Patents

Literature

40results about How to "Low noise and vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

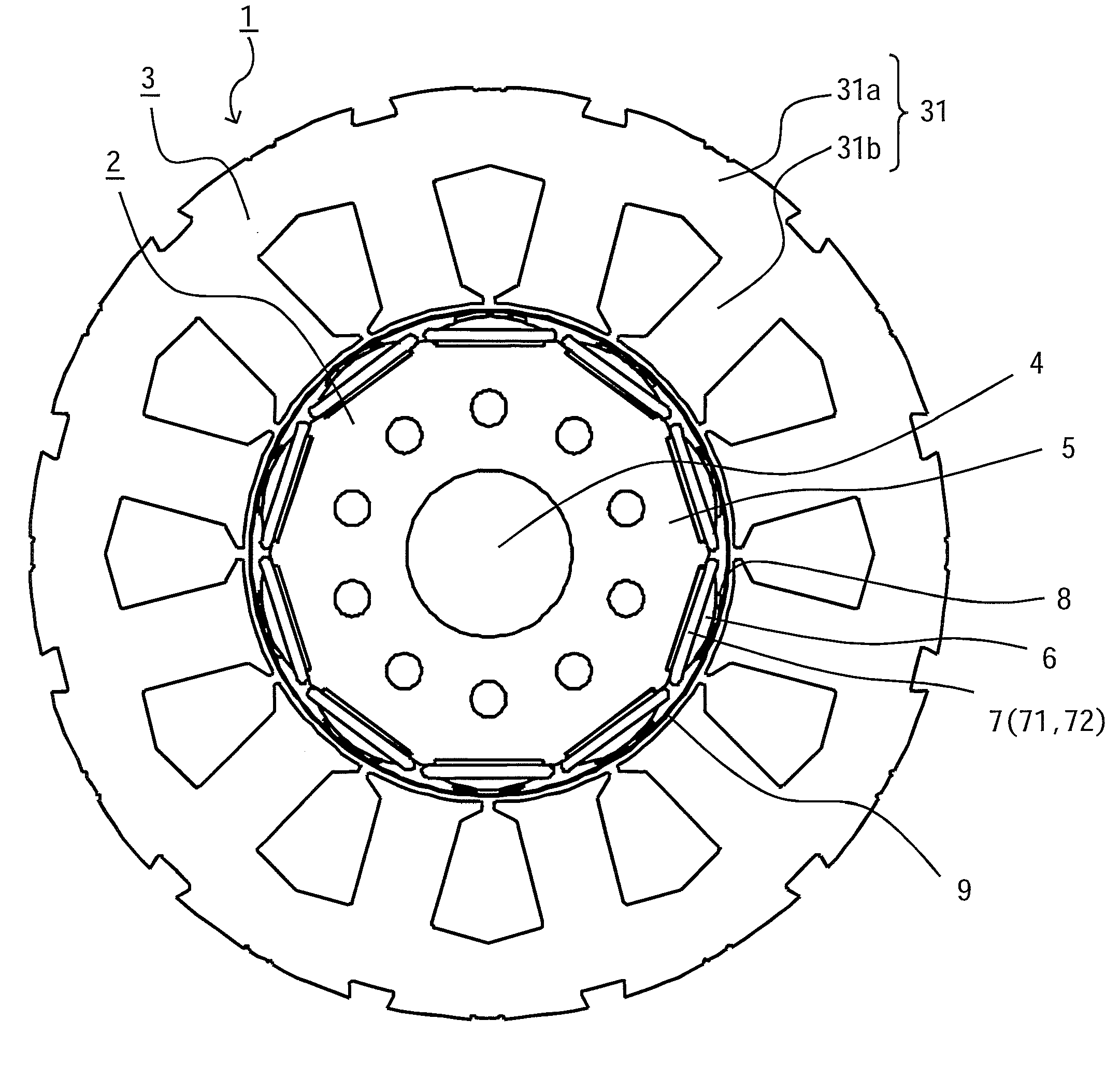

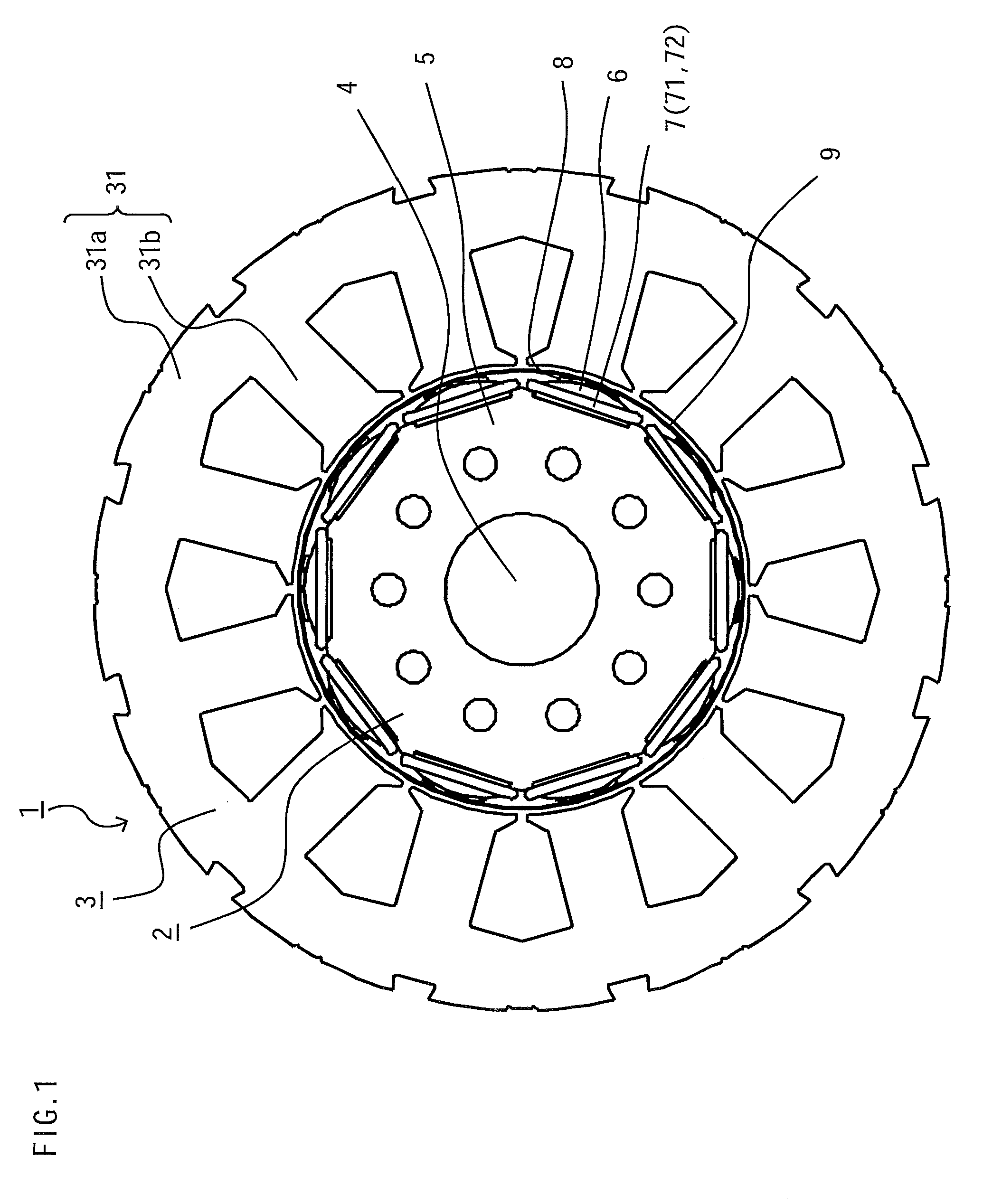

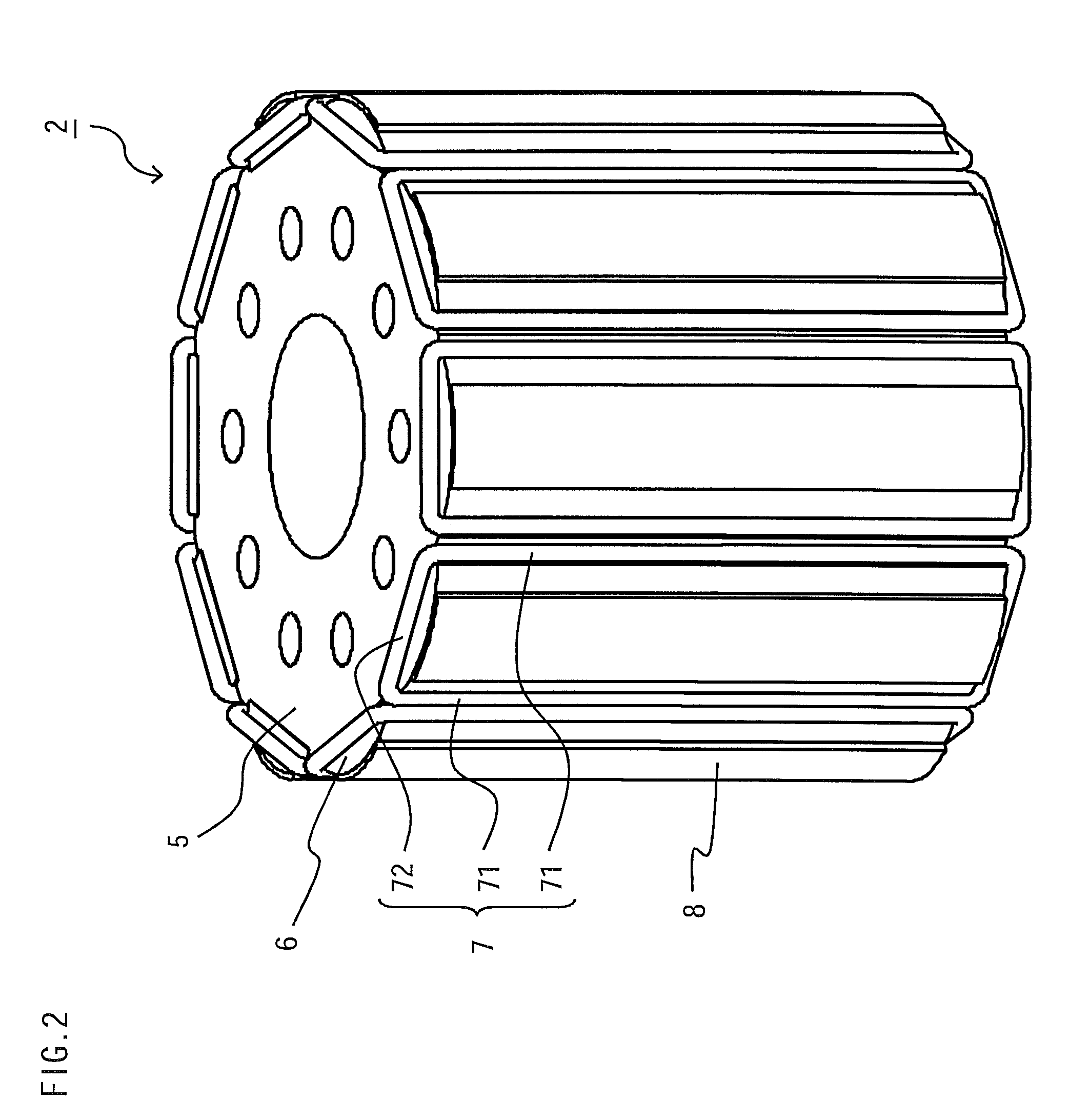

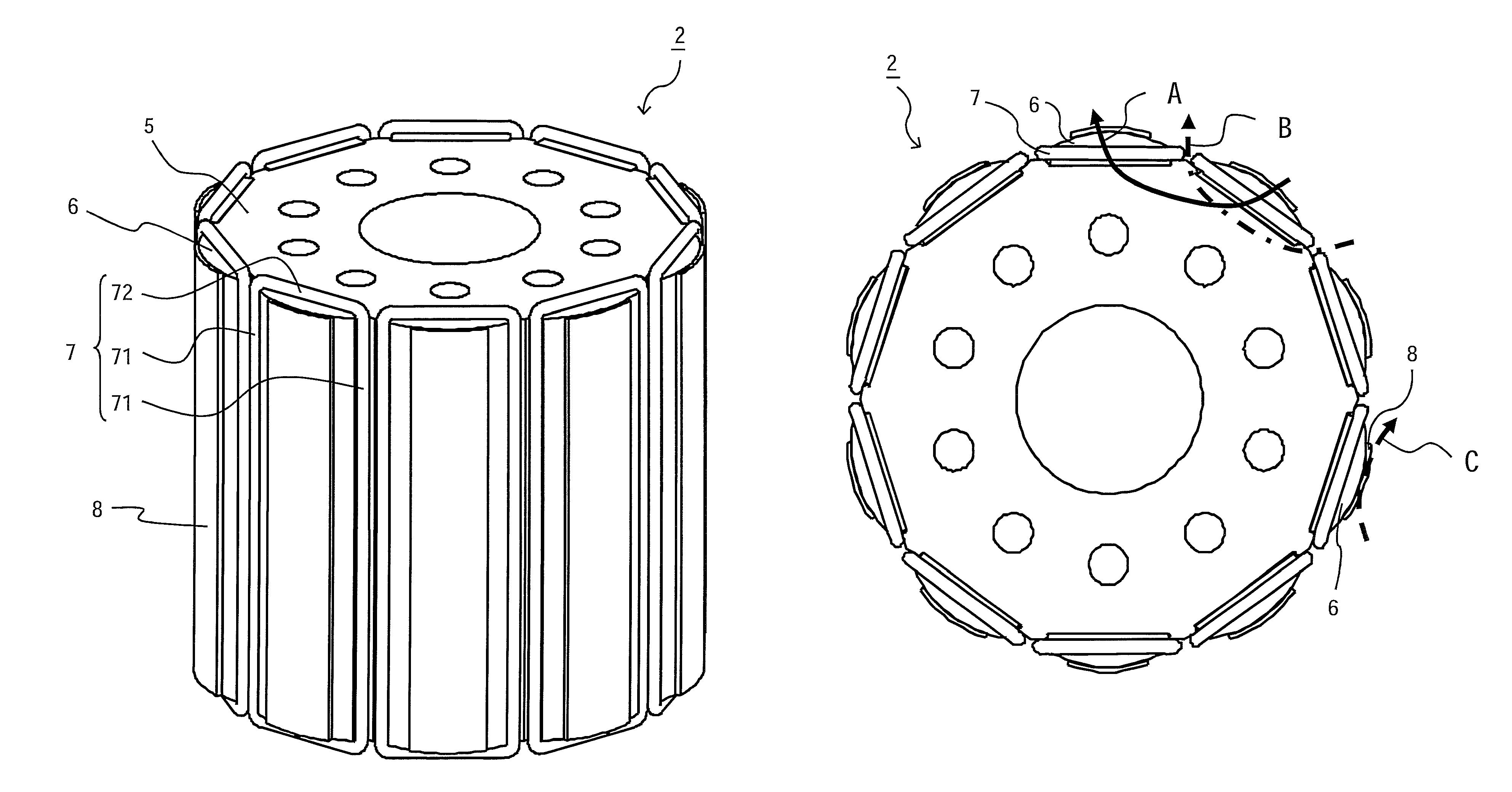

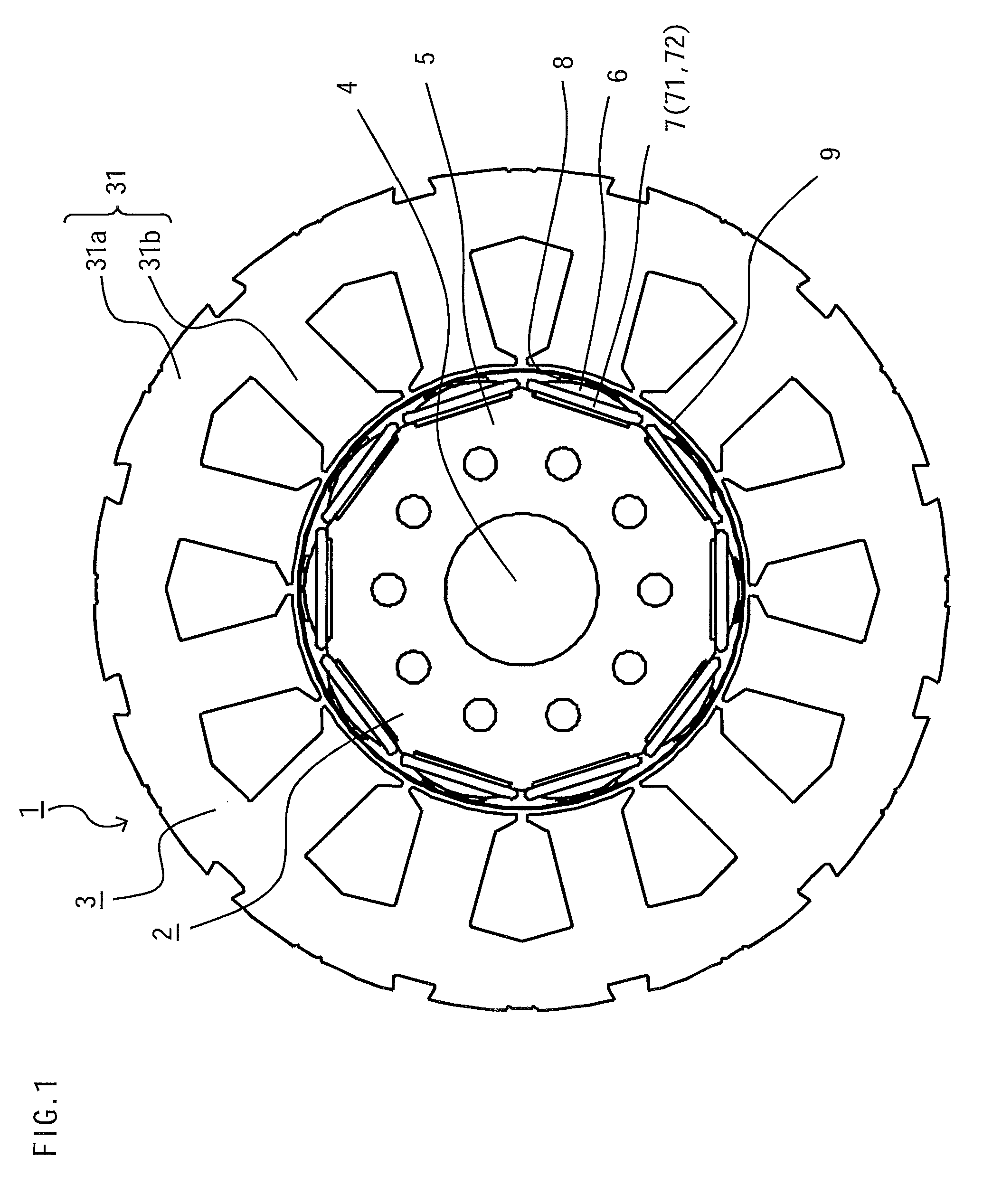

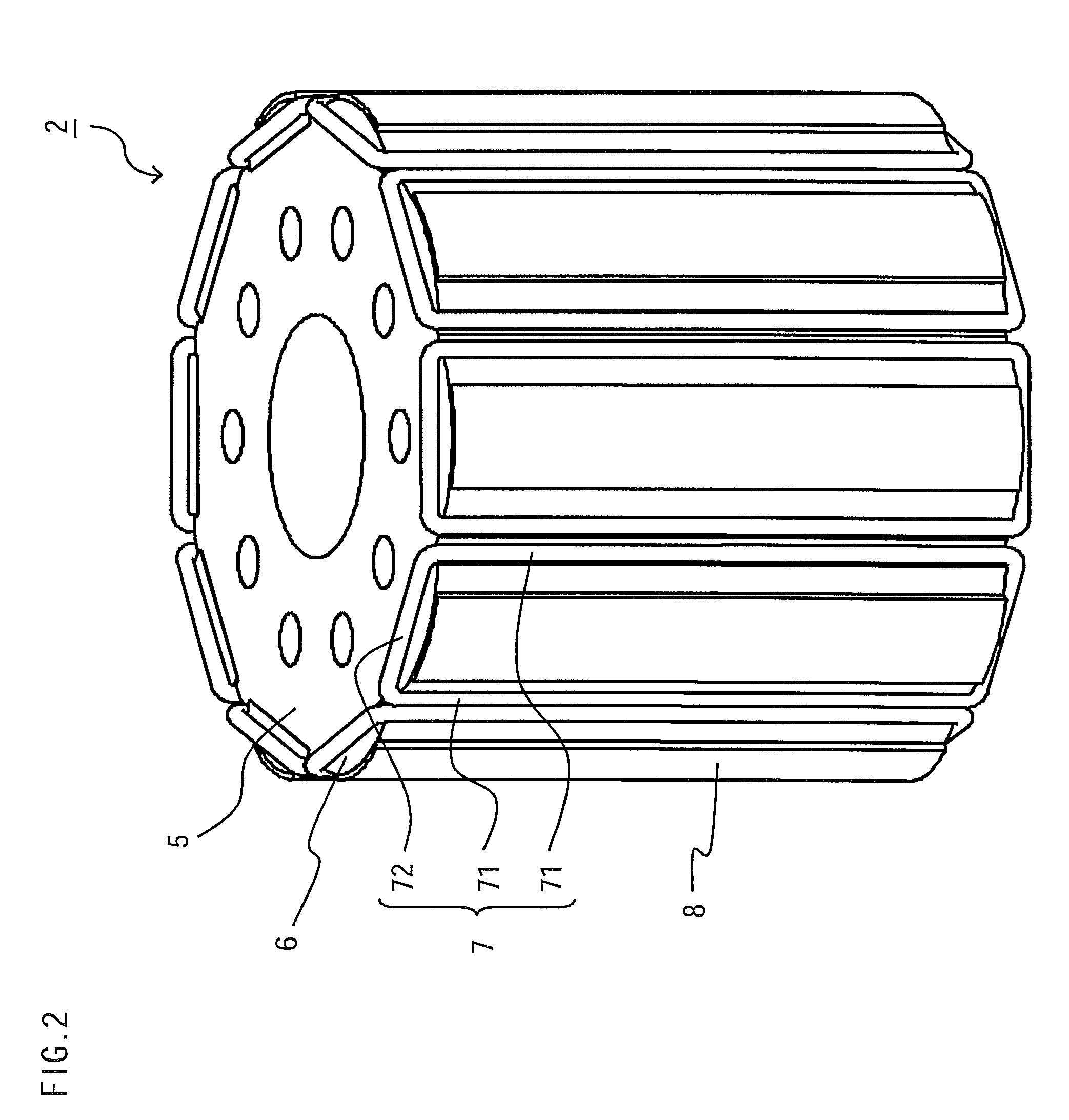

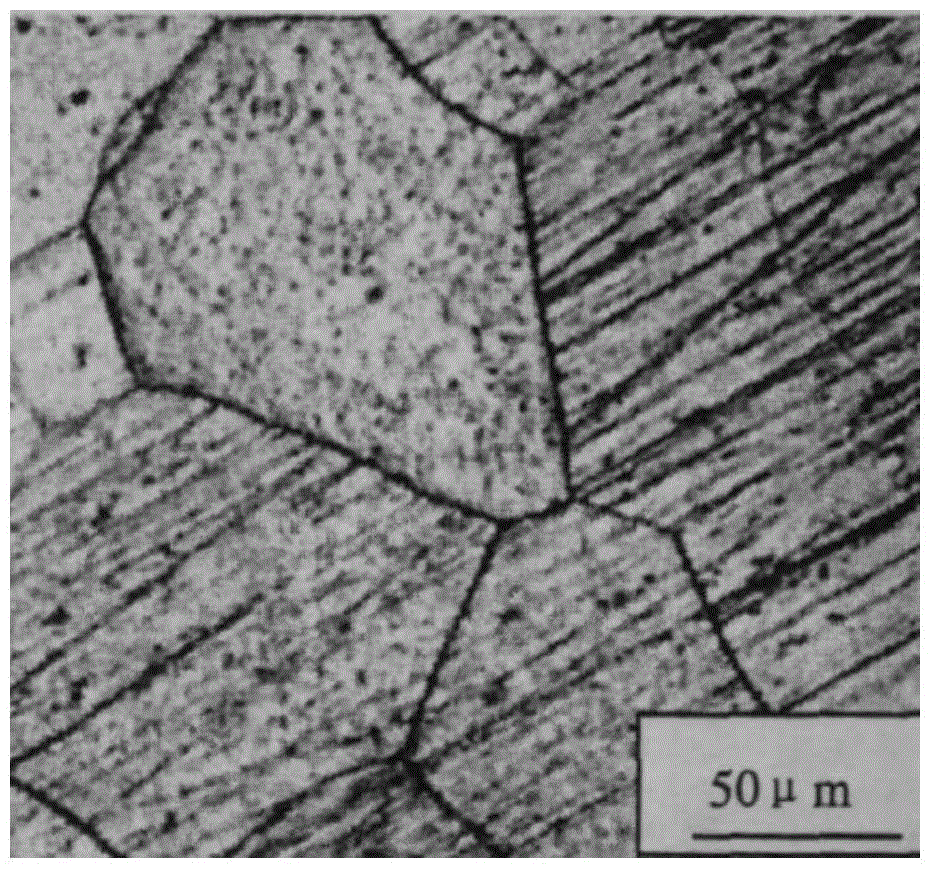

Rotor of permanent magnet rotary machine and manufacturing method of rotor

InactiveUS20100207475A1Increase saliencyEasy to detectMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectrical conductorMagnetic poles

A rotor of a rotary machine includes a rotary shaft, a rotor core fixed to a circumferential surface of the rotary shaft, a plurality of permanent magnets arranged on a circumferential surface of the rotor core at specific intervals along a circumferential direction thereof, conducting circuits arranged to surround the permanent magnets, and magnetic material pieces arranged on outer surfaces of the individual permanent magnets. Each of the conducting circuits includes a pair of first conductor sections arranged between magnetic poles formed by the adjacent permanent magnets and a pair of second conductor sections electrically connecting the first conductor sections.

Owner:MITSUBISHI ELECTRIC CORP

Rotor of permanent magnet rotary machine and manufacturing method of rotor

InactiveUS8217545B2Increase saliencyEasy to detectSynchronous generatorsWindingsElectrical conductorMagnetic poles

A rotor of a rotary machine includes a rotary shaft, a rotor core fixed to a circumferential surface of the rotary shaft, a plurality of permanent magnets arranged on a circumferential surface of the rotor core at specific intervals along a circumferential direction thereof, conducting circuits arranged to surround the permanent magnets, and magnetic material pieces arranged on outer surfaces of the individual permanent magnets. Each of the conducting circuits includes a pair of first conductor sections arranged between magnetic poles formed by the adjacent permanent magnets and a pair of second conductor sections electrically connecting the first conductor sections.

Owner:MITSUBISHI ELECTRIC CORP

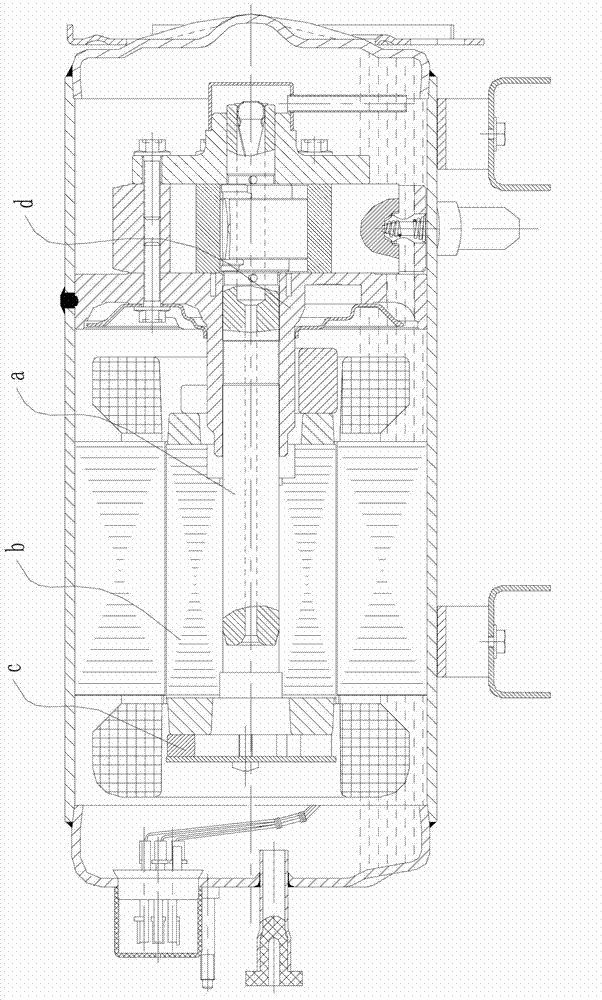

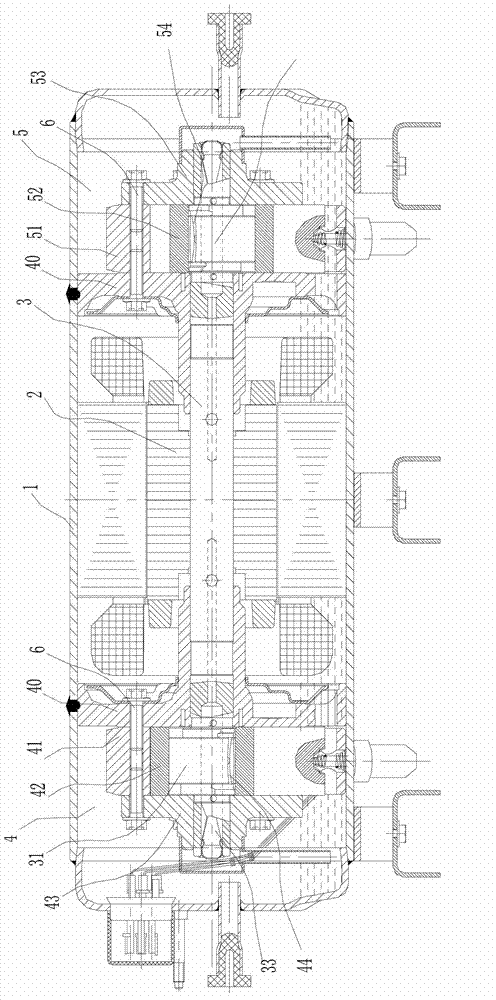

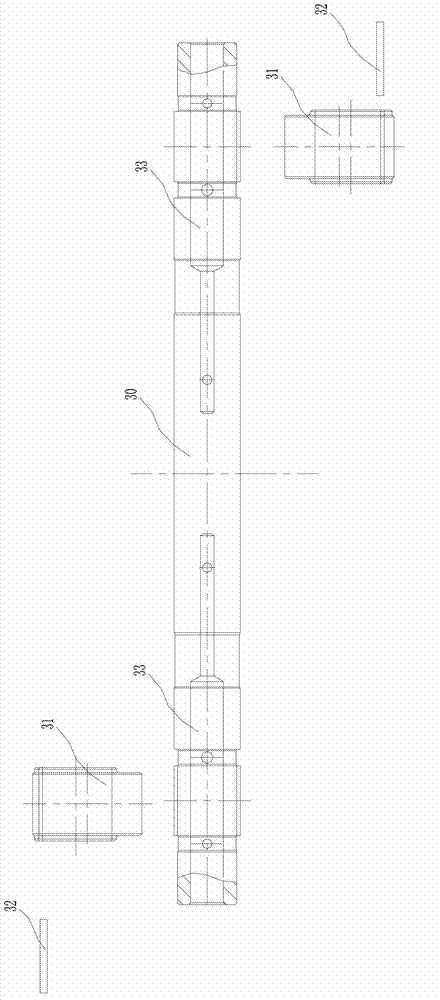

Horizontal compressor having symmetrical double cylinders

InactiveCN102900670AGuaranteed uptimeLarge displacementRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringMechanical engineering

The present invention discloses a horizontal compressor having symmetrical double cylinders. The horizontal compressor comprises a housing, a motor and a crankshaft, wherein the crankshaft is assembled on a rotor of the motor, the motor of the compressor is sealed inside the housing, a first compression unit and a second compression unit are respectively and symmetrically arranged inside the housing on both ends of the motor,and are driven by a left end portion and a right end portion of the crankshaft, the crankshaft comprises a linear main shaft and a pair of eccentric shaft sleeves, and the eccentric shaft sleeves are symmetrically arranged on both ends of the main shaft by adopting the axis core line of the main shaft as the center line.

