a non-condensation condition.

Owner:KYUNGDONG NAVIEN

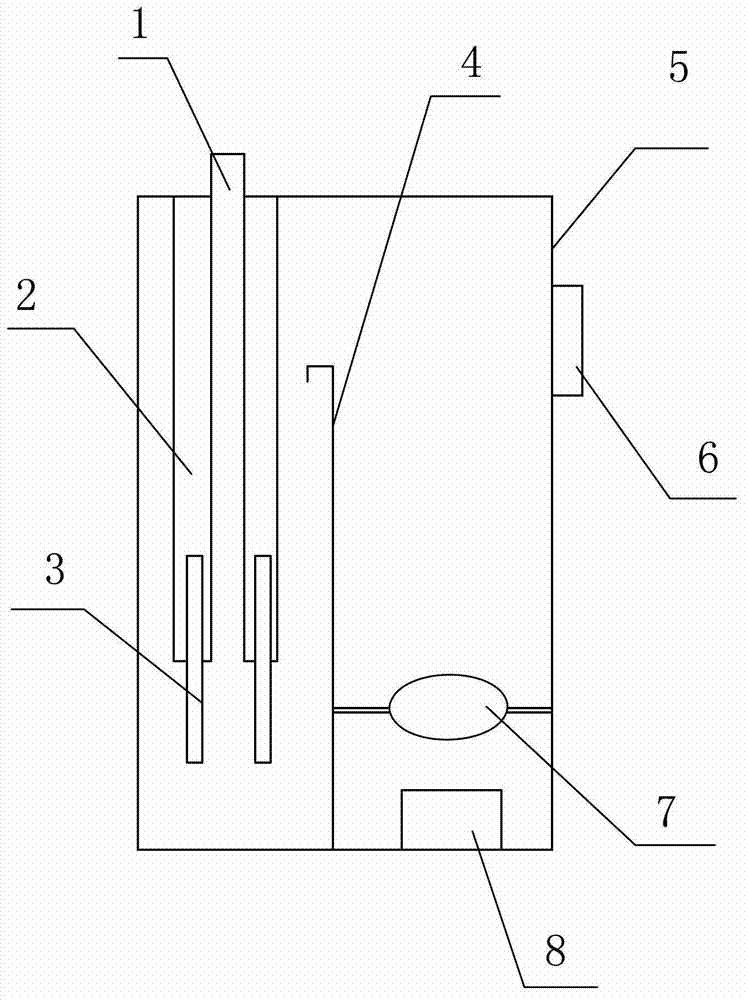

Low-nitrogen combustion device and method

InactiveCN110360568AAvoid concentrationLarge burning flame areaBurner coolingCombustion technology mitigationCombustion chamberNitrogen oxides

The invention relates to a low-nitrogen combustion device and an application method thereof. The device comprises an outer shell, a gas distribution chamber, a plurality of gas mixing pipes, an anti-backfire cavity, a combustion chamber, an ignition needle, a heat exchange tube bank, a first water inlet pipe, a first water outlet pipe, a second water inlet pipe and a second water outlet pipe, wherein the anti-backfire cavity is arranged on the rear side of the gas distribution chamber; the plurality of gas mixing pipes are transversely and uniformly distributed in the anti-backfire cavity; theignition needle is arranged in the combustion chamber and is closely attached to the wall of the anti-backfire cavity; the heat exchange tube bank is arranged on the rear side of the anti-backfire cavity, and the distance between the heat exchange tube bank and the anti-backfire cavity is 40-80 mm; and the anti-backfire cavity is connected with the first water inlet pipe and the first water outlet pipe, and the heat exchange tube bank is connected with the second water inlet pipe and the second water outlet pipe. The low-nitrogen combustion device comprehensively utilizes a water cooling technology, a premixing technology and an anti-backfire technology, effectively reduces the emission of nitrogen oxides by reducing the temperature of a flame surface, solves the problems of high emissionof nitrogen oxides and carbon monoxide or premixed backfire and the like of a full premixed condensing boiler in the current market, and can be widely suitable for a commercial or domestic distributed heating system.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

