Light foam Mn-Cu alloy high-damping material and preparation method thereof

A light foam, high damping technology, applied in the field of light foam Mn-Cu alloy high damping material and its preparation, can solve the problems of uneven pore size distribution, high alloy density, difficult process operation, etc. Easy to operate, excellent shock absorption and noise reduction, no need for mold costs

Active Publication Date: 2017-12-12

HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

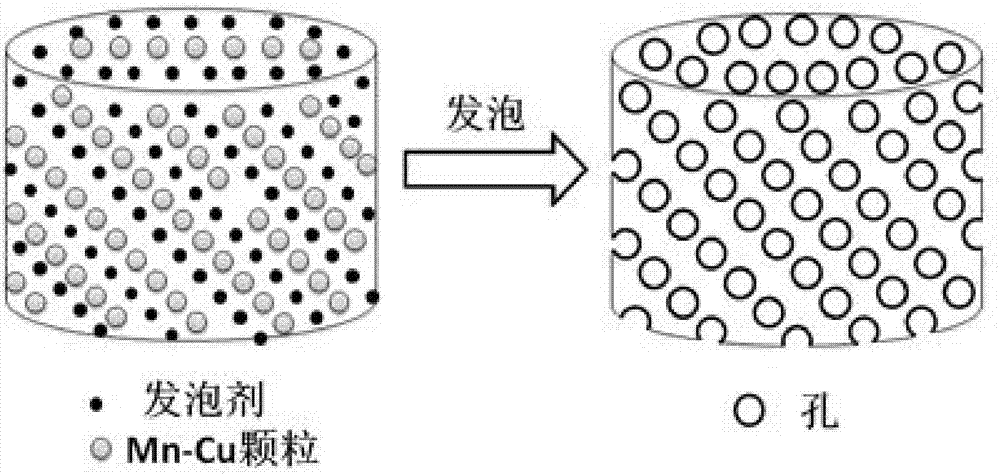

[0005] The technical problem to be solved by the present invention is to provide a light foam Mn-Cu alloy high damping material and its preparation method. The high-density defects of the Mn-Cu alloy can effectively improve the damping performance of the Mn-Cu alloy. In addition, the powder metallurgy method is used to realize the preparation of the foamed Mn-Cu alloy high-damping material, which effectively overcomes the traditional porous material preparation methods including the melt foaming method. Problems such as high foaming temperature, uneven pore size distribution, and difficult process operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

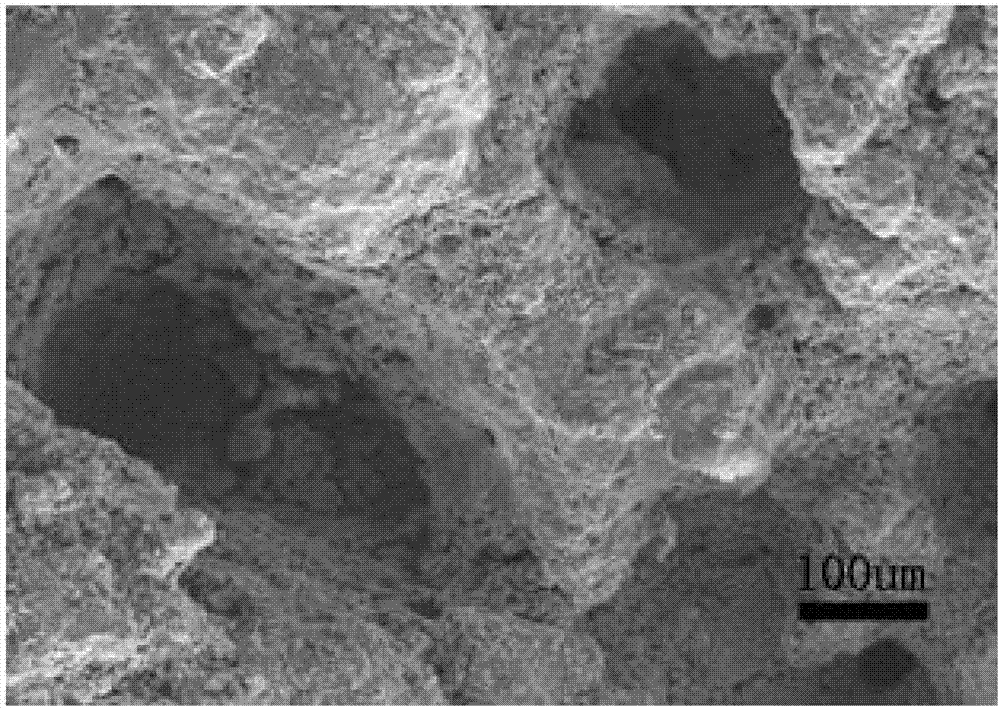

[0052] The foaming agent is selected as sodium chloride, and the cross-sectional morphology of the prepared foamed Mn-Cu alloy high damping material is as follows: figure 2 shown.