Owner:GREE ELECTRIC APPLIANCES INC +1

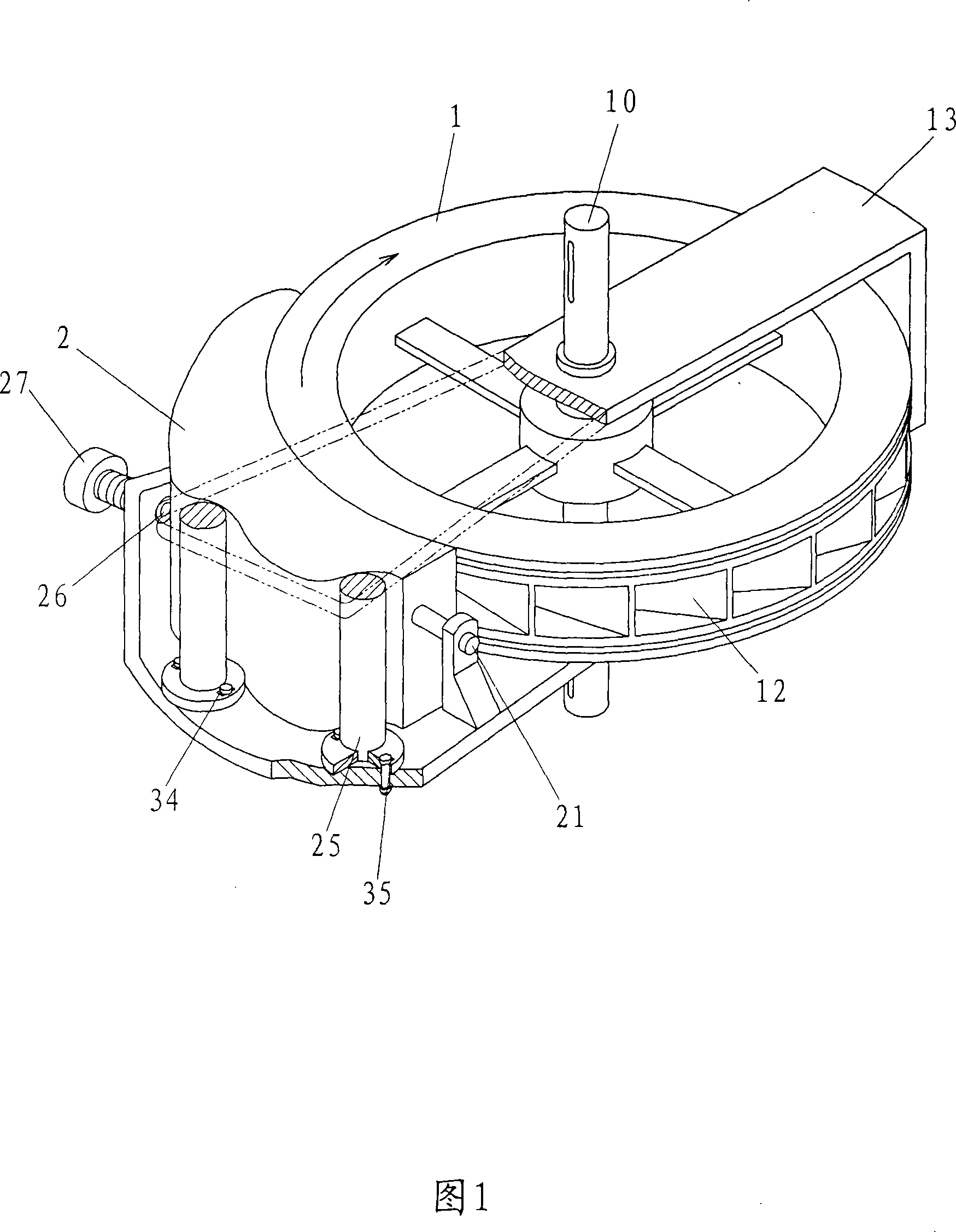

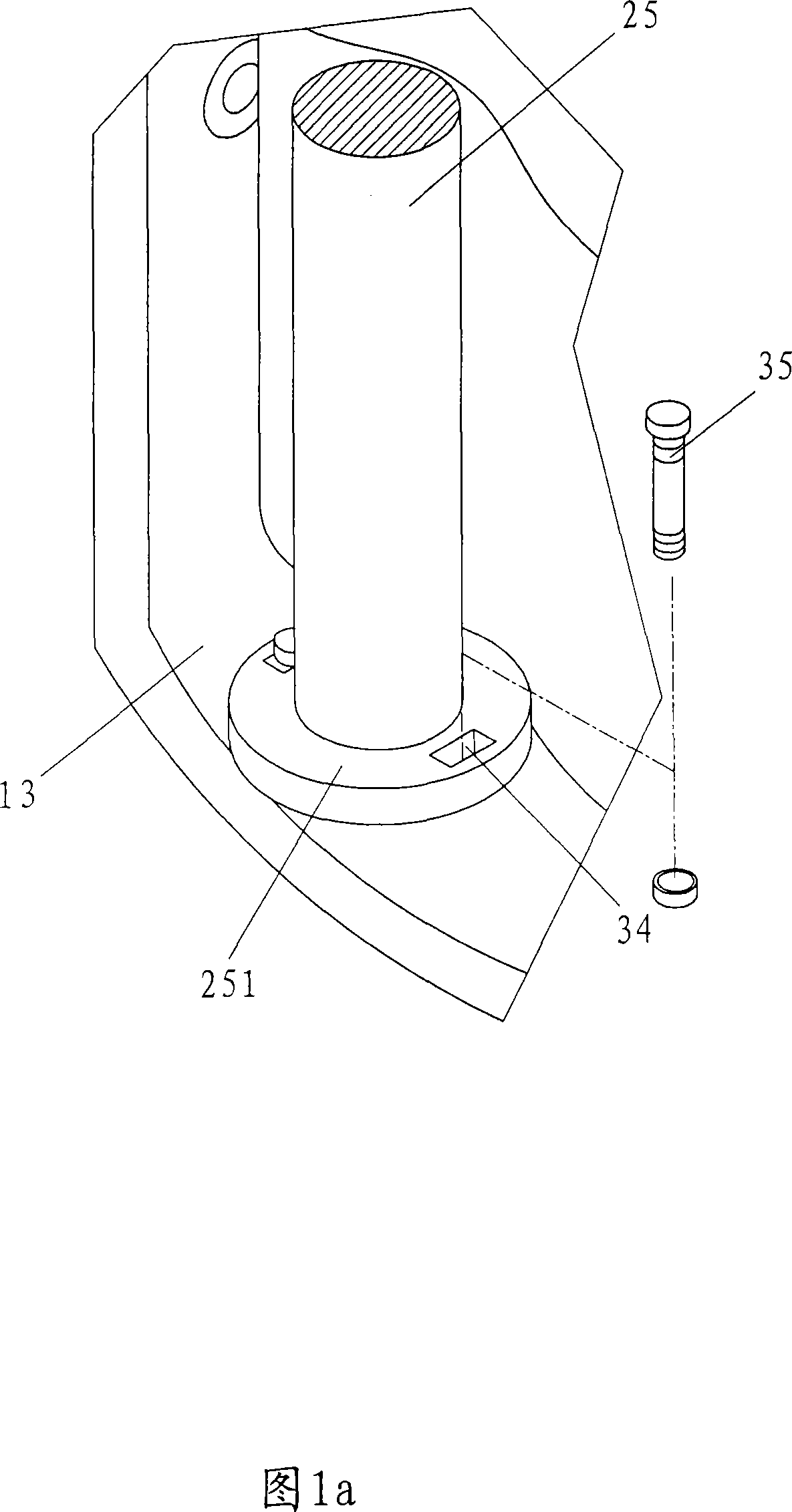

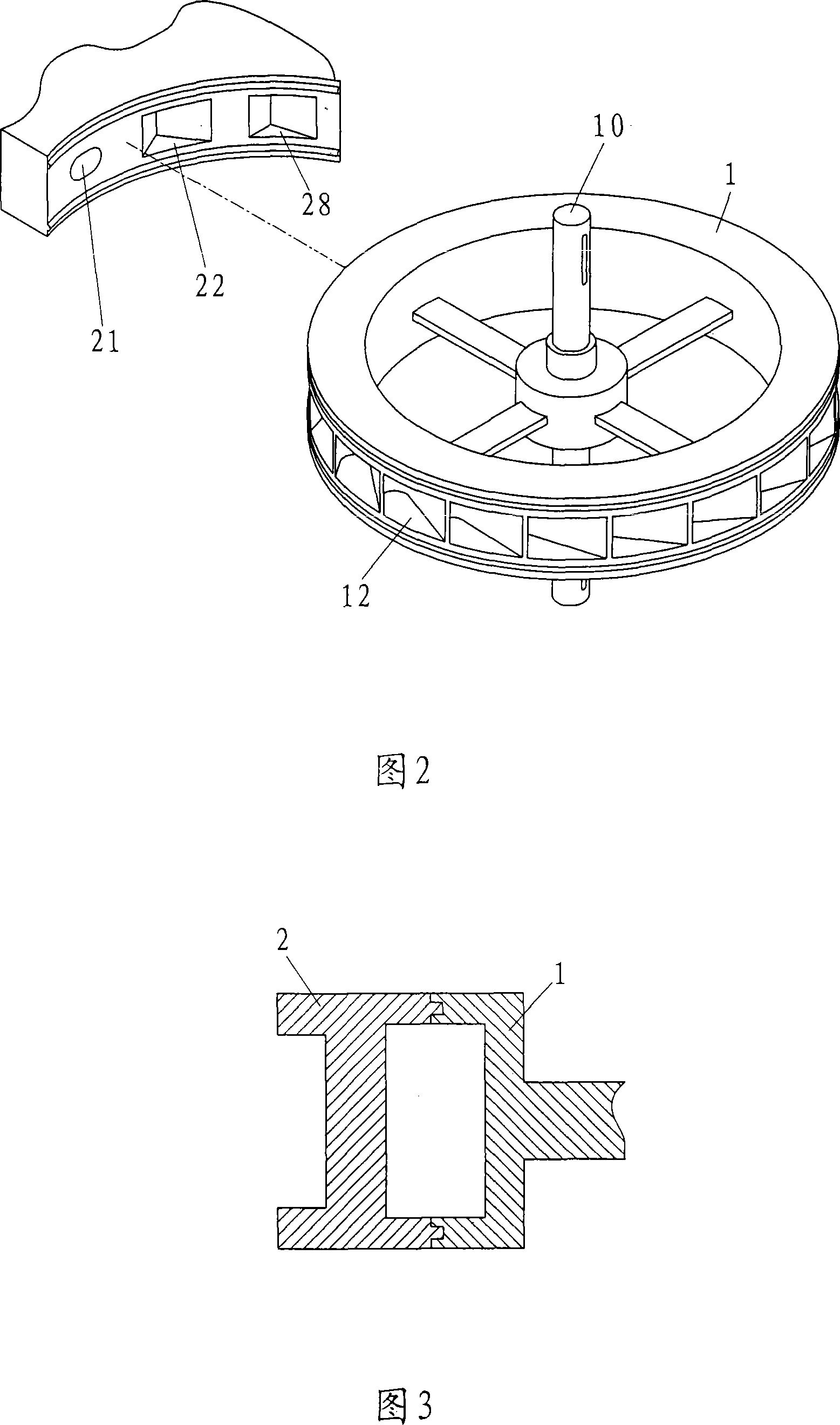

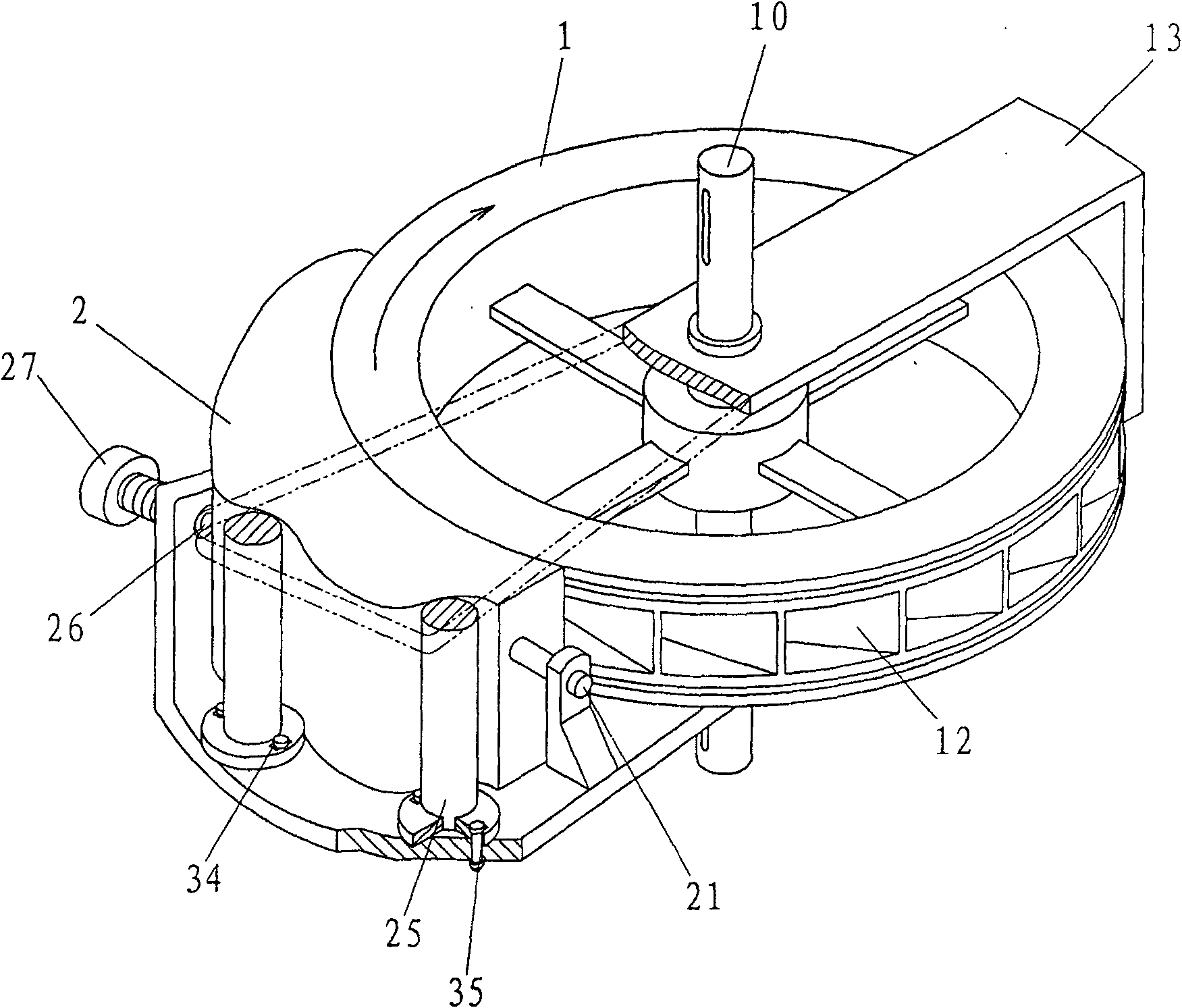

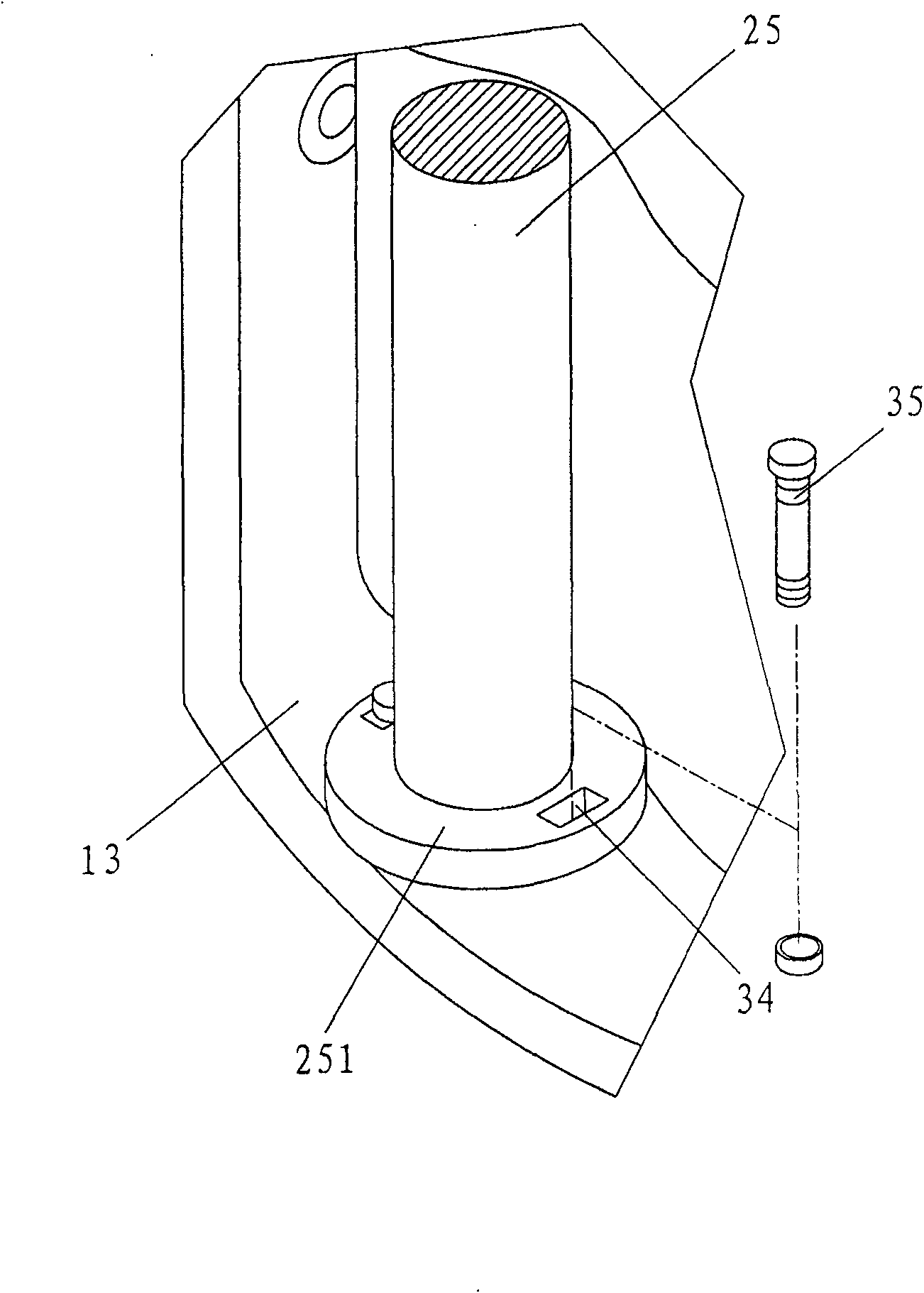

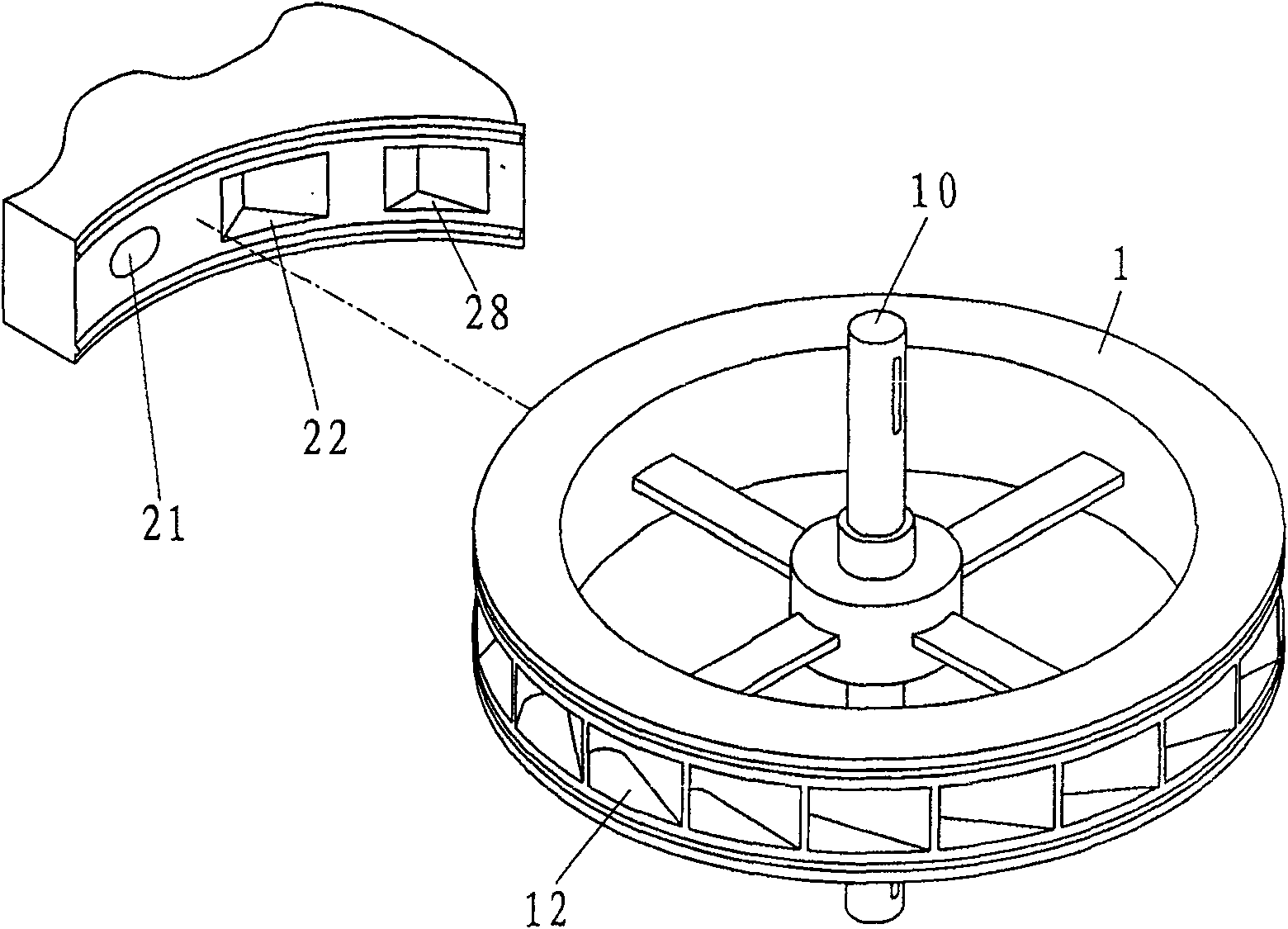

Rotary engine

InactiveCN1973119ARaise the combustion temperatureImprove efficiencyLiquid coolingInternal combustion piston enginesCombustion chamberRotary engine

The invention discloses a rotary engine which consists of a turbine, more than one slide blocks and knightheads. Several non-reverse triangular bag-type recesses as pistons that can improve unit energy are arranged emitting helically on circumferential surface or both sides of said turbine. The slide block is formed crescent-shape for matching with said turbine. The angle formed between curved slide and reverse direction of turbine can be changed by means of regulating knightheads, so as to save space and improve friction force between the curved slide and the turbine. Airflow producing in firebox and cooling chamber can be collected by a drive chamber arranged on the end of the slide block and can be used for pushing pistons to turn the turbine.

