Patents

Literature

76results about How to "Prevent misfire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

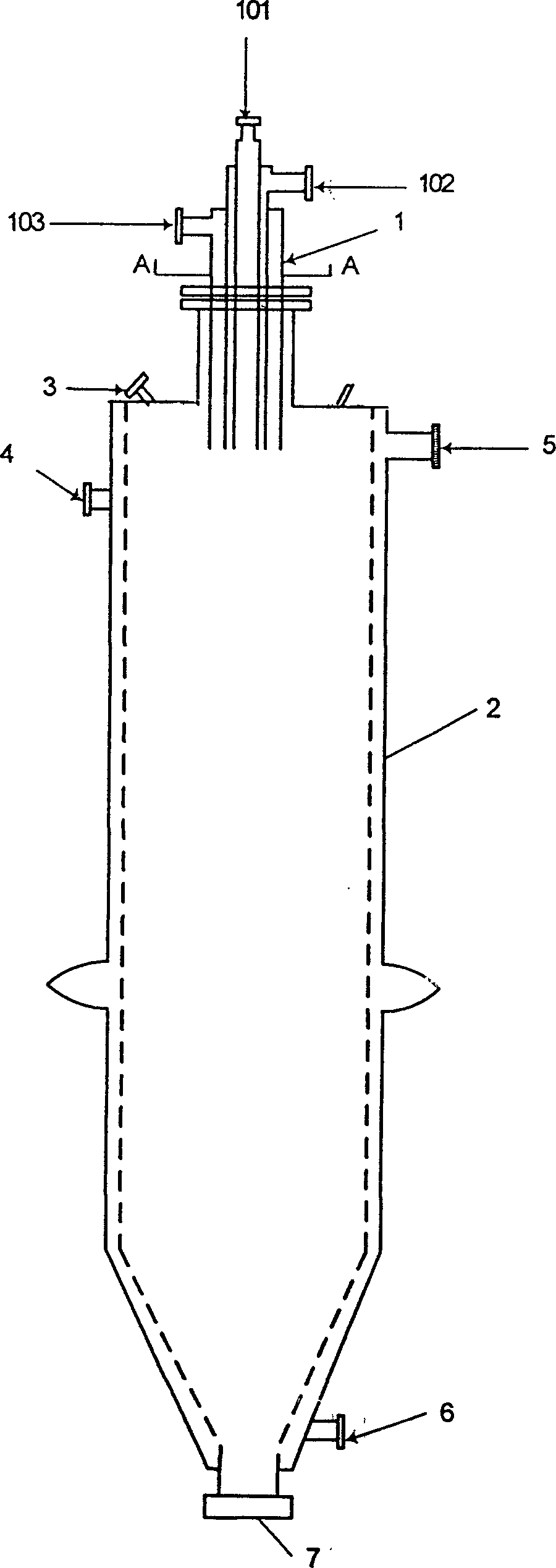

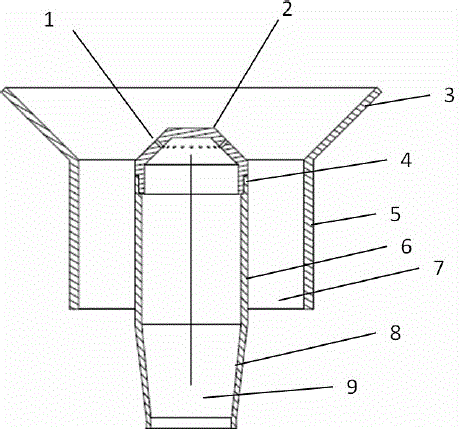

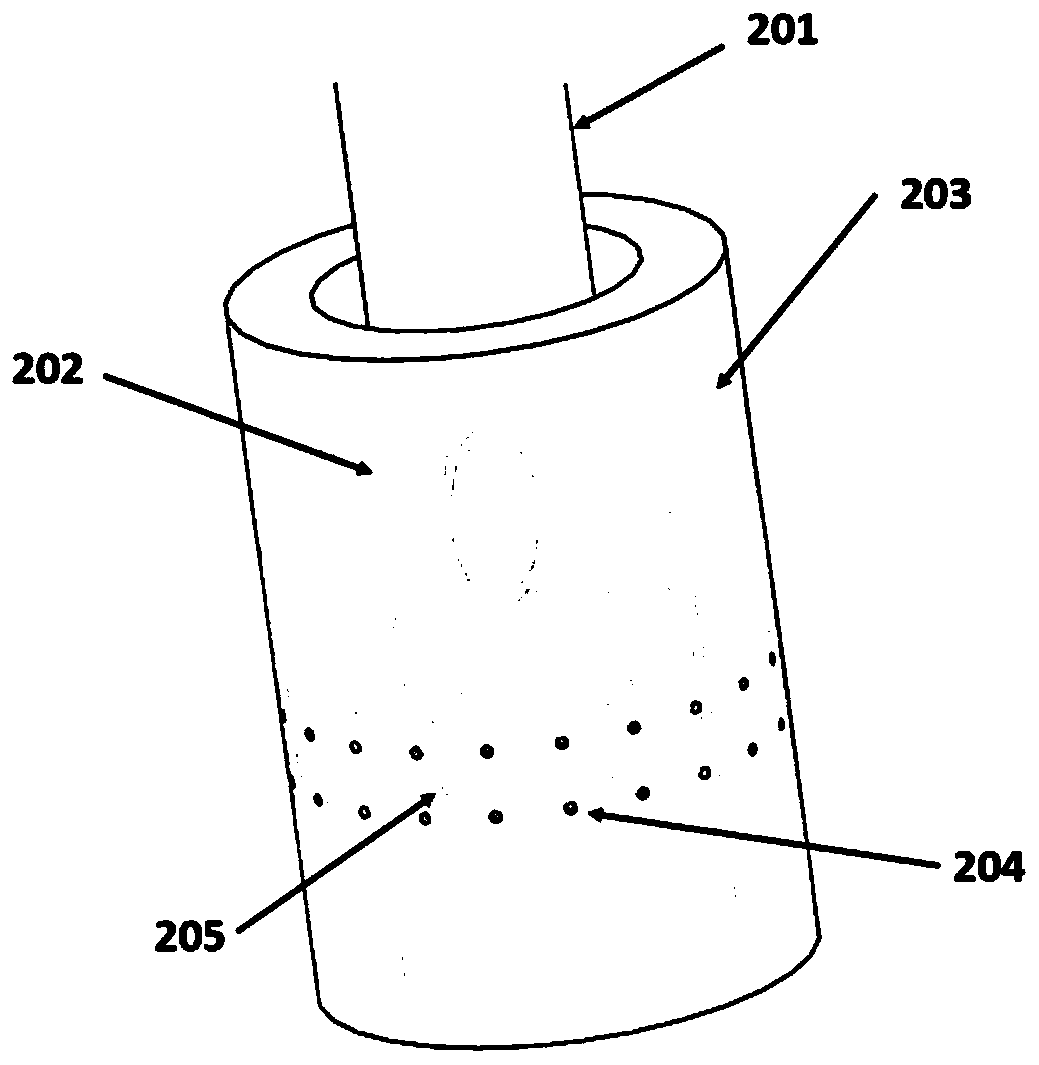

Auxiliarily burning reactor and its application in vapor process of preparing nano SiO2

The auxiliarily combustion reactor of the present invention has improved nozzle structure, and the vapor process of preparing nano SiO2 is superior to available process, which has non-homogeneous temperature field and concentration field in combustion reactor, uneven retention time of material in the combustion reaction area, and easy scaling in the nozzle outlet and other demerits. The present invention has raised nano SiO2 product quality.

Owner:EAST CHINA UNIV OF SCI & TECH +1

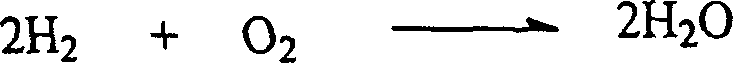

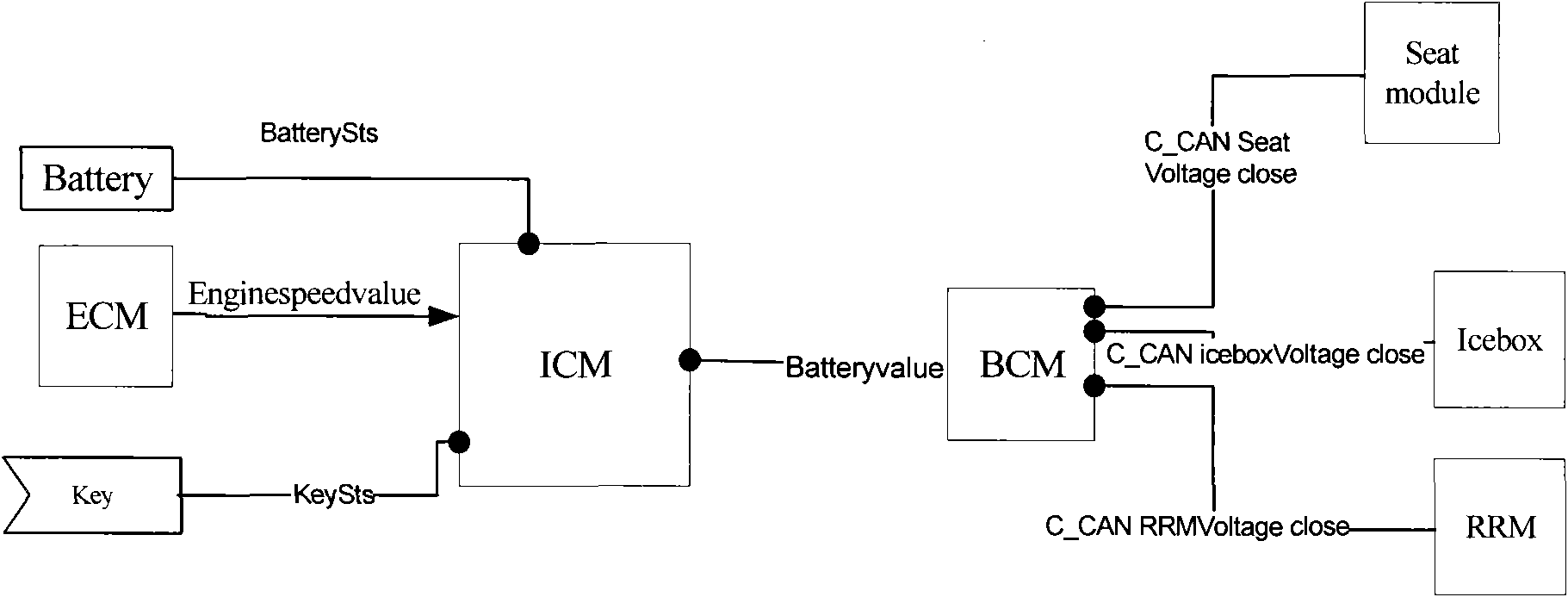

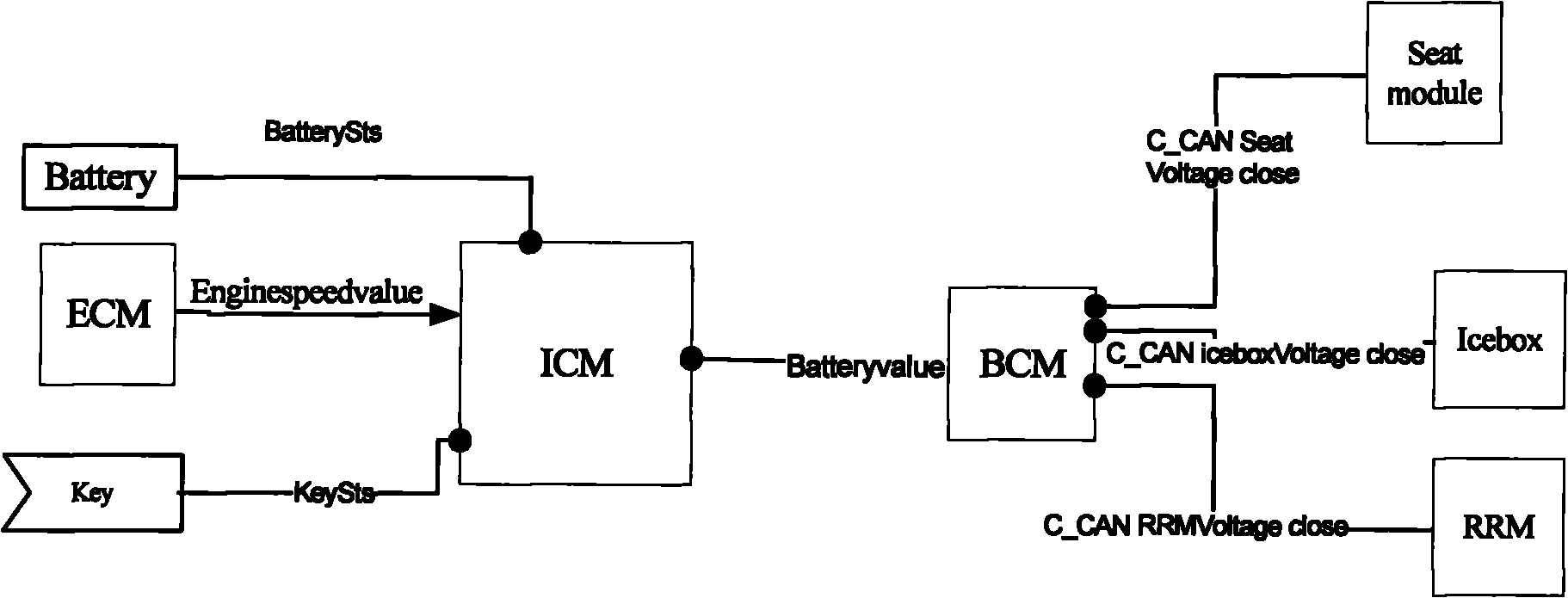

System and method for managing automobile power

ActiveCN101863254AImprove satisfactionEasy to operateElectric/fluid circuitControl signalEngineering

The invention relates to a system and a method for managing automobile power. The system comprises a combination instrument, an alarm device and a body control module BCM, wherein the combination instrument is provided with a voltage division circuit for detecting the voltage of a storage battery of the vehicle; and the combination instrument is connected to the alarm device and controls the alarm device, and is connected with the body control module BCM and can transmit a control signal to the body control module.

Owner:CHERY AUTOMOBILE CO LTD

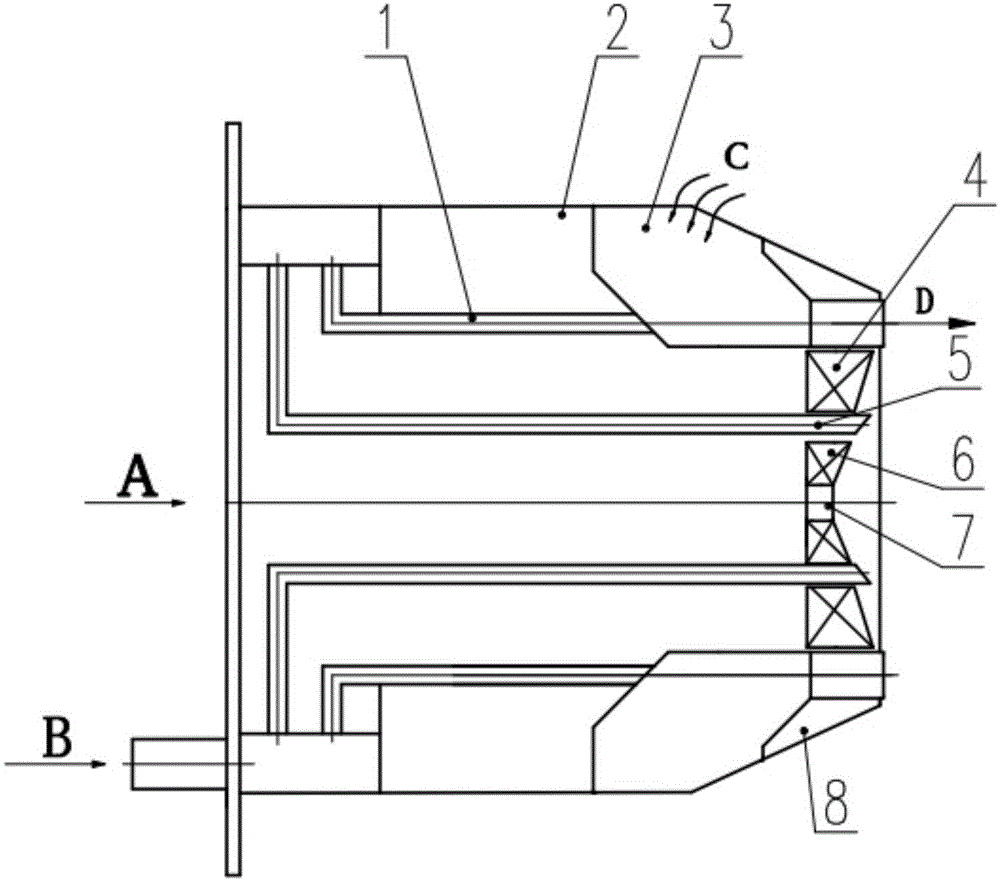

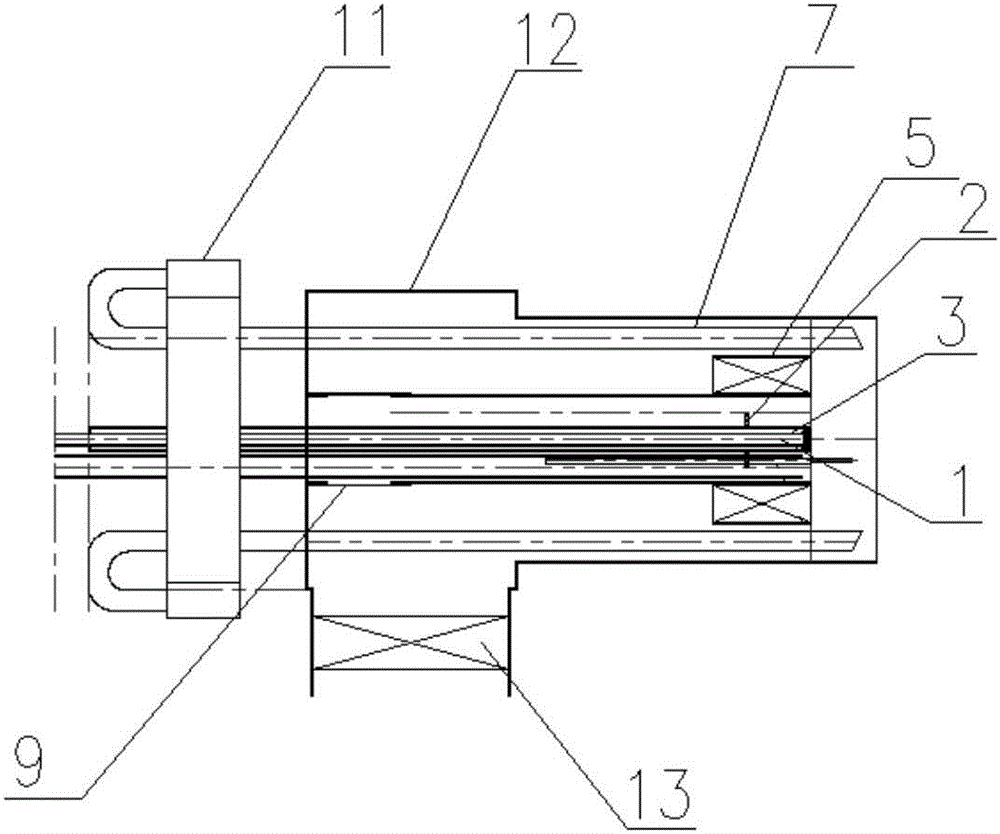

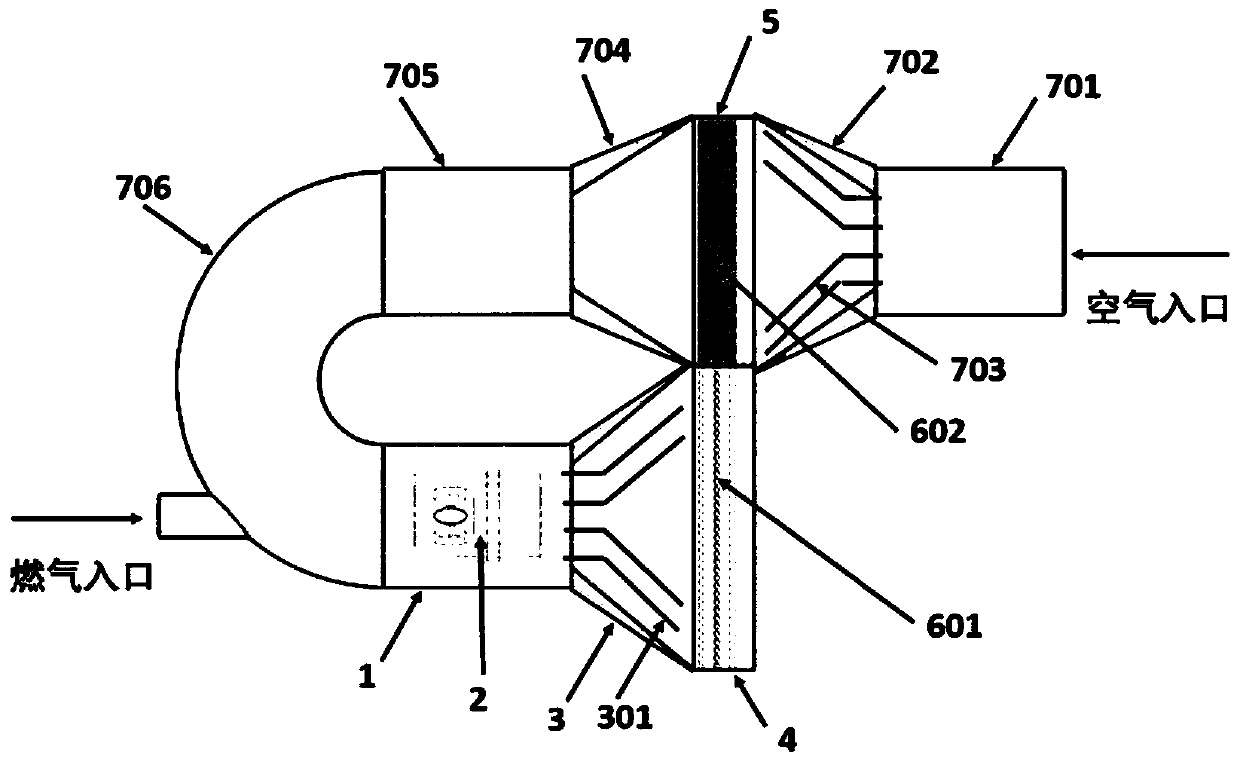

Classified-combustion fuel gas low-nitrogen combustor

ActiveCN105805746AReduce concentrationEmission reductionNon-combustible gases/liquids supplyGaseous fuel burnerCycloneCombustor

The invention discloses a classified-combustion fuel gas low-nitrogen combustor. The classified-combustion fuel gas low-nitrogen combustor comprises first-level fuel spray guns, second-level fuel spray guns, smoke inner circulation injection pipes, a combustion-supporting air channel, a center straight flow air channel, a first-time cyclone air channel, a second-time cyclone air channel and a necking-down type spray port. The center straight flow air channel is arranged in the center of the necking-down type spray port. The first-time cyclone air channel and the second-time cyclone air channel are sequentially arranged on the outer side of the center straight flow air channel. The first-level fuel spray guns are circumferentially and evenly distributed between the first-time cyclone air channel and the second-time cyclone air channel. The smoke inner circulation injection pipes are located on the outermost side in the necking-down type spray port of the combustor, the second-level fuel spray guns stretch into the smoke inner circulation injection pipes, and the smoke inner circulation injection pipes and the second-level fuel spray guns are all evenly distributed on the same reference circle. According to the classified-combustion fuel gas low-nitrogen combustor, the means of fuel classification, air classification, smoke inner circulation and the like are combined, the temperature of a flame high-temperature area is reduced, the mixing time of fuel and air is prolonged, and generation of NOx is effectively restrained.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

