Polymer-modified ceramic-coated composite separator and application thereof

A technology of ceramic composite and ceramic diaphragm, applied in the field of lithium ion battery, can solve the problems of liquid leakage, poor wettability of diaphragm substrate, affecting the performance of ceramic diaphragm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

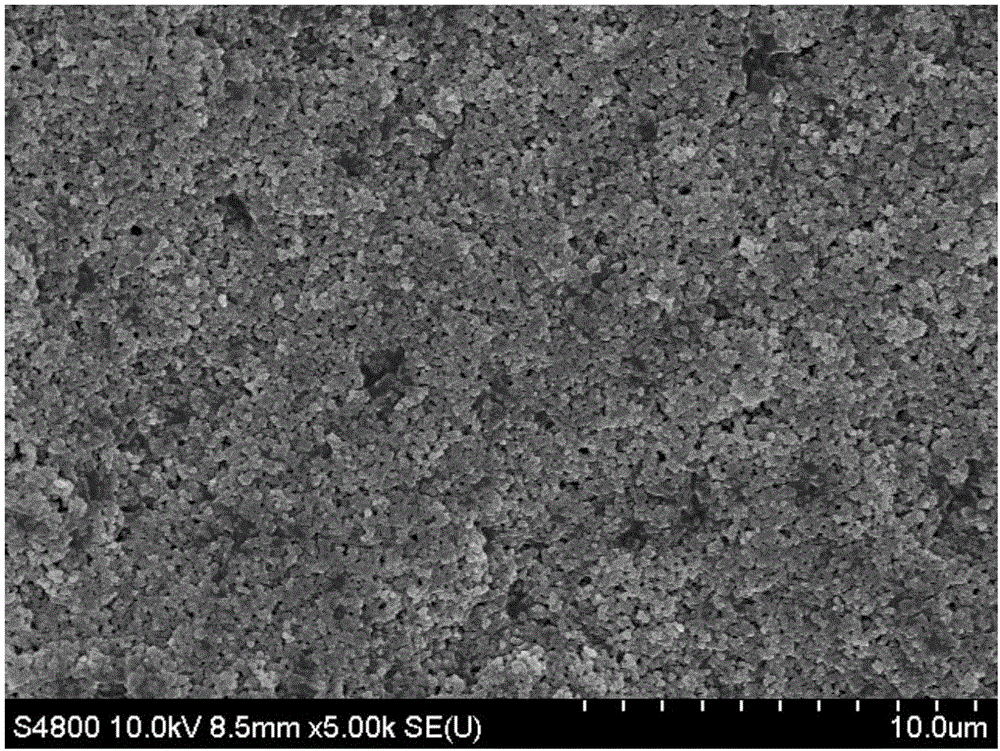

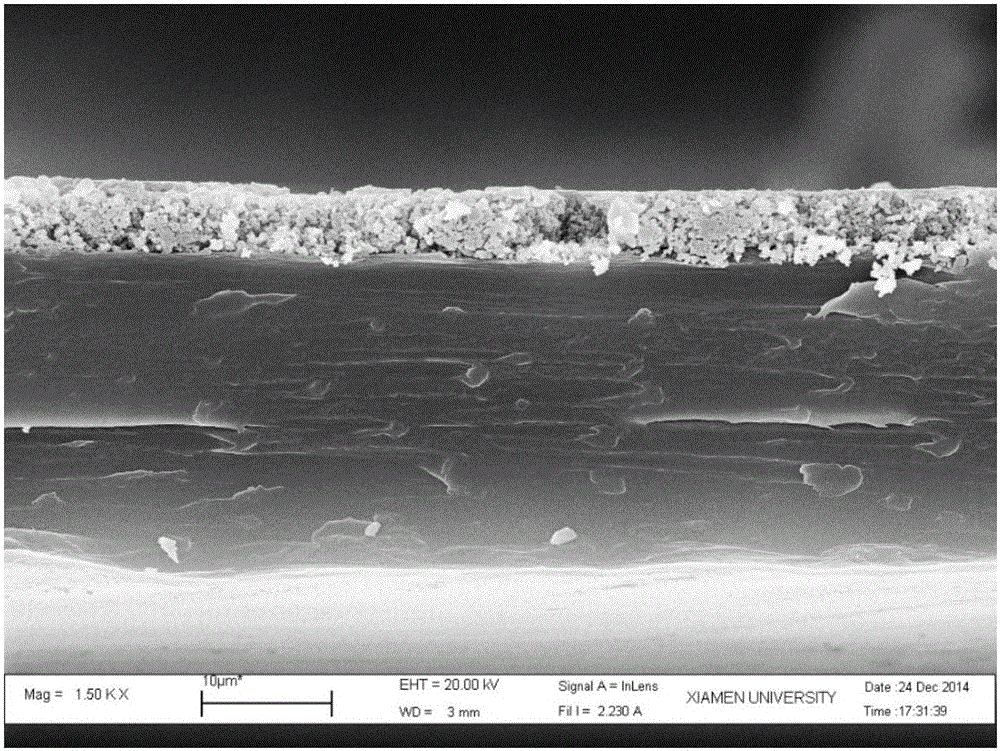

[0046] The mass ratio of the synthesized alumina nanoparticles to sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR) is 95:2:3 mixed powder 1g, add deionized water and acetone (3:1, v: v) Mix 10 ml of the solution, ball mill the obtained ceramic slurry overnight, ultrasonically disperse the mixed slurry for 20 minutes, and apply the obtained slurry to membrane coating. The ceramic diaphragm is made of ordinary polyethylene (PE) diaphragm as the diaphragm base material. The resulting slurry is uniformly coated on one side of a common polyethylene (PE) separator. Use an electric heating plate to preheat at 60°C, wait for most of the solvent to volatilize, and put it into a vacuum oven to dry at 60°C overnight to completely remove the solvent and obtain a ceramic diaphragm.

