Patents

Literature

507results about How to "Good capacity retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

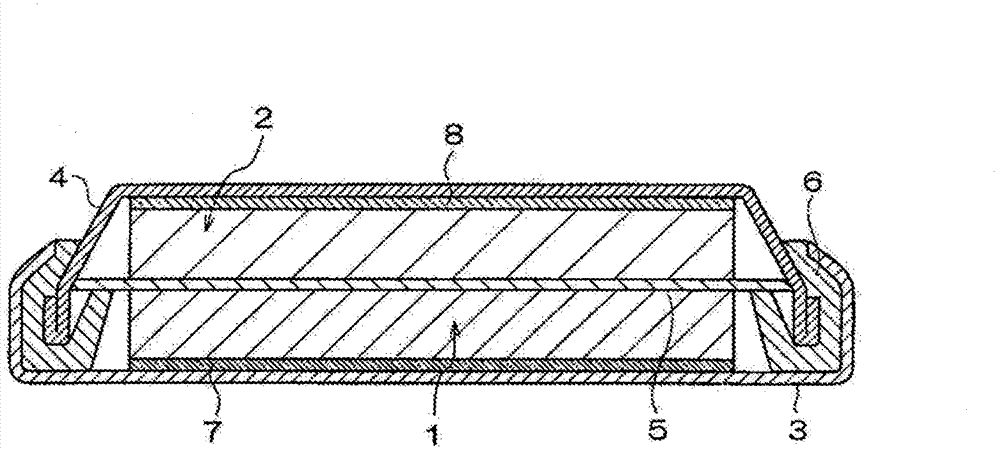

Electrode used for a non-aqueous electrolyte secondary battery and a non-aqueous electrolyte secondary battery using the same for a negative electrode

InactiveUS20050074671A1Increase capacityInsufficient releaseElectrode carriers/collectorsLi-accumulatorsPorosityMetallic materials

