Patents

Literature

1079 results about "Formate Esters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

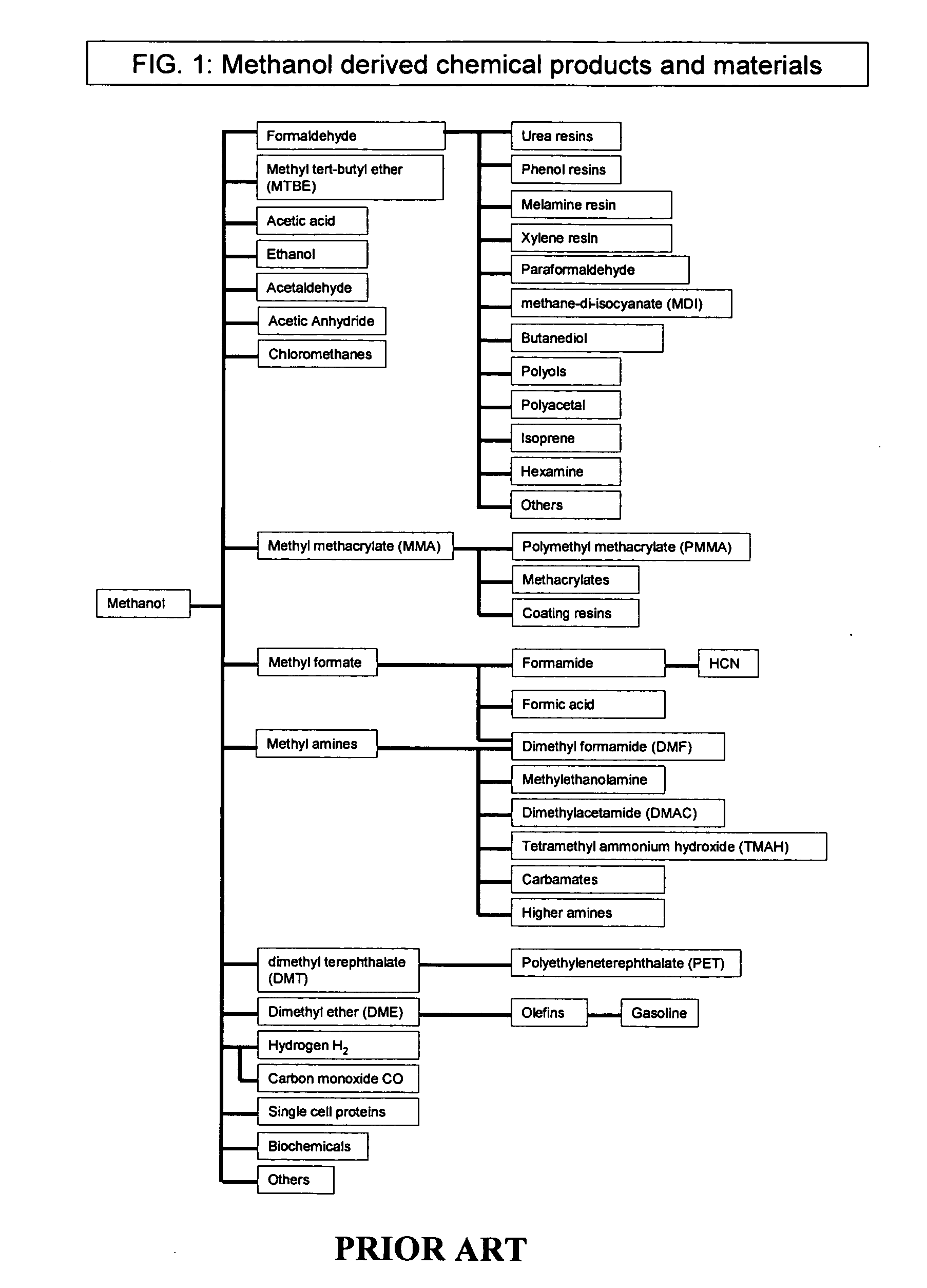

Methyl formate, also called methyl methanoate, is the methyl ester of formic acid. The simplest example of an ester, it is a colorless liquid with an ethereal odour, high vapor pressure, and low surface tension. It is a precursor to many other compounds of commercial interest.

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

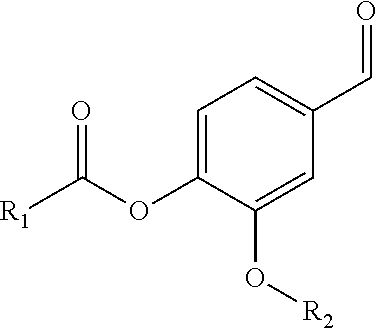

Slow release of fragrant compounds in perfumery using 2-benzoyl benzoates, 2-alkanoyl benzoates or alpha -keto esters

A fragrance delivery system which releases fragrant alcohols upon exposure to light. The system comprises 2-benzoyl benzoates of general formulae which can comprise various subtituents R1-R5 as defined in the application and a substituted R* which is the organic part of a fragrant alcohol.

Owner:FIRMENICH SA

Methods of drilling and completing well bores

Methods of drilling and completing open hole well bores and methods of removing filter cake comprised of a gelling agent and calcium carbonate are provided. A method of the invention for removing filter cake comprised of a gelling agent and calcium carbonate from the walls of an open hole well bore is basically comprised of the steps of contacting the filter cake with a delayed clean-up solution comprised of water and a formate ester and removing the clean-up solution from the well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Subterranean treatment fluids and methods of using these fluids to stimulate subterranean formations

Owner:HALLIBURTON ENERGY SERVICES INC

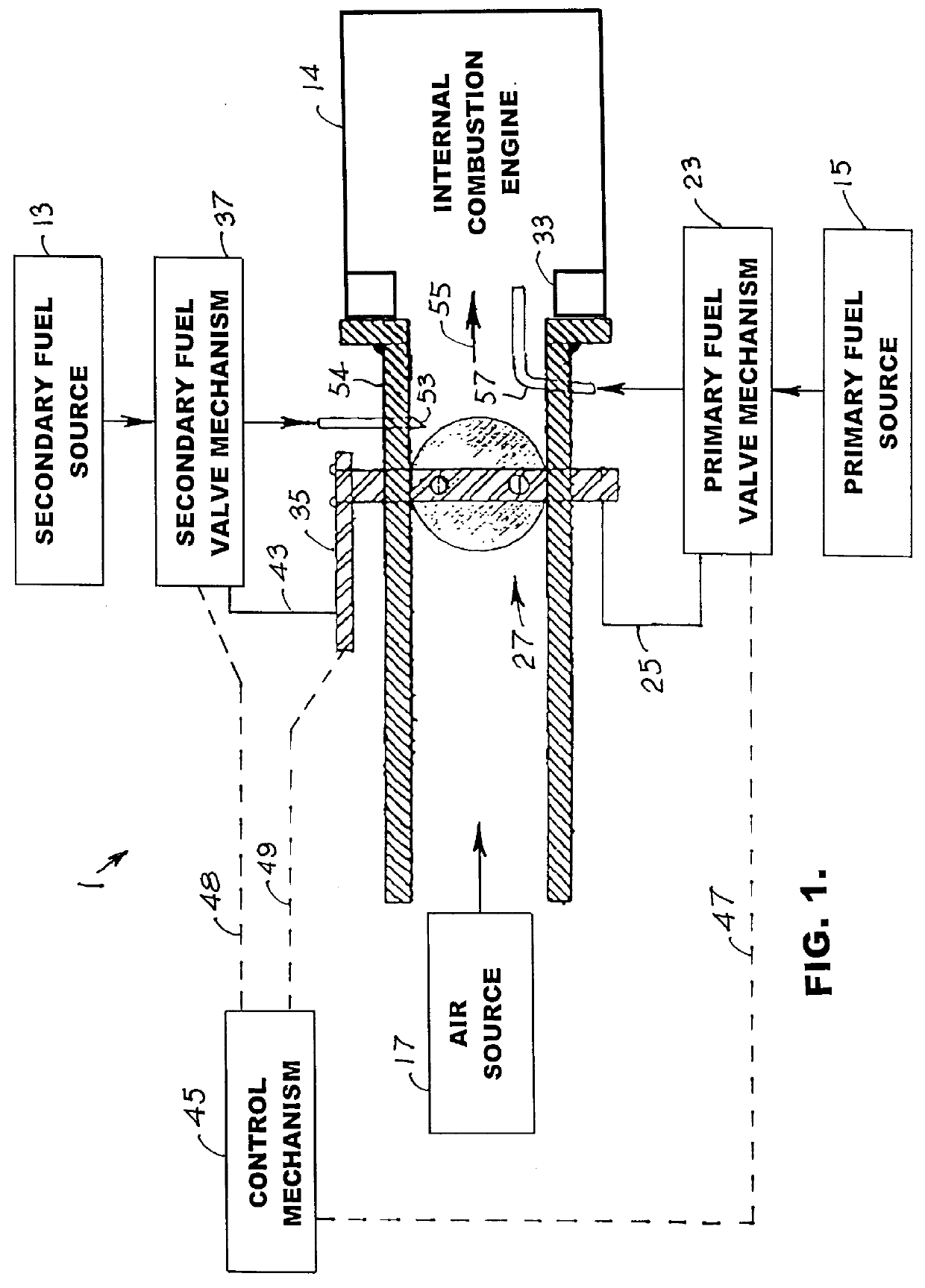

Internal combustion system using acetylene fuel

InactiveUS6076487AInternal combustion piston enginesNon-fuel substance addition to fuelCarbon chainInternal combustion engine

An environmentally clean dual fuel for an internal combustion engine, comprising acetylene as a primary fuel and a combustible fuel, such as one or more fluids selected from an alcohol such as ethanol, methanol or any other alcohol or alcohols from the group comprising C1-C20 carbon chains, ethers such as from the group comprising dimethyl ether, diethyl ether, methyl t-butyl ether, ethyl t-butyl ether, t-amyl methyl ether, di-isopropyl ether and the like, low-molecular-weight esters such as from the group comprising methyl formate, methyl acetate, ethyl acetate, methyl propionate, ethyl propionate and the like, or other suitable combustible fluid such as mineral spirits and the like, as a secondary fuel for operatively preventing early ignition and knock arising from the primary fuel. The dual fuel, internal combustion system, which generally utilizes a two-stage process for start-up and operation and can be operated with air- or liquid-cooling, is environmentally clean with hydrocarbon, CO, NOx, and SOx emissions substantially eliminated.

Owner:GOTEC

Olefin block copolymers, processes for producing the same and uses thereof

Olefin block copolymers (A-1) are disclosed represented by the formula (I) PO1-g1-B1 . . . (I) wherein PO1 is a segment comprised of repeating units derived from an olefin having 2 to 20 carbon atoms, g1 is an ester, ether, amide, imide, urethane, urea, silylether or carbonyl linkage, and B1 is a segment containing an unsaturated hydrocarbon or a hetero atom. The olefin block copolymers are suitable for uses in adhesives, various molded articles such as construction and civil engineering materials, automobile interior and exterior materials, gasoline tanks, electric and electronic parts, medical care and sanitation materials, materials of miscellaneous goods, resin materials having environmental degradation properties, films and sheets, modifiers and dispersions.

Owner:MITSUI CHEM INC

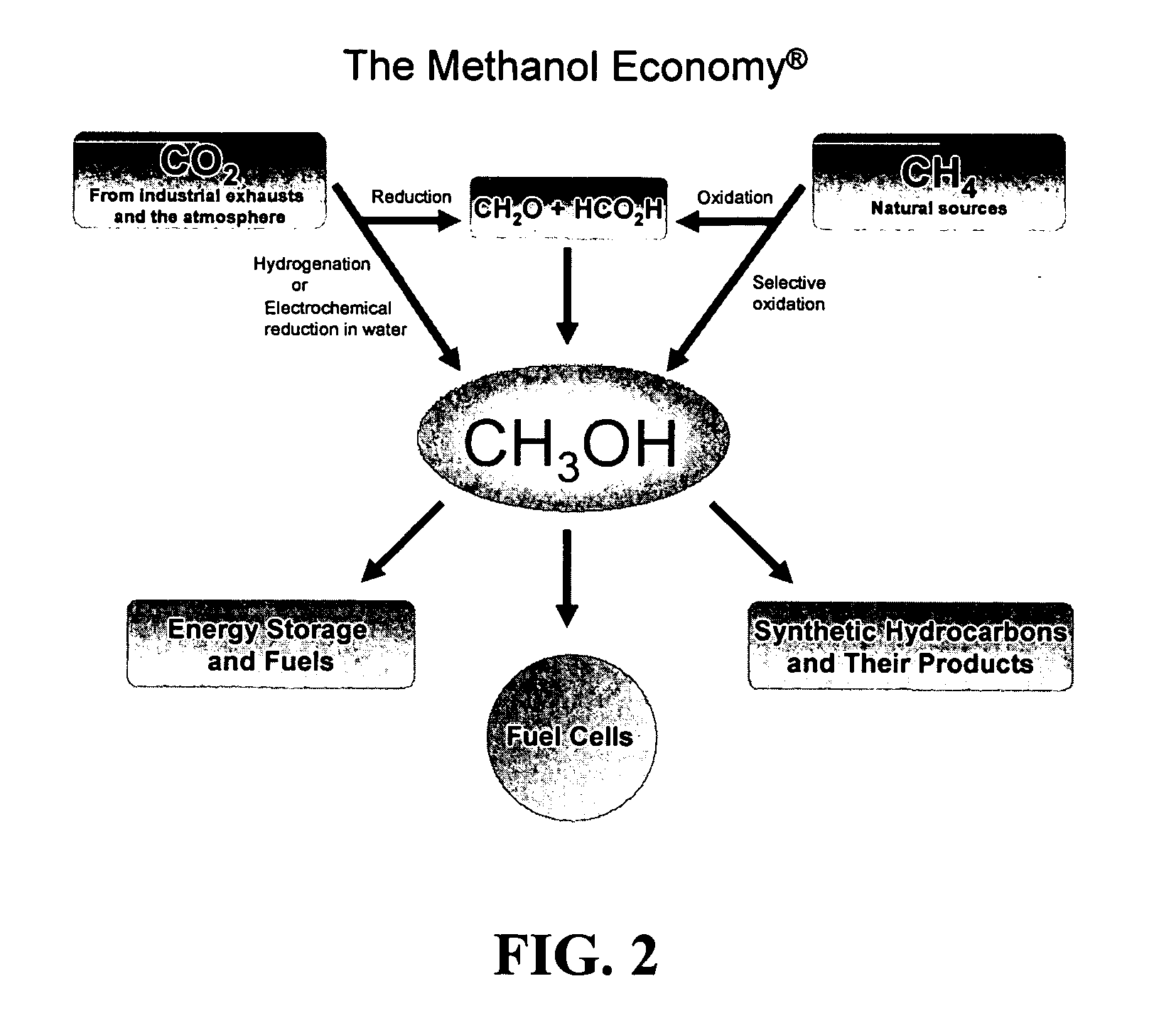

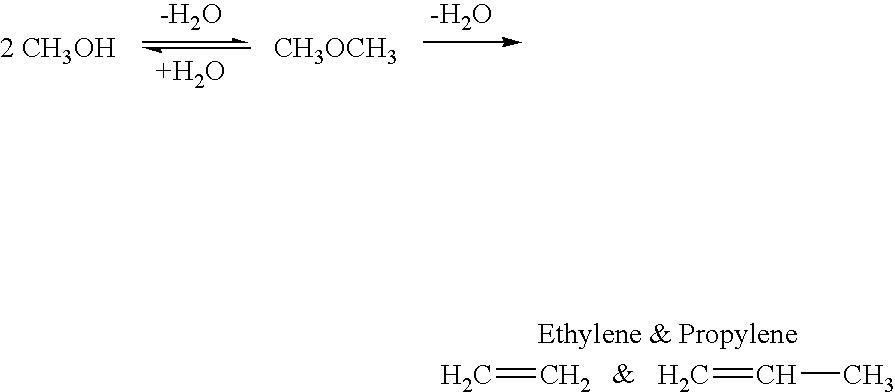

Selective oxidative conversion of methane to methanol, dimethyl ether and derived products

ActiveUS20060235088A1Minimize or eliminate the disadvantages or dangers inherentPreparation by oxidation reactionsElectrolysis componentsFormate EstersDimethyl ether

