Ce1-xZrxO2 nano solid solution homogenate modified lithium ion battery anode material and preparation method thereof

A positive electrode material and solid solution technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle performance, poor battery thermal stability, and reduced cycle performance, and achieve high initial capacity, good rate performance, and cycle life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

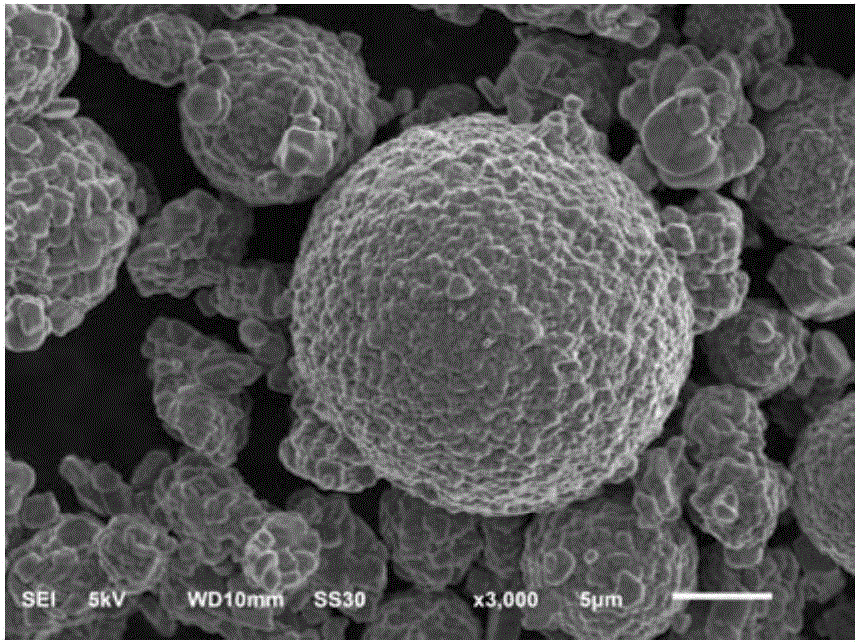

Image

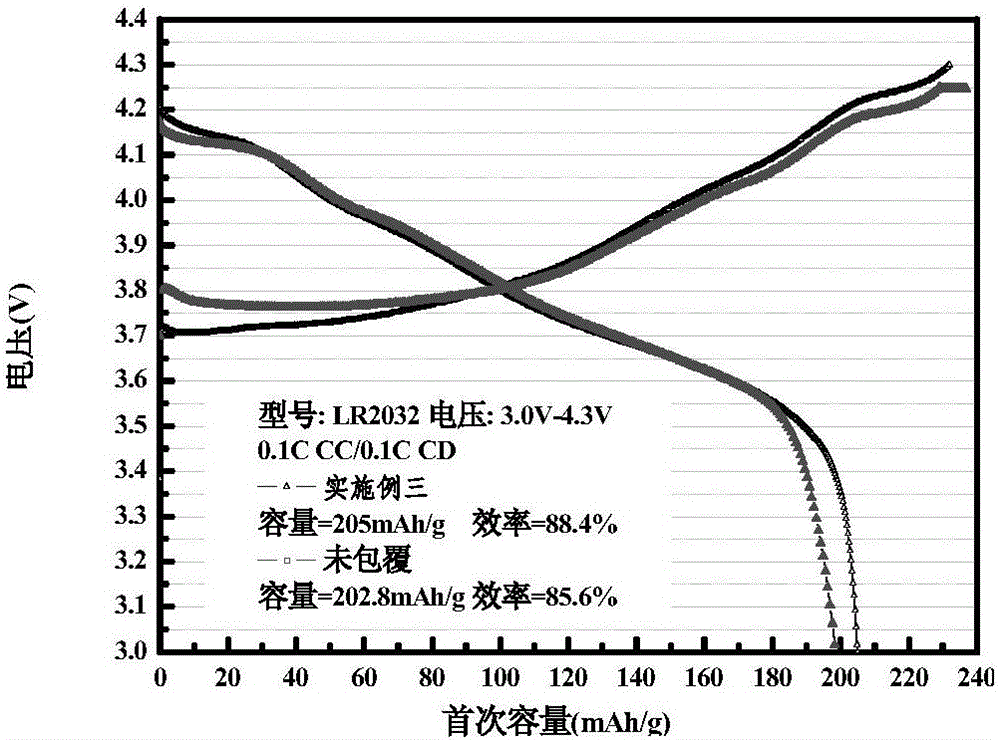

Examples

preparation example Construction

[0024] Ce of the present invention 1-x Zr x o 2 A method for preparing a nanocomposite solid solution homogeneously modified lithium ion cathode material, the method comprising the following steps:

[0025] (1) Weigh soluble cerium salt and zirconium salt according to a certain molar ratio, dissolve them in deionized water, and prepare a mixed solution so that the total concentration of metal ions in the solution is 0.2M-0.5M, and the molar ratio of the two metal elements Be Ce: Zr=(5-9):(1-5);

[0026] (2) LiNi x co y m (1-x-y) o 2 The positive electrode material is dispersed in deionized water to form a suspension, so that the solid-to-liquid mass ratio is 1: (1-3), and the solution temperature is maintained at 20-60 ° C, and a surfactant is added; LiNi x co y m (1-x-y) o 2 In terms of materials, the mass of surfactant added is 0.1%-0.5%, and after ultrasonic vibration for 10-60min, stir at room temperature for 1h-4h;

[0027] (3) According to the total mass of me...

