Patents

Literature

52results about How to "No recycling issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing modified imvite for polymer/inorganic nano composite material

A process for preparing the modified montmorillonite used to prepare composite polymer / montmorillonite nano-material with excellent properties features the direct reaction between powdered montmorillonite and organic modifier. Its advantages are no need of water and solvent, and no environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

Liquid nitrogen and ice particle abrasive material jet method and generating device thereof

ActiveCN107283326ANo need to worry about the sourcePrepare without worryAbrasive feedersSpray nozzleLiquid nitrogen

The invention provides a liquid nitrogen and ice particle abrasive material jet method and a generating device of the liquid nitrogen and ice particle abrasive material jet method. According to the liquid nitrogen and ice particle abrasive material jet method, liquid nitrogen fluid is poured into the generating device from the top, atomized water drops are poured into the generating device at the position below the top of the generating device through an atomization spray nozzle at the same time, the atomized water drops make contact with the liquid nitrogen fluid to form ice particles, after the ice particles and the liquid nitrogen fluid are mixed in the generating device, the mixed ice particles and liquid nitrogen fluid are jetted and flow out from a bottom outlet of the generating device to form liquid nitrogen and ice particle jet flow, and the liquid nitrogen and ice particle jet flow conducts jet flow operation on a treatment object. The liquid nitrogen and ice particle abrasive material jet method and the generating device of the liquid nitrogen and ice particle abrasive material jet method can achieve free control over the concentration of abrasive materials and are high in operation efficiency, clean and free of pollution.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for conjugated oil, conjugated oil and application thereof

InactiveCN103074161AImprove conversion rateReduce dosageFatty acid chemical modificationFertilizer mixturesOil and greasePtru catalyst

The invention relates to the technical fields of oil deep processing and oil comprehensive utilization, and particularly discloses a preparation method for conjugated oil and application of the conjugated oil. The preparation method comprises the following steps: adding iodine into oil, reacting at the temperature of between 80 and 200DEG C for 0.5 to 5 hours under stirring in the nitrogen environment, and removing the iodine to obtain the conjugated oil. The preparation method is simple, the using amount of a catalyst is small, the conversion rate is high and solvents are not required to be added. Illegal cooking oil also can be taken as a raw material which is low in cost. The conjugated oil prepared can serve as a raw material for preparing fine chemicals, slow release fertilizers or controlled-release fertilizers.

Owner:ZHONGKAI UNIV OF AGRI & ENG

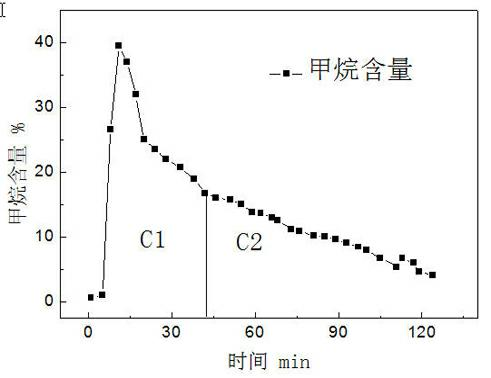

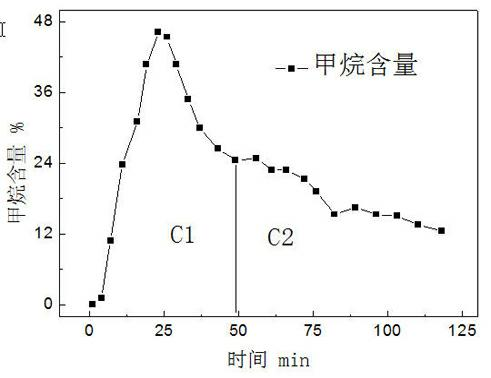

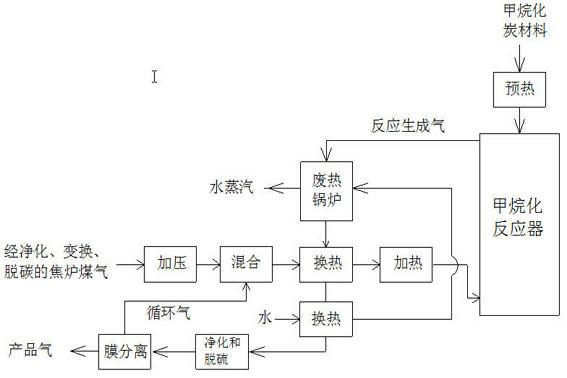

Process for preparing methane by utilizing coke oven gas

The invention relates to a process for preparing methane by utilizing coke oven gas. The adopted materials are methanation carbon materials and the coke oven gas with low oxygen content and high hydrogen content. The principle is that H2 in mixed raw material gas reactes with 30-70 percent of C with high hydrogenation activity in the methanation carbon materials to generate methane through the chemical equation that C and 2H2 generate CH4. The process flow comprises the following steps of: converting CO in the coke oven gas into H2; decarburizing and pressurizing; mixing the H2 and recycle gas according to a certain proportion to obtain mixed raw material gas rich in H2; reacting the H2 in the mixed raw material gas with 30-70 percent of C with high hydrogenation activity in the methanation carbon materials to generate reactive gas through the chemical equation that C and 2H2 generate CH4 in a methanation reactor under a certain temperature and pressure; separating the reactive gas through heat transfer, purification and desulfuration to obtain recycle gas and product gas; returning the recycle gas into the mixed raw material gas; and outputting the product gas. The process has the characteristics of low hydrogen consumption, large methane output, and environmental protection.

Owner:TAIYUAN UNIV OF TECH

Polyvinyl alcohol nanofiber membrane with excellent water resistance, preparation method thereof and composite filter material

ActiveCN110735230AHigh crystallinityImprove water resistanceDispersed particle filtrationHeating/cooling textile fabricsFiberSpinning

The invention discloses a polyvinyl alcohol nanofiber membrane with excellent water resistance, a preparation method thereof and a composite filter material. The method includes mixing water with polyvinyl alcohol, heating and stirring until the mixture is completely dissolved to obtain a polyvinyl alcohol solution; mixing an organic solvent with polyvinyl formal to obtain a polyvinyl formal solution; mixing the polyvinyl alcohol solution and the polyvinyl formal solution to obtain an electrostatic spinning solution; preparing the polyvinyl alcohol nanofiber membrane by using the electrostaticspinning solution through an electrostatic spinning process; and preforming heat treatment on the polyvinyl alcohol nanofiber membrane to obtain the polyvinyl alcohol nanofiber membrane with excellent water resistance. According to the method, a macromolecular nucleating agent polyvinyl formal is added, so that the crystallinity of polyvinyl alcohol nanofibers is improved, physical crosslinking points are increased, and the water resistance of the fibers is greatly improved. The ultra-high water-resistant polyvinyl alcohol can be used as a filter material of a mask filter layer, can efficiently adsorb salt and oily particles in air, and has basically no attenuation in filtering performance.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

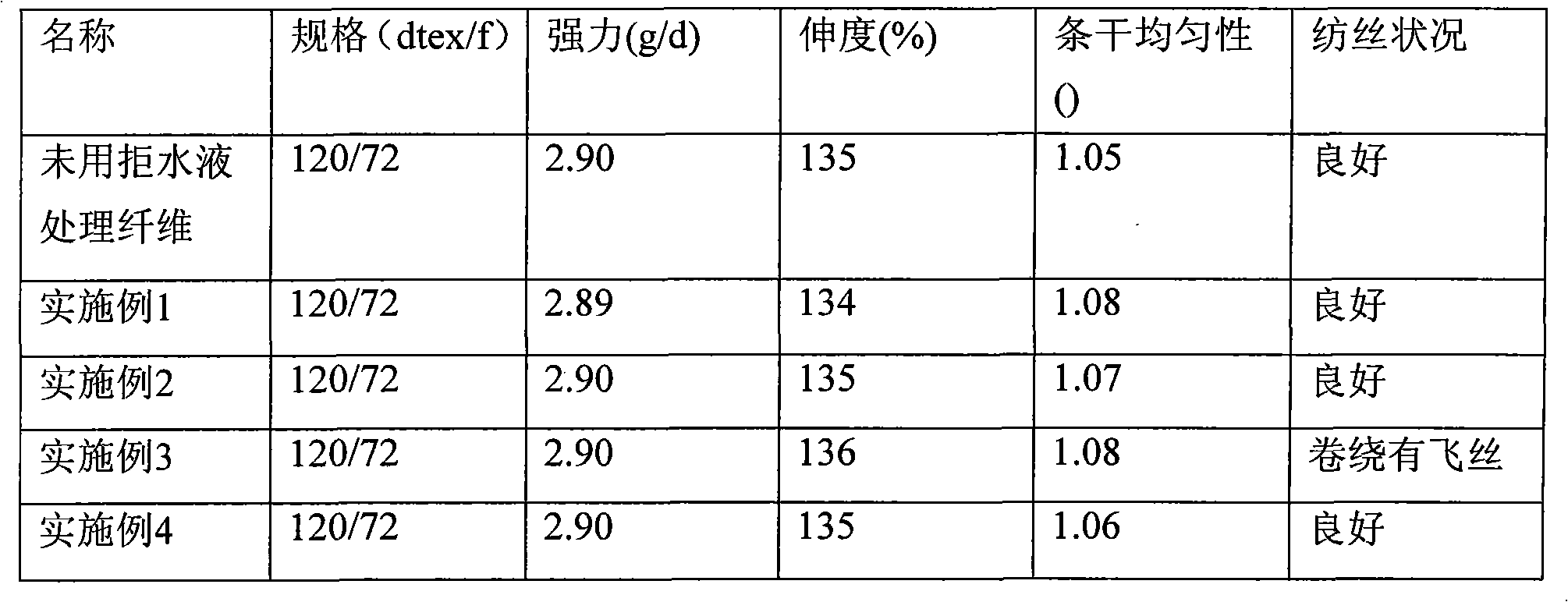

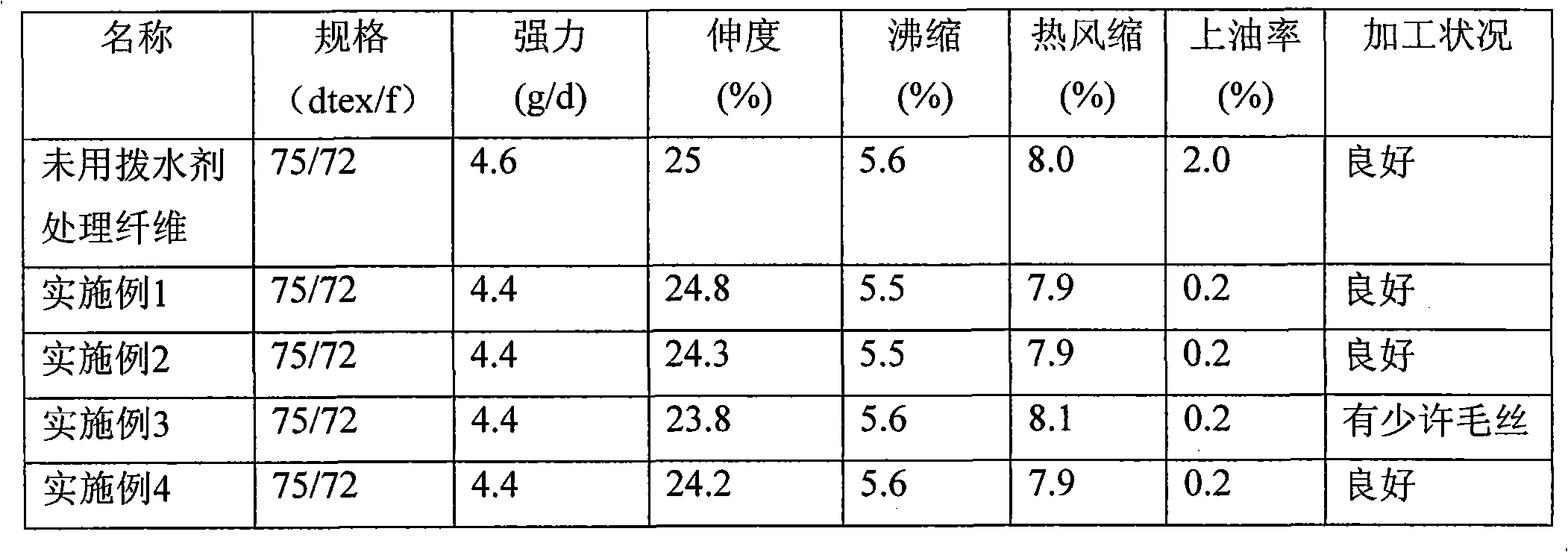

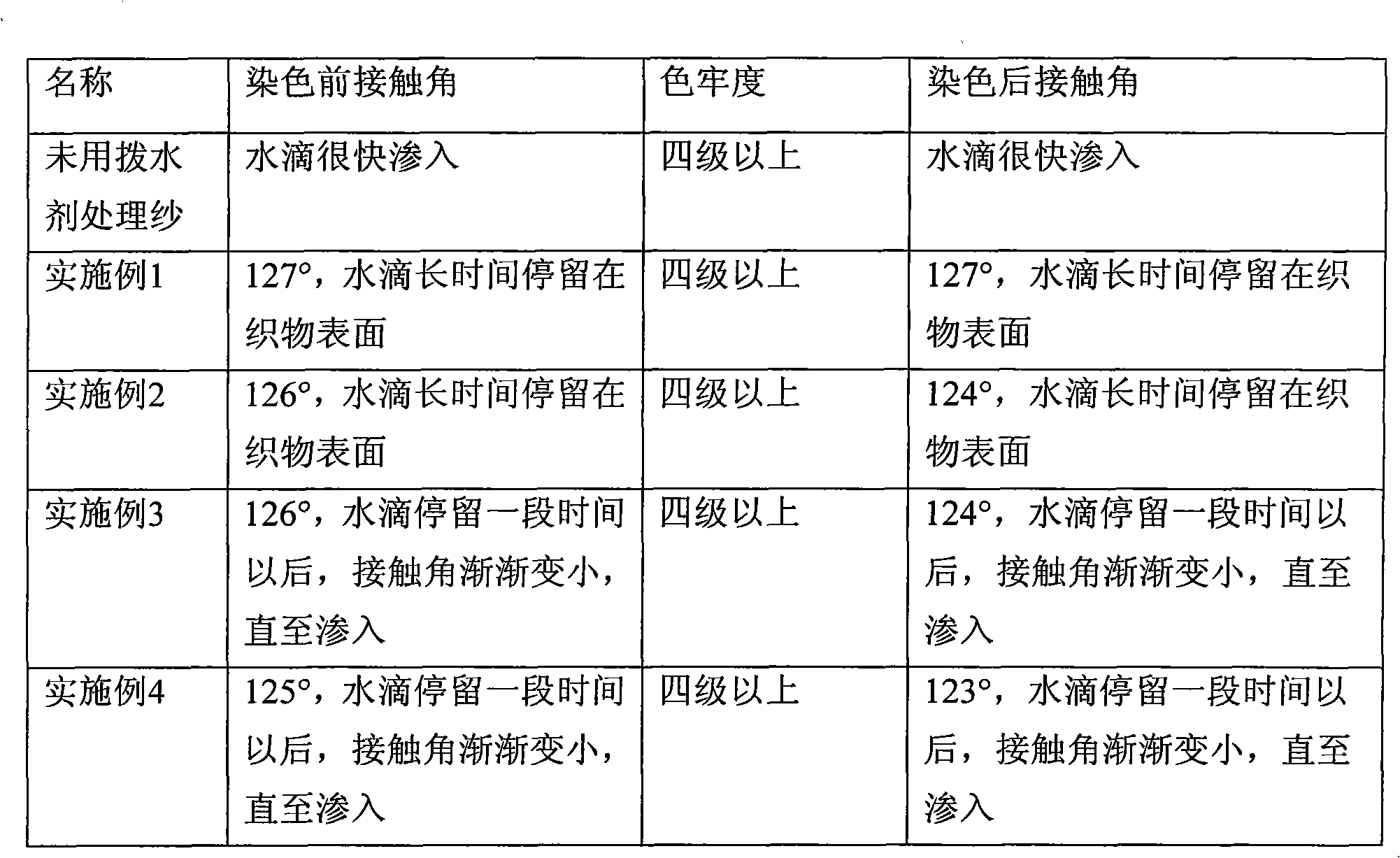

Method for preparing water-repellent polyester fibers

InactiveCN101984154AEasy to operateNo pollution in the processFibre typesMelt spinning methodsPolyesterFiber

The invention discloses a method for preparing water-repellent polyester fibers, which is characterized in that the water-repellent polyester fiber is prepared by using existing spinning equipment through the step of directly adding drying agent and bridging agent and the like into spin finishes. When the water-repellent polyester fibers are weaved into garters, the contact angle of the water-repellent polyester fiber can be over 120 degrees without damaging various performances of the fiber, thereby realizing the continuous, efficient and pollution-free water repellent finish of the polyester fiber.

