Novel tri(dichloropropyl) bisilicate flame retardant compound containing bromine and preparation method thereof

A technology of dichloropropyl and dichloropropoxy disilicate tri-silicate, which is applied in the field of new-type bromine-containing disilicate triester flame retardant compound and its preparation, can solve problems such as difficulty in finding substitutes, and achieve cheap raw materials , Good compatibility, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

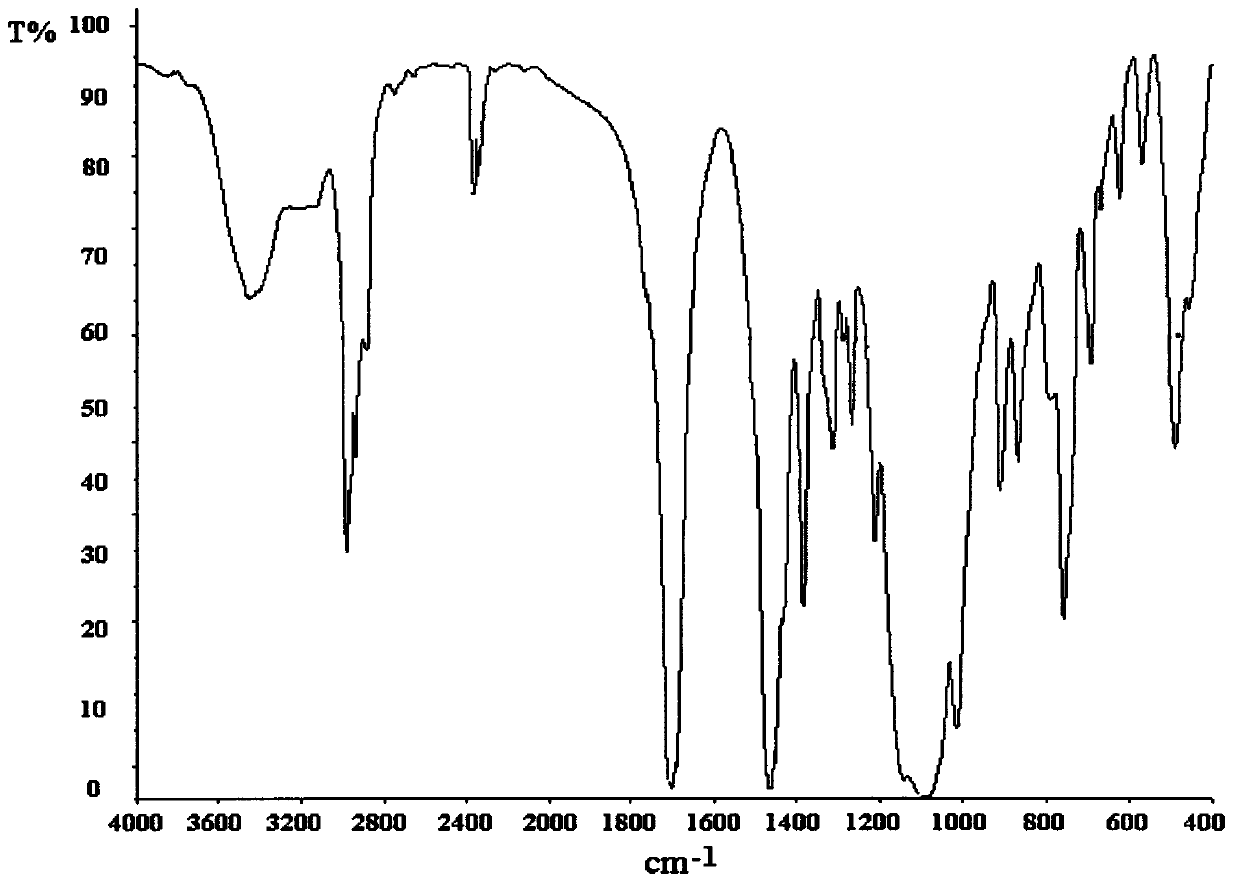

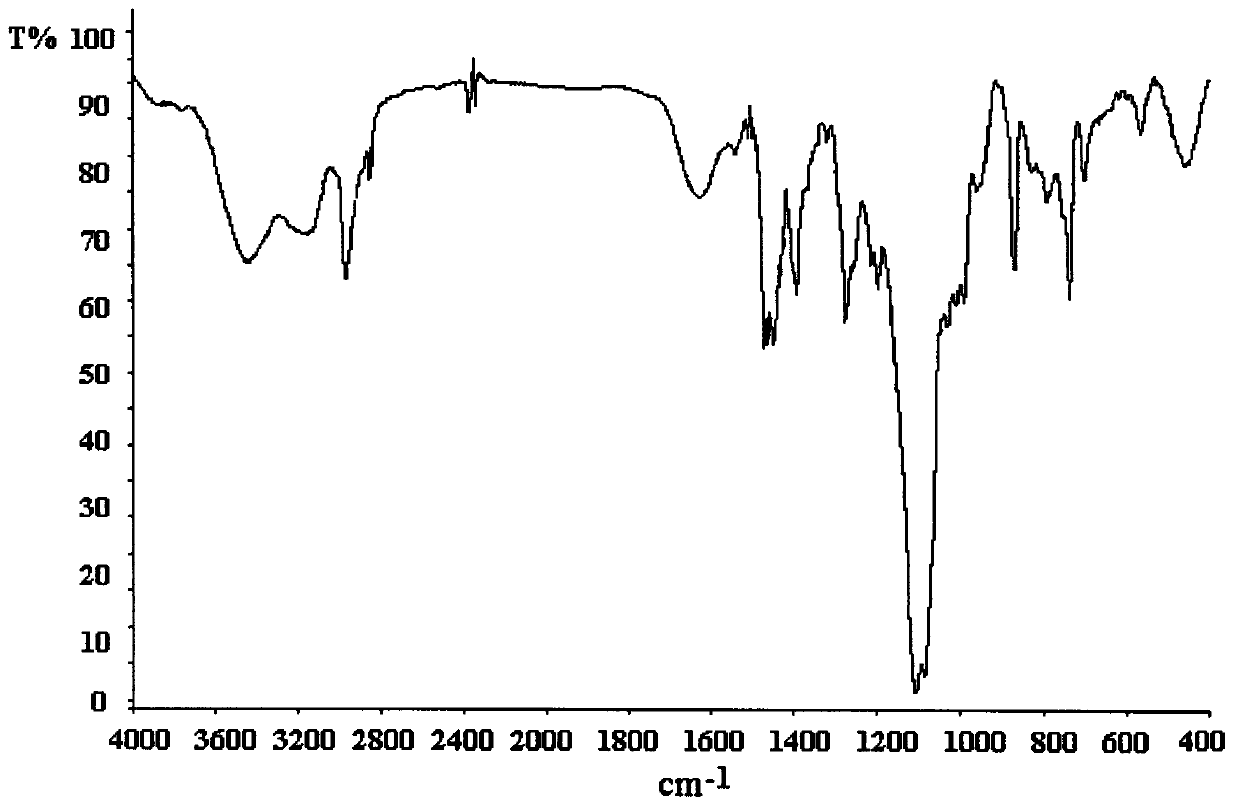

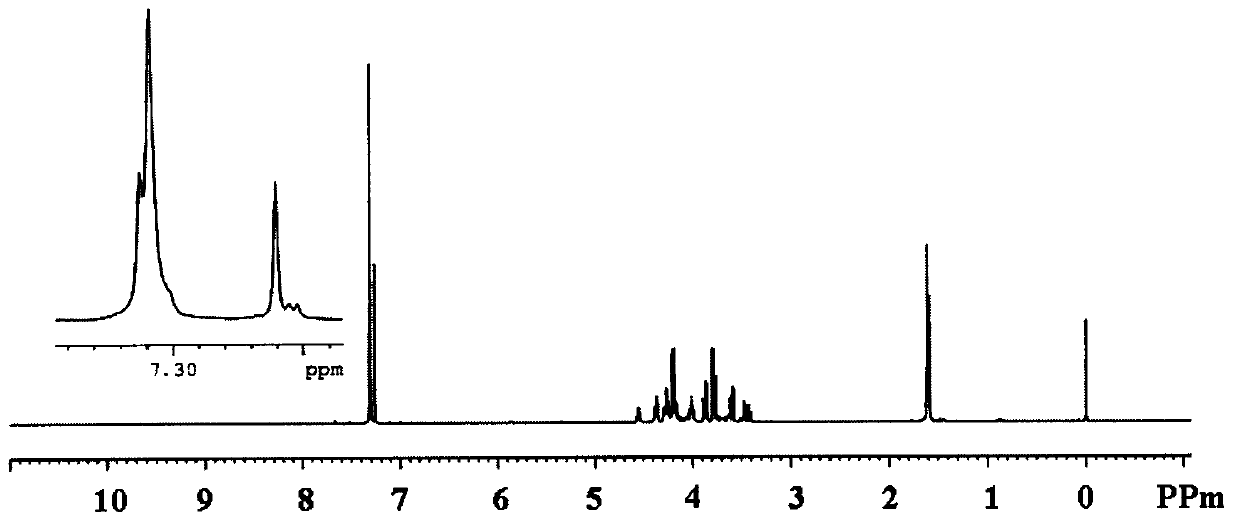

Embodiment 1

[0034] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of diethylene glycol dimethyl ether, and then add 6.8g of silicon tetrachloride (4.54ml, 0.04mol), at 25 Under the condition of ℃, a solution of 13.12g (0.02mol) tetrabromobisphenol A diglycidyl ether dissolved in 40ml of diethylene glycol dimethyl ether was dropped into silicon tetrachloride within 50min, and During the addition process, use an ice-water bath to control the temperature not higher than 50°C. After the dropwise addition, raise the temperature to 80°C within 30 