Embodiment 1

[0041] 1) Prepare a mixed solution of cerium nitrate and zirconium nitrate according to the molar ratio of elements Ce:Zr=1:1 and dissolve it in deionized water to prepare a mixed solution of 200ml so that the total concentration of metal ions in the solution Zr and Ce is 0.5M. The concentration is 0.1M (NH 4 ) 2 CO 3 .

[0042] 2) 1000g LiNi 0.8 co 0.1 mn 0.1 o 2 (BMT910, an existing product of B&M) was put into deionized water and put into 1000ml of deionized water, and stirred with an electric stirrer to keep the solution temperature at 20°C. At the same time, 1g of PEG4000 was added, and after ultrasonication for 10min, stirred for 1h. During the stirring process, the Add 200ml of cerium nitrate and zirconium nitrate mixed solution dropwise to LiNi 0.8 co 0.1 mn 0.1 o 2 Material, continue to stir for 0.5h after dropwise addition.

[0043] 3) Add 0.1M (NH 4 ) 2 CO 3 Add the solution dropwise to the suspension, and stop the dropwise addition when the pH=8-9 (NH...

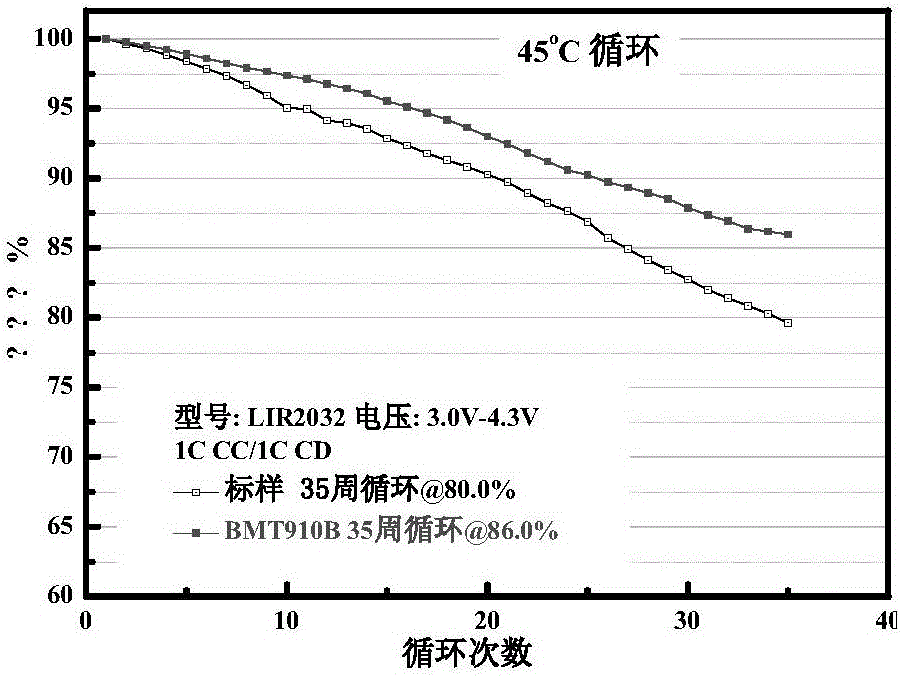

Embodiment 2

[0047] 1) Prepare a mixed solution of cerium nitrate and zirconium nitrate according to the molar ratio of elements Ce:Zr=0.7:0.3 and dissolve it in deionized water to prepare a mixed solution of 500ml so that the total concentration of metal ions in the solution Zr and Ce is 0.2M. Concentration of 0.5M NH 4 HCO 3 .

[0048] 2) 2000g LiNi 0.8 co 0.15 al 0.05 o 2 (B&M's existing product BMT920) was put into deionized water and put into 2000ml of deionized water, stirred with an electric stirrer, and kept the solution temperature at 40°C. At the same time, 2g of PEG4000 was added, and after ultrasonication for 20min, stirred for 2h. During the stirring process, 500ml The mixed solution of cerium nitrate and zirconium nitrate was added dropwise to LiNi 0.8 co 0.15 al 0.05 o 2 Material, continue to stir for 1h after dropwise addition.

[0049] 3) Add 0.5M NH 4 HCO 3 Add the solution to the suspension, stop adding NH when the pH=8~9 4 HCO 3 Solution, continue to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com