Owner:远纺工业(上海)有限公司

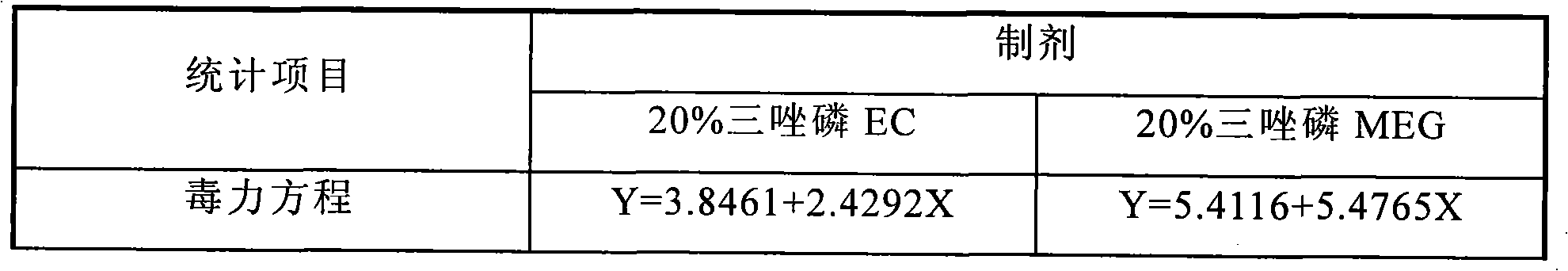

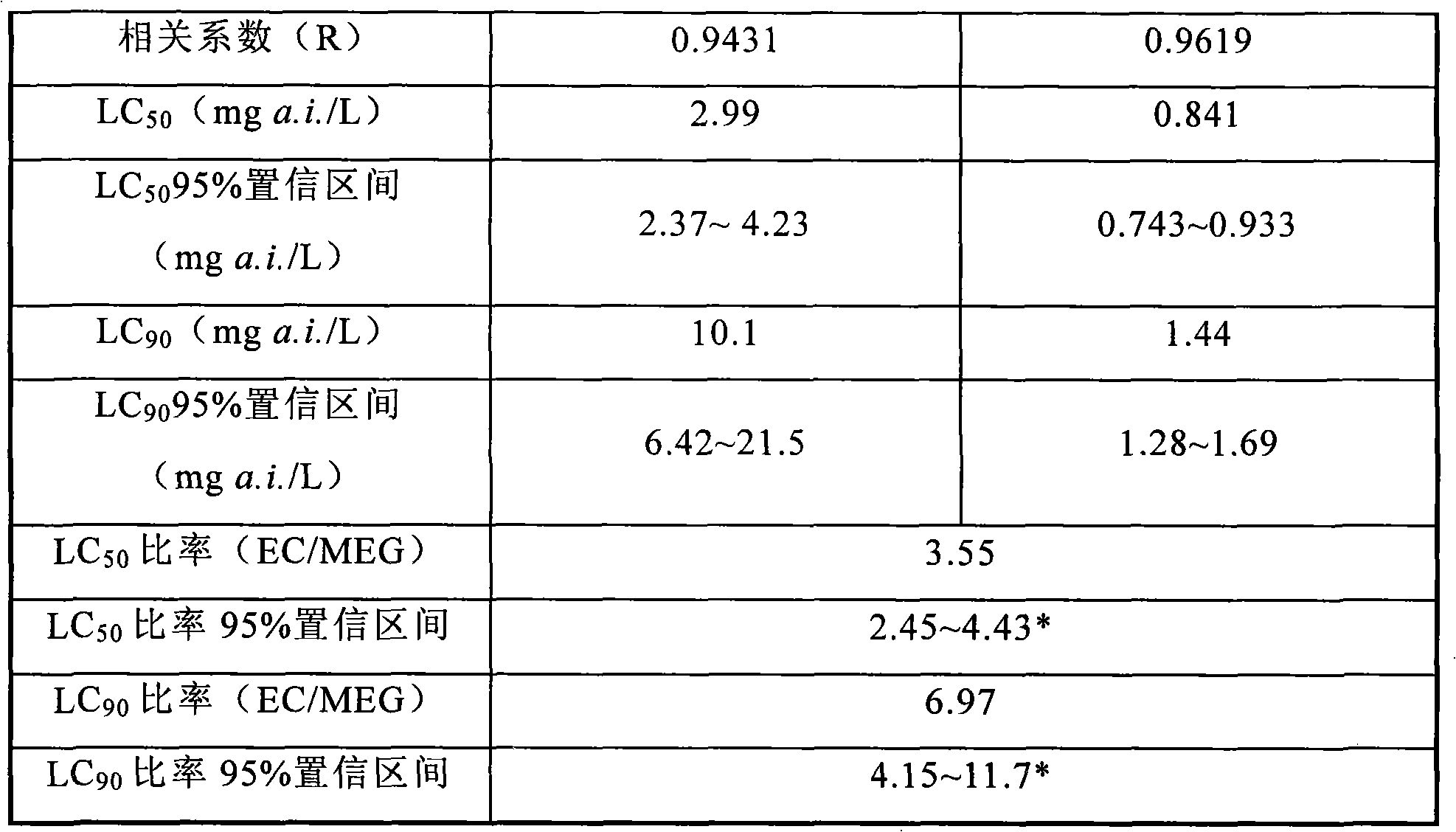

Triazophos-containing insecticidal solid microemulsion and preparation thereof

InactiveCN101258848AEffective segmentationEffective penetrationBiocideArthropodicidesSolventMicroemulsion

The invention discloses an insecticidal solid micro-emulsifier containing triazophos, the components with the weight percent is as follows: 5 to 45 percent of triazophos, 5 to 25 percent of surfactant, 0 to 3 percent of binder, 0 to 5 percent of disintegrating agent and others a carrier. The invention also provides two preparation methods of the insecticidal solid micro-emulsifier, the first preparation method is that: 1) the raw materials are mixed with water evenly to prepare wet material; 2) the wet material is made into granules or pieces; 3) the granules or the pieces are dried; the second preparation method is that: 1) the raw materials are evenly mixed to form mixture; 2) the mixture is made into granules or pieces. The insecticidal solid micro-emulsifier of the invention not only can fully bring the biological activity of the effective contents into play and enhance the shelf life of the products, but also can prevent the pollution of chemical solvents to the environment since no chemical solvents are used.

Owner:ZHEJIANG UNIV

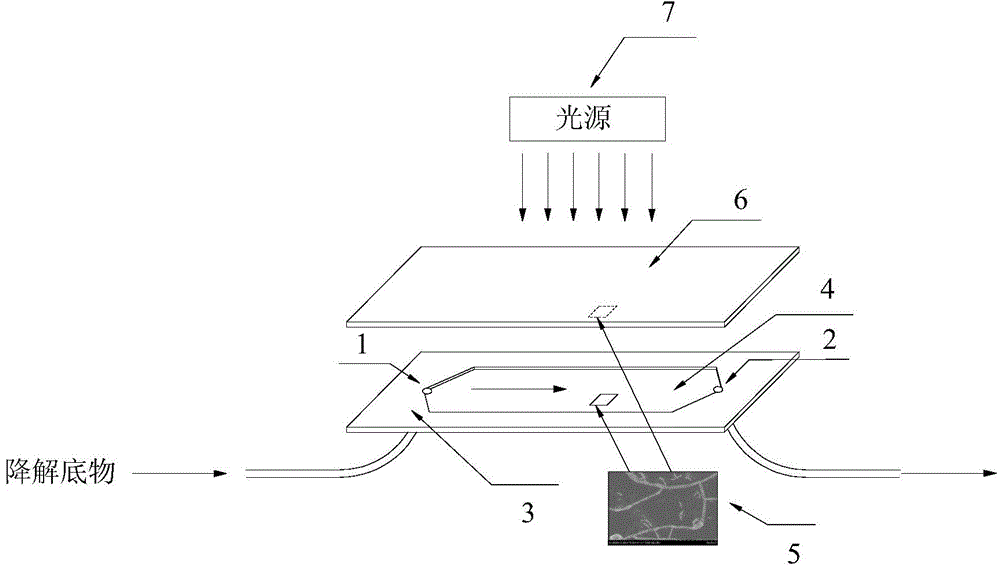

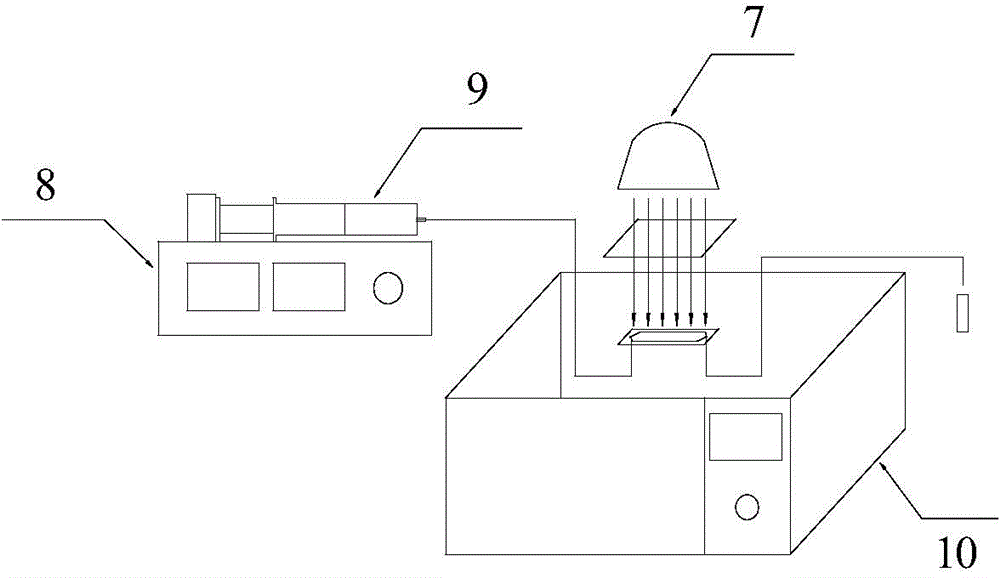

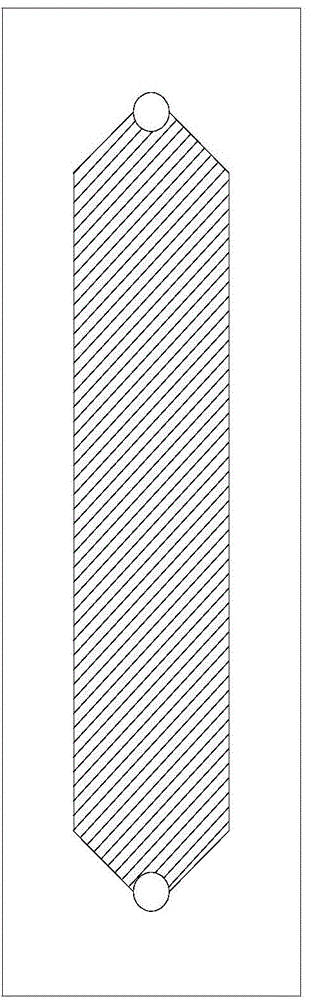

Metal ion-doped titanium dioxide plate-type photocatalytic microreactor and preparation method for catalyst thin films in reactor

ActiveCN104147994AEasy to handleIncrease light receiving areaEnergy based chemical/physical/physico-chemical processesMetal/metal-oxides/metal-hydroxide catalystsMicroreactorLine tubing

The invention discloses a metal ion-doped titanium dioxide plate-type photocatalytic microreactor and a preparation method for catalyst thin films in the reactor. The reactor includes a stainless steel plate base; a groove on the stainless steel plate base is used as a single-channel reaction region; an inlet and an outlet respectively communicated with an inlet and an outlet of the single-channel reaction region are arranged on the stainless steel plate base, the inlet is communicated with an inlet pipeline, and the outlet is communicated with an outlet pipeline; one face, having the groove, of the stainless steel plate base and one face of a light-penetrating surface are each loaded with the metal ion-doped TiO2 catalyst thin film; the face, loaded with the catalyst thin film, of the light-penetrating surface is in opposite arrangement with the face, having the groove, of the stainless steel plate base, and has the periphery edges bonded and fixed by a sealing adhesive; an incident light source is arranged above the light-penetrating surface opposite to the groove. By using the device and the method, the light utilization efficiency is higher, and the degradation rate is increased to 2 times of the original degradation rate of an undoped TiO2 catalyst.

Owner:TIANJIN UNIV

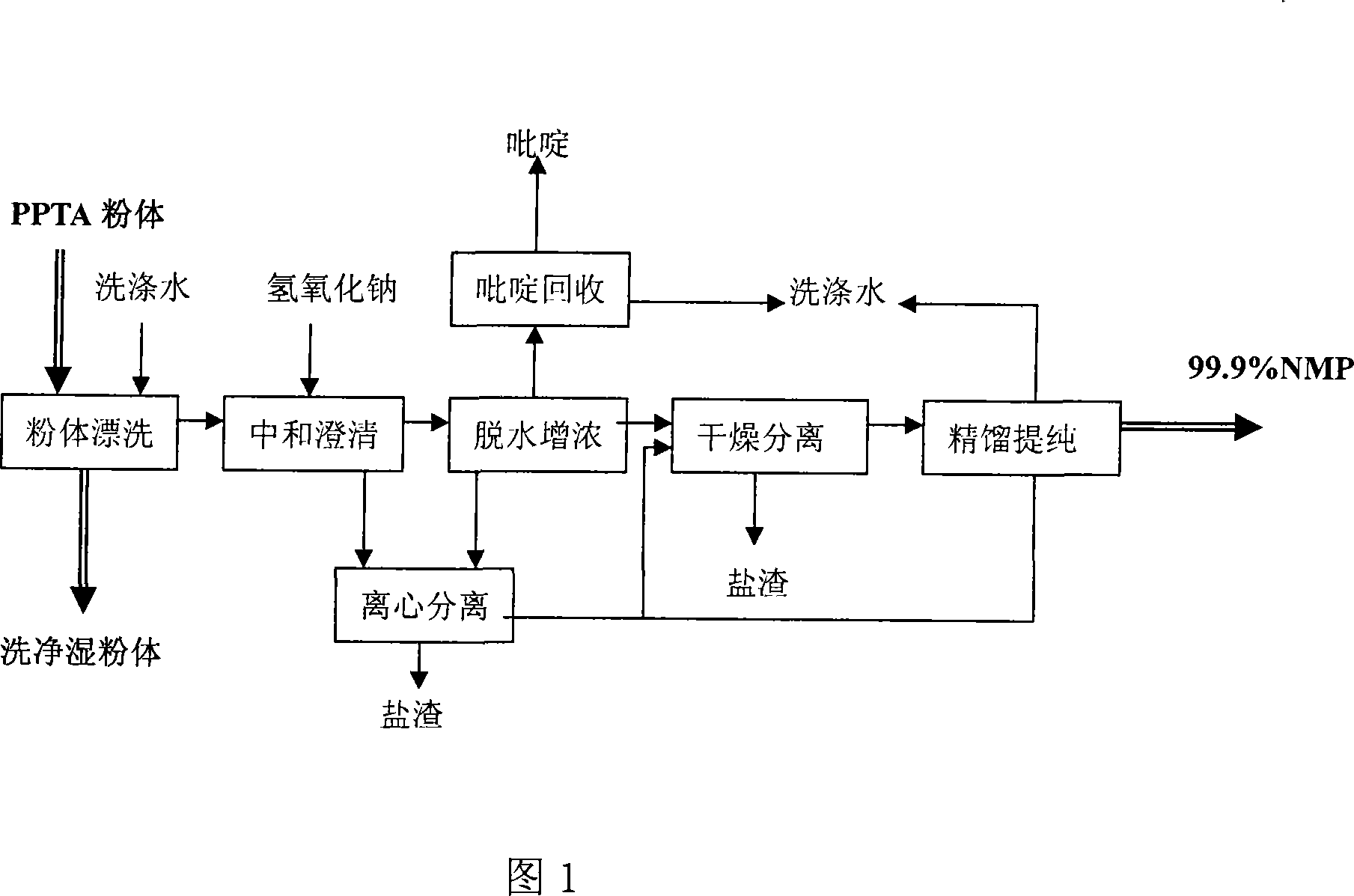

Method for reclaiming solvent from aramid fiber polymeric compound

The solvent recovering process of aramid fiber polymer includes the steps of rinsing, neutralizing, dewatering, separating and purifying. While recovering pyridine, the aramid fiber solvent and assistant are re-used. The technological process is simple and easy in control, and has been applied practically.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