Owner:周荣光

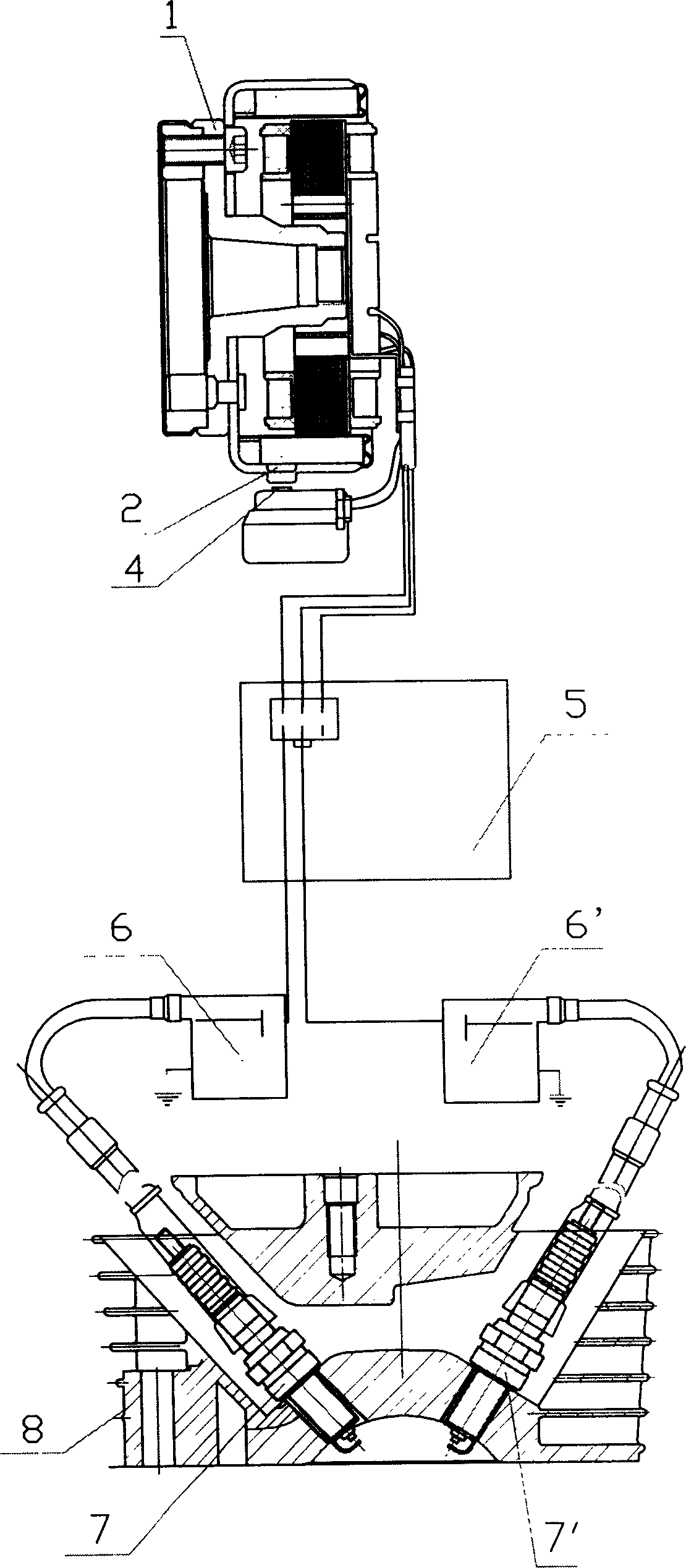

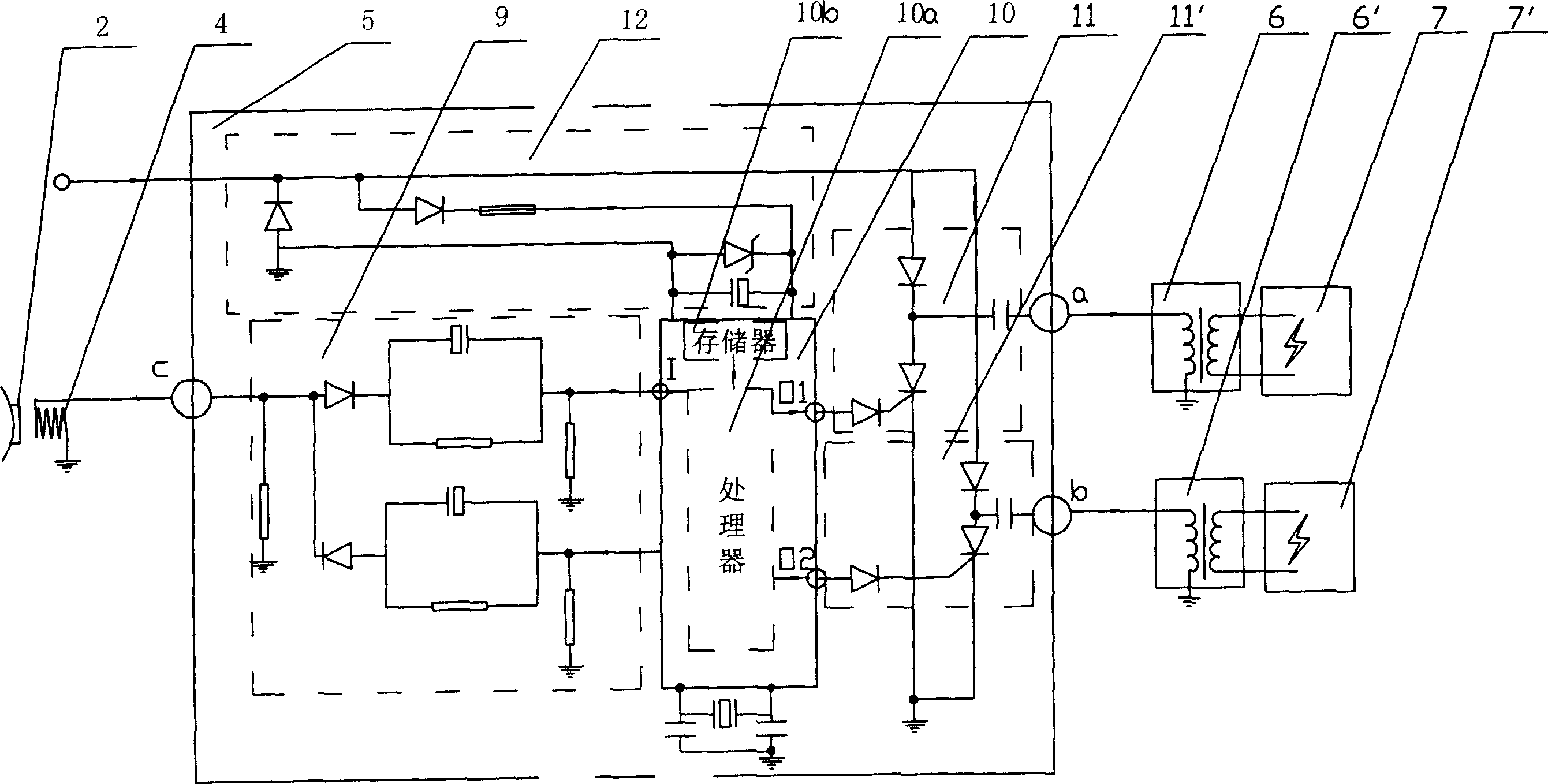

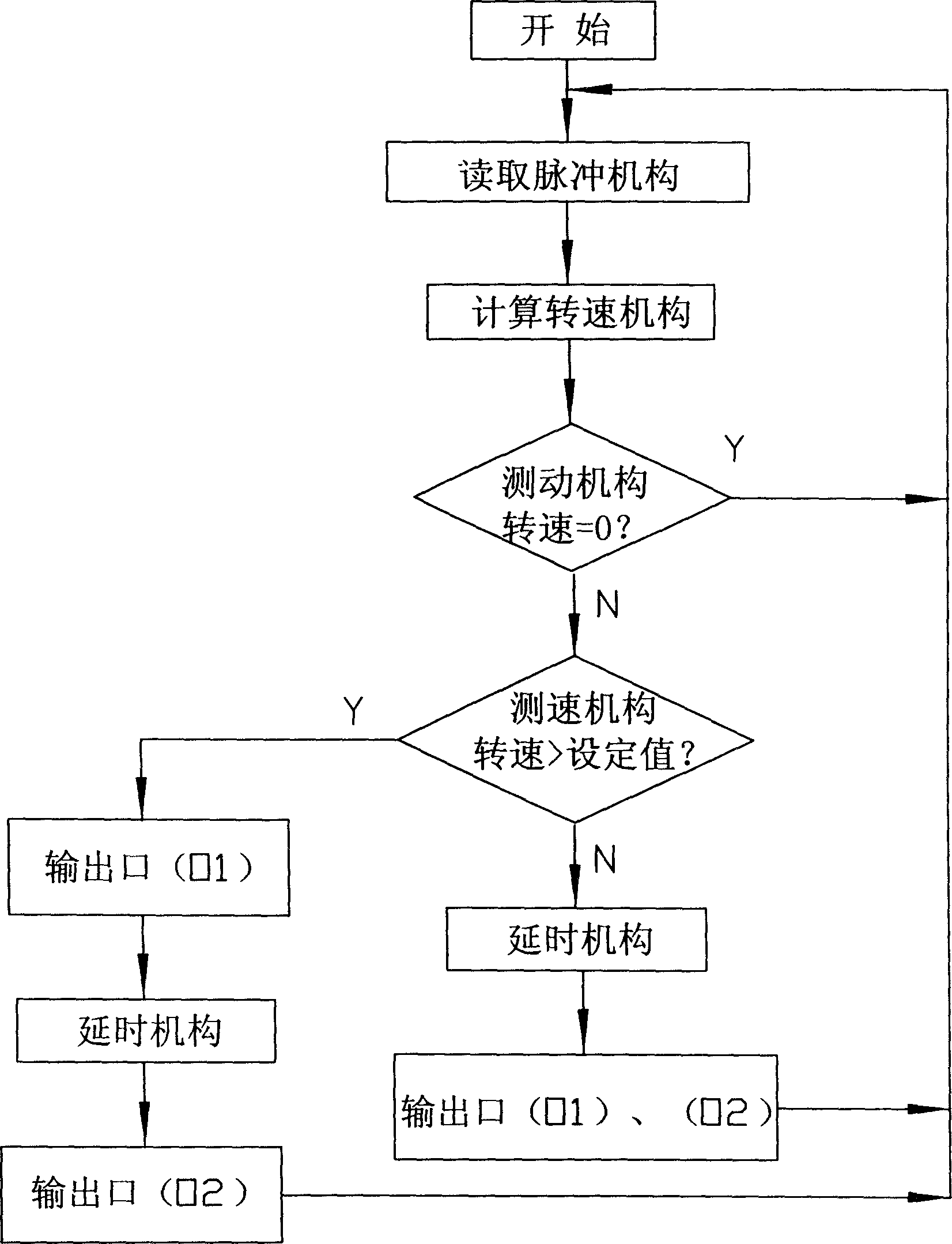

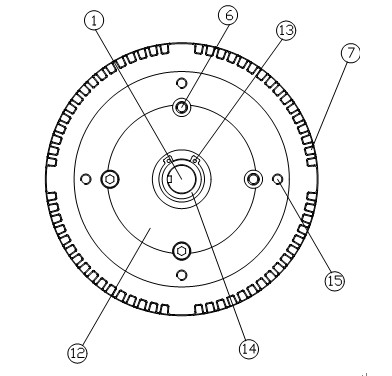

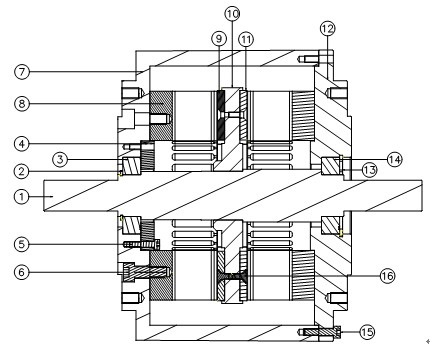

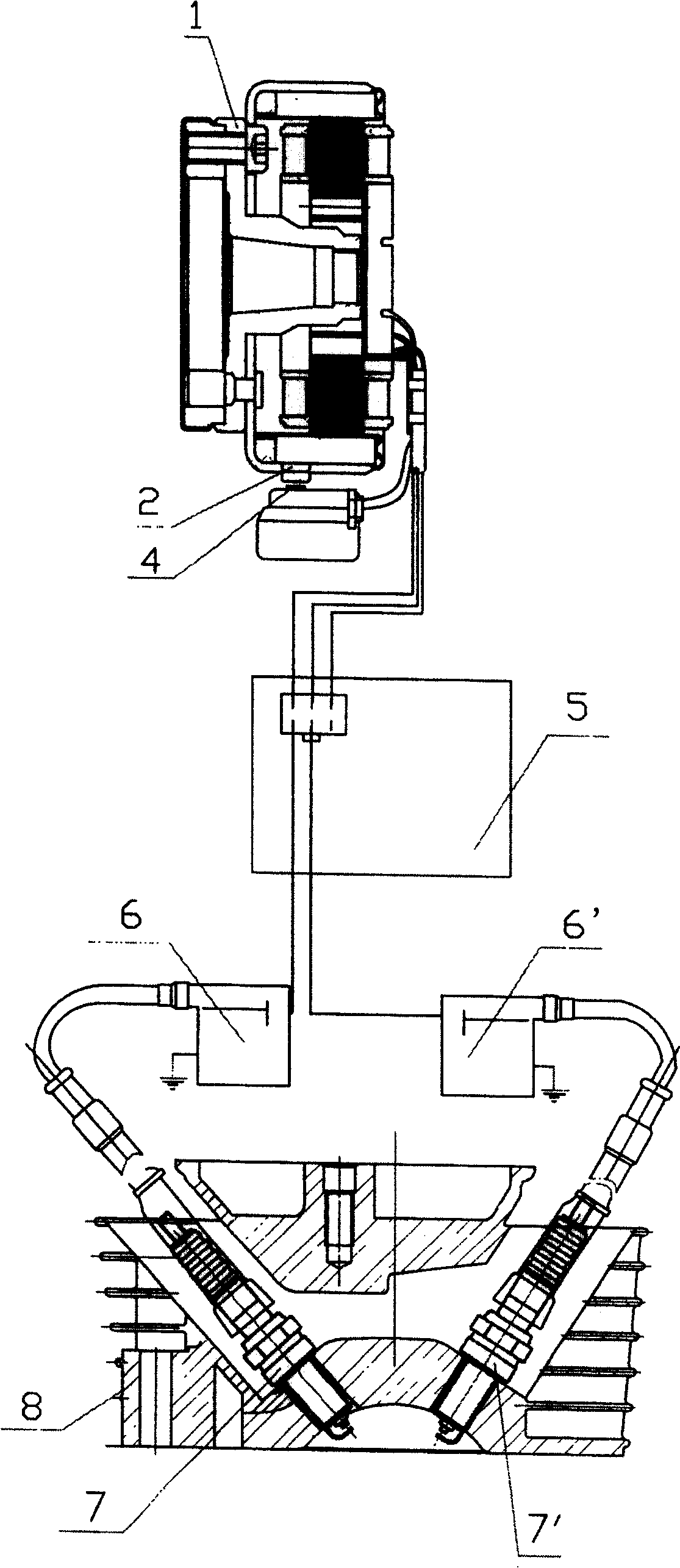

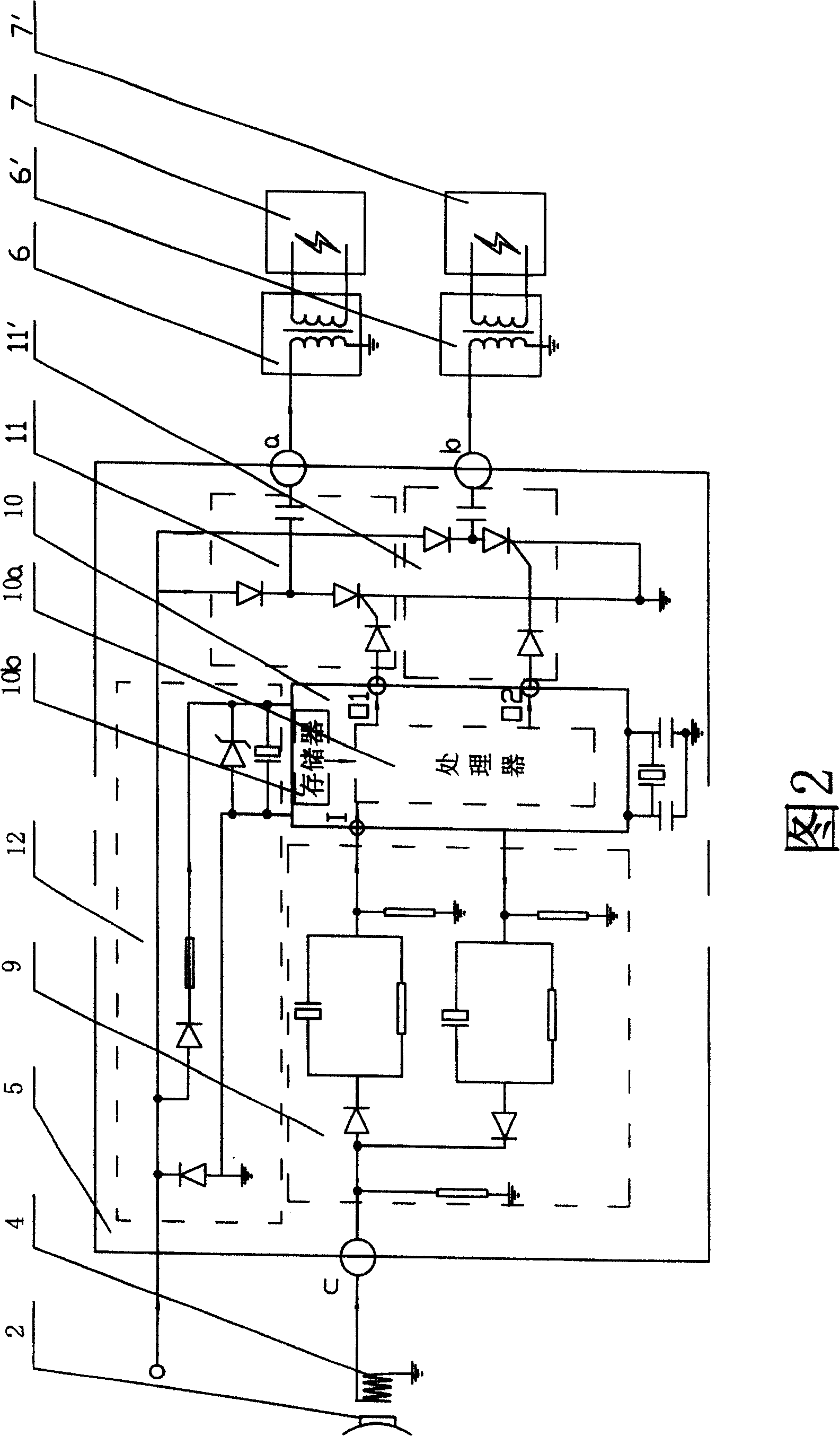

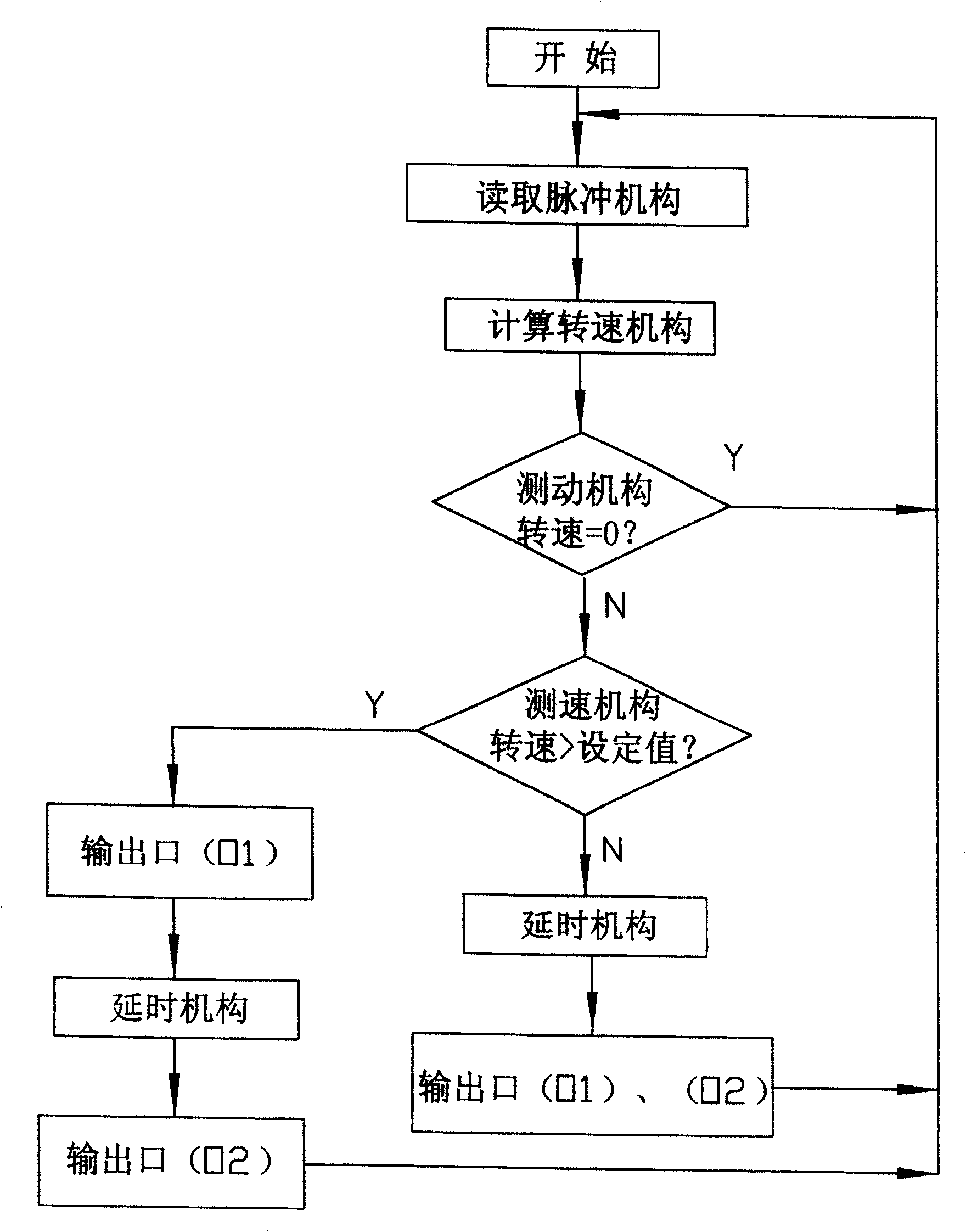

Asynchronous igniter for sparking plug of engine

ActiveCN1837601AGuaranteed separate controlWon't interfereIgnition automatic controlAutomatic controlHigh pressureLow frequency

The invention relates to a motor spark plug asynchronous igniter, which is formed by a magnetic motor rotor, a flywheel boss, an electromagnetic sensor, an electric igniter, a high-pressure boss and a spark plug. Wherein, the electric igniter receives the signal of electromagnetic sensor and sends ignition signal to the high-pressure boss to control the ignition of spark plug. The invention is characterized in that: there are morn than one high-pressure bosses, which are connected to the different outputs of electric igniter; the input of electric igniter is connected to the electromagnetic sensor to judge the speed of magnetic motor and set the ignition time sequence to send the low-frequency ignition signal or high-frequency ignition signal to several high-pressure bosses to control several spark plugs ignite synchronously or asynchronously. The invention has better anti-disturb ability and reliability.

Owner:CHONGQING ZONGSHEN ENGINE MFG

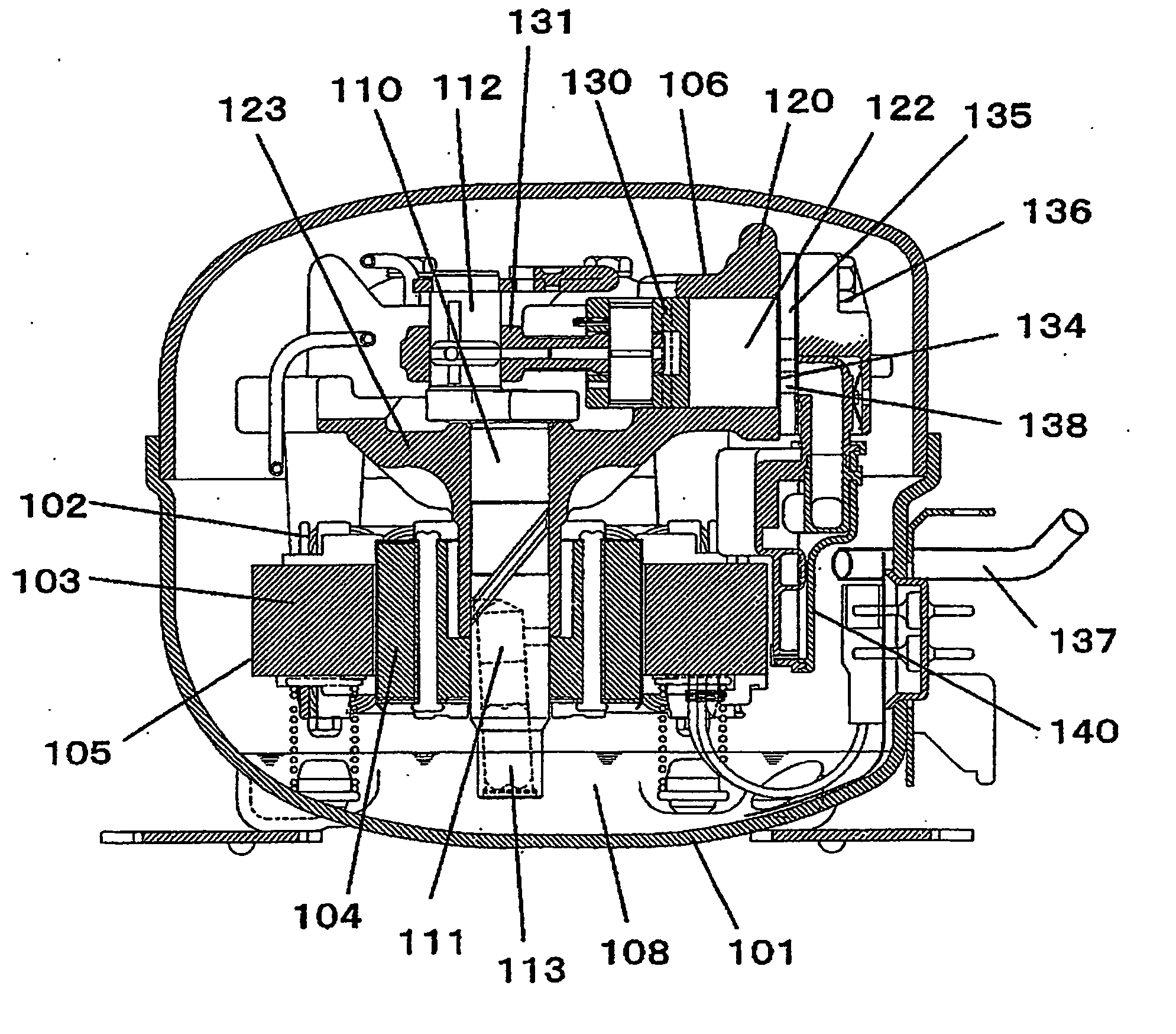

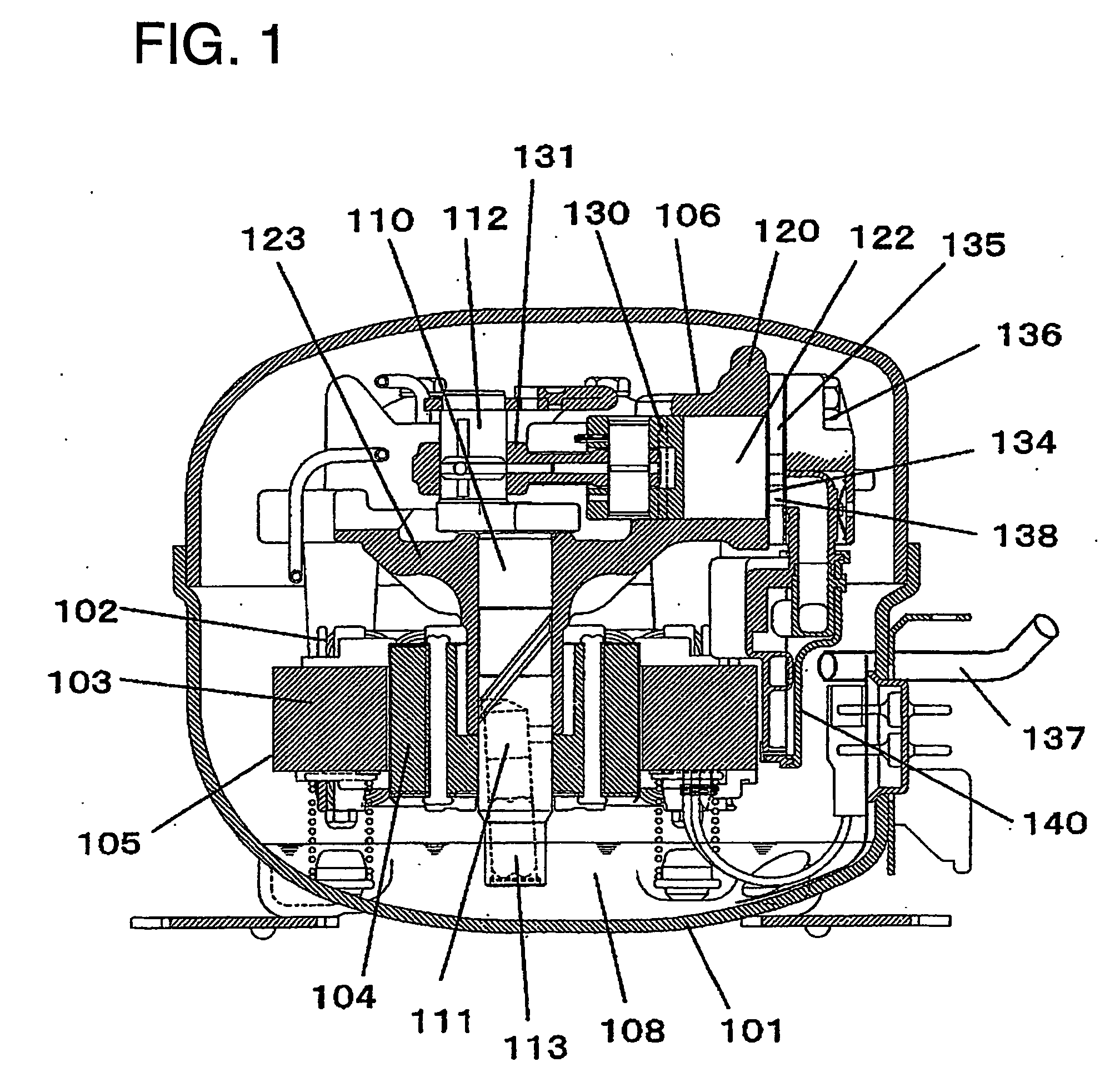

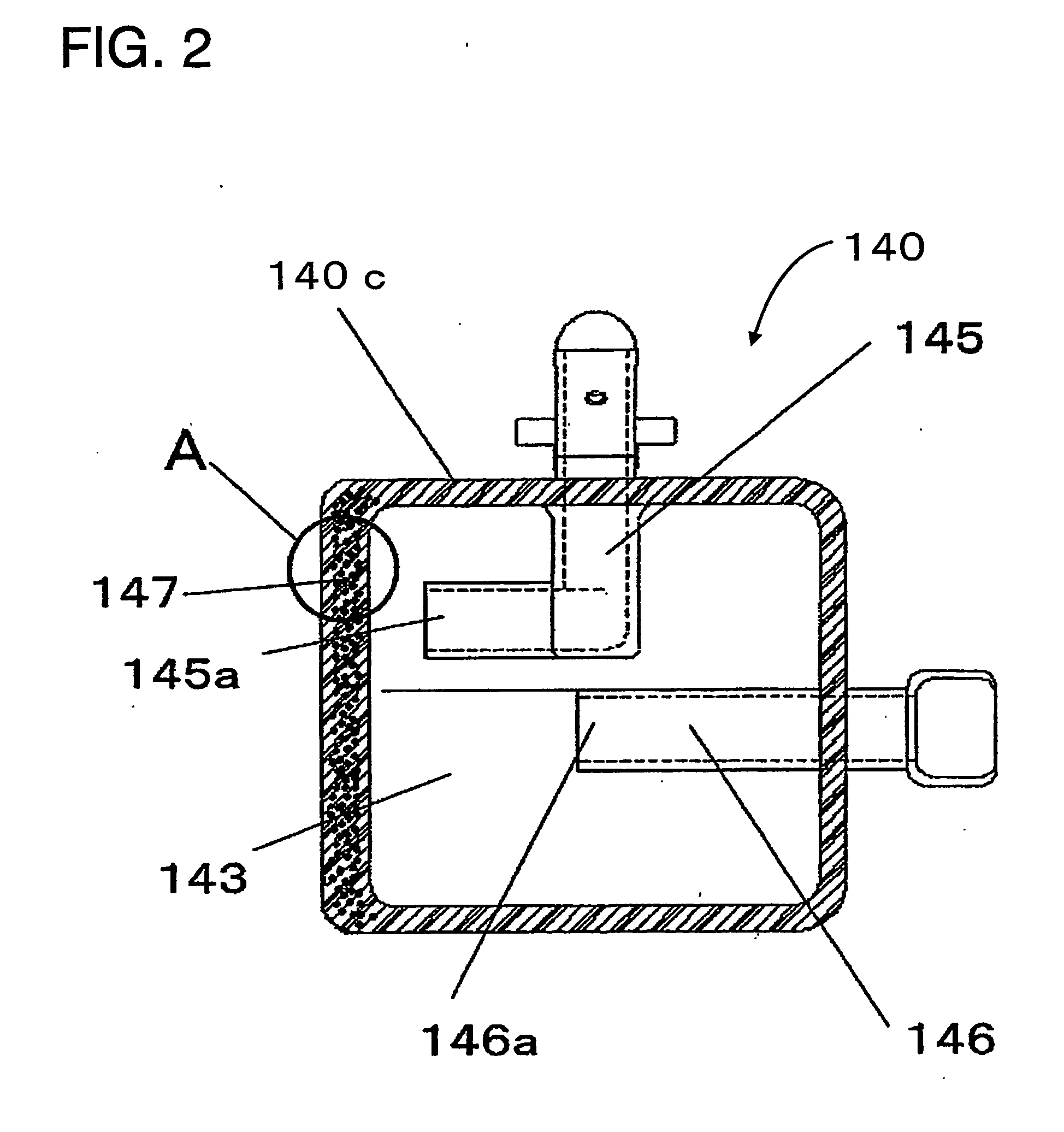

Hermetic compressor and manufacturing method of suction muffler

InactiveUS20070059189A1Improve efficiencyLow noise and vibrationPositive displacement pump componentsWorking fluid for enginesUltrasound attenuationEngineering

This relates to a hermetic compressor and a manufacturing method of a suction muffler, and discloses a technique for making energy efficiency higher and reducing noise. According to that technique, in a suction muffler 140 having a sound attenuation space 143, by foam-molding a wall 147, such as an opposite surface and the like, where open ends 145a, 146a within the sound attenuation space among the walls constituting a casing 140C of the suction muffler 140 are opened, it is possible to reduce the heating action of refrigerant gas released into the sound attenuation space 143 effectively in a space-saving manner, and make a sucking efficiency higher, and effectively absorb a refrigerant pulsation tone radiated in the open end 145a within the sound attenuation space, and consequently reduce the noise.

Owner:PANASONIC CORP

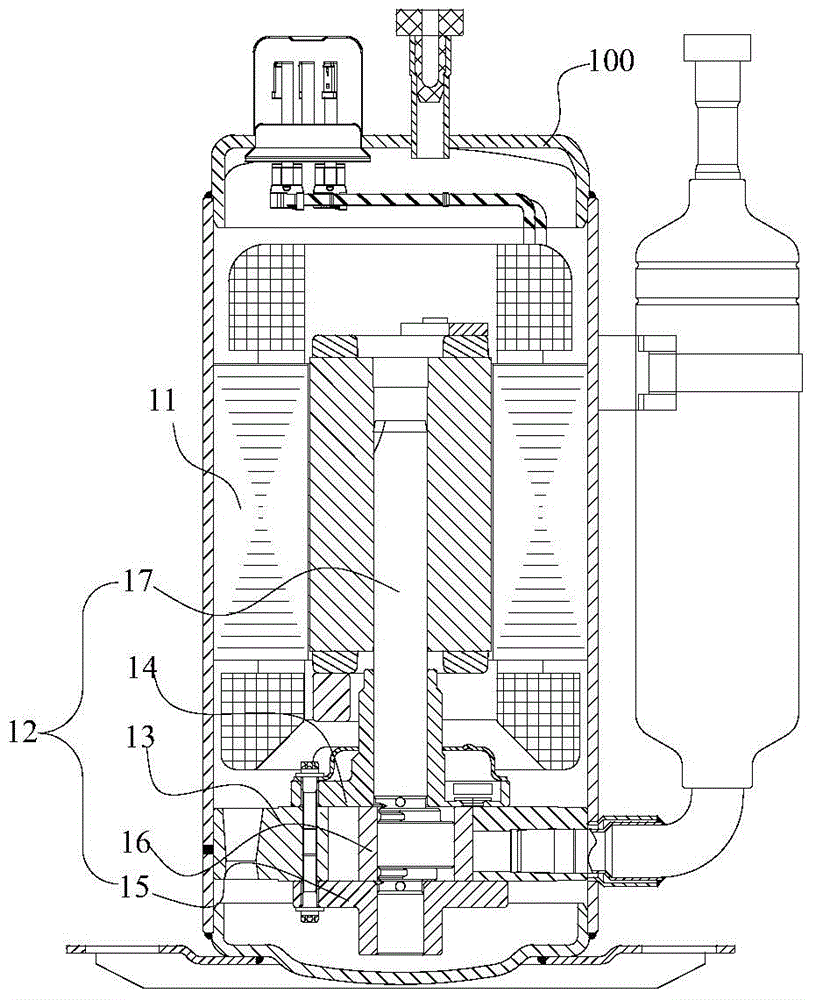

Rotary compressor and refrigeration equipment containing rotary compressor

ActiveCN104832431ALow noise and vibrationHigh dampingRotary piston pumpsRotary piston liquid enginesGas cylinderAlloy

The present invention discloses a rotary compressor and refrigeration equipment containing the rotary compressor. According to the rotary compressor, a lubricating oil and a refrigerant are packaged in the housing of the rotary compressor, the rotary compressor comprises a motor and a compression assembly, the compression assembly comprises a gas cylinder, an upper bearing, a lower bearing, a piston, a sliding sheet, and a crankshaft, at least one selected from the gas cylinder, the upper bearing, the lower bearing, the piston, the sliding sheet and the crankshaft is made from a damping alloy, and the specific damping value of the damping alloy is not less than 10. According to the present invention, the compression assembly of the rotary compressor has a high damping performance so as to minimize the noise vibration of the compressor body, such that the noise quality of the refrigeration equipment can be improved.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

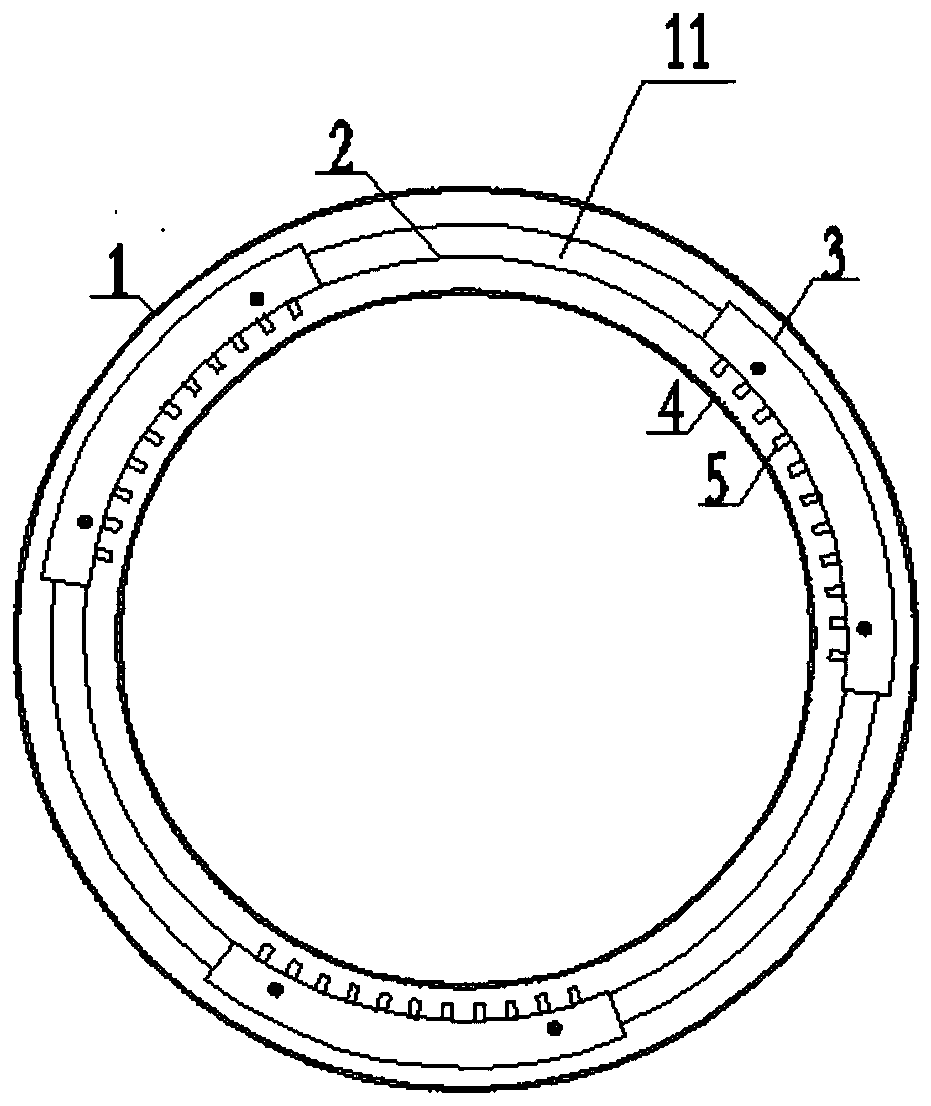

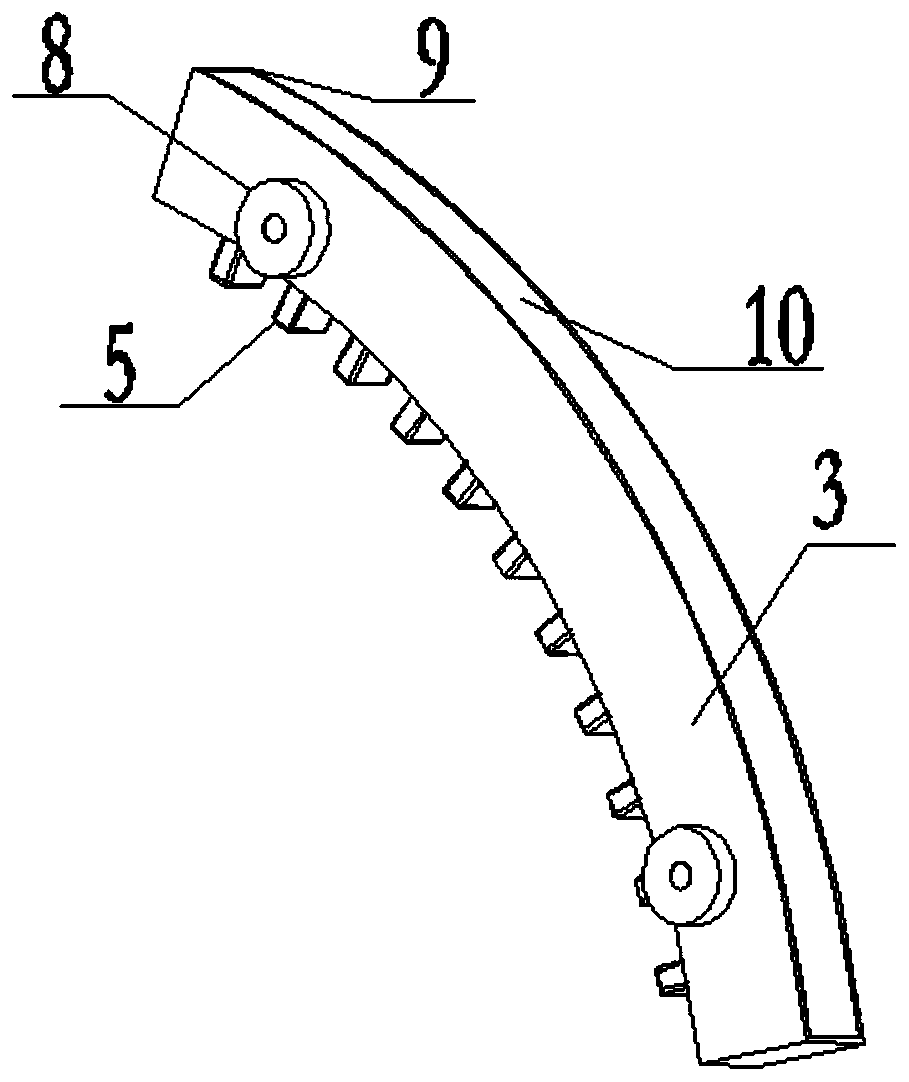

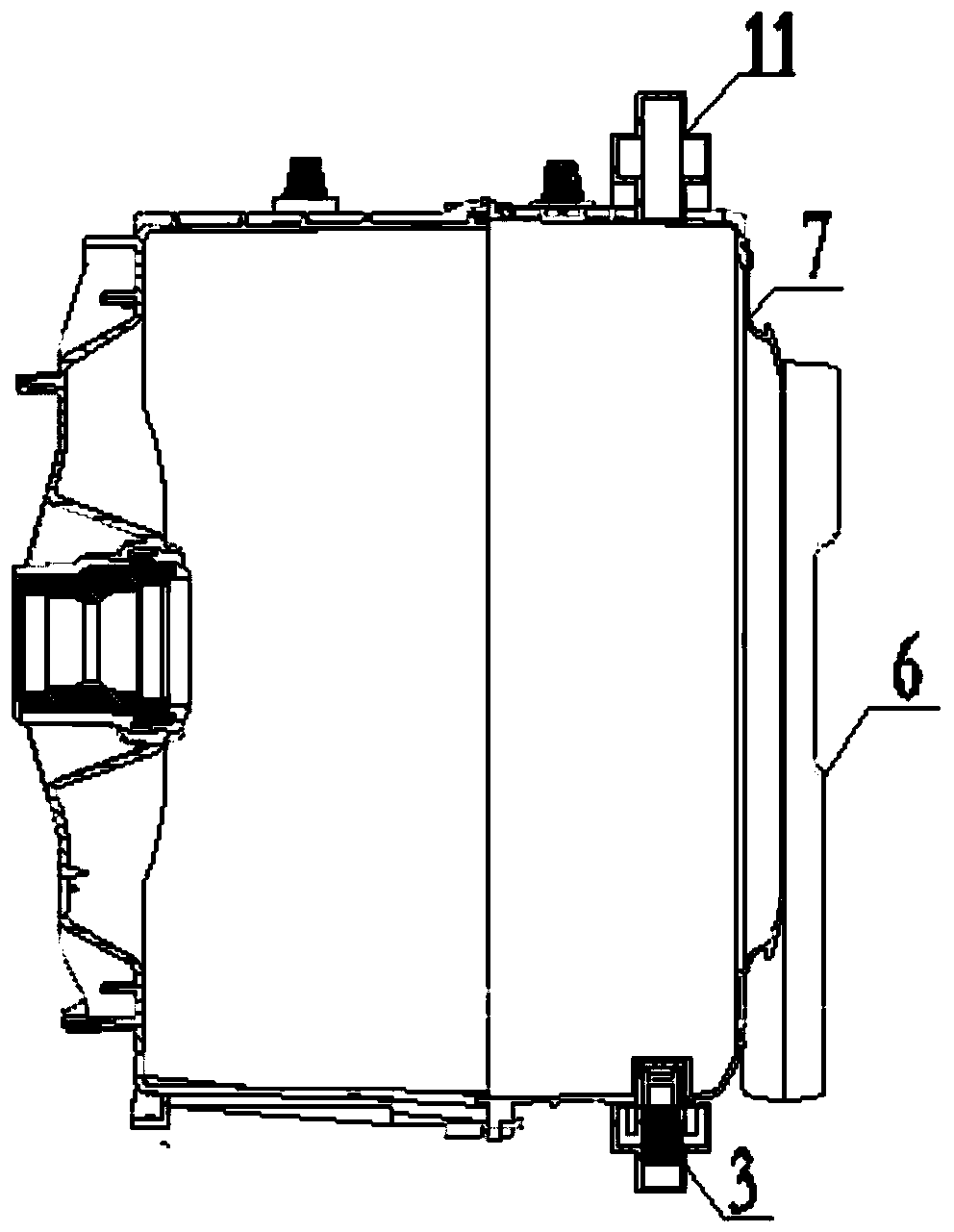

Counterweight balance ring for washing device

ActiveCN110725102ARealize dynamic balance adjustmentDoes not affect the balanceOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention discloses a counterweight balance ring for a washing device. A hollow annular structure is formed in the balance ring, a plurality of permanent magnets are alternately arranged on the inner ring wall of the balance ring according to N poles and S poles, a plurality of counterweight components are arranged in the hollow annular structure, and each counterweight component is provided with a solenoid coil and can slide or keep static in the hollow annular structure by changing the current of the solenoid coil. According to the counterweight balance ring, eccentric loads are balancedby the aid of movable balancing weights, and the counterweight balance ring is simple in structure and easy to implement by the aid of a solenoid driven mode. When the washing device is in a no-loadstate, the balancing weights are uniformly distributed in the balance ring, and balance of a drum is ensured. When the washing device is in a high-speed dewatering state, eccentric loads are balancedby the movable balancing weights, and vibration of the drum is restrained. Noise and vibration generated in the washing, rinsing and dewatering process of a drum washing machine are effectively reduced, and running stability of the drum washing machine is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Compression mechanism and compressor provided with same

InactiveCN104564690AReduced clearance volumeGuaranteed exhaust effectRotary piston pumpsRotary piston liquid enginesPulp and paper industryCrankshaft

The invention discloses a compression mechanism and a compressor provided with the compression mechanism. The compression mechanism comprises a cylinder, a crankshaft, an upper bearing, a lower bearing and a switch valve plate, wherein a compression chamber is defined in the cylinder, and a tapered cut communicated with the compression chamber is formed in the upper end or the lower end of the inner wall surface of the cylinder; the crankshaft penetrates through the compression chamber along the axial direction of the cylinder and can rotate around the central axis of the crankshaft, the part, extending into the compression chamber, of the crankshaft is provided with an eccentric shaft, and a roller is arranged on the eccentric shaft; the upper bearing and the lower bearing are arranged at the upper end and the lower end of the cylinder respectively, and an exhaust hole corresponding to the tapered cut in position is formed in the upper bearing or the lower bearing and is connected with the tapered cut; and the switch valve plate is arranged between the upper end of the cylinder and the upper bearing or between the lower end of the cylinder and the lower bearing, and can move between a first position and a second position to connect or disconnect the tapered cut and the exhaust hole, the tapered cut is connected with the exhaust hole when the switch valve plate is at the first position, and the tapered cut is disconnected with the exhaust hole when the switch valve plate is at the second position.

