Patents

Literature

282 results about "Isopropyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopropyl acetate is an ester, an organic compound which is the product of esterification of acetic acid and isopropanol. It is a clear, colorless liquid with a characteristic fruity odor. Isopropyl acetate is a solvent with a wide variety of manufacturing uses that is miscible with most other organic solvents, and moderately soluble in water. It is used as a solvent for cellulose, plastics, oil and fats. It is a component of some printing inks and perfumes.

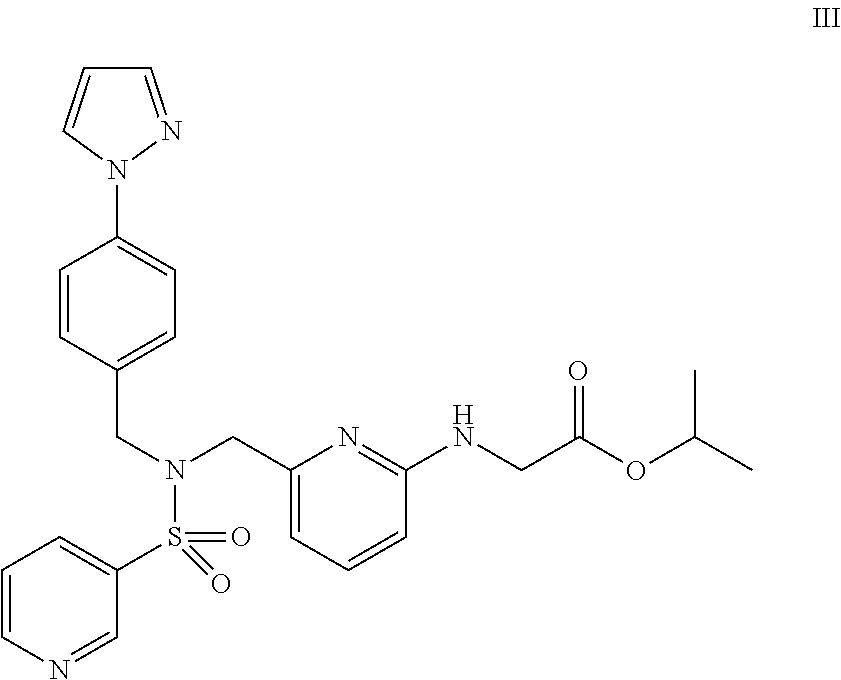

Combination of sulfonamide compound

ActiveUS20140018396A1Good effectReduce the impactBiocideOrganic chemistryIntra ocular pressureOphthalmology

The object of the present invention is to discover a combination of preventive or therapeutic drugs for glaucoma or ocular hypertension, which is useful as a preventive or therapeutic agent for glaucoma or ocular hypertension. By combining isopropyl(6-{[4-(pyrazol-1-yl)benzyl](pyridin-3-ylsulfonyl)aminomethyl}pyridin-2-ylamino)acetate with other preventive or therapeutic drug for glaucoma or ocular hypertension, their intraocular pressure lowering effects are complemented and / or enhanced each other. As for the administration form, these drugs may be administered concomitantly or may be administered as a combination drug.

Owner:SANTEN PHARMA CO LTD

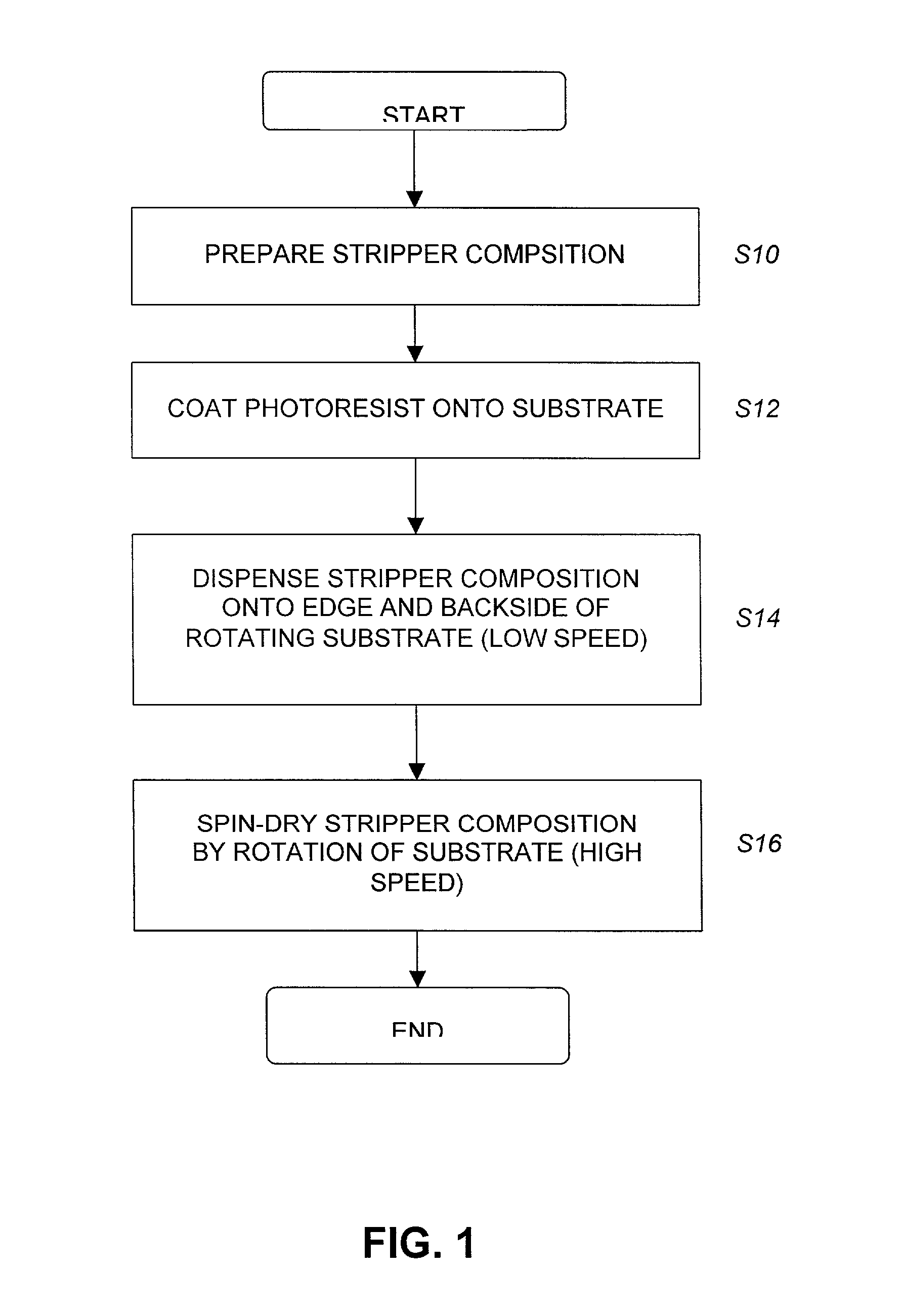

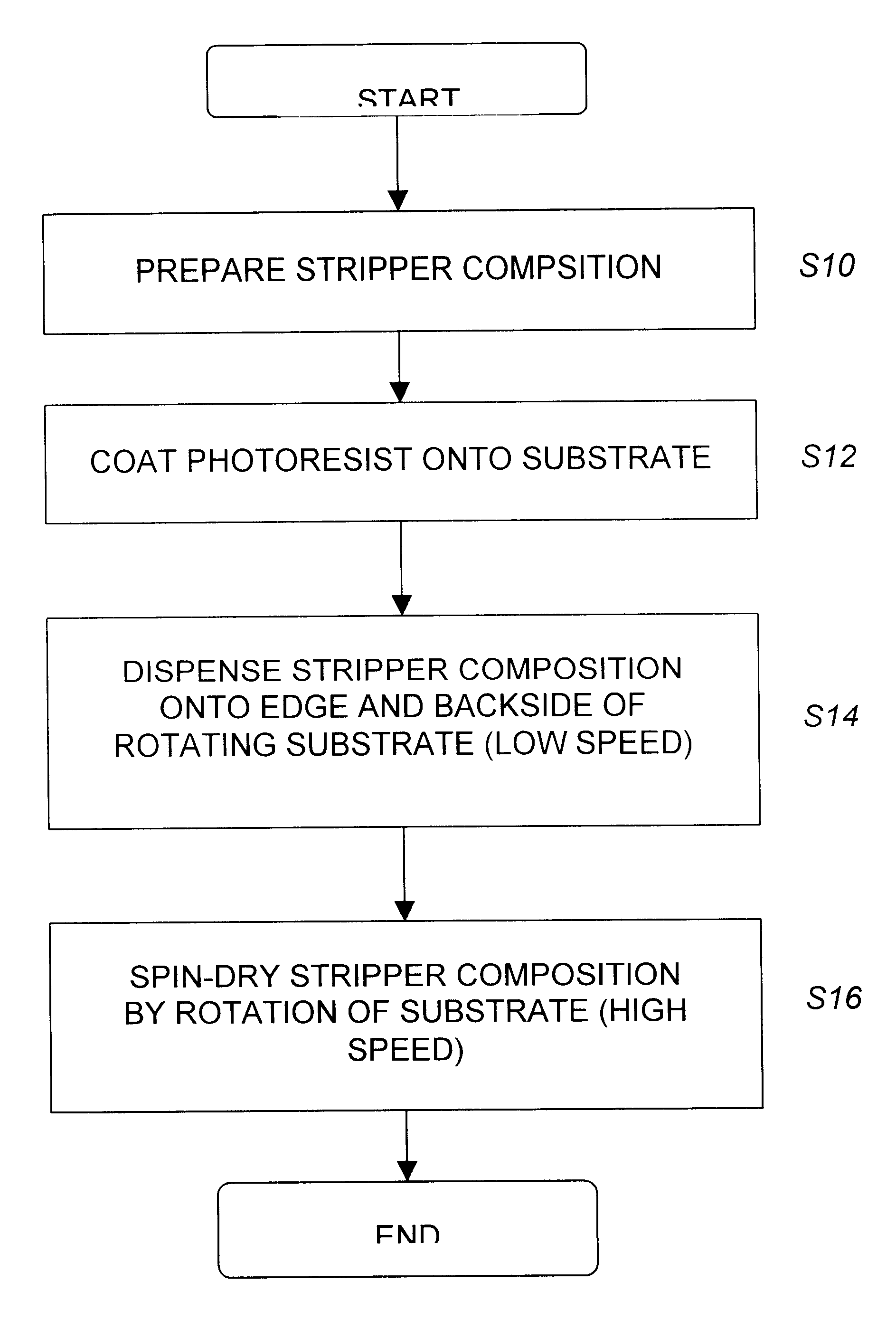

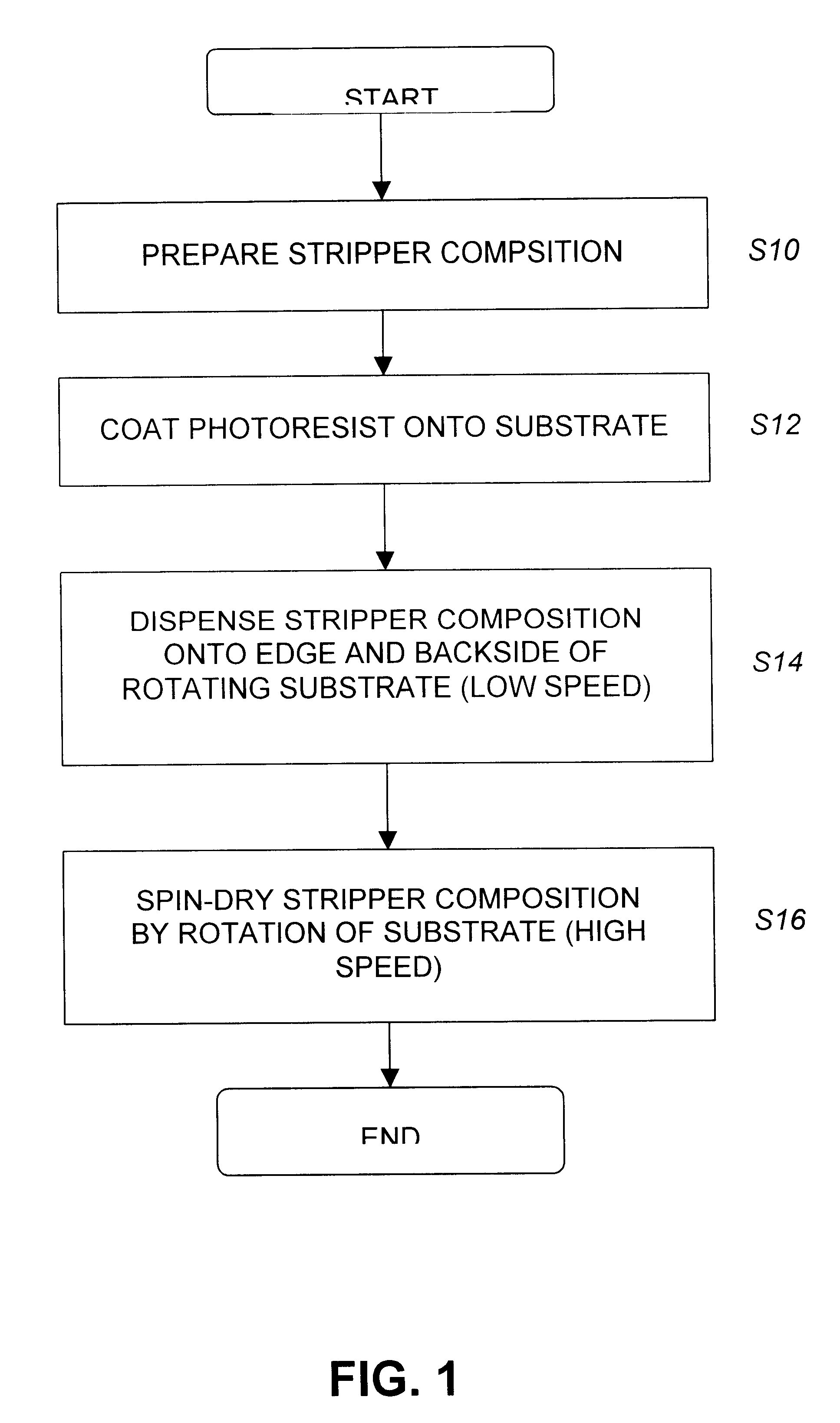

Photoresist stripper compositions

InactiveUS20030113673A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusAmyl acetateMethyl group

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

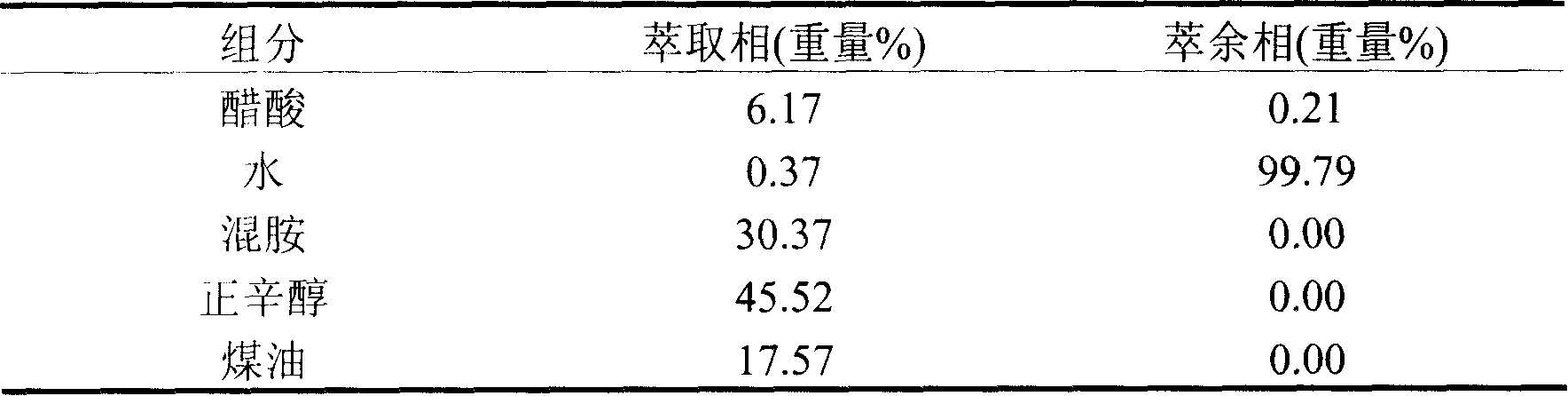

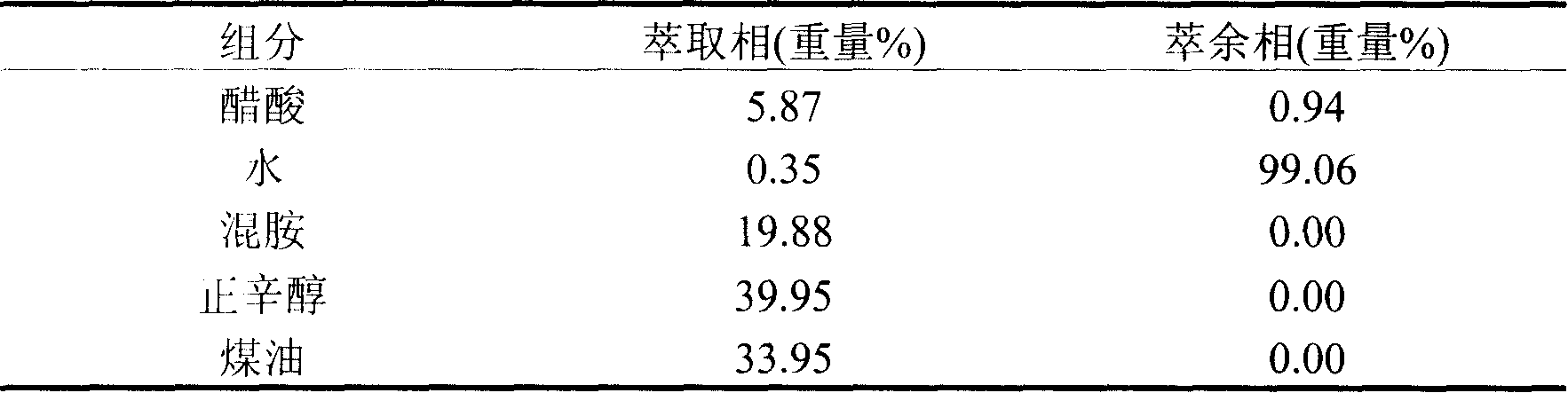

Method for recycling acetic acid in dilute acetic acid

ActiveCN101172941AImprove separation efficiencyIncreased acetic acid contentLiquid solutions solvent extractionCarboxylic compound separation/purificationBenzeneButyl acetate

