Wide-strain amplitude high-damping iron-based composite alloy and preparation method thereof

A composite alloy, high damping technology, applied in the field of damping alloys, can solve problems such as damping performance attenuation, achieve high damping performance, and solve the effect of rapid damping performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It is worth noting that the given embodiments can not be interpreted as limiting the protection scope of the present invention, and some non-essential improvements and adjustments made by those skilled in the art according to the content of the present invention above should still belong to the protection of the present invention. scope.

[0015] Damping performance test. The damping properties of alloys (Q -1 ) as a function of strain (γ). The vibration frequency is 1Hz, and the test temperature is 30°C.

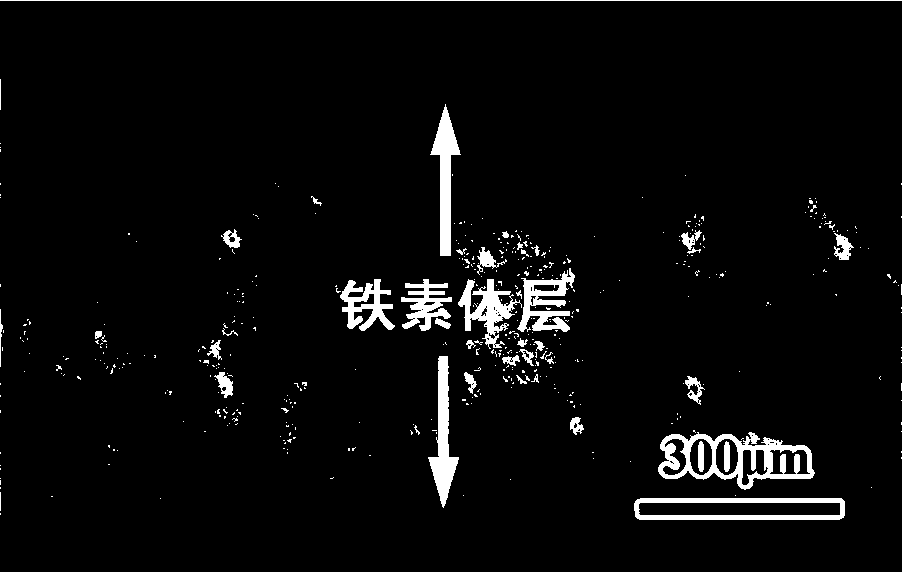

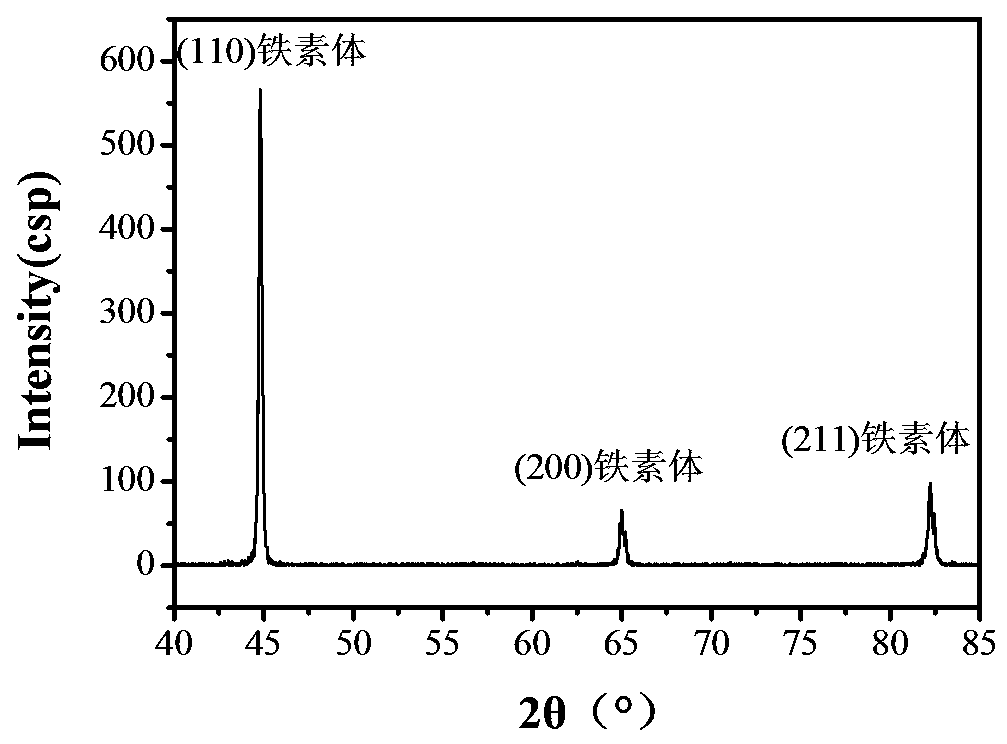

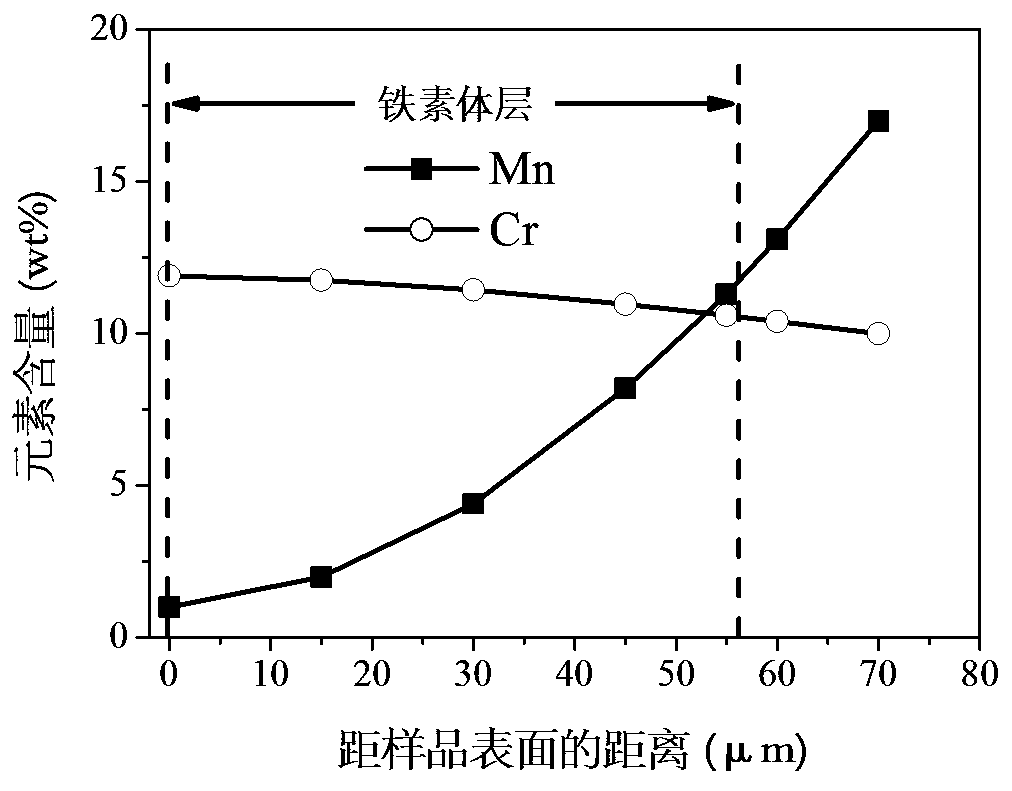

[0016] Microstructural characterization. The metallographic phase of the alloy was observed with an OLYMPUS GX51 optical microscope. The polished metallographic sample was in 20% HClO 4 +80%CH 3 Electrolytic polishing in COOH (volume fraction) solution, followed by NH 4 HF 2 and K 2 S 2 o 5Corrosion in an aqueous solution with a mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com