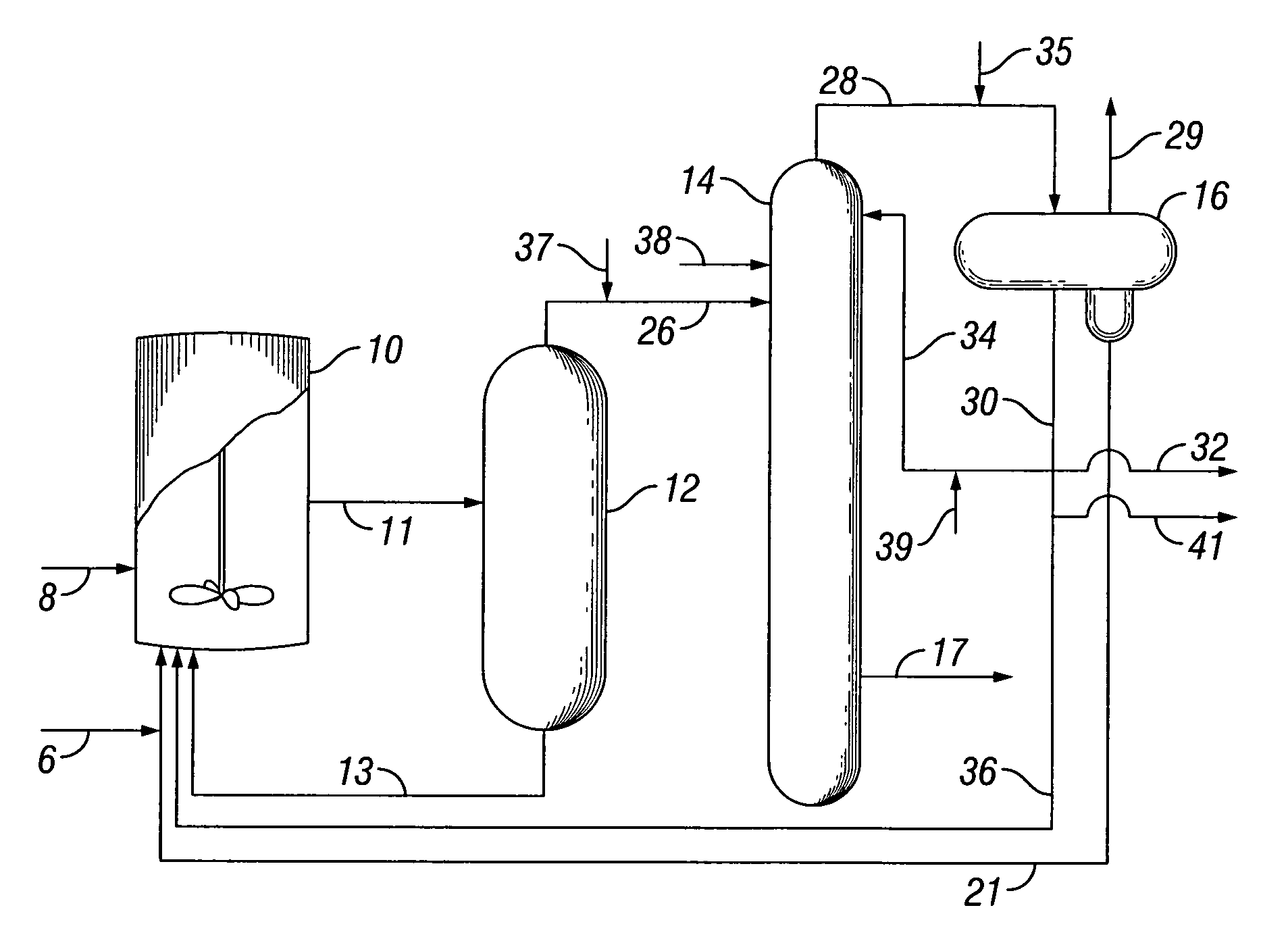

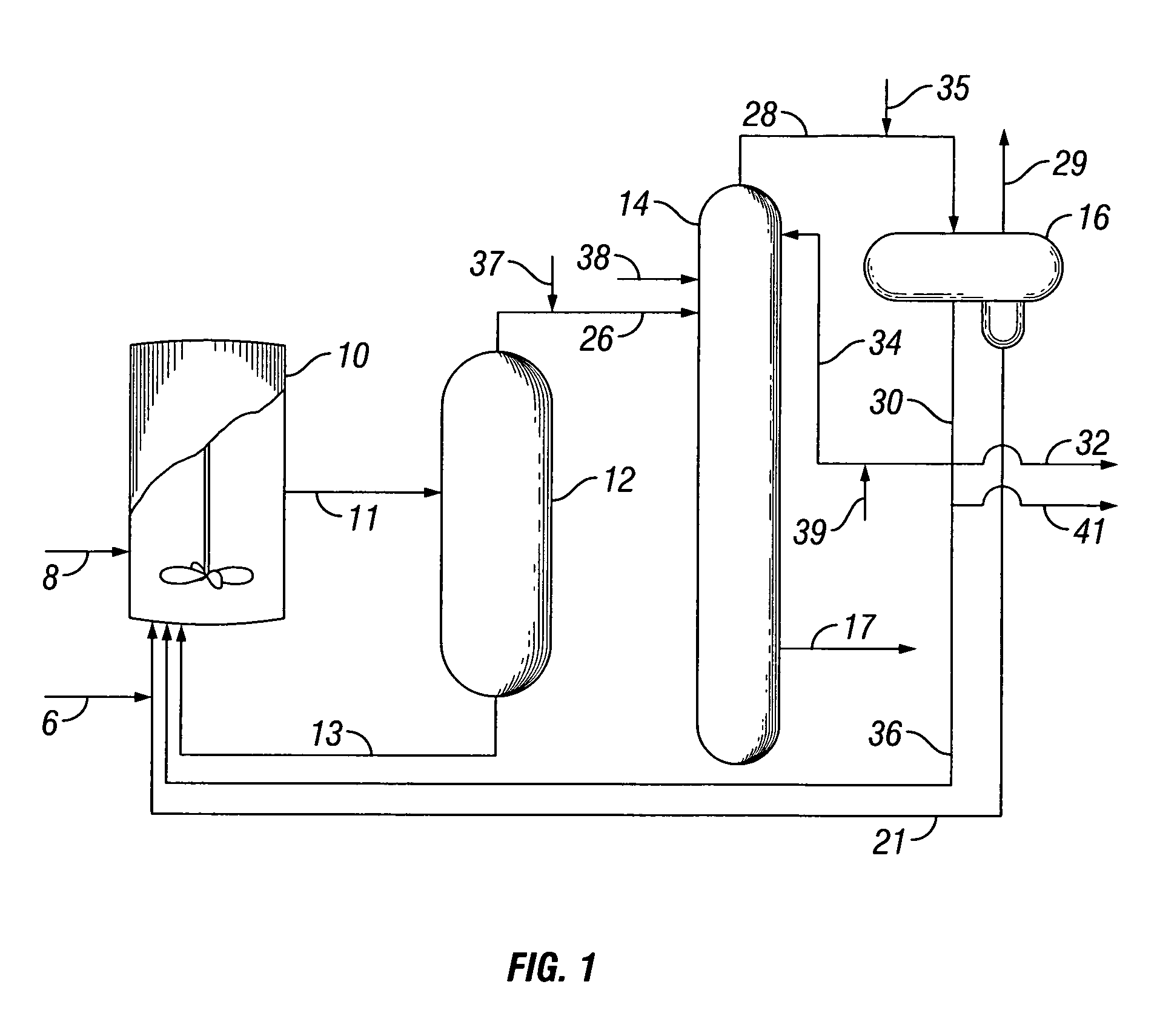

The present invention relates to a method of producing methanol from a methane source by oxidizing methane under conditions sufficient to a mixture of methanol and formaldehyde while minimizing the formation of formic acid and carbon dioxide. The oxidation step is followed by treatment step in which formaldehyde is converted into methanol and formic acid which itself can further be converted into methanol via catalytic hydrogenation of intermediately formed methyl formate.

Owner:UNIV OF SOUTHERN CALIFORNIA

Compositions and methods for the removal of oil-based filtercakes

A method of servicing a wellbore comprising providing a composition comprising a mutual solvent precursor, an acid precursor, and an aqueous fluid, and contacting the composition with oil wet solids in the wellbore. A method of servicing a wellbore comprising introducing an oil-based fluid into a wellbore, wherein the oil-based fluid forms oil wet solids in the wellbore, contacting the oil wet solids in the wellbore with a composition comprising a mutual solvent precursor; an acid precursor and an aqueous fluid, and allowing the oil wet solids to become water wet. A method of servicing a well bore comprising contacting a composition comprising a formate ester with oil wet solids in the well bore under conditions wherein the formate ester hydrolyzes to release formic acid, wherein the formic acid catalyzes the hydrolysis of additional formate ester, and wherein all or a portion of the formate ester converts at least a portion of the oil-wet solids to water-wet solids.