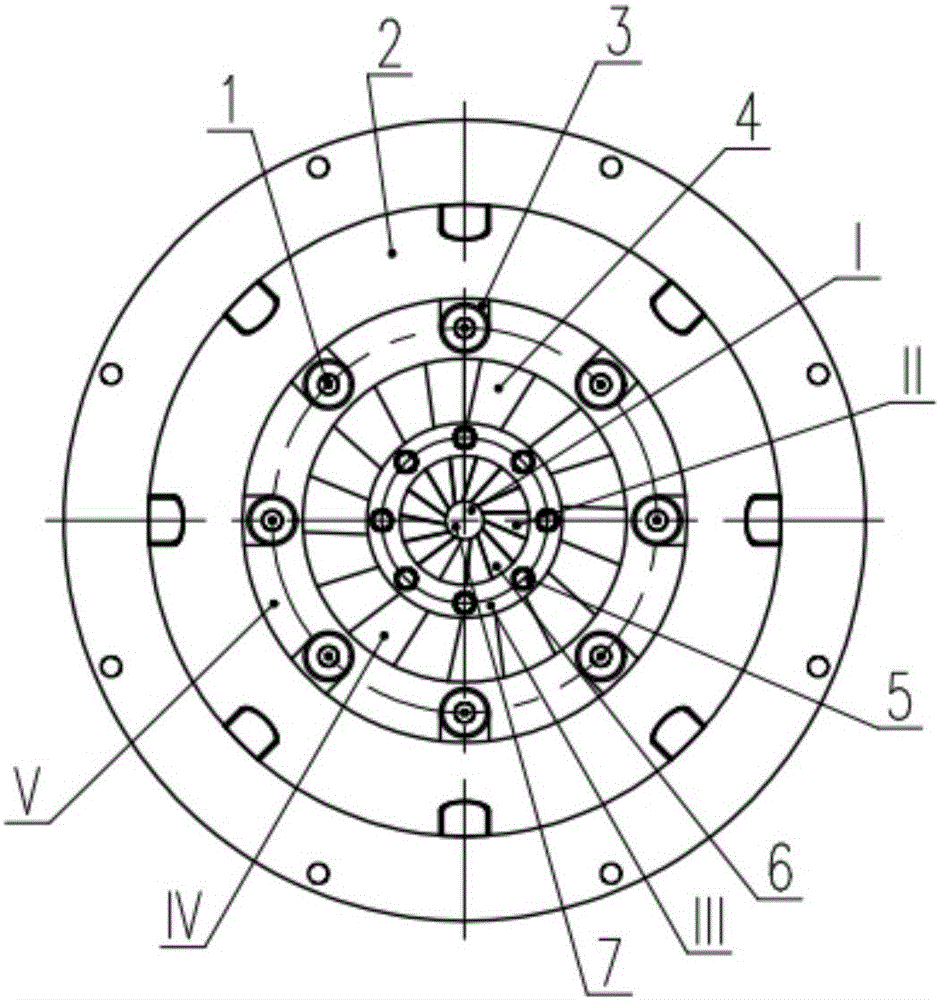

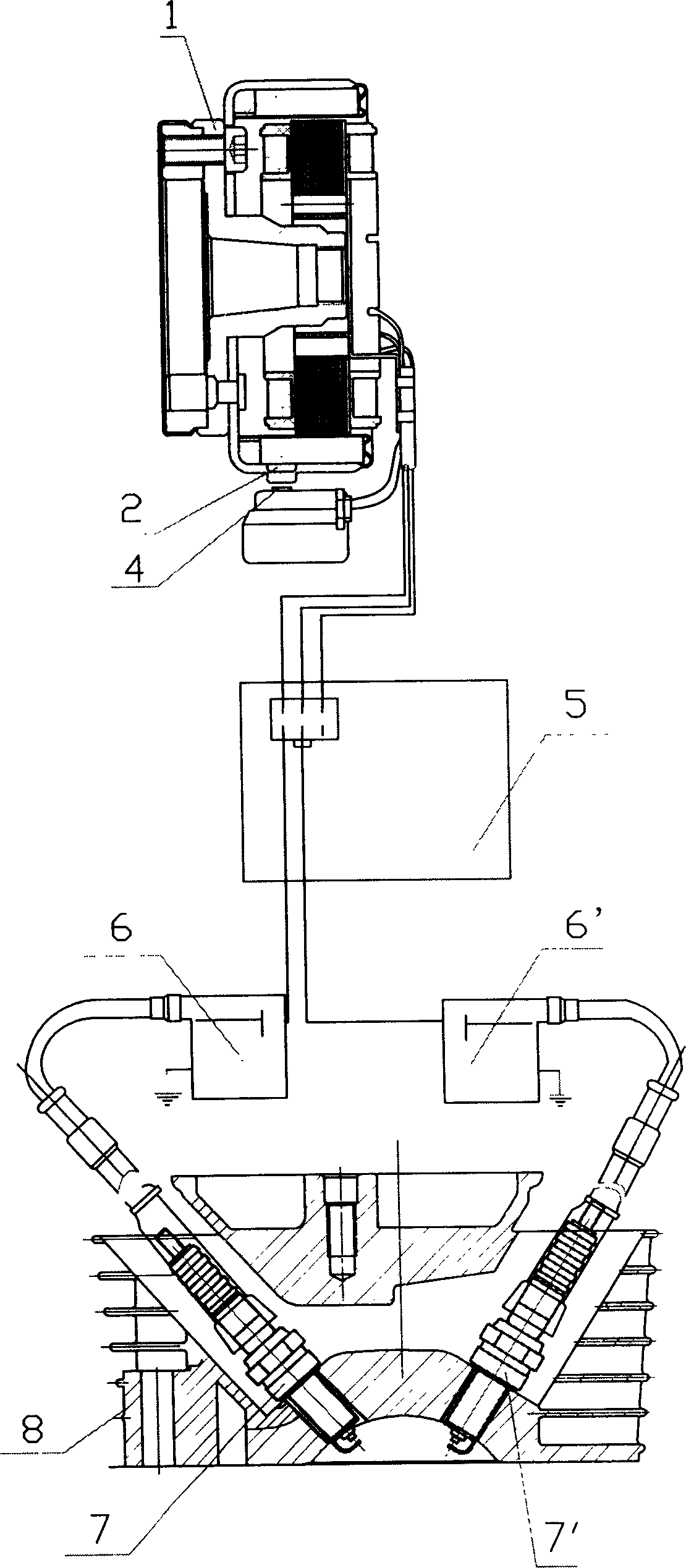

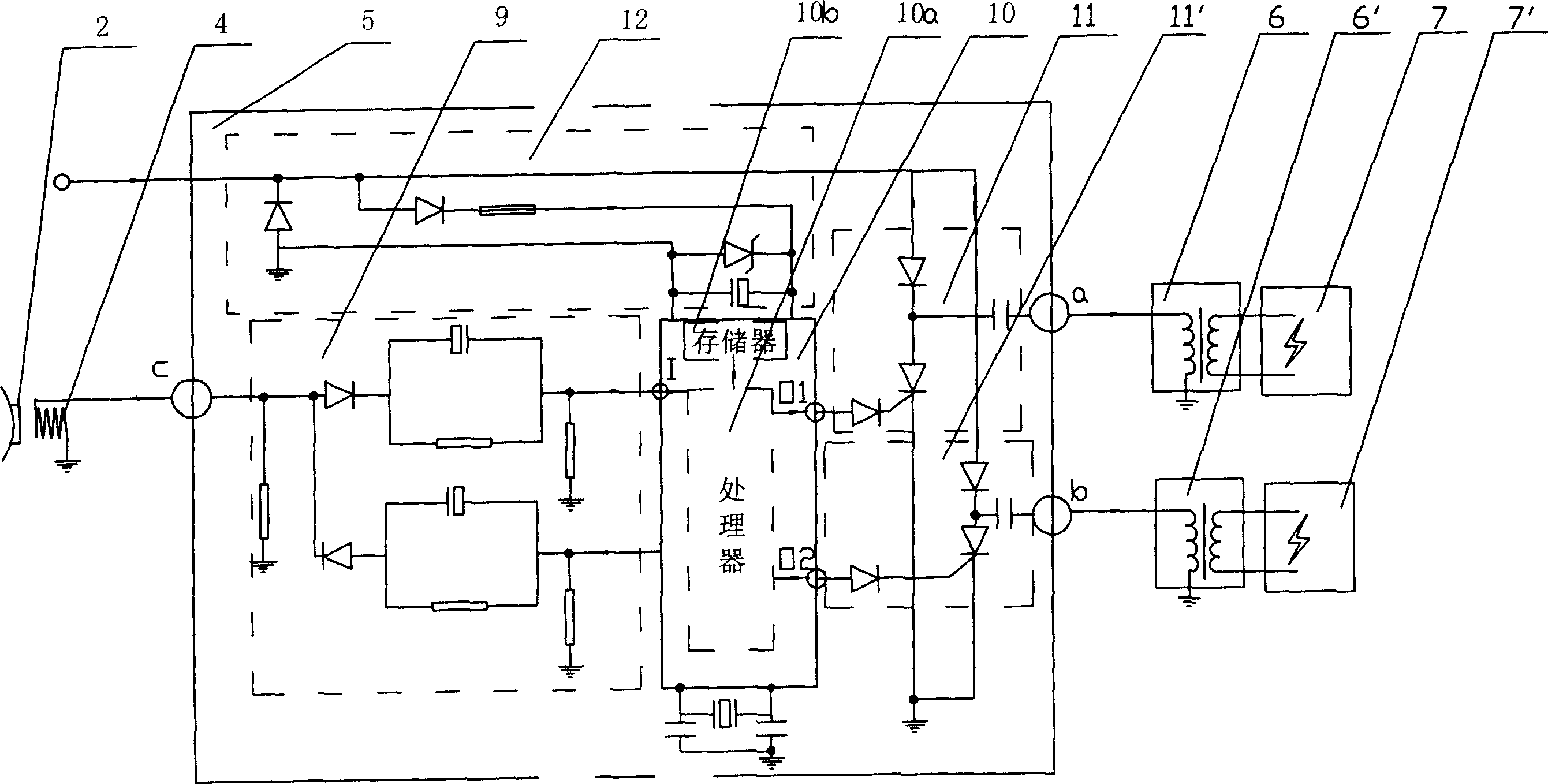

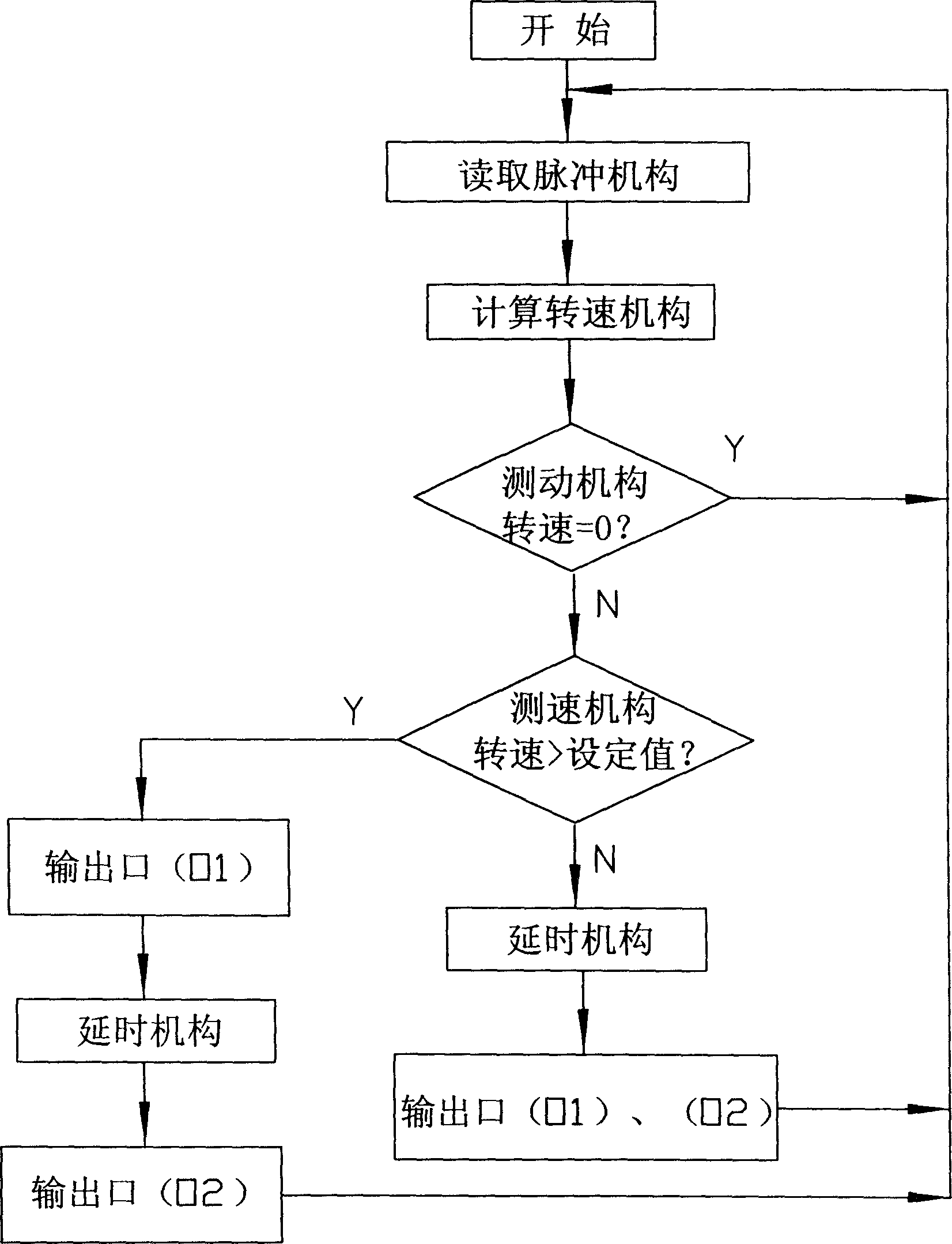

Asynchronous igniter for sparking plug of engine

ActiveCN1837601AGuaranteed separate controlWon't interfereIgnition automatic controlAutomatic controlHigh pressureLow frequency

The invention relates to a motor spark plug asynchronous igniter, which is formed by a magnetic motor rotor, a flywheel boss, an electromagnetic sensor, an electric igniter, a high-pressure boss and a spark plug. Wherein, the electric igniter receives the signal of electromagnetic sensor and sends ignition signal to the high-pressure boss to control the ignition of spark plug. The invention is characterized in that: there are morn than one high-pressure bosses, which are connected to the different outputs of electric igniter; the input of electric igniter is connected to the electromagnetic sensor to judge the speed of magnetic motor and set the ignition time sequence to send the low-frequency ignition signal or high-frequency ignition signal to several high-pressure bosses to control several spark plugs ignite synchronously or asynchronously. The invention has better anti-disturb ability and reliability.

Owner:CHONGQING ZONGSHEN ENGINE MFG

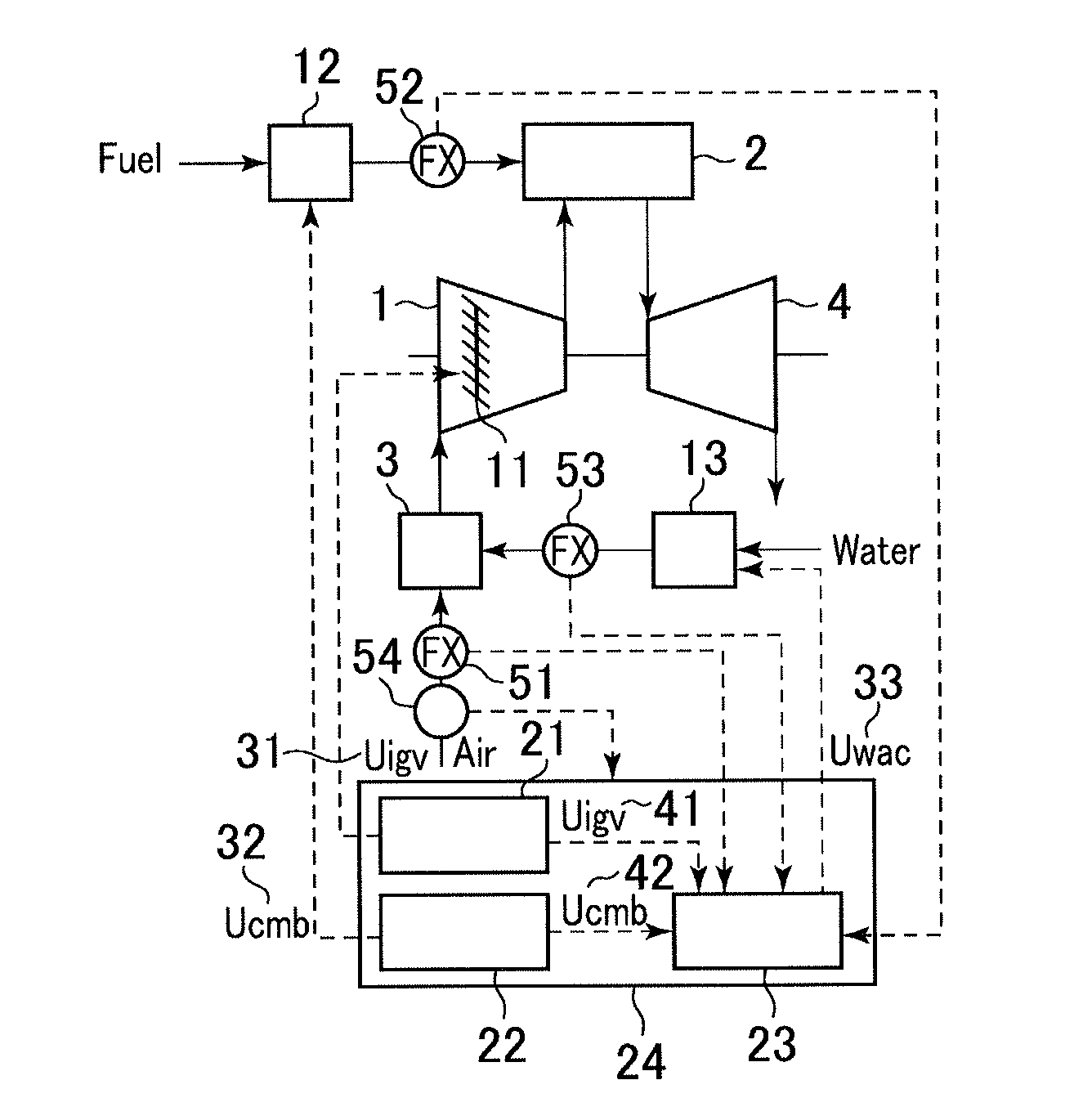

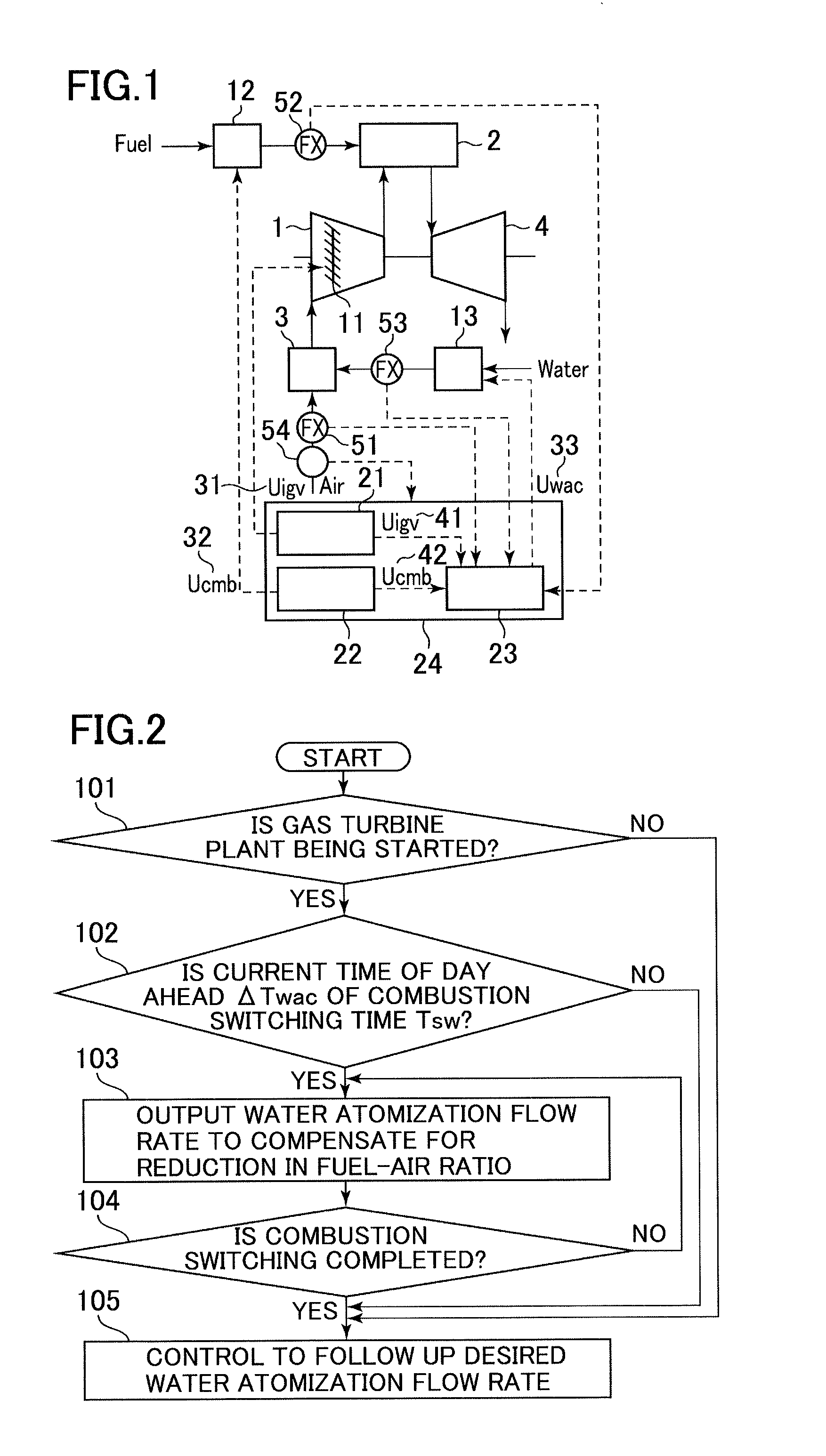

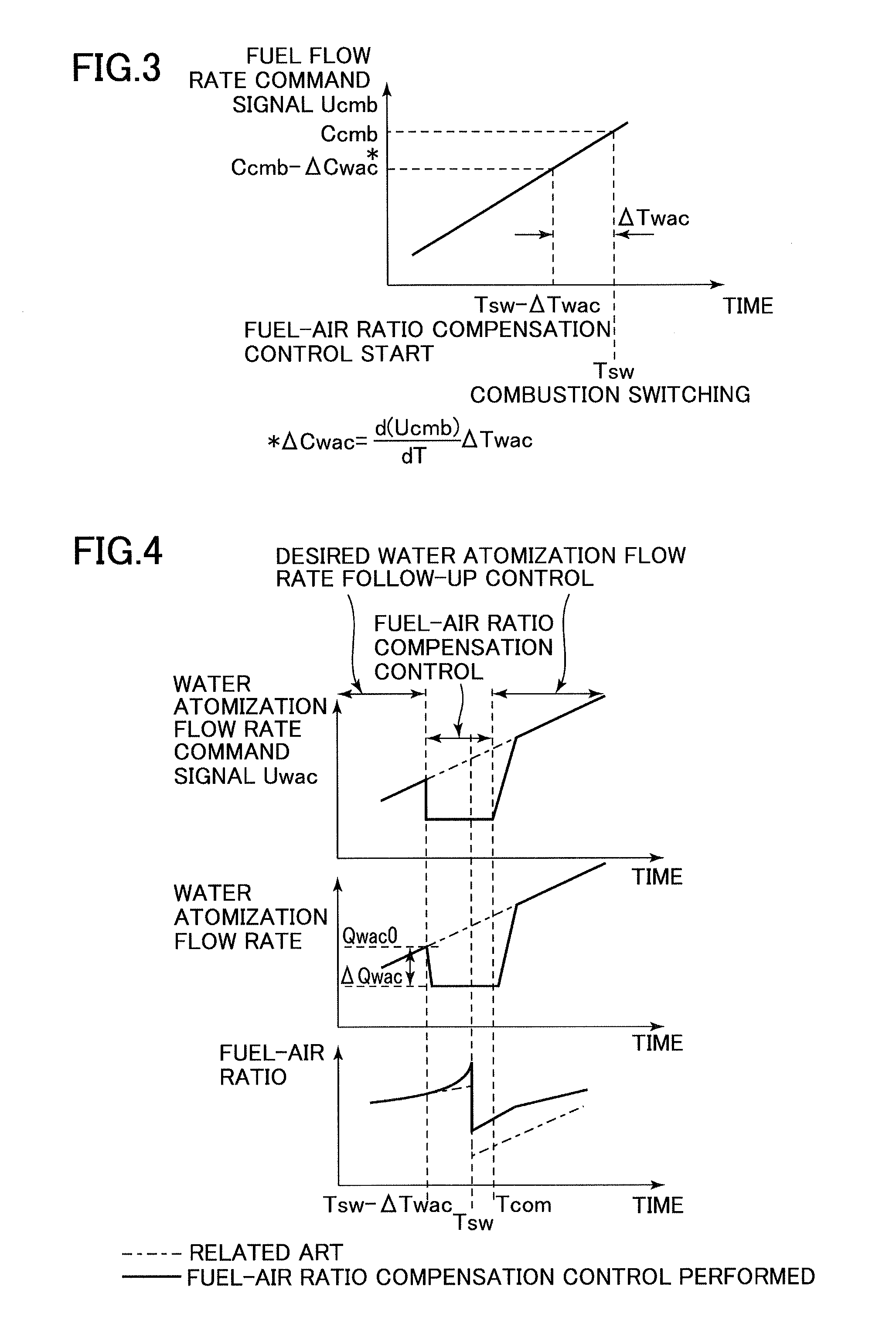

Controller for Gas Turbine Power Plant

ActiveUS20140033720A1Shorten time to attenuationPrevent misfireGas turbine plantsJet propulsion plantsAutomotive engineeringDynamo

A controller for use in a gas turbine power plant includes a compressor that compresses combustion air; a water-atomization cooling apparatus that sprays water drops of atomized water supplied via a water-atomization flow-rate regulating valve over a flow of air drawn in the compressor; a combustor that mixes the compressed combustion air with fuel to thereby burn a fuel-air mixture and generate combustion gas at high temperature and performs combustion switching during operation; a turbine that uses the combustion gas to drive the compressor and a generator; the water-atomization flow-rate regulating valve that controls a flow rate of the atomized water; and a compressor inlet inner blade that controls a flow rate of air drawn in the compressor. The controller includes control means that calculates a fuel-air ratio correction command signal for compensating for reduction in a fuel-air ratio in the combustor occurring during the combustion switching.

Owner:MITSUBISHI POWER LTD

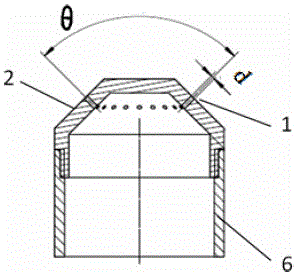

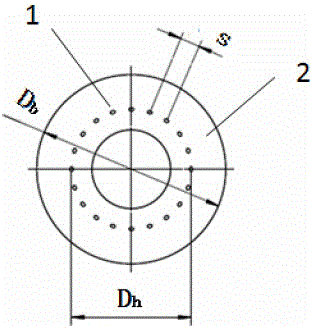

Multi-hole fuel gas jet flow burner

The invention discloses a multi-hole fuel gas jet flow burner. The burner comprises a gas pipeline, a gas nozzle, an air pipeline and an air pipeline outlet, wherein the gas pipeline is a gas flow passageway, a hollow cavity between the air pipeline and the gas pipeline is an air flow passageway, a round of fire holes are evenly formed in the wall of the gas nozzle, an axial centre line of the gas nozzle serves as a circle center of an annular ring formed by the fire holes, and the following formulas: Dh / D b = 0.4-0.8, d / s =1.5-4, theta= 20 degrees-150 degrees are satisfied; the fire holes and intervals are arranged reasonably, and fully co-firing of gas and air can be achieved; multi-hole fuel gas jet flow is injected into incoming flow air in the direction of an included angle formed by an axis of the nozzle and the multi-hole fuel gas jet flow, expansion type flow is adopted to form a negative pressure in a rear side of the gas nozzle, backflow of high temperature smoke is achieved, and flame blowoff and flameout are avoided; air flow can increase negative pressure in the rear side of the gas nozzle, the backflow of the high temperature smoke is facilitated, and flame stabilization is further facilitated; fuel gas jet flow injects into shear layer outside a backflow area, and mixing of the air and flue is facilitated.