Embodiment 2

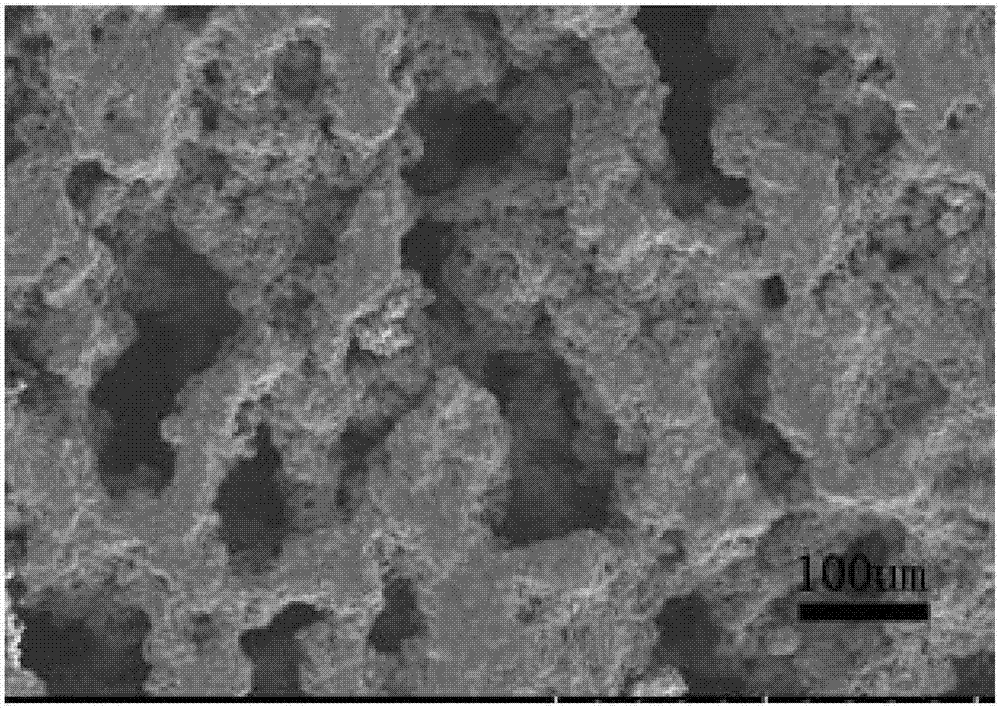

[0054] The blowing agent is selected as carbonate, and the cross-sectional morphology of the prepared foamed Mn-Cu alloy high damping material is as follows: image 3 shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a light foam Mn-Cu alloy high-damping material. The light foam Mn-Cu alloy high-damping material is a binary alloy formed by metal manganese and copper or a multicomponent alloy formed by manganese, copper and one or more of iron, nickel and aluminum. A preparation method of the light foam Mn-Cu alloy high-damping material comprises the following steps of mixing Mn-Cu alloy particles and a foaming agent evenly; putting mixed powder into a mold and conducting cold-press molding to obtain a blank body for standby application; conducting hot-press molding on the blank body to obtain a high-compactness blank body with the density greater than 80%; putting the high-compactness blank body into the mold, conducting foaming and then cooling, and finally obtaining the foam Mn-Cu alloy high-damping material with the uniform aperture. By means of the light foam Mn-Cu alloy high-damping material and the preparation method thereof, the defect that the density of a traditional high-damping Mn-Cu alloy is large is overcome; the damping property of the Mn-Cu alloy is effectively improved through the porosity and the high-density defect around cavities. Besides, by means of the method, the problems that the foaming temperature is high, the size distribution of pores is non-uniform and the technological operation is difficult are solved.

Description

technical field [0001] The invention relates to a foam-type lightweight high-damping material and a manufacturing method thereof, in particular to a lightweight foamed Mn-Cu alloy high-damping material and a manufacturing method thereof. Background technique [0002] Mn-Cu alloy is a typical twin interface relaxation type high-damping alloy, and its early commercial application was as a propeller for naval ships to reduce vibration. Since Japanese researchers developed the M2052 damping alloy (Mn-20Cu-5Ni-2Fe, at%) in 2000, the good machinability and high damping performance (maximum internal friction value of 0.06) of the Mn-Cu alloy has been favored by people. It has great potential application value especially in the fields of aerospace, mechanical engineering, biomedical engineering and instrumentation. However, for applications in the fields of aerospace structures and components that are relatively expensive in cost and operating costs, the high specific gravity of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C22/00B22F3/11C22C1/08

CPCB22F3/1125B22F3/1134C22C22/00

Inventor 高云霞蒋卫斌王先平刘旺方前锋

Owner HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com