The invention relates to a method for recycling acetic acid from diluted acetic acid, and aims at solving the problem that the recycling of acetic acid in the hydrolysis of furfural and methyl acetate as well as the Fischer-Tropsch combined production is difficult. The invention comprises the steps as follows: a) diluted acetic acid is extracted by a pulse filling extracting tower, the extractionphase containing extracting agent, the acetic acid and little water for the tower top is acquired, and the residual extraction phase of water containing micro acetic acid from the tower kettle is acquired; b) the extraction phase in an extracting agent recycling tower is conveyed; c) acetic acid 1 is fed into an azeotropic rectifying tower which utilizes one kind of benzene, cyclohexane, ethyl acetate, isopropyl acetate and butyl acetate as the extrainer, two-phase mixture of the extrainer and the water at a phase separator at the top of the tower is acquired, the water is extracted out from the tower top, and the retrainer returns into the tower. The utility model has the technical proposal of producing pure acetic acid at the tower top, solves the problems above, and adapts the industrial productions including recycling of acetic acid from wasted aldehyde water and extracting and refining acetic acid in the methyl acetate hydrolysis technique.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

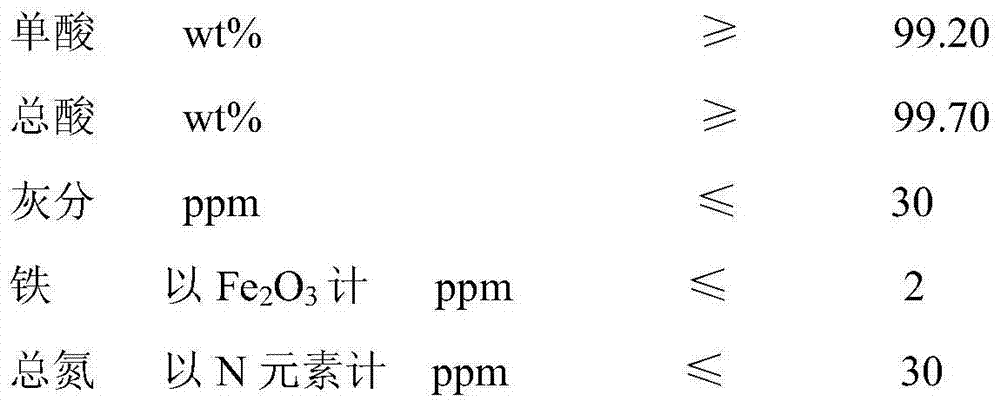

Method for refining long-carbon chain dicarboxylic acid

ActiveCN104496793AMeet the technical requirements of useLess investmentCarboxylic compound separation/purificationEngineeringCarboxylic acid

The invention relates to a method for refining long-carbon chain dicarboxylic acid. A long-chain dicarboxylic acid crude product prepared by a fermentation method is used as a raw material, acetic acid is used as a solvent, and the refining and purification are performed by recrystallization treatment. The method comprises the process steps of bleaching filtration, cooling crystallization, centrifugal separation, centrifugal material washing, secondary centrifugation and drying, and is characterized in that a. the long-chain dicarboxylic acid crude product to be refined does not need to be dried; b. the acetic acid solvent is recycled by an azeotropic distillation method, and isopropyl acetate is used as an azeotropic dehydrating agent; and c. the isopropyl acetate is used as a centrifugal material washing solvent for replacing the acetic acid. The purification method of the long-carbon chain dicarboxylic acid provided by the invention has the advantages of distillation equipment investment conservation, low operating power consumption, good product color, high purity, high refining yield and low production cost, the long-carbon chain dicarboxylic acid to be refined does not need to be dried and dehydrated, and the acetic acid solvent is completely recyclable. The quality of the refined product can meet the technical requirements of use of condensed monomer raw materials used by synthesis of high polymer materials.

Owner:山东广通新材料有限公司

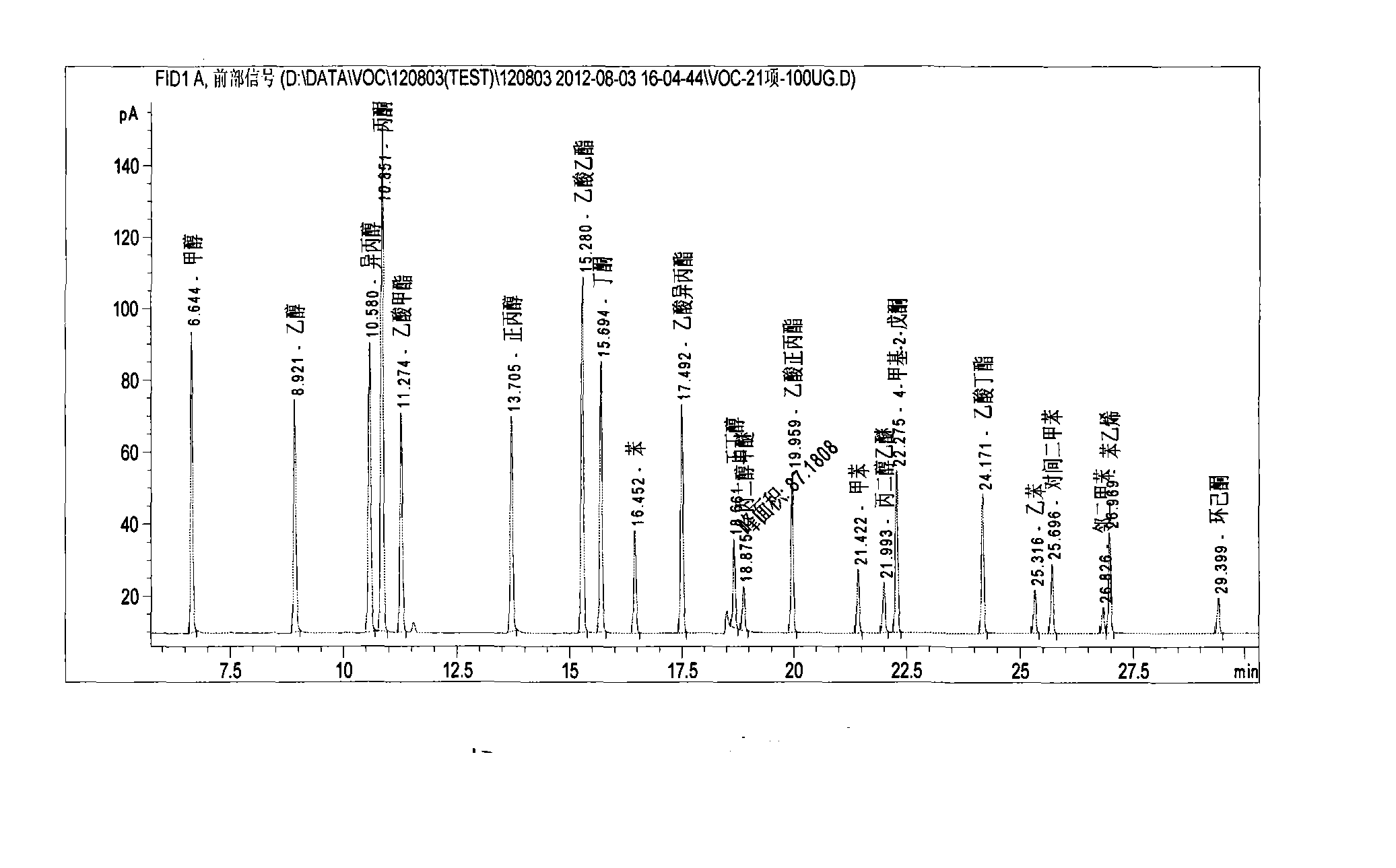

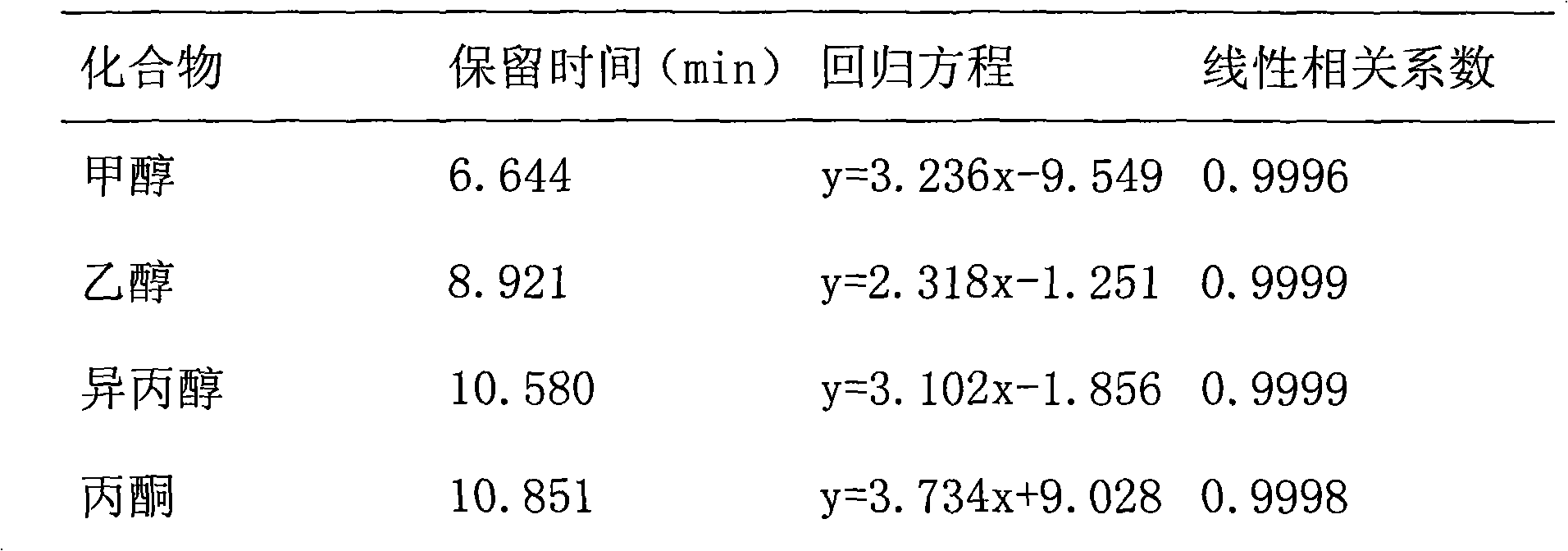

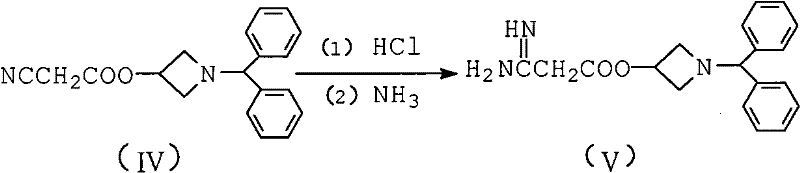

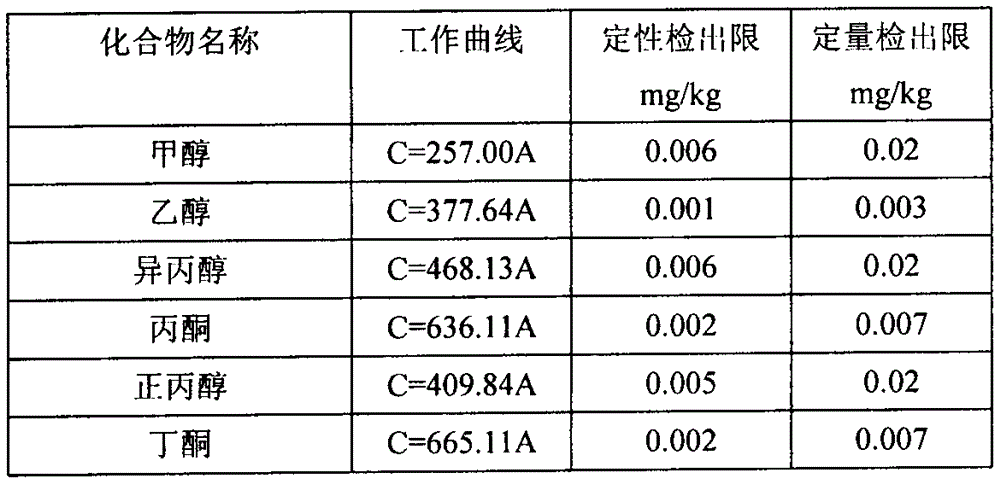

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

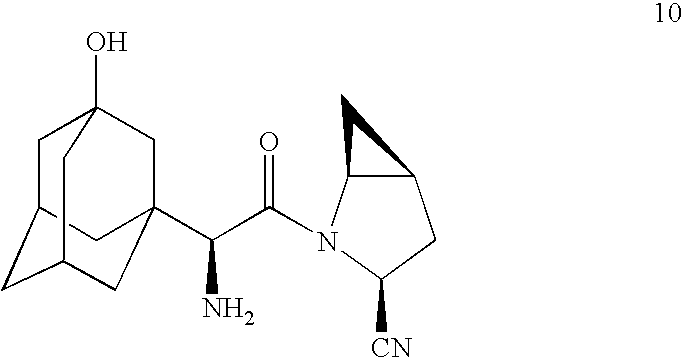

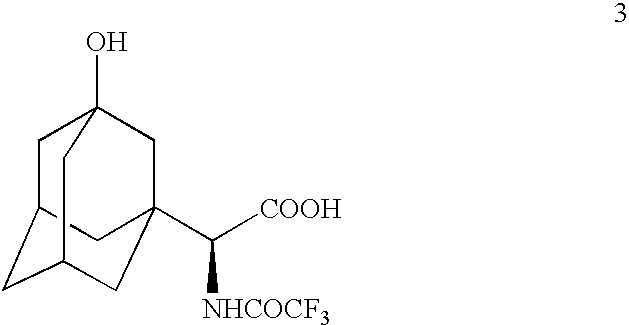

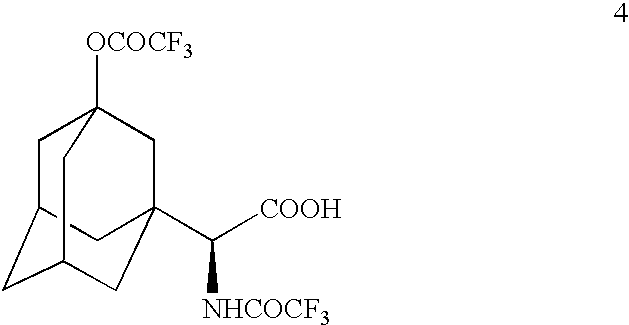

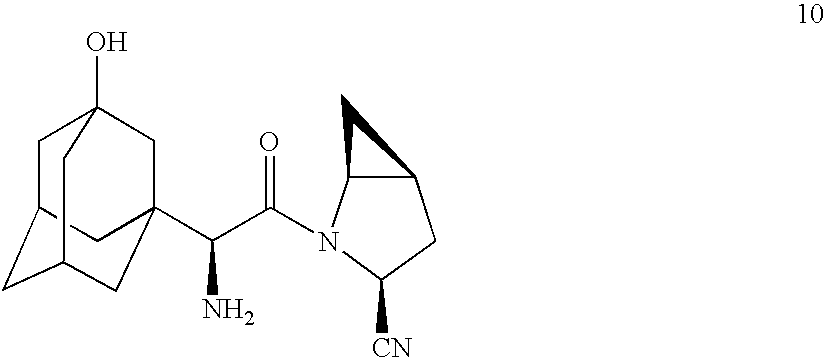

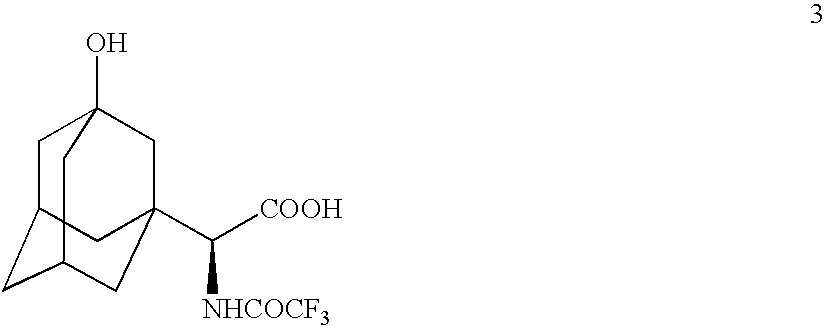

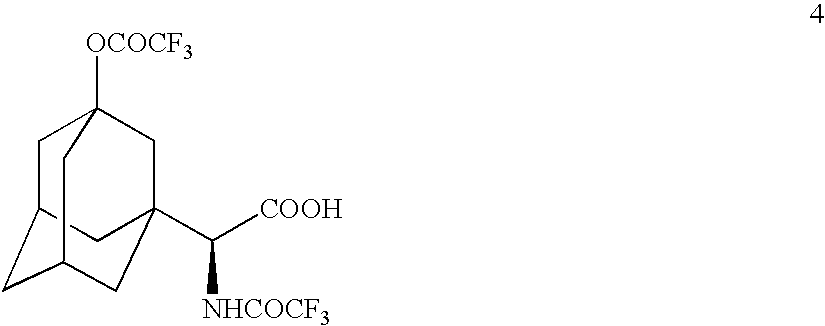

Process for preparing a dipeptidyl peptidase IV inhibitor and intermediates employed therein

