Industrial gas ultralow-nitrogen energy-saving spiral combustion head and combustor

An industrial gas, ultra-low nitrogen technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of high temperature production, loss of heat energy, environmental pollution, etc., to reduce the content of nitrogen oxides, reduce High temperature area, the effect of enhancing the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

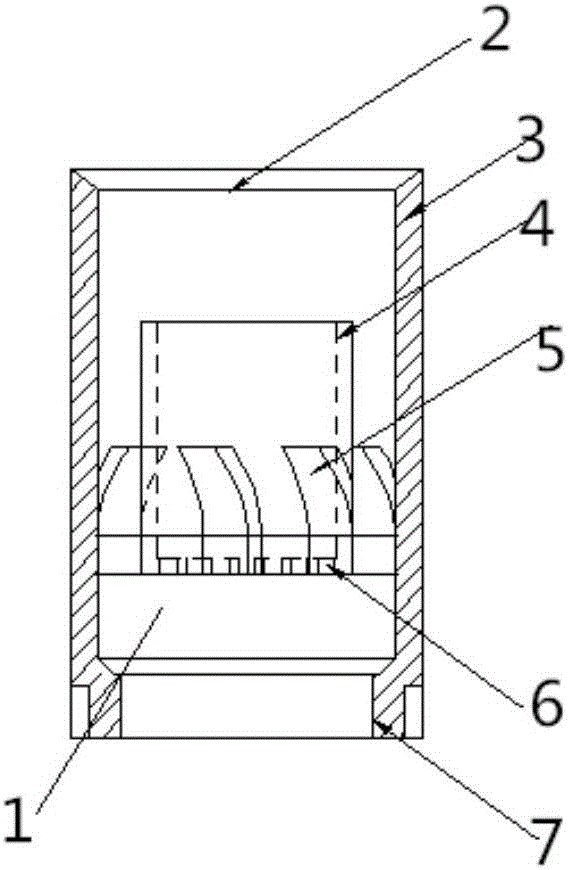

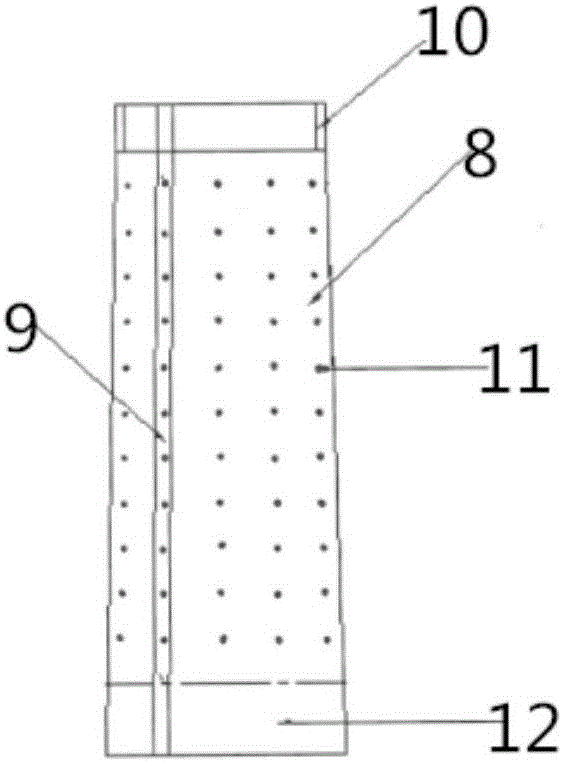

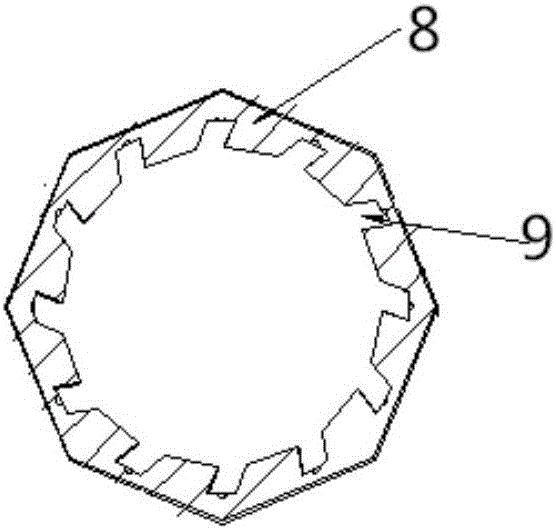

[0026] Such as Figure 1-7 As shown, the reference signs are as follows: spiral combustion head 1, fire outlet 2, cylindrical outer wall 3, cylindrical inner wall 4, spiral protrusion 5, air outlet 6, combustion head connecting section 7, combustion rod 8, gas chute 9. Combustion rod connection section 10, combustion hole 11, pouring connection section 12, primary air distribution port 13, gas nozzle 14, secondary air distribution port 15, tertiary air distribution port 16, premixing section 17, contraction section 18, mixed gas outlet 19 , expansion section 20, advection section 21, air inlet pipe 22, air chamber 23, air inlet 24, long open flame pipe 25, ignition hole 26, observation hole 27, gas chamber 28, conical control valve 29, air inlet 30, gas Metal pipe 31, burner shell 32, ceramic wool insulation layer 33, heat-insulating refractory pouring material 34, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com