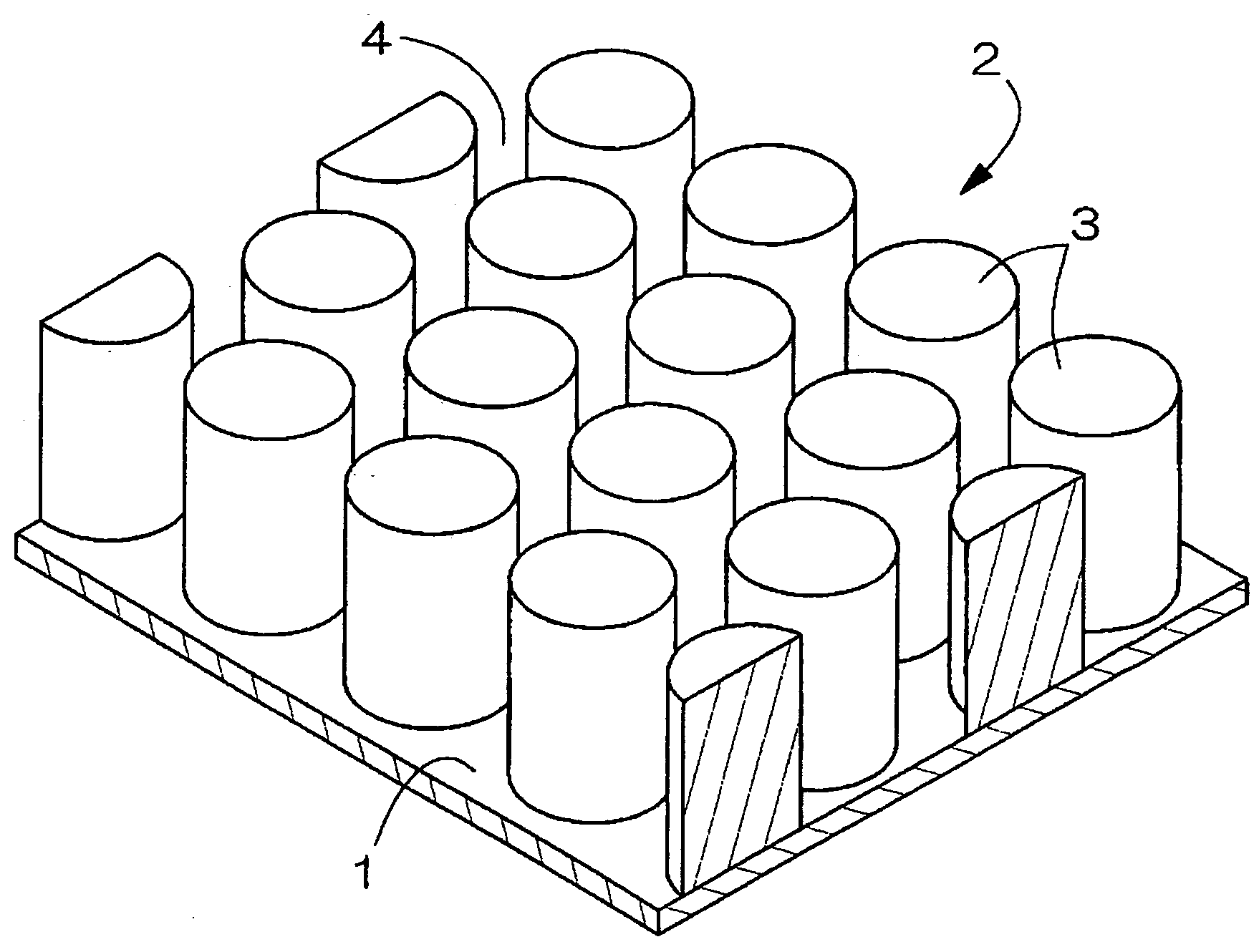

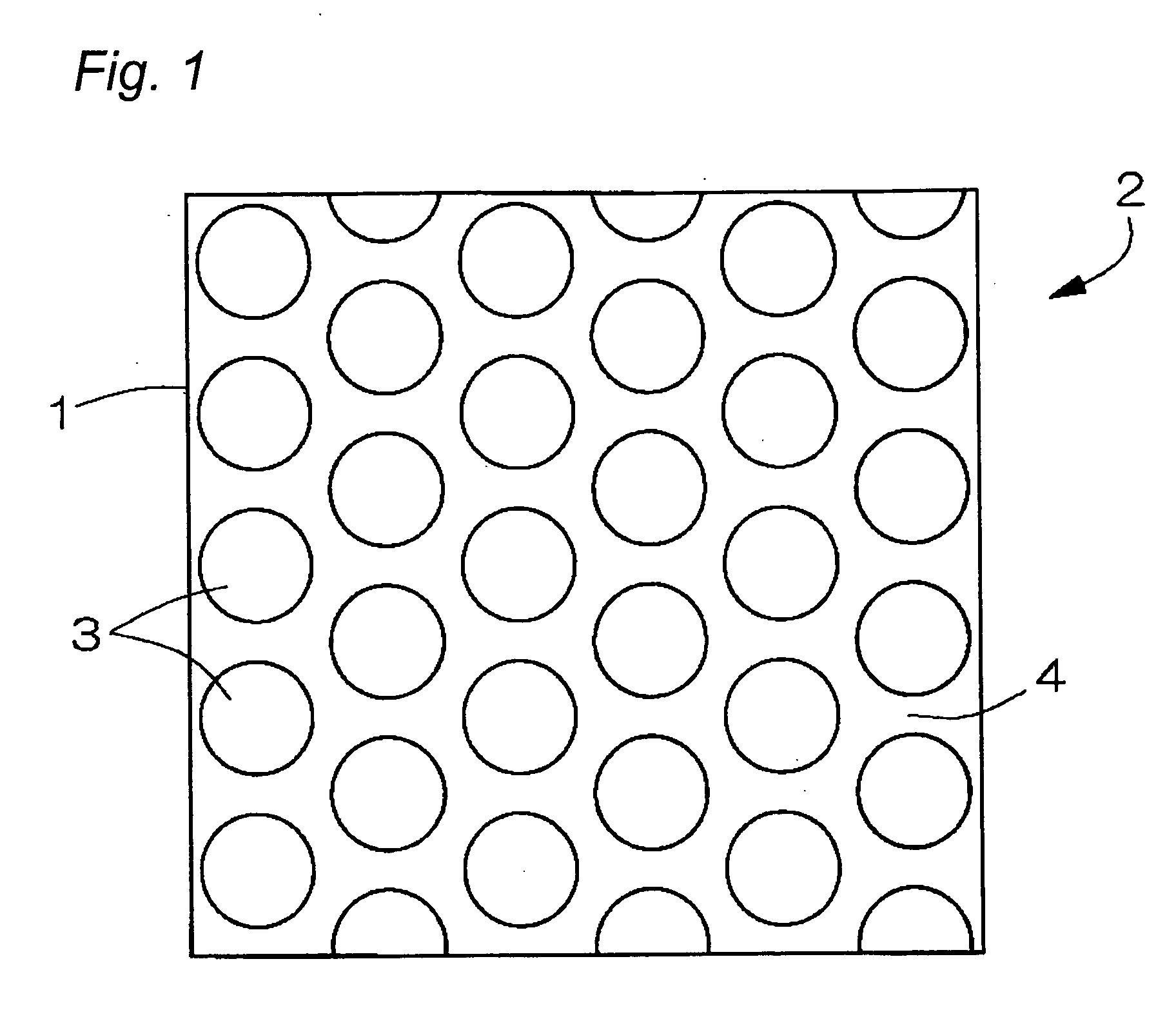

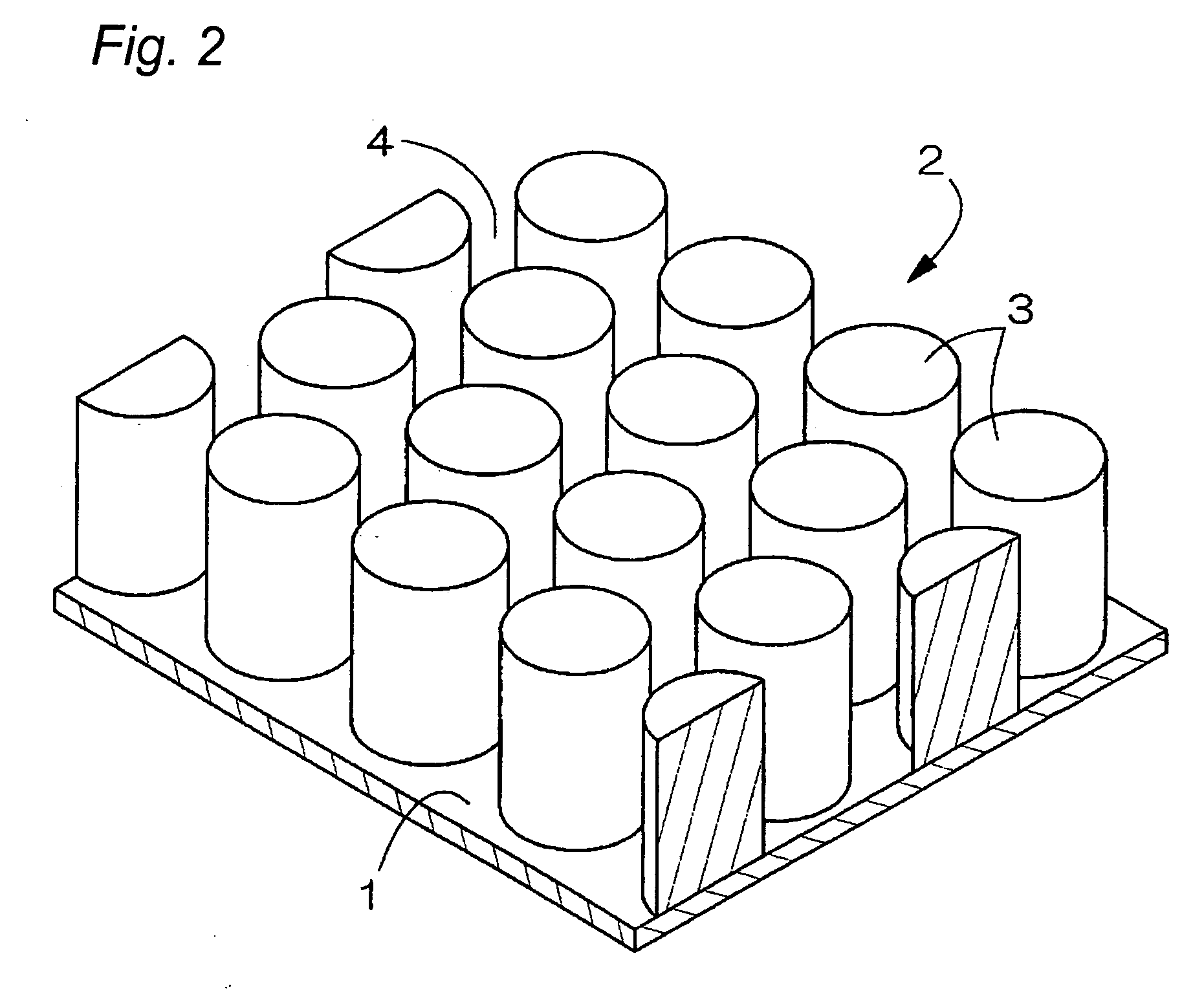

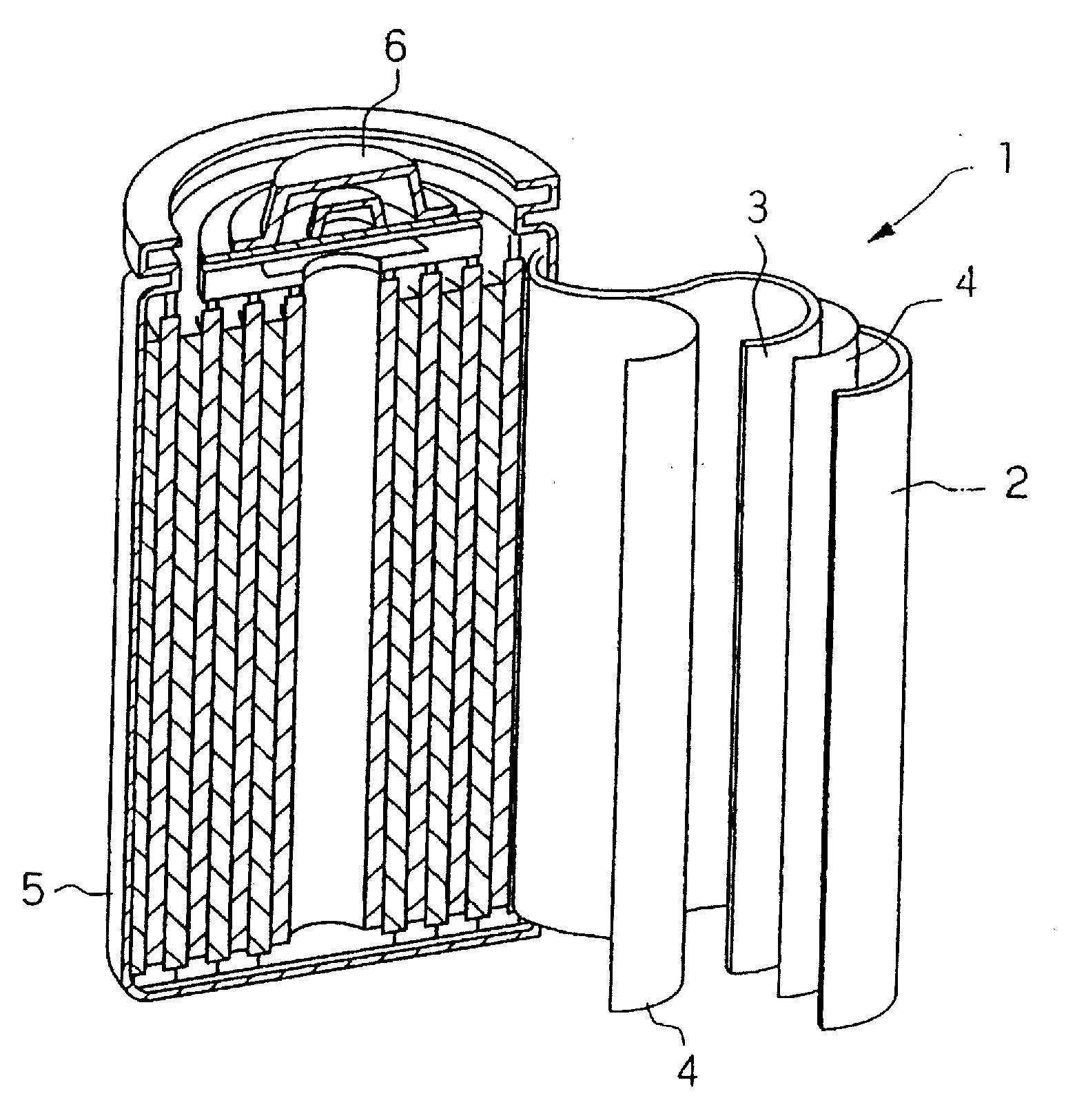

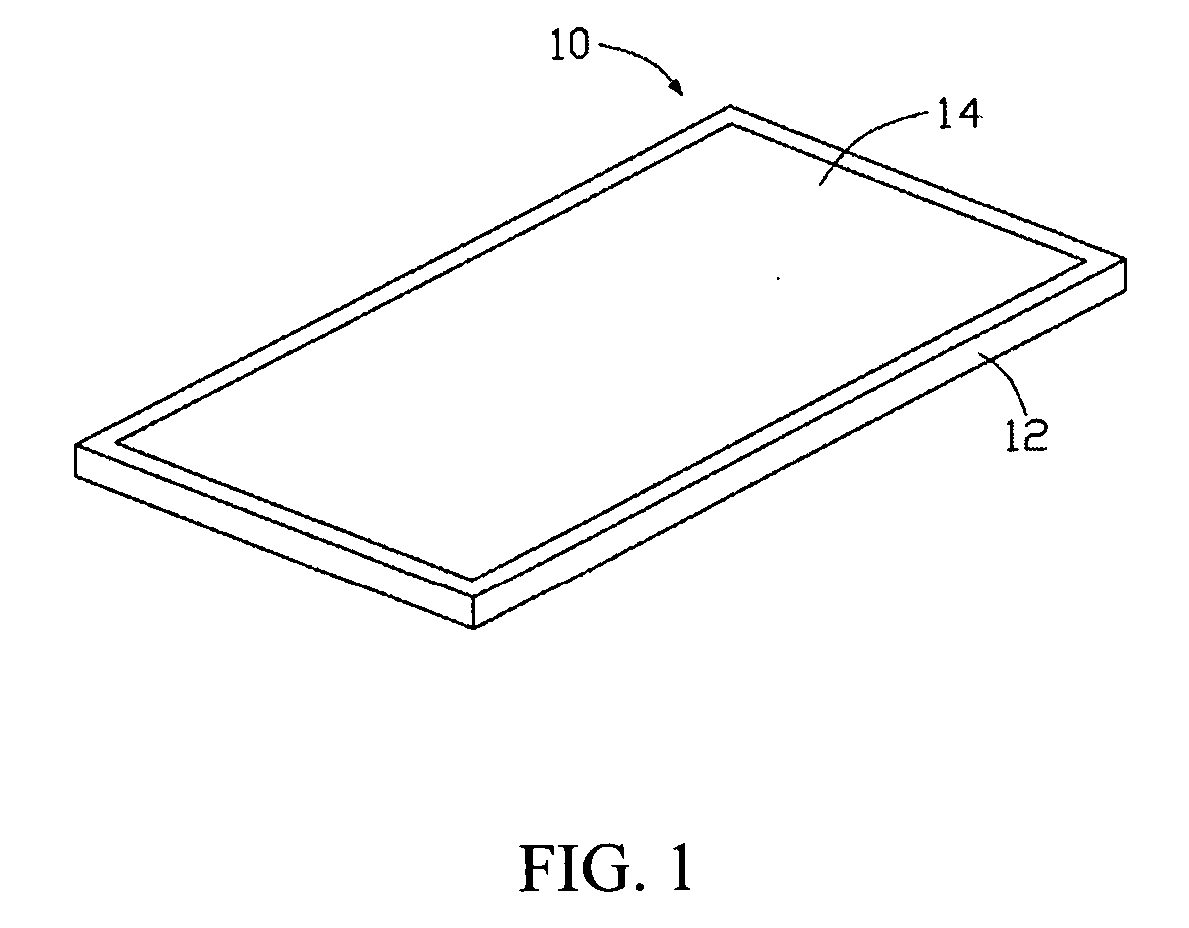

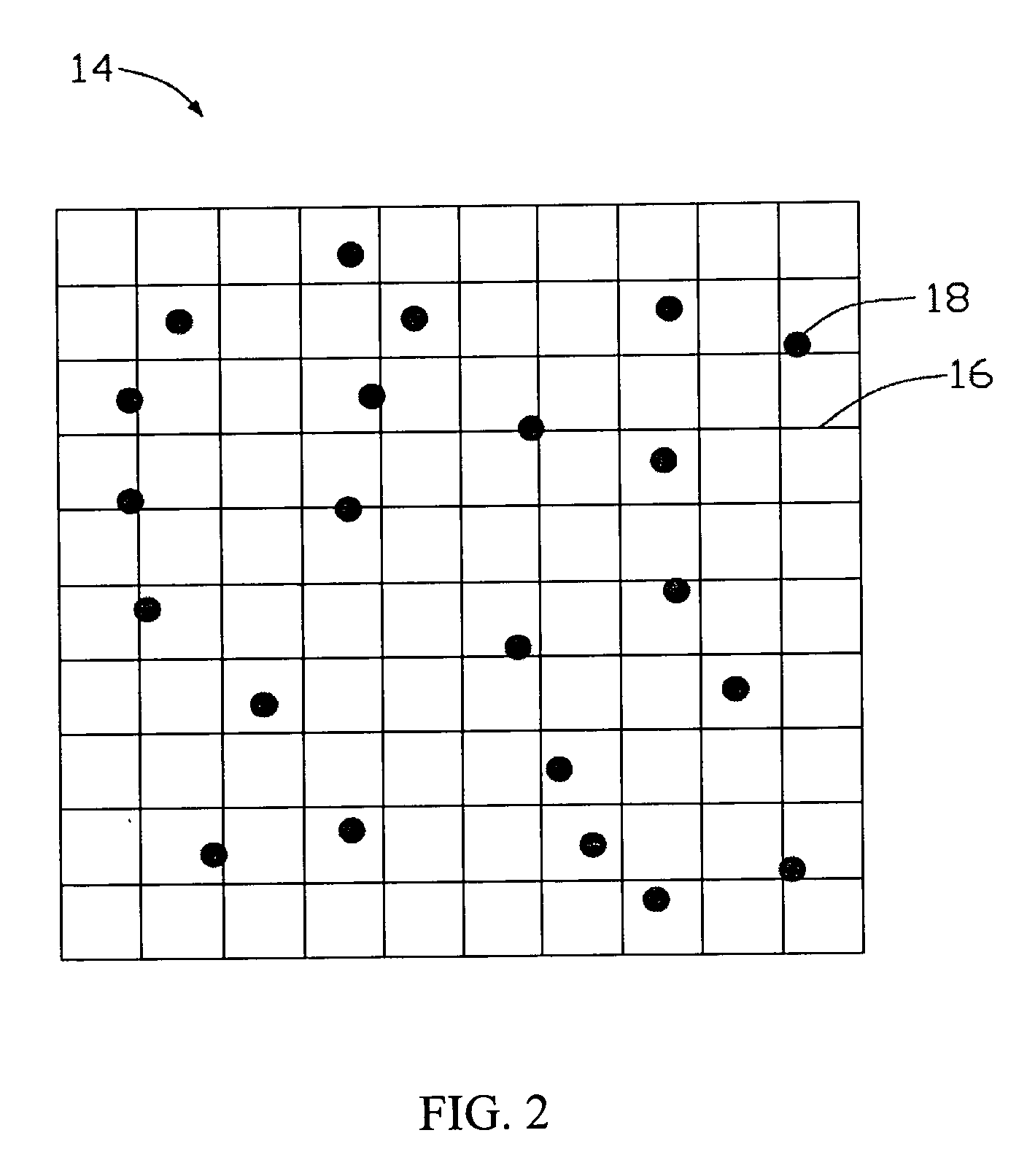

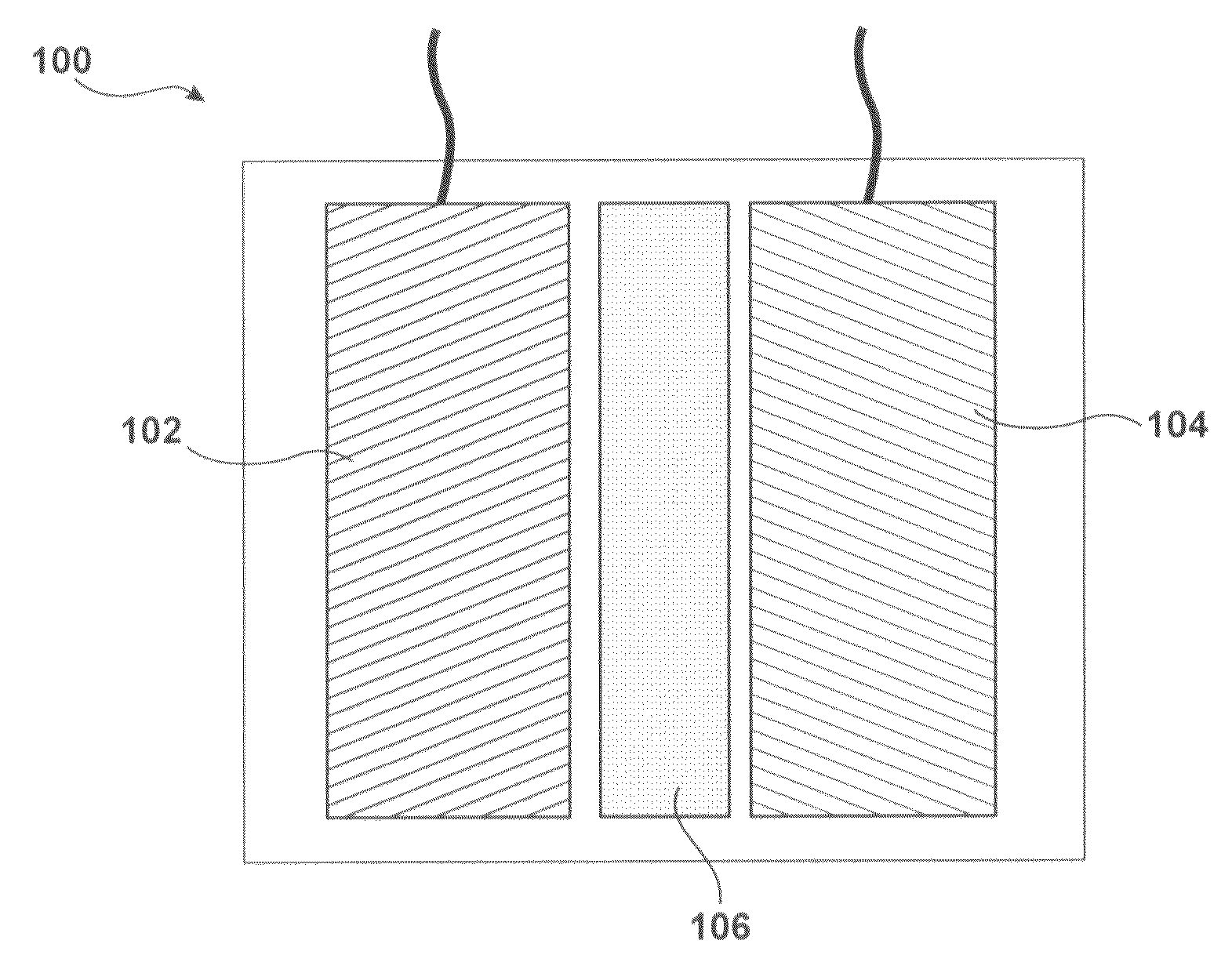

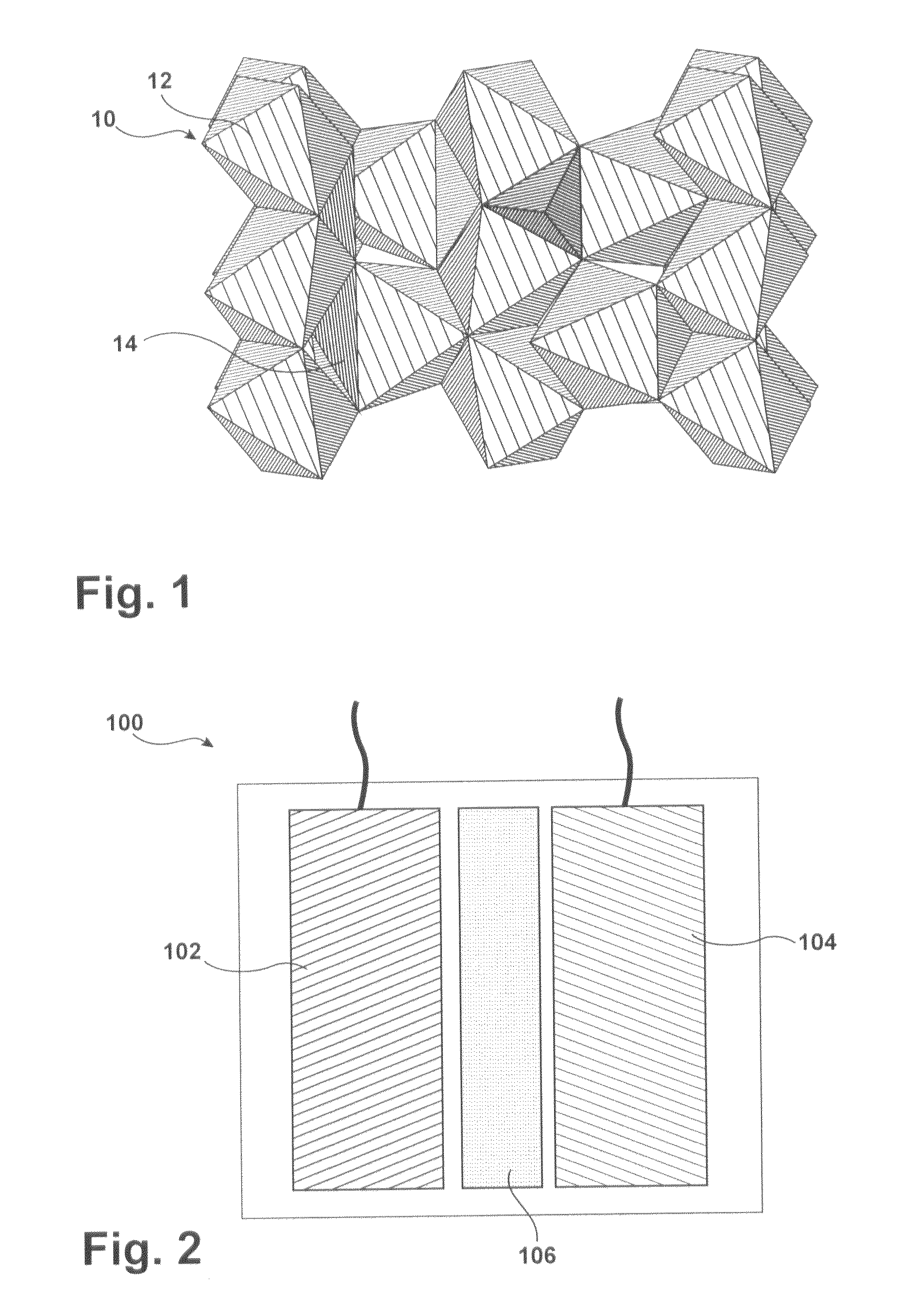

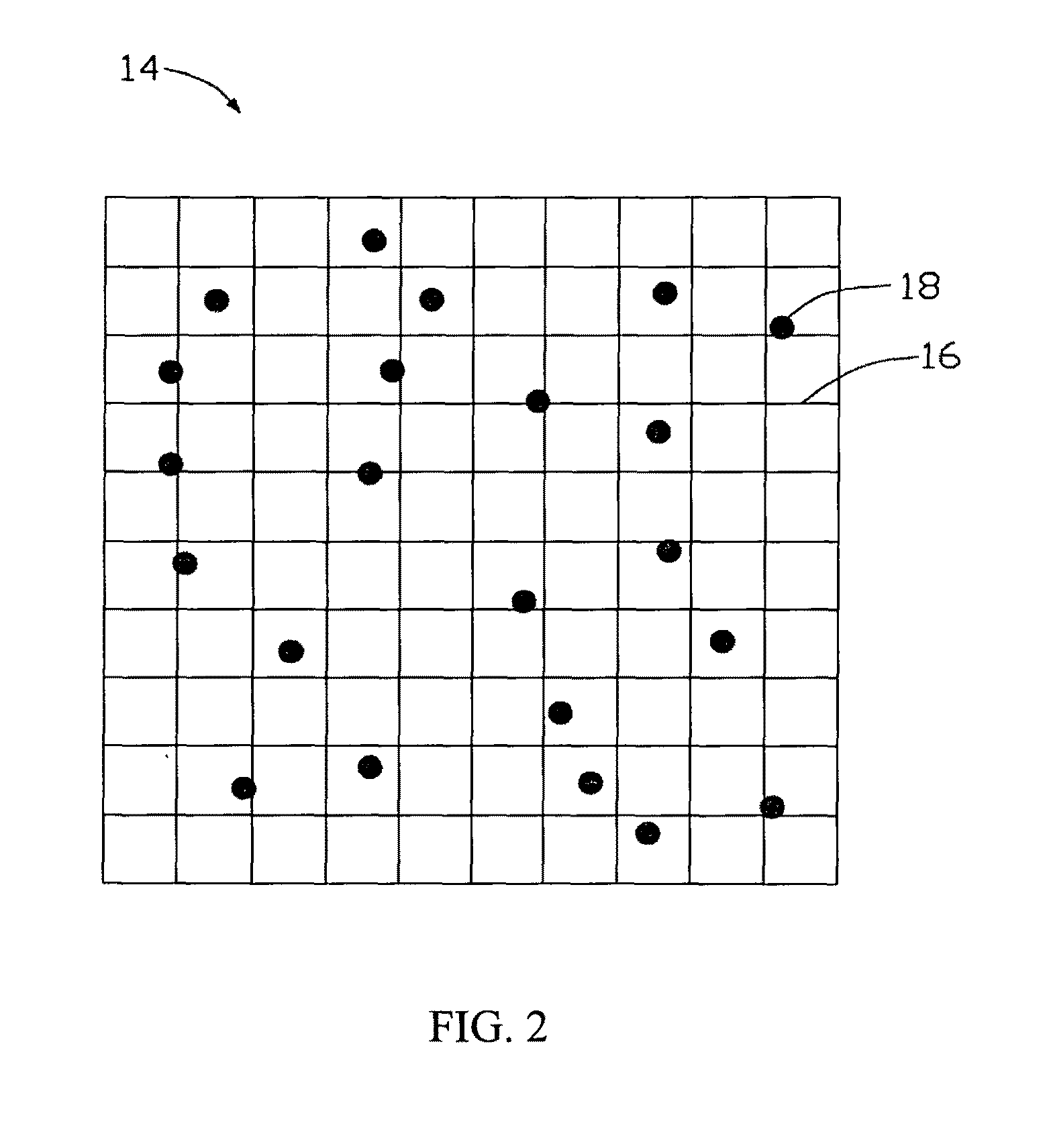

An electrode according to the invention can provide a non-aqueous electrolyte secondary battery having an ability to release a volume expansion at the time of charge and discharge as well as the time of a cycle. The electrode comprises a current collector made of a material which is not alloyed with Li, and a dot pattern 2 of a metallic material able to be alloyed with Li formed on the current collector. At the time of charge, since the volume expansion of each dot 3 is carried out so as to bury adjoining crevices 4 between the dots, a stress generated is released, thereby degradation of an electrode being avoided. Each dot may also be made into porosity.

Owner:HITACHI MAXELL ENERGY LTD

Nonaqueous electrolytic solution and nonaqeuous-electrolyte secondary battery

ActiveUS20120308881A1Improve conductivityReduce resistanceElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesPhysical chemistryFluorosulfonic acid

An object of the invention is to provide a nonaqueous electrolytic solution which is capable of bringing about a nonaqueous-electrolyte secondary battery improved in initial charge capacity, input / output characteristics, and impedance characteristics. The invention relates to a nonaqueous electrolytic solution which comprises: a nonaqueous solvent; LiPF6; and a specific fluorosulfonic acid salt, and to a nonaqueous-electrolyte secondary battery containing the nonaqueous electrolytic solution.

Owner:MU IONIC SOLUTIONS CORP +1

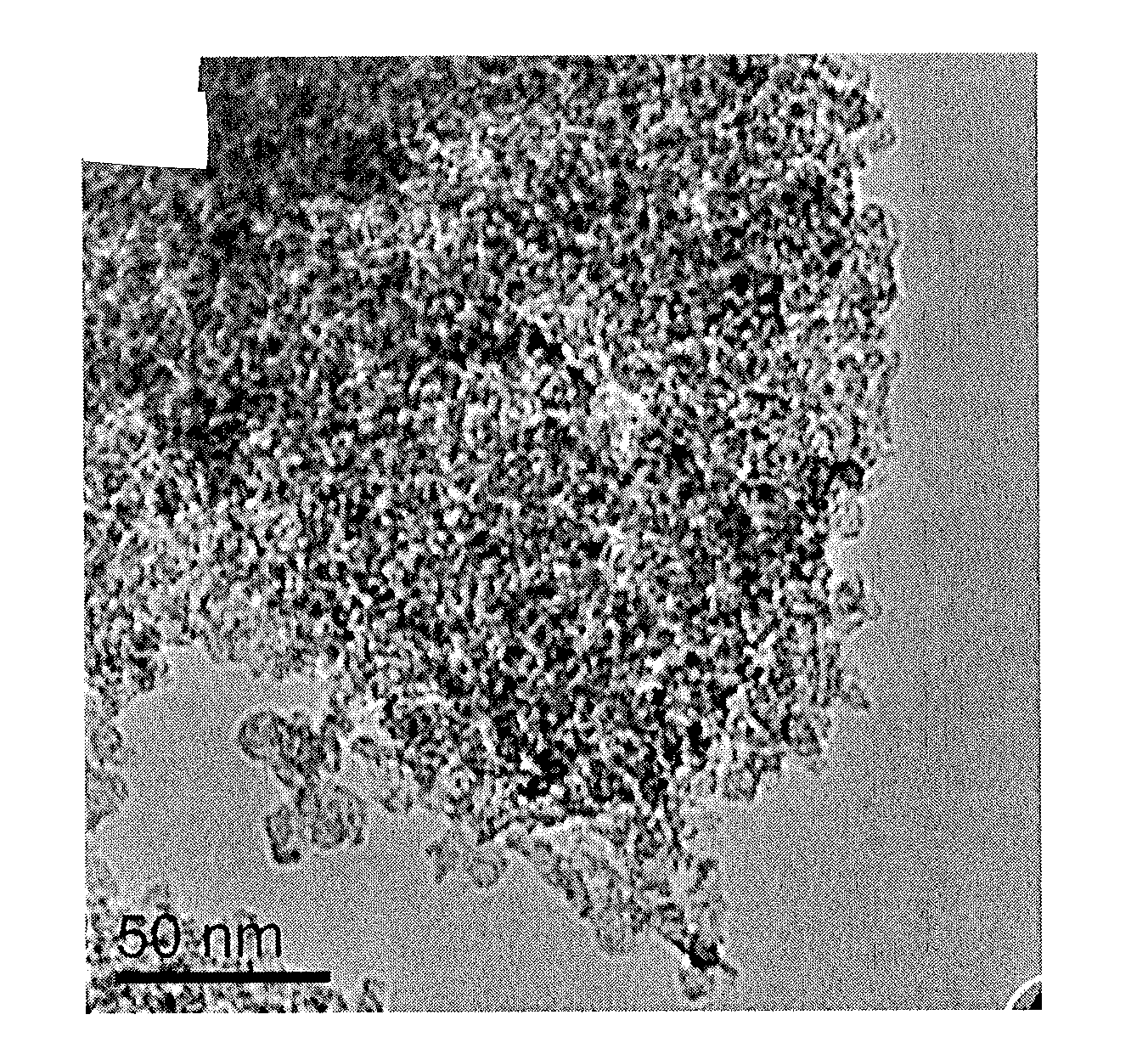

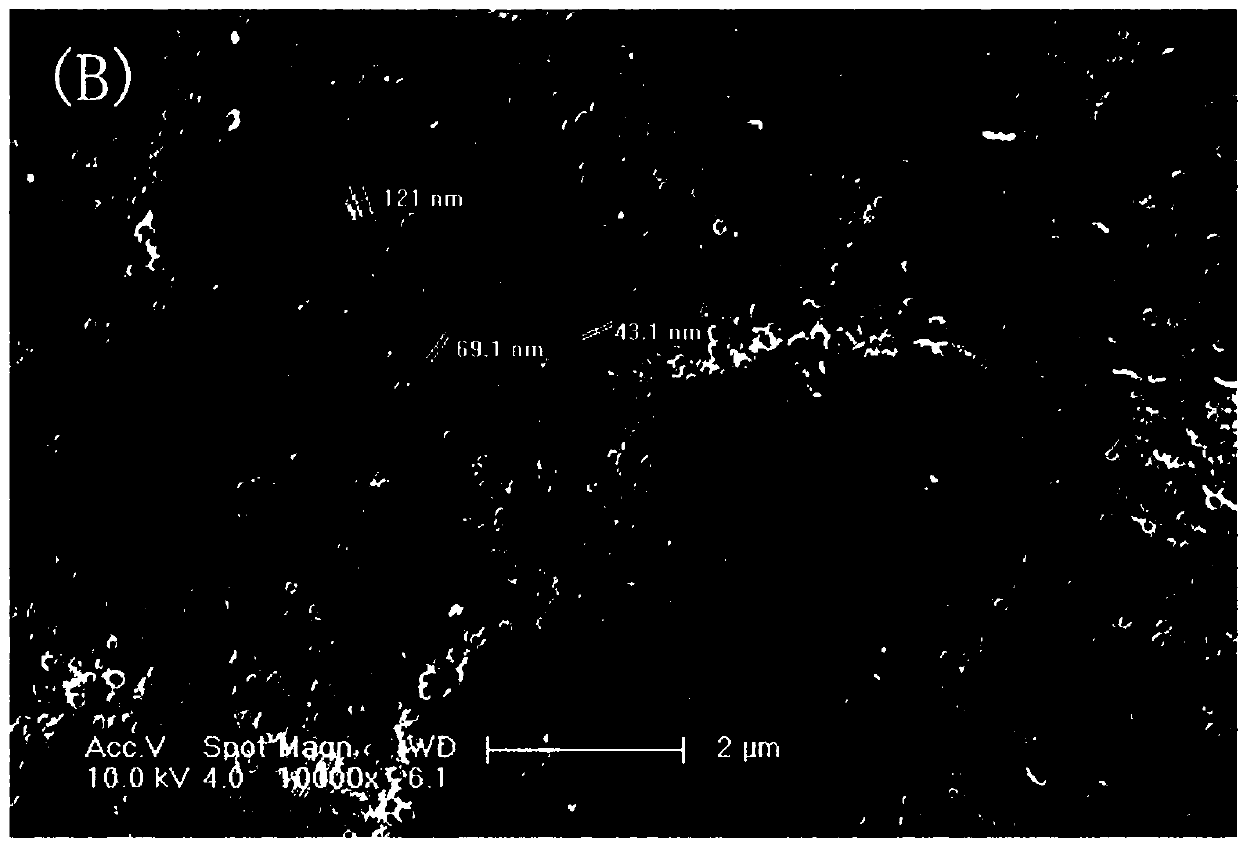

Negative active material including metal nanocrystal composite, method of preparing the same, and anode and lithium battery including the negative active material

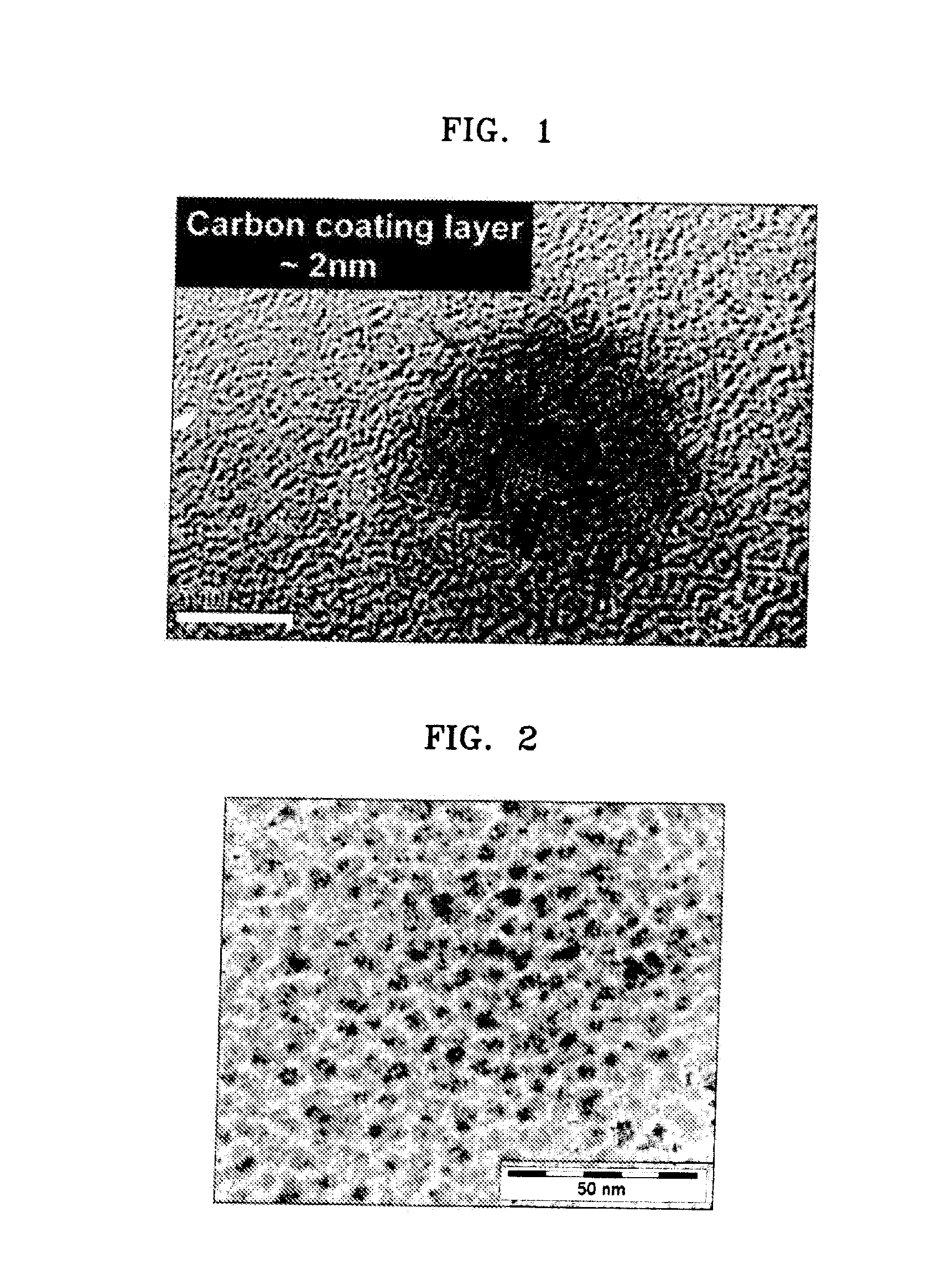

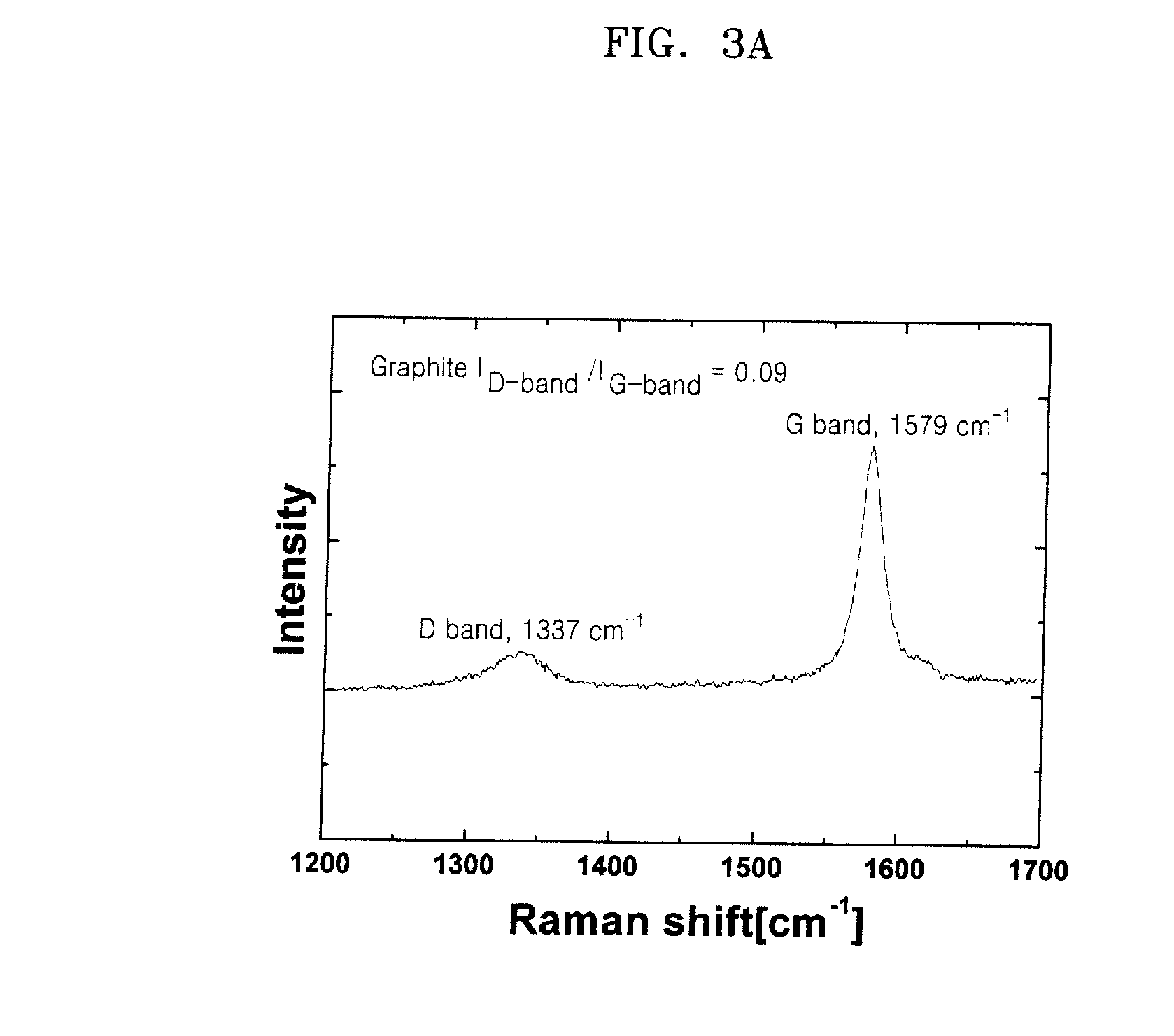

InactiveUS20070264574A1Reduce formationHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerCarbon coating

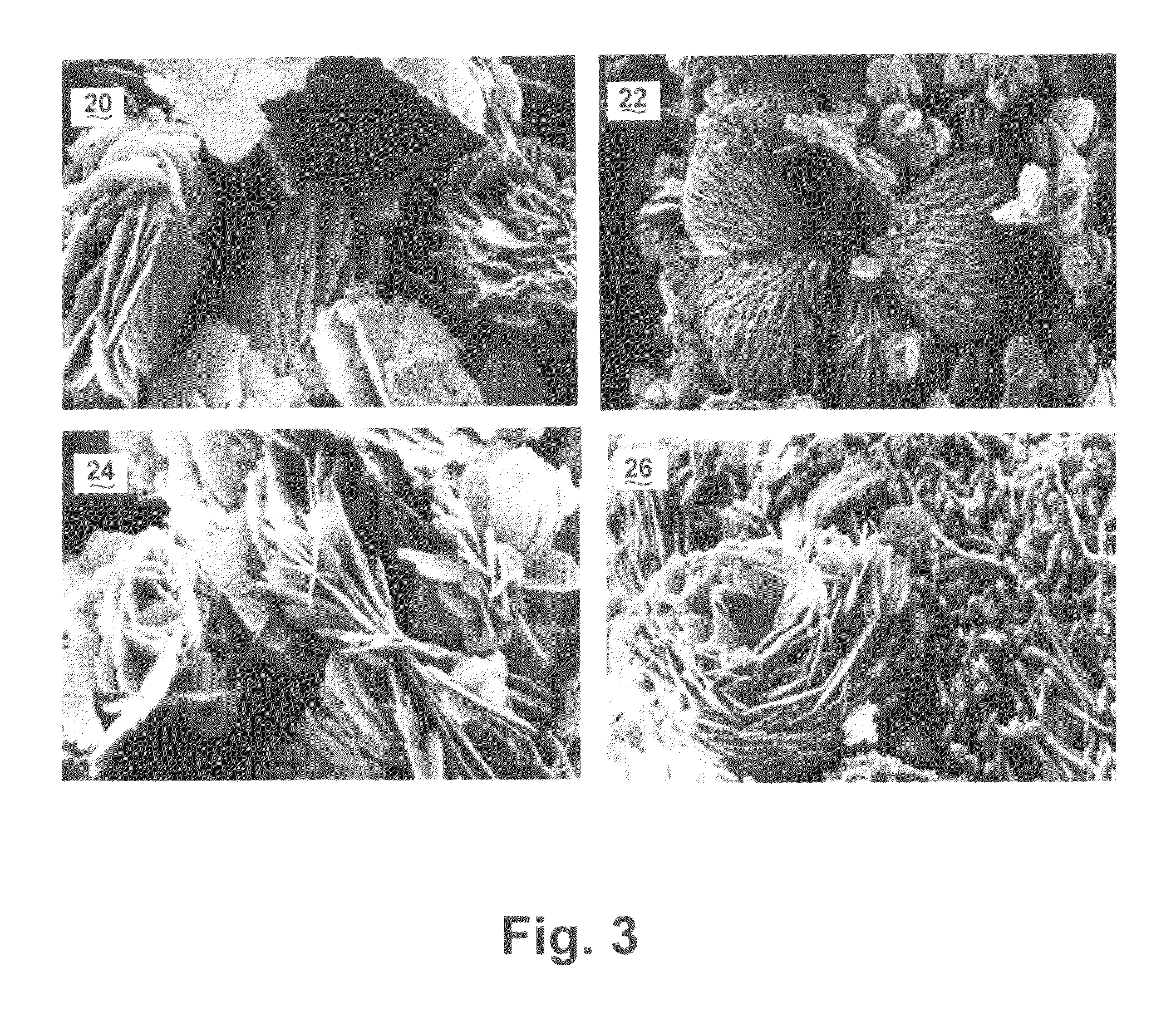

Negative active materials including metal nanocrystal composites comprising metal nanocrystals having an average particle diameter of about 20 nm or less and a carbon coating layer are provided. The negative active material includes metal nanocrystals coated by a carbon layer, which decreases the absolute value of the change in volume during charge / discharge and decreases the formation of cracks in the negative active material resulting from a difference in the volume change rate during charge / discharge between metal and carbon. Therefore, high charge / discharge capacities and improved capacity retention capabilities can be obtained.