A process is provided for preparing a dipeptidyl peptidase IV inhibitor of the structurewhereinis treated with TFAA in isopropyl acetate to protect the tertiary hydroxyl group as a trifluoroacetate group to form 4(which is a novel intermediate)which is converted to acid chloride compound 5(which is a novel compound)using Vilsmeier reagent or other chloro reagent and coupled with compound 6 in a heterogeneous mixture of ethyl acetate and aqueous bicarbonate to give compound 7The N,O-bis(trifluoroacetyl) groups of compound 7 are deprotected to give free base compound 10.

Owner:ASTRAZENECA AB

Continuous reaction rectification process and rectification equipment for synthesizing isopropyl alcohol

ActiveCN102755759AIncrease conversion rate of exchange reactionReduce production energy consumptionOrganic compound preparationHydroxy compound preparationSodium methoxideTrans esterification

The invention provides a continuous reaction rectification process that isopropyl acetate and methyl alcohol are taken as raw materials to be synthesized into isopropyl alcohol through a trans-esterification method under the existence of basic catalysts such as sodium methylate. According to the invention, a reaction rectification technology is adopted, so that the isopropyl acetate and methyl alcohol are fed from the upper part and the lower part of a reaction section of a reaction rectifying tower respectively to be reacted and separated so as to realize continuous production; and products at the top and the bottom of the reaction rectifying tower are separated and purified by a methyl ester rectifying tower, a sodium methylate rectifying tower, an evaporator and a isopropyl alcohol refining tower, so that isopropyl alcohol is obtained, and raw material and catalyst which are not reacted are recycled at the same time. The continuous reaction rectification process for synthesizing isopropyl alcohol has the characteristics of continuity in operation, low energy consumption, high reaction conversion rate and isopropyl alcohol purity, stable quality, and the like.

Owner:FUZHOU UNIV

Method for preparing and purifying propyl acetate

InactiveCN1733685AOrganic compound preparationCarboxylic acid esters preparationAcetic acidPropyl acetate

The invention relates to a method for preparing and purifying propyl acetate, which comprises charging quantitative acetic acid, n-propanol (or isopropanol) and acidic homogeneous catalyst continuously into a pre-reactor, loading into esterification tower, obtaining crude ester on the top of the tower, loading the crude ester into a liquid-liquid rotating disc extraction tower, extracting and purifying with aqueous solution extracting agent of salts, recycling the extract phase and loading into rectifying tower for continuous distillation, thus obtaining n-propyl acetate or isopropyl acetate whose content is above 99.5% on the bottom of the tower.

Owner:SHANGHAI WUJING CHEM

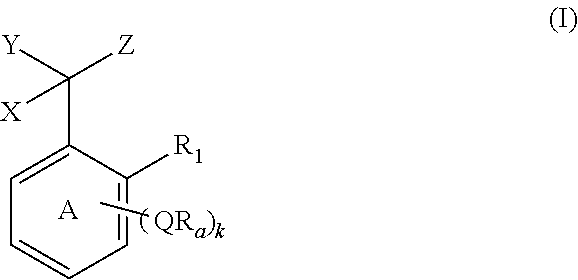

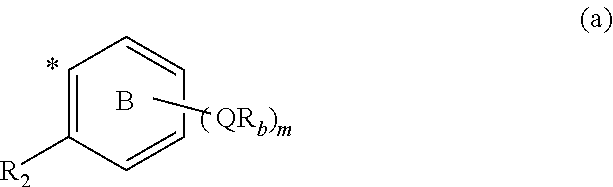

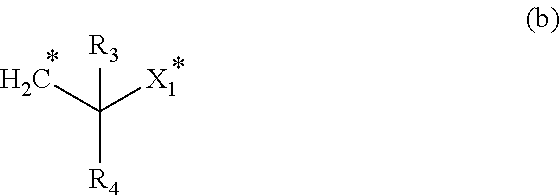

Branched chain-containing aromatic compound

ActiveUS20120059149A1Easy to operatePeptide/protein ingredientsCarboxylic acid amides preparationOperabilityCrystallization

Owner:AJINOMOTO CO INC

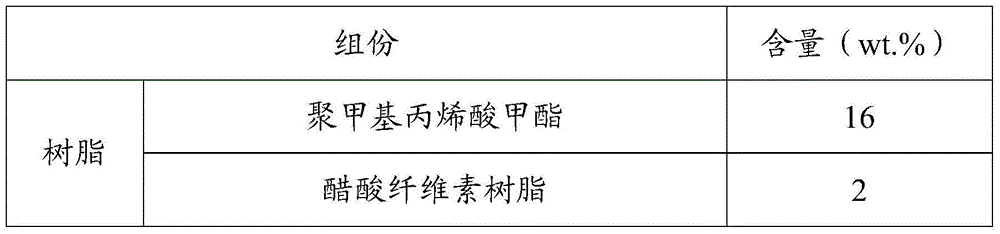

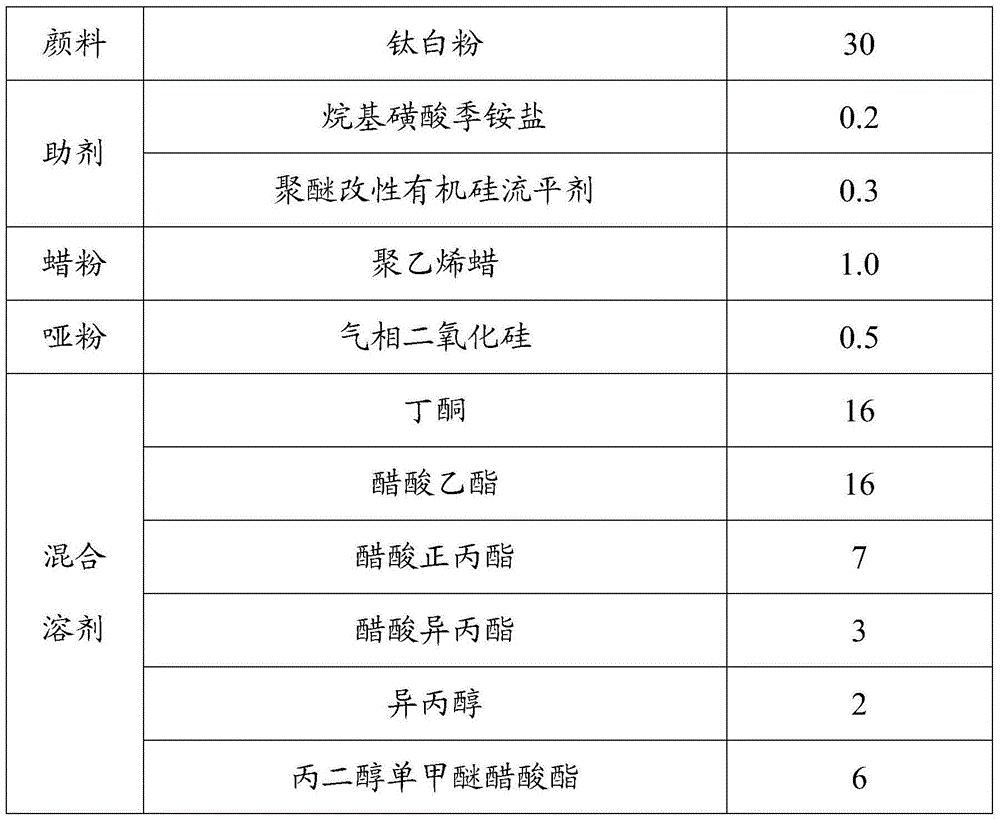

Transfer printing ink with release function

The invention relates to a transfer printing ink with a release function. The transfer printing ink comprises, by weight, 16 to 25% of a polymethacrylate resin, 1.5 to 2.5% of a cellulose acetate resin, 7 to 30% of a pigment, 50 to 62.5% of a mixed solvent, 0 to 2% of an auxiliary agent, 0 to 1% of matt powder and 0 to 2% of wax powder, wherein the mixed solvent is a mixture of two or more selected from the group consisting of ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, toluene, butanone, methyl isobutyl ketone, isopropanol, propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate mixed at any ratio, the auxiliary agent is one or a mixture of more selected from the group consisting of a dispersant, an antistatic agent and an organosilicon leveling agent, the matt powder is gas phase silica, and the wax powder is polymer micro wax powder. The transfer printing ink provided by the invention has all the properties of a traditional transfer printing ink, e.g., pigment concentration, brilliance and good printability and heat resistance, further has excellent release performance and can be used as a release agent in a transfer printing process.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

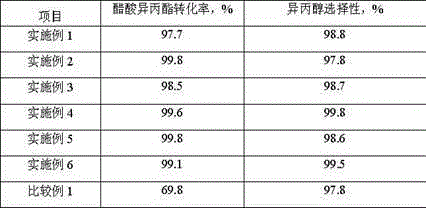

Process for synthesizing isopropyl acetate and method for preparing its catalyst

InactiveCN1483717AHigh activityGood choiceOrganic compound preparationCarboxylic acid esters preparationAcetic acidFixed bed

The present invention relates to a process for synthesizing isopropyl acetate and preparation method of its catalyst. Its process adopts fixed bed reactor, uses solid catalyst, and makes reaction under the condition of gas-liquid-solid three-phase reaction, and its solid catalyst includes modified resin catalyst, silica-gel loaded heteropolyacid catalyst, silica-gel loaded phosphoric acid catalyst and super acidic catalyst, its reaction temp. is 80-125 deg.C, propylene pressure is 0.8-1.4 MPa, acetic acid feeding space velocity is 1.0-2.8 h(-1), propylene feeding space velocity is 80-108 hr(-1), and the mole ratio of acetic acid and propylene is 1:1.15-1.80. Said invention also includes the preparation method of the above-mentioned catalysts.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of isopropanol

ActiveCN106673962ASimple processMild reaction conditionsOxygen-containing compound preparationOrganic compound preparationAcetic acidAlcohol

The invention provides a preparation method of isopropanol. The preparation method of isopropanol comprises the following steps: (1) adding conventional strong-acid cation-exchange resin into a low-carbon alcohol solvent, soaking for 8-24 hours at a temperature of 50-150 DEG C, then introducing inert gas in three stages, and obtaining a catalyst applied to hydrolysis reaction of isopropyl acetate after modification is completed; (2) hydrolyzing isopropyl acetate and water in the presence of a strong-acid cation-exchange resin catalyst modified in the step (1) to generate a mixture with isopropyl alcohol and acetic acid, separating the mixture to obtain isopropyl alcohol, and concentrating the acetic acid and then recycling the acetic acid. The method has the advantages of simple processes, high conversion rate and low energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation of mesitylene from 1,2,4-trimetyhlbenzene by azeotropic distillation

InactiveUS6136155AUsefulness and utilityEasy to separateDistillation purification/separationHydrocarbonsAmyl alcoholBoiling point

Mesitylene is difficult to separate from 1,2,4-Trimethylbenzene because of the proximity of their boiling points. They are readily separated by azeotropic distillation. Effective agents are isopropyl acetate, 2-pentanol and acetonitrile.

Owner:BERG LLOYD

Process for producing azelnidipine

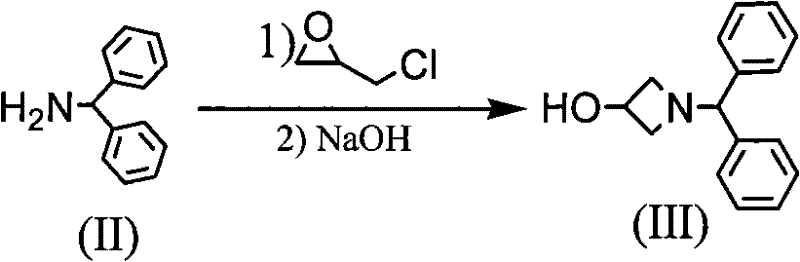

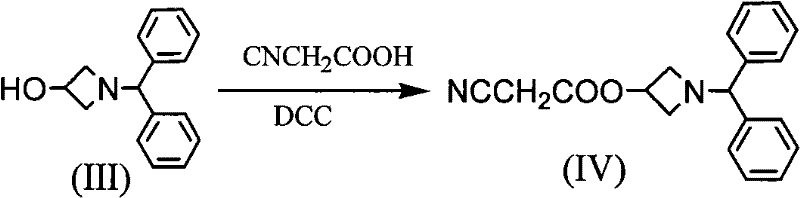

The invention relates to a process for producing azelnidipine. A yield improving and refining and purifying method is provided for synthesizing a dihydropyridine calcium antagonist. The process comprises the following steps of: performing N-alkylation cyclization, esterification and Pinner synthesis on epoxy chloropropane and aminodiphenylmethane serving as initial raw materials to obtain 3,3-diaminoacrylic acid-1-diphenylmethyl-3-azetidinyl ester acetate; and performing Hantzsch synthesis with 2-(3-nitrobenzylidene)isopropyl acetoacetate to prepare the azelnidipine, wherein the 2-(3-nitrobenzylidene)isopropyl acetoacetate is obtained by performing Knoevenagel reaction on nitrobenzaldehyde and isopropyl acetoacetate, and alpha-crystal form azelnidipine is prepared by crystal transition. By the process, the defects of a large number of side reactions, high production cost and the like of the foreign process are overcome, the process has the advantages of mild reaction condition, high yield, high product quality, no use of a class 1 solvent benzene, and the like, and the product is further purified.

Owner:大丰市天生药业有限公司

Preparation method of ethyl acetate and/or isopropyl acetate

InactiveCN102757341AReduce concentrationInhibition of the alignment reactionOrganic compound preparationCarboxylic acid esters preparationEsterification reactionReaction system

The invention provides a preparation method of ethyl acetate and / or isopropyl acetate. Catalytic dry gas from an oil refinery is used as a dilute ethylene and / or dilute propylene raw material and is introduced into a reaction system with a strong solid acidic catalyst to perform an addition esterification reaction so as to produce ethyl acetate and isopropyl acetate. The dry gas required by the method directly comes from a dry gas desulfurization treatment device of the refinery, the addition reaction pressure is low, continuous production of the ethyl acetate and isopropyl acetate can be realized by using dilute ethylene and / or dilute propylene, i.e., low-concentration ethylene and / or propylene, serving as raw material(s), the device investment is saved, the energy consumption is low, and the preparation method belongs to an advanced technology for new utilization of the catalytic dry gas.

