Asynchronous igniter for sparking plug of engine

A spark plug and igniter technology, applied in automatic control, automatic control, electrical automatic control and other directions, can solve problems such as affecting the ignition order of spark plugs, mutual interference of electromagnetic signals, etc., to improve anti-interference ability and reliability, ensure stable performance, The effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

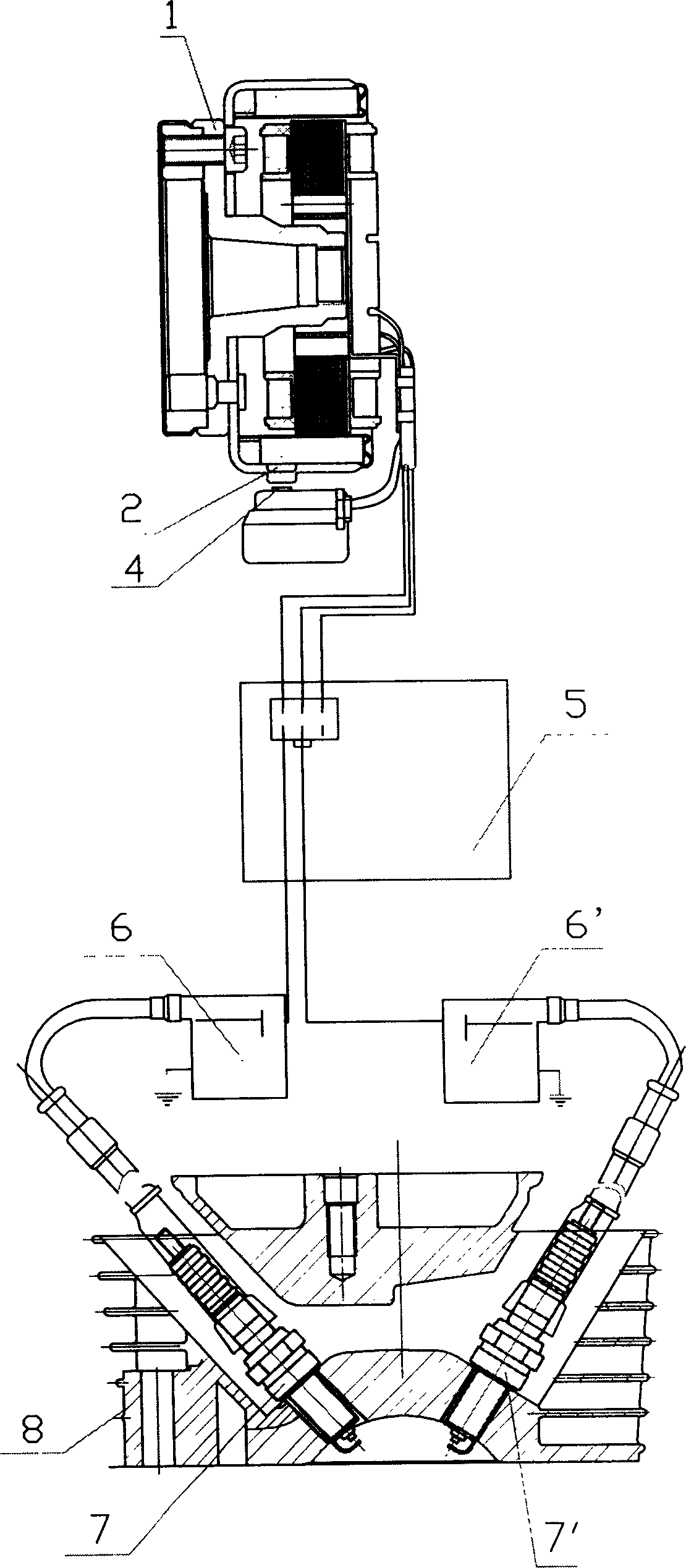