Owner:GUANGDONG MEIZHI COMPRESSOR

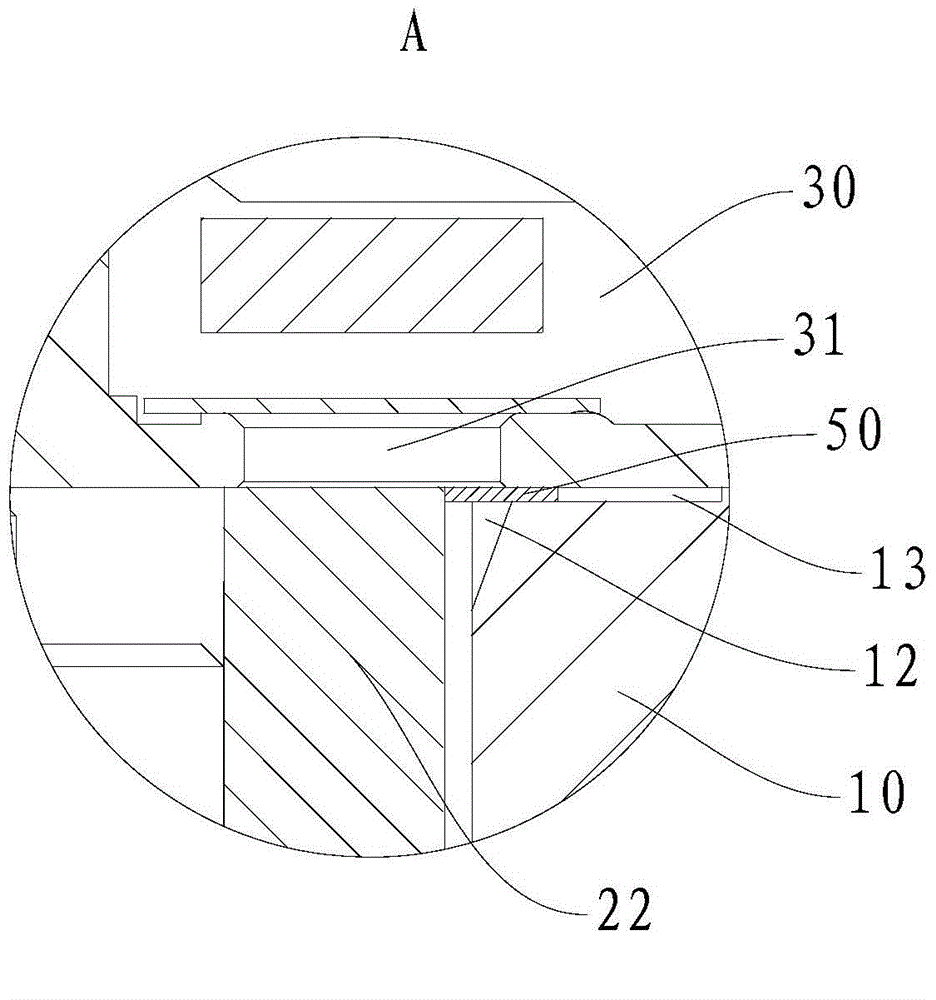

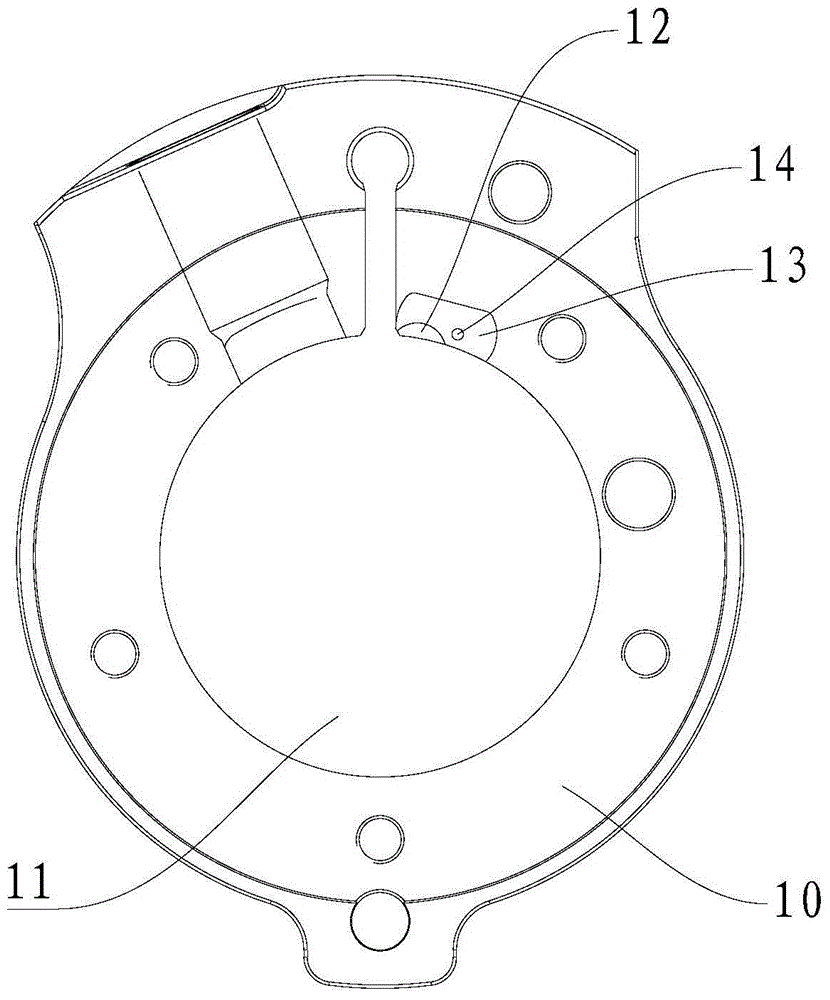

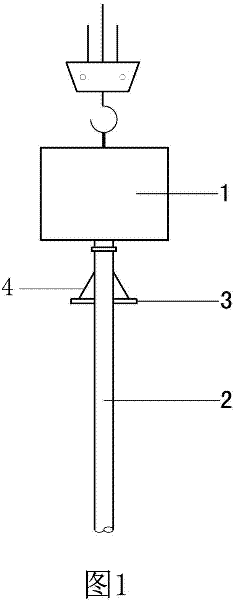

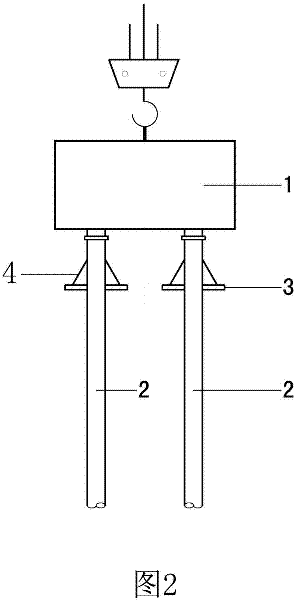

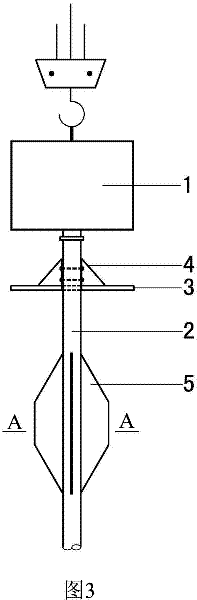

Device for treating liquefiable foundation by using vibratory hammer pipe and treatment method thereof

InactiveCN102312439ALow noise and vibrationLow costBulkheads/pilesSoil preservationLow noiseDevice form

The invention relates to a device for treating a liquefiable foundation by using a vibratory hammer pipe and a treatment method thereof, belonging to the field of liquefiable foundation treatment devices and treatment techniques. By using a vibratory hammer pipe device formed by a core pipe which is arranged below a vibratory hammer, reinforcing wings and a pressurizing plate which are arranged on the core pipe, loose liquefiable soil is compacted and the goal of eliminating the liquefiable foundation is achieved. The device and the construction method have the advantages of strong soil layer penetration capacity, low noise, low manufacturing cost, high efficiency, environmental friendliness and the like, can be widely used for the treatment of liquefiable foundations, especially the treatment of foundations with thick liquefiable sand layers.

Owner:JIAN YAN FOUND ENG

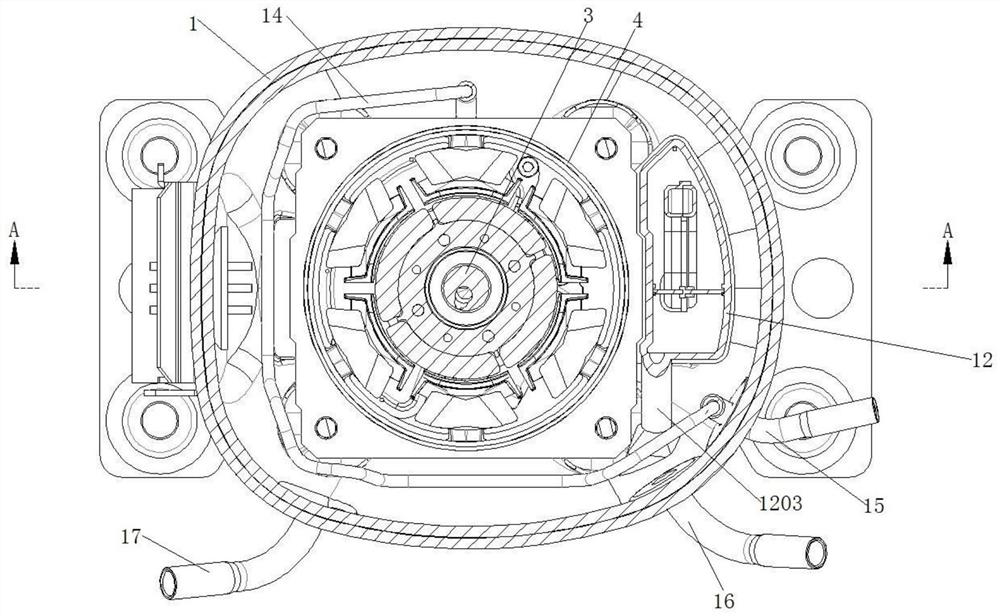

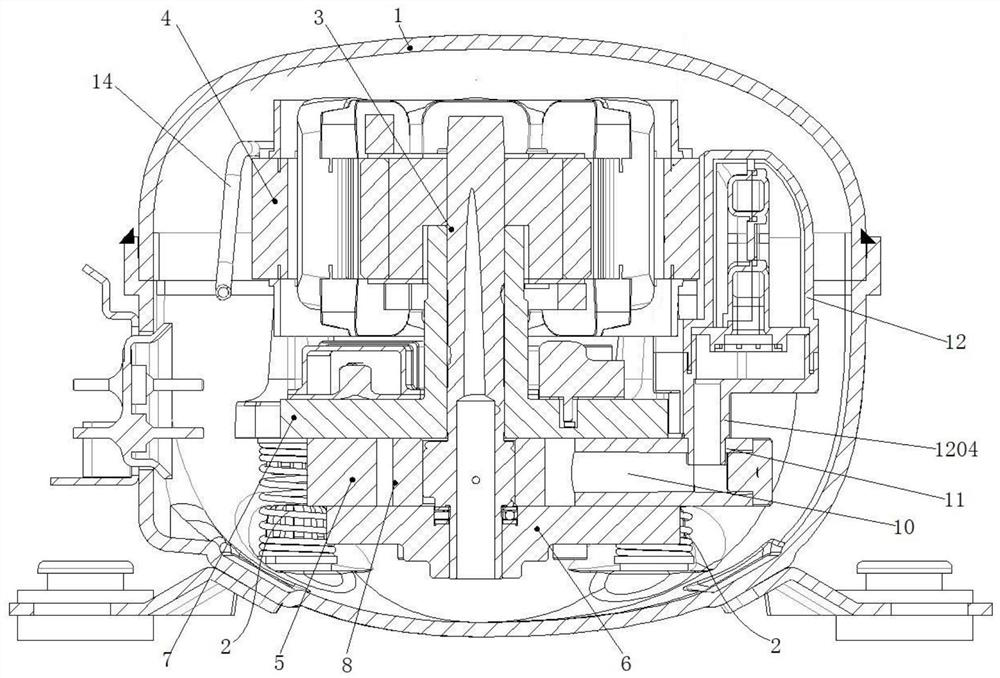

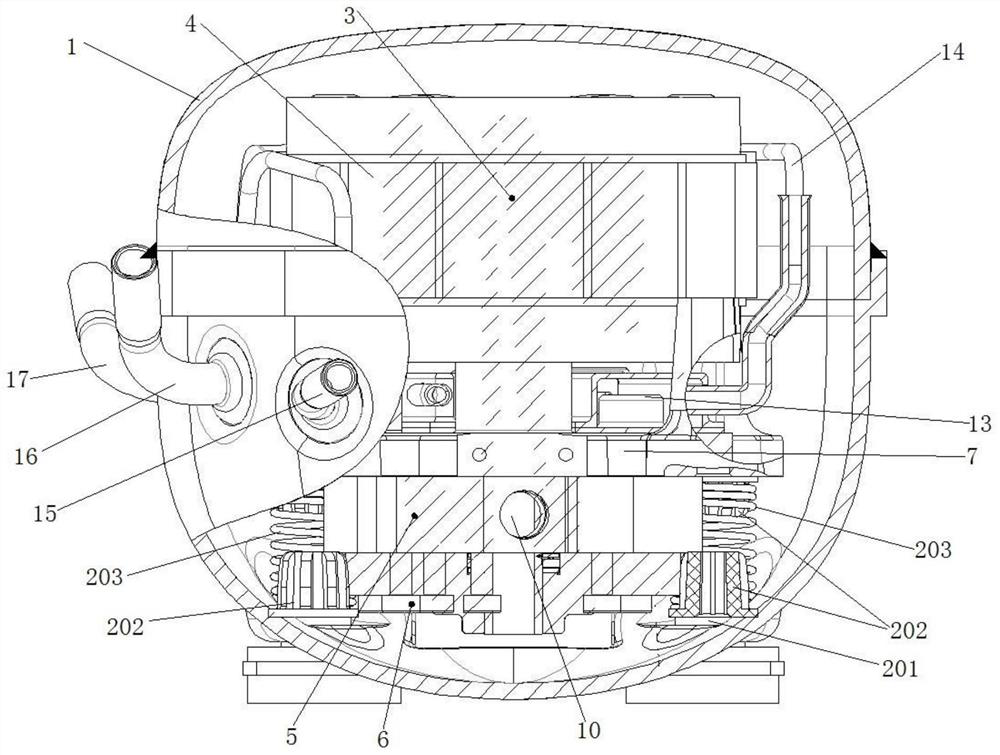

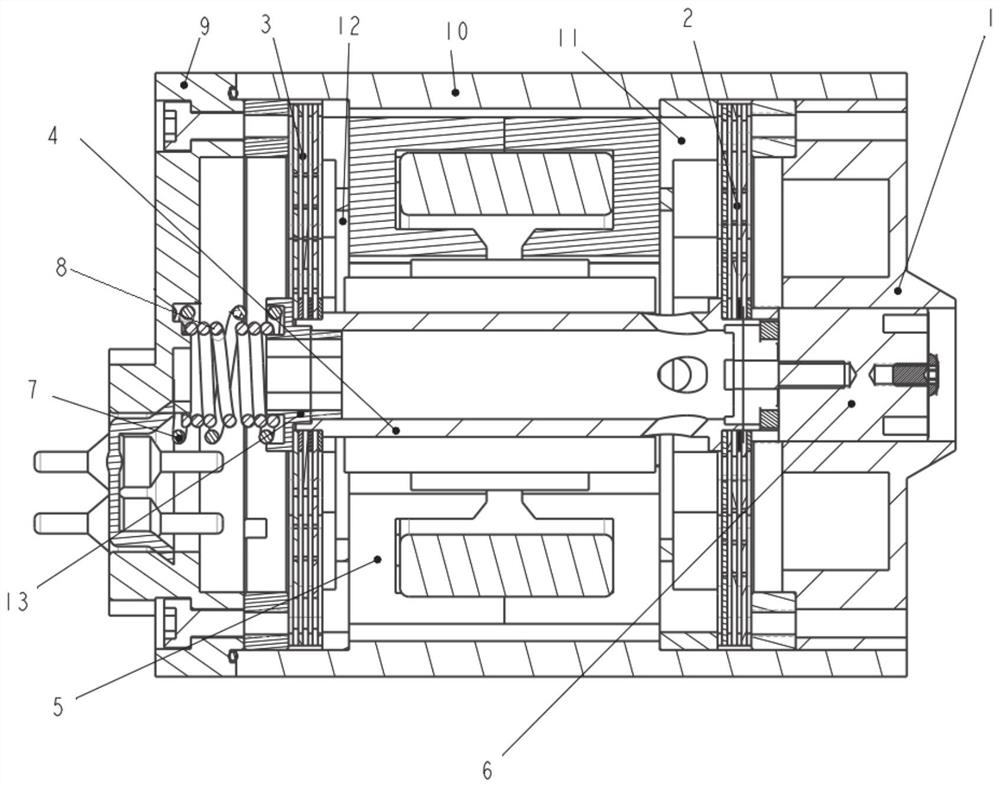

Novel swinging rotor compressor with low-pressure cavity in shell

PendingCN111720326ASolve the vibrationSolve the noiseRotary/oscillating piston combinations for elastic fluidsOscillating piston pumpsElectric machineryRefrigeration

The invention discloses a novel swinging rotor compressor with a low-pressure cavity in a shell. The novel swinging rotor compressor with the low-pressure cavity in the shell comprises a machine shelland a pump body; the pump body comprises an air cylinder component; a crankshaft is arranged on the air cylinder component in a sleeving manner; a motor is arranged above the crankshaft in a sleevingmanner; the pump body further comprises a swinging rotor arranged in the air cylinder component; the swinging rotor is connected to the air cylinder component through a sliding piece; the inner cavity of the air cylinder component is divided into a first compression chamber and a second compression chamber through the swinging rotor and the sliding piece; the first compression chamber is connected with an air suction silencing chamber through an air inlet channel; the second compression chamber is connected to an integrated exhaust cover component through an exhaust channel; and the exhaust cover component is connected to a shell exhaust pipe through an inner exhaust coil pipe. The compressor is low in vibration, low in noise, high in refrigeration amount, and excellent in starting performance.

Owner:黄石东贝压缩机有限公司

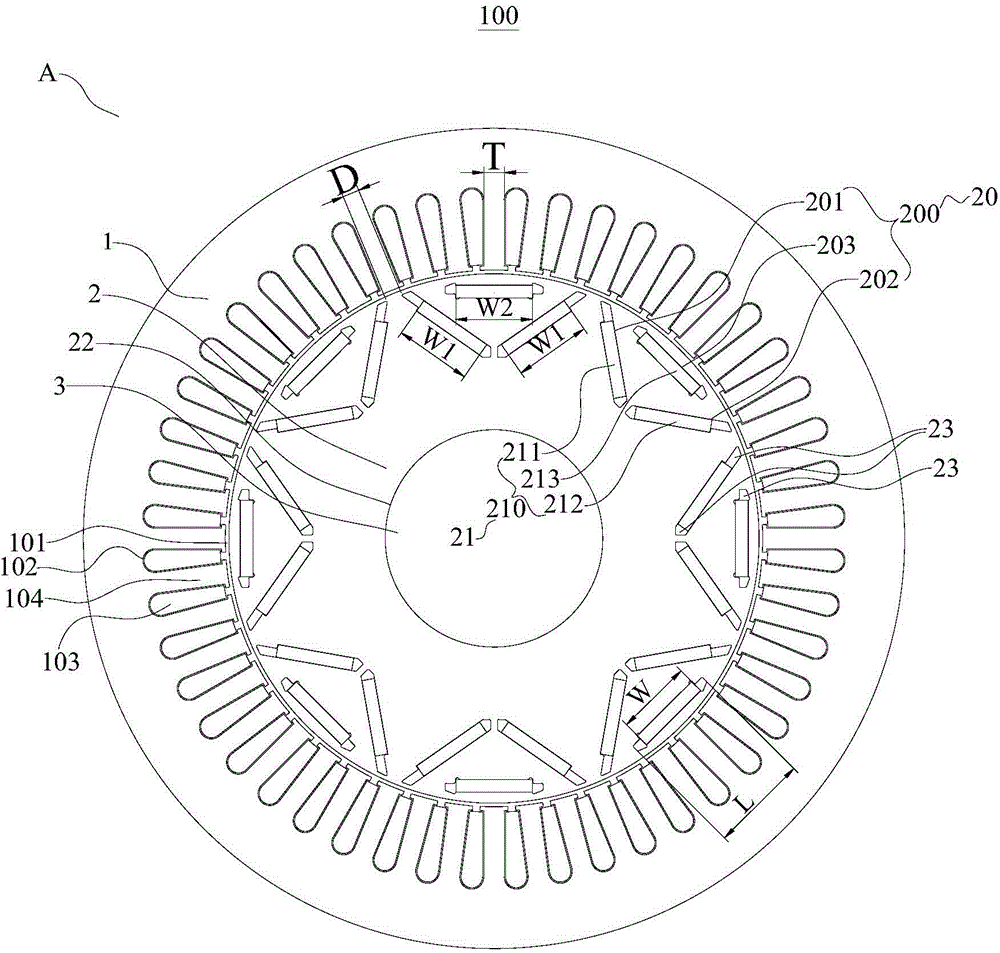

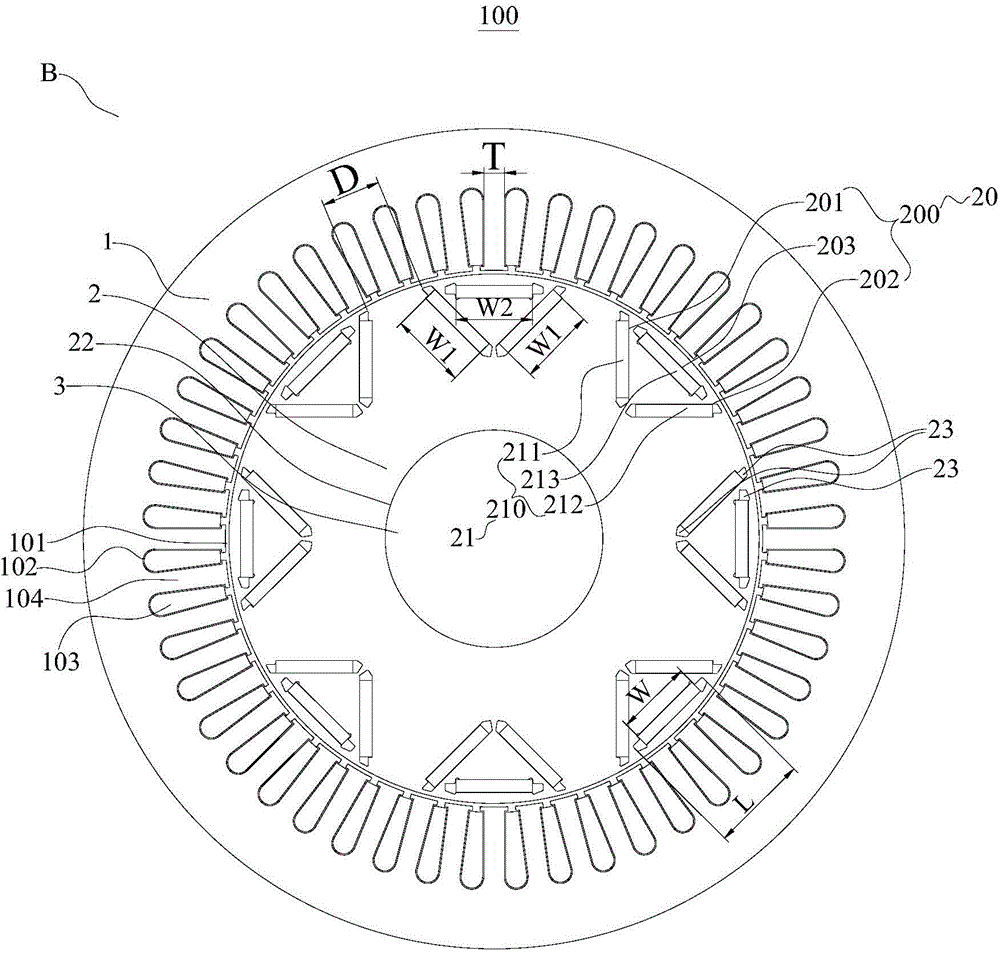

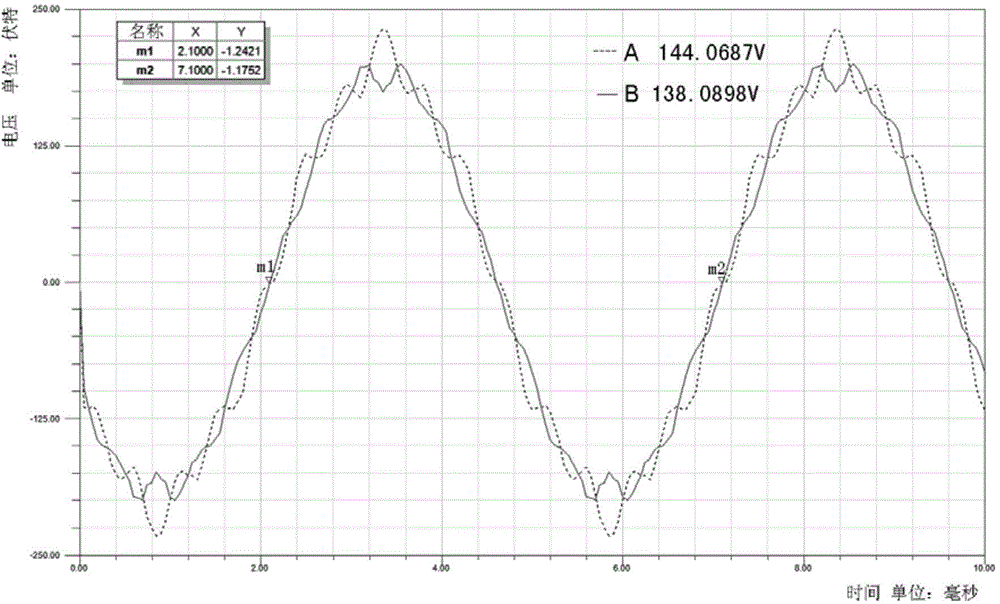

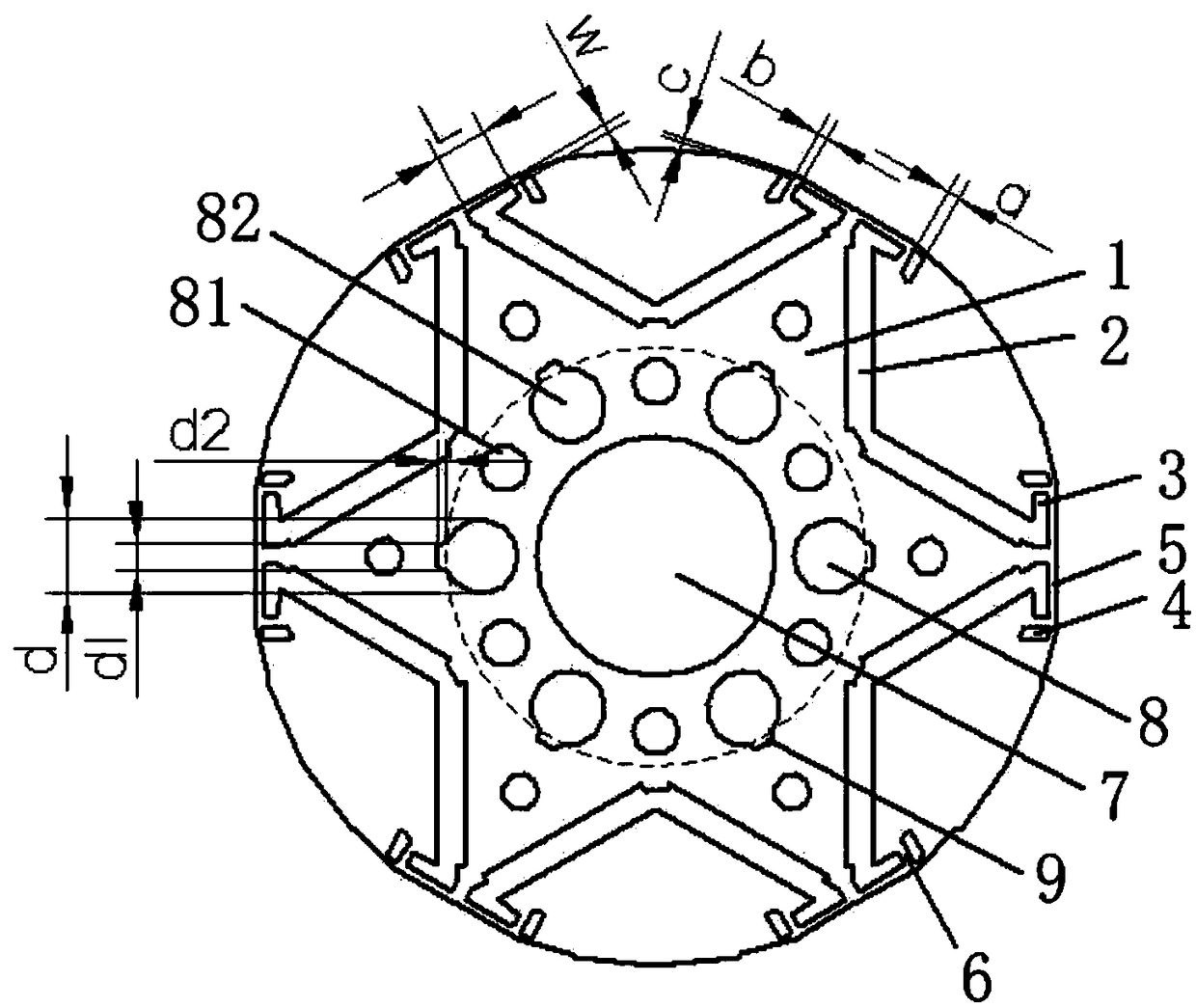

Permanent magnet synchronous reluctance motor and compressor

InactiveCN104682653AImprove efficiencyImprove power densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous reluctance motorPower flow

The invention discloses a permanent magnet synchronous reluctance motor and a compressor. The permanent magnet synchronous reluctance motor comprises a stator and a rotor, wherein the stator comprises a stator inner hole and a plurality of stator slots; a stator tooth is defined between every two adjacent stator slots; the rotor is arranged inside the stator inner hole; the rotor comprises a rotor inner hole and multiple mounting slot groups; a permanent magnet is arranged inside each mounting slot group; the width of each stator tooth is T; the shortest distance between each two adjacent mounting slot groups is D, and the ratio of D to T is greater than 0.8 and smaller than 1. According to the permanent magnet synchronous reluctance motor, the reluctance torque can be increased, and at the same time, the permanent magnet torque keeps unchanged or is slightly lowered, so that the total torque generated by the unit current of the motor is increased and the efficiency of the motor is improved; when the total torque output by the motor is unchanged, the input current of the stator can be reduced, the power density of the motor can be increased and the using amount of the permanent magnet can be reduced, so that the cost of the motor is lowered. Furthermore, the compressor with the motor has relatively high APF energy efficiency.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

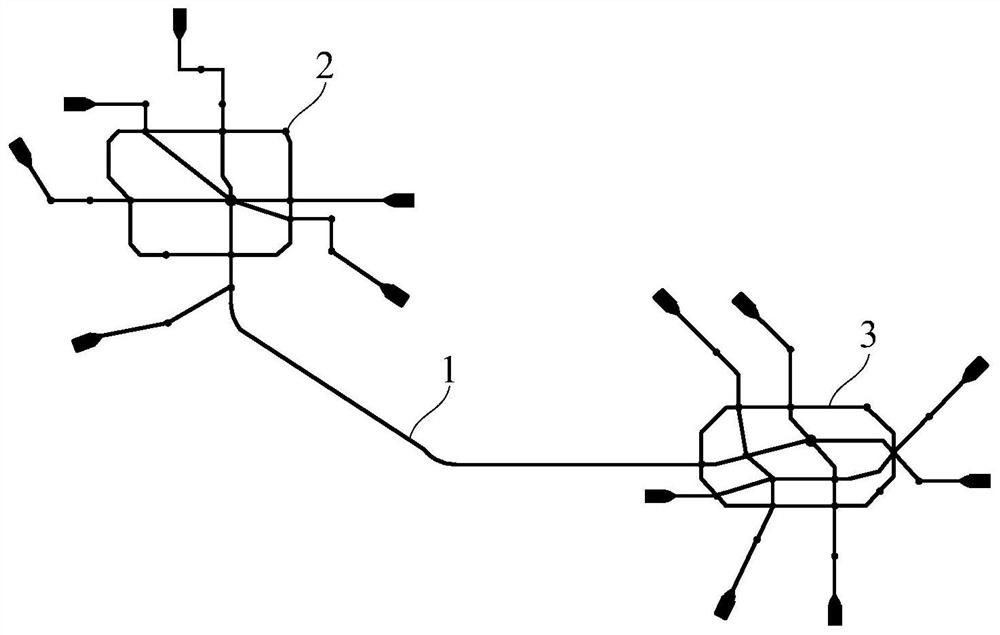

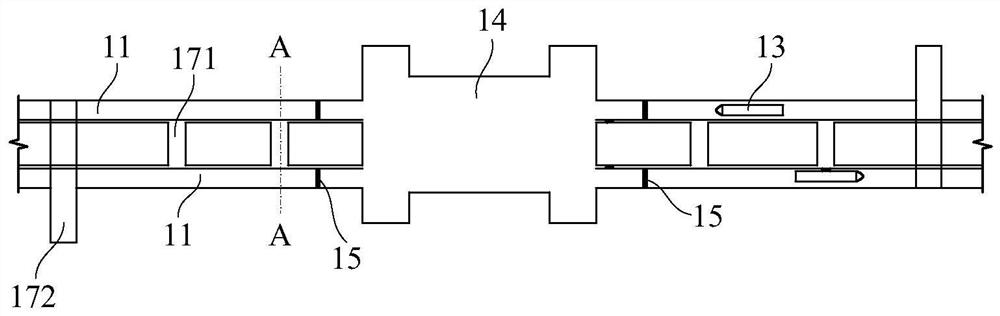

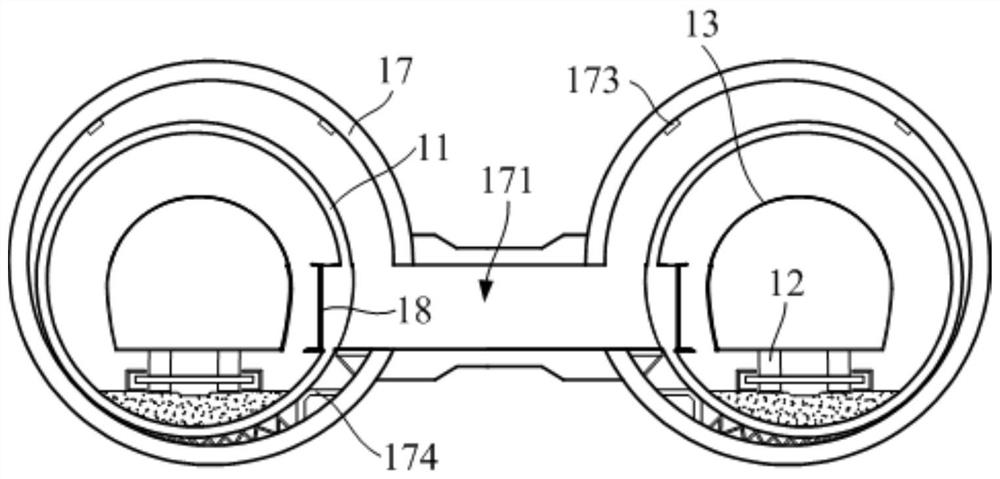

Low-vacuum pipeline transportation system

PendingCN111775971AEliminate resistanceEasy dockingMining devicesRailway tunnelsUltra high speedPipeline transport