Owner:东方电气洁能科技成都有限公司

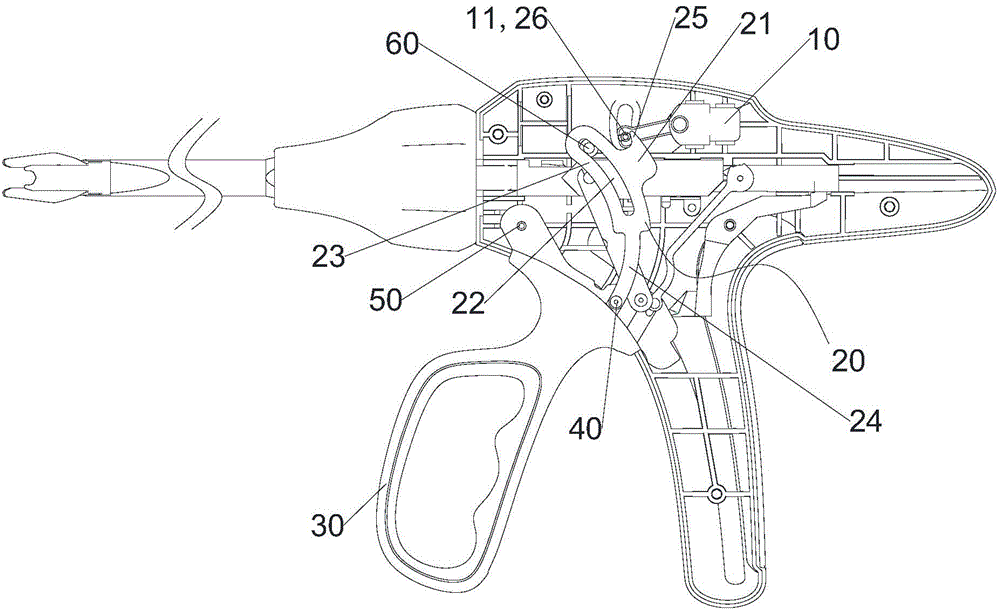

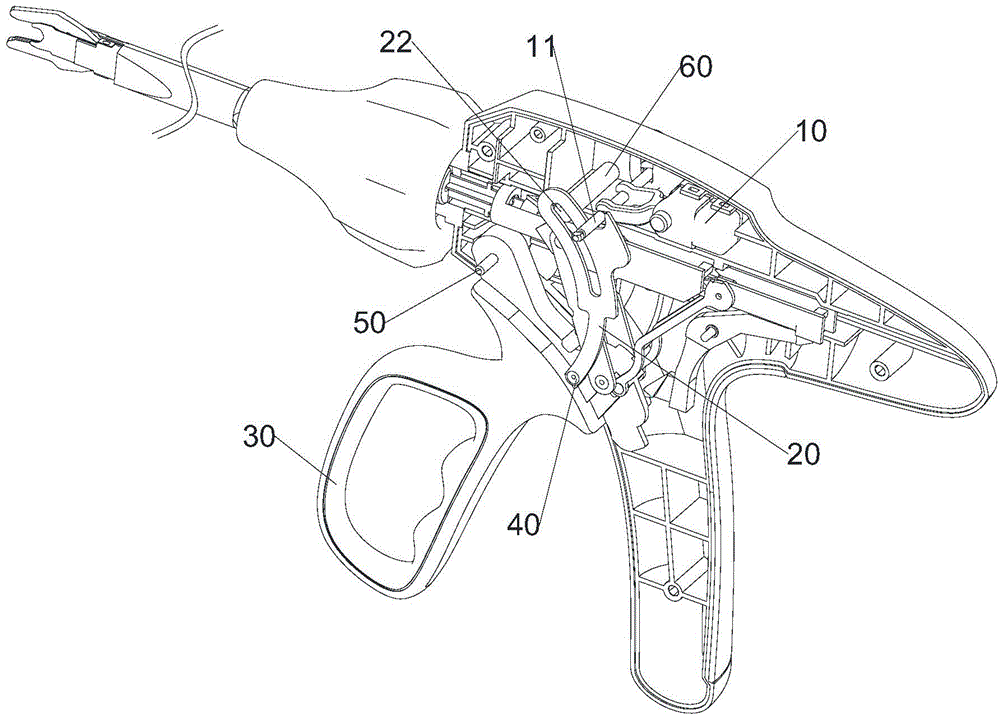

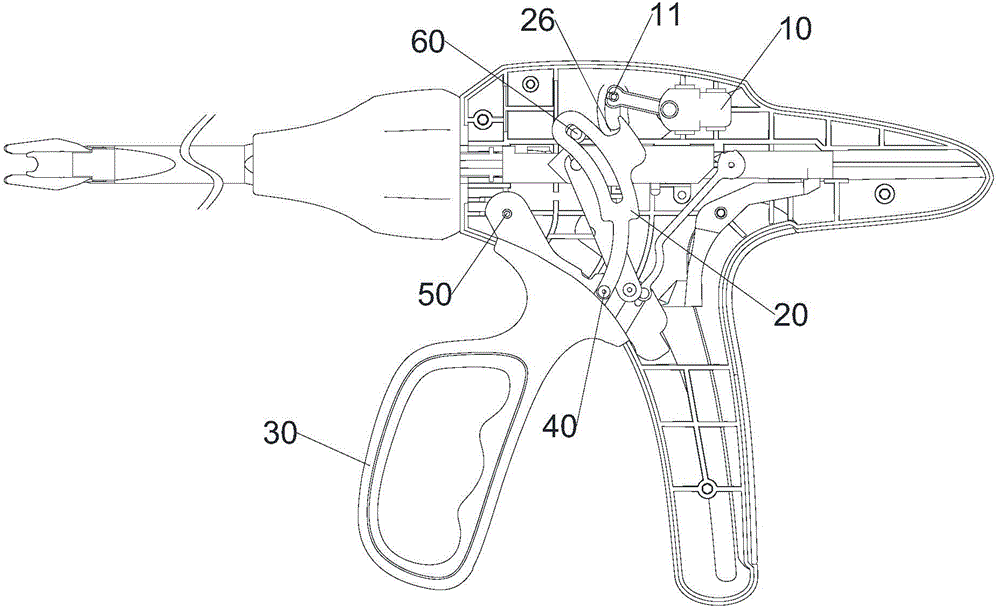

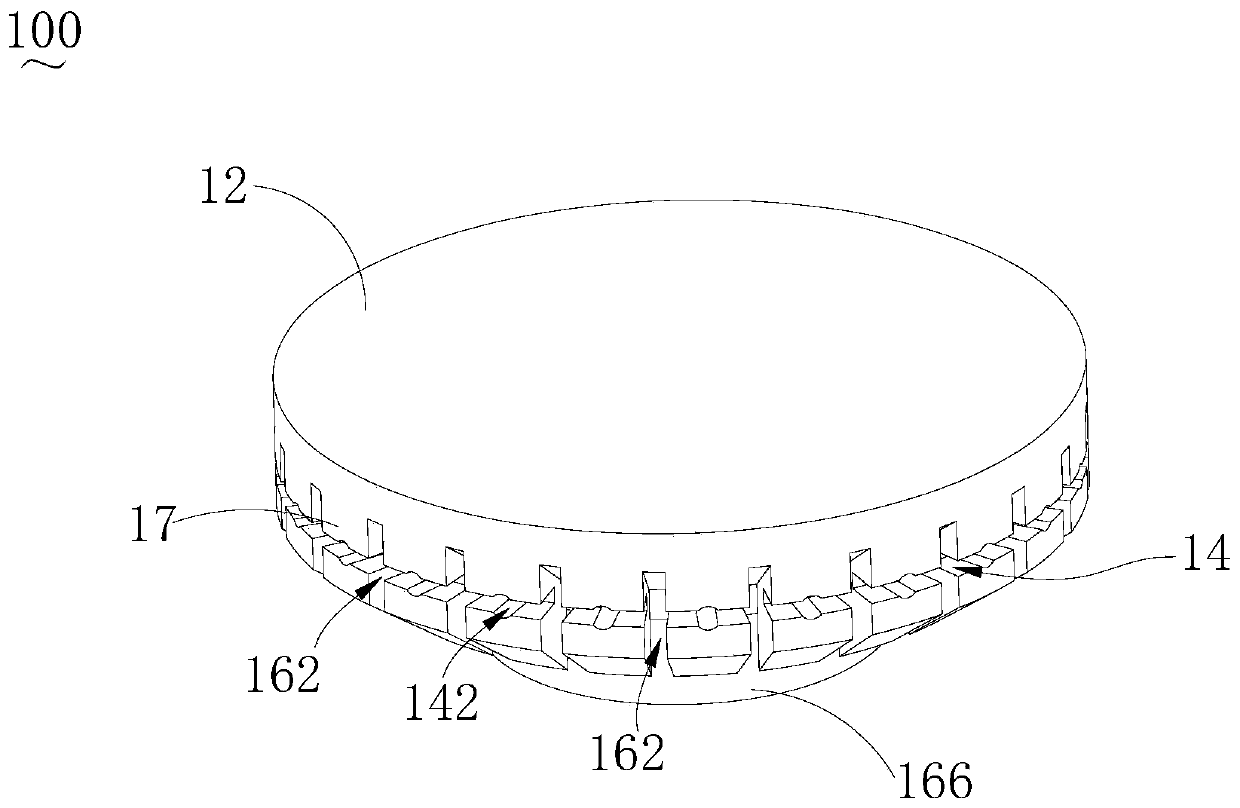

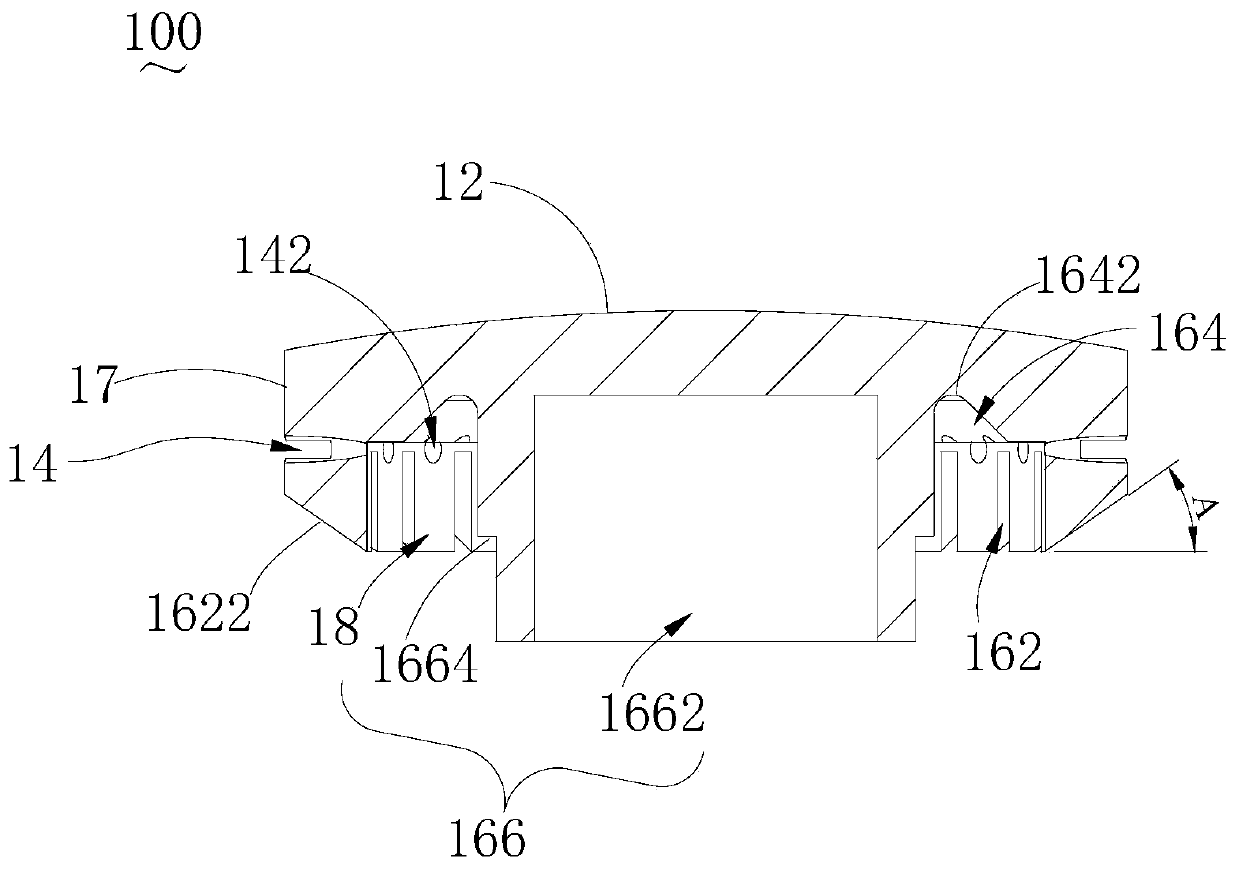

Surgical clamp and insurance connection structure thereof

The invention provides a surgical clamp and an insurance connection structure thereof. The insurance connection mechanism includes an insurance, a connecting rod and an operating part, wherein the connecting rod includes a locking part, the insurance locks or unlocks the connecting rod by the locking part, the operating part is pivotally connected to the connecting rod by a first pivotal shaft, and the operating part is pivotally arranged around a second pivotal shaft to drive the connecting rod to move along a predetermined path. According to the surgical clamp and the insurance connection structure thereof, the locking or unlocking of the connecting rod can be achieved through the operation of the insurance, thus being capable of preventing the surgical clamp from being motivating mistakenly, and thereby avoiding potential risks caused by titanium clips and the like falling into a body cavity; and the surgical clamp is very convenient and quick to operated, and has the characteristics of simple structure and low cost.

Owner:TIANJIN ONEHEALTH MEDICAL INSTR CO LTD

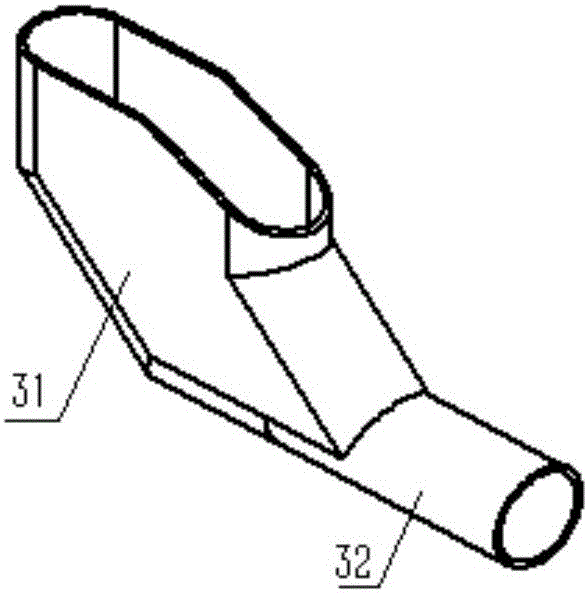

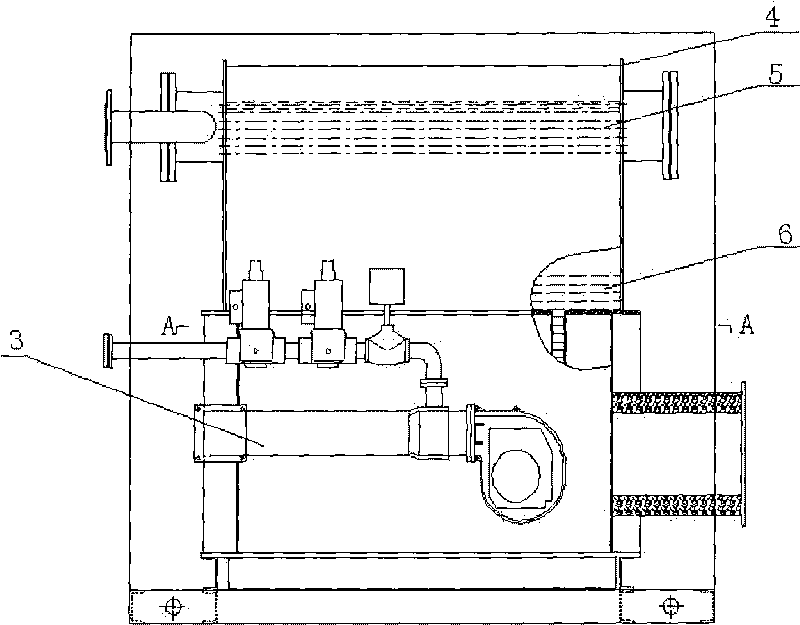

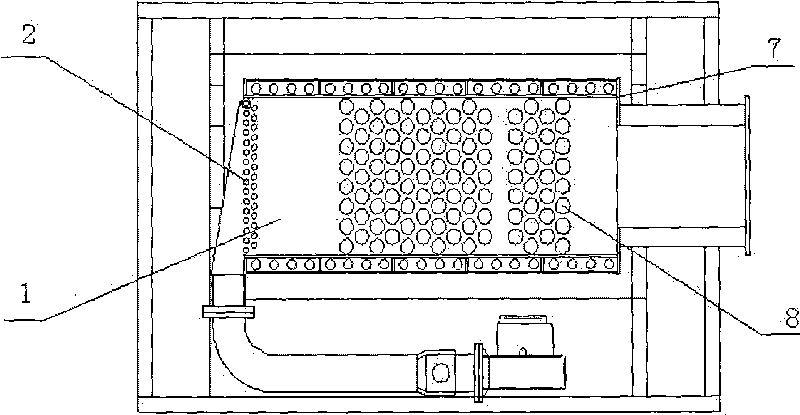

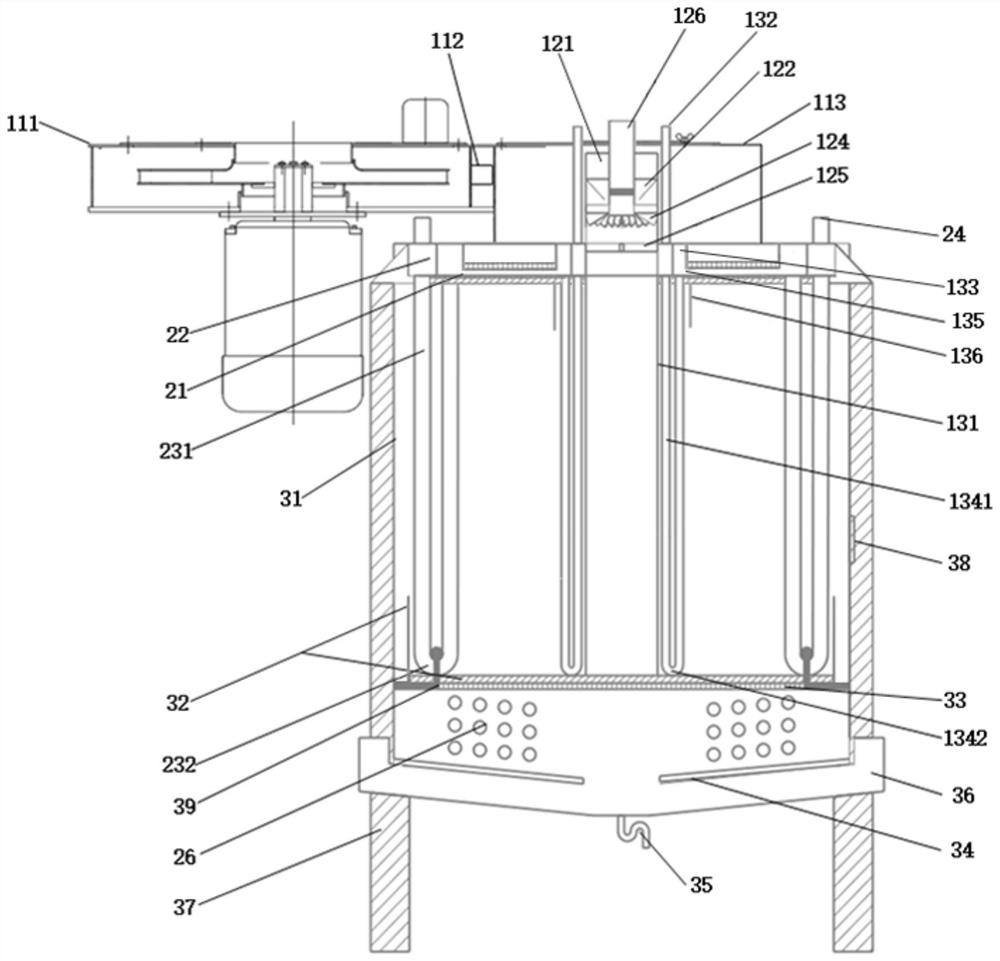

Fully premixed gas type condensate vacuum hot-water machine unit

InactiveCN101718471ABurn fullyHigh thermal efficiencyEnergy efficient heating/coolingAir heatersProcess engineeringOxygen content

The invention relates to the technology field of a gas hot-water machine, in particular to a fully premixed gas type condensate vacuum hot-water machine unit, the temperature and the oxygen content information of the waste gas are collected by a sensor and is input into a control device, the mixing ratio of the air and the gas is dynamically adjusted by the control device, thereby realizing the sufficient burning of the gas; by adopting a condensing device which heats medium water, the heat efficiency of the gas is increased, the structure of the machine unit is simplified and the volume of the machine unit is reduced. The invention provides a burner nozzle which is applied to a premixed gas type hot-water machine, the burner nozzle comprises a spraying rack pipe unit with a large pipe diameter and a damping rack pipe unit with a small pipe diameter, which are arranged side by side and can avoid flame lifting and the tempering.

Owner:ZHEJIANG UNIPOWER BOILER CO LTD

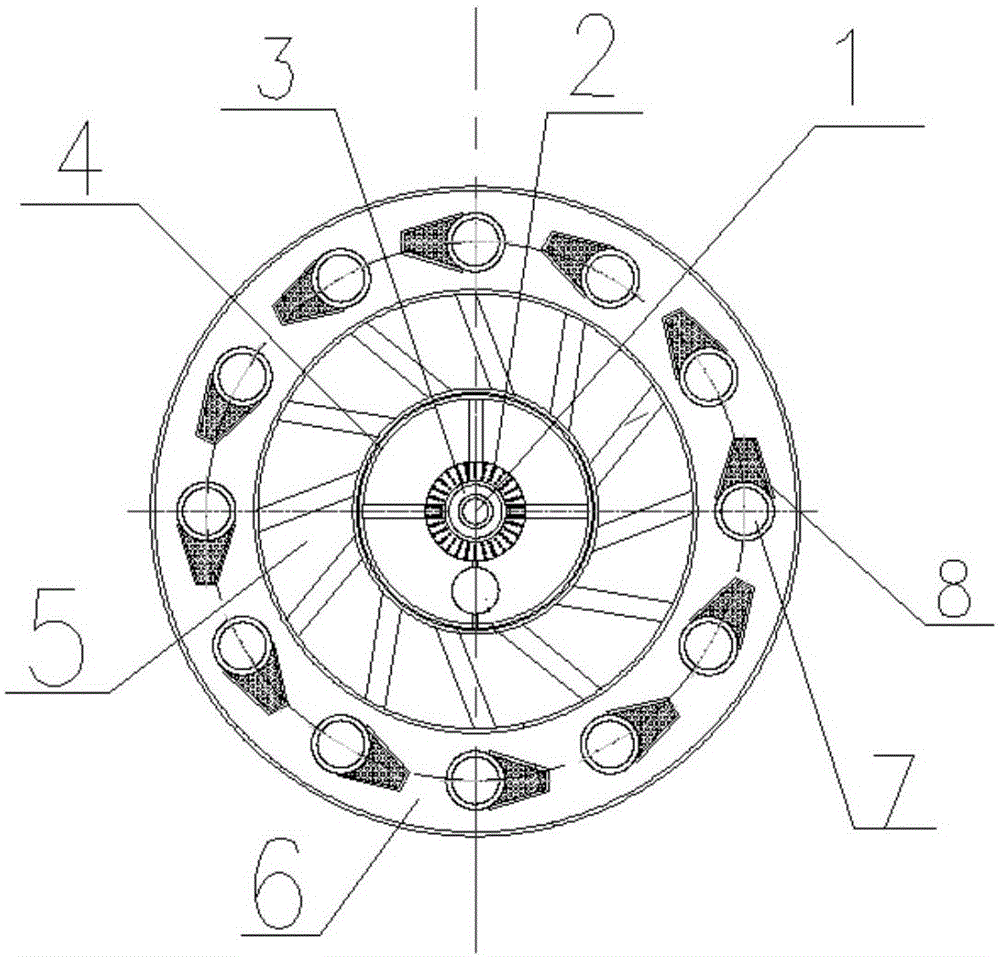

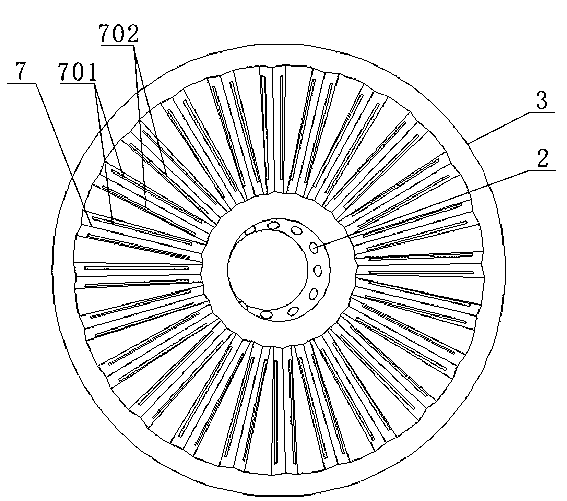

Ultra-low-nitrogen gas combustor with gun head self-combustion-stabilization devices

ActiveCN106642114AImprove combustion efficiencyWell mixedGaseous fuel burnerNitrogen oxidesLow nitrogen

The invention discloses an ultra-low-nitrogen gas combustor with gun head self-combustion-stabilization devices. The ultra-low-nitrogen gas burner comprises a combustor box shell, an inner central air barrel, a central fuel barrel, an outer central air barrel, a rotational-flow air barrel and a plurality of gas fuel spray guns, wherein the inner central air barrel, the central fuel barrel, the outer central air barrel, the rotational-flow air barrel and the combustor box shell are sequentially arranged from the inside to outside; and an annular gas collection box is arranged at the outer side of the combustor box shell, a trace fuel gun provided with a windproof cover or a flame stabilization disc is arranged on the side surface of a gun head of each gas fuel spray gun, a first fuel gas outlet is formed in the top of each trace fuel gun, a plurality of second fuel gas outlets are formed in the side surface of the top of the trace fuel gun, and the corresponding flame stabilization disc or windproof cover is arranged on the side surface of the top of the trace fuel gun. The combustor is stable in combustion, and has the characteristics of being high in combustion efficiency, low in nitrogen oxide emission, low in cost and simple in structure.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

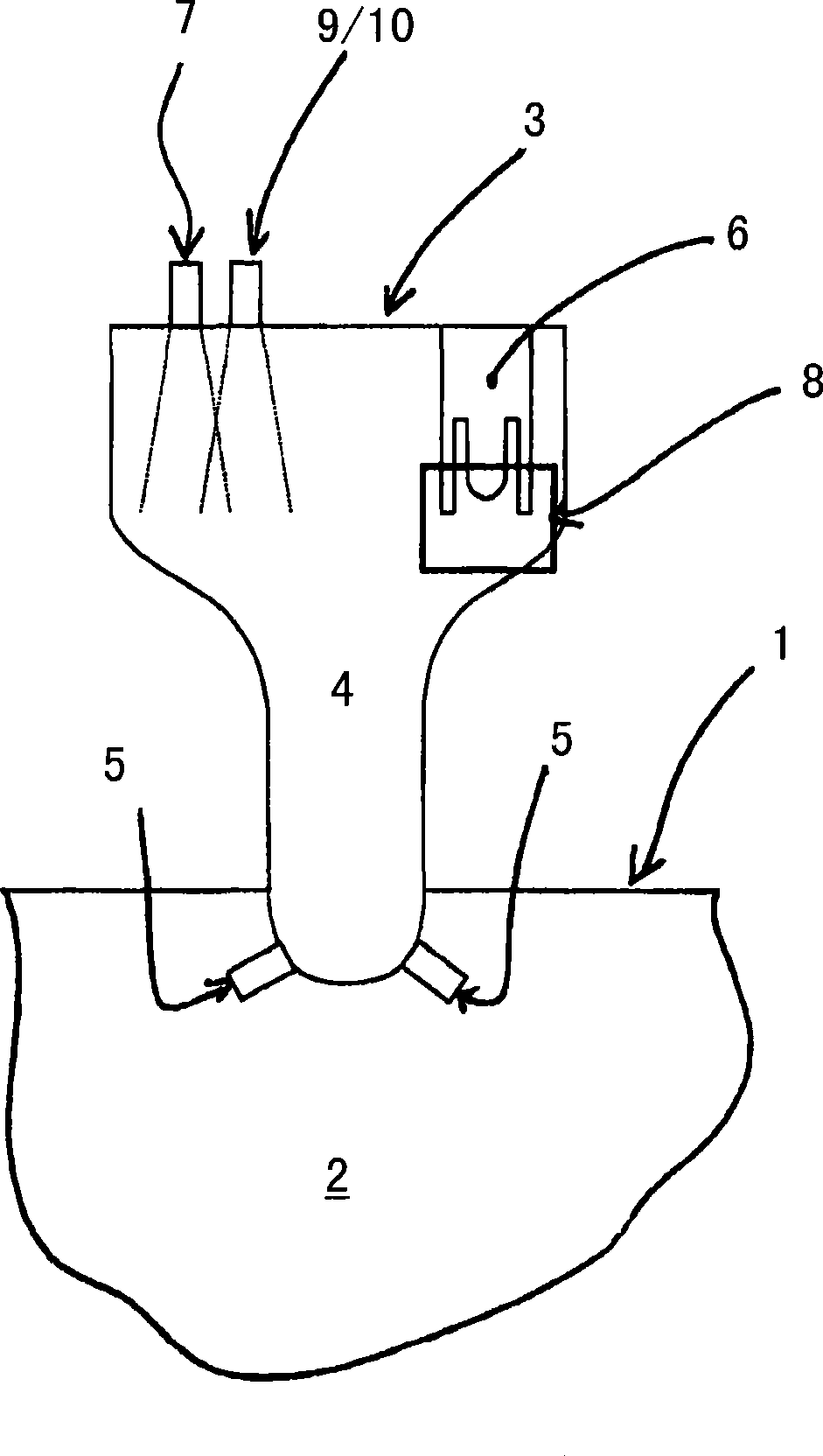

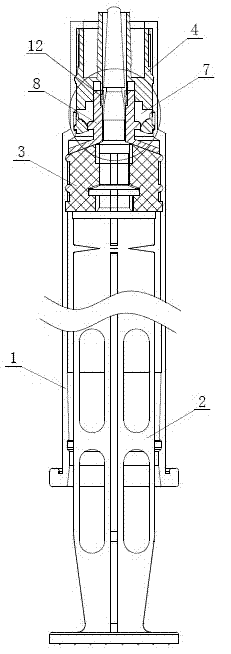

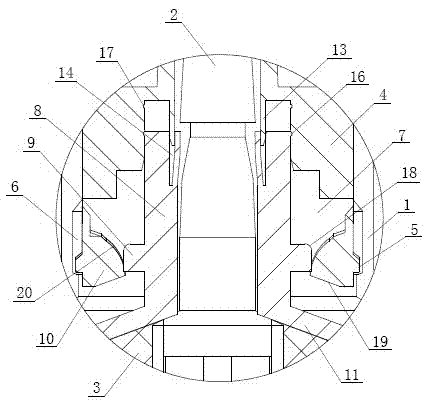

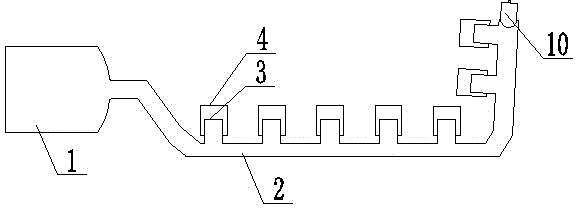

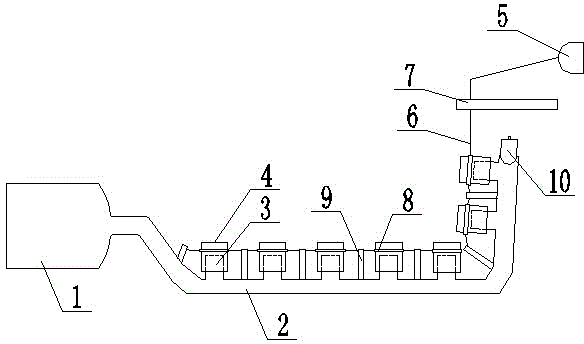

Internal-combustion engine and method for operating internal-combustion engine

InactiveCN101545397AAvoid misfirePrevent misfireInternal combustion piston enginesFuel supply apparatusFlammable gasCombustion chamber

The invention relates to an internal-combustion engine and a method for operating internal-combustion engine, comprising a main combustion chamber (2) and a precombustion chamber (4) connected with the main combustion chamber through at least an opening (5). A gas nozzle (7) connected on a high pressure gas pipeline is disposed in the precombustion chamber, and the gas nozzle is used for injecting gas into the precombustion chamber in high pressure and mixing the gas with the thin gas-air mixture in the precombustion chamber. The internal-combustion engine also comprises an ignition unit (6) stretched into the precombustion chamber to fire the thick gas-air mixture. At least one nozzle (9, 10) is arranged in the precombustion chamber for leading air and / or waste gas into the precombustion chamber and mixing the gas with the thin gas-air mixture in the precombustion chamber before the gas nozzle leads the gas, thereby the limited non-flammable gas-air mixture exists before the gas nozzle leads the gas, and the limited ignitable gas-air mixture exists after the gas nozzle leads the gas.

