Liquid nitrogen and ice particle abrasive material jet method and generating device thereof

A generating device and abrasive jet technology, which is applied in the direction of abrasive feeding device, abrasive material, metal processing equipment, etc., can solve the problems of ice particle production and storage in ice particle jet, weak impact force of pure liquid nitrogen jet, and addition of jet abrasive Difficulty and other problems, to achieve strong cleaning effect, protect the treatment object, and weak impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

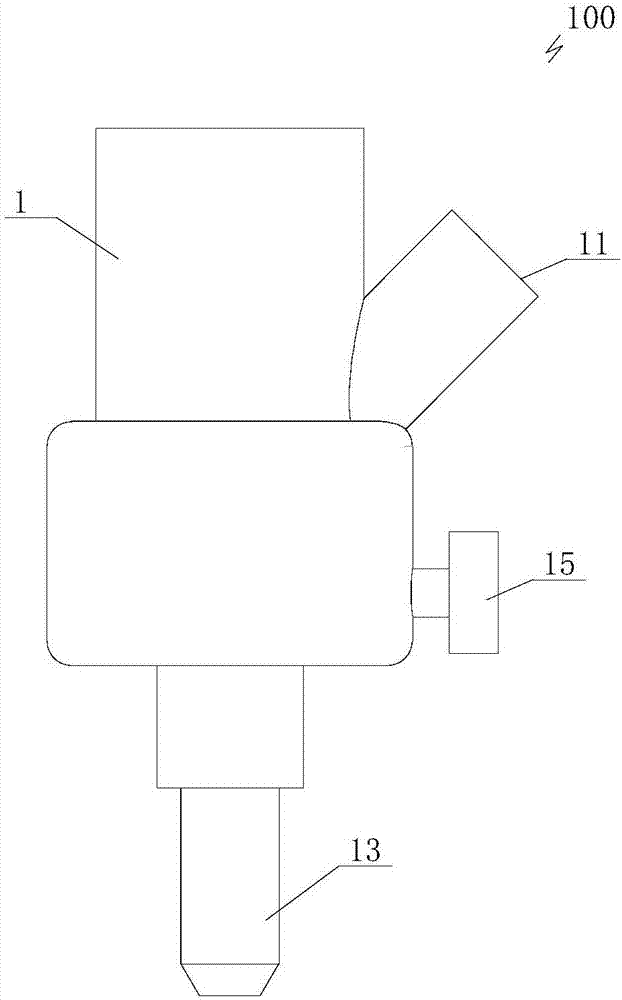

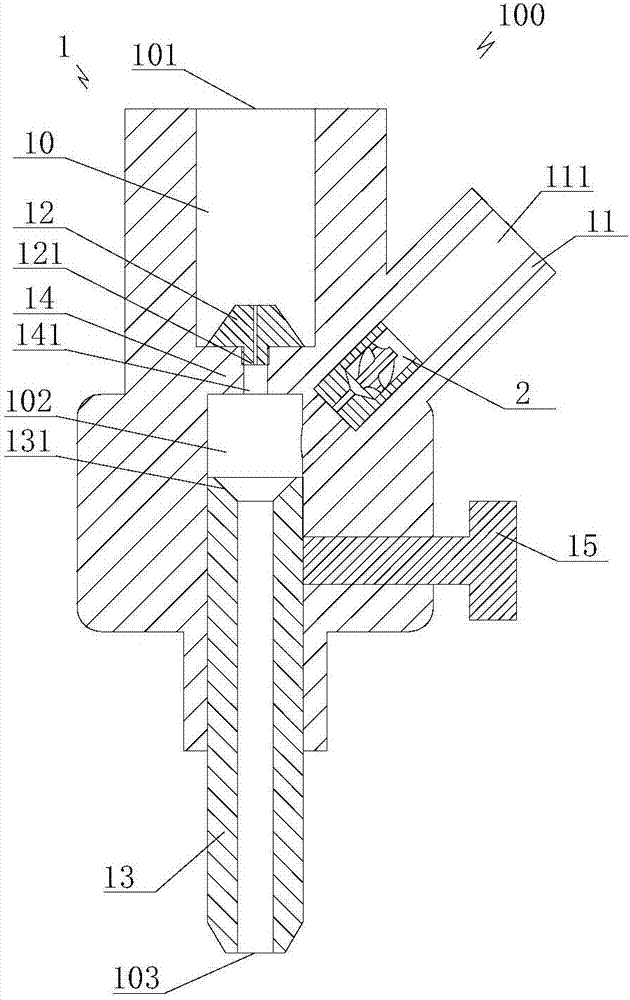

[0052] Embodiment 1, post-mixing generating device: as figure 1 , figure 2 As shown, the inner cavity 10 of the body is fixedly provided with a liquid nitrogen nozzle 12 above the outlet of the water channel 111, the bottom of the inner cavity 10 of the body is pierced with a sand mixing pipe 13 from the outside to the inside, and at least one tight fitting is pierced on the side wall of the body 1. Fasten the screw 15, one end of the fastening screw 15 is pushed against the side wall of the sand mixing pipe 13, the sand mixing pipe 13 is made of wear-resistant material, and the hardness is relatively high, so as to ensure that it can withstand the strong grinding ability of ice particles The fastening