Preparation method for steel fiber ABS/PC plastic reclaimed aggregate concrete

A technology of recycled aggregate and steel fiber, applied in the field of construction engineering materials, can solve the problems of low strength and durability of recycled aggregate concrete, reduce the strength of recycled aggregate, and low strength of cement mortar, etc. The effect of small thermal conductivity and improved thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

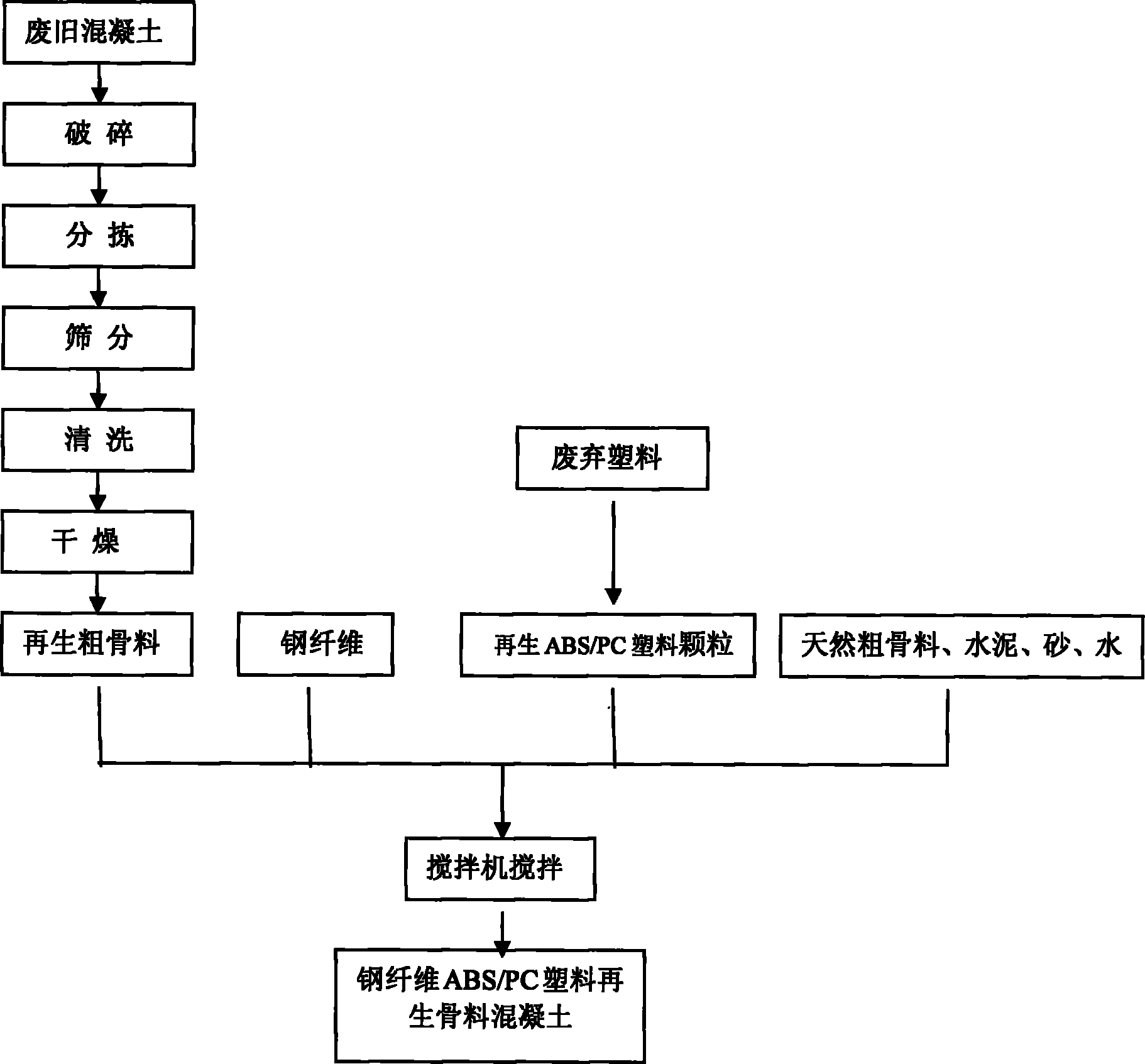

[0024] The implementation steps of the present invention are as follows:

[0025] (1) The concrete recycled aggregate is crushed by the waste concrete through the crusher, and then the sundries other than concrete are sorted, and then passed through the mesh screen to screen out the recycled coarse aggregate with the size between 5mm and 30mm, and clean it with clean water. After washing, let it dry naturally.

