Patents

Literature

148results about How to "Solve the problem of comprehensive utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

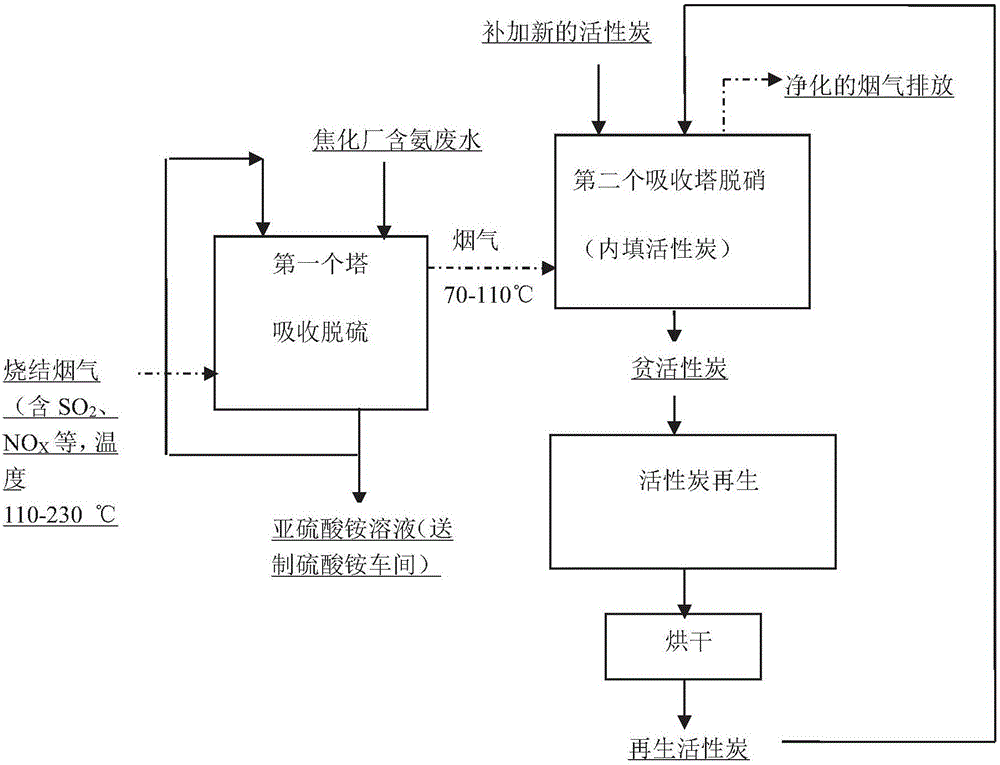

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

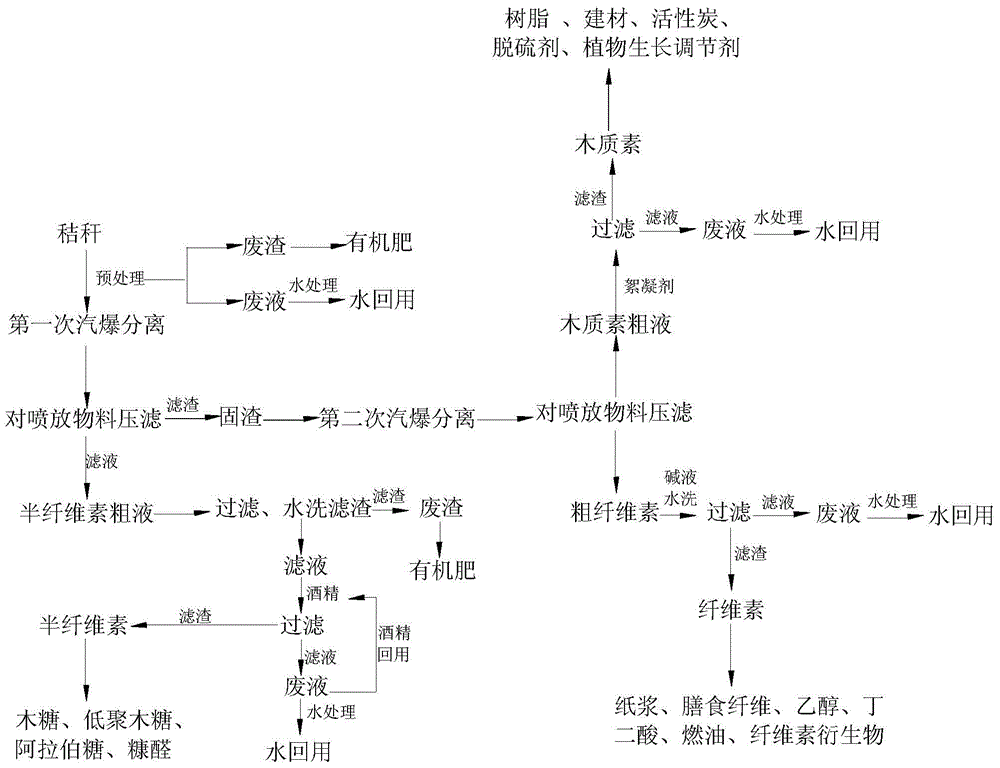

Straw component separation and straw component full utilization method

ActiveCN104404803AAchieve separationEasy to separateRaw material divisionSeparation technologyWastewater

The invention discloses a straw component separation and straw component full utilization method, and relates to the technical field of straw comprehensive utilization. According to the method, straws are subjected to a steam explosion treatment, such that hemicellulose is first separated; and the rest of the material after hemicellulose extraction is subjected to steam explosion treatment again, such that the separation of cellulose and lignin is realized. The method has the advantages of simple process, environment-friendliness, low cost, and thorough separation of hemicellulose, cellulose and lignin. With the method provided by the invention, an environment-friendly separation technology of cellulose and lignin is realized for the first time internationally, and a basis is provided for full-element, high-added-value and comprehensive utilization of straws. On the basis, products with higher added values can be derived or generated. With the production process provided by the invention, all wastewater is treated and is completely recycled, and all waste residue is used for producing organic fertilizers, such that straws are thoroughly utilized, and straw component full utilization is realized. Also, zero emission and zero pollution are realized, such that the difficulty of straw comprehensive utilization is solved.

Owner:JINAN MIDUOTAN NEW ENERGY TECH

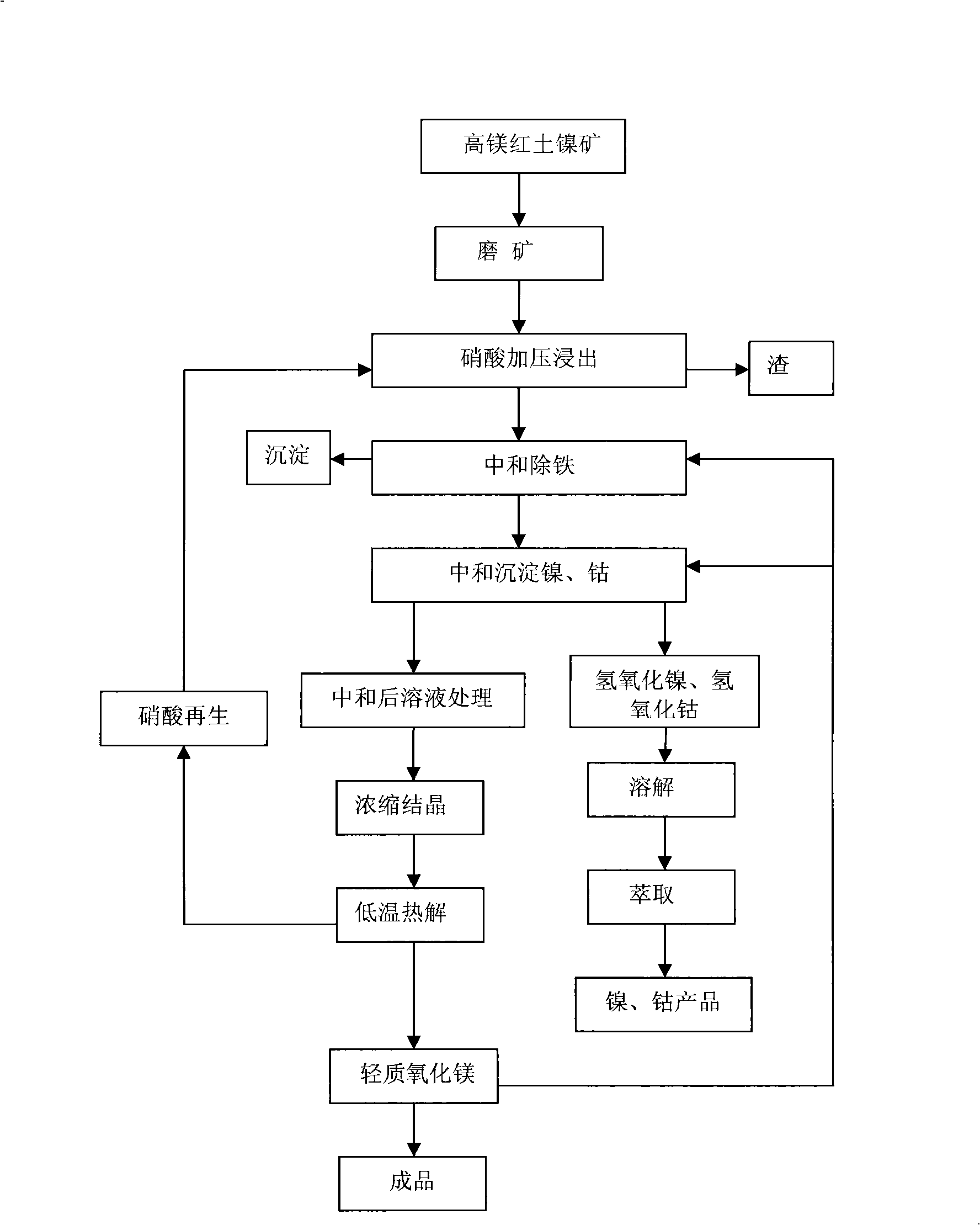

Treating method for high magnesium laterite nickel mine

InactiveCN101289704AEfficient extractionEfficient leachingProcess efficiency improvementPregnant leach solutionHigh magnesium

The invention discloses a method for treating high magnesium laterite-nickel ores. The method comprises the following steps of preliminary treatment of ore, pressurized leaching, iron purification of leach solution, deposition of nickel and cobalt, condensation and crystallization, production of light magnesium oxide by low-temperature thermal decomposition of crystals and regeneration of nitric acid. Under mild conditions of low temperature and pressure, leaching ratios of nickel and cobalt both reach 95 percent, the leaching ratio of magnesium reaches 98 percent, the iron content in the leach solution is less than 1g / L, and no silicon dioxide is leached out. The method can fully recover nickel, cobalt and magnesium, and the magnesium is generated in the form of light magnesium oxide, and the leaching agent-nitric acid can be recovered and regenerated for n, thereby better resolving the problems of highly efficient leaching-out of nickel and cobalt and reasonable utilization of magnesium; moreover, the technical flow is simple and has low requirements on equipment, and in the process of leaching out, the scab phenomenon does not occur in a high-pressure pan, so that the method is applied to the large-scale industrial production.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