screw 15 plays the role of fixing the sand mixing pipe 13 to ensure that the sand mixing pipe 13 is centered so that the liquid nitrogen and ice particle jets are in the best position to prevent partial wear. The top of the inner chamber of the sand mixing pipe 13 communicates...

Embodiment 2

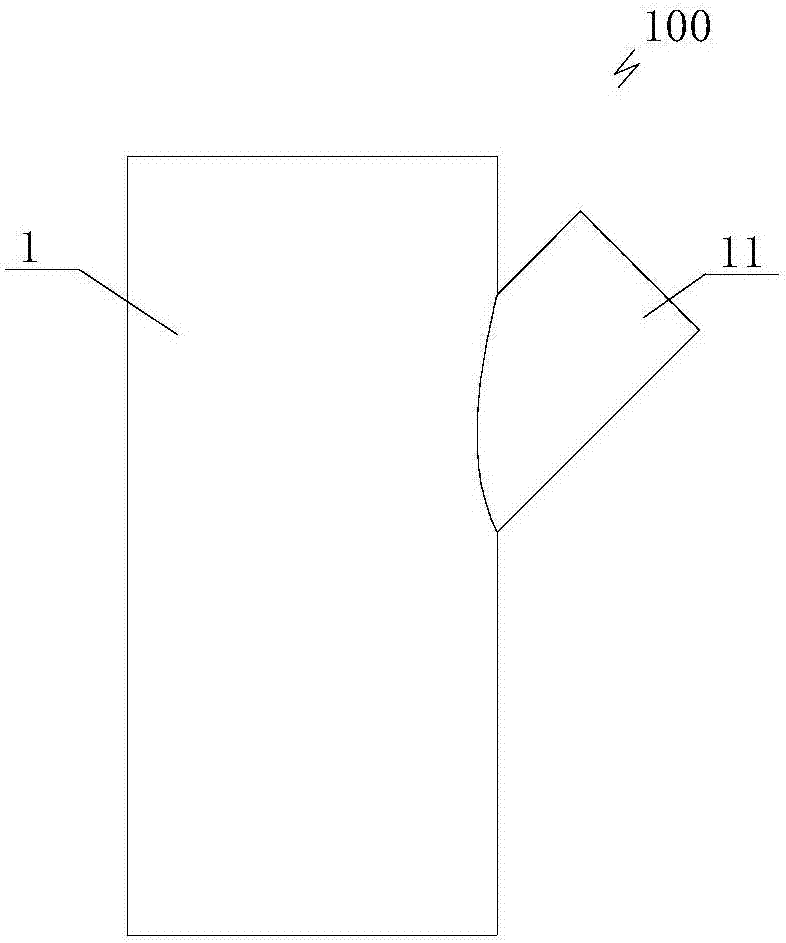

[0055] Embodiment two, pre-mixing type generating device: as image 3 , Figure 4 As shown, the reduced diameter of the lower portion of the body lumen 10 forms a jet flow hole 16 , and the bottom of the jet flow hole 16 forms a jet outlet 103 . In order to make the mixed abrasive flow smoothly, a second transition cone surface 161 whose diameter tapers downward is formed between the top of the jet flow hole 16 and the mixing chamber 102 .

[0056] When the generator 100 of this embodiment is used for jet flow, the liquid nitrogen pump injects pressurized liquid nitrogen fluid from the liquid nitrogen inlet 101, and at the same time, the water pump injects water jets from the side interface 11, and the water jets form a very small atomizing nozzle 2. The atomized water droplets are mixed with the liquid nitrogen fluid inside the mixing chamber 102, and the atomized water droplets condense into solid ice particles in a very short time after contacting the liquid nitrogen fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com