Patents

Literature

86 results about "Acetic acid product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A: Some household products that contain acetic acid include sealants, window cleaners containing vinegar, certain brands of dishwashing liquids and mildew stain removers. The most common household product that contains acetic acid is vinegar, which is produced by fermenting fruit or other items that contain sugar.

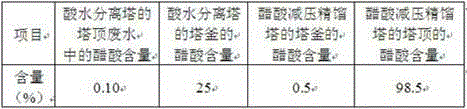

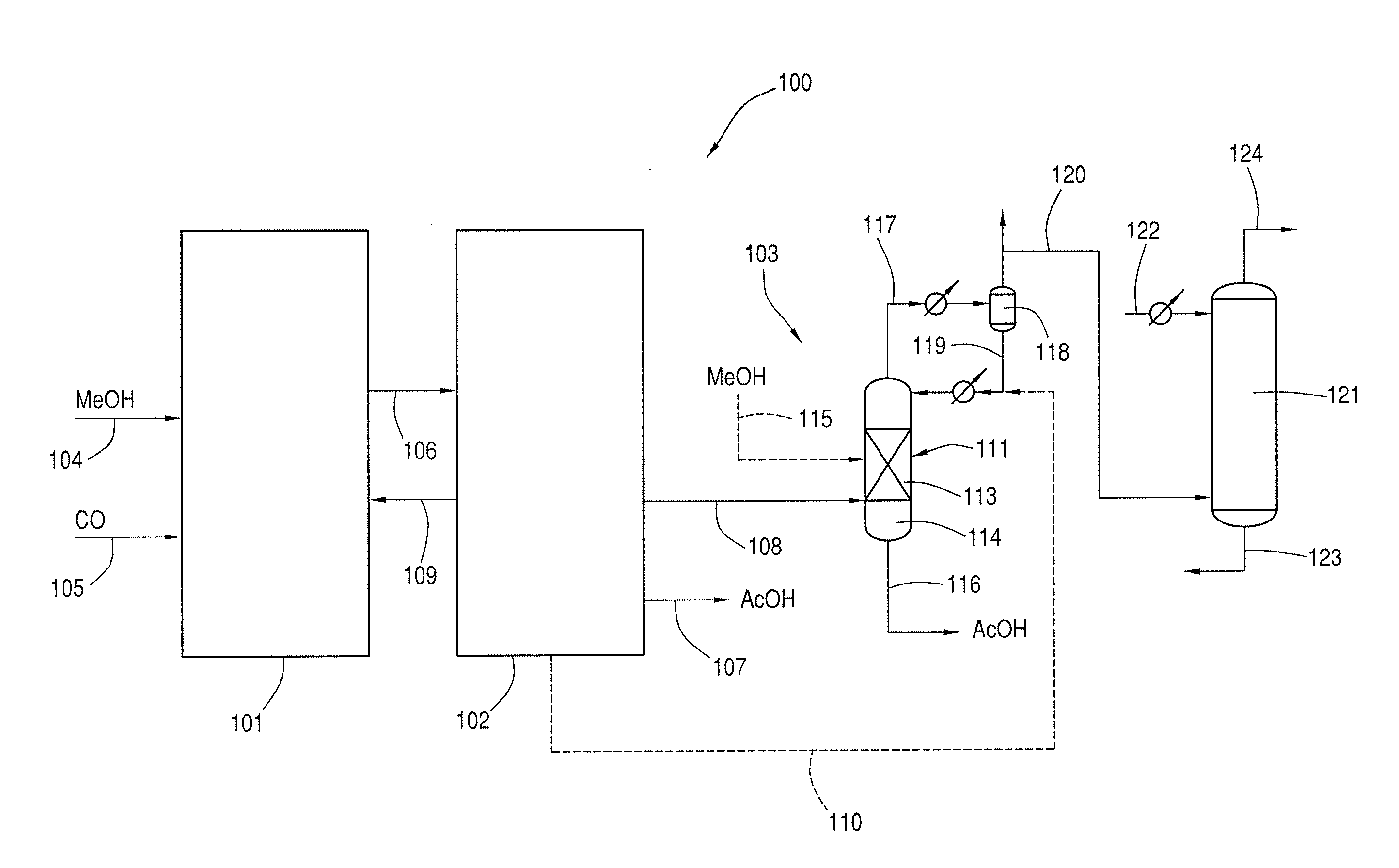

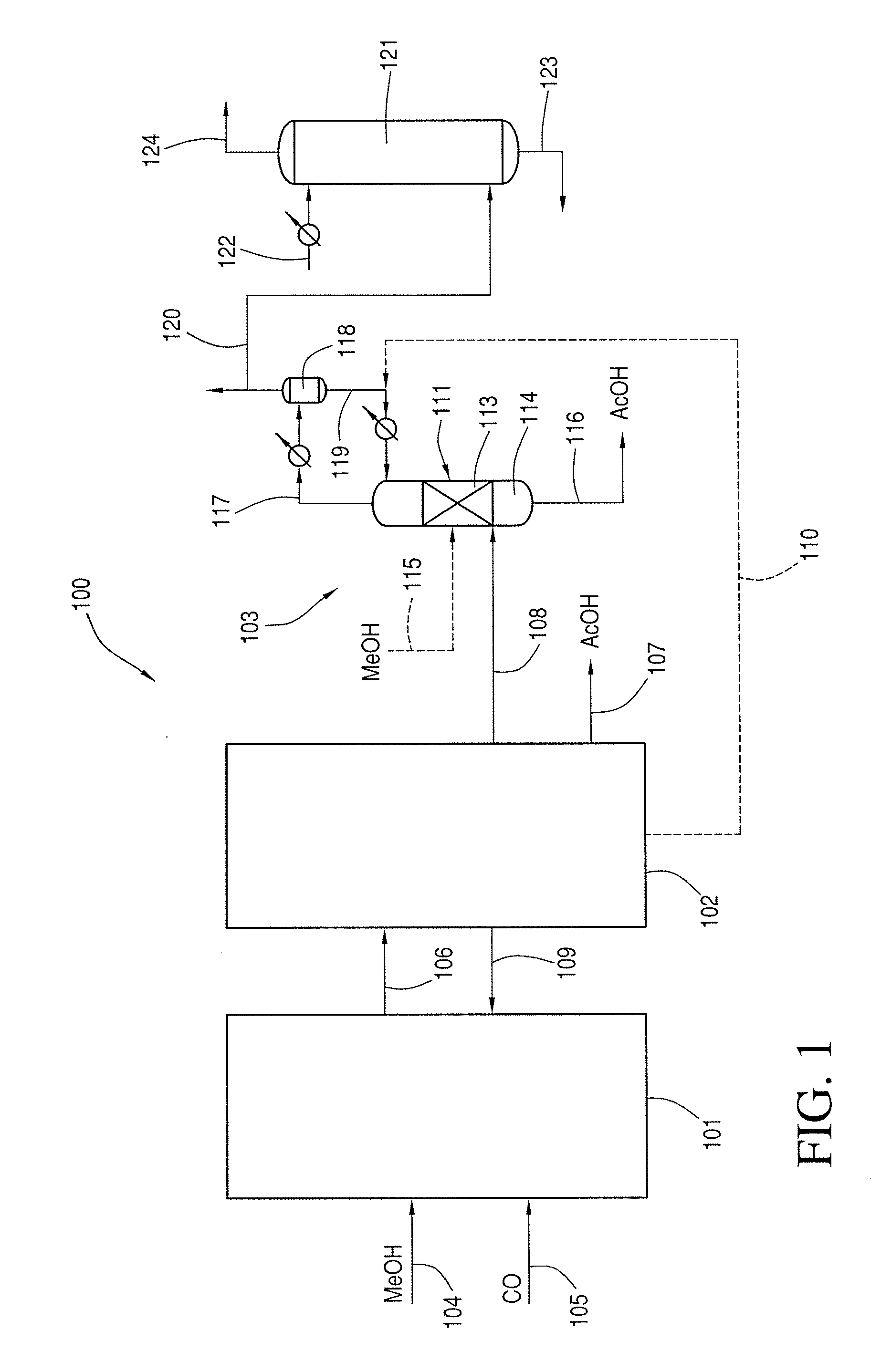

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

