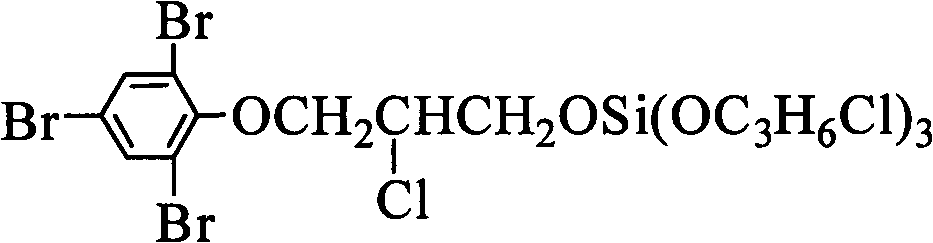

Flame retardant tri(chloropropyl)tribromophenoxychloropropoxyl silicate compound and preparation method thereof

A kind of technology of tribromophenoxy chloropropyl ester and tribromophenyl glycidyl ether, which is applied in the field of flame retardant tribromophenoxy chloropropyl silicate compound and its preparation field, which can solve the limitation , flame retardant plasticizers are few in variety, expensive and other problems, to achieve the effect of low cost, good plasticity and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

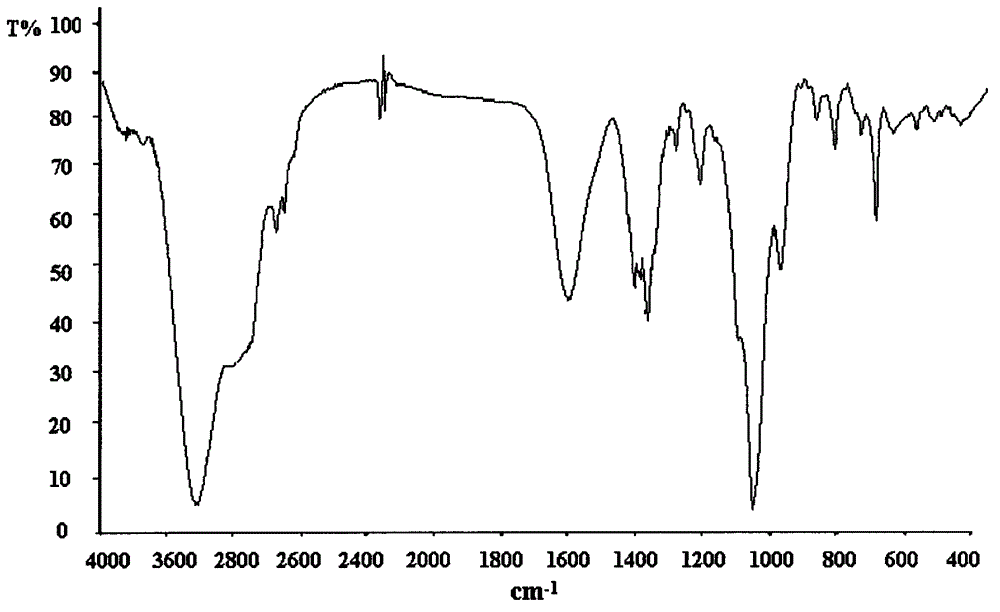

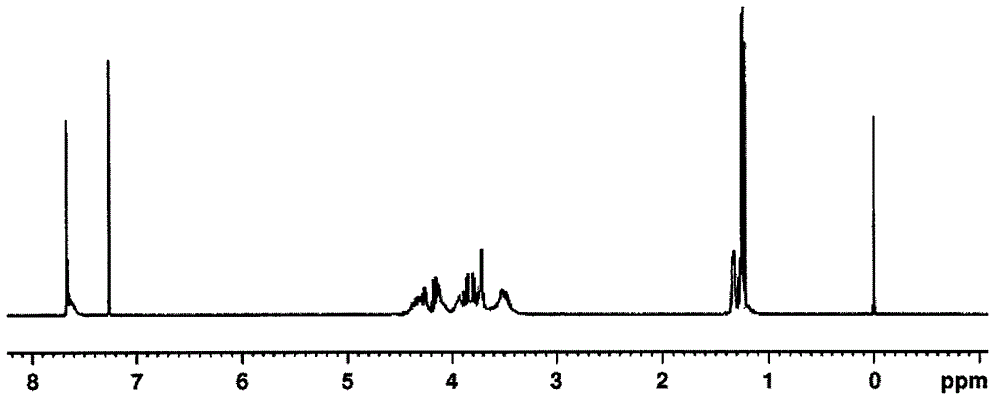

[0029] Example 1 In a 100ml three-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, 10ml of tetrahydrofuran and 0.03mol (5.1g) of silicon tetrachloride were added, and at 20°C, 0.03 mol (11.6g) solution of tribromophenylglycidyl ether, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature rises to 60°C within 1 hour, keeps the temperature for 6 hours, and then cools down to 35°C, under cooling conditions , add 0.09mol (8.51g) of 2-chloropropanol dropwise within 1 hour, and control the temperature at a rate not exceeding 45°C. After dropping, raise the temperature to 50°C for 8 hours, cool down to 40°C, and add about 0.5g of triethylamine Acid-binding agent, adjusted to pH = 5-6, stirred for 1 h, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then evaporated under reduced pressure to remove a small amount of low boiling point matte...

Embodiment 2

[0030]Example 2 In a 100ml three-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, 10ml of chloroform and 0.03mol (5.1g) of silicon tetrachloride were added, and at 20°C, 0.03 mol (11.6g) solution of tribromophenylglycidyl ether, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 60°C within 1 hour, kept for 5 hours, and then cooled to 35°C, under cooling conditions , add 0.099mol (9.36g) of 2-chloropropanol dropwise within 1h, and control the temperature at a rate not exceeding 45°C. After dropping, raise the temperature to 60°C for 7h, cool down to 40°C, and add about 0.5g N, N -Dimethylaniline acid-binding agent, adjusted to pH = 5-6, stirred for 1 hour, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then distilled under reduced pressure to remove excess chloropropanol (for recycling) and a small amount of low b...

Embodiment 3

[0031] Example 3 In a 100ml three-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of acetonitrile, 0.03mol (5.1g) of silicon tetrachloride, and dropwise add 0.03mol (5.1g) of silicon tetrachloride dissolved in 50ml of acetonitrile at 20°C within 50min. mol (11.6g) solution of tribromophenylglycidyl ether, the dropwise addition process controls the temperature not to exceed 35°C, after the drop is completed, the temperature is raised to 70°C within 1 hour, kept for 4 hours, and then cooled to 35°C, under cooling conditions , add 0.108mol (10.21g) of 3-chloropropanol dropwise within 1 hour, and control the temperature at a rate not exceeding 45°C. After dropping, raise the temperature to 70°C for 6 hours, cool down to 40°C, and add about 0.5g of pyridine-bound acid agent, adjusted to pH = 5-6, stirred for 1 h, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then distilled off excess chlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com