Patents

Literature

413results about "Saccharides production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing xylose by using squeezed waste alkali in viscose fiber production process

ActiveCN102643935AReduce preprocessingAvoid events that pollute the environmentSaccharides productionHazardous substanceIon exchange

The invention relates to a method for preparing xylose by using squeezed waste alkali in the viscose fiber production process. According to the method, xylose finished products are obtained through work procedures of hemicellulose solution preparation, hemicellulose extraction, hemicellulose hydrolysis, neutralization and deacidification, preconcentration, decoloration, ion exchange, ordinary concentration, crystallization, separation and drying. When the technical scheme provided by the invention is adopted, harmful environment-pollution substances such as waste alkali and waste water generated in the viscose production process can be thoroughly eliminated, the standard of full-flow-process clean production can be reached, viscose production enterprises can also produce xylose in the viscose production process, the goal of environment protection is reached, and meanwhile, the waste reutilization is also realized.

Owner:YIBIN GRACE +2

Method for producing wood sugar product

ActiveCN101659681AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationHydrolysis

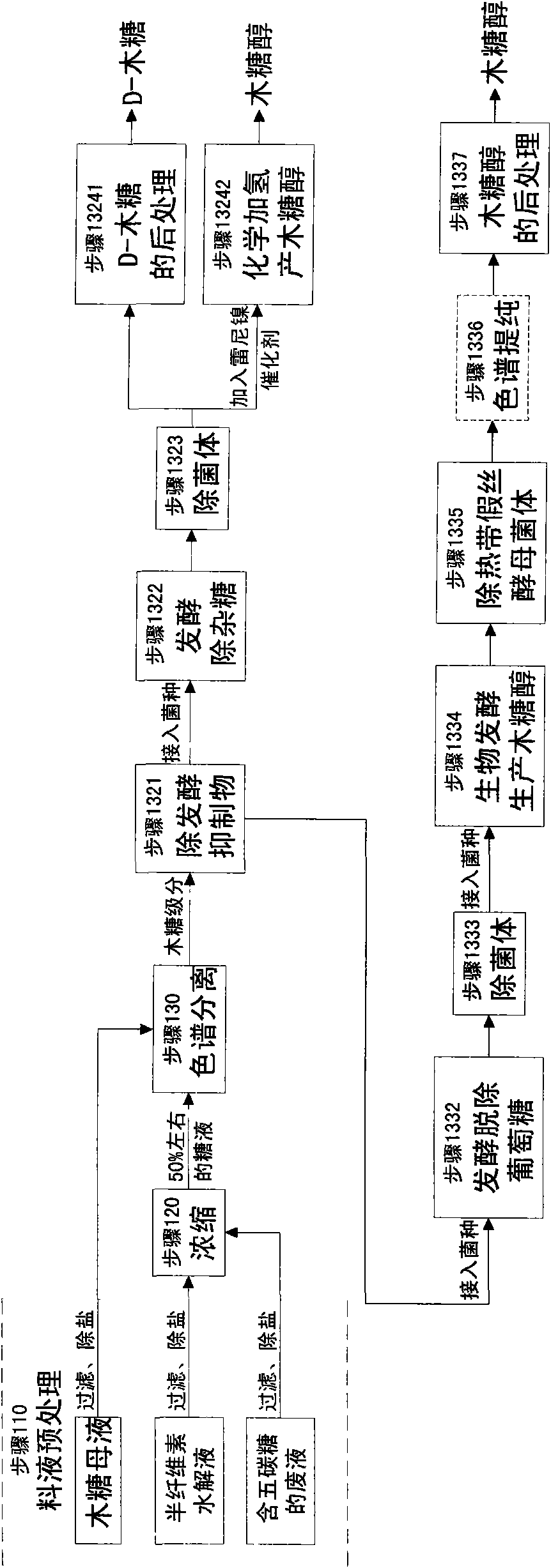

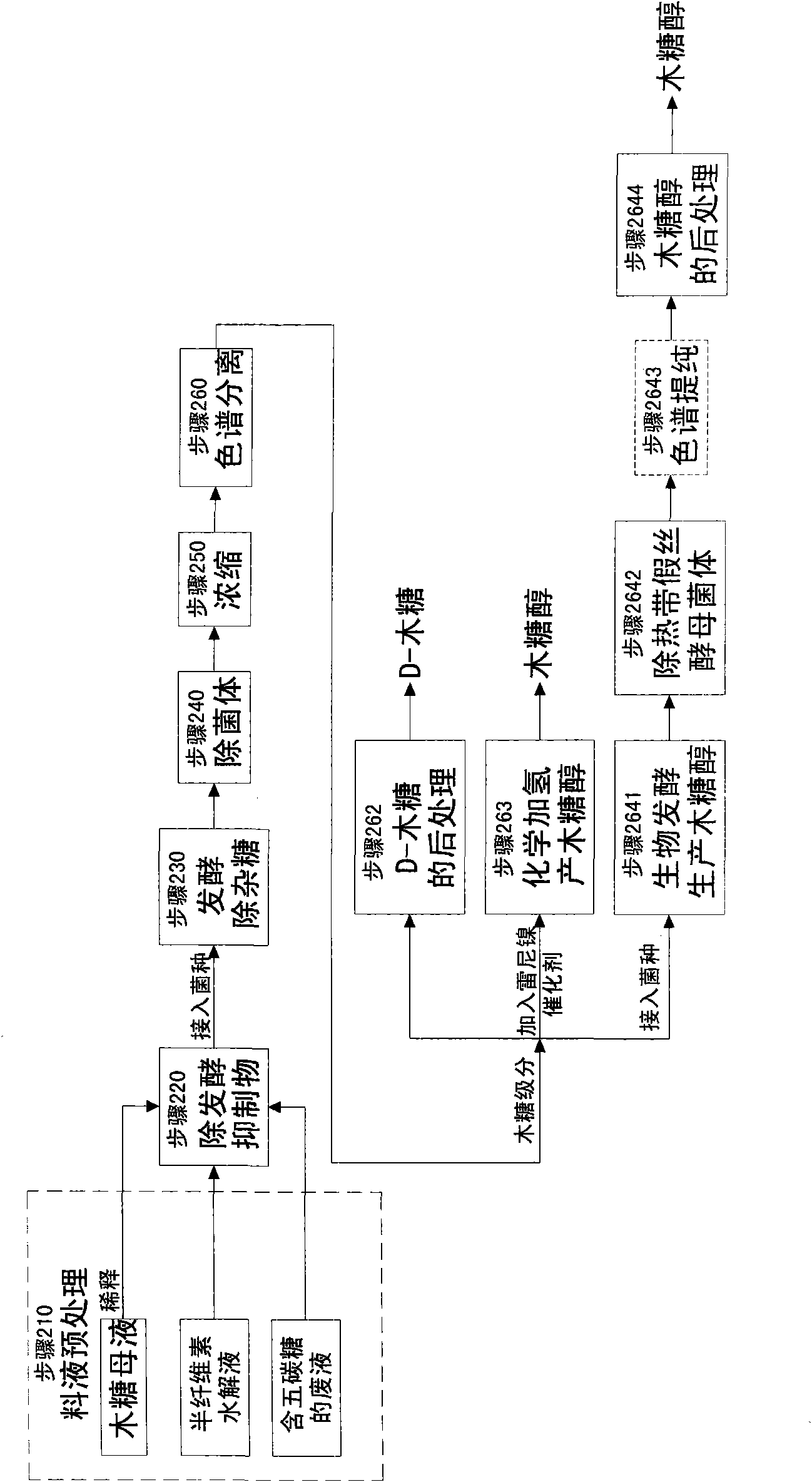

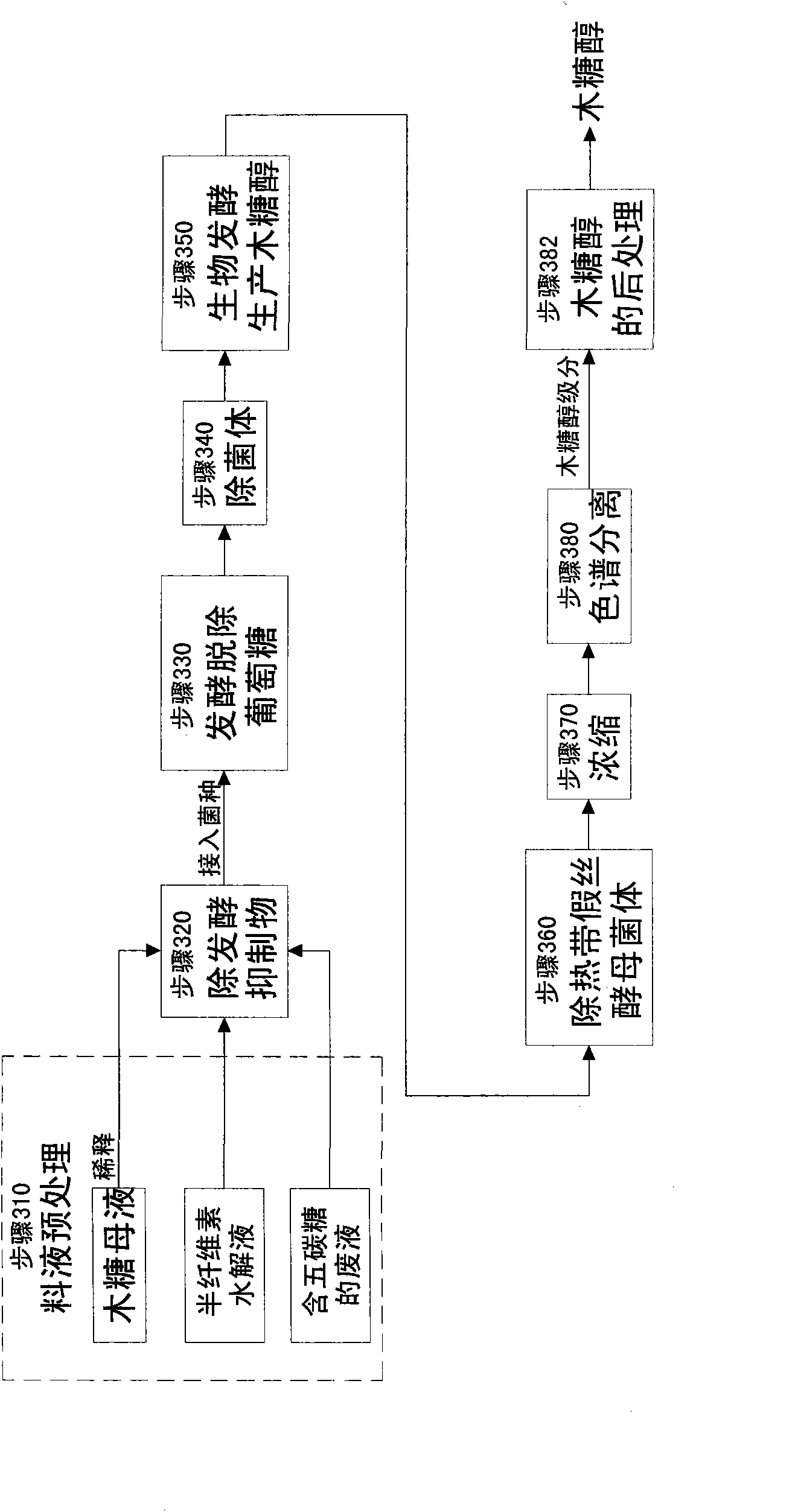

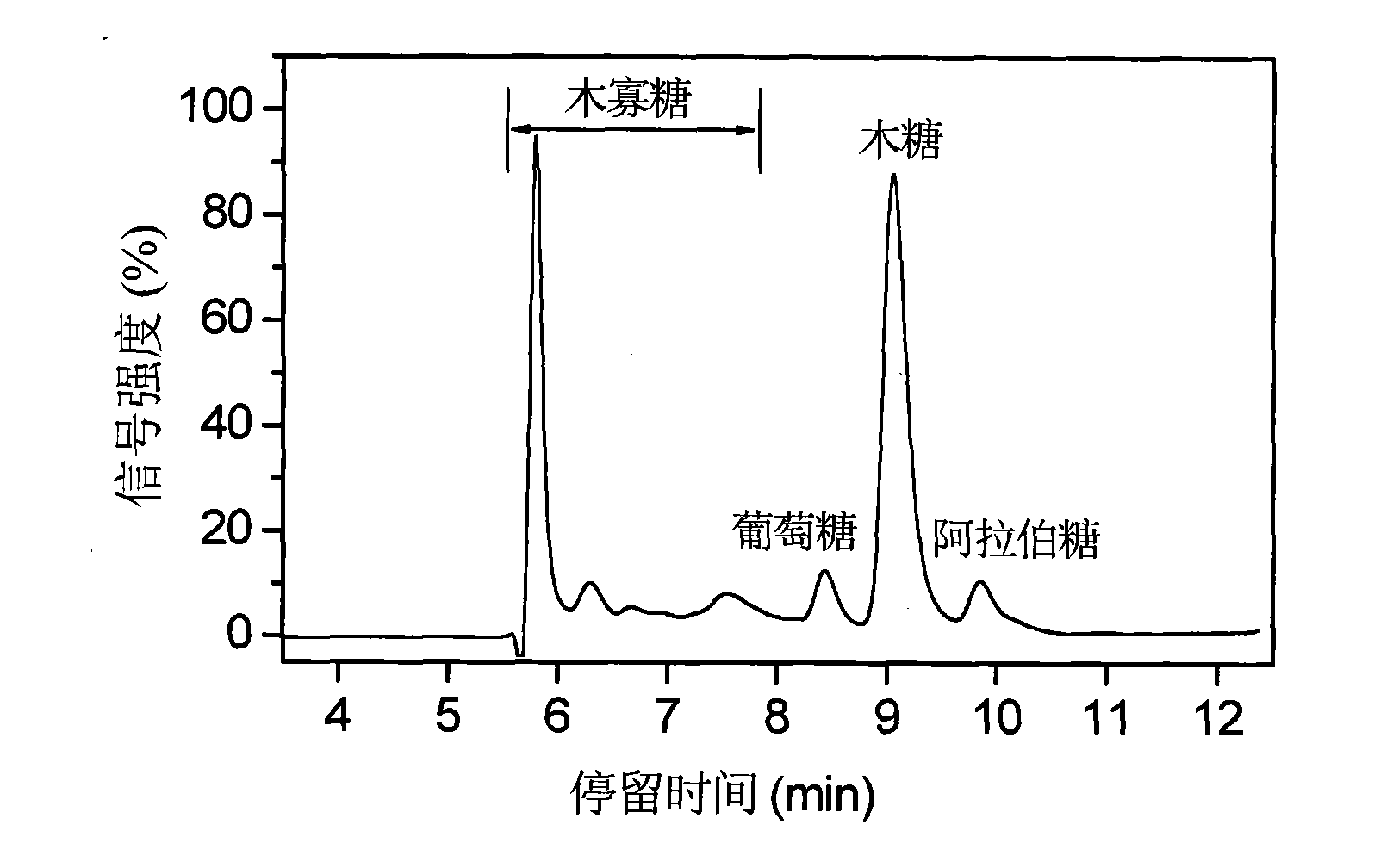

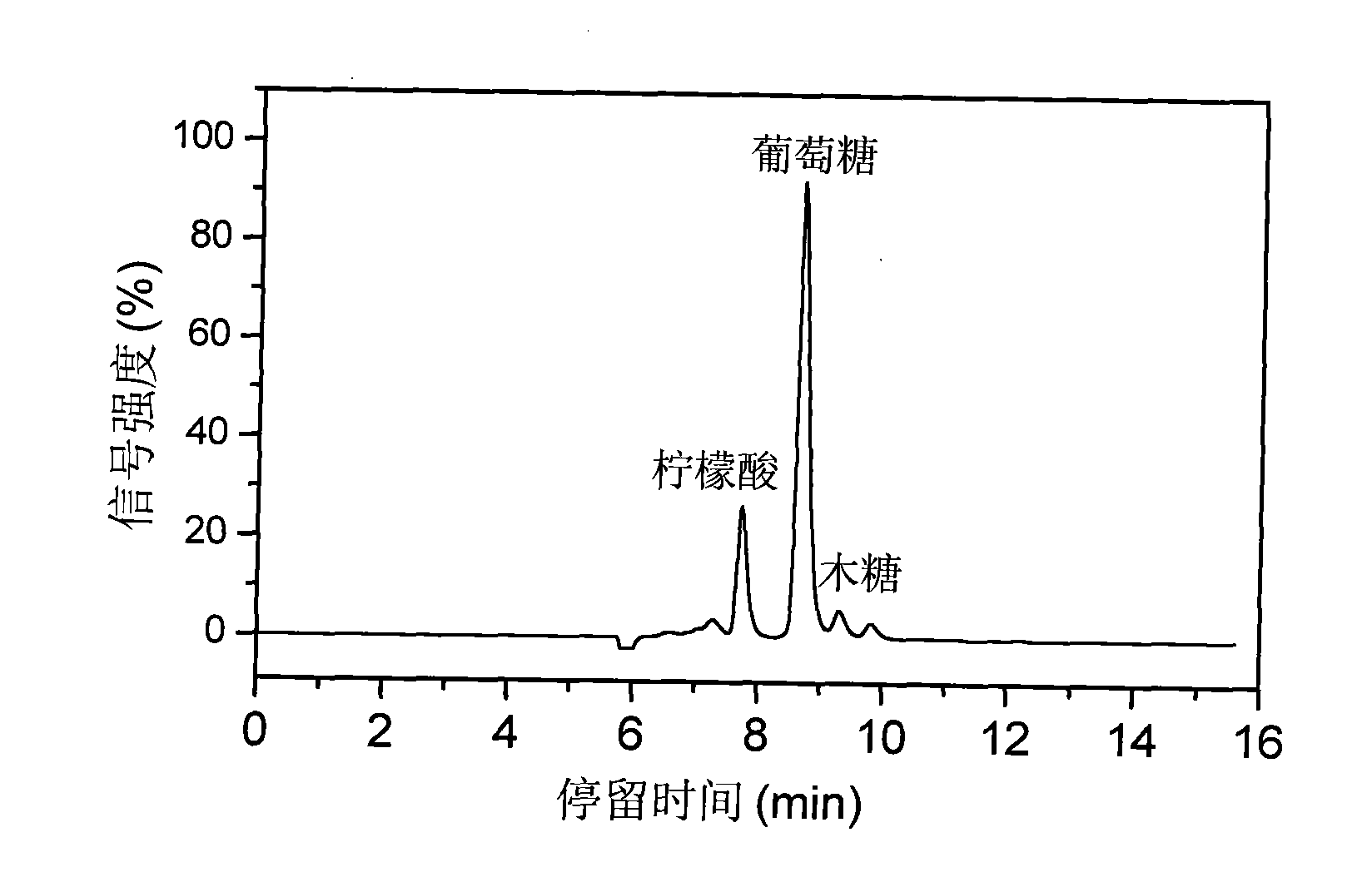

The invention relates to a method for producing a wood sugar product and a byproduct of ethanol or D-ribose or citric acid. The method takes hydrolysis liquid, wood sugar mother liquor and / or production waste liquid containing pentose of agricultural or forestry waste as the raw materials, comprising the following steps: (a) preprocessing feed liquid; (b) colour spectrum separation: separating thefeed liquid into arabinose fraction feed liquid and wood sugar fraction feed liquid; (c) removing mixed sugar at least containing glucose and galactolipin; and (d) carrying out aftertreatment on thewood sugar fraction feed liquid to obtain the wood sugar product. The wood sugar product comprises xylitol and D-wood sugar. The invention has low production cost and high efficiency and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

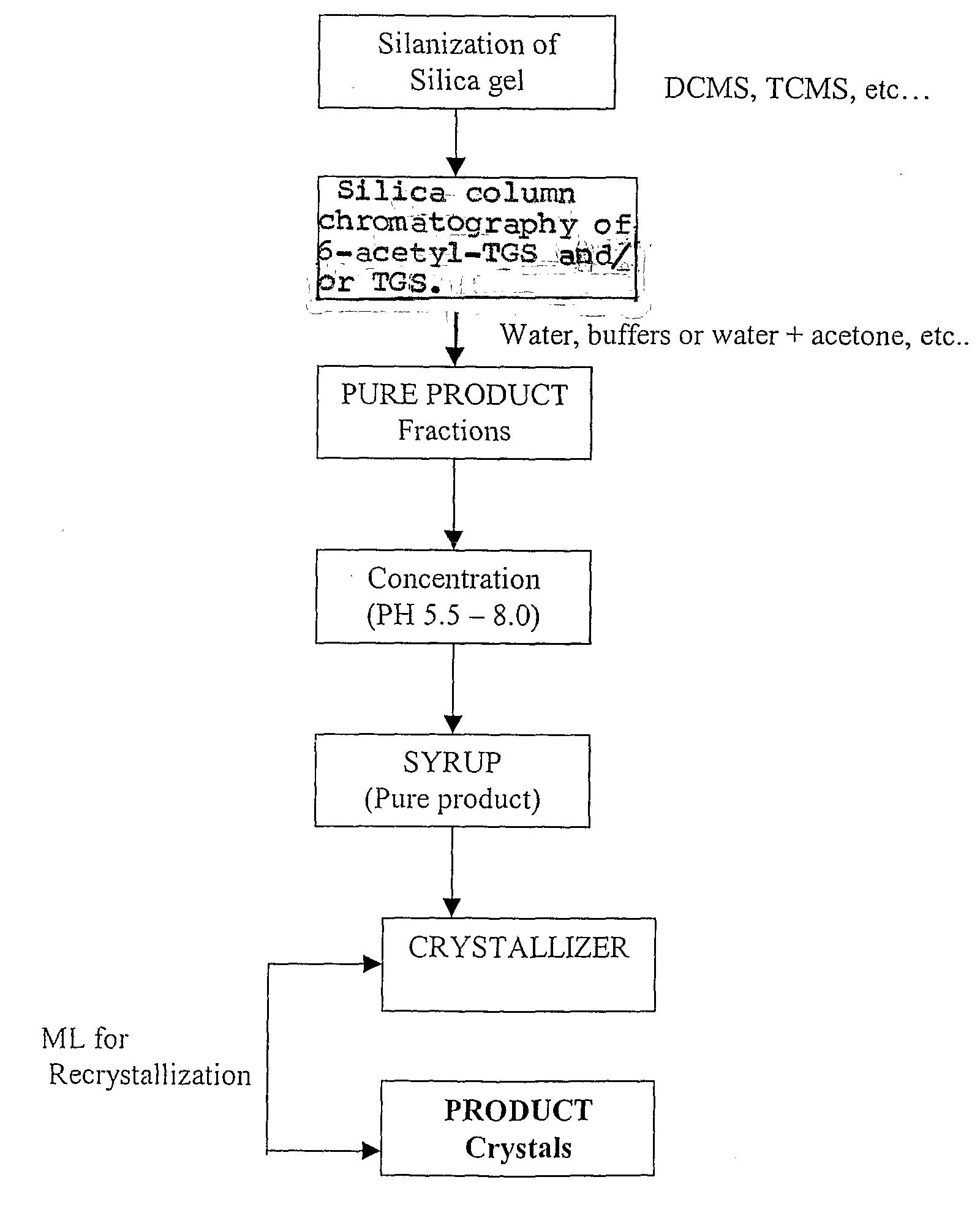

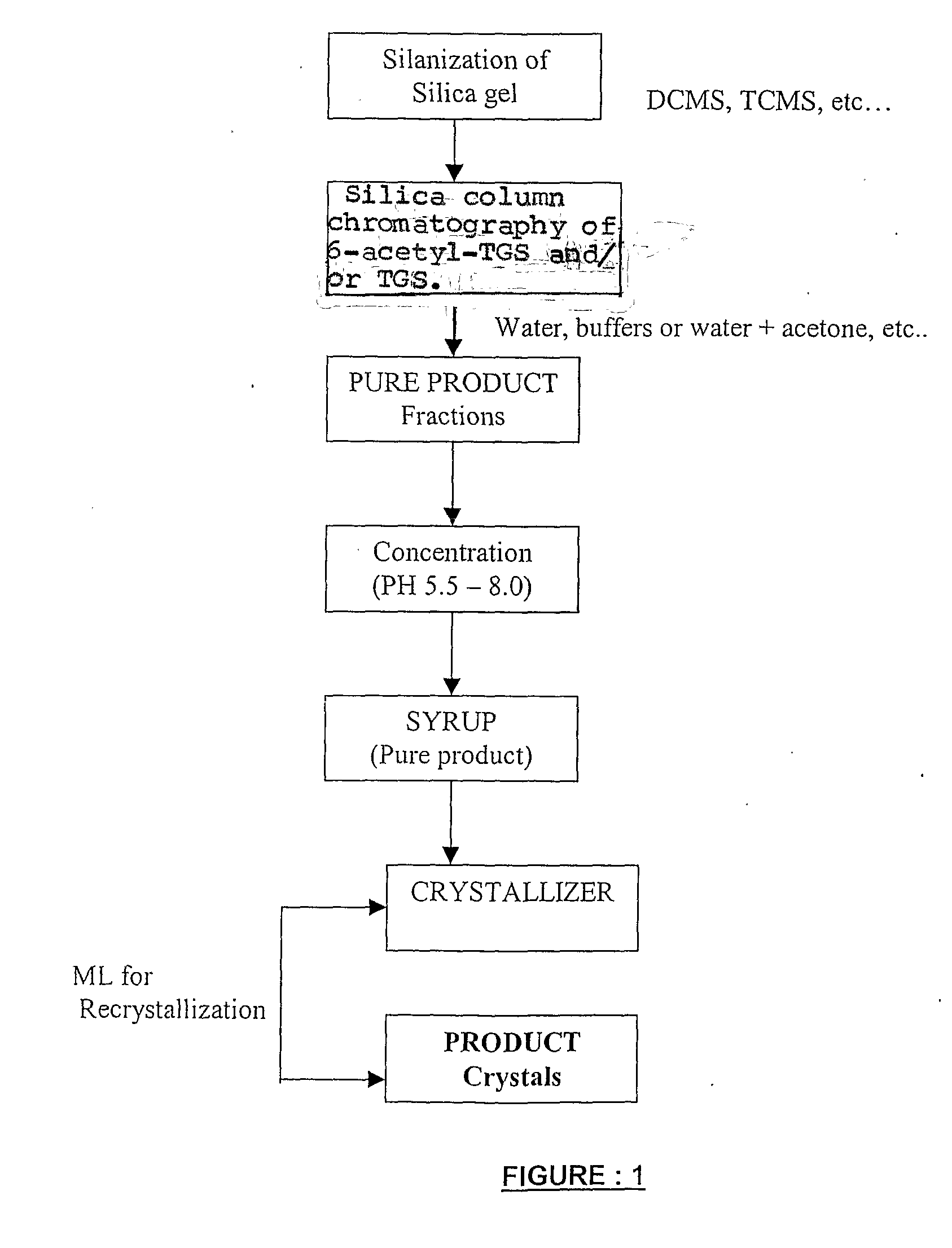

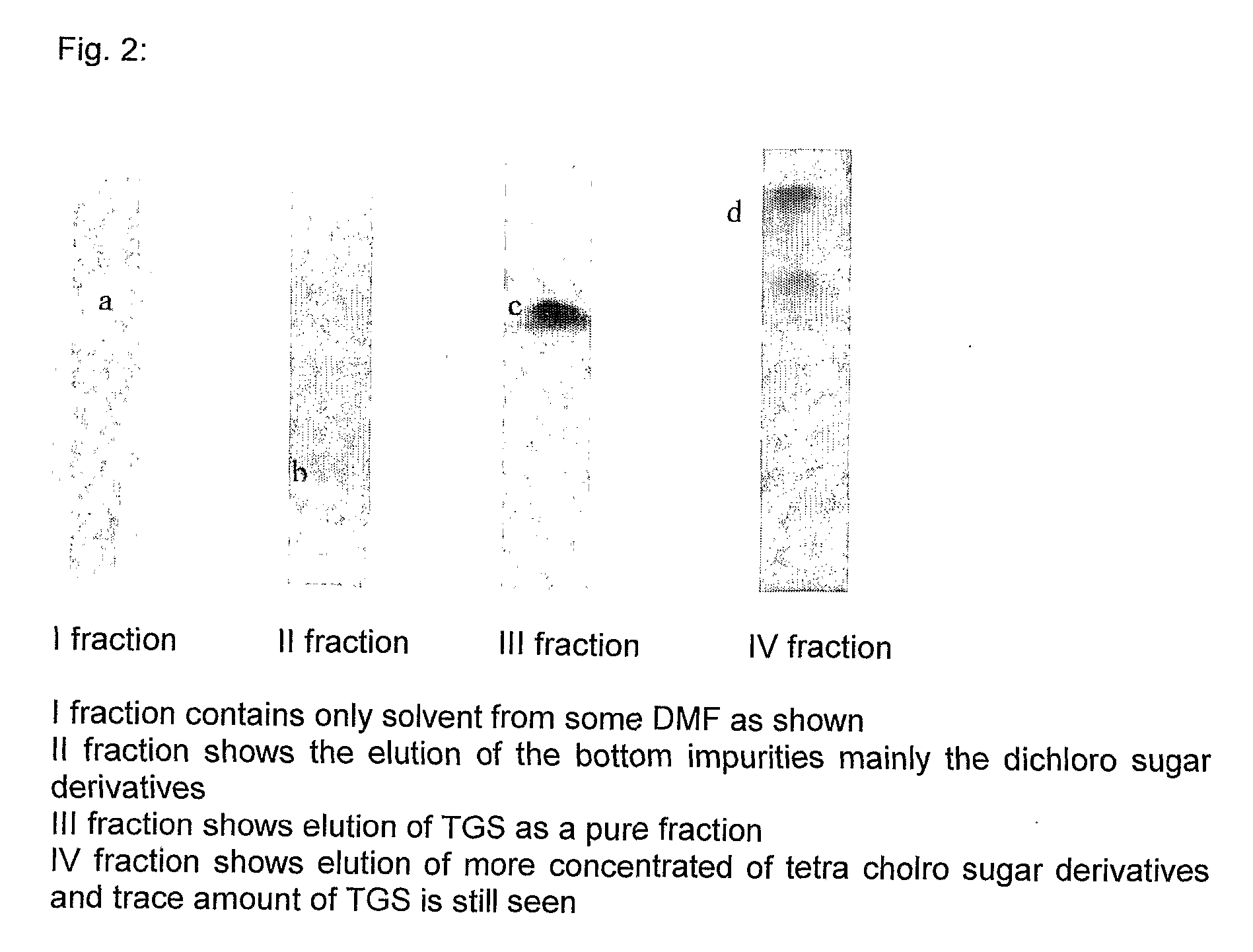

Process for Purification of 6 Acetyl 4,1', 6' Trichlorogalactosucrose and 4,1', 6' Trichlorogalactosucrose by Chromatography on Silanized Silica Gel

InactiveUS20070270583A1Purification using adsorption agentsSugar derivativesStationary phaseOrganic solvent

A reverse phase column chromatographic process of purification of 6-acetyl-4,1′,6′trichlorogalactose and 4,1′,6′trichlorogalactose is described which uses silanized silica as stationary phase and water or predominatly aqeous mixture derived from water and small proportion of organic solvents as a mobile phase.