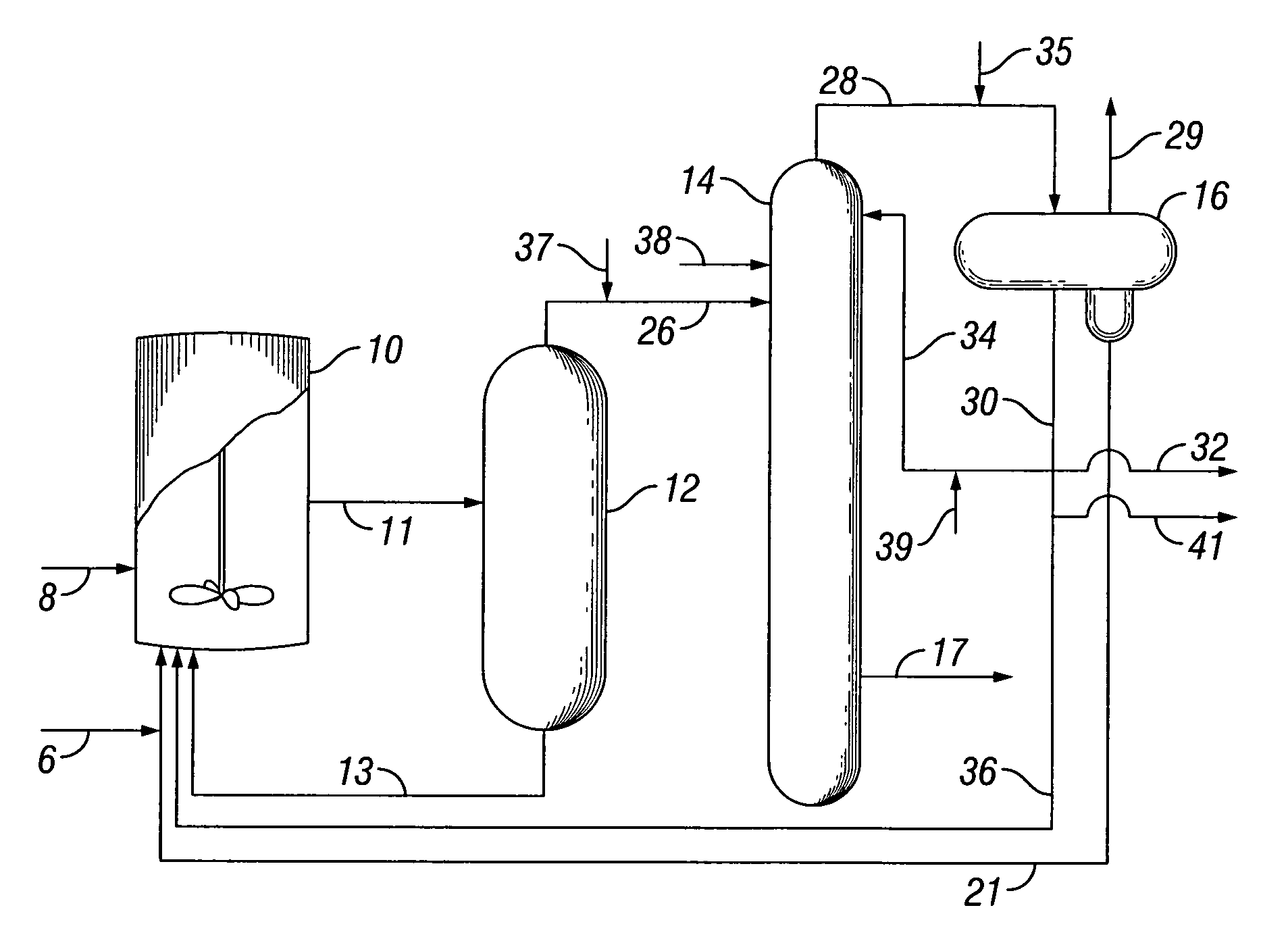

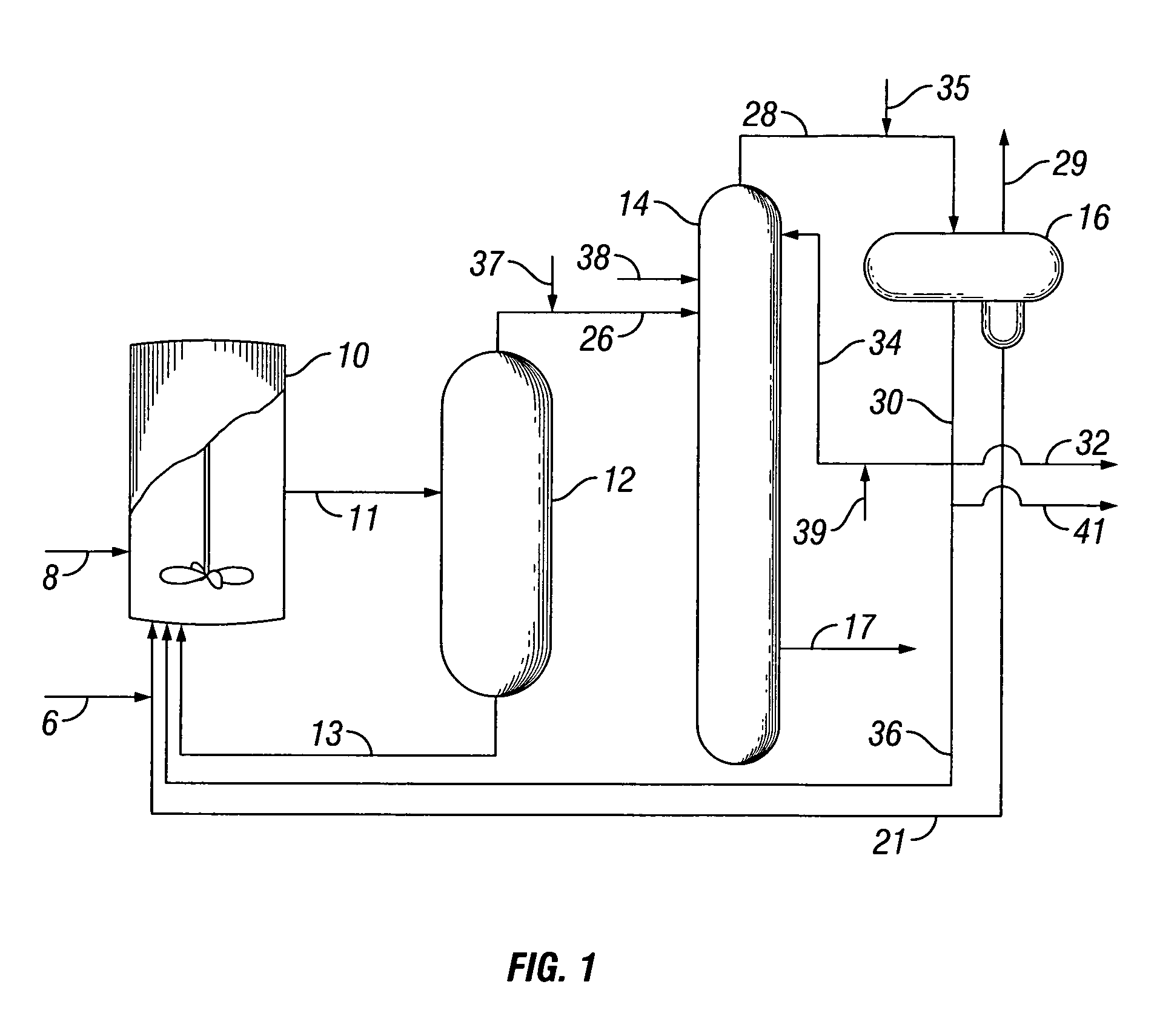

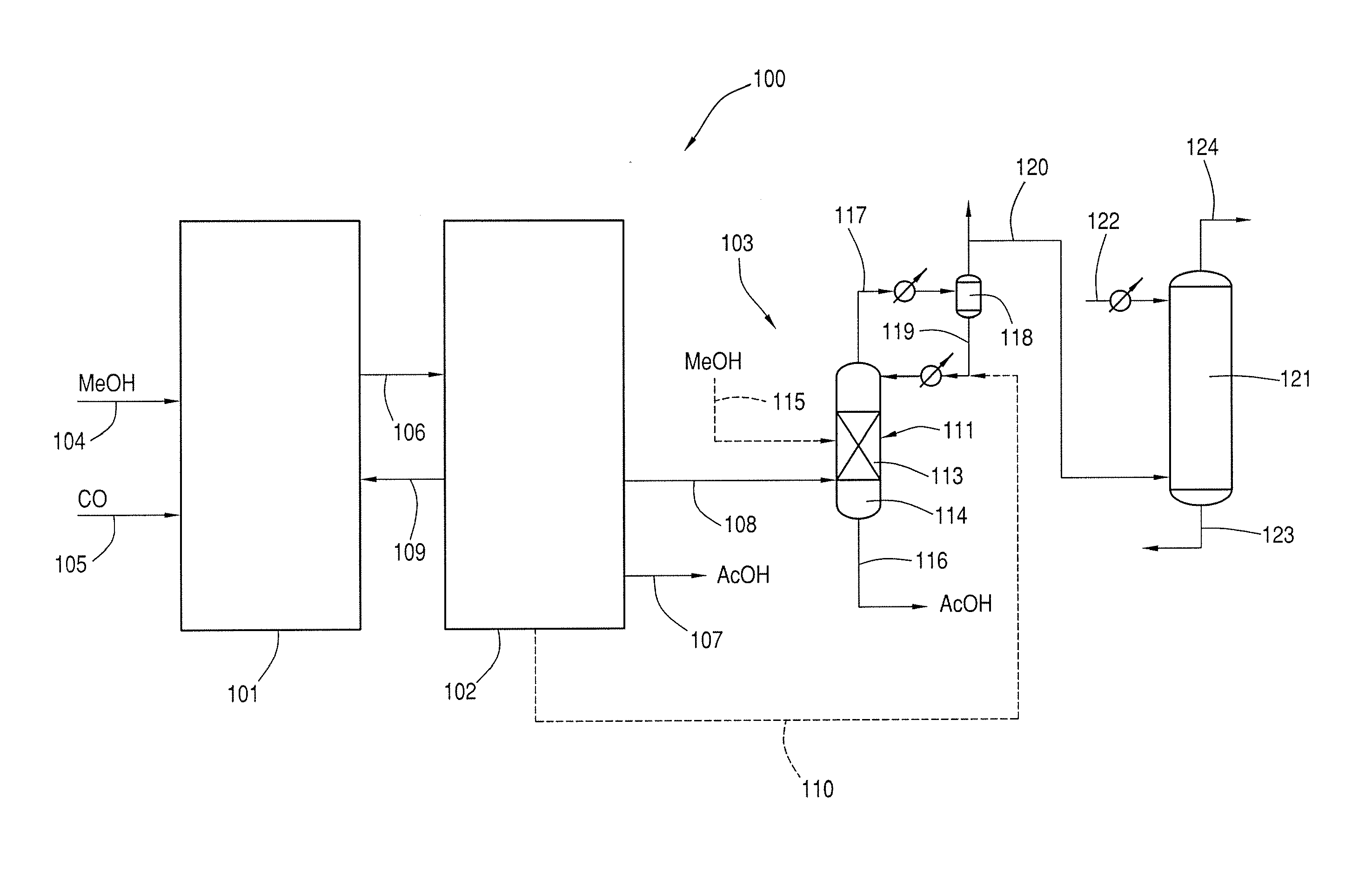

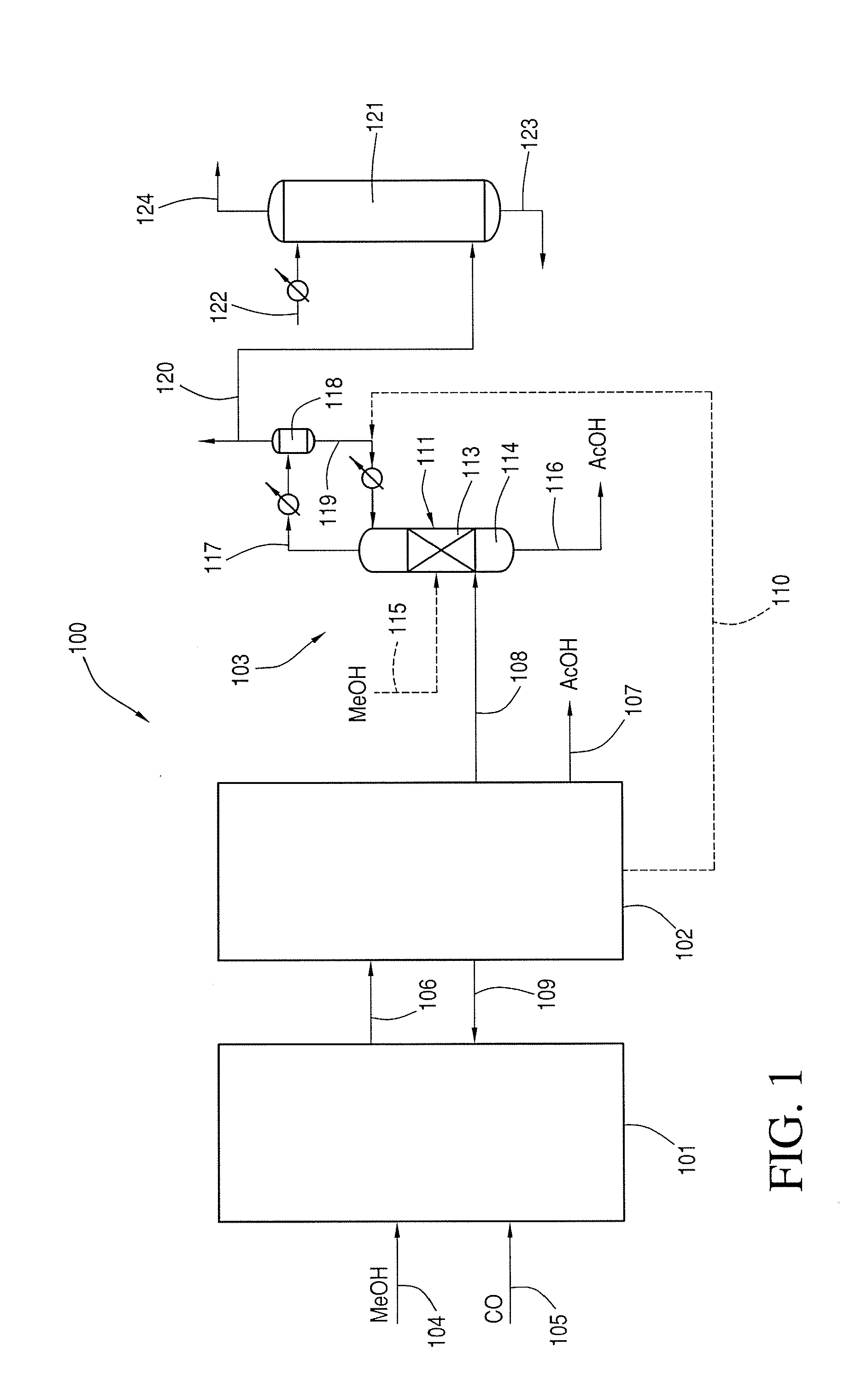

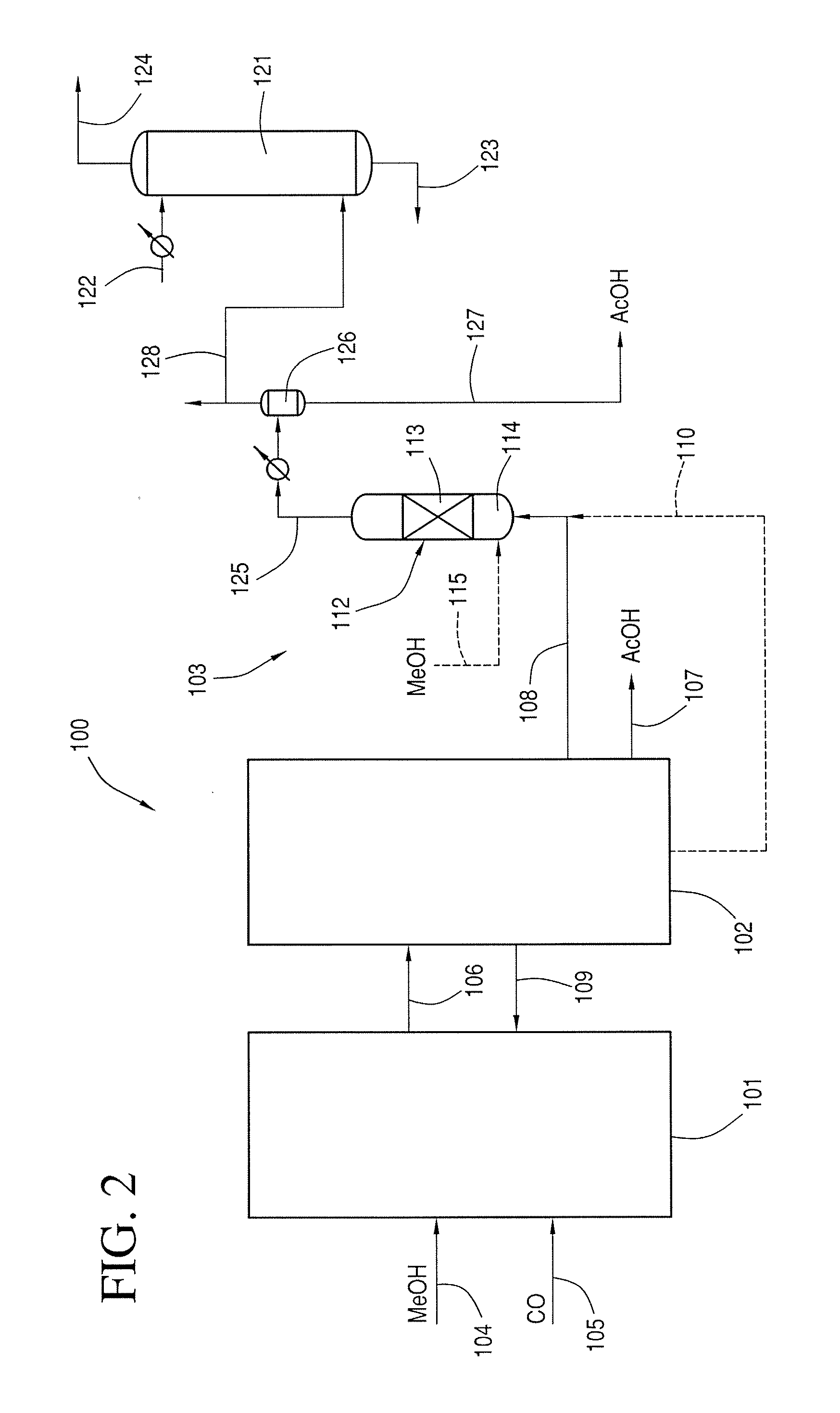

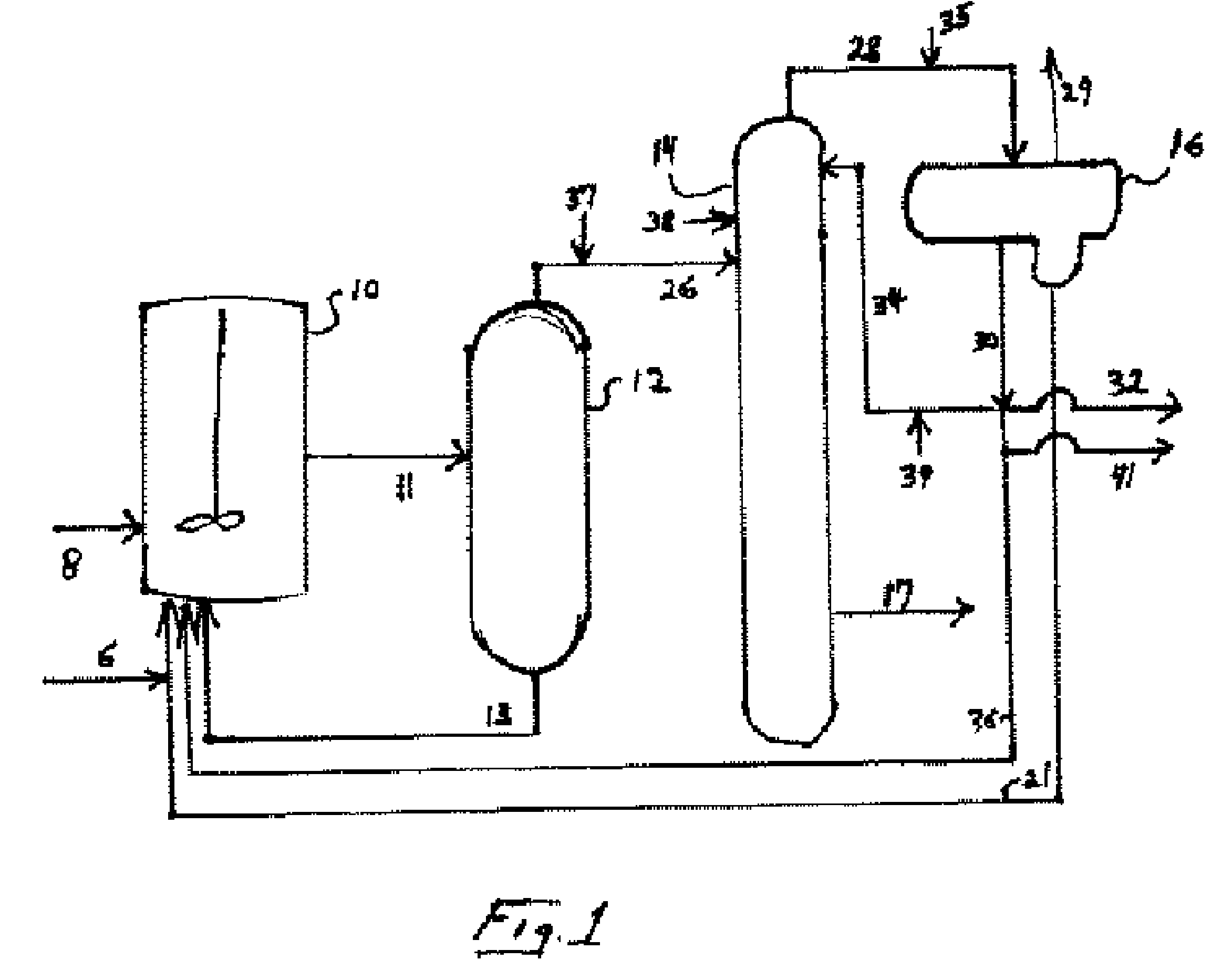

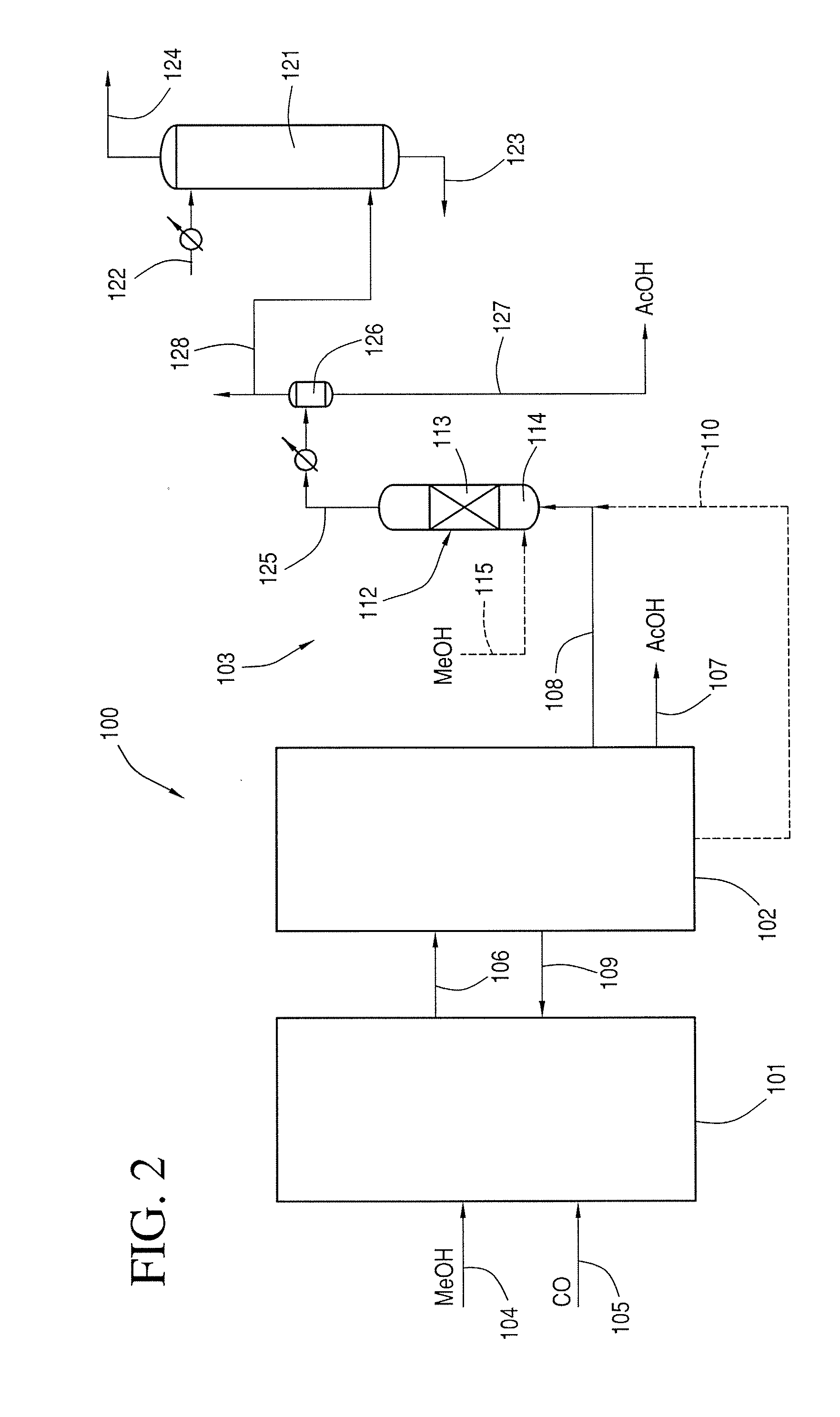

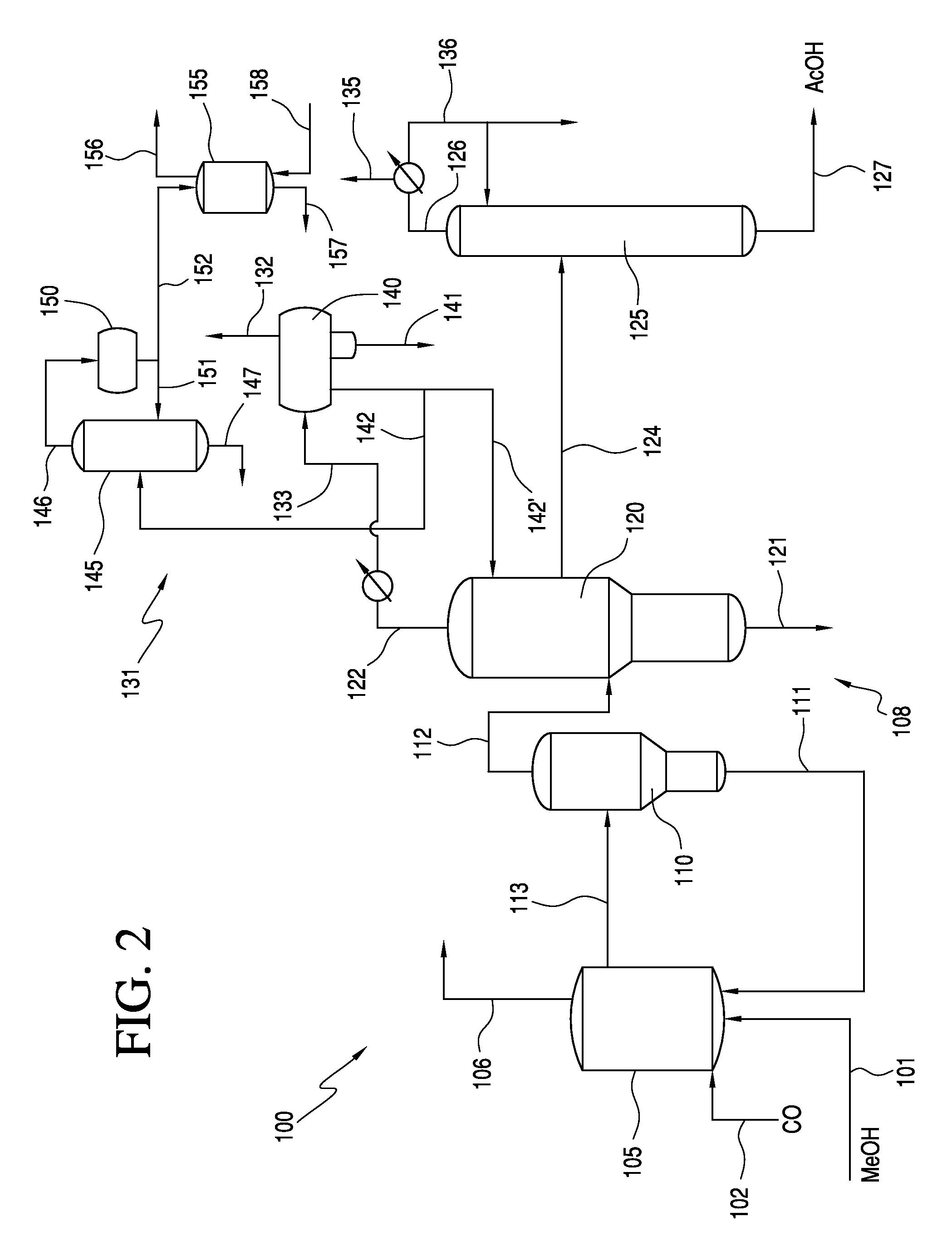

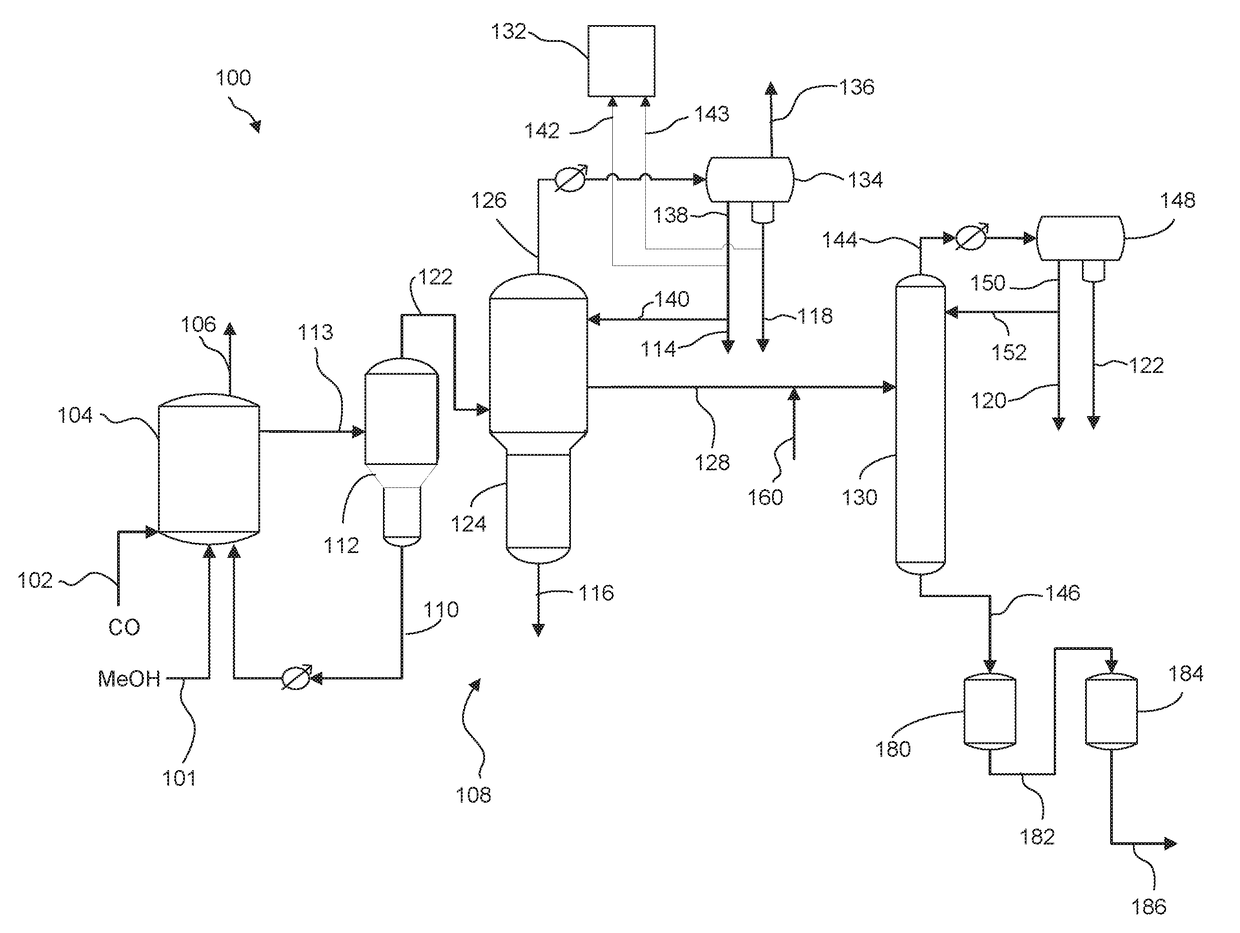

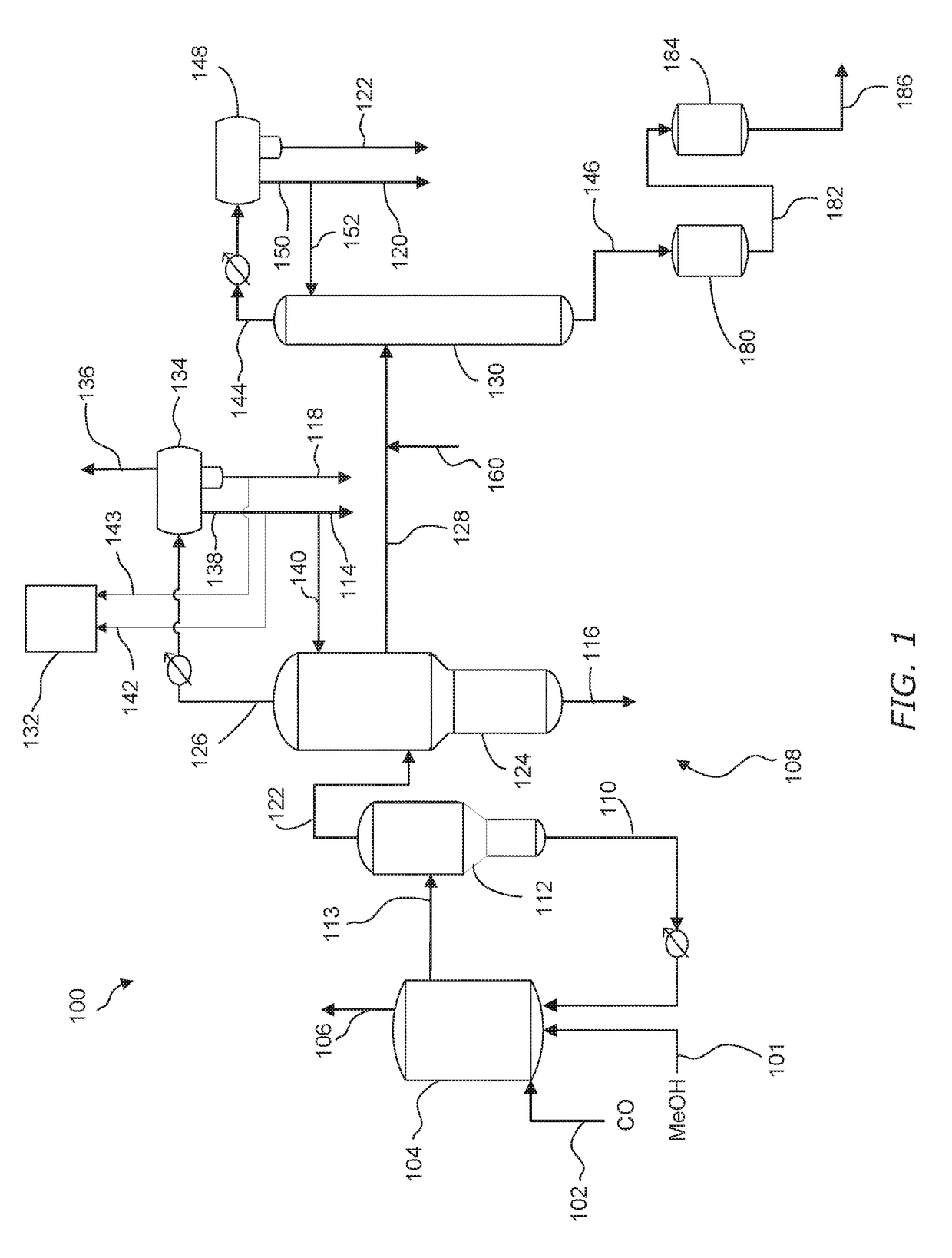

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

Distillation process

ActiveUS7884241B2Avoid condensationAvoid corrosionOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateDistillation method