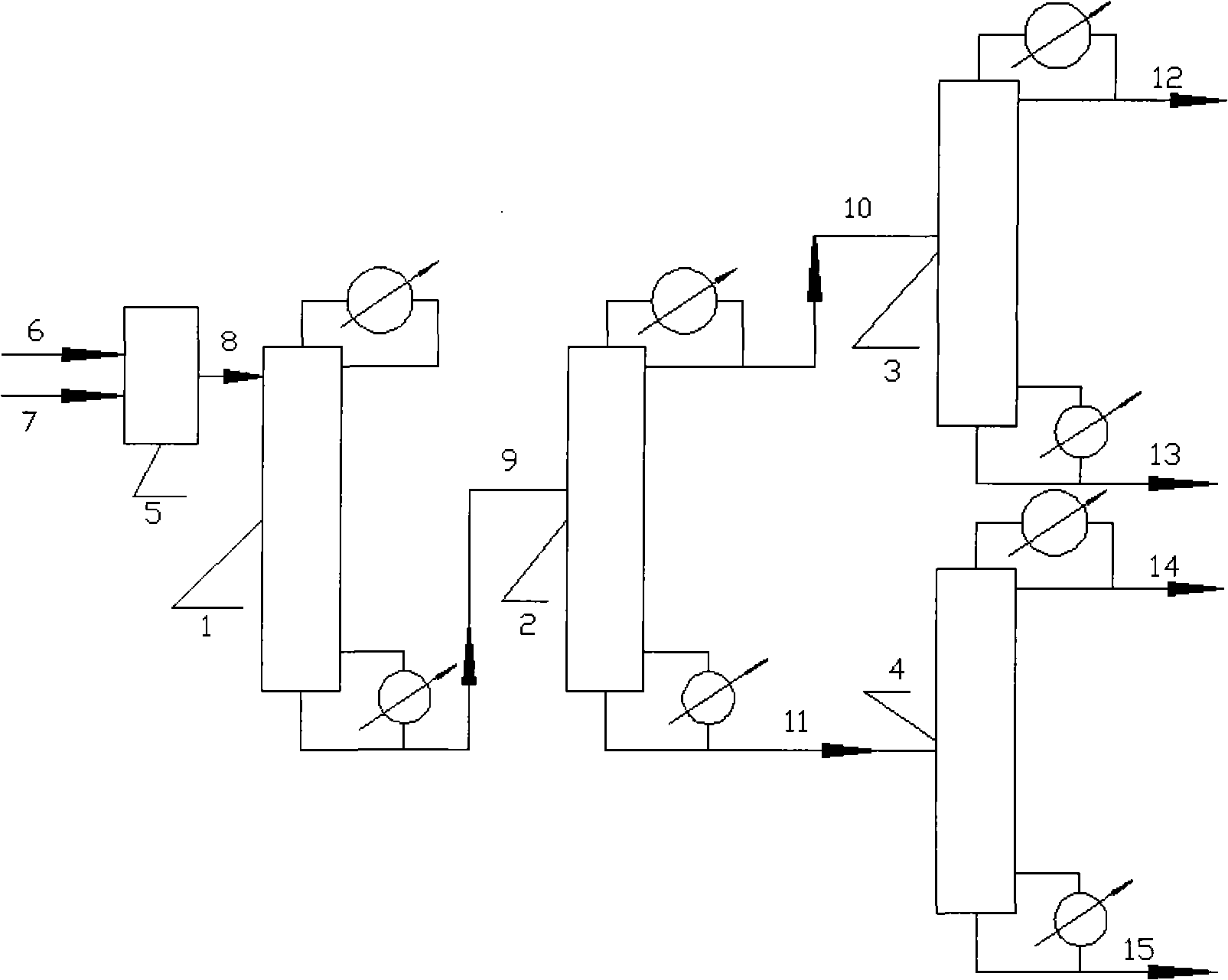

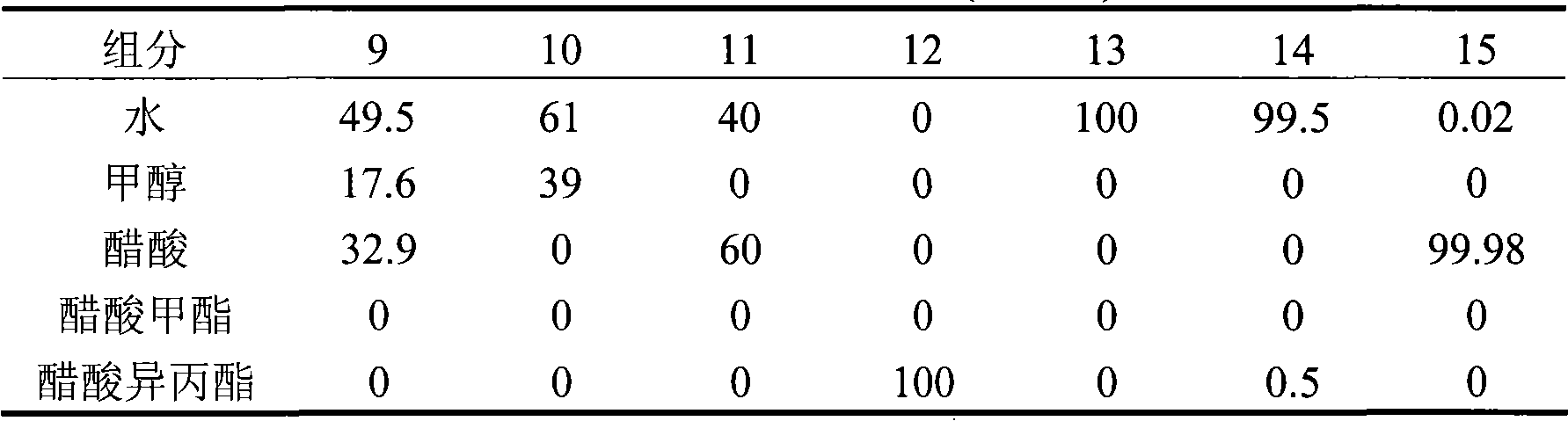

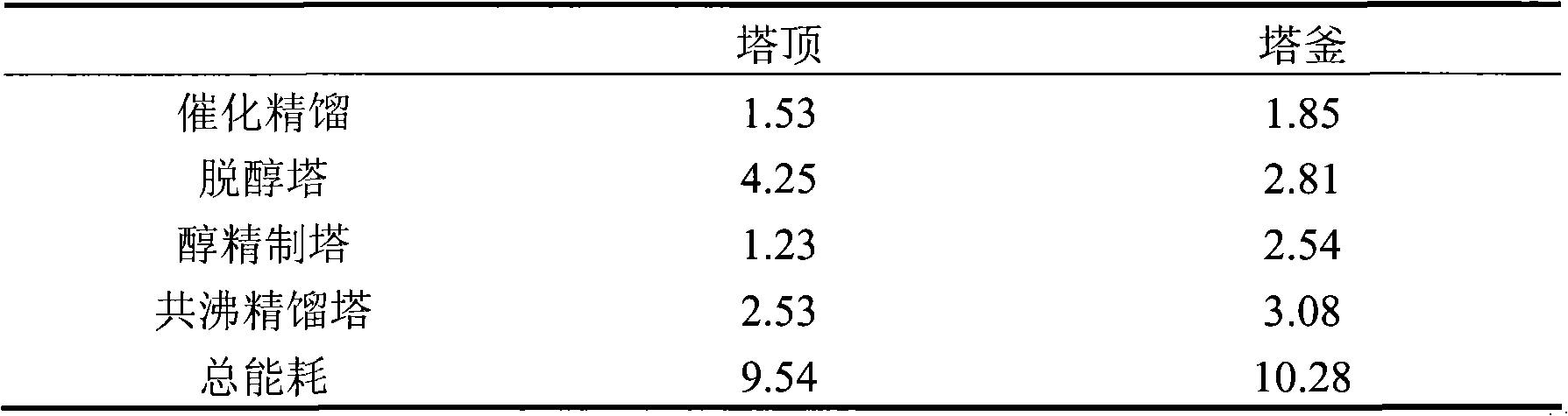

Azeotropy process for catalyzing, rectifying and hydrolyzing methyl acetate

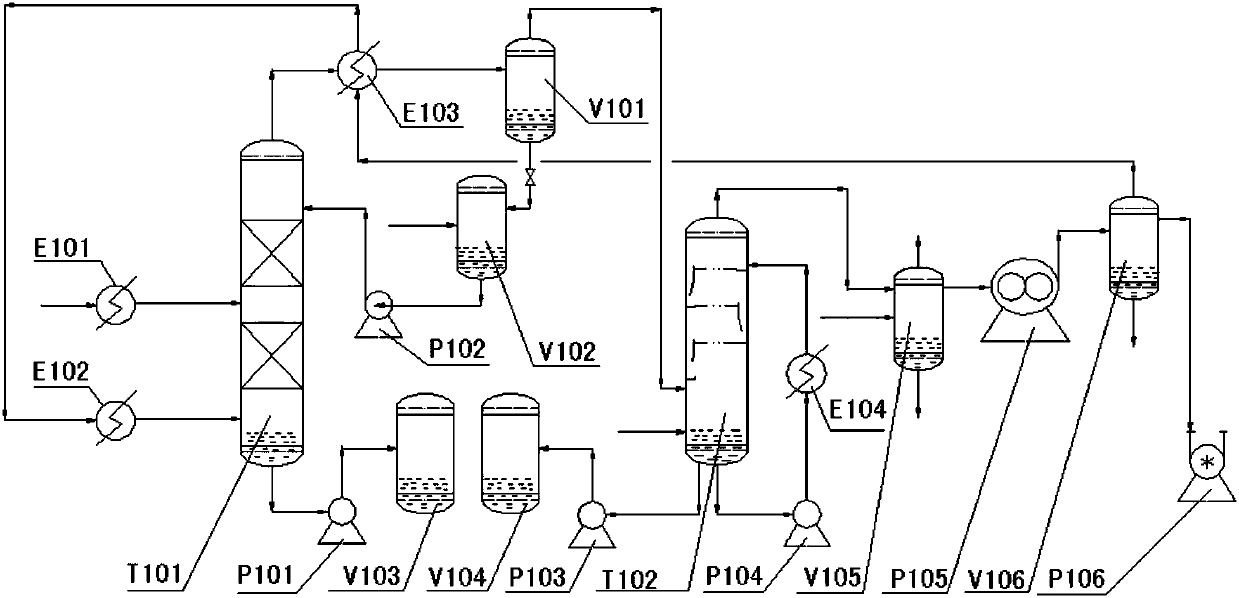

ActiveCN101306981ANo recycling issuesReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationAlcoholPolyvinyl alcohol

The invention relates to an azeotropic method used in methyl acetate catalyzing rectification hydrolysis, mainly solving the problems of the prior methyl acetate catalyzing rectification hydrolysis process including complex flows and high energy consumption. The azeotropic method solves the problems better through adopting the technical proposal which comprises the following steps that: water and methyl acetate are mixed and fed in a catalyzing rectification tower from the top of the tower; the top of the tower is of total reflux and a mixture comprising methanol, acetic acid and water is obtained inside a tower bottom; the mixture is fed in a dealcoholization tower, and the distillate at the top of the dealcoholization tower is a methanol aqueous solution, while an acetic aqueous solution is obtained inside a tower bottom; the methanol aqueous solution is fed in an alcohol treating tower, and the distillate at the top of the alcohol treating tower is methanol, while waste water is generated inside a tower bottom; the acetic aqueous solution is fed in an azeotropic rectification tower which takes one sort of benzene, cyclohexane, isopropyl acetate and n-butyl acetate as an azeotropic agent; a biphase mixture of the azeotropic agent and water is obtained inside the top phase splitter of the azeotropic rectification tower with the water collected from the top of the tower and the azeotropic agent returned to the inside of the tower, while pure acetic acid is obtained inside the tower bottom of the azeotropic rectification tower. The azeotropic method can be used in the industrial production for reclaiming byproduct methyl acetate during producing polyvinyl alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

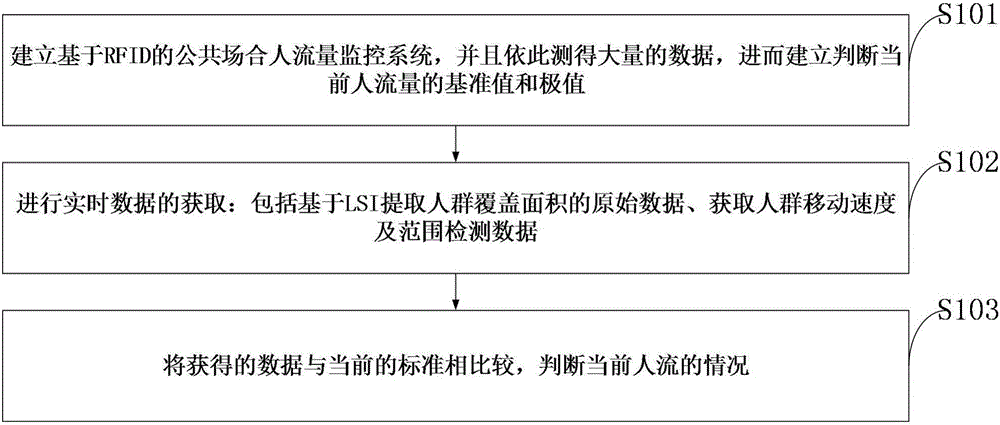

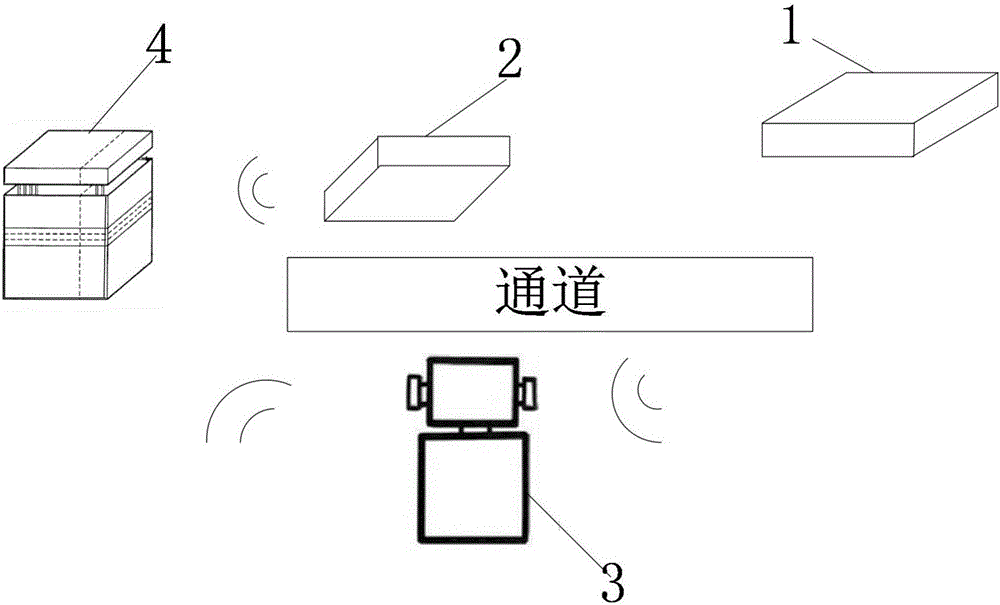

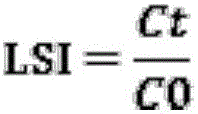

A public place visitors flow rate monitor method based on RFID

InactiveCN106228209ANo recycling issuesThe principle of changing the applicationCo-operative working arrangementsIndividual entry/exit registersOriginal dataCrowds

The invention discloses a public place visitors flow rate monitor method based on RFID. The method comprises the following steps of setting up a visitors flow rate monitoring system based on RFID in a public place, and measuring a large amount of data according to the system; establishing a reference value and an extreme value for judging the current visitors flow rate; acquiring real-time data, which includes extracting the population coverage area based on LSI and obtaining population movement speed and the range detection data; and comparing the obtained data with a current standard to judge the current visitor flow situation. According to invention, RFID technology related equipment is high in cost performance, and has a characteristic of high environment resistance, so that investment cost can be substantially reduced; in a public place where a crowd do not carry cards embedded with electronic labels, the current flow of people can also be subjected to real-time monitoring; the LSI can be used to analyze the population coverage, so that not only can the current test results be verified, but also certain prediction can be made for short-term changes in the flow of people.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