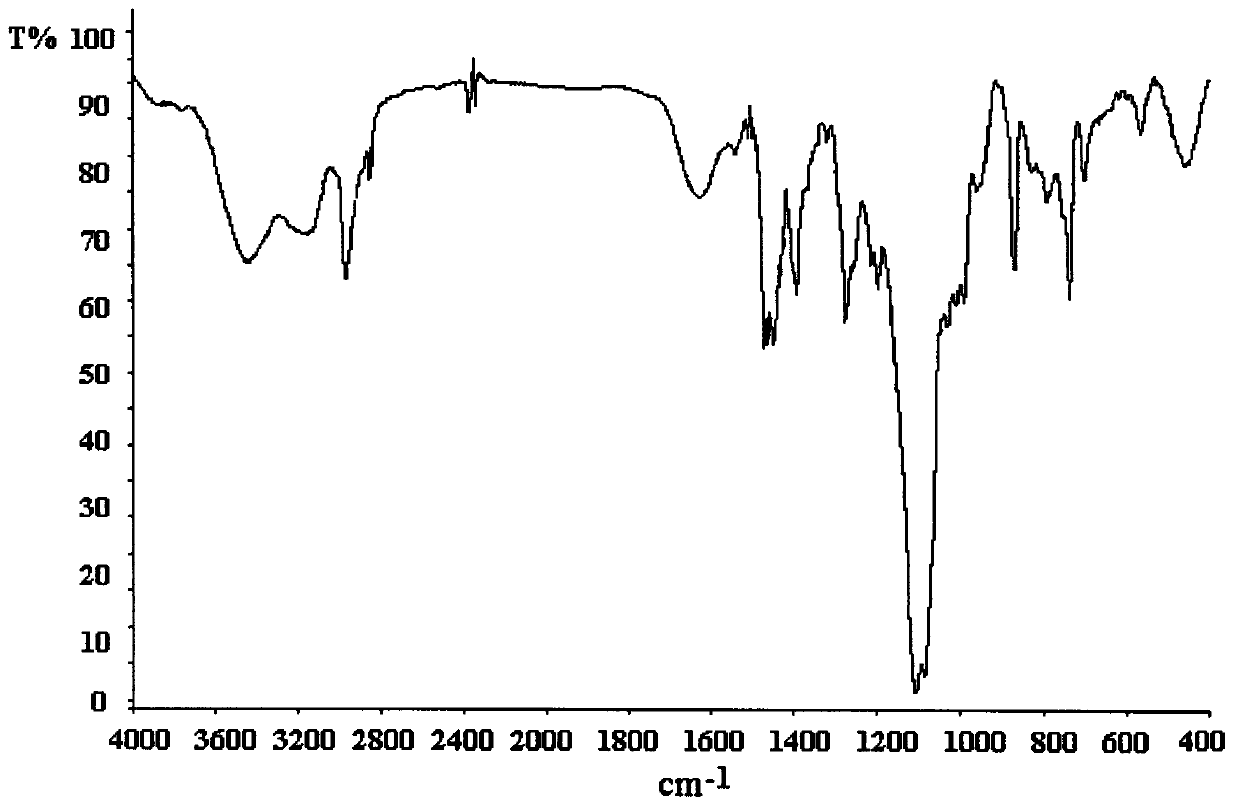

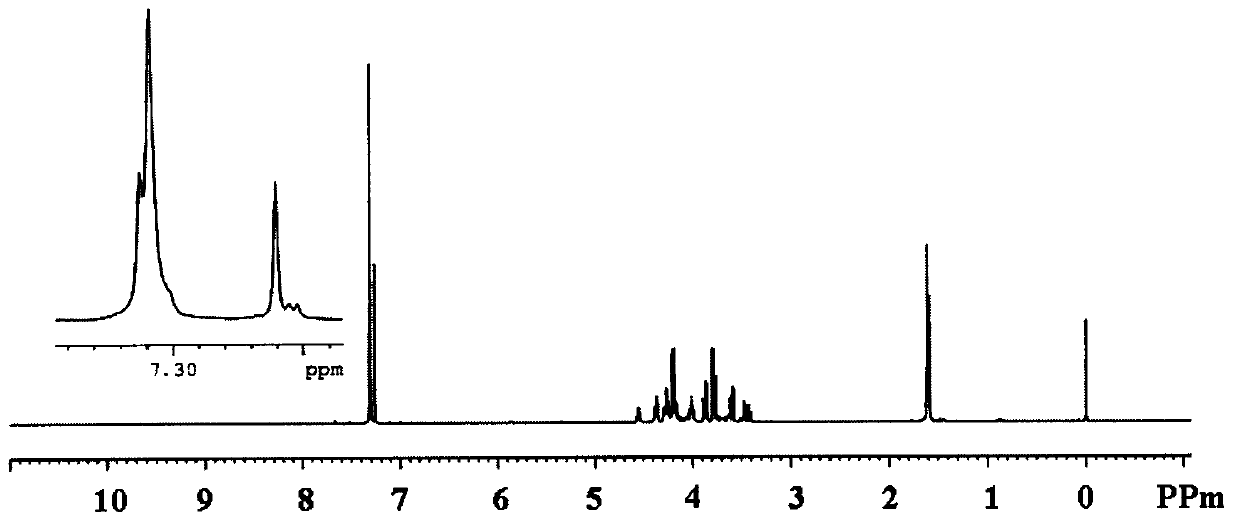

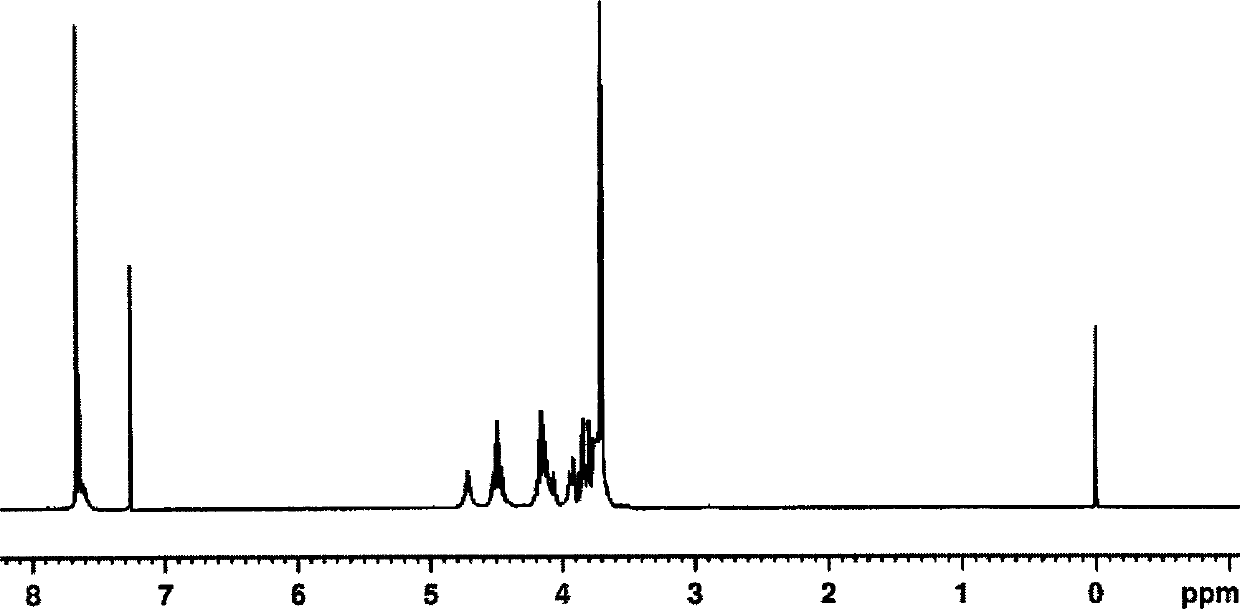

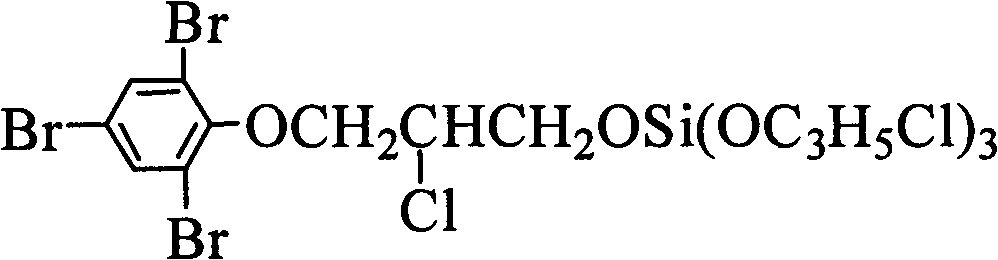

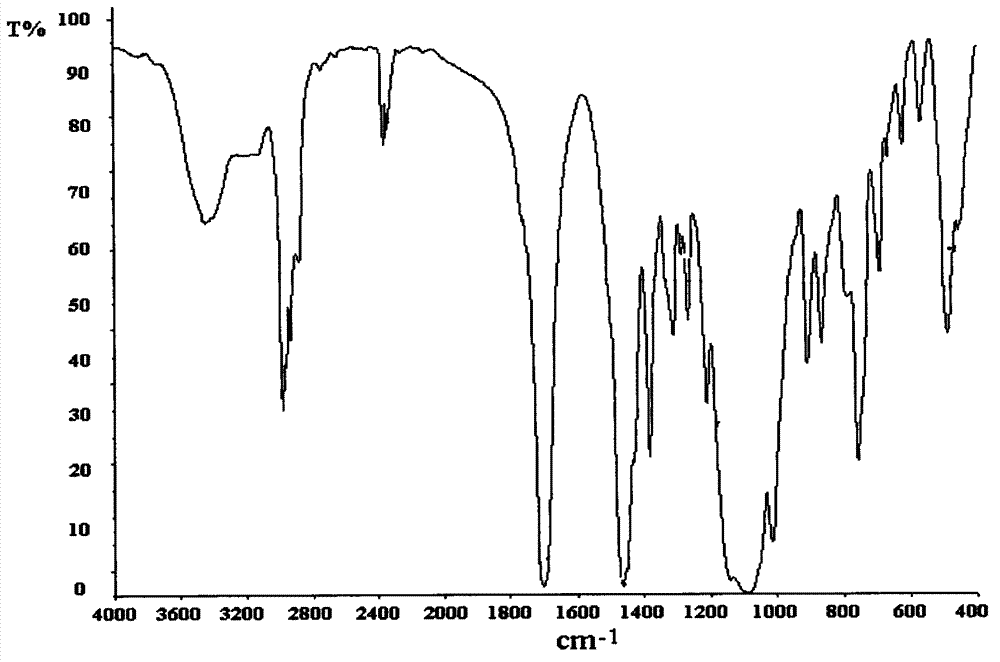

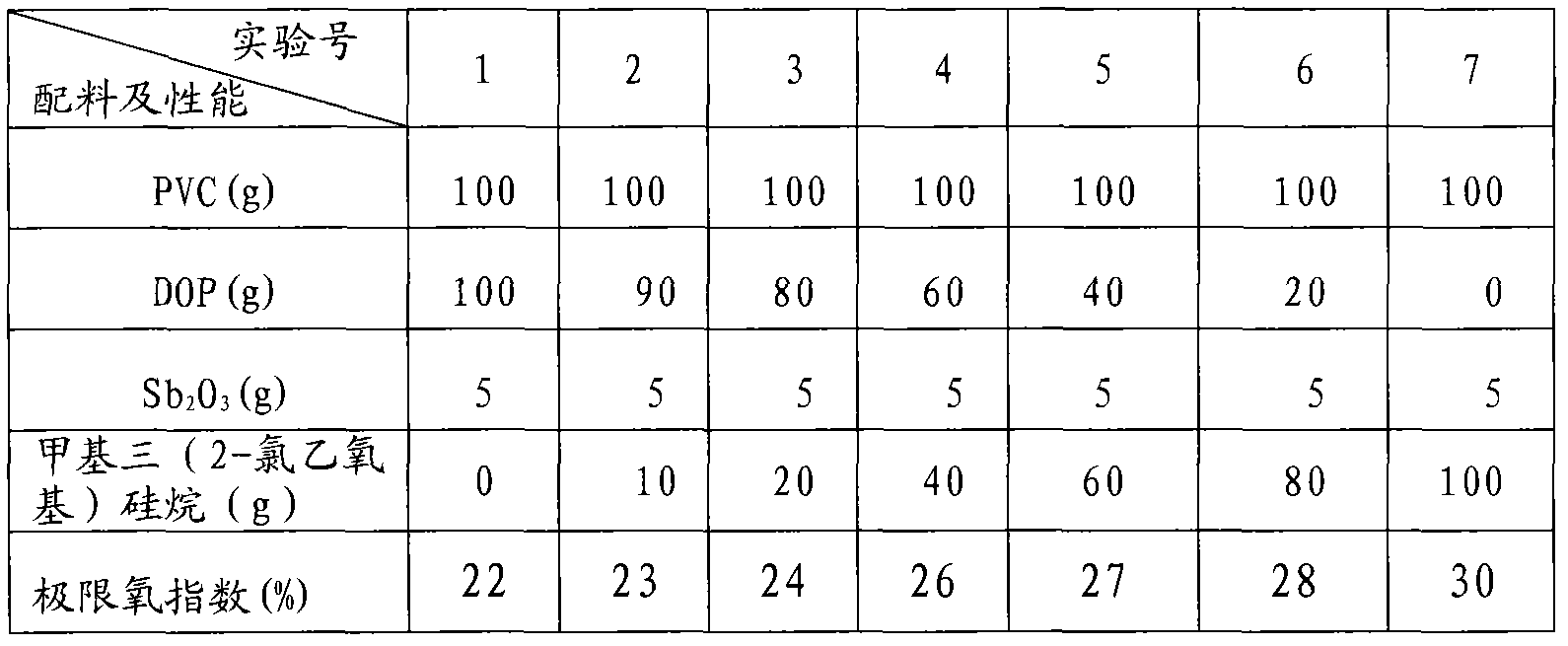

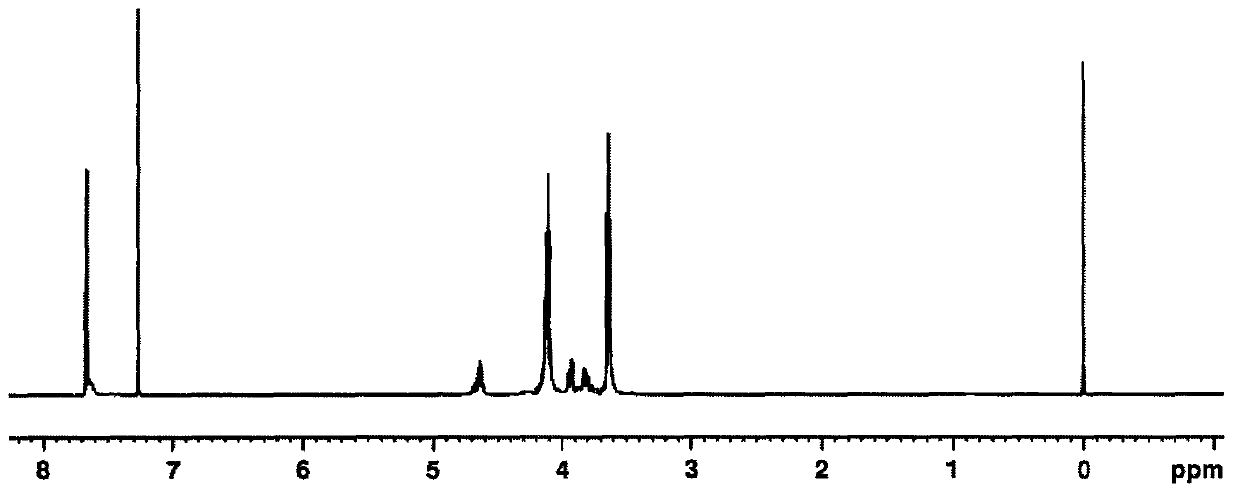

Tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound and preparation method thereof

ActiveCN102731553AGood symmetryPhysicochemically stableSilicon organic compoundsOrganic solventHalogen

The invention relates to a tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound which is a silicon-halogen synergistic fire retardant, and a preparation method of the compound. The compound has a structure shown in a formula described in the specification; and in the formula, OC3H5Cl2 is OCH2CHClCH2Cl or OCH (CH2Cl) 2. The preparation method of the compound comprises the following steps: reacting tribromophenyl glycidyl ether and silicon tetrachloride according to the same molar ratio in an organic solvent for 4-6h at 60-80 DEG C; then dropwise adding dichloropropanol according to a certain molar ratio, reacting for 4-8h at 50-100 DEG C; and finally purifying to obtain faint yellow liquid which is the tris(dichloropropyl) tribromophenoxy chloropropyl silicate. The compound is applicable to fire retardants for polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and other materials; and the production process is simple, low in equipment investment and cost, and suitable for industrial production.

Owner:张家港市乐余科创园投资发展有限公司

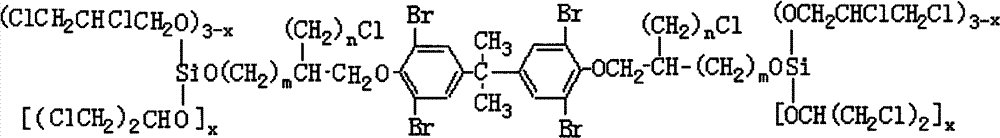

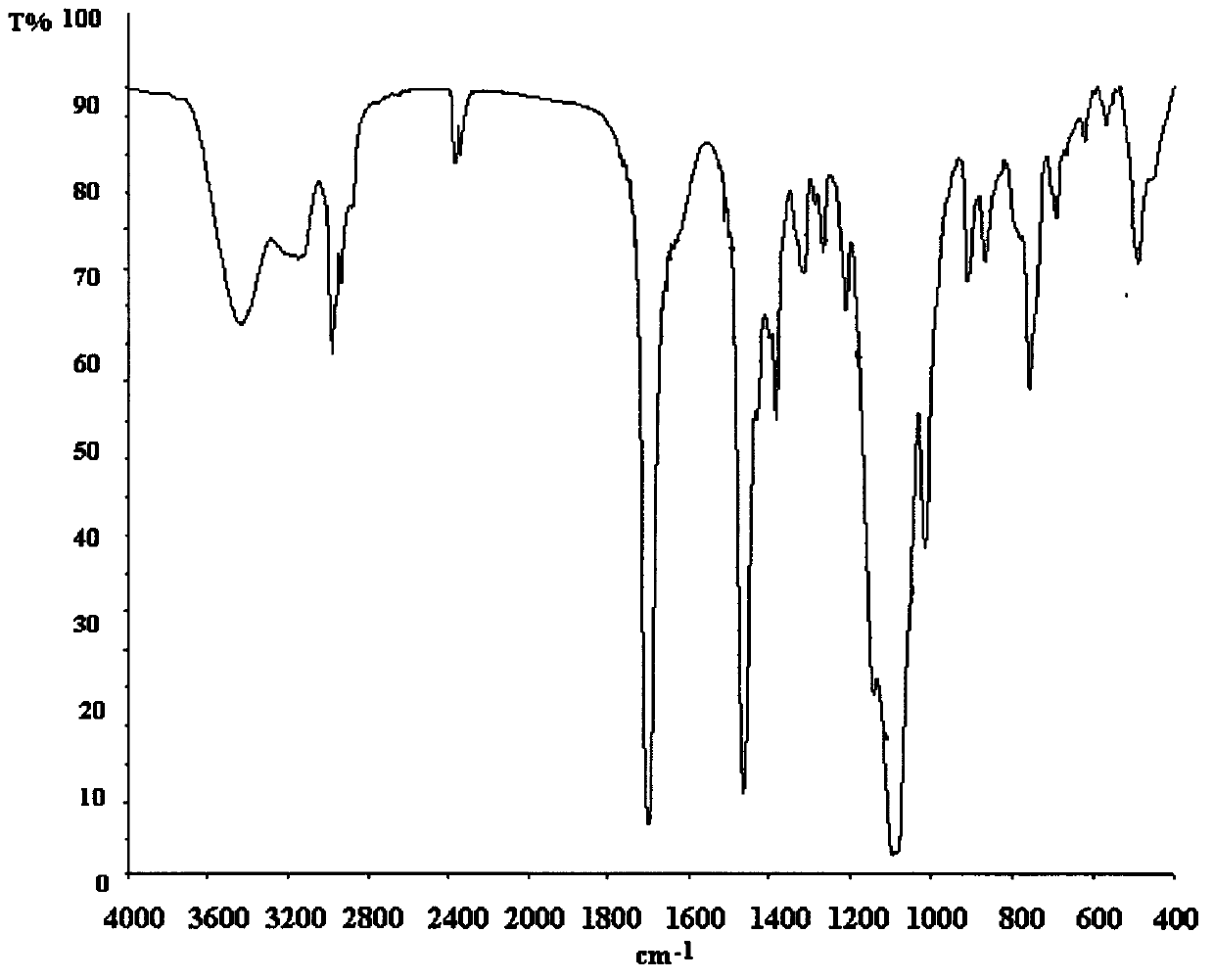

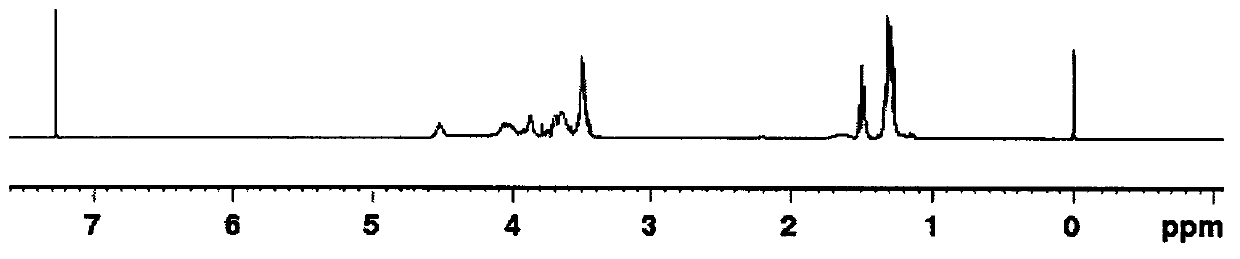

Novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and preparation method thereof

ActiveCN102775431AGood structural plasticityHigh synergistic flame retardant performanceSilicon organic compoundsTetrabromobisphenol APolyvinyl chloride

The invention relates to a novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and a preparation method thereof, and in particular relates to a silicon halide coordinate flame retardant plasticizer tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether compound and a preparation method. The structure of the compound is expressed by the following formula: n is equal to 1 when m is 0, the n is equal to 1 when the m is 1, and x is 0, 1, 2 or 3. The preparation method comprises the following steps of: under stirring, dissolving tetrabromobisphenol A bisepoxy propyl ether in an organic solvent; dropping the mixture in silicon tetrachloride at the temperature of 25 DEG C; after dropping, carrying out insulation reaction for 3-4 hours at the temperature of 70-80 DEG C; dropping epoxychloropropane according to a certain mole ratio; reacting for 7-8 hours at the temperature of 80-100 DEG C; and carrying out purification treatment to obtain the tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether. The product isa good flame retardant plasticizer, and is suitable for being used as a flame retardant plasticizing additive such as epoxy resin, polyvinyl chloride, unsaturated polyester resin, and polyurethane.