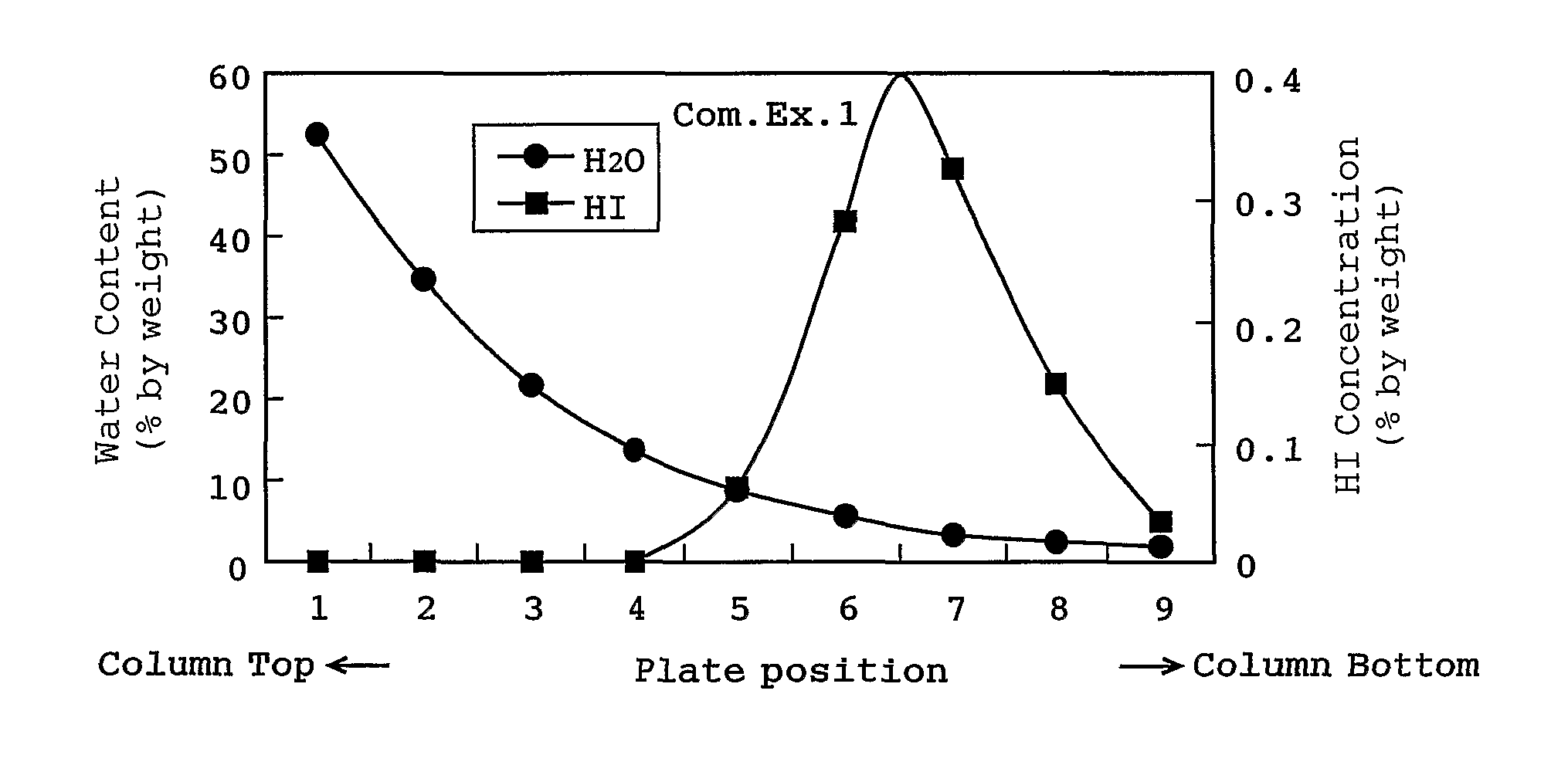

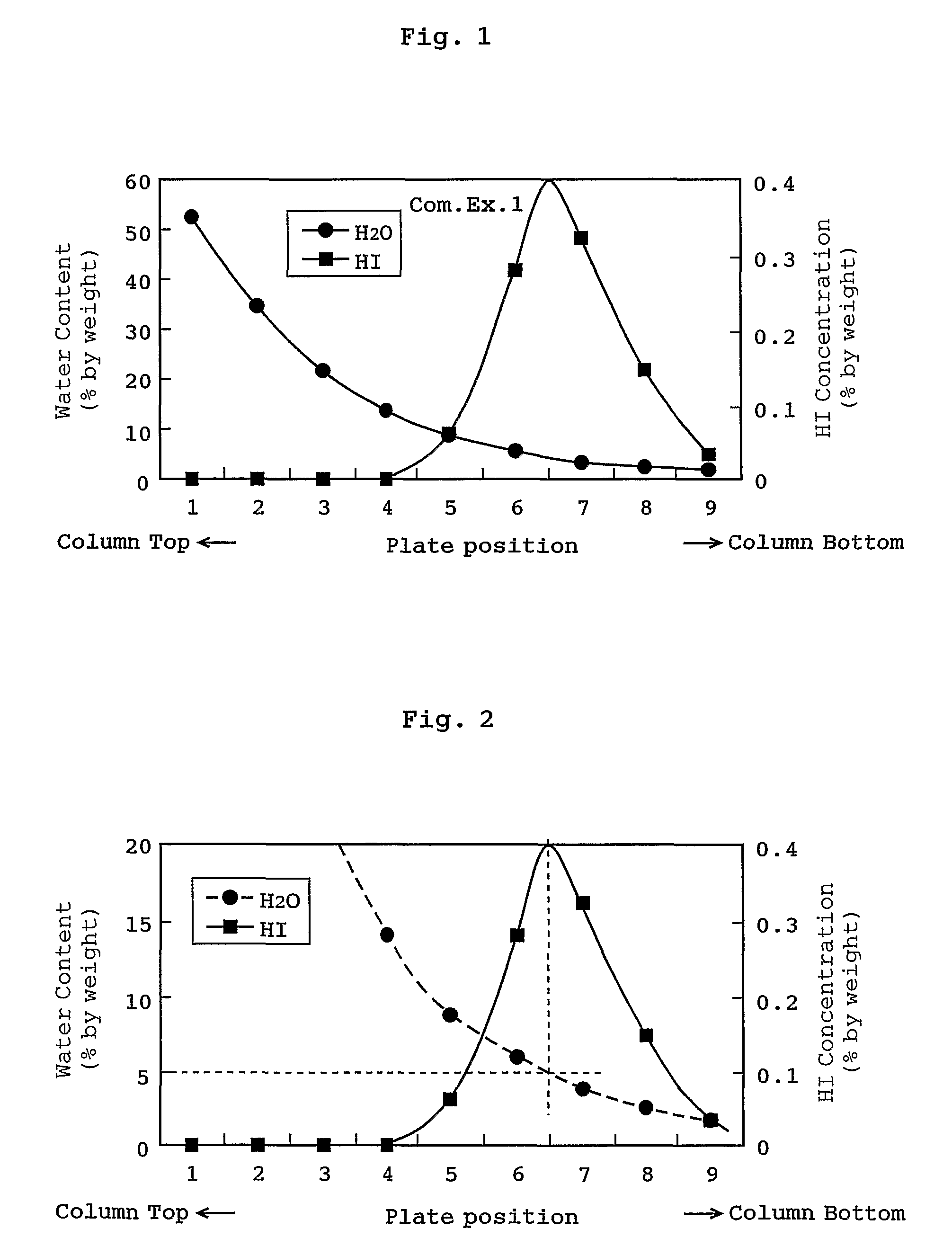

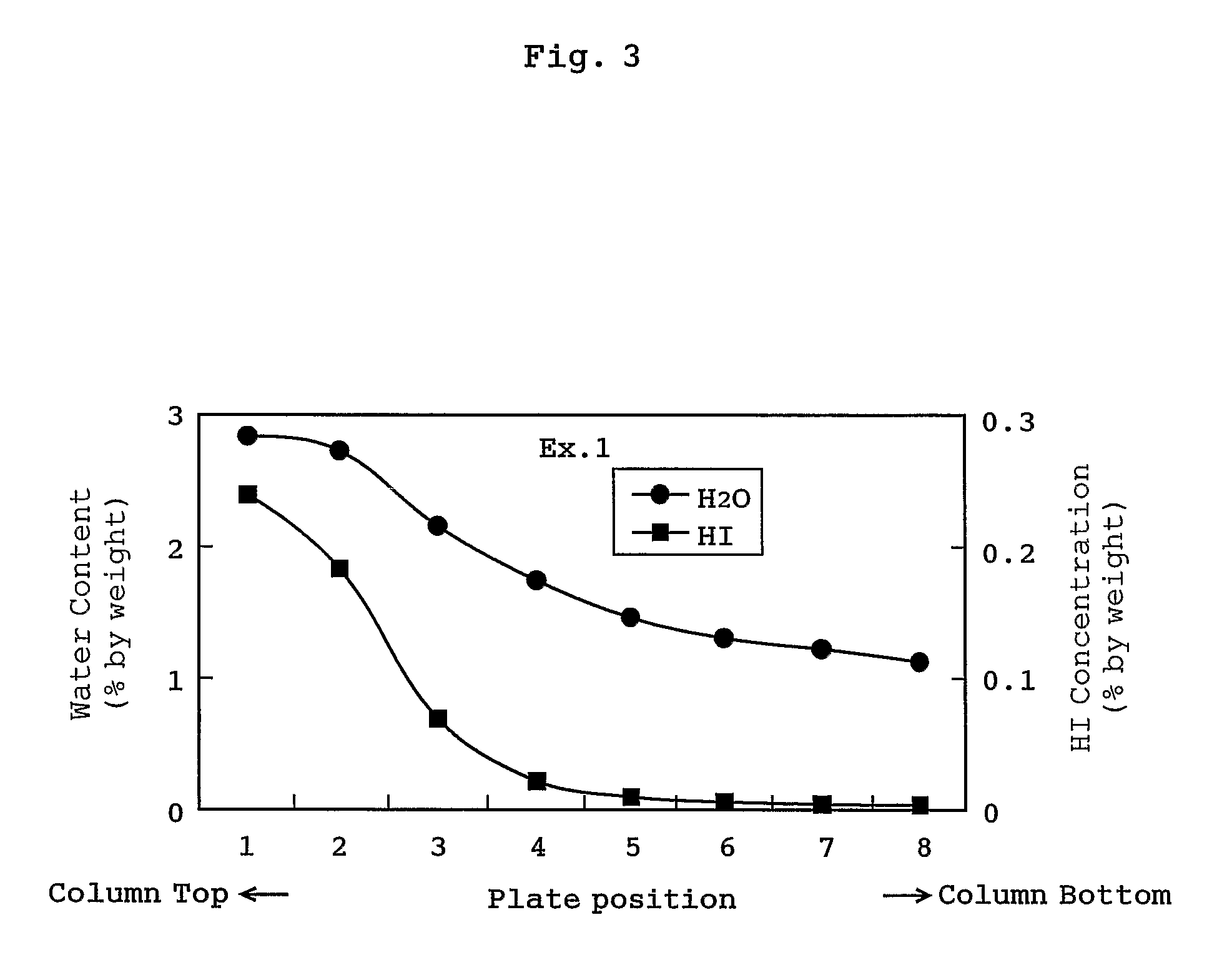

A mixture containing hydrogen iodide and water and having a water content of not more than 5% by weight (particularly not more than 3% by weight) in a distillation system is distilled to prevent condensation of hydrogen iodide in the distillation system. The mixture may comprise hydrogen iodide, water, methanol, methyl iodide, acetic acid, and methyl acetate. Even when the mixture contains hydrogen iodide at a concentration of 1 to 3000 ppm on the basis of weight, an acetic acid product having a concentration of hydrogen iodide of not more than 50 ppm can be obtained by withdrawing a fraction containing hydrogen iodide from the top of the column, and withdrawing acetic acid as a side-cut stream or a stream from the bottom of the column. Such a process (distillation process) effectively inhibits condensation of hydrogen iodide in the distillation system and corrosion in the distillation system.

Owner:DAICEL CHEM IND LTD

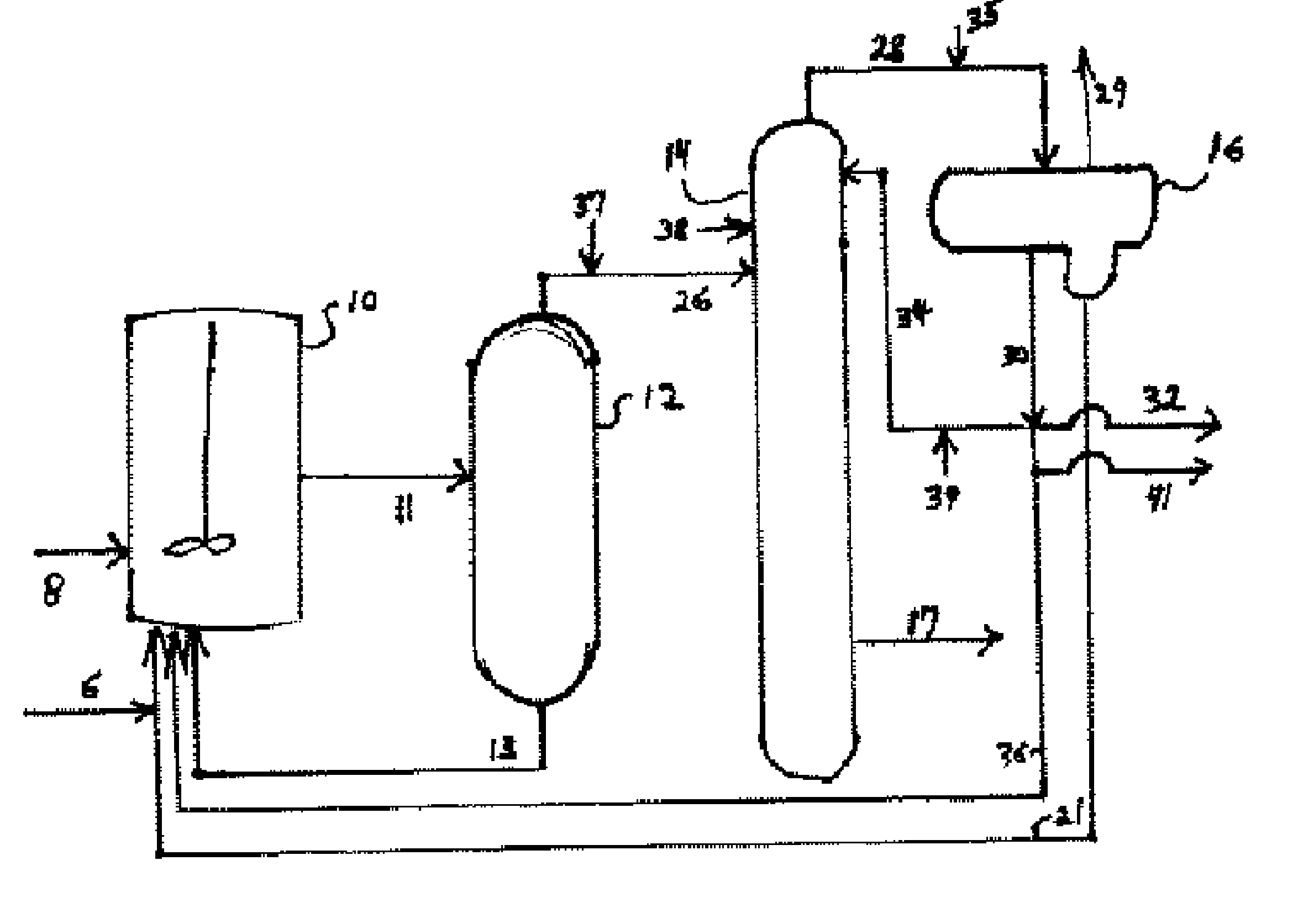

Production of acetic acid with high conversion rate

InactiveUS20120078012A1Physical/chemical process catalystsOrganic compound preparationAcetic acidMetal catalyst

A process for producing acetic acid comprising the steps of reacting carbon monoxide and at least one of methanol and a methanol derivative in a first reactor under conditions effective to produce a crude acetic acid product; separating the crude acetic acid product into at least one derivative stream, at least one of the at least one derivative stream comprising residual carbon monoxide; and reacting at least a portion of the residual carbon monoxide with at least one of methanol and a methanol derivative over a metal catalyst in a second reactor to produce additional acetic acid.

Owner:CELANESE INT CORP

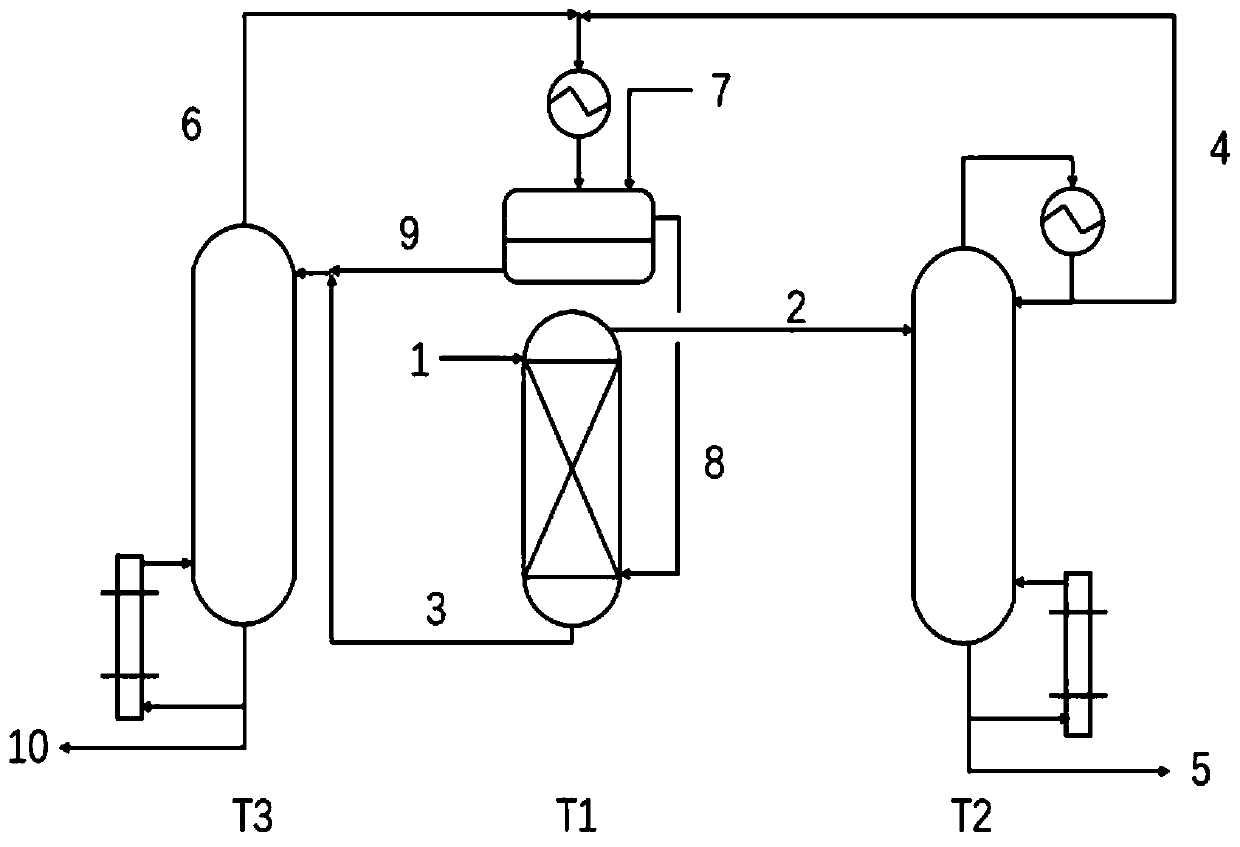

A kind of dilute acetic acid recovery method combining extraction and azeotropic distillation