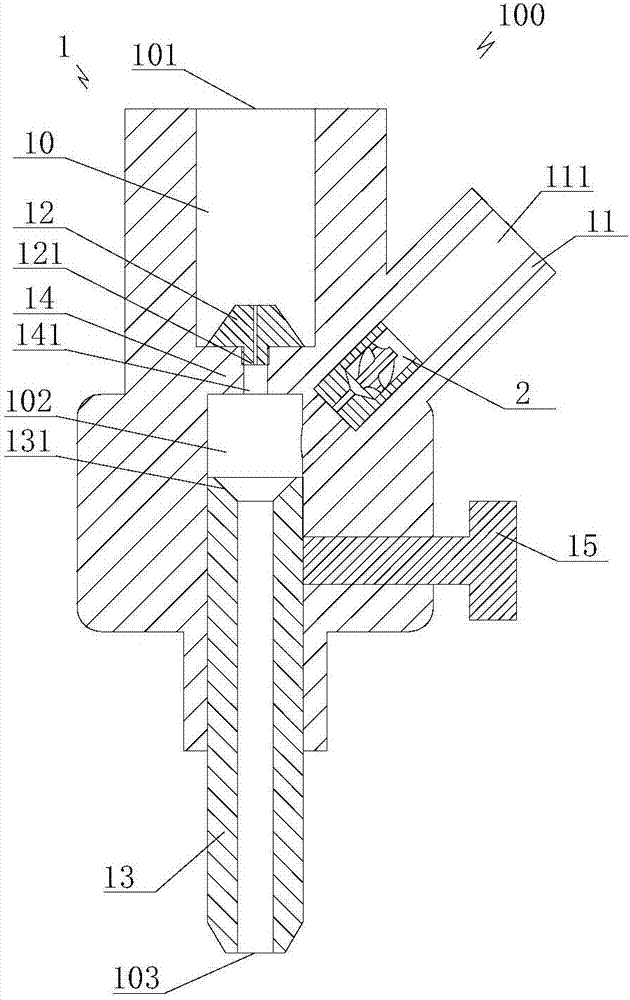

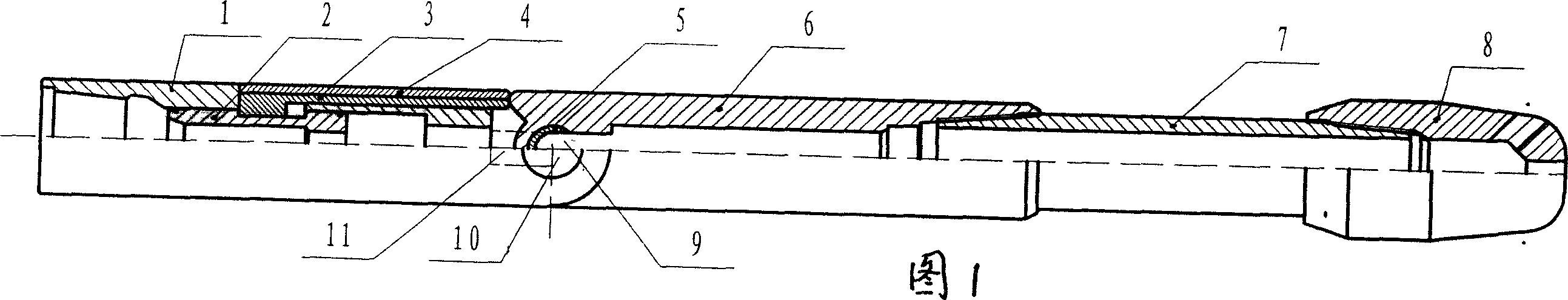

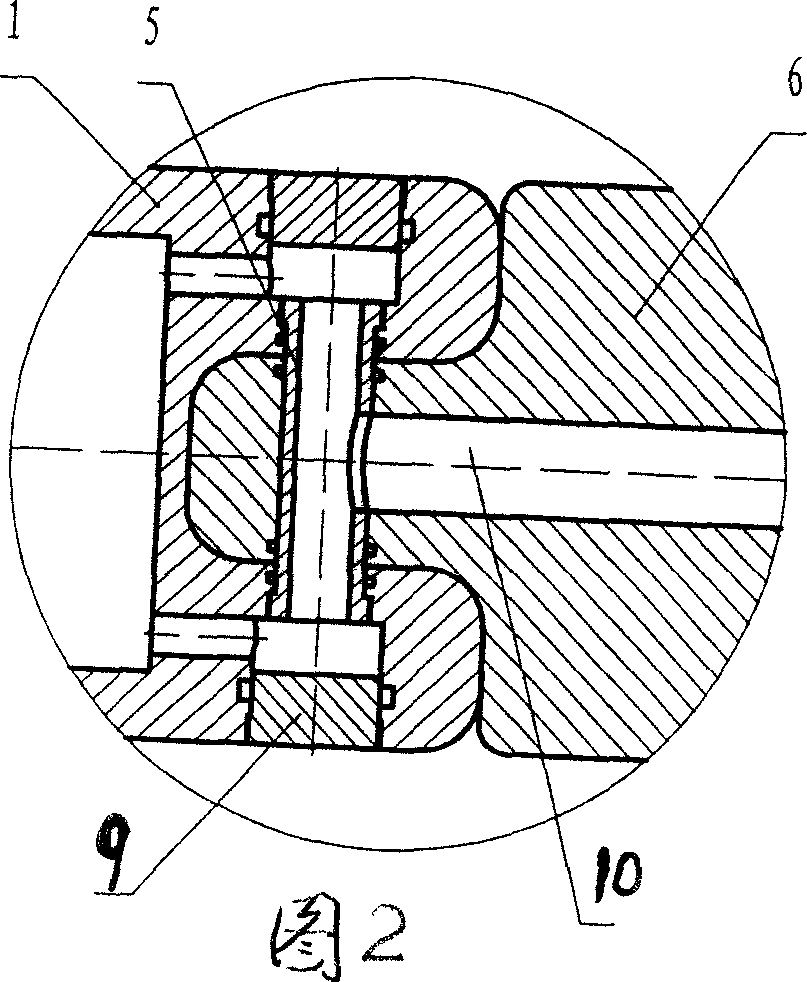

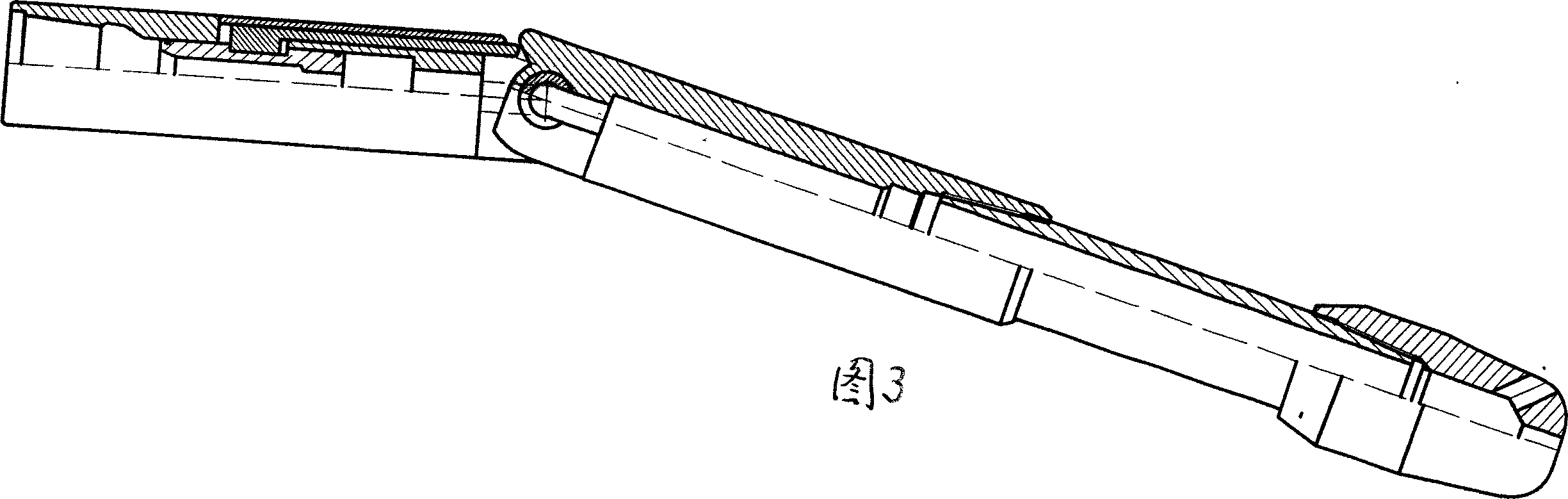

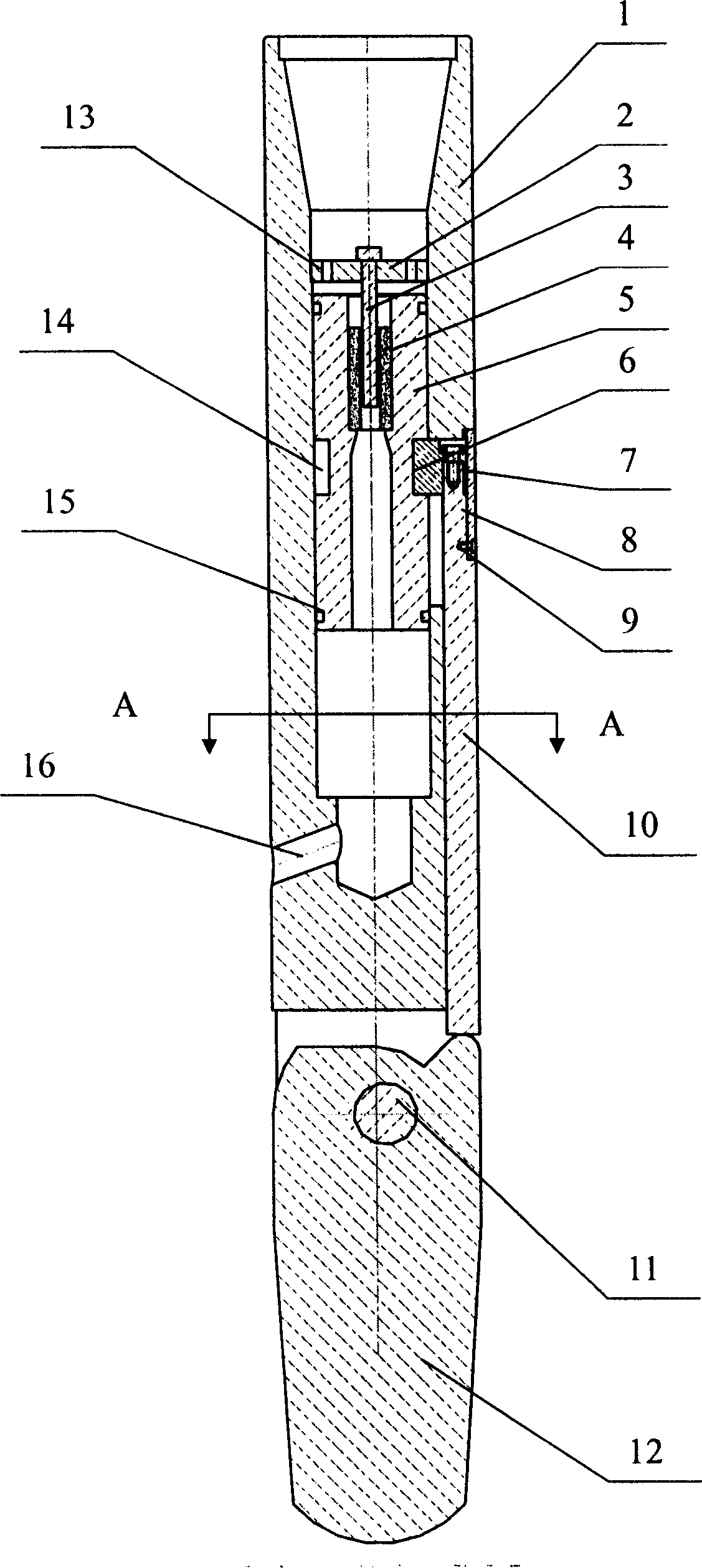

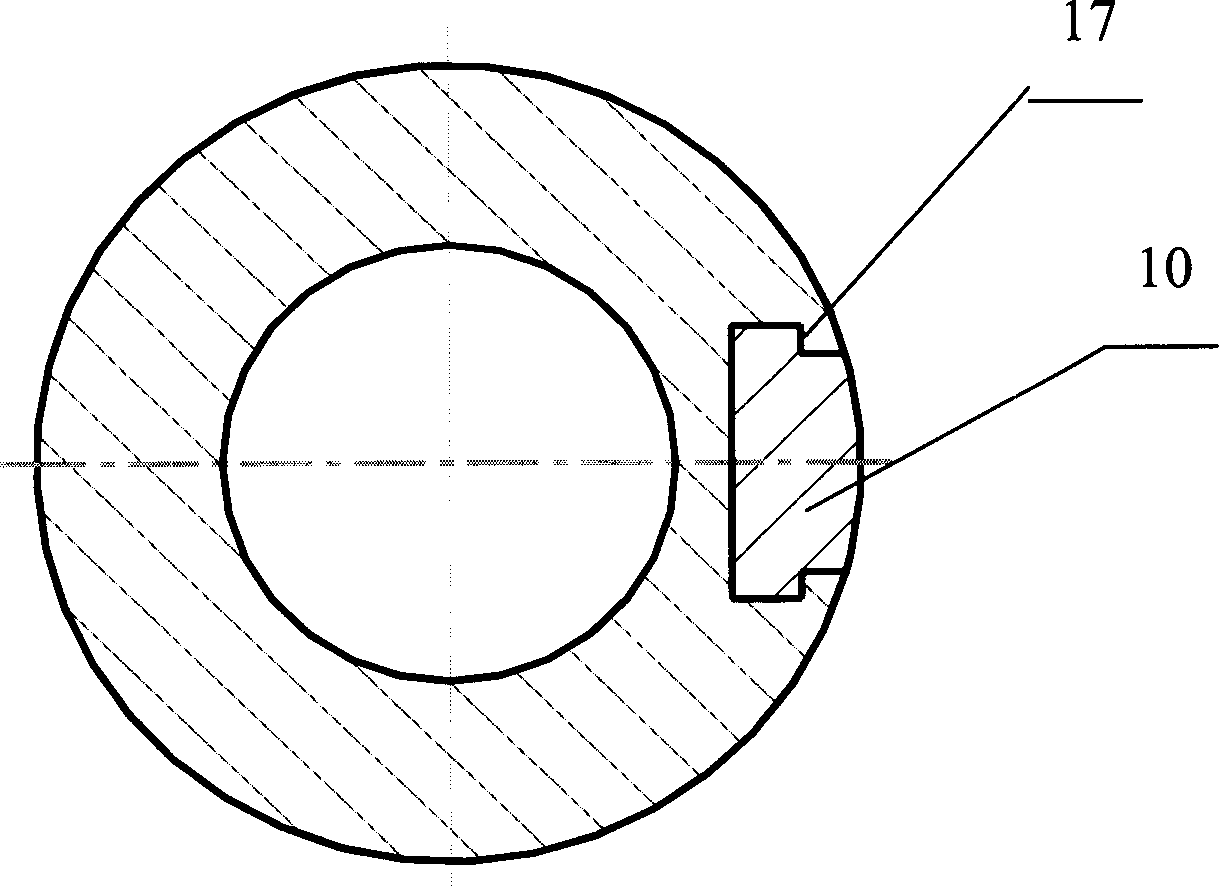

Branched selective reentry method and apparatus

InactiveCN1932231AReasonable structureImprove sealingDirectional drillingBorehole/well accessoriesIt equipmentOil well

The present invention relates to a branch hole selective reentry method for making downhole remedial operation of complex gas-oil well and its equipment. Said equipment is formed from self-body, piston, push rod, gland, hollow fixed pin, guide head, connecting rod, guide shoe and sealing plug. Said invention also provides the concrete working principle of said equipment, and the utilization of said method and equipment can smoothly make the work string be fed into branch well and implement following construction operations.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Branch well reentering tool

This invention discloses a tool reentering the branch well, used in completion operation in oil gas branch well in the industry of petro well-drilling. This tool consists of body, flow distribution plate, flow rod, piston, push block, press plate, push rod and guide head. When operated, this invention is put into the well connected with the lower part of completion limb or oil limb; when it approaches the predefined window of the branch well, the driven well pump should be started and a fall of pressure which works on the piston will push the push rod that deflects the guide head in a certain angle. When it continues going down, the limb should be rotated and the guide head will guide the limb into the branch well.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Preparation method of polyacrylic acid large-particle size bead-like water-absorbent resin

The invention discloses a preparation method of polyacrylic acid large-particle size bead-like water-absorbent resin, which comprises the following steps: firstly neutralizing an acrylic acid monomer solution with sodium hydroxide alkaline liquor to obtain a pH value of 6-7, adding acrylamide, an oxidizing agent and a cross-linking agent, stirring for dissolving to obtain a water phase; adding a dispersant into a grease solution, stirring uniformly, heating to 85 DEG C-90 DEG C to obtain an oil phase; adding the water phase into the oil phase, performing suspension polymerization; after the polymerization, performing oil filtration, washing, drying and sieving to obtain the bead-like water-absorbent resin. The preparation method provided in the invention has no solvent recovery problem; by changing the component of the oil phase, the particle size is determined according to the surface tension of the water phase in the oil phase without stirring; therefore, polymerization of products with different particle sizes is realized; the obtained product has a uniform and controllable particle size, and the particle size is up to 10 mm.

Owner:QINGDAO SANLI BENNUO CHEM IND

Synthesis method of diphenyl isophthalate

InactiveCN102643199AImprove conversion rateHigh yieldPreparation from carboxylic acid halidesOrganic synthesisChloride

The invention belongs to the technical field of organic synthesis, and particularly relates to a synthesis method of diphenyl isophthalate. The method comprises the steps of: directly reacting sodium salt of phenol with isophthaloyl chloride in dichloroethane as a solvent at the temperature of 5-30 DEG C under stirring for multiple hours, washing reaction liquid with water after reaction is finished, separating, distilling to remove solvent, recrystallizing and the like to obtain a diphenyl isophthalate finished product. The method is a green environment-friendly synthesis method, is high in reaction conversion rate and yield, and simple and convenient in operation of the whole synthesis process.