Owner:V B MEDICARE PVT LTD

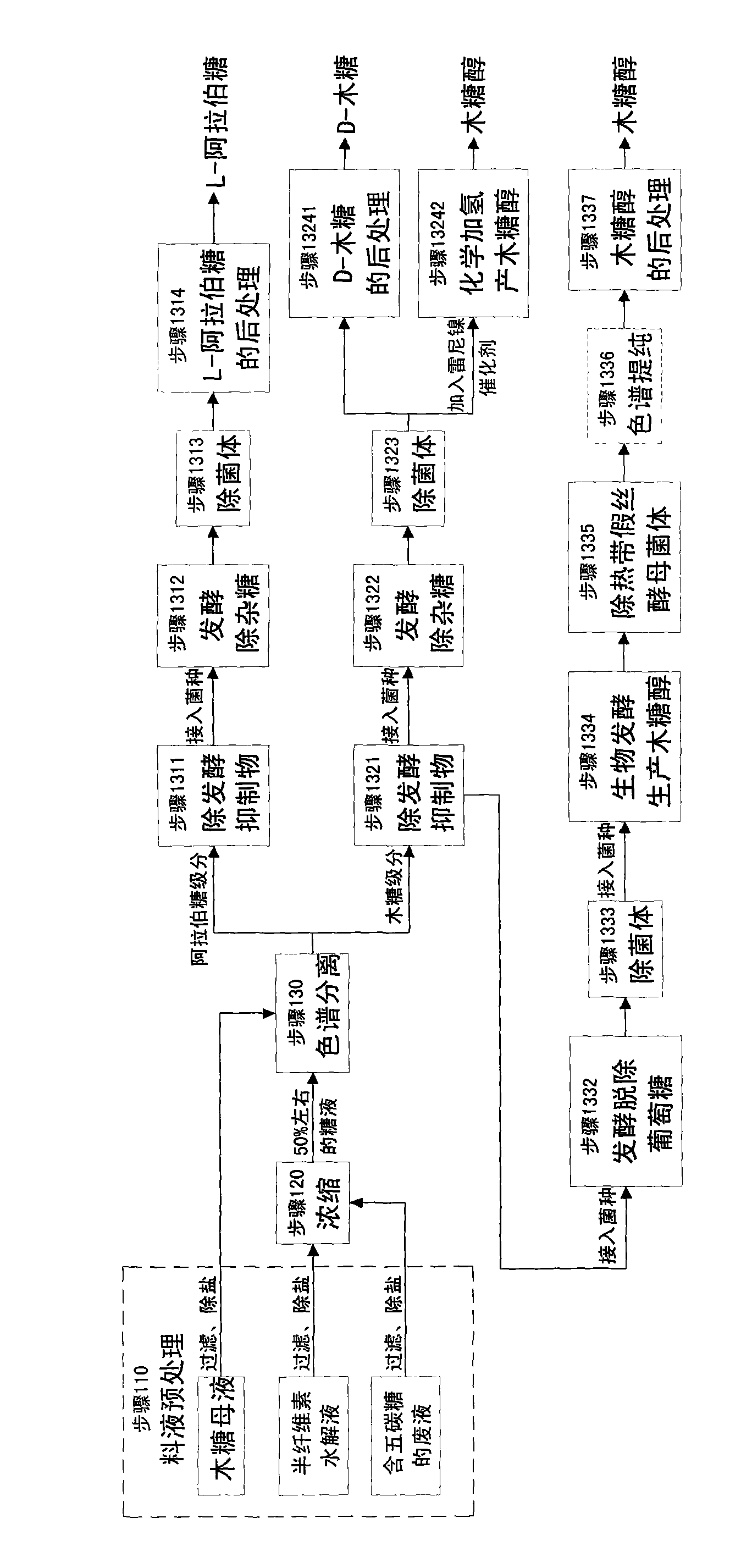

Method for producing L-arabinose and D-xylose

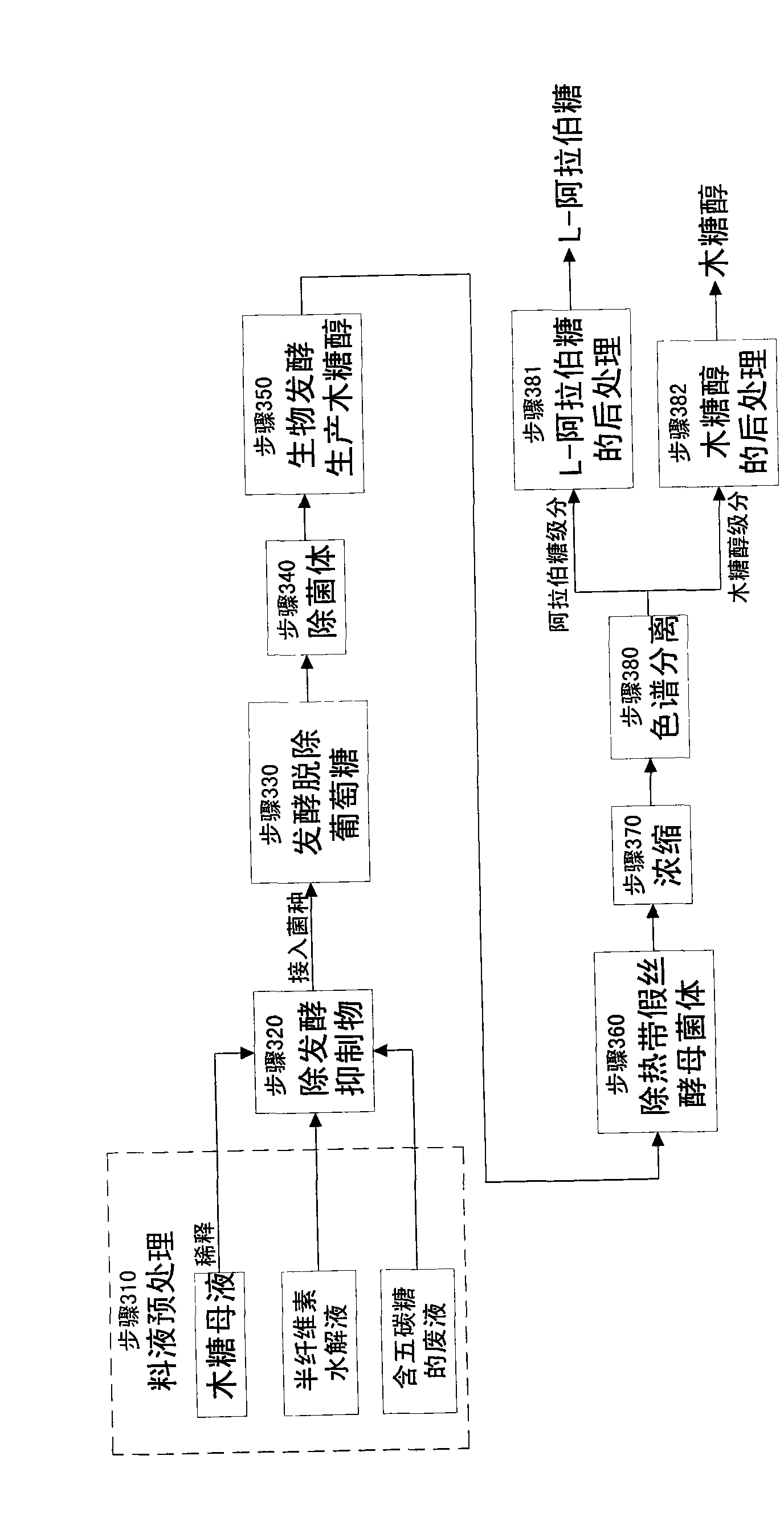

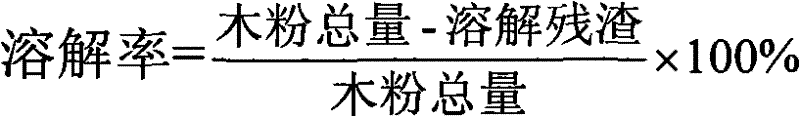

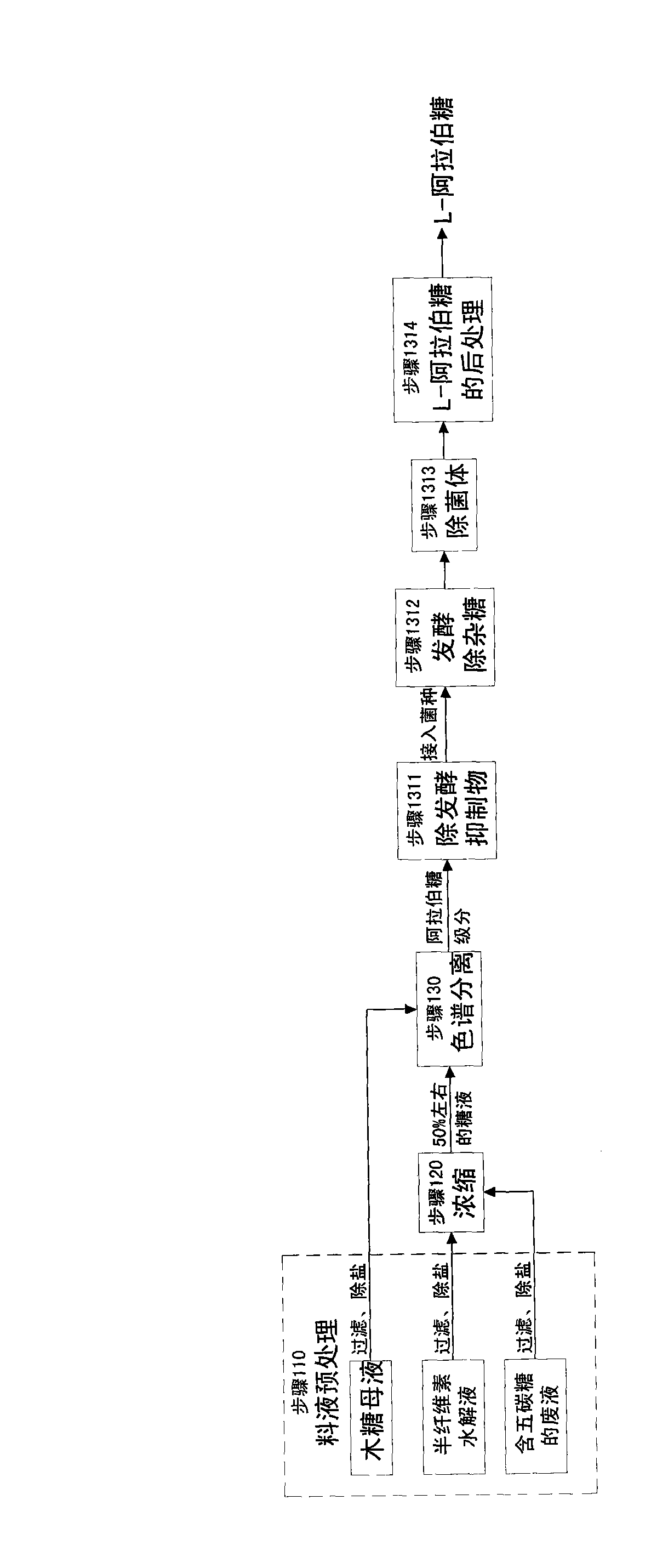

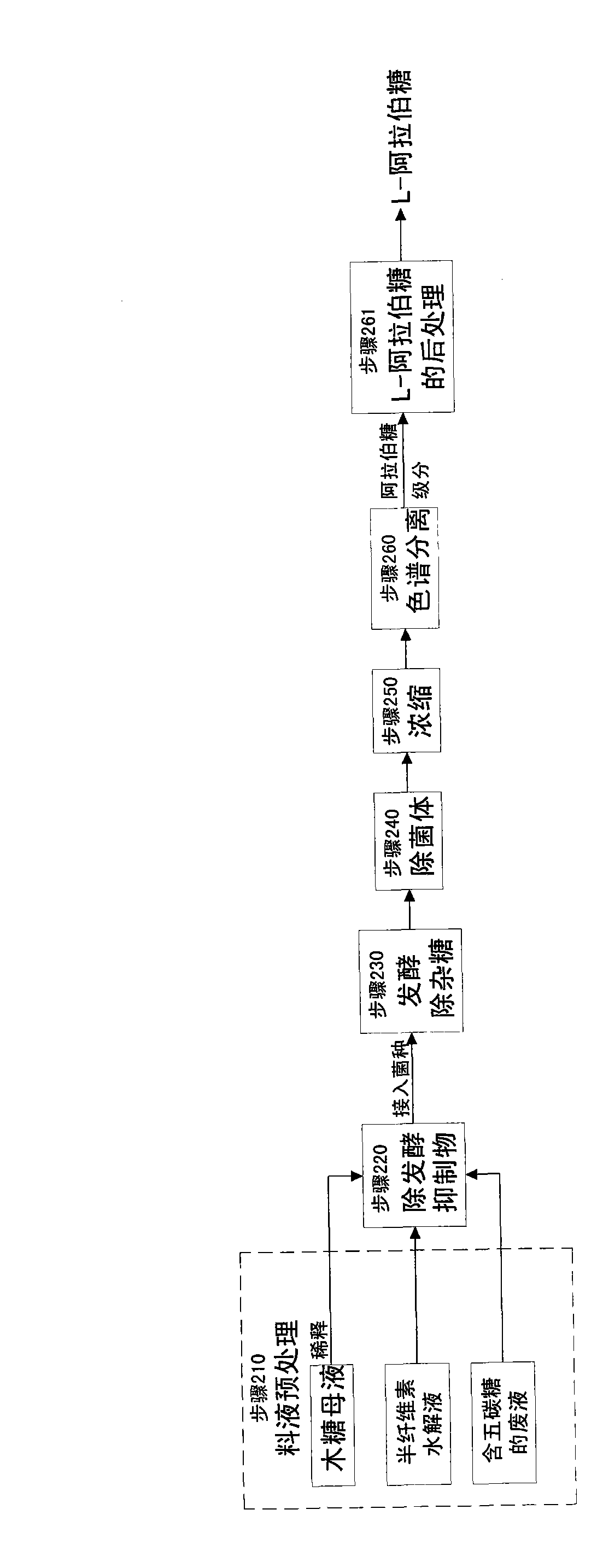

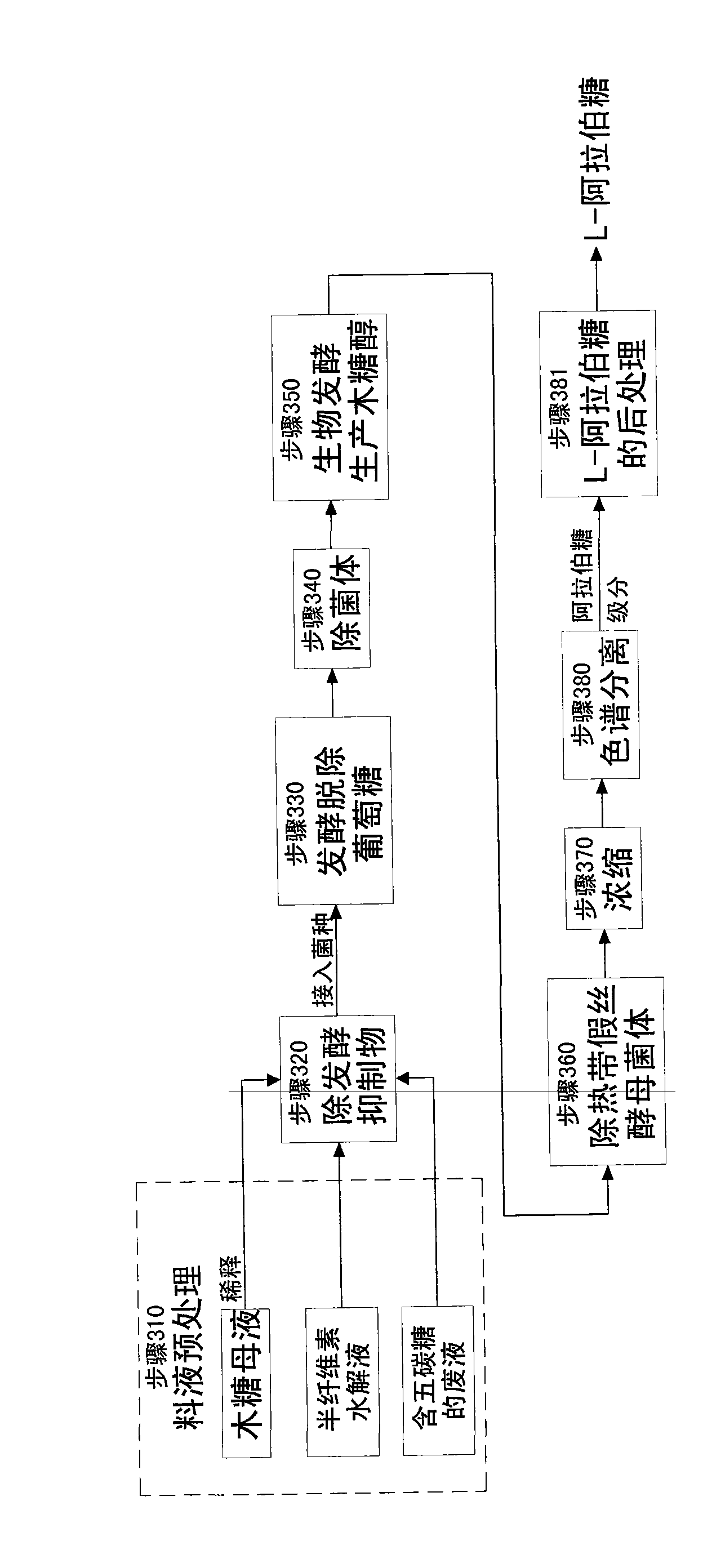

ActiveCN101665523AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesBiotechnologyChromatographic separation

The invention relates to a method for producing L-arabinose and D-xylose, which can simultaneously produce ethanol or D-ribose or citric acid as a byproduct. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (1) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c1) removing fermentation inhibitors which are impurities and unwanted bacteria, which have an inhibiting effect on the fermentation; (c2) fermenting to remove unwanted saccharides at least comprising glucose and galactose; (d) and finally, respectively carrying out the post treatment on the arabinose-stage liquor and the xylose-stage liquor to obtain the L-arabinose and the D-xylose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The method has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Lignocellulose acid/alkali coupling pretreatment method

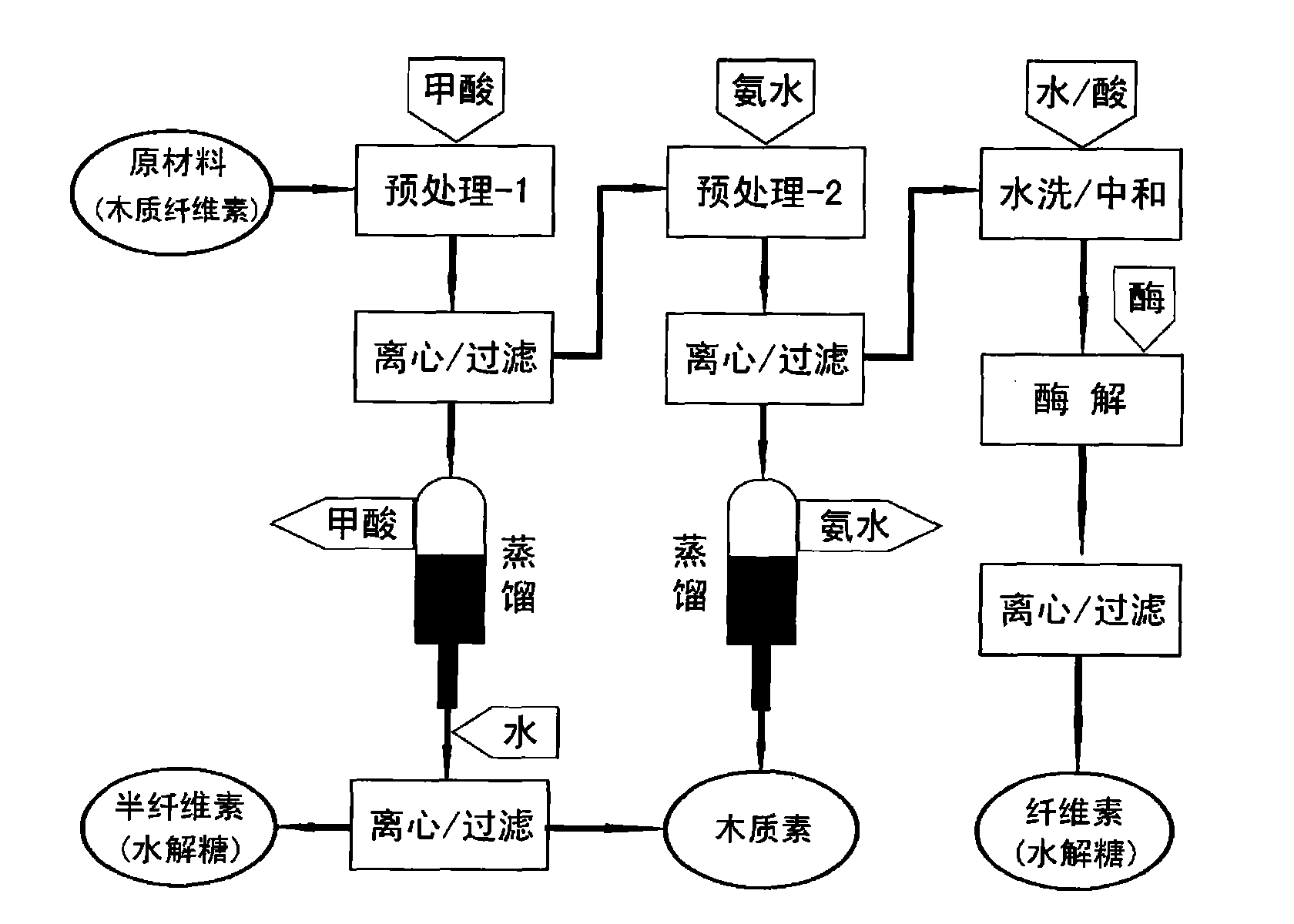

InactiveCN102153763ARealize the separation of all componentsHigh purity of componentsFermentationSaccharides productionSolid componentPretreatment method

The invention relates to a lignocellulose acid / alkali coupling pretreatment method. Lignocellulose is separated into cellulose, hemicellulose and lignin by acid / alkali coupling pretreatment; and simultaneously, lignocellulose components are separated and subjected to high-efficiency enzymolysis and saccharification. The method comprises the steps of lignocellulose pretreatment, component separation, cellulose enzymolysis, solvent recovery and the like. The lignocellulose material is pretreated by formic acid or dilute sulphuric acid and is then subjected to solid-liquid separation, wherein the liquid component is used for recovering hemicellulose hydrolyzed sugar and part of lignin; and the solid component is further treated by ammonia water or a sodium hydroxide solution and is then subjected to solid-liquid separation, the liquid component is used for recovering lignin, and the solid component (cellulose) is subjected to enzymolysis and saccharification. By converting the lignocellulose into cellulose hydrolyzed sugar (glucose), hemicellulose hydrolyzed sugar (xylose and xylooligosaccharide) and lignin, the invention provides a basis for full-biomass utilization and develops a green process route for recovering the pretreatment solvent.