Owner:HALLIBURTON ENERGY SERVICES INC

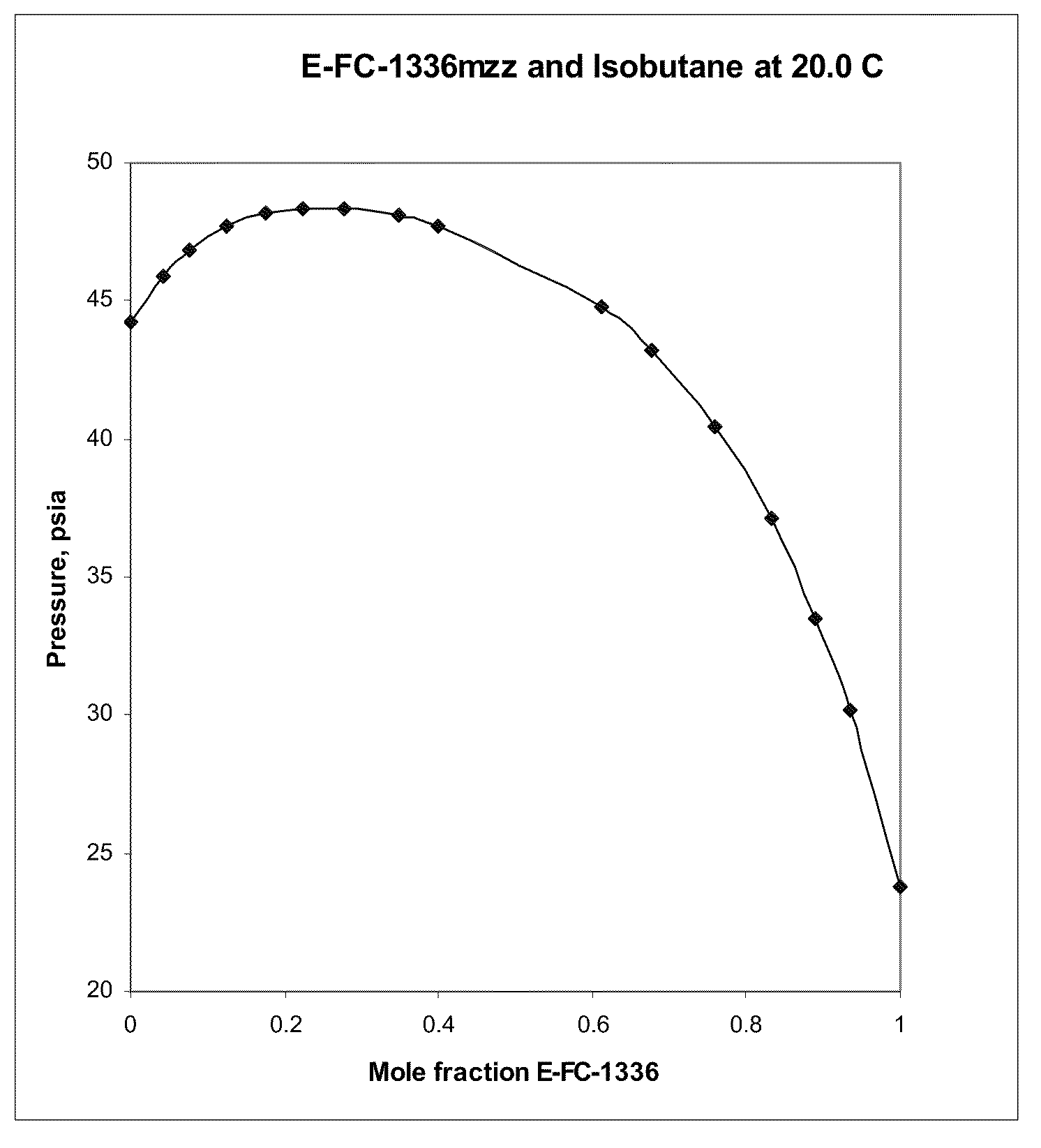

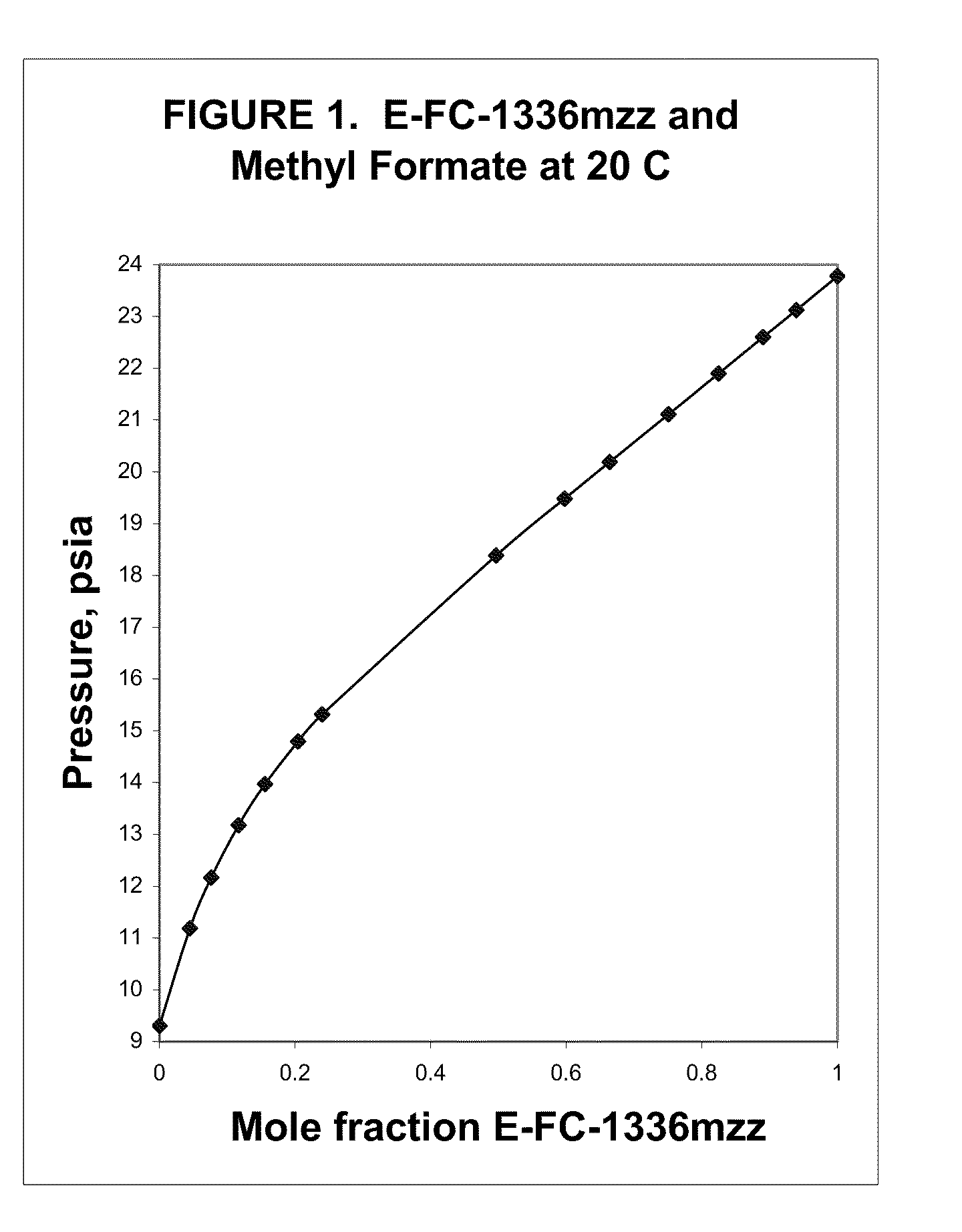

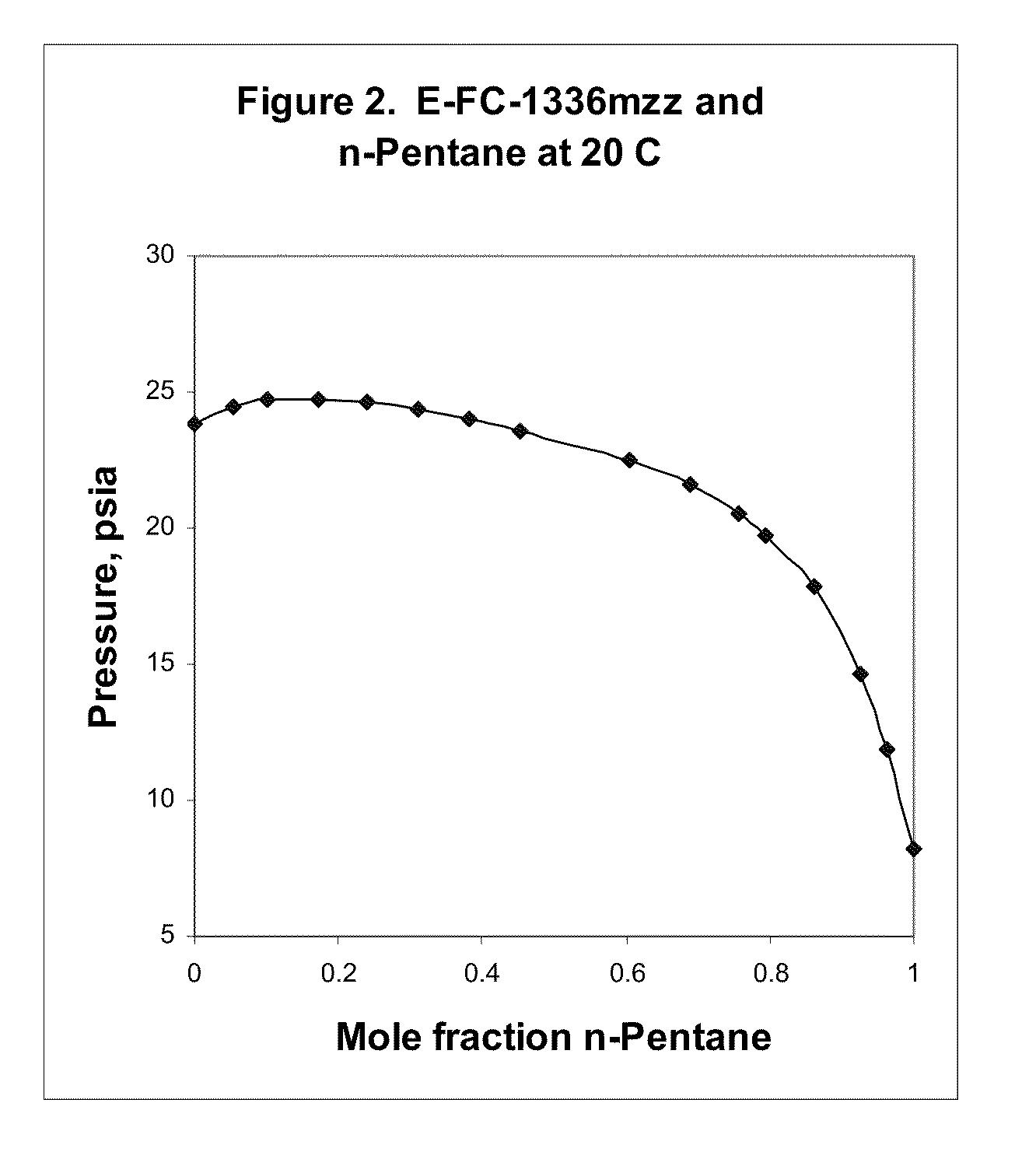

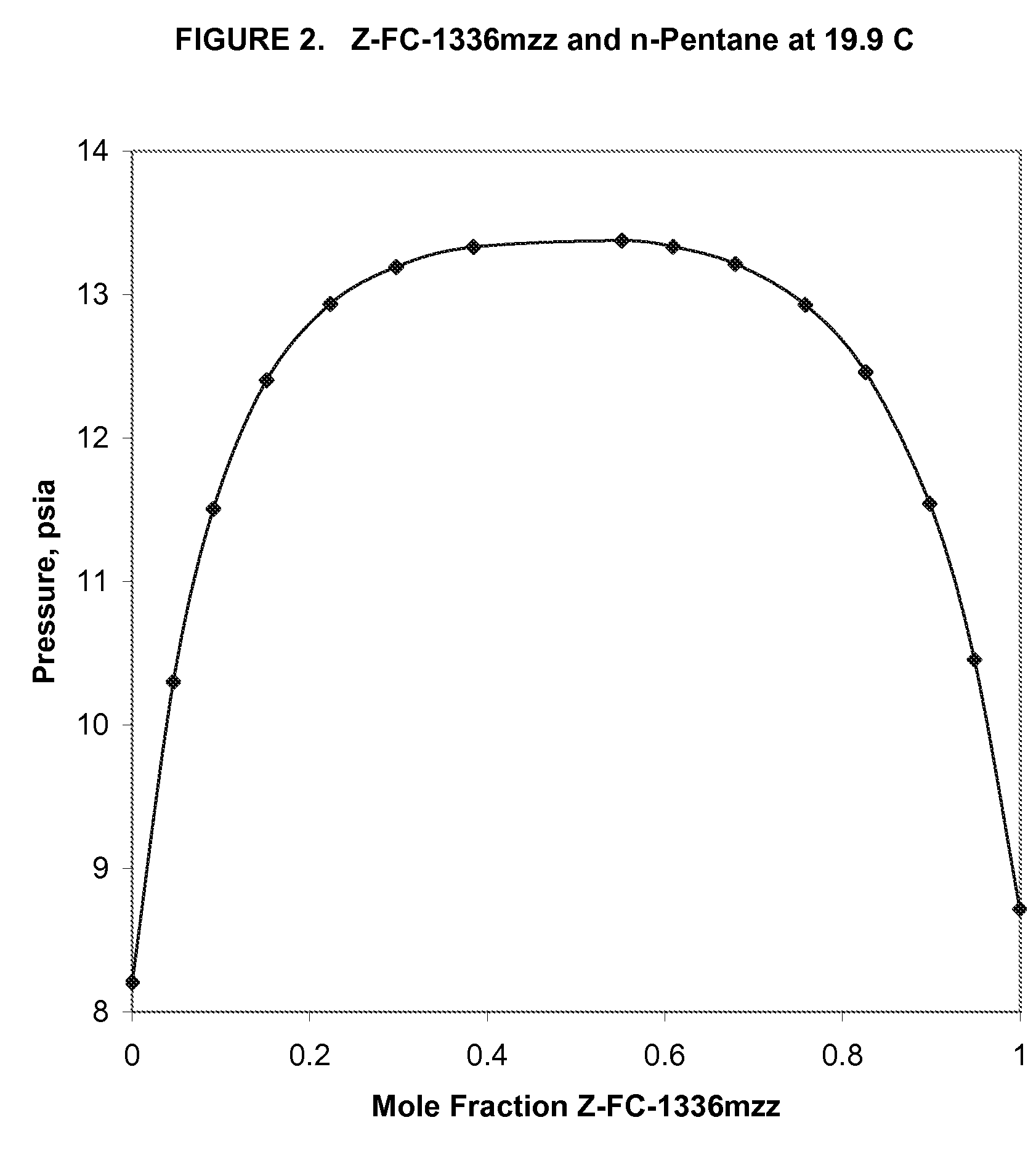

Azeotropic and azeotrope-like compositions of e-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of E-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, n-pentane, 2-methylbutane trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, n-butane or isobutane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

Oral Care Compositions With Improved Flavor

Oral care compositions having improved taste, said compositions comprising: a carrier material; from about 0.001 to about 10%, by weight of the composition, of an oral care component selected from metal salts, antimicrobial agents, bad breath reduction agents, bleaching agents, surfactants, or a combination thereof; and from about 0.0001 to about 1%, by weight of the composition, of a TRPA1 agonist selected from vanillin esters; benzoate esters; hydroxybenzoate derivatives; methoxy benzoate derivatives; hydroxybutanedioate derivatives; benzamidobenzoate derivatives; methylpropanoate derivatives; phenyl acetate derivatives; hex-3-enoate derivatives; 2-(furan-2-ylmethylsulfanyl)-3-methylpyrazine; phenylmethoxymethylbenzene; (2R)-2-azaniumyl-3-[(2R)-2-azaniumyl-3-oxido-3-oxopropyl]disulfanylpropanoate; (3E)-2-hydroxy-4,8-dimethylnona-3,7-dienal; (2R)-2-azaniumyl-3-[(2S)-2-azaniumyl-3-oxido-3-oxopropyl]disulfanylpropanoate; (3Z)-3-butylidene-2-benzofuran-1-one; 3-methyl-N-(3-methylbutyl)butan-1-imine; 2-(furan-2-ylmethyldisulfanylmethyl)furan; and combinations thereof. Uses thereof and methods of improving the taste of an oral care composition.

Owner:THE PROCTER & GAMBLE COMPANY

Fluoropropene compounds and compositions and methods using same

InactiveUS20110037016A1Reduce negative impactImprove environmental desirabilitySolvent extractionOther chemical processesHydrocotyle bowlesioidesKetone

Various uses of fluorinated olefin having an MRI value of less than ethane, in combination with one or more other components, including other fluoroalkenes, hydrocarbons; hydrofluorocarbons (HFCs), ethers, alcohols, aldehydes, ketones, methyl formate, formic acid, water, trans-1,2-dichloroethylene, carbon dioxide and combinations of any two or more of these, in a variety of applications, including as blowing agents, are disclosed.

Owner:HONEYWELL INT INC

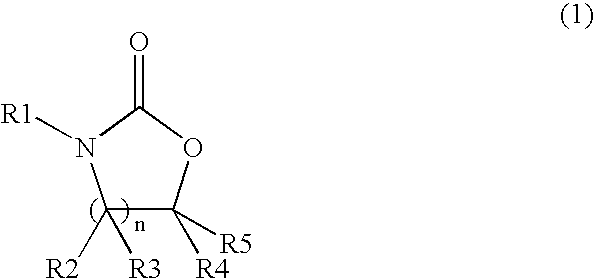

Method for producing cyclic carbamate ester

A method for producing a cyclic carbamate ester produces the cyclic carbamate ester by reacting an organic compound having at least two halogen atoms per molecule, an amine having at least two hydrogen atoms on a nitrogen atom, and carbon dioxide.

Owner:MITSUBISHI GAS CHEM CO INC

Compositions and Methods for the Removal of Oil-Based Filtercakes

A method of servicing a wellbore comprising providing a composition comprising a mutual solvent precursor, an acid precursor, and an aqueous fluid, and contacting the composition with oil wet solids in the wellbore. A method of servicing a wellbore comprising introducing an oil-based fluid into a wellbore, wherein the oil-based fluid forms oil wet solids in the wellbore, contacting the oil wet solids in the wellbore with a composition comprising a mutual solvent precursor; an acid precursor and an aqueous fluid, and allowing the oil wet solids to become water wet. A method of servicing a well bore comprising contacting a composition comprising a formate ester with oil wet solids in the well bore under conditions wherein the formate ester hydrolyzes to release formic acid, wherein the formic acid catalyzes the hydrolysis of additional formate ester, and wherein all or a portion of the formate ester converts at least a portion of the oil-wet solids to water-wet solids.

Owner:HALLIBURTON ENERGY SERVICES INC

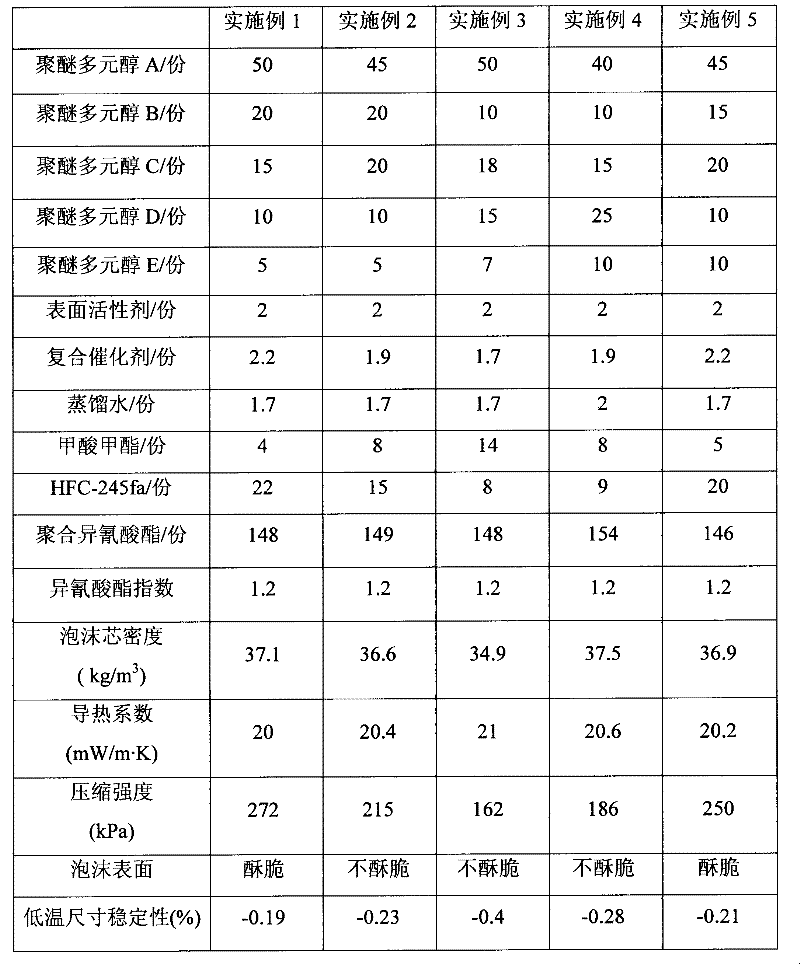

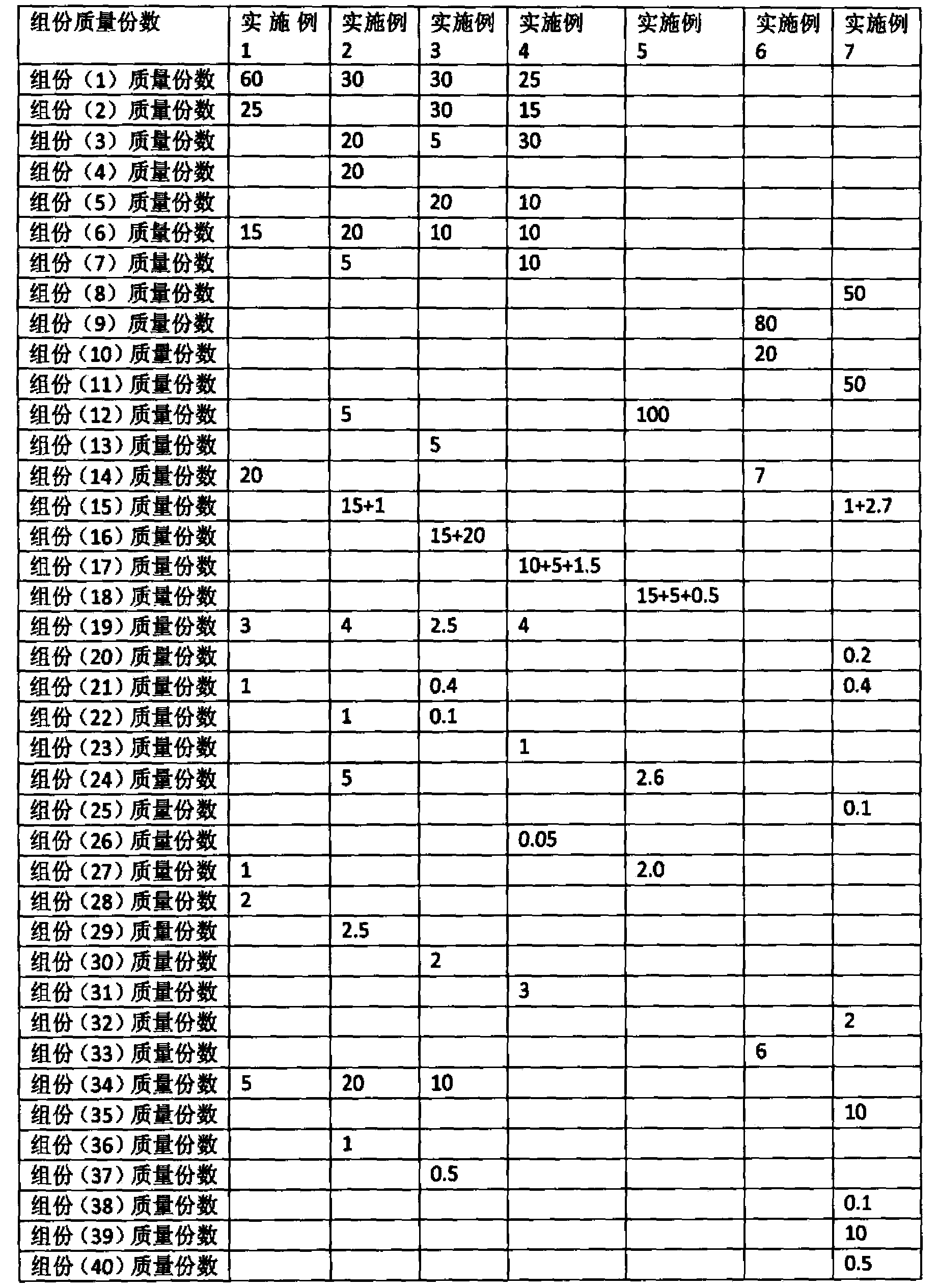

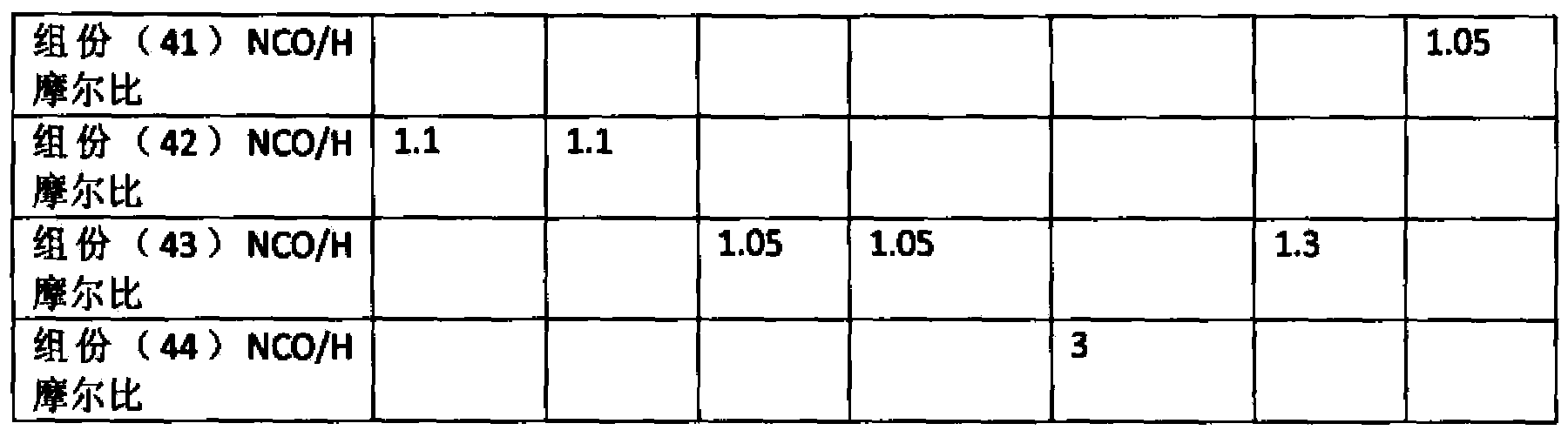

Polyurethane rigid foam and preparation method thereof

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

Methods of making alkyl lactates and alkyl levulinates from saccharides

InactiveUS20150045576A1Organic compound preparationPreparation by carbon monoxide or formate reactionLevulinic acidAlcohol

Unique methods have been developed to convert saccharides into value-added products such as alkyl lactates, lactic acid, alkyl levulinates, levulinic acid, and optionally alkyl formate esters and / or hydroxymethylfurfural (HMF). Useful catalysts include Lewis acid catalysts and Brønsted acid catalysts including mineral acids, metal halides, immobilized heterogeneous catalysts functionalized with a Brønsted acid group or a Lewis acid group, or combinations thereof. The saccharides are contacted with the catalyst in the presence of various alcohols.