Owner:CHINA PETROLEUM & CHEM CORP +1

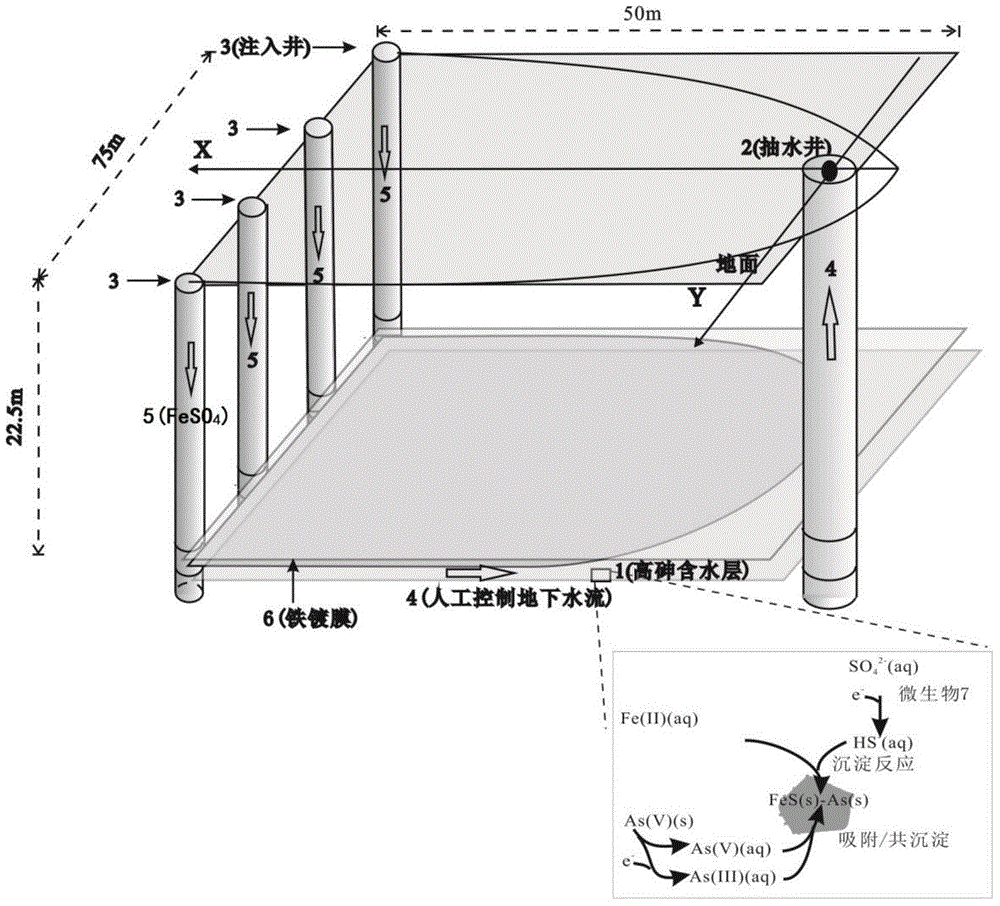

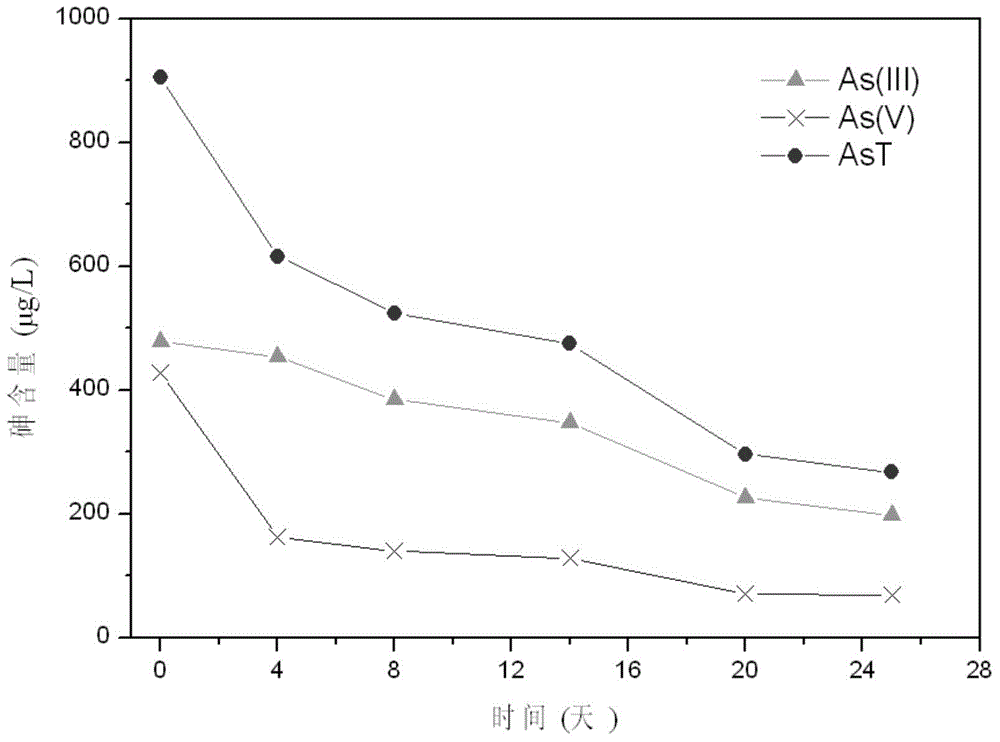

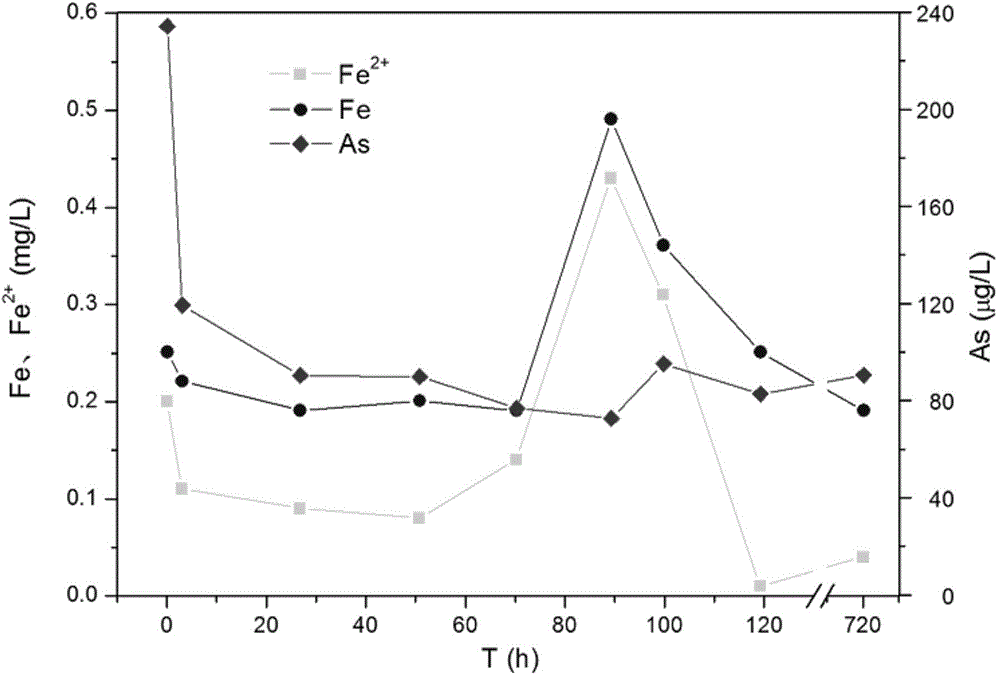

In-situ arsenic removing method of reductive underground water based on sulfate

InactiveCN104787830AProcess stabilityDoes not change the physical and chemical conditions of groundwaterWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionWater basedIn situ remediation

The invention relates to an arsenic removing method, particularly to an in-situ arsenic removing method of underground water based on a reducing action of a sulfate (ferrous sulfate), and belongs to the technical field of underground water in-situ remediation. The method comprises: selecting FeSO4 as a basic arsenic removing agent; periodically injecting a ferrous sulfate agent; making a partial flow field by utilizing a pumping well to lead the agent to be diffused and to react; and prompting injected FeSO4 and sulfide widely present in a high-arsenic content aquifer to be subjected to a reduction-precipitation reaction through mediation of indigenous microorganism to generate a stable and uniform iron sulfide (the main mineral morphologies of which are mackinawite (FeS) and iron pyrite (FeS2)). On one side, the arsenic concentration in the underground water is reduced by the resultant iron sulfide through an absorption and co-precipitation action, on the other side, the resultant iron sulfide can form a dense iron plating layer on the surface of the precipitation, so that release of solid arsenic can be controlled from the source.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

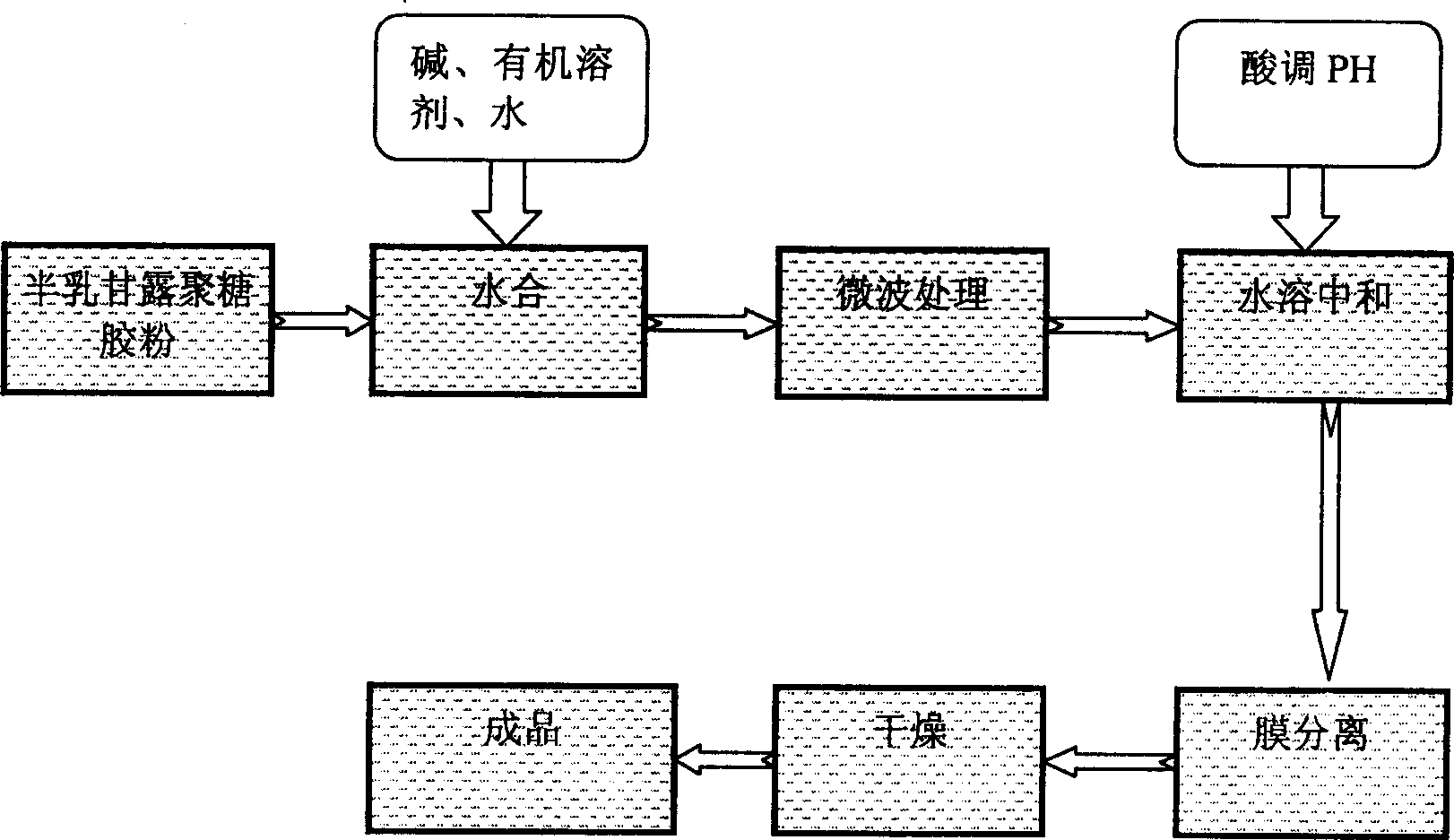

Semi-dry microwave treating process of preparing galactomannan

The present invention discloses semi-dry microwave treating process of preparing galactomanoligose. Galactomanoligose is prepared with galactomannan powder as material and through the steps of hydration, microwave treatment, water dissolving and neutralizing, membrane separating and drying. The process has short production period, high production efficiency, less pollution and low power consumption.

Owner:昆明旭日丰华农业科技有限公司

Method for preparing chitosan oligosaccharides through semi-wet method microwave treatment

A method for preparing chitosan oligosaccharides through semi-wet method microwave treatment relates to a production method of chitosan oligosaccharides. The method comprises the following steps: using chitosan gelatine powder as raw material to perform hydration and microwave treatment, dissolving in water, neutralizing, and performing membrane separation, drying and the like to prepare chitosan oligosaccharides. The method does not consume organic solvent, thus the problem of recycling solvent does not exist and the pollution is low; and as the volume of the reaction system is from 1 / 3 to 1 / 5 of that of the solution method, the production efficiency is obivously increased. The method adopts microwave treatment to promote the polysaccharide degradation reaction, thus the heating effect is greatly increased. The radiation thermal effect of microwave and the non-thermal effect of microwave are utilized to prepare the product. Meanwhile, microwave is an efficient and clean energy, thus the speed of the chemical reaction can be greatly increased. The method also adopts the membrane separation mean, thus the refining efficiency is high and the product quality is controllable.

Owner:YANGZHOU RIXING BIO TECH +1

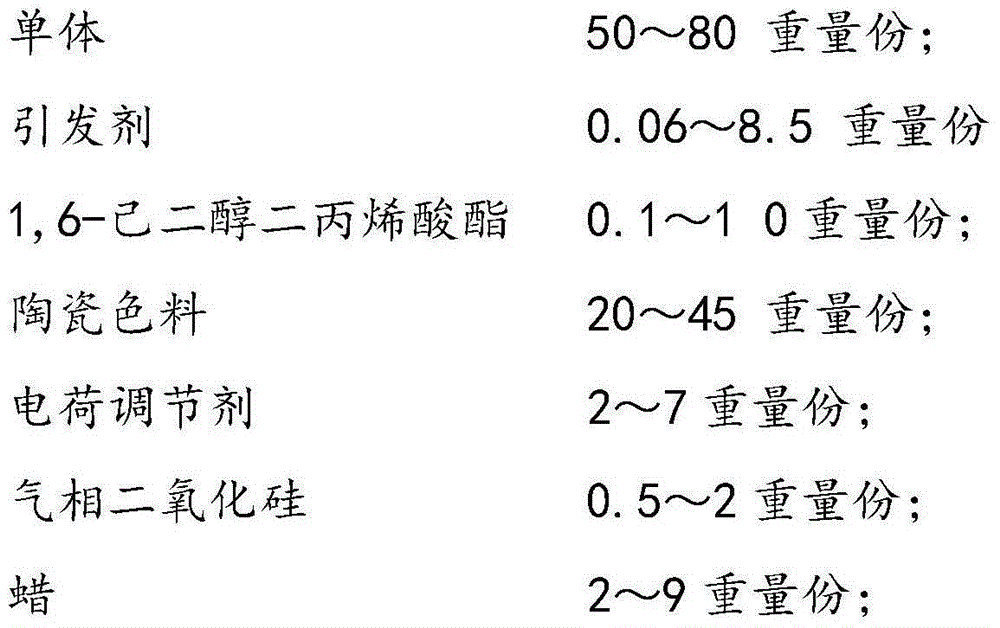

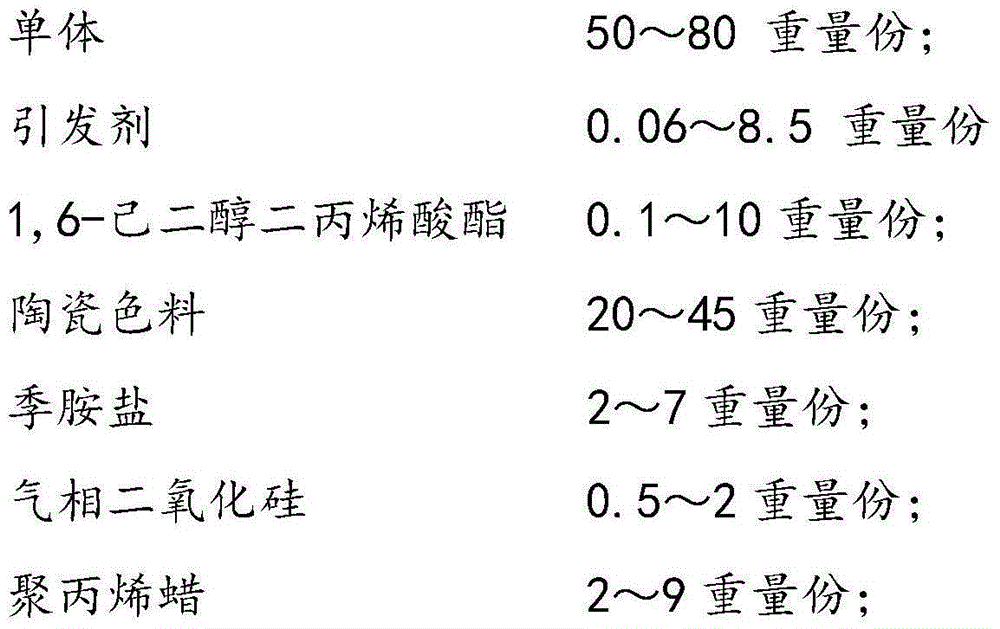

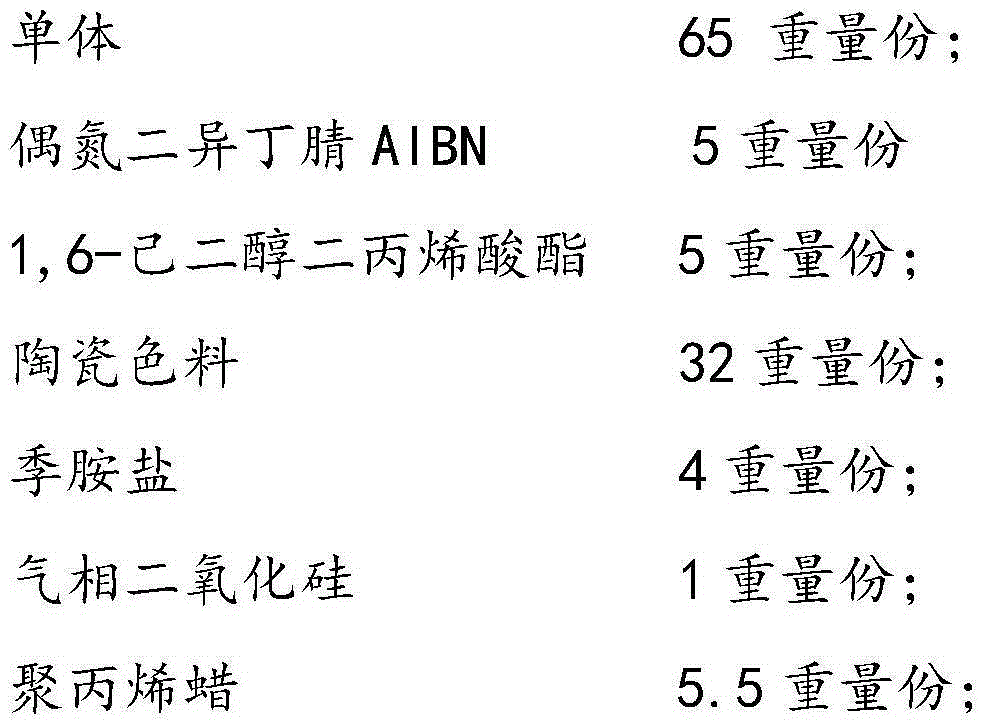

Colored ceramic ink powder for mass-polymerization architectural ceramic and preparation method thereof

The invention belongs to the technical field of ceramic printing, and particularly relates to a colored ceramic ink powder for mass-polymerization architectural ceramic and a preparation method thereof. The ceramic ink powder comprises acrylate, polyethylene, 1,6-hexanediol diacrylate, an initiator, a ceramic pigment, a charge regulator and vapor-phase silicon dioxide. The preparation method comprises the following steps: proportionally mixing the components of the ceramic ink powder to obtain a mixed solution, injecting into a nitrogen-protected extruder, carrying out mass polymerization on the mixed solution in the extruder, extruding, and carrying out after-treatment. The prepared ink powder granules have regular shape and fine appearance; and the printed colored graph has the advantages of high high-resolution quality, high level contrast grade and high development density. The method does not use any solvent or abundant washing water, does not have the problem of subsequent solvent recovery, has the advantages of simple technique, energy saving and environment friendliness, lowers the cost, and has great market prospects and economic value.