Owner:SUZHOU UNIV OF SCI & TECH

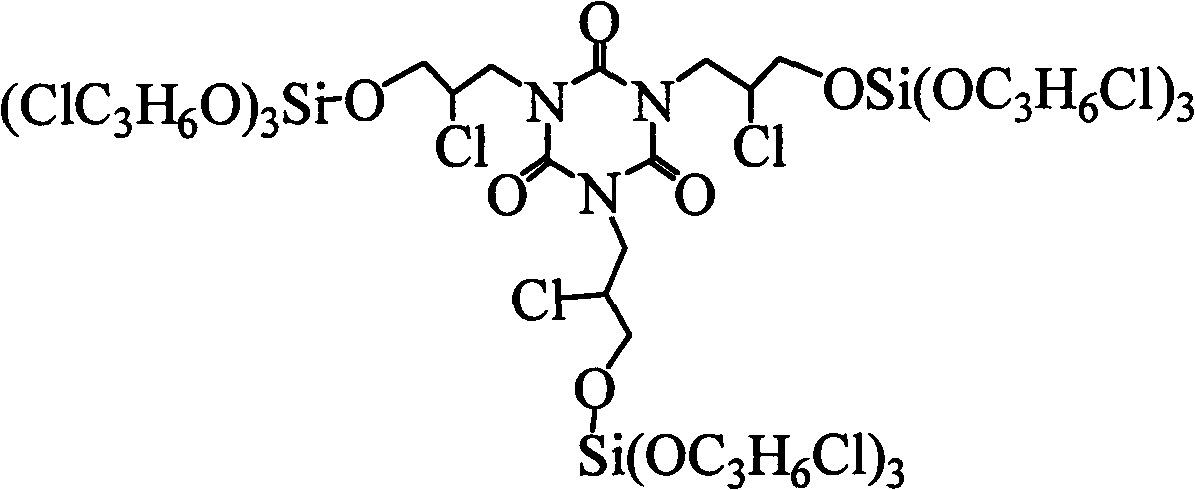

Triazinetri-tri(chloropropyl) silicate compound and preparation method thereof

ActiveCN102731549AGood symmetryStable molecular structureSilicon organic compoundsPlasticizerSilicon tetrachloride

The invention relates to a silicon-halogen synergic flame retardant triazinetri-tri(chloropropyl) silicate compound and a preparation method thereof, in particular to a tri{2-chloro-3-[tri(chloropropoxy)siacryloxy]propyl}isocyanurate compound and a preparation method thereof. The compound has the structural formula shown in the specification, wherein OC3H6Cl is OCH2CHClCH3 or OCH2CH2CH2Cl or OCH(CH3)CH2Cl. The preparation method comprises the following steps of: controlling a certain molar ratio of raw materials; enabling triepoxypropylisocyanurate to react with silicon tetrachloride at 60 DEG C for 4-6 hours in an organic solvent; adding epoxypropane and reacting at 50-60 DEG C for 4-6 hours; and purifying to obtain the product triazinetri-tri(chloropropyl) silicate. The triazinetri-tri(chloropropyl) silicate provided by the invention has good flame-retardant plasticizing property and is suitable to be used as a flame-retardant plasticizer of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the production technology is simple, the cost is low, and the industrial production is easy to realize.

Owner:张家港市乐余科创园投资发展有限公司

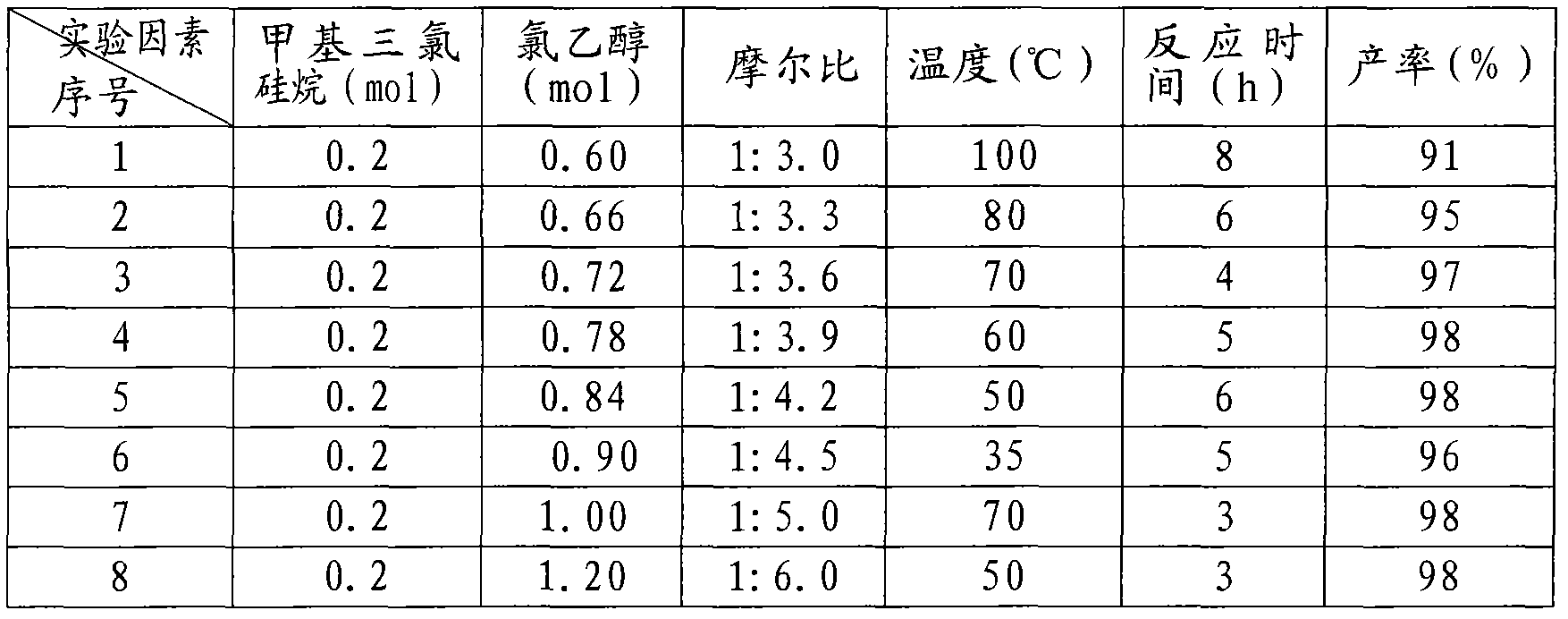

Methyl tri(2-chloroethoxy) silane compound and preparation method thereof

ActiveCN102174055AStabilize the C-Si bond structureSymmetrical ester structureGroup 4/14 element organic compoundsSilane compoundsHalogen

The invention relates to a methyl tri(2-chloroethoxy) silane compound which is used as a silicon-halogen synergistic flame-retardant plasticizer and a preparation method thereof. The methyl tri(2-chloroethoxy) silane compound has the following structural formula: CH3Si(OCH2CH2Cl)3. The preparation method of the methyl tri(2-chloroethoxy) silane compound comprises the following steps: dropwise adding and stirring chloroethanol at a certain molar ratio to methyl trichlorosilane, carrying out a reaction on the chloroethanol and the methyl trichlorosilane for a certain time at a certain temperature, and purifying after finishing hydrogen chloride release and reaction to obtain methyl tri(2-chloroethoxy) silane. The methyl tri(2-chloroethoxy) silane can be used as the good flame-retardant plasticizer, and the process for producing the methyl tri(2-chloroethoxy) silane is simple, has low equipment investment and cost and is easy to realize industrial production.

Owner:河南森远科技有限公司

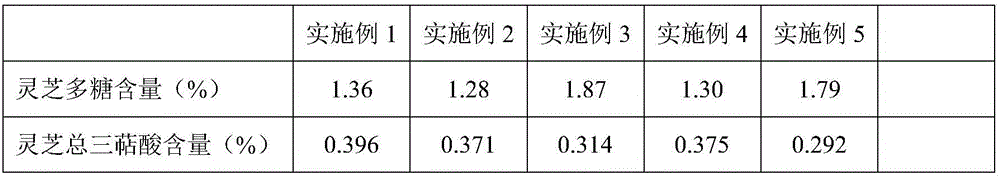

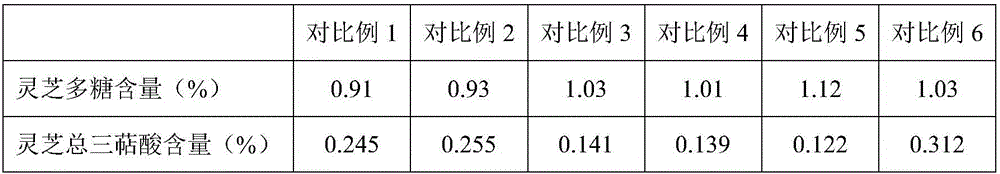

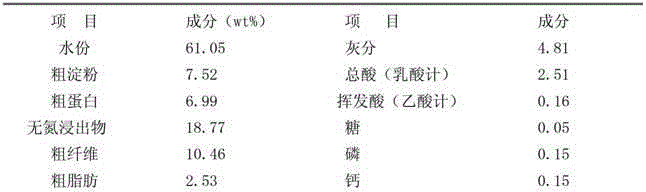

Method for cultivating ganoderma lucidum karst

The invention belongs to the technical field of artificial cultivation of medicinal fungi, and particularly relates to a method for cultivating ganoderma lucidum karst. The method includes the steps of obtaining ganoderma lucidum karst mother species, ganoderma lucidum karst protospecies and ganoderma lucidum karst cultispecies respectively, and conducting substitute cultivation of the ganoderma lucidum karst cultispecies to obtain ganoderma lucidum karst, wherein a cultispecies culture medium is prepared from corn straw, sawdust, pig manure, cow dung, rapeseed meal, humic acid, an amillariella mellea fermented liquid, a bacillus subtilis fermentation liquid and gypsum, and a culture medium of the substitute cultivation is same as the cultispecies culture medium. According to the method, the yield of ganoderma lucidum karst sporophore and conidial powder is significantly improved, and the contents of effective components, like ganoderma lucidum karst polysaccharide and ganoderma lucidum karst total triterpenoid, are significantly improved.

Owner:北京京诚生物科技有限公司

Method for producing microbe feed probiotics by using white spirit vinasse

ActiveCN103141666AStrengthen intestinal mucosal tissueFacilitate absorption and utilizationFood processingAnimal feeding stuffNutrientChemistry

The invention relates to a method for producing microbe feed probiotics by using white spirit vinasse. The method comprises the following steps of: (1) adding water in the vinasse, sieving, adding an acid proteinase solution, hydrolyzing, regulating the pH value, adding a glucoamylase solution, hydrolyzing and concentrating to prepare a vinasse extracting solution; (2) mixing Bullard saccharomycetes fermentation liquor, lactobacillus plantarum and bacillus licheniformis fermentation liquor to prepare a mixed liquor, and separating thallus in the mixed liquor to prepare a mixed wet thallus; (3) preparing a protecting liquor and a compound carrier; and (4) uniformly mixing the mixed wet thallus with the protecting liquor, then adding the vinasse extracting solution and the compound carrier, and drying after uniform mixing to prepare the microbe feed probiotics. According to the method, the microbe feed probiotics are prepared by using the vinasse as the main material, adding a proper amount of nutrient substances and cultivating three probiotics in the liquid form, so that the additional value of the vinasse is improved; and the vinasse is processed by a microbe fermenting method, so that the problem of utilization of the vinasse is solved.

Owner:QILU UNIV OF TECH +1

Method for preparing xylooligosaccharide and cellulose by using crop straws

InactiveCN103320548ASolve the problem of comprehensive utilizationSimple production processPaper material treatmentSaccharides productionCelluloseHydrolysate

The invention belongs to the technical field of comprehensive utilization of subsidiary agricultural products, and relates to a method for preparing xylooligosaccharide and cellulose by using a crop straw acid hydrolysis method. The method for preparing the xylooligosaccharide by using the crop straws is used for preparing the xylooligosaccharide by four steps of pretreatment, acid hydrolysis, decoloration and desalination for hydrolysate and concentration drying; and a cellulose product can be obtained by performing alkaline treatment, stewing, pulping and drying on solid residues produced in a xylooligosaccharide preparation process. According to the method for preparing the xylooligosaccharide and the cellulose by using the crop straw, the crop straw is used as a raw material; the xylooligosaccharide and the cellulose are prepared by hot water pretreatment and acid hydrolysis by using the agricultural forest byproducts; the production technology is simple; the practicability is high; the economical value of the product is improved; the difficulty in utilization of the straw is well solved.

Owner:JIAHE BIOTECH

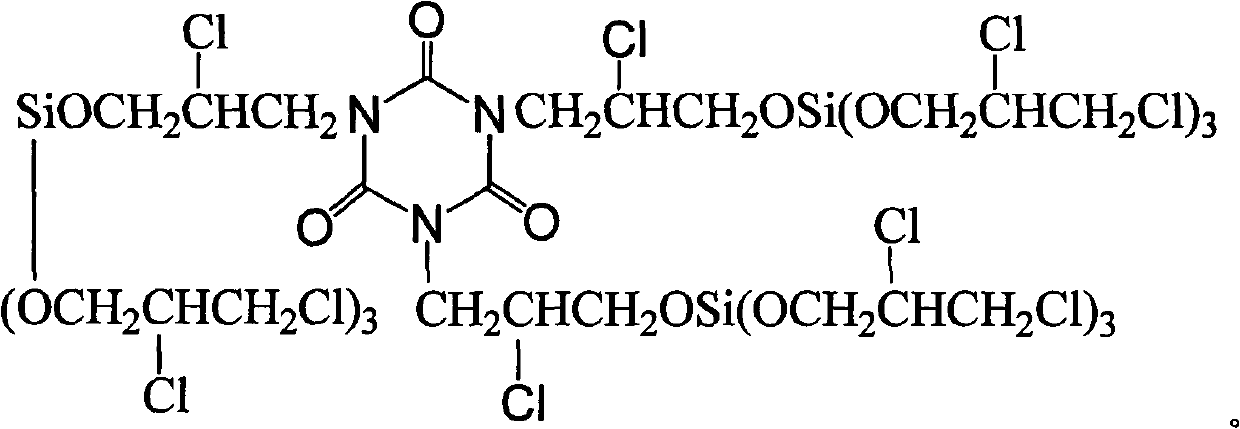

Nitrogen-containing chloro-polysilicate compound and preparation method thereof

The invention relates to a tri{2-chloro-3-[tri(dichloropropoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the steps of adding triglycidyl isocyanurate in a certain molar ratio to silicon tetrachloride, preserving heat at 60 DEG C and reacting for 4-5 hours, then dropwise adding epoxy chloropropane in a certain molar ratio, preserving heat at 70-90 DEG C and reacting for 6-8 hours to obtain tri{2-chloro-3-[tri(dichloropropoxy)silicon acyloxy]propyl}isocyanurate through purification treatment. The compound is an excellent flame-retardant plasticizer; and the preparation method is simple in production process and low in equipment investment and is easy for industrial production.