Owner:SAMSUNG SDI CO LTD

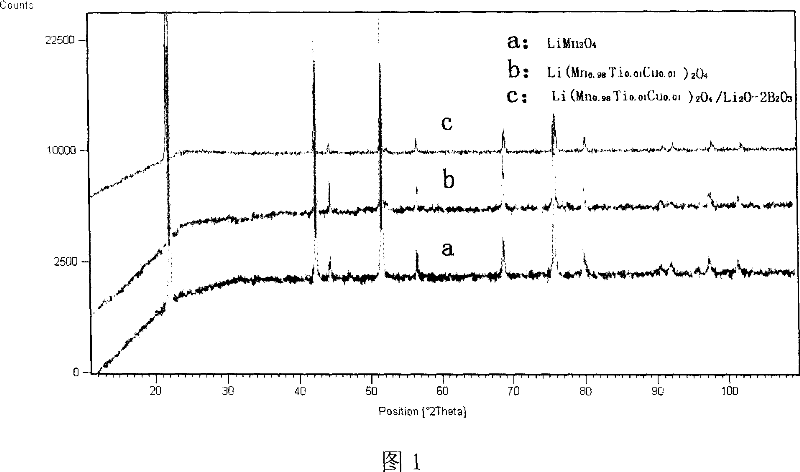

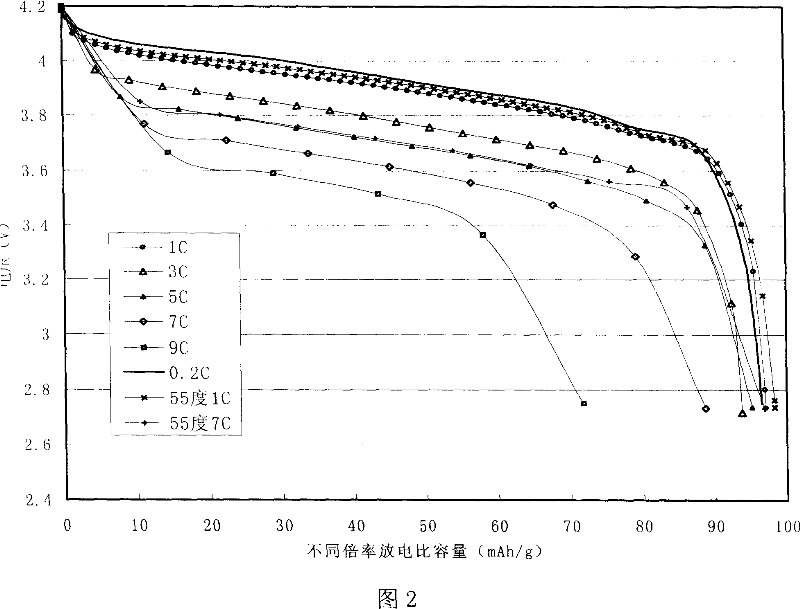

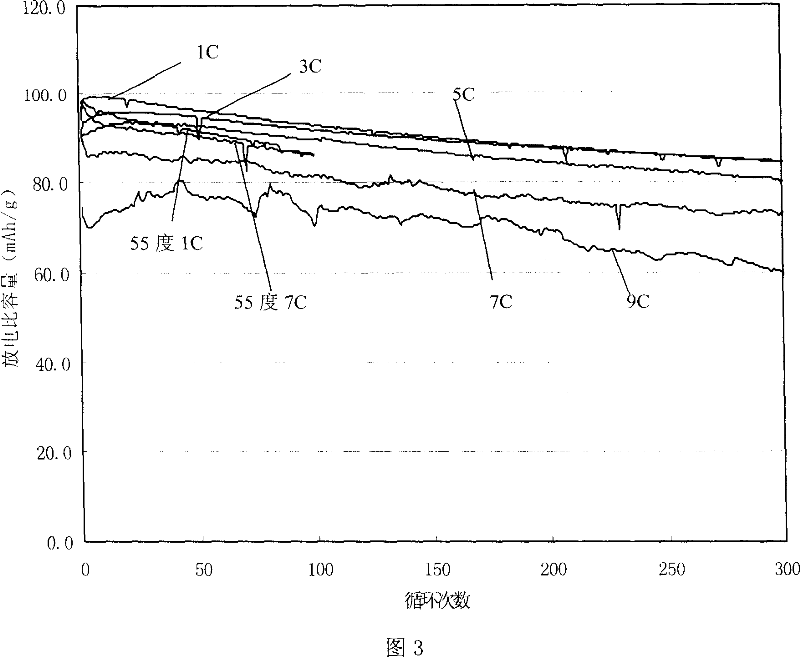

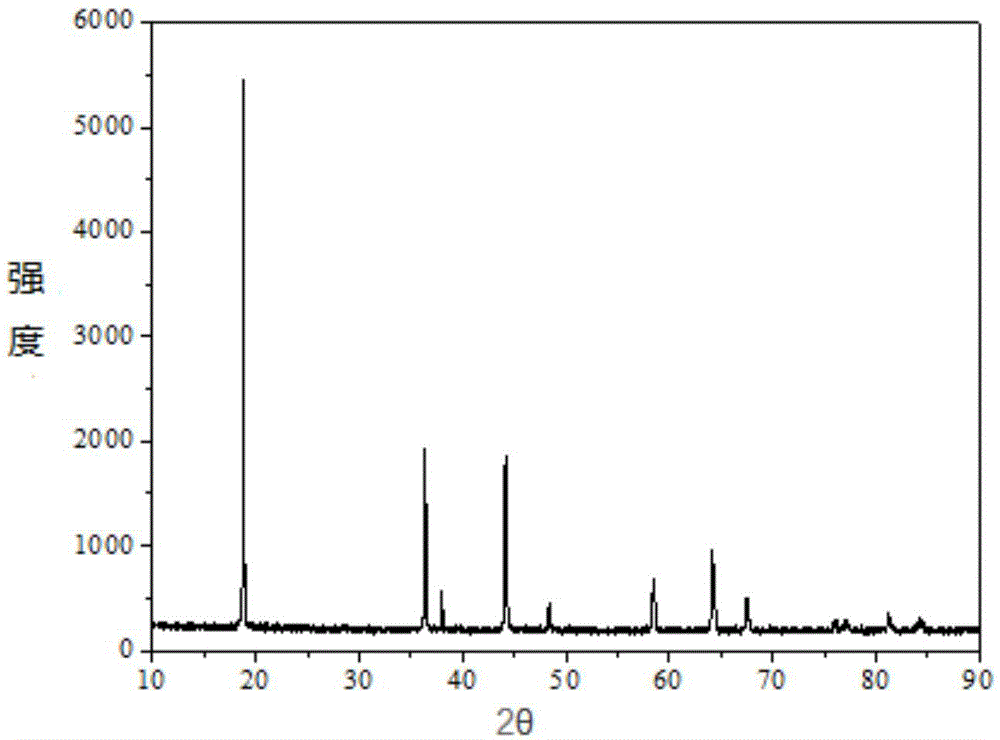

Method for preparing modified spinelle manganic acid lithium material and lithium secondary battery

ActiveCN101038965AImprove structural stabilityHigh capacity retentionElectrode manufacturing processesLithium compoundsComposite oxideChemistry

The invention discloses a modified spinel lithium manganate material used in anode material of lithium secondary battery, the lithium manganate is a kind of doped lithium manganate LiaMn2-bXbO4 with other metallic element X, wherein X is at least one element of chroumium, gallium, magnesium, titanium, cuprum, zincum, 0.97 <= a <= 1.07, 0 <= b <= 0.1; and the surface of the said doped lithium manganate LiaMn2-bXbO4 is provided with a coat which contains at least one kind of boron-lithium composite oxides, cobalt-lithium composite oxides, vanadium-lithium composite oxides or carbon layer. The invention also discloses a preparing method for the said material and the lithium secondary battery using the said material as anode material. The invention provided modified spinel lithium manganate material has relative good high rate deep discharge capacity in normal temperature or high temperature, in mean time, the preparing method is easy for control and operation and industrialisation, and production cost thereof is low.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

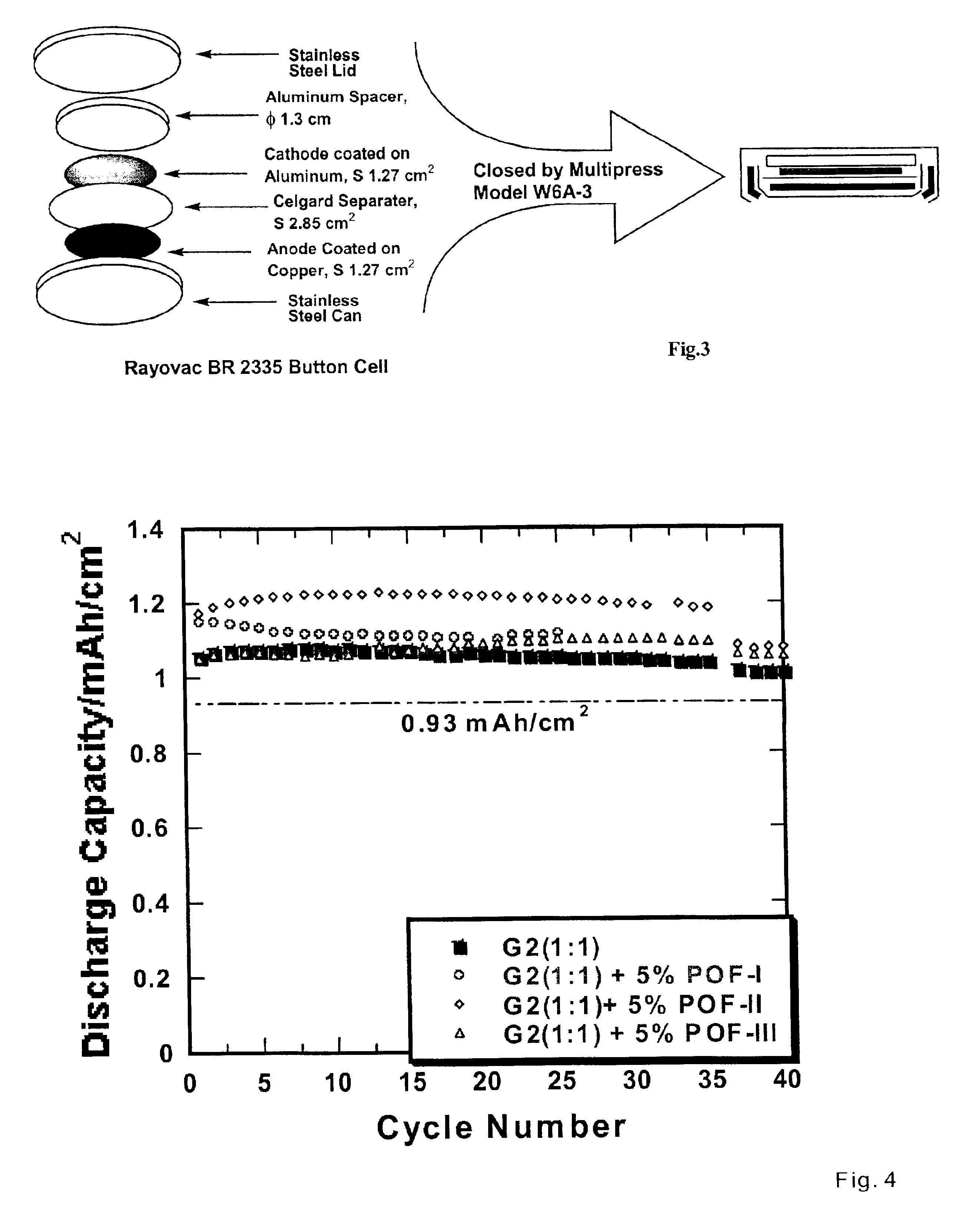

Nonflammable non-aqueous electrolyte and non-aqueous electrolyte cells comprising the same

InactiveUS6924061B1Improve rate performanceEffective and stableElectrolytic capacitorsOrganic electrolyte cellsPhysical chemistryCarbonate

A non-aqueous electrolyte to be used in a Li-ion battery includes a lithium salt, a cyclic carbonate, a linear carbonate and an alkyl fluorinated phosphate, of the following general formula wherein R1, R2 and R3, independently, are selected from the group consisting of straight and branched alkyl groups having 1-5 carbon atoms, and at least one of said alkyl groups is fluorinated, with the locations of said fluorination being at least β-positioned away from the phosphorous of said phosphate, such that said alkyl phosphate has a F / H ratio of at least 0.25, and said electrolyte solution is non-flammable.

Owner:ARMY US SEC THE

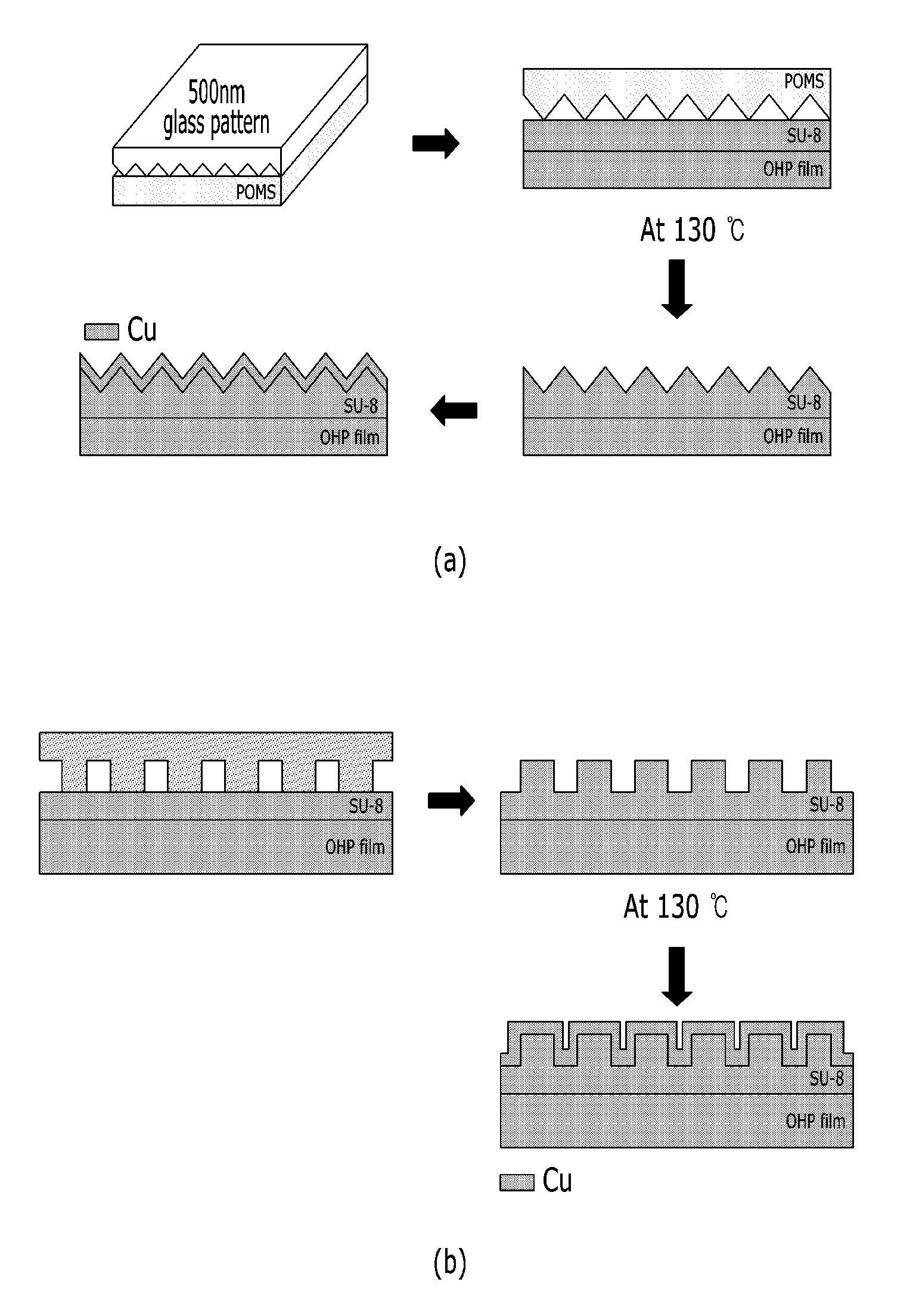

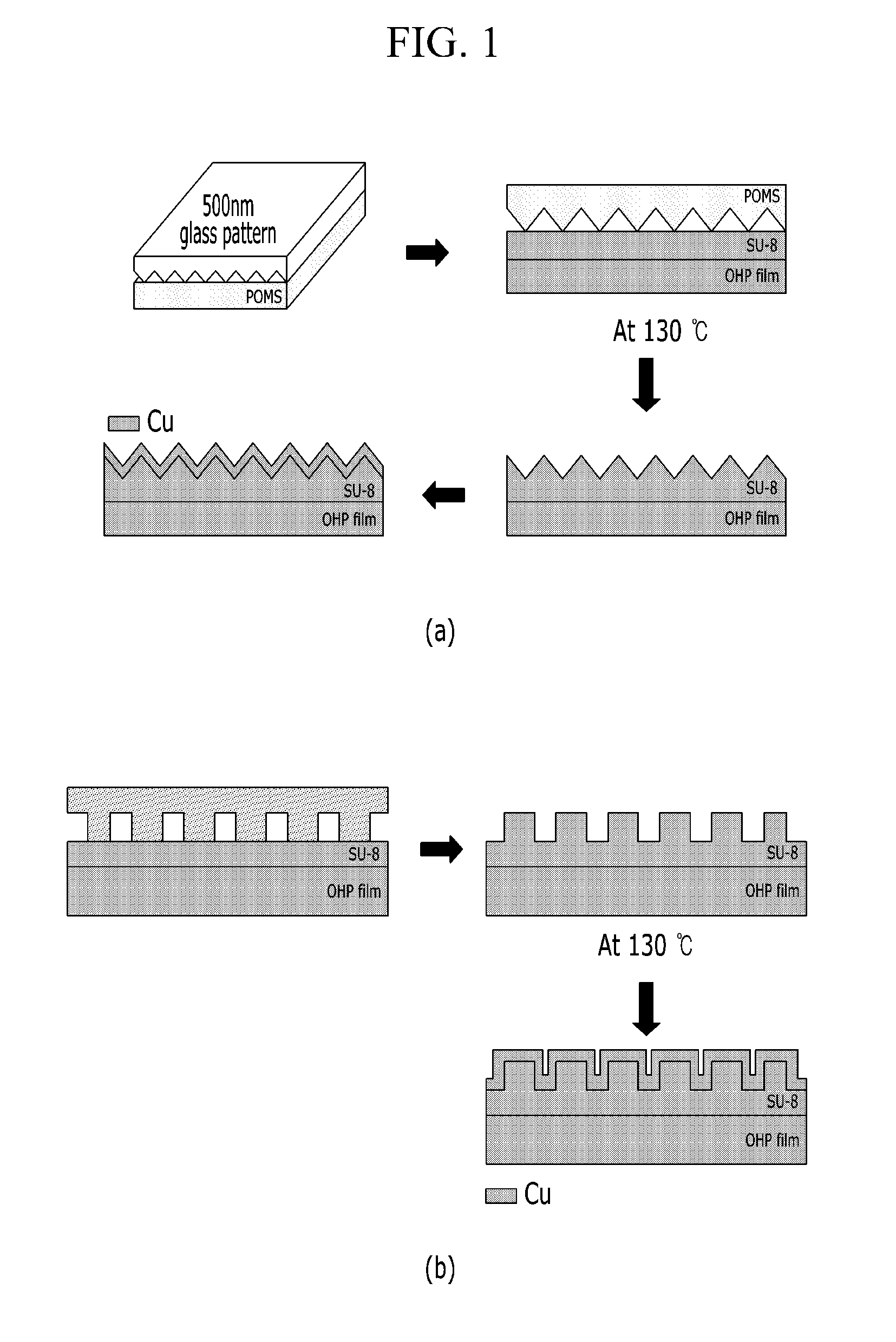

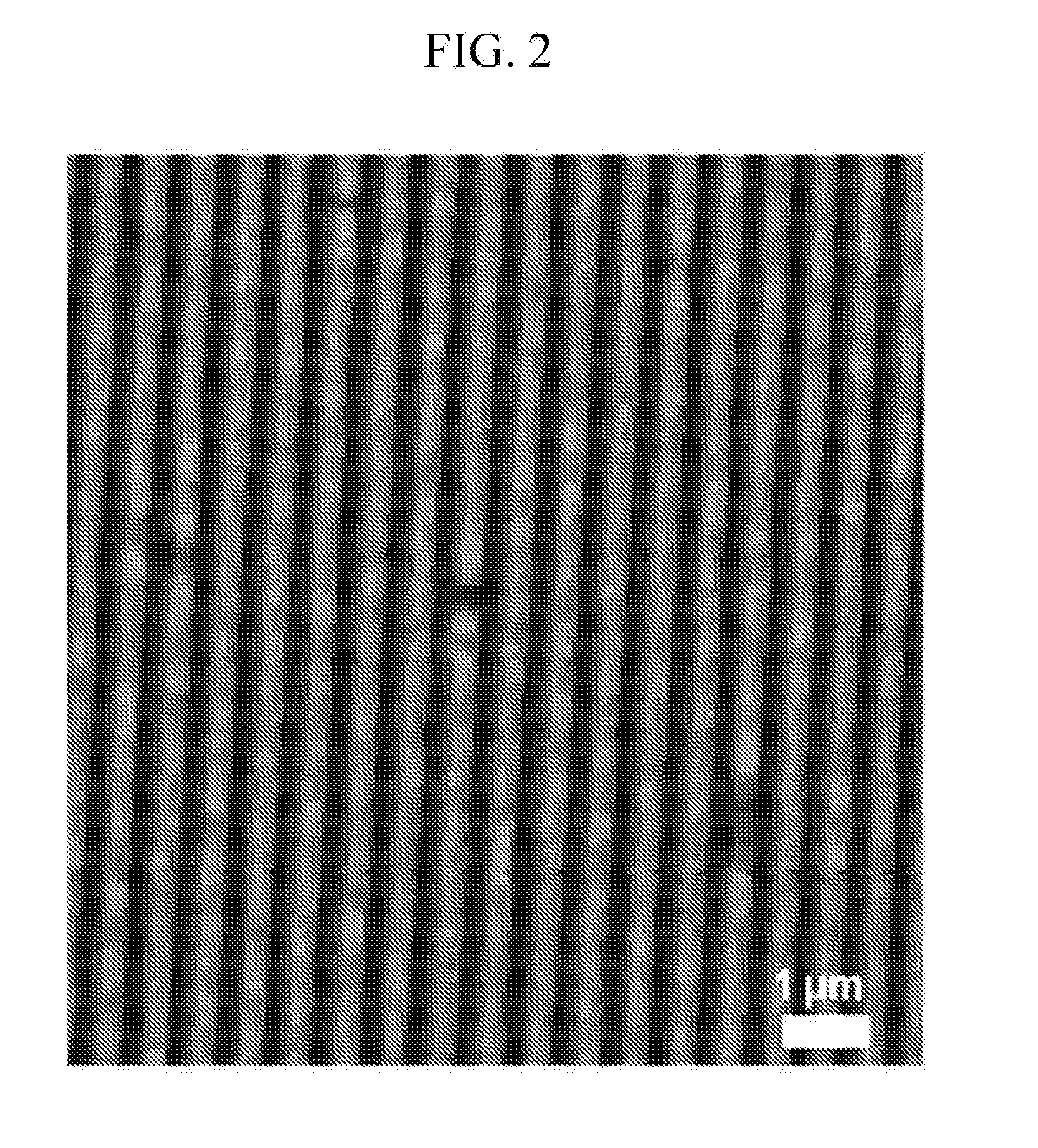

Current collector for flexible electrode, method of manufacturing same, and negative electrode including same

InactiveUS20130011742A1Excellent capacity characteristicsPrevent materialElectrode manufacturing processesFinal product manufacturePolymer sciencePolymer substrate

Disclosed are a current collector for a flexible electrode, a method of manufacturing the same, and a negative electrode including the same. The current collector for a flexible electrode includes: a flexible polymer substrate; a cross-linkable polymer layer disposed on the polymer substrate; and a metal layer disposed on the cross-linkable polymer layer, wherein the surface of the cross-linkable polymer layer includes a plurality of protrusions and grooves.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

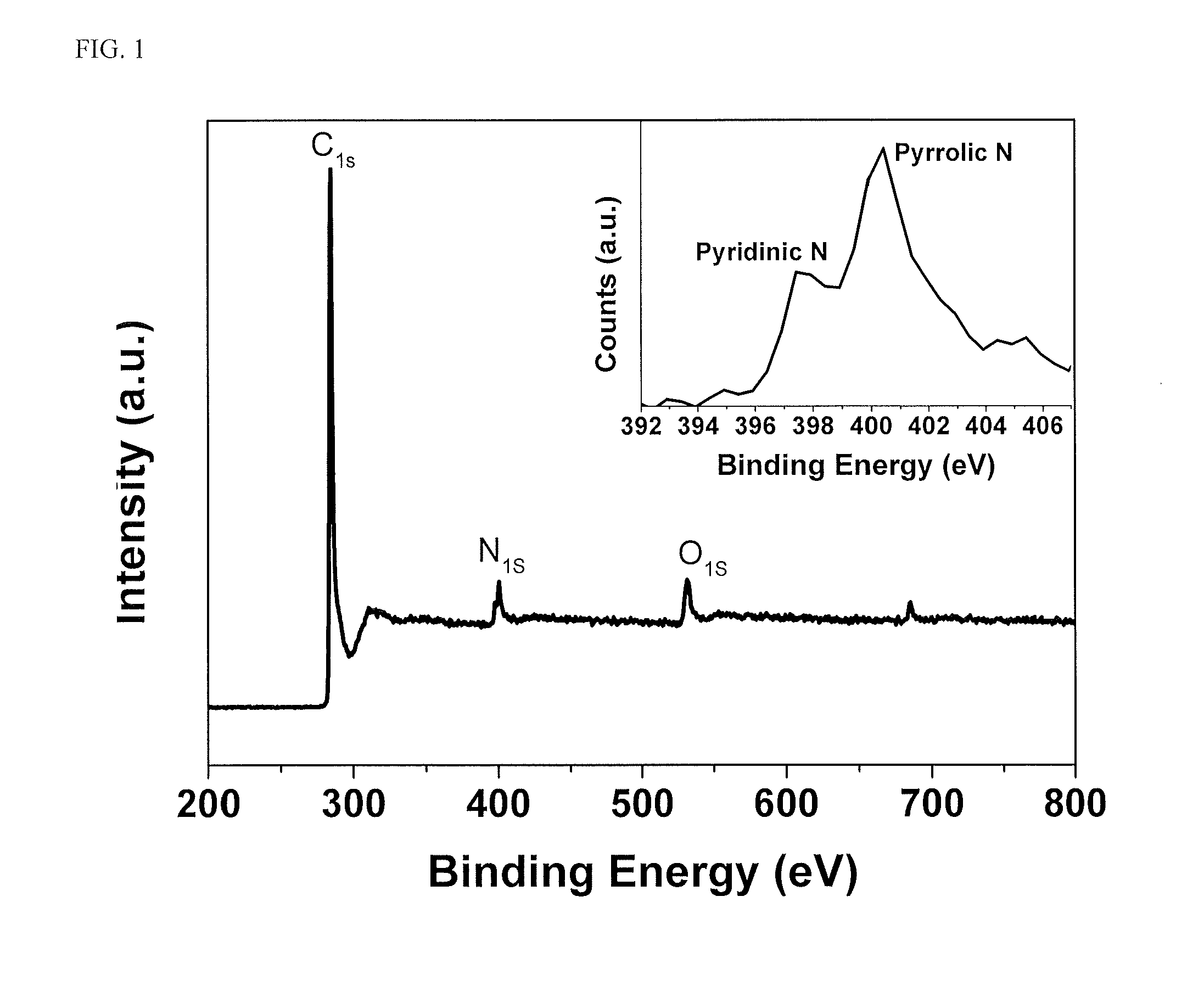

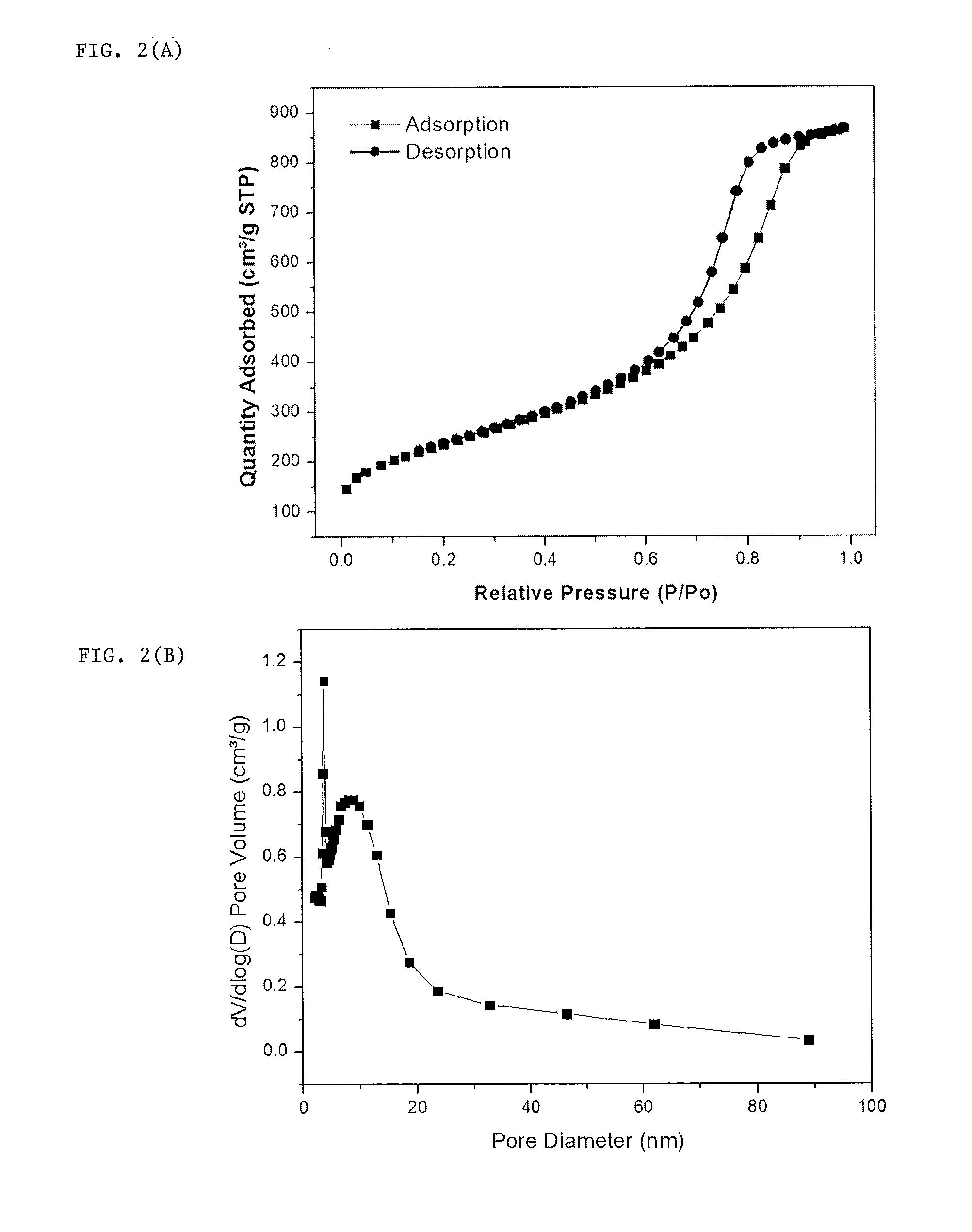

Doped carbon-sulfur species nanocomposite cathode for li-s batteries

ActiveUS20140017569A1Reduced diffusion lossImprove Coulombic efficiencyConductive materialOrganic conductorsLithium sulfurHeteroatom

We report a heteroatom-doped carbon framework that acts both as conductive network and polysulfide immobilizer for lithium-sulfur cathodes. The doped carbon forms chemical bonding with elemental sulfur and / or sulfur compound. This can significantly inhibit the diffusion of lithium polysulfides in the electrolyte, leading to high capacity retention and high coulombic efficiency.