Owner:TIANJIN UNIV

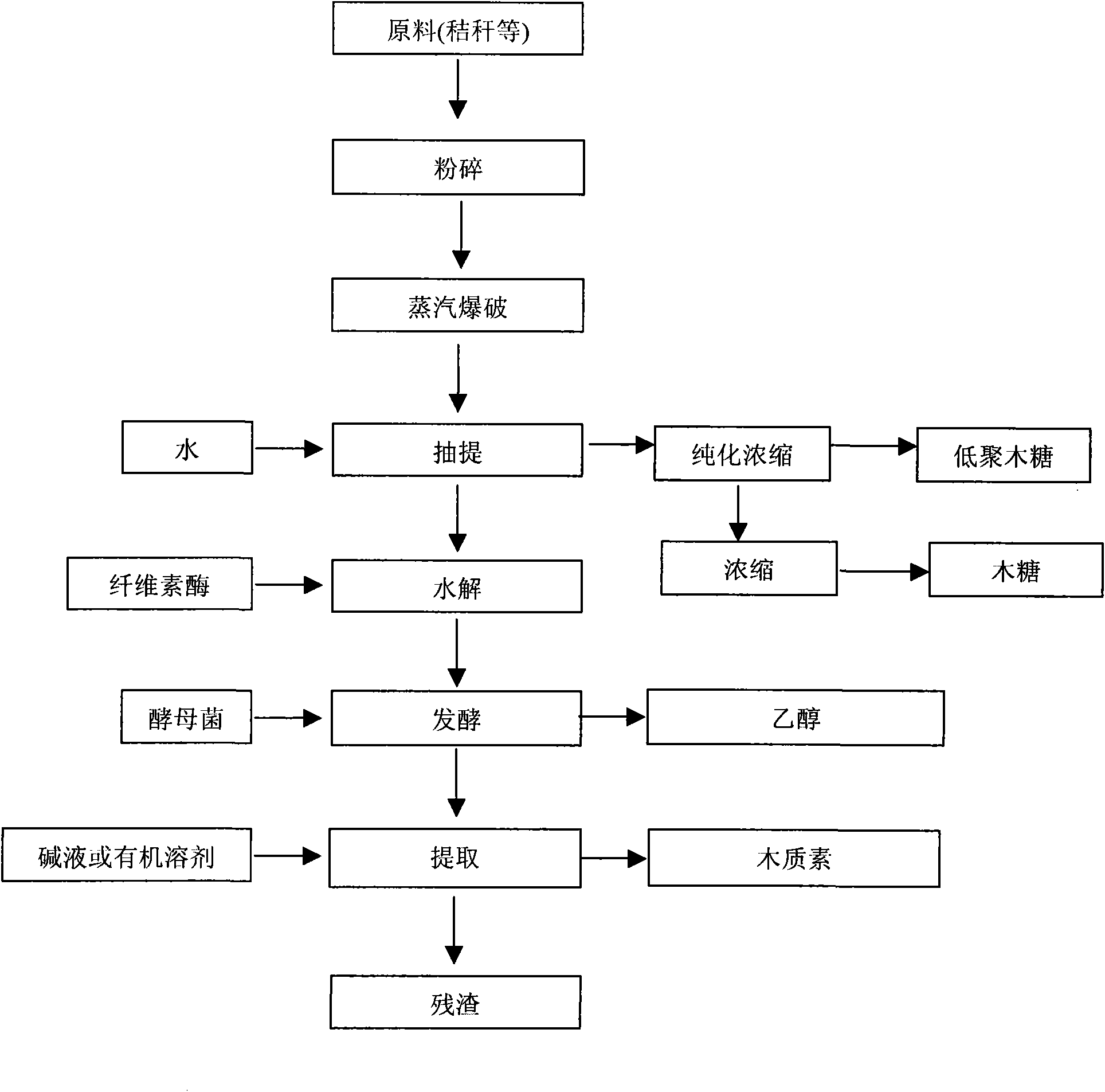

Method for utilizing straw biomass by grades

InactiveCN101643796AMaximize utilizationOvercome costsBiofuelsLignin derivativesWater insolubleWater soluble

The invention discloses a method for utilizing straw biomass by grades, comprising the following steps: carrying out steam explosion to straw biomass; extracting and separating water soluble constituents and water insoluble constituents in steam exploded straw by water, wherein the water soluble constituents are purified and concentrated to obtain active low polyxylose and xylose and the water insoluble constituents are used for further fermentation to generate ethanol; and extracting lignin from the fermentation residue. The invention realizes the maximization of utilization of biomass and overcomes the disadvantages of high production cost, low efficiency and environmental pollution and the like in the prior art.

Owner:CENT FOR CLEAN ENERGY TECH OF SHANGHAI

Preparation technology of xylose

ActiveCN103409565AReduce manufacturing costReduce conductivitySaccharides productionUltrafiltrationHydrolysate

The invention provides a preparation technology of xylose, which mainly comprises the following technical steps: hydrolyzation, ultrafiltration purification, primary decoloring, electrodialytic deacidification and desalination, membrane concentration, primary evaporation and concentration, secondary decoloring, ion exchange refined desalting, secondary evaporation and concentration, crystallization, centrifugation, and drying to obtain a finished product xylose crystal. The technology has the advantages that the membrane technology is used to remove macromolecule impurities of colloid, protein, and the like in xylose hydrolysate, electrodialytic deacidification and desalination technology is used to lower the electric conductivity of an xylose solution, and meanwhile, neutralization and positive-negative-positive resin combined one-step purification process is removed to simplify the technical process; therefore, the manufacturing cost of xylose is lowered, meanwhile, the waste water discharge load of the manufacturing of xylose can be allowed to be lowered by more than 40%, and well environmental benefits and economic benefits are achieved.