Owner:张家港市乐余科创园投资发展有限公司

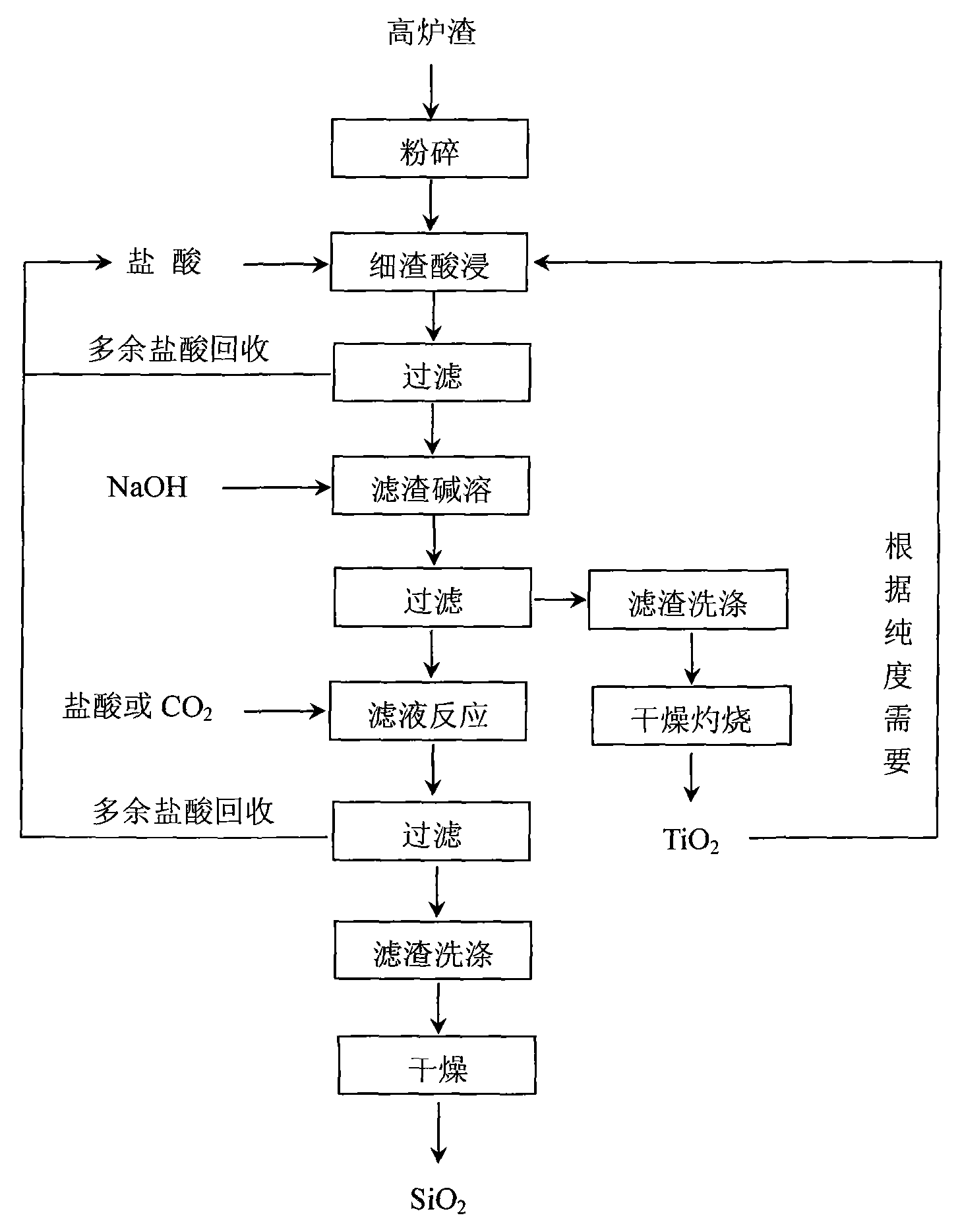

Method for extracting TiO 2 and SiO 2 in blast furnace slag

The invention relates to a method for extracting TiO 2 and SiO 2 in blast furnace slag, comprising the steps of dissolving the blast furnace slag with hydrochloric acid, treating the filtrate with alkali, separating TiO 2 and the SiO 2, and the like. The method can completely recover titanium component and silicon component in the blast furnace slag, and has low cost, little pollution and high efficiency.

Owner:MICROVAST POWER SYST CO LTD

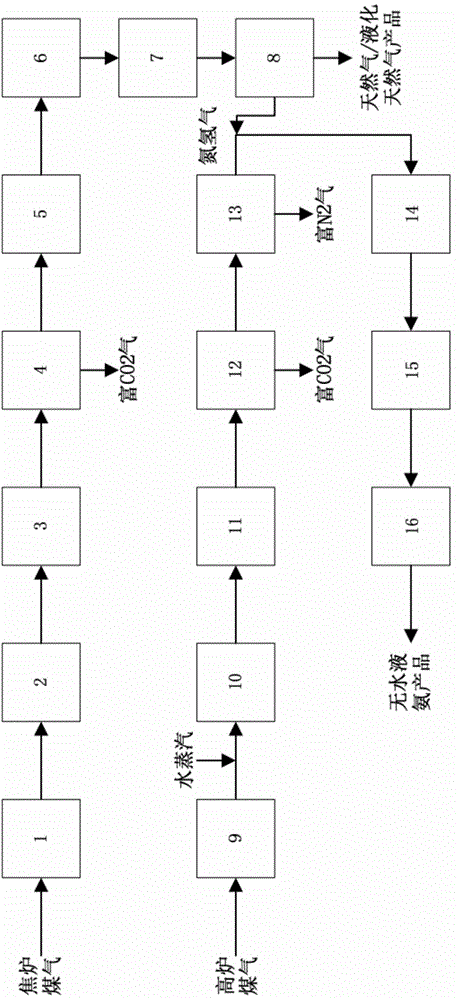

Method for joint production of natural gas and liquid ammonia by using coke oven gas and blast-furnace gas

ActiveCN104449920ABroad marketIncrease economic value addedCombustible gas chemical modificationHydrogen separationCoke oven gasLiquefied natural gas

The invention relates to a method for joint production of natural gas and liquid ammonia by using coke oven gas and blast-furnace gas. The method comprises the following steps: firstly, pressurizing the coke oven gas through a Roots blower or a screw compressor; feeding to the compressor and carrying out first-stage and second-stage compression pressurization through a temperature swing adsorption device; carrying out third-stage compression pressurization through the compressor after passing through a pressure swing adsorption decarburizing device; feeding to a coke oven gas desulphurization device, feeding to a methane synthesis device and obtaining a natural gas or liquefied natural gas product through the pressure swing adsorption device or a cryogenic separation device; carrying out first-stage and second-stage compression pressurization on the coke oven gas through the compressor, mixing with vapor, feeding to a sulphur-tolerance shift device, and carrying out low-temperature sulphur-tolerance shift; sequentially feeding to a blast-furnace gas desulphurization device, the pressure swing adsorption decarburizing device and a pressure swing adsorption denitrification device; and mixing the purified blast-furnace gas with nitrogen and hydrogen, which are separated from the coke oven gas, then carrying out third-stage, fourth-stage, fifth-stage and sixth-stage compression pressurization through the the compressor, and feeding to a synthesis ammonia device after passing through a methanation device, so as to produce an anhydrous liquid ammonia product.

Owner:XINAO ENERGY TRADE

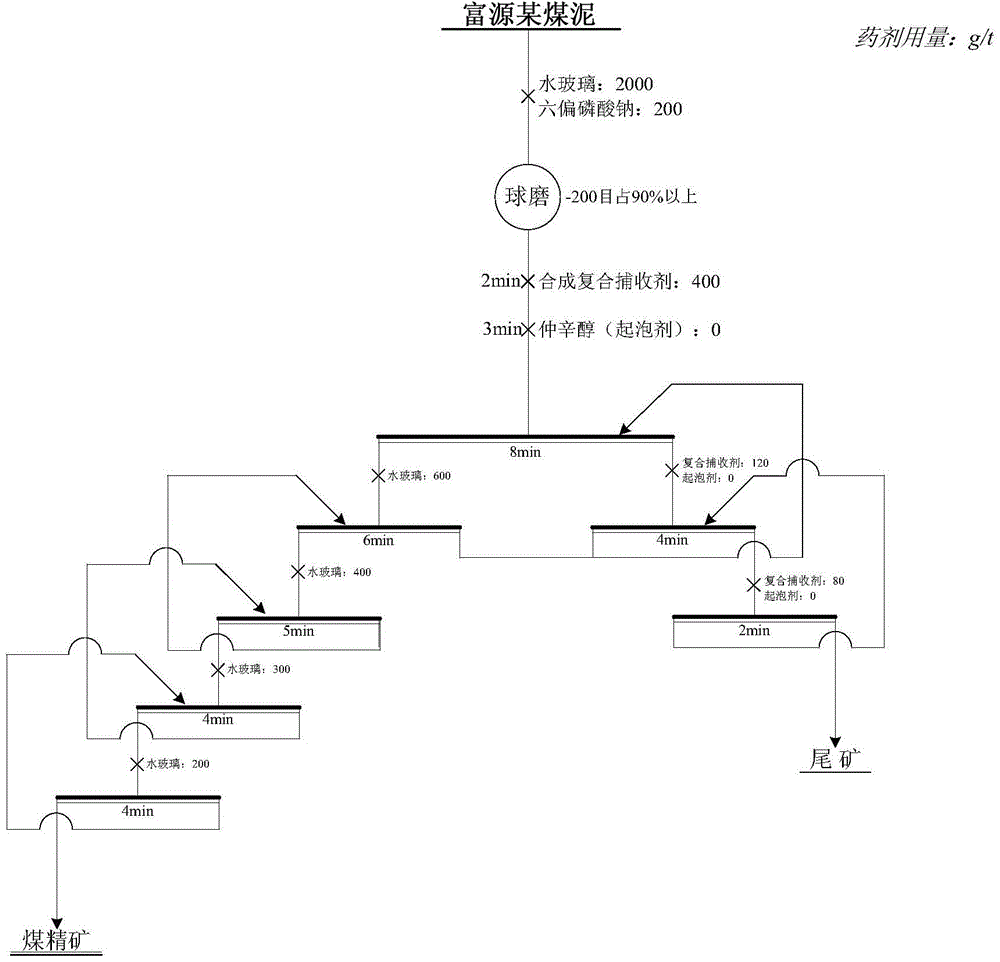

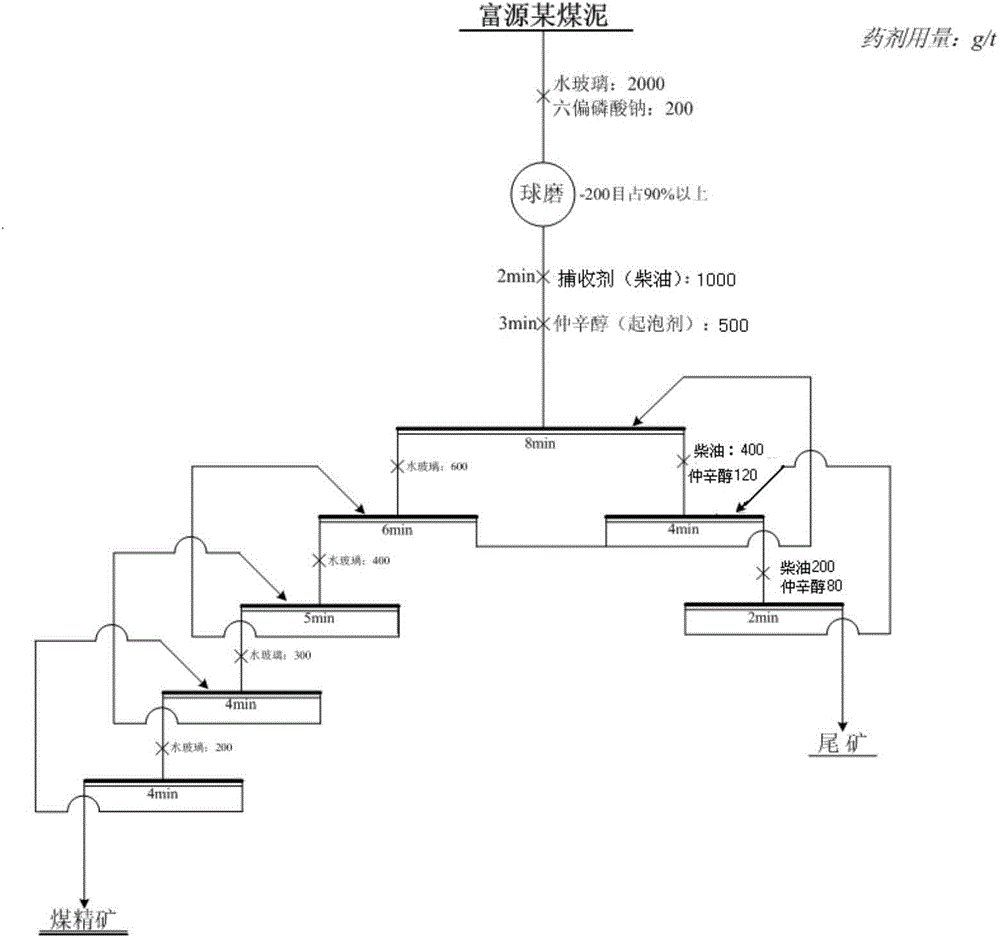

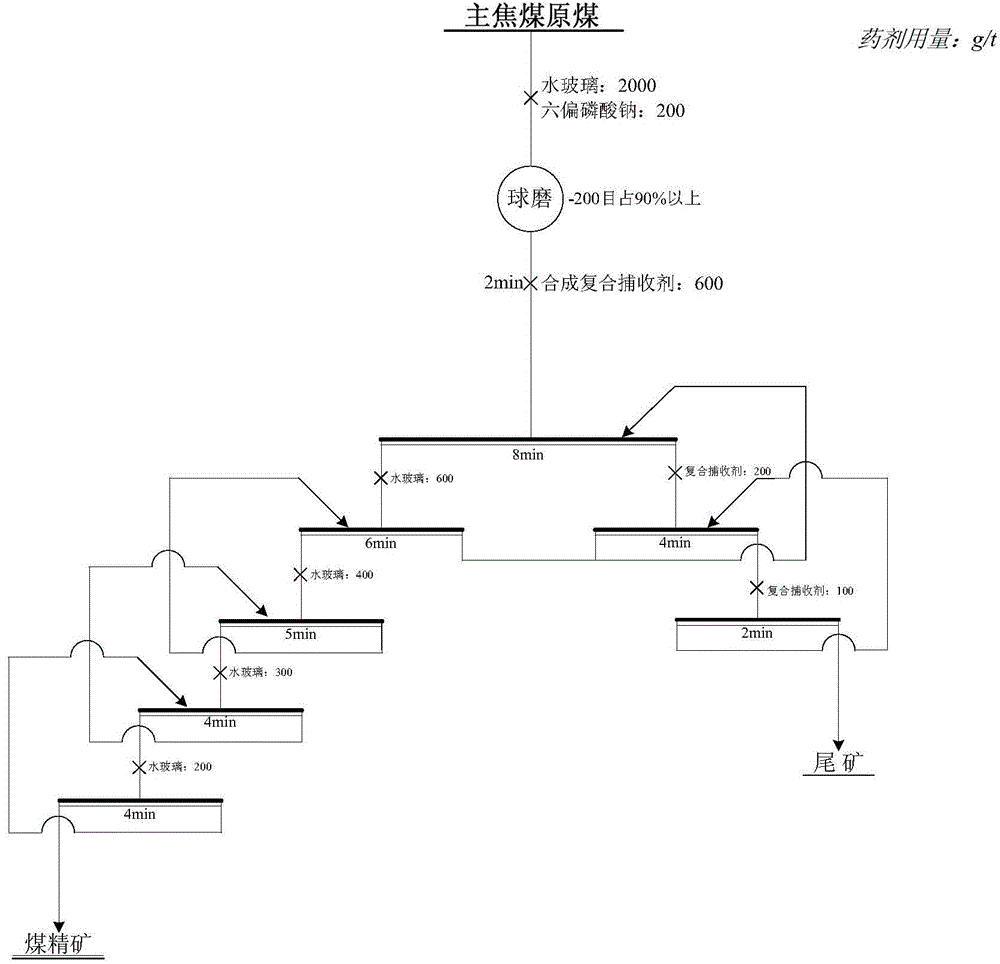

Coal dressing collecting agent and preparing method thereof

The invention relates to a coal dressing collecting agent and a preparing method of the coal dressing collecting agent, in particular to a coal collecting agent with butyl-octyl alcohol residual liquid in petrochemical enterprises as raw materials and a preparing method of the coal collecting agent and belongs to the technical field of preparing of coal slime flotation collecting agents. According to the coal dressing collecting agent, the butyl-octyl alcohol residual liquid in the petrochemical enterprises and phthalic anhydride serve as raw materials, under the action of catalysts, firstly, the temperature is raised to 70-150 DEG C, and a backflow reaction is performed for 1-5 hours; then, the temperature is raised to 120-300 DEG C, water phases and organic phases are separated after the backflow reaction is performed for 1-5 hours, drying and dewatering are performed on the organic phases, and the coal dressing collecting agent can be obtained. According to the coal dressing collecting agent and the preparing method of the coal dressing collecting agent, the preparing process is simple, the obtained product is good in flotation capacity, and industrialized production and industrialized application are facilitated. Meanwhile, the problem that the butyl-octyl alcohol residual liquid cannot be easily processed with high efficiency and high yield is well solved.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

Method and device for preparing novel fuel from municipal domestic waste completely

The invention relates to a method and a device for preparing novel fuel from municipal domestic waste completely and belongs to environmental protection on energy sources. The method comprises the following steps: separating out reusable substances such as plastic, metal and glass bottles from the municipal domestic waste serving as the only raw material; removing unrecoverable substances such as stones, bricks and cement; using the residual garbage as the raw materials of the novel fuel; breaking bags; sorting; sieving; drying; and performing extrusion molding to obtain the novel fuel. The method and the device can solve the problems of treatment and comprehensive utilization of municipal domestic waste. The fuel product can replace the resources such as solid combustible mineral coal, coke and the like, becomes a substituted energy product for large-scale thermal power plant and domestic fuel, is an important energy replacement and supplement measure, and has very important social and economic significance.