The invention relates to the technical field of pipeline transportation, in particular to a low-vacuum pipeline transportation system. The low-vacuum pipeline transportation system comprises at leastone low-vacuum pipeline, a tunnel, a track, a station, an ultra-high-speed maglev train, an interval air-tight door, a folding channel, a plurality of low-vacuum pump stations and a control system, wherein the low-vacuum pipeline is fixedly mounted in the tunnel, and a rail is fixedly mounted in the low-vacuum pipeline; the ultra-high-speed maglev train is used for running along the track; the low-vacuum pump station is communicated with the low-vacuum pipeline; the interval air-tight door is arranged at the position where the low-vacuum pipeline is connected with the station; and the controlsystem is in signal connection with the low-vacuum pump station and the interval air-tight door and used for controlling the low-vacuum pump station and the interval air-tight door to act. The low-vacuum pipeline transportation system has the advantages of being high in speed, low in energy consumption, small in influence of external weather, small in noise and vibration and convenient for urban personnel to take and transfer.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

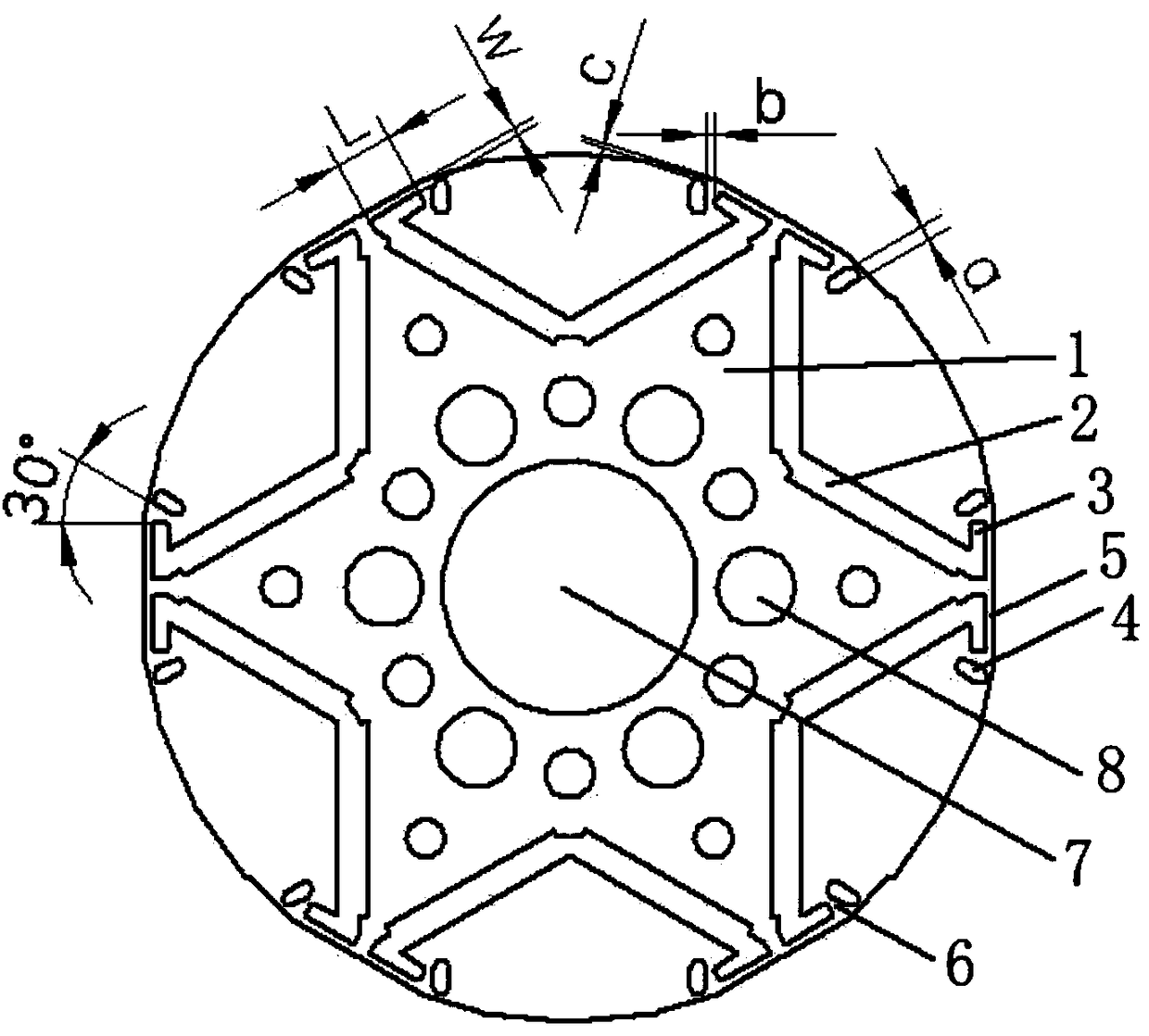

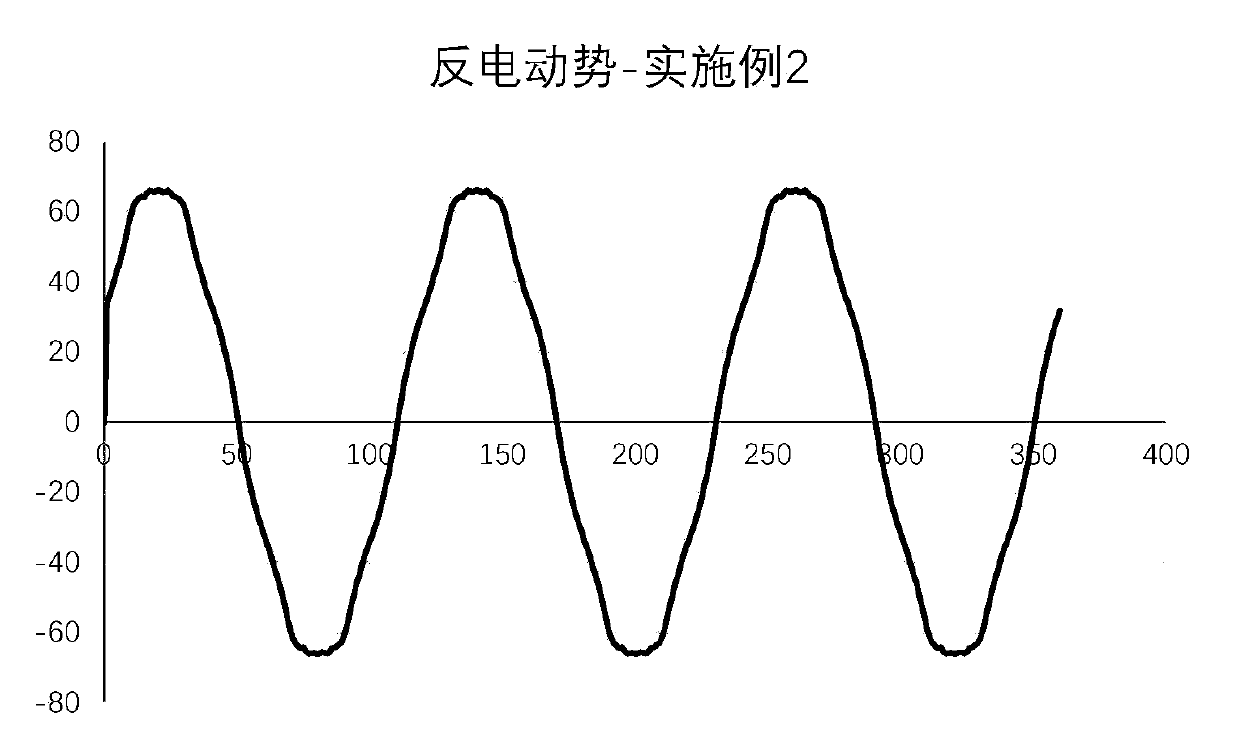

Electric motor rotor, electric motor and direct current variable frequency compressor

PendingCN109104012AReduce the no-load back EMF harmonic distortion rateImprove controlMagnetic circuit rotating partsMagnetic reluctanceElectromotive force

An electric motor rotor, an electric motor, and a direct current variable frequency compressor are provided. A magnetic beam finishing groove is added on the rotor core of the electric motor rotor, sothat a magnetic bridge is formed between the magnetic beam finishing groove and the magnetic isolation groove, and the distance between the magnetic beam finishing groove and the magnetic isolation groove causes the magnetic bridge to be magnetically saturated, and then the magnetoresistance increases significantly, close to air magnetoresistance. According to the principle of minimum magnetoresistance, that is, the flux is always closed along the path with the smallest magnetoresistance, magnetic lines of force will be confined to the magnetic bridge. At this time, the magnetoresistances ofthe magnetic beam finishing groove, the magnetic bridge, and magnetic isolation grooves are equivalent, which co-determine the polar arc coefficient, so that on the basis of ensuring the mechanical strength of the magnetic isolation bridge between the magnetic isolation groove and the edge of the rotor core, the pole arc coefficient can be set in a larger range, the optimal pole arc coefficient can be designed, and the optimal pole arc coefficient can be obtained, the harmonic distortion rate of the no-load back electromotive force, the tooth groove torque and the torque ripple can be reduced,the motor control ability is improved, and the motor noise vibration is reduced.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

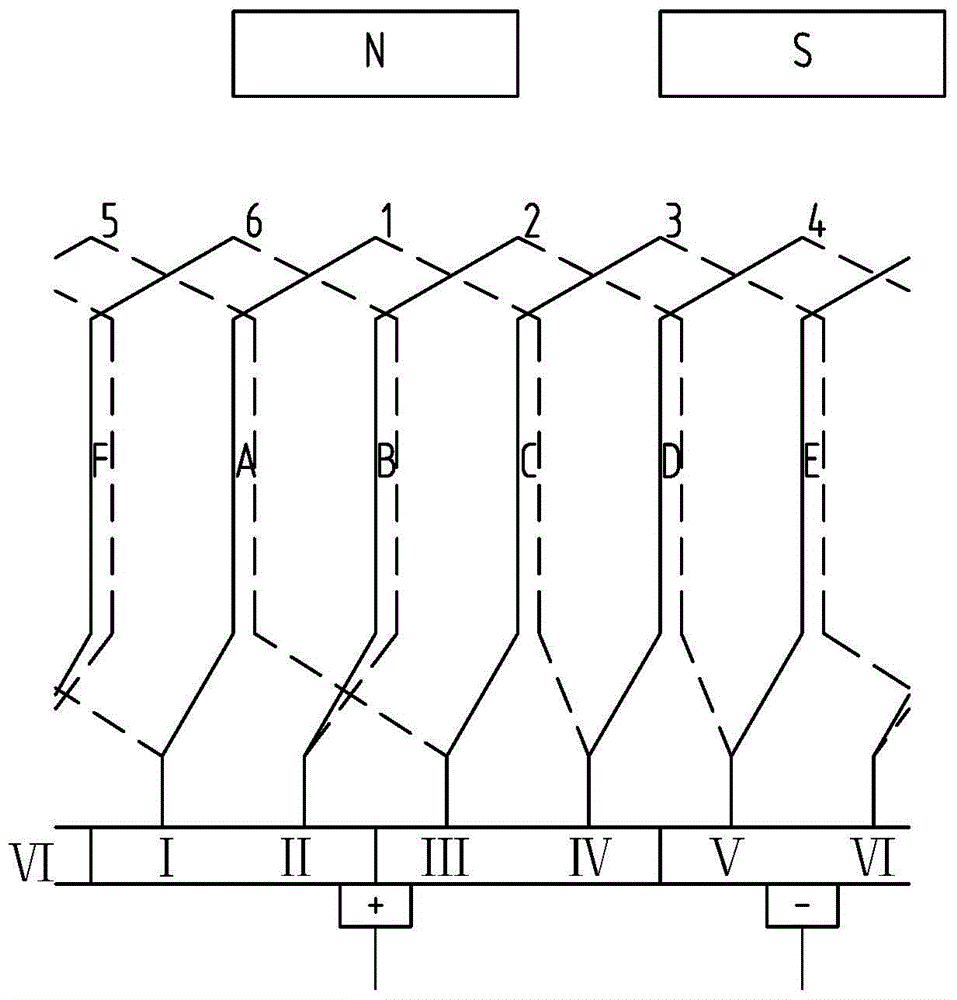

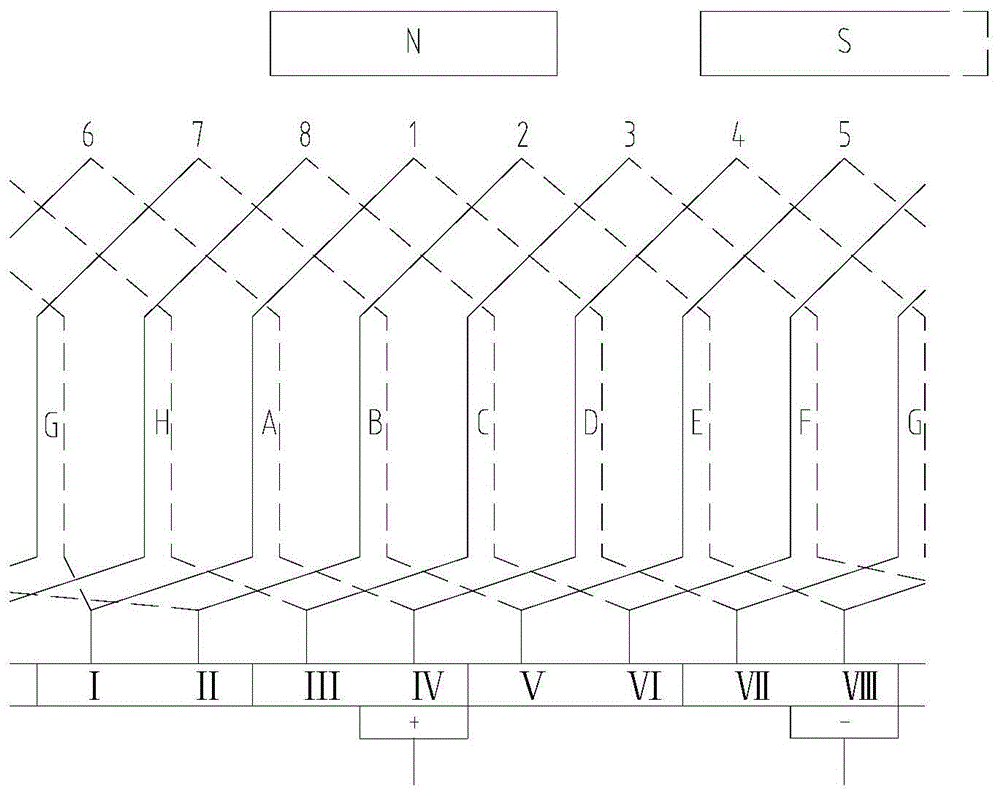

Rotor of a permanent magnet DC motor

ActiveCN103545962BReduce the numberShort processing timeDC commutatorWindings conductor shape/form/constructionLow noiseCoil array

A rotor of a permanent magnet DC motor provided by the present invention, the rotor uses an even group of coils, and y1 is N is a natural number, so as to realize short wire winding; there are two hooks on each commutator piece, so as to reduce the number of commutator pieces, and also realize flexible winding and symmetrical winding. Moreover, the size of the end portion is also small, the processing time is short, the power density of the whole machine is high, the noise and vibration are small, and the manufacturing cost is low, and it can be applied to all even-numbered slot connections.

Owner:CHIAPHUA COMPONENTS SHENZHEN

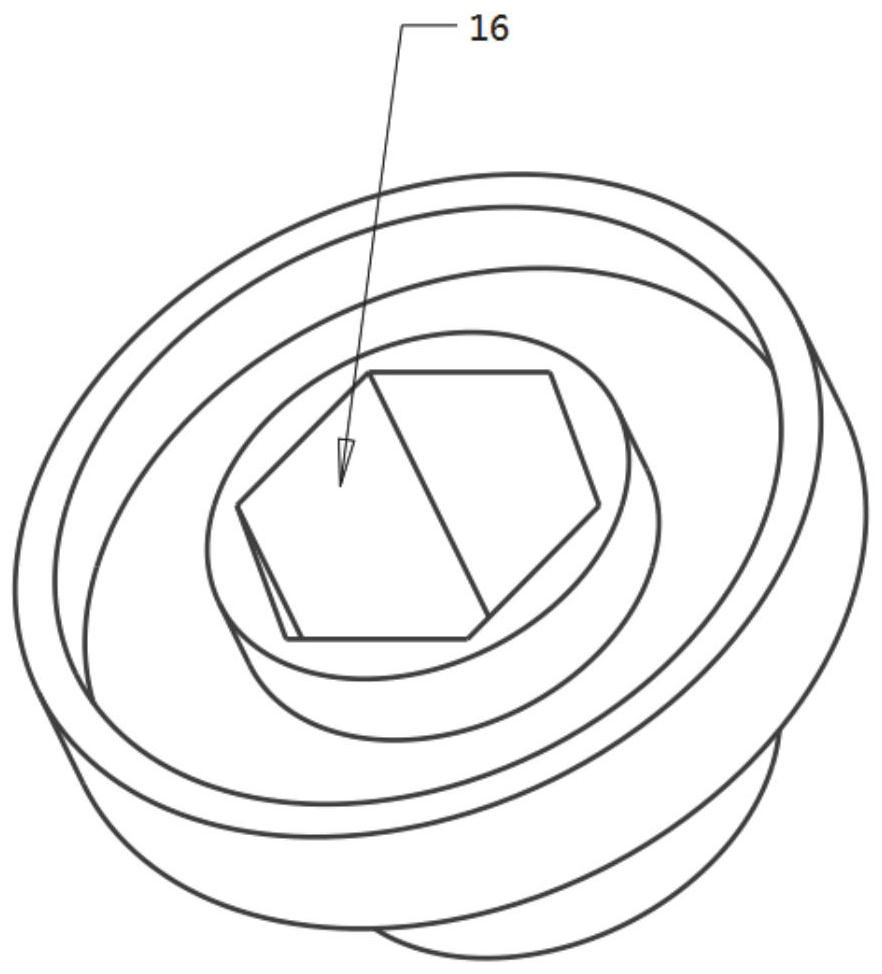

Linear compressor with resonant system

InactiveCN111852817AReduce vibrationIncrease operating frequencyPositive displacement pump componentsNon-rotating vibration suppressionLinear compressorElectric machinery

The invention relates to a linear compressor with a resonant system. The linear compressor comprises a cylinder, one end of the cylinder is plugged by a cylinder base, and the other end of the cylinder is plugged through an end cover. A motor is disposed in the cylinder, a moving part is installed at an inner hole of the motor, and one end of the moving part extends into a compression cavity in the cylinder base and is connected with a piston. A plate spring is installed on the side surface of the outer circle of the moving part. The plate spring can realize radial limiting of the moving partand the piston. The end, close to the end cover, of the moving part is sleeved with a cylindrical spring assembly, and the cylindrical spring assembly can realize axial limiting of the moving part. The linear compressor can solve the problem of insufficient axial stiffness or radial stiffness when cylindrical spring positioning and plate spring positioning are independently used.

Owner:QINGDAO WANBAO COMPRESSOR

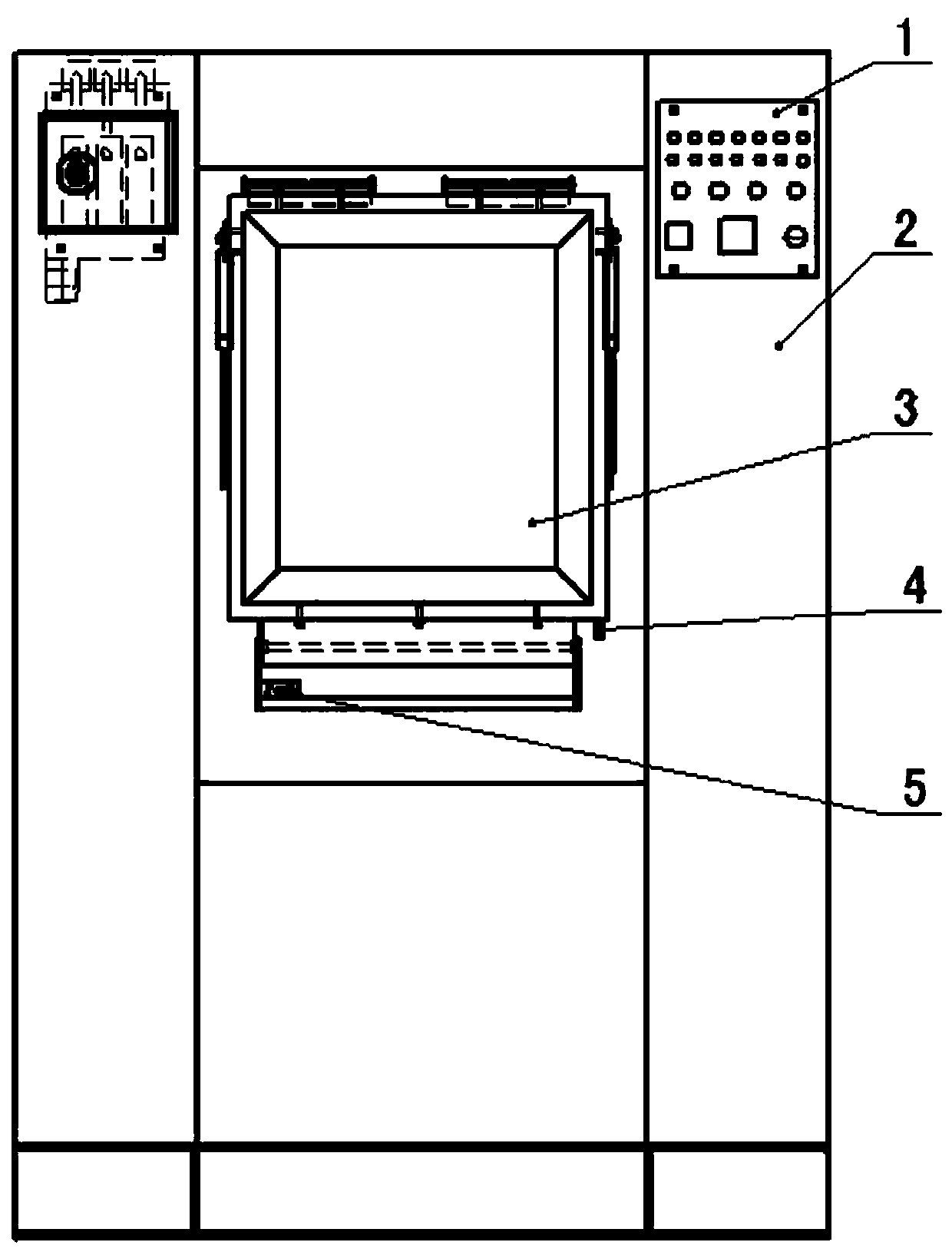

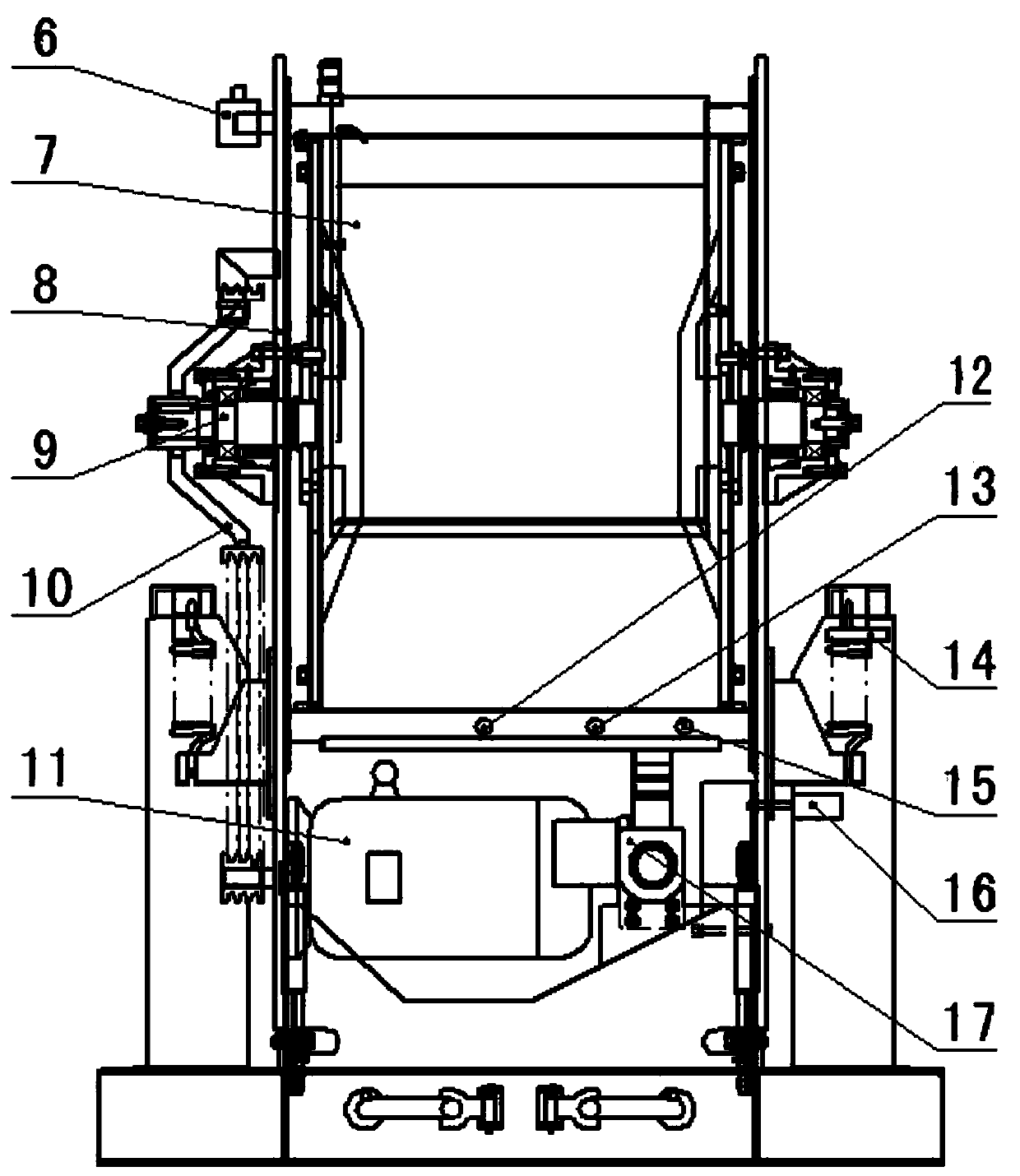

Isolated disinfection and washing integrated machine

PendingCN111364200AAvoid cross infectionTo offer comfortOther washing machinesControl devices for washing apparatusDisinfectantSewage

The invention discloses an isolation disinfection and washing integrated machine. The isolation disinfection and washing integrated machine comprises a frame, an inner roller and an outer roller; a clothes inlet door and a panel with a controller are installed at the front end of the outer roller, a clothes outlet door is installed at the rear end of the outer roller, and a door lock device and atravel switch are arranged on the front side wall, provided with the clothes inlet door, of the outer roller and the rear side wall, provided with the clothes outlet door, of the outer roller respectively; a water inlet pipe with a water inlet electromagnetic valve is arranged on the outer roller, a drainage electric valve is arranged at the bottom of the outer roller, and an automatic liquid preparation box for adding a detergent, a disinfectant and a neutralizer into the inner roller is installed in the frame; the controlled ends of the water inlet electromagnetic valve, the drainage electric valve and the automatic liquid distribution box are connected with the controller; and a fixing mechanism for keeping the outer roller and the frame relatively static during transportation is arranged between the bottom of the outer roller and the bottom of the frame. According to the isolation disinfection and washing integrated machine, the functional requirements for disinfection, washing, isolation, sewage disposal, convenient transportation and the like of the equipment in the field battle and infectious disease epidemic treatment process can be met.

Owner:GENERAL HOSPITAL OF PLA

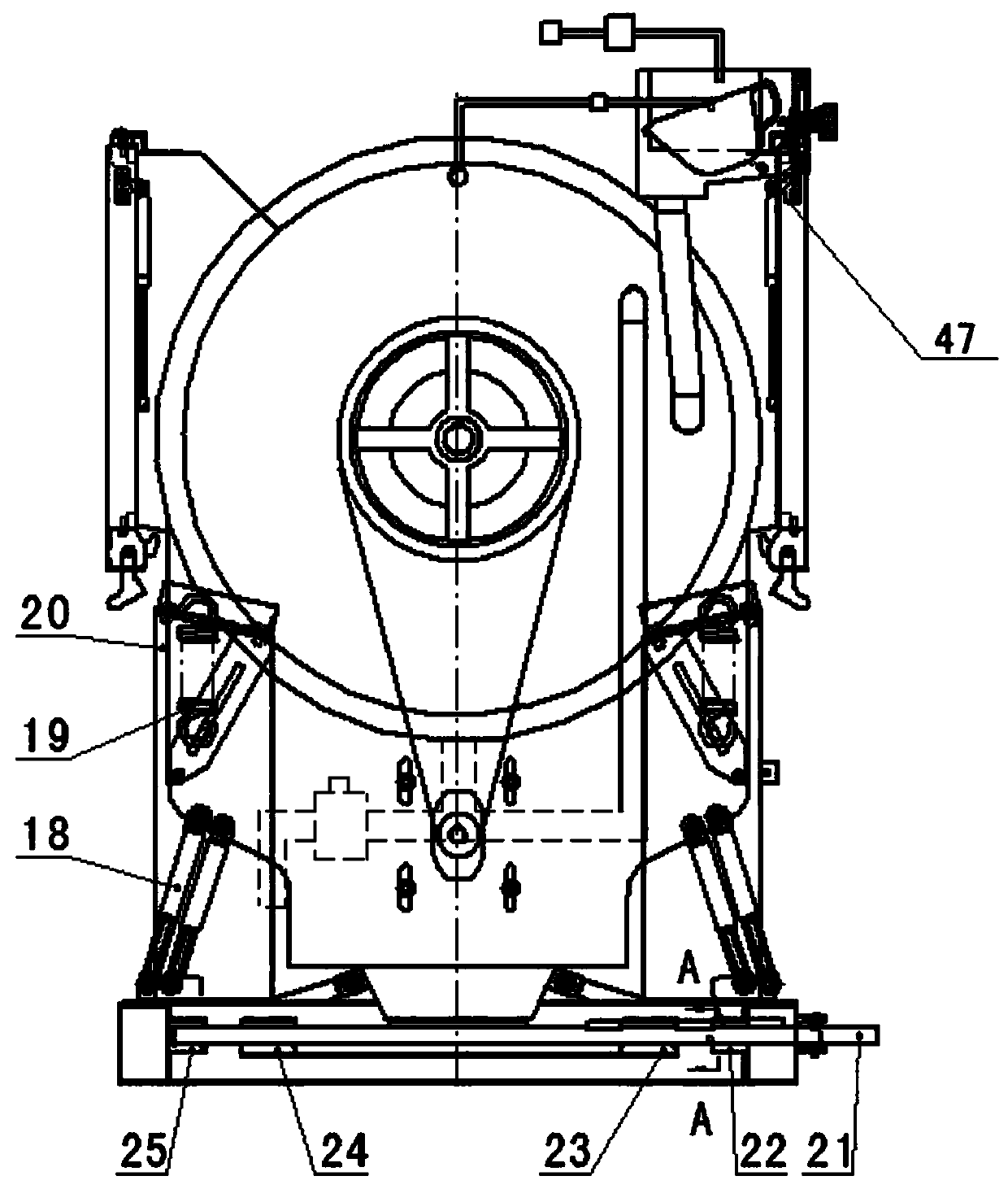

Civil aviation fuel filling equipment training platform

PendingCN109949643ADoes not affect fuel filling operationsProficiency in skillsCosmonautic condition simulationsEducational modelsFuel tankAviation law

The invention discloses a civil aviation fuel filling equipment training platform. The training platform is provided with a filling operation panel, a processing system, a fuel tank platform protective fence, a tank roof manhole, a maintenance escalator, an escalator protective cage, a supporting frame A, an auxiliary power box, a supporting frame B, a simulated gravity fuel filling port, a simulated pressure fuel filling port and a simulated plane fuel tank; the supporting frame A and the supporting frame B form a supporting mechanism of the fuel tank; the auxiliary power box is positioned atthe bottom of the fuel tank; the fuel tank platform protective fence, the tank roof manhole, the maintenance escalator and the escalator protective cage are arranged at the top of the fuel tank, wherein the simulated plane fuel tank is positioned on a mobile bracket to form a movable structure, and is provided with the simulated gravity fuel filling port and the simulated pressure fuel filling port. According to the platform, field-close, whole-process, safe, environment-friendly and reproducible theoretical teaching assisting and practical training operation of undergraduates and college students of aviation fuel filling related industry and new employees in the industry are realized.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