Owner:PENN STATE RES FOUND

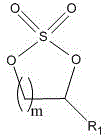

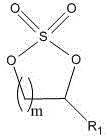

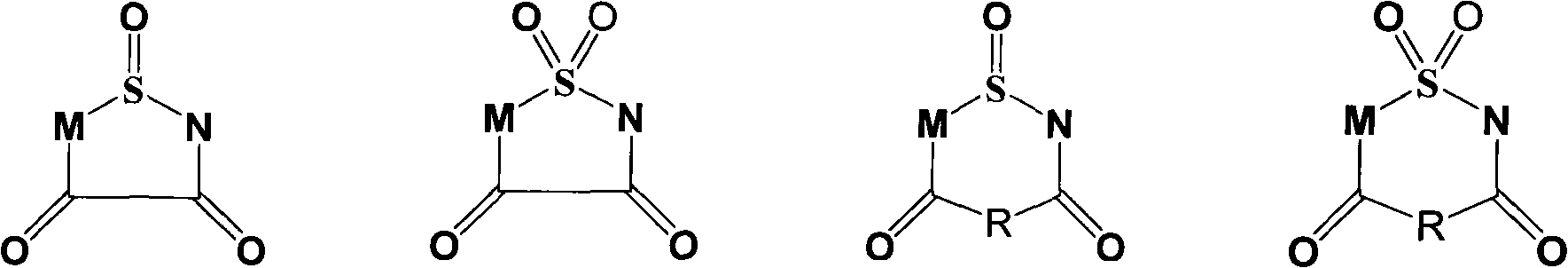

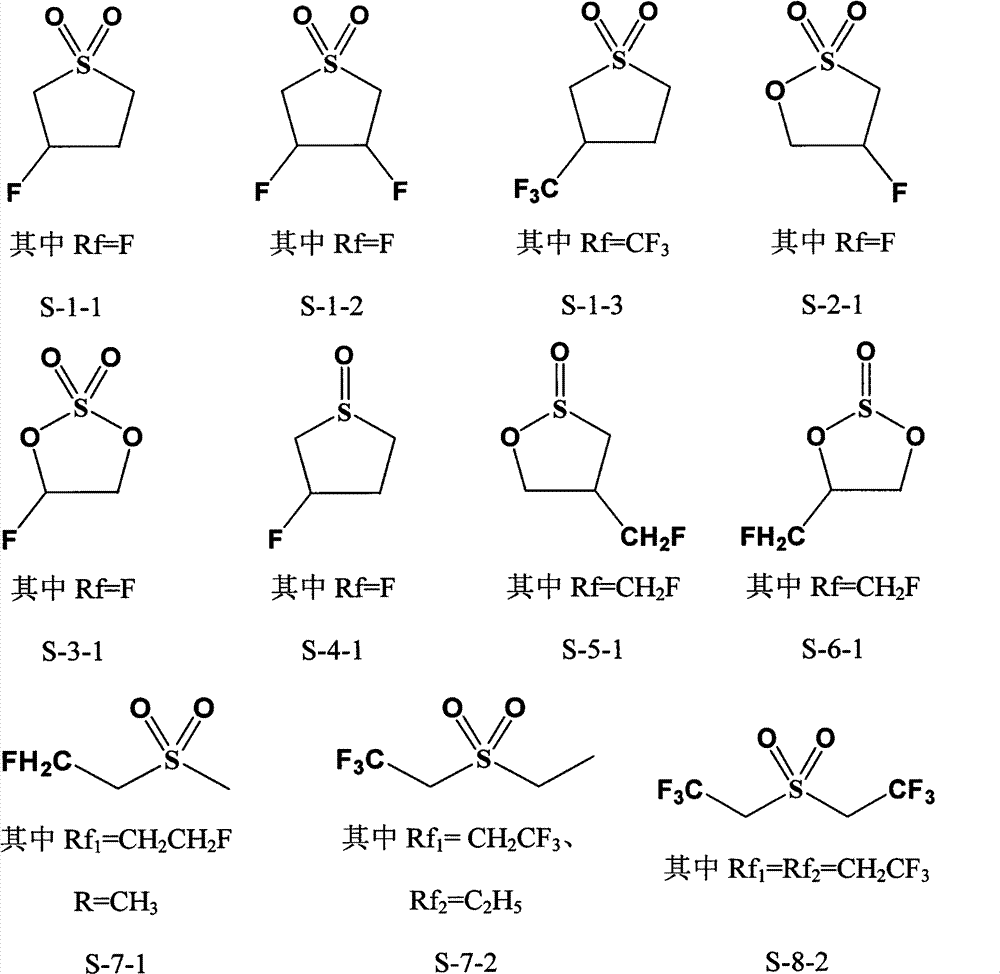

Cyclic sulfate compound, non-aqueous electrolyte solution containing same, and lithium secondary battery

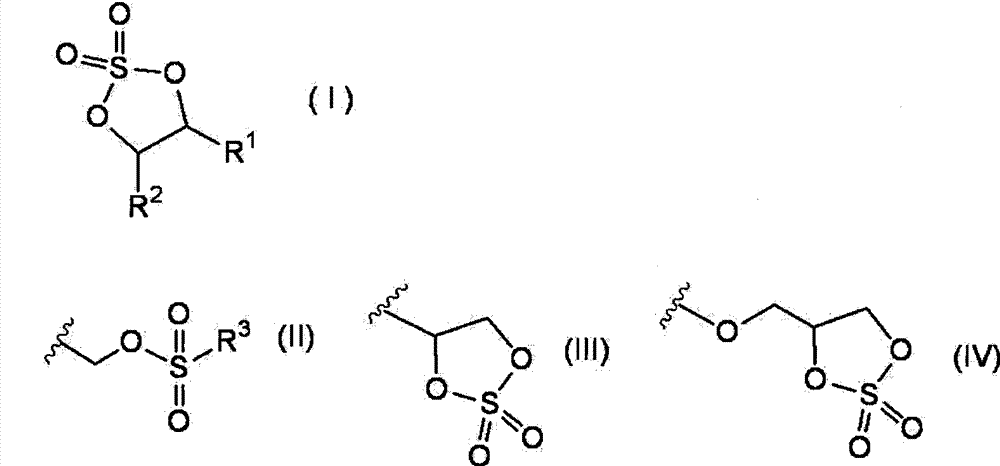

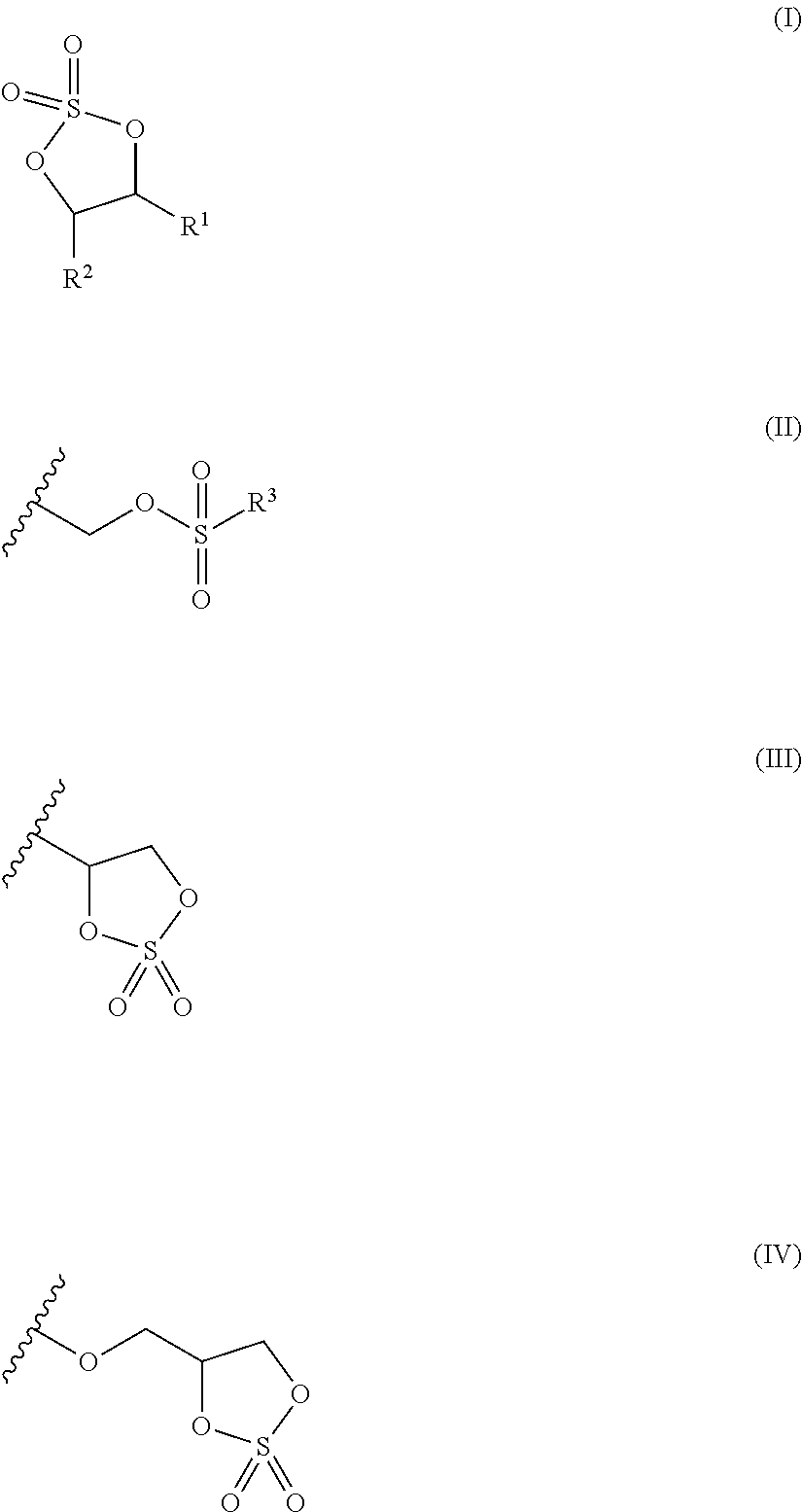

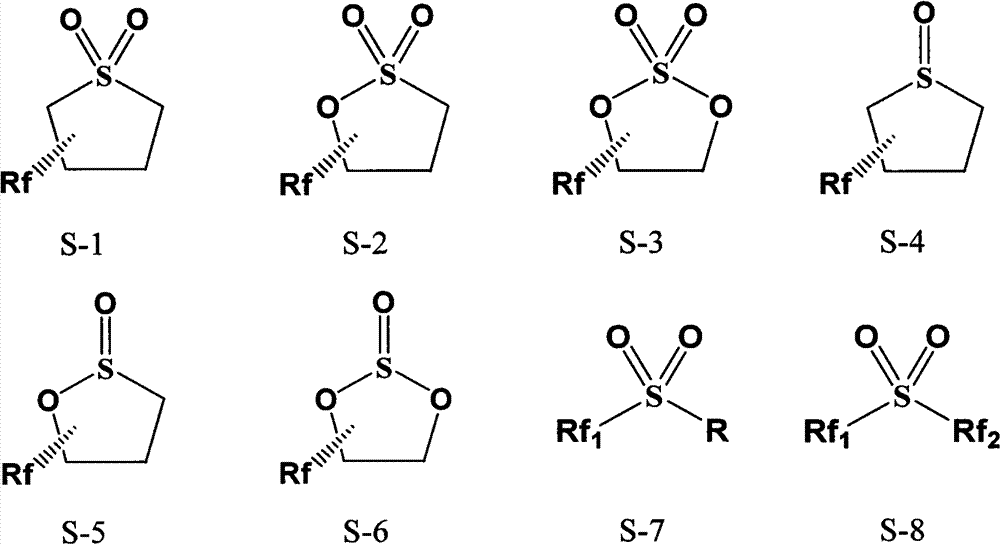

ActiveCN103098290AGood capacity retentionLower open circuit voltageOrganic chemistryFinal product manufactureHydrogen atomHalogen

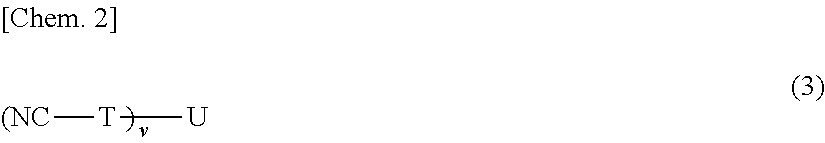

A non-aqueous electrolyte solution containing a cyclic sulfate compound represented by formula (I) is provided, wherein in formula (I), R1 represents a group represented by formula (II) or a group represented by formula (III); R2 represents a hydrogen atom, an alkyl group having from 1 to 6 carbon atoms, a group represented by formula (II), or a group represented by formula (III); and in formula (II), R3 represents a halogen atom, an alkyl group having from 1 to 6 carbon atoms, a halogenated alkyl group having from 1 to 6 carbon atoms, an alkoxy group having from 1 to 6 carbon atoms, or a group represented by formula (IV).

Owner:MITSUI CHEM INC

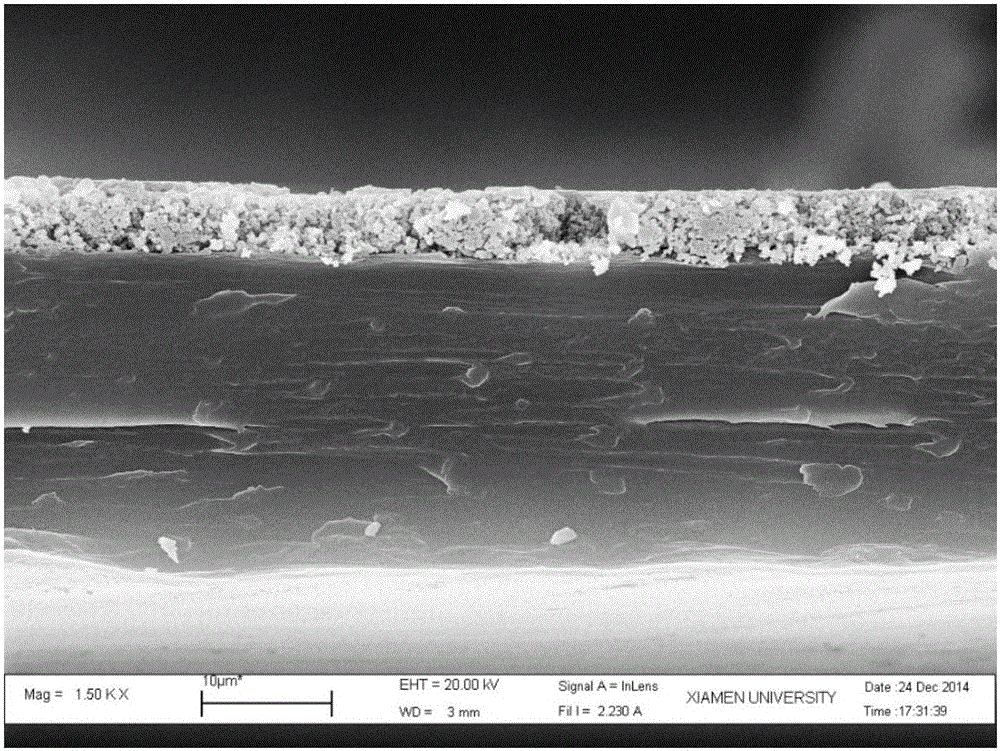

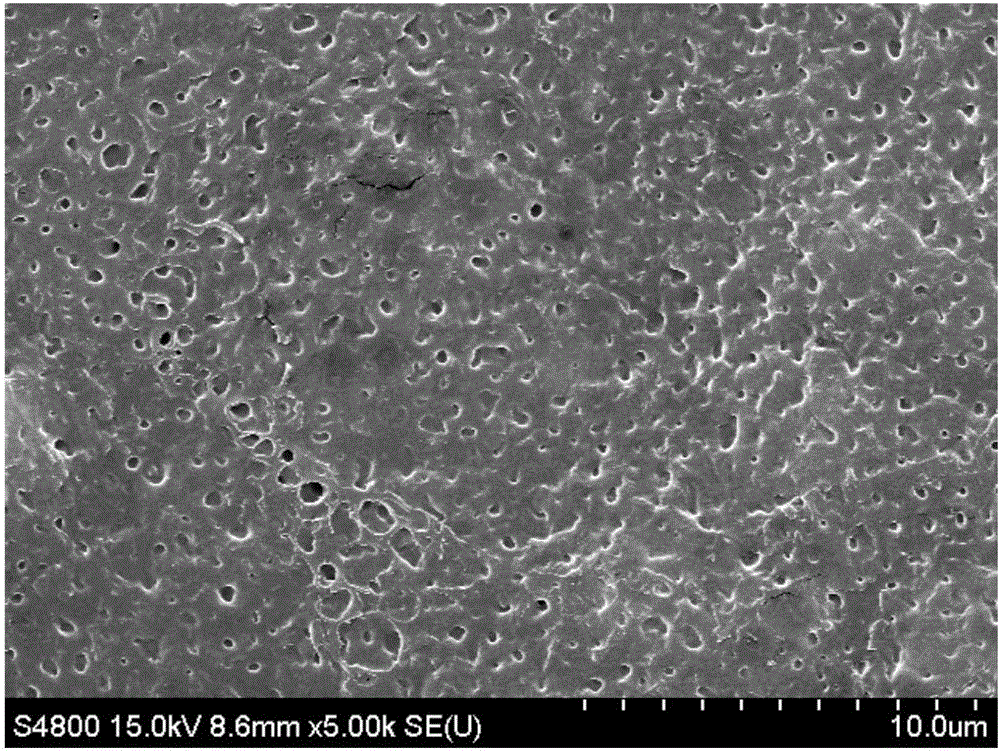

Dopamine-modifying ceramic composite separator and application thereof

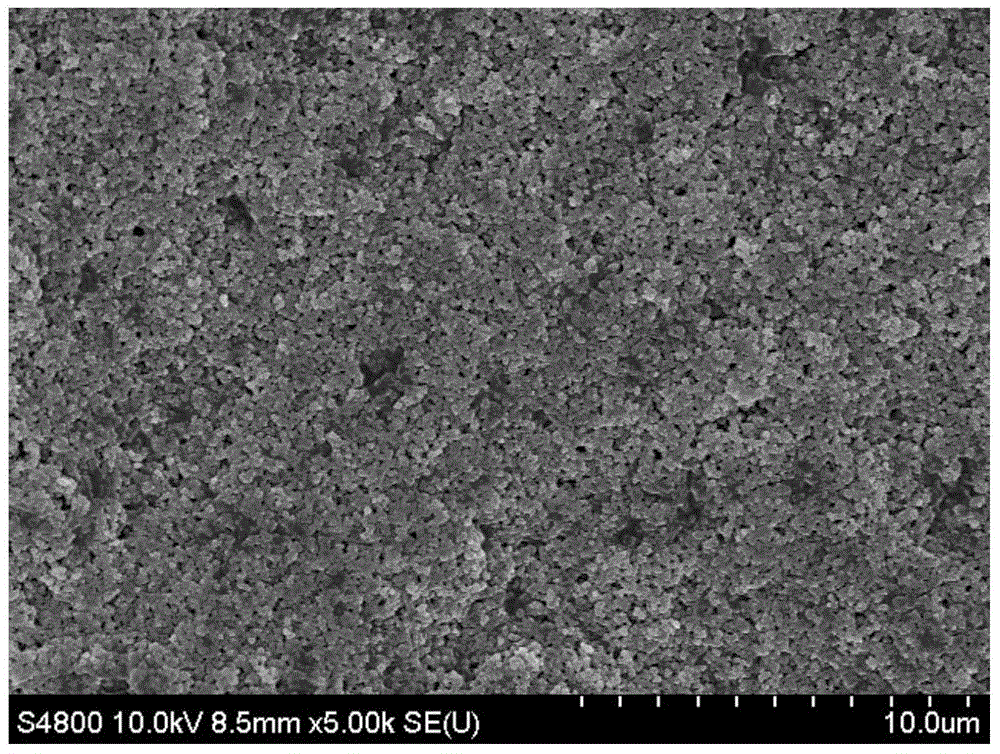

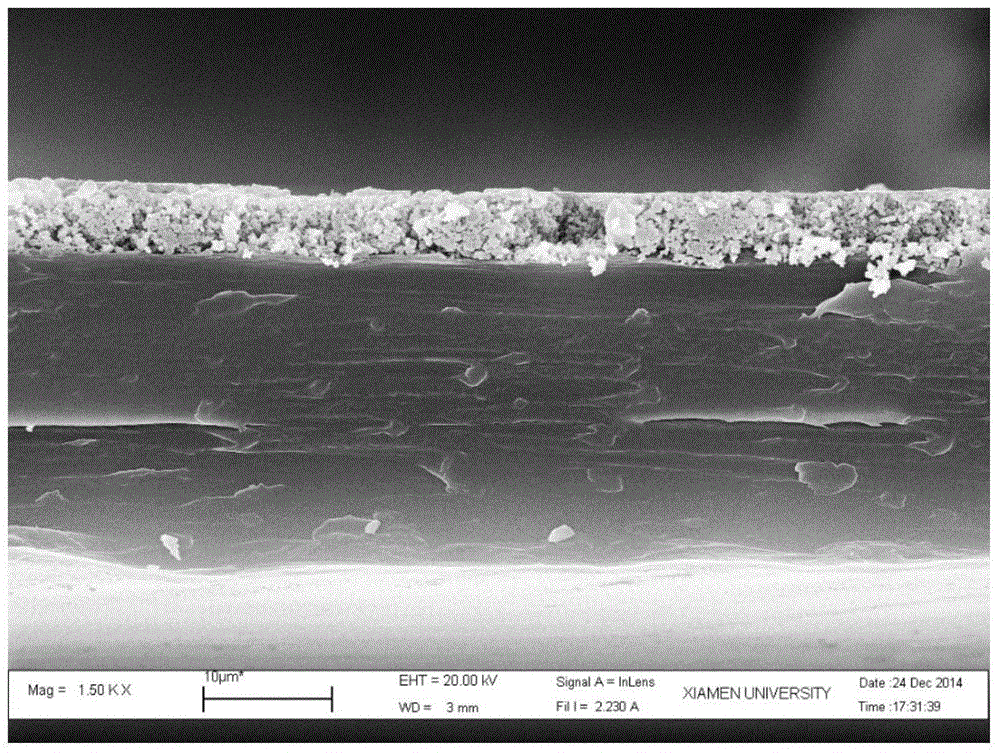

ActiveCN105070868AImprove physical performanceImprove electrochemical performanceSecondary cellsCell component detailsLithiumCeramic composite

The invention discloses a dopamine-modifying ceramic composite separator and an application thereof. The dopamine-modifying ceramic composite separator comprises an organic separator base material and a ceramic layer arranged on the surface of the separator base material in a coated mode, wherein the thickness of the ceramic layer ranges from 0.1 micrometer to 20 micrometers. The dopamine-modifying ceramic composite separator further comprises dopamine polymers grown on the surfaces and the interiors of the separator base material and the ceramic layer in an in-situ mode. The dopamine polymers are copolymers of polydopamine or 5-hydroxy- polydopamine or polydopamine acrylamide and polydopamine acrylamide. The particle size of inorganic powder in the ceramic layer ranges from 5 nanometers to 10 micrometers. The molecular weight of materials of the organic separator base material ranges from 1,000 to 100,000,000. According to the dopamine-modifying ceramic composite separator, due to the dopamine polymers, potential safety hazards caused by powder falling and liquid leaking of the ceramic layer can be effectively reduced, and the physical performance and the electrochemical performance of the separator are effectively improved; meanwhile, due to the dopamine polymers, the stability of an interface between separator electrolysis and an electrode can be improved, lithium dendrites can be effectively suppressed through the improvement of the stability of the interface, and therefore the capacity holding capacity of a battery can be easily improved.