[0026] (2) ABS / PC plastic granules are regenerated from waste plastics.

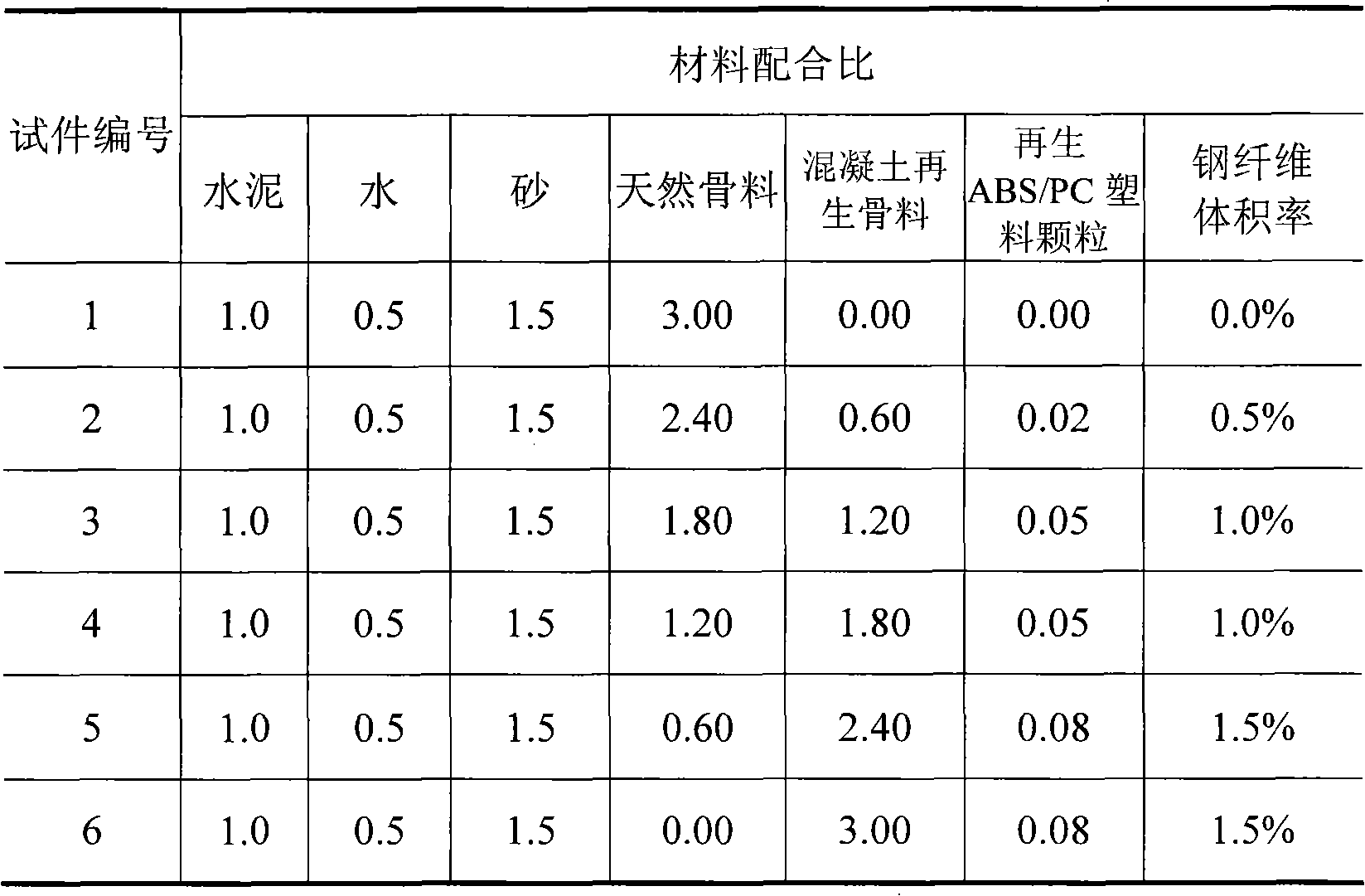

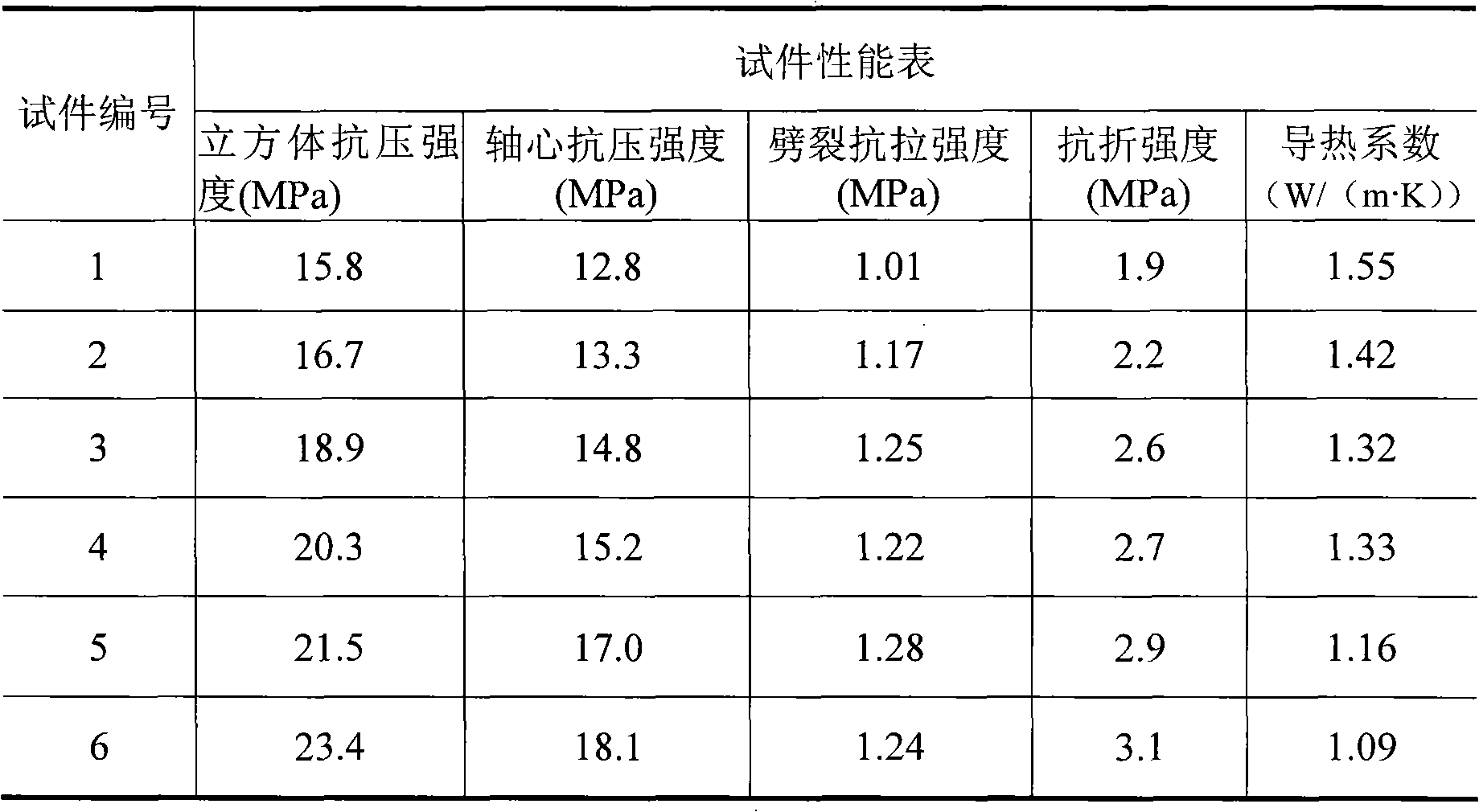

[0027] (3) Steel fiber, recycled ABS / PC plastic particles, concrete recycled aggregate, natural coarse aggregate, sand, cement, and water are mixed in proportion to prepare steel fiber ABS / PC plastic recycled aggregate concrete as shown in Table 1. The properties of fiber ABS / PC plastic recycled aggregate concrete specimens are shown in Table 2.

[0028] Table 1

[0029]

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com