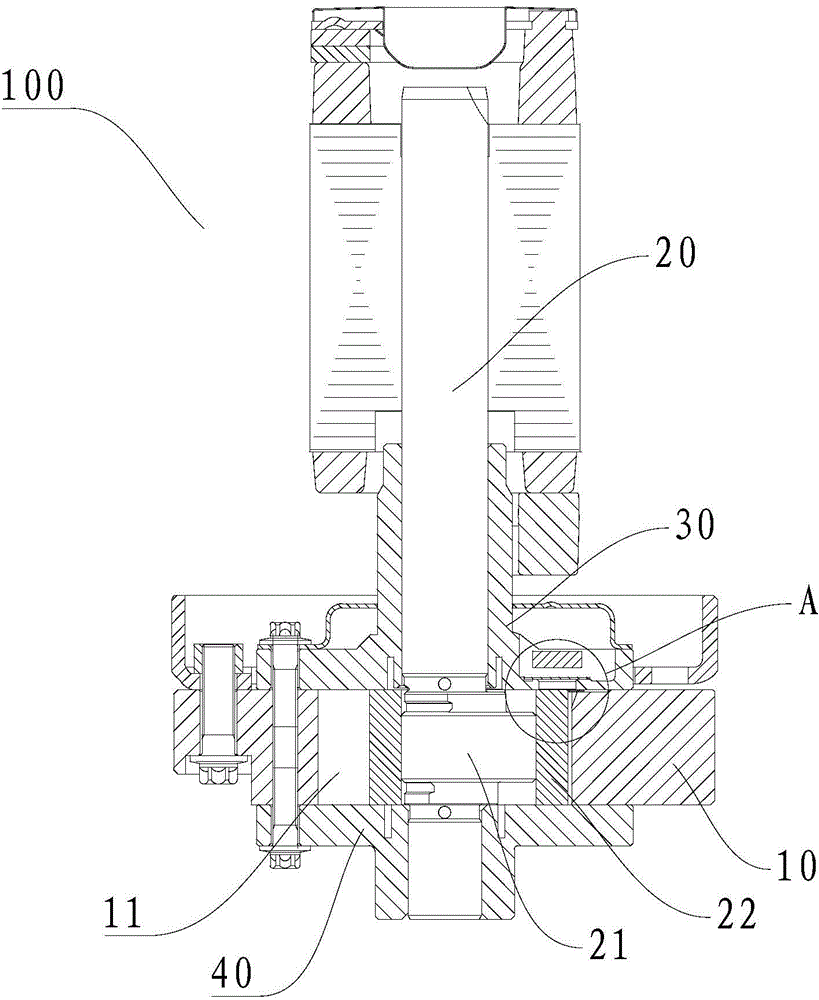

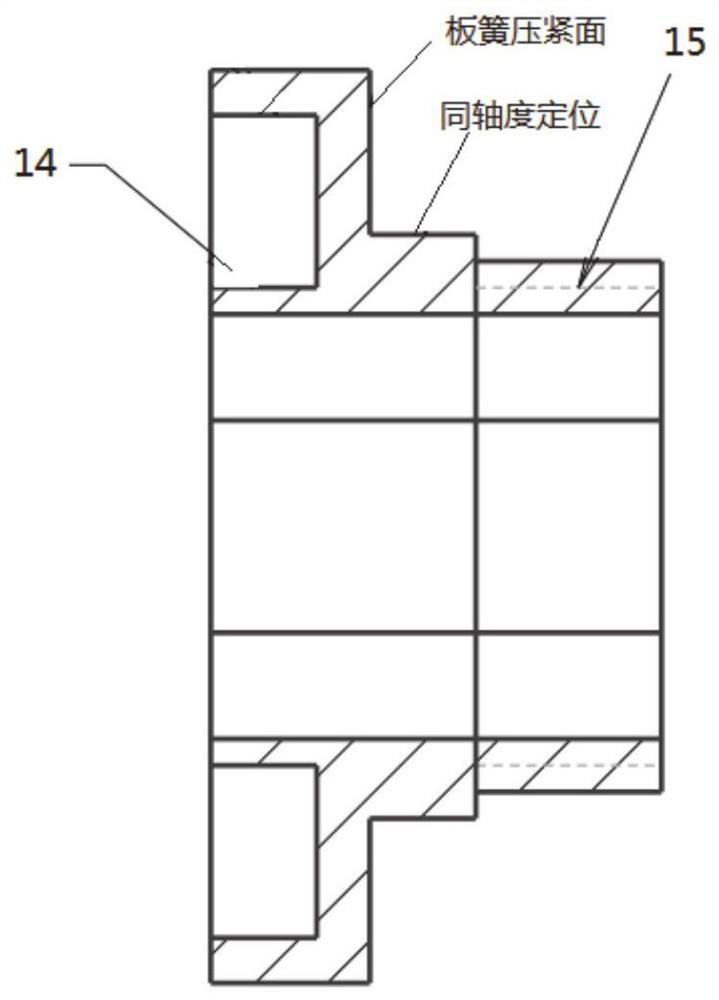

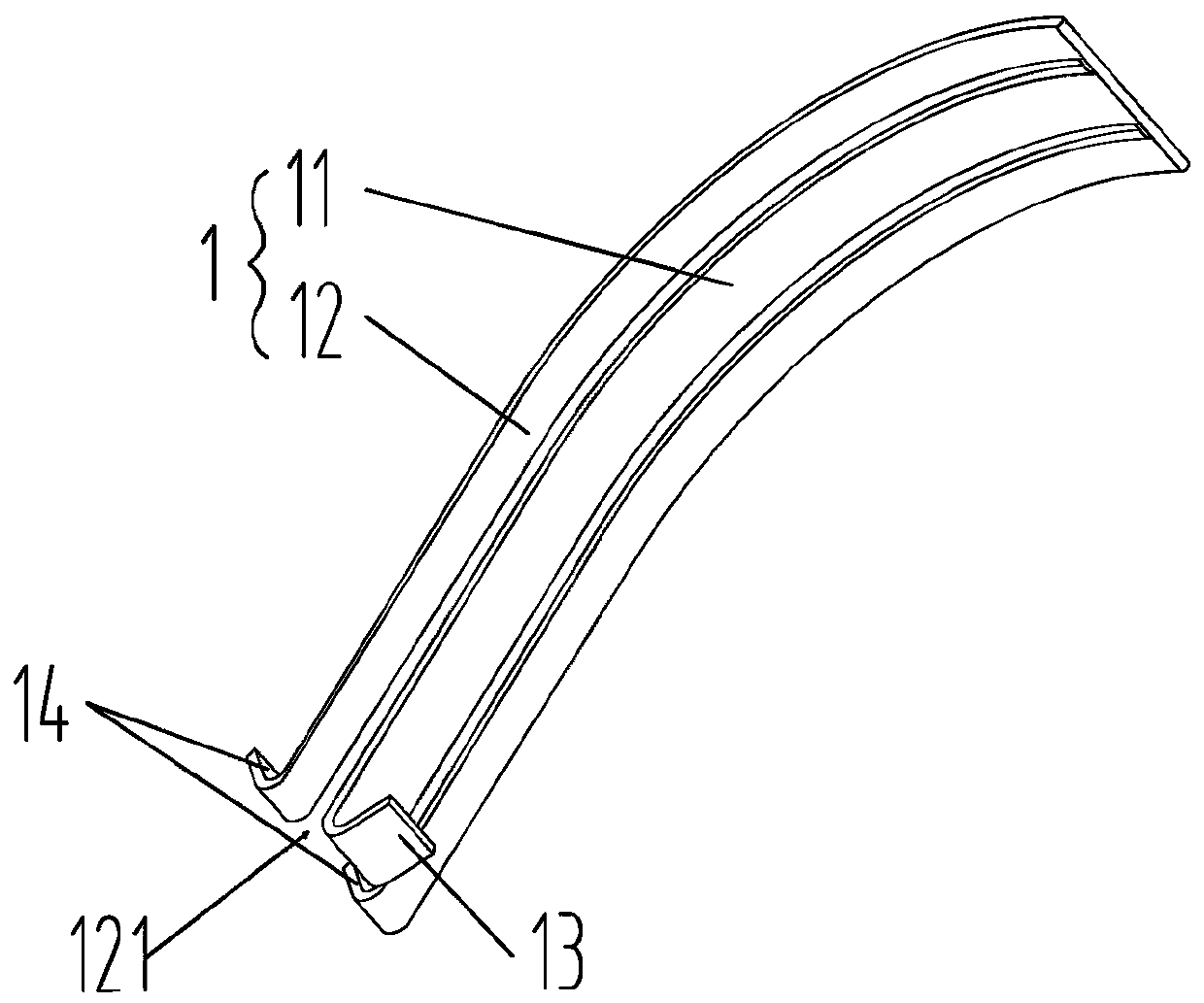

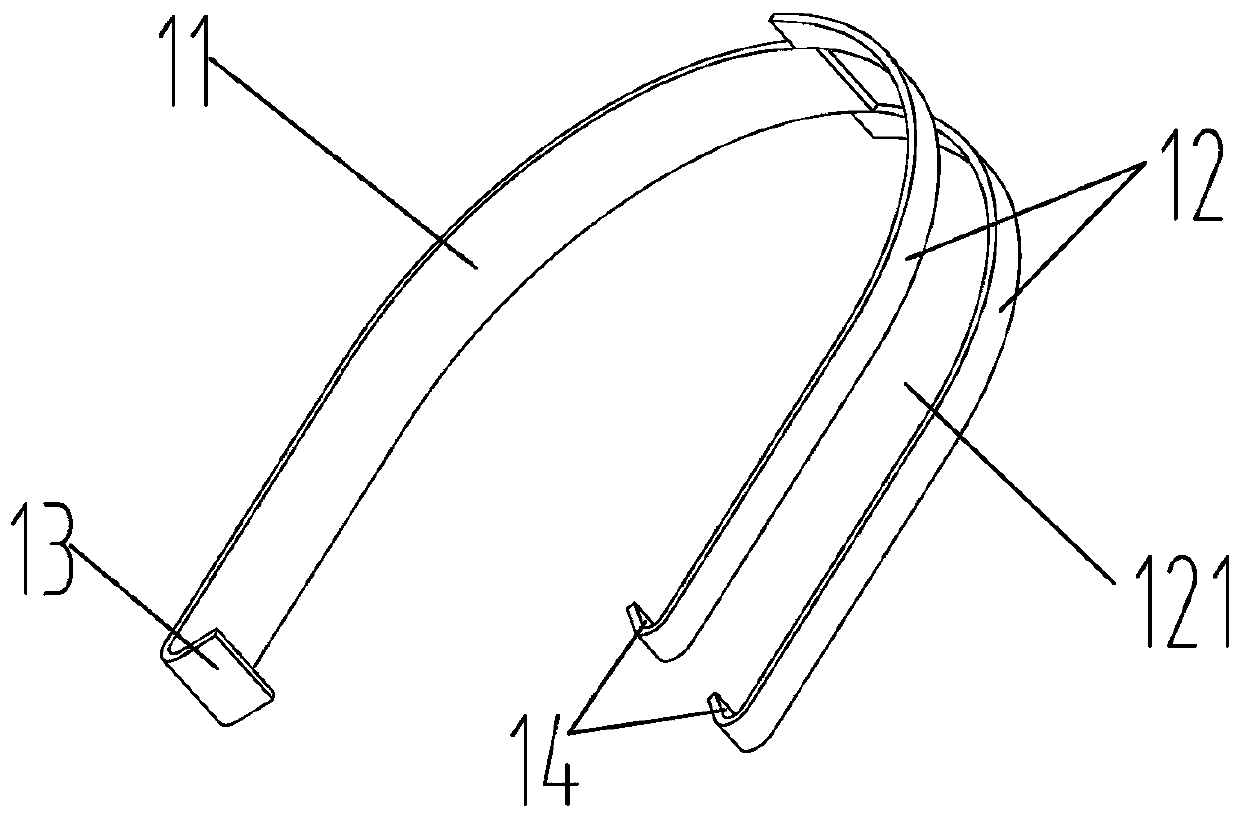

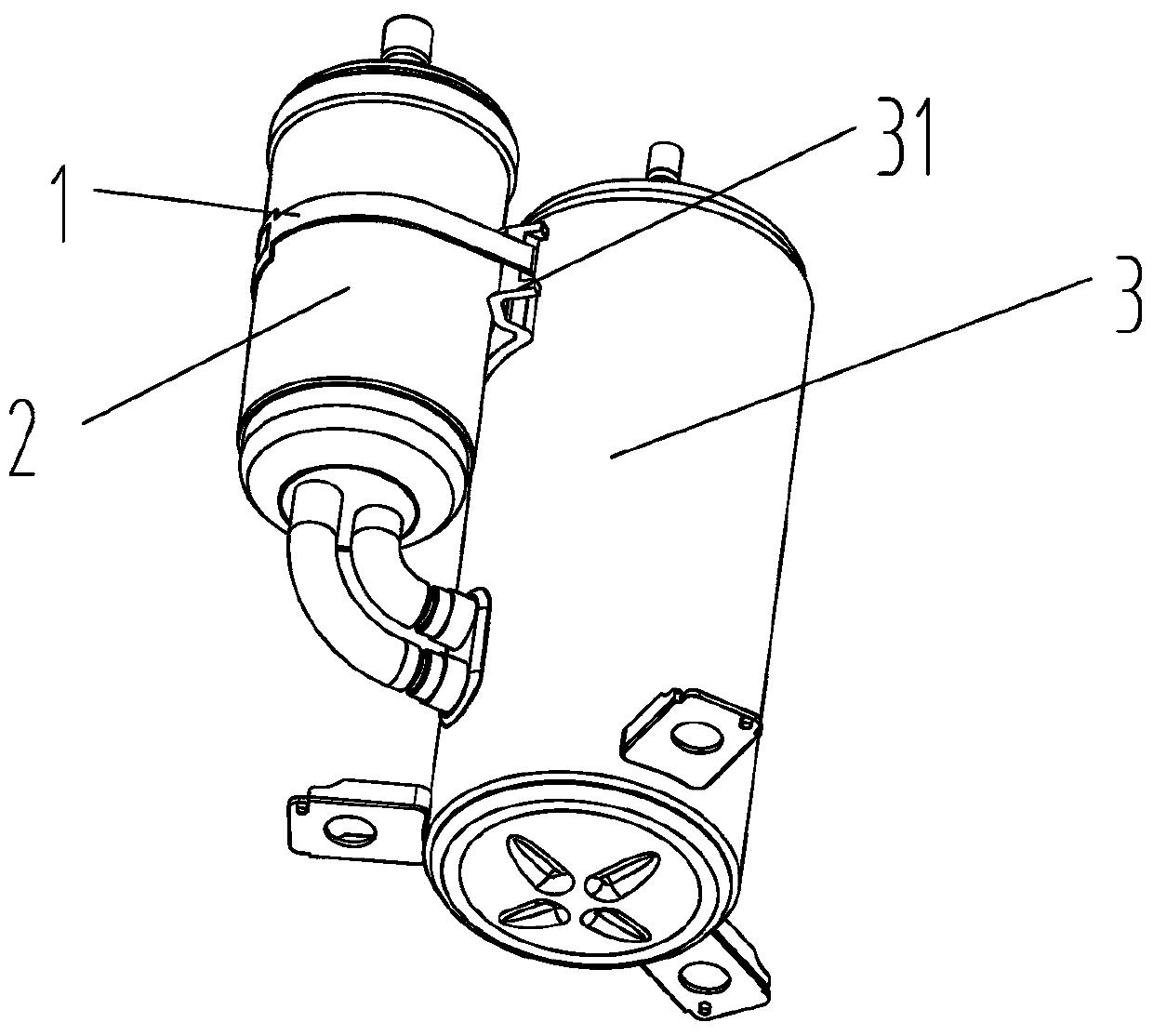

Pressing plate and compressor

PendingCN110332120AWith shock absorbing functionSave spaceRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention provides a pressing plate and a compressor. The pressing plate comprises a first plate body and a second plate body with flexibility; one end of the first plate body is connected with one end of the second plate body; through overturning, the first plate body and the second plate body are opened or closed; the other end of the first plate body and the other end of the second plate body are both fixed with the compressor, so that the pressing plate circularly fixes a liquid separator on the compressor; and the pressing plate is fixed with the compressor through a bent hook. The invention further provides the compressor comprising the pressing plate. Compared with the prior art, the pressing plate provided by the invention can be closed to save the space and to reduce the transportation cost; during assembling of the pressing plate, the pressing plate is opened through overturning, and is fixed with the compressor through the bent hook for two-way assembly to improve the assembly efficiency; and meanwhile, one end of the first plate body and one end of the second plate body are flexibly hinged, so that one end of the first plate body is rotationally connected with the second plate body, and the pressing plate achieves a certain vibration buffering function to reduce both noise and vibration.

Owner:ZHUHAI LANDA COMPRESSOR +1

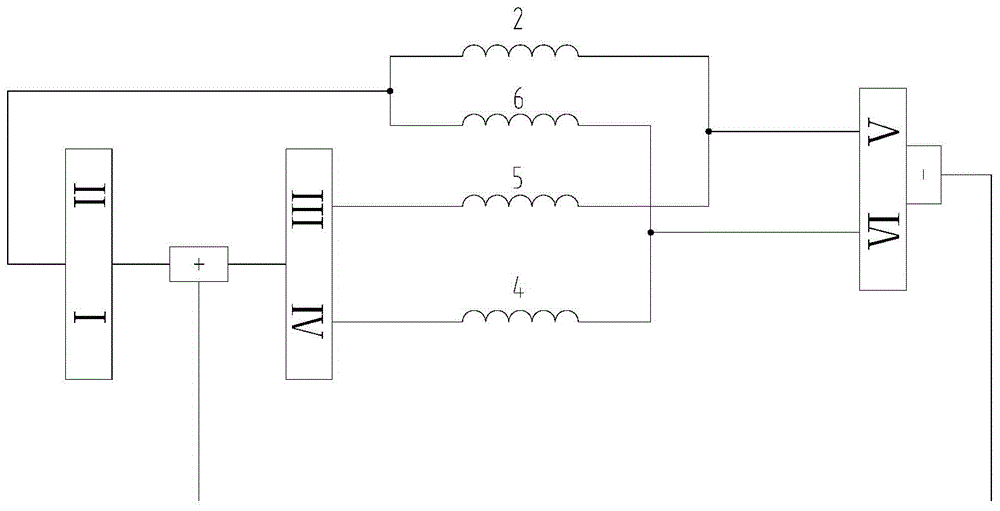

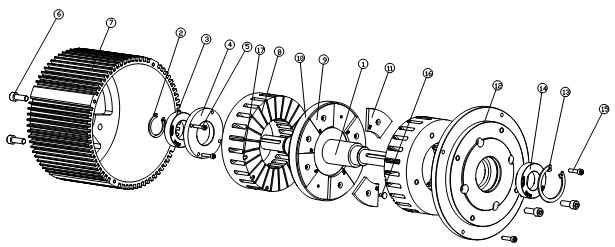

Dual-power disc type DC brushless motor

InactiveCN102684443AStable structureEasy to operateMagnetic circuit rotating partsBrushless motorsLow noise

The invention discloses a dual-power disc type DC (direct current) brushless motor which comprises a rotation shaft, sealing ball bearings and Hall sensors, wherein a rotor disc is sleeved at the center of the rotation shaft; an S-pole permanent magnet and an N-pole permanent magnet are embedded into the two surfaces of the rotor disc respectively and fixedly screwed down by an M4 grub screw; a coil component is arranged on the two sides of the rotor disc respectively; the sealing ball bearings are arranged at the left and right ends of the rotation shaft respectively; a motor shell and a motor rear cover are sleeved on the sealing ball bearings on the left and right ends of the rotation shaft respectively and fixedly connected together by a clamp spring; the motor shell and the motor rear cover are connected through an M5 inner hexagon screw; and multiple Hall sensors are arranged on the coil components. In the invention, the two coil components can be started at the same time or a single-power mode or dual-power mode is adopted according to the need; the motor can be switched at will between the single-power mode and the dual-power mode; and the motor has the advantages of stable operation, low noise and vibration, low fault rate, safety and energy conservation, little abrasion, reliable performance and long service life, is convenient to operate and easy to manufacture, and saves material.

Owner:邱昌

Rotor for permanent magnet synchronous motor and permanent magnet synchronous motor

PendingCN114744790ASmall torqueLow noise and vibrationSynchronous machine detailsMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention discloses a rotor for a permanent magnet synchronous motor and the permanent magnet synchronous motor. The rotor for the permanent magnet synchronous motor comprises a rotor iron core, the rotor iron core is provided with a plurality of magnetic pole grooves extending along the axial direction, and permanent magnets extending along the axis are arranged in the magnetic pole grooves; the outer surface of the rotor core is provided with a plurality of auxiliary grooves, and the auxiliary grooves and the magnetic pole grooves are mutually independent; and the auxiliary groove has a deviation angle. By adopting the scheme, the cogging torque of the motor can be reduced, the air gap flux density waveform can be corrected, the sine degree of the back electromotive force waveform can be improved, noise vibration caused by defects of the motor body can be reduced, and the electromagnetic performance of the motor can be improved. According to the scheme, the increase of assembly procedures caused by a traditional rotor skewed pole can be avoided, meanwhile, the structural strength of the motor rotor punching sheet is not influenced, more effects of selecting the position and the axial shape of the auxiliary groove are not influenced, and in some specific positions, the noise and vibration performance of the motor can be improved, and the output of the motor is not reduced or even improved.

Owner:XIAMEN TUNGSTEN

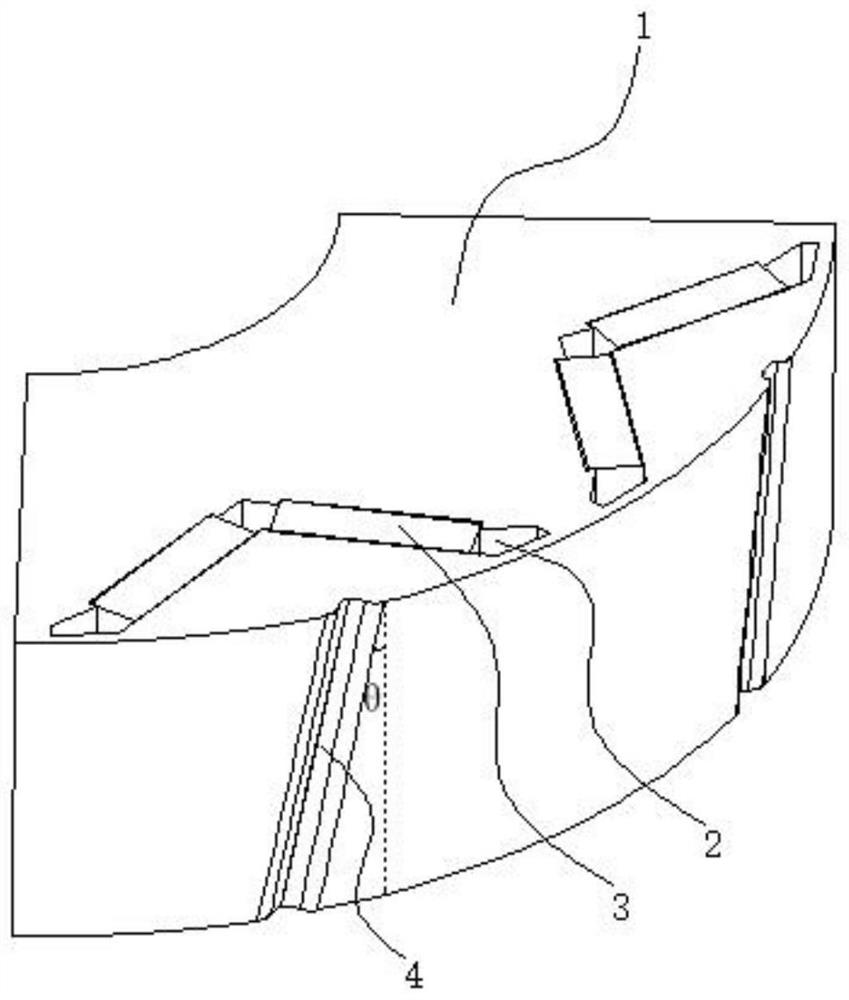

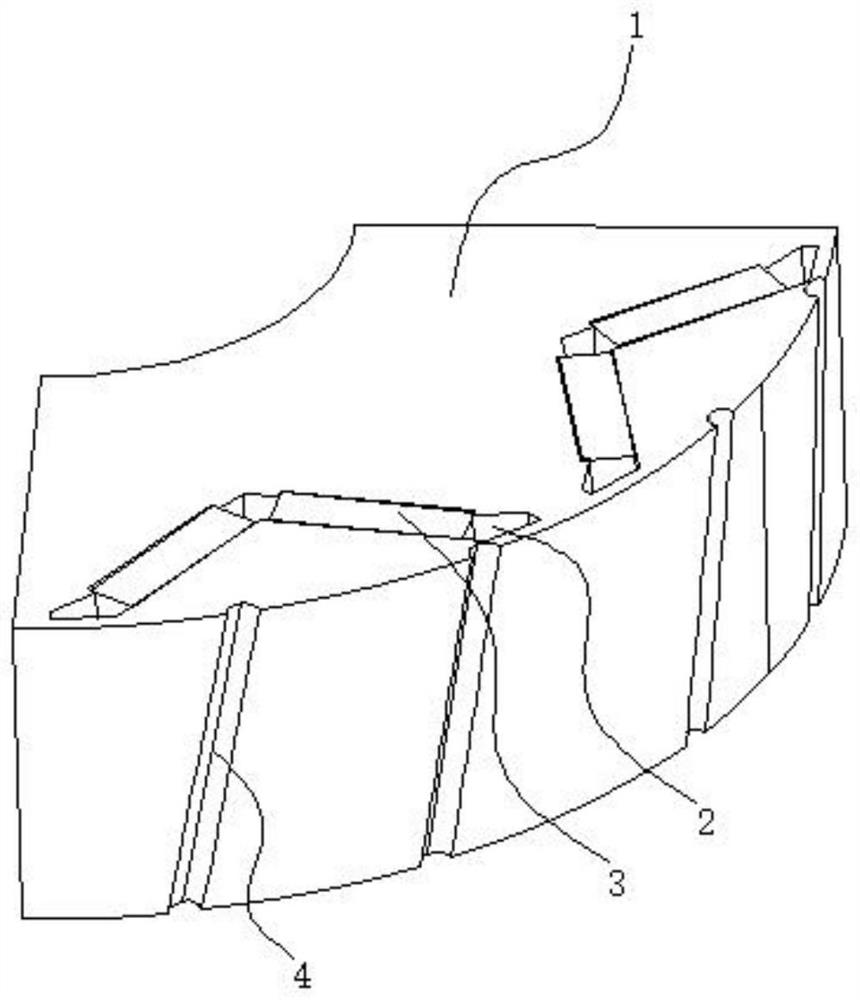

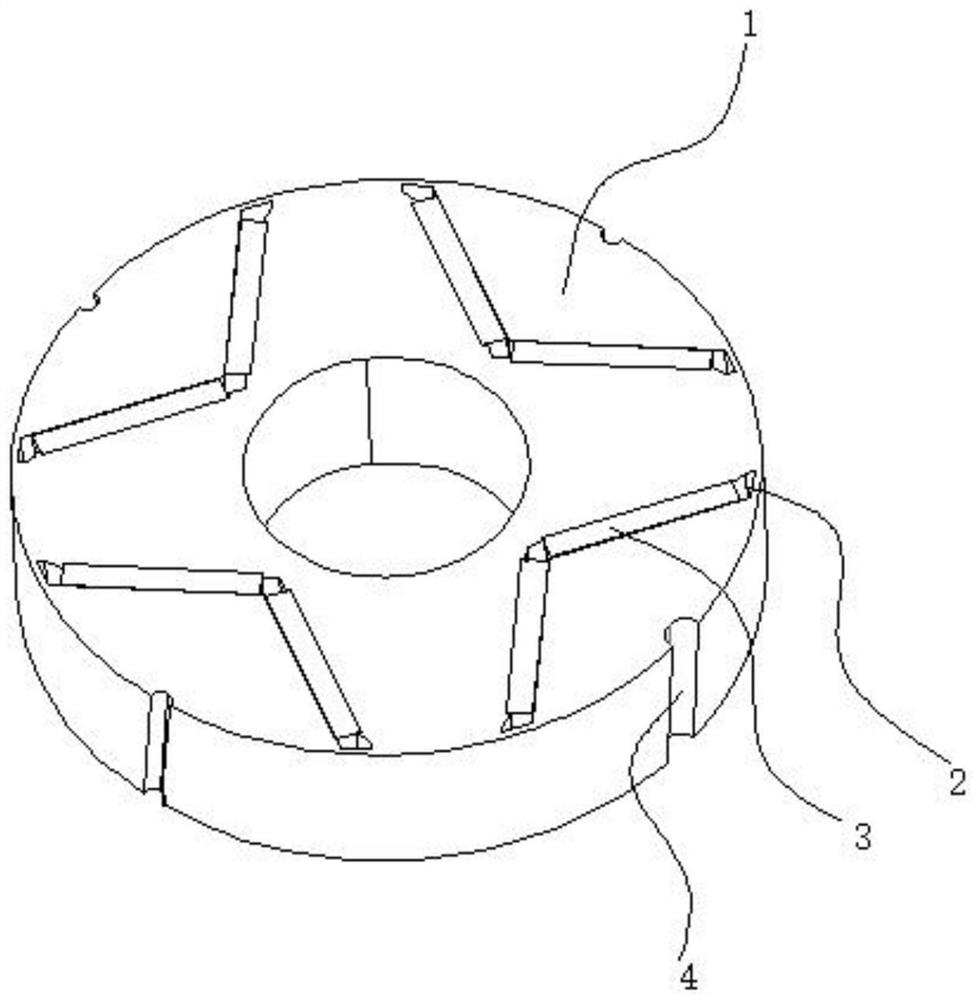

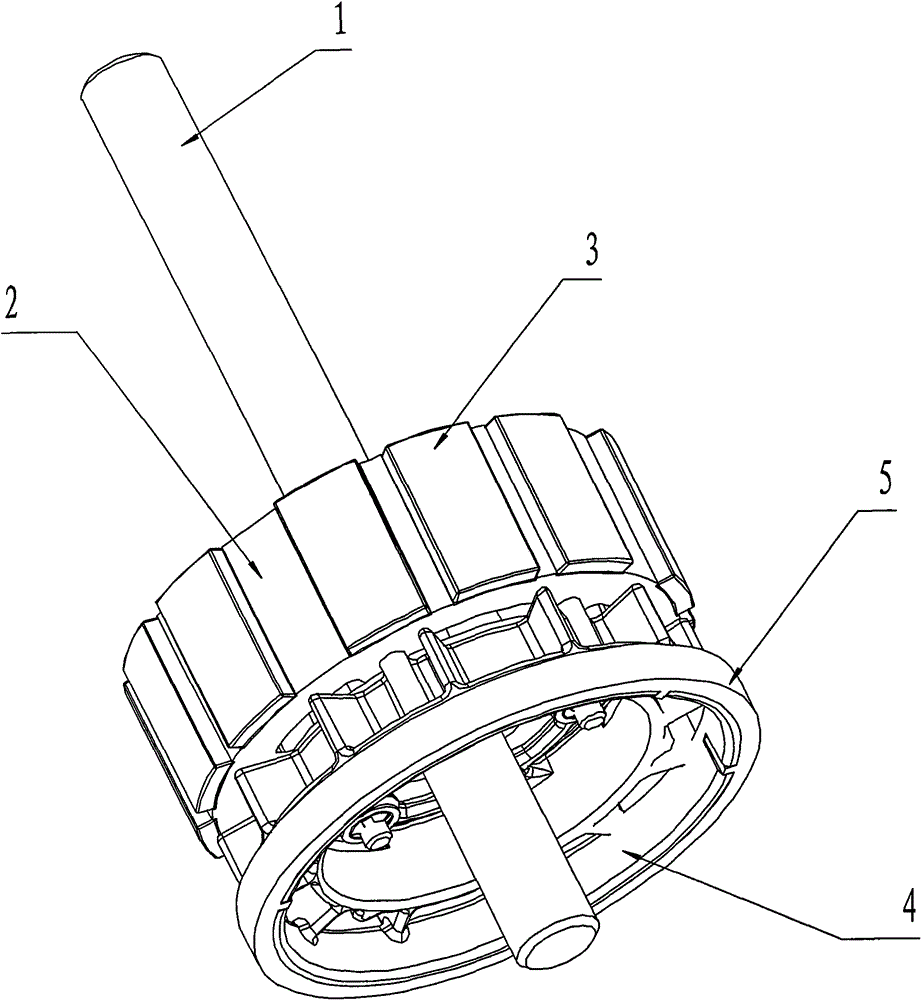

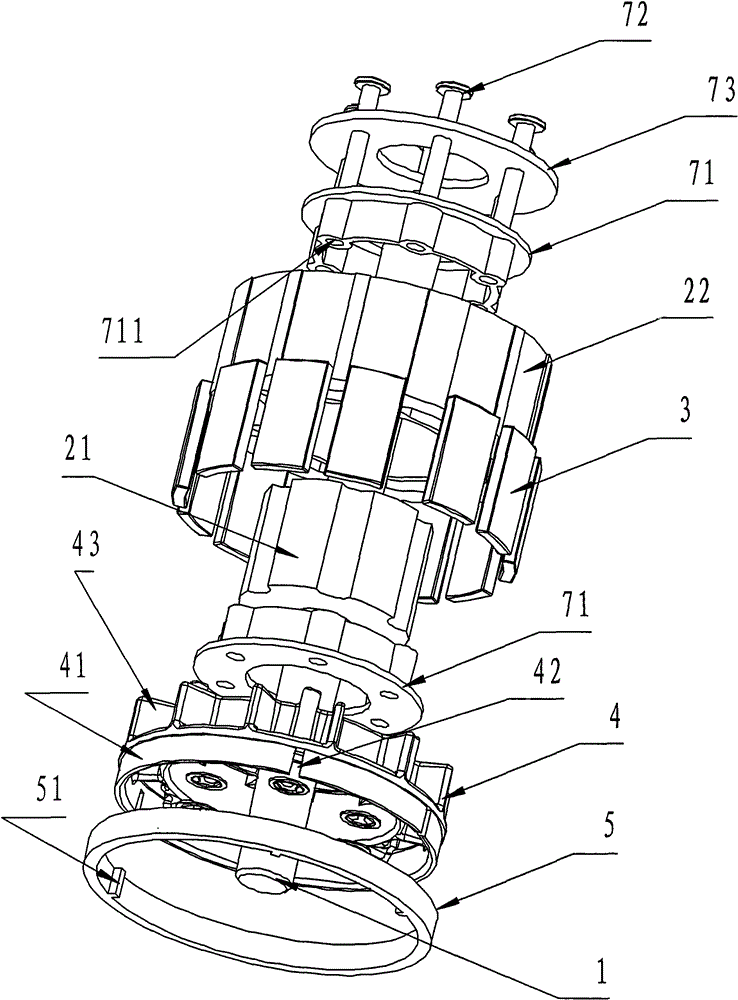

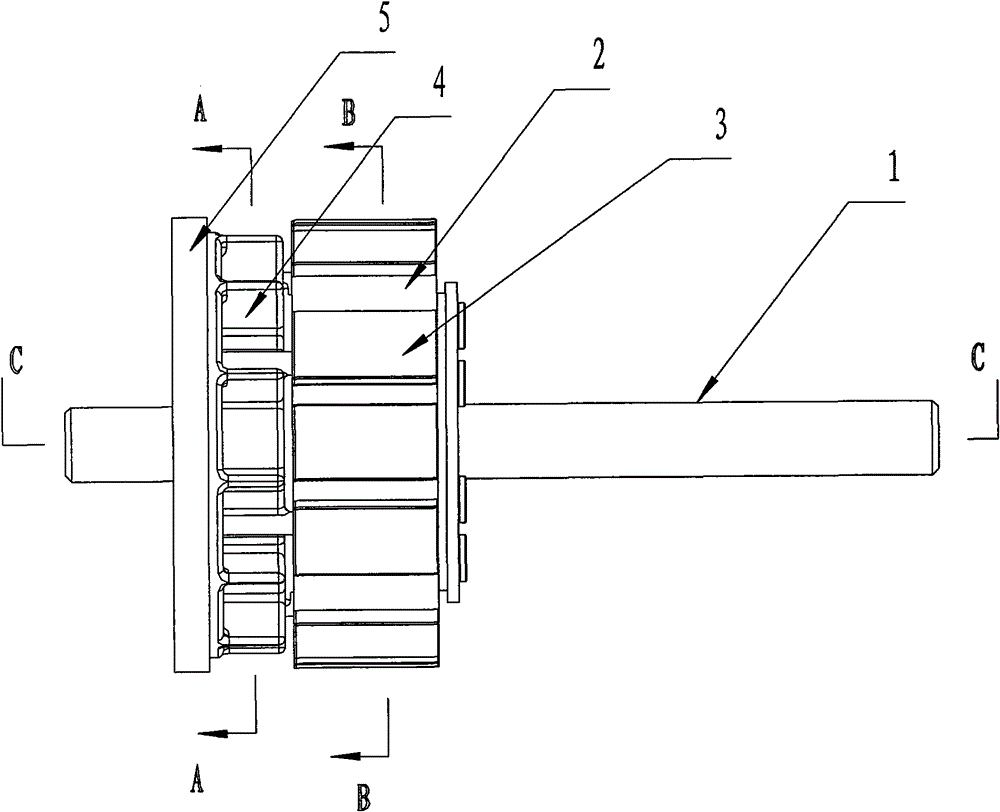

Motor rotor system

ActiveCN102315744BEffective coolingReduce distractionsMagnetic circuit rotating partsStructural associationHigh volume manufacturingElectric machine

The invention discloses a motor rotor system, which comprises a revolving shaft (1), a rotor core (2), a permanent magnet (3), a magnet ring support (4) and a magnet ring (5), wherein the rotor core is the arranged on the revolving shaft (1); the permanent magnet (3), the magnet ring support (4) and the magnet ring (5) are arranged on the rotor core (2); the magnet ring (5) is sleeved on the magnet ring support (4); and the magnet ring support (4) is positioned on one side of the rotor core (2) and connected with an end face of the rotor core (2). The motor rotor system has the advantages that: the main field corresponds to the induced field of the rotor accurately; the motor rotor system is high in consistency, is suitable for batch production, has a simple structure, and is convenient to install; and sine wave driving control mode with a position sensor can be implemented.