Owner:XIAMEN UNIV

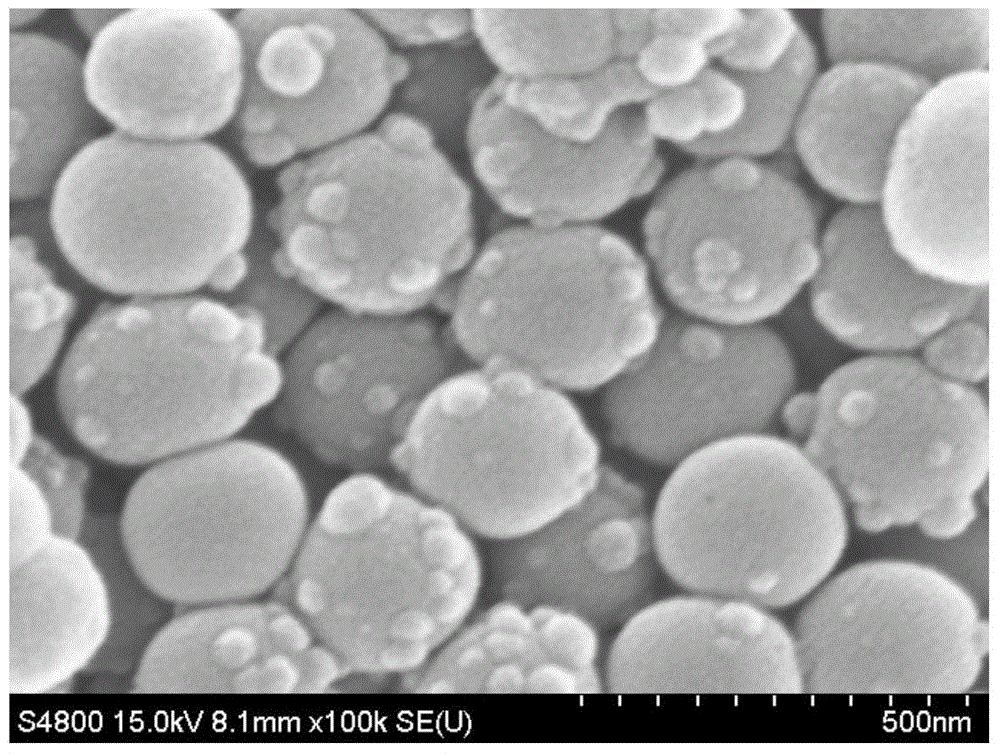

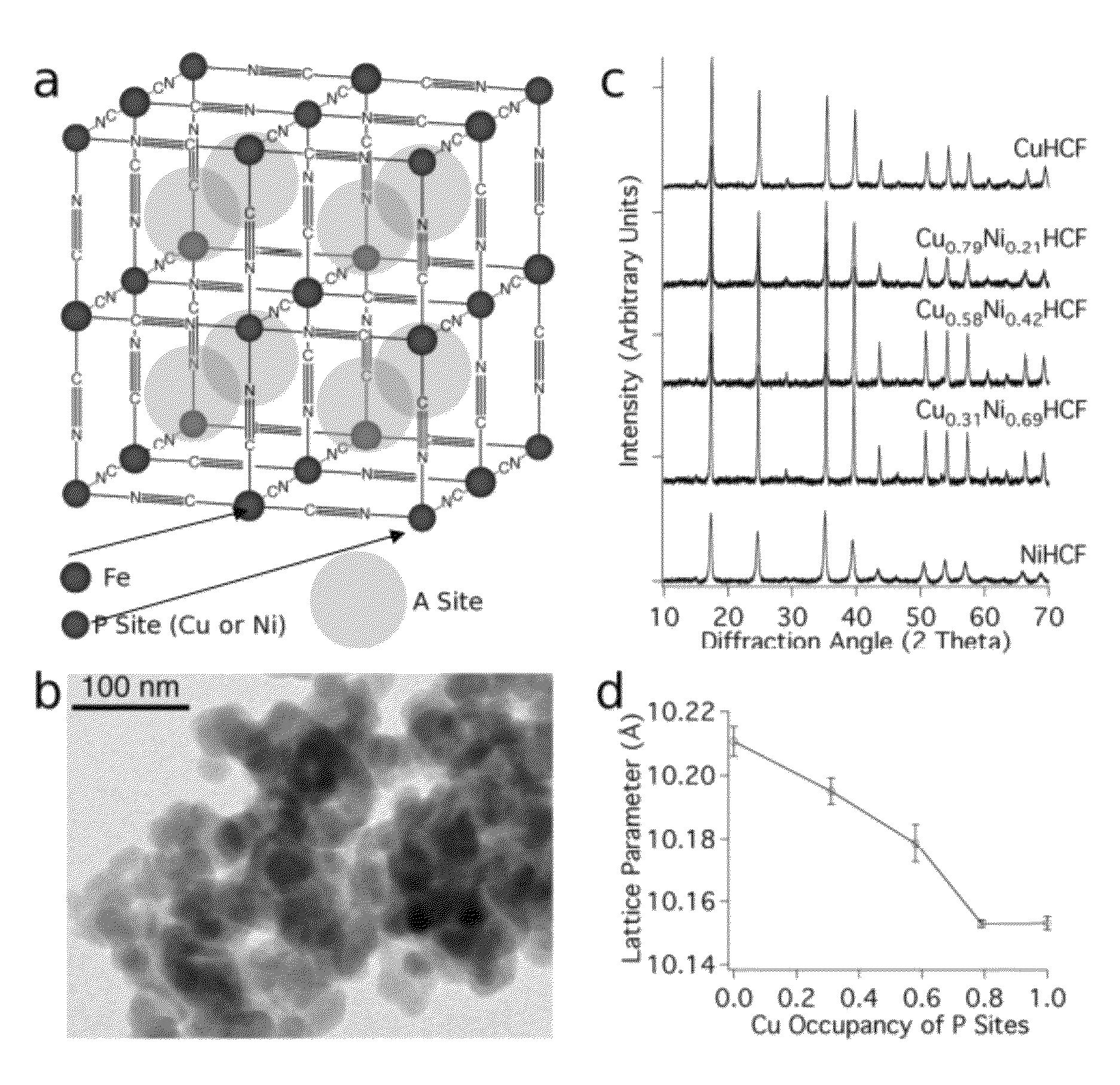

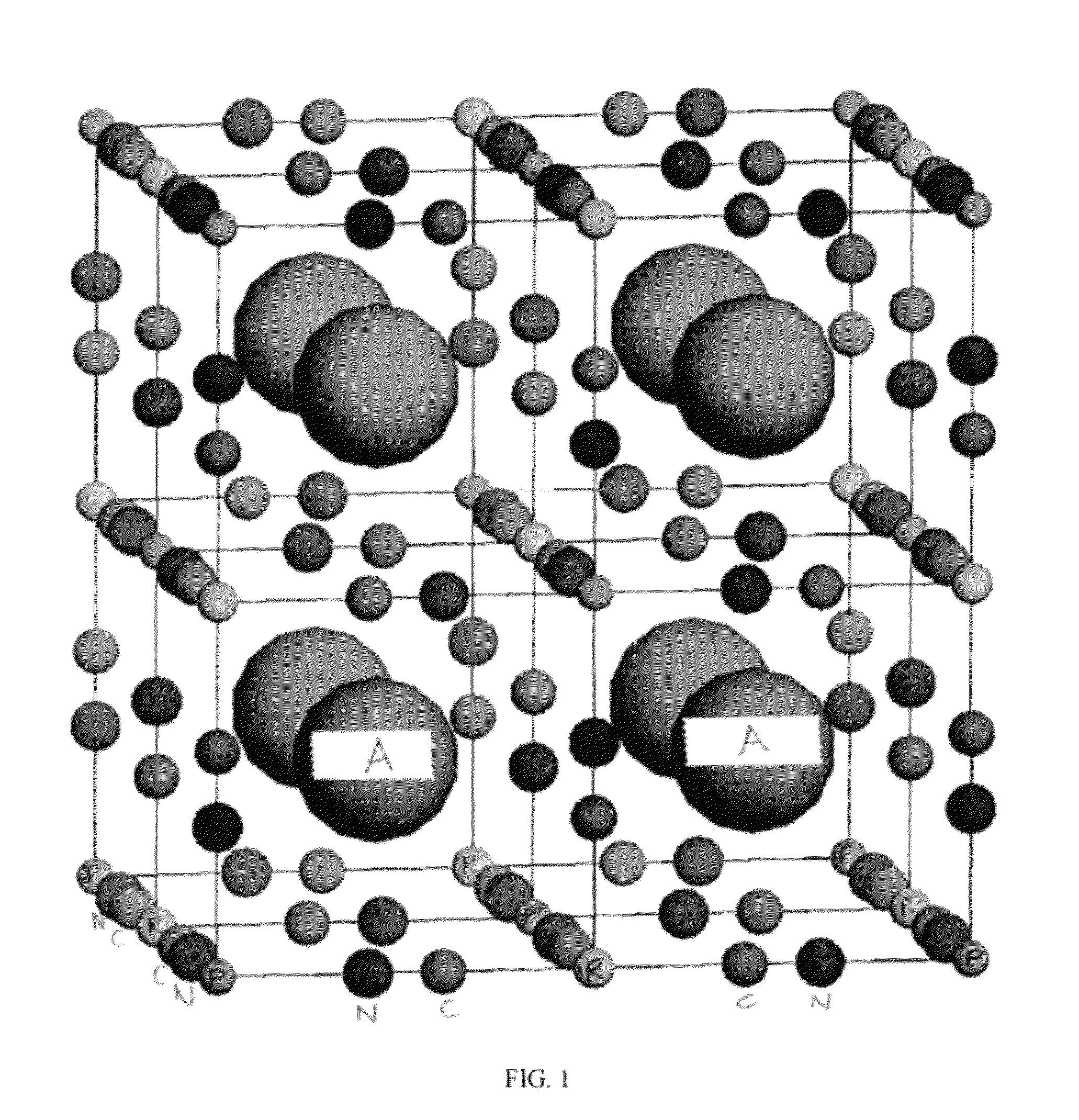

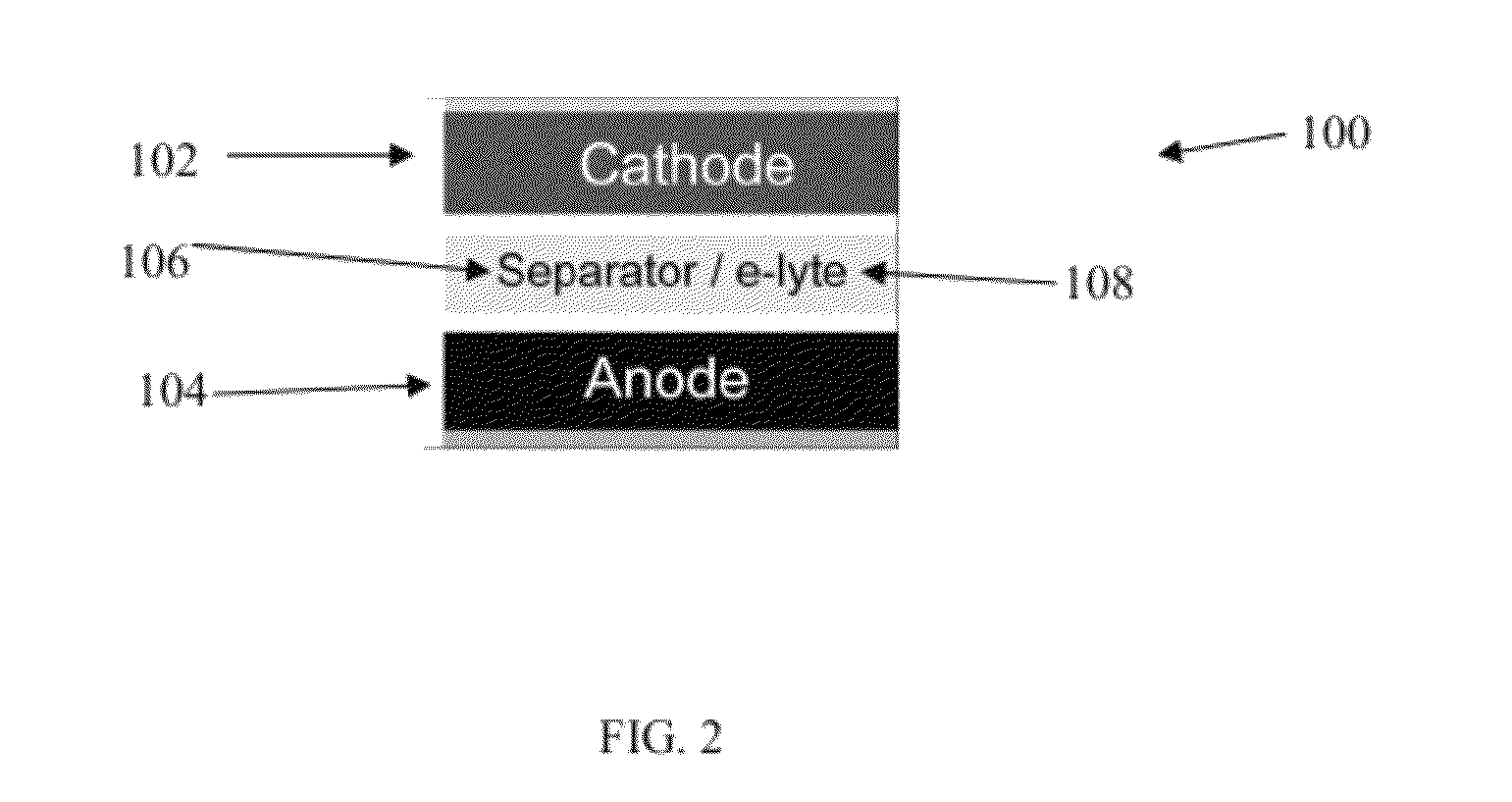

High rate, long cycle life battery electrode materials with an open framework structure

InactiveUS8951673B2Extreme durabilityImprove rate performanceFinal product manufactureActive material electrodesHigh rateReference rate

A battery includes a cathode, an anode, and an aqueous electrolyte disposed between the cathode and the anode and including a cation A. At least one of the cathode and the anode includes an electrode material having an open framework crystal structure into which the cation A is reversibly inserted during operation of the battery. The battery has a reference specific capacity when cycled at a reference rate, and at least 75% of the reference specific capacity is retained when the battery is cycled at 10 times the reference rate.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Negative electrode material for lithium ion secondary battery, composite negative electrode material for lithium ion secondary battery, resin composition for lithium ion secondary battery negative electrode for lithium ion secondary battery, and lithium ion secondary battery

ActiveUS20150325848A1High capacity retentionImprove initial efficiencyNegative electrodesSecondary cellsLithiumPhysical chemistry

The present invention provides a negative electrode material for a lithium ion secondary battery, a composite negative electrode material for a lithium ion secondary battery, a resin composition for a lithium ion secondary battery negative electrode, and a negative electrode for a lithium ion secondary electrode, which may provide high charge / discharge capacity, and excellent initial charge-discharge characteristics and capacity retention. The surfaces of core particles of silicon of 5 nm or more and 100 nm or less in average particle size are coated with a coating layer to use a negative electrode material containing substantially no silicon oxide in the coating layer, or a composite negative electrode material for a lithium ion secondary battery, which includes the negative electrode material and a matrix material, further with the use of a polyimide resin or a precursor thereof as a bonding resin, thereby making it possible to achieve high charge / discharge capacity and excellent capacity retention, as well as high initial efficiency.

Owner:TORAY IND INC

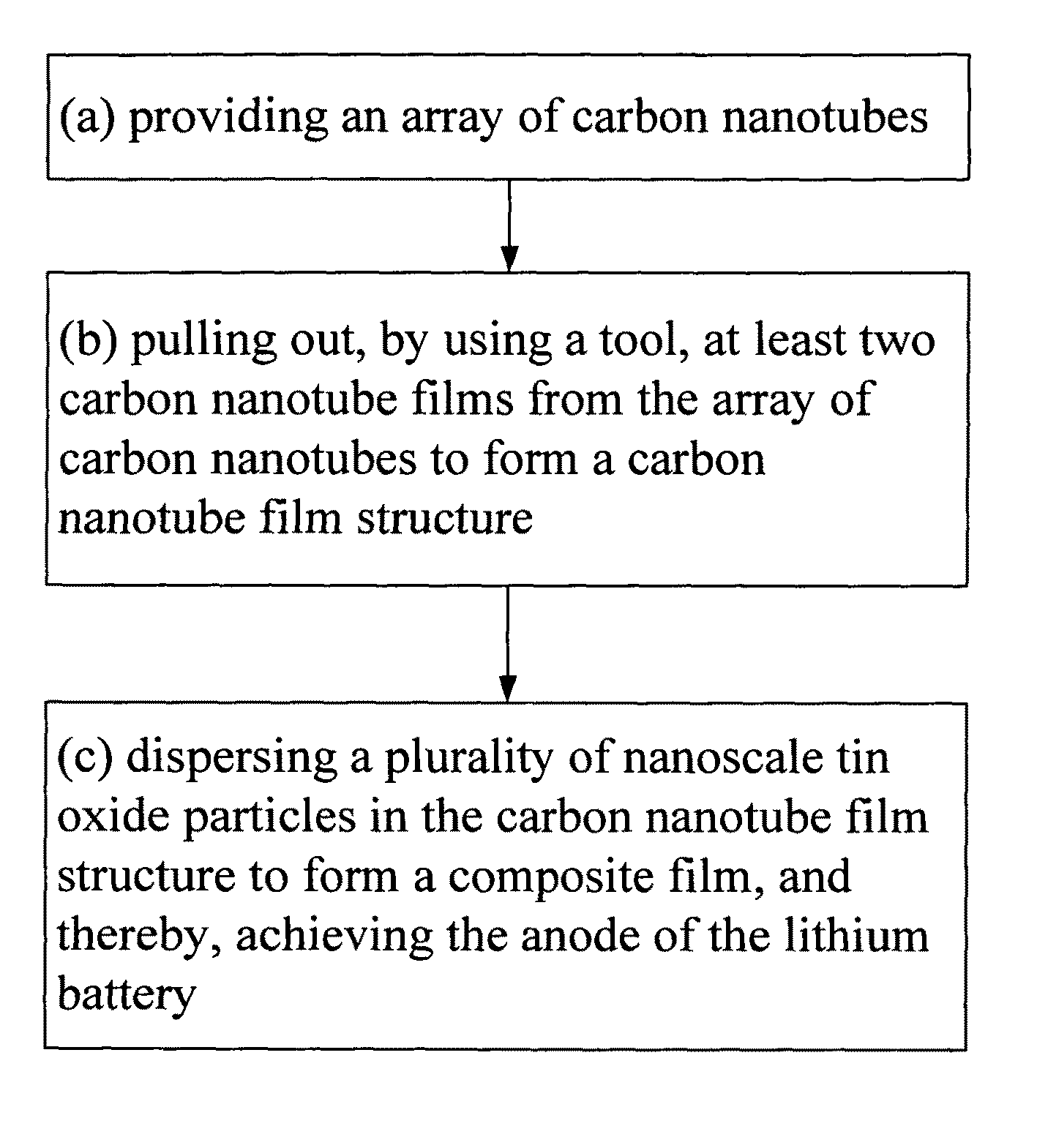

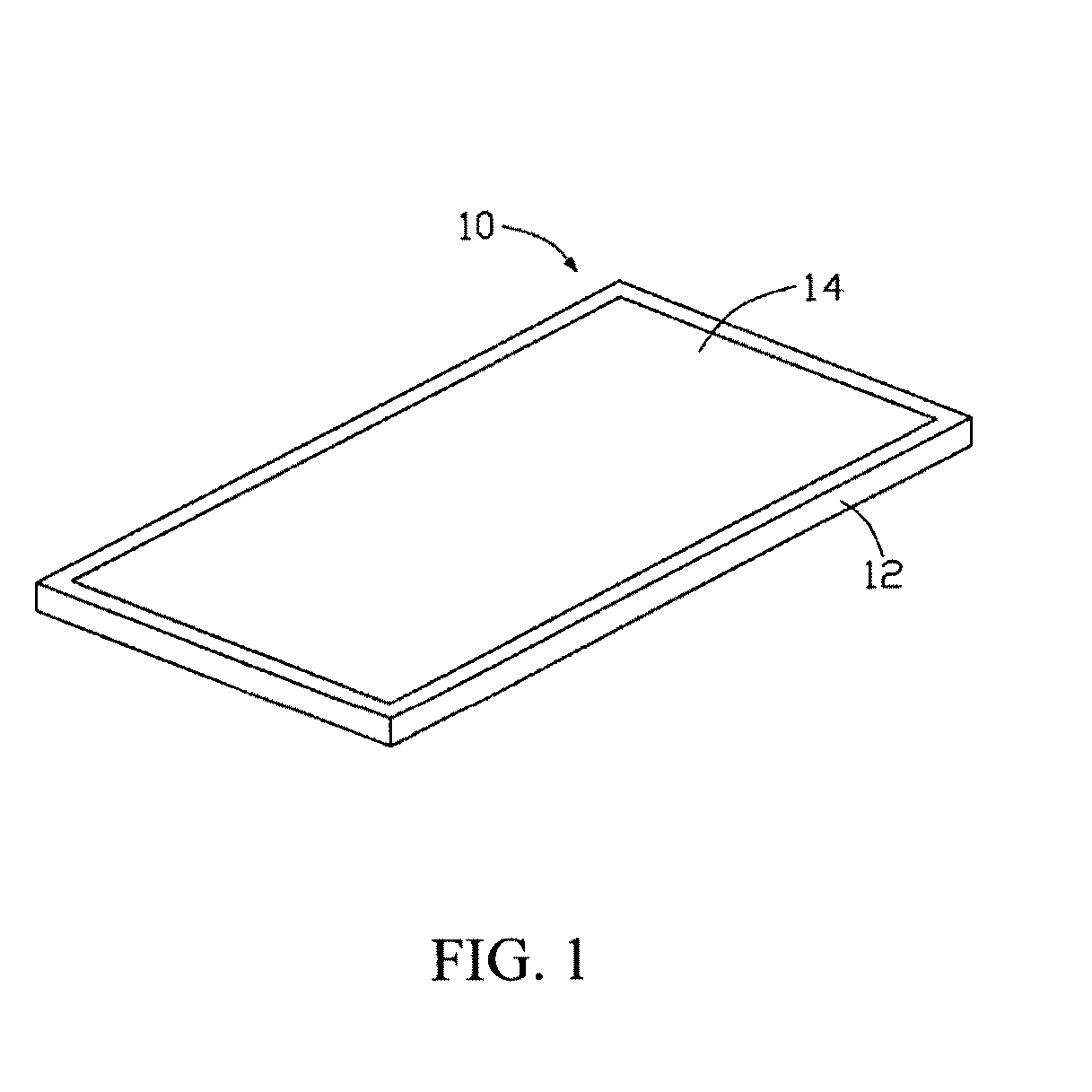

Anode of a lithium battery and method for fabricating the same

ActiveUS20090075171A1Increase energy densityLarge capacityConductive materialActive material electrodesThin membraneCarbon nanotube

An anode of a lithium battery includes a composite film, the composite film comprising a carbon nanotube film structure and a plurality of nanoscale tin oxide particles dispersed therein. A method for fabricating an anode of a lithium battery, the method includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, by using a tool, at least two carbon nanotube films from the array of carbon nanotubes to form a carbon nanotube film structure; and (c) dispersing a plurality of nanoscale tin oxide particles in the carbon nanotube film structure to form a composite film, and thereby, achieving the anode of the lithium battery.

Owner:TSINGHUA UNIV +1

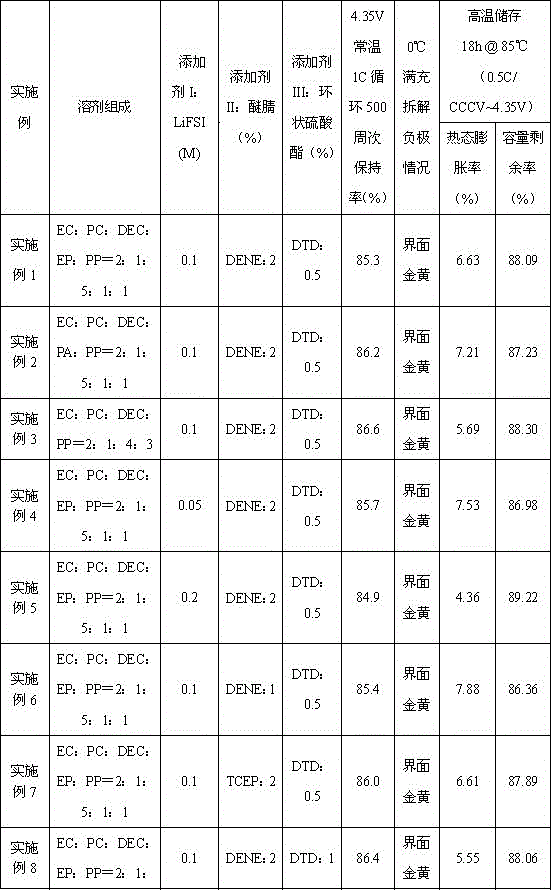

High voltage electrolyte considering high and low temperature performance and lithium ion battery using the electrolyte

InactiveCN105576283AImprove wettabilityImprove cycle performanceSecondary cellsElectrolytesElectrolytic agentCarboxylic acid

The invention discloses high voltage electrolyte considering high and low temperature performance and a lithium ion battery using the electrolyte. The high voltage electrolyte comprises a non-aqueous organic solvent, an electrolyte lithium salt, an ether nitrile compound and a low impedance additive, wherein the non-aqueous organic solvent comprises a carbonate solvent and a linear carboxylic acid ester solvent with a wide liquid range; the electrolyte lithium salt is a combination of lithium hexafluorophate and lithium triflurosulfimide according to a molar ratio of 0.01-0.5; and the low impedance additive is a cyclic sulfate compound. The linear carboxylic acid ester solvent for perfecting the electrode / electrolyte interface is contained in the high voltage electrolyte, by means of the optimized combination of the ether nitrile compound, the lithium triflurosulfimide and the cyclic sulfate compound and other additives, a high voltage battery can be guaranteed to have excellent circulation performance, and meanwhile, the excellent high and low temperature performance of the high voltage battery of storage for 18 h in a full charge state at 85 DEG C and no lithium separation in the full charge state at 0 DEG C is considered.

Owner:GUANGZHOU TINCI MATERIALS TECH

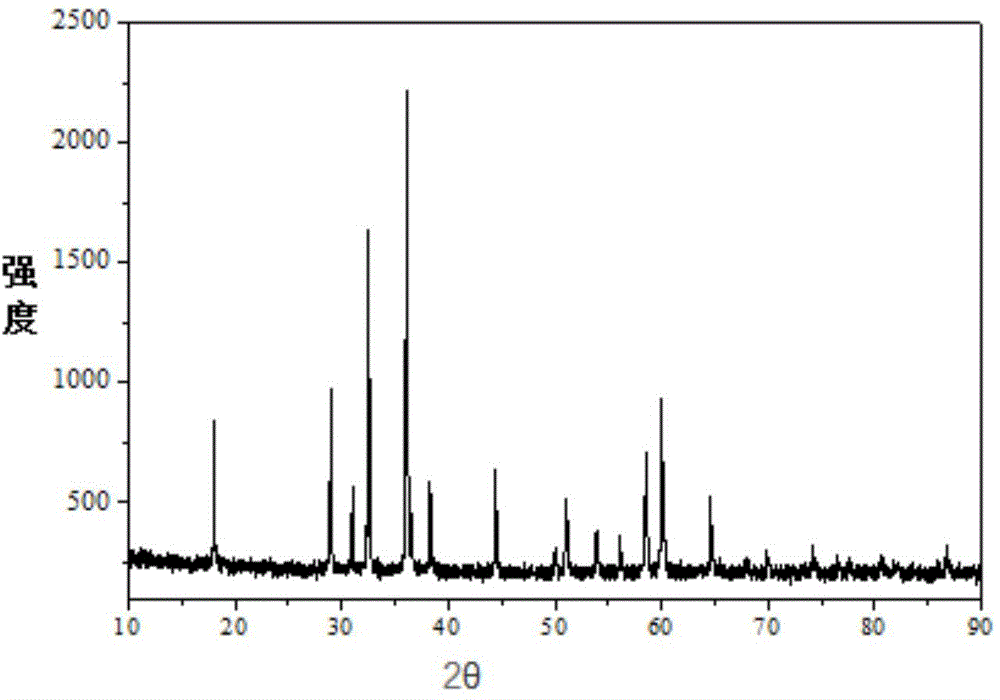

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

Composite membrane, preparation method of composite membrane, and lithium-ion battery

InactiveCN103474601AEvenly dispersedImprove electrochemical cycle performanceSecondary cellsCell component detailsPolyolefinHexafluoropropylene

The invention relates to a method for preparing a composite membrane. The method comprises the following steps: a solution with nano sol is prepared, and the nano sol is selected from at least one of titanium sol, alumina sol, silica sol and zirconium sol; a silane coupling agent and methyl methacrylate are added to the solution; the solution is uniformly mixed to form a first mixture; an initiator is added to the mixture to polymerize the methyl methacrylate and the silane coupling agent while the silane coupling agent and the nano sol-gel generates condensation reaction, therefore the nano sol is grafted on a polymethyl methacrylate substrate to form an inorganic-organic grafted hybrid polymer; the inorganic-organic grafted hybrid polymer is mixed with a copolymer of vinylidene fluoride and hexafluoropropylene in an organic solvent to form a uniform second mixture; the second mixture is spread onto the surface of a porous polyolefin membrane; the porous polyolefin membrane coated with the second mixture is dried. The invention further relates to the composite membrane and a lithium-ion battery.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

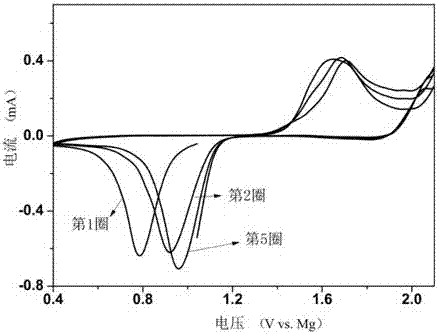

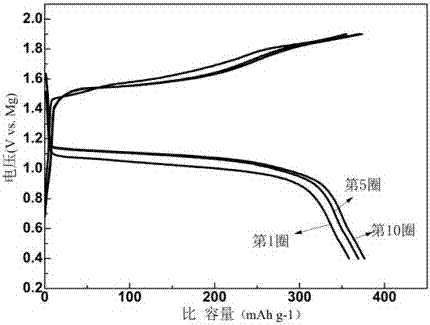

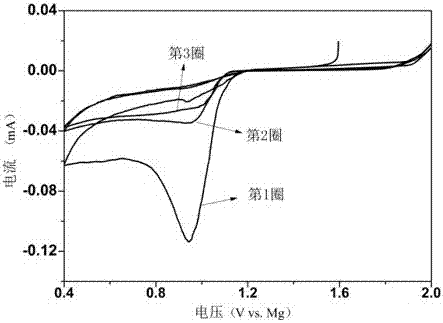

Sulfur/sulfide/copper ternary composite cathode and preparation and application thereof in magnesium-sulfur battery

ActiveCN106935796AGood capacity retentionImproved magnification performanceSecondary cellsPositive electrodesCopper foilCopper sulfide

The invention relates to the technical field of magnesium batteries, and discloses preparation and application of a sulfur / sulfide / copper ternary composite cathode in a magnesium-sulfur battery. The sulfur / sulfide / copper ternary composite cathode comprises sublimation sulfur, metal sulfide and metal copper foil. Meanwhile, the magnesium-sulfur battery is assembled by the sulfur / sulfide / copper ternary composite cathode, a magnesium ion electrolyte and a metal magnesium anode. The composite cathode not only can effectively bind polysulfide ions to the cathode region, thus suppressing a 'shuttle effect', but also generate a non-stoichiometric copper sulfide (CuxS, x<=2) interphase by means of dissolution of the metal copper foil, thus promoting the electrochemical conversion reaction of a discharging product MgS, significantly improving the charge and discharge capacity of the battery and improving the cycling stability of the magnesium-sulfur battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