Owner:BATTELLE MEMORIAL INST

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

Owner:EASTMAN SPECIALITIES HLDG CORP

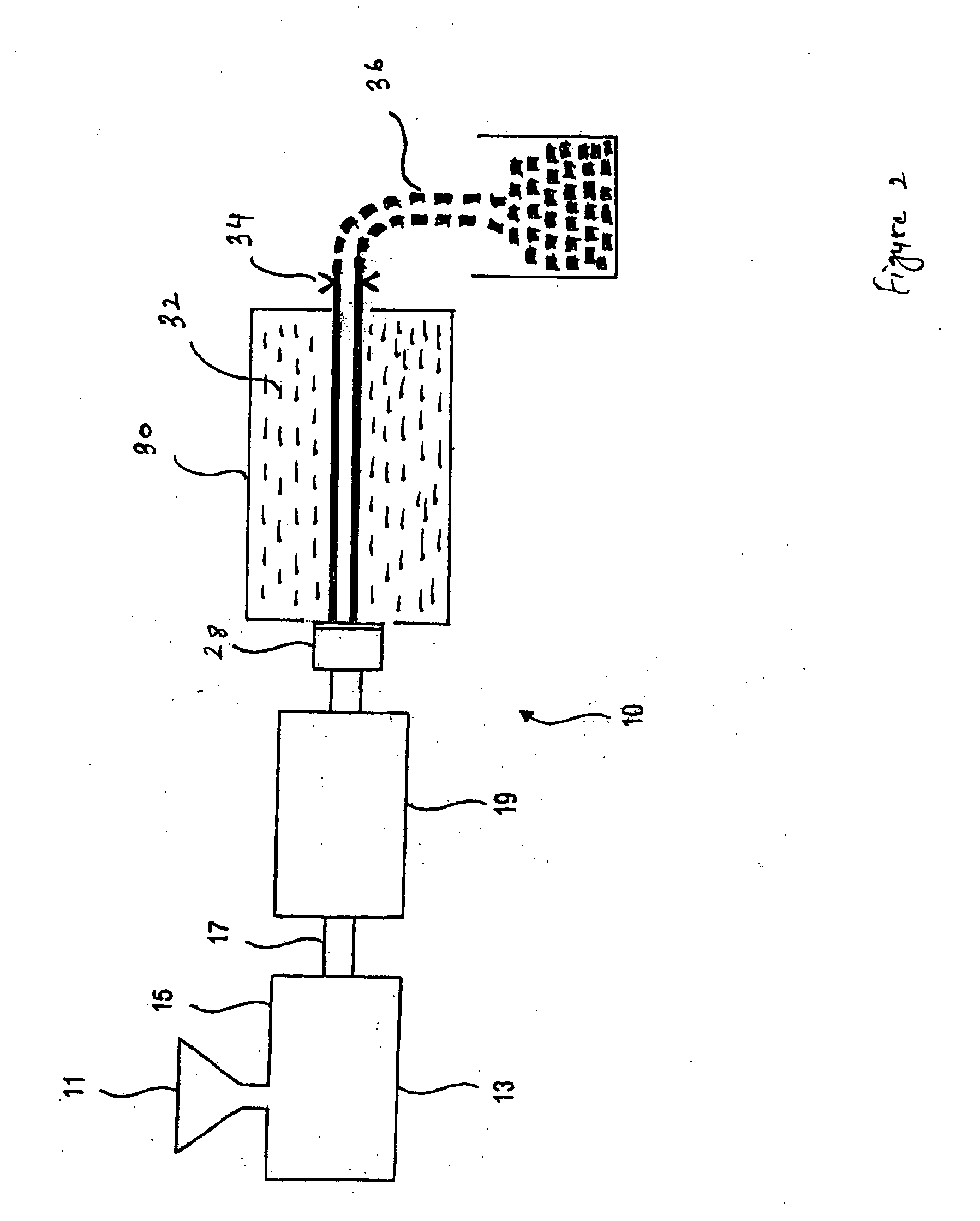

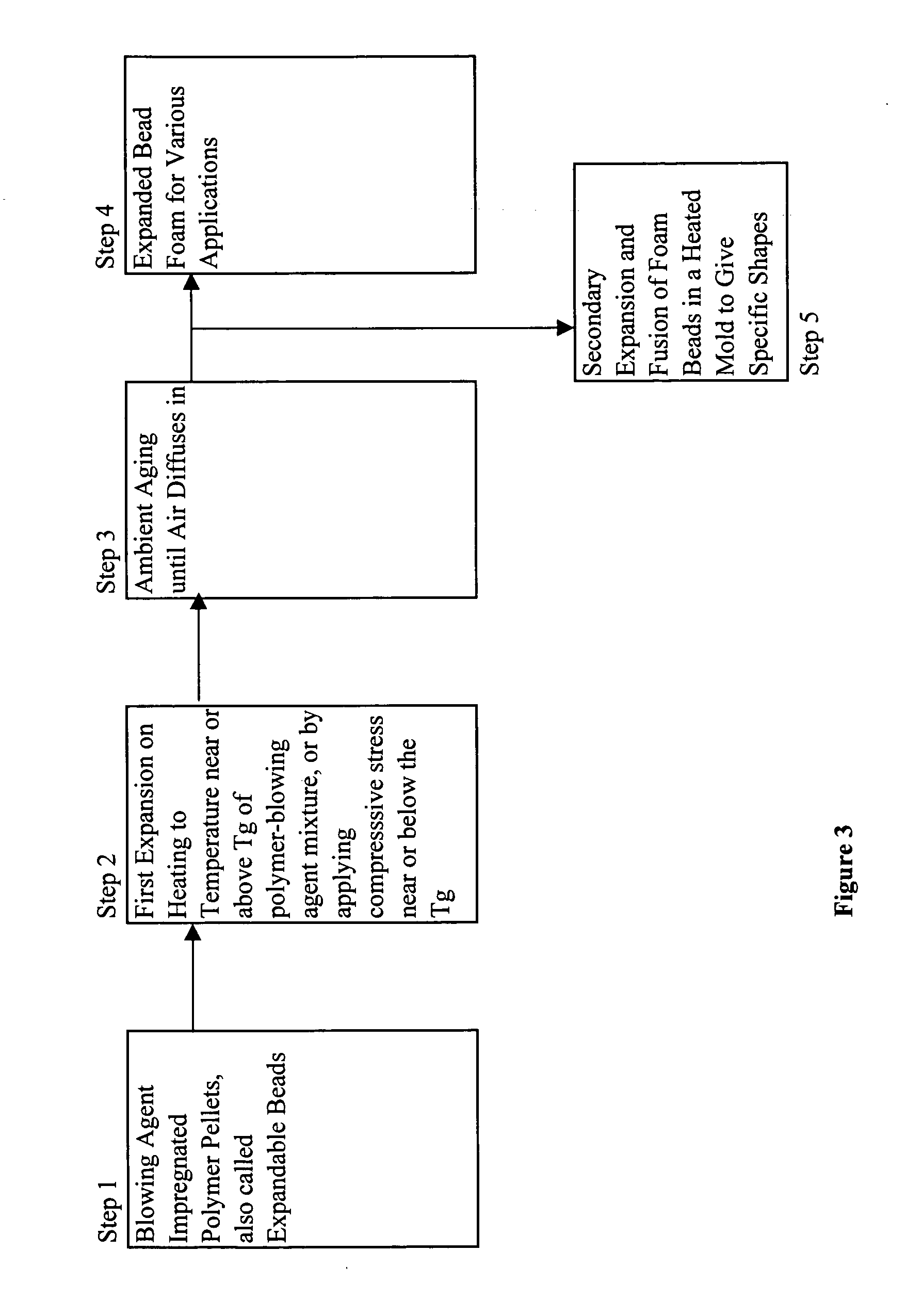

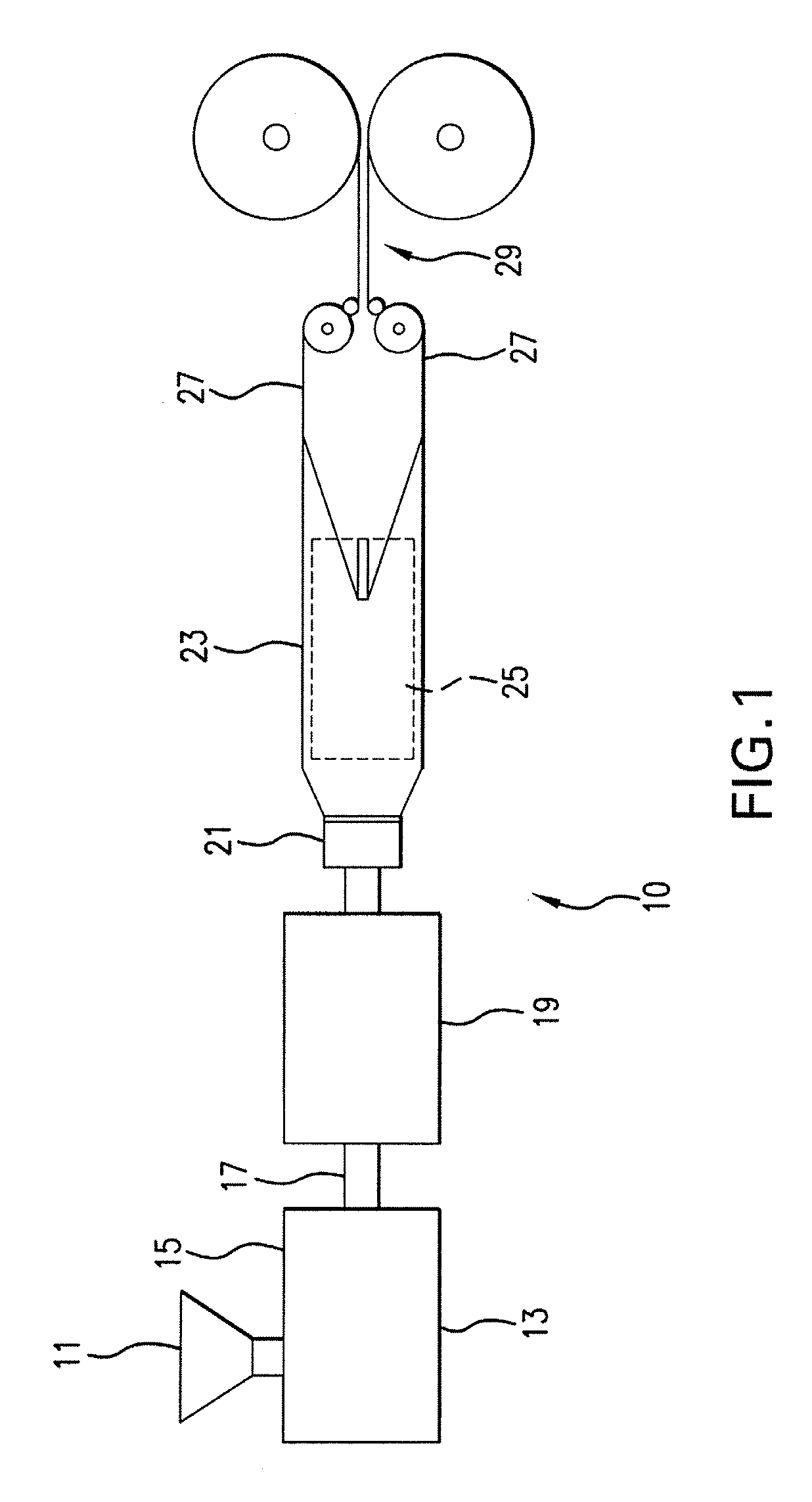

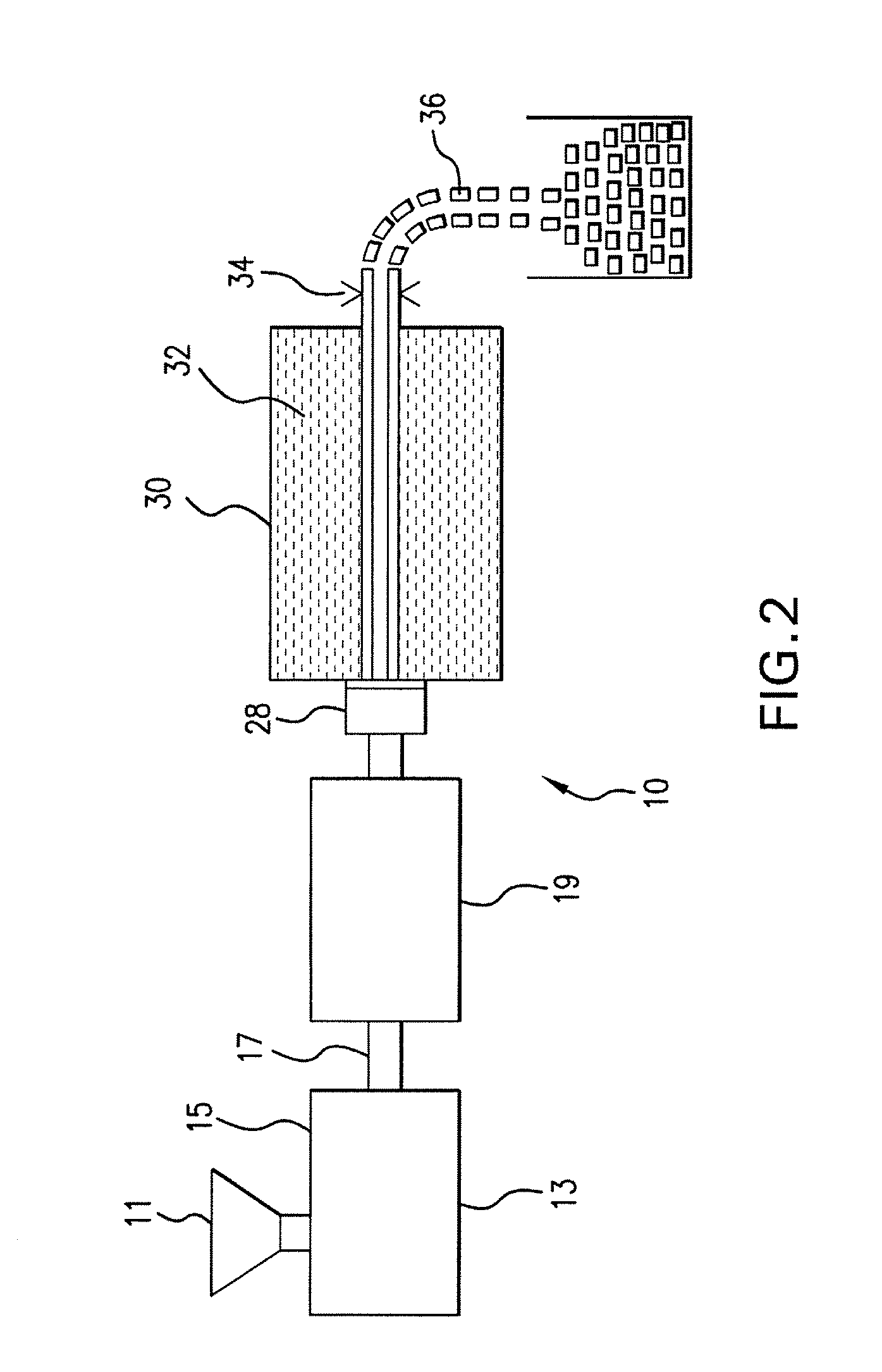

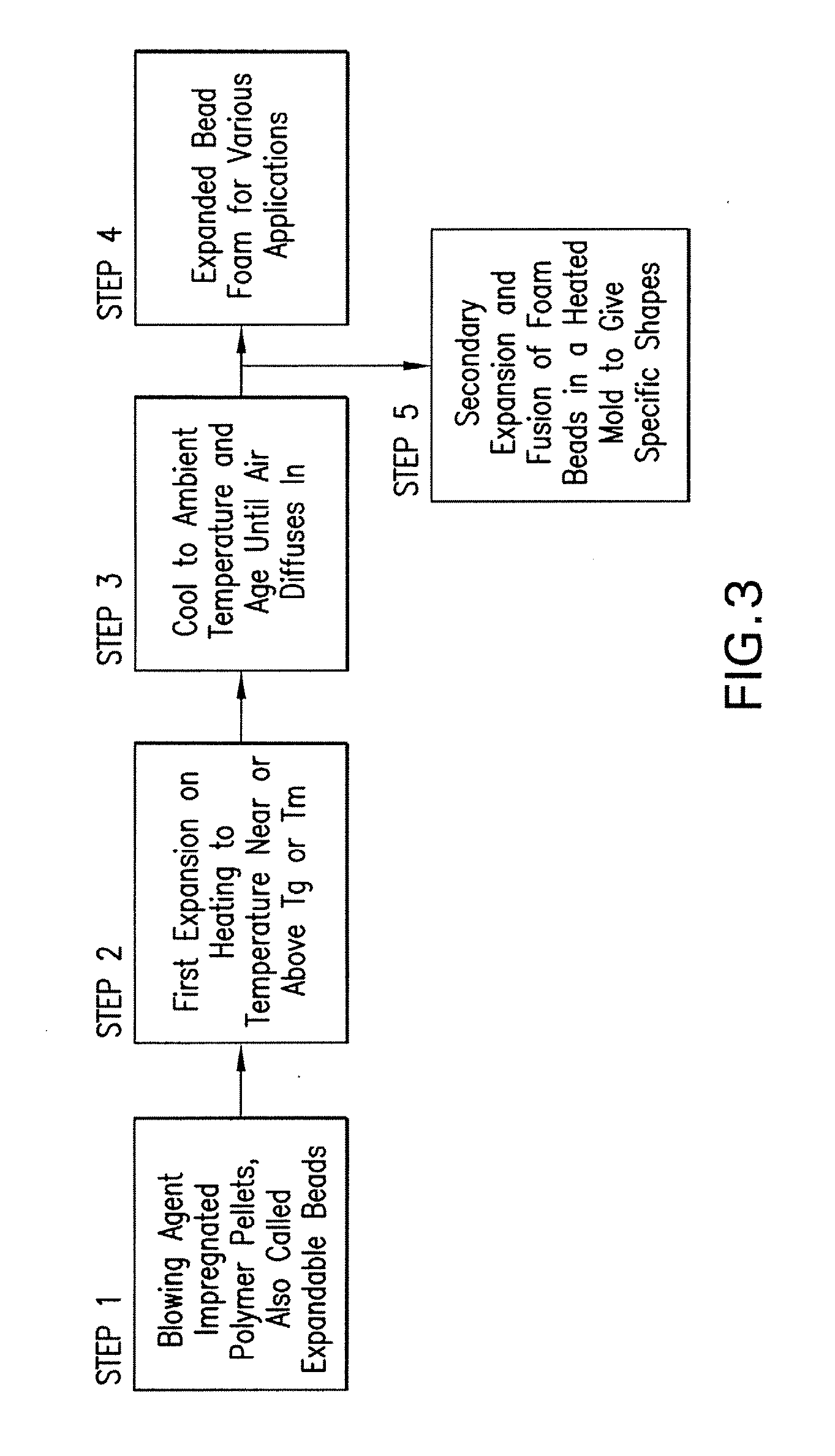

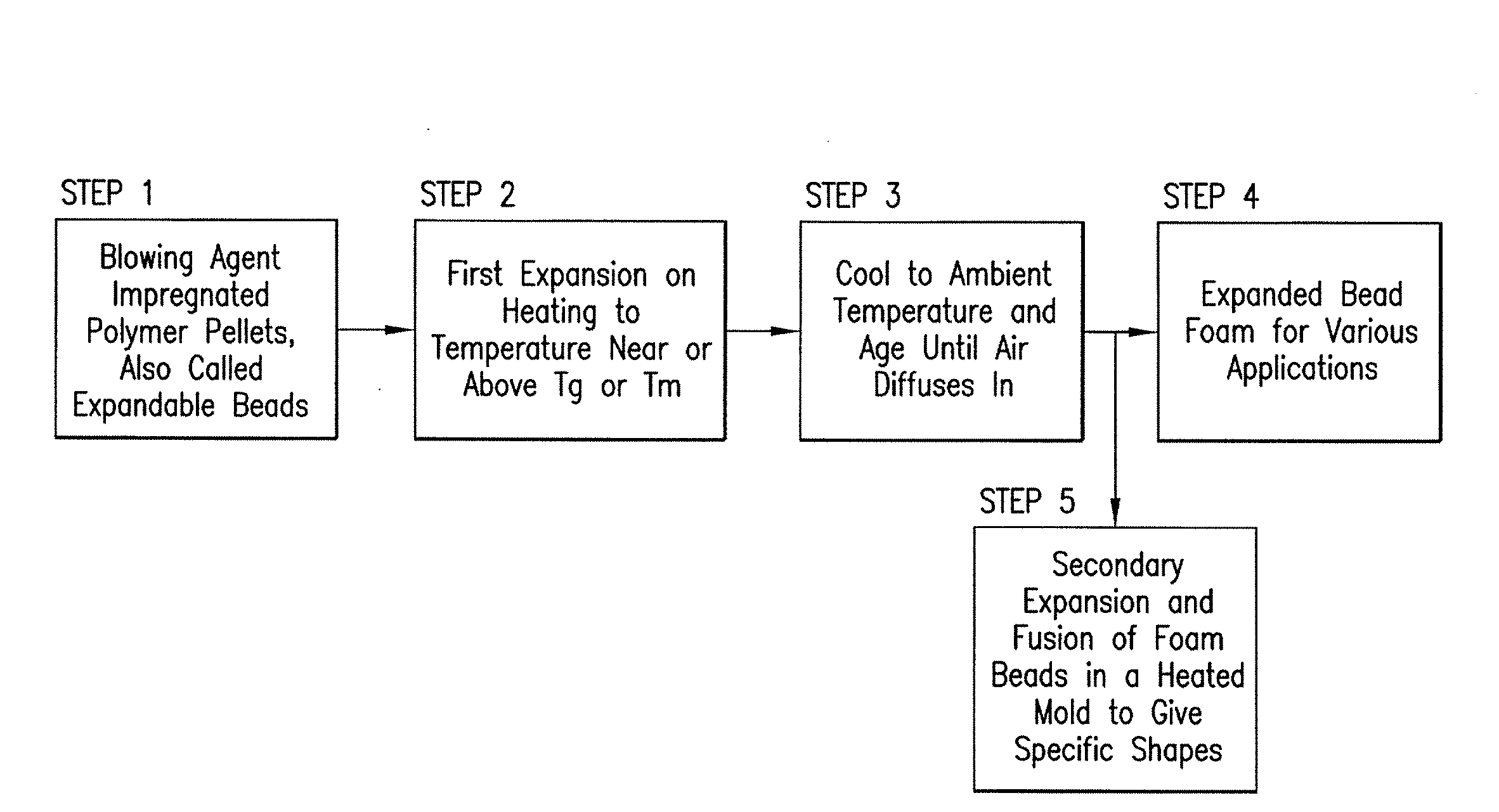

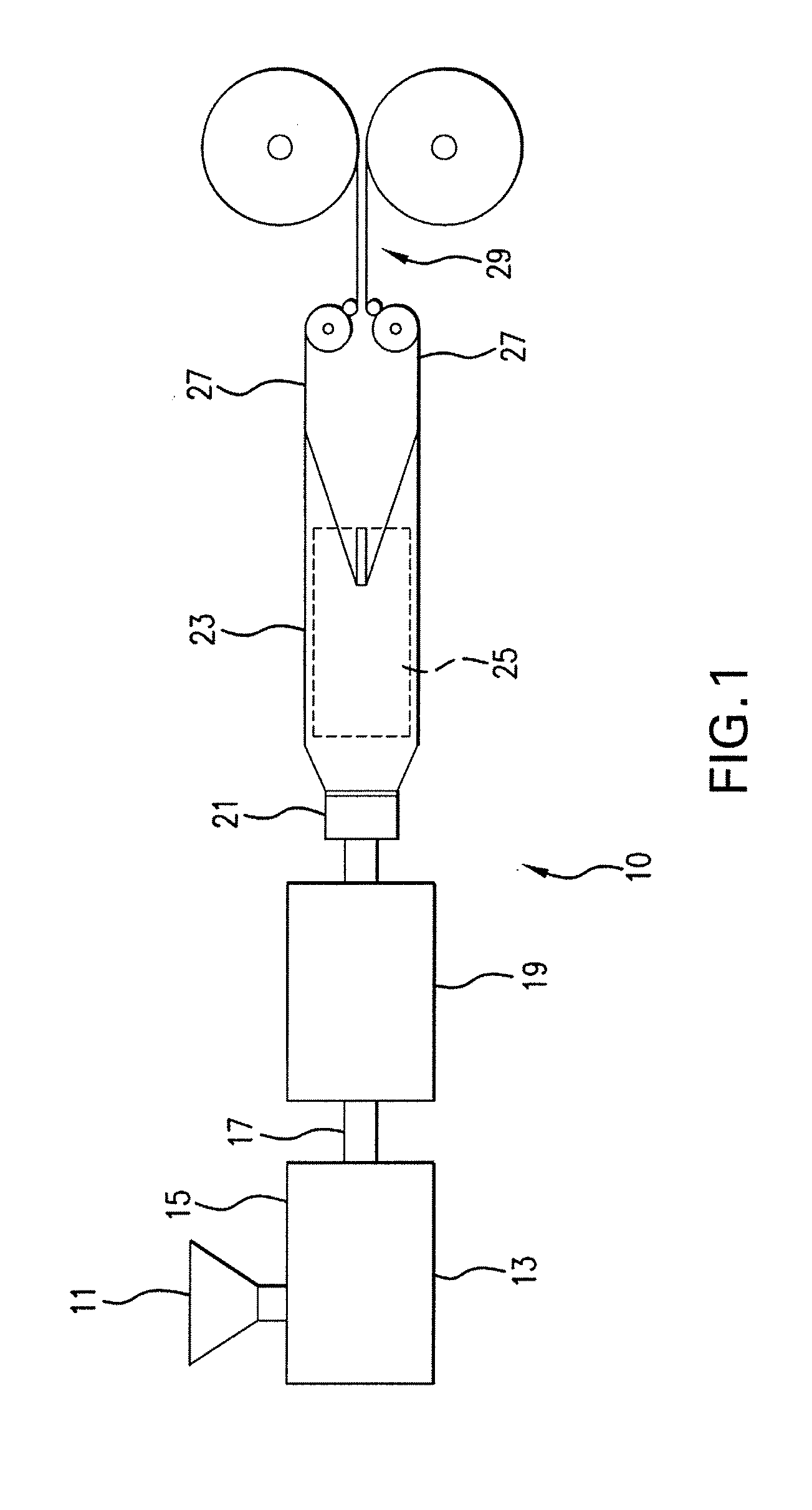

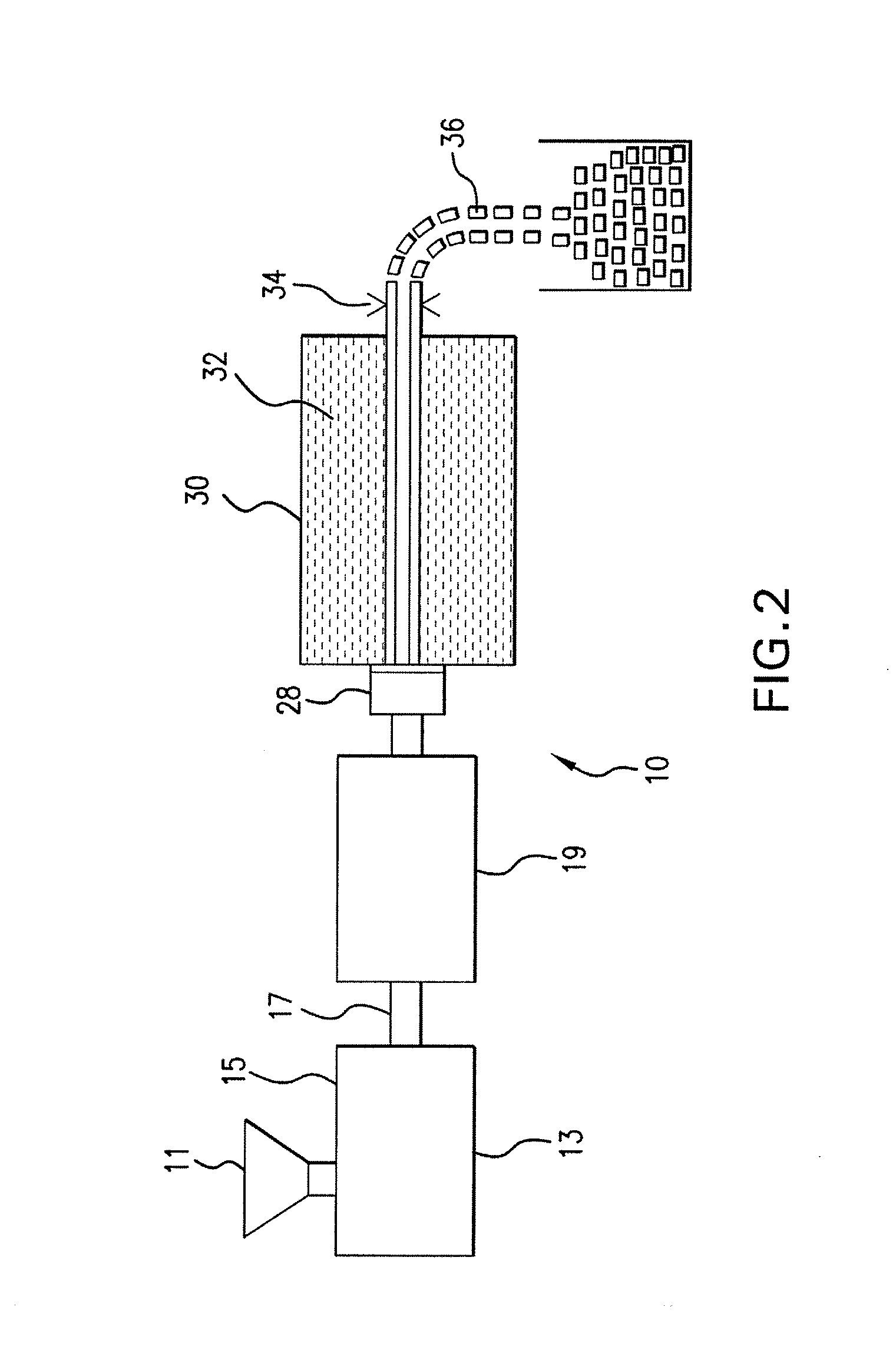

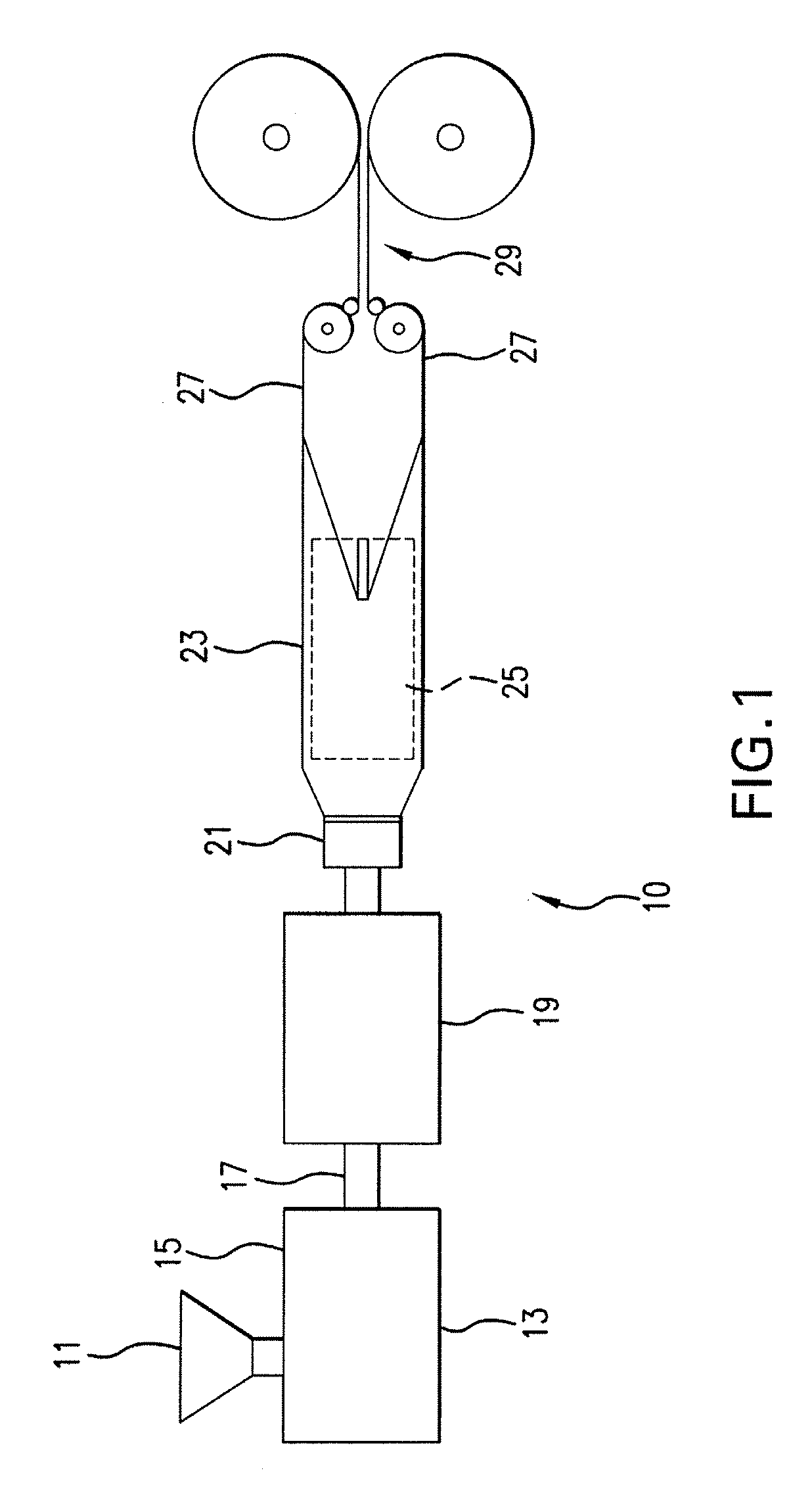

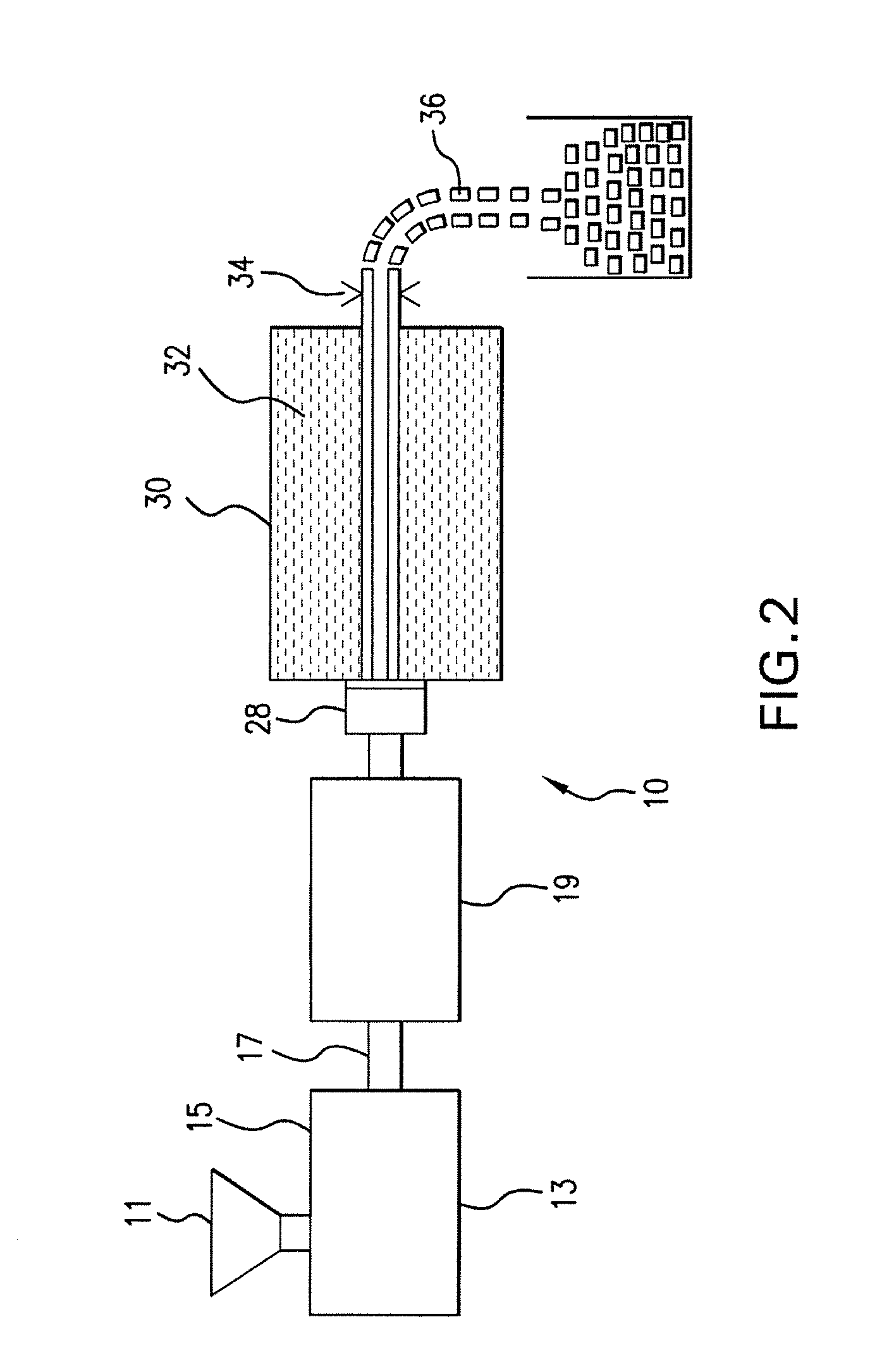

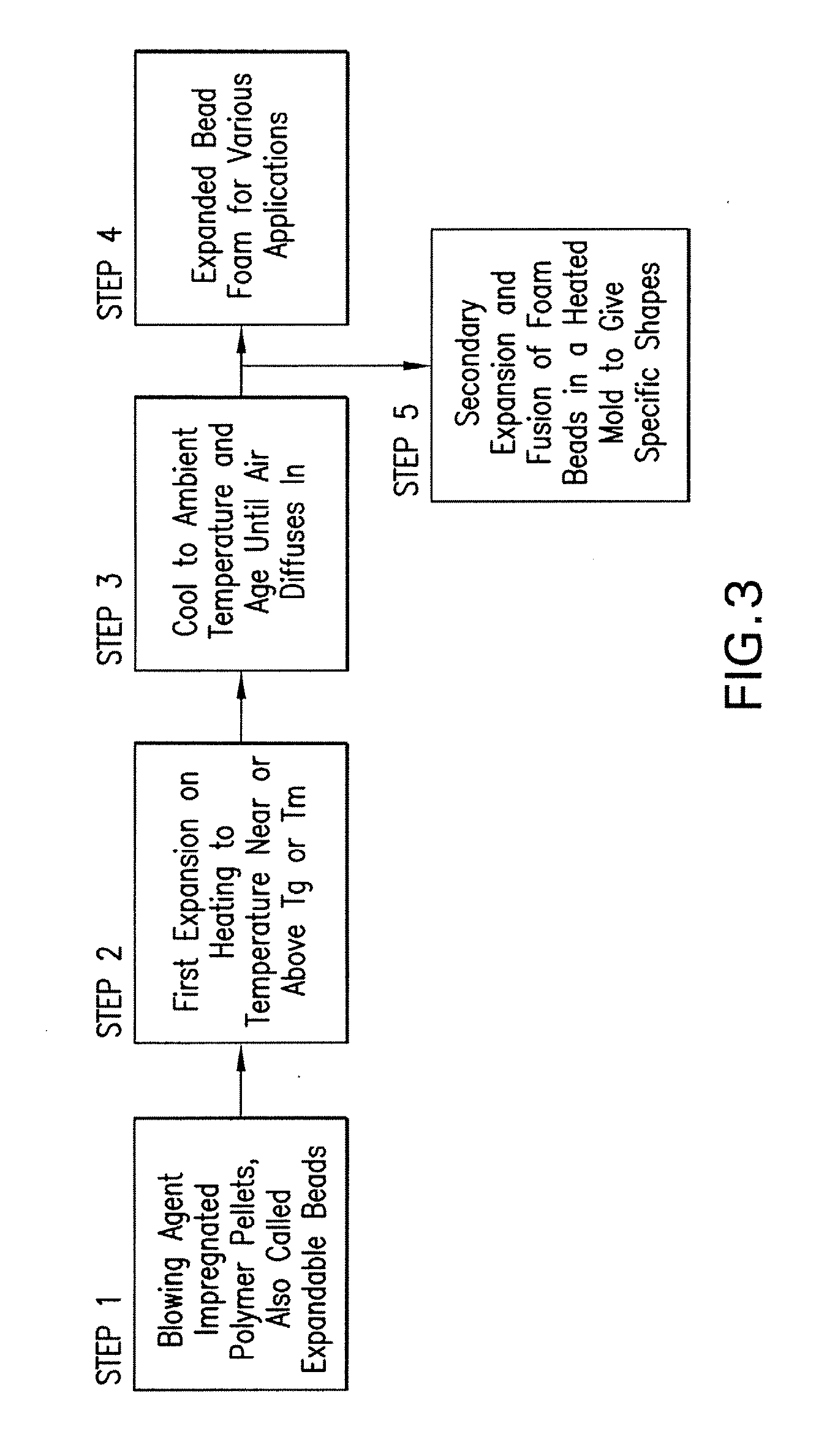

Expanded and extruded thermoplastic foams made with methyl formate-based blowing agents

Low density expanded and extruded thermoplastic polymer foams are obtained using an environmentally benign non-VOC and non-HAP methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC and / or non-HAP). The co-blowing agent