Owner:CHINA PETROCHEMICAL CORP

Method for detecting volatile organic compounds in cigarette tipping paper printing ink

InactiveCN104597166AEasy to handleAchieving Simultaneous DetectionComponent separationCyclohexanoneN-Propyl alcohol

The invention relates to a method for detecting the contents of 22 kinds of volatile organic compounds in cigarette tipping paper printing ink, including benzene, toluene, ethylbenzene, ortho / meta / para-xylene, phenethylene, methanol, ethanol, isopropyl alcohol, n-propyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate, 1-methoxy-2-propyl alcohol and 1-ethoxy-2-propyl alcohol. Detection is performed by headspace gas chromatography by taking glyceryl triacetate as a matrix rectifier. According to the method provided by the invention, a sample pretreatment process is simple, the automation degree of the whole operation is high, the simultaneous detection of various volatile organic compounds can be realized, and the detection sensitivity, the recovery rate and the result precision are high.

Owner:GUANGXI ZHENLONG IND

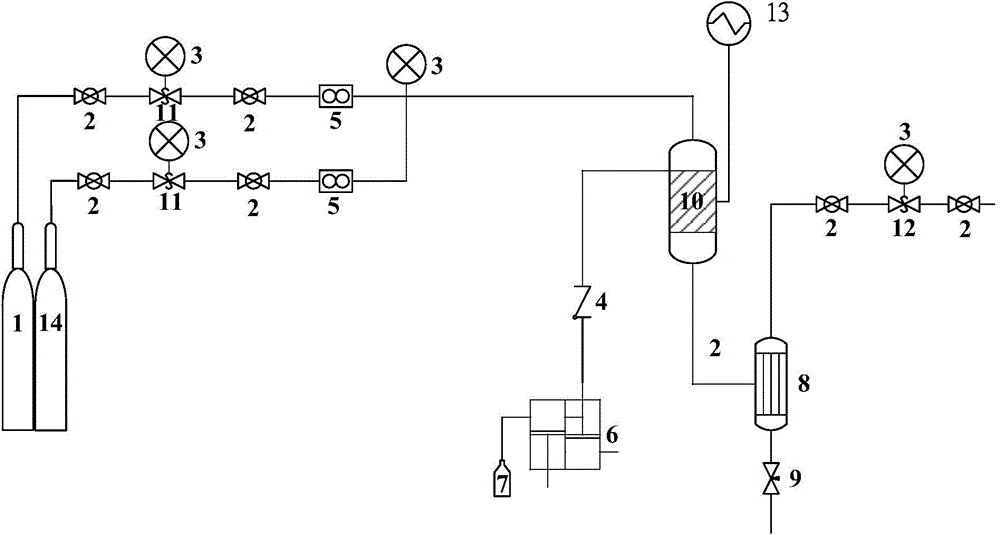

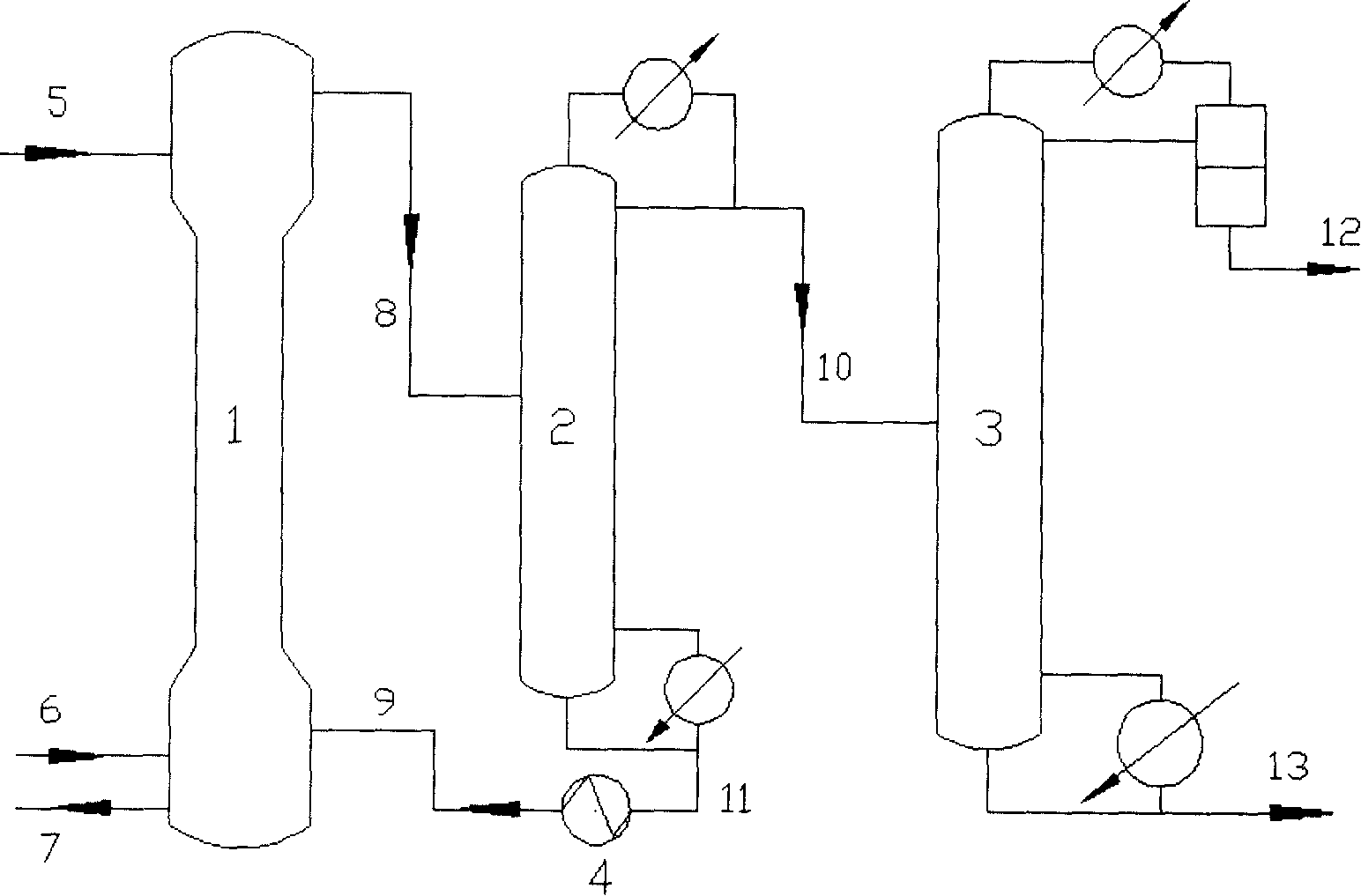

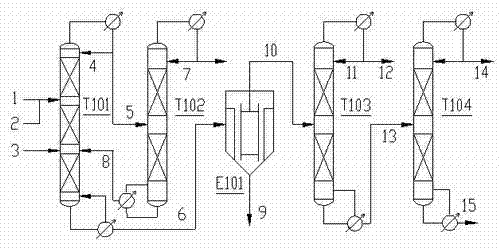

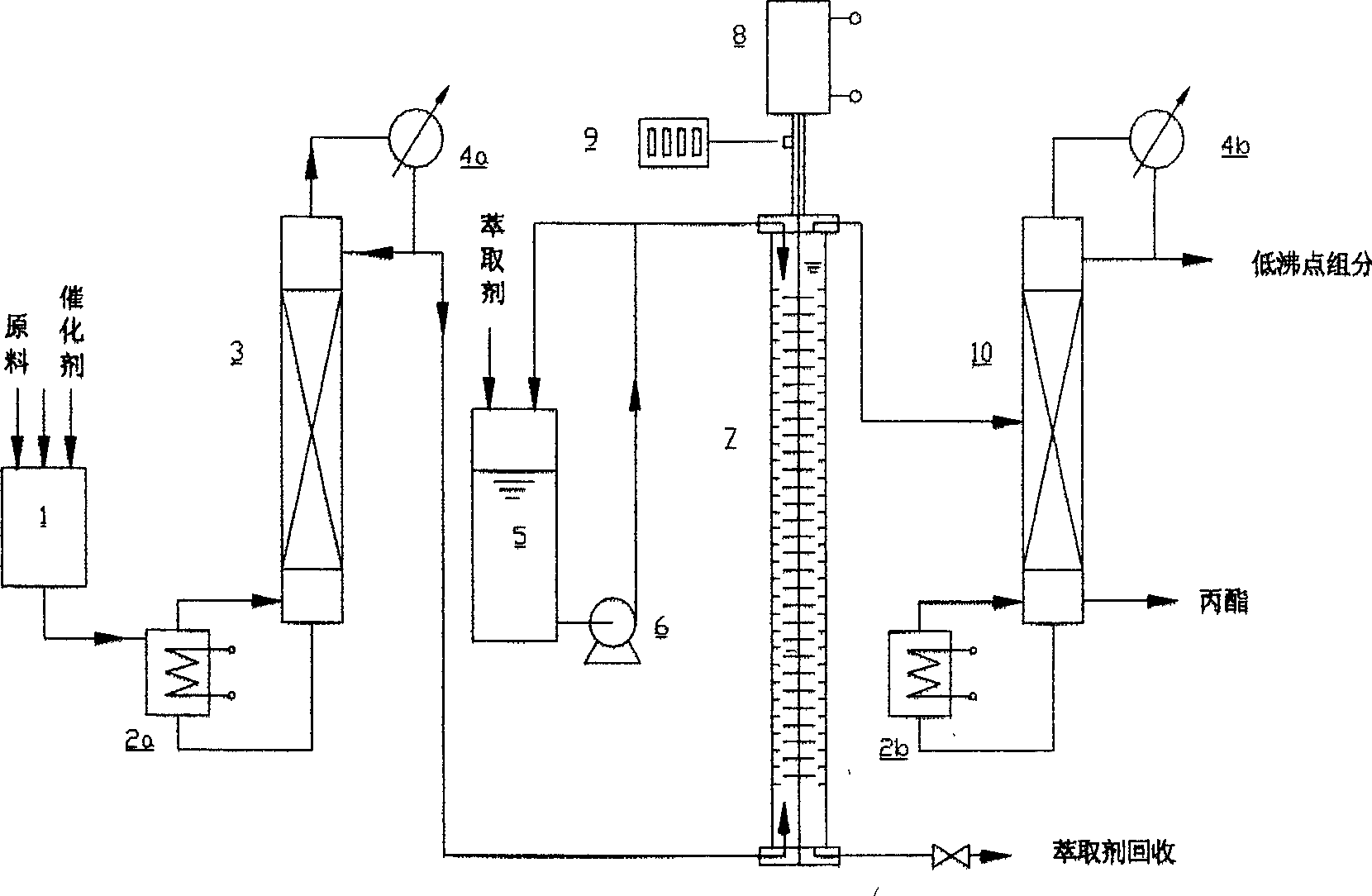

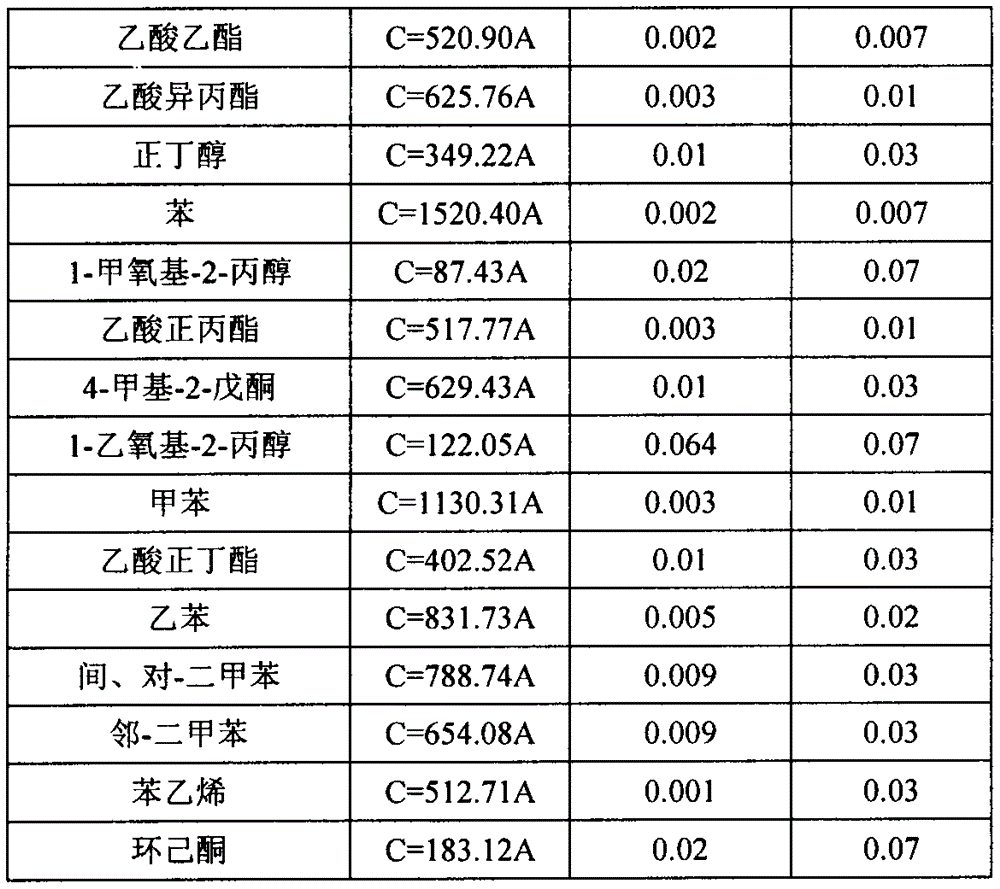

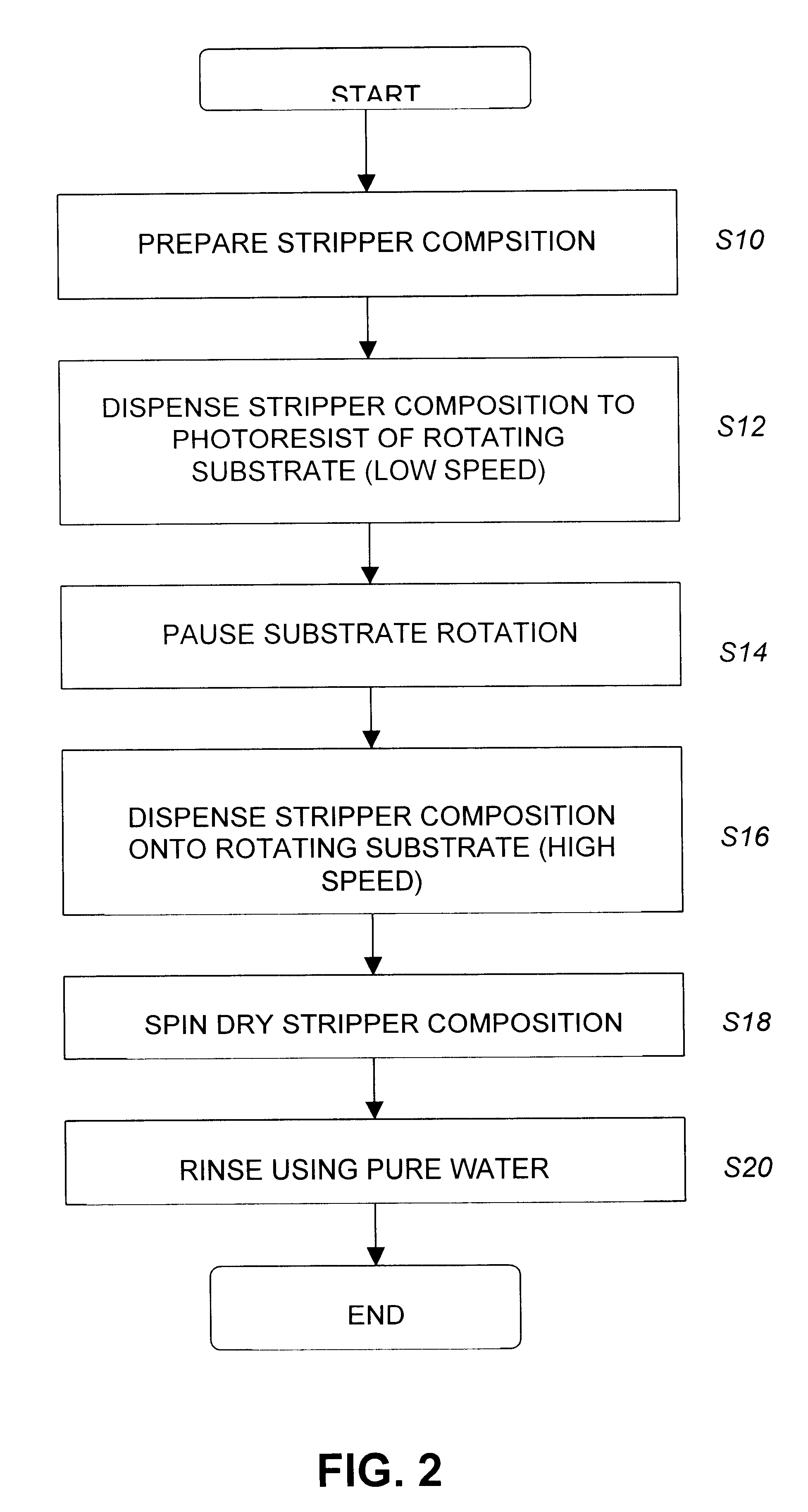

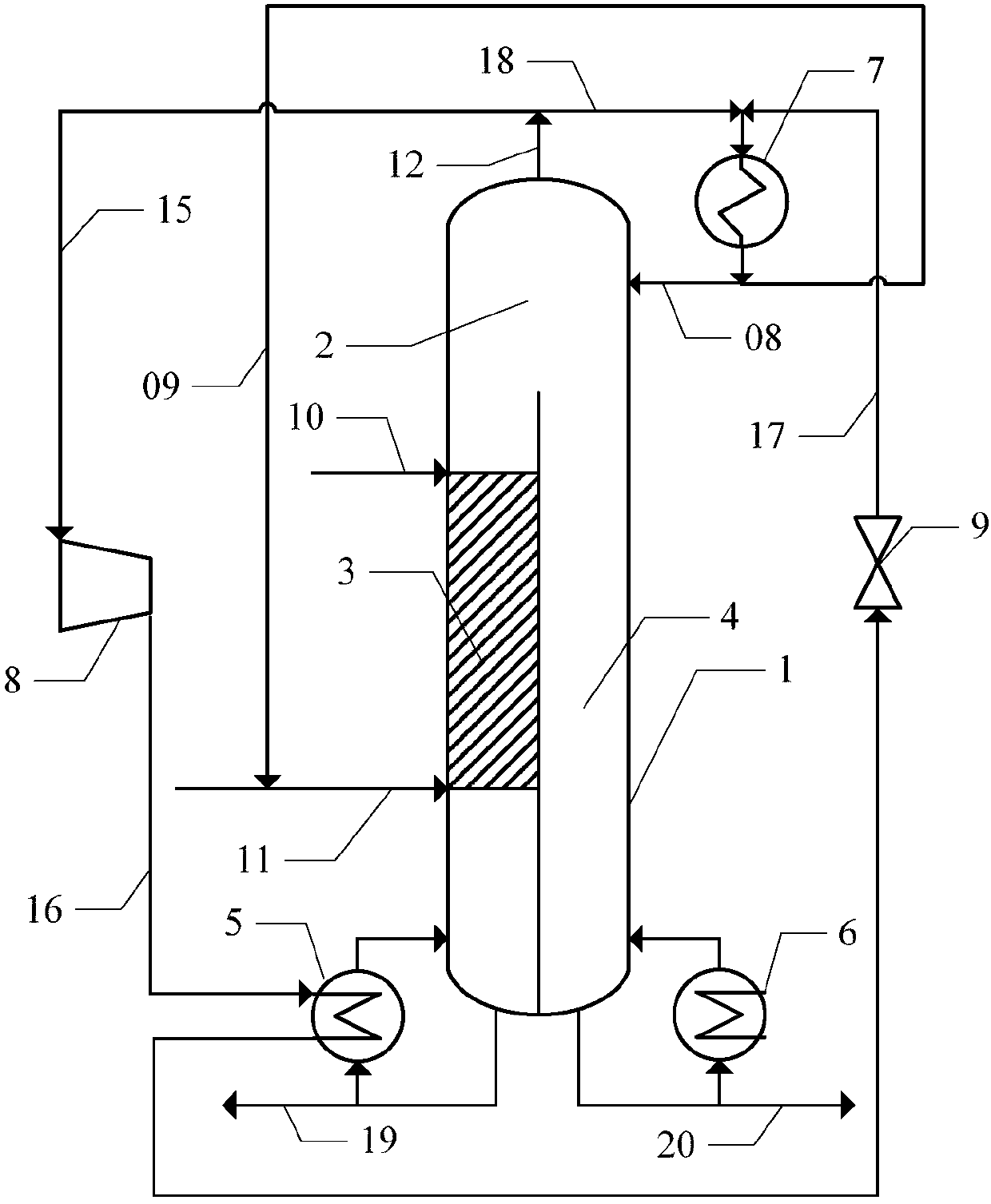

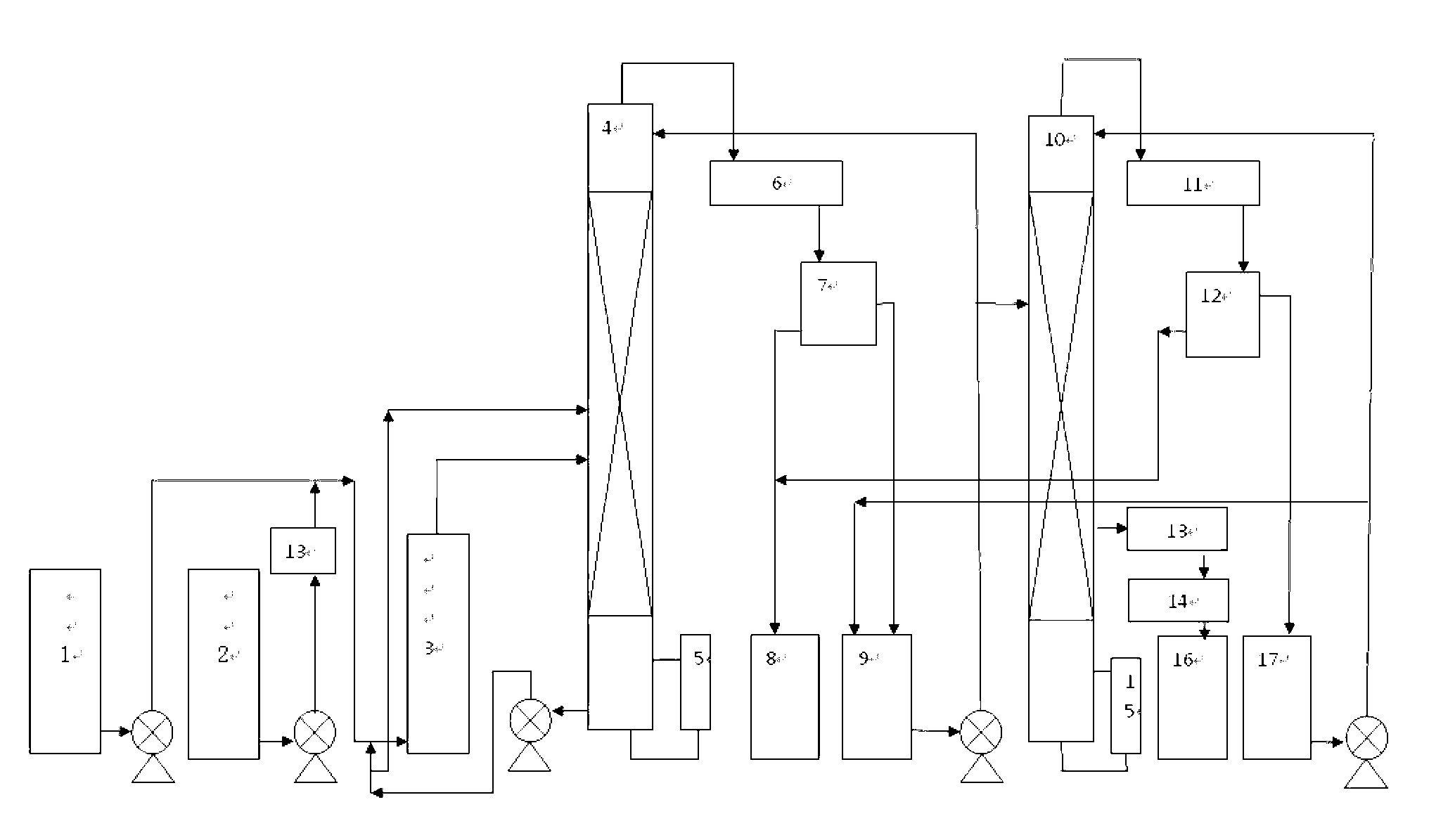

Method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation

PendingCN107954866AAchieve integrationImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationReboilerPhase splitter

The invention relates to a method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation. The apparatus comprises: a feeding mixer, a low-pressure reaction column, a high-pressure distillation column, a product refining column, a phase splitter, a separator, a compressor, a thermal coupling heat exchanger, a condenser and an auxiliary reboiler. Theapparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation allows synthesis of high-purity isopropyl acetate during distillation process; a traditional reactive distillation column is split into the high-pressure distillation column and the low-pressure reaction column, high-temperature steam at the top of the high-pressure distillation column is used to heat the reboiler of the low-pressure reaction column, the two columns share one heat exchanger, heat of the top steam of the high-pressure distillation column is made full use, and heat efficiency of the process is improved. By synthesizing isopropyl acetate via the differential thermal coupling reactive distillation process, esterification, distillation separation and thermal coupling are integrated; material that is not fully reacted flows back for reuse, so that total conversion rate of a reactant is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