Owner:MAN B & W DIESEL AS

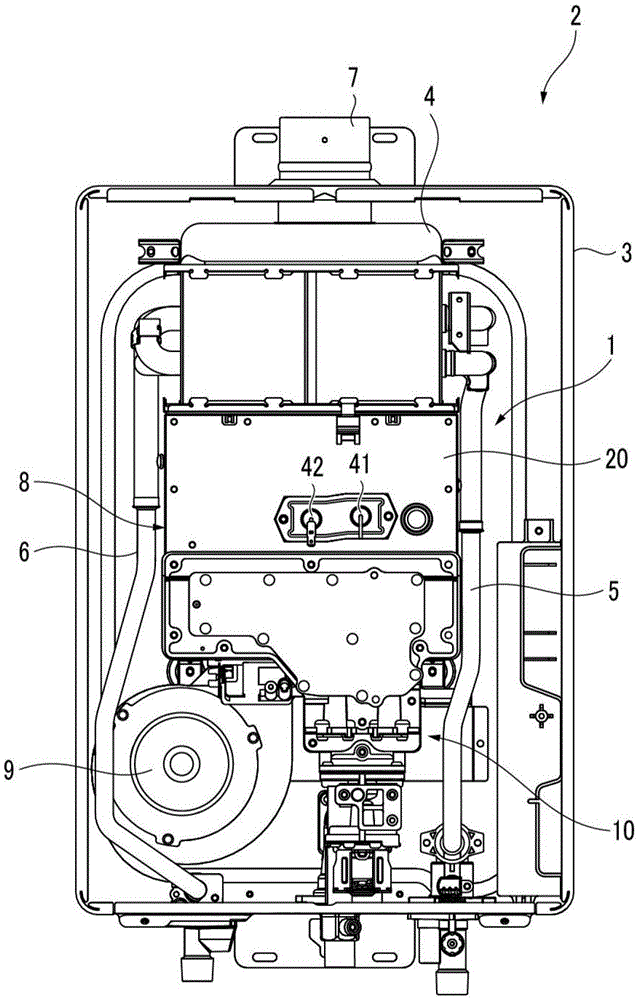

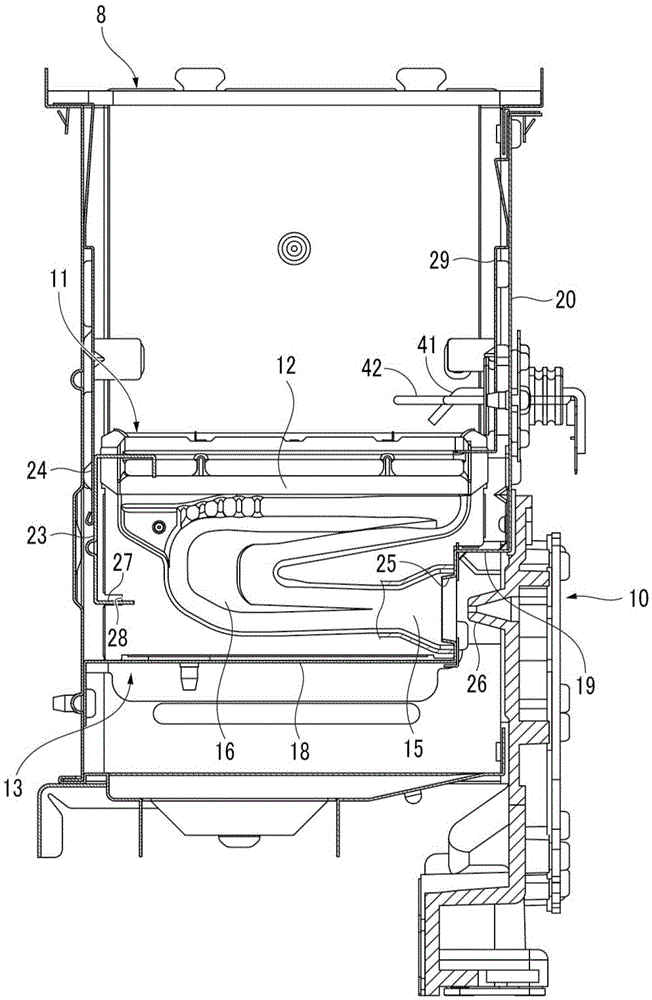

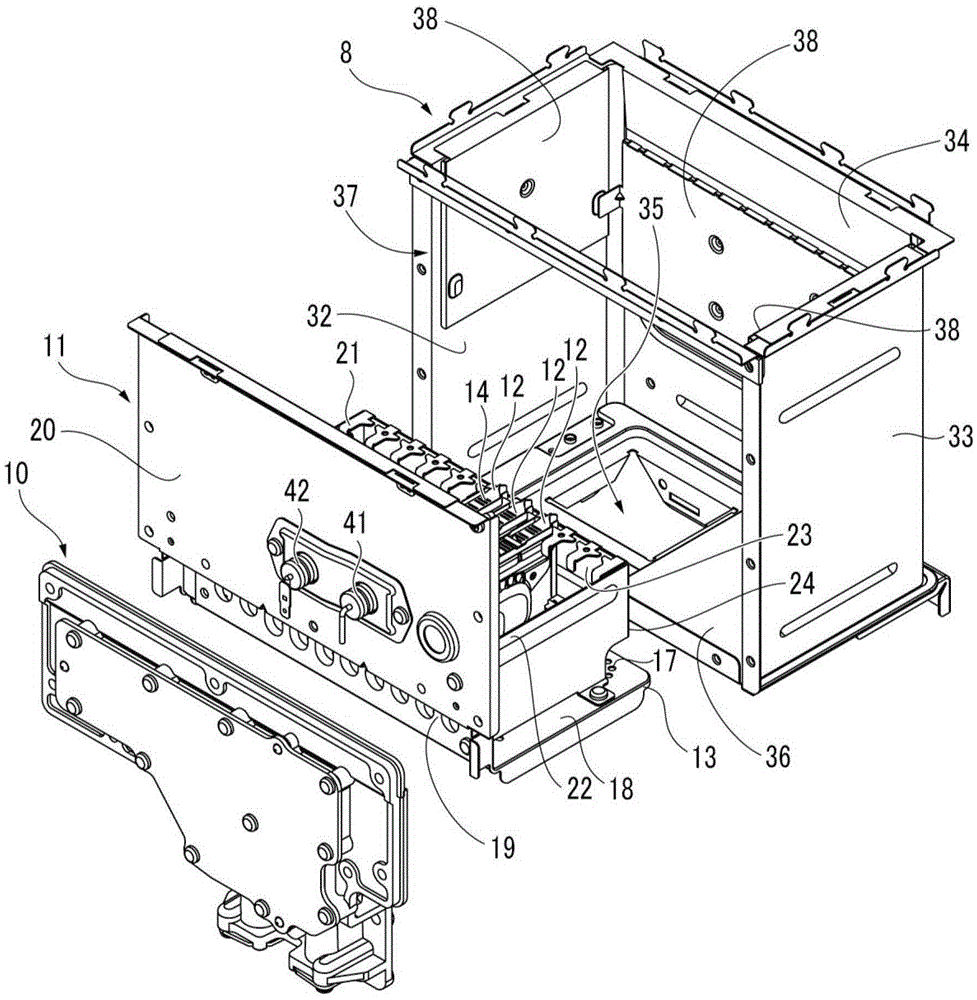

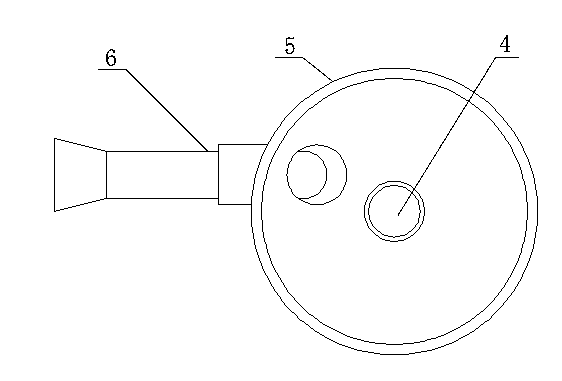

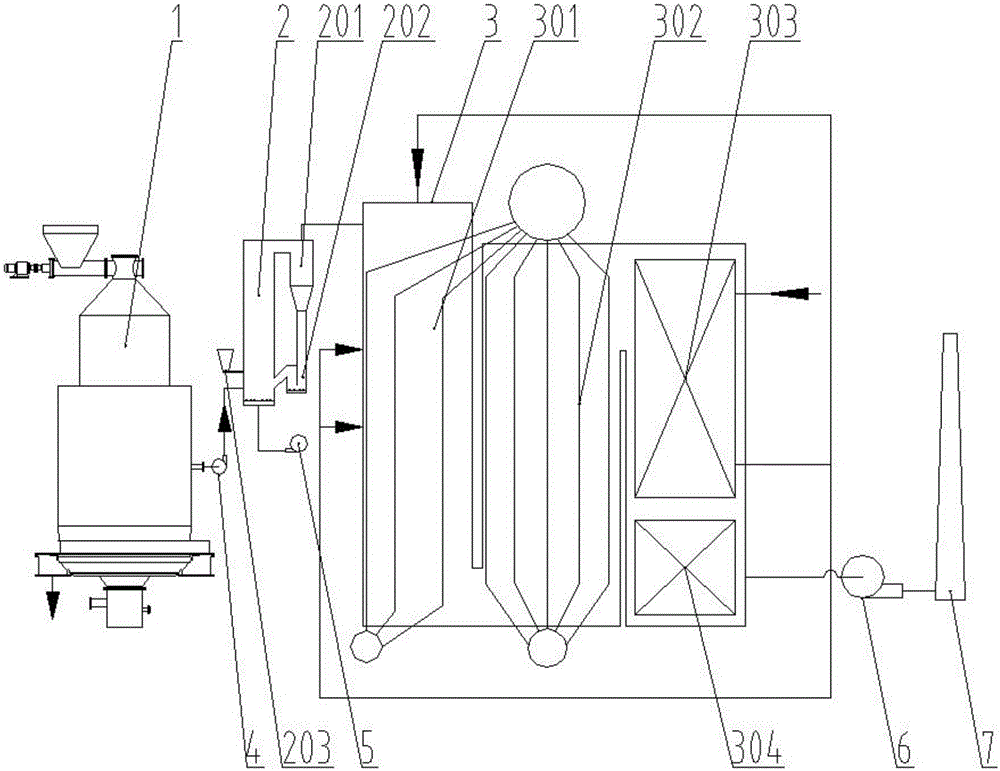

Combustion Device

ActiveCN105889916AEasy maintenanceReduce the number of accessoriesBurner ignition devicsWater heatersCombustorEngineering

The invention provides a combustion device. The combustion device comprises a combustion unit (11), a combustion case (8) and an ignition electrode (41). In the combustion unit (11), a burner support (13) is used for integrally supporting multiple single burners (12); a combustion housing (8) contains the combustion unit (11); the ignition electrode (41) generates a spark toward the single burner (12), in order to carry out ignition. An open surface (37) is arranged in the front of the combustion housing (8). A front plate (20) of the burner support covers the open surface (37) of the combustion housing (8). The ignition electrode (41) is installed on the front plate (20) of the burner support (13). The combustion device (1) can be used for precisely arranging the distance between a tip of the ignition electrode to the single burner, in order to prevent bad ignition.

Owner:RINNAI CORP

Heat-pipe-based heat exchange low-nitrogen gas burner

ActiveCN111121022AEmission reductionAvoid destructionIndirect heat exchangersIndirect carbon-dioxide mitigationWater circulationNitrogen gas

The invention discloses a heat-pipe-based heat exchange low-nitrogen type gas burner. The burner comprises an air-fuel mixing section and a combustion head which are sequentially connected in a gas flow direction, wherein a gas nozzle is arranged in the air-fuel mixing section, the combustion head comprises a plurality of heat pipes arranged in a pipe bundle mode, a heat pipe evaporation heat absorption section in the pipe bundle is arranged to form a combustion gap as the combustion head, and a heat pipe condensation heat release section is provided with a condensing device and is arranged outside a furnace. According to the burner, the combustion head formed through intermittent arrangement of the plurality of heat pipes is arranged between the furnace and the air-fuel mixing section, two phase-change heat exchange processes of evaporation heat absorption and condensation heat release in a heat pipe heat transfer process have the advantages of good heat conductivity, isothermal property and the like, so that pipe inner working media in the heat pipes are evaporated into steam when the heat pipe evaporation heat absorption section absorbs heat of a combustion zone of the furnace,the condensation device of air cooling, water cooling and the like is adopted for condensation and heat releasing, liquid after the steam in the pipes is subjected to heat releasing and condensation flows back the heat absorption section under the action of gravity, and the damage caused to a boiler hydrodynamic cycle of a water-cooled combustor water cycle is effectively solved.

Owner:XI AN JIAOTONG UNIV +1

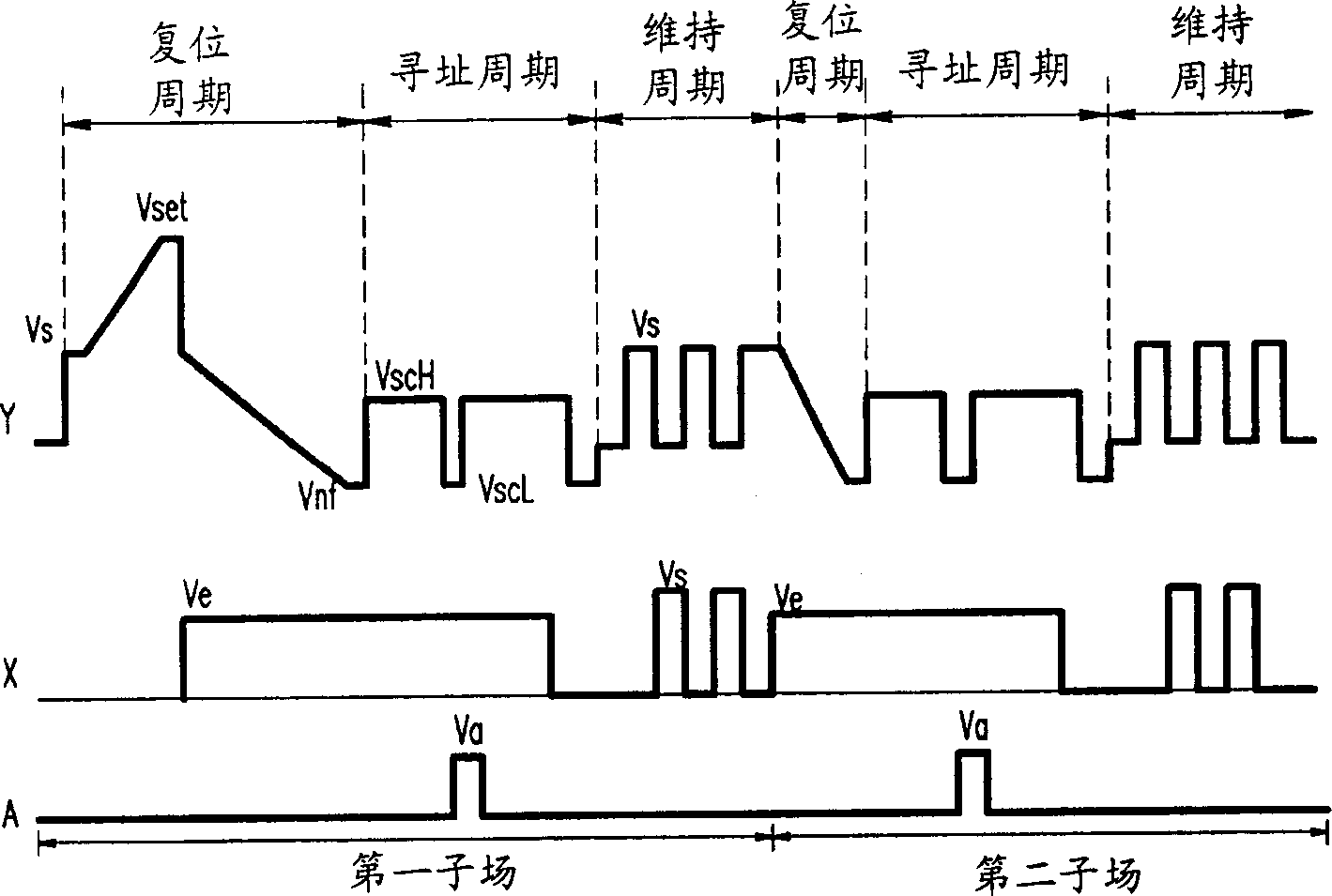

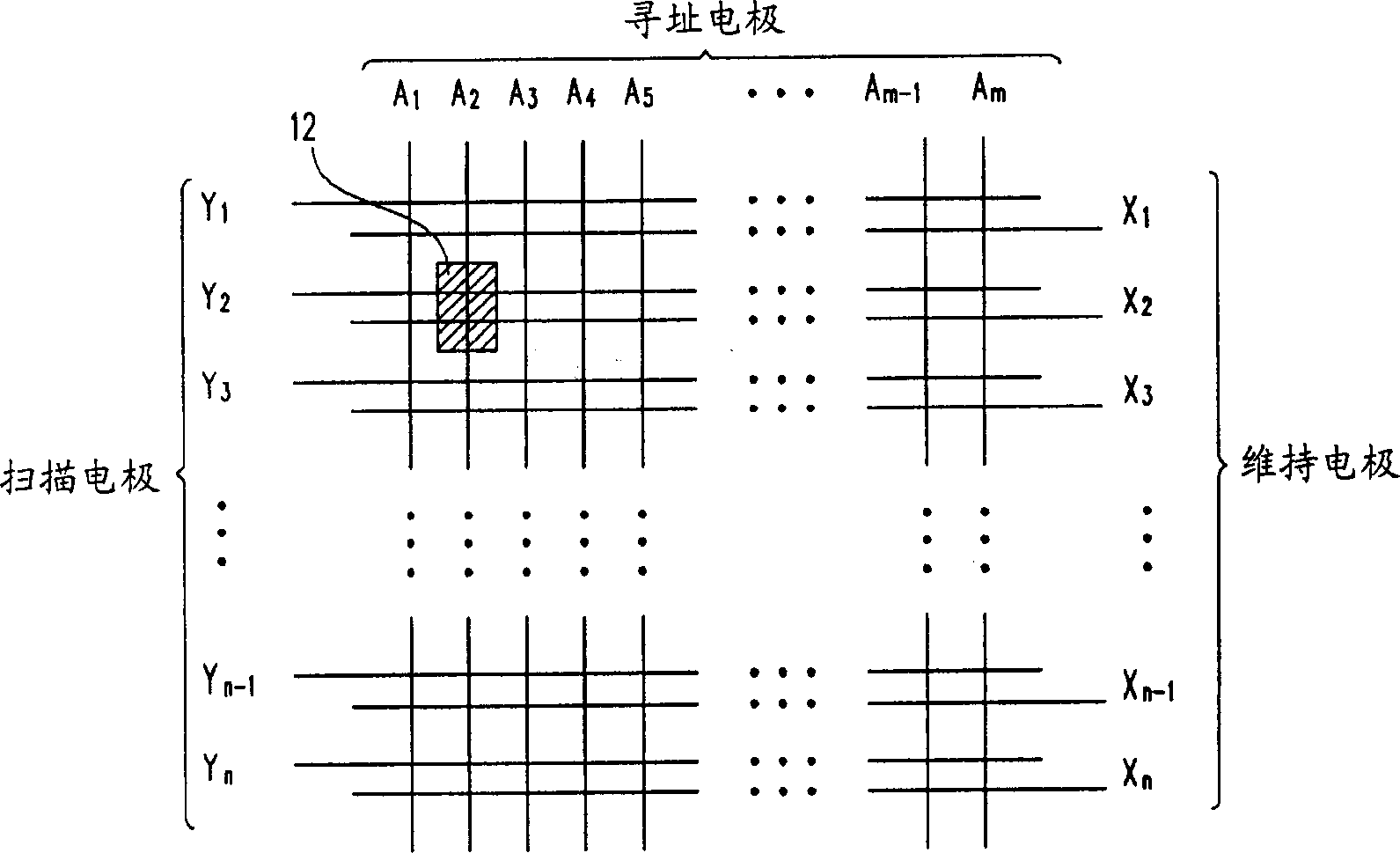

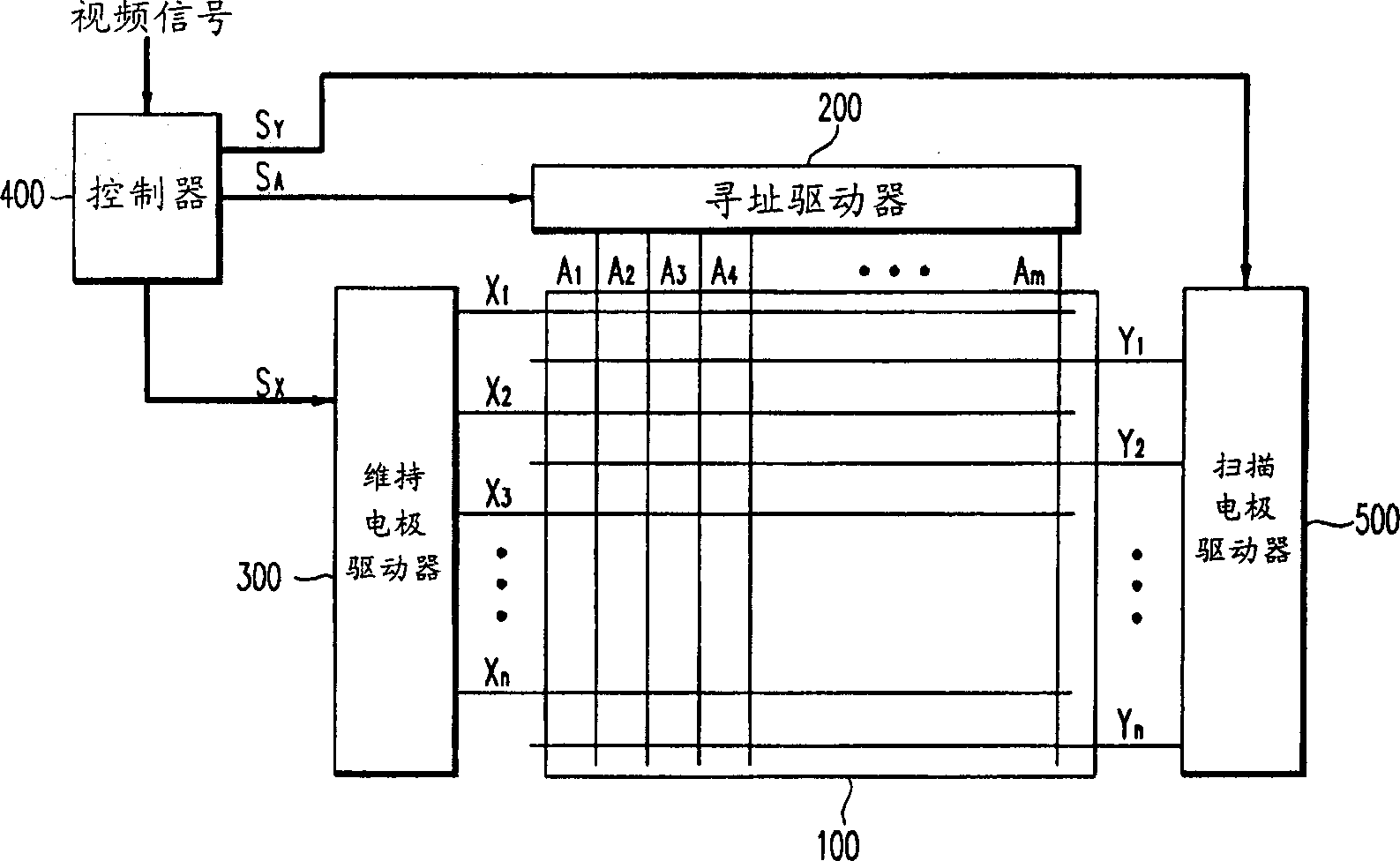

Plasma display device and driving method for stabilizing address discharge

InactiveCN1773579APrevent misfireStatic indicating devicesCold-cathode tubesDisplay deviceEngineering