Owner:佛山市明朝科技开发有限公司 +1

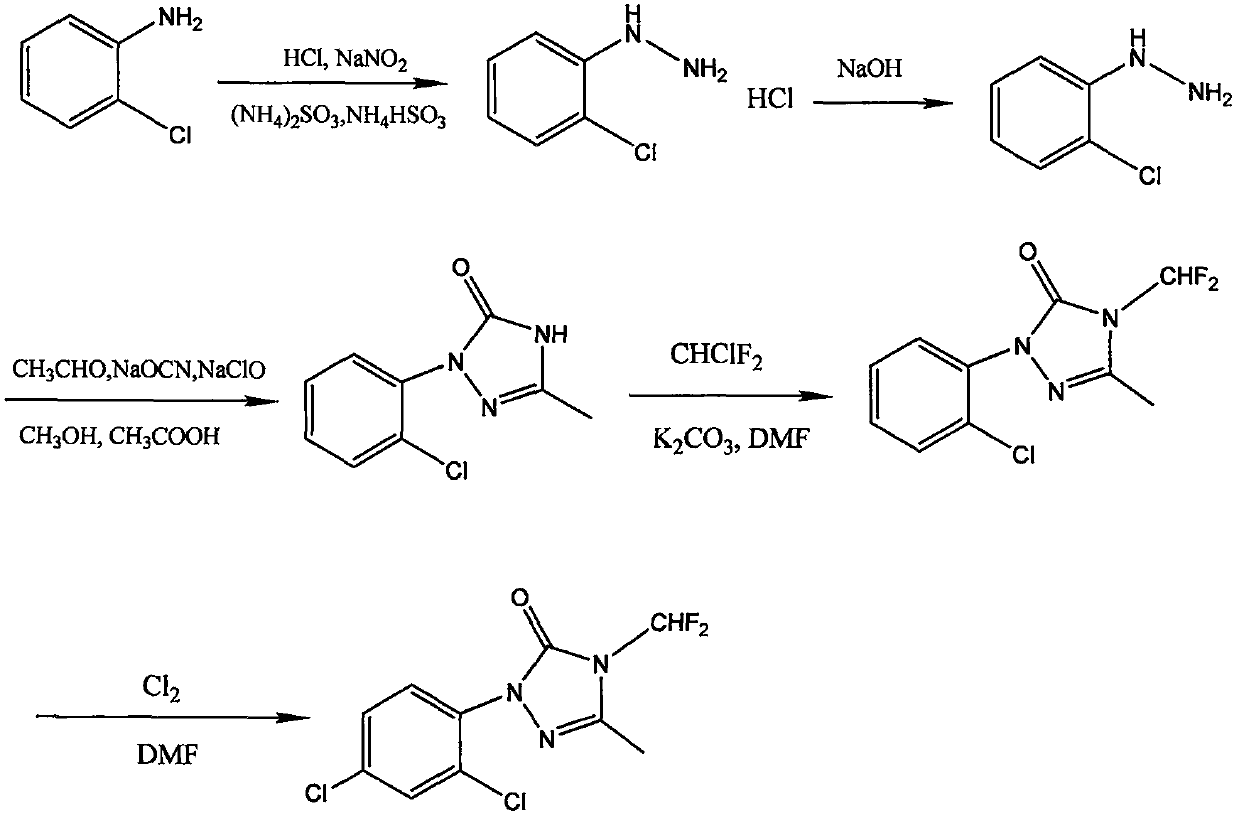

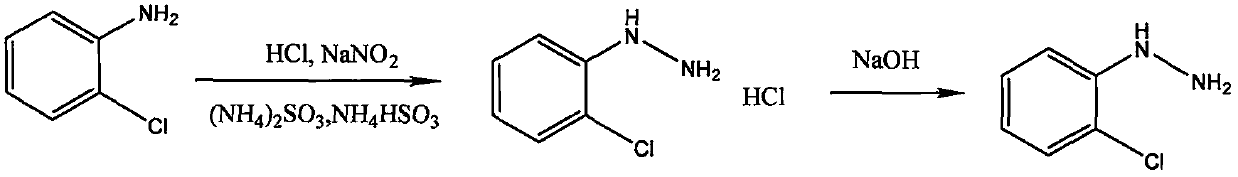

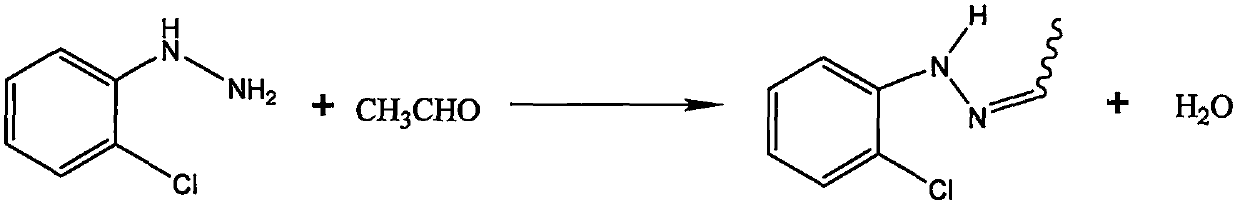

Method for synthesizing 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone

The invention discloses a method for synthesizing 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone. The method comprises the following steps: with o-chloroaniline as a raw material, carrying out diazotization, reduction and salification so as to synthesize o-chlorophenylhydrazine hydrochloride, carrying out alkali neutralization so as to prepare free o-chlorophenylhydrazine, subjecting o-chlorophenylhydrazine, acetaldehyde, sodium cyanate and sodium hypochlorite to condensation, cyclization and oxidation reactions so as to generate 1-o-chlorophenyl-3-methyl-1H-1,2,4-triazole-5-ketone, subjecting 1-o-chlorophenyl-3-methyl-1H-1,2,4-triazole-5-ketone to salification, potassium fluorination and chlorination reactions so as to obtain 1-(2,4-dichlorophenyl)-3-methyl-4-difluoromethyl-1,2,4-triazole-5-ketone (a sulfentrazone intermediate). The synthetic method provided by the invention uses o-chloroaniline as the raw material, can synthesize an intermediate with small steric hindrance and few impurities, improves the yield, has the advantages of easily-available and cheap raw materials, mild reaction, simple and convenient operation and high safety, and facilitatesindustrial production.

Owner:连云港世杰农化有限公司

A kind of circulation gas stripping distillation method for extracting EPA&DHA from fish oil

ActiveCN106916062BIncreased EPA&DHA contentShort heating timeOrganic compound preparationSteam distillationFish oilVaporization

The invention relates to a circulation gas extractive rectification technology for extracting EPA and DHA from fish oil. The method is characterized in that the fish oil is pre-heat, is introduced into a rectifying tower and rectified under extractive rectification of inert gas circulation gas to obtain a mixture of EPA and DHA. The method employs light component of the inert gas circulation gas, and employs a backflow mode for high purity separating of the components, rectification and gas stripping are fusion during a whole process, the difference of the components volatility in the fish oil can be used, so that multitime partial vaporization and partial condensation can be carried out, the light component of the hot inert gas is used, partial pressure of the light component is reduced, the light component is developed to vaporization, and the light component content in a heavy phase is reduced. In the invention, high vacuum is not required, one time purification can be used for increasing the EPA and DHA content to more than 70%.