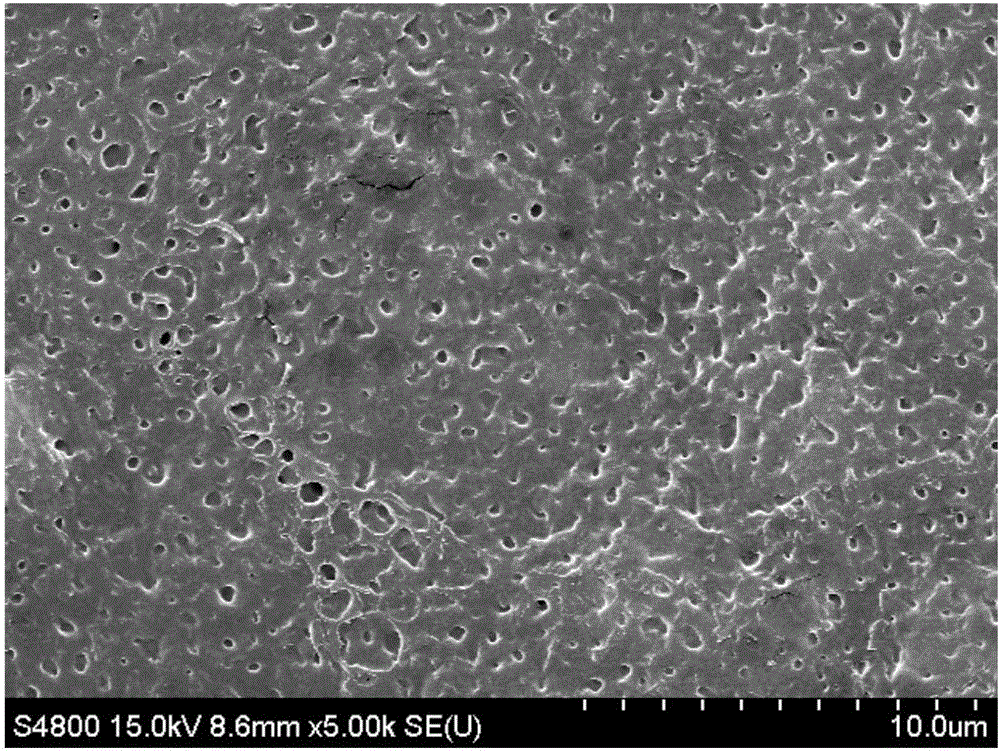

[0047] Add 0.2 g of methyl methacrylate (MMA) into 5 ml of a mixed solvent of nitrogen-methylpyrrolidone and acetone (1:1, V:V), stir mechanically for 10 h, and perform membrane coating ...

Embodiment 2

[0051] Mix 1g of the synthesized silicon oxide nanoparticles and polyacrylate terpolymer latex (LA132) in a mass ratio of 90:4:6, and put a mixed solvent of deionized water and ethanol solvent (3:1, v:v) 15ml, the obtained ceramic slurry was ball-milled overnight, and the mixed slurry was ultrasonically dispersed for 30 minutes, and the obtained slurry was subjected to diaphragm coating. The ceramic diaphragm is made of ordinary polypropylene (PP) diaphragm as the diaphragm base material. The resulting slurry was evenly coated on both sides of a common polyethylene (PP) separator. Use an electric heating plate to preheat at 60°C, wait for most of the solvent to volatilize, and put it into a vacuum oven to dry at 60°C overnight to completely remove the solvent and obtain a ceramic diaphragm.

[0052] Add 0.2 g of methyl methacrylate (MMA) into 10 mL of a mixed solvent of water and ethanol (10:1, V:V), stir mechanically for 5 h, and perform methyl methacrylate modified ceramic ...

Embodiment 3

[0056] Mix 1 g of the synthesized magnesium oxide nanoparticles and polyacrylate terpolymer latex (LA133) in a mass ratio of 85:6:9, and put in a suitable ratio of deionized water and acetone (3:1, v:v ) mixed solvent 20ml, ball-milled the obtained ceramic slurry overnight, ultrasonically dispersed the mixed slurry for 40 minutes, and applied the obtained slurry to membrane coating. The ceramic diaphragm is made of polyvinylidene fluoride (PVDF) diaphragm as the diaphragm substrate. The resulting slurry is evenly coated on one or both sides of a polyvinylidene fluoride (PVDF) diaphragm. Use an electric heating plate to preheat at 60°C, wait for most of the solvent to volatilize, and put it into a vacuum oven to dry at 60°C overnight to completely remove the solvent and obtain a ceramic diaphragm.

[0057] Add 0.5 g of biphenyltetracarboxylic dianhydride (BPDA) and 0.5 g of p-phenylenediamine (PDA) into 10 ml of a mixed solvent of nitrogen-methylpyrrolidone and acetone (5:1, V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com