Owner:SAMSUNG SDI CO LTD

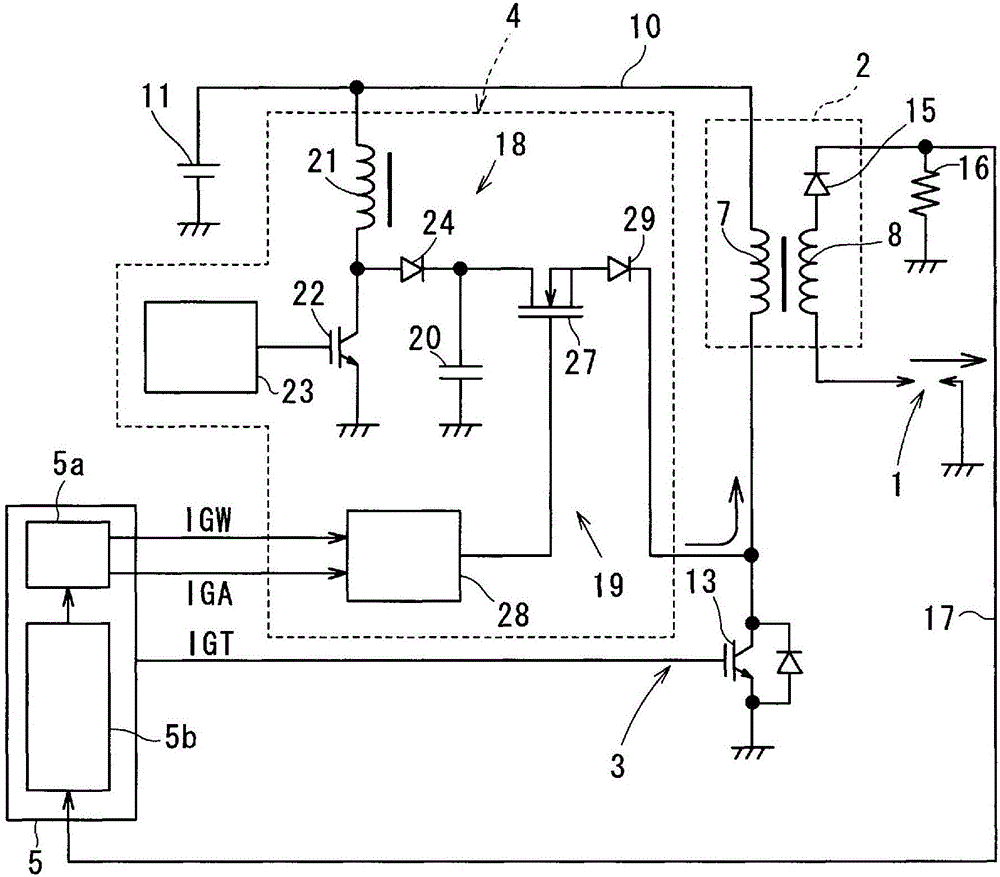

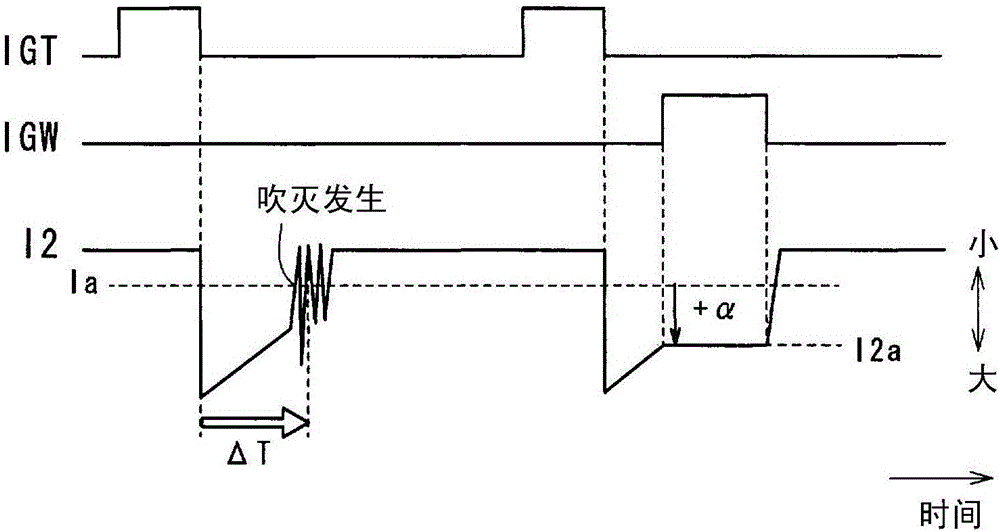

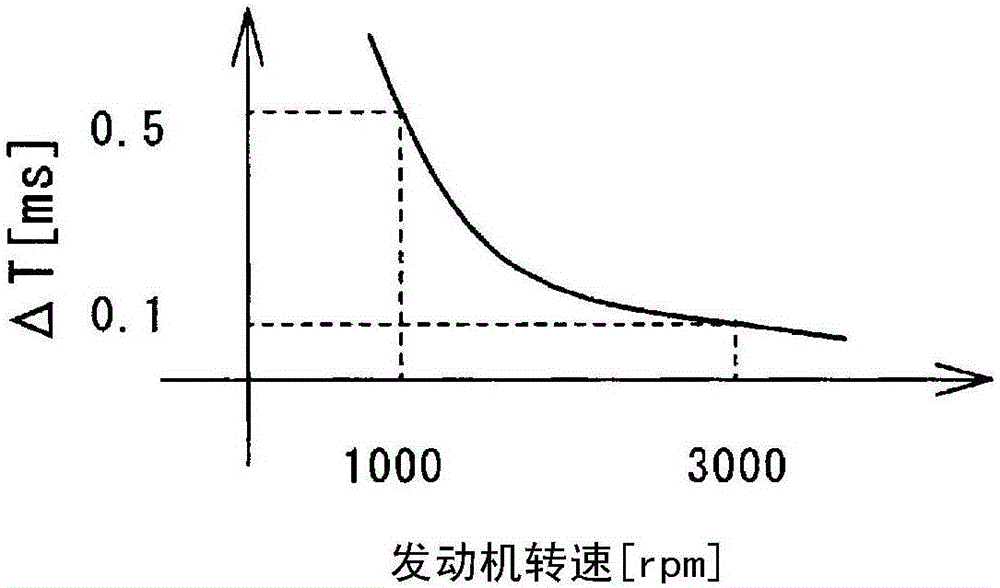

Ignition device for internal combustion engine

ActiveCN106170623ABlowout preventionPrevent misfireTransformersInternal combustion piston enginesEngineeringGreek letter alpha

An ignition device comprising a blow-out determination unit that determines that a blow-out has occurred, if a secondary current has dropped below a prescribed threshold (Ia) during a determination period, said determination period being a prescribed time ([delta]T) from the start of spark discharge by a main ignition circuit. If a determination is made that a blow-out has occurred during main ignition (during full-transistor ignition), the ignition device controls so as to perform continuous spark discharge after main ignition in the next cycle. The secondary current command value (I2a) at this time is set as a current value having a prescribed current value ([alpha]) added to the prescribed threshold (Ia) used for the blow-out determination. As a result, escalation to a misfire can be reliably prevented because blow-out can be reliably prevented in the next cycle.

Owner:DENSO CORP

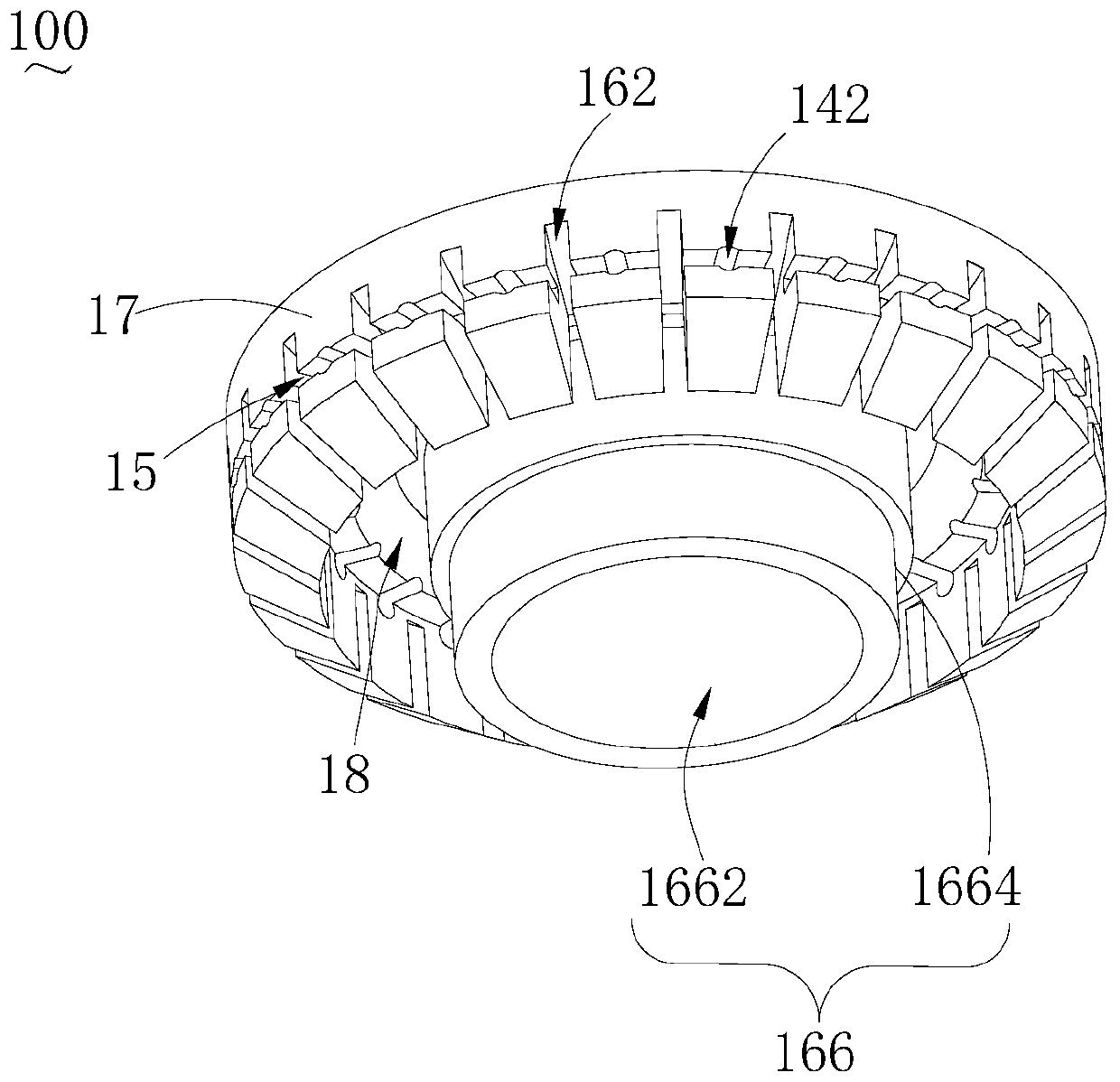

Outer burner cap for fuel gas type burner

The invention discloses an outer burner cap for a fuel gas type burner. The outer burner cap comprises an outer burner cap body with inner holes, wherein the lower side of the outer burner cap body is provided with a gas mixing chamber; the inner wall of the outer burner cap body is provided with a plurality of laminated steps in a gradually reduced arrangement from outside to inside; the laminated steps are used for partitioning the inner wall of the outer burner cap body into a plurality of side walls; an annular groove is formed in each side wall; the lower side of the outer burner cap body is provided with a plurality of fuel gas through hole units in one-to-one correspondence to the annular grooves respectively; each fuel gas through hole unit comprises a plurality of annularly arranged fuel gas through holes; one ends of the fuel gas through holes of any fuel gas through hole unit are respectively communicated with the gas mixing chamber, and the other ends of the fuel gas through holes of any fuel gas through hole unit are respectively communicated with the inner sides of the corresponding annular grooves. The outer burner cap has the advantages that the outer burner cap is free of flame lifting and flame floating during burning, good in flame-stabilizing effect and good in heat gathering effect, and an energy-gathering flame inside a floating flame is used for central heating.

Owner:周崇高

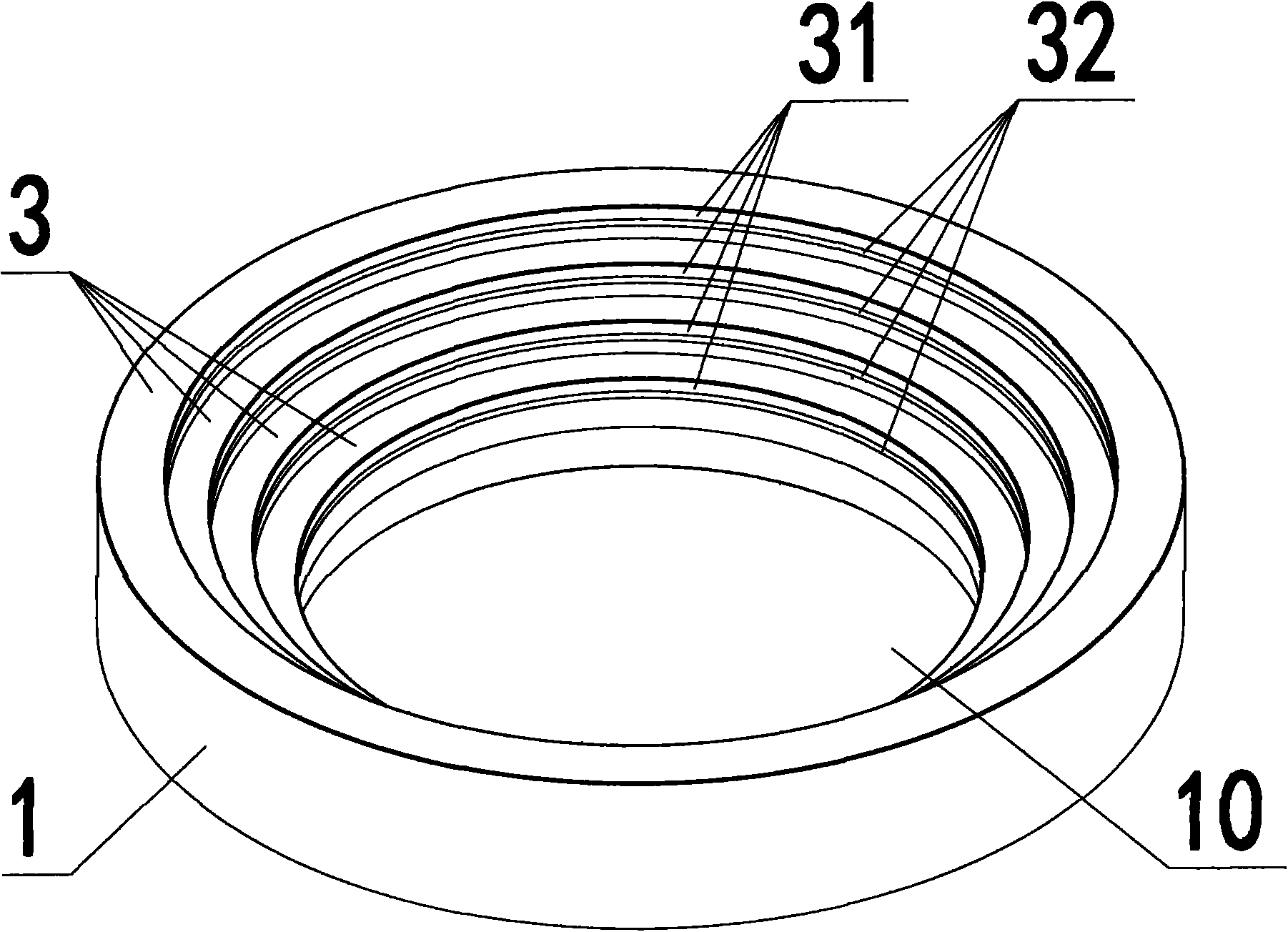

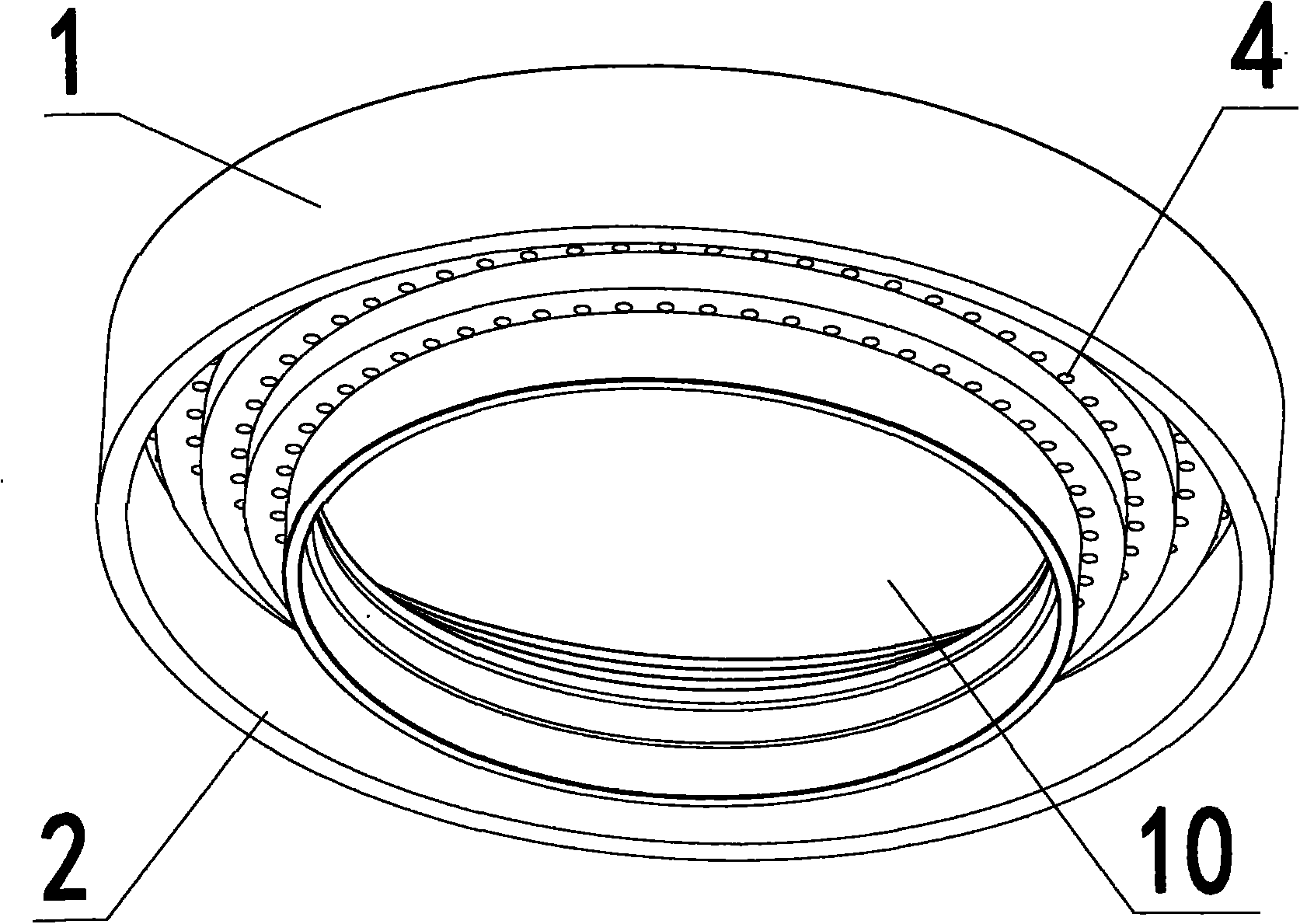

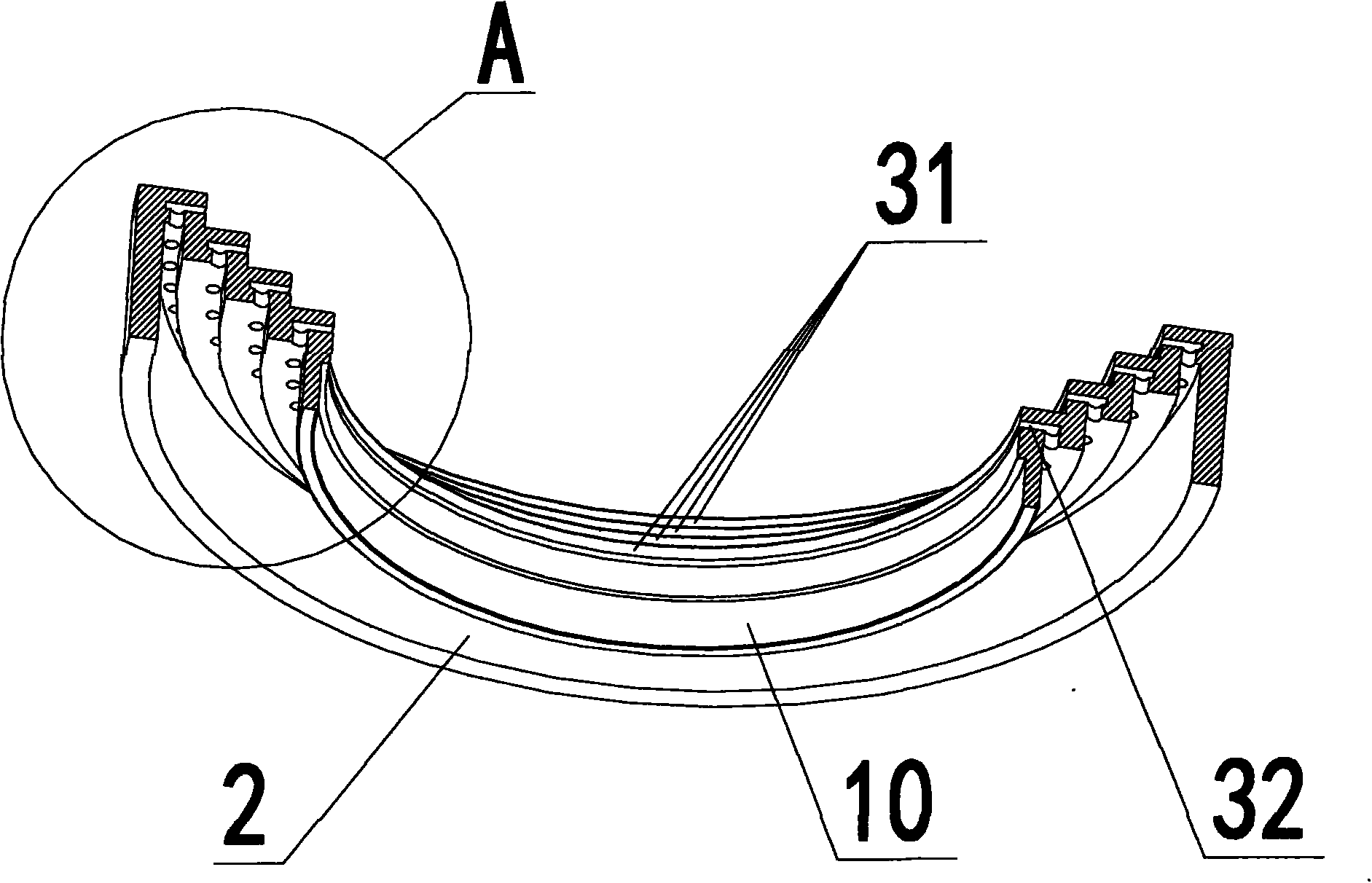

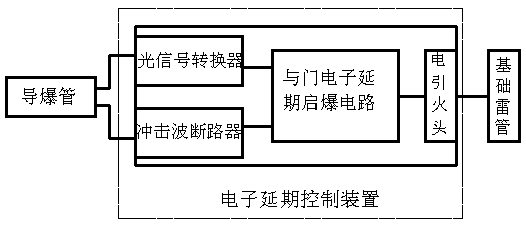

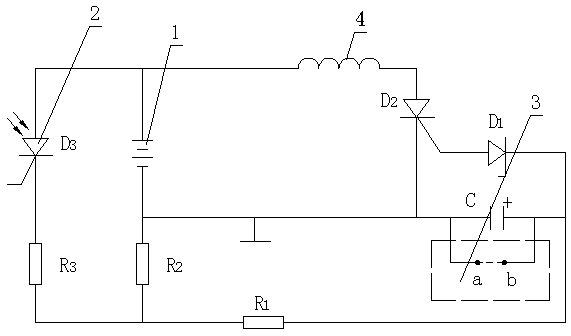

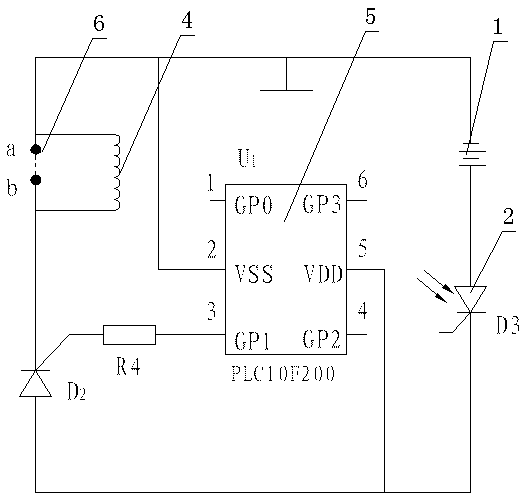

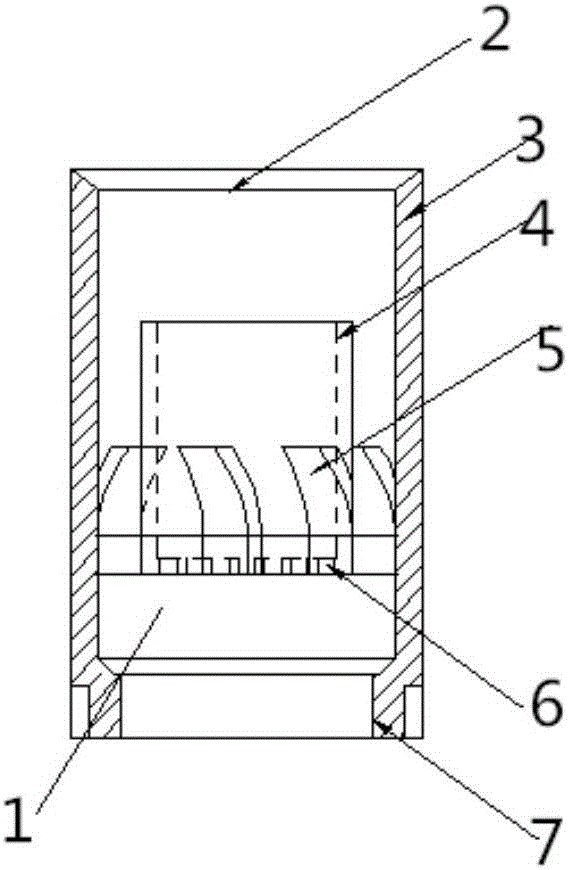

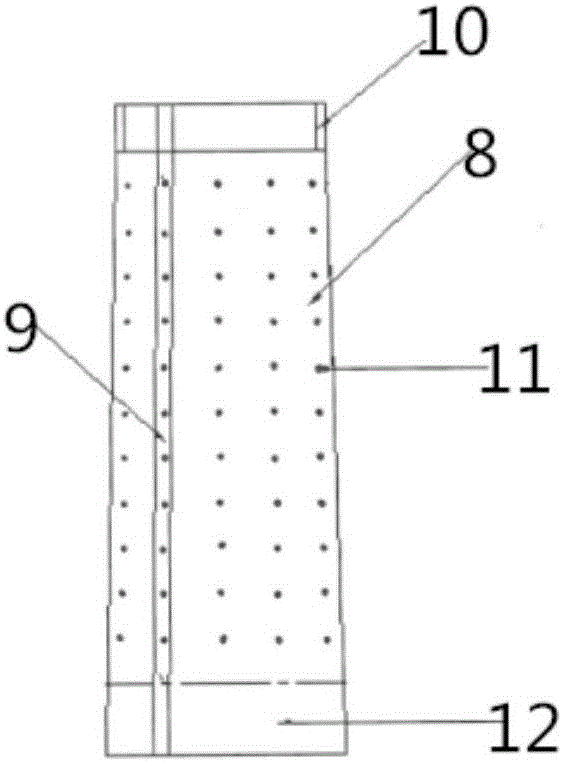

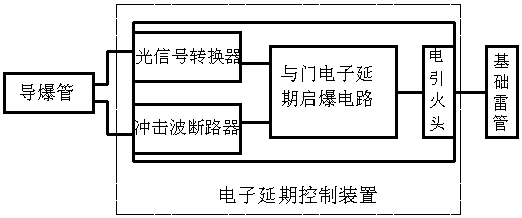

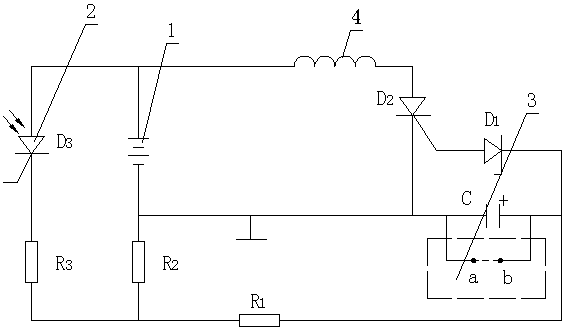

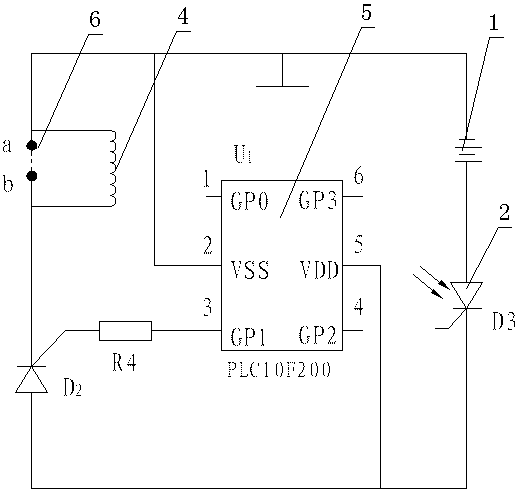

Detonating tube electronic delay detonator and method for detonating detonator under double control of light and shock waves

ActiveCN105403112AReduce the probability of accidental explosionPrevent misfireElectric fuzesDetonatorShock wave

The invention relates to a detonating tube electronic delay detonator and a method for detonating the detonator under the double control of light and shock waves. The detonating tube electronic delay detonator comprises a detonating tube, a basic detonator body and an electronic delay control device. The electronic delay control device comprises an AND gate electronic delay detonation circuit, an electric firing head, a light signal converter and a shock wave circuit breaker, wherein the electric firing head is connected with the output end of the AND gate electronic delay detonation circuit, the light signal converter receives a light signal after the detonating tube is detonated to enable one control end of the AND gate electronic delay detonation circuit to be switched on, and the shock wave circuit breaker receives a shock wave signal after the detonating tube is detonated to enable the other control end of the AND gate electronic delay detonation circuit to be switched on. The electronic delay control device carries out the double control through the light and the shock waves, the light signal converter and the shock wave circuit breaker can trigger the AND gate electronic delay detonation circuit to start a delay procedure after simultaneously switching on the respectively controlled control ends, and after set time is up, the electric firing head emits fire to detonate the basic detonator body.