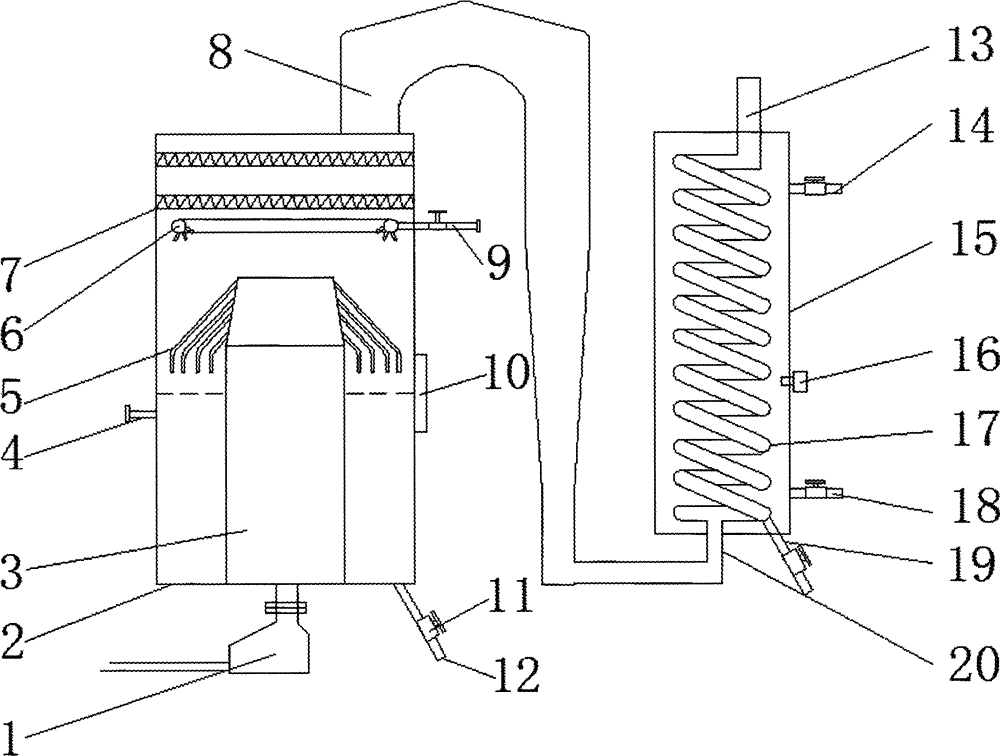

Condensation boiler and water preheating device thereof

InactiveCN104390357AEffective direct contact heat transferEfficient use ofAir heatersSustainable buildingsCombustion chamberEngineering

The invention discloses a condensation boiler and a water preheating device thereof. The condensation boiler comprises a condensing heat exchanger, a combustion chamber, a residual smoke flue and the water preheating device, wherein the top cylinder wall of the combustion chamber is provided with multiply uniformly-distributed smoke guide tubes; the condensing heat exchanger is internally provided with a condensation dehydrator; a water feeding device is arranged between the combustion chamber and the condensation dehydrator; a tube port of the water feeding device is connected with a feedwater shunting spraying nozzle; the water preheating device comprises a gas exhaust tube, a water outlet tube, a heat exchange box, a spiral heat exchanger tube, a water inlet tube, a waste liquid discharge tube and a gas inlet tube. By virtue of the smoke guide tubes and the condensation dehydrator, high-temperature smoke can be in direct contact with boiler feedwater so as to exchange heat, so that the thermal efficiency is effectively improved, the temperature of exhaust smoke is reduced and the environment pollution is reduced; the cooled afterheat smoke is cooled and recycled once again by virtue of the water preheating device; hot water subjected to heat exchange is used as preheating water so as to be effectively used, and the production cost is lowered.