Owner:山东禹王制药有限公司 +1

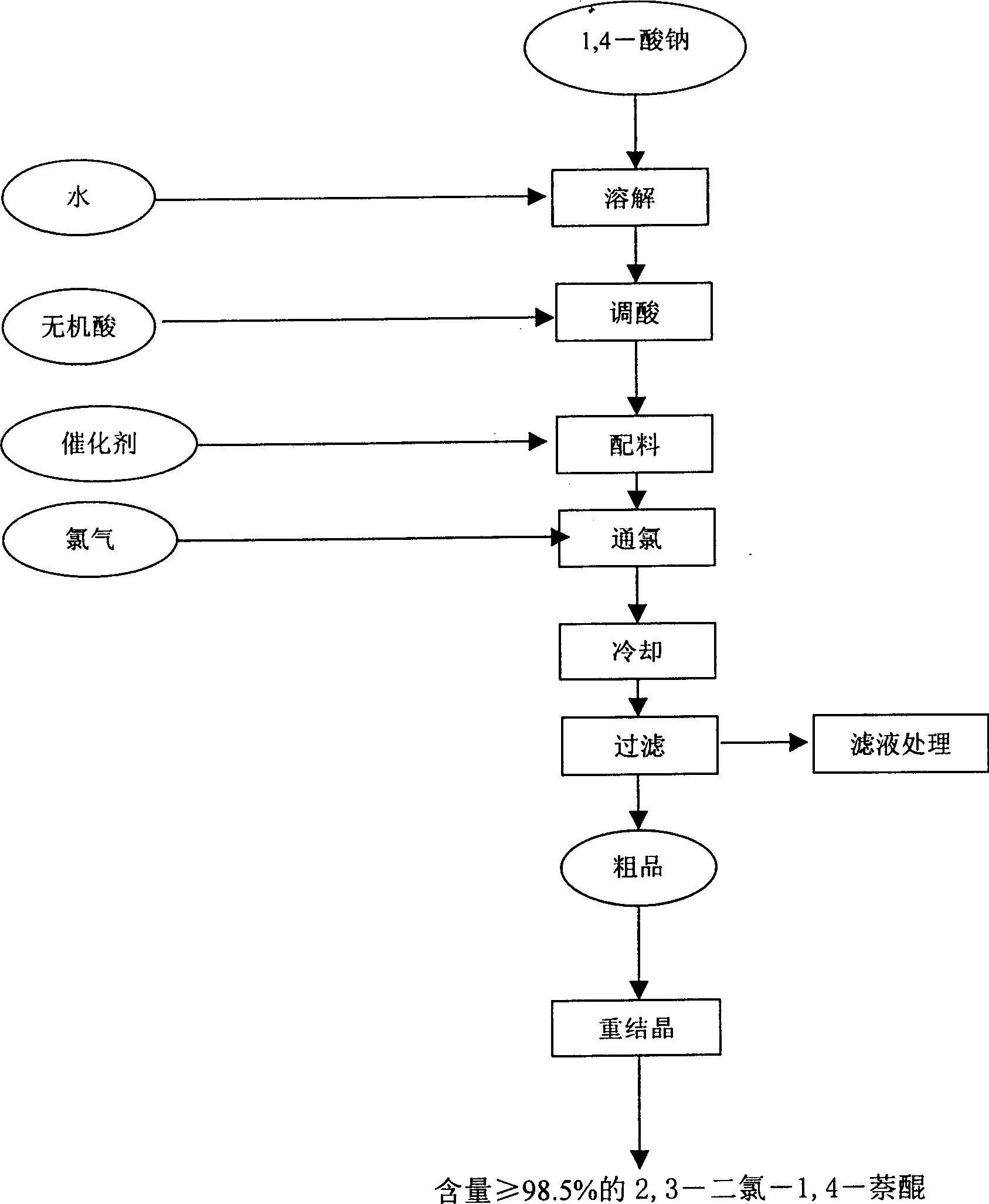

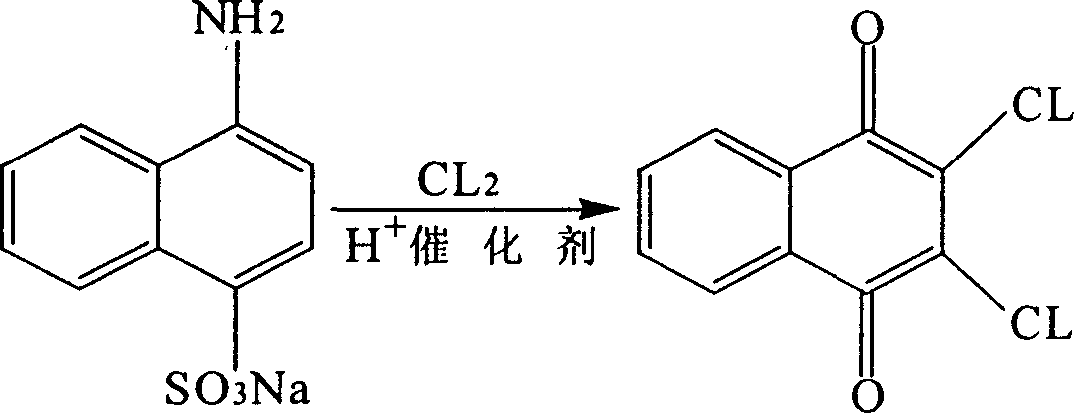

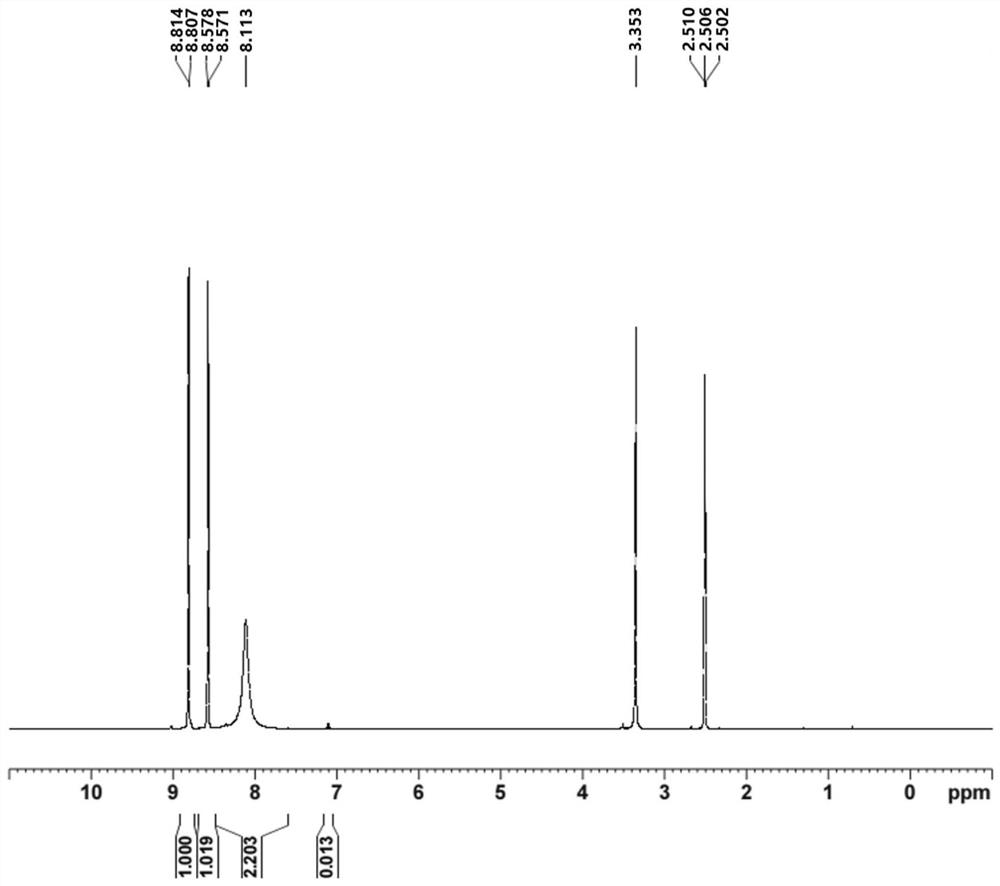

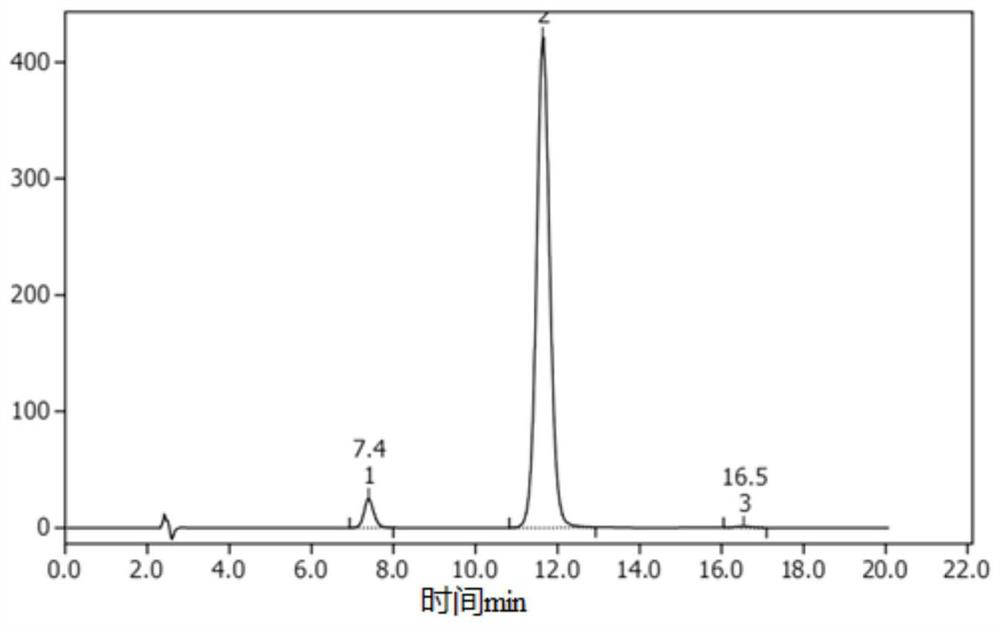

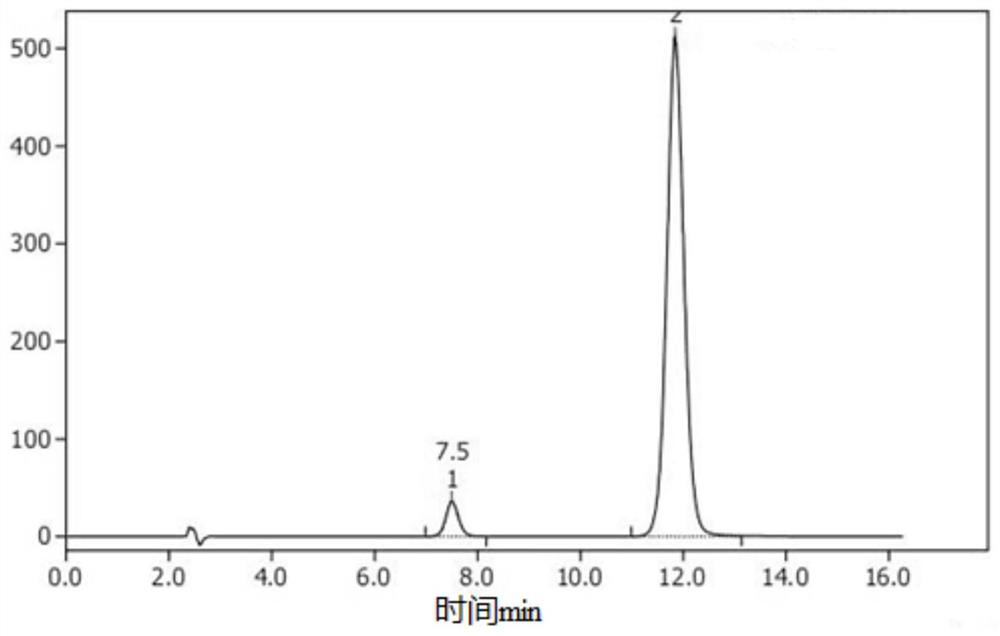

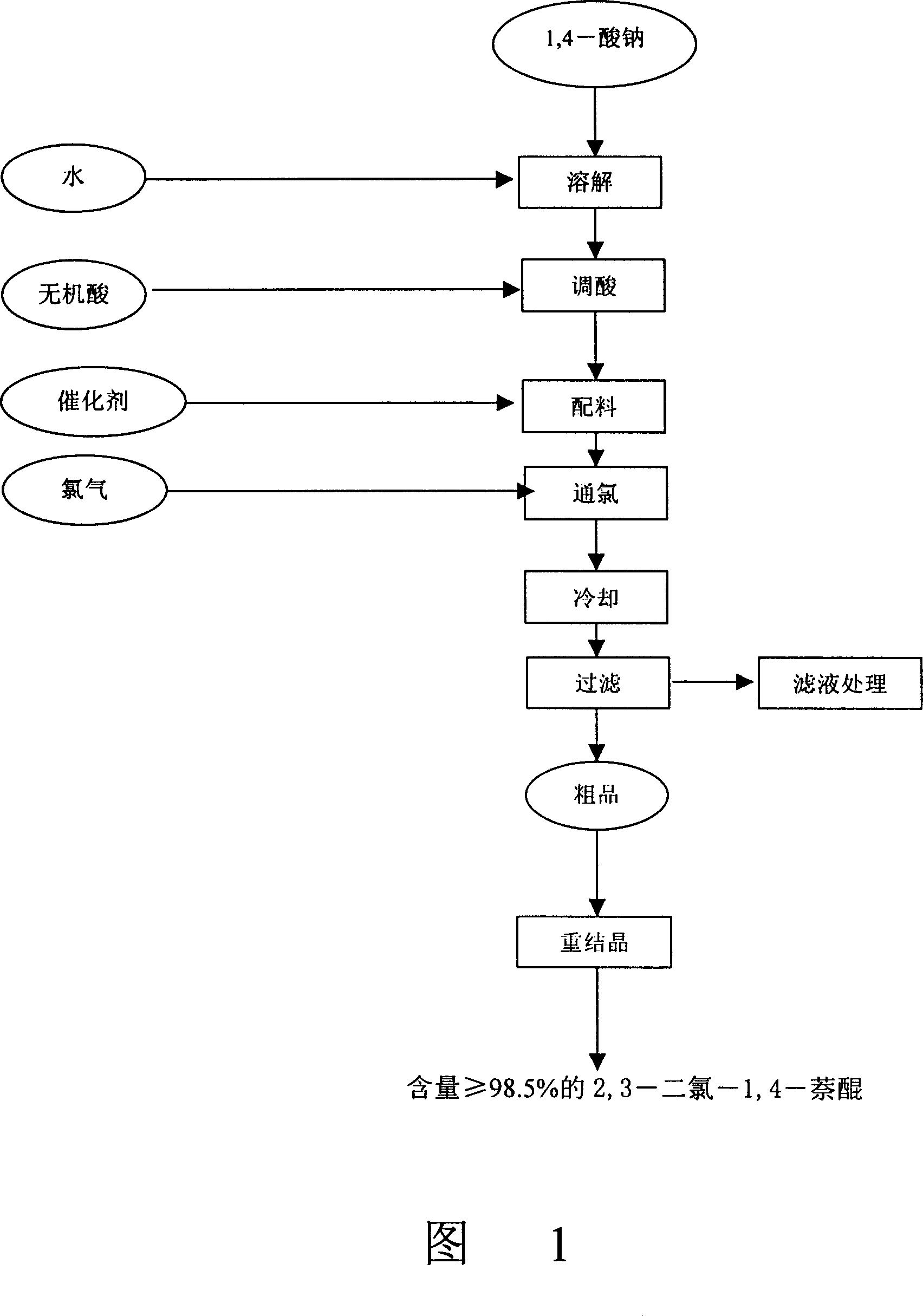

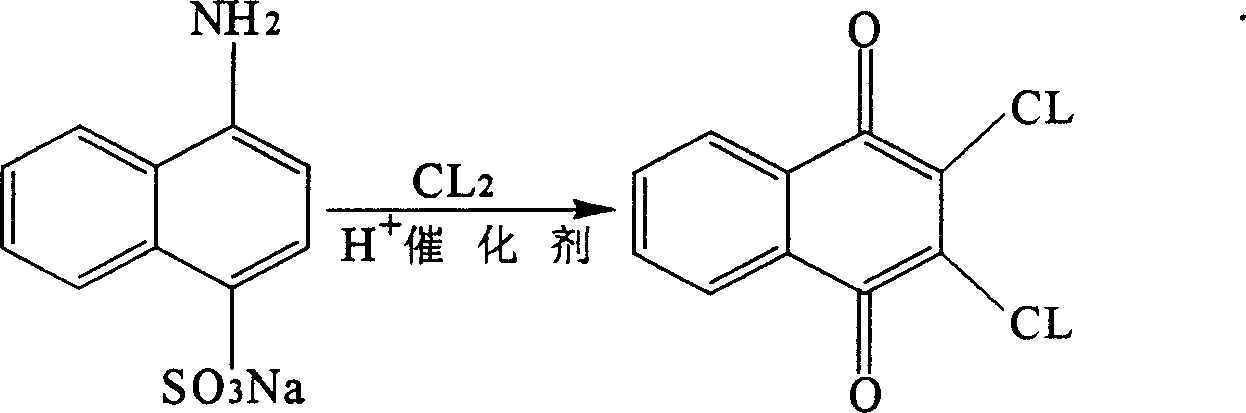

Preparation method of 2,3-dichlor-1,4-naphthaquinones

ActiveCN1733678AConvenient sourceLow costOrganic compound preparationQuinone preparationOrganic solventIron powder

The invention relates to the preparation method of 2,3-dichlor-1,4-naphthaquinones, which comprises, (1) charging sodium-1-naphthylamine-4-sulfonate into water, adjusting pH to 2-5 by charging acid, (2) charging 1-10% of iron powder, zinc powder, ferric salt, ferrous salt or zinc salt, (3) letting in chlorine, (4) cooling down the reaction product at normal temperature, filtering to obtain 2,3-dichloro-1,4-naphthaquinone crude product, finally recrystallizing with organic solvents to obtain product with the content higher than 98.5%.

Owner:常州华达纳米材料科技有限公司

Membrane catalytic reactor

ActiveCN102500283ASame concentrationUniform temperatureLiquid hydrocarbon mixture productionBio-feedstockPhase conversionCompound (substance)

The invention belongs to chemical equipment, and particularly relates to a membrane catalytic reactor. The membrane catalytic reactor comprises a feed port, a discharge port, a raw material chamber, a product chamber, a jacket, an electric stirrer and a catalytic membrane, wherein the electric stirrer is arranged above the raw material chamber; stirring paddles extend into the raw material chamber; the catalytic membrane is arranged between the raw material chamber and the product chamber; the feed port is formed on the top of the raw material chamber; the discharge port is formed at the bottom of the product chamber; and the jacket is arranged outside the raw material chamber, the catalytic membrane and the product chamber. By adopting the membrane catalytic reactor for performing esterification reaction, the energy consumption is low, and the reaction efficiency is high; the problems of separation and recovery of a catalyst are avoided, and the product cost is reduced; strongly acidic cation exchange resin powder is used as a catalytically active matter; polyethersulfone is used as a base material; a hybrid membrane which is prepared by a phase conversion method is a catalytic membrane which has higher efficiency for catalytic esterification reaction and has no problems of equipment corrosion, environment pollution and the like; and the membrane catalytic reactor has the advantages of simple equipment structure, high adaptability, easiness in control of process, convenience in operation and suitability for industrial implementation.

Owner:SHANDONG UNIV OF TECH

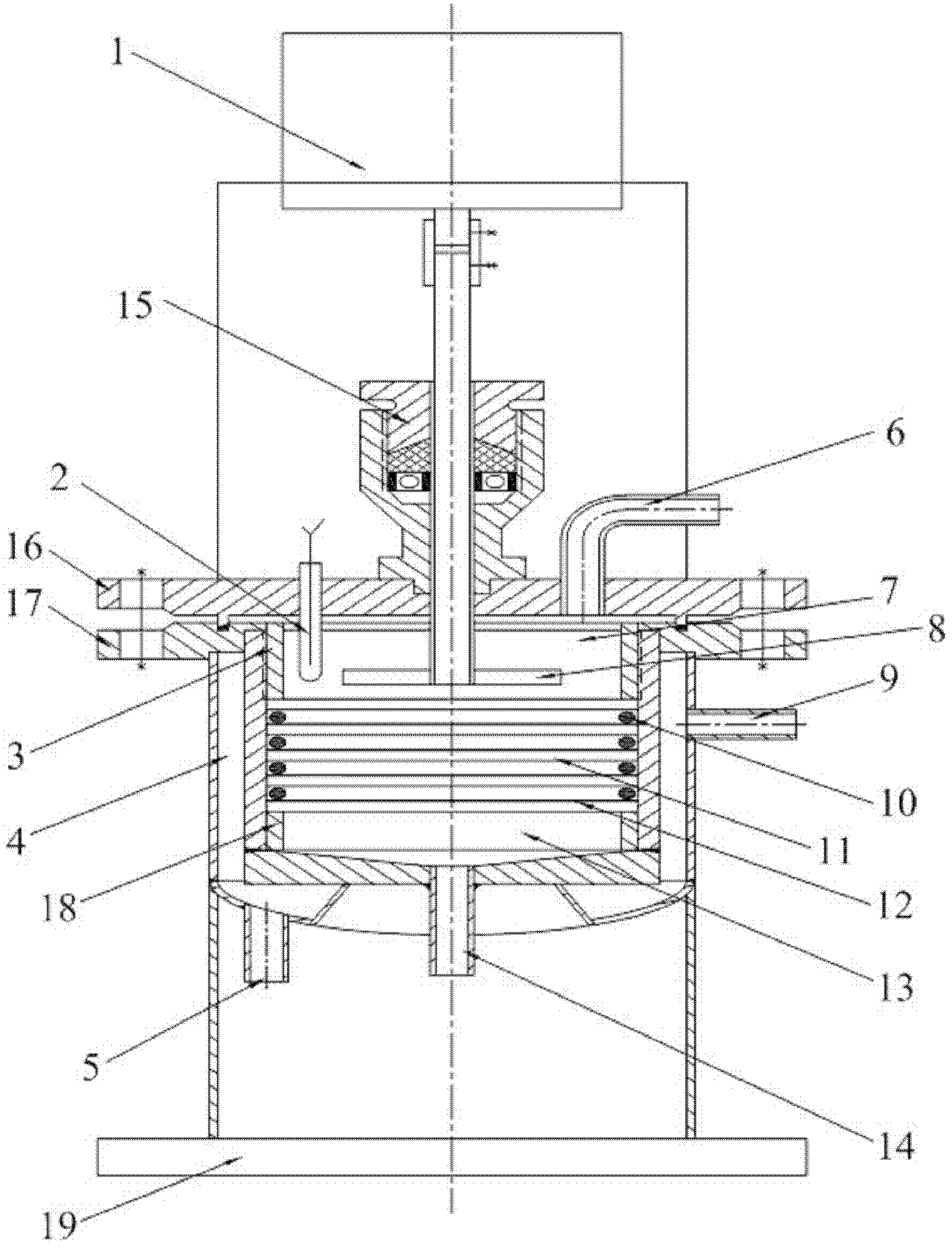

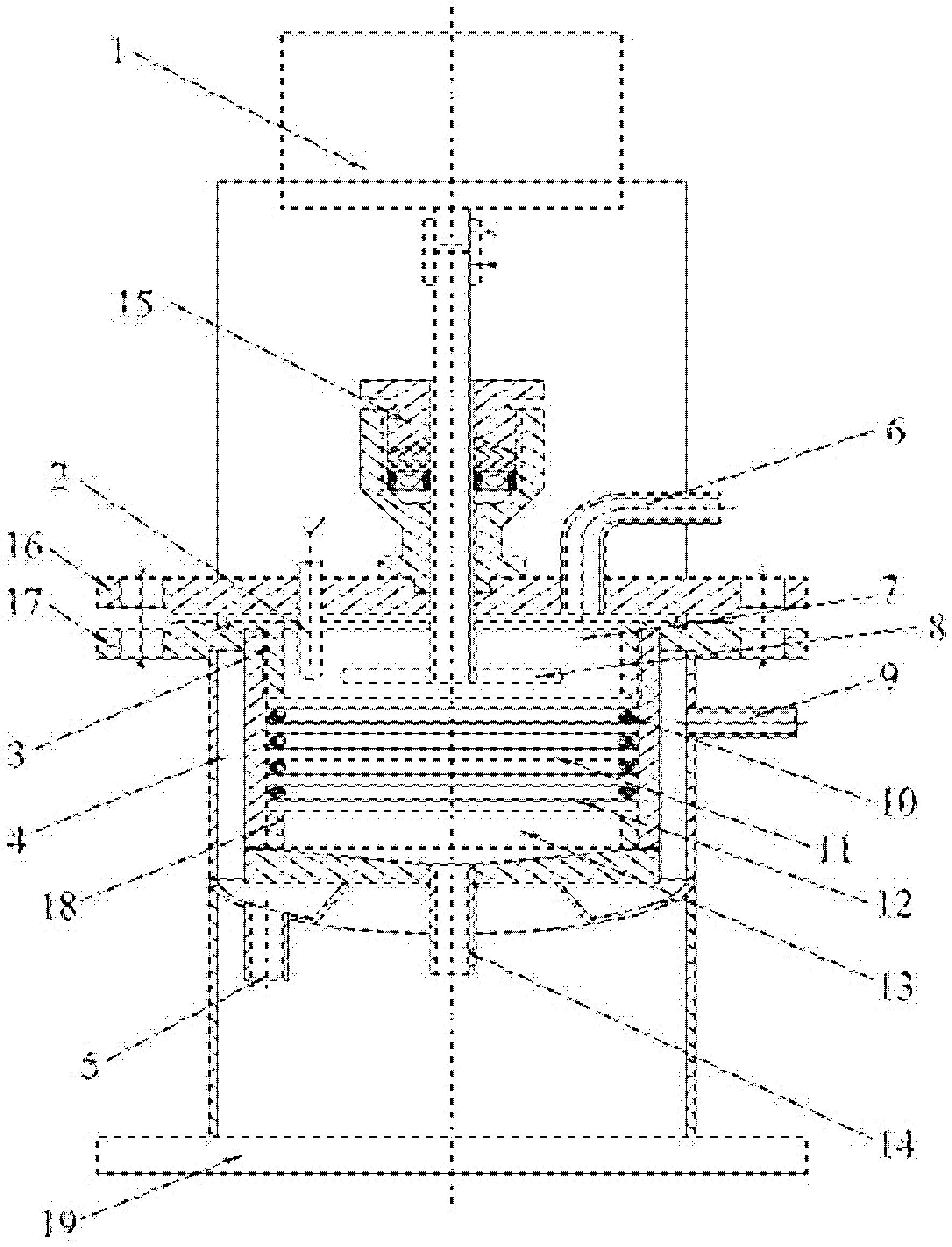

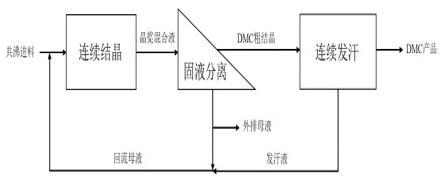

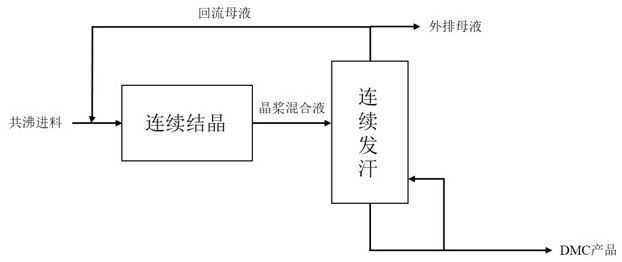

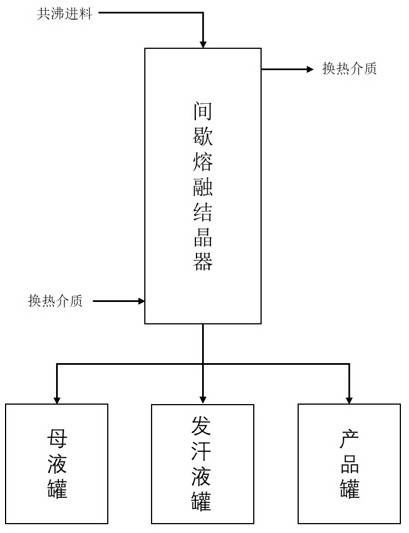

Method and Application of Melting Crystallization to Separation of Dimethyl Carbonate Methanol Azeotrope

ActiveCN111704545BLess investmentOperational securityCarbonic/haloformic acid esters purification/separationExtractive distillationPhysical chemistry

The invention relates to a method for separating dimethyl carbonate methanol azeotrope through melt crystallization and application thereof. The method specifically comprises the following steps: introducing a dimethyl carbonate methanol azeotrope with the dimethyl carbonate content of 25-35% into a melt crystallization device, separating out dimethyl carbonate in a crystal form through cooling, then partially melting dimethyl carbonate crystals through heating sweating, removing impurities contained in the crystallization process, further purifying dimethyl carbonate, and finally obtaining ahigh-purity dimethyl carbonate product and a low-concentration crystallization mother solution. The crystallization temperature of dimethyl carbonate in a self-azeotropic system is -20 to -40 DEG C, and the operation equilibrium temperature of a crystallization section is -50 to -60 DEG C, the purity of the dimethyl carbonate product is 99.9%-99.999%, and the concentration of the crystallization mother solution is 5%-15%. The method can be used for separation and purification of dimethyl carbonate methanol azeotropic composition in the process of producing dimethyl carbonate by a synthesis method or producing dimethyl carbonate as a byproduct in the coal-to-ethylene glycol process, and has the advantages of low energy consumption, high product purity and the like compared with traditionalseparation modes such as pressurized distillation, extractive distillation or azeotropic distillation.