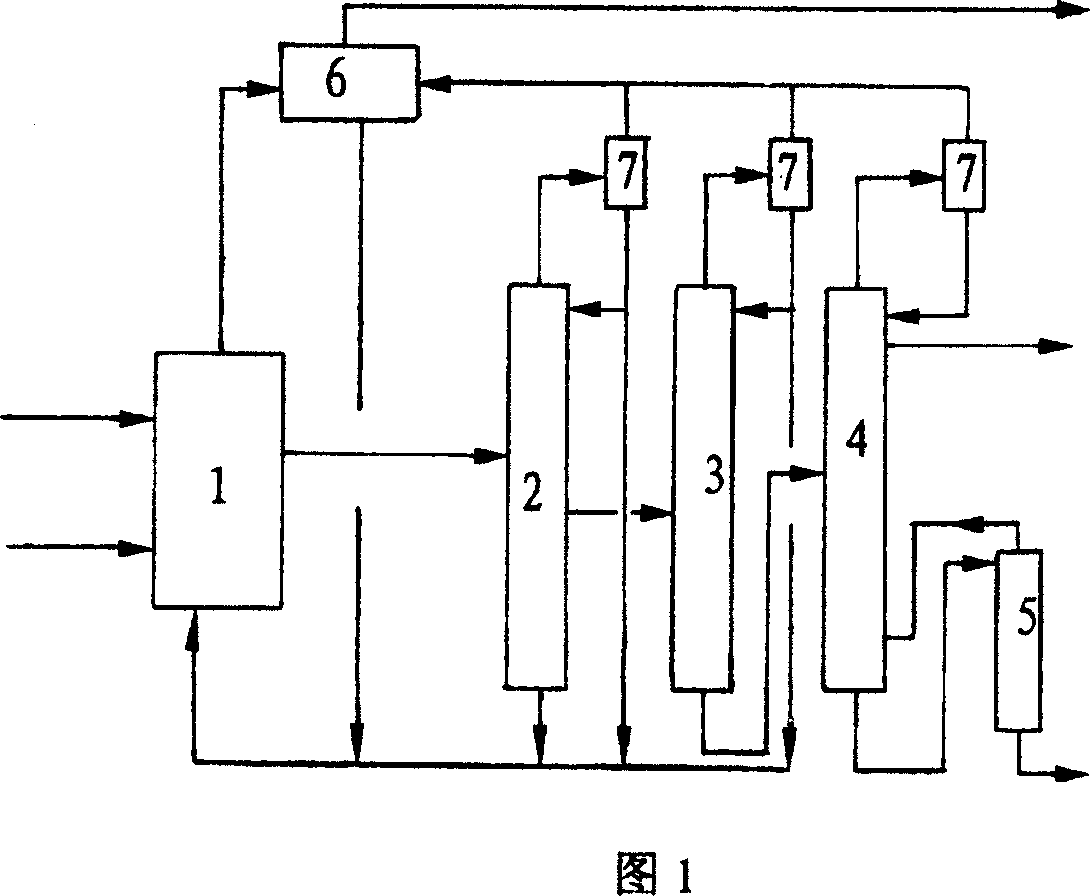

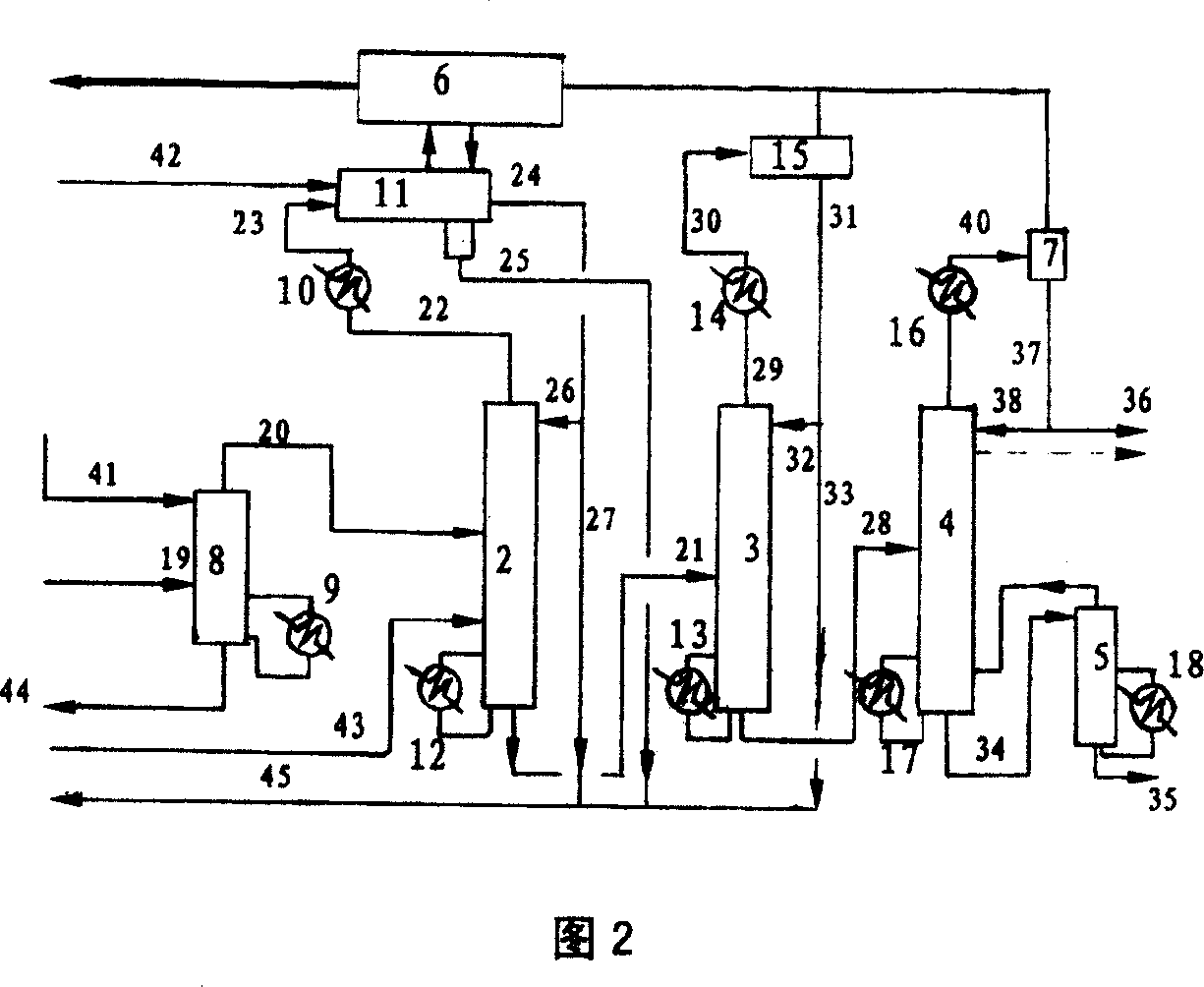

InactiveCN102267889AReduce energy consumptionReduce contentChemical recyclingCarboxylic compound separation/purificationAcetic acidAlcohol

The invention relates to a method for recovering dilute acetic acid by combining extraction and azeotropic rectification. The method first carries out liquid-liquid extraction on part of the acetic acid-water component to be separated, the extractant is injected into the bottom of the extraction tower, and is extracted by countercurrent contact with dilute acetic acid to obtain the top component (extract phase) comprising acetic acid and the extractant and meet environmental protection requirements. The waste water (raffinate phase) is discharged; then, the extract phase and another part of dilute acetic acid enter the azeotropic rectification tower to carry out azeotropic rectification. Azeotrope of boiling agent and water. The azeotropic agent and water achieve liquid-liquid separation in the phase separator, the organic phase returns to the azeotropic rectification tower as an azeotropic agent and returns to the extraction tower for use as an extraction agent, and the water phase enters the azeotropic agent recovery tower or is discharged. The extractant and entrainer used in the present invention are the mixture of alkyl acetate and corresponding alcohol. The extraction technology reduces the water content entering the azeotropic distillation, thereby reducing the amount of the entrainer and saving the heating steam flow of the azeotropic distillation column, so as to reduce the amount of the azeotrope and the energy consumption of the device.