Owner:JILIN PROVINCE MINGTAI RENEWABLE SOURCES

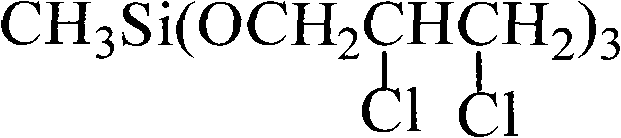

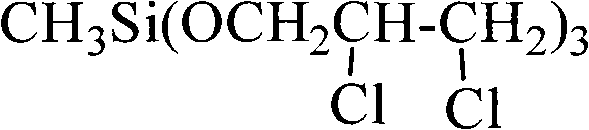

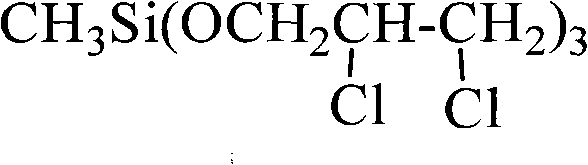

Methyl silicic acid tri(2,3-dichloropropyl) ester compound and preparation method thereof

InactiveCN102140114AImprove flame retardant performanceStabilize the C-Si bond structureGroup 4/14 element organic compoundsMethyltrichlorosilaneSilicic acid

The invention relates to a Si and Cl synergistic fire retardant methyl silicic acid tri(2,3-dichloropropyl) ester compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the following steps: dropwise adding dichloropropanol with a certain molar ratio in methyl trichlorosilane at the temperature of 25 DEG C; heating to react for a period of time; after discharging hydrogen chloride, and purifying, so as to obtain the methyl silicic acid tri(2,3-dichloropropyl) ester. The methyl silicic acid tri(2,3-dichloropropyl)ester is high in inflaming retarding efficiency and is good in compatability with polymer materials, and has the advantages of simple process, less equipment investment and low cost. The preparation method is easy to achieve industrial production.

Owner:枣阳市佳宝硅助剂有限公司

Chloro- and bromo-containing silicate flame retardant compound and preparation method thereof

ActiveCN102731825AImprove flame retardant performanceGood symmetrySilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a silicon-halogen synergistic flame retardant plasticizer tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy)propyl silicate compound and a preparation method of the compound. The compound is characterized in that the structure is shown as follows in the specification. The method comprises the steps of adding tetrachlorosilane into a reactor, dripping equivalent molartribromophenylglycidyl ether organic solvent solution, performing a heat preservation process for a reaction at 60 DEG C-80 DEG C for 4-6 hours after the organic solvent solution is dripped, pumping ethylene oxide into the 40 DEG C solution at a certain molar ratio and below the liquid surface, performing another heat preservation process for another reaction at 50 DEG C-60 DEG C for 3-5 hours, and purifying to obtain a yellow liquid of tri(2-chloroethyl)-2-chloro-3-(2, 4, 6-tribromophenoxy) propyl silicate. The compound is a highly effective flame retardant and used as the flame retardant for poly(vinyl chloride), polyurethane, epoxy resin, unsaturated resin and the like. The method is simple in manufacturing technique, low in investment, and easily realizes the industrial production.

Owner:张家港市乐余科创园投资发展有限公司

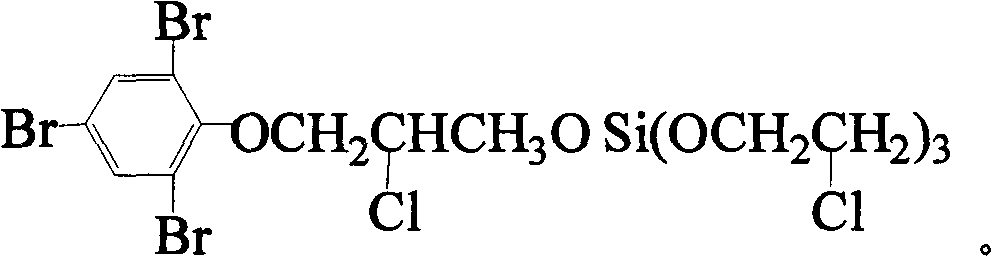

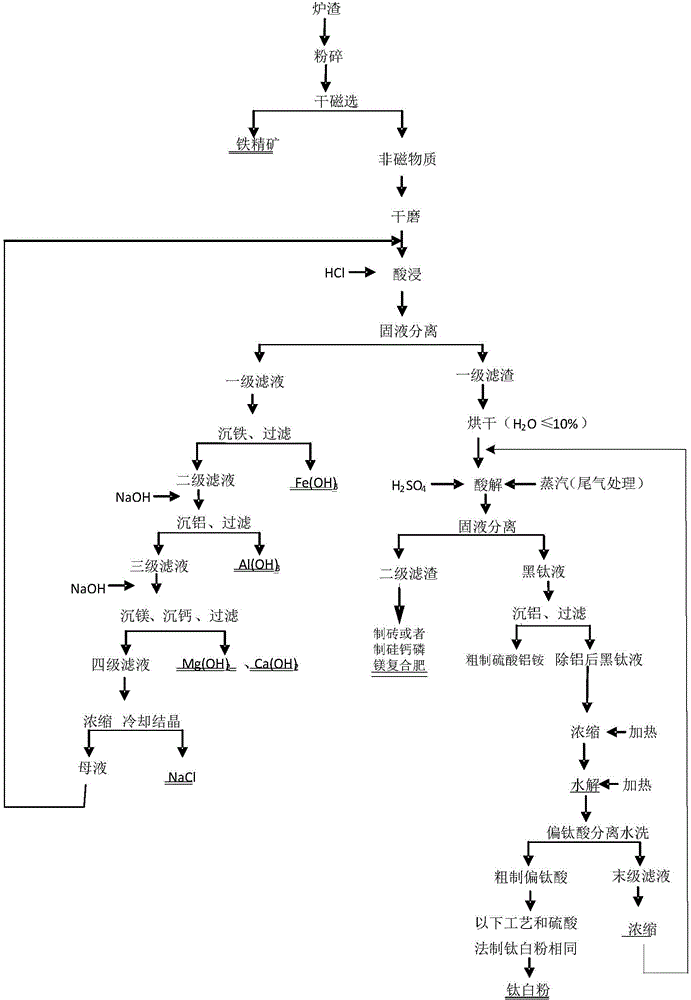

Comprehensive utilization method of high titanium slag

The invention discloses a comprehensive utilization method of high titanium slag in the slag treatment technology. The method comprises the following steps: firstly, carrying out acid leaching by using diluted hydrochloric acid; then, carrying out acidolysis by using dilute sulphuric acid, wherein the leaching rate is improved; using a black titaniferous liquid after acidolysis to prepare titanium dioxide; settling Fe(OH)3, Al(OH)3, Mg(OH)2 and Ca(OH)2 from a primary filtrate obtained by acid leaching and recovering sodium chloride; and using Si, Mg and Ca in slag to prepare an Si-Ca-P-Mg composite fertilizer. The method disclosed by the invention is extremely low in acid consumption of acid which is recycled, various effective components of high titanium slag can be comprehensively utilized, and factors in many aspects such as environment friendliness, technology and economical benefit are taken into consideration. The slag is low in cost, and titanium, ferrum, aluminum, magnesium, calcium, silicon, sodium chloride and the like can be comprehensively recovered, so that the economic benefit is remarkable, the long-term pendent problem on utilization of high titanium slag is solved, the land for slag is saved, the environmental pollution is reduced, wastes are turned into wealth, and the high titanium slag has a good social benefit.

Owner:攀枝花市德信科技有限公司

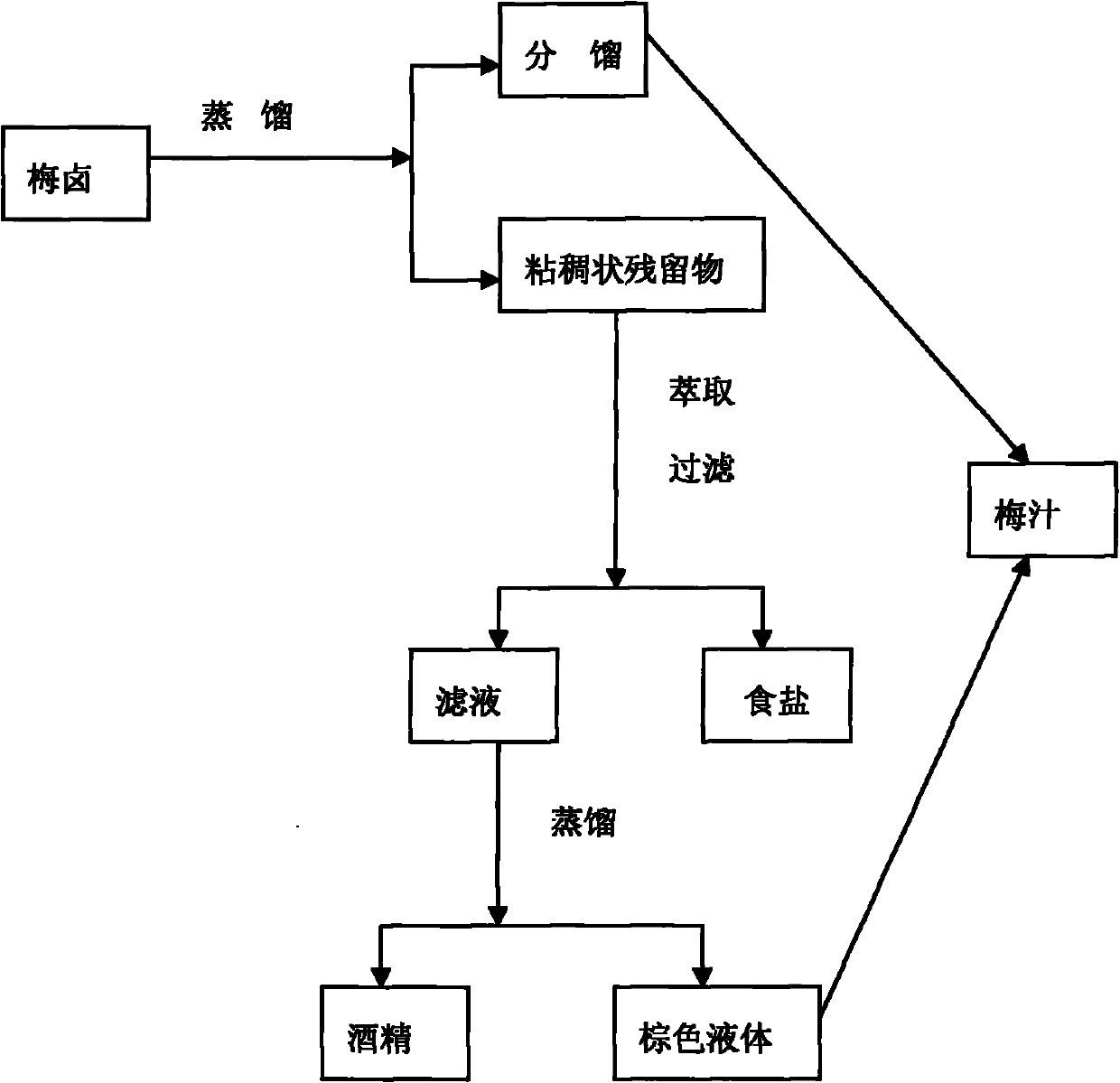

Method for producing plum juice via plum halogen desalination

InactiveCN101904528ASolving Recycling ProblemsSolve the problem of comprehensive utilizationFood scienceSocial benefitsAlcohol

The invention provides a method for producing plum juice via plum halogen desalination, comprising the steps of: distilling plum halogen as the raw material under normal pressure to obtain fraction and thick residue, mixing the thick residue with edible alcohol and then extracting at 40 to 60 DEG C, cooling and filtering to obtain filtrate and salt, distilling the obtained filtrate, reclaiming the alcohol to obtain liquid, and merging the obtained fraction and the liquid to obtain the desalinated plum juice. The plum juice can be directly prepared into plum beverage after being diluted, for example, the plum juice can be made into plum wine or plum vinegar via the traditional fermentation technology. The invention has the advantages of stable technology, strong operability, low investment, high benefit and changeable production scale, thereby having very high economic and social benefit and being worthy of popularization and application.