Owner:XIANGNAN EXPLOSION APPLIANCES HUNAN PROV

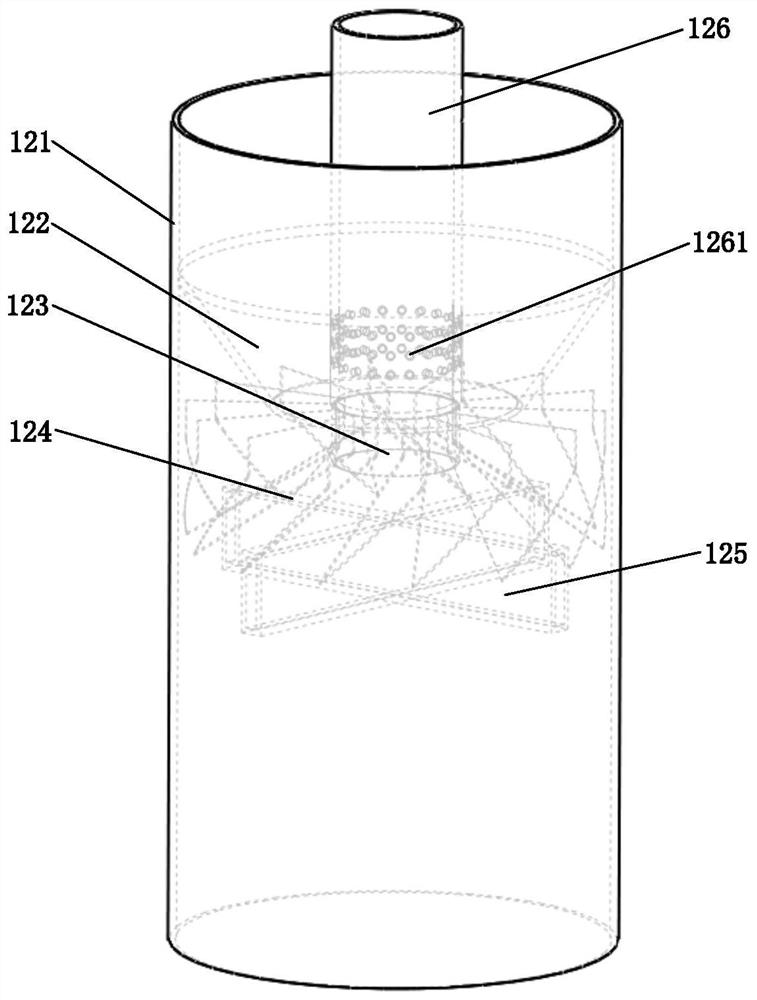

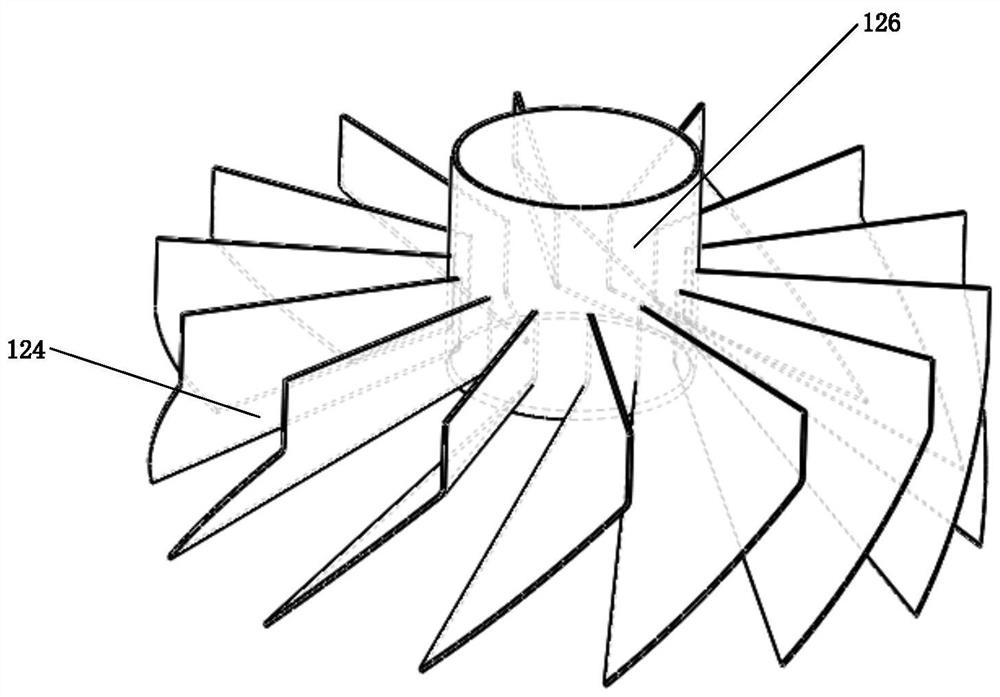

Industrial gas ultralow-nitrogen energy-saving spiral combustion head and combustor

The invention discloses an industrial gas ultralow-nitrogen energy-saving spiral combustion head and belongs to the technical field of gas combustion devices. The spiral combustion head comprises an outer cylindrical wall; an inner cylindrical wall is sleeved inside the outer cylindrical wall; the outer cylindrical wall and the inner cylindrical wall are connected into an integrated structure through a spiral bulge; air outlet holes are uniformly distributed in the bottom of the inner cylindrical wall; a fire outlet hole is formed in the top of the outer cylindrical wall; and the bottom of the outer cylindrical wall is provided with a combustion head connecting section. The invention also discloses a combustor comprising the spiral combustion head. By using the spiral combustion head disclosed by the invention, a flame rotates in a fixed direction, so that the heat exchange efficiency is increased, and the utilization ratio of heat energy is increased; meanwhile the combustion speed of the flame is stabilized, so that flame lifting and backfire are avoided; by using the combustor comprising the spiral combustion head, the radiated heat energy can be increased, so that a nitrogen reducing effect is achieved; and air and gases are sufficiently and uniformly stirred in a mixing pipe, so that an air / fuel ratio approaching to a theoretical value is achieved.

Owner:江苏弗雷姆环境科技有限公司

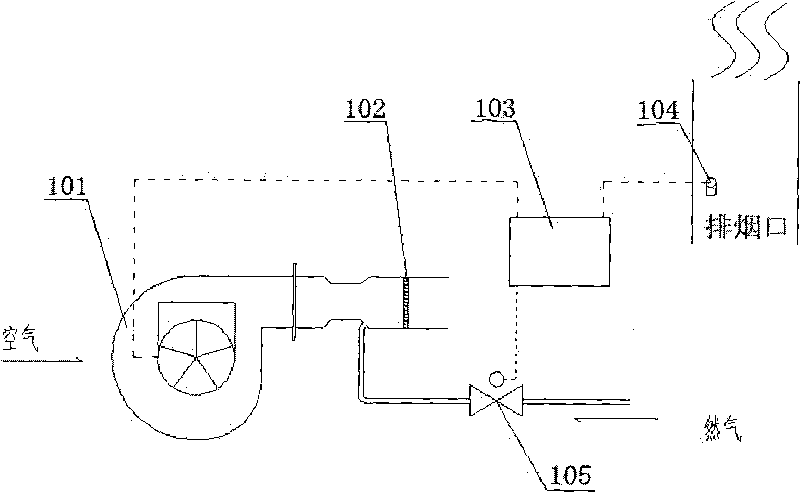

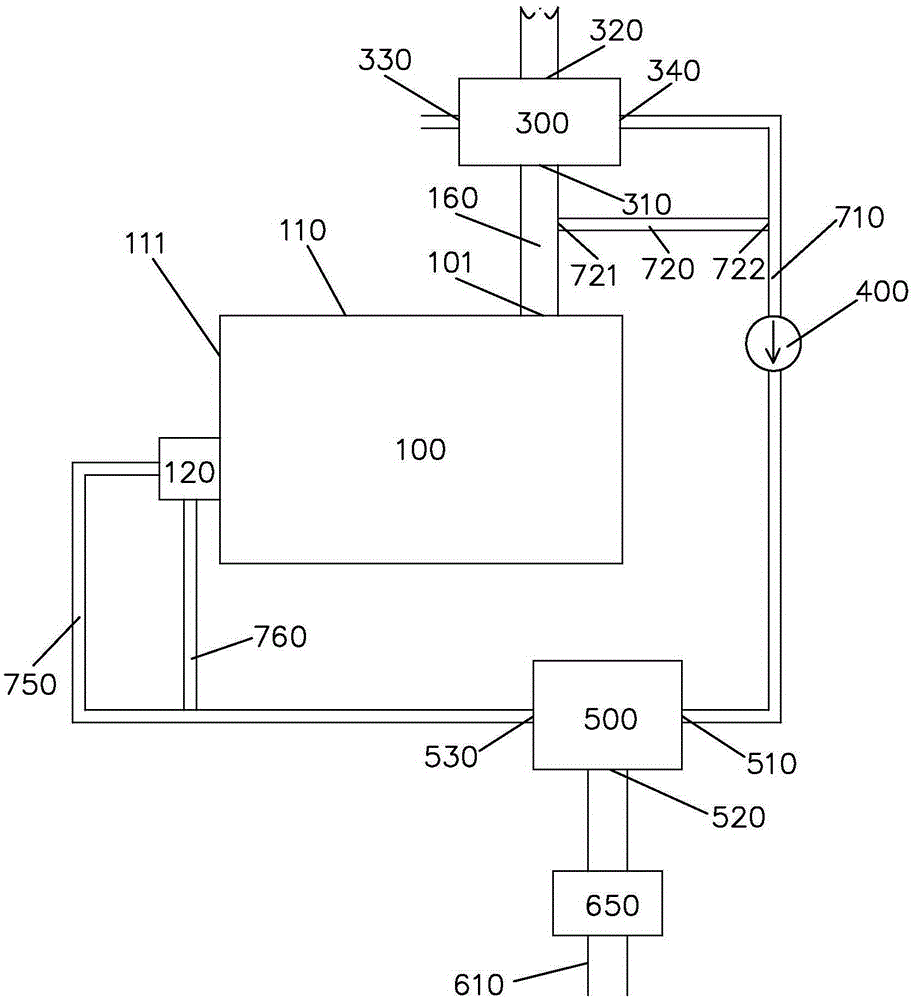

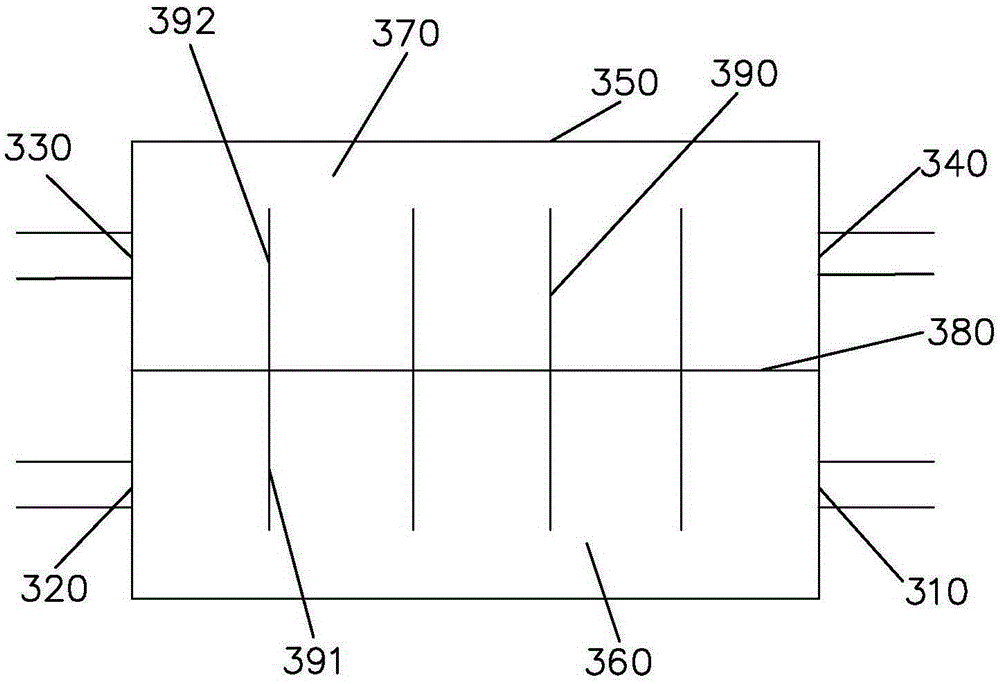

Low-carbon type flue gas backflow type steam boiler low-oxygen combustion system

ActiveCN105333449ARealize energy-saving transformationImprove utilization efficiencyCombustion processIndirect carbon-dioxide mitigationCombustion systemFlue gas

The invention discloses a low-carbon type flue gas backflow type steam boiler low-oxygen combustion system which comprises a steam boiler, a combustor and a flue gas pipeline. The combustor is used for jetting flames into the steam boiler for combustion heat emitting, and a high-temperature flue gas outlet in the steam boiler is connected to a chimney through the flue gas pipeline. The system further comprises a first heat exchanger, a gas conveying pipeline and a flue gas backflow branch pipe. The first heat exchanger is arranged in the flue gas pipeline and comprises a flue gas flow path and an air flow path. Air flowing through the air flow path of the first heat exchanger and high-temperature flue gas flowing through the flue gas flow path are subjected to heat exchange and then conveyed to the combustor through the gas conveying pipeline to support combustion. The inlet end of the flue gas backflow branch pipe is communicated with the flue gas pipeline at the part between the high-temperature flue gas outlet and the first heat exchanger, and the outlet end of the flue gas backflow branch pipe is communicated with the gas conveying pipeline to enable part of flue gas and preheated air in the flue gas pipeline to flow back to the combustor together to support combustion.

Owner:SOUTH CHINA NORMAL UNIVERSITY

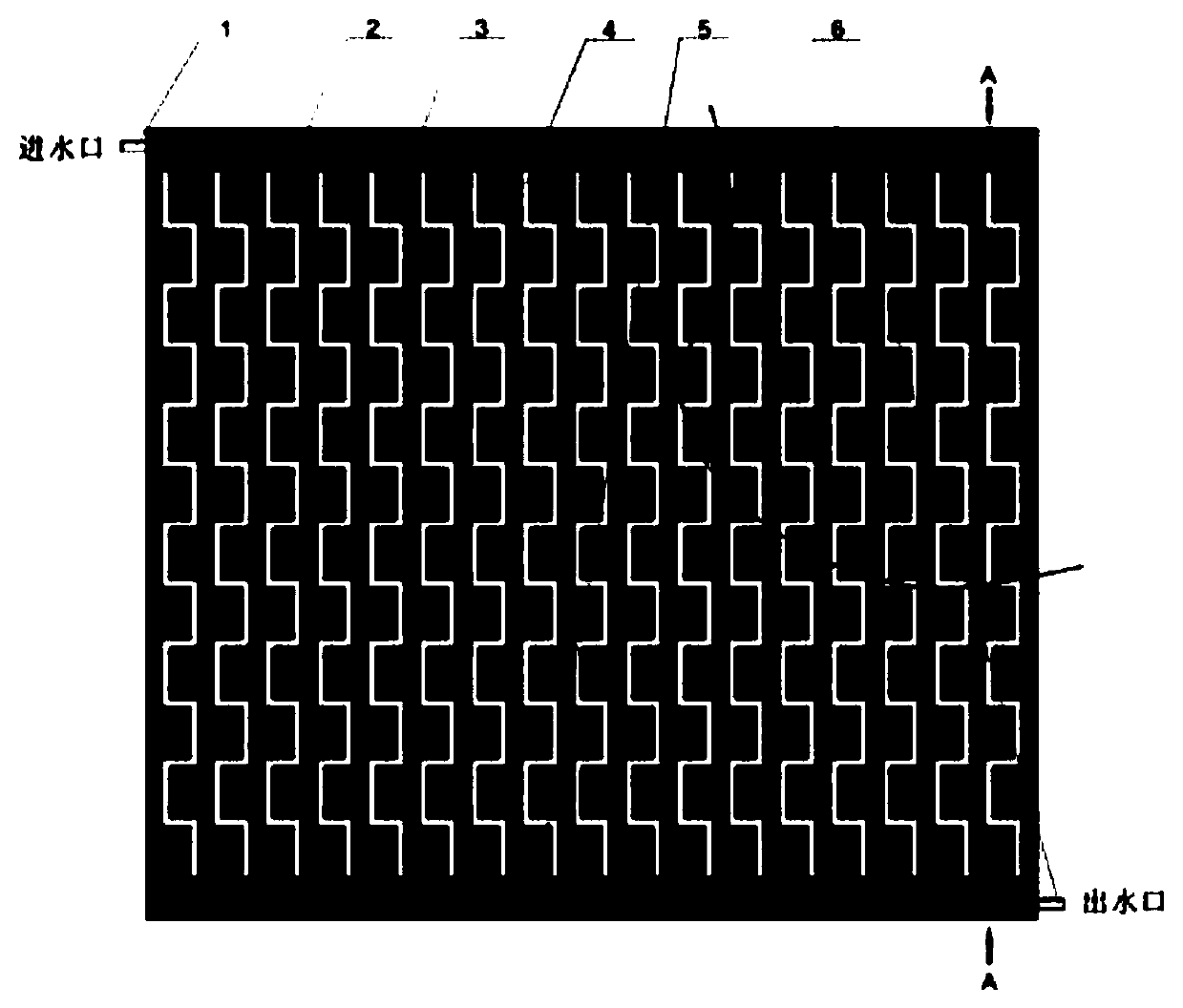

Variation microchannel cooling type surface flame low NOx gas device

ActiveCN110822426APromote gas ignition and efficient combustionEliminate local high temperature phenomenonGaseous fuel burnerEngineeringEnvironmental geology

The invention discloses a variation microchannel cooling type surface flame low NOx gas device. The variation microchannel cooling type surface flame low NOx gas device comprises an upper header, a lower header, variation structure water cooling components, a plurality of compact variation airflow microchannels constructed by the upper header, the lower header and the multiple groups of parallel variation structure water cooling components, a water inlet and a water outlet, wherein the water inlet and the water outlet are connected with the upper header and the lower header separately. Gas andair mixed airflow is ignited and combusted after flowing through the compact variation airflow microchannels, but because the variation structure water cooling components absorb heat, the low-temperature surface combustion of the airflow flame front at outlets of the variation airflow microchannels and the surfaces of the variation structure water cooling components is realized, the airflow combustion temperature is obviously reduced, and the low-temperature low-NOx combustion is further realized; meanwhile, the variation structures of the airflow microchannels remarkably promote disturbanceof flame air flow, and are combined with the compact variation structure water cooling components and the variation airflow microchannels, so that backfire and deflagration are effectively prevented,low-temperature and low-NOx surface combustion is realized, meanwhile, the local high-temperature phenomenon is eliminated, and combustion stability, safety and high efficiency are guaranteed.