Owner:EAST CHINA UNIV OF SCI & TECH

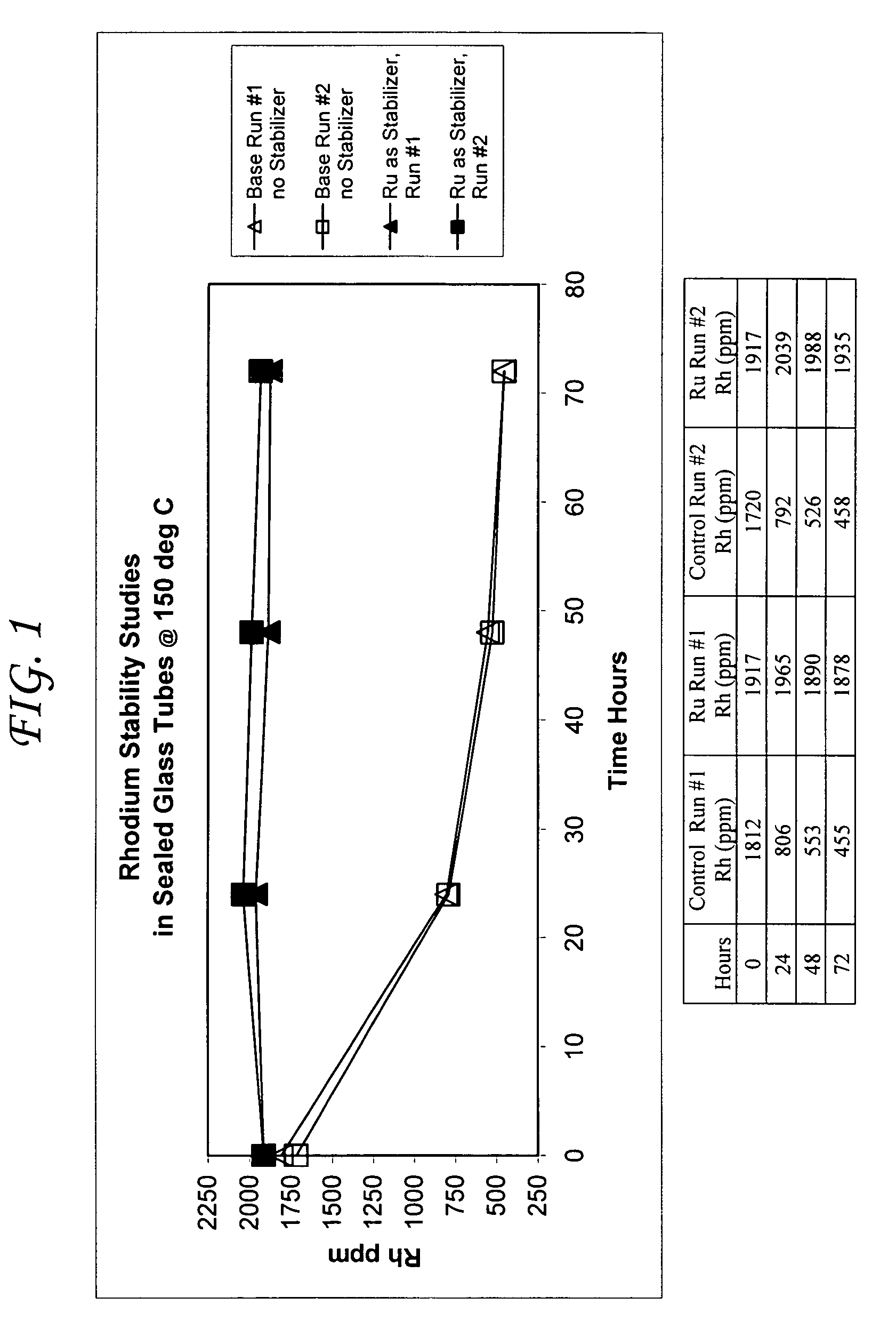

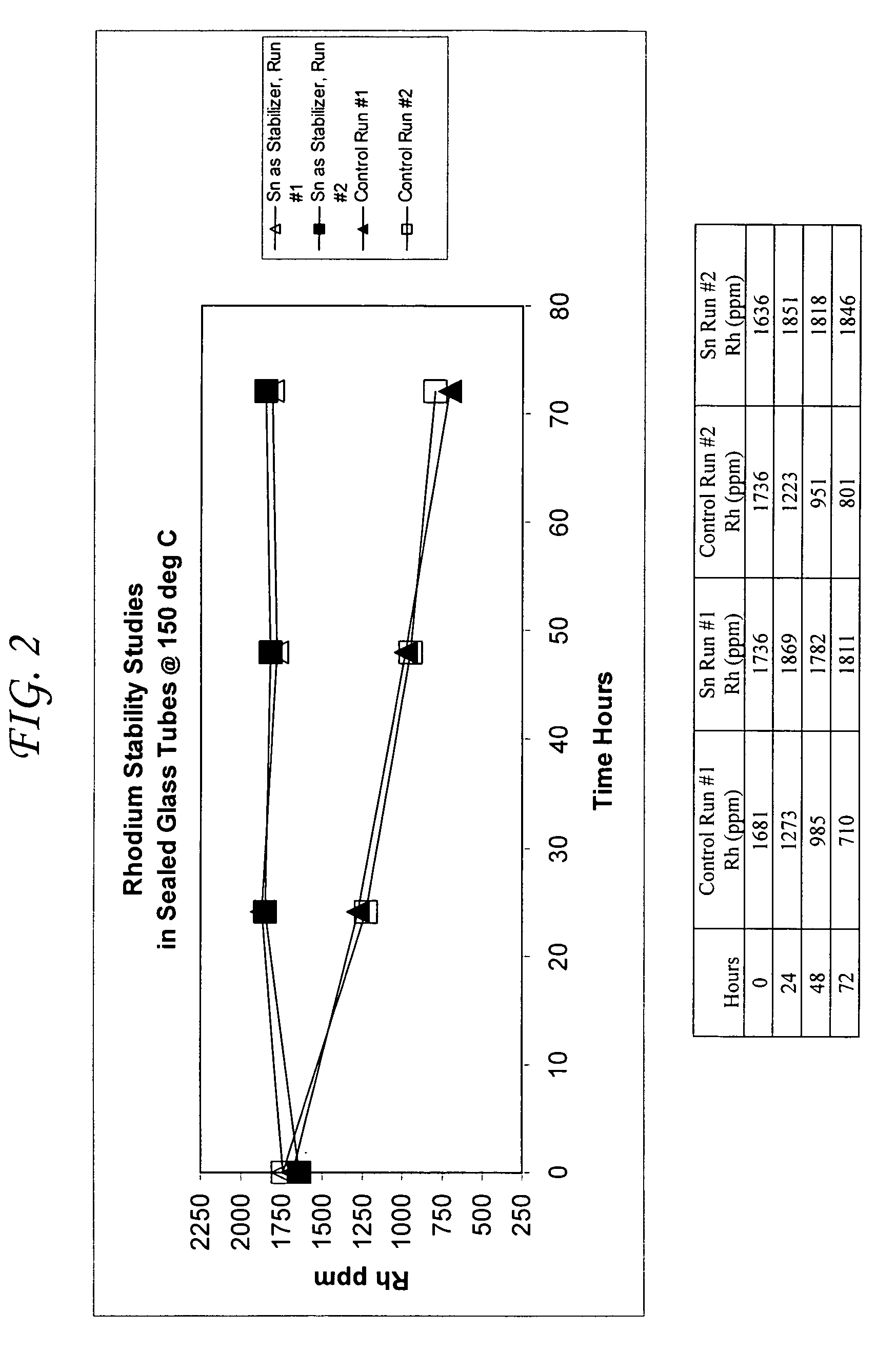

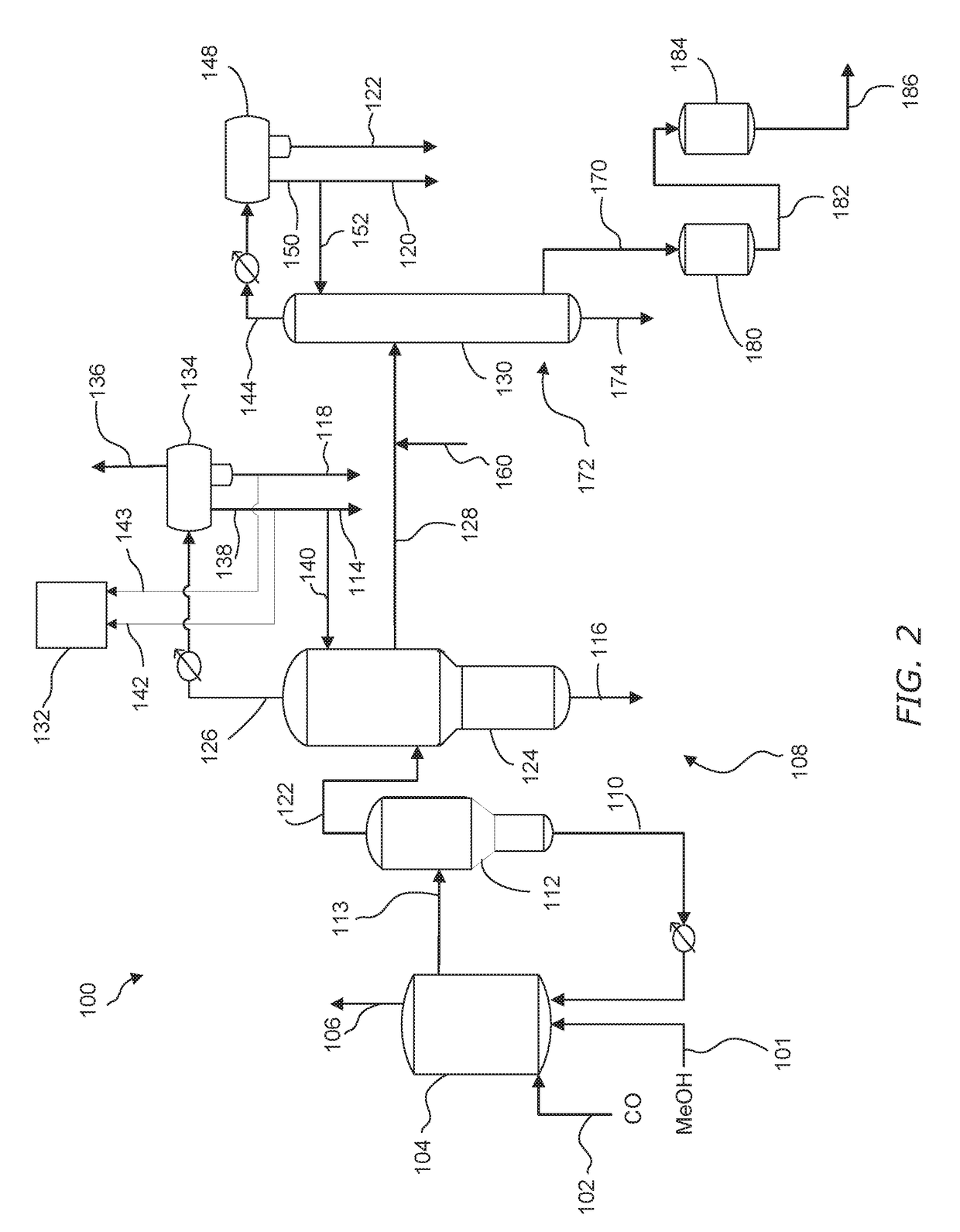

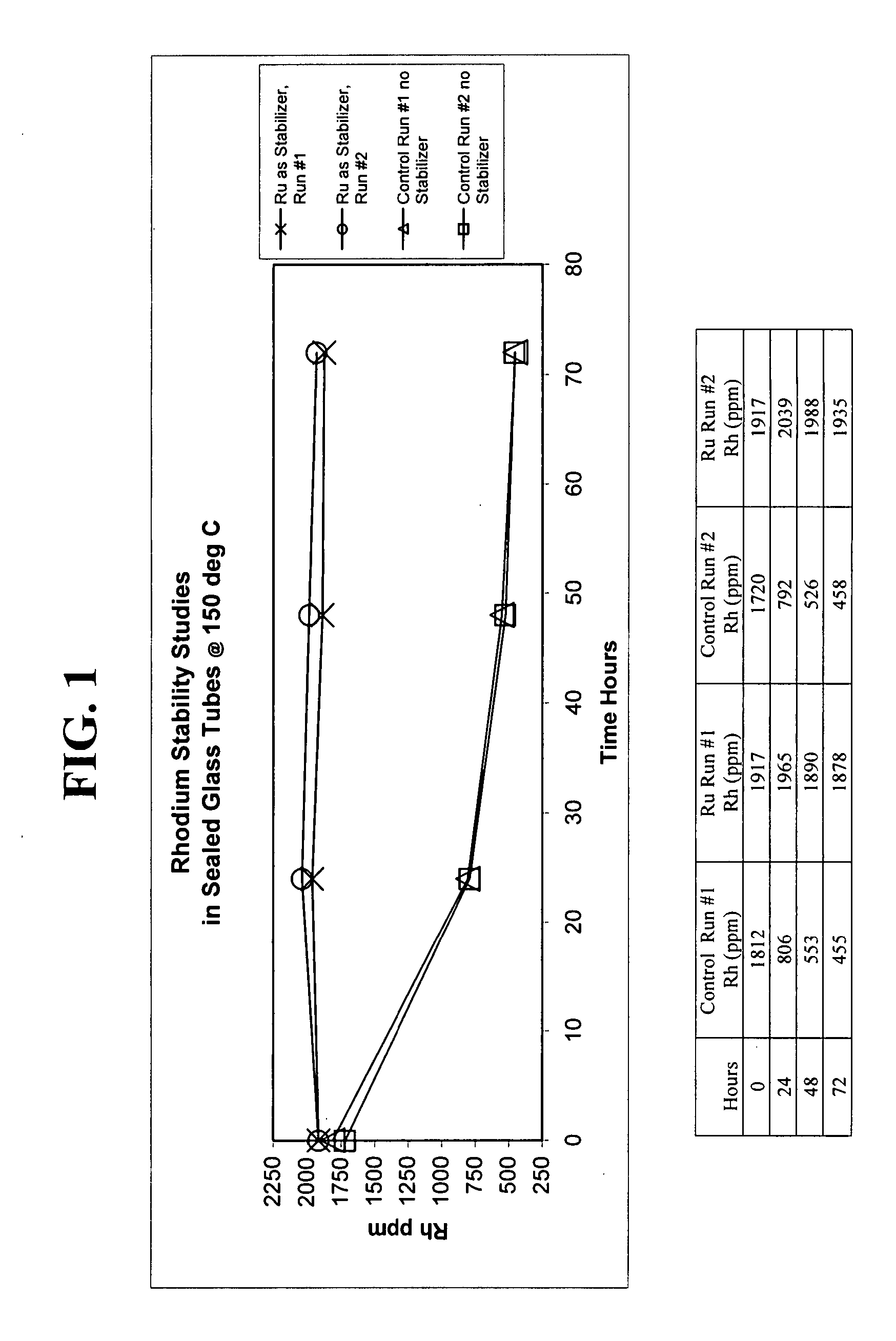

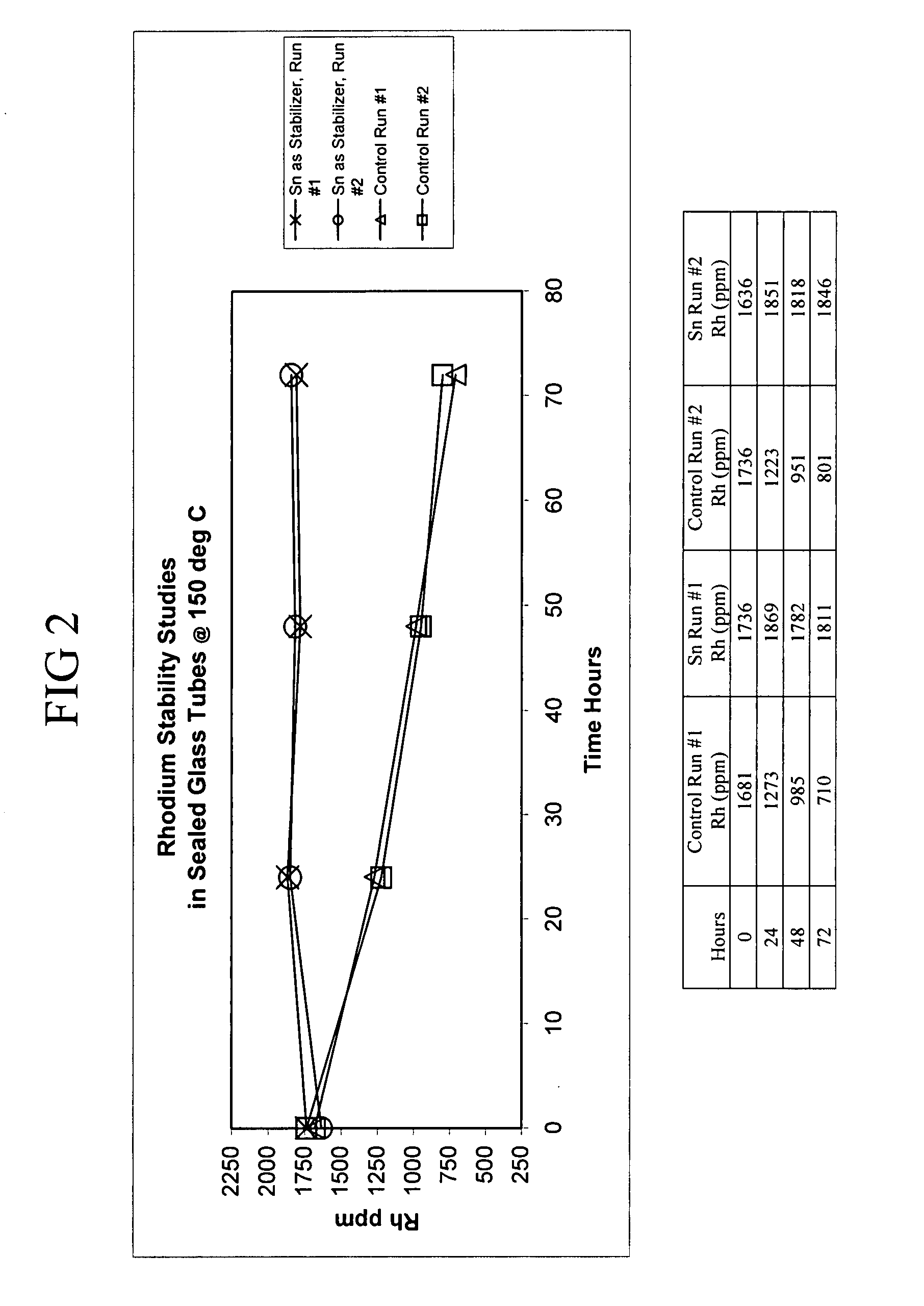

Acetic acid production methods incorporating at least one metal salt as a catalyst stabilizer

ActiveUS7053241B1Organic compound preparationCarboxylic preparation from carbon monoxide reactionAccelerantProtein carbonyl

Processes for the production of acetic acid by carbonylation of methanol, and reactive derivatives thereof, in a reaction mixture using a rhodium-based catalyst system with at least one metal salt catalyst stabilizer selected from the group of ruthenium salts, tin salts, and mixtures thereof are provided. The metal salt stabilizers minimize precipitation of the rhodium metal during recovery of the acetic acid product, particularly in flasher units in an acetic acid recovery scheme. Stability of the rhodium metal is achieved even when the acetic acid is produced in low water content reaction mixtures in the presence of an iodide salt co-promoter at a concentration that generated an iodide ion concentration of greater than about 3 wt. % of the reaction mixture. The stabilizing metal salts may be present in the reaction mixtures for the production of acetic acid at molar concentrations of metal to rhodium of about 0.1:1 to about 20:1. The stabilizing metal salts may be combined with other catalyst stabilizers as well as catalyst promoters.

Owner:CELANESE INT CORP

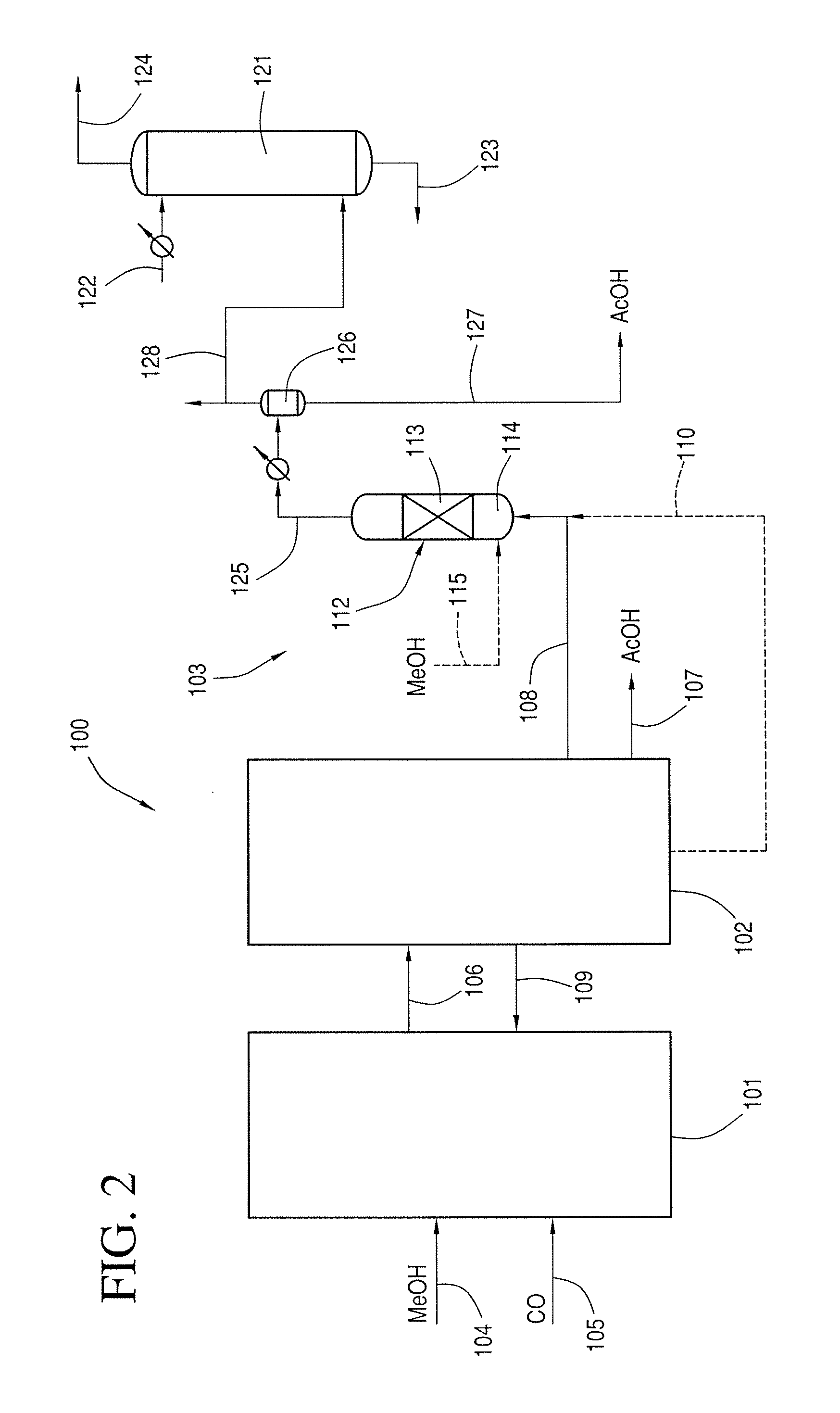

Process for Producing Acetic Acid

ActiveUS20050197506A1Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

Improved acetic acid purifying method

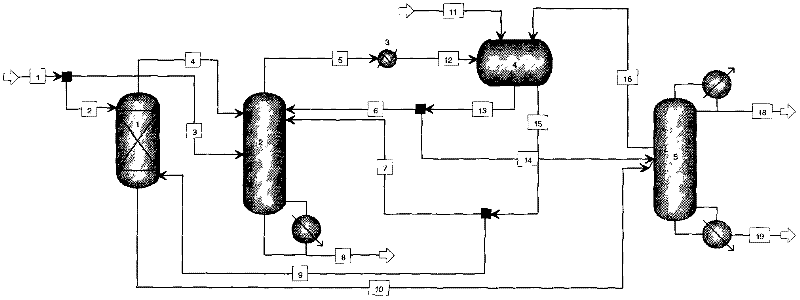

ActiveCN1944374AHigh reaction yieldReduce energy consumptionCarboxylic compound separation/purificationReaction rateGas phase

The improved acetic acid purifying method includes available technological steps of eliminating light component, dewatering, and eliminating heavy component as well as increased absorption and steam stripping step before the step of eliminating light component. In the absorption and steam stripping step, the initial acetic acid product from flash evaporation and the added absorbing liquid are absorbed and steam stripped to form the gaseous material entering to the light component eliminating tower and liquid material returned to the reaction system. The corresponding apparatus includes one refining system comprising light component eliminating tower, dewatering tower, heavy component eliminating tower and waste acid tower; one gas scrubbing system; one decanter set in the top of the light component eliminating tower; and one increased multifunctional tower. The present invention has high acetic acid synthesizing reaction rate, less side products and lowered power consumption.

Owner:SHANGHAI HUAYI ENERGY CHEM

Removing permanganate-reducing impurities from acetic acid

ActiveUS7208625B1Organic compound preparationCarboxylic compound separation/purificationAcetic acidCrotonaldehyde

A method for removing permanganate-reducing impurities from an acetic acid product is disclosed. The method comprises contacting an acetic acid product containing permanganate-reducing impurities with peracetic acid and an oxygen-containing gas. The method is particularly suitable for post treatment of acetic acid that contains permanganate-reducing impurities such as crotonaldehyde.

Owner:LYONDELLBASELL ACETYLS

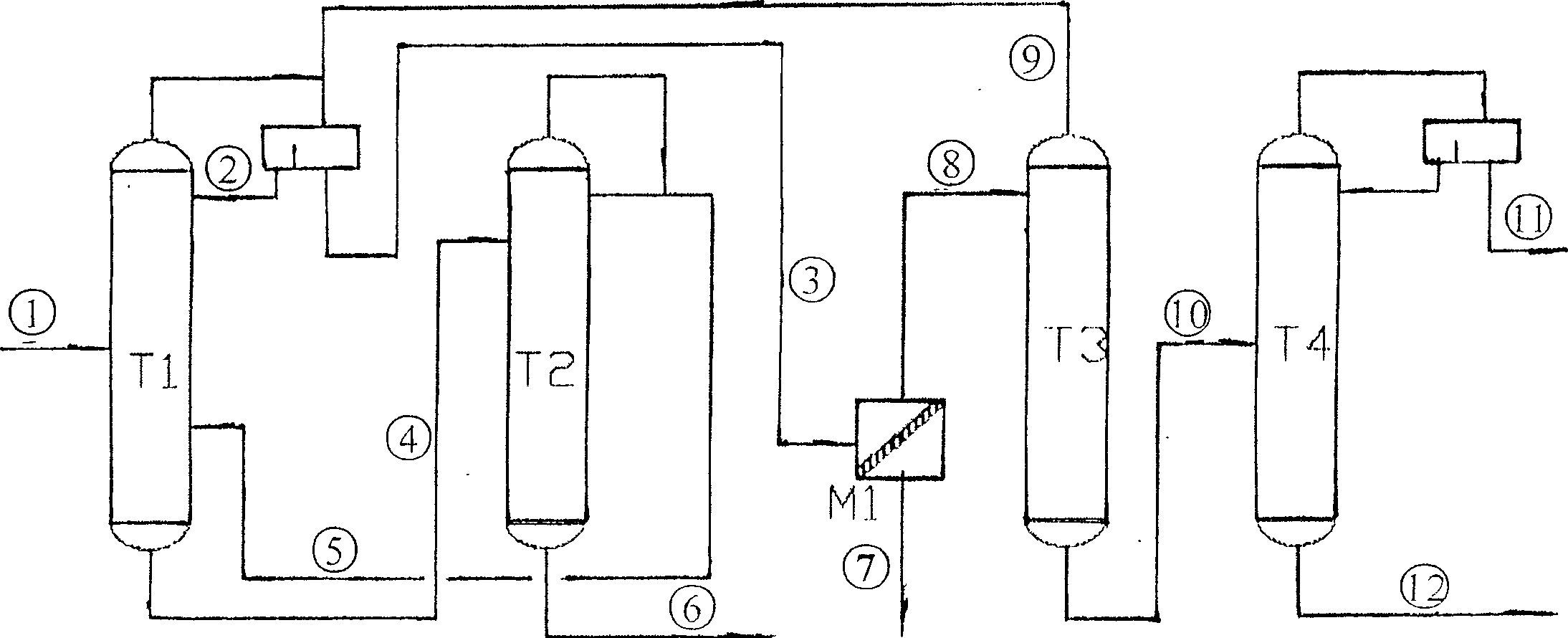

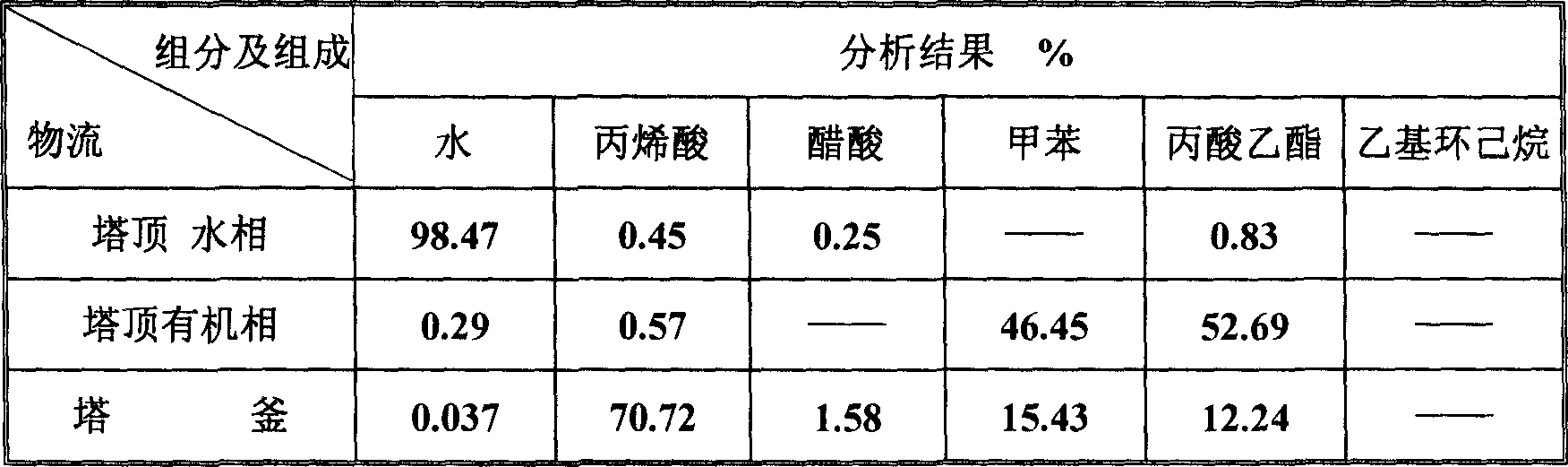

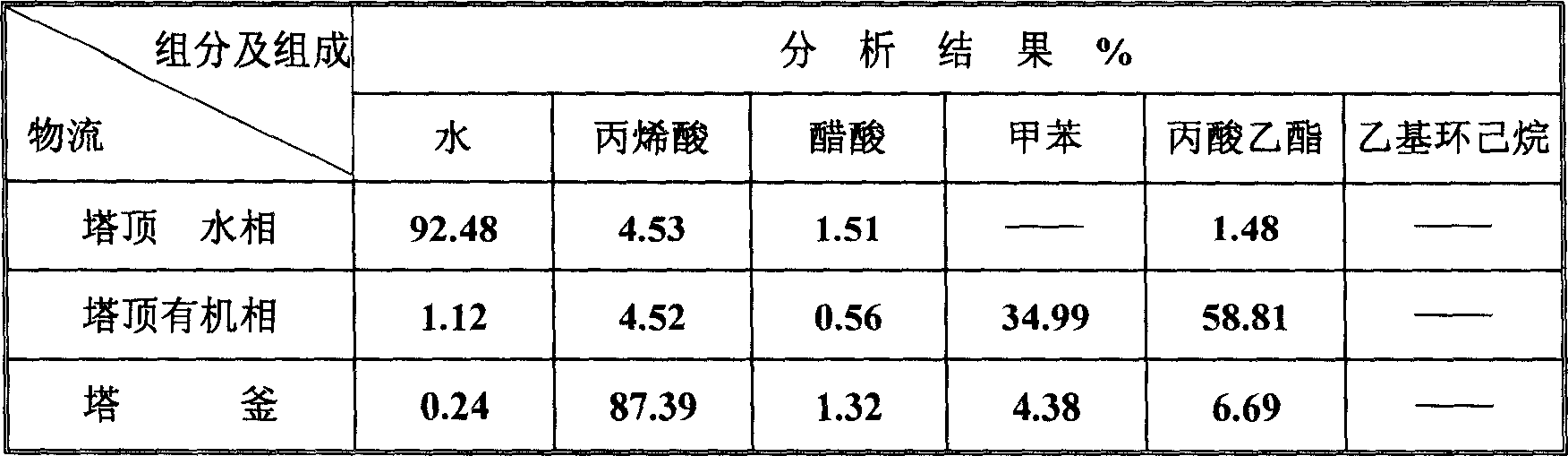

Process for crylic acid azeotropism refining and recovering acetic acid

ActiveCN1865216AReduce operating loadAlleviate high temperature self-polymerizationCarboxylic compound separation/purificationOrganic filmAzeotropic distillation

This invention relates to a process for producing acroleic acid and esters thereof, concretely to acroleic acid azeotropic refining and acetic acid recovering process, wherein: apply ethyl cyclohexane, toluene, ethyl propionate and toluene derivative as the entrainer during the acroleic acid azeotropic distillation, set up a acroleic acid azeotropic column and an acetic acid removing column to remove the water and acetic acid in the crude acroleic acid solution, set up an organic film and air extraction column and an acetic acid azeotropic column to purify the 2-8% side produced acetic acid to be acetic acid product with concentration more than 85%. This invention is characterized of high dehydration rate and acetic acid removing rate. The byproduct acetic ester can be produced to be acetic acid product, which saves waste water treatment cost and improves the equipment benefits. By applying ethyl cyclohexane, toluene, ethyl propionate and toluene derivative as the entrainer, it can decrease the bottom temperature of the acroleic acid azeotropic column, which can decrease the polymerization tendency of the acroleic acid, improve the conversion rate of propone, decrease the acroleic acid carry-over loss and acroleic acid consumption, improve the product yield, extend the production cycle and improve the economical benefits of the apparatus.