Owner:WUXI BOLIDA HEAT EXCHANGER

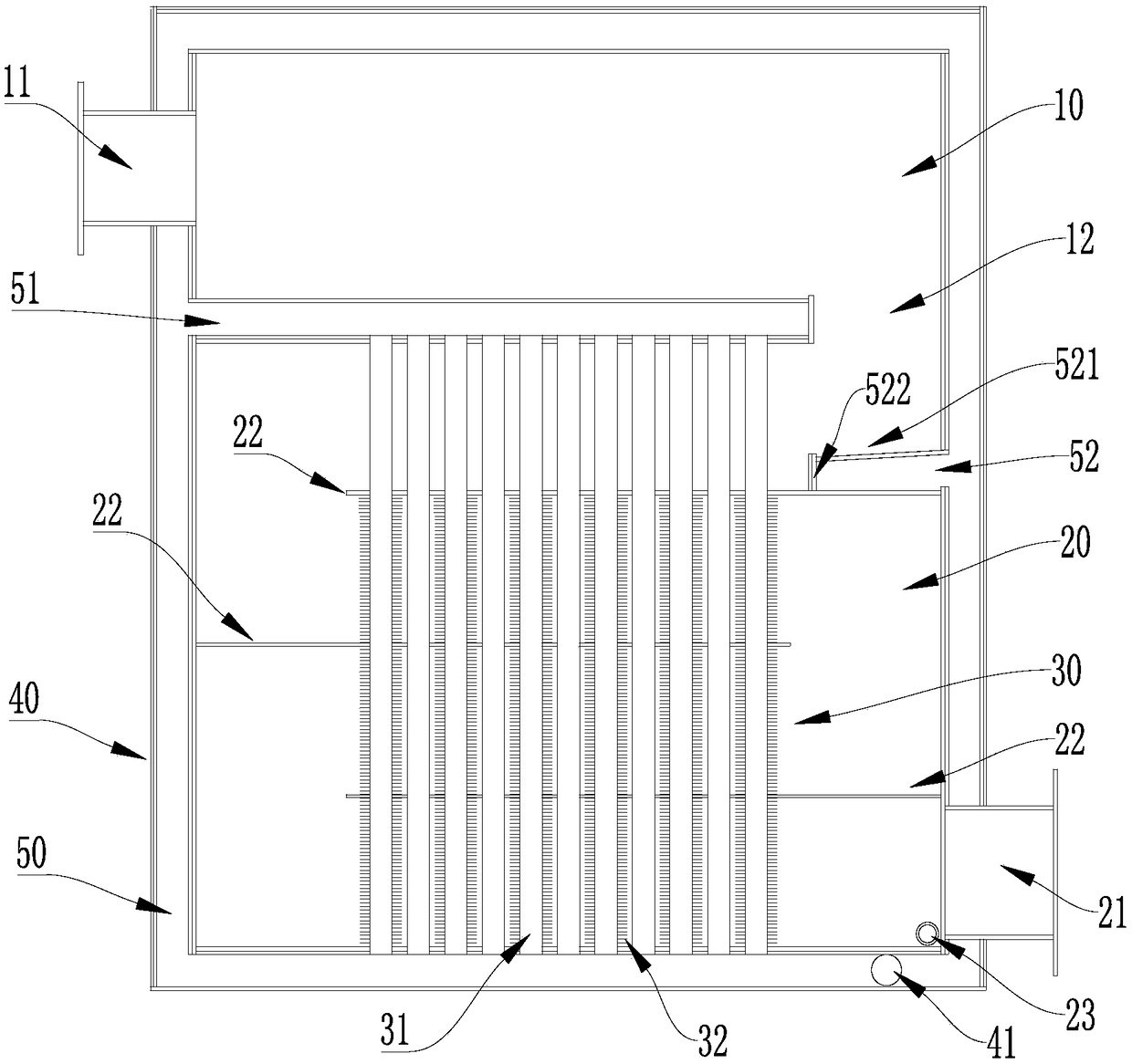

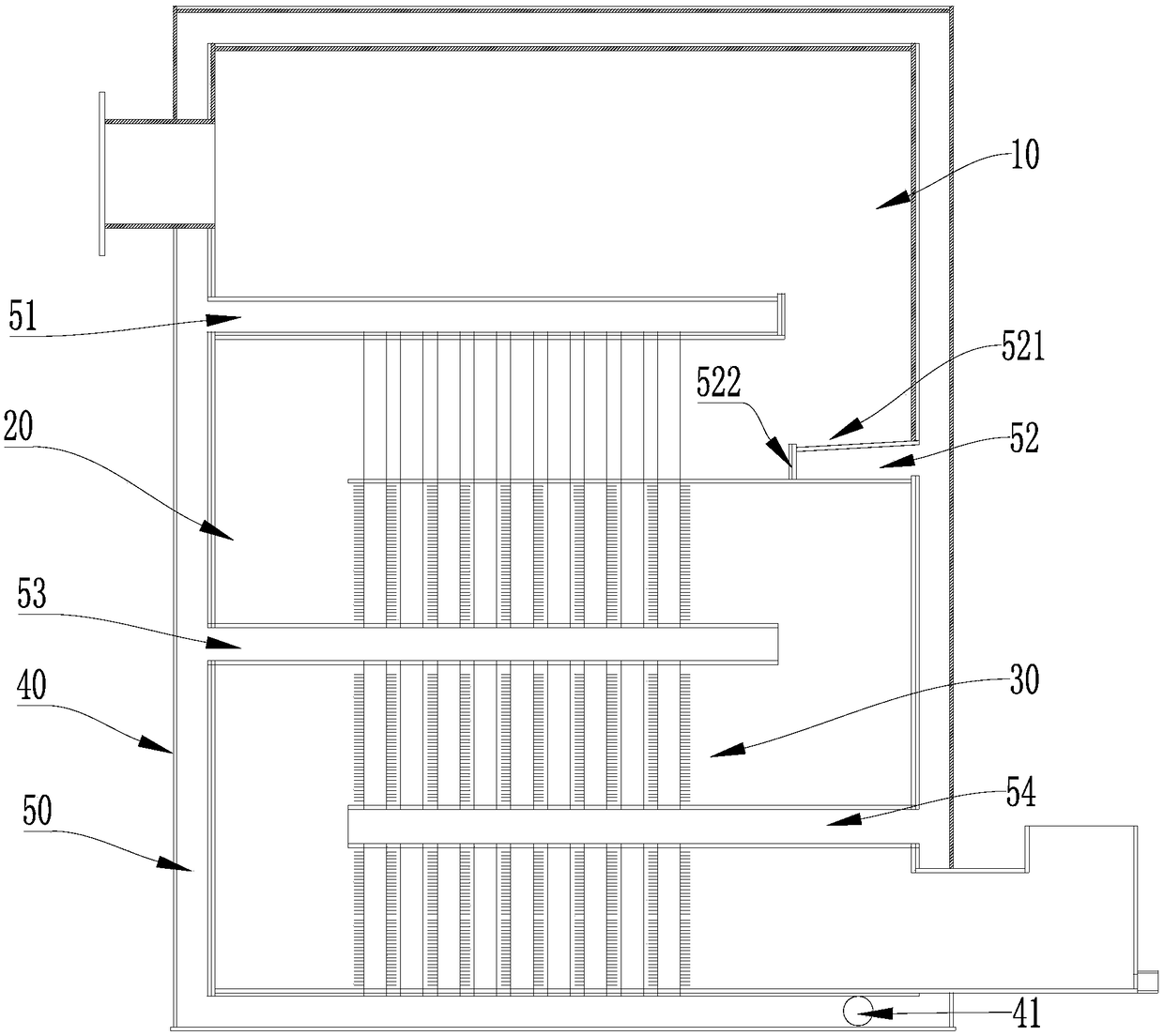

Condensation boiler

PendingCN108826688AIncrease flow lengthImprove thermal efficiencyAir heatersSustainable buildingsCombustion chamberCombustor

The invention provides a condensation boiler, and belongs to the technical field of boilers. The condensation boiler comprises a combustion chamber, a smoke cooling chamber communicating with the combustion chamber, and a cooling pipe set fixed into the smoke cooling chamber. At least one smoke baffle plate for forming a continuous smoke channel with at least one level of turning structure throughdivision is fixed in the smoke cooling chamber, the combustion chamber is provided with a combustor connector communicating with a combustor, and the smoke cooling chamber is provided with a smoke outlet communicating with a smoke outlet pipeline. A communication port of the combustion chamber and the smoke cooling chamber is an inlet of the continuous smoke channel, a smoke outlet is an outlet of the continuous smoke channel, and the cooling pipe set communicates with a cooling water supply assembly of the boiler. According to the provided condensation boiler, effective cooling of smoke in the smoke cooling chamber is achieved, water steam in the smoke is cooled and condensed, low-temperature emission of smoke is guaranteed, the heat efficiency of the boiler is high, and additional heatexchanger arrangement is not needed. The structure is simple, and the equipment cost is low.

Owner:LANGFANG JINHUA BOILER

Numerically-controlled methanol condensation boiler

InactiveCN103115434ANo pollution in the processMeet the needs of energy saving and emission reductionEnergy efficient heating/coolingAir heatersNumerical controlTemperature control

The invention discloses a numerically-controlled methanol condensation boiler, and provides a boiler which takes methanol as a fuel, and can meet the requirements of energy conservation and emission reduction. The methanol numerical control condensation boiler is characterized in that a shell is internally divided into a first heat transfer chamber and a second heat transfer chamber which are mutually communicated through a partition plate, the lower part of the first heat transfer chamber is provided with a methanol burner, the methanol burner is provided with an inclosed pan body, and the pan body is provided with a first water inlet and a first hot water outlet; the second heat transfer chamber is internally provided with a flue, the periphery of the flue is covered by a heat exchanger, the heat exchanger is internally provided with a superconductive pipe, and the heat exchanger is respectively provided with a second hot water outlet and a second water inlet; and the shell is provided with a combustion control device, and the combustion control device controls the start and stop of a methanol burner according to the temperature of the hot water outlet of the boiler. The numerically-controlled boiler adopts the methanol as a fuel, the combustion of the methanol can not generate the pollution, the requirements of energy conservation and emission reduction are met, and an environmental requirement is met; and the heat exchanger is arranged on the periphery of the flue, the water in the heat exchanger is heated through the superconductive pipe, the fume is condensed, the fume emission temperature is low, and the fuel utilization ratio is high.

Owner:王永强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com