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

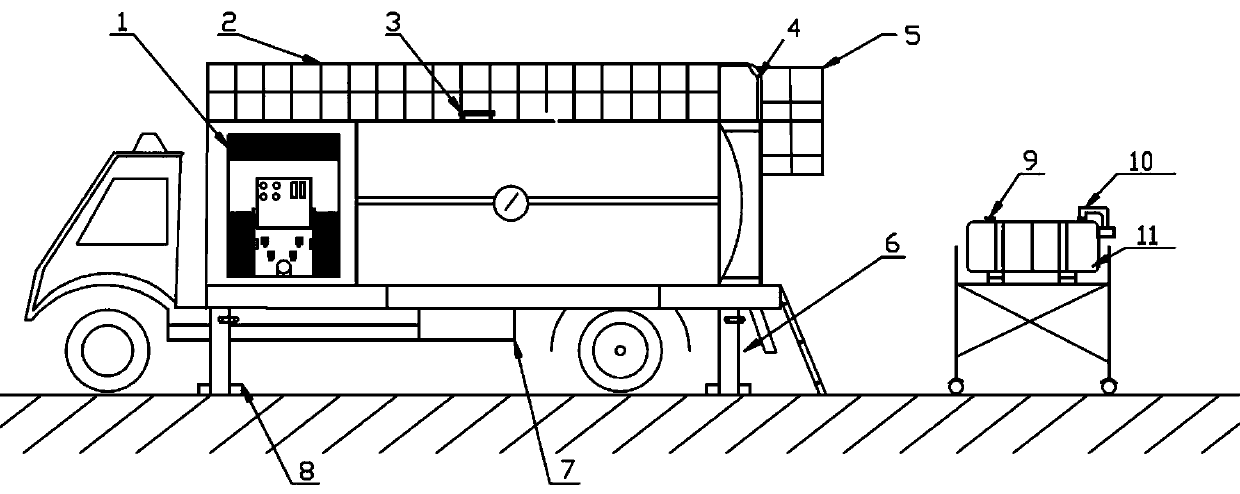

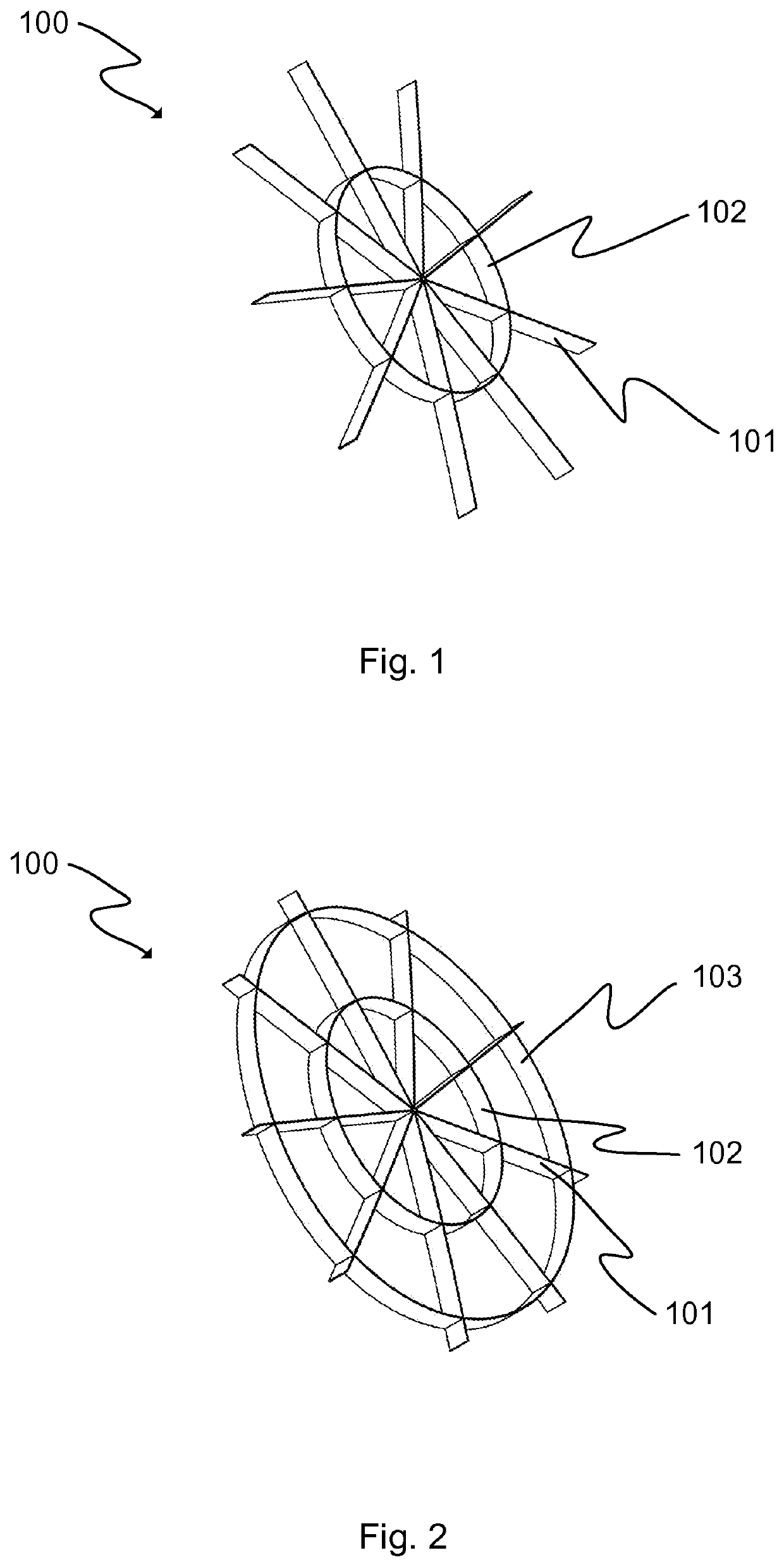

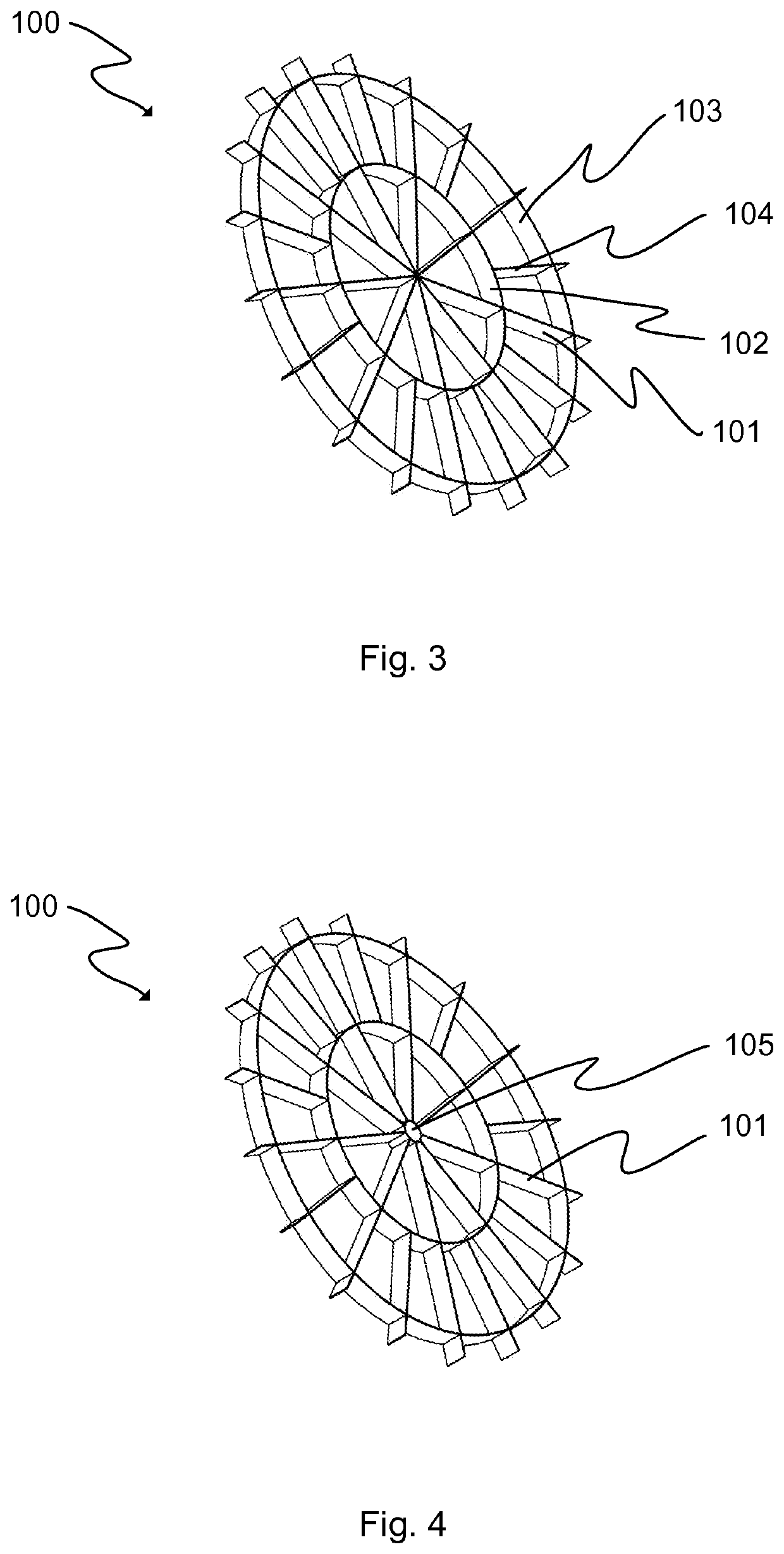

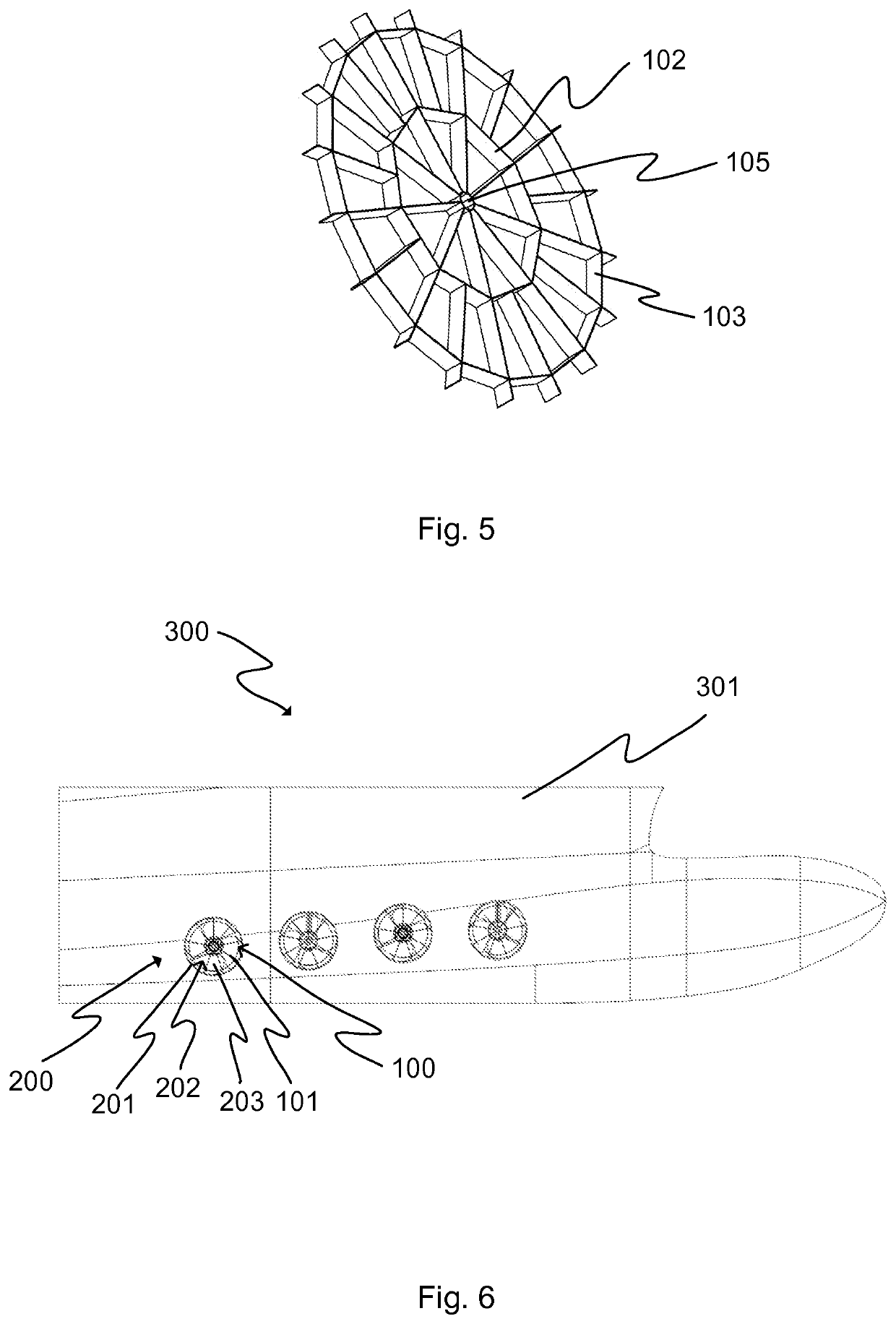

Grid for a tunnel thruster

PendingUS20220063784A1Increase thrustReduce noiseSelf-bailing equipments/scuppersSteering by propulsive elementsClassical mechanicsEngineering

Owner:ELOMATIC

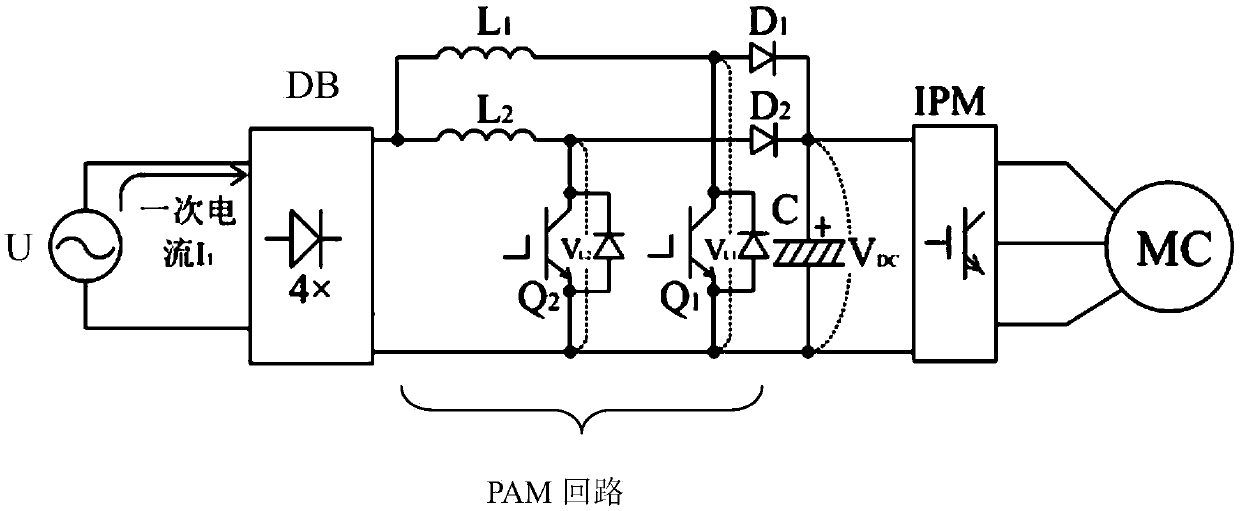

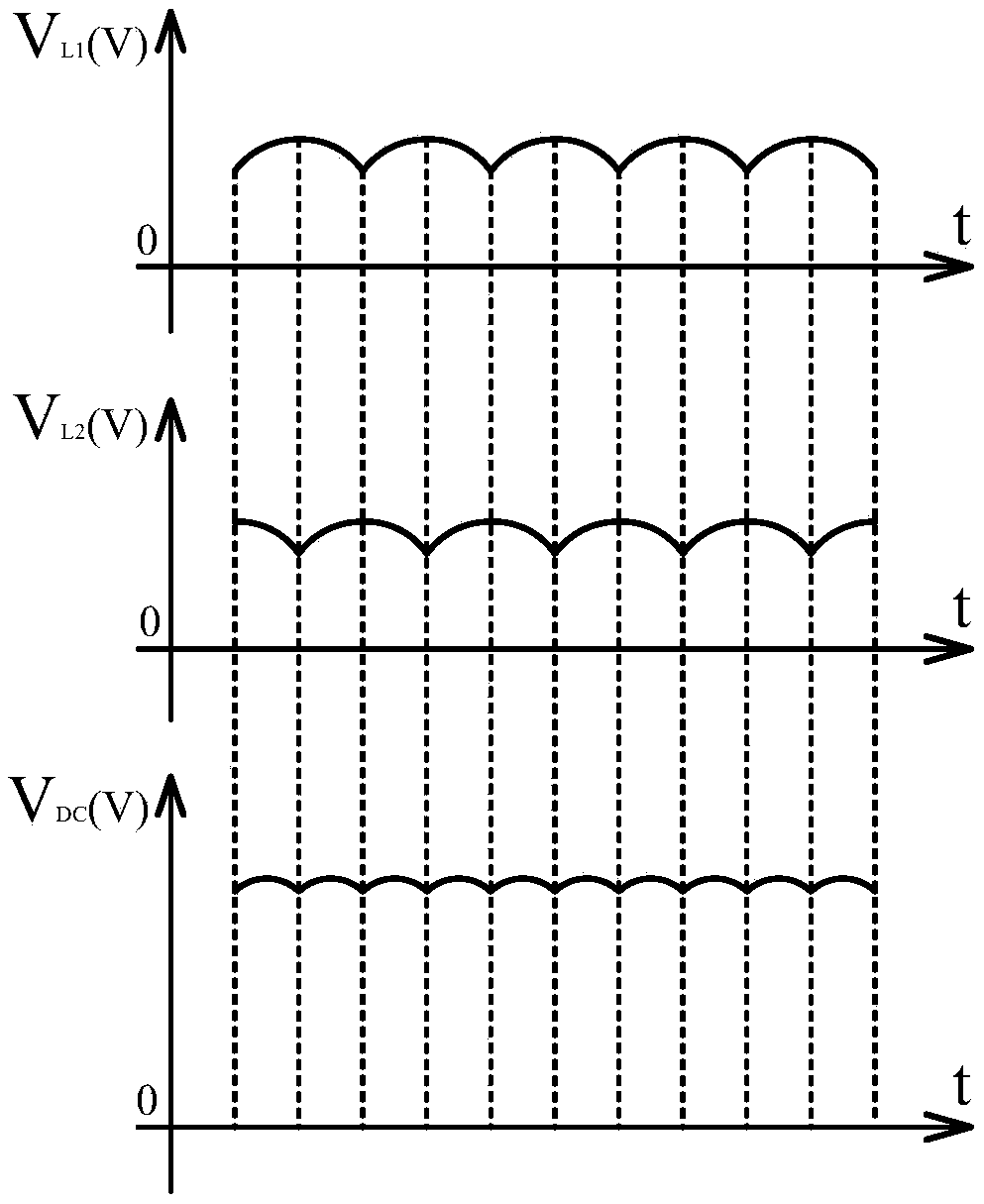

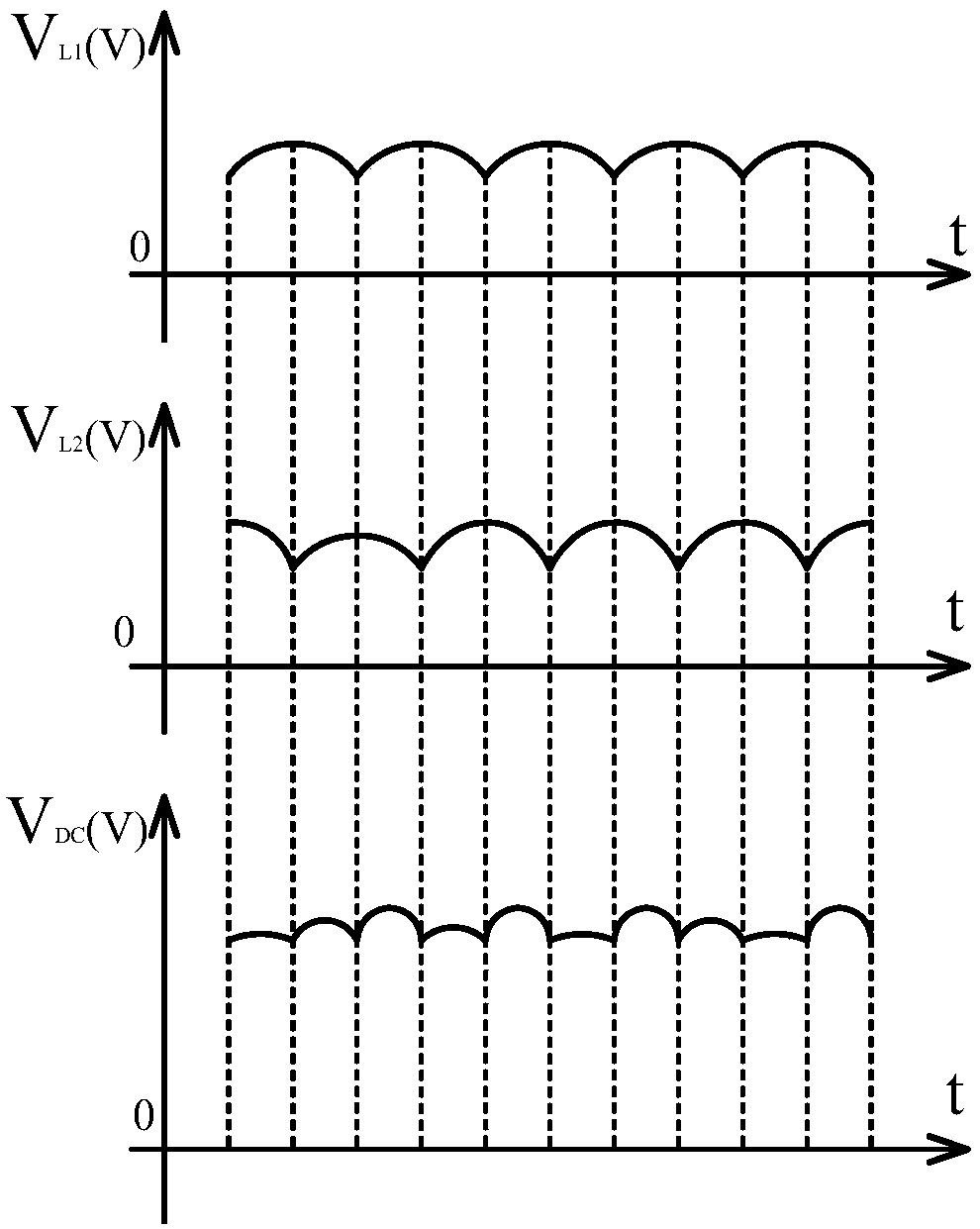

A Frequency Conversion Circuit with Interleaved Mode and Its Deviation Suppression Method

ActiveCN106787795BLow noise and vibrationUniform and smooth waveformDc-dc conversionAc-ac conversionHarmonicFrequency conversion

A frequency conversion circuit with an interleaving mode and a method for suppressing deviation thereof, by changing the bus voltage V DC After comparing the Fourier calculation value with the standard value, the conduction time of the IGBT tube is adjusted, which effectively reduces the bus voltage ripple caused by the inductance difference of the reactor, so that the bus voltage V DC The waveform of the compressor is uniform and smooth, which ensures the stability of the voltage input to the compressor, thereby reducing the noise and vibration of the compressor, and effectively improving the compressor noise, vibration and harmonic current problems.

Owner:SHANGHAI MITSUBISHI ELECTRIC&SHANGLING AIR CONDITIONER & ELECTRIC APPLIANCE CO LTD

Rotary engine

InactiveCN100540864CRaise the combustion temperatureImprove efficiencyLiquid coolingInternal combustion piston enginesCombustion chamberRotary engine

The invention discloses a rotary engine which consists of a turbine, more than one slide blocks and knightheads. Several non-reverse triangular bag-type recesses as pistons that can improve unit energy are arranged emitting helically on circumferential surface or both sides of said turbine. The slide block is formed crescent-shape for matching with said turbine. The angle formed between curved slide and reverse direction of turbine can be changed by means of regulating knightheads, so as to save space and improve friction force between the curved slide and the turbine. Airflow producing in firebox and cooling chamber can be collected by a drive chamber arranged on the end of the slide block and can be used for pushing pistons to turn the turbine.

Owner:周荣光

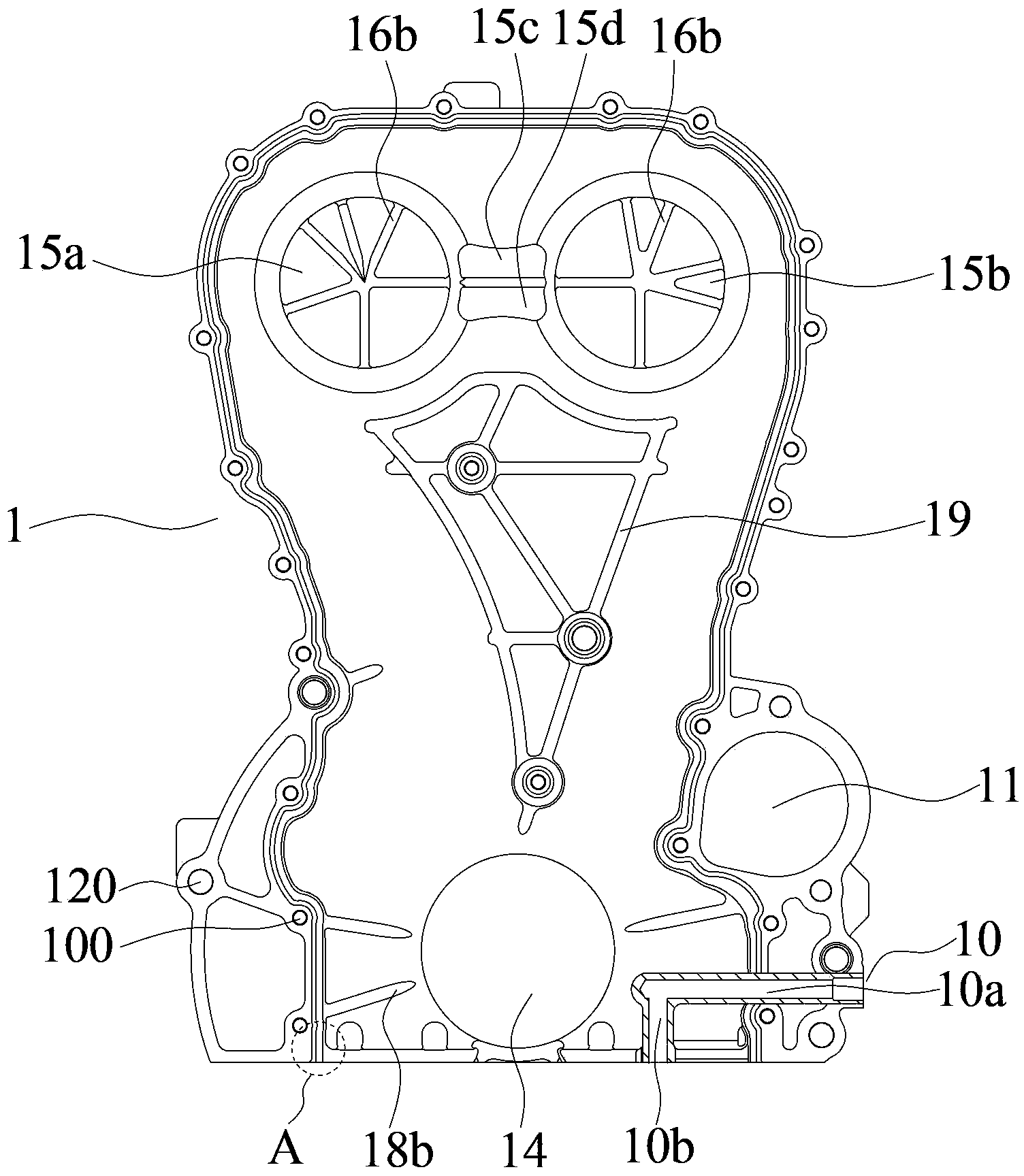

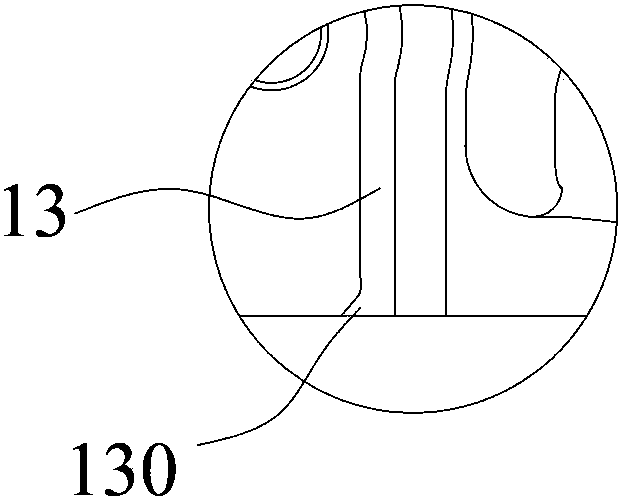

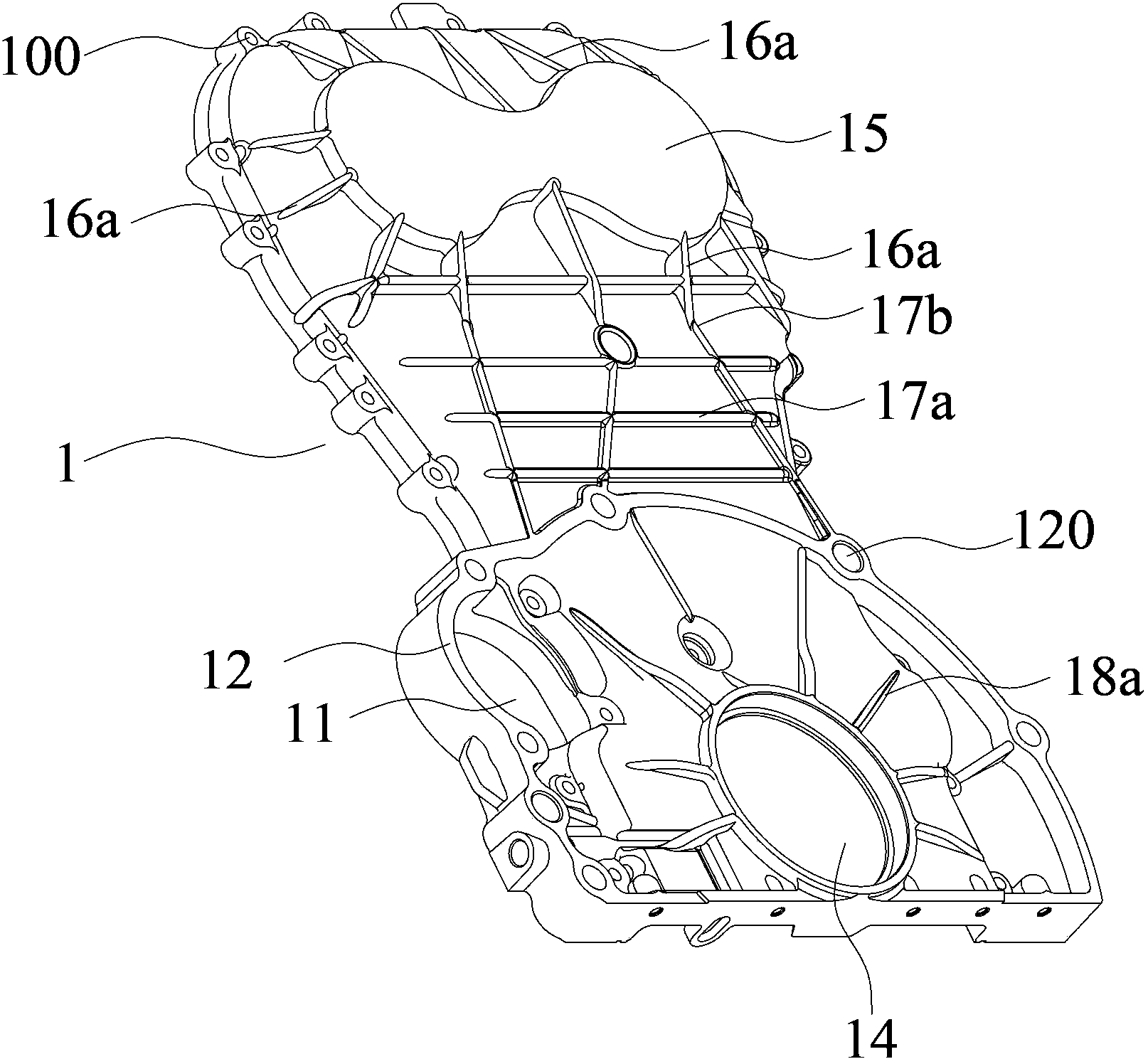

Timing cover lid of engine

ActiveCN102733990BImprove compactnessIncrease stiffnessCasingsValve arrangementsPetroleum engineering

The invention discloses a timing cover lid of an engine, and relates to the technical field of engines. The purposes of reducing noise generated by the timing cover lid when the engine works and improving the structural compactness of the timing cover lid are achieved. The timing cover lid comprises a cover lid body, wherein an oil return hole is formed in the cover lid body; an inlet of the oil return hole is connected with an oil outlet opening of an oil and gas separator of the engine; and an outlet of the oil return hole is connected with an oil inlet of an oil return box of the engine. The timing cover lid is mainly applicable to engines of vehicles.