Owner:XI AN JIAOTONG UNIV

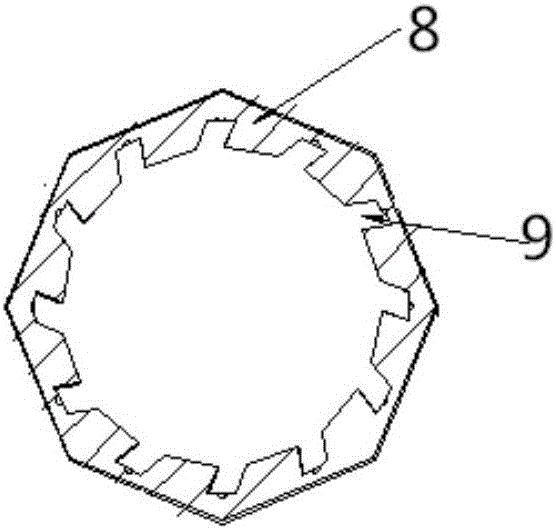

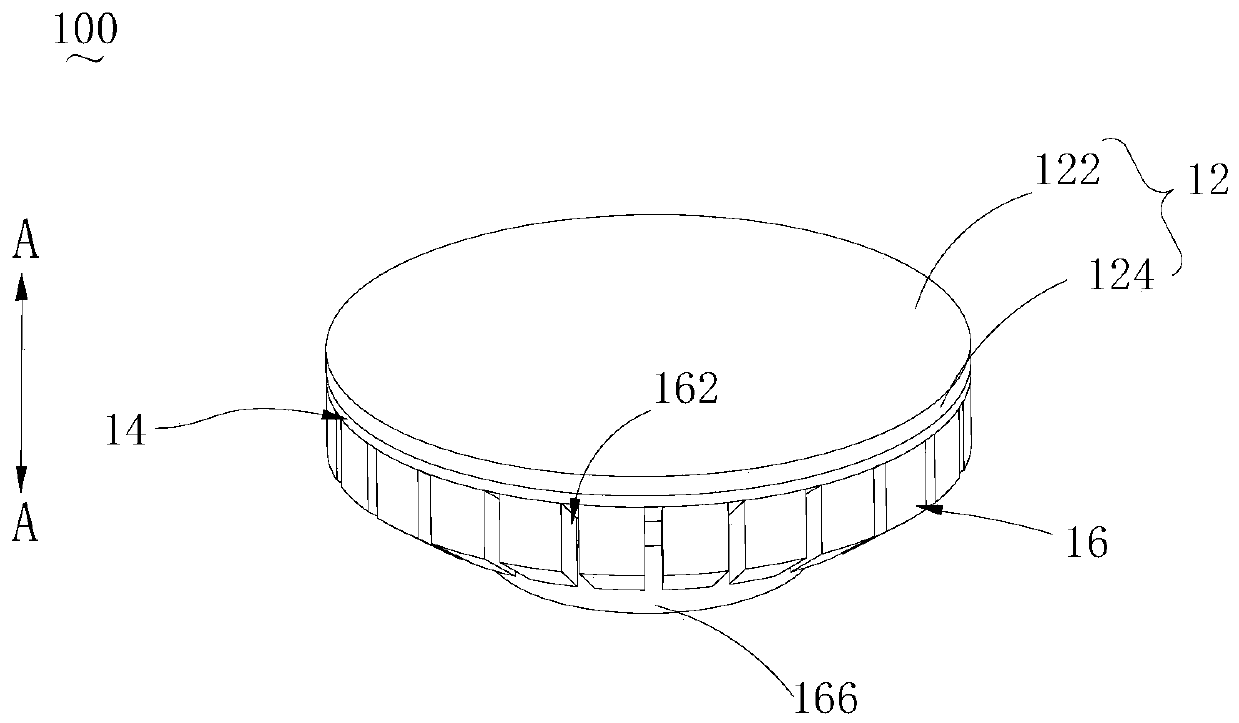

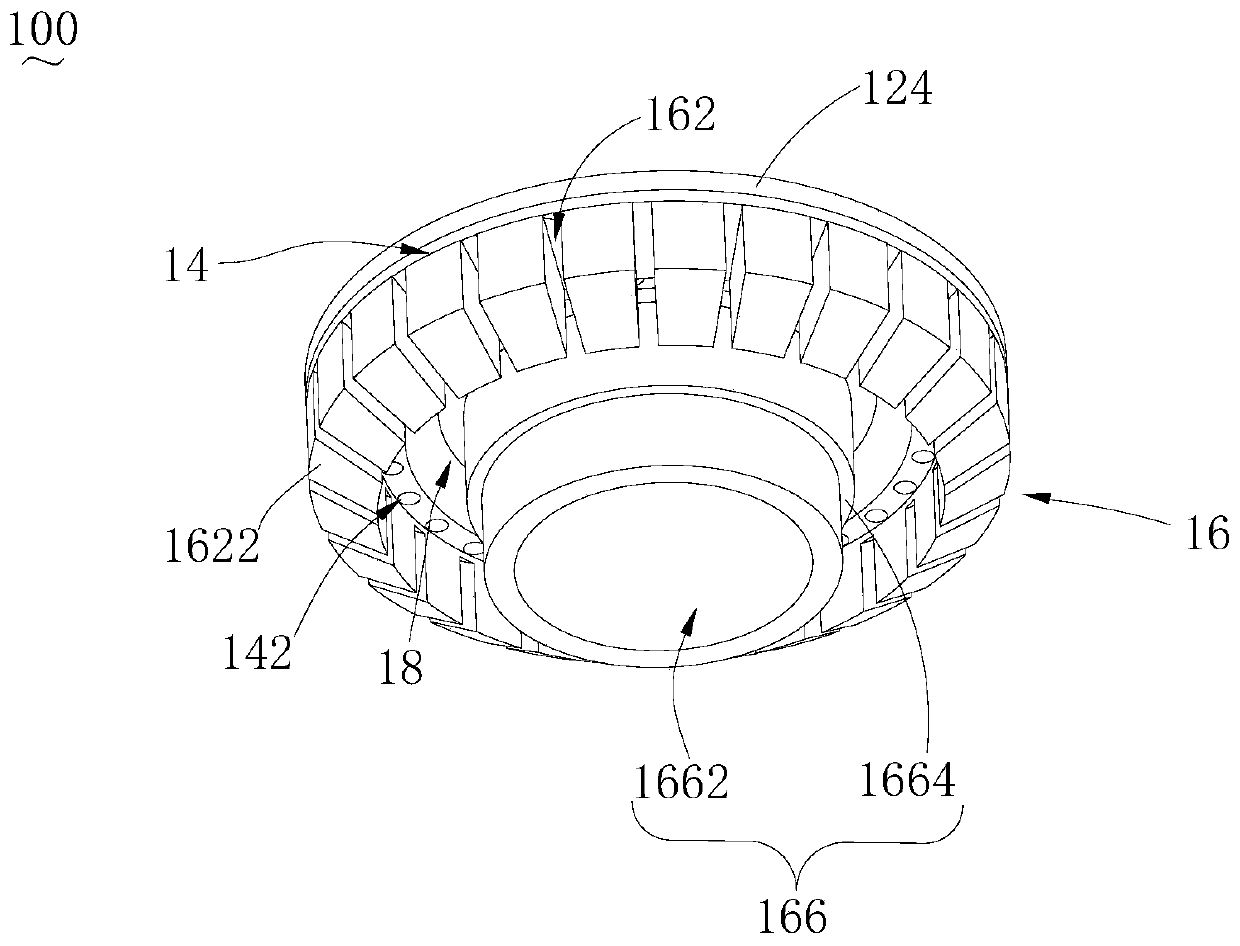

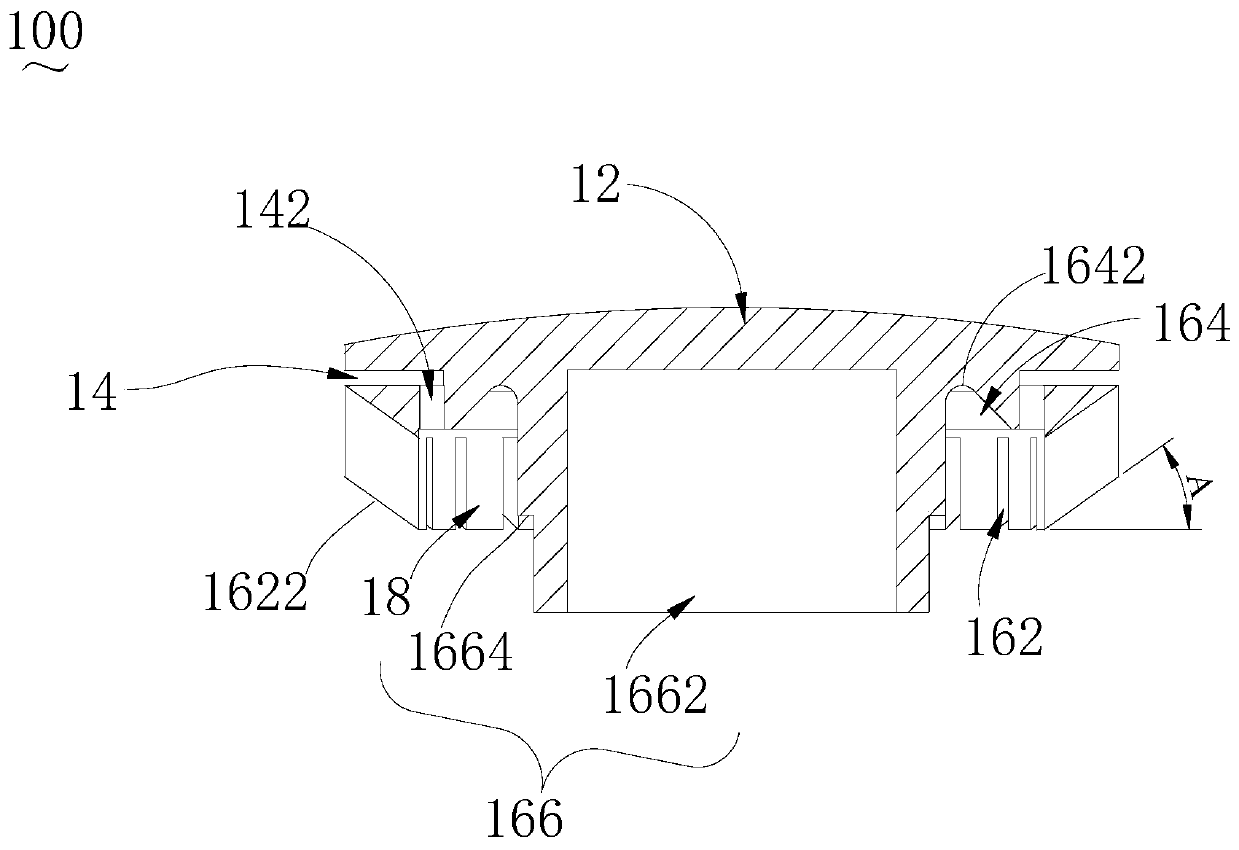

Burner cap of burner, burner and gas cooker

The invention discloses a burner cap of a burner, the burner and a gas cooker. The burner cap of the burner comprises a fire hole part, and a cavity is formed in the fire hole part. Multiple tooth-shaped fire holes communicating with the cavity are formed in the side wall of the cavity, and the multiple tooth-shaped fire holes are formed in the circumferential direction of the fire hole part at intervals. An annular flame stabilizing groove is formed in the fire hole part in the circumferential direction of the fire hole part, and an upper end and a lower end are formed at the position, on thecircumferential side face of the fire hole part, of each tooth-shaped fire hole. The flame stabilizing groove is located between the upper ends and the lower ends of the tooth-shaped fire holes. Theflame stabilizing groove communicates with the multiple tooth-shaped fire holes and the cavity. According to the burner cap of the burner, the flame stabilizing groove is located between the upper ends and the lower ends, formed on the circumferential side face, of the tooth-shaped fire holes, thus when the burner works, flames formed by the flame stabilizing groove can stabilize flames formed bythe tooth-shaped fire holes, the probability of flame floating and flame lifting of the tooth-shaped fire holes can be avoided, or the probability of flame floating and flame lifting of fuel gas in the tooth-shaped fire holes can be reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

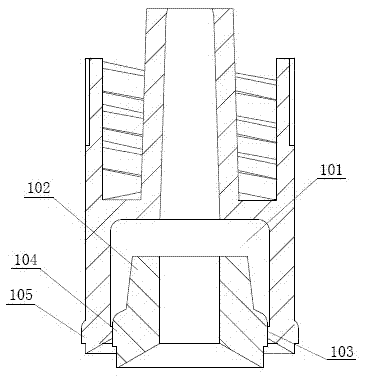

Injector

InactiveCN103041477ASatisfy the habit of pushing the needle to the endPrevent misfireInfusion syringesEngineeringSyringe needle

The invention discloses an injector comprising a syringe, a push rod and a syringe needle. The push rod is arranged in the syringe, a sealing rubber plug is sleeved at the front end of the push rod, and the syringe needle is arranged at the front end of the syringe through a Ruehl cone. The injector is characterized in that a conical surface structure matched with the top end of the sealing rubber plug is arranged at the bottom of an unloading sealing sleeve, the outer edge of the conical surface structure and the inner wall of the syringe form a hydraulic seal, and an interval section in 1-2mm is arranged between the conical surface structure and an expansion rib, so that a null-traveling stroke is obtained between the upper surface of the conical structure and the inner wall of the syringe, an elastic lock catch is arranged at the top end of the unloading sealing device, a fastening ring matched with the elastic lock catch in a socket manner is arranged in an unloading cavity, and pushing force of the unloading sealing sleeve moving along the null-traveling stroke is at least twice times of that for injecting medical liquid. By the aid of the null-traveling stroke and the elastic lock catch, pushing force triggering unloading is increased, false triggering of the Ruehl cone is avoided, and conventional using habits are complied.

Owner:SUZHOU YASI PRECISION MOLD

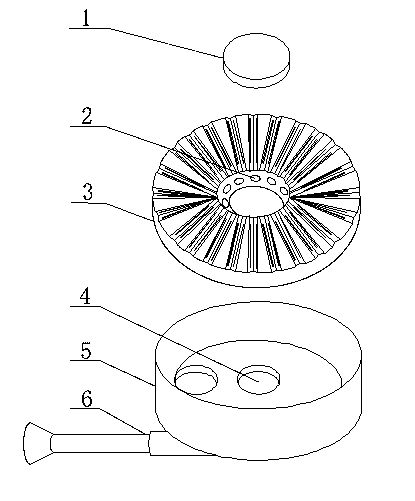

Fire cap, burner and household fuel gas device

The invention discloses a fire cap, a burner and a household fuel gas device. The fire cap comprises a cap part and a fire hole part, wherein the cap part comprises flanges arranged above the fire hole part at intervals, an annular flame stabilizing groove is formed between the flanges and the fire hole part, a cavity is formed in the fire hole part, a plurality of tooth-shaped fire holes communicating with the cavity are formed in the side wall of the cavity, the plurality of the tooth-shaped fire holes are arranged at intervals in the circumferential direction of the fire hole part, and theflame stabilizing groove is located above the plurality of the tooth-shaped fire holes and communicates with the tooth-shaped fire holes and the cavity. In the fire cap, the flame stabilizing groove is located above the tooth-shaped fire holes, and then when the burner works, a flame formed by the flame stabilizing groove can stabilize a flame formed by the tooth-shaped fire holes, and therefore flame separation and flame lifting of fuel gas are prevented from occurring on the tooth-shaped fire holes, or the occurrence probability of the flame separation and the flame lifting of the fuel gas on the tooth-shaped fire holes is reduced.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

Gas stove head device

ActiveCN103343972AIncrease profitPut an end to yellow fireNon-combustible gases/liquids supplyGaseous fuel burnerEngineeringCombustion

A gas stove head device comprises a base, a cover body with a through hole in the center and a sealing plug arranged in the through hole. The base is matched with the cover body, the cover body is of an annular structure with a conical inward-concave face, and blind holes are circumferentially distributed in the wall of the through hole in the center of the cover body. The upper surface of the cover body is provided with V-shaped grooves which are arranged at intervals, and inclined faces on the two sides of each V-shaped groove are provided with a gas groove and an air groove respectively. The air grooves are communicated with the insides of the blind holes, and the gas grooves penetrate through the upper surface and the lower surface of the cover body. The lower bottom face of the base is provided with a side leading-in pipe and a ventilation opening for installing a supercharge turbo-blower. The ventilation opening is arranged corresponding to the through hole in the cover body. The gas stove head device can achieve convection of gas and air, air is added through the air grooves, so that gas gathers together upwards, heat loss is reduced, combustion is more sufficient, and the effect of energy conservation and environment protection is achieved. After the gas stove head device is used for a long time, the gas stove head device can not expand and deform easily, and service life is prolonged.

Owner:常加林

Electroless self-starting firefighting extinguishing system

InactiveCN104801000AReduce wasteGuarantee the safety of lifeFire rescueElectroless nickelElectricity

The invention relates to an electroless self-starting firefighting extinguishing system. The powerless self-starting firefighting extinguishing system is characterized by comprising an extinguishing material storage tank, a guide pipe and a spray nozzle, wherein the spray nozzle is fixedly connected to the guide pipe and is communicated with the guide pipe, the outlet end of the extinguishing material storage tank is communicated with a head end inlet of the guide pipe, the spray nozzle is sleeved by a spray nozzle housing which can seal the spray nozzle and is made of a material easy to smelt. Compared with the prior art, the electroless self-starting firefighting extinguishing system has the following advantages that the structure is simple, easiness in installation can be realized, and the cost is low; the opening of the spray nozzle is realized to carry out the automatic extinguishing by virtue of the spontaneous smelting of the spray nozzle housing after being suffered from the high temperature, starting a power supply is not needed, the extinguishing time is shortened, timeliness in extinguishing can be realized, the fault extinguishing can be avoided, the resource waste is reduced, and the life and property safety of people can be guaranteed.

Owner:施建明

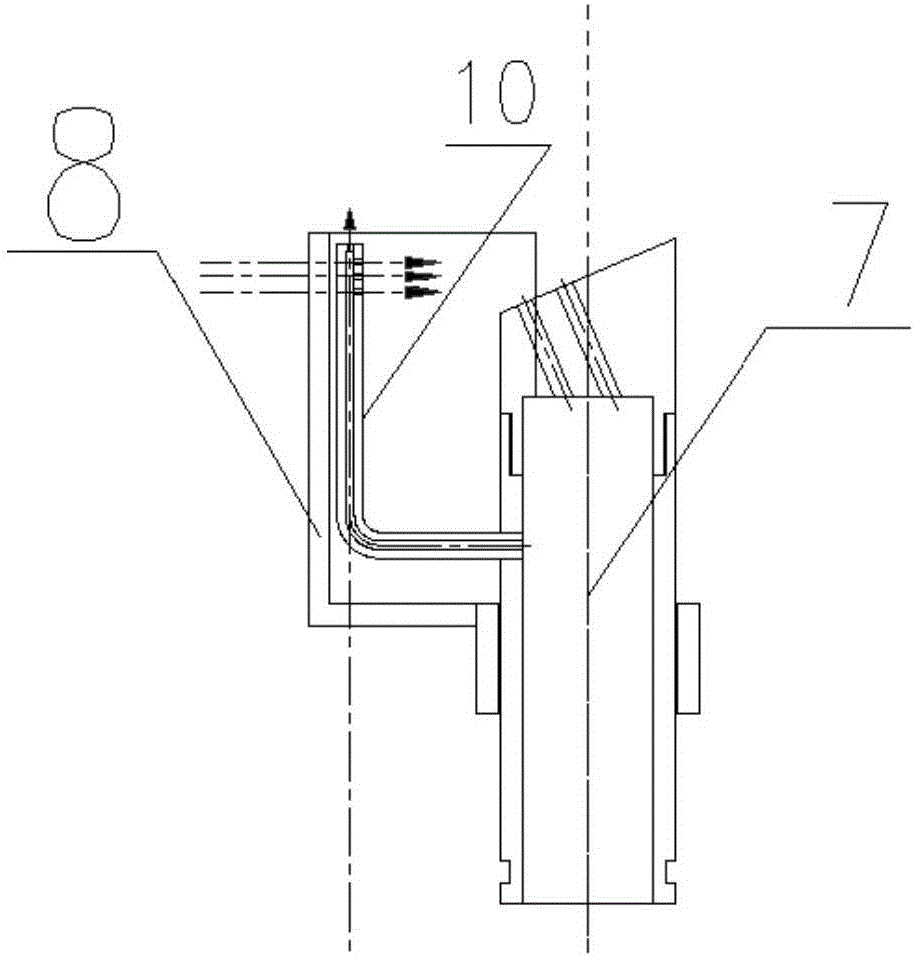

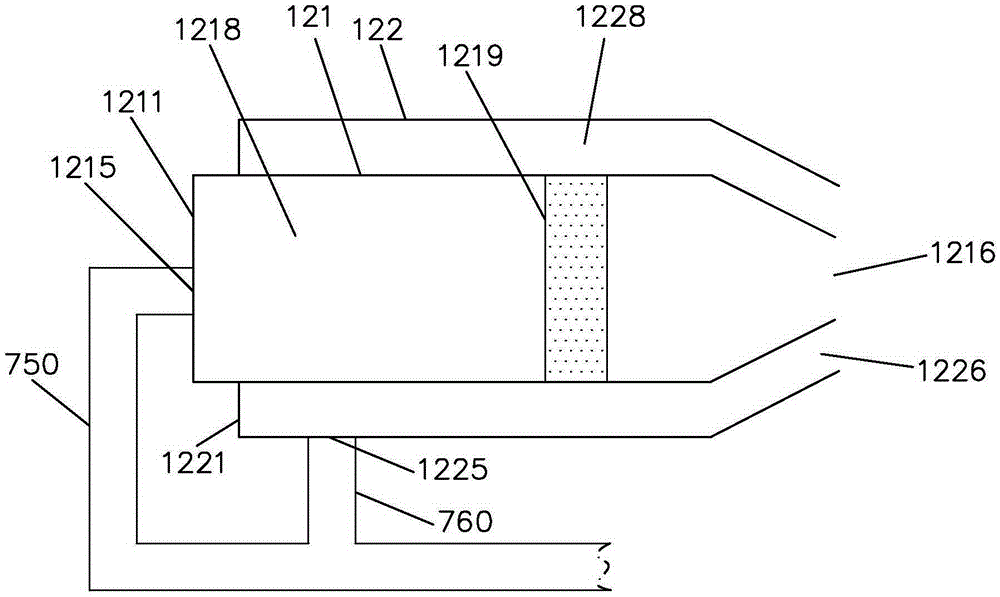

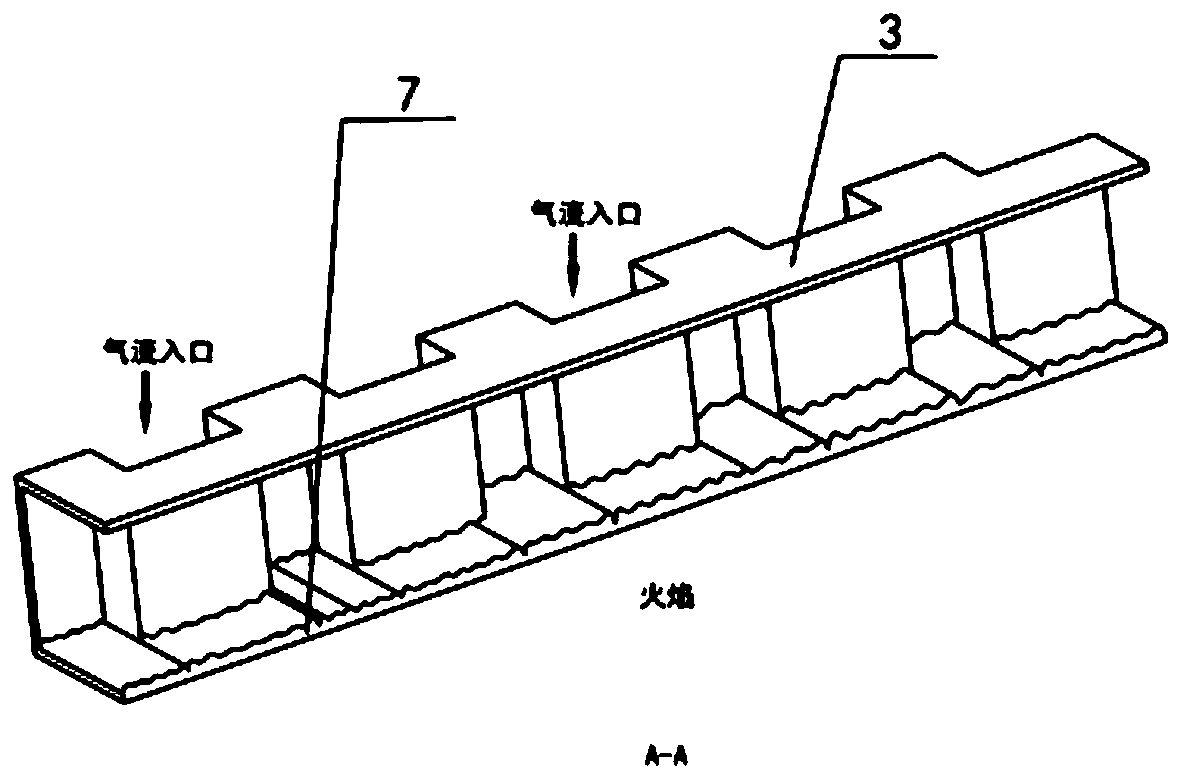

Full-premixing water-cooling gas boiler with U-shaped pipe structure

ActiveCN112460568AFlame stabilizationUniform flow and heat transferSteam generation using pressureWater heatersFlue gasEngineering

The invention discloses a full-premixing water-cooling gas boiler with a U-shaped pipe structure. The full-premixing water-cooling gas boiler comprises a water-cooling combustor and a water-cooling heat exchanger which are coaxially arranged, a premixer and a water-cooling combustion head are arranged in the water-cooling combustor, a water outlet of the water-cooling combustor is in communicationwith a water inlet of the water-cooling heat exchanger, and the premixer is in communication with a gas inlet of the water-cooling combustion head; the water-cooling combustion head comprises combustion head water-cooling tube bundles and a combustion head upper header, the combustion head upper header is nested inside and outside, and the two ends of each combustion head water-cooling tube bundle are in communication with the combustion head upper header on the inner side and the combustion head upper header on the outer side respectively; a water inlet of the combustion head upper header isin communication with boiler feed water, and a single water cooling tube of each water cooling tube bundle is U-shaped; a flow equalizing pore plate is arranged on the inner side of the water-coolingcombustion head, and an ignition gun is arranged on the outer side of the water-cooling combustion head; and flue gas flows out of the water-cooling combustion head, then uniformly flows to each water-cooling tube bundle in the water-cooling heat exchanger, then flows downwards to a dew containing disc from a gap between an outer-ring water-cooling tube bundle and the boiler wall and is discharged through a chimney, so that the heat exchange capacity is greatly improved, and the safe and stable operation of the boiler is facilitated.

