Method and system for recovering acetic acid from acetic acid aqueous solution

A kind of acetic acid aqueous solution and acetic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of large-scale industrial production difficulties, low membrane flux affecting production, replacement affecting normal production, etc., to achieve comprehensive utilization of heat , good reliability and low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

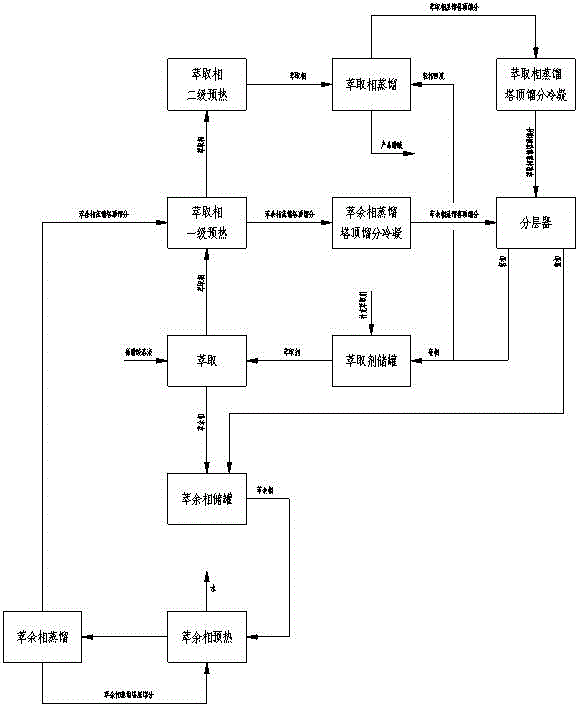

Method used

Image

Examples

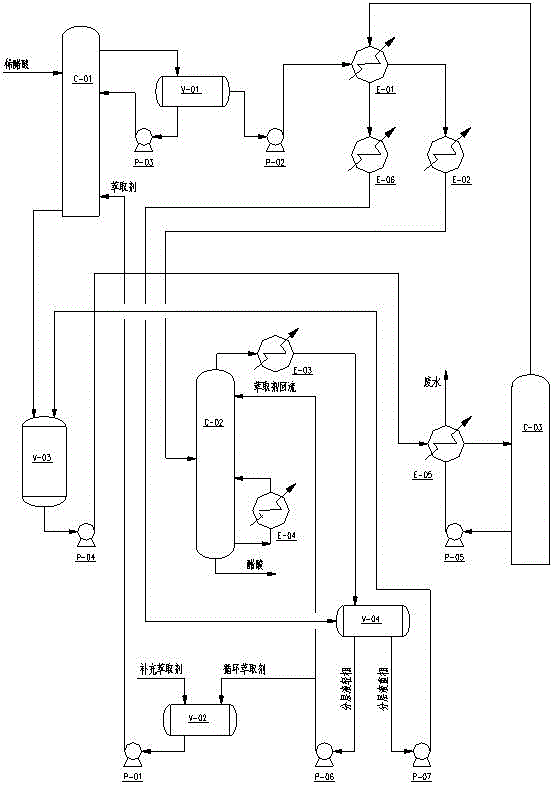

Embodiment 1

[0030]Acetic acid aqueous solution 50000kg / h with a mass concentration of 30% and extractant (extractant is a mixture of isopropyl acetate, methyl ethyl ketone and hexane, wherein the mass fraction of isopropyl acetate is 85.00%, the mass fraction of methyl ethyl ketone is 6.50%, hexane The mass fraction is 8.50%) 71500kg / h enters the extraction tower C-01 for liquid-liquid extraction operation, and the operating pressure of the extraction tower C-01 is controlled at 0.30MPaG and the temperature is 40°C. Extraction phase 96985kg / h from the top of extraction tower C-01 enters extraction phase storage tank V-01, the upper liquid phase of extraction phase storage tank V-01 92330kg / h enters the primary preheater E-01 of the extraction phase, and the lower liquid 4655kg / h is refluxed to the extraction tower C-01 through the drain pump P-03 of the extractant storage tank. The raffinate phase from the bottom of the extraction tower C-01 enters the raffinate phase storage tank V-03 a...

Embodiment 2

[0032] 60000kg / h of acetic acid aqueous solution with a mass concentration of 50% and extractant (the extractant is a mixture of isopropyl acetate, methyl ethyl ketone and hexane, wherein the mass fraction of isopropyl acetate is 85.00%, the mass fraction of methyl ethyl ketone is 6.50%, and the mass fraction of hexane The mass fraction is 8.50%) 85800kg / h enters the extraction tower C-01 for liquid-liquid extraction operation, and the operating pressure of the extraction tower C-01 is controlled at 0.30MPaG and the temperature is 40°C. The extraction phase 119798 from the top of the extraction tower C-01 enters the extraction phase storage tank V-01, the upper liquid phase of the extraction phase storage tank V-01 114985kg / h enters the primary preheater E-01 of the extraction phase, and the lower liquid 4813kg / h Return to the extraction column C-01 through the pump P-03. The raffinate phase from the bottom of the extraction tower C-01 enters the raffinate phase storage tank V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com