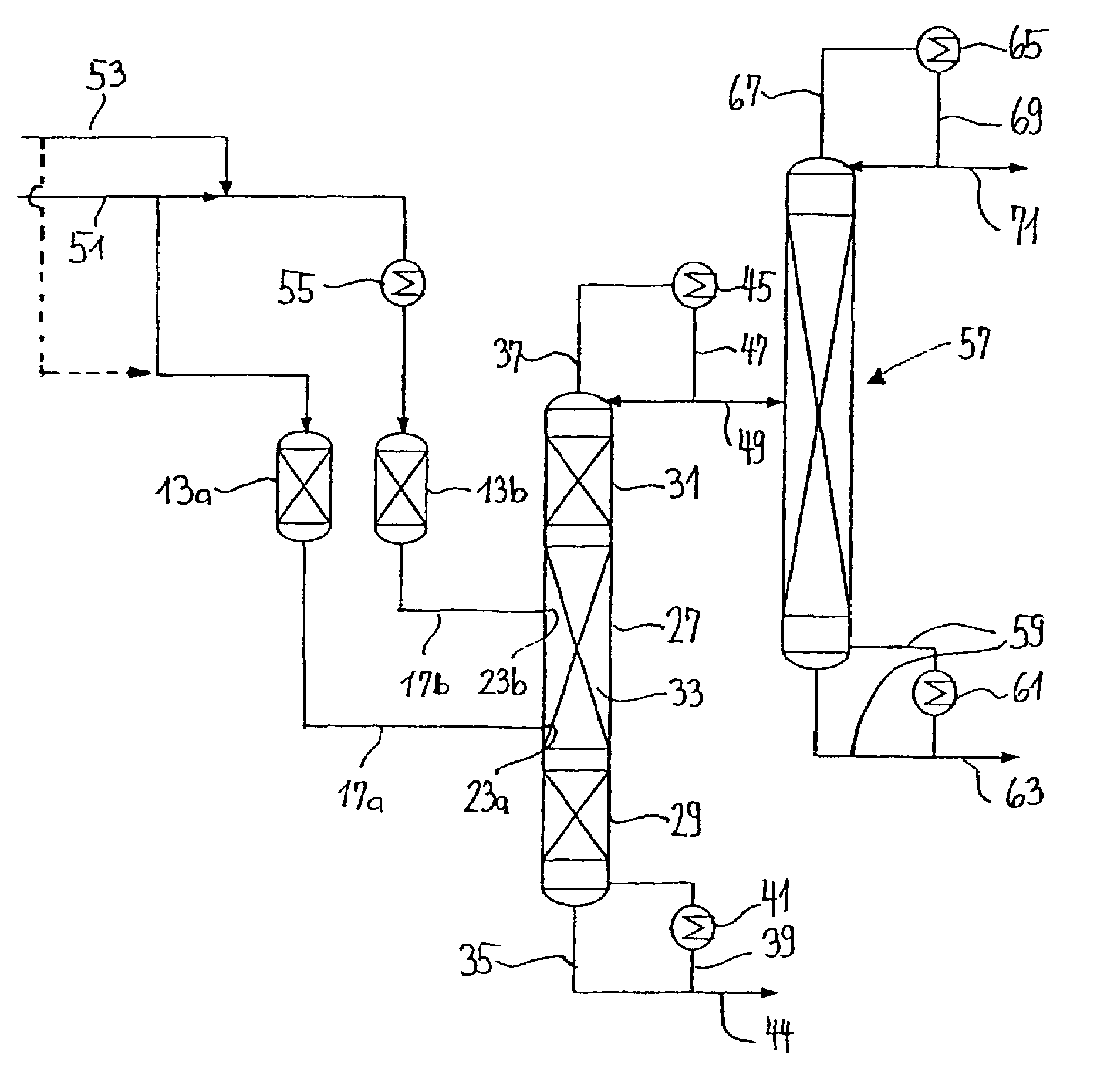

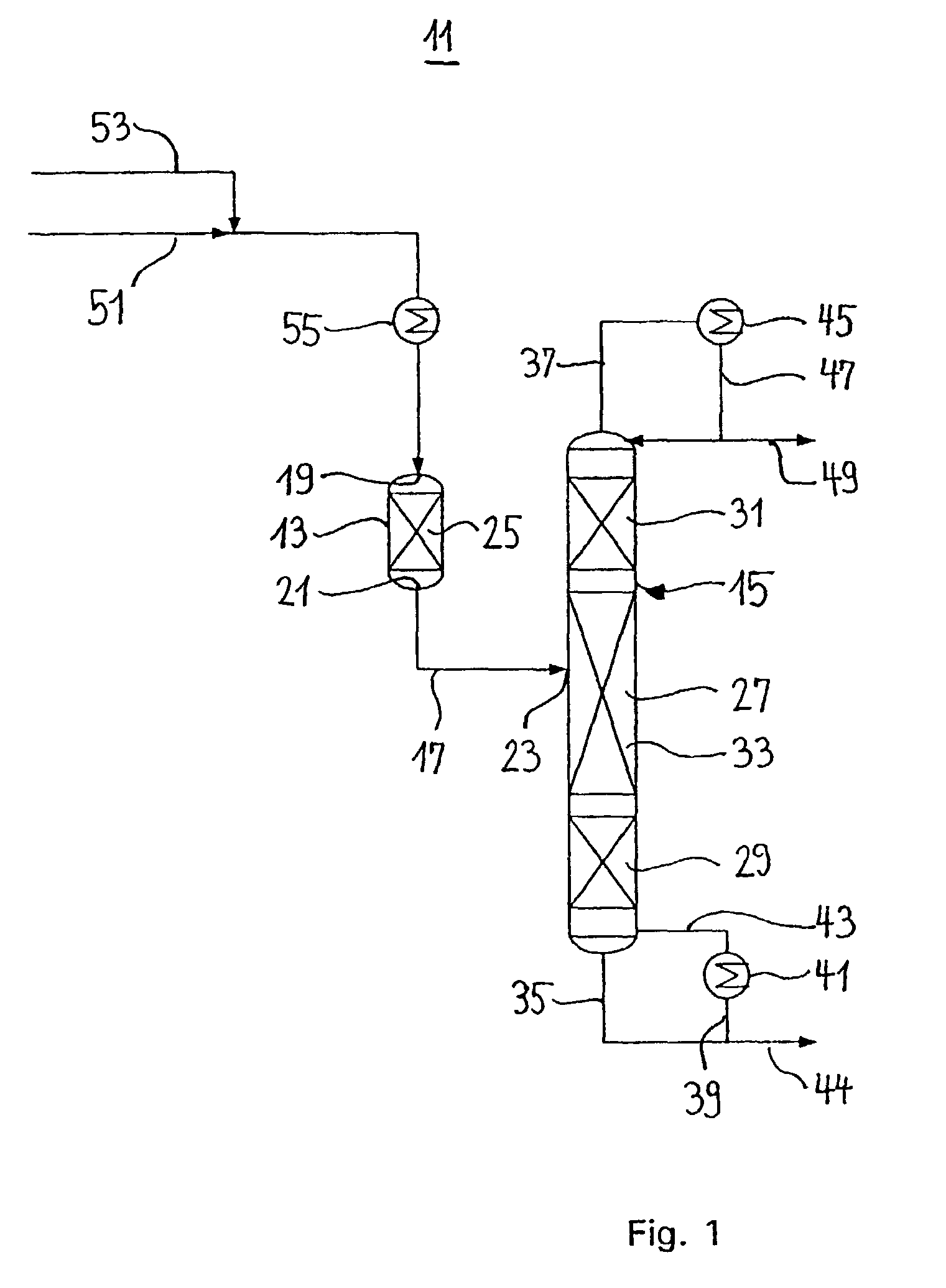

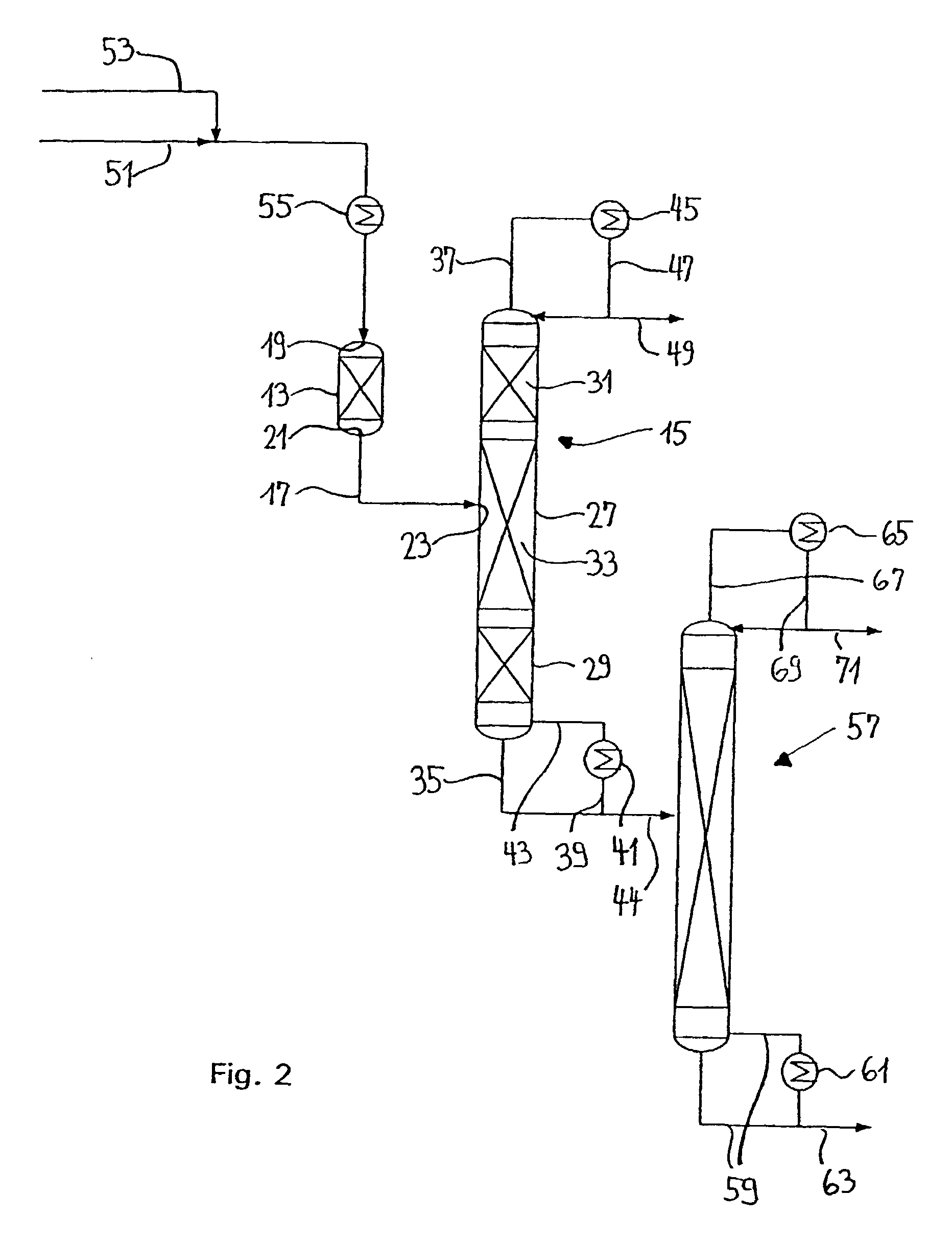

Process and device for hydrolytically obtaining a carboxylic acid alcohol from the corresponding carboxylate

InactiveUS7041199B1Raise the ratioConvenience to workSolvent extractionOrganic chemistry methodsAllyl acetateAlcohol

A process and a device for the catalytic hydrolysis of a carboxylate, e.g., methyl acetate, ethyl acetate, i- or n-propyl acetate, i- or n-butyl acetate, allyl acetate and methyl formate, into the corresponding carboxylic acid and alcohol, by a combination of a pre-reactor and a reactive distillation column are disclosed. By the combination of a pre-reactor and a reactor distillation column, the conversion ratio can be substantially improved. The device can compensate for fluctuations in the supply quantity or in the composition of the feed flow. The product composition can also be controlled in a wide range.

Owner:SULZER CHEMTECH AG +1

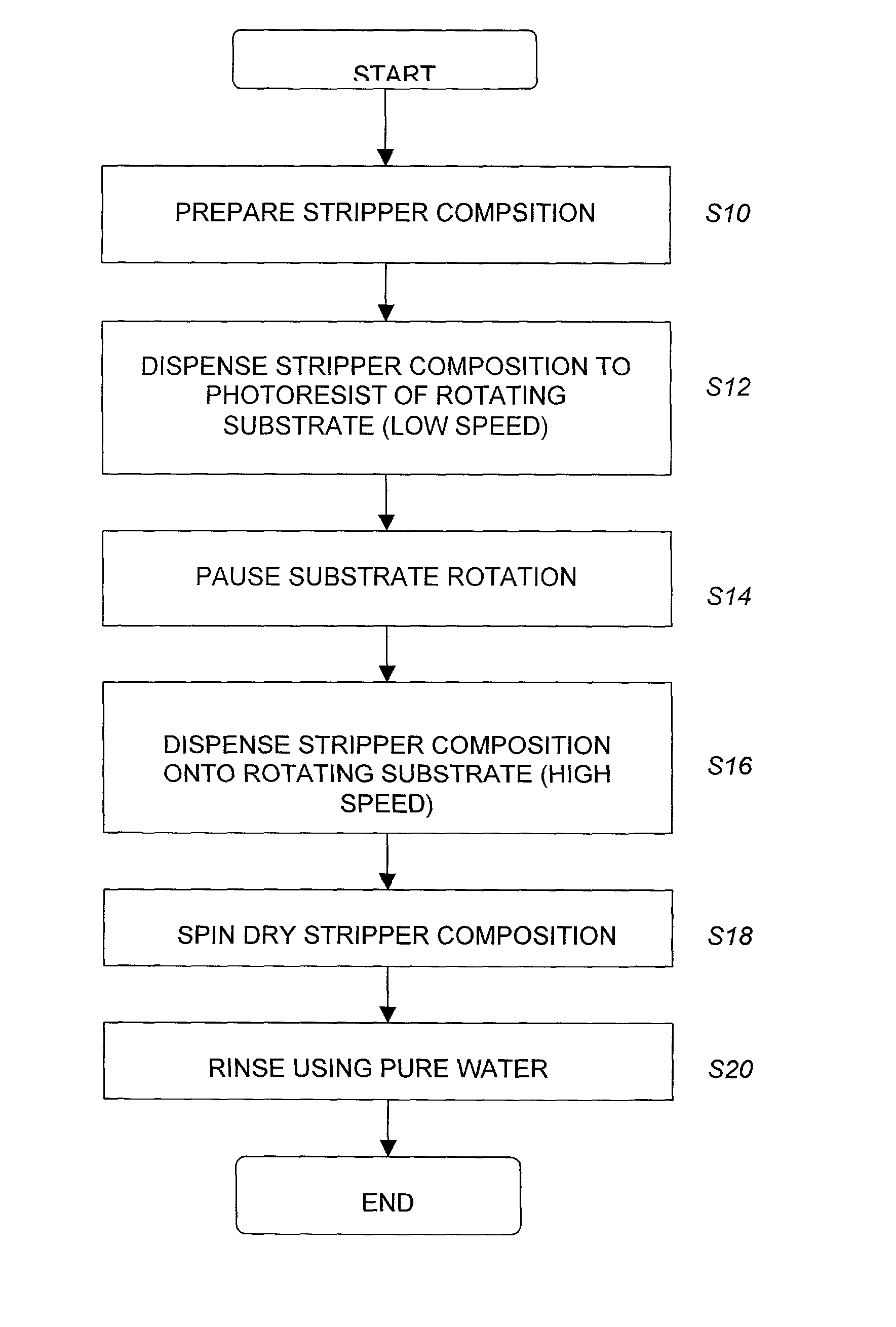

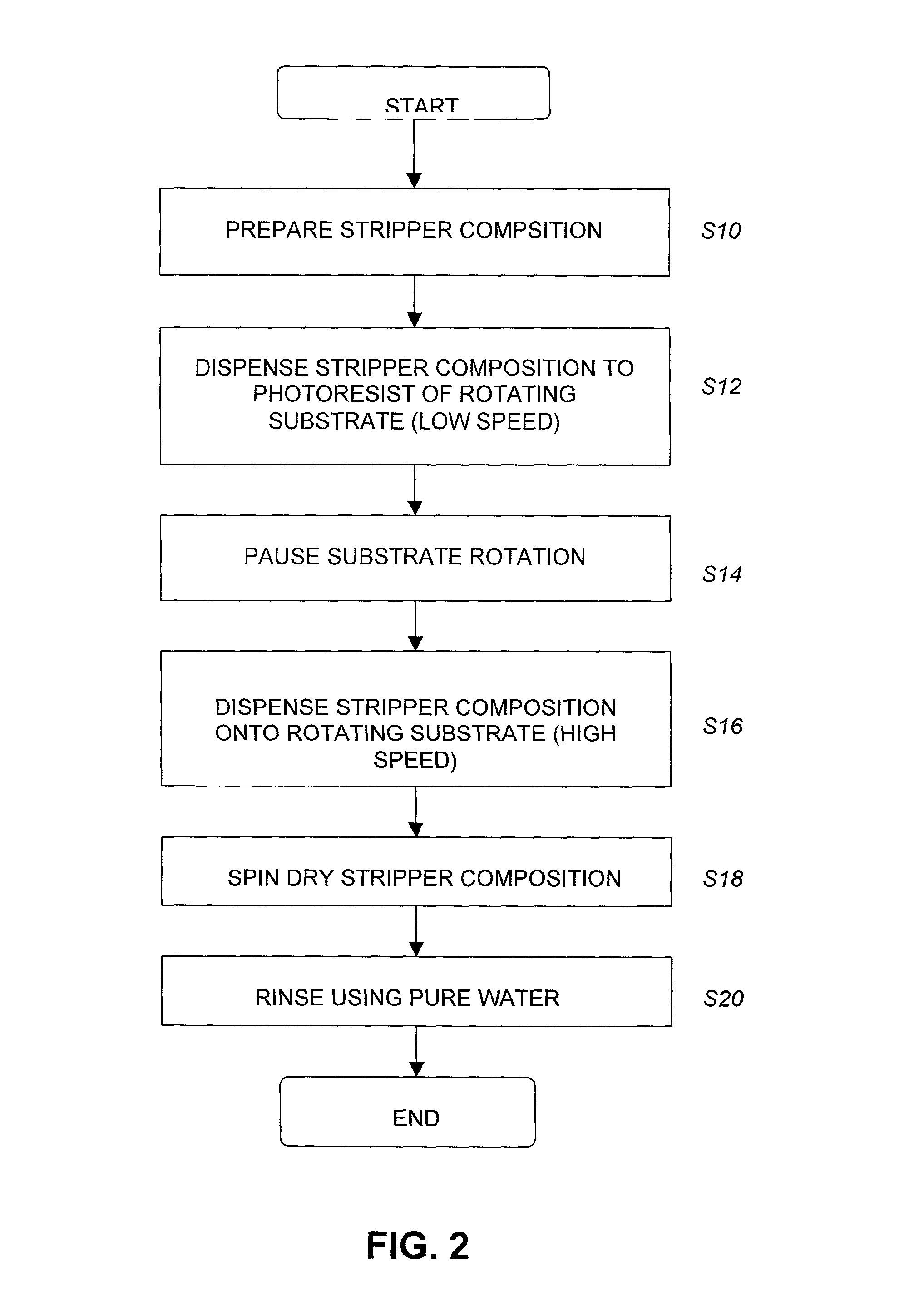

Photoresist stripper compositions

InactiveUS6589719B1Multicolor photographic processingSemiconductor/solid-state device manufacturingAmyl acetateN-Butyl acetate

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

Device for preparing isopropyl acetate in heat pump dividing-wall reactive distillation column

InactiveCN106748758AReduce energy consumptionLess investmentOrganic compound preparationPreparation by ester-hydroxy reactionReboilerEnergy coupling

The invention discloses a device for preparing isopropyl acetate in a heat pump dividing-wall reactive distillation column, and belongs to the technical field of distillation. The device is the heat pump dividing-wall reactive distillation column for synthesizing isopropyl acetate by taking methyl acetate and isopropanol as raw materials through a transesterification method. According to the process, production of the high-density isopropyl acetate is achieved in the heat pump dividing-wall reactive distillation column, by means of energy coupling of gas-liquid streams in the tower, latent heat of gas on the tower top is fully utilized to supply heat to two bottom reboilers of the dividing-wall reactive distillation tower simultaneously after being subjected to pressurization and temperature rising of a compressor, an external heat source is not needed to supply heat energy, and therefore energy consumption is greatly reduced. Meanwhile, multiple traditional columns for reactive distillation and subsequent separation and purification processes are integrated into one dividing-wall reactive distillation column, and therefore equipment investment is reduced.

Owner:CHANGZHOU UNIV

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

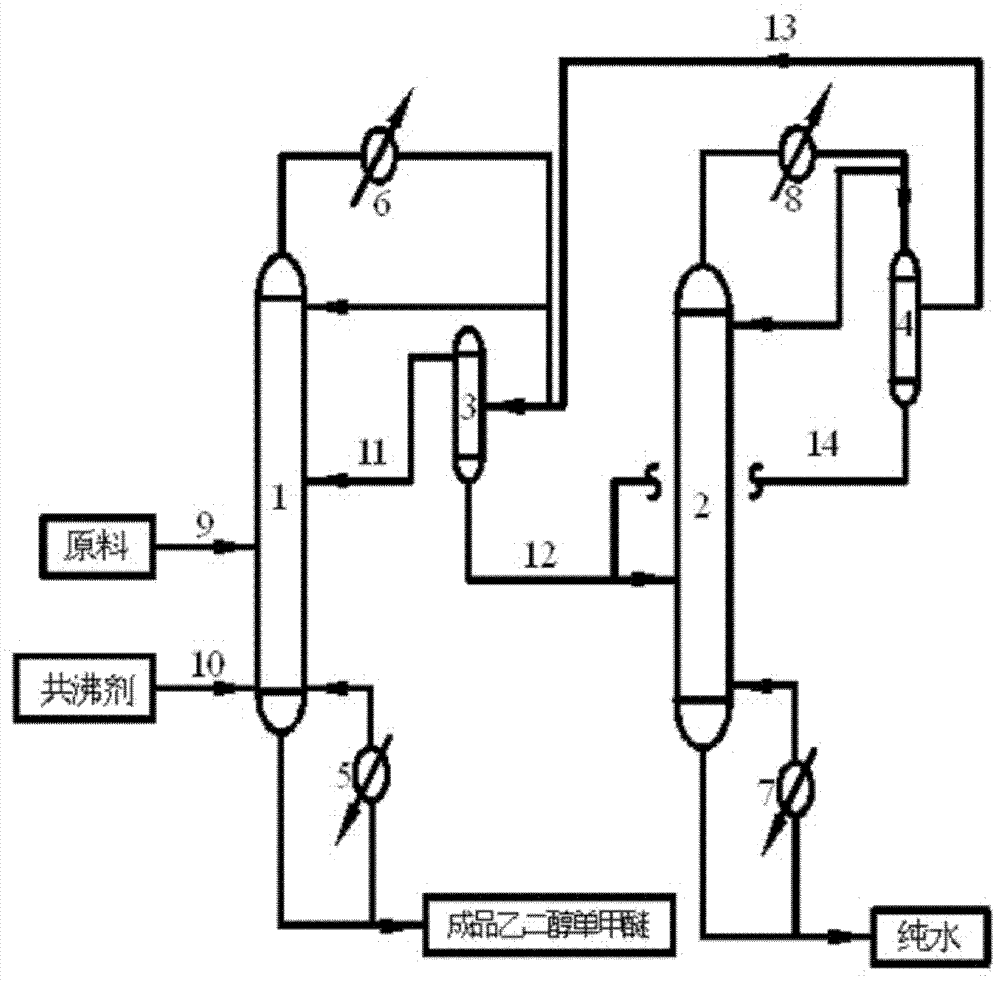

Technology for separating ethylene glycol monomethyl ether and water by use of continuous azeotropic distillation method

ActiveCN102952004ASolve the problem of high toxicity of the original processLow toxicityEther separation/purificationPhase splittingTower