minutes and keep it warm for 3 hours; then cool down to 25°C and add 16.77g (0.13mol) of 2,3-dichloropropanol dropwise , use a cold water bath and drop rate to control the reaction temperature not higher than 50°C. After the drop is completed, the temperature will be raised to 70°C within 1 hour, and the reaction will be carried out for 6 hours. , N-dimethylaniline acid-bind...

Embodiment 2

[0035] Example 2 In a 100ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of toluene, then add 6.8g of silicon tetrachloride (4.54ml, 0.04mol), and at 25°C, the A solution of 13.12g (0.02mol) tetrabromobisphenol A diglycidyl ether dissolved in 40ml of toluene was dropped into silicon tetrachloride within 50 minutes, and the temperature was controlled not higher than 50°C with an ice-water bath during the dropping process , after the dropwise addition, the temperature was raised to 80°C within 30min, and the temperature was kept for 3h; then the temperature was lowered to 25°C, and 15.48g (0.12mol) of 2,3-dichloropropanol was added dropwise, and the reaction temperature was controlled by a cold water bath and a drop rate. At 50°C, after dripping, raise the temperature to 100°C within 1 hour, and react for 4 hours. After the hydrogen chloride is released, the reaction ends, drop the temperature to 50°C and add about 1ml...

Embodiment 3

[0036] Example 3 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of dichloroethane, and then add 6.8g (4.54ml, 0.04mol) of silicon tetrachloride. , a solution of 13.12g (0.02mol) tetrabromobisphenol A diglycidyl ether dissolved in 40ml dichloroethane was dropped into silicon tetrachloride within 50min, and the dropping process was controlled by an ice-water bath The temperature is not higher than 50°C. After the dropwise addition is completed, the temperature is raised to 70°C within 30 minutes and kept for 4 hours; then the temperature is lowered to 25°C, and 16.77g (0.13mol) of 2,3-dichloropropanol is added dropwise. Acceleration controls the reaction temperature not to be higher than 50°C. After dripping, raise the temperature to 80°C within 1 hour, and react for 5 hours. After the hydrogen chloride is released, the reaction ends, and the temperature is lowered to 50°C. Add about 1g of melamine acid-binding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com