Owner:天津乐科节能科技有限公司 +1

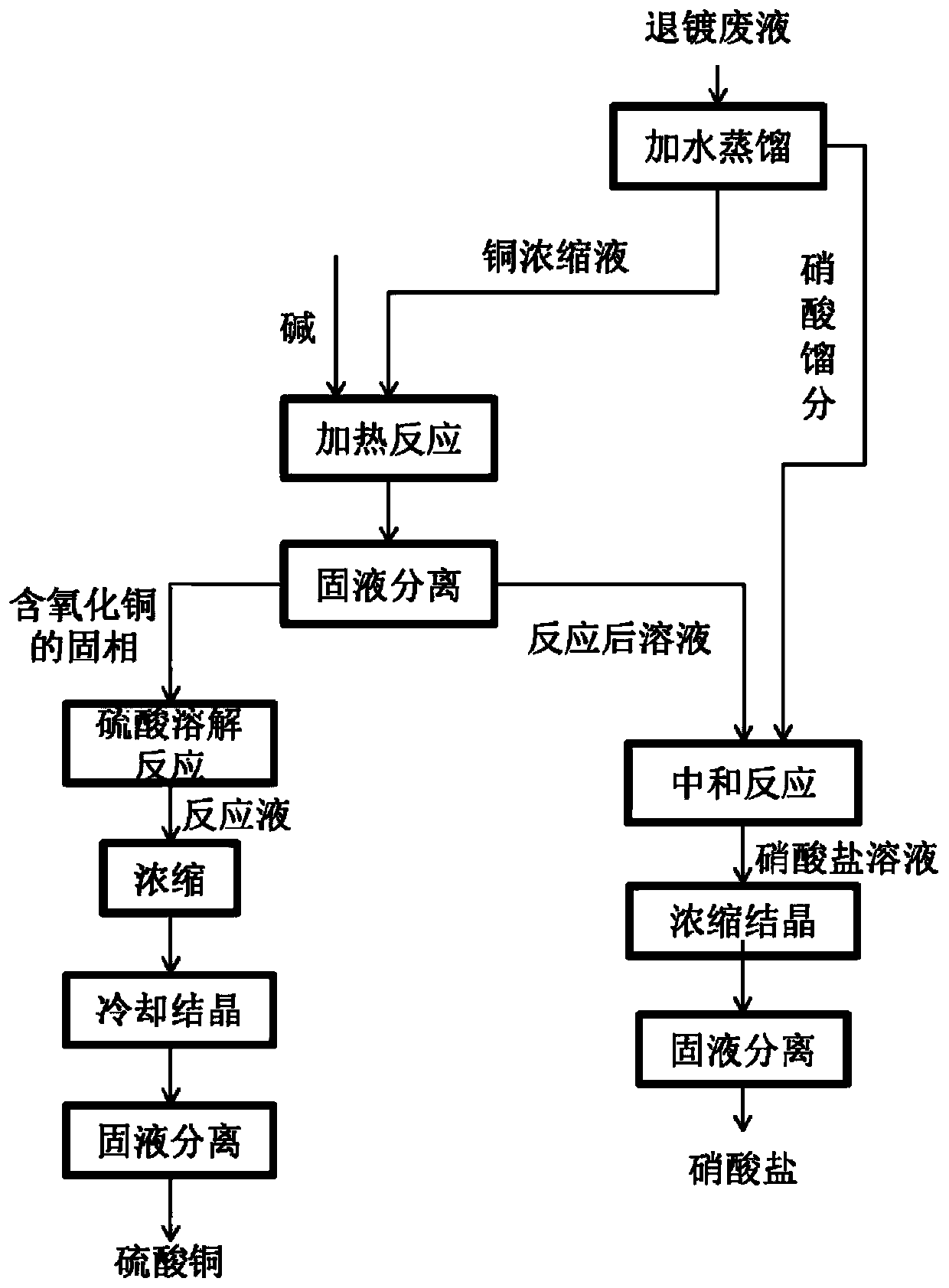

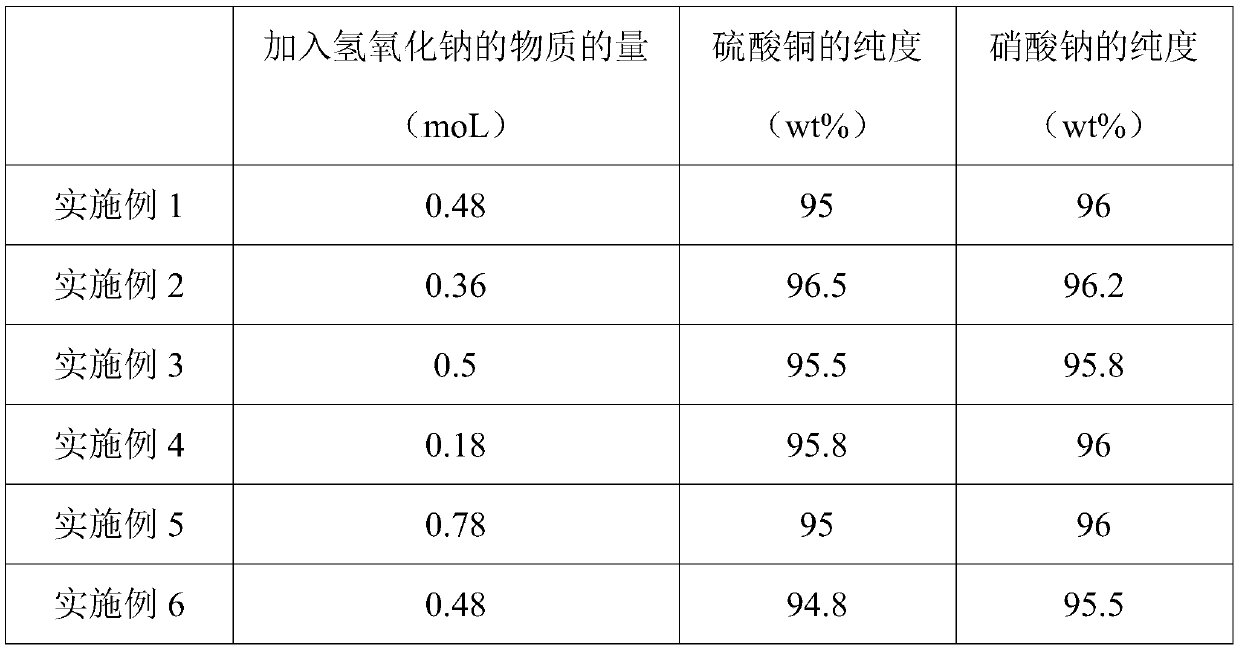

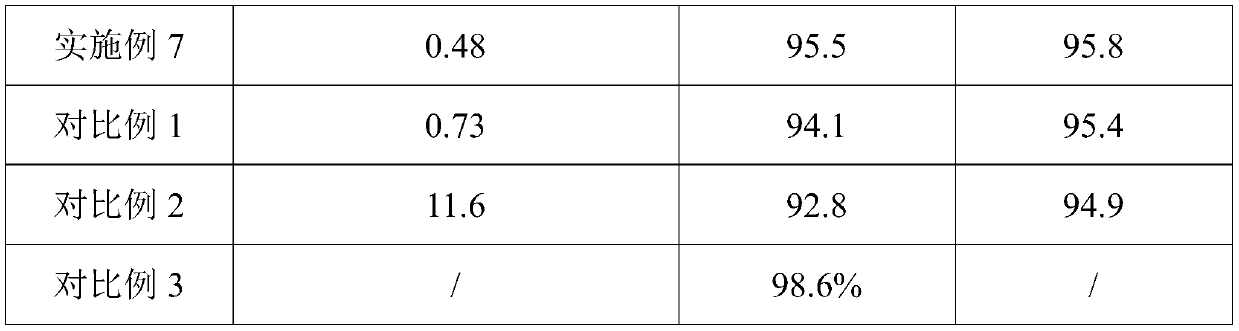

Printed circuit board stripping waste liquid treatment method

ActiveCN111573762AReduce the amount addedNon-existent processingWaste water treatment from metallurgical processAlkali metal nitrate preparationCu2 ionsOrganic solvent

The invention provides a printed circuit board stripping waste liquid treatment method. The method comprises the following steps of: mixing waste liquid with water, and performing distilling; and separating nitric acid, and then carrying out post-treatment on a copper concentrated solution to prepare copper sulfate. With the method adopted, an alkali addition amount in a stripping waste liquid neutralization treatment process is greatly reduced, an organic solvent is not needed to add in the whole process, so that the post-treatment problem of the solvent can be avoided; nitrate and copper ions in stripping waste liquid can be recycled at the same time, resource utilization is realized, and the environmental pressure is relieved.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Synthesis process of 6-chloro-2, 4-dinitroaniline

PendingCN113461542AThe reaction system is stableThorough responseAmino compound purification/separationOrganic compound preparationFluid phaseOrganosolv

The present invention provides a synthesis process for 6-chloro-2, 4-dinitroaniline, which comprises: a pulping step in which 2, 4-dinitroaniline is dissolved in an organic solvent; a chlorination step in which a chlorinating agent is added to the primary pulp obtained by pulping for a reaction; and a post-treatment step after the completion of the chlorination. In the pulping step, an acid solution is also added. The chlorinating agent is 1,3-dichloro-5,5-dimethylhydantoin. According to the synthesis process, 1,3-dichloro-5,5-dimethylhydantoin is adopted as a chlorinating agent for chlorination in the liquid phase, the reaction system is stable, the material reaction is thorough, the side reaction is few, the raw material conversion rate is high, the reaction product is good in crystal form, good in color and luster, easy to separate and high in yield, the production efficiency is high, the production cost is low, the energy-saving and emission-reducing effects are remarkable, and the whole process is safe and controllable.

Owner:内蒙古融创宜博科技有限公司

Preparation method of 2,3-dichlor-1,4-naphthaquinones

ActiveCN100347141CConvenient sourceLow costOrganic compound preparationQuinone preparationOrganic solventIron powder

The invention relates to the preparation method of 2,3-dichlor-1,4-naphthaquinones, which comprises, (1) charging sodium-1-naphthylamine-4-sulfonate into water, adjusting pH to 2-5 by charging acid, (2) charging 1-10% of iron powder, zinc powder, ferric salt, ferrous salt or zinc salt, (3) letting in chlorine, (4) cooling down the reaction product at normal temperature, filtering to obtain 2,3-dichloro-1,4-naphthaquinone crude product, finally recrystallizing with organic solvents to obtain product with the content higher than 98.5%.

Owner:常州华达纳米材料科技有限公司

A kind of production technology of glyphosate salt granule

The invention provides a process for directly preparing trisodium phosphate by using a glyphosate mother solution, which aims at effectively recovering a phosphor resource in a mother solution to prepare trisodium phosphate. The preparation process is characterized in that after the glyphosate mother solution is subjected to catalysis and air oxidation, organophosphorus in the mother solution is oxidized into orthophosphate ions, then sodium hydroxide or soda is added into the mother solution to regulate the pH value to 9-10, the temperature is lowered to minus 5 DEG C to 8 DEG C under the condition of agitating to achieve crystallization, and separation, washing and drying are performed, as a result, the trisodium phosphate is obtained. The preparation process is simple and easy to achieve industrial application, the obtained trisodium phosphate is widely used, besides, difficulty in meeting the drainage standard of the terminal treatment of the glyphosate mother solution is lowered, and further the treatment of solid waste is reduced.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

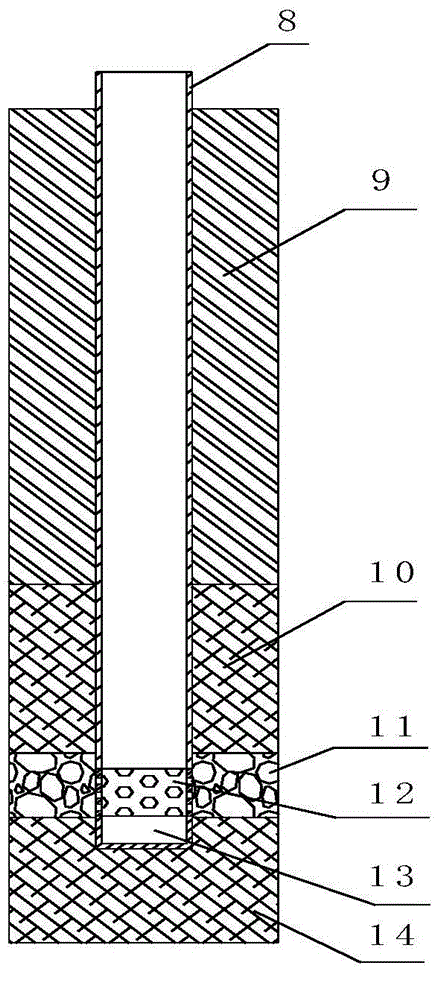

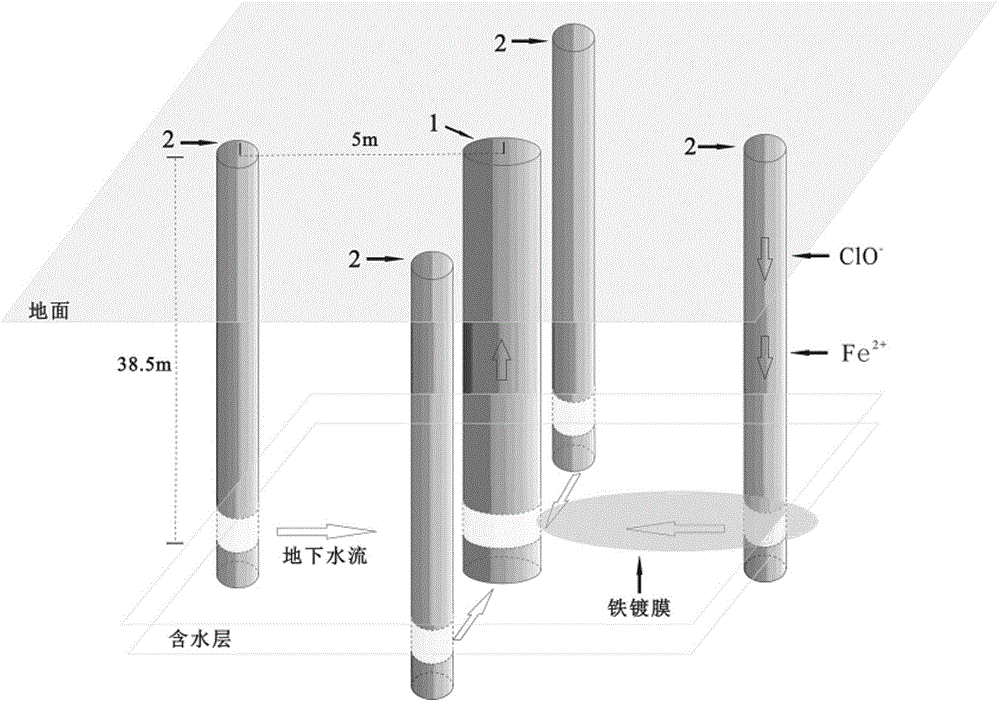

Method for plating iron and in situ removing arsenic for regional aquifer

InactiveCN103880142BReduce usageReduce operating costsWater/sewage treatment by sorptionOsmotic coefficientInjection well

The invention provides a method for plating iron and removing arsenic for a regional aquifer. The method comprises the following steps: selecting a target regional aquifer, determining the depth, osmotic coefficient, underwater flow velocity and dispersion coefficient of the target aquifer, arranging a central pumping well at the center of the target region, defining the 5m regions around the central pumping well as a working regions, arranging four injection wells at the boundaries of the working regions, arranging a water pump in the central pumping well to pump water, respectively injecting a ferrous reagent into the target aquifer in the four injection wells by adopting an injection pump, injecting a sodium hydrochloride reagent into the target aquifer in the four injection wells by adopting the injection pump, and then injecting water to completely push the sodium hydrochloride reagent into the target aquifer. According to the method for plating iron and removing arsenic for the regional aquifer, the deficiencies in the background technology can be solved, and the method for removing arsenic can fulfill the purposes of obviously improving the arsenic removal effect and lowering the arsenic removal cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing chitosan oligosaccharides through semi-wet method microwave treatment

A method for preparing chitosan oligosaccharides through semi-wet method microwave treatment relates to a production method of chitosan oligosaccharides. The method comprises the following steps: using chitosan gelatine powder as raw material to perform hydration and microwave treatment, dissolving in water, neutralizing, and performing membrane separation, drying and the like to prepare chitosanoligosaccharides. The method does not consume organic solvent, thus the problem of recycling solvent does not exist and the pollution is low; and as the volume of the reaction system is from 1 / 3 to 1 / 5 of that of the solution method, the production efficiency is obivously increased. The method adopts microwave treatment to promote the polysaccharide degradation reaction, thus the heating effect is greatly increased. The radiation thermal effect of microwave and the non-thermal effect of microwave are utilized to prepare the product. Meanwhile, microwave is an efficient and clean energy, thus the speed of the chemical reaction can be greatly increased. The method also adopts the membrane separation mean, thus the refining efficiency is high and the product quality is controllable.

Owner:YANGZHOU RIXING BIO TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com