Owner:HEBEI UNIV OF TECH

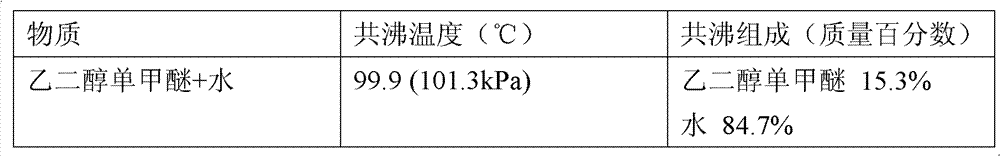

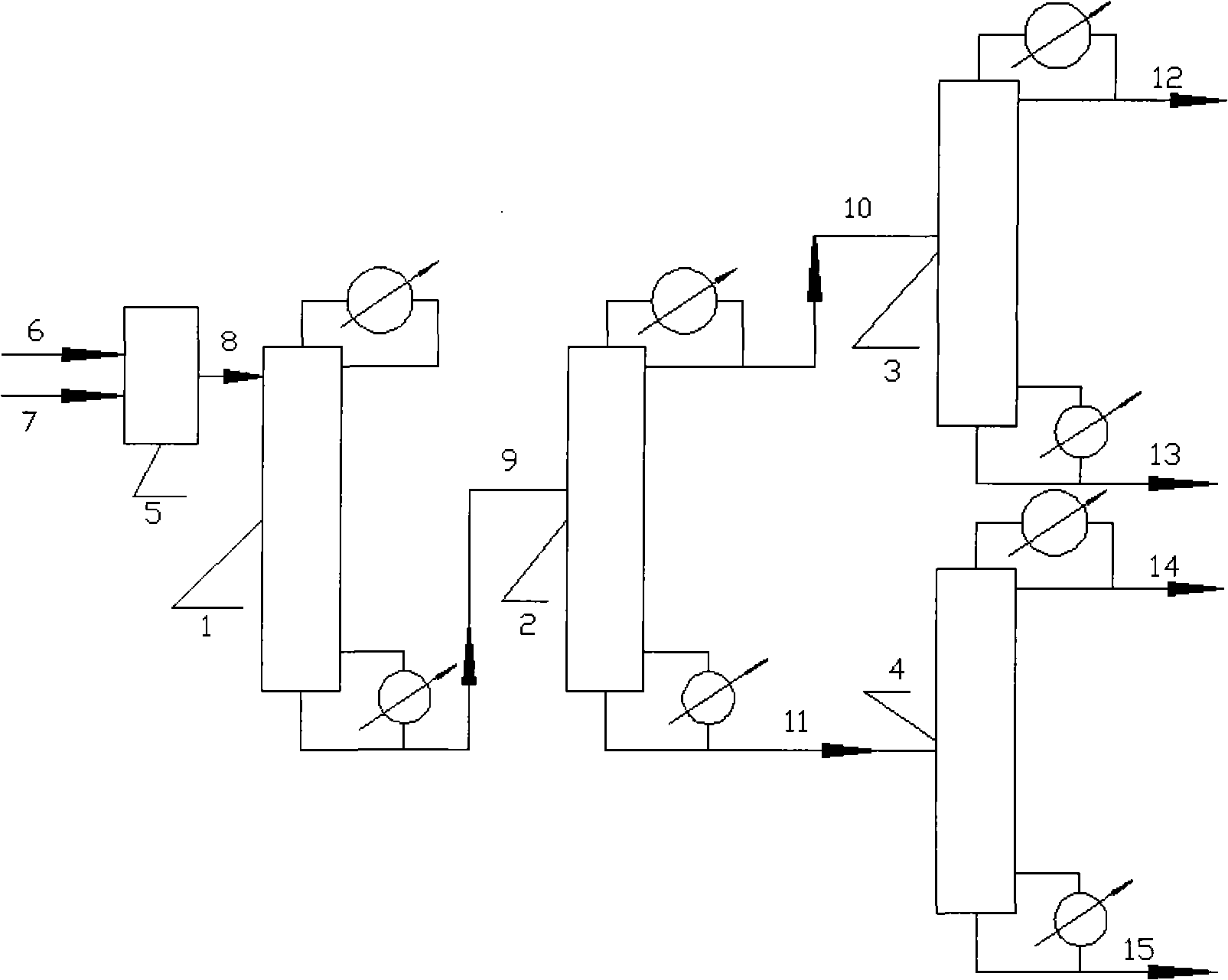

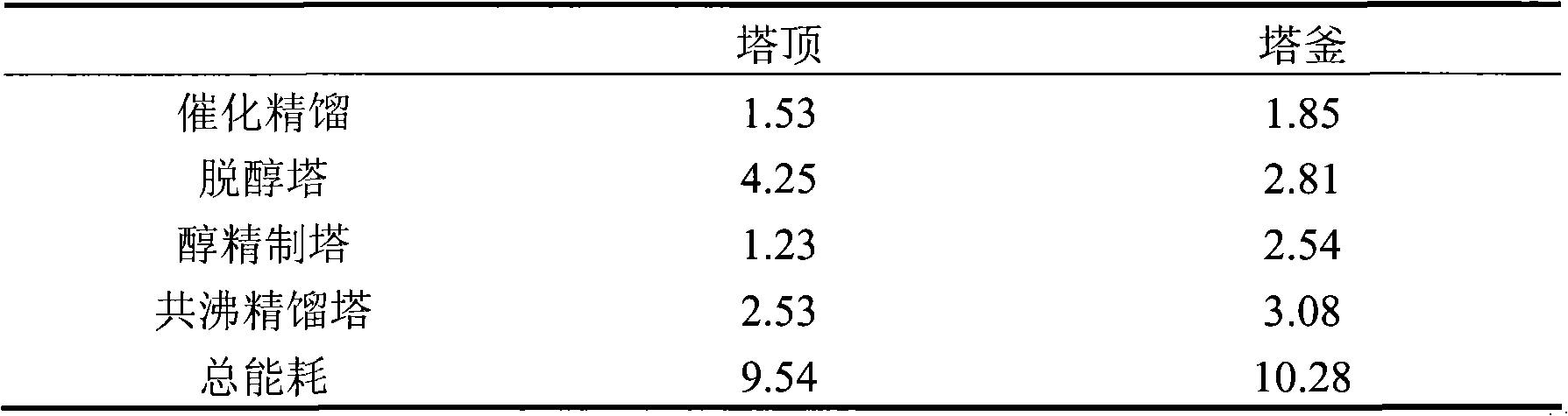

Azeotropy process for catalyzing, rectifying and hydrolyzing methyl acetate

ActiveCN101306981ANo recycling issuesReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationAlcoholPolyvinyl alcohol

The invention relates to an azeotropic method used in methyl acetate catalyzing rectification hydrolysis, mainly solving the problems of the prior methyl acetate catalyzing rectification hydrolysis process including complex flows and high energy consumption. The azeotropic method solves the problems better through adopting the technical proposal which comprises the following steps that: water and methyl acetate are mixed and fed in a catalyzing rectification tower from the top of the tower; the top of the tower is of total reflux and a mixture comprising methanol, acetic acid and water is obtained inside a tower bottom; the mixture is fed in a dealcoholization tower, and the distillate at the top of the dealcoholization tower is a methanol aqueous solution, while an acetic aqueous solution is obtained inside a tower bottom; the methanol aqueous solution is fed in an alcohol treating tower, and the distillate at the top of the alcohol treating tower is methanol, while waste water is generated inside a tower bottom; the acetic aqueous solution is fed in an azeotropic rectification tower which takes one sort of benzene, cyclohexane, isopropyl acetate and n-butyl acetate as an azeotropic agent; a biphase mixture of the azeotropic agent and water is obtained inside the top phase splitter of the azeotropic rectification tower with the water collected from the top of the tower and the azeotropic agent returned to the inside of the tower, while pure acetic acid is obtained inside the tower bottom of the azeotropic rectification tower. The azeotropic method can be used in the industrial production for reclaiming byproduct methyl acetate during producing polyvinyl alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing a dipeptidyl peptidase IV inhibitor and intermediates employed therein

A process is provided for preparing a dipeptidyl peptidase IV inhibitor of the structure wherein is treated with TFAA in isopropyl acetate to protect the tertiary hydroxyl group as a trifluoroacetate group to form 4 (which is a novel intermediate) which is converted to acid chloride compound 5 (which is a novel compound) using Vilsmeier reagent or other chloro reagent and coupled with compound 6 in a heterogeneous mixture of ethyl acetate and aqueous bicarbonate to give compound 7 The N,O-bis(trifluoroacetyl) groups of compound 7 are deprotected to give free base compound 10.

Owner:ASTRAZENECA AB

Method for producing isopropyl acetate through heat pump partition-wall reactive distillation tower

InactiveCN106699552ASave energyLess investmentPreparation by ester-hydroxy reactionOrganic compound preparationAlcoholReboiler

The invention discloses a method for producing isopropyl acetate through a heat pump partition-wall reactive distillation tower and belongs to the technical field of rectification. Isopropanol and methyl acetate are respectively fed into a reaction and separation zone of the heat pump partition-wall reactive distillation tower to be in contact with a catalyst for reaction and separation zone, a vapor-phase mixture of methyl alcohol and methyl acetate flows out of a tower top separation zone and is divided into two ways, one way of mixture is compressed by a compressor and then provides reboiling heat for an isopropyl acetate reboiler at the bottom of the reaction and separation zone, then the way of mixture passes through a throttling valve and then is mixed with the other way of mixture, one part flows back to the tower after condensation, the other part is mixed with the raw material methyl acetate, and the mixture returns to the reaction and separation zone again. The target product high-purity isopropyl acetate is extracted from the lower portion of the reaction and separation zone, and the methyl alcohol is extracted from the lower portion of a methyl alcohol recovery zone. Multiple towers for traditional reaction, rectification and follow-up separation and purification processes are integrated to one partition-wall reactive distillation tower, and device investment is saved.