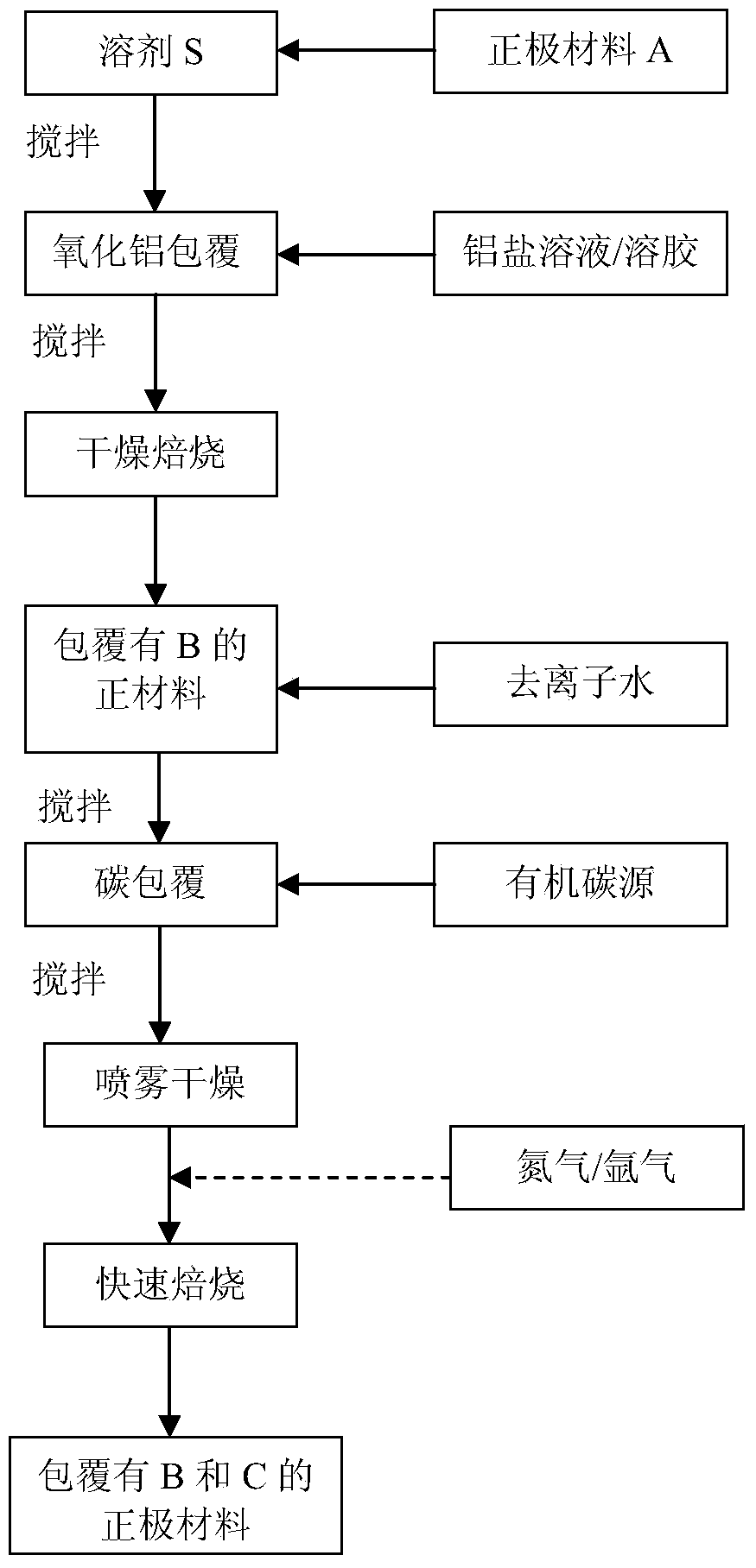

Lithium ion battery anode material and preparation method thereof

ActiveCN103647073AAvoid metal reductionQuick releaseElectrode thermal treatmentSecondary cellsCarbon coatingCarbon source

The invention discloses a preparation method of a lithium ion battery anode material. The method is characterized in that the outer surface of the existing lithium ion battery anode material is sequentially coated with an aluminum oxide layer and a carbon layer, wherein the coating condition is liquid-phase coating, in the coating process of the aluminum oxide, the addition sequence of the existing lithium ion battery anode material and aluminum salt is adjusted, and the coating substance organic aluminum salt is added under the continuously stirring condition, so that a hydrolytic product is uniformly adsorbed onto the surface of an active substance. The carbon coating is carried out through a spray drying and rapid sintering way in the inert gas atmosphere, so that the problems that the metal is reduced due to the high-temperature carbon coating and the organic carbon source is difficultly carbonized in low temperature can be avoided. The invention also discloses a lithium ion battery anode material prepared through the method. The energy density and power density of the battery can be remarkably improved, and the cycling performance, the capacity retention rate and the safety performance of the battery can be improved.

Owner:EVE ENERGY CO LTD

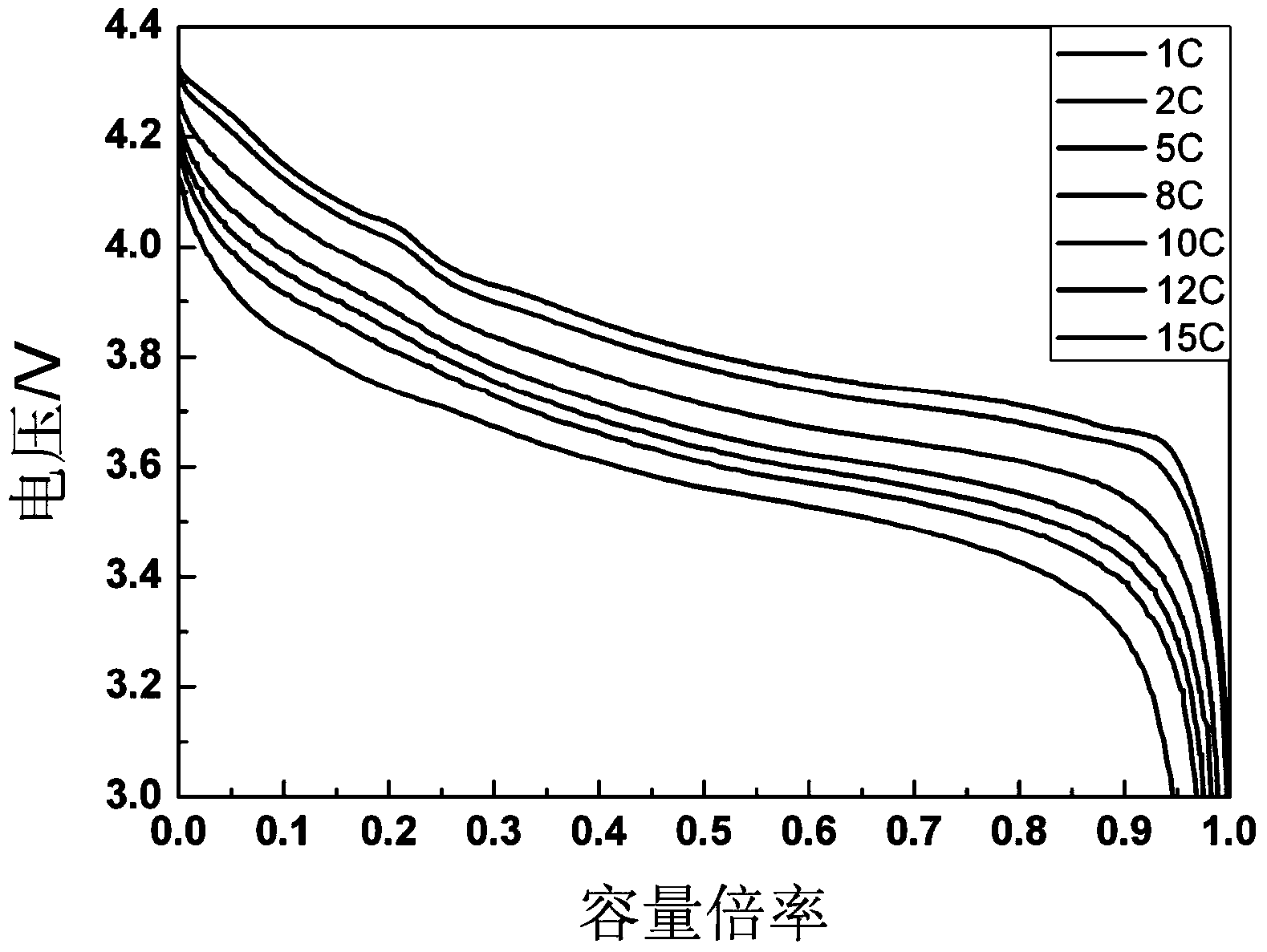

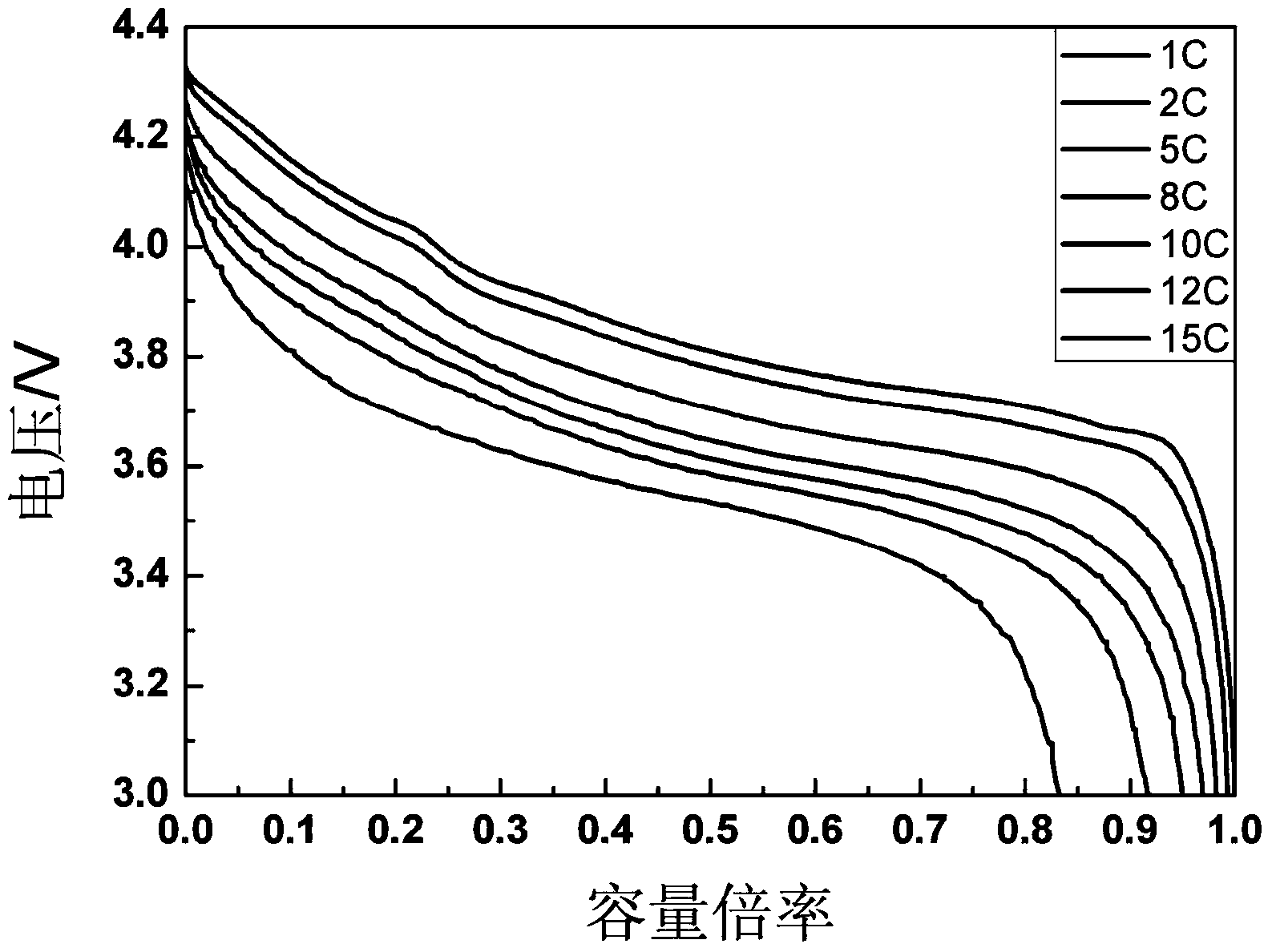

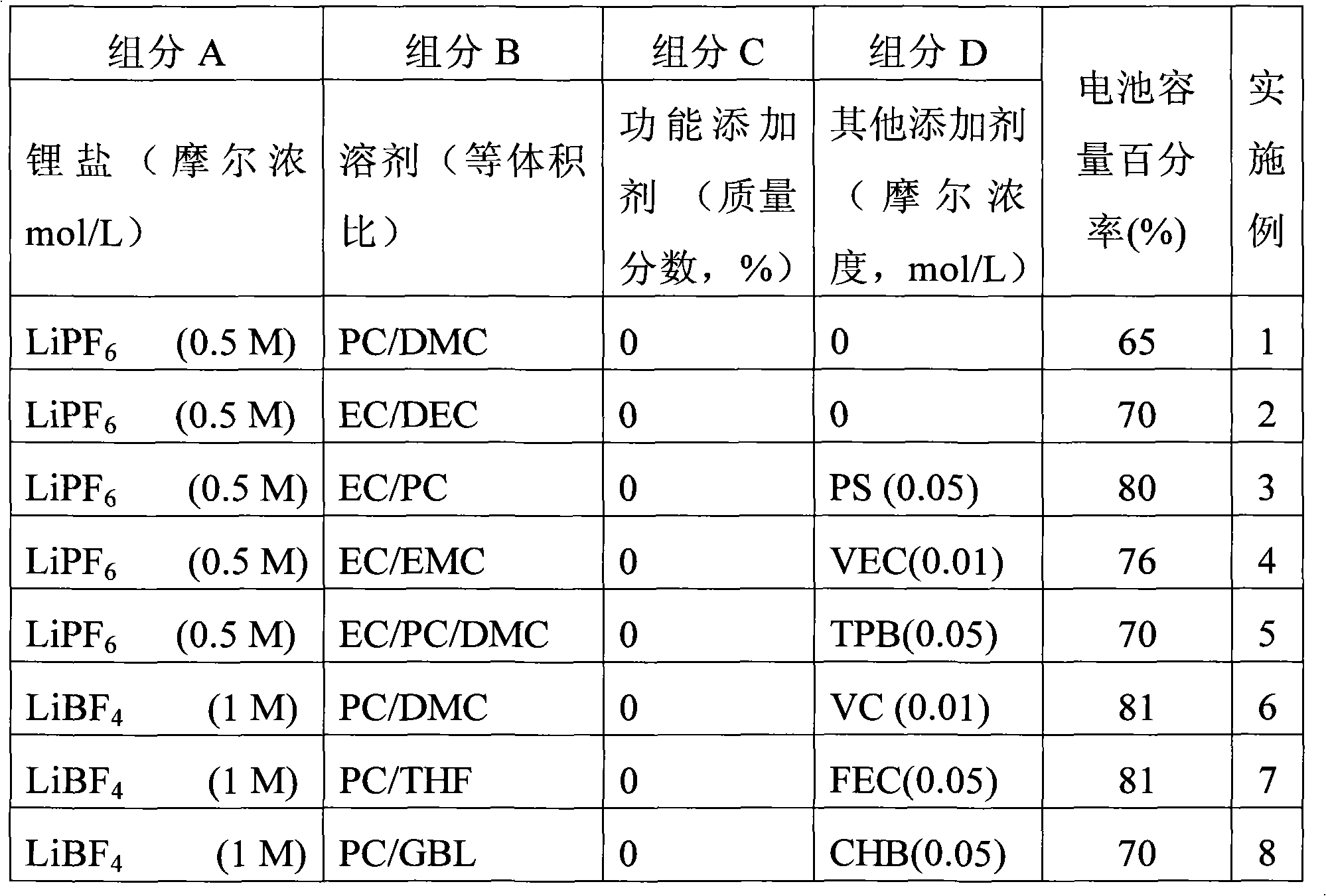

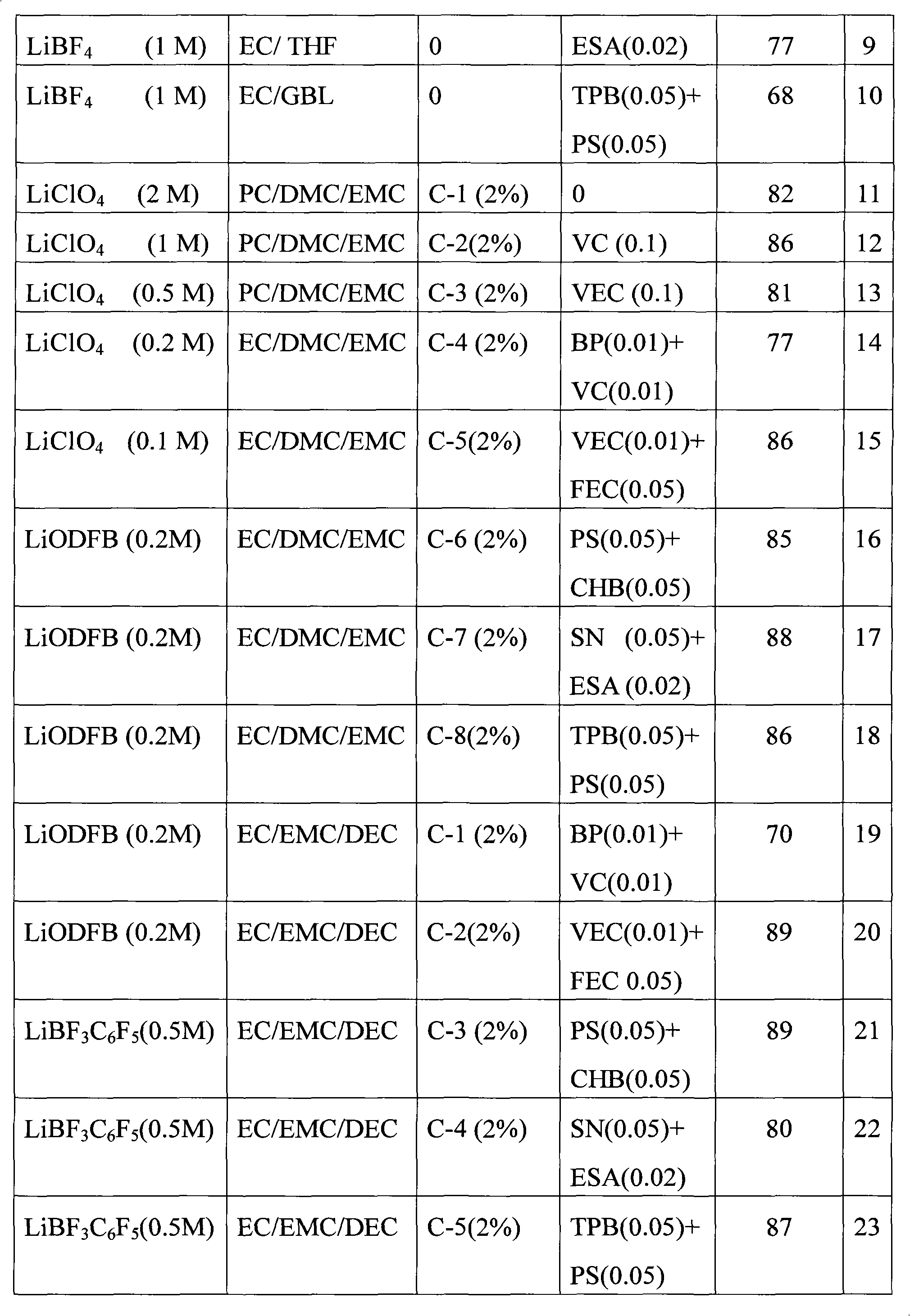

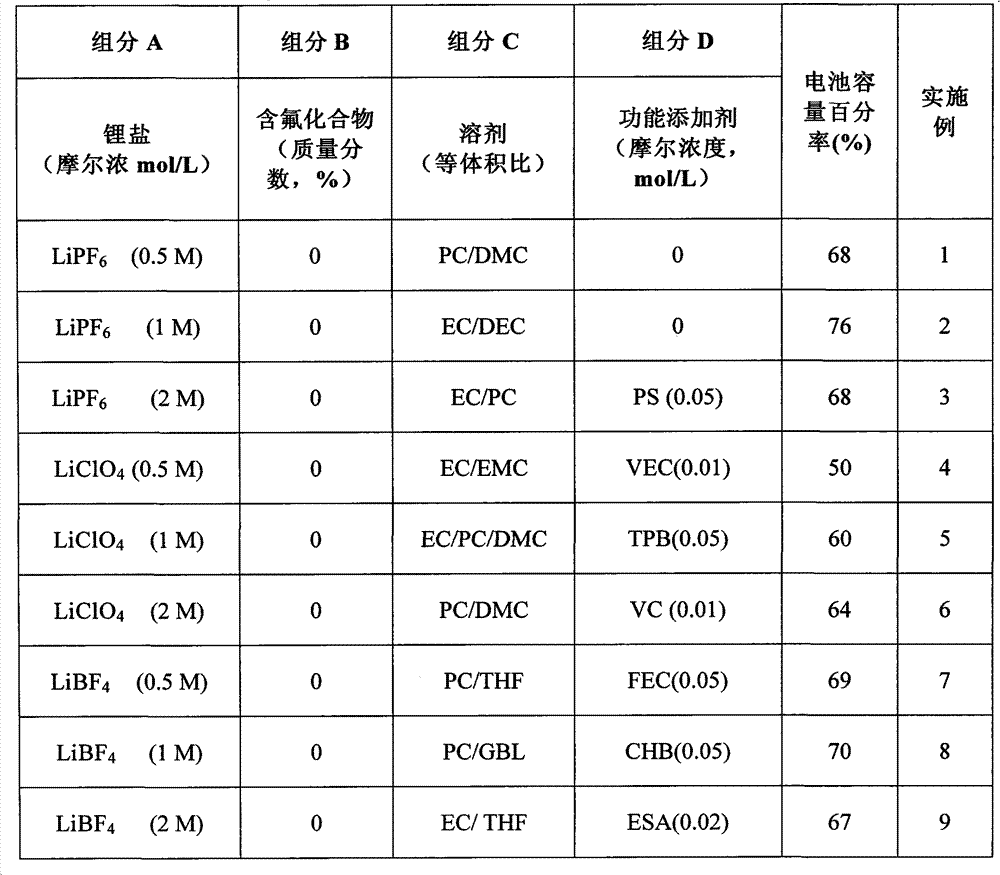

Non-aqueous electrolyte solution and application thereof

InactiveCN102074738AAvoid decompositionLower resistanceFinal product manufactureNon-aqueous electrolyte cellsOrganic solventDecomposition

The invention provides a non-aqueous electrolyte solution and application thereof. The electrolyte solution comprises the following four components: lithium salt, a carbonic ester and / or ether organic solvent, a function additive and other additives, wherein the molar concentration range of lithium salt in the electrolyte is 0.001-2 mol / L; the mass proportion range of the function additive in the electrolyte is 0.01-20 percent; and the molar concentration range of the other additives in the electrolyte is 0-0.5 mol / L. The non-aqueous electrolyte solution provided by the invention can inhibit the decomposition of the solvent, prolong the cycle life and service life of a lithium battery, inhibit the resistance increase of the battery, improve the volume maintenance rate of the battery and prolong the volume maintenance rate and cycle life of the battery in a high-temperature environment and can be applied to the manufacture of a primary lithium battery, a secondary lithium battery or a lithium ion battery.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

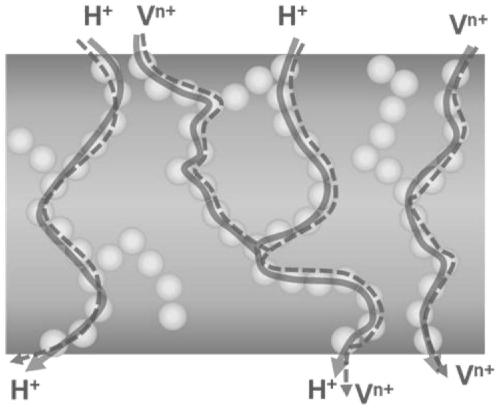

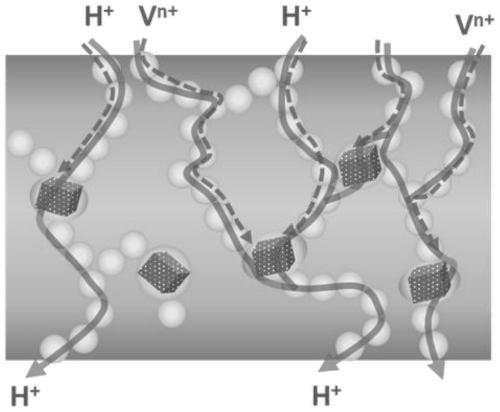

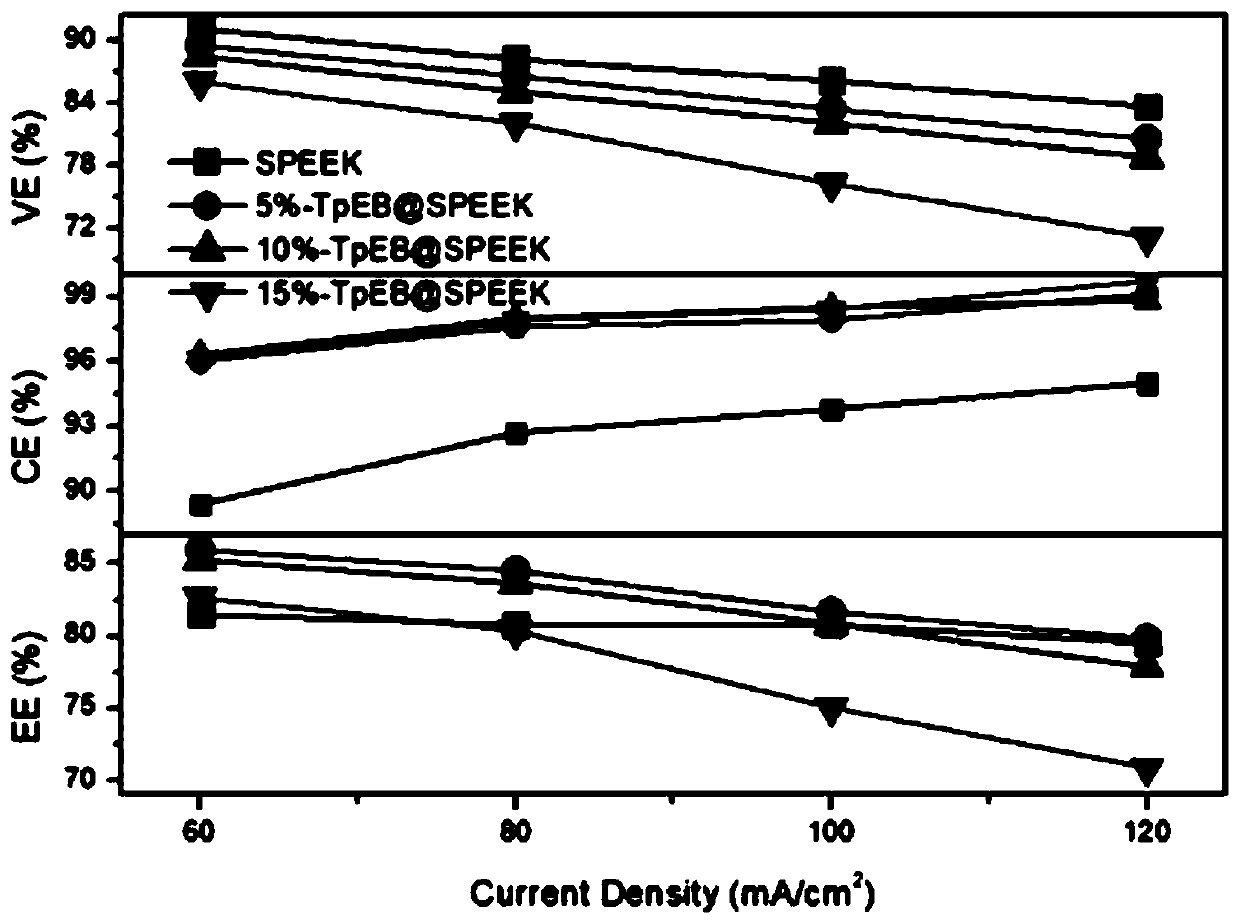

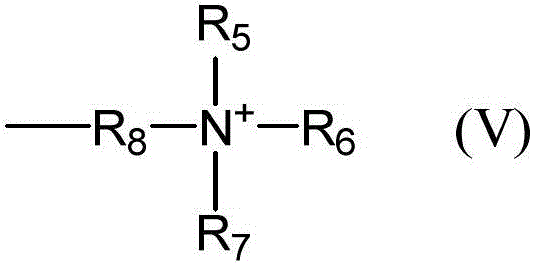

Mixed matrix type cation exchange membrane and preparation method thereof

ActiveCN110336052AInhibit water swellingImprove tensile propertiesRegenerative fuel cellsOrganic structureFunctional modification

The invention relates to a mixed matrix type cation exchange membrane and a preparation method thereof. The cation exchange membrane takes a sulfonated modified polymer material as a substrate and isdoped with Schiff base type covalent organic framework materials loaded with different functional groups. The preparation method comprises the following steps of: sequentially performing monomer preparation and polymerization of a covalent organic framework material, sulfonation modification of a polymer, uniform mixing of the covalent organic framework material and a sulfonated polymer, and flow-spreading film formation; and finally, performing acid treatment to obtain the cation exchange membrane. The covalent organic framework material can effectively improve the vanadium resistance of themembrane based on the rigid porous structure; the organic porous structure of the covalent organic framework and the different functional modifications can partially compensate the loss of membrane proton conductivity caused by the introduction of particles; the rigid framework can obviously inhibit the swelling in the membrane and can improve the tensile strength of the membrane; COFs is composedof organic structures and can promote compatibility between sulfonated polymers and covalent organic framework materials; and moreover, the polymer as the substrate can improve the film forming performance of the covalent organic framework material, so that the covalent organic framework material has the better mechanical strength.