Owner:DALI UNIV

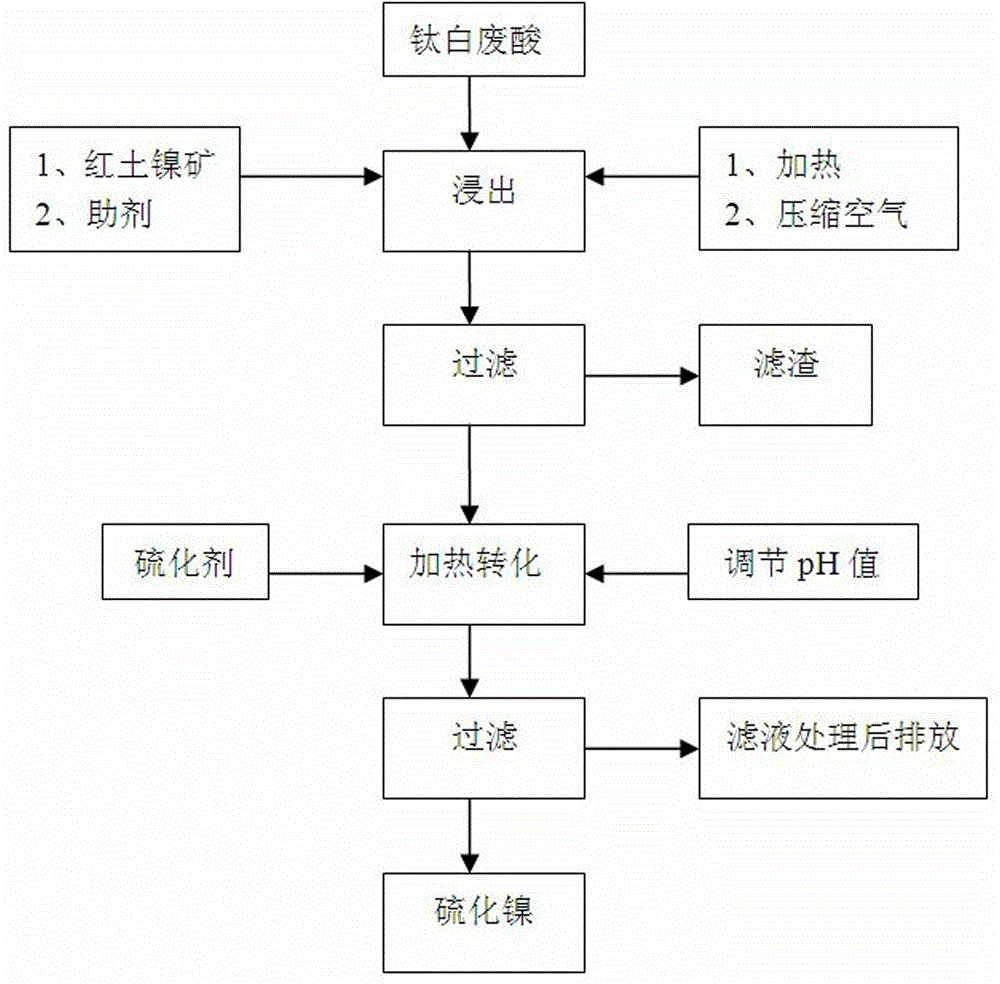

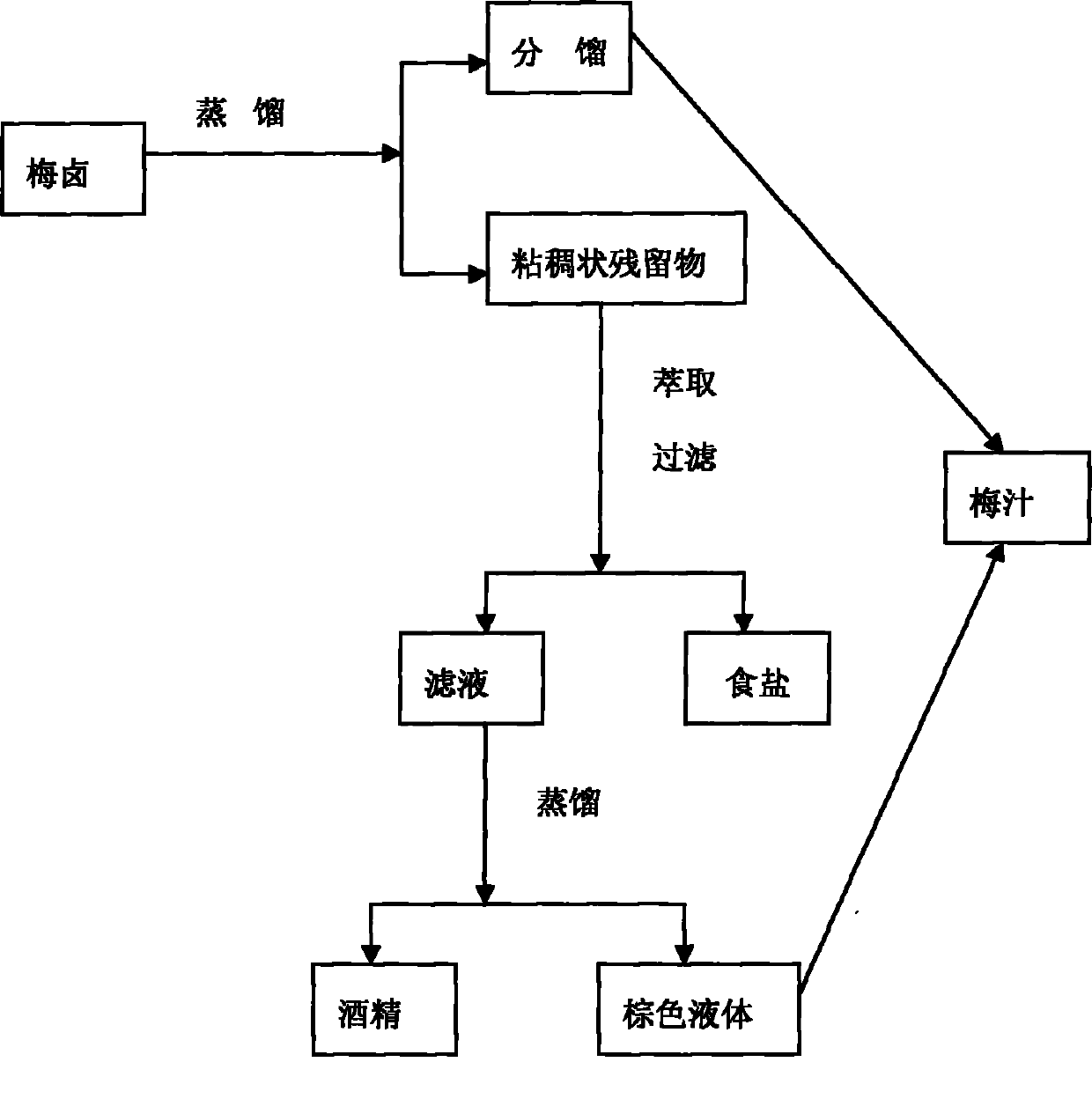

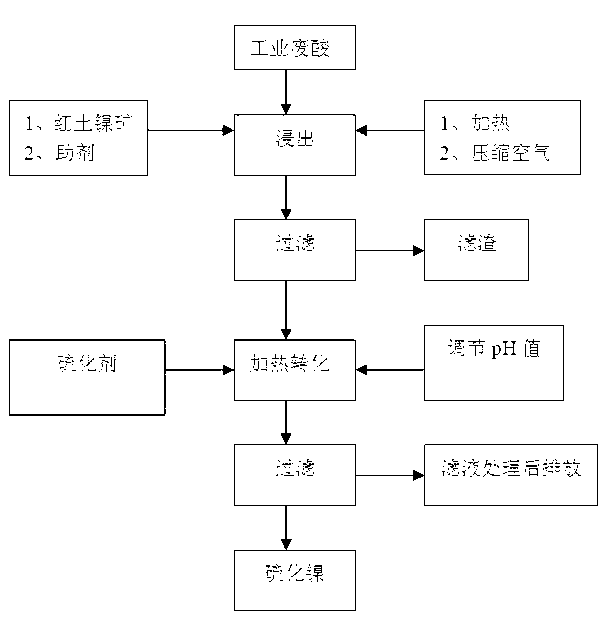

Method for producing nickel sulfide ore concentrate by use of industrial waste acid

ActiveCN102994746ASolve the problem of comprehensive utilizationReduce manufacturing costProcess efficiency improvementEconomic benefitsOxygen

The invention provides a method for producing nickel sulfide ore concentrate by the use of industrial waste acid. The specific technical scheme is as follows: adopting industrial waste acid to soak laterite-nickel ore, heating, stirring and extracting, and after a period of time, adding assistant, blowing in compression air or oxygen, reacting for a period of time, filtering, heating filtrate to a required temperature, and then adding vulcanizing agent, stirring, keeping the temperature for a period of time, and filtering to obtain the nickel sulfide ore concentrate. The method is an effective way for comprehensively utilizing the industrial waste acid to change waste into wealth, thereby reducing the cost for producing nickel sulfide ore by hydrometallurgical process, lowering air pollution and having a good economic benefit.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

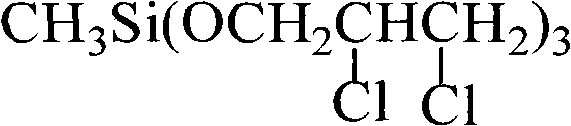

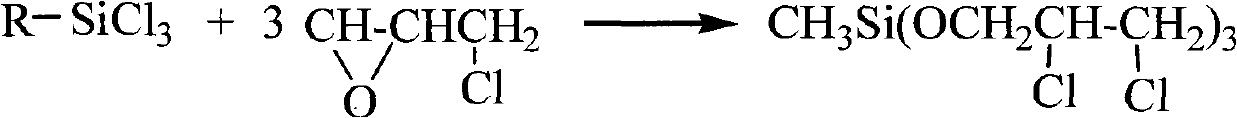

Methyltri(2,3-dichloropropoxy)silane compound and preparation method thereof

ActiveCN102174056AHigh synergistic flame retardant performanceGood symmetryGroup 4/14 element organic compoundsSilane compoundsSilanes

The invention relates to a synergetic fire retardant methyltri(2,3-dichloropropoxy)silane compound containing two elements of Si and Cl and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the following steps of: dropwise adding epichlorohydrin with certain molar ratio into methyl trichlorosilane at 25 DEG C; heating and reacting for a period of time; and distilling a low-boiling-point product out at a reduced pressure to obtain the methyltri(2,3-dichloropropoxy)silane. The methyltri(2,3-dichloropropoxy)silane disclosed by the invention has the advantages of high fire retardant efficiency, high intermiscibility with macromolecule materials, simple production process, less equipment investment and low cost and is easy to realize industrialized production.

Owner:JIAOSU CHAOSHU INFORMATION TECH CO LTD

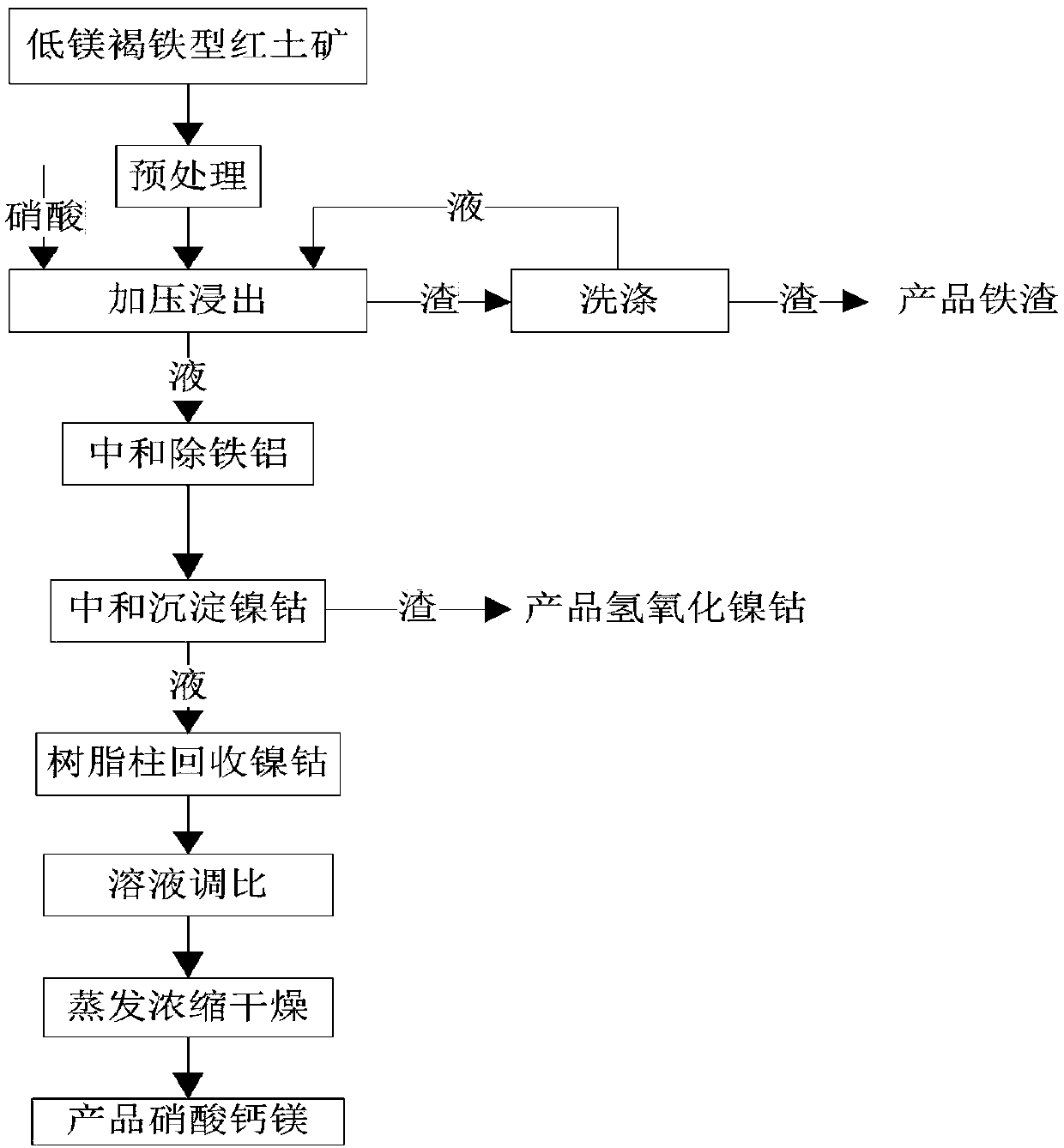

Method for treating low-magnesium limonitic laterite nickel ore

InactiveCN109252056ASolve the problem of comprehensive utilizationAvoid secondary pollutionMagnesium nitratesCalcium/strontium/barium nitratesLateriteCobalt

The invention discloses a method for treating a low-magnesium limonitic laterite nickel ore. The method concretely comprises the following steps: ore grinding pretreatment, nitric acid pressurizationleaching, neutralization for removing iron and aluminum, neutralization for precipitating nickel and cobalt, recovery of the nickel and cobalt through a resin column, solution ratio adjustment, and evaporative concentrating drying. The selective use of a leaching agent and an acid-base regulator in the treatment method makes all steps in the whole method cooperate with each other in order to realize the efficient and sufficient leaching and recovery of cobalt and nickel in the laterite nickel ore, and chemical agents added in the treatment method cooperate with each other to completely convertcalcium and magnesium metals in the laterite nickel ore into a calcium magnesium nitrate mixed fertilizer which can be directly recycled, so completely efficient utilization treatment of resources isachieved, and the problem of comprehensive utilization of the low-magnesium limonitic laterite nickel ore is solved. Substances discharged in the whole treatment process are directly recyclable products, and no wastewater / waste residue / waste gas is discharged, so the method has the advantages of simple and easily-controlled treatment steps, low energy consumption, low cost and high industrial actual values.

Owner:MEISHAN SHUNYING POWER BATTERY MATERIALS CO LTD

Iron ore sintering method by using light-burnt magnesium ball

ActiveCN108070713AReduce contentOptimizing technical indicators of sintering productionBlast furnace detailsBlast furnace smeltingIron ore sintering

The invention discloses an iron ore sintering method by using light-burnt magnesium ball. During the iron ore sintering process, light-burnt magnesium ball, iron ore powder, return mine, coke powder,and a flux are configured in proportion, and then steps of uniform mixing by adding water, granulation, material distribution, ignition, sintering, cooling, and fragmentation are carried out to obtainan agglomerate finished product. The light-burnt magnesium ball can substitute dolomite powder, so that a sintering mineralization rate is increased, a reasonable mineral composition and an ore-phasestructure are obtained, the method can guarantee the requirement of blast-furnace smelting on an agglomerate chemical component MgO, cannot deteriorate a sintering process, and has important practical significance.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for culturing ganoderma lucidum in open field

InactiveCN107810780AReduce the rate of bacterial contaminationImprove the quality of Ganoderma lucidumCalcareous fertilisersExcrement fertilisersGanoderma pseudoferreumGanoderma lucidum

The invention discloses a method for culturing ganoderma lucidum in an open field. The method comprises the following steps: inoculating a ganoderma lucidum mother culture on a mother culture medium to obtain a ganoderma lucidum mother culture; inoculating the ganoderma lucidum mother culture on a stock culture medium to be cultured to obtain a ganoderma lucidum stock culture; inoculating the ganoderma lucidum stock culture on a cultivar culture medium to be cultured to obtain a ganoderma lucidum cultivar; and carrying out substitute culture on the ganoderma lucidum cultivar to obtain ganoderma lucidum. By using the method disclosed by the invention, the growth speeds of mycelia are high, the average daily growth speeds of the mycelia can reach 18-20mm / d, the biological efficiency of sporocarps can reach 9%-15%, and the sporocarps are high in yield and good in quality. The method disclosed by the invention is simple, convenient and easy, low in investment, capable of rapidly taking effects and easy to popularize.