Owner:CHANGZHOU UNIV

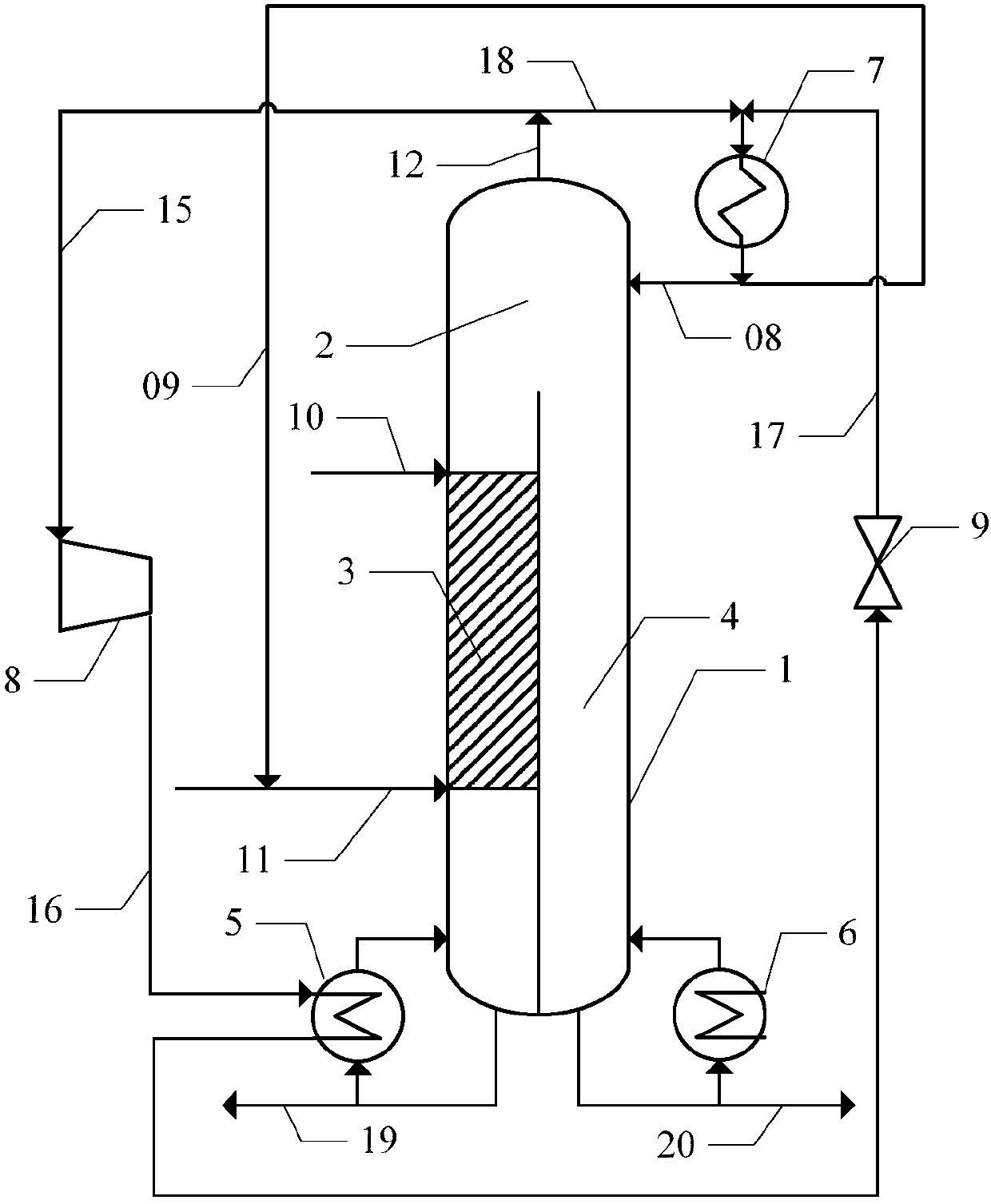

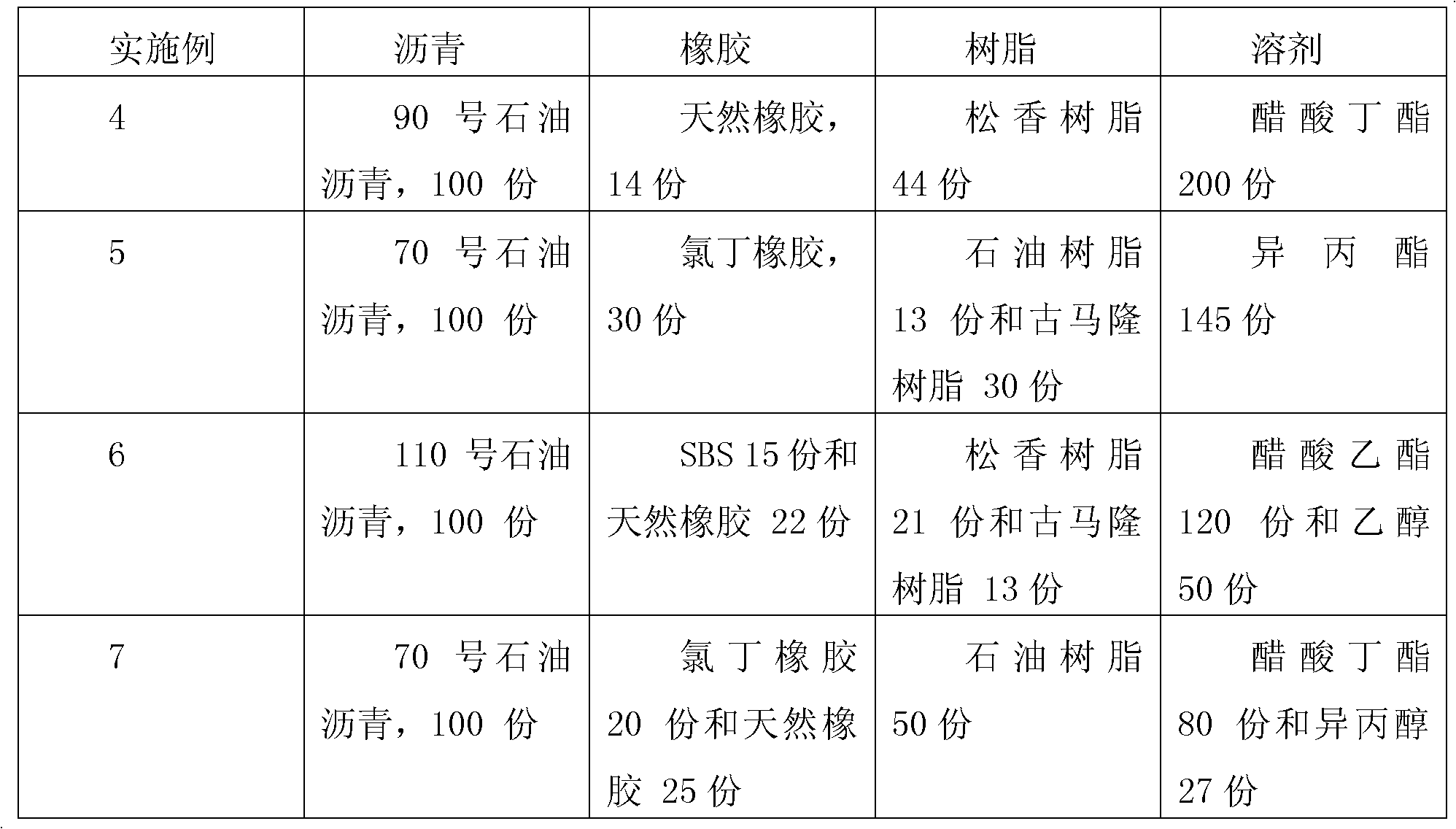

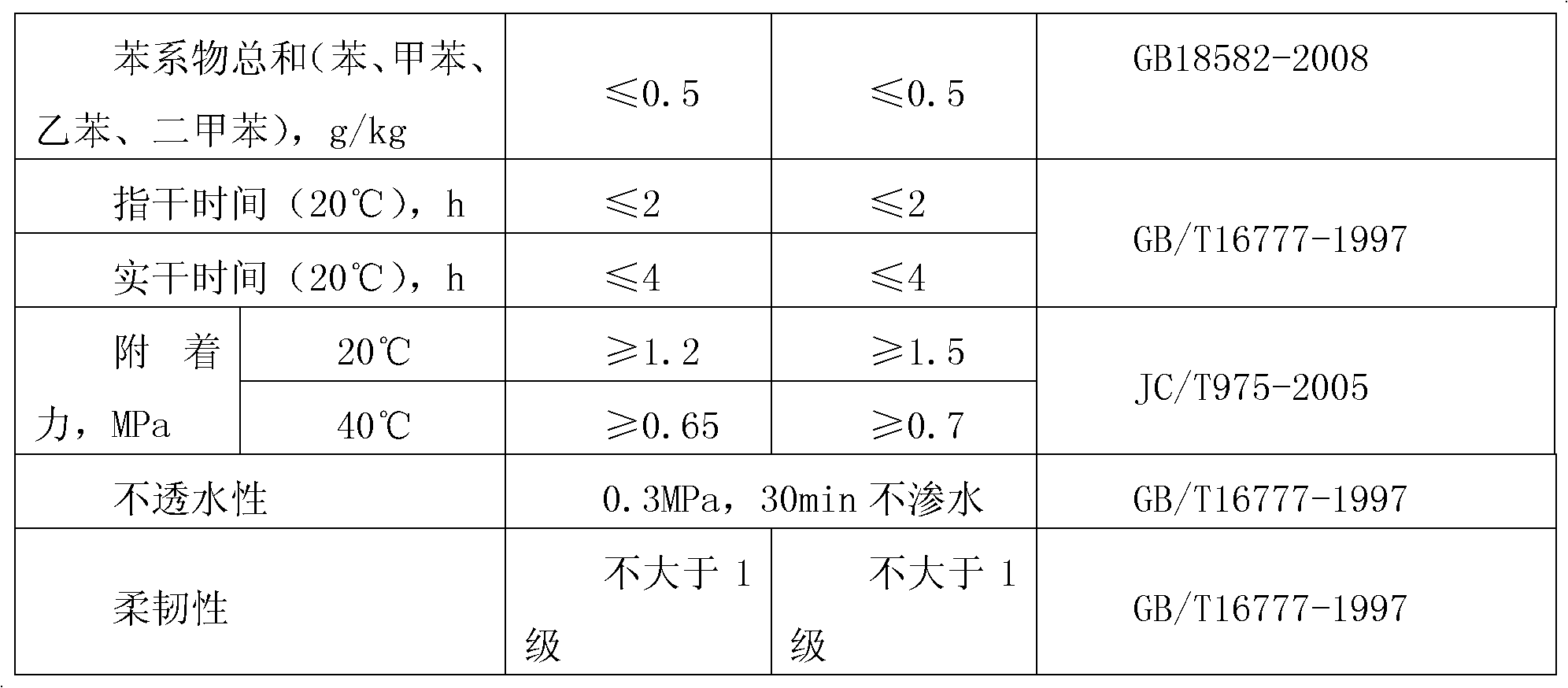

Waterproof adhesive and preparation method thereof

ActiveCN102153873ALow viscosityReduce penetrationNatural rubber coatingsBuilding insulationsPolymer sciencePetroleum

The invention discloses a waterproof adhesive, which is prepared from raw materials including 100 parts of asphalt, 10 to 50 parts of rubber, 10 to 50 parts of resin and 100 to 200 parts of solvent, wherein the asphalt is No.70, No.90 or No.110 petroleum asphalt; the rubber is natural rubber or / and synthetic rubber, and the synthetic rubber is styrene-butadiene-styrene (SBS) or / and neoprene; the resin is one or a random combination of more of petroleum resin, coumaroneindene resin and abietic resin; and the solvent is one or a random combination of more of isopropyl acetate, acetic ether, butyl acetate, isobutyl alcohol, isopropanol and ethanol. The waterproof adhesive is directly sprayed onto treated cement concrete pavement, bridge surface or steel bridge surfaces, and has low viscosity, high permeability, high waterproof performance, high adhesive force, high compatibility with and high affinity to asphalt concrete in a paved layer, the coating has high toughness and strength, the adhesive force for cement of the adhesive can reach over 1.2Mpa and the adhesive force for steel plate can reach over 1.5Mpa; meanwhile, the adhesive disclosed by the invention is nontoxic, safe and environmentally friendly, and the total content of benzene series is not more than 0.5g / kg.

Owner:重庆市智翔铺道技术工程有限公司

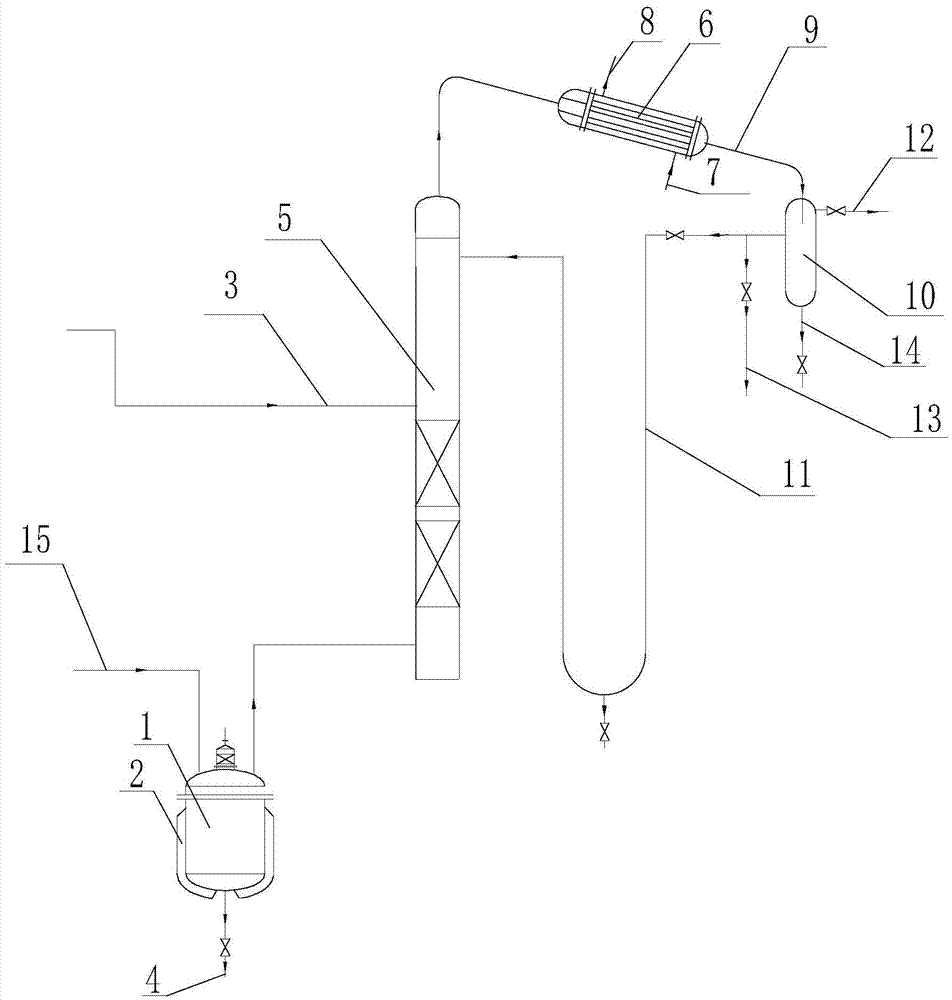

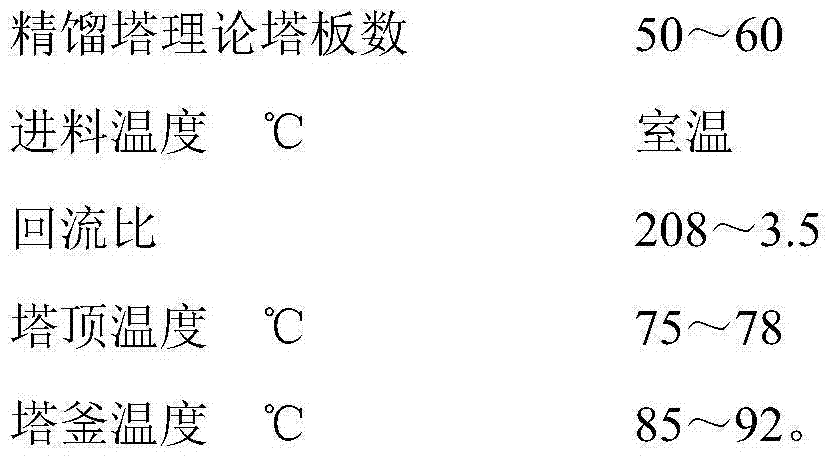

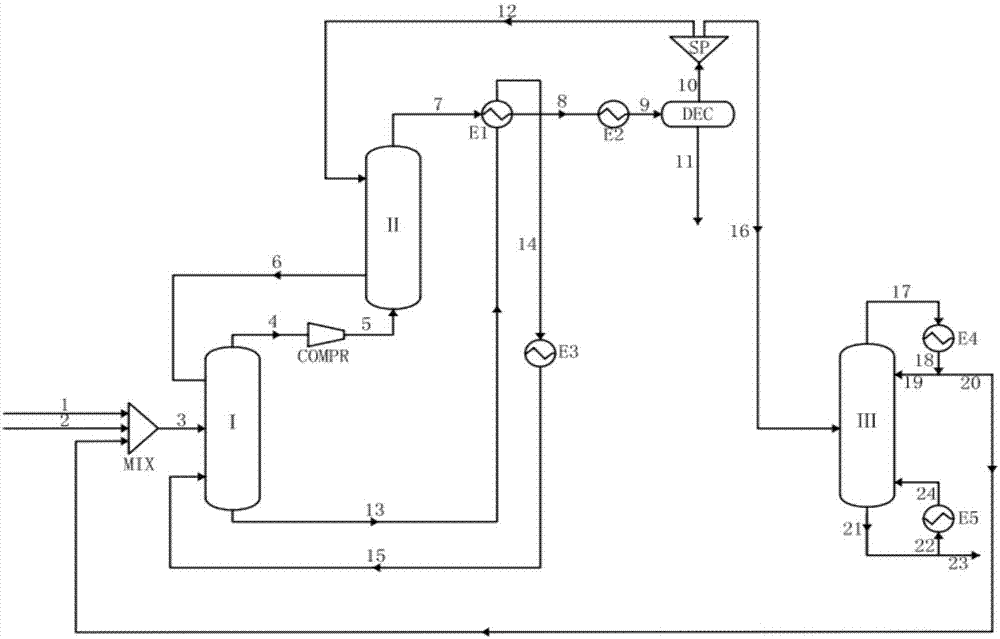

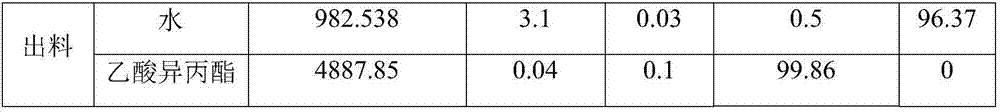

Continuous production device and method for isopropyl acetate

ActiveCN103214367ATernary azeotropic stabilityReach conversion rateOrganic compound preparationCarboxylic acid esters preparationAcetic acidEsterification reaction

The invention provides a continuous production device and a continuous production method for isopropyl acetate. The continuous production method for the isopropyl acetate comprises the following steps of: continuously feeding acetic acid and isopropanol in a reactor, and carrying out an esterification reaction under the catalysis of concentrated sulfuric acid to obtain a reaction mixture; feeding the reaction mixture to a reaction rectification tower; carrying out an esterification reaction and rectification when the liquid level exceeds 4 / 5; feeding one part of an obtained tower-bottom mixture to the reactor, returning the rest part of the obtained tower-bottom mixture to a reaction rectification tower, and keeping the circulation; carrying out condensation and phase separation onto the obtained tower-top mixture in sequence to obtain an isopropyl acetate crude product; feeding the isopropyl acetate crude product to a finished product rectification tower for carrying out rectification and condensation to obtain an isopropyl acetate finished product. The continuous production method for the isopropyl acetate can be used for obviously increasing the front esterification reaction time, so that the ternary azeotropy of reaction rectification tower-top isopropanol, isopropyl acetate and water is relatively stable; the layered interface in the phase slitter is clear, so that the generated water can be automatically separated out, and therefore, a qualified product is obtained in thousand-ton level production.

Owner:JIANGSU RUIJIA CHEM

[((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy

The present invention pertains generally to the field of coolants and medical therapy. More particularly, the present invention relates to certain anti-nociceptive agents, such as [((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester, that are potent and long-acting and selectively cooling for non-keratinized epithelial tissues as compared to keratinized epithelial tissues, and are useful, for example, for the treatment of (e.g., the alleviation of symptoms of; the amelioration of) sensory discomfort of non-keratinized stratified epithelial (NKSE) tissue; and so for treatment of: sensory discomfort of an ocular surface, an eyelid, a margin of an eyelid, an anterior part of an eyeball, a conjunctiva, a lachrymal system, a pre-corneal film, or a cornea, a lining of the oral cavity, an internal portion of the lips, a pharyngeal surface, an esophageal surface, or an anogenital surface; eye discomfort, e.g., caused by extended wear of contact lenses, by eye strain and / or fatigue, by air pollutants, by excessive exposure to the sun, by conjunctivitis, by dry eye syndrome; sensory discomfort associated with oral mucositis; airway (e.g., larynx, trachea, and / or bronchi) tightness, discomfort in the airways (e.g., larynx, trachea, and / or bronchi), choking, cough, and / or dyspnea, e.g., associated with asthma and / or chronic obstructive pulmonary diseases (COPD).

Owner:AXALBION SA

Gravure antibiotic printing ink of cork paper

The invention relates to gravure antibiotic printing ink of cork paper, which is characterized in that the product is composed of the following raw materials by weight: 15 to 35 parts of pigment, 10 to 25 parts of resin, 30 to 60 parts of solvents, 0.5 to 3 parts of antiseptic A and 0.2 to 1 parts of antiseptic B. The mentioned resin is a mixture composed of one selected from polyvinyl butyral, nitrocellulose and polyurethane, and one of modified abietate and polyketone resin; the mentioned solvent is selected from one or more than one of ethyl acetate, n-propyl acetate, isopropyl acetate, ethanol, isopropanol and n-propanol; the mentioned antiseptic A is a nanometer level modified titanium dioxide; and the mentioned antiseptic B is is one selected from sulphadimethoxine, sulphamethazine, trimethoprim and dimethoxypyrimidine. The gravure antibiotic printing ink of cork paper of the invention has reasonable formulation, can realize gravure on cork paper and has antibiotic and bacteriostasis effects.

Owner:江苏泰格油墨有限公司

Method for preparing ethyl alcohol and isopropyl alcohol

InactiveCN103980089ASimple processMild reaction conditionsOrganic compound preparationHydroxy compound preparationAcetic acidAlcohol

The invention relates to a method for preparing ethyl alcohol and isopropyl alcohol and belongs to the technical field of catalysis. According to the method, a copper oxide catalyst is placed in a reactor and a H2 / N2 gas mixture is used as a reducing gas, wherein volume of hydrogen accounts for 20-35% of the volume of the gas mixture, reduction temperature is 150-500 DEG C, reduction pressure is no greater than 1.0 MPa, gas hourly space velocity is 300-2000 h<-1>, and reduction time is 2-10 h; after reduction, the reactor is filled with hydrogen, reaction temperature is adjusted to 150-300 DEG C, and pressure is 4.0-10.0 MPa; and acetic acid isopropyl ester is blown into the reactor, liquid space velocity is 0.1-1.0 h<-1>, and a hydrogenolysis reaction between acetic acid isopropyl ester and hydrogen is carried out to generate ethyl alcohol and isopropyl alcohol. The catalyst provided by the invention has a high activity, and conversion rate can reach the highest level. Meanwhile, the preparation method is simple; cost is low; and the catalyst has stable performance.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy [((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy](https://images-eureka.patsnap.com/patent_img/3499c14e-412a-46ba-8fa2-403eaf3114b1/US20120251461A1-20121004-C00001.png)

![[((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy [((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy](https://images-eureka.patsnap.com/patent_img/3499c14e-412a-46ba-8fa2-403eaf3114b1/US20120251461A1-20121004-C00002.png)

![[((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy [((1R,2S,5R)-2-isopropyl-5-methyl-cyclohexanecarbonyl)-amino]-acetic acid isopropyl ester and related compounds and their use in therapy](https://images-eureka.patsnap.com/patent_img/3499c14e-412a-46ba-8fa2-403eaf3114b1/US20120251461A1-20121004-C00003.png)