Owner:XI AN JIAOTONG UNIV

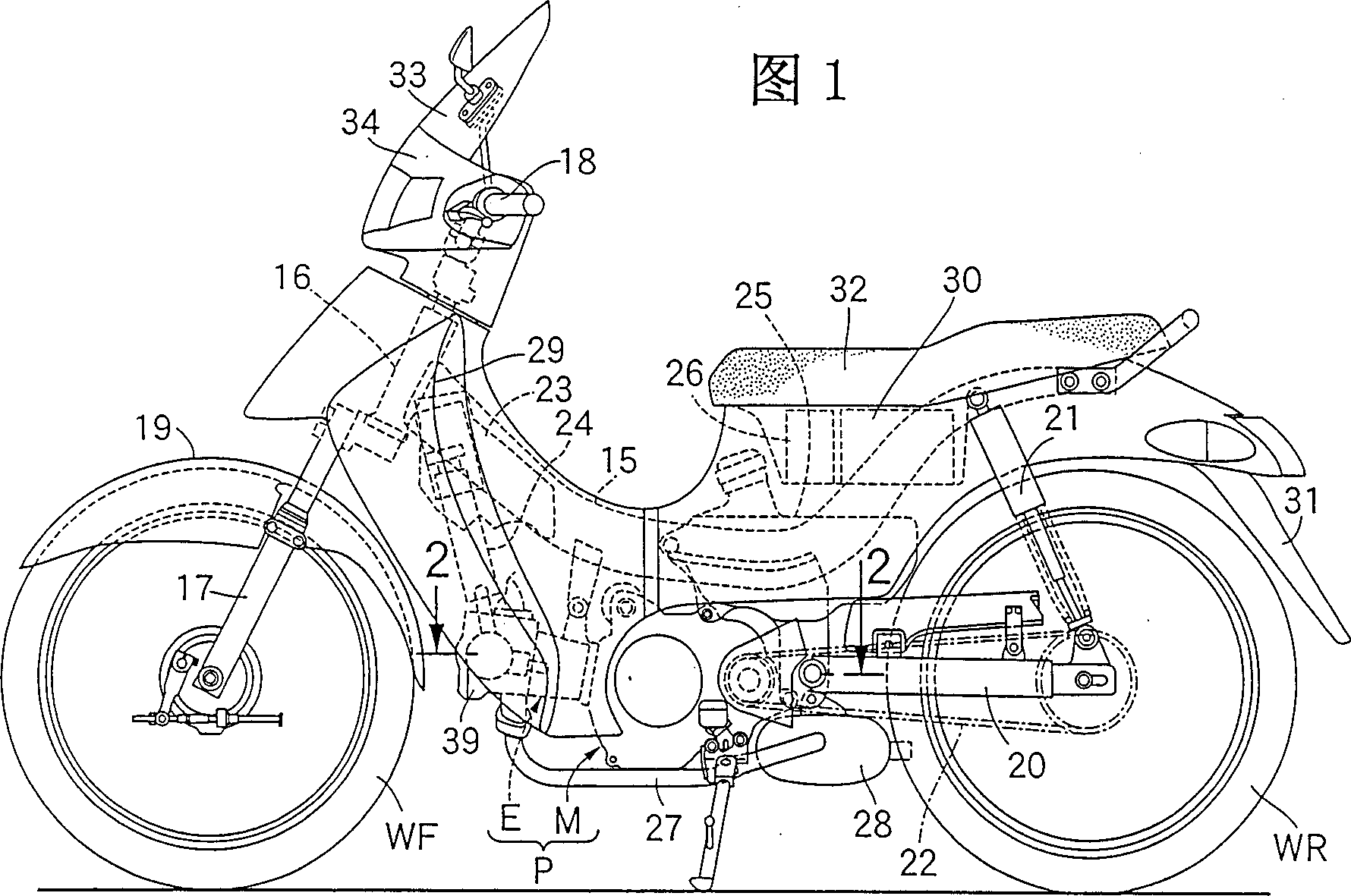

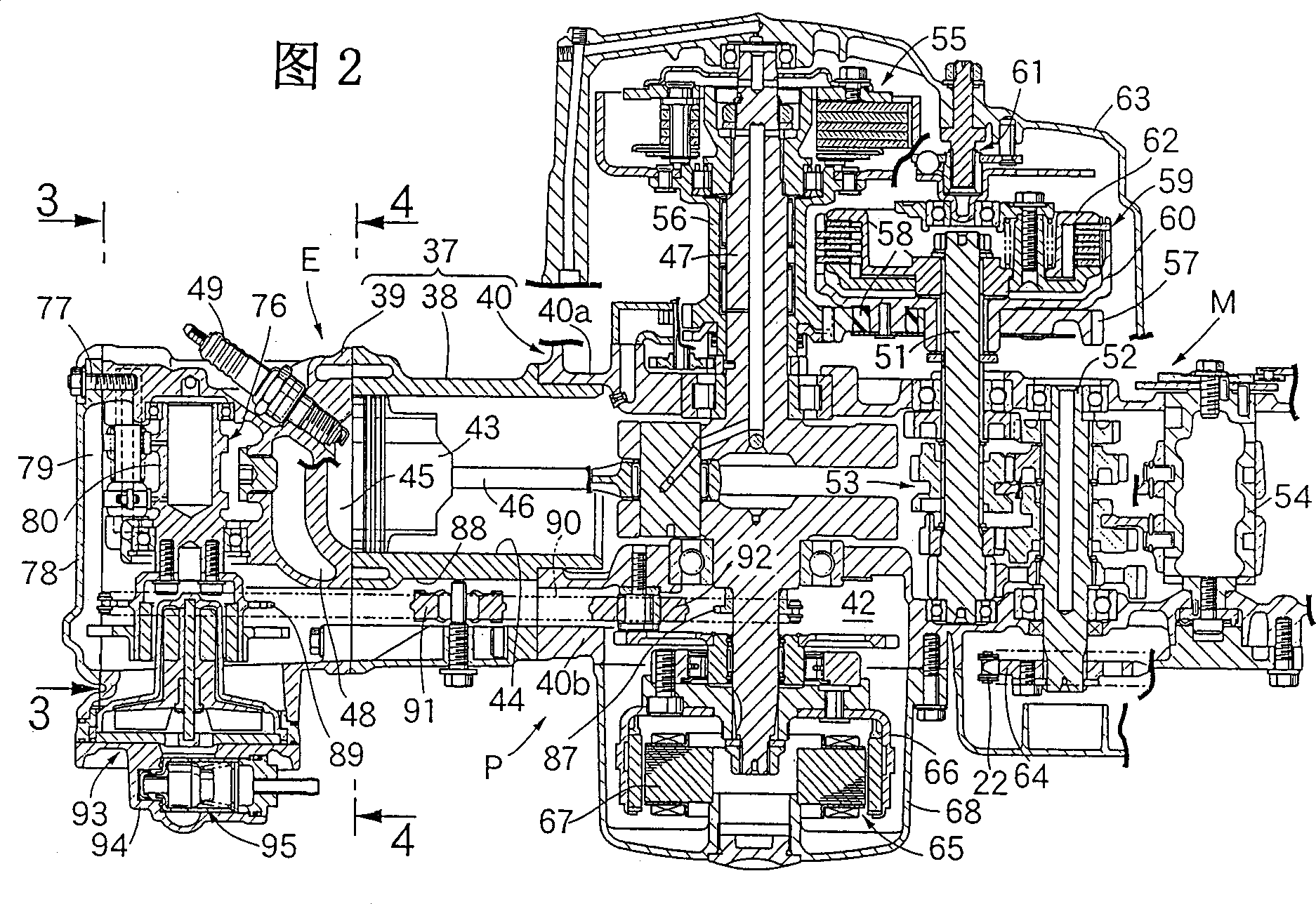

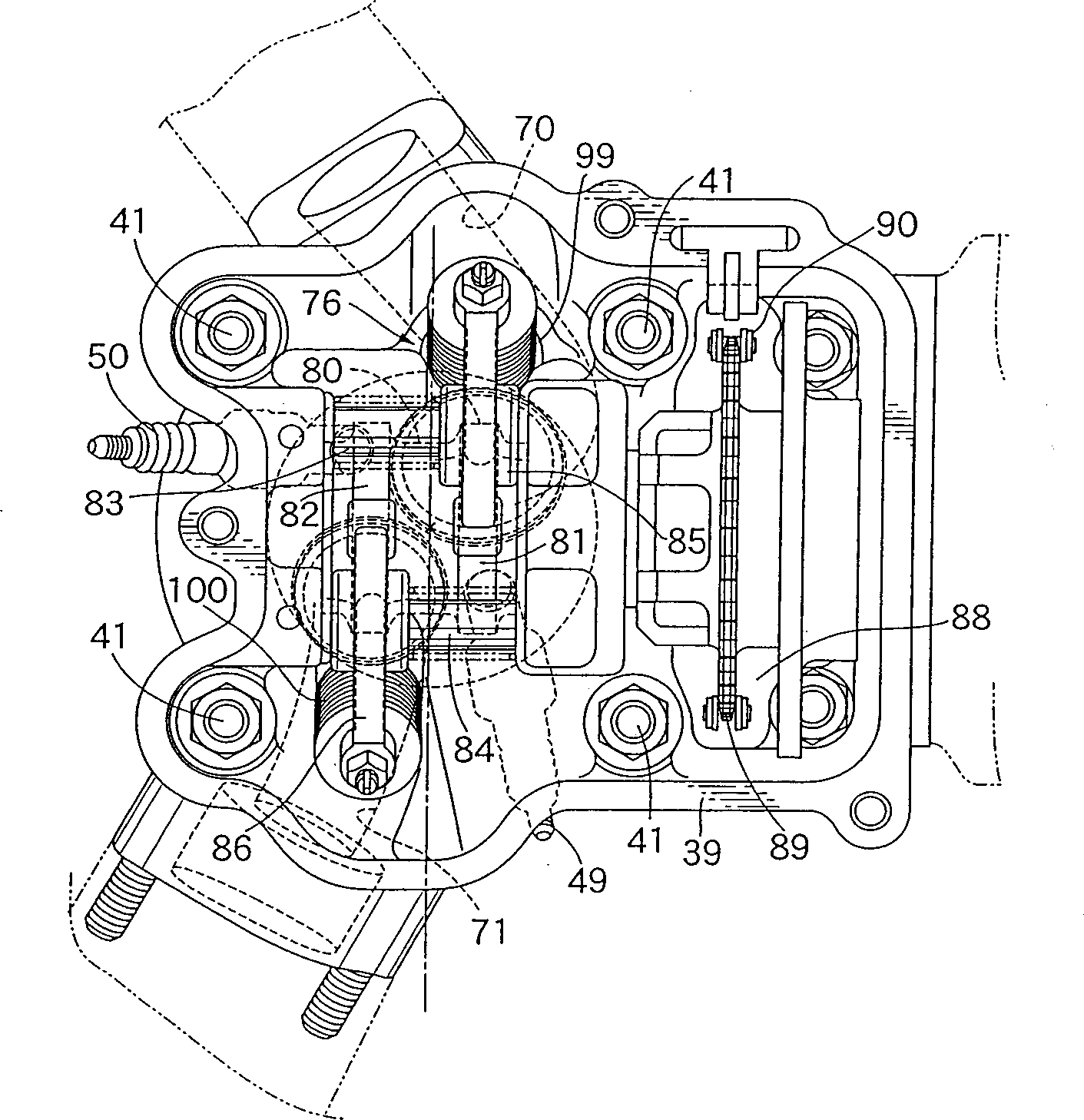

Spark-ignition four-stroke engine

InactiveCN1337526AAvoid smokingPrevent misfireInternal combustion piston enginesElectric ignition installationCylinder headFour-stroke engine

The invention provides a spark-ignition four-stroke engine, in which a plurality of ignition plugs facing the same combustion chamber are mounted on a cylinder head, which can prevent ignition failure by an ignition plug . An intake port 70 is mounted on a cylinder head 39 to enable to produce a swirl in a combustion chamber 45, and the heating value becomes higher as the ignition plugs are apart from the intake port 70 along the flow direction of the swirl in the combustion chamber 45.

Owner:HONDA MOTOR CO LTD

Low-emission biomass gasification poly-generation reburning device and technology

InactiveCN106047417AIncrease varietyIncrease moisture contentGasification processes detailsCombustible gas productionCombustorFluidized bed

The invention discloses a low-emission biomass gasification poly-generation reburning device and technology. The low-emission biomass gasification poly-generation reburning device comprises a biomass updraught type gasification cogeneration device, wherein the gas outlet of the biomass updraught type gasification cogeneration device is connected with a gas pressure boost fan inlet; a gas pressure boost fan outlet is connected with a circulating fluidized bed gas heating furnace; the circulating fluidized bed gas heating furnace comprises a gas-solid separator and a return feeder; the circulating fluidized bed gas heating furnace is also connected with an air blaster; the outlet of the gas-solid separator is connected with a boiler; the tail of the boiler is connected with an induced draft fan; the outlet of the induced draft fan is connected with a chimney. Biomass gas is preheated by the circulating fluidized bed gas heating furnace, the biomass gas is firstly preheated to be above a fire point, and then, air distribution burnout is carried out. Compared with a traditional burner, the low-emission biomass gasification poly-generation reburning device is characterized in that the temperature and calorific value requirements of the biomass gas are lowered, the type and the moisture content of the biomass which can be used for gasification are enlarged, and an environment protection effect is good.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

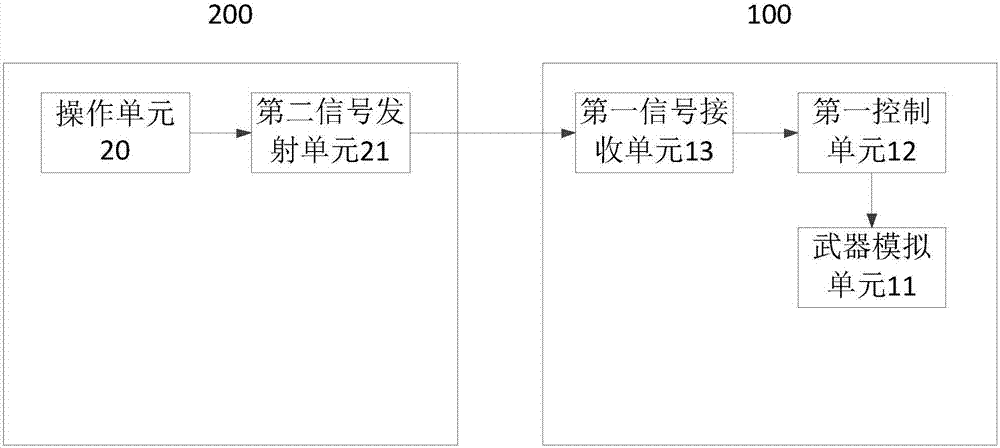

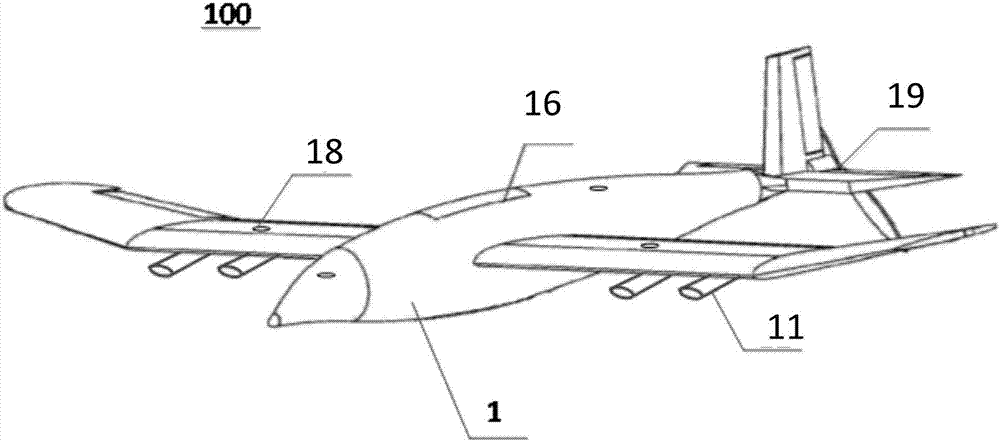

Mounting and debugging method of weapon simulating unit in remote-control model

ActiveCN107401952AAvoid elasticAvoid the situationTraining adaptationElectrical resistance and conductanceRemote control

The invention relates to a mounting and debugging method of a weapon simulating unit in a remote-control model. The mounting and debugging method comprises the steps that S10, preset voltage is applied to each fuse wire, wherein current, generated by the preset voltage, of each fuse wire is less than fusing current of the corresponding fuse wire; S11, whether each return circuit is conducted is judged, if not, scrap disposal is carried out and the operation is finished, and if so, S12 is carried out; S12, actual resistance of each fuse wire is acquired according to the generated current of the corresponding fuse wire; S13, fireworks are inserted into launching drums, and the fuse wires are aligned to lead wire ends mutually; S14, the preset voltage is applied to the fuse wires for the second time through first lead wires and second lead wires; S15, according to the generated current of each fuse wire, mounting resistance of the corresponding fuse wire is acquired; and S16, whether the mounting resistance is less than the actual resistance is judged, if so, mounting in place is determined and the operation is finished, and if not, S13 is carried out.

Owner:黄巧香

Nonel electronic delay detonator and method for detonating the detonator with double control of light and shock wave

ActiveCN105403112BReduce the probability of accidental explosionPrevent misfireElectric fuzesShock waveDetonator

The invention relates to a detonating tube electronic delay detonator and a method for detonating the detonator under the double control of light and shock waves. The detonating tube electronic delay detonator comprises a detonating tube, a basic detonator body and an electronic delay control device. The electronic delay control device comprises an AND gate electronic delay detonation circuit, an electric firing head, a light signal converter and a shock wave circuit breaker, wherein the electric firing head is connected with the output end of the AND gate electronic delay detonation circuit, the light signal converter receives a light signal after the detonating tube is detonated to enable one control end of the AND gate electronic delay detonation circuit to be switched on, and the shock wave circuit breaker receives a shock wave signal after the detonating tube is detonated to enable the other control end of the AND gate electronic delay detonation circuit to be switched on. The electronic delay control device carries out the double control through the light and the shock waves, the light signal converter and the shock wave circuit breaker can trigger the AND gate electronic delay detonation circuit to start a delay procedure after simultaneously switching on the respectively controlled control ends, and after set time is up, the electric firing head emits fire to detonate the basic detonator body.

Owner:XIANGNAN EXPLOSION APPLIANCES HUNAN PROV

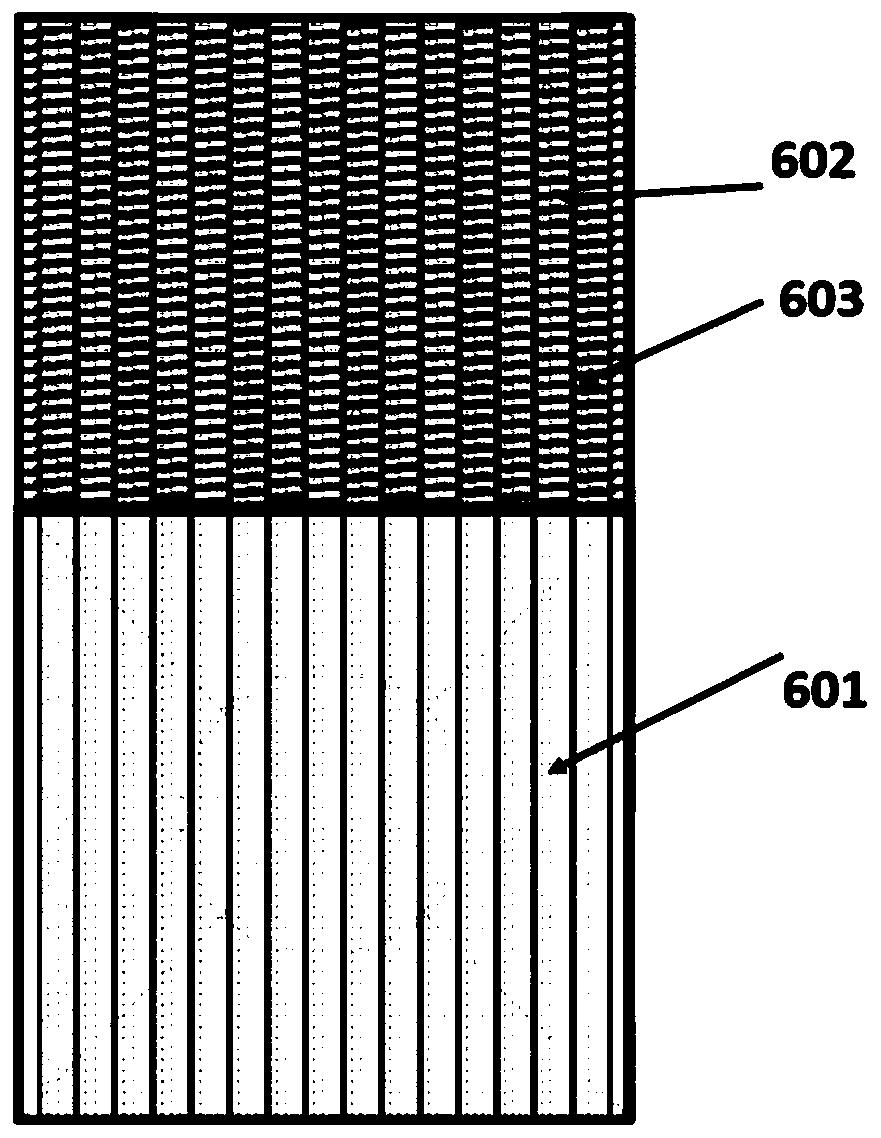

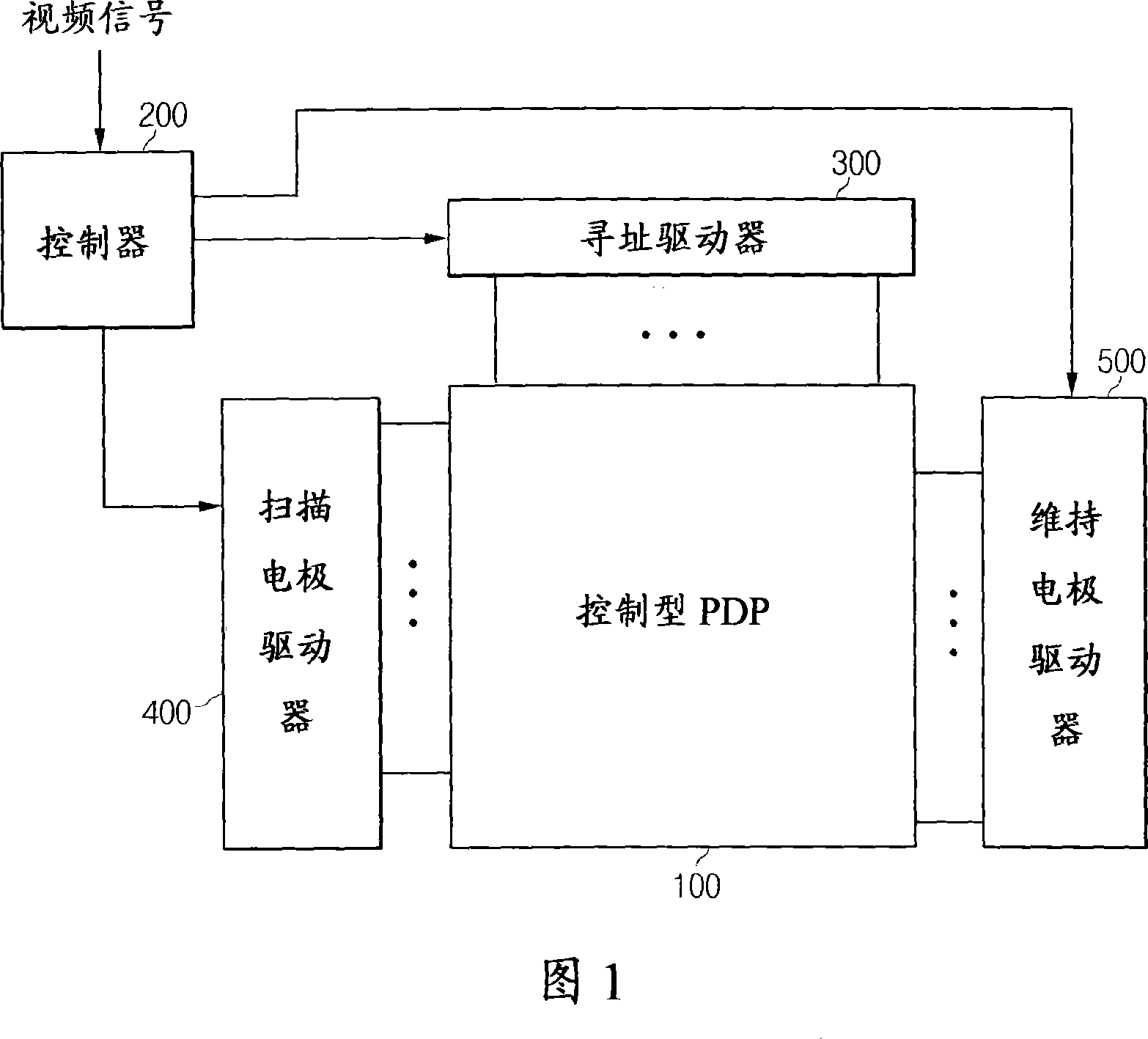

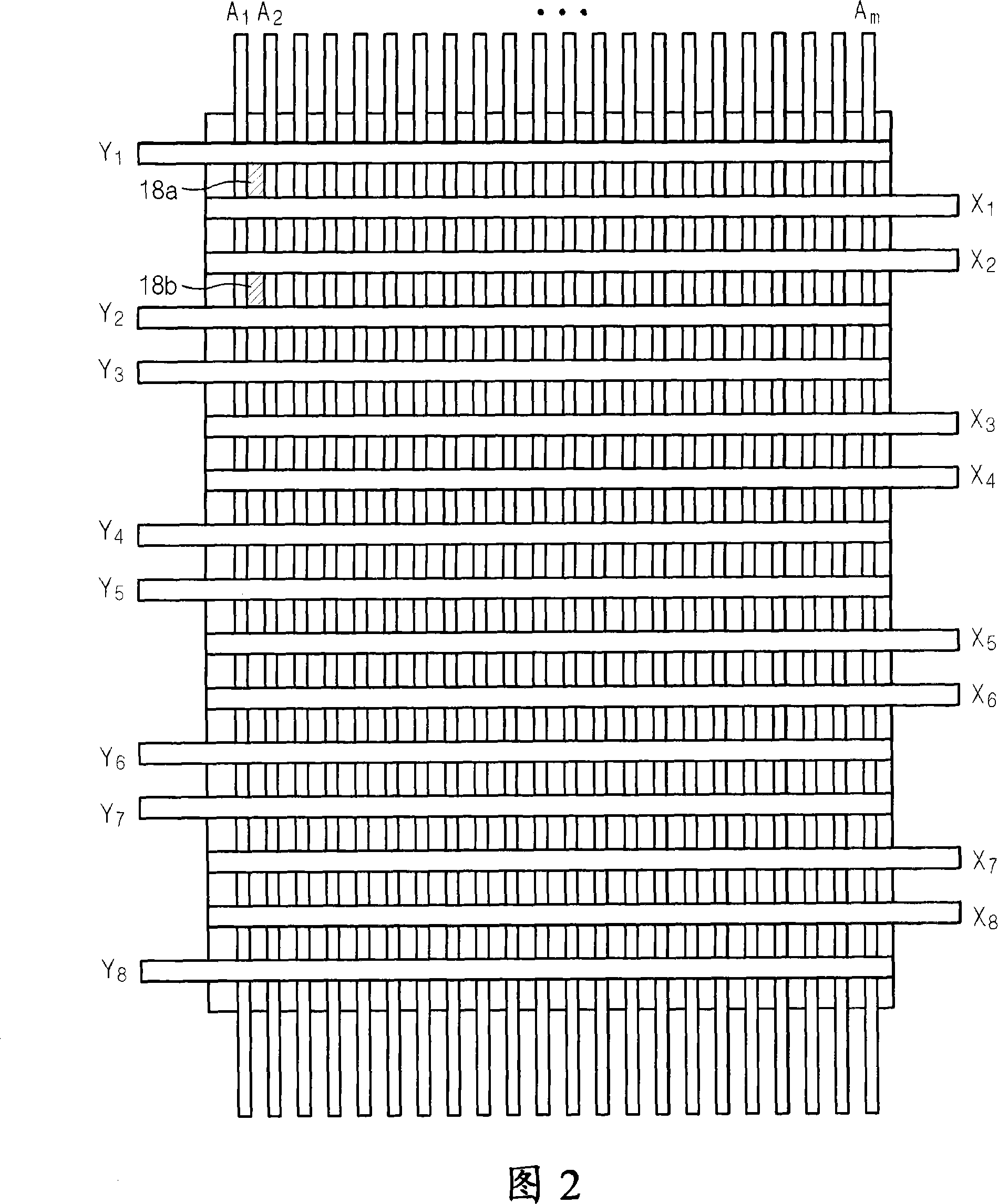

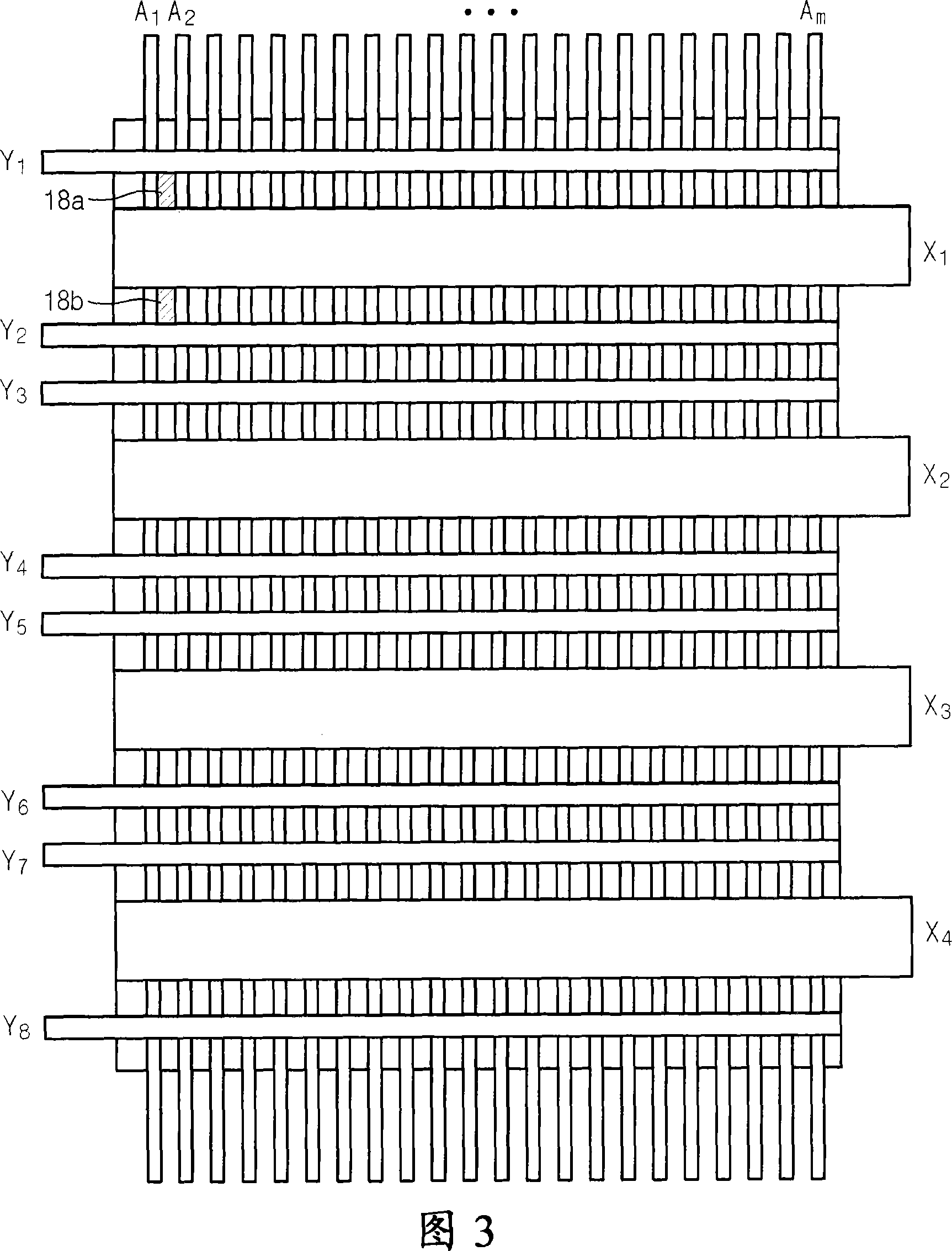

Plasma display and driving method thereof

InactiveCN101188086APrevent misfireAddress electrodesSustain/scan electrodesDisplay deviceEngineering

A plasma display and a driving method for the plasma display. The plasma display is constructed with a control type plasma display panel having a closed barrier rib configuration, and each pair of column-wise neighboring discharge cells have different electrode arrangement. In the driving method, when the control type plasma display panel has an alignment error for a first electrode and a second electrode, a scan pulse having a first width is applied to an odd-numbered first electrode, and the scan pulse having a second width that is different from the first width is applied to an even-numbered first electrode.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com