Non-aqueous electrolyte secondary battery

一种非水电解质、二次电池的技术,应用在非水电解质蓄电池、二次电池、锂蓄电池等方向,能够解决循环特性变差、放电容量降低、加速正极侧电解质氧化分解等问题,达到循环特性和充电保存性能优良、初期容量大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100]

[0101] Lithium-cobalt composite oxide (active material A), which is one of positive electrode active materials, was produced as follows.

[0102] Zirconium (Zr) which is 0.15 mol% relative to cobalt (Co) and magnesium (Mg) which is 0.5 mol% relative to cobalt are co-precipitated as hydroxides, and thermal decomposition reactions occur, thereby obtaining a product containing zirconium and magnesium. tricobalt tetroxide (Co 3 o 4 ).

[0103] This tricobalt tetroxide was mixed with lithium carbonate, and fired at 850° C. for 24 hours in an air atmosphere. This was pulverized in a mortar to an average particle diameter of 14 μm to obtain a lithium-cobalt composite oxide (active material A) containing zirconium and magnesium.

[0104] In addition, another component in the positive electrode active material: lithium manganese nickel composite oxide (active material B) was produced as follows.

[0105] Lithium carbonate (Li 2 CO 3 ) and Ni 0.33 mn 0.33 co 0.34 (OH...

Embodiment 2

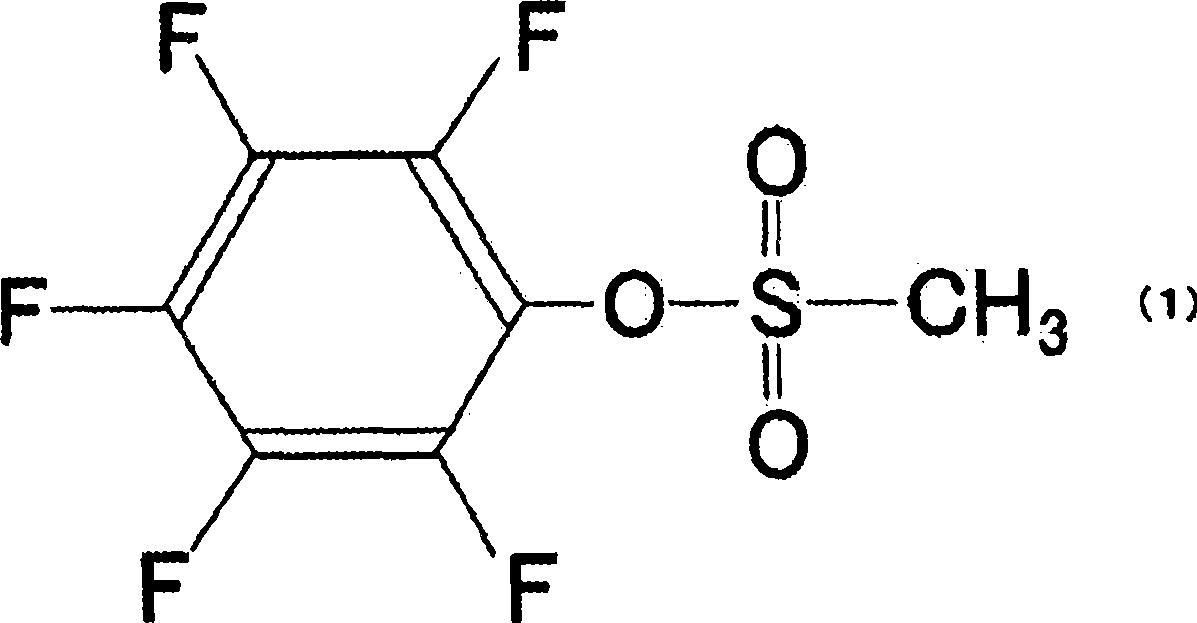

[0115] A nonaqueous electrolyte secondary battery was produced in the same manner as in Example 1 except that the amount of pentafluorophenyl methanesulfonate added was 2.0% by mass relative to the total mass of the nonaqueous electrolyte.

Embodiment 3

[0117] A nonaqueous electrolyte secondary battery was manufactured in the same manner as in Example 1 except that the amount of pentafluorophenyl methanesulfonate added was 3.0% by mass relative to the total mass of the nonaqueous electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com