Owner:SHANDONG FUTASTE

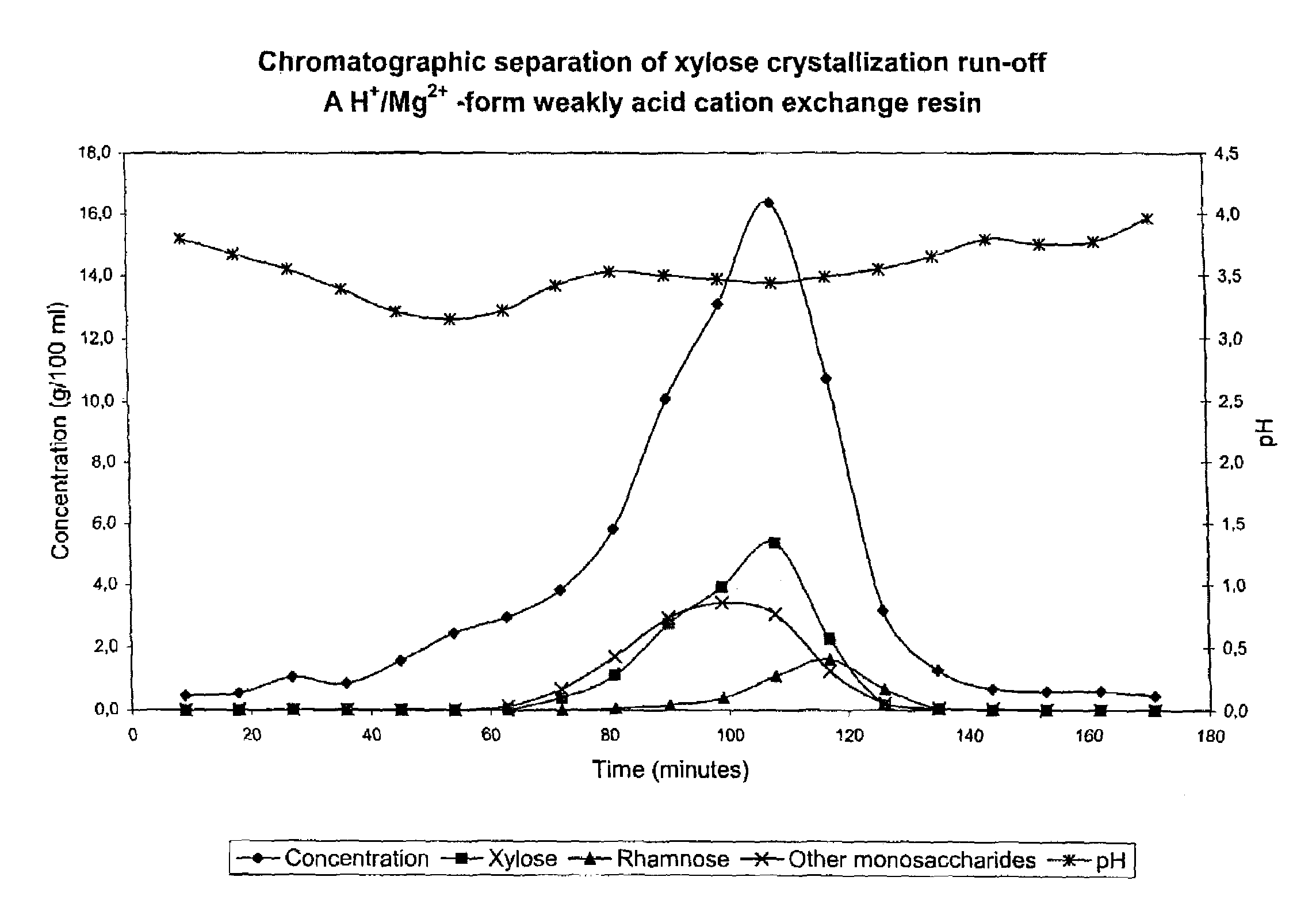

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

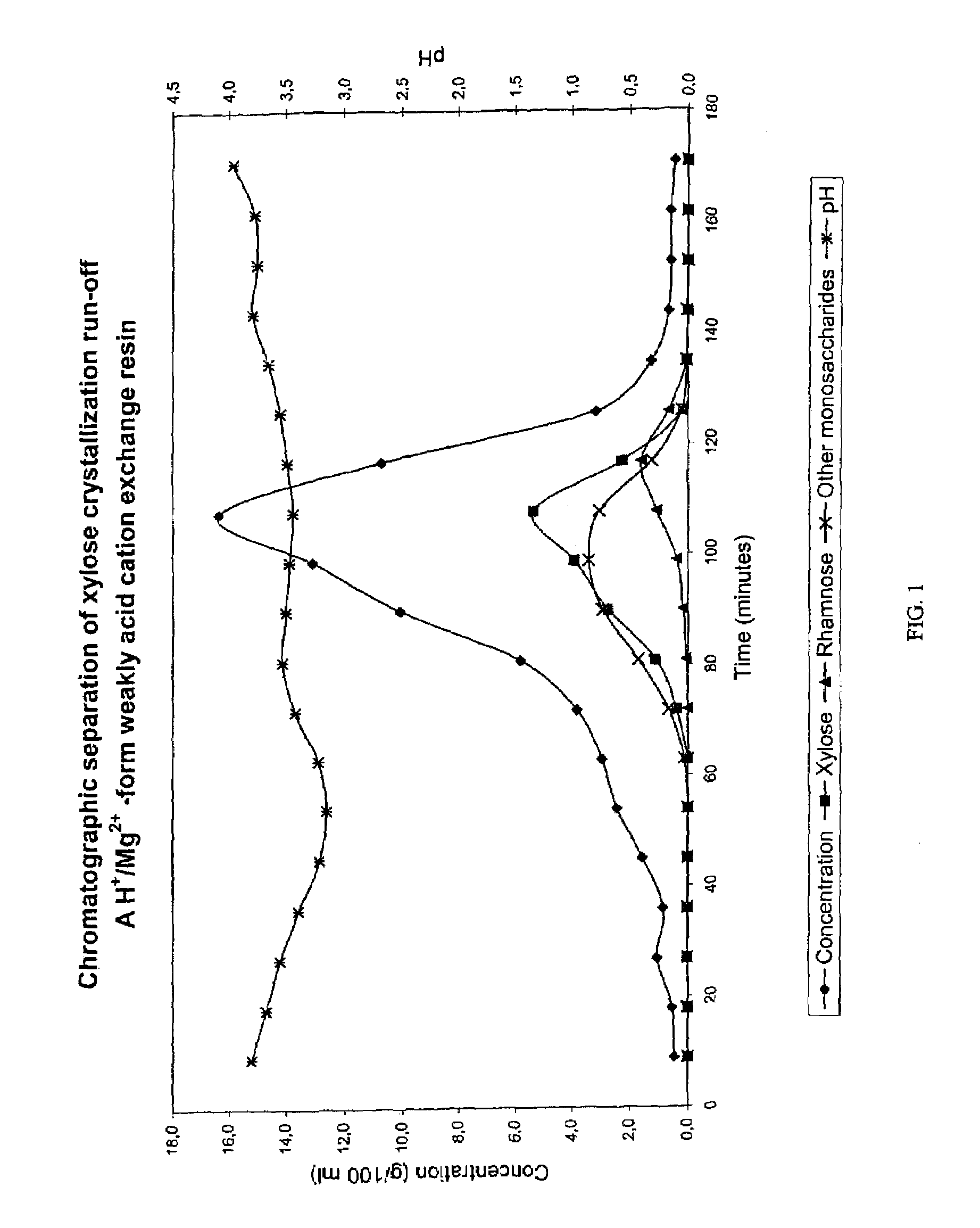

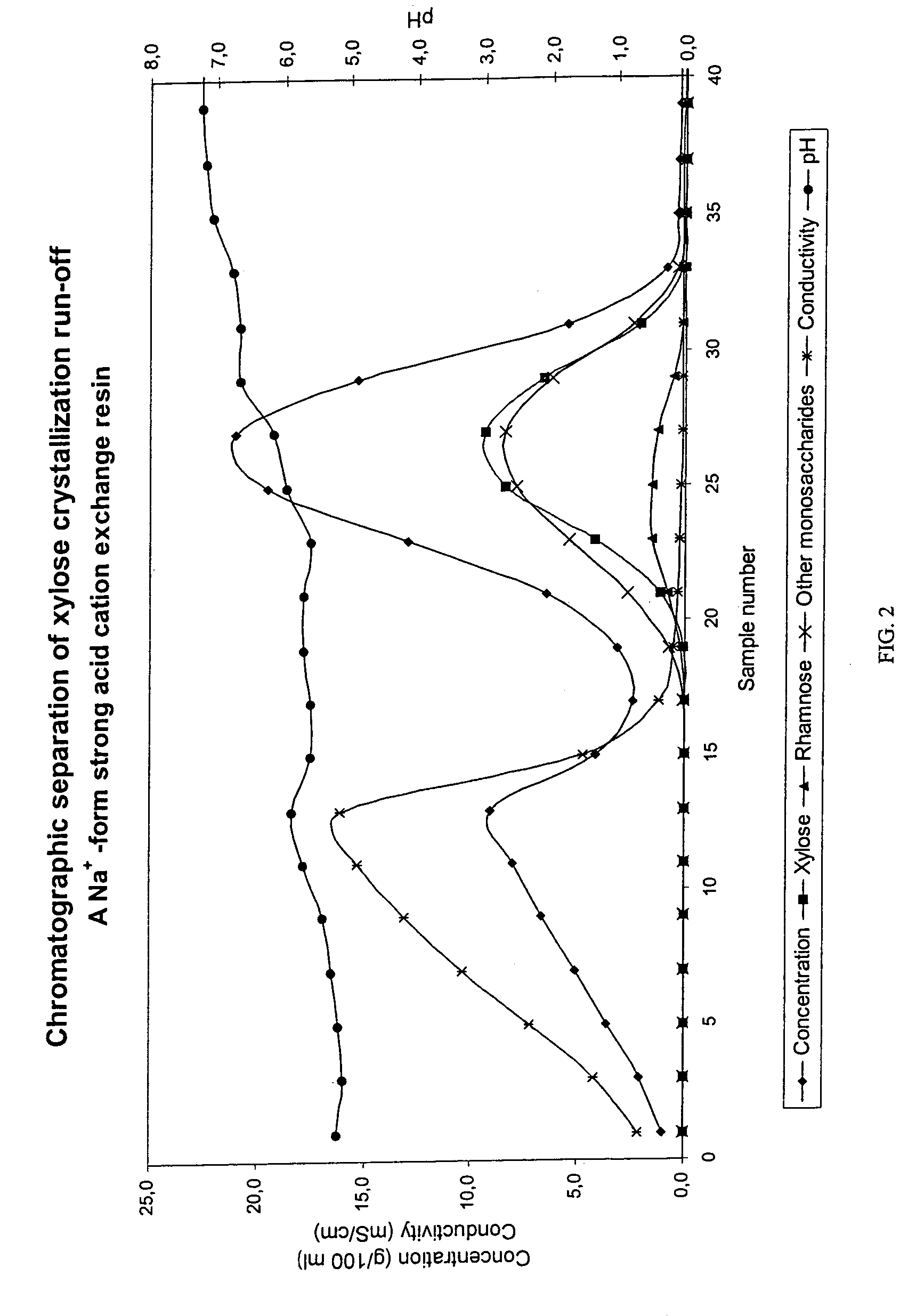

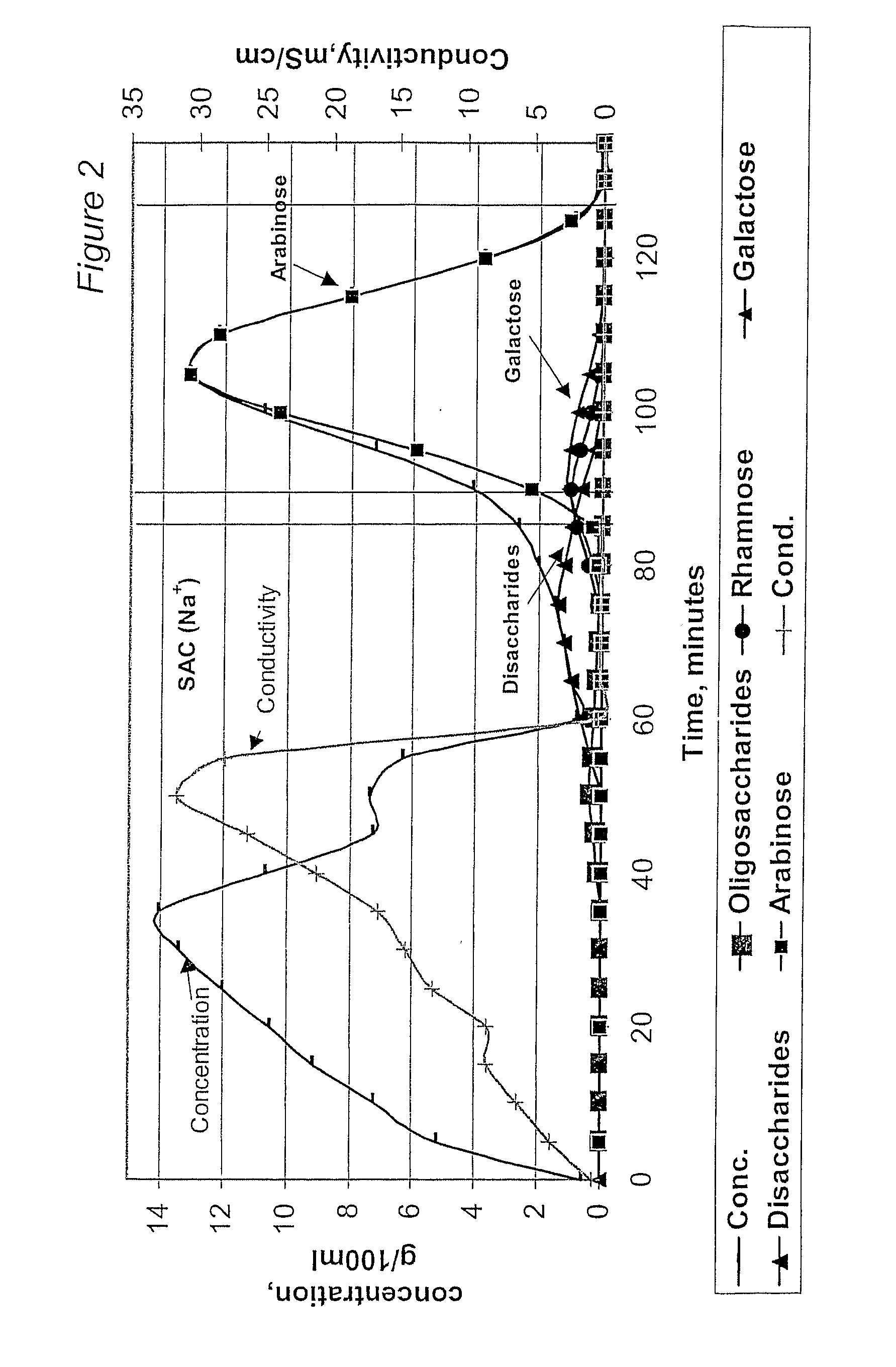

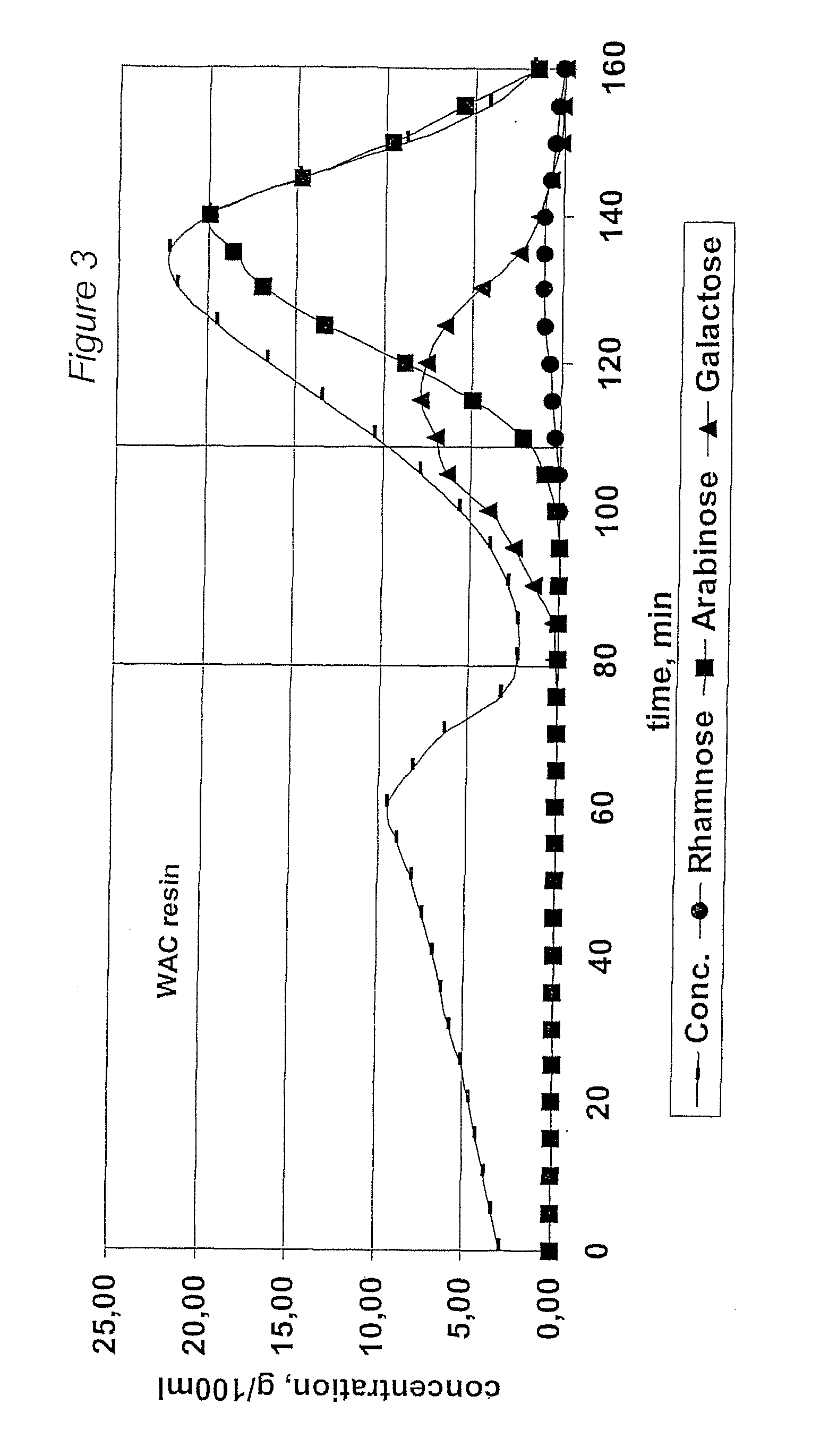

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

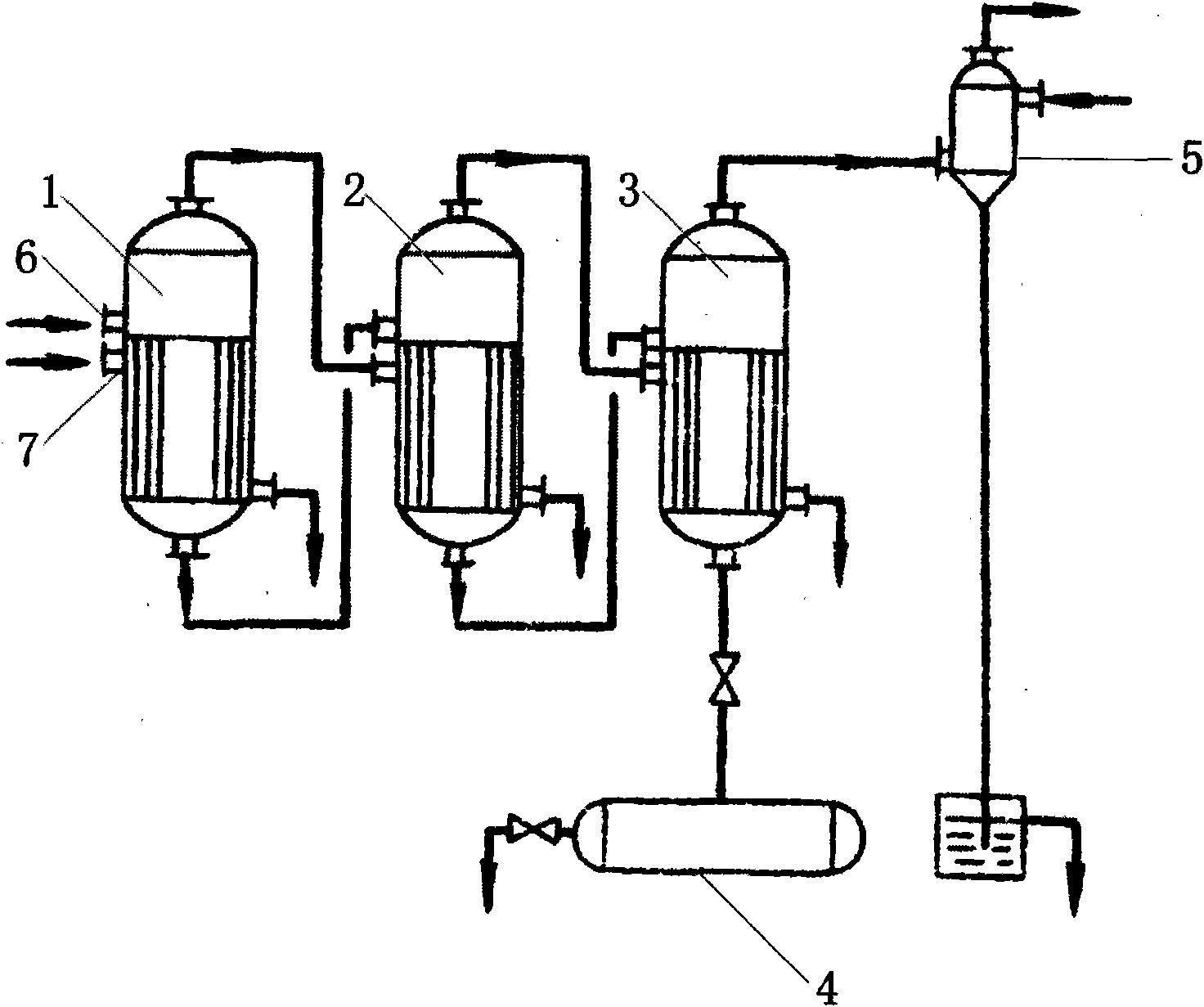

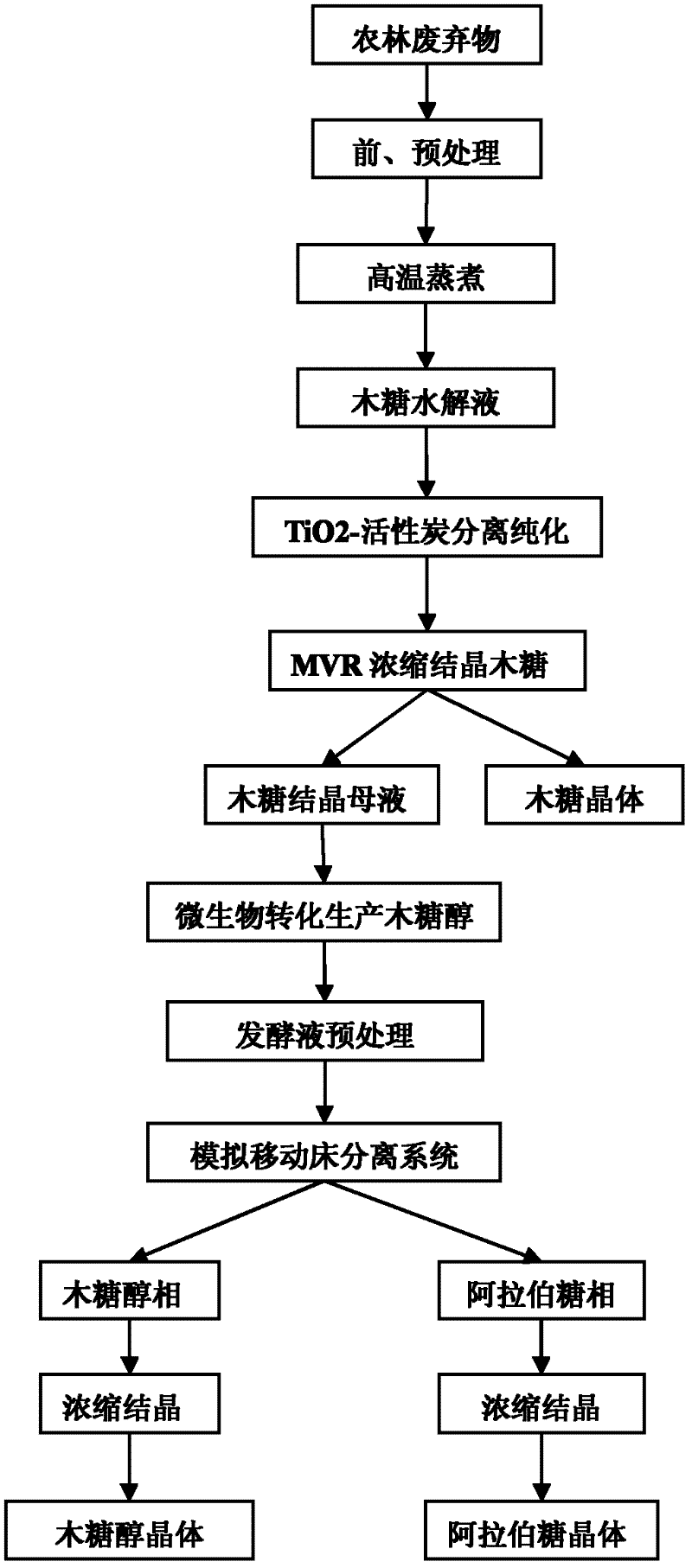

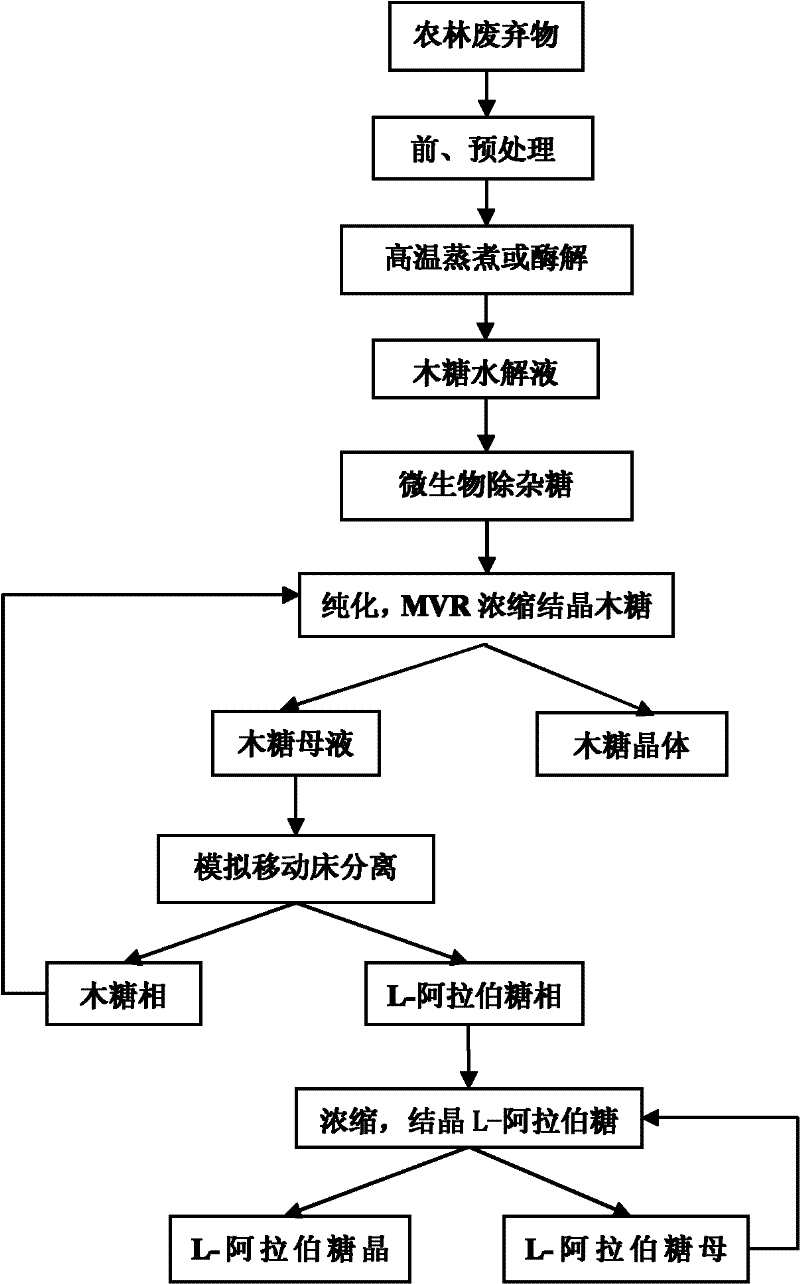

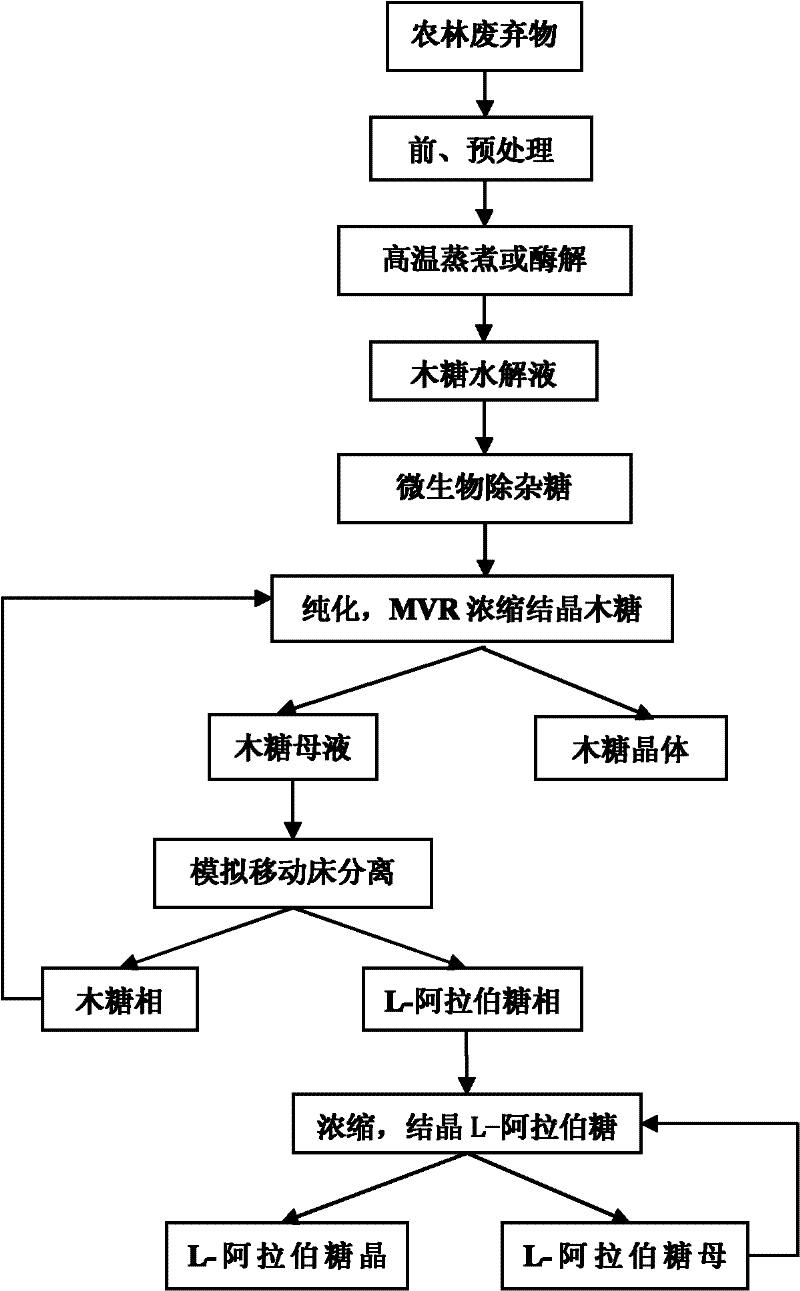

Co-production of xylose, xylitol and arabinose from agricultural and forestry wastes

ActiveCN102268490AEmission reductionReduce salt contentMicroorganism based processesFermentationChromatographic separationHydrolysate

The invention relates to a clean technique for co-producing xylose, xylitol and arabinose from agricultural and forestal waste, belonging to the field of utilization of agricultural and forestal waste. The technique comprises the following steps: pretreating and preprocessing the raw material, and hydrolyzing in a thermophilic digestion mode to prepare a hemicellulose hydrolysate; after centrifugalizing to remove solid residues, carrying out TiO2-loaded activated carbon photocatalysis or ion exchange resin decolorization and detoxification treatment on the hydrolysate; carrying out MVR (mechanical vapor recompression) concentration treatment and gradient-cooling crystallization to obtain a xylose product and a xylose mother solution; fermenting L-arabinose unconverted xylitol fermentationhigh-yield strain xylitol by using the xylose mother solution as the medium to produce the xylitol; centrifugalizing to remove thalli, and carrying out decolorization and desalting treatment by membrane-process or resin adsorption; separating by using a simulated moving bed or chromatographic separation technology to obtain a xylitol phase and an L-arabinose phase; and carrying out MVR or vacuum concentration treatment on the two phases, and crystallizing in a gradient programmed cooling mode to respectively obtaining a xylitol product and an L-arabinose product, wherein the two mother solutions can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