Owner:CHINA GASOLINEEUM ENG

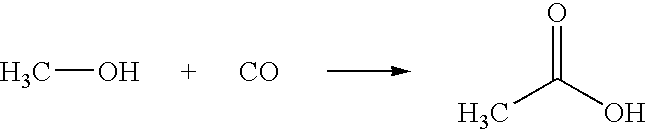

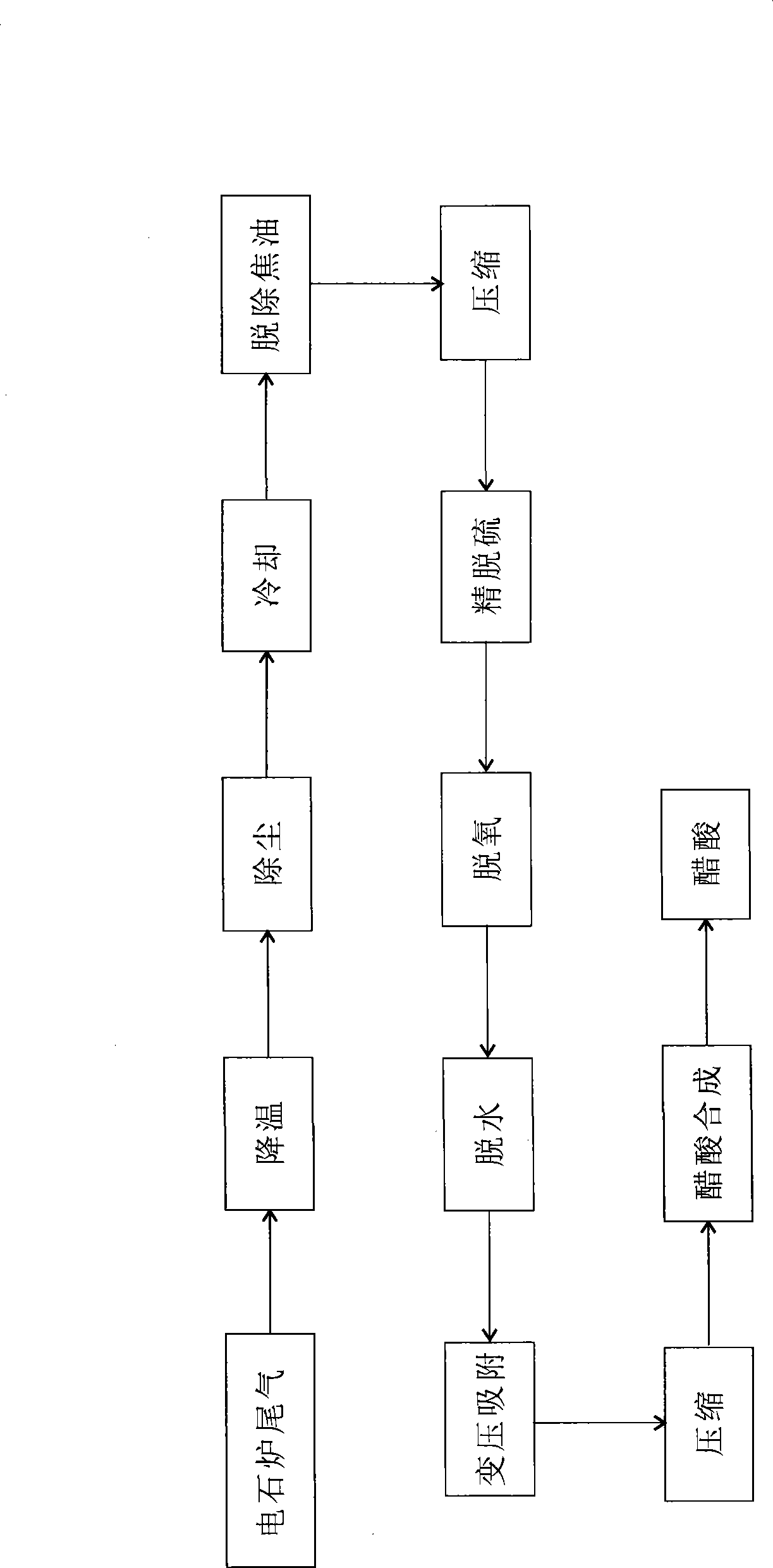

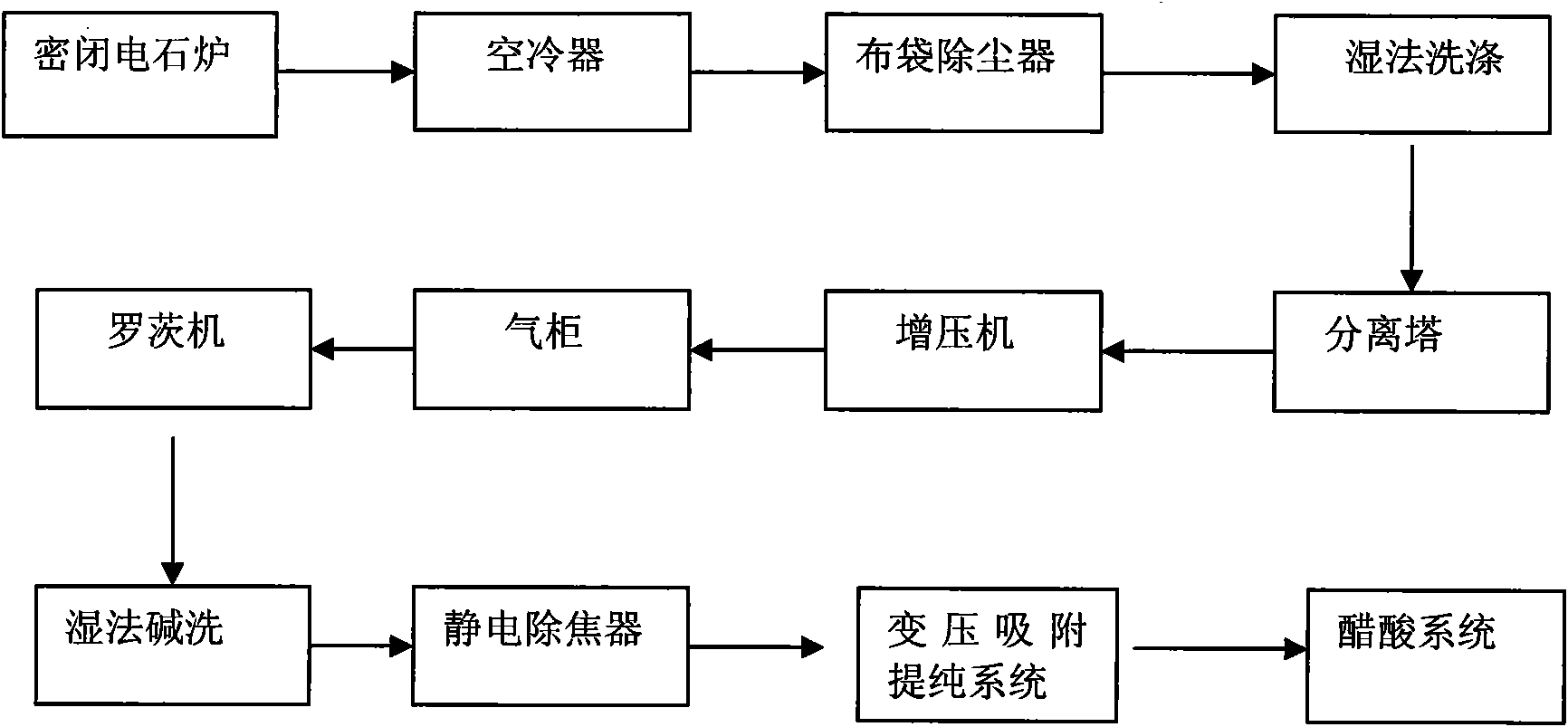

Technological process for preparing acetic acid from calcium carbide furnace tail gas

InactiveCN101462940ARealize comprehensive utilizationHigh tar recovery efficiencyCarbon monoxideCarboxylic preparation from carbon monoxide reactionImpurityDust abatement

The invention discloses a technique for preparing acetic acid by utilizing tail gas of a calcium carbide furnace, comprising the steps: first, temperature reduction and cooling are carried out on the tail gas of the calcium carbide furnace, then, dust abatement and cooling are carried out on the tail gas of the coolled calcium carbide furnace; after the processes of temperature reduction and dust abatement, the tail gas of the calcium carbide furnace enters an electric detarring precipitator for detarring; after being pressurized, the tail gas is transmitted into a purification apparatus for desulfurization, deoxidation and dehydration; CO2 and other impurities in the purified tail gas of the calcium carbide furnace are removed by a pressure-swing absorption apparatus (SPA), and high purity gas of CO with the purity of 97-99% is obtained; after pressure swing adsorption, the CO is pressurized and sent into a acetic acid synthesizer, and then reacts with methyl alcohol to produce the acetic acid. The technique not only realizes recycling of the tail gas of the calcium carbide furnace and reduces the environmental pollution, but also can produce acetic acid products with high added value, thus improving the economic benefit of the product.

Owner:高恒 +1

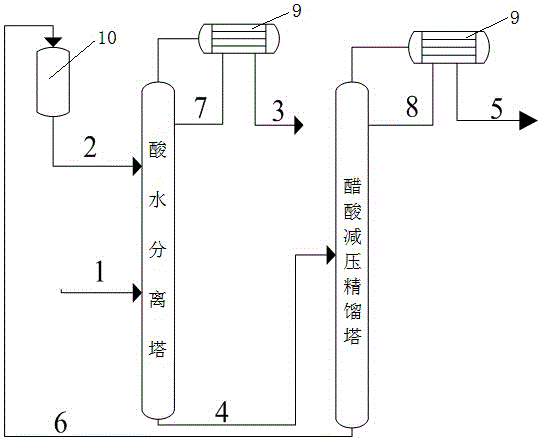

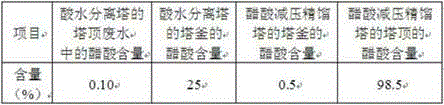

Method for purifying acetic acid from acetic acid wastewater

InactiveCN104447275AReduce energy costsLess investmentCarboxylic compound separation/purificationAcetic acidExtractive distillation

The invention relates to a method for purifying acetic acid from acetic acid wastewater, and adopts a wastewater treatment process for treating acetic acid wastewater with medium-low concentration. According to the method, acetic acid in the acetic acid wastewater is brought into an extraction agent in an extractive distillation mode, and moisture is evaporated out of a tower top; and then a reduced pressure distillation tower is used for separating acetic acid and the extraction agent, and a qualified finished acetic acid product is obtained. The method is suitable for treating acetic acid wastewater with medium-low concentration, preferably, the appropriate extraction agent is adopted, so that relatively, the energy consumption cost for wastewater treatment is lower, equipment investment is low, the acid and water separation effect is good, and the method is more environment-friendly.

Owner:ZHEJIANG NHU PHARMA

Removing iodobenzene compounds from acetic acid

InactiveUS20100113827A1Organic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidTriphenylphosphine oxide

A method for removing iodobenzene compounds from an acetic acid is disclosed. The method comprises contacting an acetic acid with palladium supported on macroreticular ion-exchange resins. A process for producing acetic acid is also disclosed. The process comprises carbonylating methanol in the presence of a carbonylation catalyst and a triphenylphosphine oxide stabilizer to produce acetic acid which contains iodobenzene compounds and removing the iodobenzene compounds by contacting the acetic acid product with palladium.

Owner:LYONDELL CHEM TECH LP

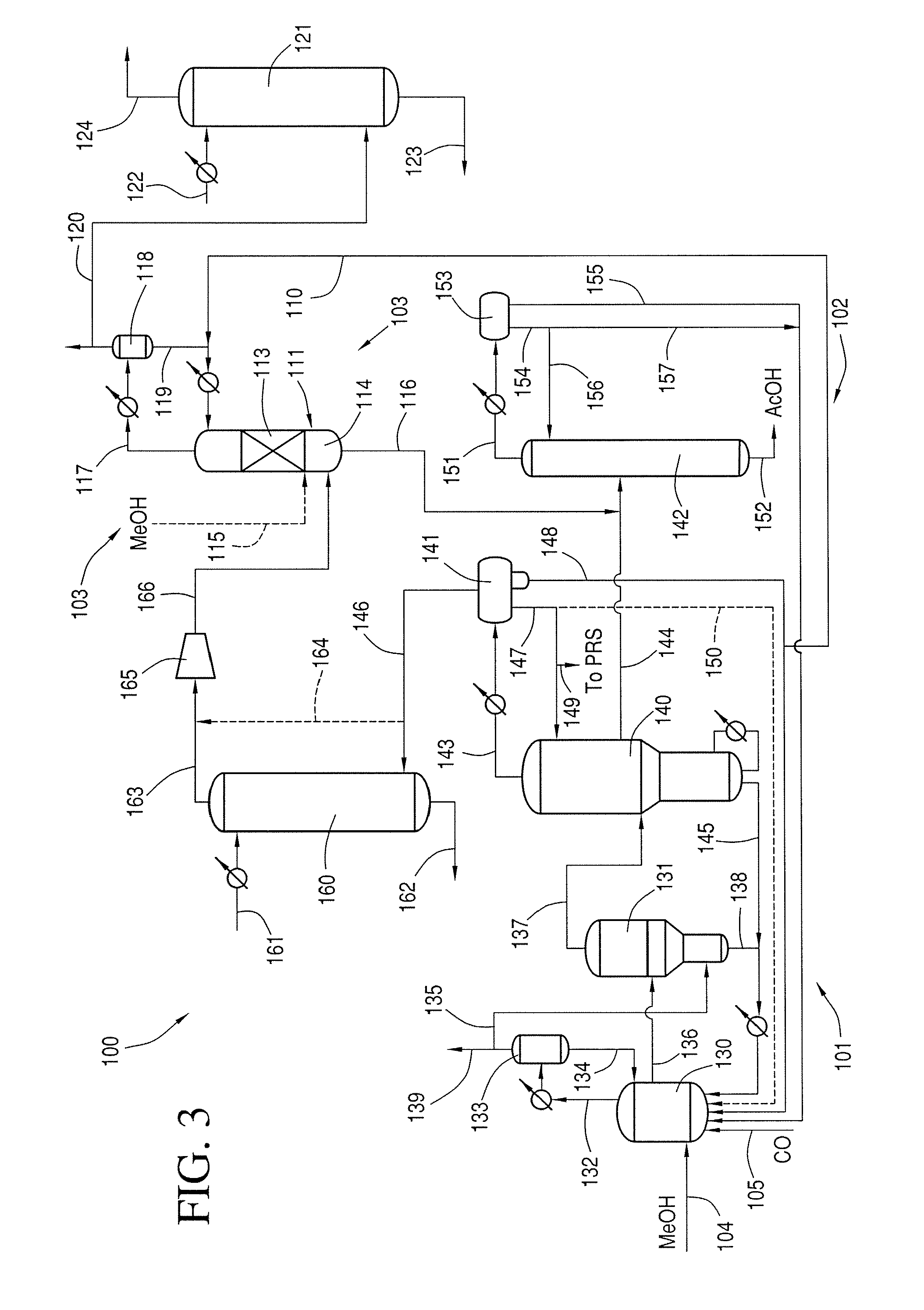

Production of acetic acid with high conversion rate

InactiveUS8394988B2Physical/chemical process catalystsOrganic compound preparationAcetic acidMetal catalyst

A process for producing acetic acid comprising the steps of reacting carbon monoxide and at least one of methanol and a methanol derivative in a first reactor under conditions effective to produce a crude acetic acid product; separating the crude acetic acid product into at least one derivative stream, at least one of the at least one derivative stream comprising residual carbon monoxide; and reacting at least a portion of the residual carbon monoxide with at least one of methanol and a methanol derivative over a metal catalyst in a second reactor to produce additional acetic acid.

Owner:CELANESE INT CORP

Production of Acetic Acid with High Conversion Rate

InactiveUS20120083623A1Low purityOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidResidual carbon

The present invention is to a process for producing acetic acid comprising the step of reacting a carbon monoxide feed and methanol and / or a methanol derivative in a first reactor to produce a crude acetic acid product. The carbon monoxide may comprise less than 99.5 mol % carbon monoxide. The process further comprises the step of purging a carbon monoxide purge stream comprising a first amount of residual carbon monoxide and one or more impurities. Preferably, the first amount is greater than 20 mol %. The process further comprises the step of separating the crude acetic acid product into at least one derivative stream comprising a second amount of residual carbon monoxide. The process further comprises the step of reacting at least a portion of the second amount of residual carbon monoxide and methanol and / or a methanol derivative in a second reactor to produce additional acetic acid.

Owner:CELANESE INT CORP

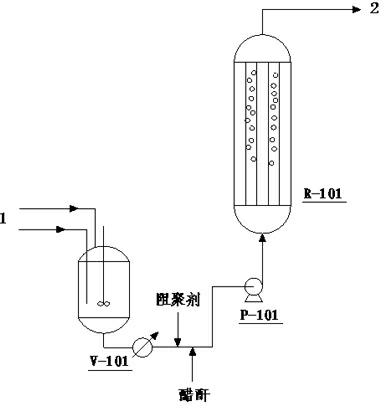

A kind of method for preparing isobornyl acetate by esterification of camphene

InactiveCN102276453AExtended service lifeImprove adsorption capacityOrganic compound preparationCarboxylic acid esters preparationAcetic acidIsobornyl acetate

The invention relates to a continuous preparation method for synthesizing isobornyl acetate by esterification of camphene and acetic acid. Using camphene and acetic acid as raw materials, using solid acid as a catalyst, and adding a certain amount of polymerization inhibitor and acetic anhydride, the esterification reaction is carried out under certain process conditions in a catalyst bed filled with suspension, and the target product acetic acid is obtained. Isobornyl. The invention has the advantages of mild reaction conditions, long service life of the catalyst, good product quality, high raw material conversion rate, continuous production and simple operation, and can be widely used in large-scale industrial production of isobornyl acetate.

Owner:FUZHOU UNIV

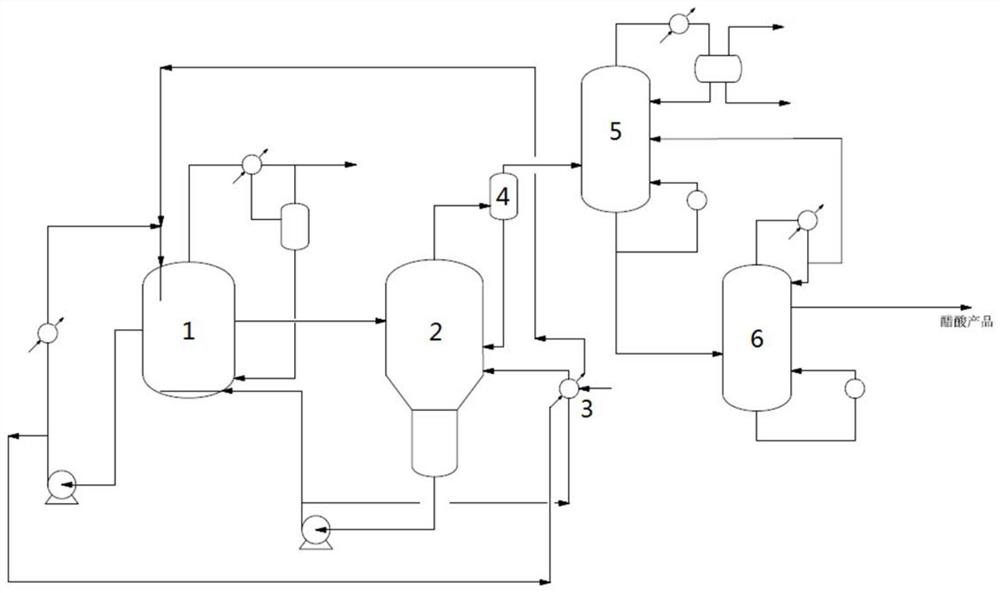

Method for synthesizing acetic acid through carbonylation of low-pressure methanol

ActiveCN111646894ATo achieve the purpose of warming up in advanceNo stirring effectCarboxylic preparation from carbon monoxide reactionCarboxylic compound separation/purificationAcetic acidPtru catalyst

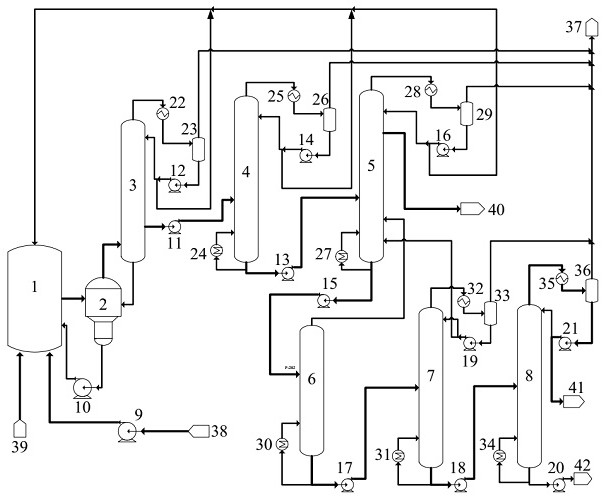

The invention relates to a method for synthesizing acetic acid by carbonylation of low-pressure methanol. The method comprises the following steps: (1) in the presence of a catalyst, introducing methanol and CO into a non-stirring reactor, carrying out a carbonylation reaction, feeding a liquid-phase part in the middle of the non-stirring reactor into a flash evaporator, carrying out flash evaporation, and separating to obtain a liquid-phase component and a gas-phase component; (2) carrying out heat exchange on the liquid-phase component and a mother liquor flash evaporation heat exchanger, carrying out secondary flash evaporation after heating, and separating to obtain a secondary liquid-phase component and a secondary gas-phase component; (3) feeding the separated primary gas-phase and secondary gas-phase components into a catalyst catcher, returning the caught and recovered catalyst into the flash evaporator, and feeding the gas-phase component into a light-component rectifying tower, and rectifying and separating to obtain a light component and a heavy component; (4) sending the liquid-phase components in steps (1) and (2) back to the non-stirring reactor, and reacting; and (5)feeding the heavy component in step (3) into a heavy component rectifying tower, and performing rectification separation to obtain the acetic acid product. Reaction heat is utilized to deeply separate the reaction liquid, invalid circulation is reduced, and power consumption and steam consumption are saved.