Owner:GREAT WALL MOTOR CO LTD

Asynchronous igniter for sparking plug of engine

ActiveCN100458140CImprove powerImprove economyElectric ignition installationMachines/enginesHigh pressureLow frequency

The invention relates to a motor spark plug asynchronous igniter, which is formed by a magnetic motor rotor, a flywheel boss, an electromagnetic sensor, an electric igniter, a high-pressure boss and a spark plug. Wherein, the electric igniter receives the signal of electromagnetic sensor and sends ignition signal to the high-pressure boss to control the ignition of spark plug. The invention is characterized in that: there are morn than one high-pressure bosses, which are connected to the different outputs of electric igniter; the input of electric igniter is connected to the electromagnetic sensor to judge the speed of magnetic motor and set the ignition time sequence to send the low-frequency ignition signal or high-frequency ignition signal to several high-pressure bosses to control several spark plugs ignite synchronously or asynchronously. The invention has better anti-disturb ability and reliability.

Owner:CHONGQING ZONGSHEN ENGINE MFG

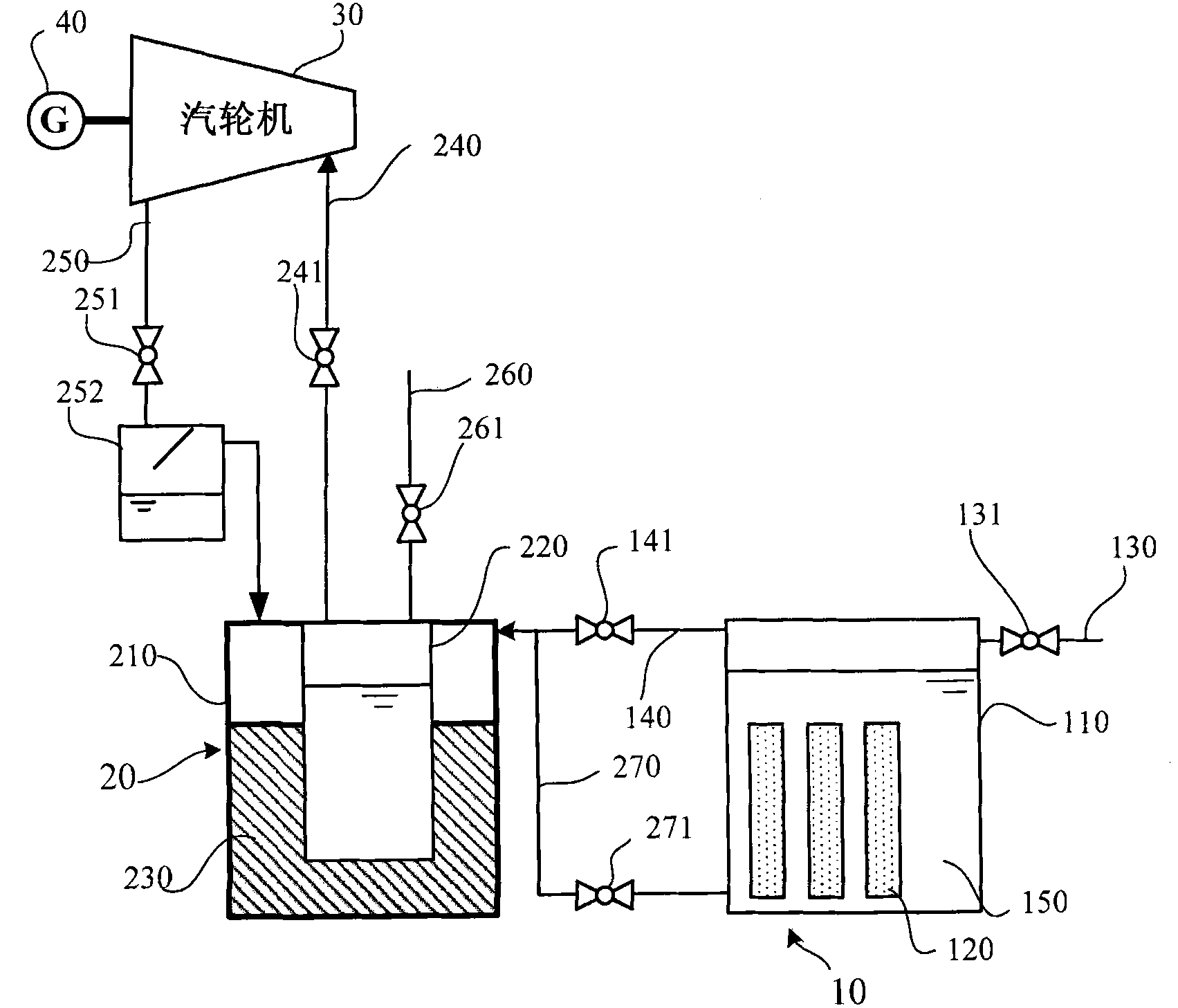

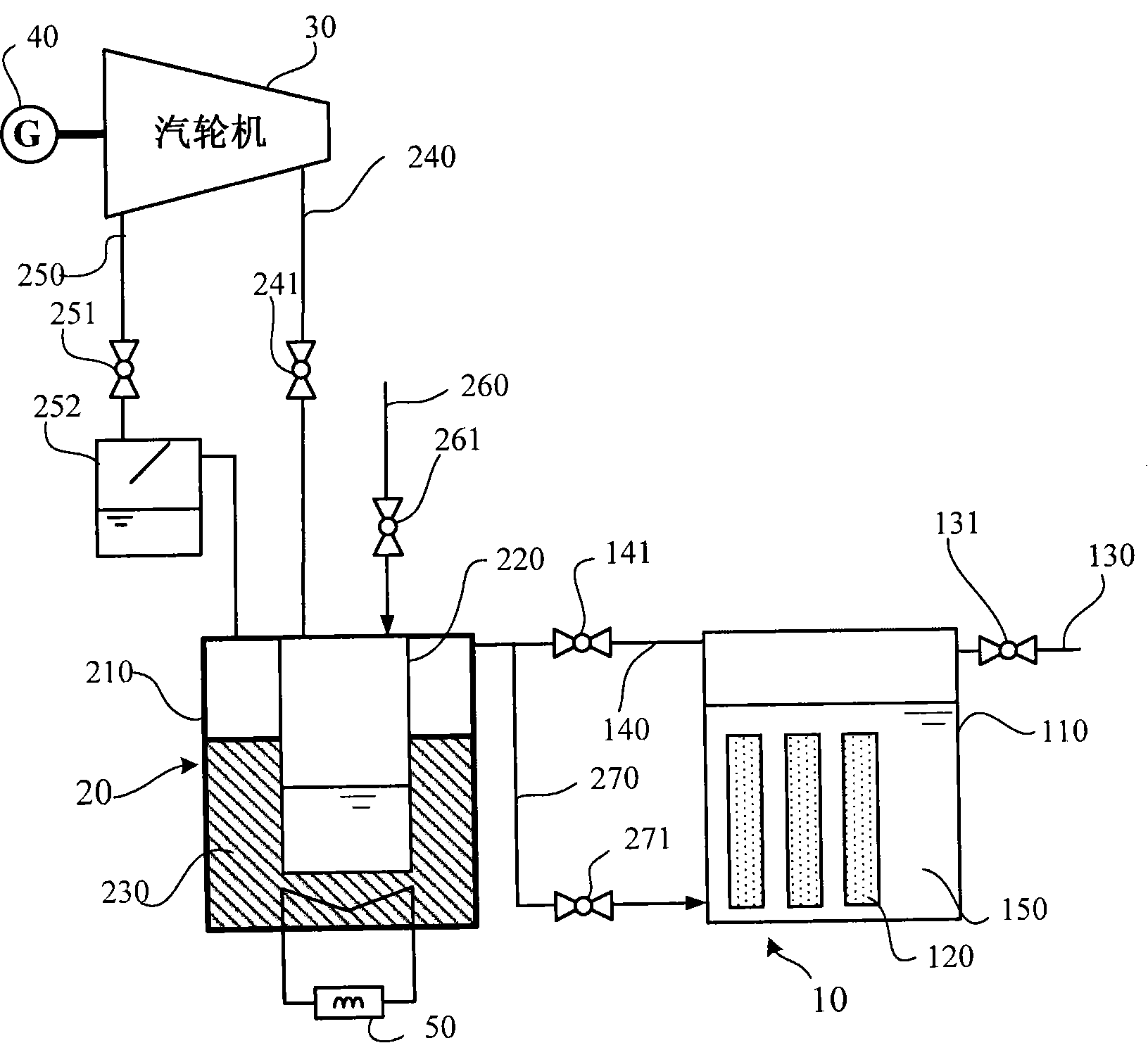

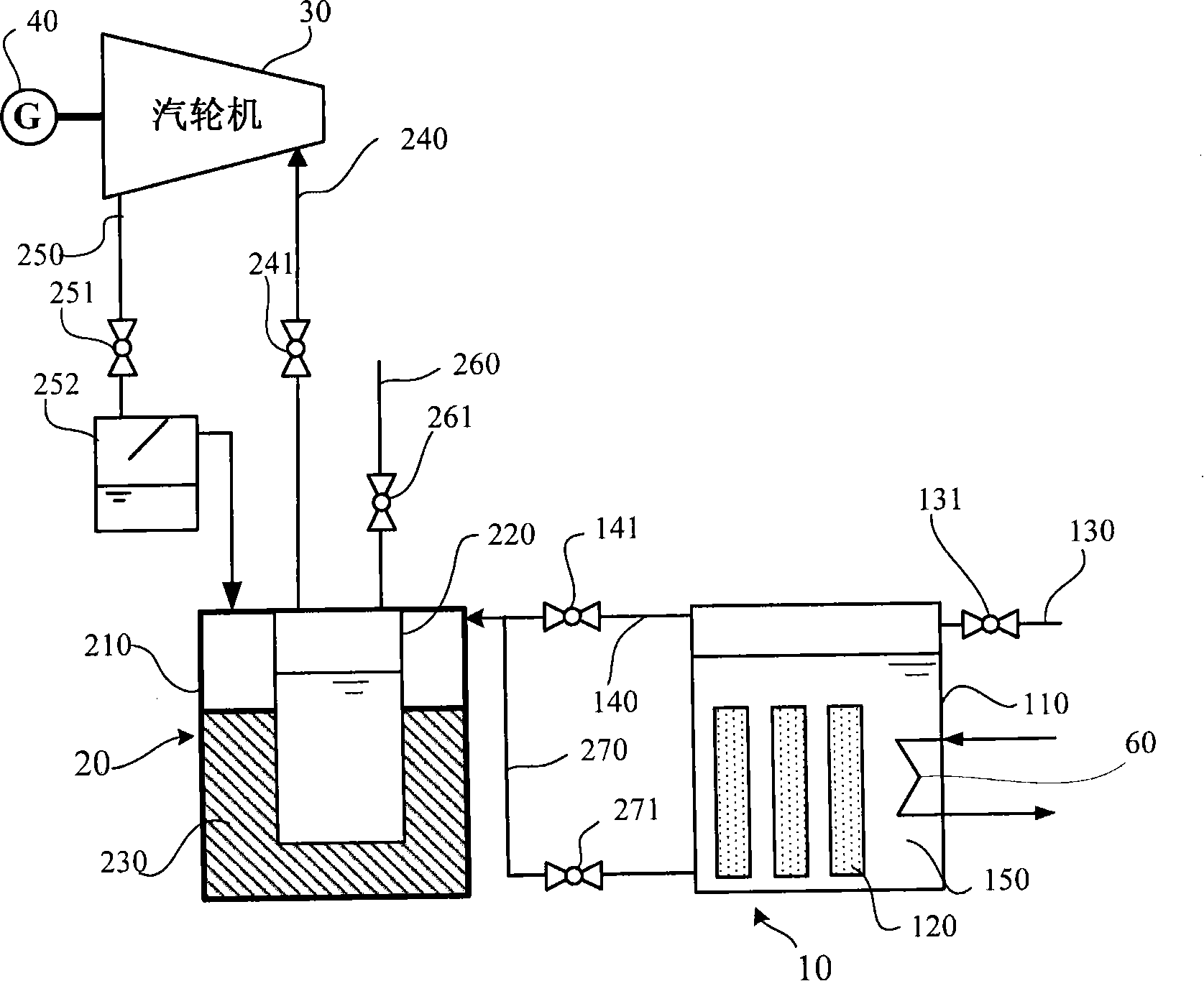

Standby power system and power supply method thereof

InactiveCN101552488BNo noise vibrationLow noise and vibrationSteam engine plantsEmergency power supply arrangementsStandby powerProcess engineering

The invention relates to a standby power system and a power supply method thereof. The standby power system comprises energy storage equipment, a steam cycle installation, a steam turbine and a generator, wherein the energy storage equipment comprises an energy storage shell and at least one heat accumulator arranged in the energy storage shell; the steam cycle installation comprises a steam cycleshell which is filled with absorbent solution and connected to the exhaust steam end of the steam turbine, and a steam generator which is arranged in the steam cycle shell and connected to the upstream end of the steam turbine; and the energy storage shell is connected to the steam cycle shell by a pipeline. The standby power system can convert heat stored by the heat accumulator into electric power and can accumulate heat to the heat accumulator by other heat sources. The power system has good cycle performance, wide application and simple and reliable using method, is safe, clean and environment-friendly, and is suitable for use.

Owner:苏庆泉

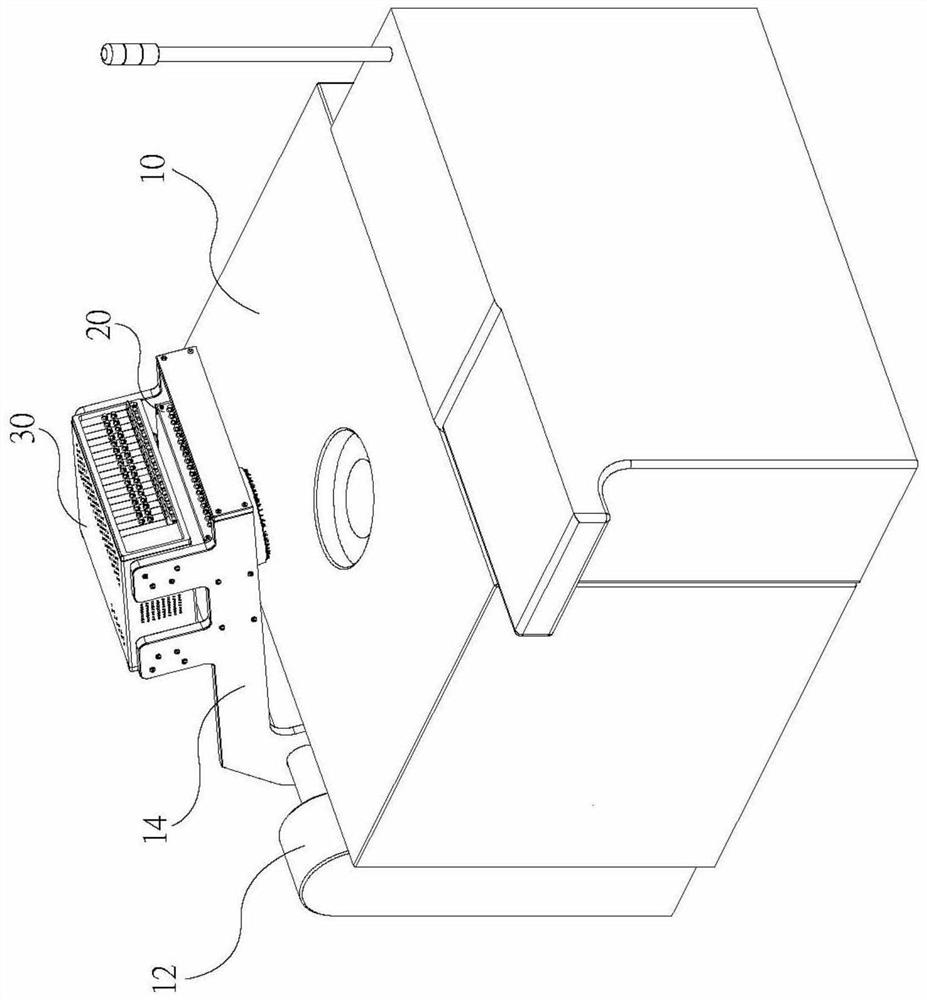

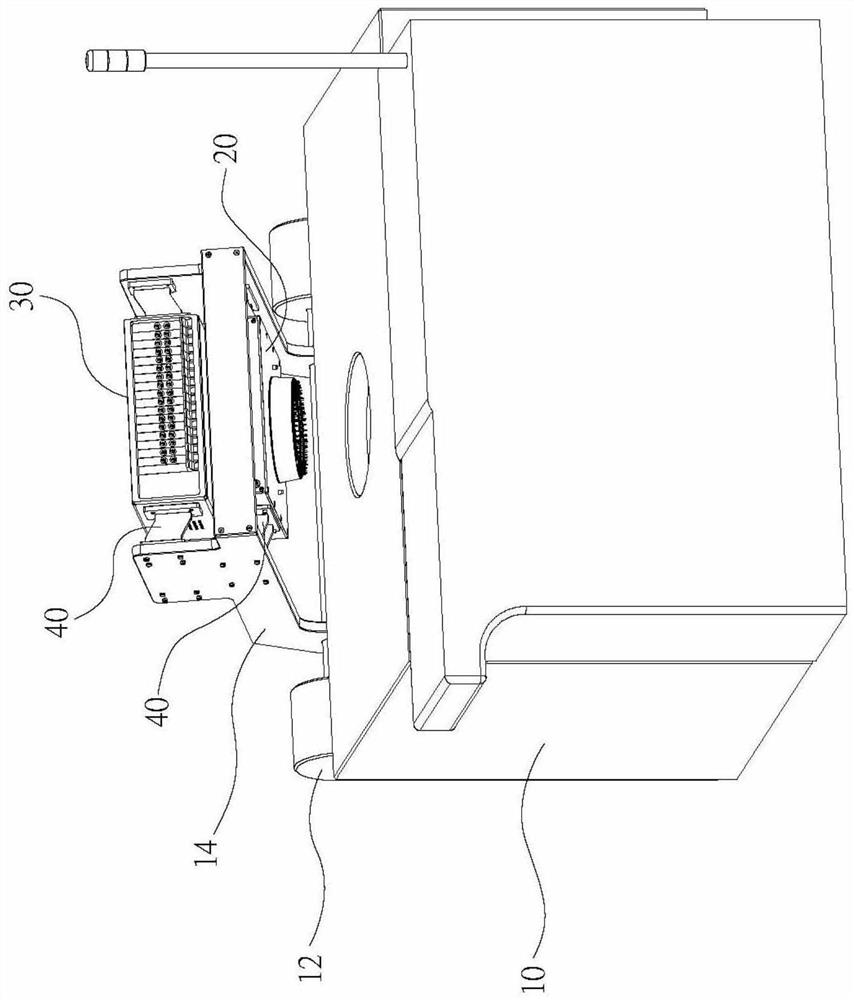

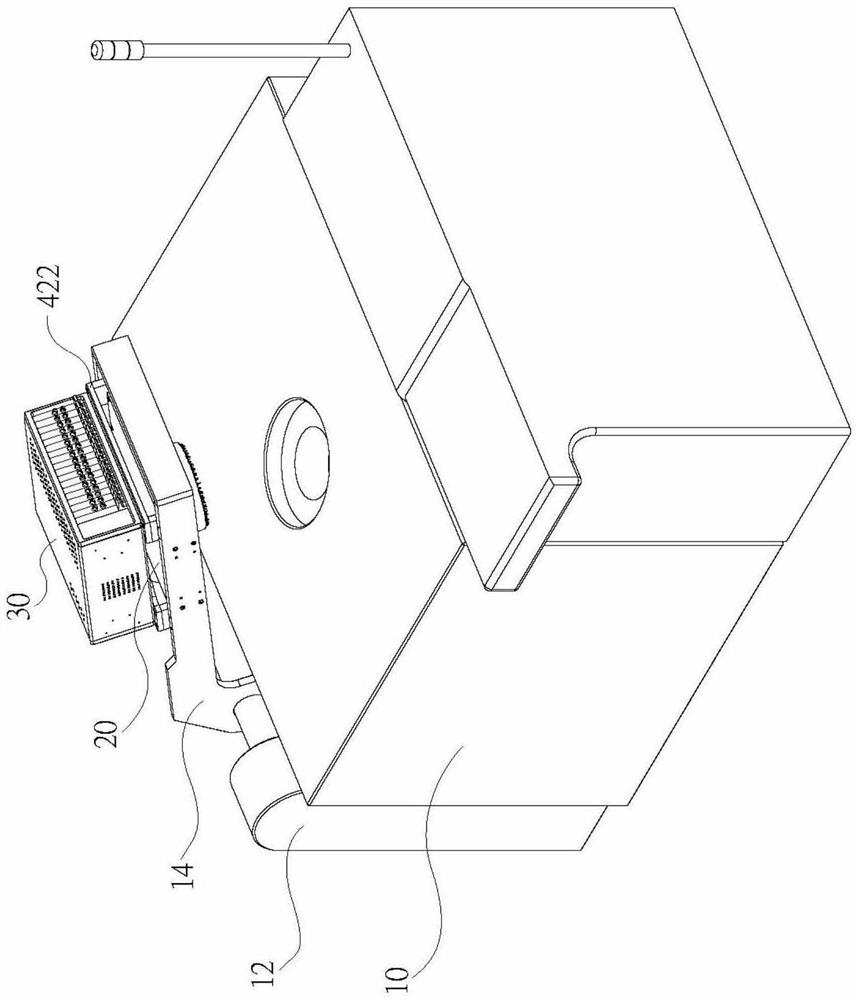

Open type test head of wafer automatic test system

PendingCN114200179ASpeed up development timeSmall footprintElectronic circuit testingElectrical measurement instrument detailsWaferSimulation

Owner:BENEWITS INT CO LTD

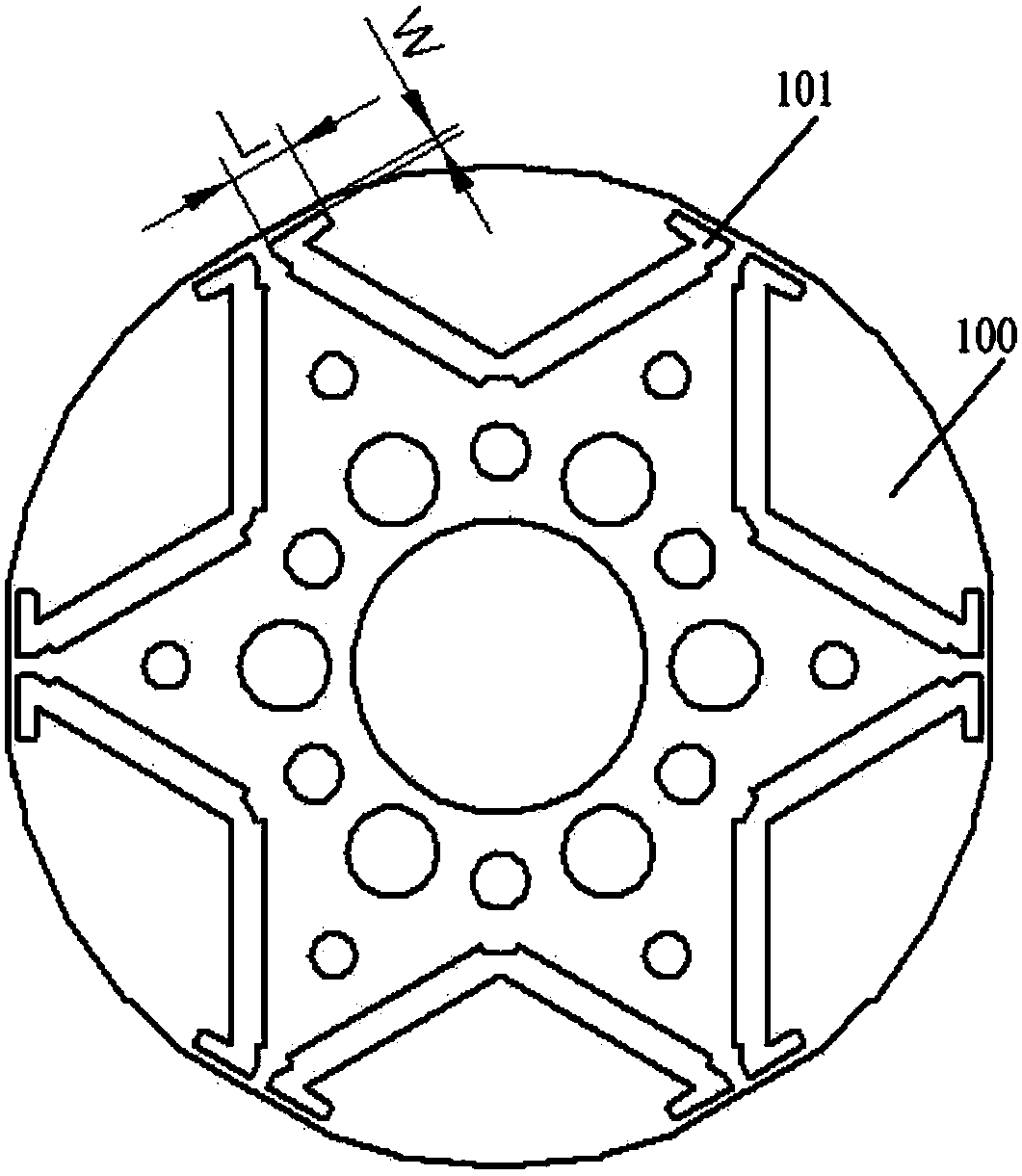

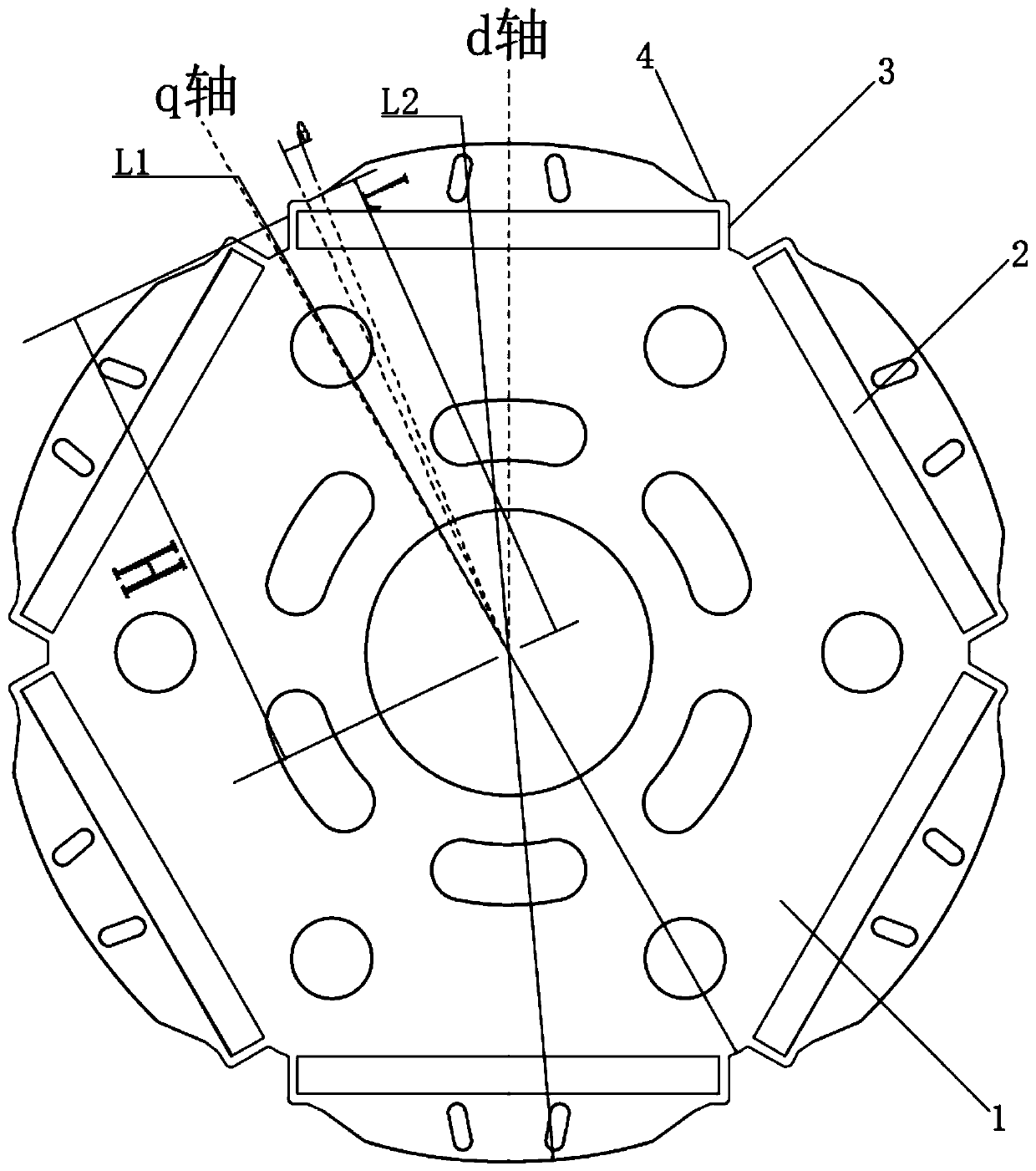

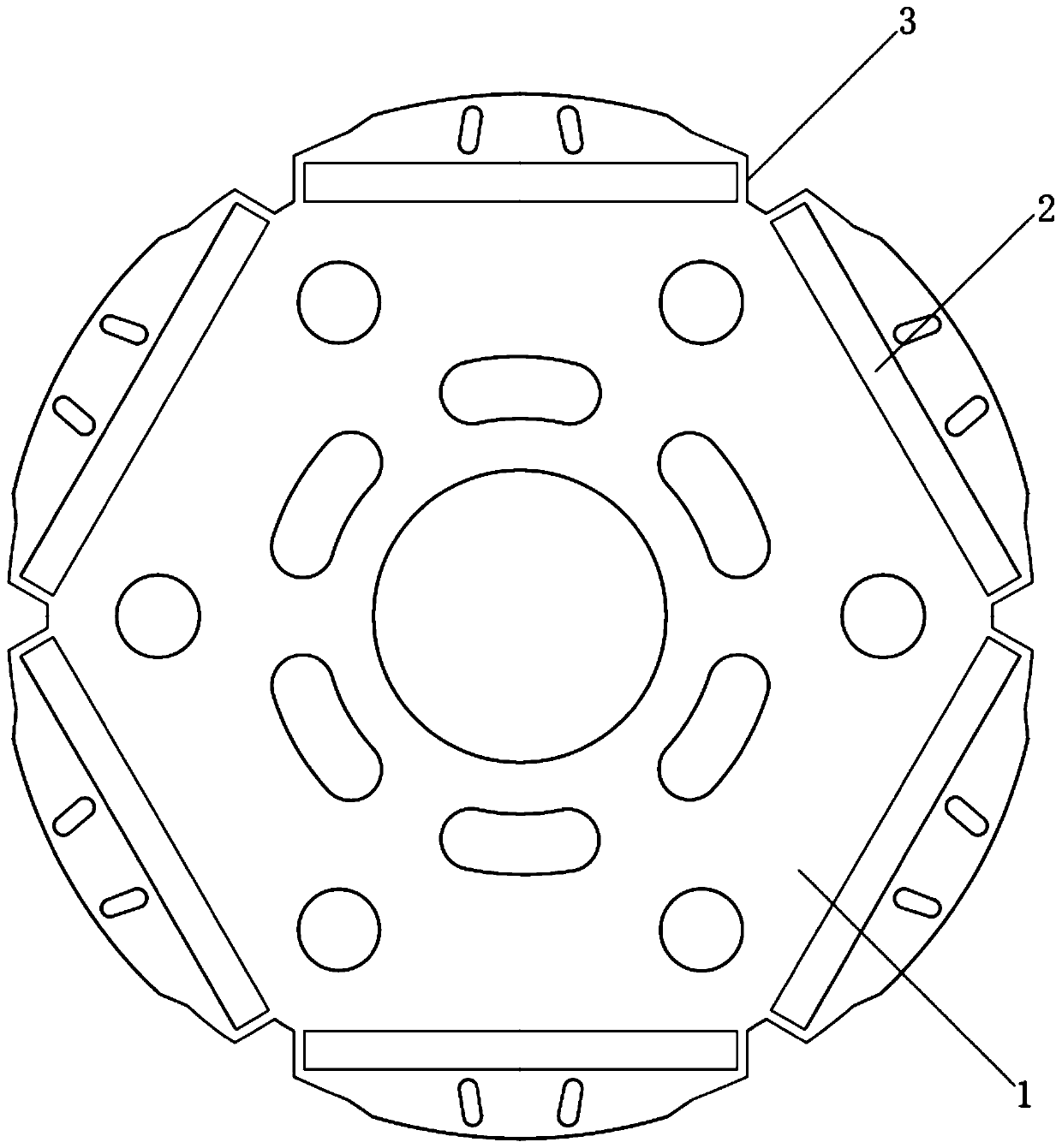

Rotor, motor and compressor

PendingCN111106690AIncreased reluctanceLow noise and vibrationMagnetic circuit rotating partsSupports/enclosures/casingsElectric machineryEngineering

The invention discloses a rotor, a motor and a compressor. The rotor comprises a rotor iron core. The edge of the rotor iron core is provided with a magnetic steel groove for inserting magnetic steel.The cylindrical surface of the rotor iron core is provided with a plurality of arc surfaces which are concentrically arranged, and the arc surfaces comprise a first arc surface intersected with a q axis and a second arc surface intersected with a d axis. The radius L1 of the first arc surface, the radius L2 of the second arc surface and the maximum distance H between the magnetic steel groove andthe circle center of the rotor iron core satisfy L2 > H > L1, so that the rotor iron core forms first magnetic isolation bridges at the two ends of the magnetic steel groove along the length direction respectively. According to the rotor provided by the invention, the noise vibration of the motor is effectively reduced, and the performance of the motor is improved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com