Owner:南充有机蔬菜工程技术中心

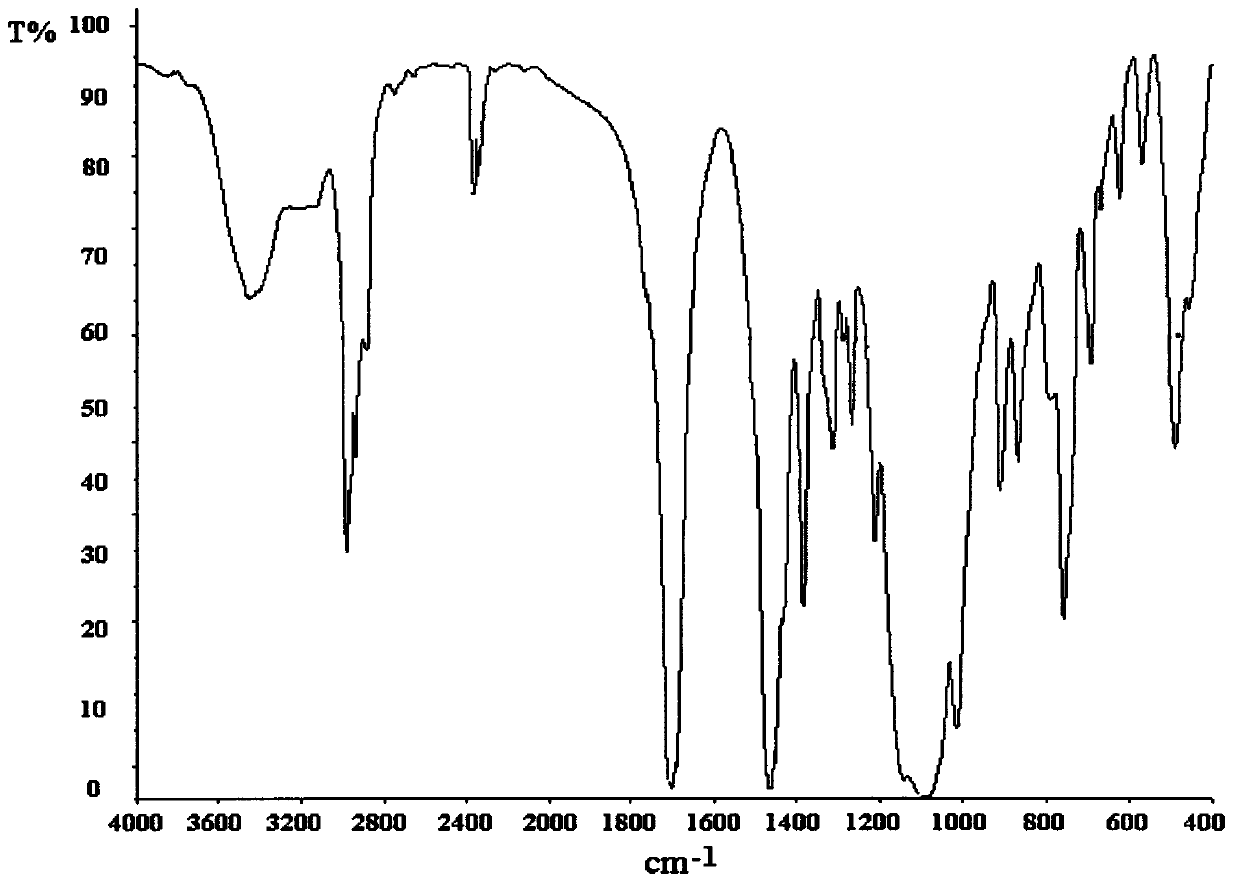

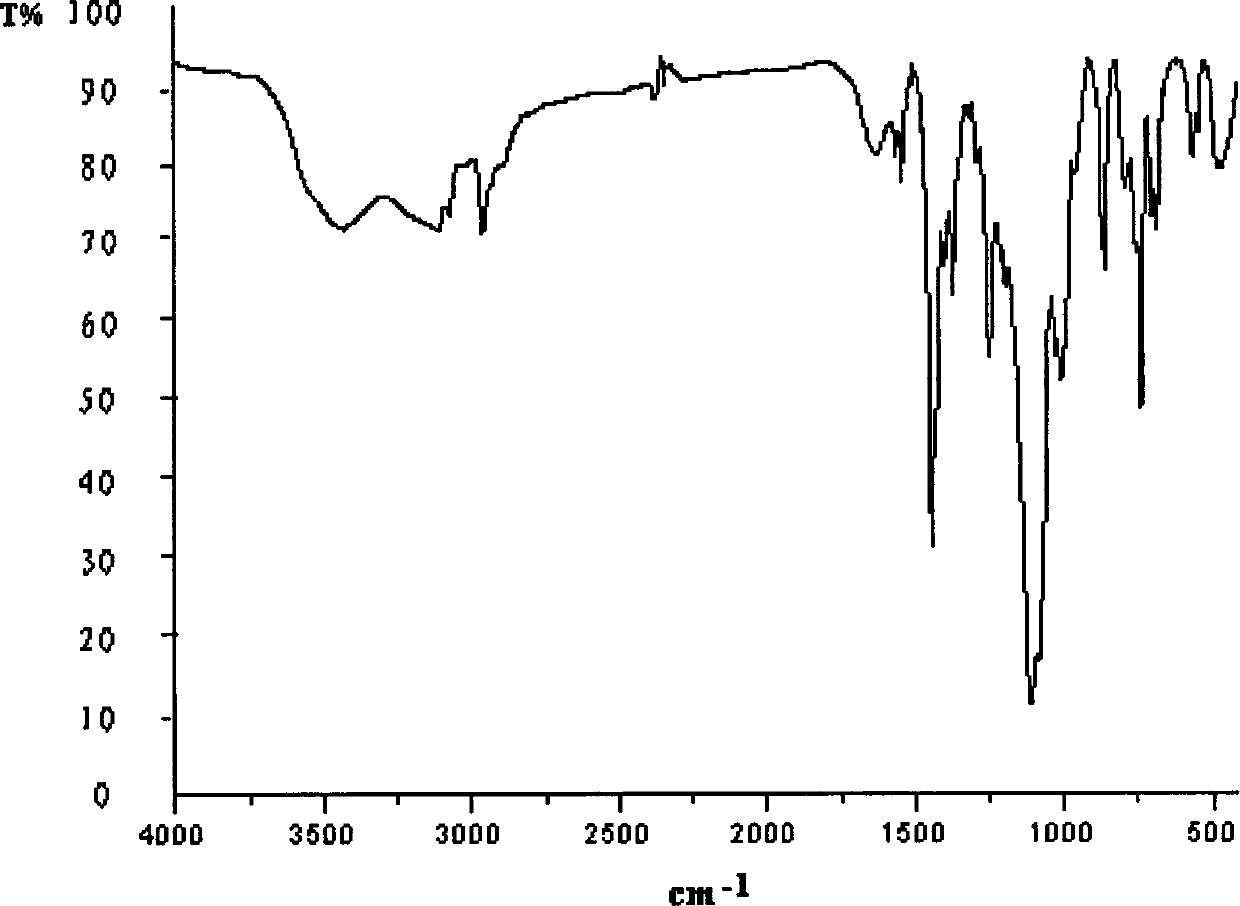

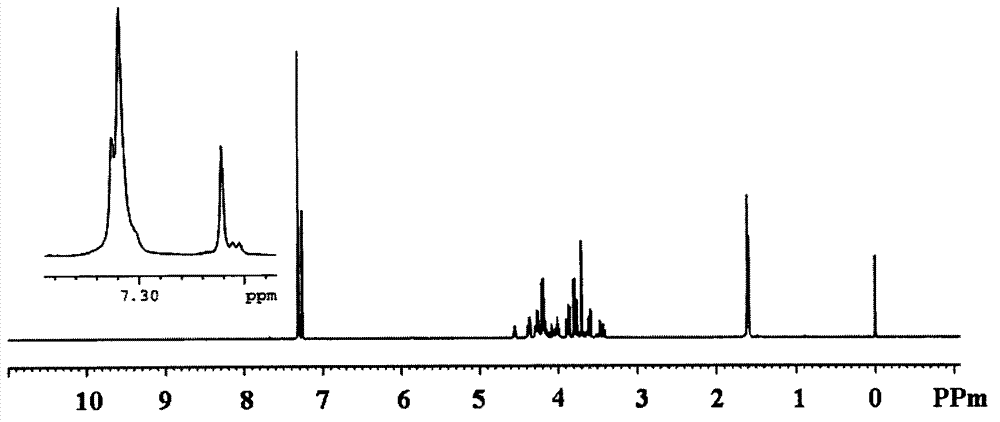

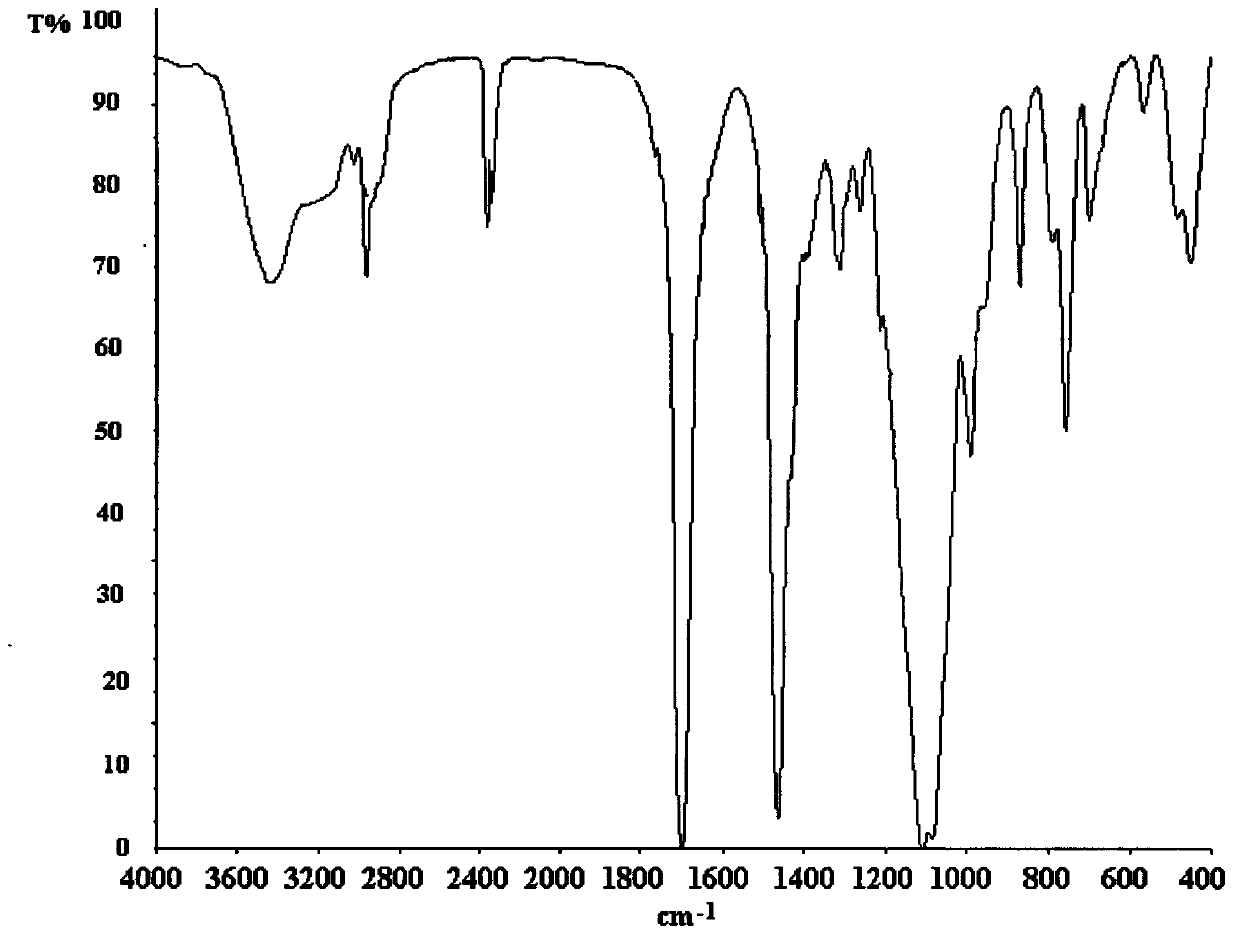

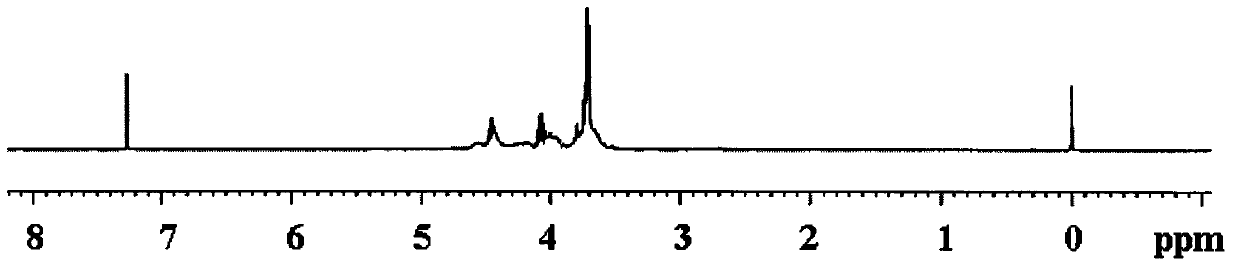

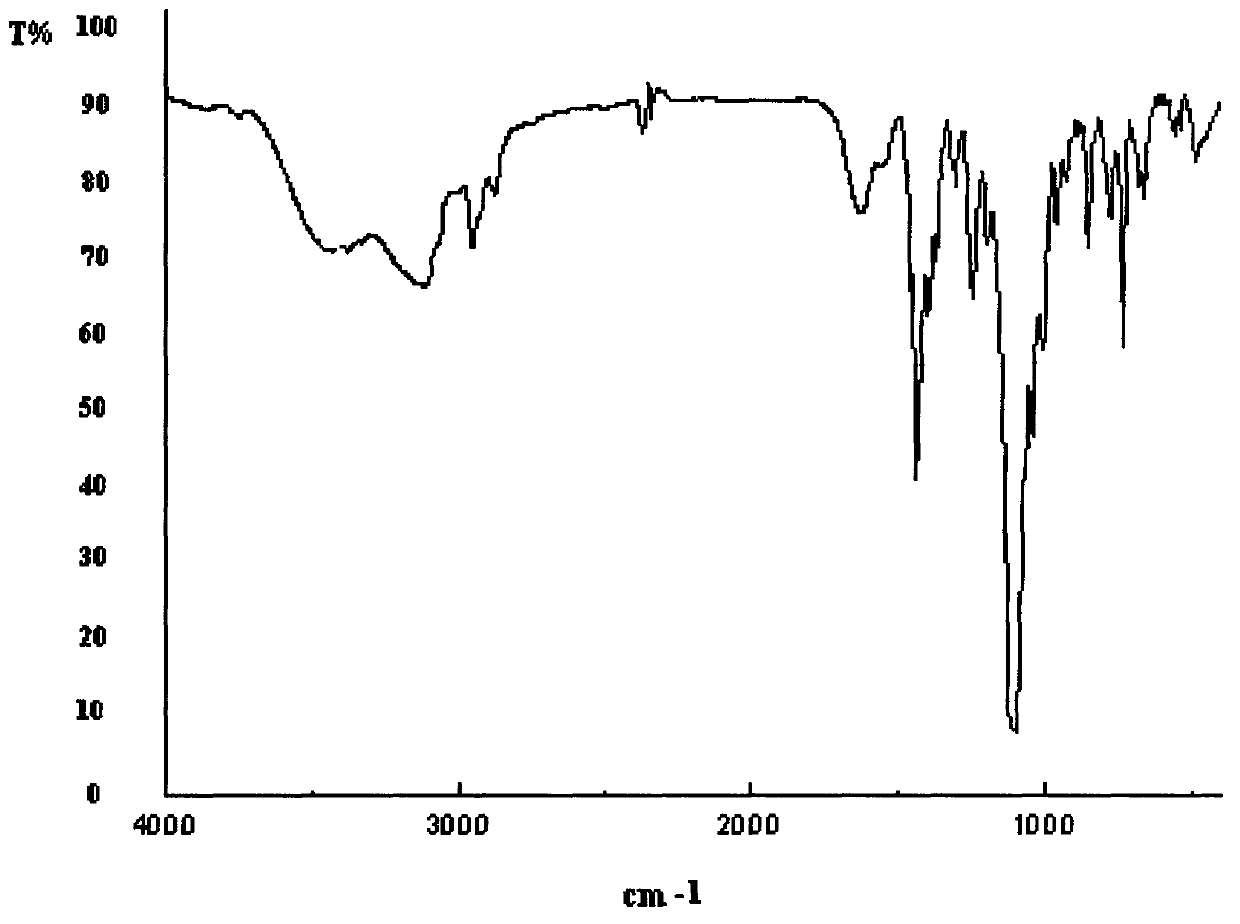

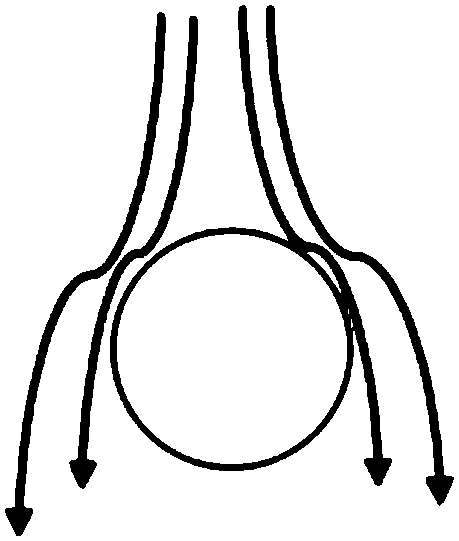

Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof

ActiveCN104017025ANovel structureImprove stabilityGroup 5/15 element organic compoundsPolyesterEpoxy

The invention relates to a flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and a preparation method thereof. The compound has a structural formula shown in the specification. The preparation method comprises the following steps of dropwise adding silicon tetrachloride into a solution of 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo-[2.2.2]-octane (PEPA) and an organic solvent at 20 DEG C, heating to 80-140 DEG C, performing stirring reaction for 4-10 hours, adding a fixed quantity of an acid-binding agent, stirring for 1 hours, and ending the reaction when detecting that the pH value of the solution is 5-6; cooling, performing suction filtration, washing by water, and drying to obtain tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate. The compound is the excellent halogen-free phosphorus-silicon synergistic flame retardant charring agent and can be applied to polyolefin, polyester, polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, the process is simple, the equipment investment is low, and the industrialized production is easy to realize.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

Method for preparing hemicellulose, humate and feed additive by utilizing straws

The invention provides a method for preparing hemicellulose, humate and a feed additive by utilizing straws, and belongs to the technical field of integrated utilization of subsidiary agricultural products. The method provided by the invention is a method by which a hemicellulose stock solution, the humate and the feed additive are obtained through microbial fermentation treatment and alkaline hydrolysis by taking the straws as a raw material and mainly comprises the following steps of crushing the straws, and degrading a wax positioned on the surface of the straws through a microbial fermentation treatment method; carrying out pressure filtration, adding alkali liquor to a solid, treating by adopting a heating extraction method to obtain a hemicellulose supernatant; adding the alkali liquor to the rest solid, digesting, and then carrying out pressure filtration to obtain the solid which is the feed additive; concentrating and filtering filter liquor which is rich in humate to obtain a humate solid. According to the invention, the consumption of the total weight of process chemicals is reduced by combining a biological fermentation method and a chemical treatment method. The production process is simple and high in applicability, enhances the economic added value of the crop straw and preferably solves the problem of straw utilization.