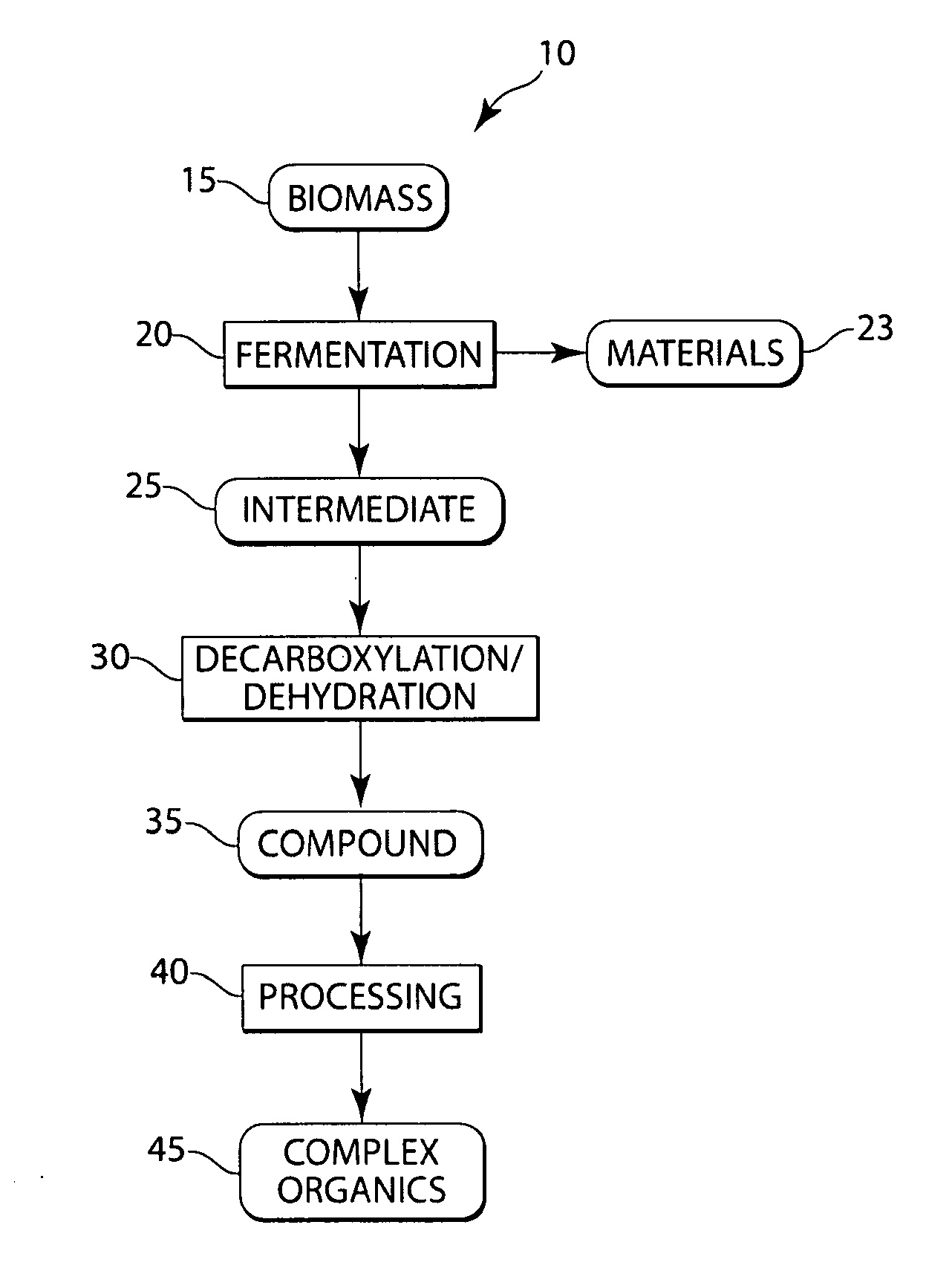

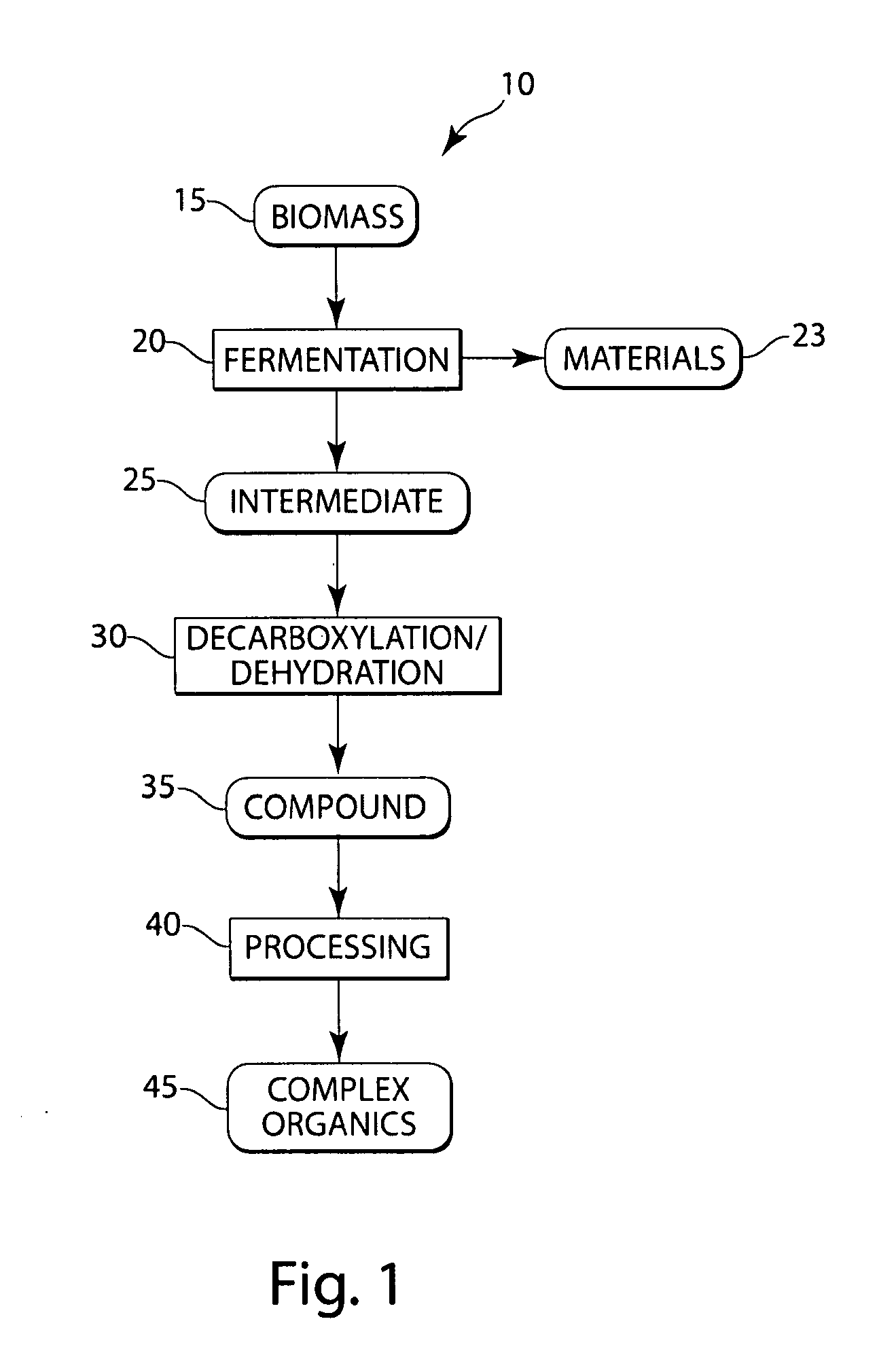

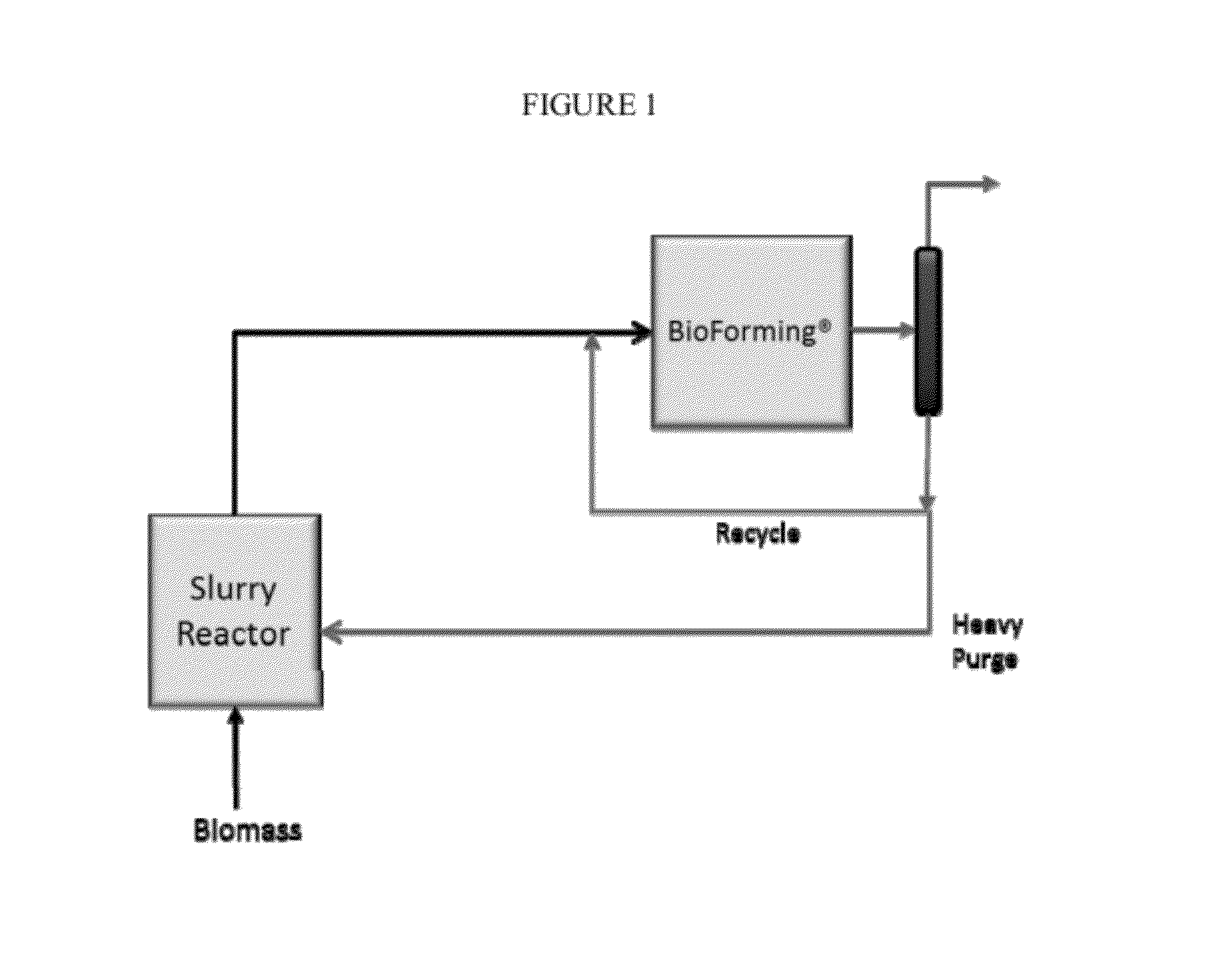

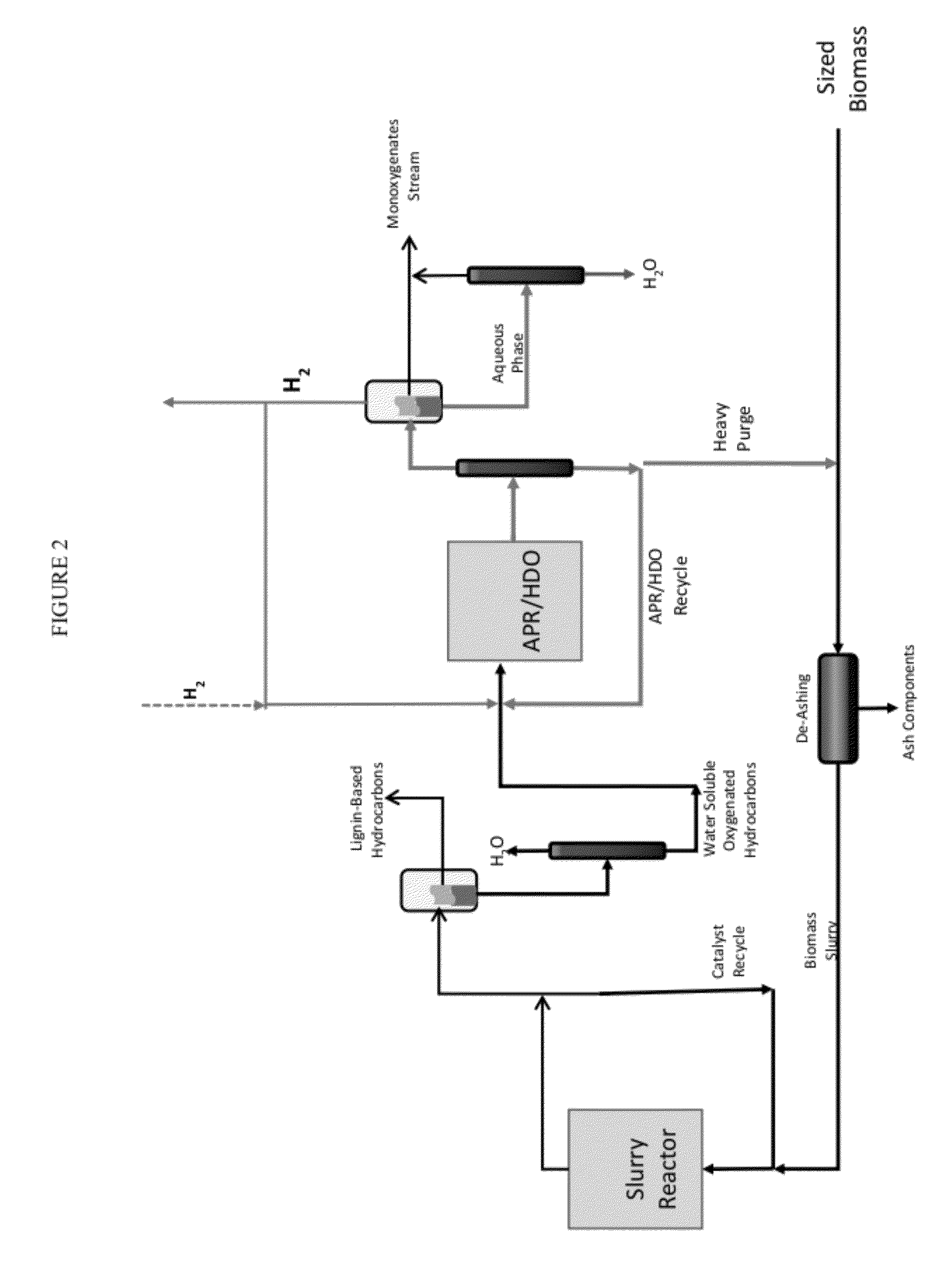

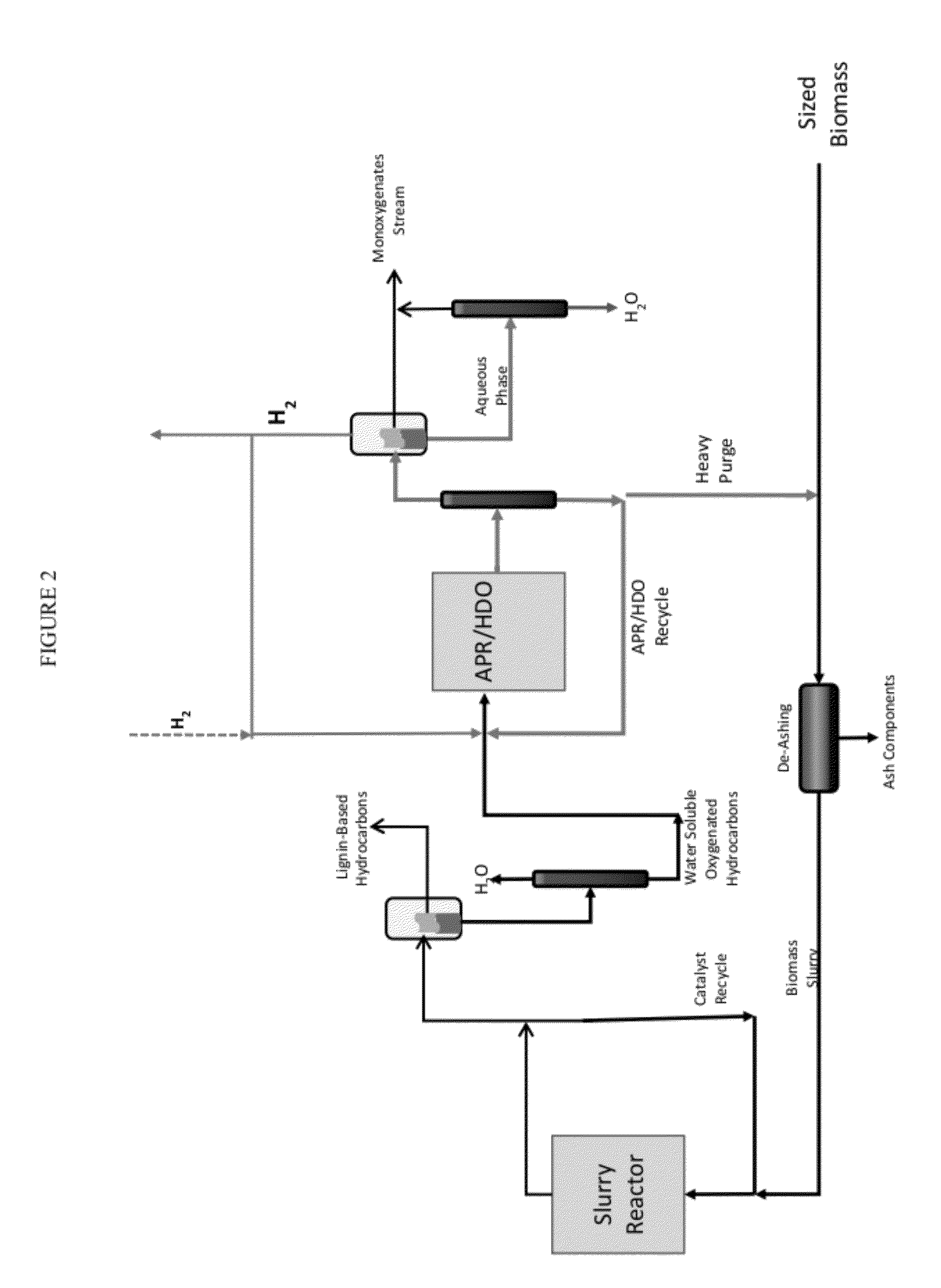

Conversion of natural products including cellulose to hydrocarbons, hydrogen and/or other related compounds

The present invention generally relates to the conversion of sugars and / or other biomass to produce hydrocarbons, hydrogen, and / or other related compounds. In one aspect, the invention includes fermenting biomass to produce one or more organic intermediates, for example, a carboxylic acid, and optionally, hydrogen. The carboxylic acid may then be decarboxylated to produce CO2 and one or more hydrocarbon compounds, for example, an alkane or an alkene, such as propane or ethylene. Such reactions can occur, in some cases, under hydrothermal conditions, and in some instances, without the use of or need for electrolysis of the reactants. In some cases, for example, if the carboxylic acid (or other organic intermediate) includes a hydroxide moiety, the carboxylic acid may be dehydrated, i.e., reacted such that the hydroxide moiety is removed from the molecule as H2O. In certain embodiments, a hydrocarbon compound may then be further reacted to produce other compounds, for example, hydrocarbons having at least 4 carbon atoms (e.g., gasoline), polymers such as polypropylene or polyethylene, or the like. Other aspects of the invention relate to devices for performing such reactions, methods of promoting the making or use of such reactions, or the like.