Owner:PUJING CHEM IND SHA

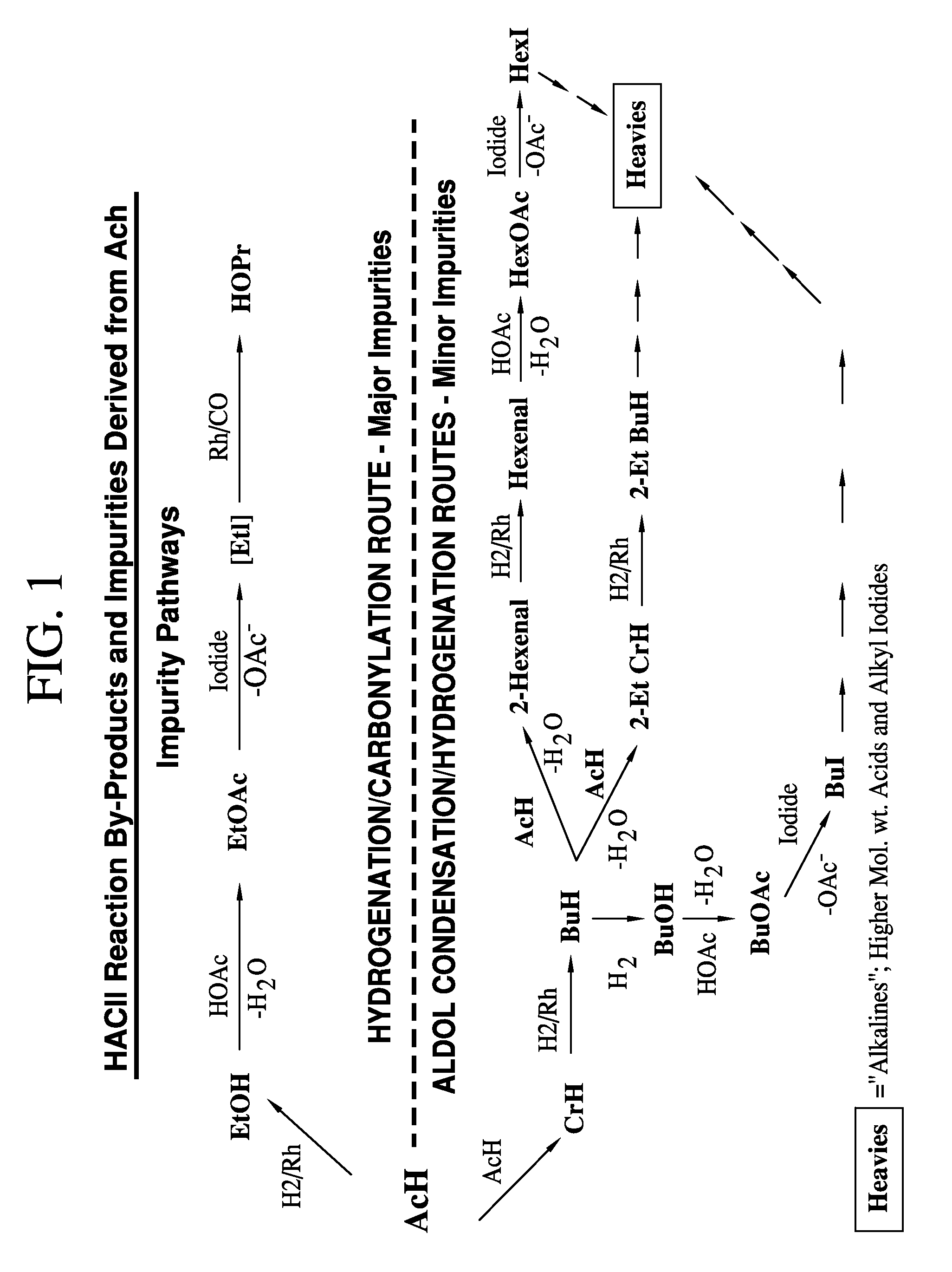

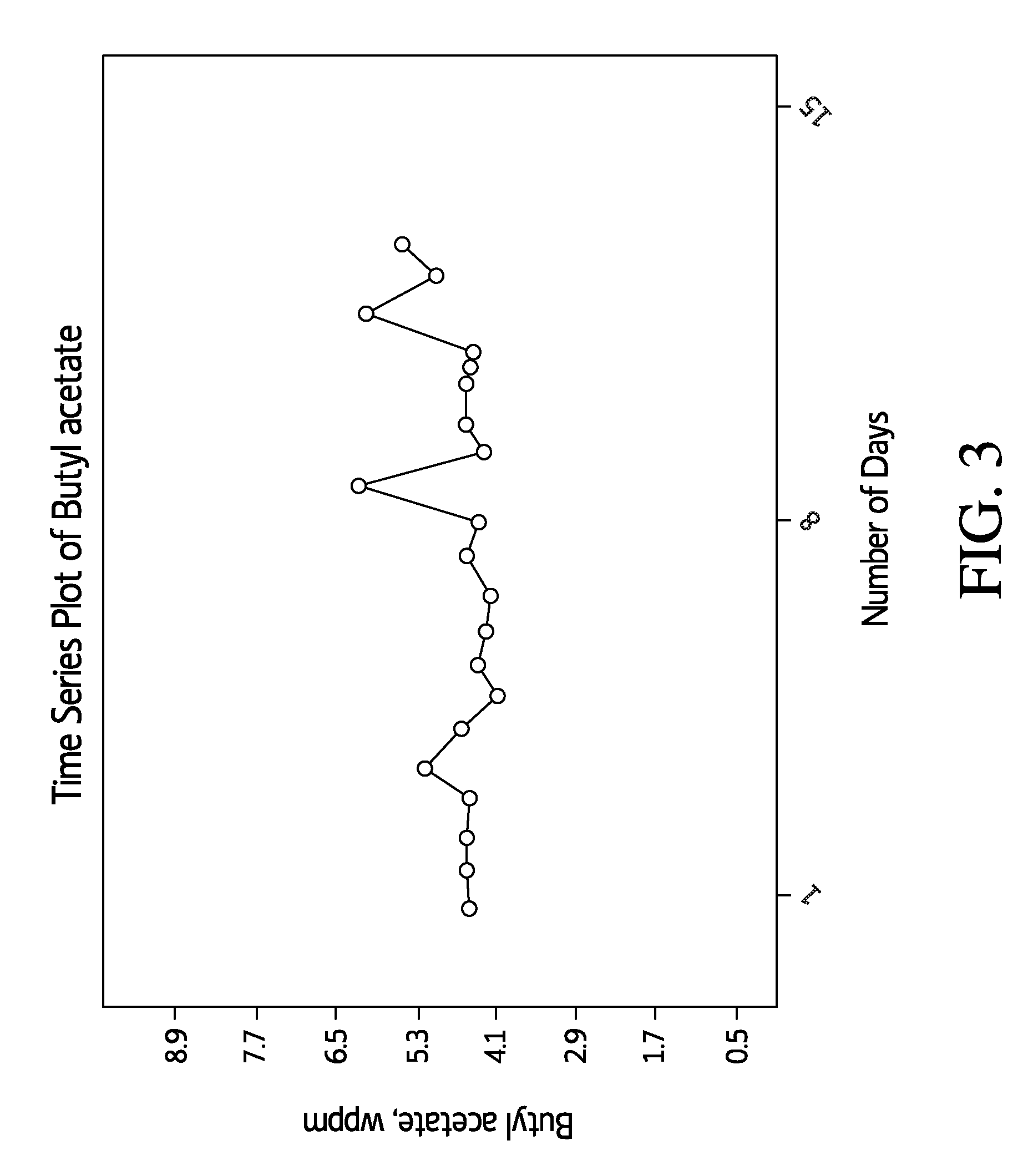

Processes for producing an acetic acid product having low butyl acetate content

ActiveUS9540304B2Carboxylic preparation from carbon monoxide reactionCarboxylic compound separation/purificationMetal catalystReaction temperature

A process for producing an acetic acid product having low butyl acetate content via a carbonylation reaction. The carbonylation reaction is carried out at a temperature from 100 to 300° C., a hydrogen partial pressure from 0.3 to 2 atm, and a rhodium catalyst concentration from 100 to 3000 wppm, based on the weight of the reaction medium. The butyl acetate concentration in the acetic acid product may be controlled by removing acetaldehyde from a stream derived from the reaction medium and / or by adjusting at least one of reaction temperature, hydrogen partial pressure, and metal catalyst concentration.

Owner:CELANESE INT CORP

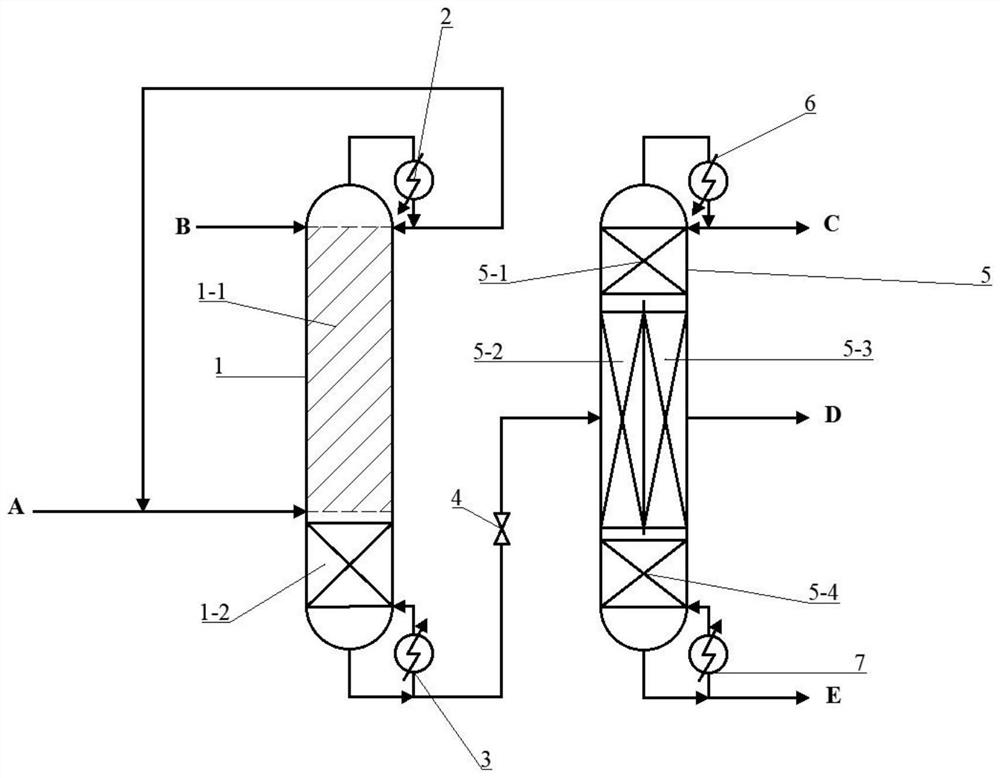

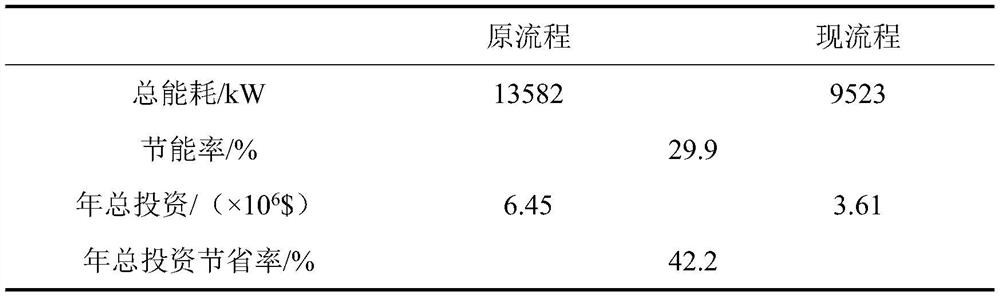

Novel reactive distillation process for separating methyl acetate hydrolysate by dividing wall column

PendingCN111606797AIncrease conversion rate per passReduce energy consumptionOrganic compound preparationChemical industryHydrolysateReactive distillation

The invention relates to a novel reactive distillation process for separating a methyl acetate hydrolysate by a dividing wall column. A device comprises a reactive distillation tower for generating amethyl acetate hydrolysis reaction and a dividing wall column for separating the methyl acetate hydrolysate. An azeotrope of methyl acetate and methyl alcohol enters the lower part of the reaction section of the reactive distillation tower, and water is added into the upper part of the reaction section. Tower top products of the reactive distillation tower comprise methyl acetate and methyl alcohol, and tower bottom products comprise methyl alcohol, water and acetic acid. A tower bottom product is decompressed and then enters the dividing wall column for separation of the three products including methyl alcohol, water and acetic acid. A high-concentration methyl alcohol product is obtained at the top of the dividing wall column, a high-concentration acetic acid product is obtained at the bottom of the dividing wall column, and water and part of acetic acid are obtained laterally. The process has the advantages that methyl acetate circulates in the reactive distillation tower, the one-way conversion rate is increased, and the tower kettle does not contain methyl acetate. The dividing wall column is used for separating the three products of methyl alcohol, water and acetic acid, so that the energy consumption and the equipment investment cost are reduced.

Owner:TIANJIN UNIV

Purification method for glacial acetic acid

InactiveCN102746136AEfficient removalSimple and safe purification processOrganic compound preparationCarboxylic compound separation/purificationChemical industryAcetic acid

The invention discloses a purification method for glacial acetic acid. The method uses industrial grade glacial acetic acid as raw material, acetic anhydride and potassium permanganate are added in turn and heated and refluxed, and then tetraacetyl borax for drying and 4A molecular sieve for adsorption purification are added in turn; at last, purified glacial acetic acid is obtained by distillation method. The purity of the glacial acetic acid obtained by the purification method of the invention is greater than 99.8%. Compared with the prior art, the purification process of the method is safe, simple, energy-saving and emission-reducing. The added raw material of purification agent can be recycled after treatment, and the requirements of green chemical industry and environmental protection are met. The glacial acetic acid product obtained by the purification method has the advantages of stable quality and high purity, and has prospect for industrial production.

Owner:TAICANG HUSHI REAGENT

Process for producing acetic acid by utilizing tail gas of calcium carbide furnace

InactiveCN101648858AIncrease added valueReduce manufacturing costCarboxylic preparation from carbon monoxide reactionHigh concentrationSynthesis methods

The invention relates to a process for producing acetic acid by utilizing the tail gas of a calcium carbide furnace. The process is characterized in that after the tail gas of the calcium carbide furnace is treated by dry dedusting, wet dedusting, alkaline wash, coal tar removal and CO purification, a methanol-carbon monoxide low-pressure oxo-synthesis method is adopted to produce acetic acid in aprocess production system. The process places emphasis on purifying the tail gas of calcium carbide and providing CO which is a raw material gas for a production system for producing the acetic acidwith a high added value by recovering, optimizing and utilizing high-concentration CO in the tail gas of the calcium carbide. The invention has the following technical characteristics of opening a newraw material source of acetic acid production, sufficiently recovering and utilizing the CO in the tail gas of the calcium carbide so as to convert the CO into an acetic acid product with a higher added value, reducing the production cost of acetic acid, improving the economic benefit of the product, reducing the pollution treatment cost of the tail gas of the calcium carbide and being beneficialto the establishment of a circulating economic circle in the field.

Owner:傅永茂

Processes for purifying acetic and hydrating anhydride

ActiveUS9908835B2Reduce acetic anhydride concentrationEasy to produceOrganic compound preparationPreparation from carboxylic acid anhydridesAcetic acidAcetic anhydride

Processes for purifying acetic acid by distilling a process in a column in which acetic anhydride is formed in the lower portion of the column. The product stream withdrawn from the column comprises acetic acid, water at a concentration of no more than 0.2 wt. %, and acetic anhydride at a concentration of no more than 600 wppm. The process further comprises hydrating the acetic anhydride in the product stream to form a purified acetic acid product comprising acetic anhydride at a concentration of no more than 50 wppm.

Owner:CELANESE INT CORP

Citric acid and its preparation method

InactiveCN102336651AIncrease incomeOrganic compound preparationCarboxylic compound separation/purificationAscorbic acid productCitric acid

The invention relates to citric acid and a preparation method, which belongs to the food processing technical field. The invention is characterized in that citric acid uses the fruits of lemon, orange, plum, apricot, peach and the like, and the raw materials are carried out the processes of clearing, filtering, neutralizing, decolouring, concentrating and the like to obtain a citric acid product. The citric acid can be widely utilized in the food processing industry, is an important food organic acidity, and is an additive for beverage, candy and caned food, the market prospect is wide and the citric acid processing is capable of raising the income of the peasants.

Owner:耿庆水

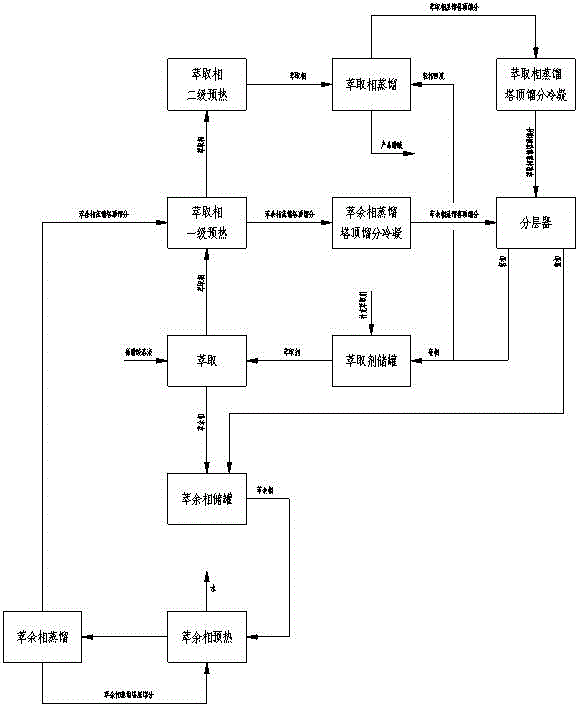

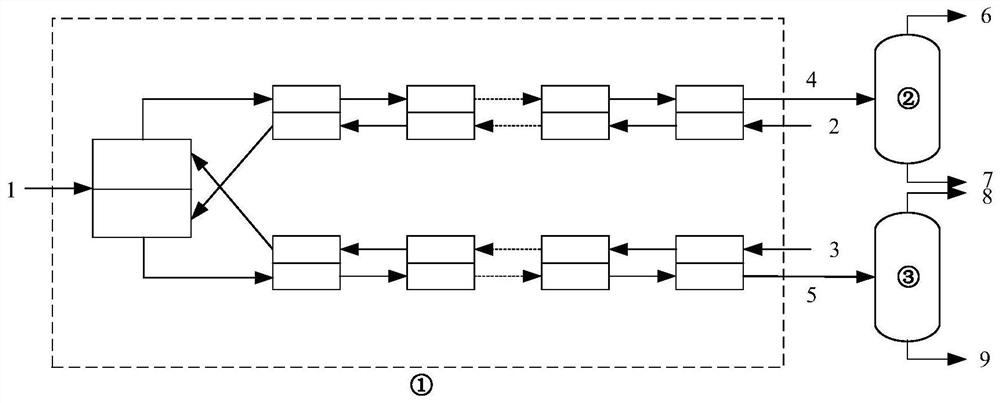

Method for recovering dilute acetic acid based on extraction/azeotropic distillation coupling process

InactiveCN110156590ALow extraction energy consumptionExtraction energy consumption is goodCarboxylic compound separation/purificationRaffinateAzeotropic distillation

The present invention relates to a process for recovering dilute acetic acid through extraction / azeotropic distillation coupling using a mixture of isopropyl acetate and isopropyl alcohol as a solvent. In this method, isopropyl acetate and isopropyl alcohol act as both extractants in an extraction column and azeotropic agent in an azeotropic distillation column. At first, that low-concentration acetic acid waste water and the solvent are contacted in the extraction column in a counter-current to generate liquid-liquid extraction. The extractive phase rich in acetic acid is sent to the azeotropic distillation column to obtain a high purity acetic acid product at the bottom of the azeotropic distillation column. The water-rich raffinate is fed to the top of the solvent recovery column for solvent recovery. The products at the top of azeotropic distillation tower and solvent recovery tower are sent to a phase separator for liquid-liquid phase separation, the organic phase is sent back tothe bottom of extraction tower for circulation, and the aqueous phase is sent to the solvent recovery tower. The invention uses the liquid-liquid extraction method for carrying out the pre-concentration operation, and the energy consumption is greatly reduced; at that same time, isopropyl acetate and isopropyl alcohol are adopted as a mixed solvent to reduce the circulating amount of the solvent,thereby reducing the equipment investment and further reducing the energy consumption. The invention has the characteristics of high separation efficiency and high recovery rate.

Owner:EAST CHINA UNIV OF SCI & TECH

Acetic acid production methods incorporating tin or ruthenium catalyst stabilizers

InactiveUS20070225521A1Organic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidProtein carbonyl

Processes for the production of acetic acid by carbonylation of methanol, and reactive derivatives thereof, in a reaction mixture using a rhodium-based catalyst system with at least one catalyst stabilizer selected from the group of ruthenium catalyst stabilizers, tin catalyst stabilizers, and mixtures thereof are provided. The catalyst stabilizers minimize precipitation of the rhodium metal during recovery of the acetic acid product, particularly in flasher units in an acetic acid recovery scheme. Stability of the rhodium metal is achieved even when the acetic acid is produced in low water content reaction mixtures in the presence of an iodide salt co-promoter at a concentration that generated an iodide ion concentration of greater than about 3 weight % of the reaction mixture. The stabilizing ruthenium or tin compounds may be present in the reaction mixture for the production of acetic acid at molar concentrations of ruthenium or tin metal to rhodium of about 0.1:1 to about 20:1.