is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s), water or any combination thereof), or a chemical co-blowing agent, or combinations thereof The thermoplastic polymer foam can be an alkenyl aromatic polymer foam, e.g. a polystyrene foam. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as insulation boards and building materials. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

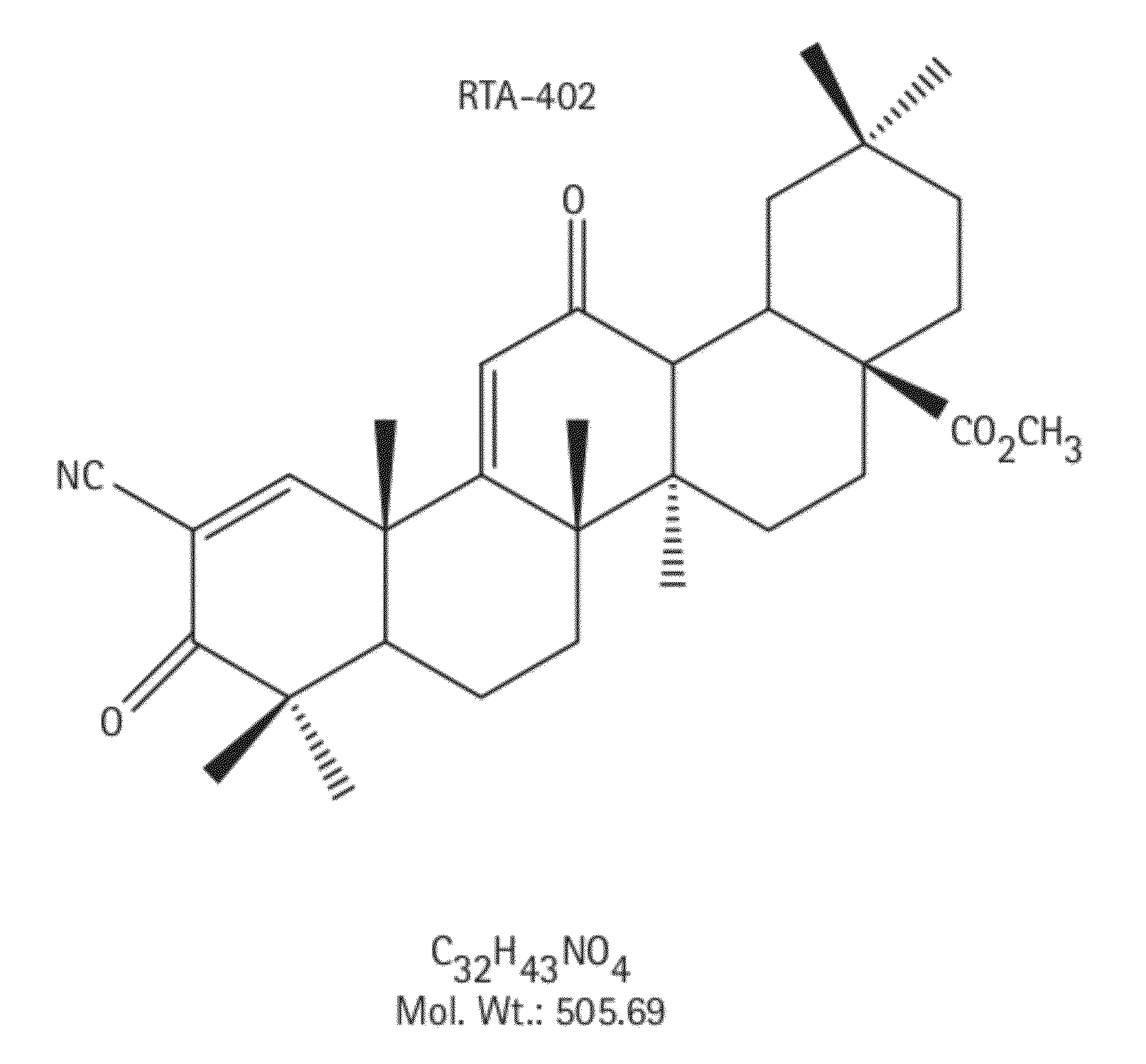

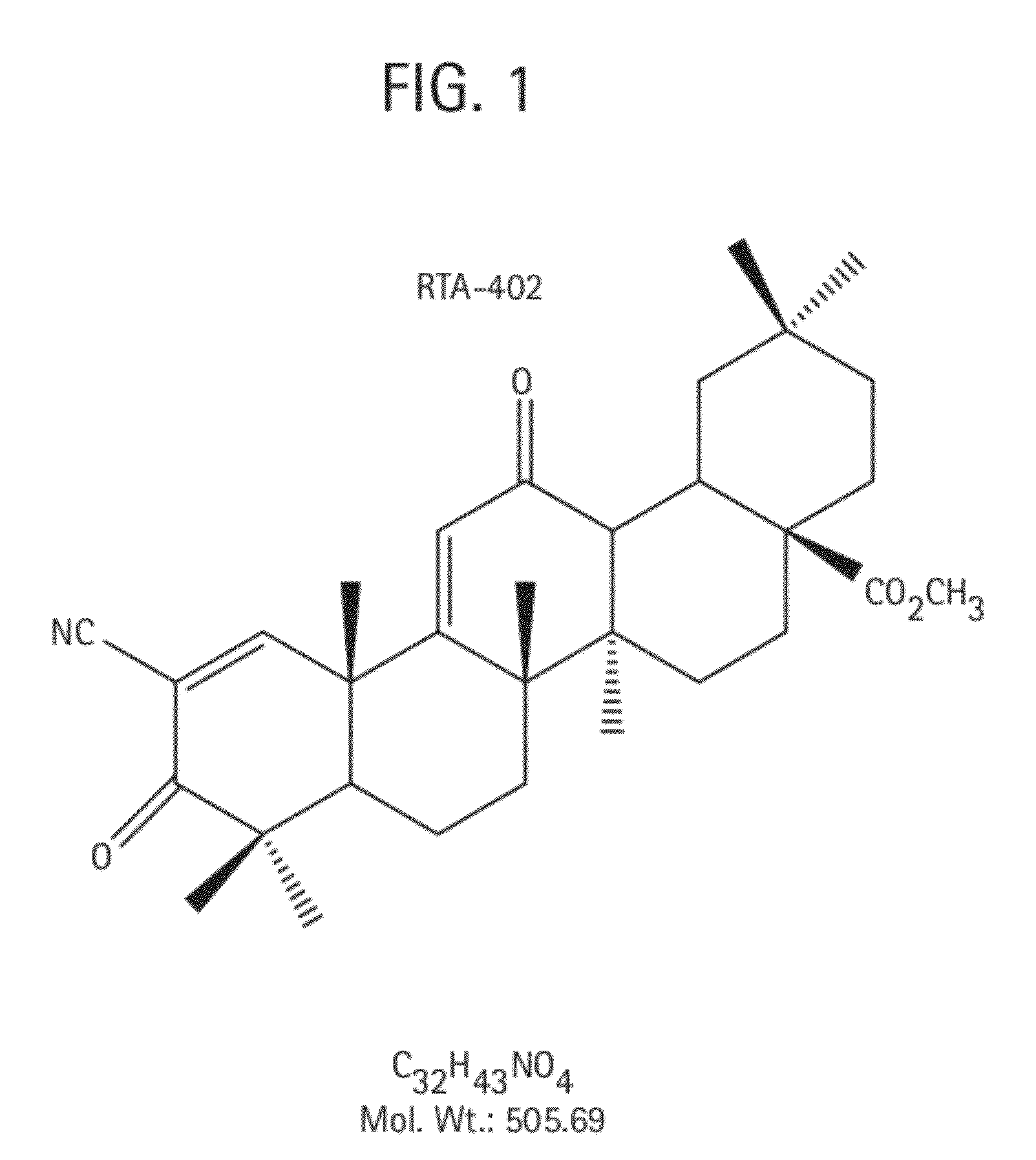

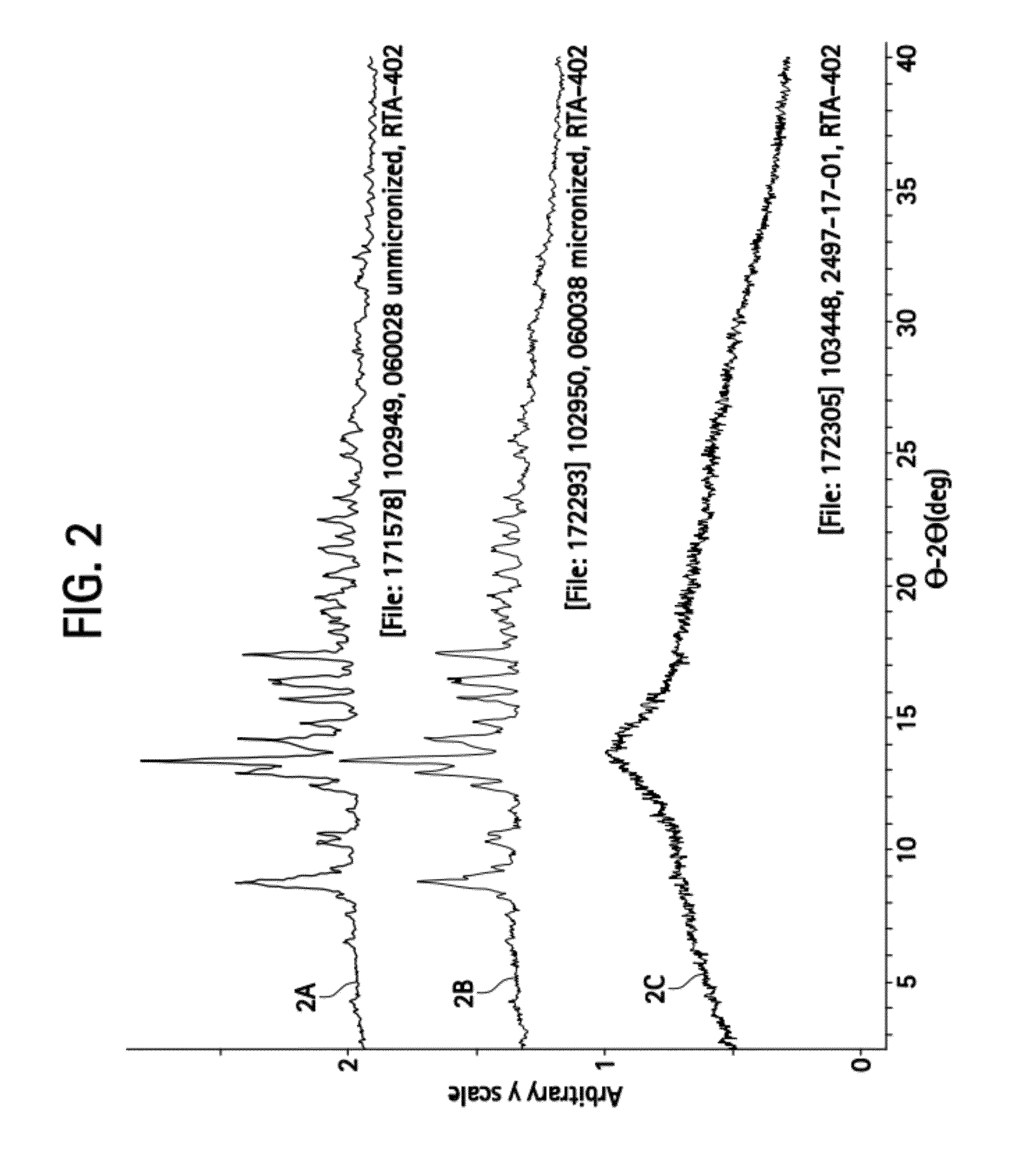

Novel forms of cddo methyl ester

A triterpenoid compound, methyl 2-cyano-3,12-dioxoleana-1,9(11)-dien-28-oate (CDDO methyl ester), has a non-crystalline, glassy solid form and a non-hydrous crystalline form that can prepared, for example, from a saturated methanol solution. The glassy form displays an enhanced bioavailability over the non-hydrous crystalline form. Each form of CDDO methyl ester is a superior candidate for use, typically in solid dosage form, for treating a variety of disease states, generally associated with inflammation.

Owner:REATA PHARM HLDG LLC

Process and catalysts for the oxidation of methanol and/or ethanol

InactiveUS20050059839A1Good choiceIncrease surface densityOrganic compound preparationCarboxylic acid esters preparationOxygenProcess conditions

A process for oxidation of methanol, ethanol, or a mixture of methanol and ethanol comprising contacting the methanol and / or ethanol with an oxygen-containing gas and a supported catalyst comprising one or more platinum group oxides. The process conditions and / or catalyst may be selected to as to selectively produce methyl formate from methanol or diethoxyethane from ethanol. The invention also includes certain novel supported platinum group metal oxide catalysts. Preferred catalysts include one or more ruthenium oxides.