Owner:MASSACHUSETTS INST OF TECH

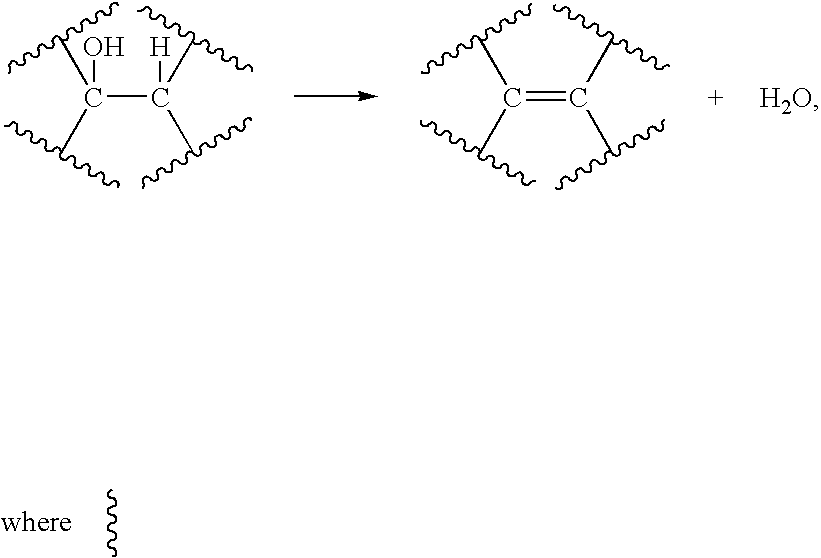

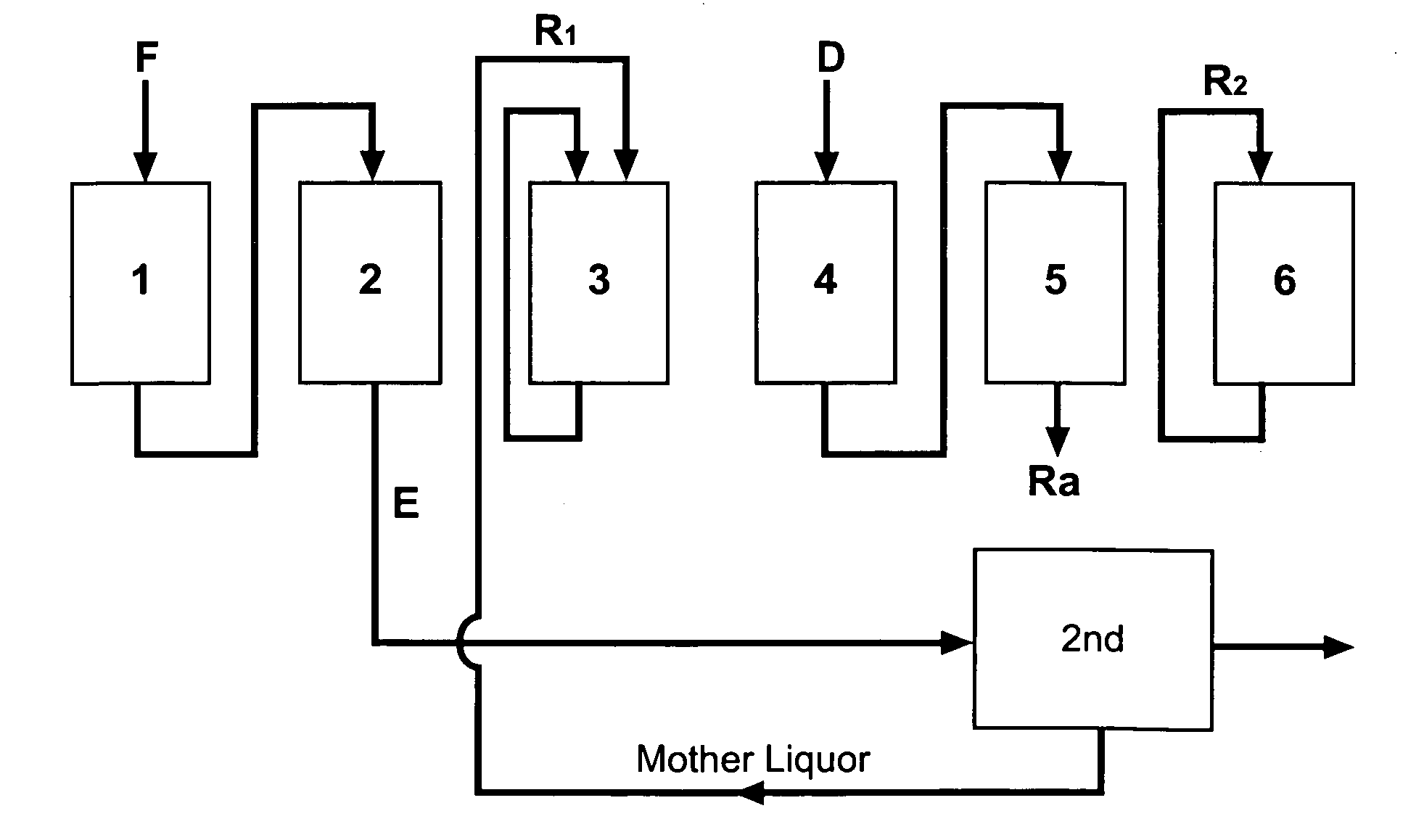

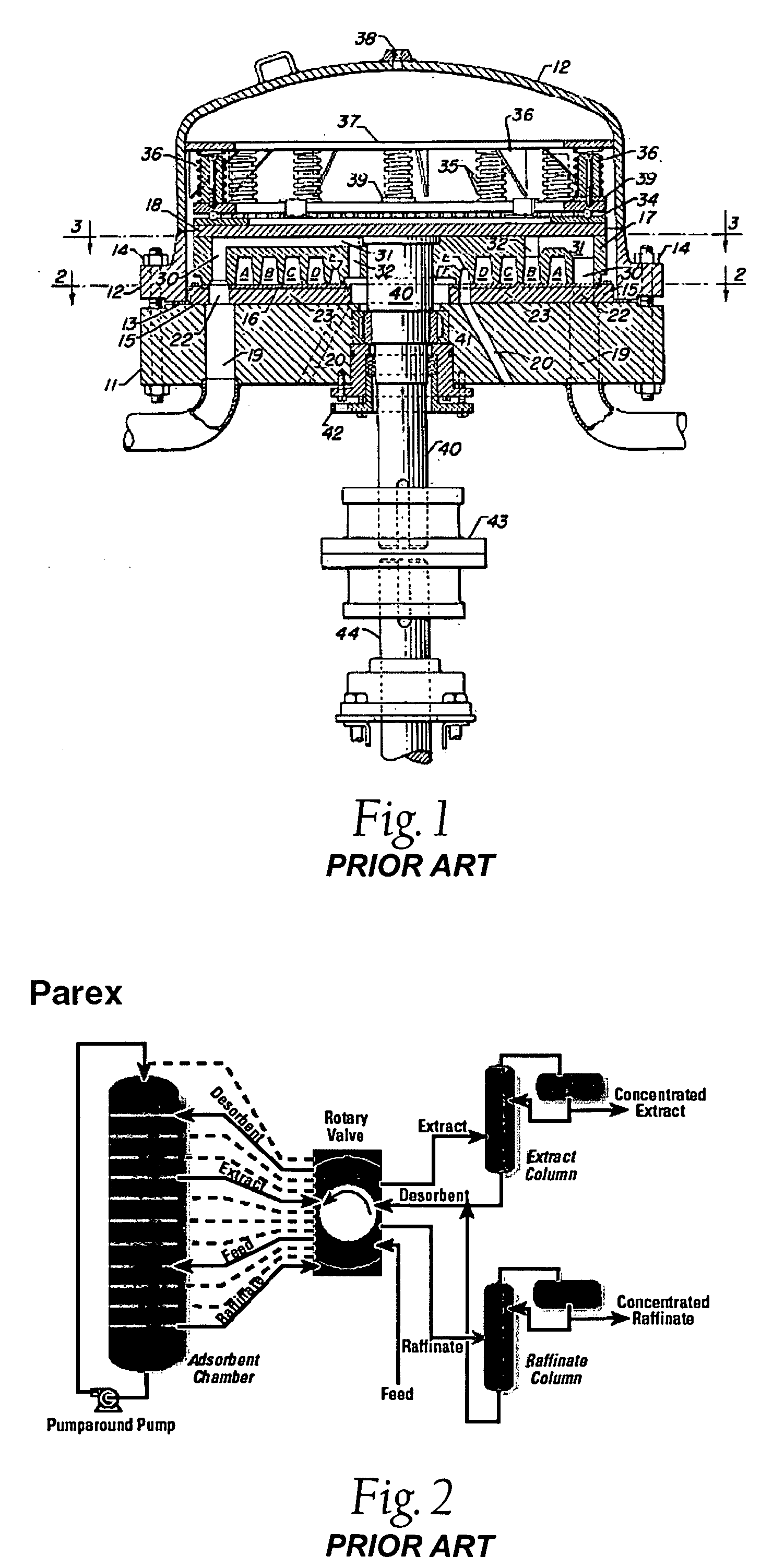

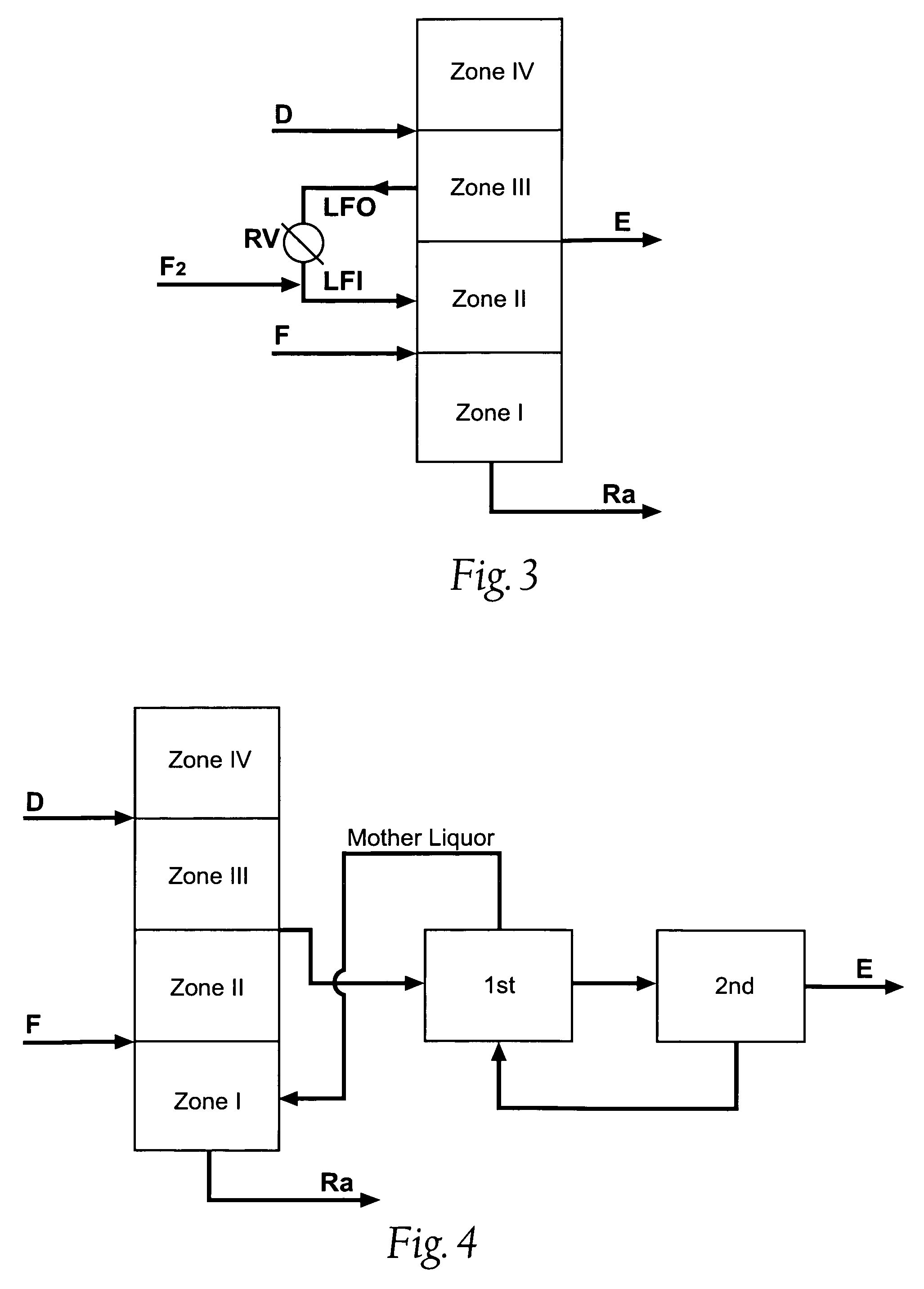

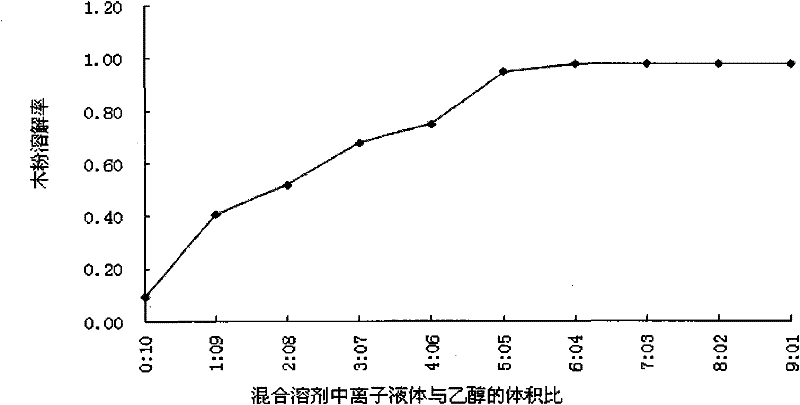

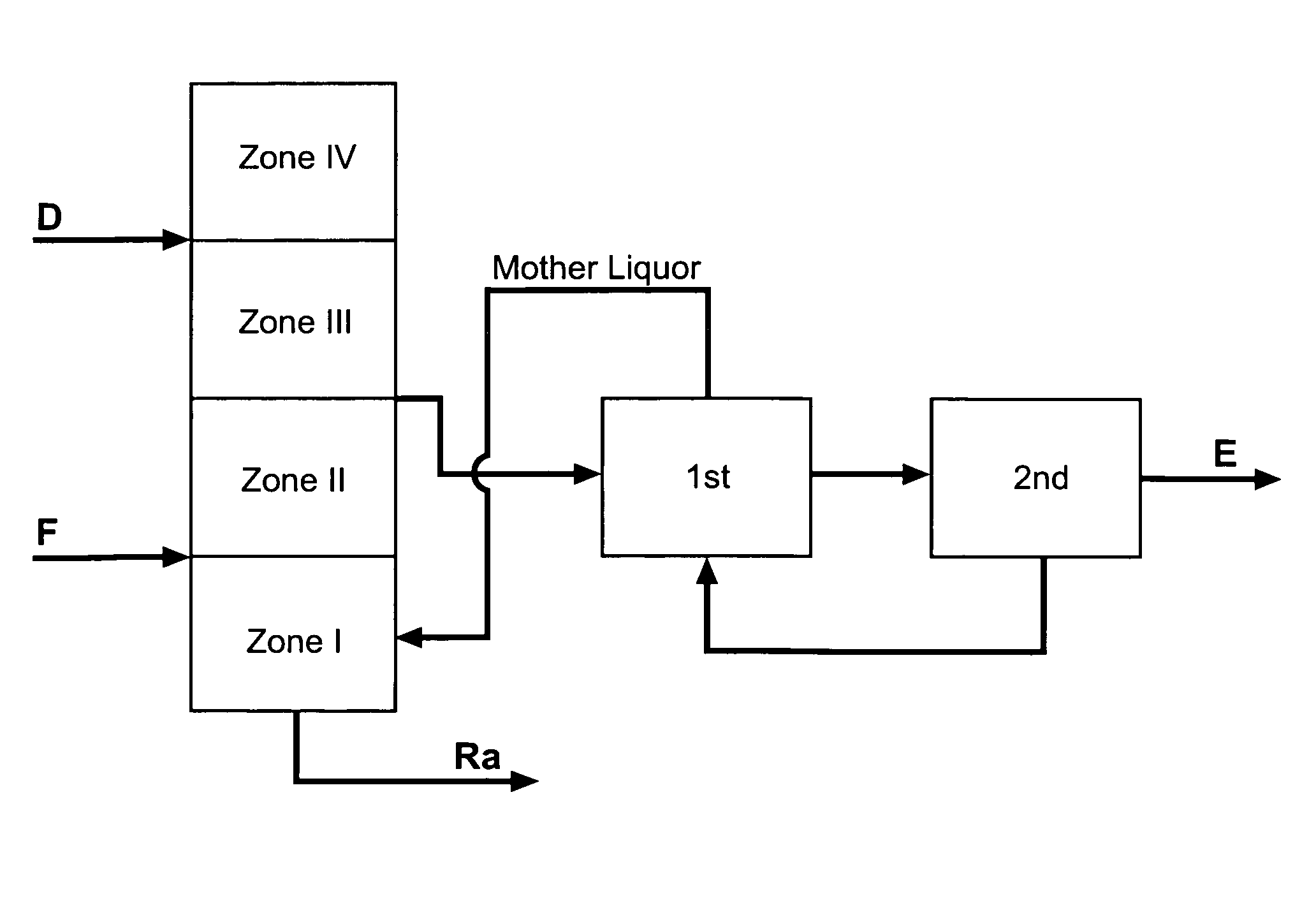

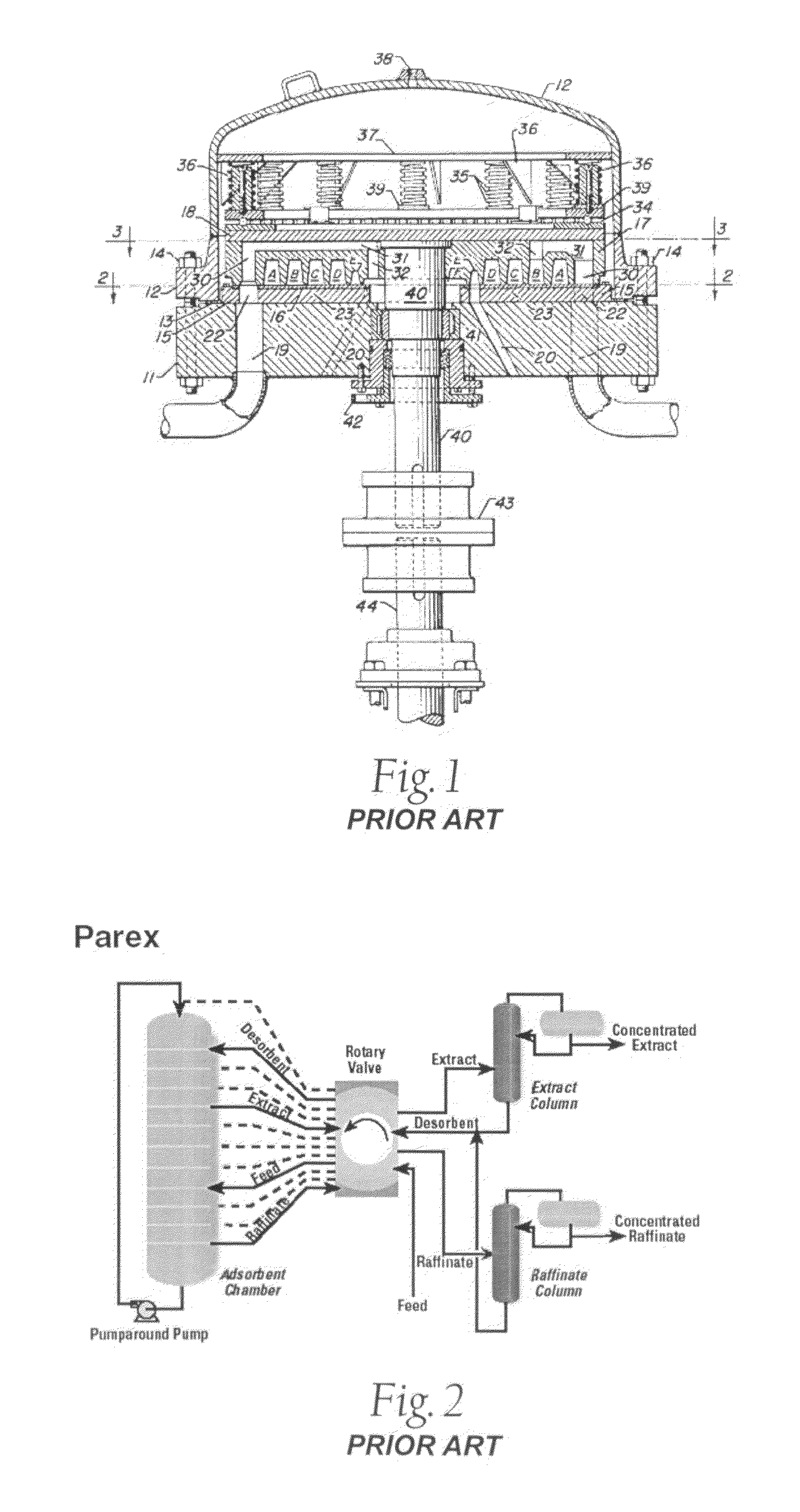

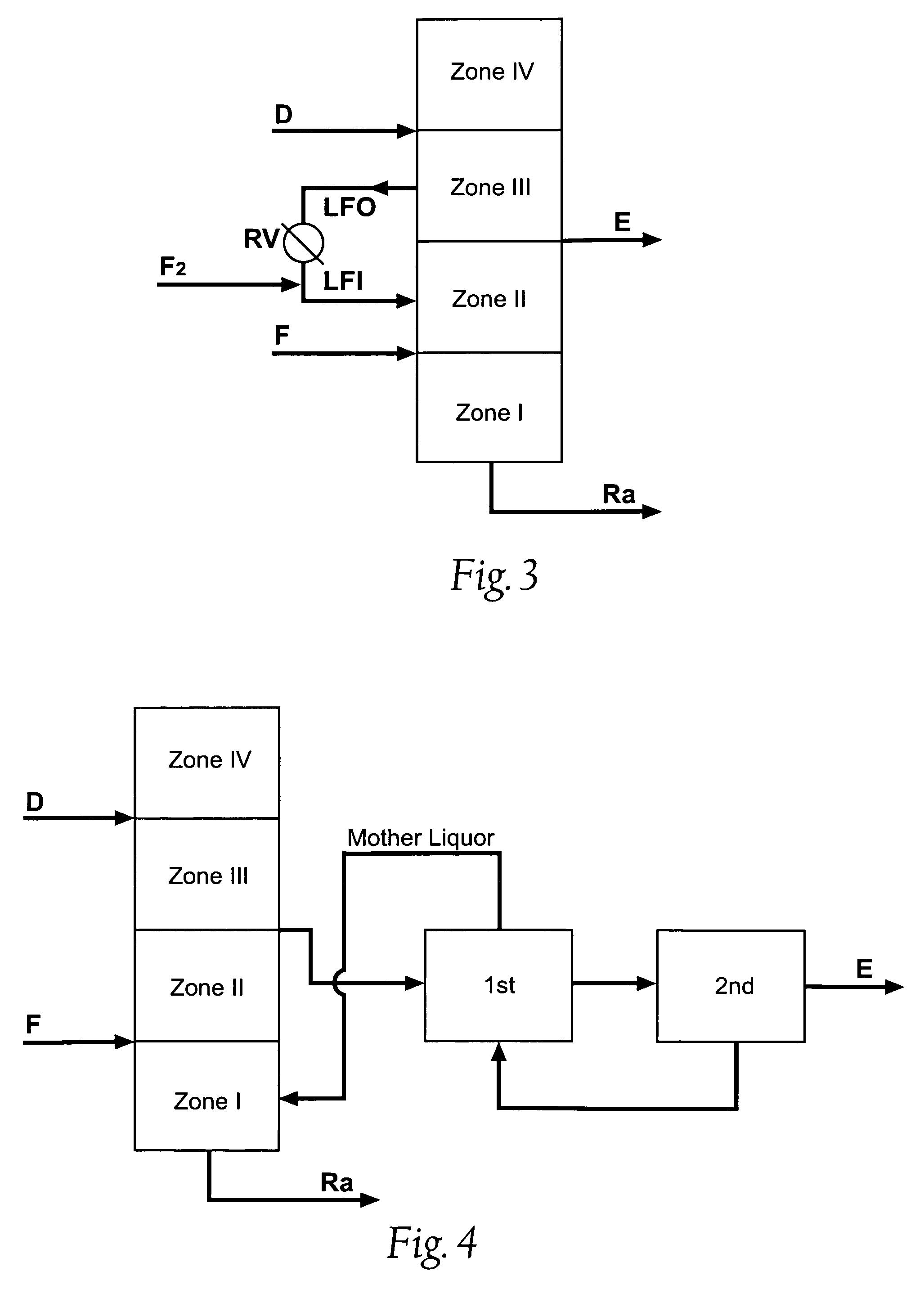

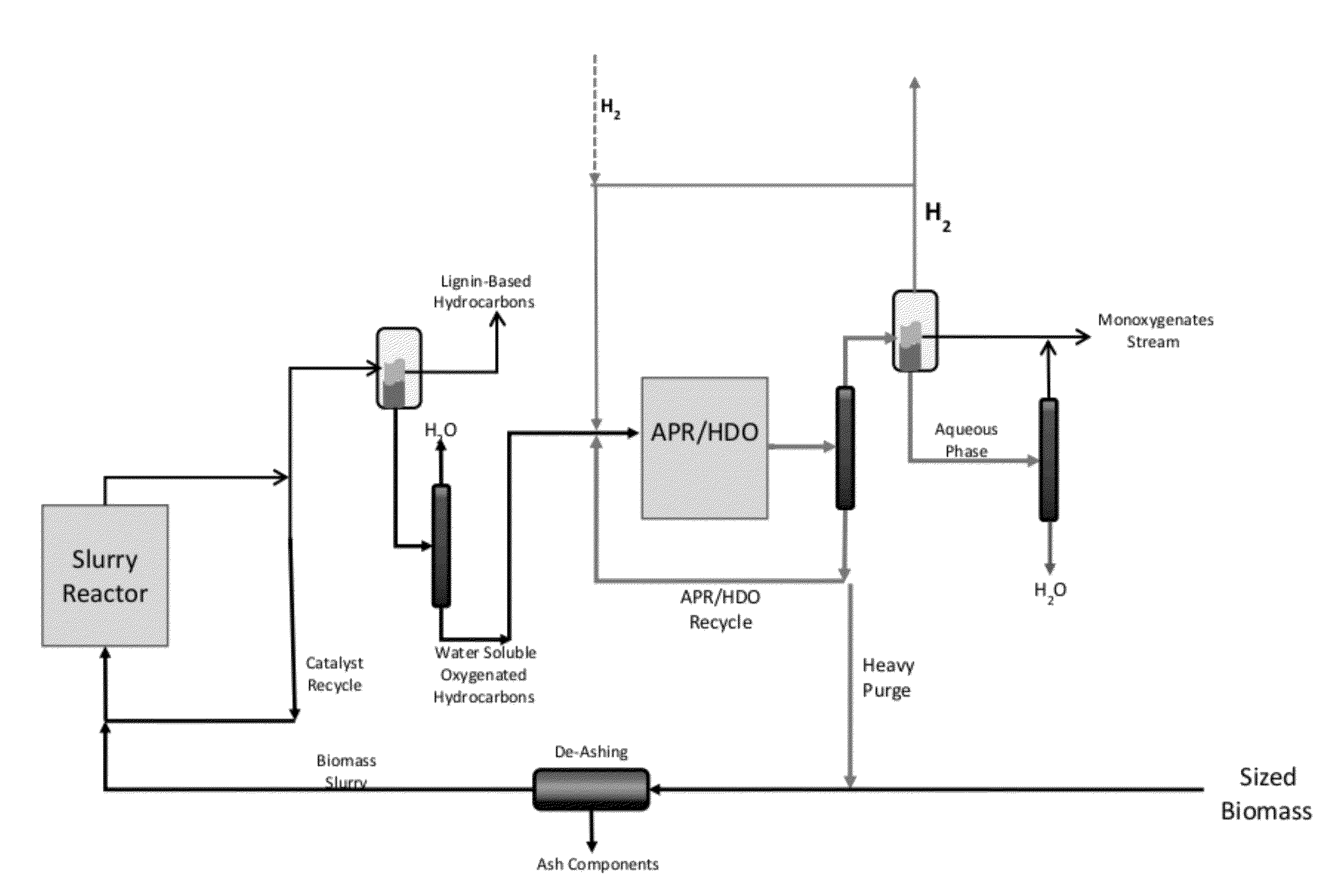

Simulated moving bed adsorptive separation process for handling multiple feedstocks

InactiveUS20090105515A1Increase capacityIncrease flexibilitySolid sorbent liquid separationHydrocarbonsSimulated moving bedChemistry

An improved process for the production capacity and feedstock handling flexibility of a simulated moving bed adsorptive separation process by introducing a second feed stream to the adsorbent chamber comprising a feed material of a different concentration of the desired compound than the concentration of the desired compound in the first feed material stream. The introduction of this second feed material stream may be performed at any location on the adsorbent chamber between (i) a transfer point located immediately upstream of the point of the raffinate material stream withdrawal from the adsorbent chamber to (ii) a transfer point located immediately downstream of the point of extract material stream withdrawal from the adsorbent chamber. A recycle stream may be introduced into the system at a location having a concentration similar to the concentration of the first feed material stream.

Owner:WINTER GEORGE R +1

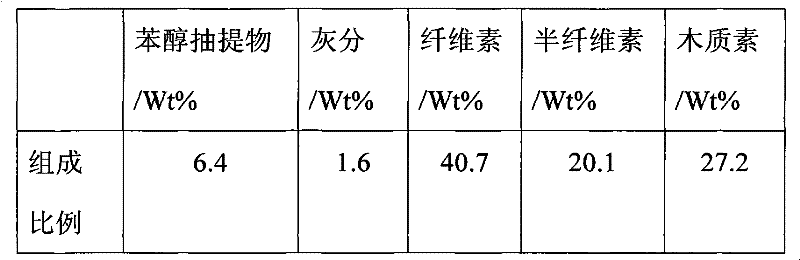

Solvent for separating biomass, and application thereof in selective separation of biomass

InactiveCN102174754AHigh purityEfficient separationOrganic chemistryPulping with organic solventsDissolutionIonic liquid

The invention relates to a solvent for separating biomass, and application thereof in selective separation of biomass. The system consists of ionic liquid, an organic solvent and water, wherein the ionic liquid is imidazole ionic liquid; the organic liquid comprises one or a plurality of methanol, ethanol, formic acid, acetic acid, dioxane or tetrahydrofuran; the components of the mixed solvent are conditioned according to the dissolution and hydrogen bond theories; and the mixed solvent is capable of hydrolyzing semicellulose and lignin under a certain hydrogen bond capability and a dissolution parameter and reserving solid high purity cellulose, and is capable of completely dissolving and hydrolyzing the biomass under another hydrogen bond capability and another dissolution parameter. By adding the water for precipitation and filtering for separation, crude lignin and hydrolysis sugar of carbohydrate can be obtained. The biomass can be selectively separated and transformed by controlling the mixing ratio of the three components; besides, the application of the solvent for separating biomass is moderate in condition, simple in process and environment-friendly; furthermore, all the components of the solvent system can be recovered and reused.

Owner:SOUTH CHINA UNIV OF TECH

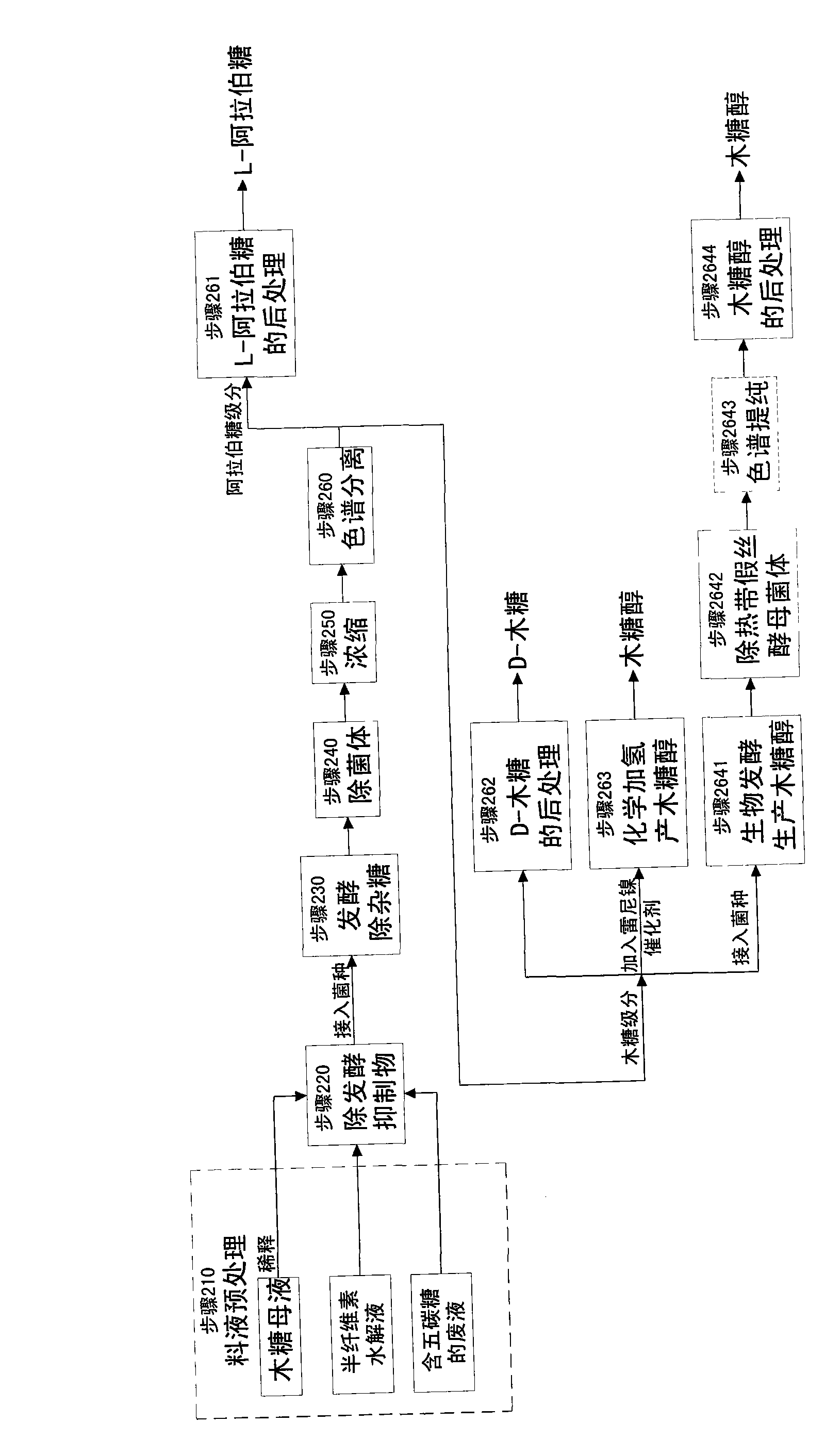

Method for producing L-arabinose

ActiveCN101665524AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationImpurity

The invention relates to a method for producing L-arabinose, which can simultaneously produce ethanol, D-ribose and citric acid as byproducts. The method utilizes a hydrolyzate of agricultural waste, a xylose mother liquor and / or a production waste liquor containing pentose as the raw materials and comprises the following steps: (a) pretreating the raw materials; (b) carrying out the chromatographic resolution to separate the raw materials into an arabinose-stage liquor and a xylose-stage liquor; (c) removing impurities and unwanted bacteria, which have an inhibiting effect on fermentation, as well as unwanted saccharides at least comprising glucose and galactose; (d) and carrying out the post treatment on the arabinose-stage liquor to obtain the L-arabinose. Steps (c1) and (c2) are arranged before the chromatographic resolution in step (b) or after step (b). The invention has the advantages of low production cost and high efficiency, and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

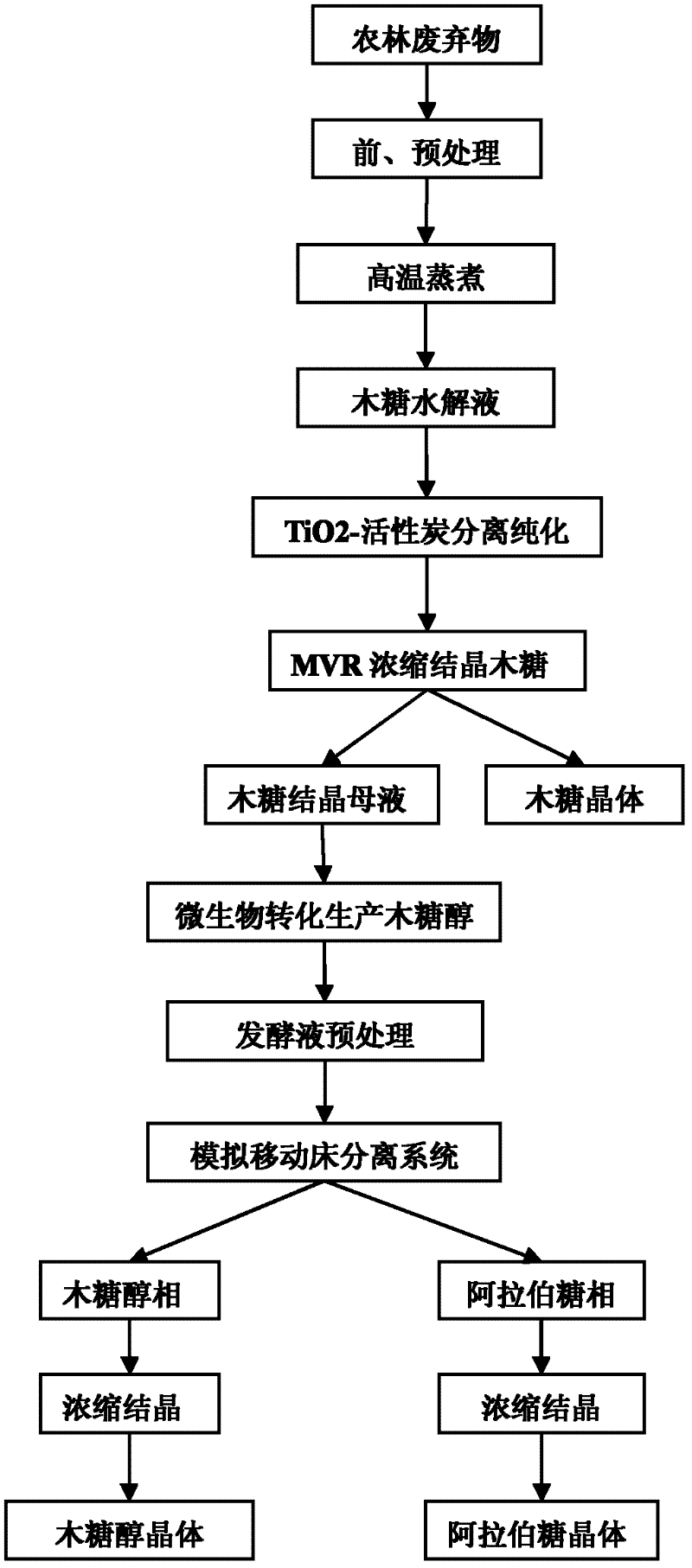

A clean and efficient production process for preparing xylose and l-arabinose

ActiveCN102286571AAddressing the effects of crystallizationHigh yieldSugar derivativesSugar derivatives preparationChromatographic separationYeast

The invention relates to a clean and high-efficiency production process for preparing xylose and L-arabinose and belongs to the field of application of wastes of agriculture and forestry. The production process comprises the following steps of: performing pretreatment on raw materials; hydrolyzing the raw materials in a high-temperature cooking mode; performing neutralizing treatment and performing centrifugal separation on solid slag to obtain xylose or xylooligosaccharide hydrolyzate; adding coarse enzyme solution into xylooligosaccharide solution to hydrolyze to obtain xylose solution; treating the hydrolyzate by Angle yeast; purifying by using active carbon and resin; performing recompression and concentration treatment on the purified hydrolyzate by using a mechanical vapor recompression (MVR) machine; crystallizing the concentrated solution in a gradient program cooling mode to obtain xylose products and xylose mother solution; separating the xylose mother solution by a simulated moving bed or a chromatographic separation technology to obtain a xylose phase and an L-arabinose phase; returning the xylose phase to the xylose solution to concentrate and recrystallize; reusing the xylose mother solution; performing MOVR concentration treatment on the L-arabinose phase and crystallizing in a gradient program cooling mode to obtain L-arabinose products; and reusing the L-arabinose mother solution.

Owner:BEIJING UNIV OF CHEM TECH

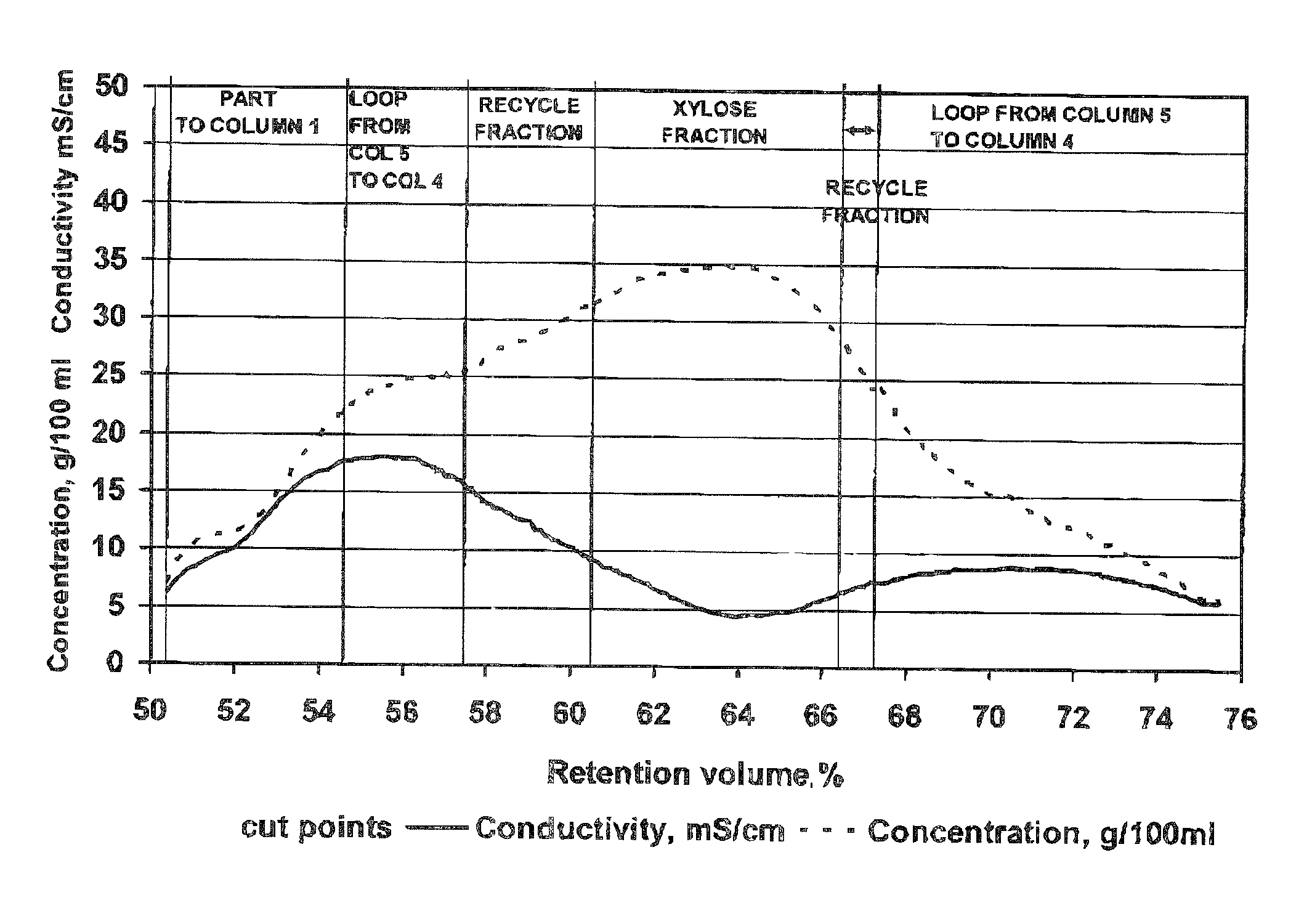

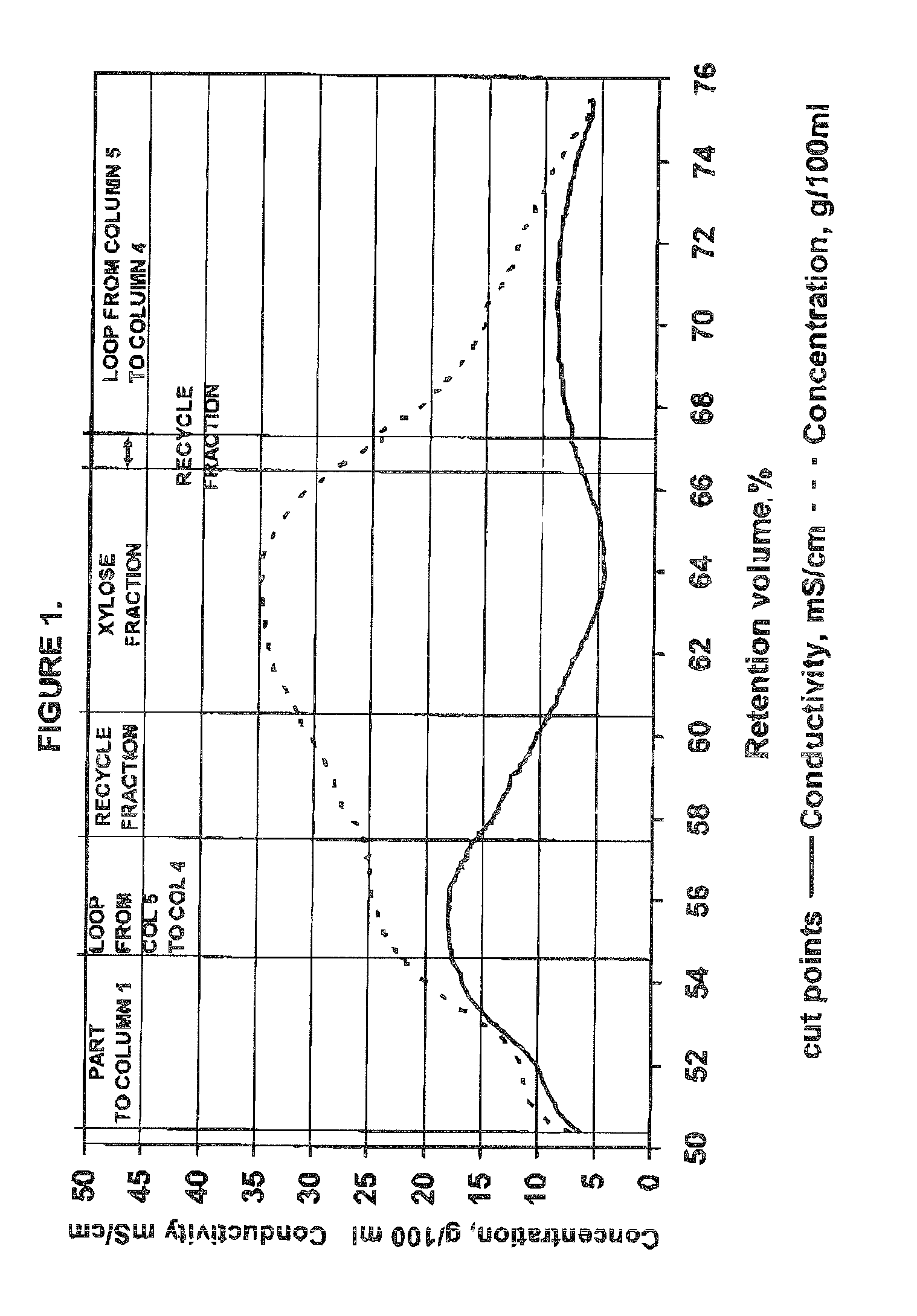

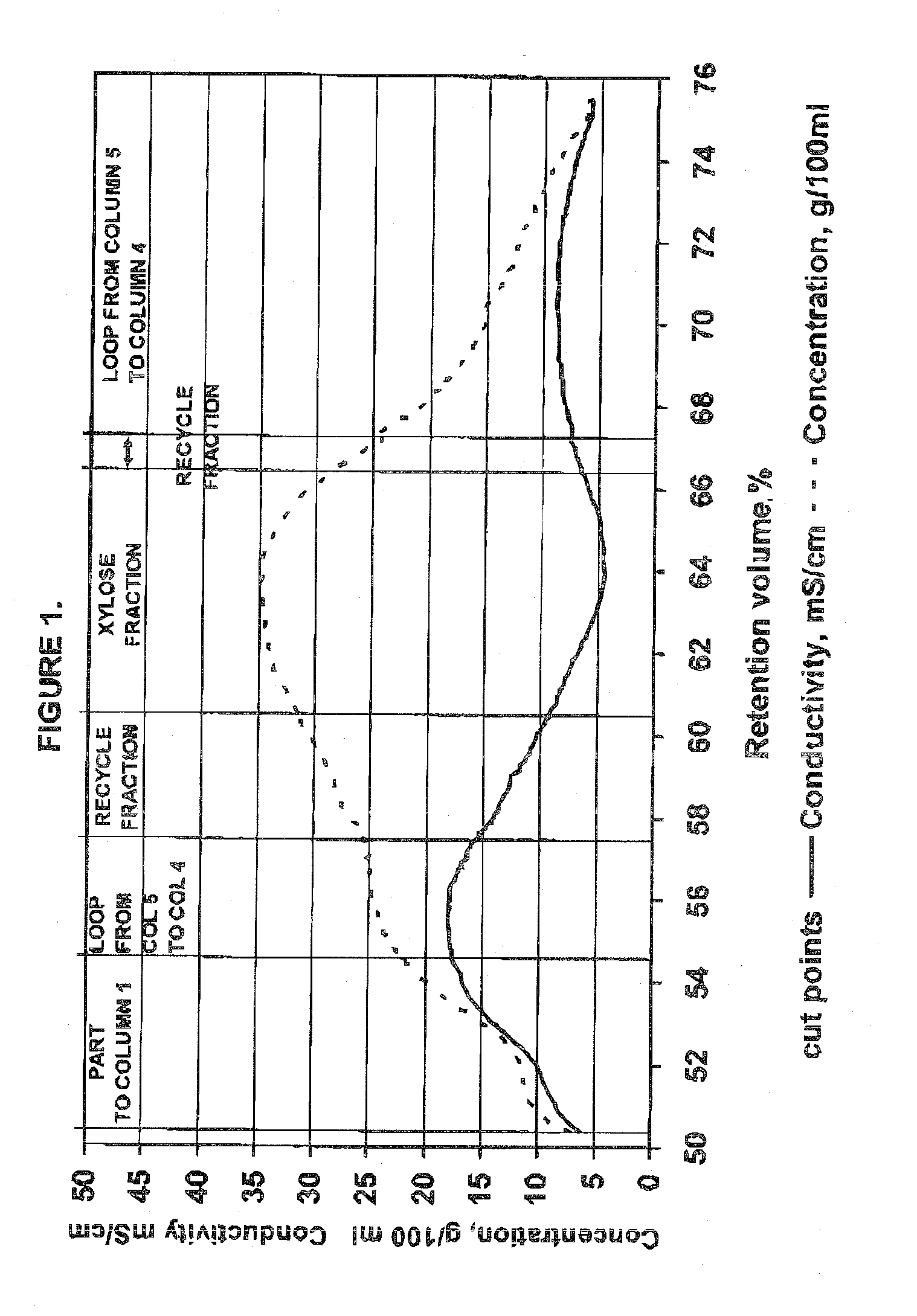

Separation process

ActiveUS7959811B2Disturb separation efficiency of separationLower the volumeIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Simulated moving bed adsorptive separation process for handling multiple feedstocks