Owner:DALIAN UNIV OF TECH

Binder for lithium cell

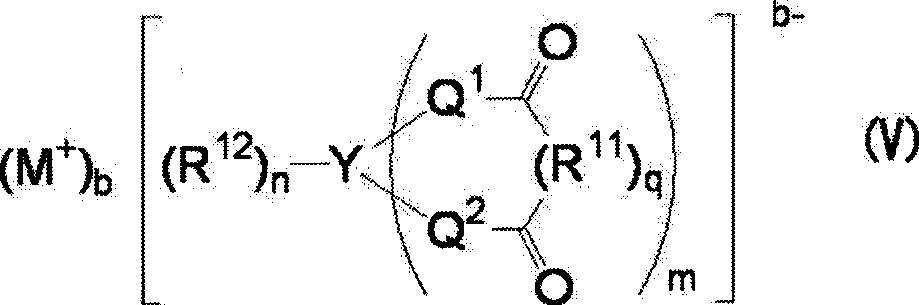

InactiveCN106233514AHigh charge and discharge capacityImprove Coulombic efficiencyCell electrodesSecondary cellsElectrical batteryCross linker

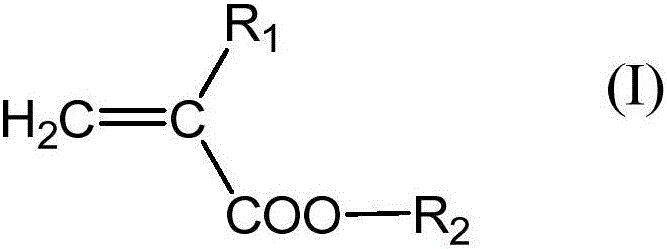

This invention addresses the problem of providing an electrode with which excellent charge / discharge capacity can be obtained even when an active material containing silicon is used. The present invention pertains to: a binder for a lithium cell comprising a polymer that has, as constituent elements, an acrylic acid-derived monomer unit and one or two monomer units derived from compounds represented by general formulae (I), (II), or (III), the binder being crosslinked by a crosslinking agent selected from compounds indicated in general formulae [1]-[13] and the monomer indicated in general formula [14]; a composition for producing an electrode of a lithium cell, the composition containing 1) a silicon-containing active material, 2) an electroconductive aid, and 3) the binder for a cell; and an electrode for a lithium cell having 1) a silicon-containing active material, 2) a conductive aid, 3) the binder for a cell, and 4) a collector.

Owner:FUJIFILM WAKO PURE CHEM CORP +1

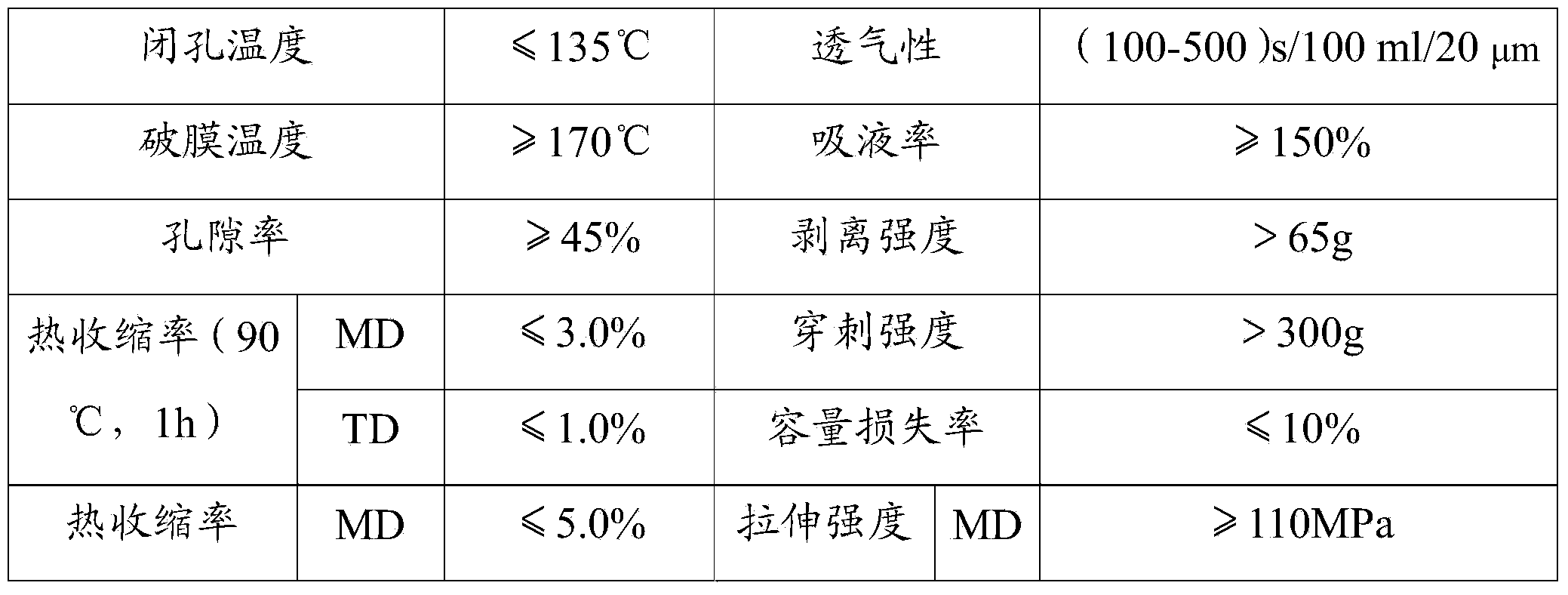

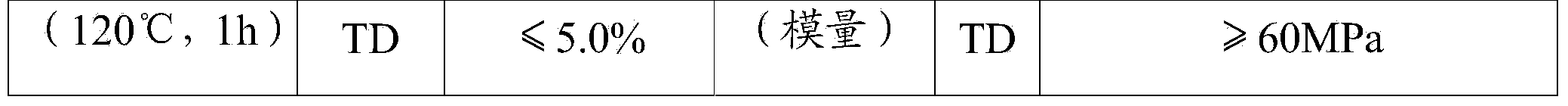

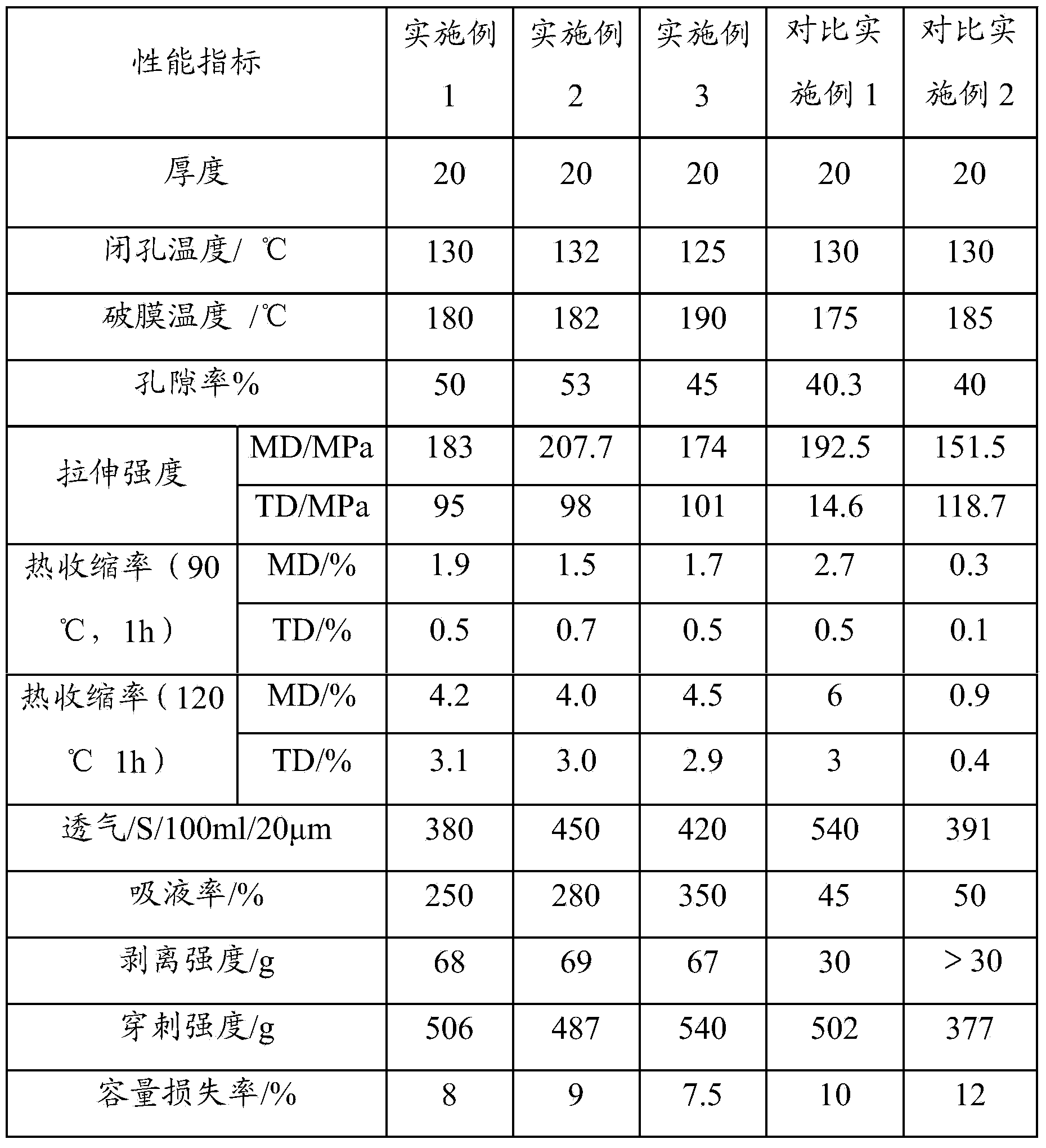

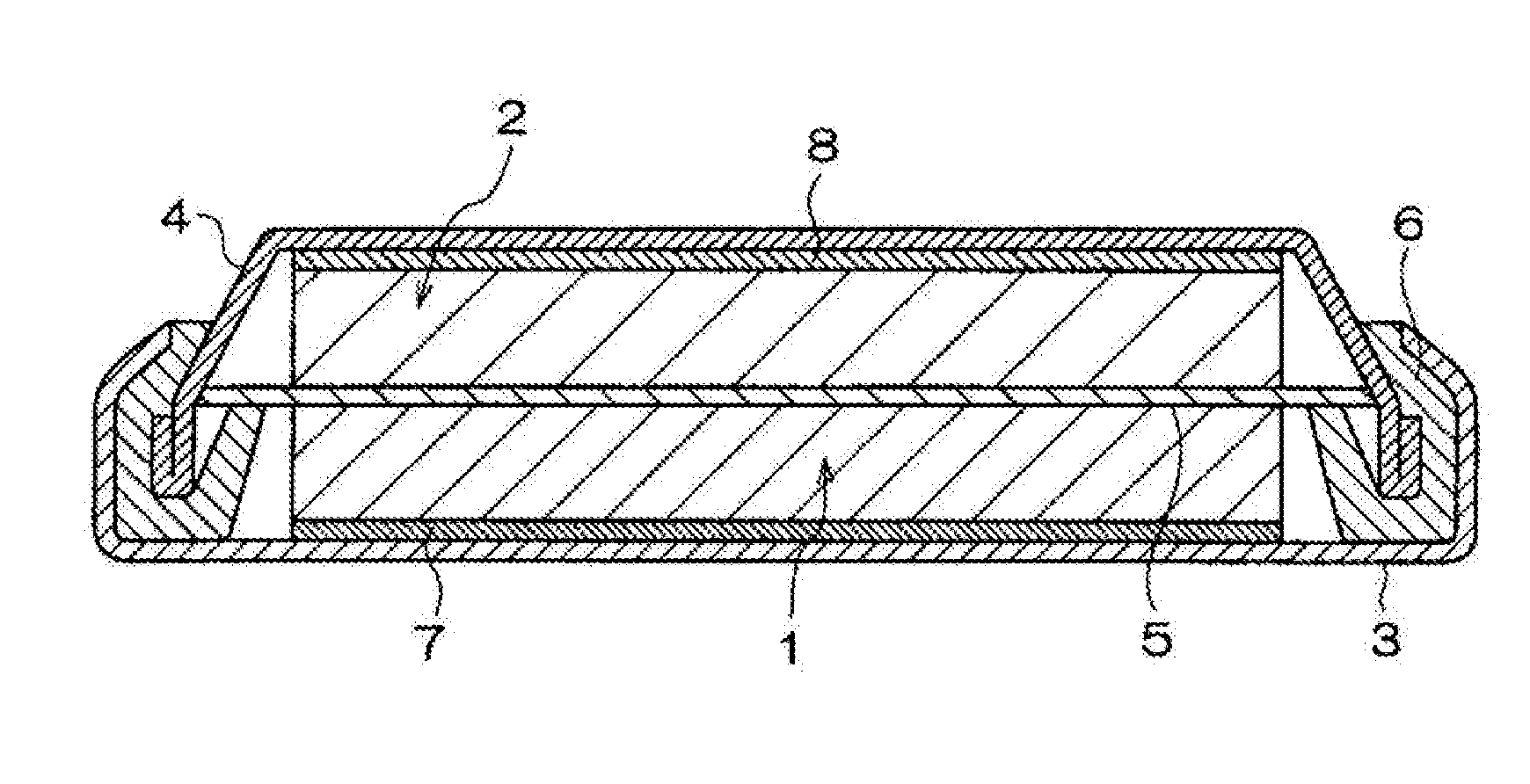

Polyolefin multilayer micro porous diaphragm for lithium ion battery and preparation method of polyolefin multilayer micro porous diaphragm

ActiveCN103531735AWith ion acceleration functionExcellent Adhesive FunctionCell component detailsPolyolefinHigh diaphragm

The invention relates to a polyolefin multilayer micro porous diaphragm for a lithium ion battery and a preparation method of the polyolefin multilayer micro porous diaphragm. The polyolefin multilayer micro porous diaphragm comprises a polyethylene micro porous layer, wherein an ion acceleration layer is arranged on each of the upper surface and the lower surface of the polyethylene micro porous layer, and a polypropylene micro porous layer is arranged on the outer surface of each ion acceleration layer. According to the polyolefin multilayer micro porous diaphragm, due to the adoption of a five-layer structure, a low hole closing temperature and a high diaphragm breaking temperature of the diaphragm can be provided, thus a safety window of the diaphragm is increased and the good safety performance is provided; and meanwhile, the ion acceleration layers provide low resistance, high electron conduction rate and good solution absorption performance and solution maintaining performance of the diaphragm, thus the charge-discharge power and the cycle service life of the lithium ion battery can be improved; and the ion acceleration layers have micro porous net-shaped structures and have excellent lyophilic performance and adhering performance, the ion transmission performance of the diaphragm is improved when all layers of the multilayer micro porous diaphragm are well compounded, and good gas permeability is kept.

Owner:河南惠强新能源材料科技股份有限公司

Cyclic sulfate compound, non-aqueous electrolyte solution containing same, and lithium secondary battery

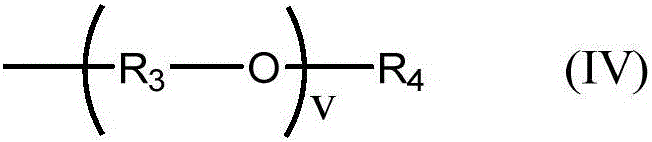

ActiveUS20130171514A1Reduce voltageGood capacity retentionOrganic chemistryFinal product manufactureHydrogen atomHalogen

A non-aqueous electrolyte solution containing a cyclic sulfate compound represented by formula (I) is provided, wherein in formula (I), R1 represents a group represented by formula (II) or a group represented by formula (III); R2 represents a hydrogen atom, an alkyl group having from 1 to 6 carbon atoms, a group represented by formula (II), or a group represented by formula (III); and in formula (II), R3 represents a halogen atom, an alkyl group having from 1 to 6 carbon atoms, a halogenated alkyl group having from 1 to 6 carbon atoms, an alkoxy group having from 1 to 6 carbon atoms, or a group represented by formula (IV).

Owner:MITSUI CHEM INC

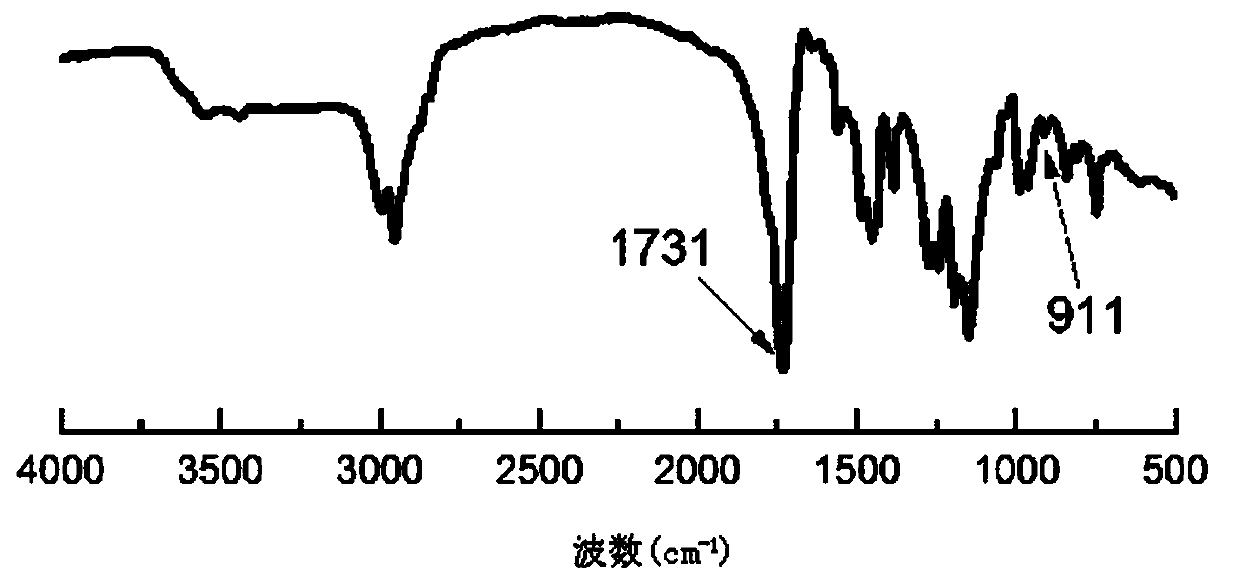

Anode material of lithium-sulfur battery, lithium-sulfur battery and method for preparing anode material

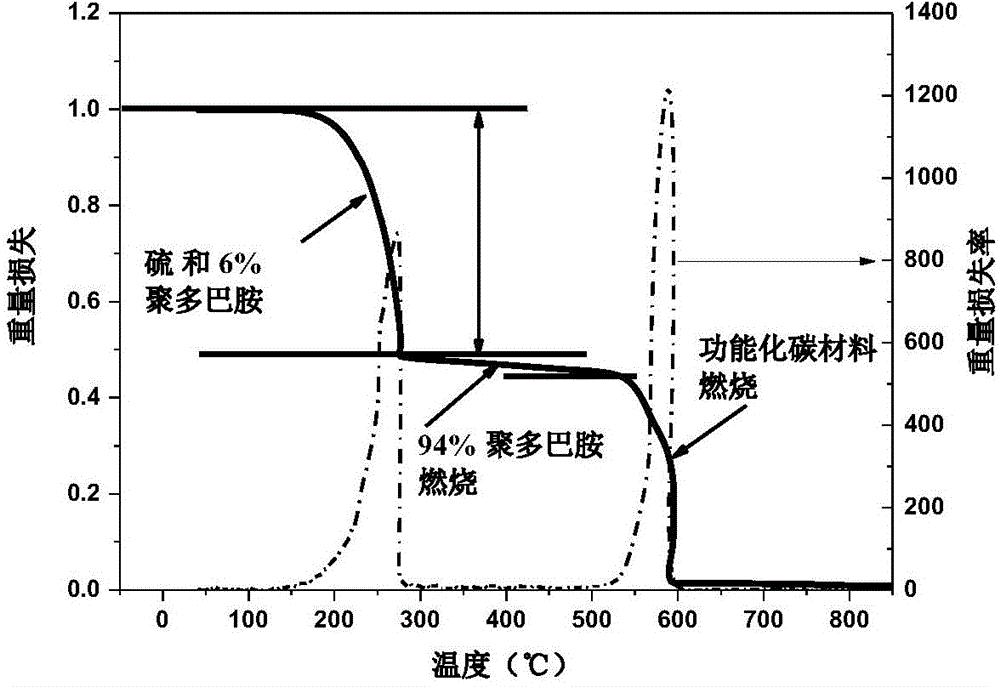

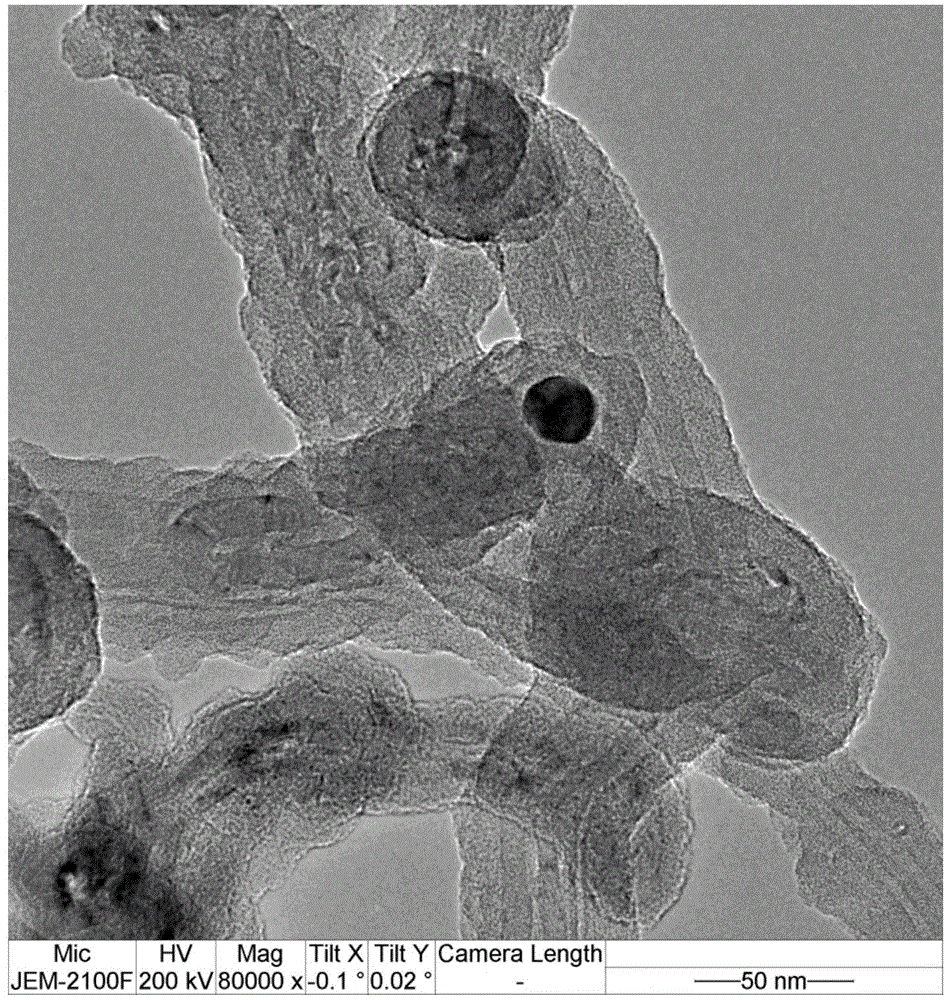

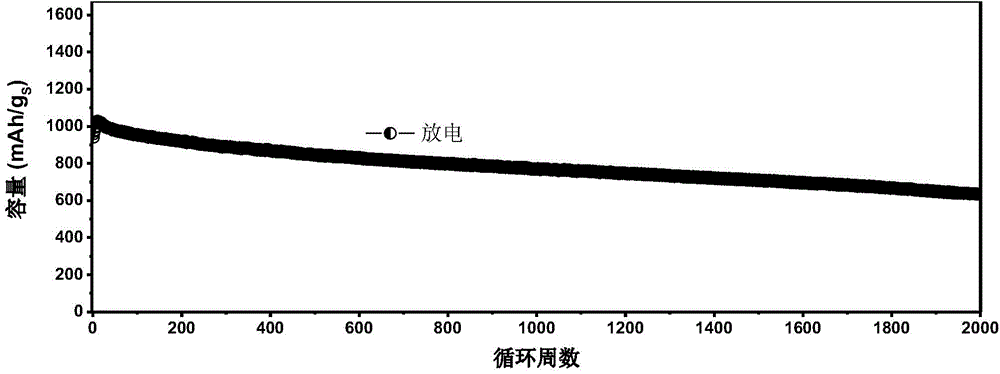

ActiveCN104617327AGuaranteed conductivityGood structural stabilityCell electrodesLi-accumulatorsCarboxylationDopamine hcl

The invention relates to an anode material of a lithium-sulfur battery, the lithium-sulfur battery and a method for preparing the anode material, and belongs to the field of battery materials. The center of the anode material is made of a functionalized carbon nano-material, the middle interlayer is made from sulfur, and the outer layer adopts a polydopamine film, wherein the functionalization method is hydroxylation or carboxylation. The preparation method comprises the following steps: dissolving the carbon nano-material in an alkaline or acid liquid to obtain the functionalized carbon nano-material; adding the functionalized carbon nano-material in a sulfur water solution, stirring, dropwise adding diluted acid to the solution, and obtaining the functionalized carbon nano-material coated with sulfur on the outer side; adding the functionalized carbon nano-material coated with sulfur on the outer side in a tris(hydroxymethyl) methane buffer solution, and performing a polymerization reaction to a dopamine hydrochloride solution, so as to obtain the anode material. The invention further relates to the lithium-sulfur battery using the anode material. The battery can further comprise a polyethylene diaphragm modified by polydopamine. The anode material can inhibit the shuttle flying effect and the structural damage caused by volume expansion; and the lithium-sulfur battery is good in cycle performance and capacity retention ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Lithium battery with silicon-based anode and silicate-based cathode

ActiveUS20130234674A1High energy capacityImprove cycle efficiencyMaterial nanotechnologyBatteries circuit arrangementsNickel–lithium batteryCarbon nanofiber

A lithium-ion battery is provided and related methods. The lithium-ion battery includes an electrode comprising an Olivine flake-like structure and an electrode comprising a plurality of coated carbon nanofibers. The Olivine flake-like structures form clusters through which the lithium ions are transported while reducing initial cycle irreversibility. The electrode comprising the coated carbon nanofibers additionally reduce initial cycle irreversibility by controlling expansion of the substrate forming the electrode comprising the coated carbon nanofibers.