Owner:RGT UNIV OF CALIFORNIA

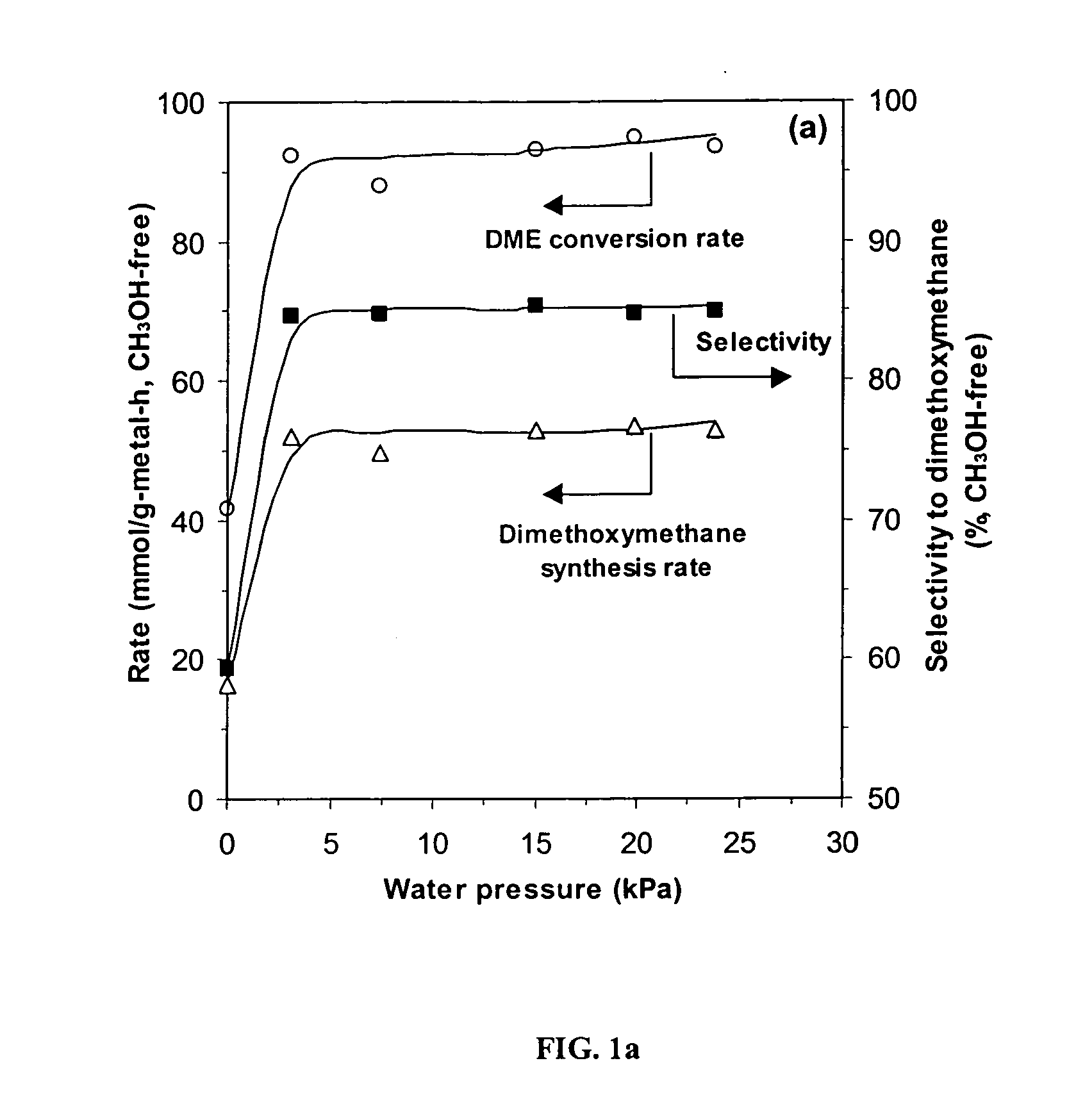

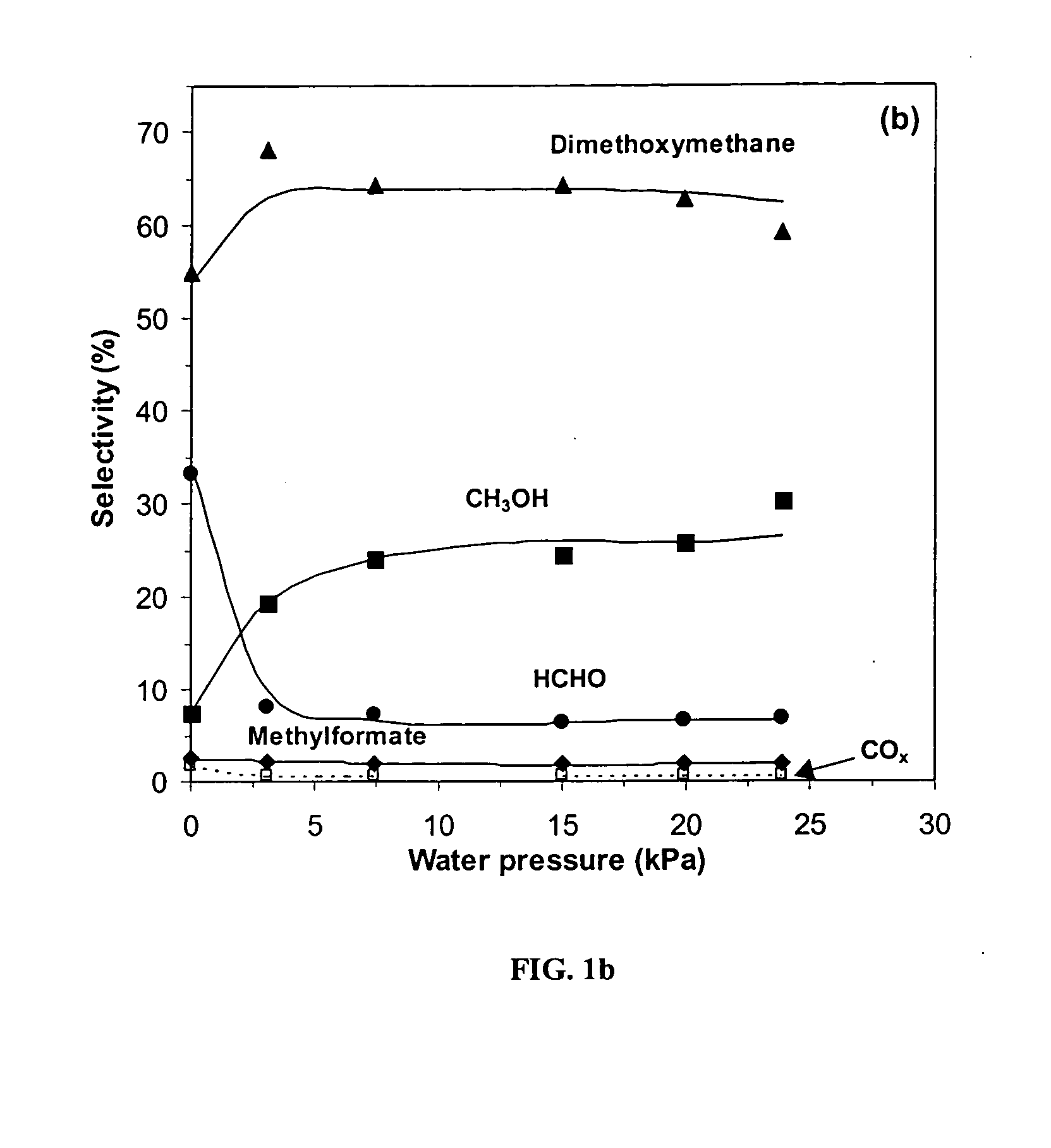

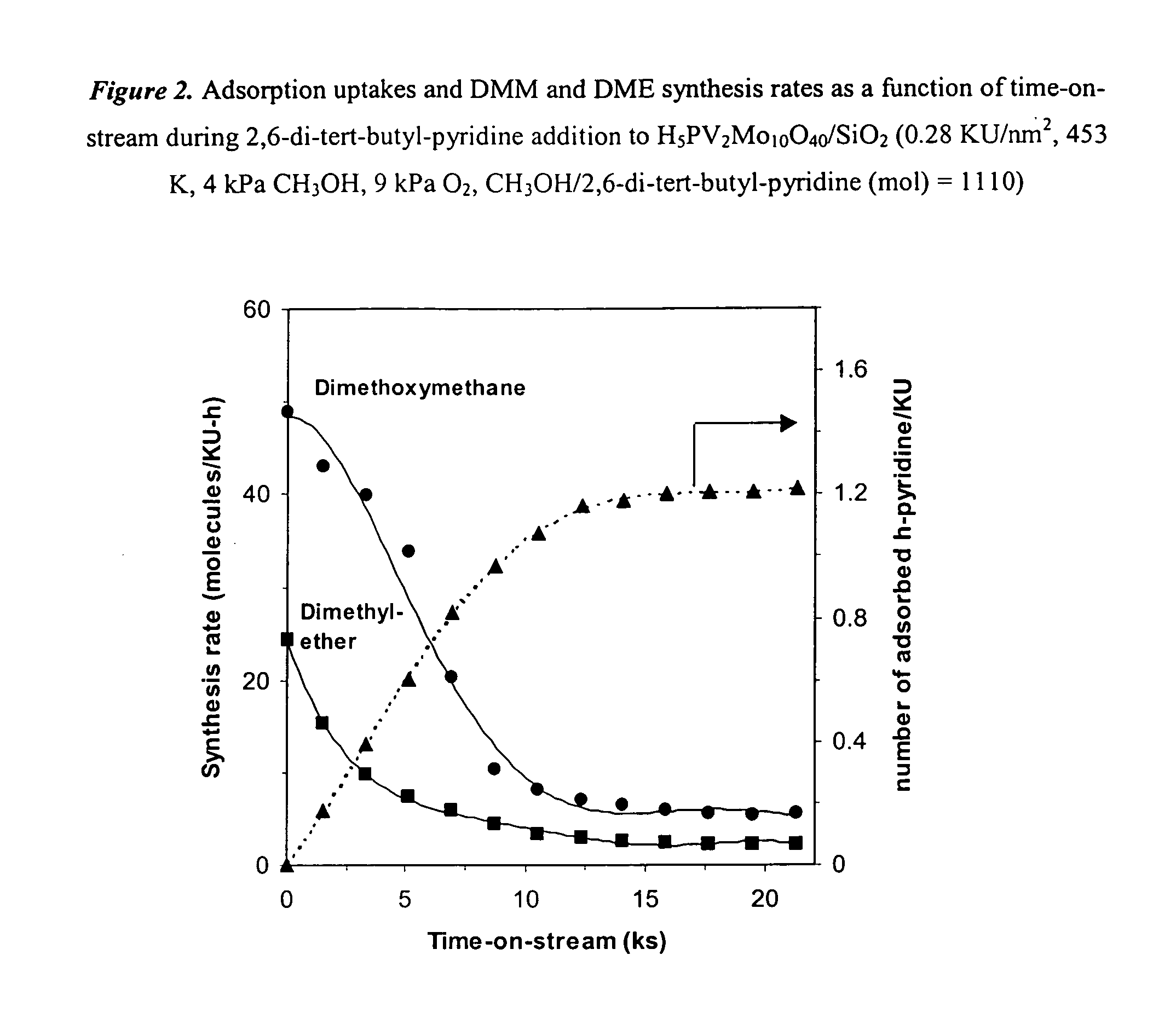

Oxidation of methanol and/or dimethyl ether using supported molybdenum-containing heteropolyacid catalysts

InactiveUS20050154226A1Reduce productionPromote conversionOrganic compound preparationPreparation by carbon monoxide or formate reactionOxygenDimethoxymethane

Feeds comprising methanol, dimethyl ether or a mixture of the two are oxidized by contacting the feed with an oxygen-containing gas and a supported heteropolyacid catalyst containing molybdenum or molybdenum and vanadium. The primary products are methylal (dimethoxymethane) and methyl formate. Production of dimethyl ether from methanol can be inhibited by partial deactivation of acid sites on the Keggin catalyst.

Owner:REGENTS OF CALIFORNIA UNIV OF THE +1

High content environmental protection alcohol ether fuel for vehicle

InactiveCN101100618AHigh calorific valueImprove thermal efficiencyLiquid carbonaceous fuelsIsobutanolNitromethane

A high-content environmental-protecting alcohol ether fuel for vehicle consists of additives and methanol or alcohol 75-87 proportion. The additives contain methanol, alcohol, isopropyl alcohol, isobutanol, dimethylcuprate, n-amyl alkyl, dipropyl, cyclopentane, nitro-methane, dimethyl benzene, pinecone oil, cyclopentadienyl, poly-isobutylene, propane diamine, carbomethoxy formate, dimethoxyester carbonate, natural gasoline, hydrocarbon solvent oil, diisopropyl ester, dimethoxy-methane, petroleum ether, methyl tert-amyl ether, tert-amyl tert-butyl ether, lauryl phenol poly-ethenoxy ether, anti-static agent, metal-corrosive inhibitor, rubber plastic swelling inhibitor and anti-oxidant. It's clean and universal; it has excellent burning stability, shock resistance and dynamic character and less oil consumption.

Owner:鲁家政

Expanded and extruded polyolefin foams made with methyl formate-based blowing agents

Expanded and extruded polyolefin foams are obtained using environmentally benign non-VOC methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC), which is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s) or any combination thereof), or a chemical co-blowing agent, or combinations thereof. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The polymer foam can include polyethylene, polypropylene or a combination thereof. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as for insulation and protective cushioning. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

Expanded and extruded biodegradable and reduced emission foams made with methyl formate-based blowing agents

Expanded and extruded biodegradable polymer foams are obtained using biodegradable polymers and environmentally benign non-VOC methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC), which is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s), water or any combination thereof), or a chemical co-blowing agent, or combinations thereof. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The polymer foam can include a biodegradable polymer or its blends with other biodegradable polymers or conventional (non-biodegradable) polymers. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as for insulation and protective cushioning. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

