Flameless catalytic combustion condensing boiler with near zero pollutant discharge

A technology for pollutant discharge and condensing boilers, which is applied in the direction of combustion, combustion methods, and combustion types using catalytic materials, and can solve the problem of low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

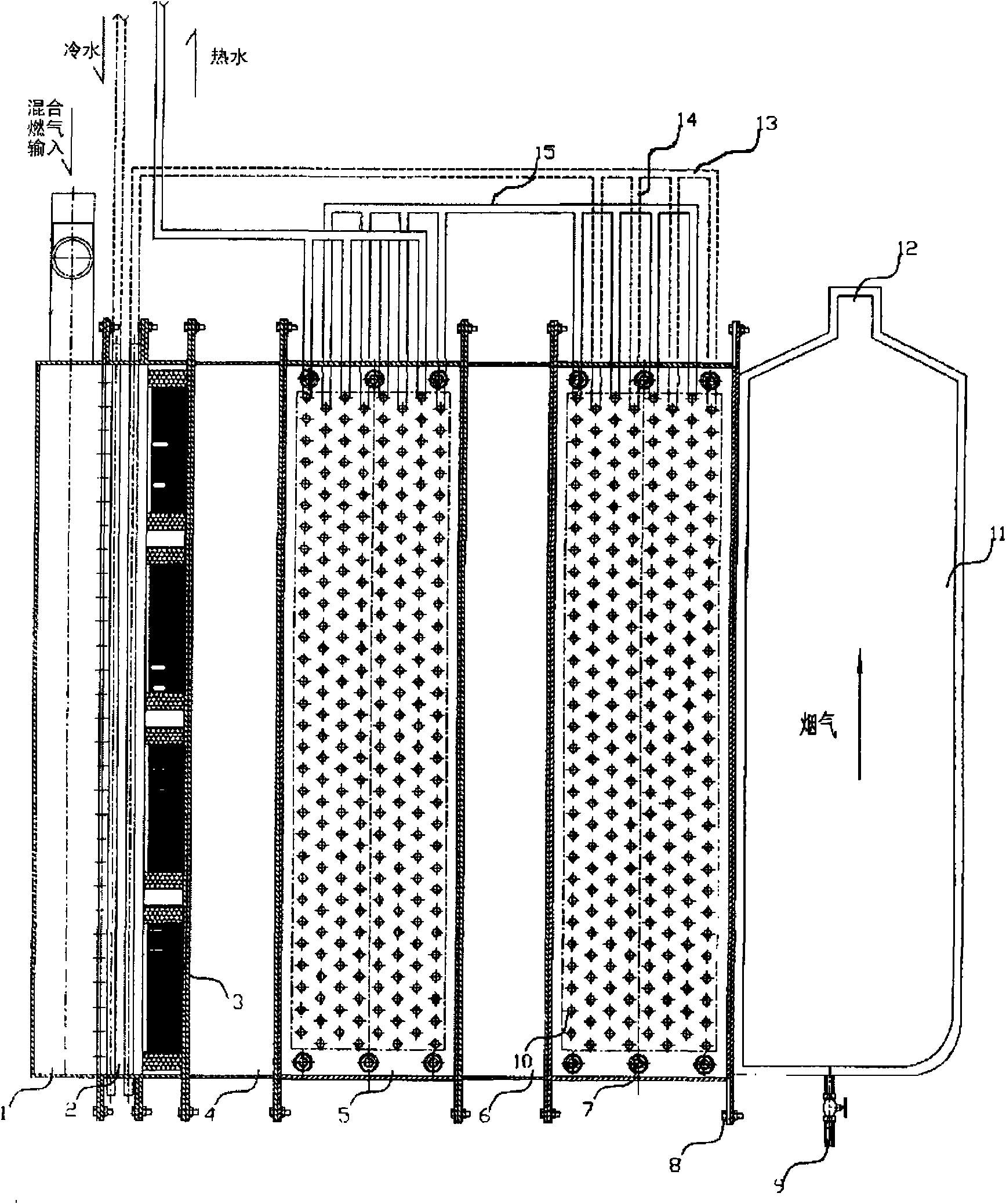

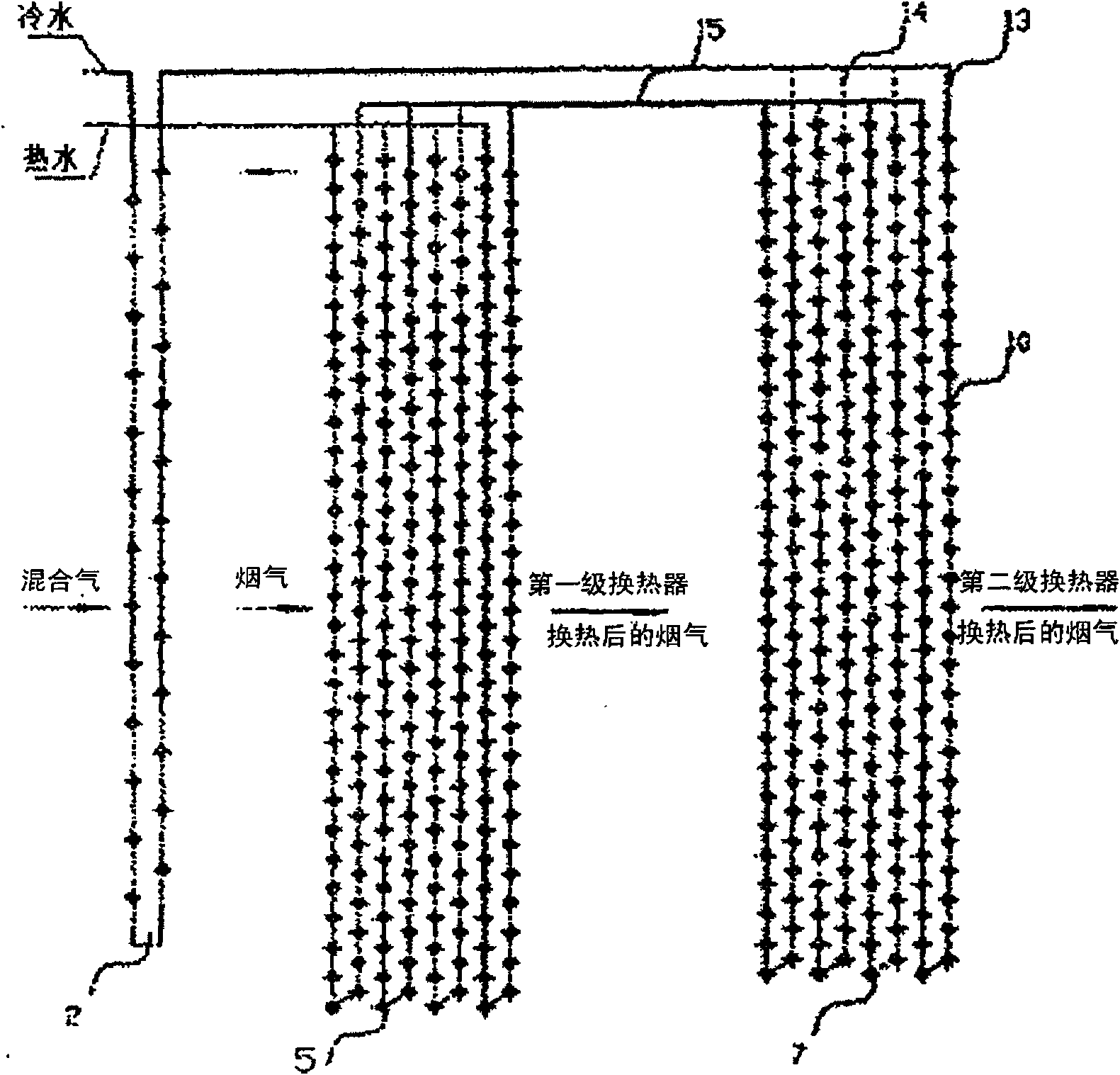

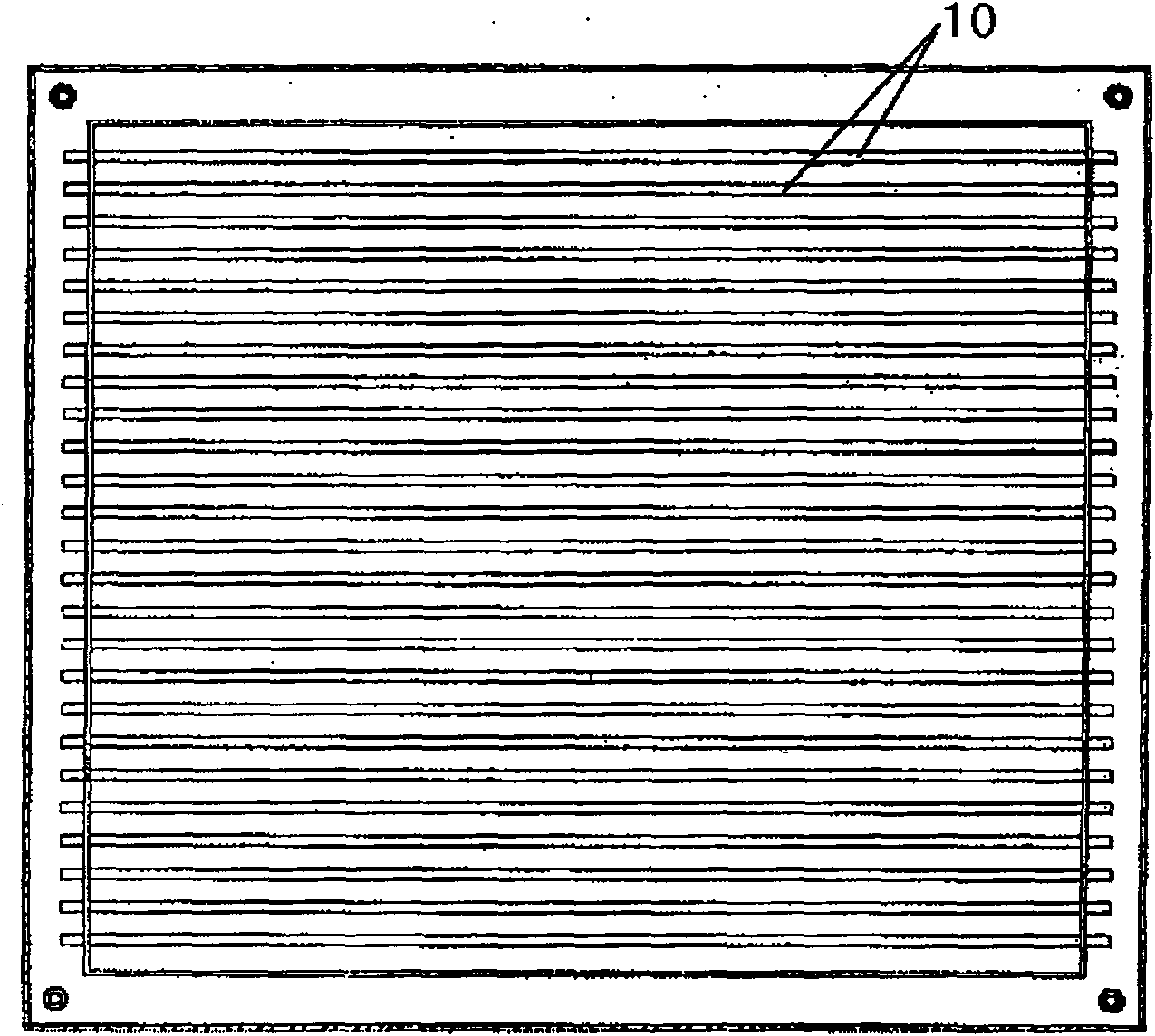

[0012] The invention provides a flameless catalytic combustion condensing boiler with near zero pollutant discharge. The present invention will be further described below in conjunction with the accompanying drawings.

[0013] figure 1 Shown is a schematic diagram of the catalytic combustion boiler structure. In the figure, the catalytic combustion condensing boiler consists of a burner cavity 1, a burner cooling device 2, a catalyst monolith loading container 3 at the head of the burner, a primary heat exchanger 5, and a secondary Composed of condensing heat exchanger 7 and smoke exhaust device 11, platinum or palladium catalyst is plated on the honeycomb monolith support in the catalyst monolith loading container 3 at the head of the burner, and the honeycomb monolith made of cordierite material The amount of catalyst on the support is calculated as 1.2 to 2.5 grams per liter according to its space volume; it is characterized in that the flameless catalytic combustion conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com