ActiveUS7396973B1Increase capacityIncrease flexibilitySolid sorbent liquid separationHydrocarbonsSimulated moving bedChemistry

The present invention discloses a means to improve the production capacity and feedstock handling flexibility of a simulated moving bed adsorptive separation process by introducing a second feed stream to the adsorbent chamber, such second feed stream comprising a feed material of a different concentration of the desired compound than the concentration of such desired compound in the first feed material stream. The introduction of this second feed material stream may be performed at any location on the adsorbent chamber between (i) a transfer point located immediately upstream of the point of the raffinate material stream withdrawal from the adsorbent chamber to (ii) a transfer point located immediately downstream of the point of extract material stream withdrawal from the adsorbent chamber. The specific transfer point used for the introduction of the second feed material stream will depend upon the concentration of the desired component in the second feed material stream.

Owner:WINTER GEORGE R

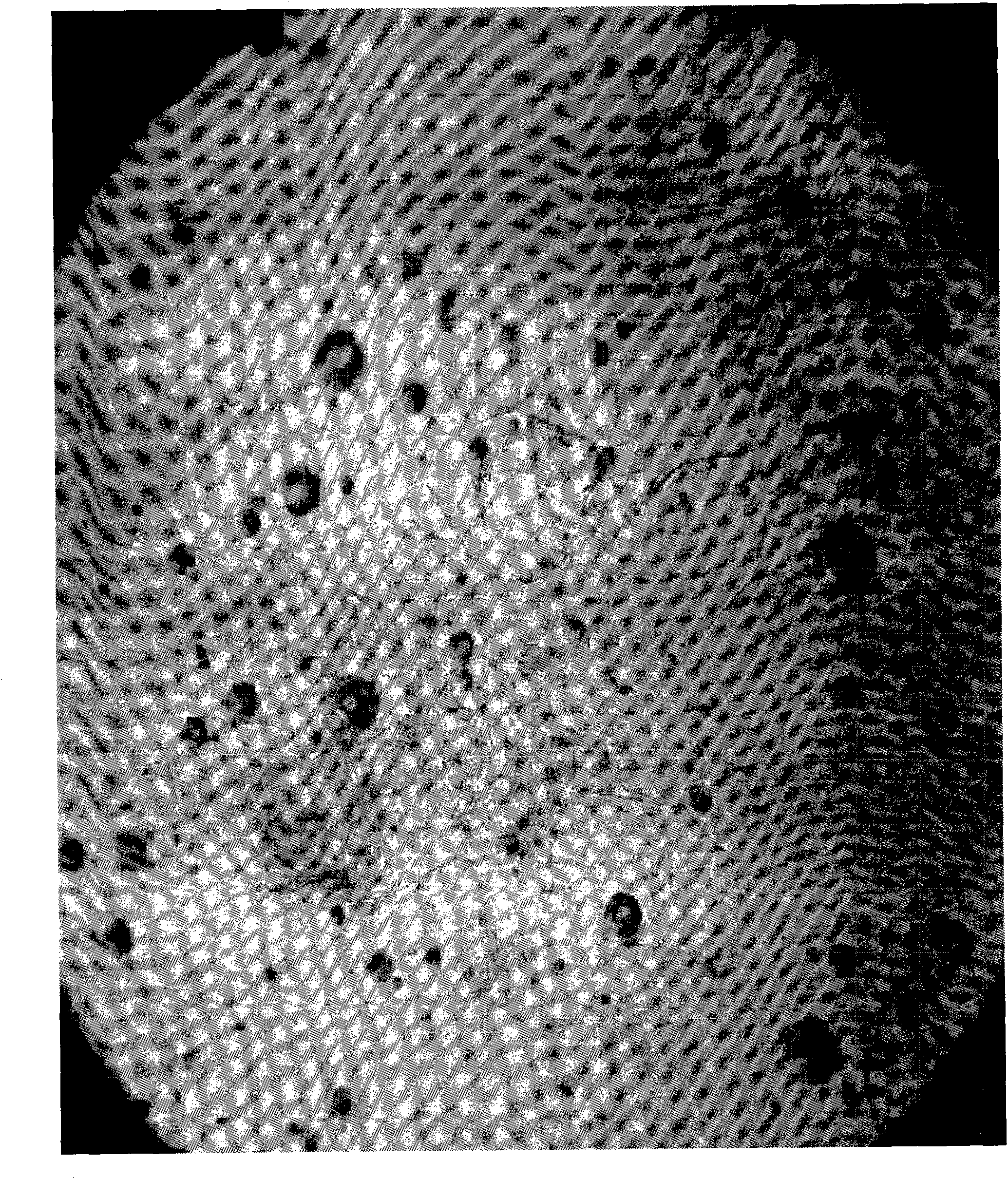

Plants and seeds of corn variety cv601120

According to the invention, there is provided seed and plants of the corn variety designated CV601120. The invention thus relates to the plants, seeds and tissue cultures of the variety CV601120, and to methods for producing a corn plant produced by crossing a corn plant of variety CV601120 with itself or with another corn plant, such as a plant of another variety. The invention further relates to corn seeds and plants produced by crossing plants of variety CV601120 with plants of another variety, such as another inbred line. The invention further relates to the inbred and hybrid genetic complements of plants of variety CV601120.

Owner:MONSANTO TECH LLC

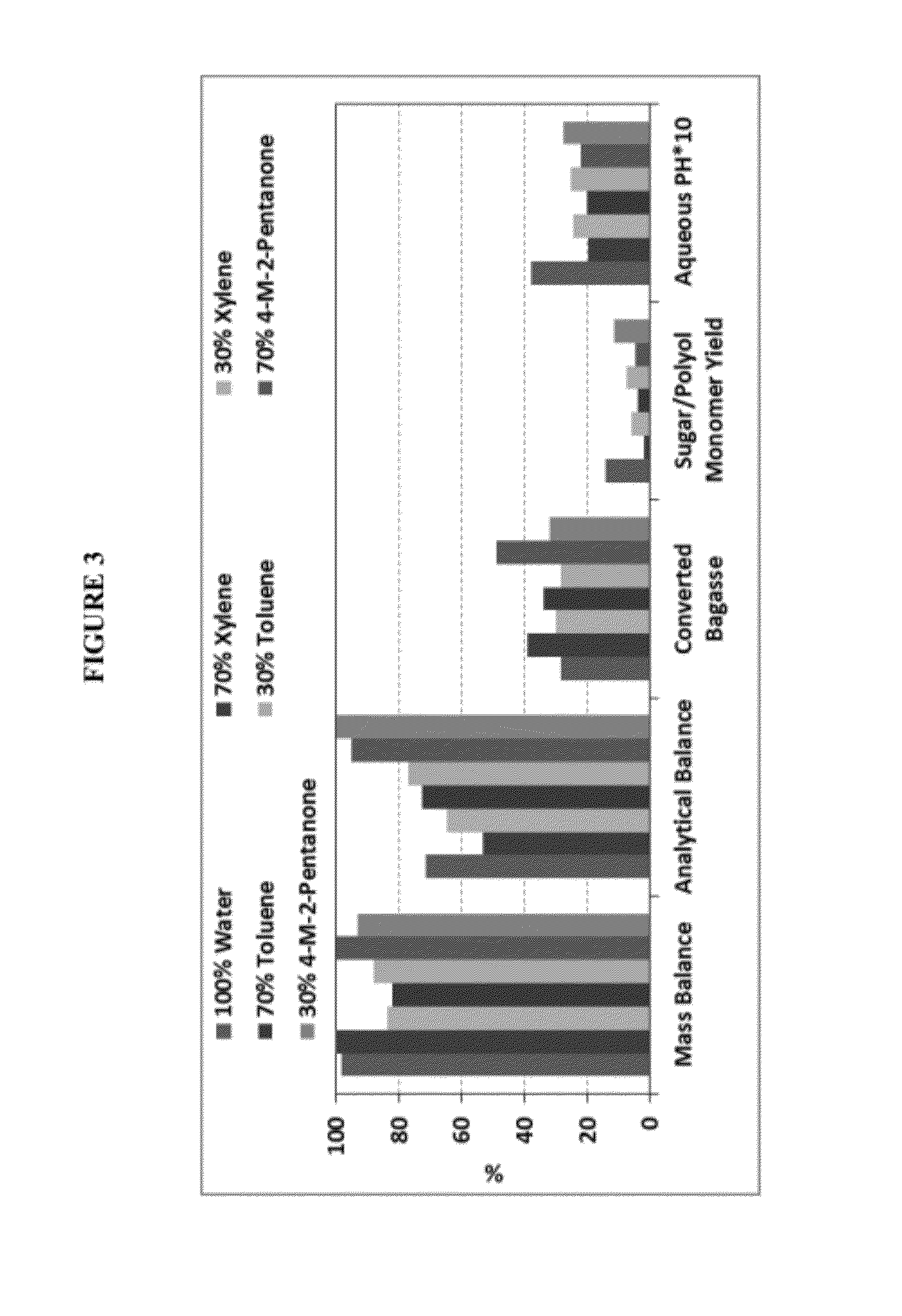

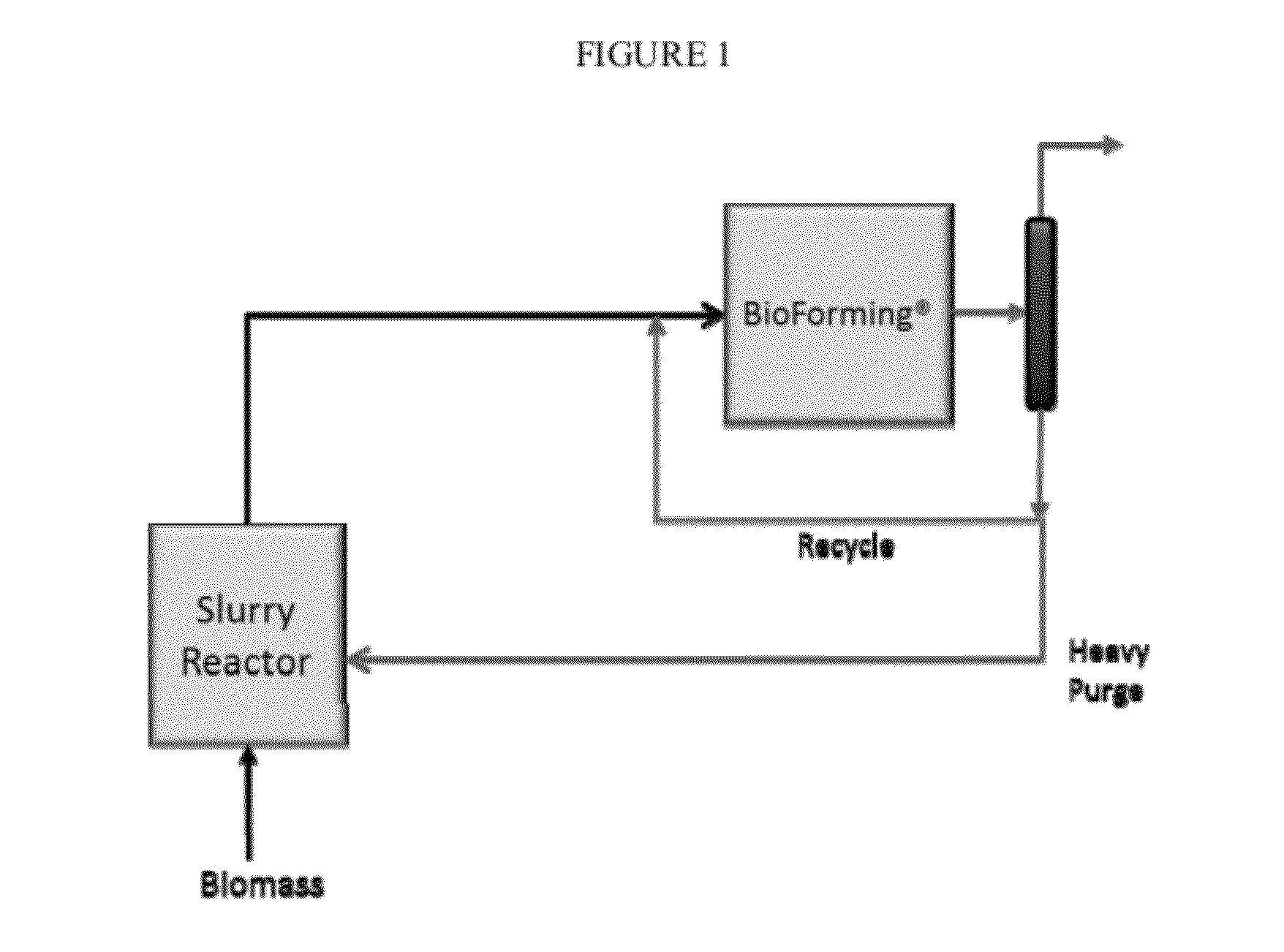

Methods for biomass Deconstruction and Purification

ActiveUS20120323053A1Organic compound preparationOxygen compounds preparation by reductionHydrolysateTemperature and pressure

The present invention provides processes for deconstructing and purifying biomass using water. The method includes the steps of loading a reactor with biomass and water, establishing and maintaining a deconstruction temperature and pressure for a deconstruction period, flushing the reactor with water, and repeating these steps to produce a solid phase and a biomass hydrolysate.

Owner:VIRENT

Method for extracting xylose from viscoce chemical fiber squeezed alkali liquor

InactiveCN104099431ASave resourcesReduce pollutionArtificial filament recoveryTextile/flexible product manufactureFiberHydrolysate

The invention relates to a method for extracting xylose from viscoce chemical fiber squeezed alkali liquor. According to the technical scheme, the method comprises the following steps: pre-filtering to obtain pre-concentrated liquor; filtering the pre-concentrated liquor through a nanofiltration membrane to obtain concentrated liquor; adding hydrochloric acid to the concentrated liquor to obtain hydrolysate; adding hydrolysate to NaOH until being neutral; decolorizing; regulating the concentration of NaCl; cooling at constant speed until reaching room temperature; enabling glucose in hydrolysate to cocrystallize with NaCl to remove glucose; treating filtrate through ion exchange columns to obtain purified liquor; crystallizing and purifying the purified liquor for the second time to obtain coarse xylose; refining the coarse xylose to obtain final xylose. With the adoption of the method, the resource is saved, the economic benefit is brought to enterprises, and the environment is protected.

Owner:沈阳新华环保技术有限公司

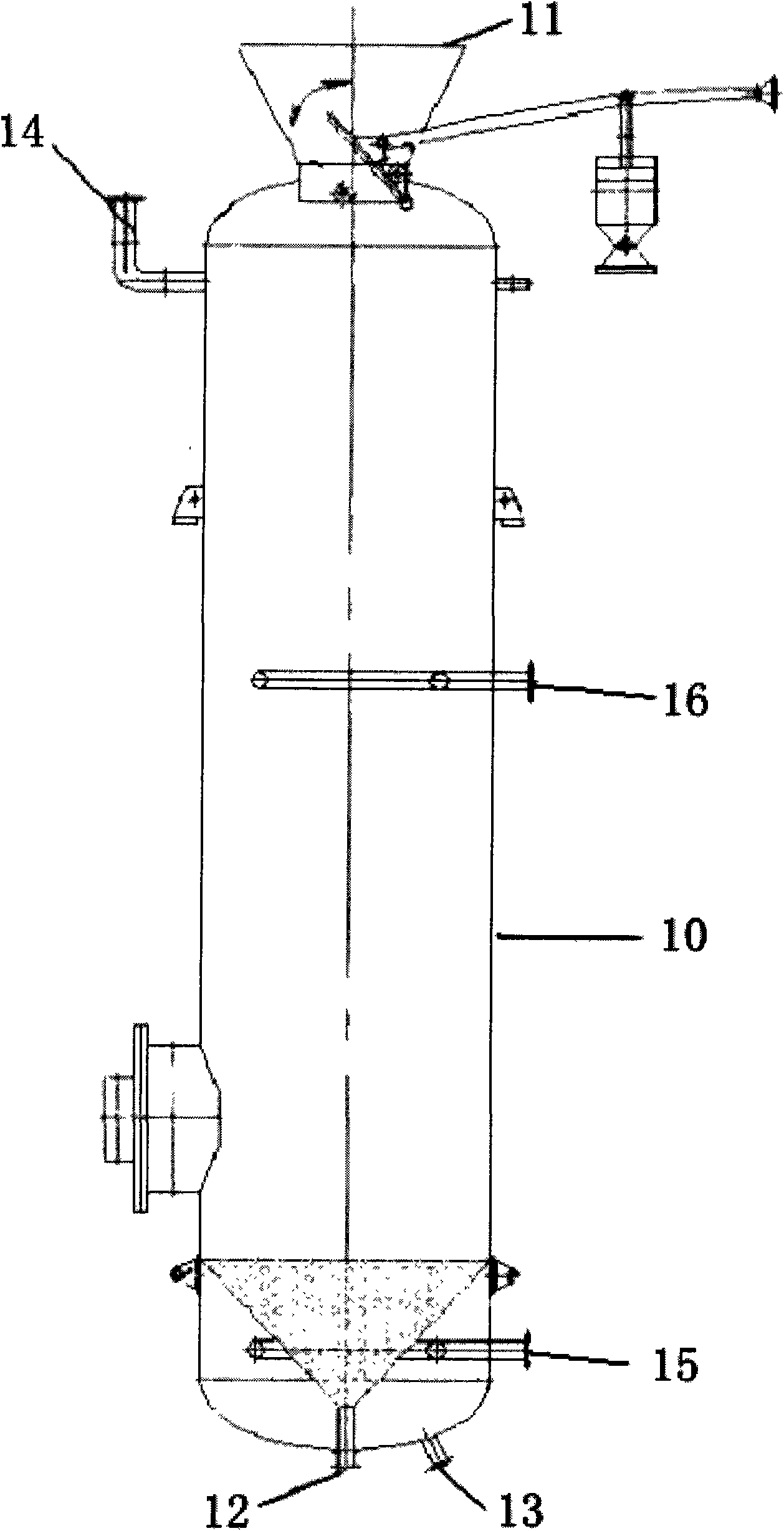

Method for preparing xylooligosaccharide and cellulose by using crop straws

InactiveCN103320548ASolve the problem of comprehensive utilizationSimple production processPaper material treatmentSaccharides productionCelluloseHydrolysate

The invention belongs to the technical field of comprehensive utilization of subsidiary agricultural products, and relates to a method for preparing xylooligosaccharide and cellulose by using a crop straw acid hydrolysis method. The method for preparing the xylooligosaccharide by using the crop straws is used for preparing the xylooligosaccharide by four steps of pretreatment, acid hydrolysis, decoloration and desalination for hydrolysate and concentration drying; and a cellulose product can be obtained by performing alkaline treatment, stewing, pulping and drying on solid residues produced in a xylooligosaccharide preparation process. According to the method for preparing the xylooligosaccharide and the cellulose by using the crop straw, the crop straw is used as a raw material; the xylooligosaccharide and the cellulose are prepared by hot water pretreatment and acid hydrolysis by using the agricultural forest byproducts; the production technology is simple; the practicability is high; the economical value of the product is improved; the difficulty in utilization of the straw is well solved.

Owner:JIAHE BIOTECH

Method for coproduction of xylose, lignin and ethanol from corncobs

The invention discloses a method for the coproduction of xylose, lignin and ethanol from corncobs in the technical field of biochemical industry, comprising the following steps of: 1) hydrolyzing the corncobs under an acidic condition to obtain xylose solution and acidolysis residues; 2) performing alkaline liquor / alcohol extraction on the acidolysis residues to obtain lignin and lignin-free residues; 3) taking the lignin-free residues as an enzymolysis zymolyte, adding enzymolysis buffer solution, and performing enzymolysis using cellulase, thereby obtaining enzymolysis mixed solution; and 4) fermenting the enzymolysis mixed solution to produce ethanol solution. The method of coproduction of the invention comprehensively utilizes three components of the corncobs to obtain high value-added xylose and lignin products; and the cellulose content in the enzymolysis substrate is increased and the accessibility of the cellulase is improved, so that high transformation ratio of cellulose enzymolysis is realized. The method causes the utilization ratio of the lignocellulose raw material to be increased and the production cost of the cellulose ethanol to be reduced.