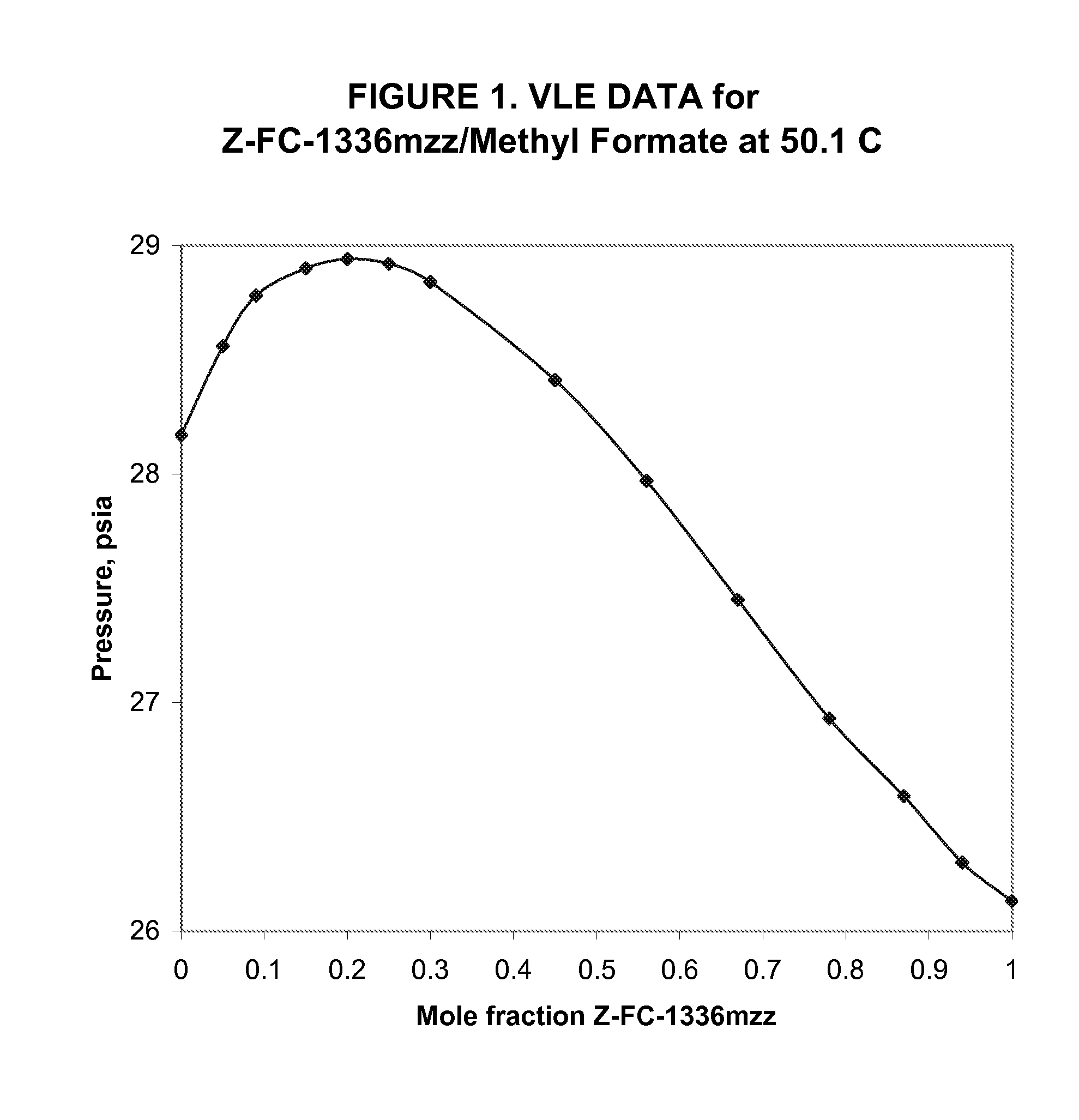

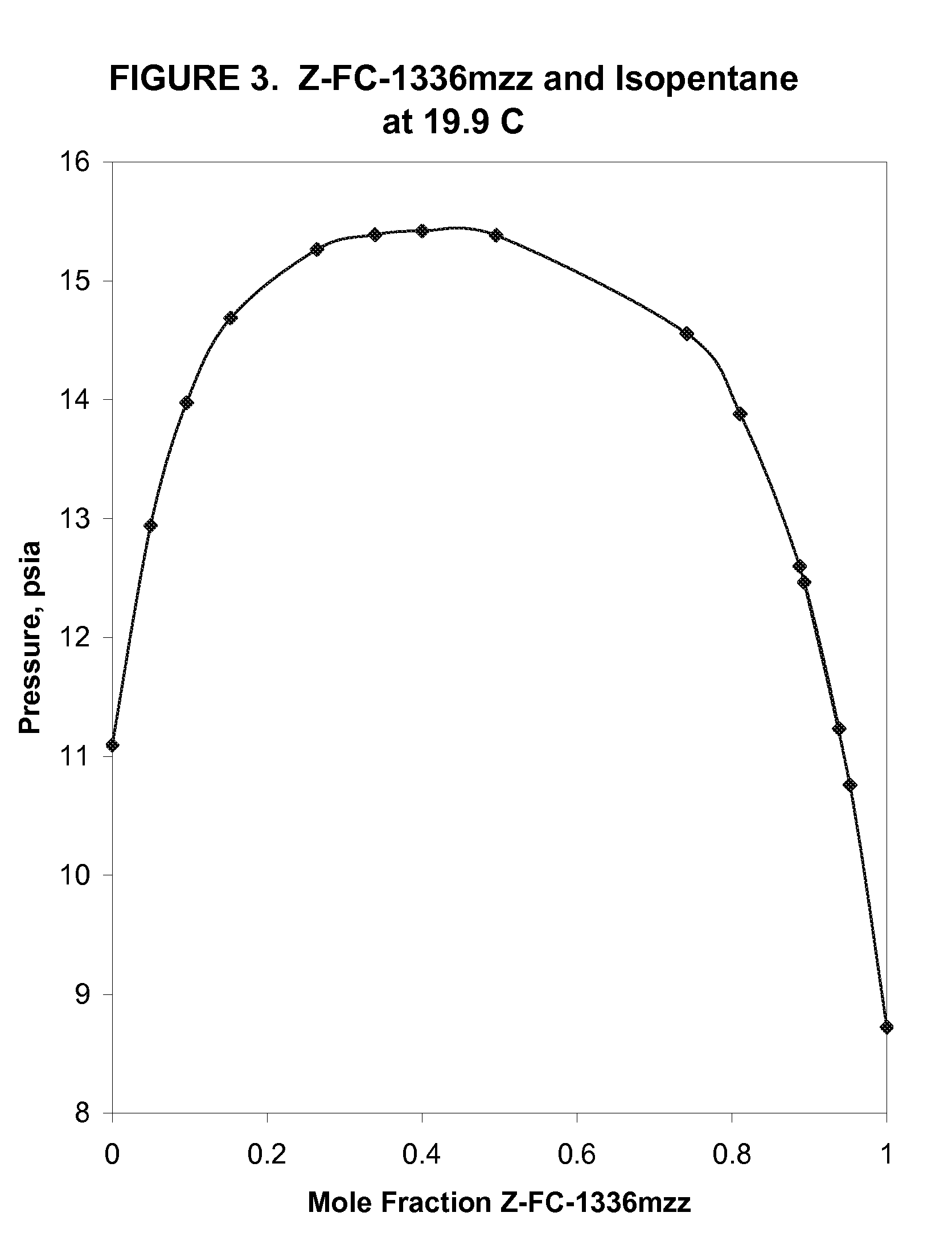

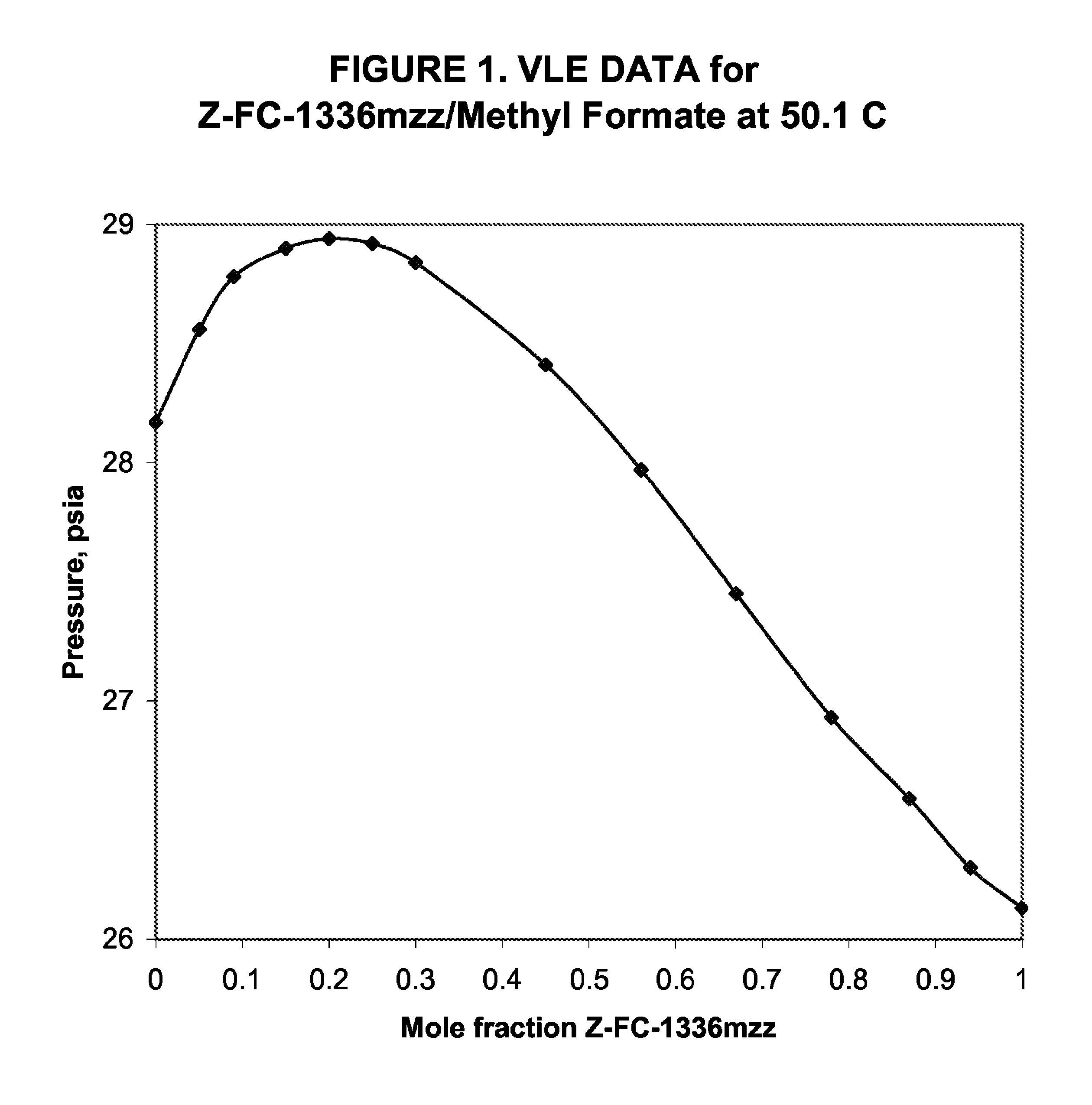

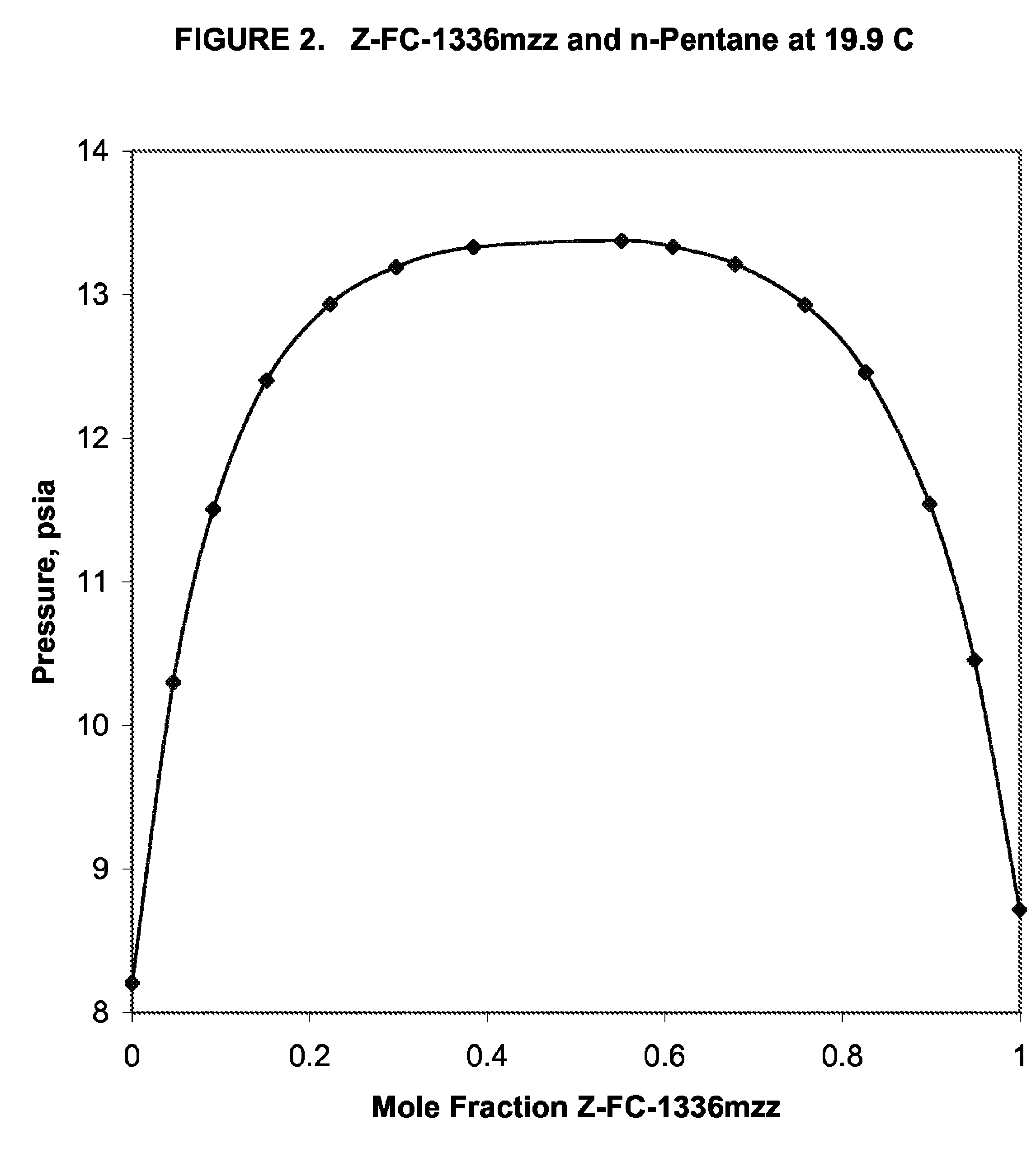

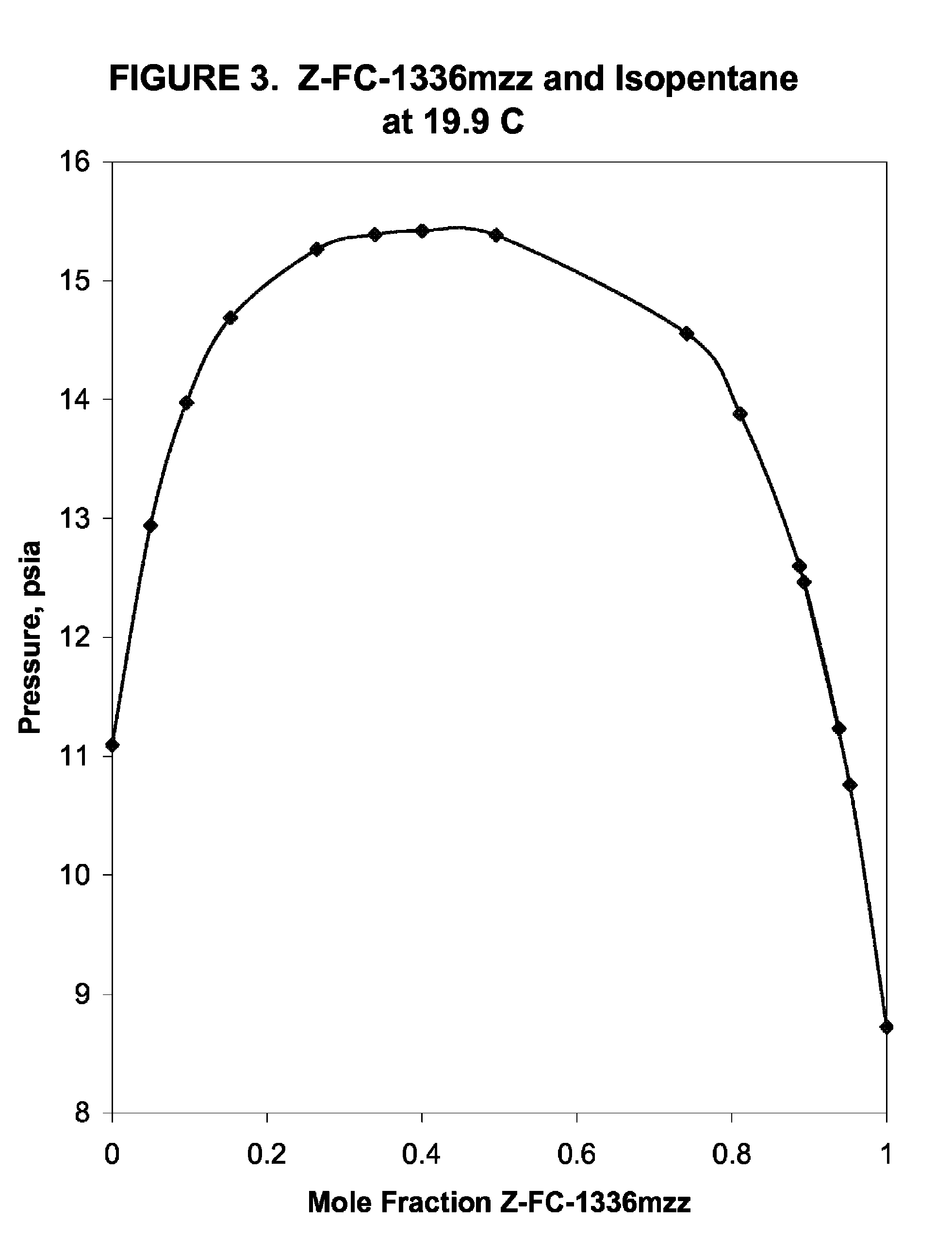

Azeotropic and azeotrope-like compositions of z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

UV curable coating composition

The present invention is directed to a non-aqueous composition curable by UV radiation broadly comprising a mixture of two UV curable urethane acrylates. The invention is also directed to a coating process using such composition. One of the urethane acrylates is the reaction product of an isocyanate and a specific OH functional lactone ester (meth)acrylate. The other urethane acrylate is the reaction product of an isocyanate and a specific hydroxy functional (meth)acrylate.

Owner:ALLNEX NETHERLANDS BV

Azeotropic and azeotrope-like compositions of Z-1,1,1,4,4,4-hexafluoro-2-butene

Azeotropic or azeotrope-like compositions are disclosed. The azeotropic or azeotrope-like compositions are mixtures of Z-1,1,1,4,4,4-hexafluoro-2-butene with methyl formate, pentane, 2-methylbutane, 1,1,1,3,3-pentafluorobutane, trans-1,2-dichloroethylene, 1,1,1,3,3-pentafluoropropane, dimethoxymethane, or cyclopentane. Also disclosed is a process of preparing a thermoplastic or thermoset foam by using such azeotropic or azeotrope-like compositions as blowing agents. Also disclosed is a process of producing refrigeration by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as solvents. Also disclosed is a process of producing an aerosol product by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as heat transfer media. Also disclosed is a process of extinguishing or suppressing a fire by using such azeotropic or azeotrope-like compositions. Also disclosed is a process of using such azeotropic or azeotrope-like compositions as dielectrics.

Owner:THE CHEMOURS CO FC LLC

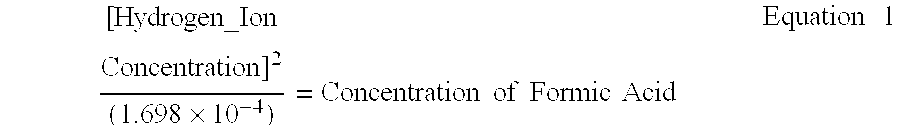

Low contaminant formic acid fuel for direct liquid fuel cell

InactiveUS7618725B2Improve performanceHigh power outputFuel cell auxillariesActive material electrodesAcetic acidFuel cells

A low contaminant formic acid fuel is especially suited toward use in a direct organic liquid fuel cell. A fuel of the invention provides high power output that is maintained for a substantial time and the fuel is substantially non-flammable. Specific contaminants and contaminant levels have been identified as being deleterious to the performance of a formic acid fuel in a fuel cell, and embodiments of the invention provide low contaminant fuels that have improved performance compared to known commercial bulk grade and commercial purified grade formic acid fuels. Preferred embodiment fuels (and fuel cells containing such fuels) including low levels of a combination of key contaminants, including acetic acid, methyl formate, and methanol.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

InactiveUS20030050372A1Antifouling/underwater paintsOther chemical processesPolymer scienceDiethylene glycol

The addition of at least about 30 weight percent of diethylene glycol (DEG) monobenzoate or dipropylene glycol (DPG) monobenzoate to diethylene glycol (DEG) dibenzoate, which is a solid at 28° C., results in a mixture that is unexpectedly a liquid at this temperature. The resultant mixtures are effective plasticizers for aqueous polymer compositions, including adhesives and caulks.

Owner:EASTMAN SPECIALITIES HLDG CORP

Expanded and extruded polyolefin foams made with methyl formate-based blowing agents

Expanded and extruded polyolefin foams are obtained using environmentally benign non-VOC methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC), which is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s) or any combination thereof), or a chemical co-blowing agent, or combinations thereof. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The polymer foam can include polyethylene, polypropylene or a combination thereof. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as for insulation and protective cushioning. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

Polyurethane foam plastic and preparation method thereof

The invention relates to polyurethane foam plastic and a preparation method thereof, and belongs to the field of high molecular material. In the technology, methyl formate is used for replacing CFCs, HCFCs, HFCs, alkane, dichloromethane, water and other foaming agents, or methyl formate is used for being mixed with CFCs, HCFCs, HFCs, alkane, dichloromethane, water and the like to be used as a foaming agent for preparation of the polyurethane foam plastic.

Owner:上海抚佳精细化工有限公司 +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com