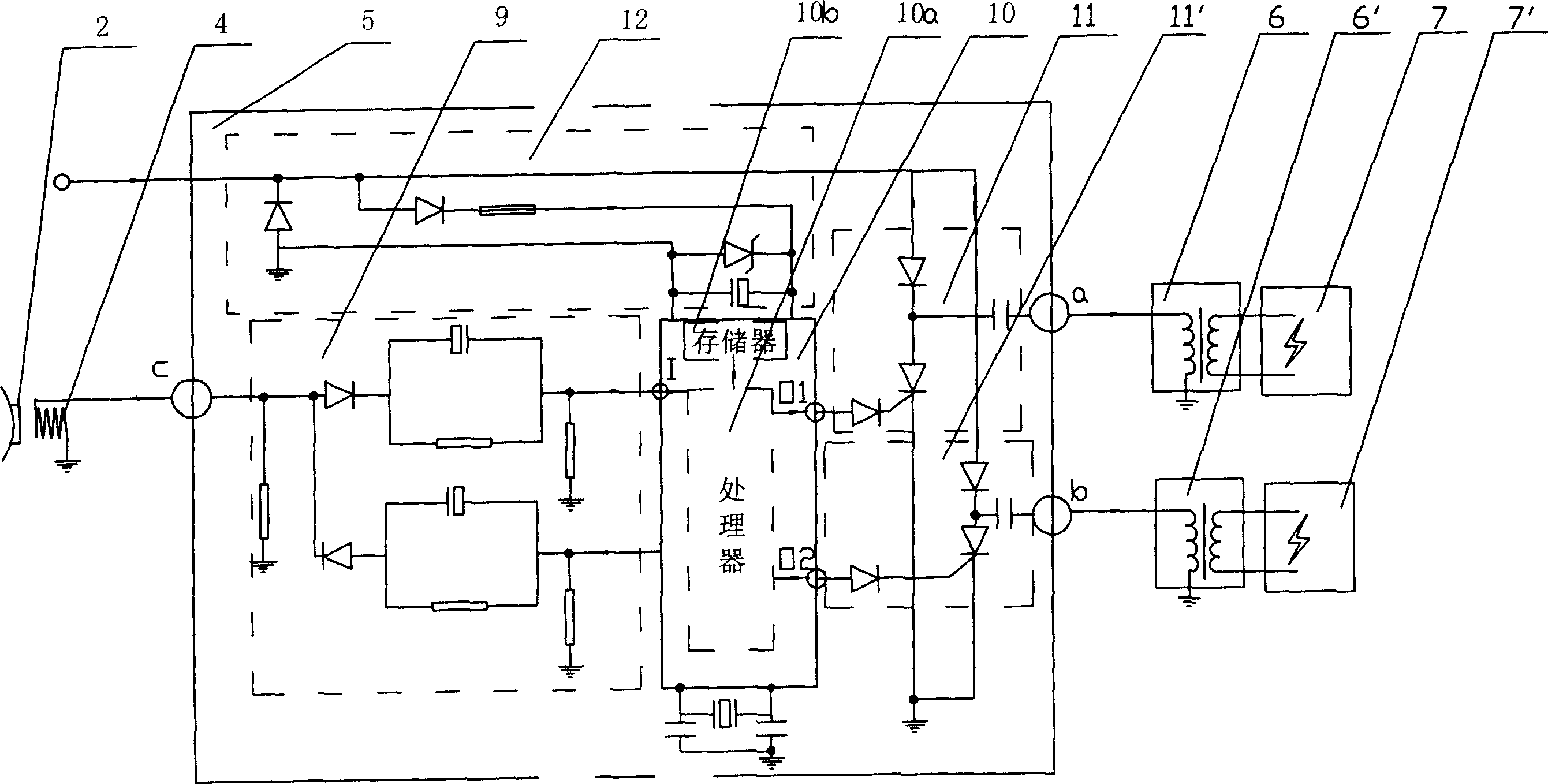

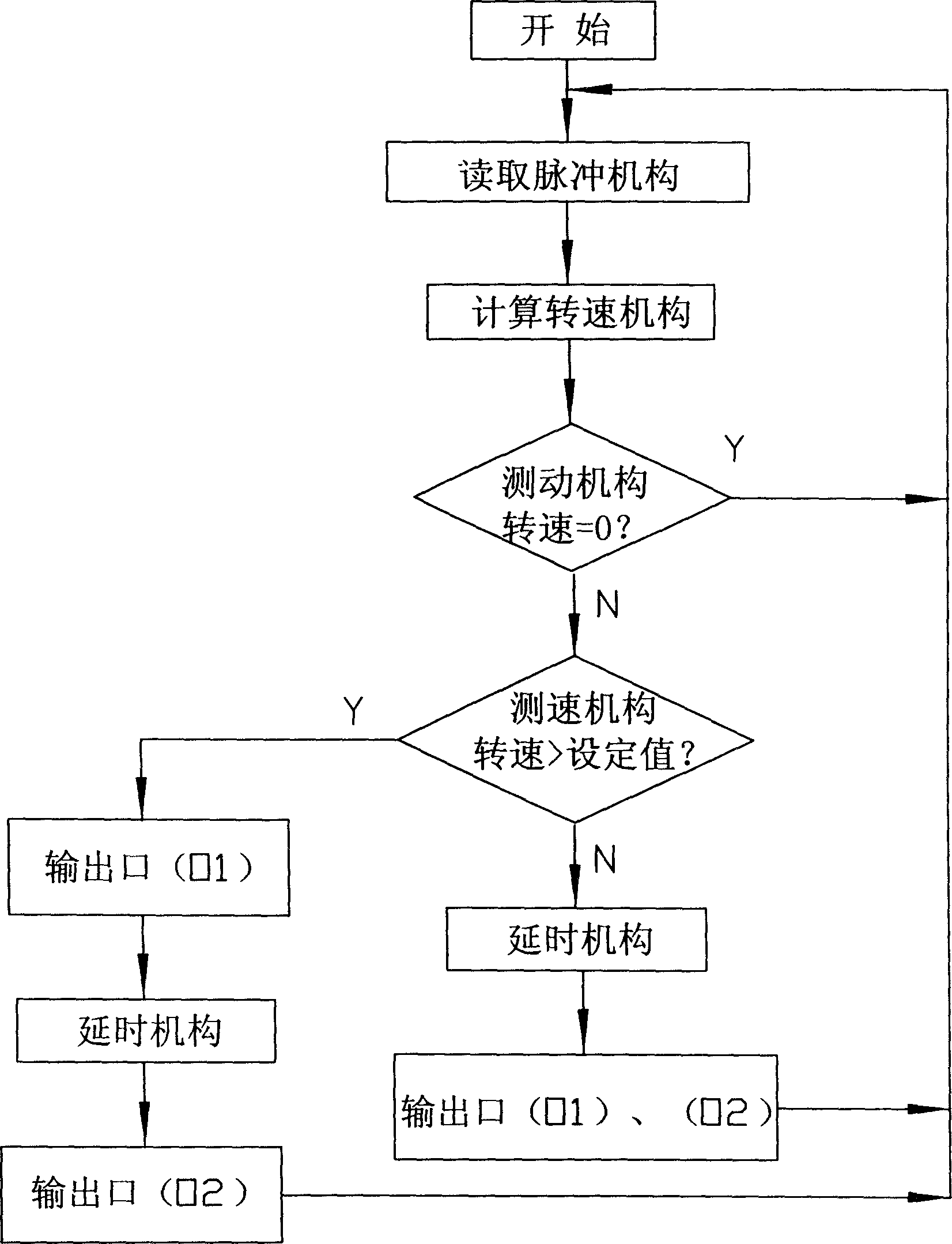

[0035] like figure 1 , image 3 Shown: an engine spark plug asynchronous igniter, which consists of a magneto rotor 1, a flywheel convex hull 2, an electromagnetic sensor 4, an electronic igniter 5, a main high voltage package 6, a secondary high voltage package 6', a main spark plug 7, and a secondary spark plug 7' , Cylinder head 8 composition. Among them: the flywheel convex 2 arranged on the outer wall of the magneto rotor 1 and the electromagnetic sensor 4 fixed on the inner wall of the left front cover, the electromagnetic sensor 4 corresponds to the position of the flywheel convex 2, and the electromagnetic sensor 4 passes through the electronic igniter 5 It is connected with the high-voltage package, and the high-voltage package is connected with the input end of the spark plug, and the spark plug is installed on the cylinder head 8; Composition, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com