Method for synthetic using oxidation residue of para-xylene

A technology of p-xylene and p-toluic acid, which is applied in the field of comprehensive utilization of p-xylene oxidation residues, can solve problems such as the exit of TA residues, achieve good economic benefits, improve utilization rates, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

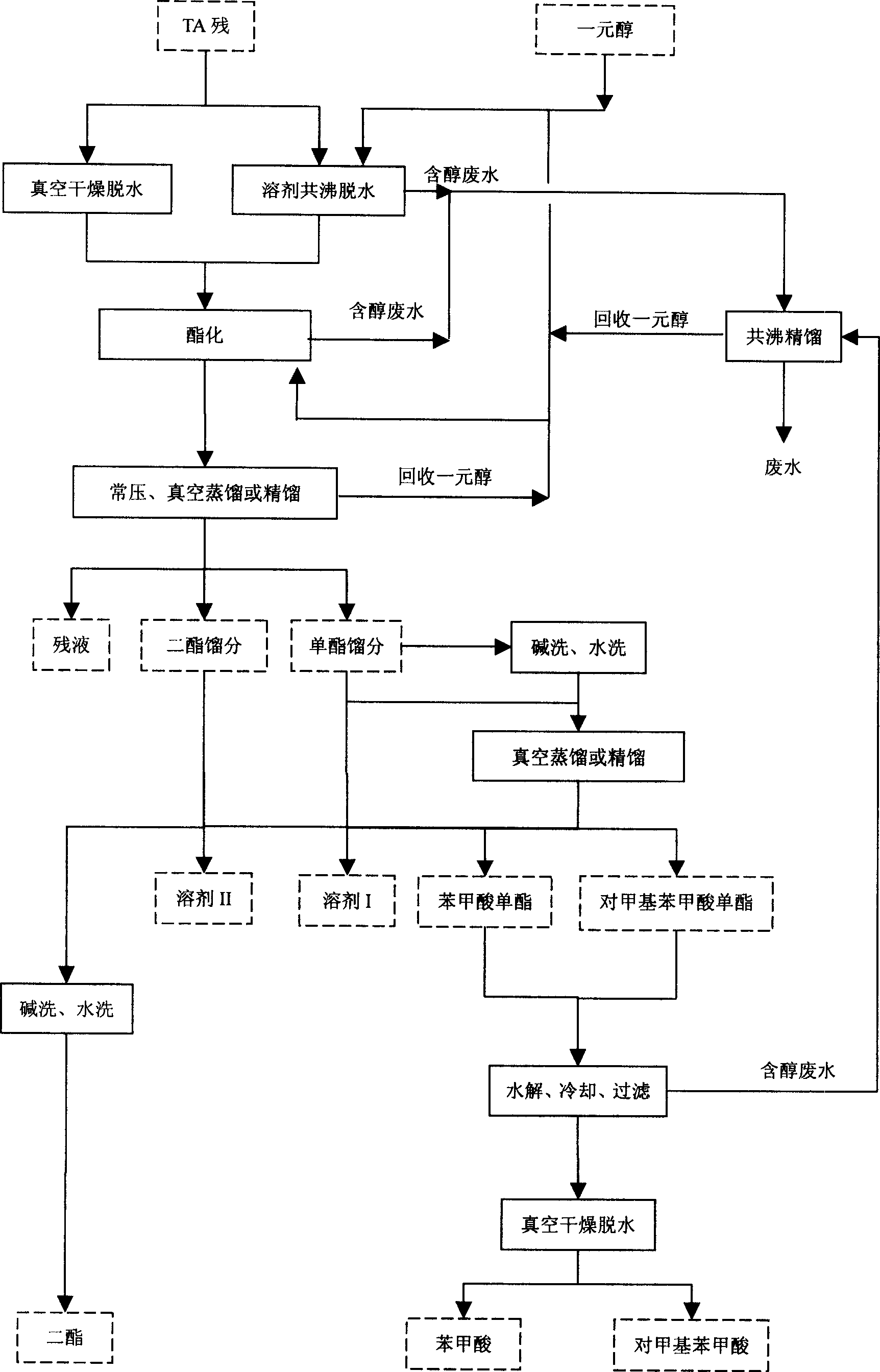

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Vacuum drying and dehydration

[0054] Put 454.6Kg of TA residue (with a water content of 45%) into a vacuum drying oven, heat and evacuate, the temperature in the drying oven is controlled between 50-80°C, the vacuum is 680-720mmHg, and the drying time is 5- 6 hours. The water content of TA residue was reduced from 45% to below 3%.

Embodiment 2

[0055] Example 2 Azeotropic dehydration of monoalcohol.

[0056] Put 454.6Kg of TA residue (water content is 45%) into the kettle with water separator, add 300Kg of monohydric alcohol, heat until the temperature rises to 95-100°C, monohydric alcohol and water are azeotropically distilled out. Stratify in the device, emit the water of the lower layer, when the amount of emitted water reaches the theoretical value of 204Kg, the dehydration is completed.

Embodiment 3

[0057] Example 3 Esterification of TA residue

[0058] Add the catalyst tetrabutyl titanate 500g to the residue after the azeotropic dehydration of monohydric alcohol in Example 2 (or the dried TA residue in Example 1) for esterification, the esterification temperature is 160-250°C, and the reaction pressure is 0.3-0.6 Mpa, the phase separation temperature is 30-80°C, the monohydric alcohol and the reaction water are distilled out azeotropically, layered in the water separator, and the water in the lower layer is released until anhydrous is distilled out. The reaction water released is about 42Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com