Owner:JIAHE BIOTECH

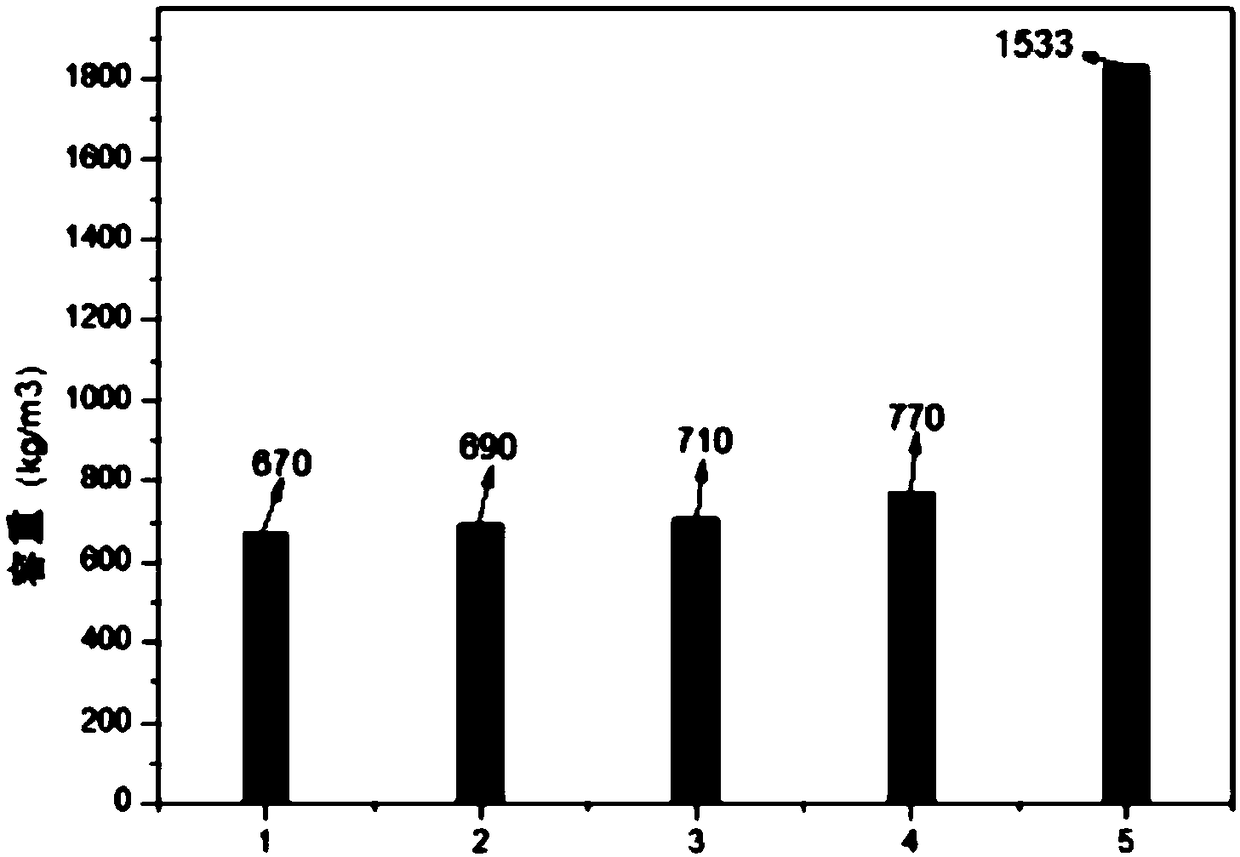

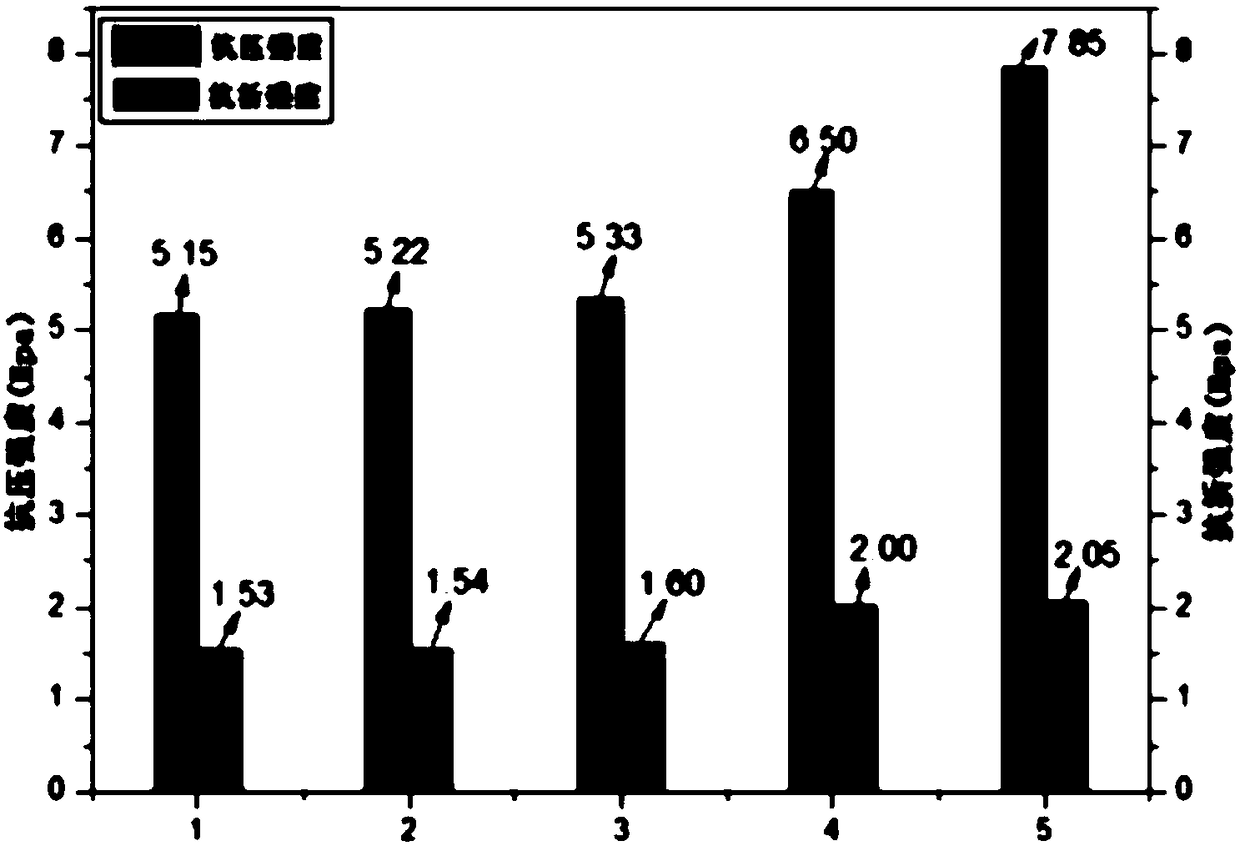

Polybasic compound flue gas desulfurization gypsum lightweight mortar and preparation method thereof

The invention relates to the technical field of building material mortar, in particular to a novel lightweight gypsum mortar material. The material is prepared from, by weight, 44-48 parts of flue gasdesulfurization gypsum, 4-11 parts of glass bead, 44-48 parts of heavy calcium carbonate, 0.2-0.5 part of retarder, 0.20-0.30 part of cellulose ether and 58-70 parts of water. The polybasic compoundflue gas desulfurization gypsum lightweight mortar utilizes solid waste of the flue gas desulfurization gypsum, the production cost is effectively reduced, and the environmental pollution is reduced;the heavy calcium carbonate is cheap and easy to obtain, and the cost is effectively reduced; based on ensuring the material strength, the glass bead effectively reduces the material unit weight, andthe unification between the environmental benefit and the economic benefit is achieved.

Owner:南京益夫新材料科技有限公司

Novel tri(dichloropropyl) bisilicate flame retardant compound containing bromine and preparation method thereof

ActiveCN102731827AGood structural plasticityHigh synergistic flame retardant performanceTetrabromobisphenol APolymer science

The invention relates to a silicon halide three elements synergized flame retarding plasticizer tetrabromo bisphenol A diether dichloropropoxy tri(2,3-dichloropropyl) bisilicate compound and a preparation method thereof. The structure of the compound is shown in the following formula, wherein when m is equal to 0, n is equal to 1; when m is equal to 1, n is equal to 0; x is equal to 0, 1, 2 or 3. The preparation method comprises the following steps: tetrabromo bisphenol A diglycidyl ether is dissolved in organic solvent while being mixed; the obtained solution is dripped in silicon tetrachloride at 25 DEG C, then reacted for 3-4h at 70-80 DEG C in heat preservation, and added with dichloropropanol with a certain mol ratio to react for 4-6h at 70-100 DEG C, at last the solution is purified to obtain the product tetrabromo bisphenol A diether dichloropropoxy tri(2,3-dichloropropyl) bisilicate. The product is an excellent flame retarding plasticizer, and suitable to be used as flame retarding plasticizer additive for epoxy resin, polyvinyl chloride, unsaturated resin, polyurethane, and the like.

Owner:SUZHOU UNIV OF SCI & TECH

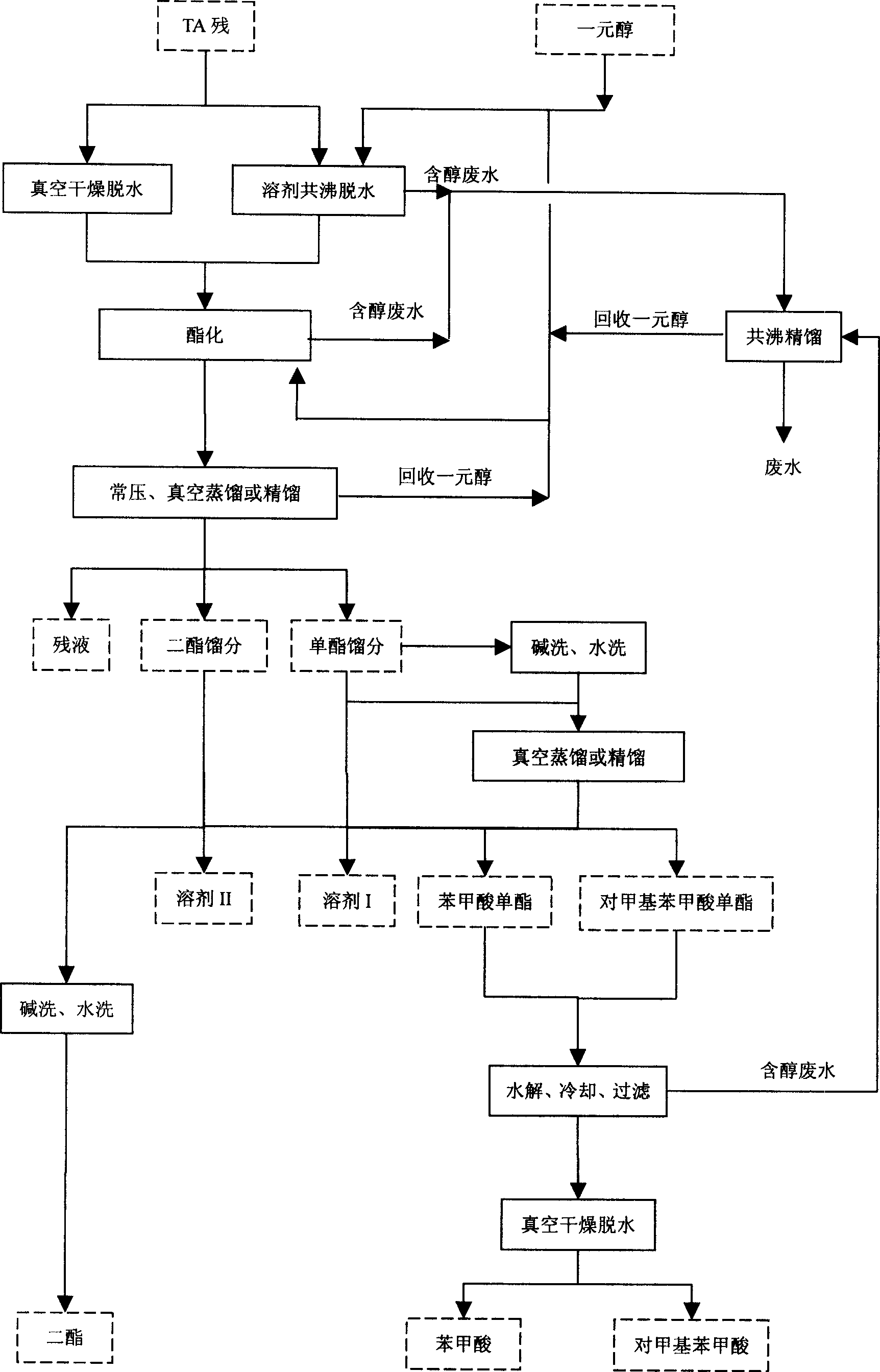

Method for synthetic using oxidation residue of para-xylene

InactiveCN1796010ASolve the problem of comprehensive utilizationSolve the way outSolid waste disposalSolventCatalytic hydrolysis

The present invention discloses a method for comprehensively utilizing paraxylene oxidative residue. Said method includes the following steps: firstly, dehydrating paraxylene oxidative residue; making the dehydrated residue and monobasic alcohol undergo the process of esterification reaction under the action of catalyst; distilling or rectifying the esterification product to obtain recovered monobasic alcohol, monoester fraction, diester fraction and residue; rectifying and separating monoester fraction to obtain solvent A, high-purity benzoic acid monoester, high-purity p-methyl benzoic acid monoester and solvent B; making the high-purity benzoic acid monoester and high-purity p-methyl benzoic acid monoester undergo the process of catalytic hydrolysis reaction to obtain high-purity benzoic acid and high-purity p-methyl benzoic acid.

Owner:中国石化集团天津石油化工公司

Method for preparing nickel sulfide concentrate through titanium dioxide waste acids

InactiveCN102943174AReduce manufacturing costSimple equipmentProcess efficiency improvementDigestionSpent acid

The invention provides a method for preparing nickel sulfide concentrate through titanium dioxide waste acids. The specific technical scheme includes that waste acids produced in the nickel sulfide industry are used for immersing nickel laterite ore, assistants are added after warming, agitation and digestion are performed for a certain time, compressed air or oxygen is blown in, filtration is performed after a certain period, a vulcanizing agent is added after the filtration solution is heated to a designated temperature, and filtration is performed again after agitation and heat preservation are performed for a certain period to obtain the nickel sulfide concentrate. The method is an effective way to use titanium dioxide waste acids comprehensively, wastes are turned into treasures, the cost used by a wet process to process metallic nickel can be reduced, air pollution is reduced, and good economic benefits can be produced.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000011.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000012.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/BSA0000105126520000021.PNG)