Owner:GENERAL MOTORS COMPANY

Non-aqueous electrolyte solution of fluorine-containing compound

The invention discloses a non-aqueous electrolyte solution of a fluorine-containing compound. The non-aqueous electrolyte solution comprises a lithium salt, the fluorine-containing compound, a carbonate and / ether organic solvent, and an additive having other functions, wherein the molar concentration of the lithium salt in the electrolyte solution is 0.001-2mol / L, the mass percentage of the fluorine-containing compound in the electrolyte solution is 0.01-90%, the mass percentage of the carbonate and / ether organic solvent in the electrolyte solution is 0-90%, and the molar concentration of the additive having other functions in the electrolyte solution is 0-0.5mol / L. The non-aqueous electrolyte solution provided in the invention can inhibit the decomposition of battery materials, increase the cycle life and the service life of a lithium battery, inhibit the improvement of the resistance of the battery, improve the capacity retention rate of the battery, and improve the capacity retention rate and the cycle life of the battery in a high temperature environment.

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

Anode of a lithium battery and method for fabricating the same

ActiveUS8017272B2Increase energy densityLarge capacityNon-metal conductorsConductive materialComposite filmCarbon nanotube

An anode of a lithium battery includes a composite film, the composite film comprising a carbon nanotube film structure and a plurality of nanoscale tin oxide particles dispersed therein. A method for fabricating an anode of a lithium battery, the method includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, by using a tool, at least two carbon nanotube films from the array of carbon nanotubes to form a carbon nanotube film structure; and (c) dispersing a plurality of nanoscale tin oxide particles in the carbon nanotube film structure to form a composite film, and thereby, achieving the anode of the lithium battery.

Owner:TSINGHUA UNIV +1

Method for preparing foamed metal

InactiveCN101298686AUniform densityCapacity balanceElectroforming processesAqueous solutionElectroplating

The invention relates to a preparation method of a foam metal, which comprises the conductivity attachment of a foam plastic substrate, the metal galvanization on the foam plastic substrate that is attached with conductivity and the removing of the foam plastic substrate; the method of metal galvanization on the foam plastic substrate that is attached with conductivity comprises following steps: the foam plastic substrate that is attached with conductivity is used as a cathode so as to contact with electroplate liquid and implement galvanization under the galvanization condition, and the electroplate liquid is an aqueous solution of a salt of a galvanized metal; wherein, in the galvanization process, an insoluble anode is adopted, the content of the salt of the galvanized metal in the electroplate liquid is maintained between 100 and 500 grams per liter, and pH value is maintained between 2 and 5. The foam metal produced by adopting the preparation method of a foam metal provided by the invention has excellent uniformity of planar density.

Owner:BYD CO LTD

Cross-linked polymer-based all-solid-state electrolyte material and application of cross-linked polyoxyethylene ether

ActiveCN103500845AImprove conductivityImprove conduction abilitySecondary cellsCross-linkAll solid state

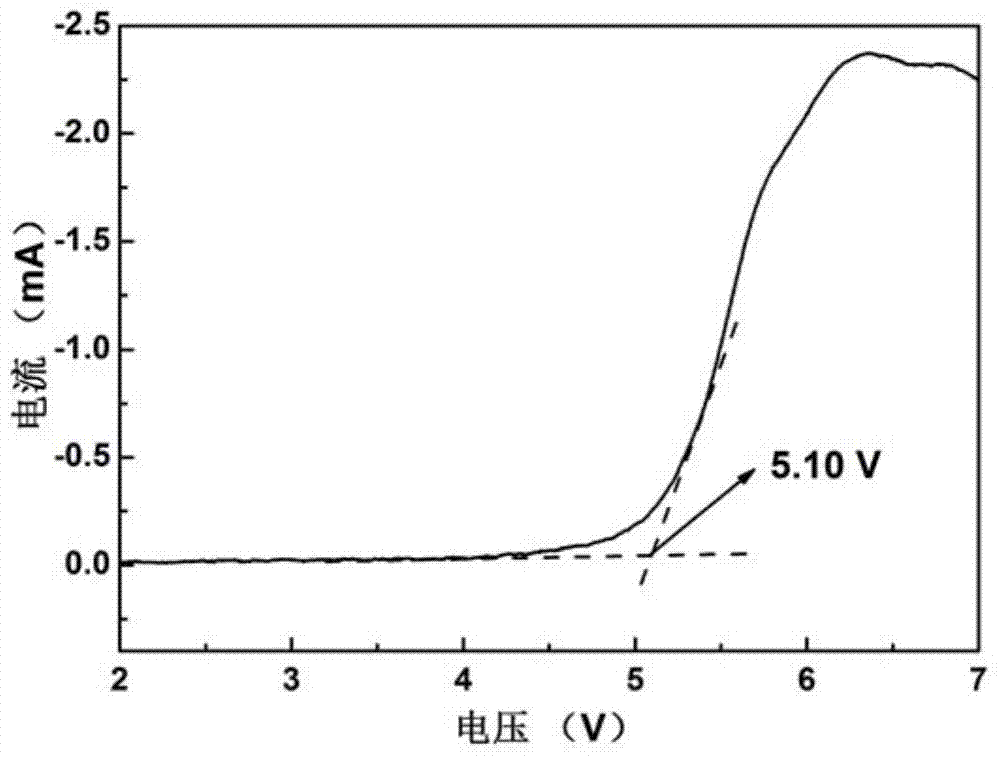

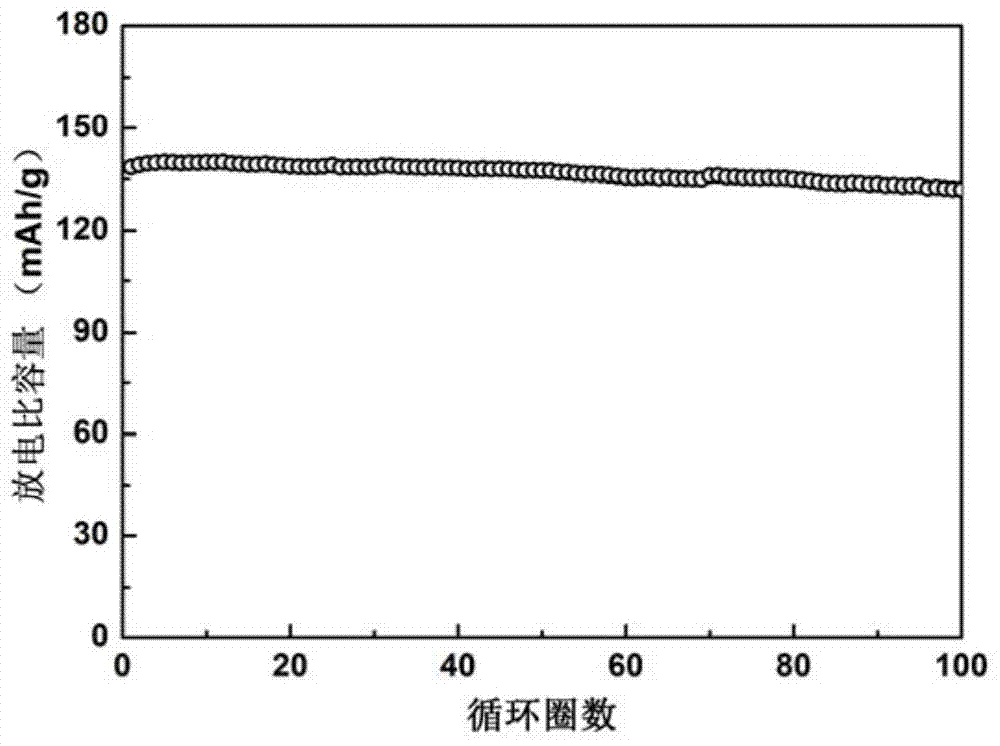

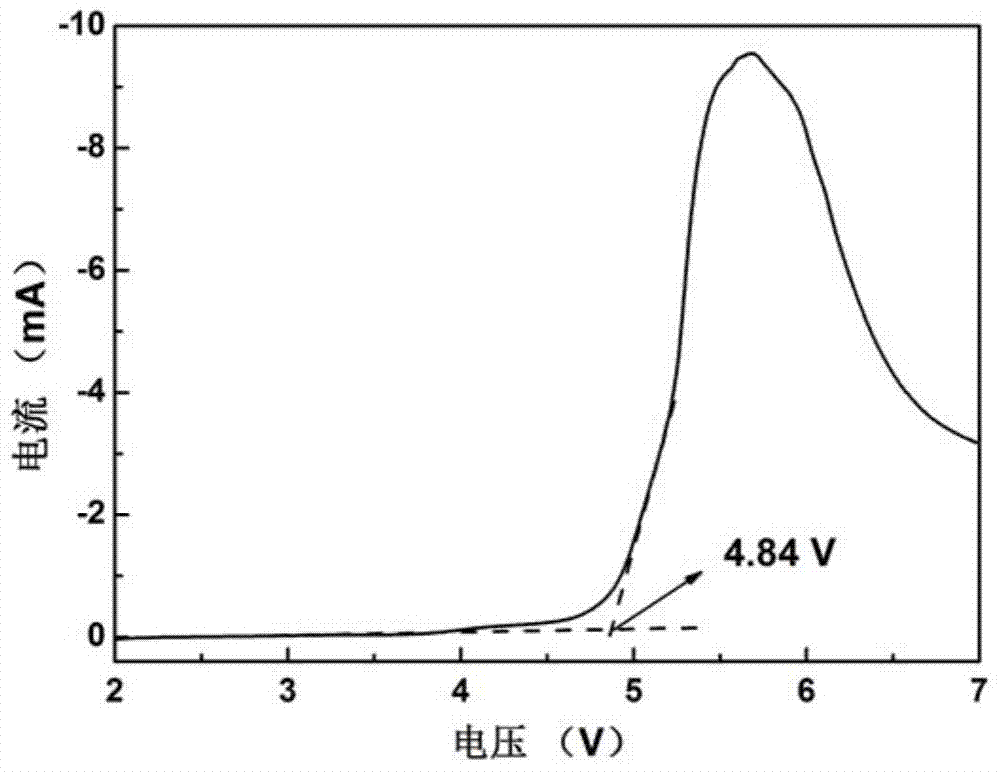

The invention discloses a cross-linked polymer-based all-solid-state electrolyte material and an application of cross-linked polyoxyethylene ether. The cross-linked polymer-based all-solid-state electrolyte material comprises cross-linked polyoxyethylene ether, lithium salt and a modifying agent. An electrolyte membrane prepared from the electrolyte material containing the cross-linked polyoxyethylene ether has relatively high conductivity and a wide electrochemical window; and an assembled half-cell has good high-temperature cycle performance, and the retention rate of the charge-discharge specific capacity of the half-cell is high.

Owner:王海斌

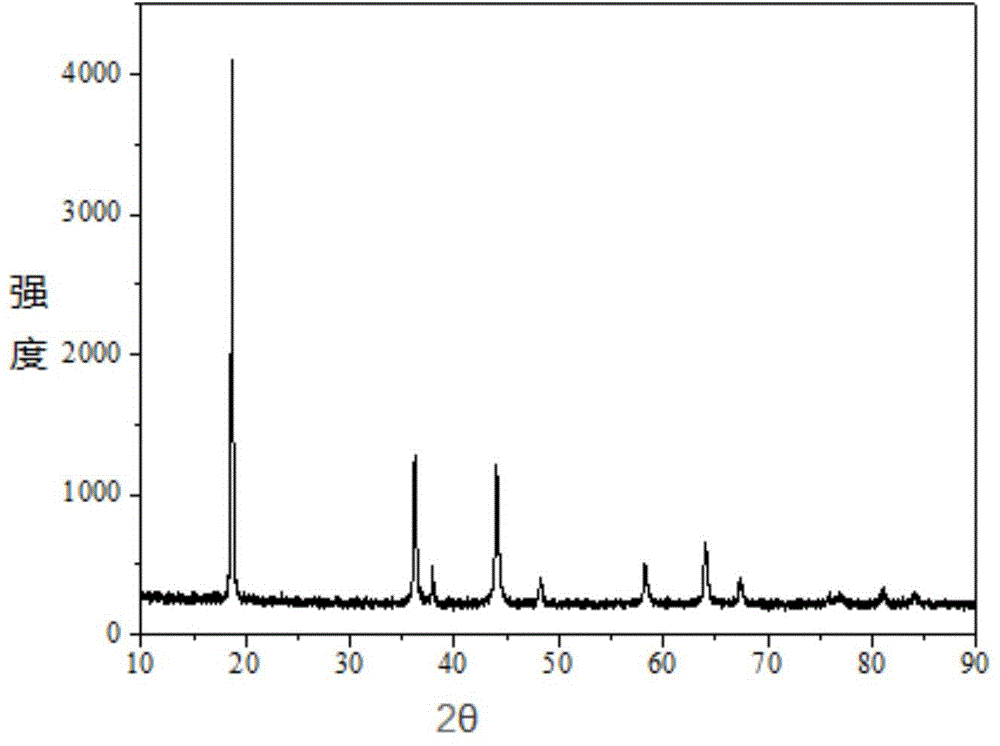

High-nickel ternary lithium-ion positive electrode material and preparation method thereof

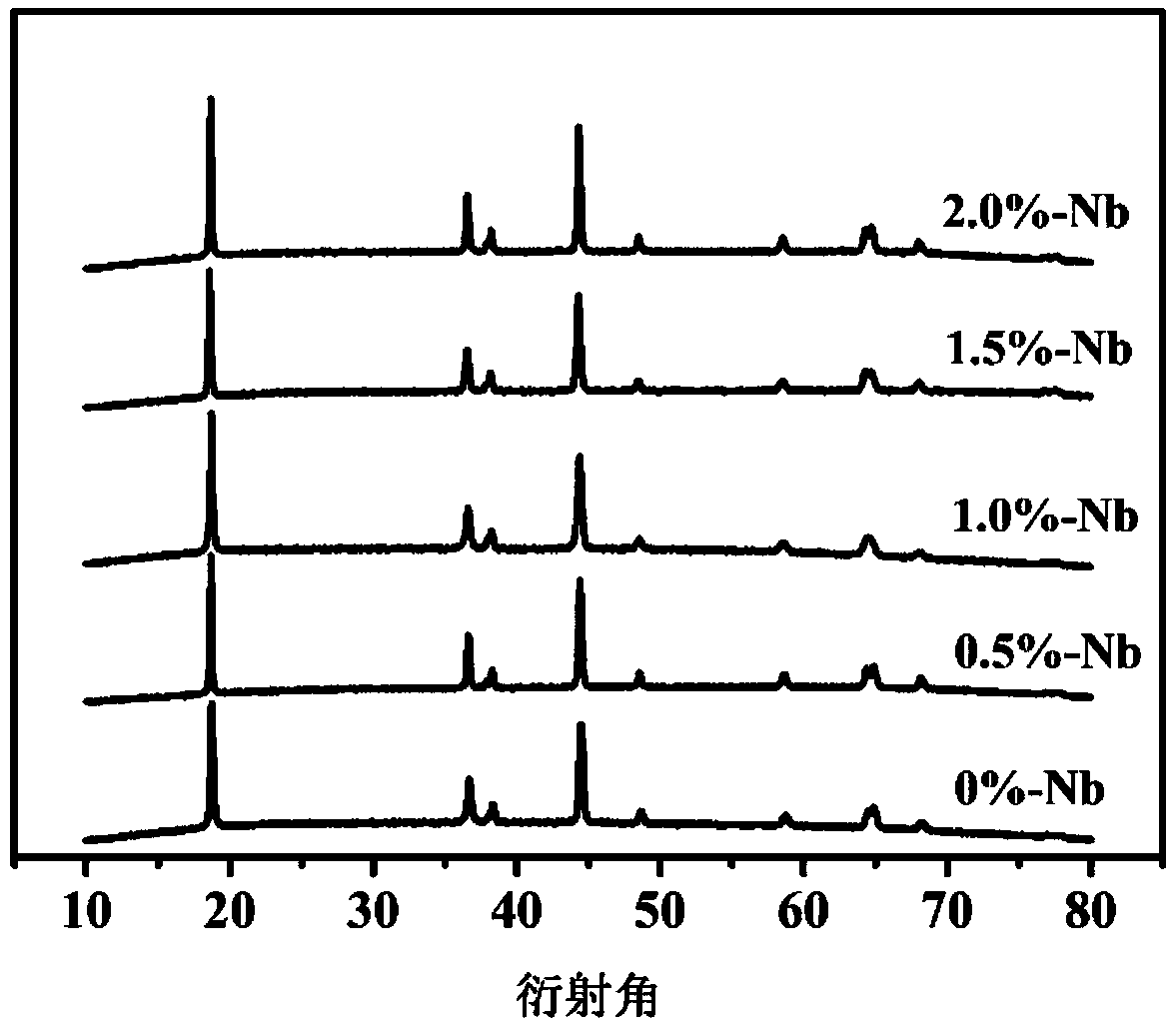

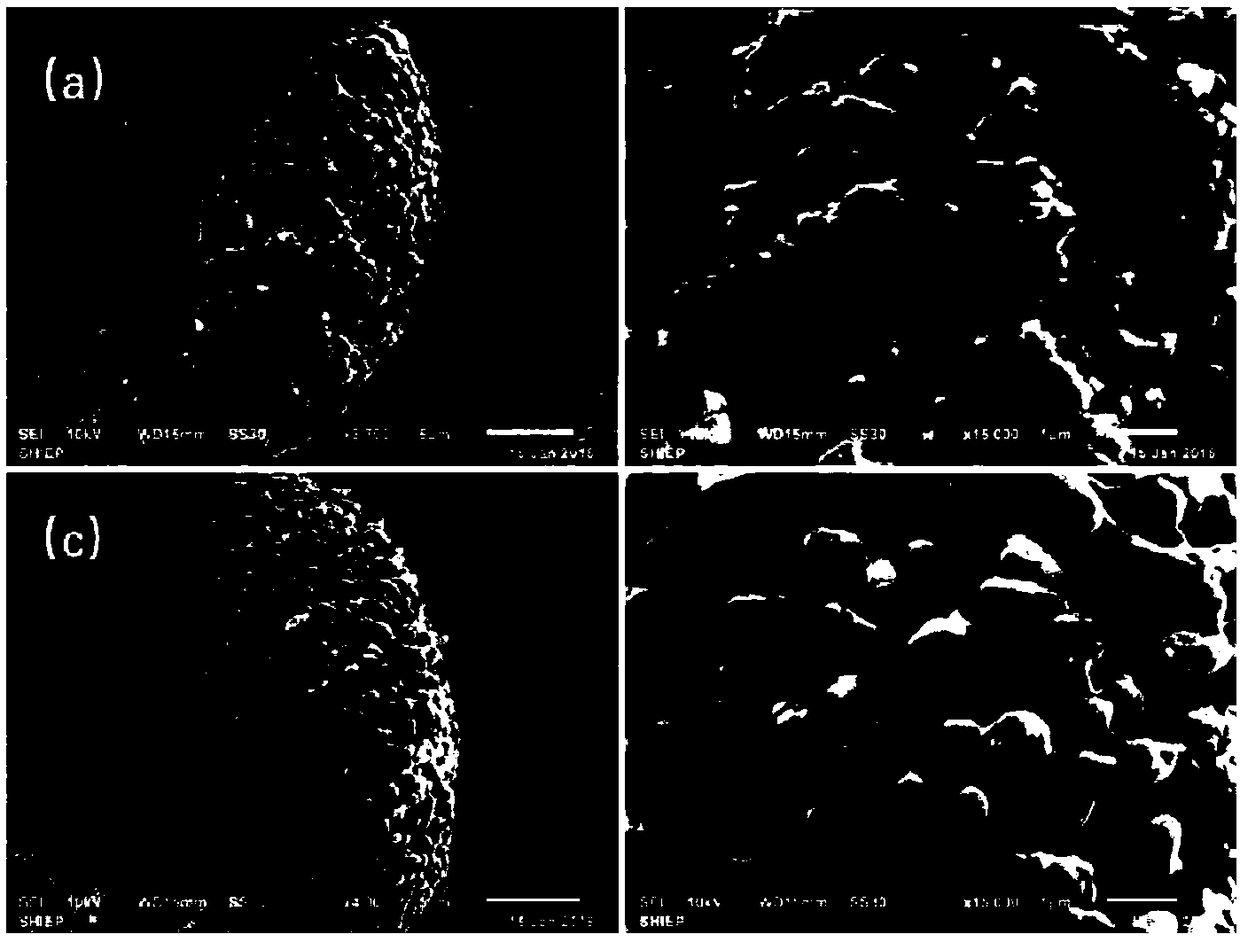

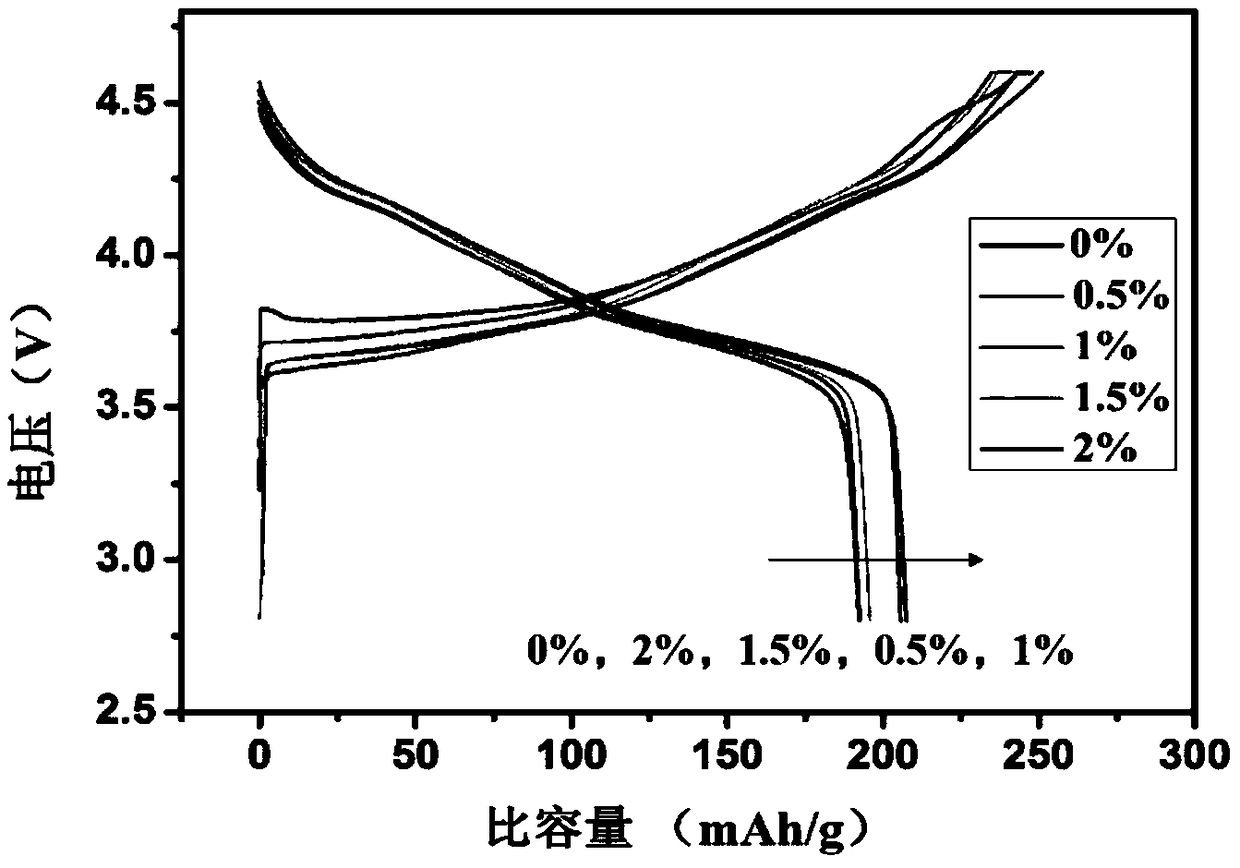

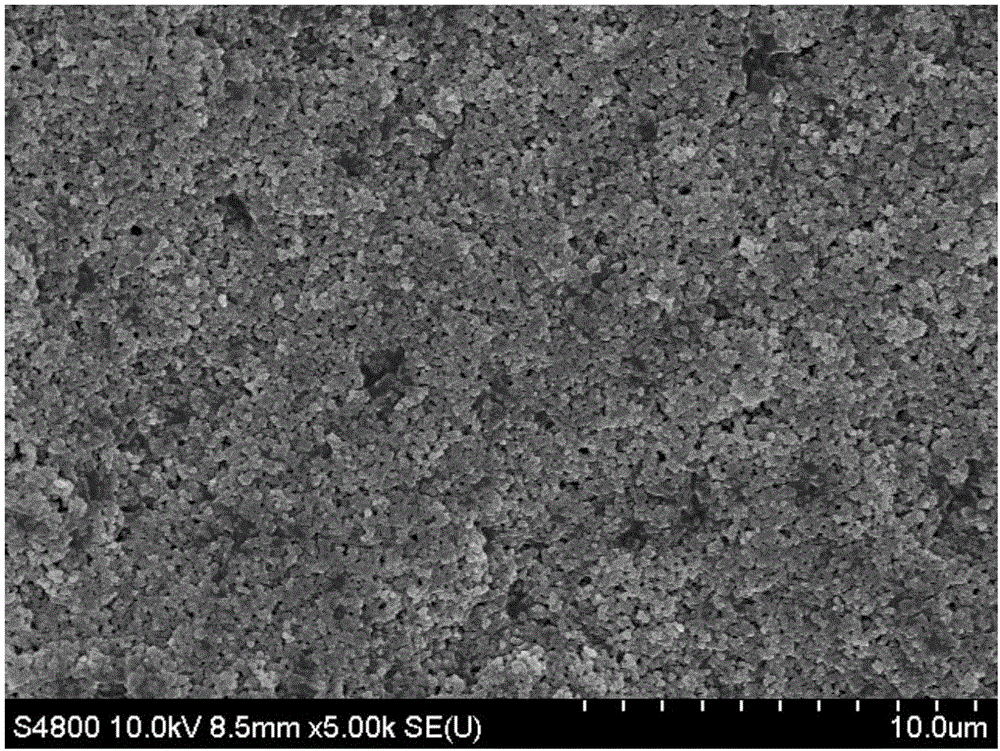

InactiveCN108899539AEasy to shapeImprove electrochemical performanceSecondary cellsPositive electrodesLithiumNiobium

The invention relates to a high-nickel ternary lithium-ion positive electrode material and a preparation method thereof. The high-nickel ternary lithium-ion positive electrode material is niobium-doped LiNi0.8Co0.1Mn0.1O2, the chemical formula of the high-nickel ternary lithium-ion positive electrode material is Li(Ni0.8Co0.1Mn0.1)1-xNbxO2, wherein x is more than 0 and less than or equal to 2%. The preparation method comprises the following steps: mixing a nickel source, a cobalt source, a manganese source and a niobium source with urea, adding water and stirring till being dissolved for hydrothermal reaction; after reaction is ended, filtering and washing solution and precipitants in a reaction kettle, drying to obtain precursor, grinding the precursor into powder, mixing with an equimolar lithium source, mixing and grinding uniformly, carrying out high-temperature sintering on the mixed powder in an oxygen atmosphere, cooling to room temperature, and after grinding the powder, obtaining the high-nickel ternary lithium-ion positive electrode material. Compared with undoped materials, the high-nickel ternary lithium-ion positive electrode material shows better multiplying power andcycling performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Polymer-modified ceramic-coated composite separator and application thereof

ActiveCN105161658AImprove physical performanceImprove electrochemical performanceSecondary cellsCell component detailsPolymer modifiedPolyethylene oxide

The invention discloses a polymer-modified ceramic-coated composite separator and an application thereof. The polymer-modified ceramic-coated composite separator comprises an organic separator base material, a ceramic layer and polymers, wherein the ceramic layer coats the surface of the separator base material and is 0.1-20 microns in thickness; the polymers grow in situ on the surfaces of the separator base material and the ceramic layer and inside the separator base material and the ceramic layer; the polymers are polymethyl methacrylate, polyvinylidene fluoride-perfluoropropylene, polyacrylonitrile, polyimide, polyether amide, or polyethylene oxide and the like ; the particle size of inorganic powder in the ceramic layer is 5nm to 10 microns; and the molecular weight of the material of the organic separator base material is 1,000-100,000,000. According to the polymer-modified ceramic-coated composite separator disclosed by the invention, due to the presence of the polymers, and the potential safety hazards caused by dusting and liquid leakage of the ceramic layer can be effectively reduced; the physical property and the electrochemical properties of the separator are effectively improved; meanwhile, due to the presence of the polymers, the interface stability between a separator electrolyte and an electrode can also be improved; and generation of lithium dendrites can be effectively suppressed by improvement of the interface stability. Therefore, improvement of the capacity retention ability of a battery is facilitated.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com