Owner:TSINGHUA UNIV

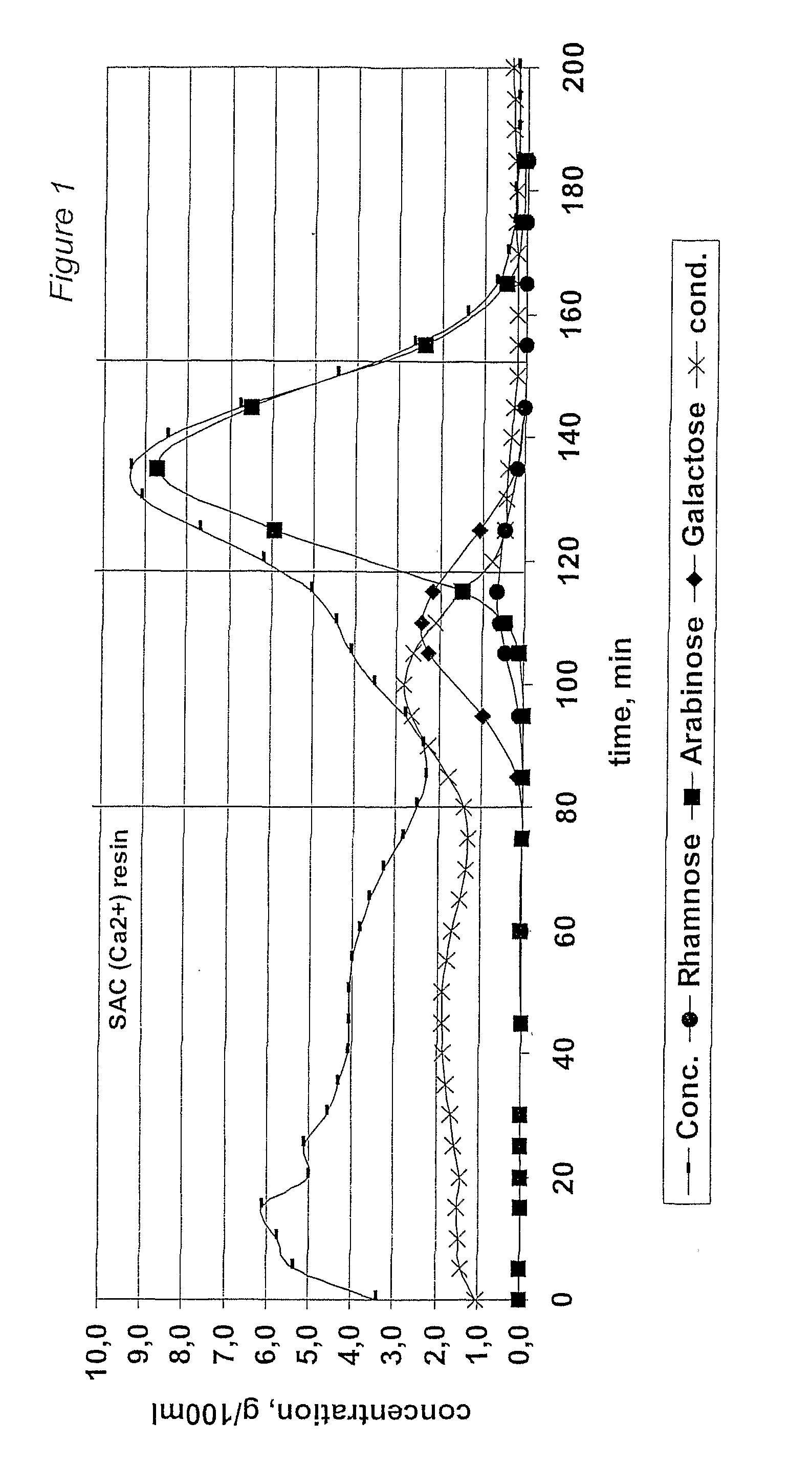

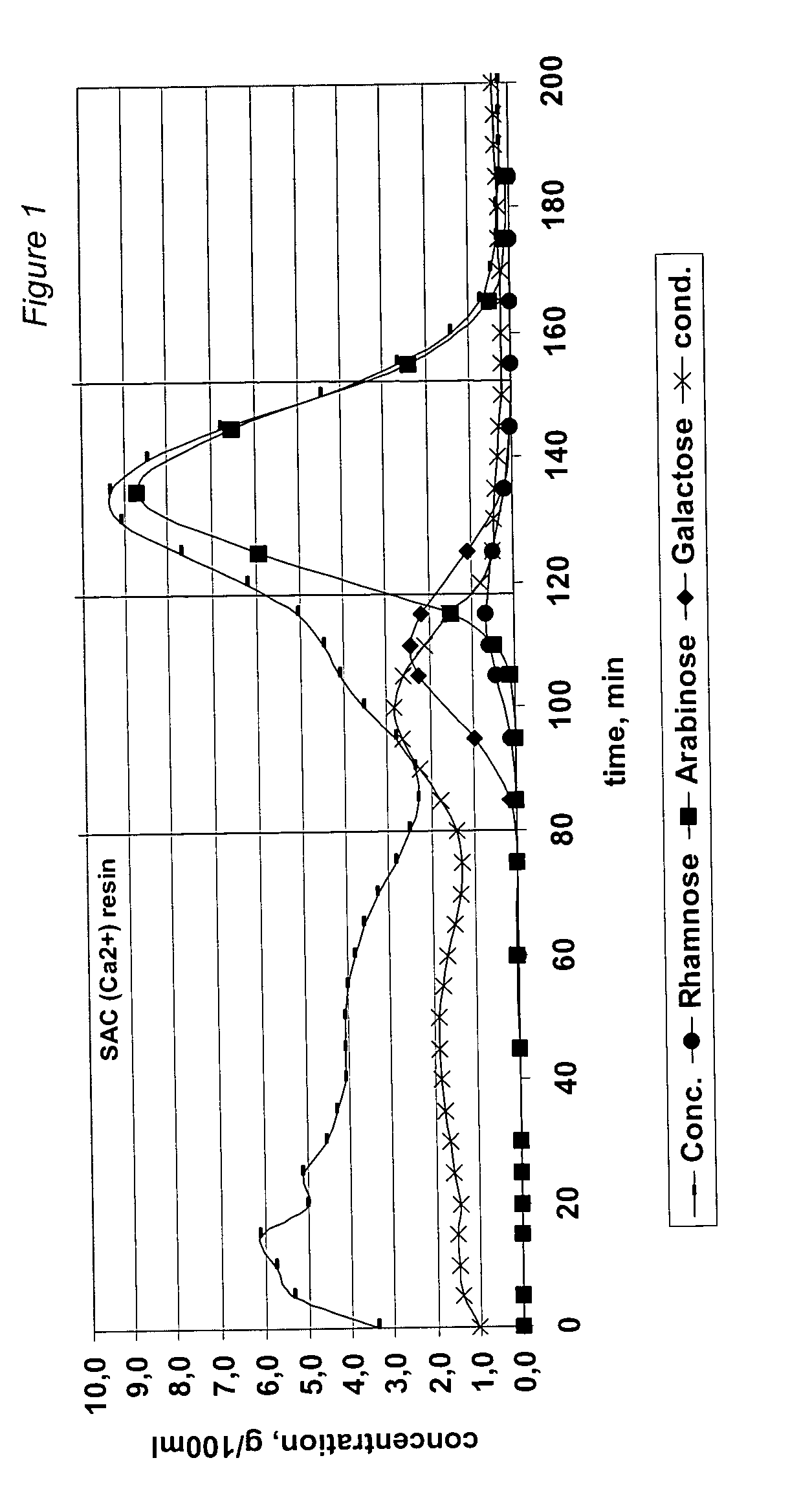

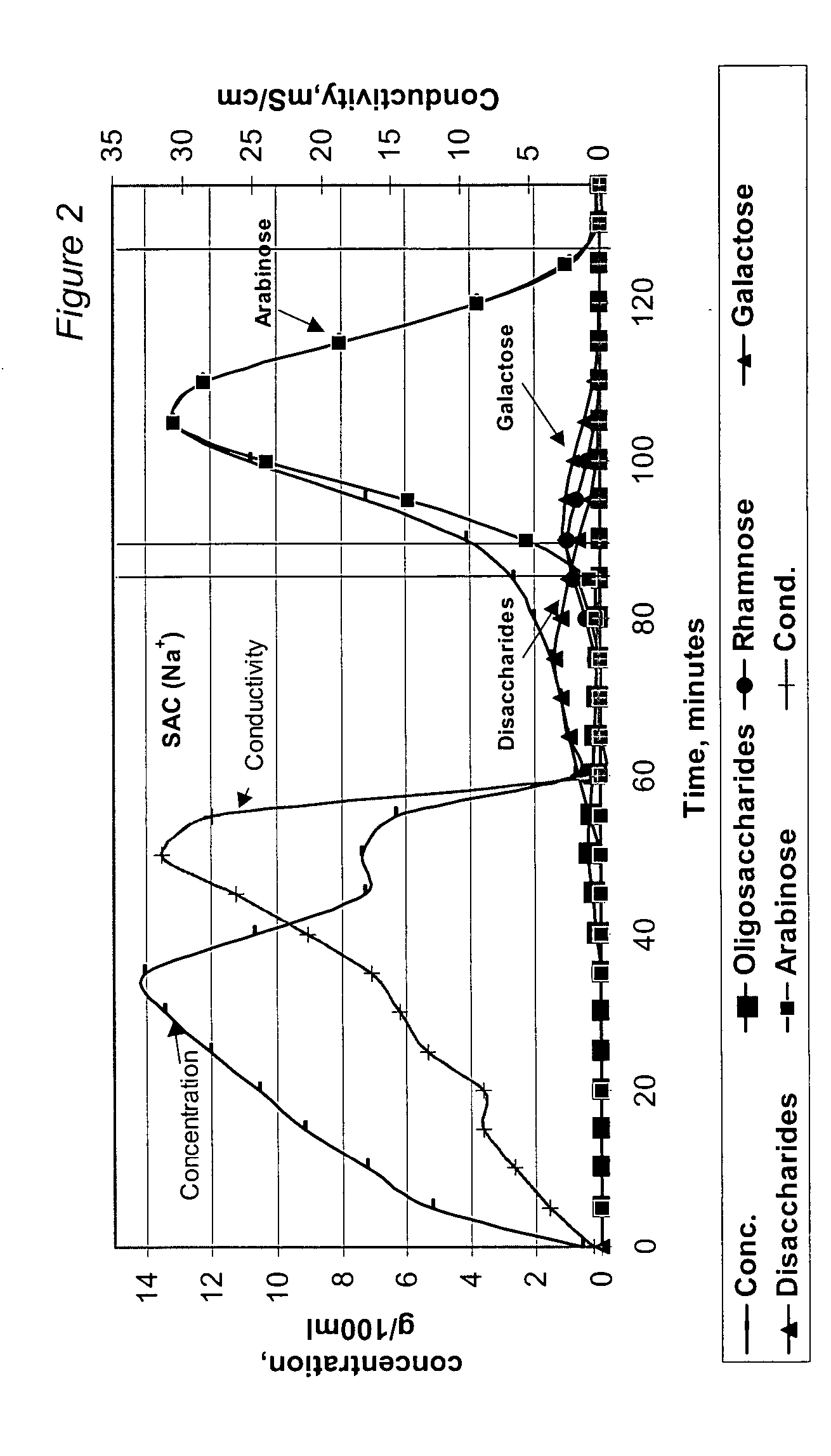

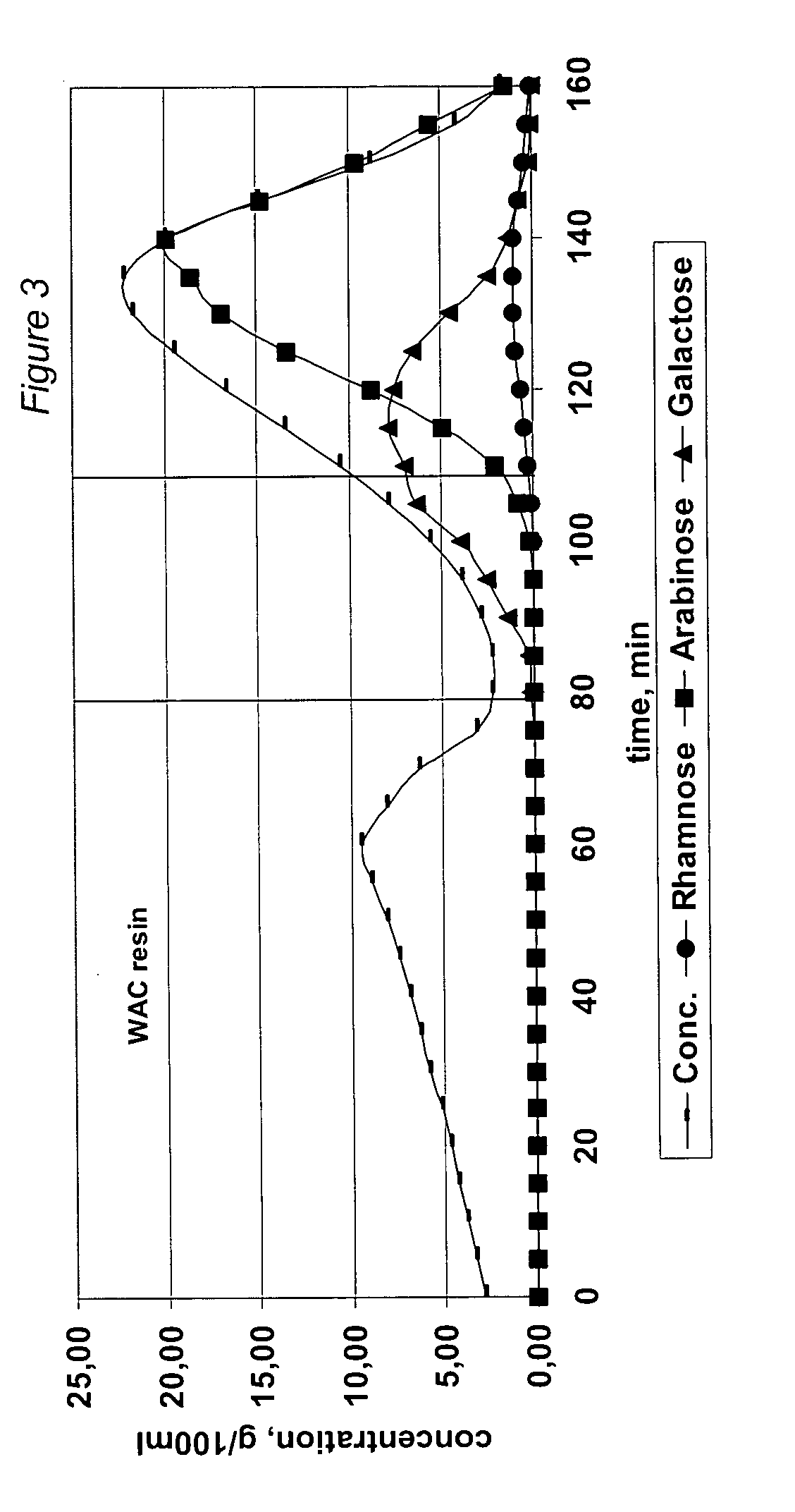

Separation process

InactiveUS20070112187A1High purityHigh yieldSugar derivativesSugar derivatives preparationHydrolysateVegetable fibers

The invention relates to a process of recovering arabinose and optionally other monosaccharides from vegetable fiber rich in heteropolymeric arabinose, such as gum arabic. Said other monosaccharides are typically selected from galactose and rhamnose. The process of the invention comprises controlled hydrolysis of the arabinose-rich vegetable fiber and fractionation of the hydrolysis product to obtain a fraction enriched in arabinose and optionally other product fractions followed by crystallization of arabinose. The invention also relates to a novel method of crystallizing arabinose from biomass-derived material. Furthermore, the invention relates to novel crystalline L-arabinose.

Owner:DANISCO SWEETENERS

Method for improving extraction ratio of trehalose

InactiveCN101230407ATotal production cost reductionAchieving a green circular economySaccharides productionChromatographic separationSimulated moving bed

The invention discloses a method of increasing the extraction yield of trehalose, which belongs to sugar industry technical field. Adopting the techniques of hydrogenation and chromatographic resolution, the microorganism or enzyme are used for transforming the starch and the trehalose obtained undergoes the hydrogenation reaction with the mixing solution of the maltose, glucose and maltotriose; therefore the impurity in the mixing solution produces the maltitol, sorbierite and maltotriitol; the trehalose has no reducibility, and is stable in the hydrogenation reaction; and the trehalose is separated from the maltitol, sorbierite and maltotriitol in the mixing solution by the chromatographic resolution technique simulating the moving bed; and the purity and extraction yield of the trehalose are largely increased; the trehalose is crystallized by cooling, and the trehalose product is finally obtained. Compared with the technique of producing the trehalose by adopting the original microorganism or enzyme method, the technique of the invention increases the extraction yield over 80 percent, the sub product maltitol has a comparatively high utilization value; and therefore the production cost for producing the trehalose and the market price are reduced, which makes sense for increasing the market competition of trehalose.

Owner:FUTASTE PHARM CO LTD

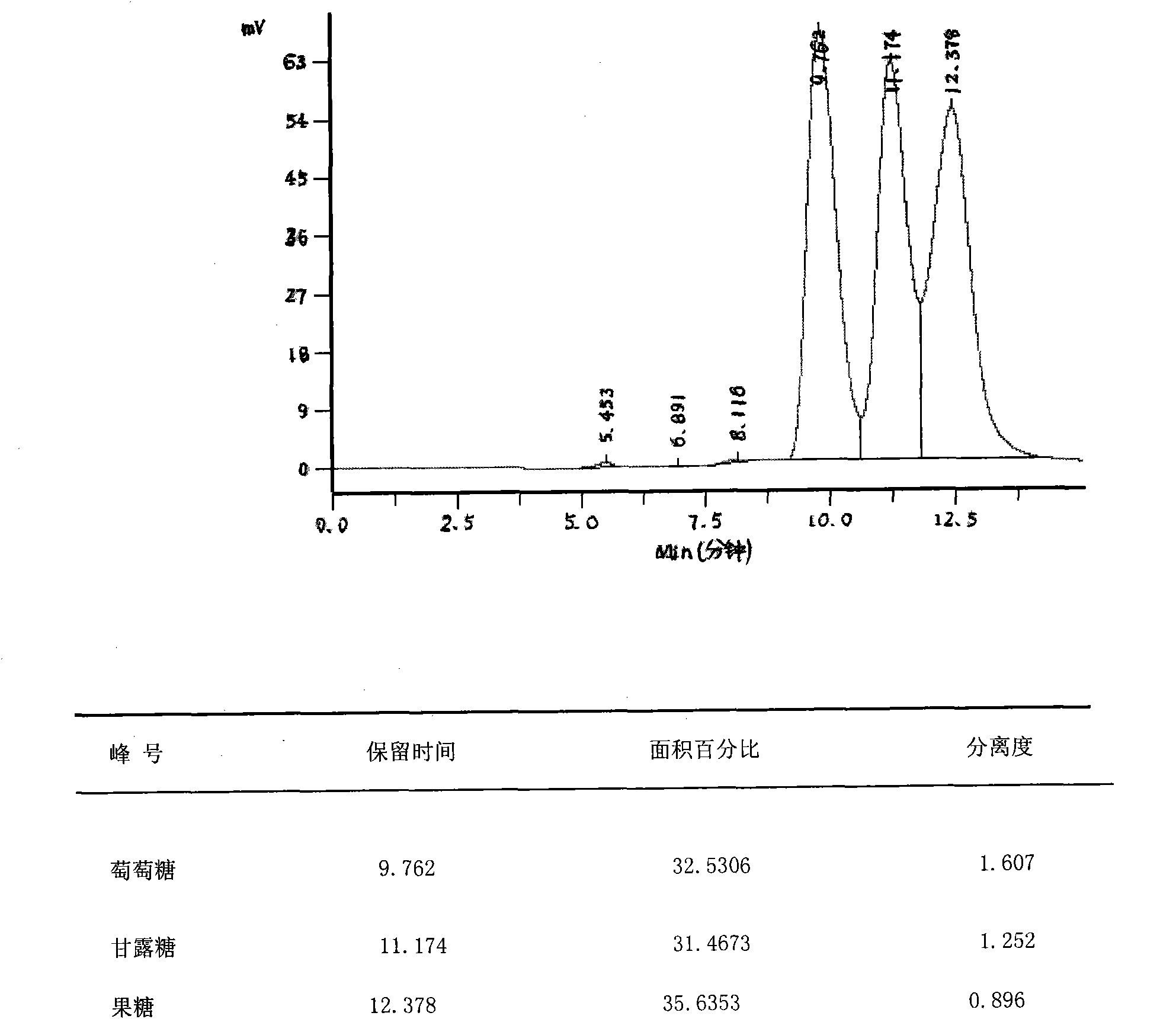

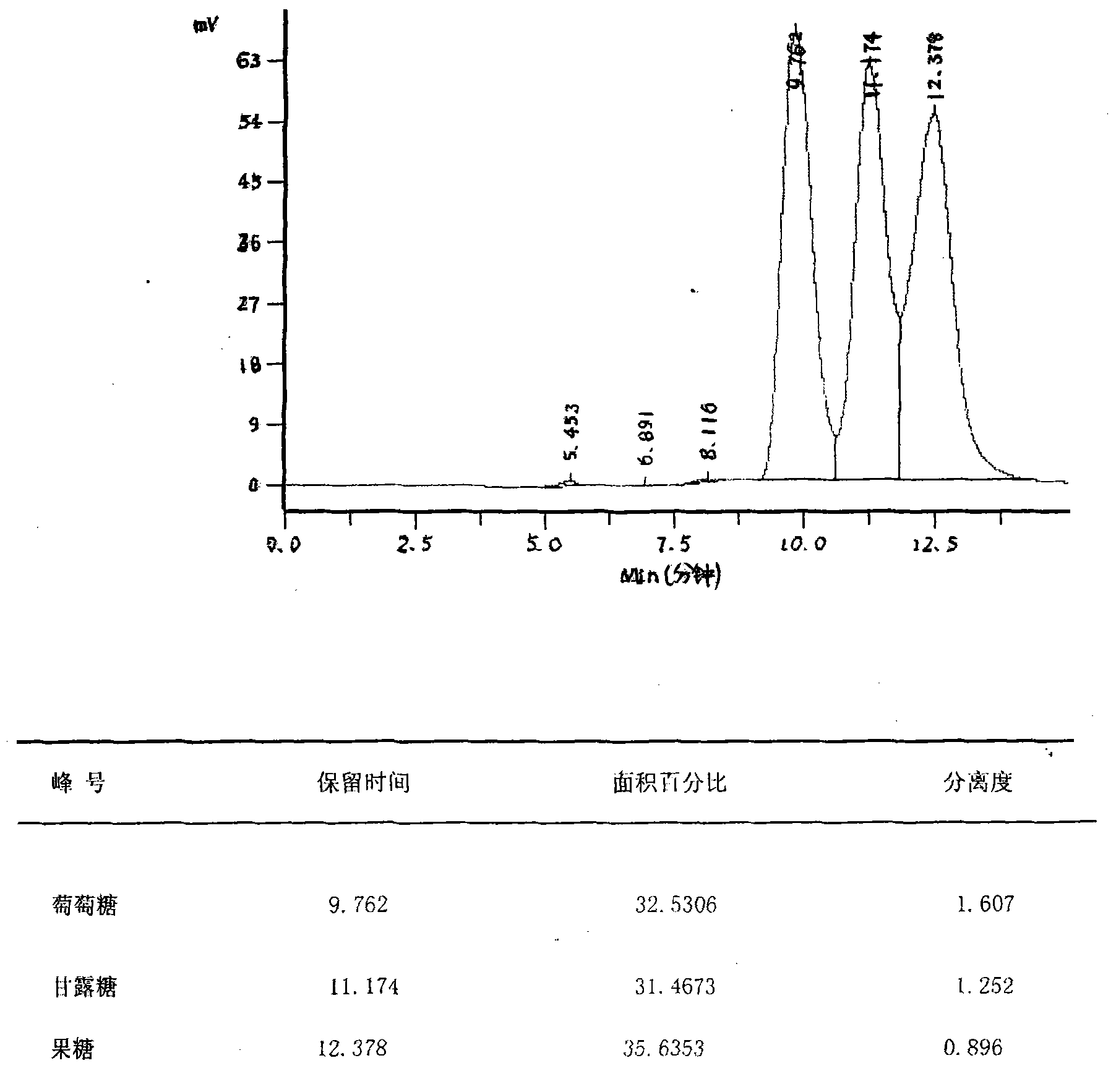

Preparation process of D-mannose

ActiveCN101851689ANo Contamination ConsequencesGuaranteed separation effectSaccharides productionMolybdateAlcohol

The invention discloses a preparation process of D-mannose, which comprises the following steps that: glucose takes molybdate as a catalyst to be epimerized and converted into mannose under acidic conditions; through simulating the separation of a moving bed, a mannose-rich component B1 and a glucose-rich composition A1 are obtained; the glucose-rich component A1 returns to be epimerized; the mannose-rich component B1 is concentrated; the feed liquid is crystallized in an aqueous phase and centrifuged to obtain crystalline D-mannose C1and mannose mother liquor D1; and the crystalline D-mannose C1 is soaked in absolute ethyl alcohol, refined and dried to obtain a high-purity crystalline D-mannose finished product. The invention has simple process, low environmental pollution degree, low production cost and high purity of products.

Owner:石家庄华旭药业有限责任公司

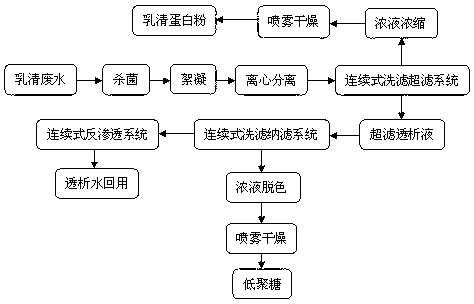

Method for recycling of soybean whey wastewater by membrane separation technology

InactiveCN103012580APrevent rancidityAvoid fouling of ultrafiltration membranesAlbumin peptidesPeptide preparation methodsFiltration membraneUltrafiltration

The invention discloses a method for recycling of soybean whey wastewater by a membrane separation technology. The method includes: sterilization pretreatment; flocculation and centrifugal separation for impurity removal; whey protein recovery by ultrafiltration membrane continuous separation; whey protein powder recovery; oligosaccharide syrup recovery by nanofiltration membrane continuous concentration; oligosaccharide recovery; and dialysis water recovery by reverse osmosis membrane continuous concentration. The method provided in the invention can avoid whey wastewater rancidity and ultrafiltration membrane pollution and plugging, and improves the product quality. Employment of the continuous separation concentration mode reduces stay of intercepted objects or protein, impurity concentrated liquors in a membrane assembly to the utmost, and back-and-forth circulation between a membrane liquid inlet tank and a membrane system no longer exists. Meanwhile, the membrane surface flow speed is controlled, so that the problems of membrane pollution and low separation efficiency are solved. An osmosis filtration membrane washing process is adopted, and water is added automatically for filter wash, so that the membrane pollution and plugging problems are solved, and the product quality is improved. The selection of high temperature resistant hydrophilic membrane materials guarantee a high water flux and help to reduce membrane pollution.

Owner:上海诚洲科技中心(有限合伙)

Separation process

ActiveUS20100213130A1Lower the volumeLower energy requirementsIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Simulated moving bed adsorptive separation process for handling multiple feedstocks

InactiveUS8008536B2Increase capacityIncrease flexibilitySolid sorbent liquid separationHydrocarbonsSorbentSimulated moving bed

An improved process for the production capacity and feedstock handling flexibility of a simulated moving bed adsorptive separation process by introducing a second feed stream to the adsorbent chamber comprising a feed material of a different concentration of the desired compound than the concentration of the desired compound in the first feed material stream. The introduction of this second feed material stream may be performed at any location on the adsorbent chamber between (i) a transfer point located immediately upstream of the point of the raffinate material stream withdrawal from the adsorbent chamber to (ii) a transfer point located immediately downstream of the point of extract material stream withdrawal from the adsorbent chamber. A recycle stream may be introduced into the system at a location having a concentration similar to the concentration of the first feed material stream.

Owner:WINTER GEORGE R +1

Solvolysis of biomass using solvent from a bioreforming process

ActiveUS20120167875A1Hydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionSolventSolvolysis

Owner:VIRENT

Method for coproducing xylose, white carbon black and active carbon from rice hulls

InactiveCN102071267AHigh yieldTake advantage ofSilicaSaccharides productionActivation methodPorosity

A method for coproducing xylose, white carbon black and active carbon from rice hulls comprises the following steps that: the rice hulls are washed and boiled by water, and the xylose is hydrolyzed by diluted acid; low-temperature carbonization is carried out, then, reaction with concentrated alkaline is taken to extract silicon dioxide, and the white carbon black is prepared by a coprecipitation method; and solid is added into liquor zinci chloride to be soaked for a certain time at a low temperature, then, high-temperature activation and acid washing are carried out, the materials are washed by water to the neutral state, and the materials are dried and ground to obtain active carbon. In the method provided by the invention, one line is adopted for coproducing the xylose, the white carbon black and the active carbon with high specific surface area in a branch way, the xylose preparation process for continuously hydrolyzing the hemicellulose in the rice hulls is adopted for the xylose, the xylose yield is improved, the method belongs to a simple and feasible xylose preparation process, the white carbon black is prepared by adopting an advanced chemical coprecipitation method, higher dispersing degree of the precipitation particles is maintained through adding surfactants into a solution system, and high-purity and ball-shaped white carbon black particles are prepared. The active carbon is activated by adopting the chemical activation method, the activation temperature is low, micro carbon crystals with small dimension can be favorably formed, and the active carbon with more developed porosity and better absorption performance can be obtained. The method provided by the invention has the advantages that the integrated and sufficient utilization of the rice hulls is realized, the maximum use of raw materials is realized, the integrated investment is low, the process technology is simple, and the industrialized production is easy to realize.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Separation process

InactiveUS20050096464A1High purityFew process stepsSugar derivativesSugar derivatives preparationHydrolysateFractionation

The invention relates to a process of recovering arabinose and optionally other monosaccharides from vegetable fiber rich in heteropolymeric arabinose, such as gum arabic. Said other monosaccharides are typically selected from galactose and rhamnose. The process of the invention comprises controlled hydrolysis of the arabinose-rich vegetable fiber and fractionation of the hydrolysis product to obtain a fraction enriched in arabinose and optionally other product fractions followed by crystallization of arabinose. The invention also relates to a novel method of crystallizing arabinose from biomass-derived material. Furthermore, the invention relates to novel crystalline L-arabinose.

Owner:DANISCO SWEETENERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com