Owner:CELANESE INT CORP

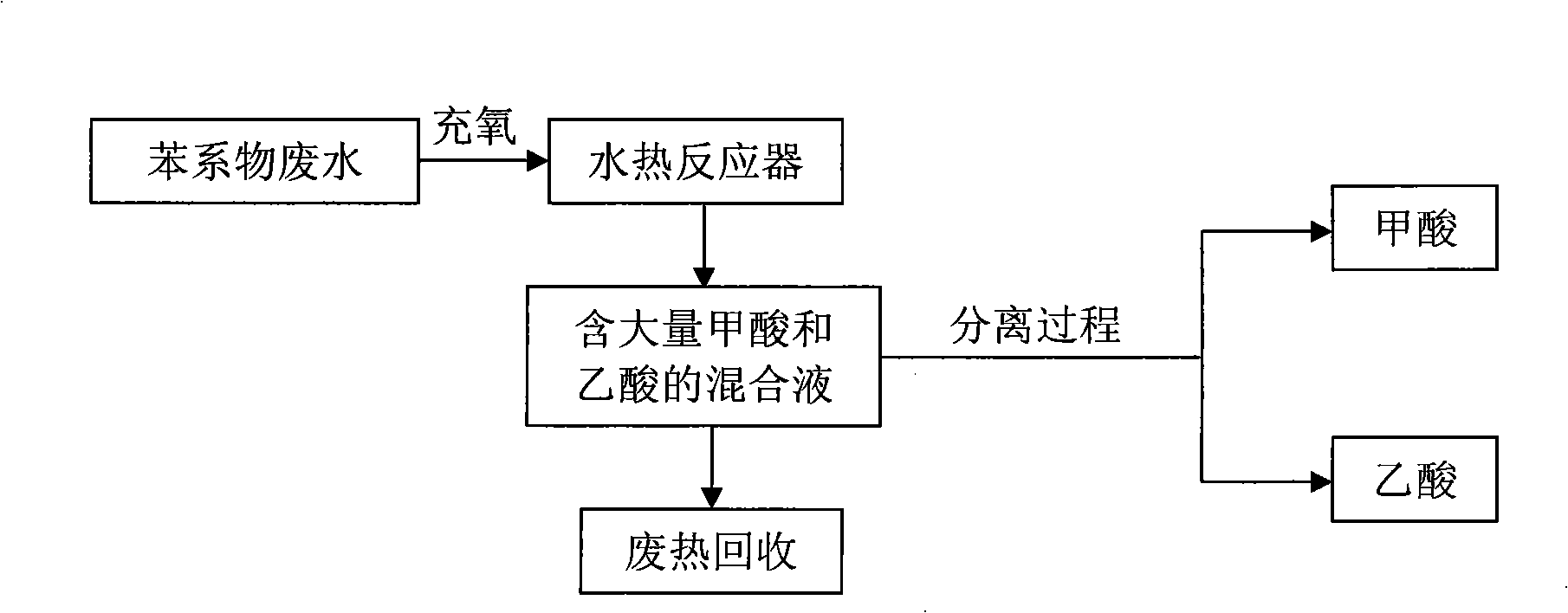

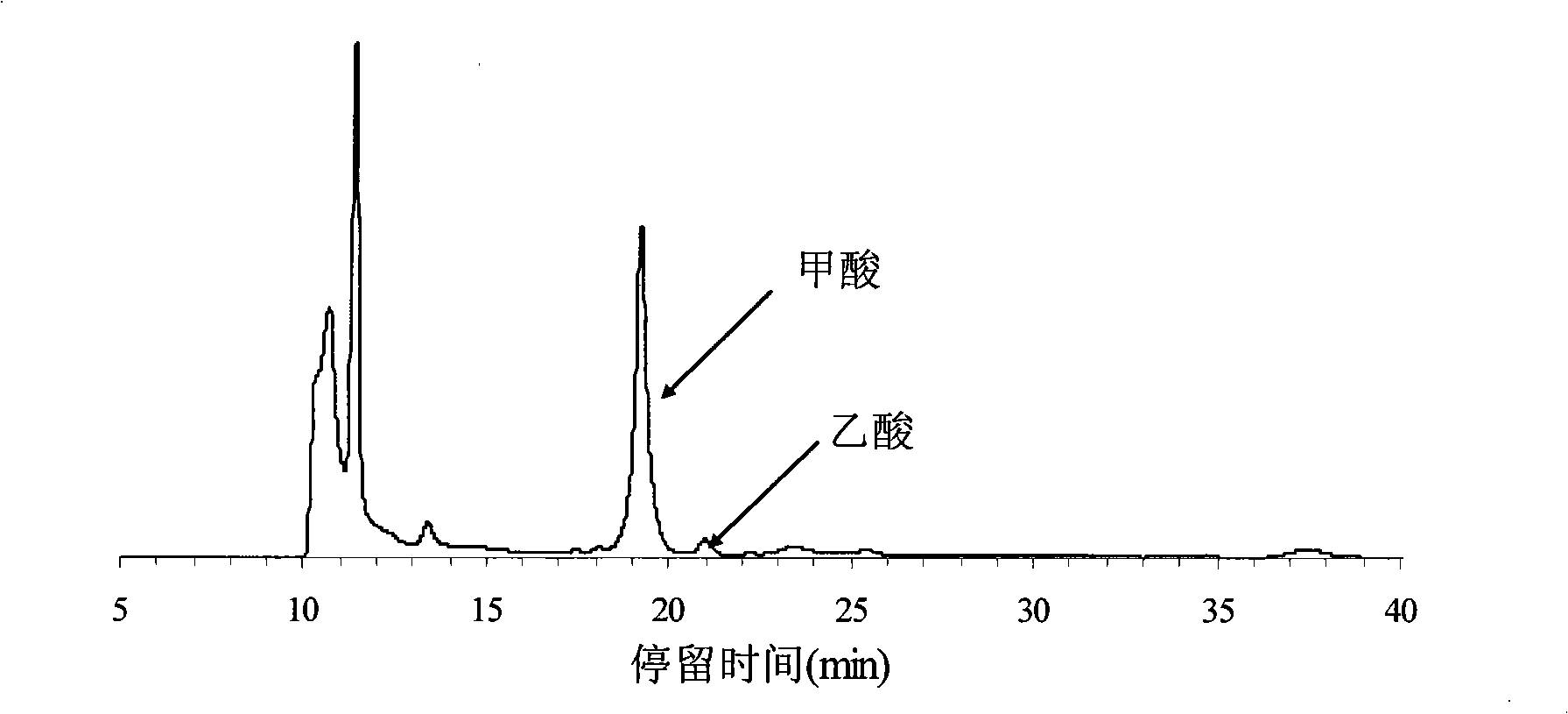

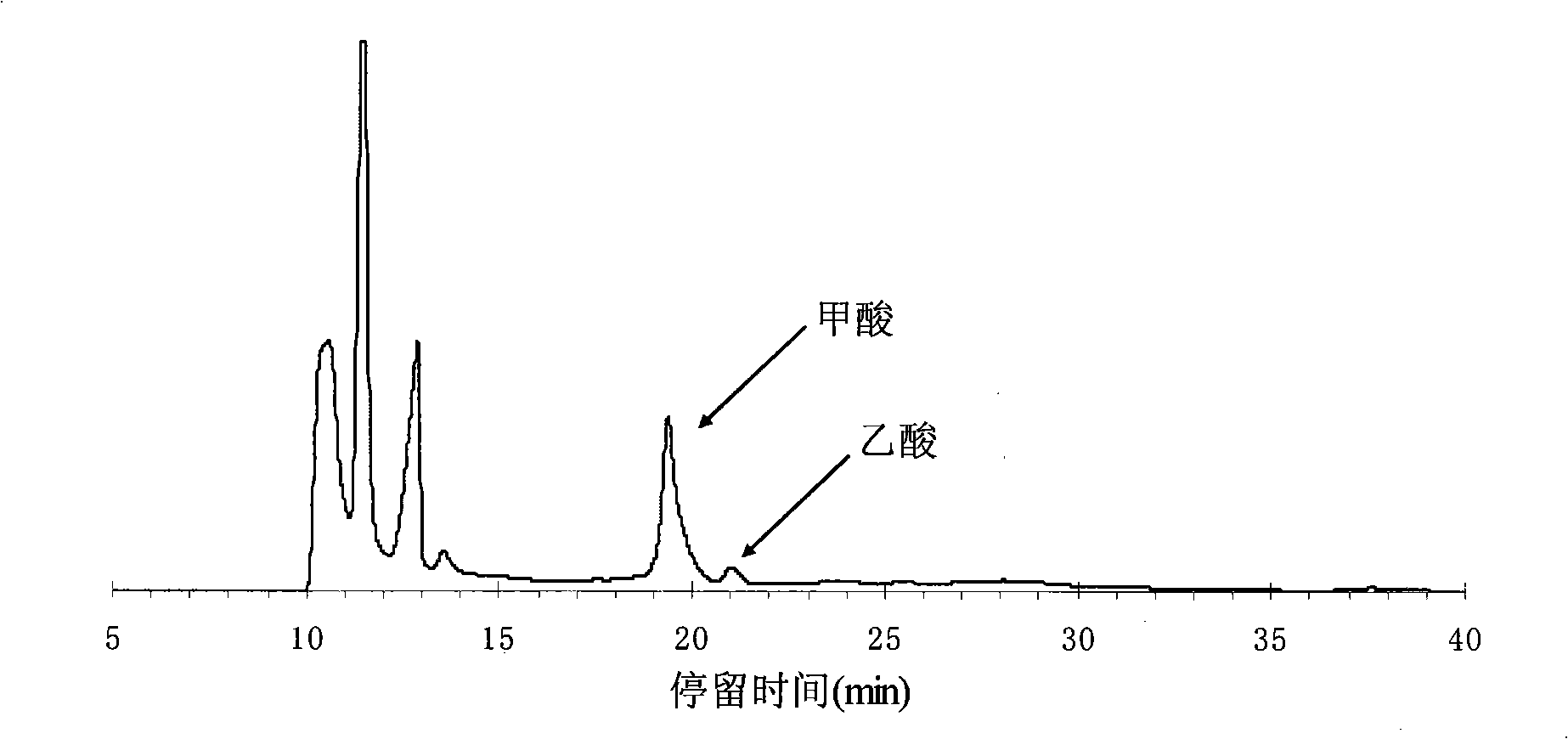

Method for preparing low-grade aliphatic acid from benzene and its homologues waste water

InactiveCN101260031AIncrease concentrationLow costCarboxylic preparation by oxidationDecompositionResource utilization

The invention relates to a method of using benzene series wastewater to prepare low-class fatty acid, in particular to a method of transforming benzene series wastewater into formic acid and acetic acid. The benzene series material of the invention is the organic matter with the molecular structure containing benzene rings. Benzene series wastewater and oxygen (oxygen gas, air or hydrogen peroxide) are first input into a hydrothermal oxidation reactor; then reaction is carried out under the conditions that: the temperature is 200-450 DEG C; the pressure is 5-20 Mpa; the pH value is 7-14; the addition amount of oxygen is 10-200 percent of the needed oxygen content to oxidize all carbon contained in the benzene series material of wastewater into CO2; reaction time is from 30 s to 30 min. The benzene series material is first oxidized to crack benzene rings, generate muconic acid and other unsaturated diacid; a great amount of formic acid and acetic acid is generated further by controlling the hydrothermal oxidation reaction of unsaturated diacid; finally mixed solution containing a great amount of formic acid and acetic acid is separated to prepare formic acid and acetic acid. Differing from the prior method of realizing mineralization through the thermal oxidative decomposition of wastewater, the invention aims to transform wastewater containing benzene series material into formic acid and acetic acid products which can be utilized, so as to realize the resource utilization of wastes.

Owner:TONGJI UNIV

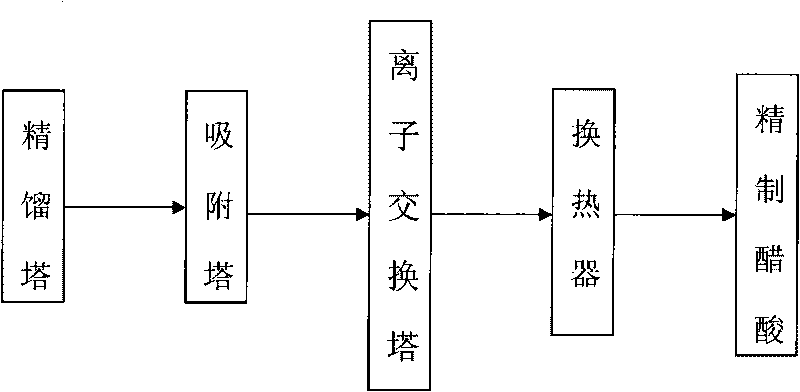

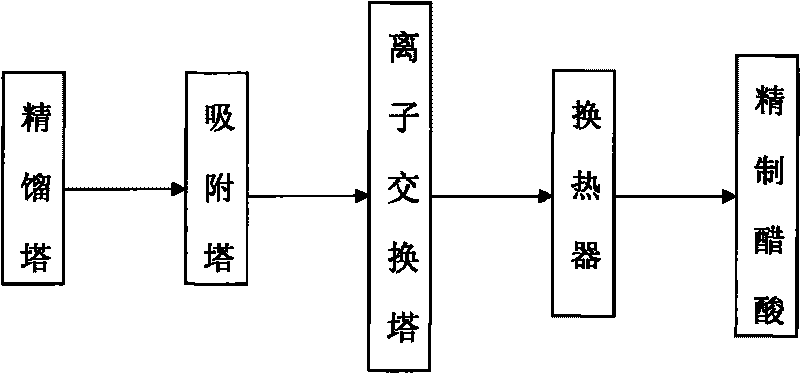

Method for de-iodinating and refining acetic acid

ActiveCN101712613AMeets requirementsIon-exchange process apparatusIon-exchanger regenerationAcetic acidSorbent

The invention belongs to the field of refining chemical products, and particularly discloses a method for de-iodinating and refining acetic acid. The refining method comprises the following steps: absorbing an acetic acid finished product collected from a rectifying tower by an adsorbent or an ion exchange resin; reducing iodine in the acetic acid to below 10PPb; and reducing the content of formic acid to less than or equal to 30PPm. The refined acetic acid product obtained through the refining process meets the requirements of downstream high-end products and the requirements of high-end customers for producing vinyl acetate and the like.

Owner:YANKUANG GRP CO LTD

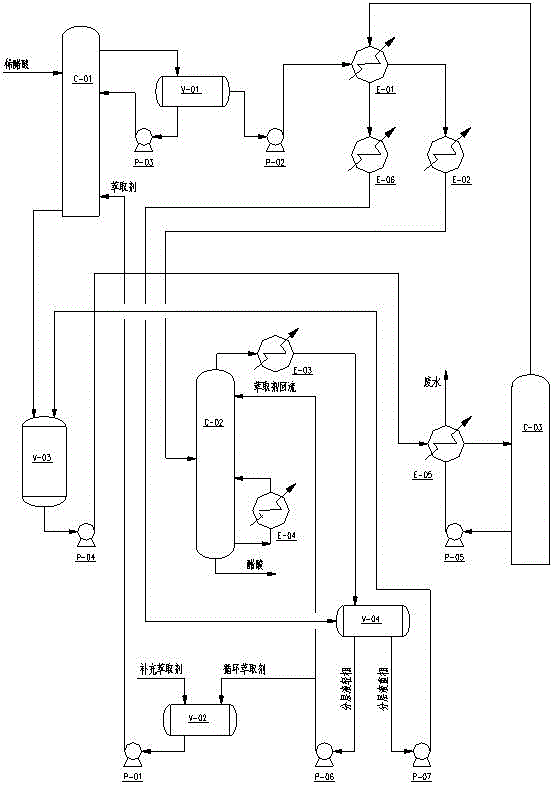

Method and system for recovering acetic acid from acetic acid aqueous solution

InactiveCN106542990AHigh purityMeet acetic acid requirementsCarboxylic compound separation/purificationAcetic acidDistillation

The present invention discloses a method and a system for recovering acetic acid from an acetic acid aqueous solution. The technical scheme of the method comprises that an acetic acid aqueous solution and an extractant enter an extraction tower and liquid-liquid extraction operation is performed; the extraction phase is pre-heated and then enters an extraction phase distillation tower, the tower bottom distillate is an acetic acid product, and the tower top distillate is condensed and then enters a layering device; the raffinate phase is pre-heated and then enters the extraction phase distillation tower, the tower top distillate is condensed and then enters the layering device, and the tower bottom distillate is wastewater; and the heavy phase separated by the layering device is the extractant, one part of the extractant returns to the liquid-liquid extraction process, the other part of the extractant refluxes to the extraction phase distillation process, and the light phase separated by the layering device returns to the raffinate phase distillation process. According to the present invention, the treatment process is simple, the investment cost is low, the reliability is good, the separation effect is good, and the purity of the separated acetic acid is high and meets the industrial raw material acetic acid requirement.

Owner:SINOPEC NANJING ENG & CONSTR +1

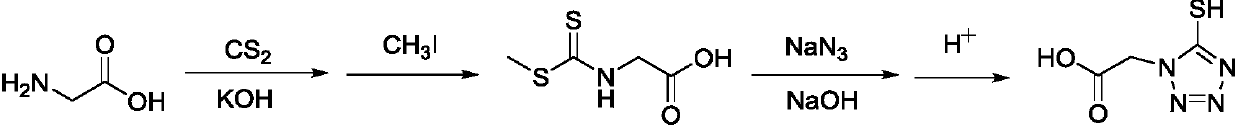

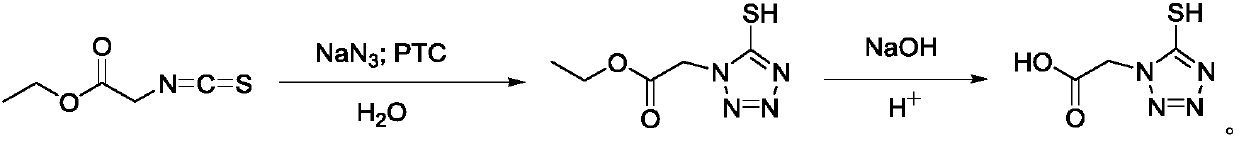

5-tetrazole-thione acetic acid and preparation method of sodium salt thereof

The invention discloses a preparation method of 5-tetrazole-thione acetic acid. Sodium azide, benzyl trimethyl ammonium chloride and water are added into a three-mouth flask of 500mL, and ethyl acetate for an ethyl isothiocyanatoacetate reaction system is dropwise for extraction; organic phases are mixed, and a solvent is spin-dried to obtain a crude 5-tetrazole-thione acetic acid product; the obtained crude 5-tetrazole-thione acetic acid product is heated, dissolved and clarified, and activated carbon is added and stirred; a filter cake is subjected to vacuum drying to obtain the product 5-tetrazole-thione acetic acid. The preparation method has the advantages that a poisonous reagent methyl iodide is omitted in the synthesis of the 5-tetrazole-thione acetic acid and sodium salt thereof according to the above steps, the yield of the whole 5-tetrazole-thione acetic acid synthesis method is as high as 80%, and the single-step yield of the mono-sodium salt and disodium salt of the 5-tetrazole-thione acetic acid is as high as 90%. By adopting the method, the process cost is greatly reduced, and a feasible way is provided for industrialized production of the5-tetrazole-thione acetic acid.

Owner:九江中星医药化工有限公司

Separation of N,N-dimethylacetamide-acetic acid mixed system

ActiveCN112574059ABreak the constraintsSimple processCarboxylic acid amide separation/purificationCarboxylic compound separation/purificationAcetic acidPhysical chemistry

The invention relates to a separation method of an N, N-dimethylacetamide-acetic acid mixed system, which comprises the step of carrying out two-phase multistage counter-current extraction on the N,N-dimethylacetamide-acetic acid mixed system by using an extracting agent group consisting of a hydrophobic phase extracting agent and a hydrophilic phase extracting agent; and feeding the N,N-dimethylacetamide-acetic acid mixed system from the middle of the two-phase multistage counter-current extraction, rectifying an extraction phase and a raffinate phase of the two-phase multi-stage extraction separately, and finally obtaining N,N-dimethylacetamide and acetic acid products separately, so as to realize separation of the mixed system. According to the invention, the two-phase multi-stage counter-current extraction of the selected solvent can effectively break through the restriction of the N,N-dimethylacetamide-acetic acid mixed system, so that the recovery of N,N-dimethylacetamide and acetic acid is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for producing propionic acid through OXO process

PendingCN112441903ASimple production processTake advantage ofCarboxylic preparation from carbon monoxide reactionChemical recyclingPropanoic acidPtru catalyst

The invention provides a device and method for producing propionic acid through an OXO process. The device comprises a reactor, a flash tank, a light component tower, a drying tower, a heavy componenttower, a stripping tower, an acetic acid removing tower, a propionic acid tower, an ethanol-rich methanol raw material pump, a catalyst mother liquor pump, a light component tower bottom pump, a drying tower bottom pump, a heavy component tower bottom pump, a stripping tower bottom pump and an acetic acid removing tower bottom pump which are connected through pipelines. The method comprises the following steps: adding a carbon monoxide raw material and an ethanol-rich methanol raw material into the reactor, and carrying out an OXO reaction under the action of a catalyst to generate a mixed solution of acetic acid and propionic acid; rectifying the mixed solution in an acetic acid rectifying area and a propionic acid rectifying area to obtain an acetic acid product and a propionic acid product respectively; pumping the catalyst into the reactor for recycling through the catalyst mother liquor pump in the flash tank,; and pumping light components such as methyl acetate, methyl iodide and water rectified from each tower top back into the reactor from the tower tops for recycling. According to the method, an ethanol-rich methanol product is used for producing acetic acid and propionicacid through the OXO process, so good economic benefits are obtained.

Owner:SINOPEC CHANGCHENG ENERGY CHEM NINGXIA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com