Low-emission biomass gasification poly-generation reburning device and technology

A biomass gas and biomass technology, applied in the field of biomass, can solve the problems of low gas outlet temperature, high moisture content of biomass, and high tar content, and achieve the effects of stable combustion, reduction of S element content, and reduction of NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

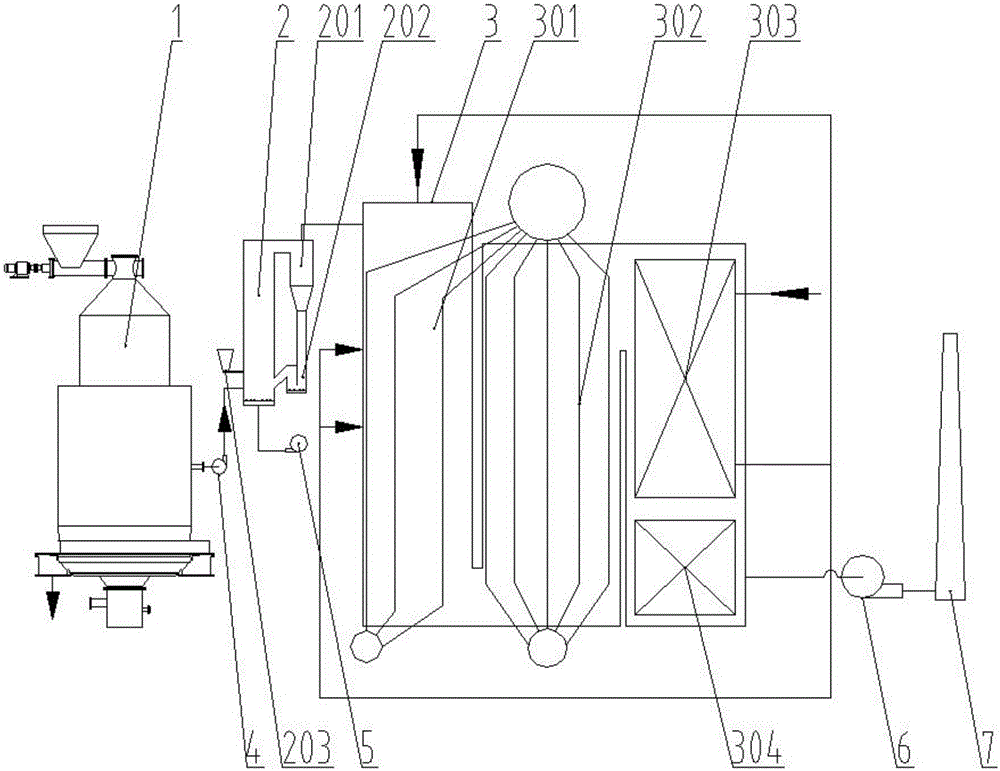

[0050] The raw material is 5cm bamboo chips with a water content of 35%. The circulating fluidized bed gas heating furnace 2 is filled with wear-resistant bed material, and the biomass gasification gasification cogeneration device 1 is gasified to produce biomass gas. The temperature of the gas is about 60°C. Value 680kcal / Nm 3 The biomass gas is pressurized by the gas booster fan 4 and sent into the circulating fluidized bed gas heating furnace 2 equipped with wear-resistant bed material. The circulating fluidized bed gas heating furnace 2 organizes the mixing and combustion of biomass gas and air to heat the gas to 750°C. The high-temperature gas is sent into the boiler 3, and is combusted with the preheated high-temperature air in the boiler combustion furnace 301. The high-temperature flue gas generated by combustion passes through the heating surface 302, the air preheater 303, and the economizer 304 to recover heat and then discharge it. The NOx content in the exhaust g...

Embodiment 2

[0052] The raw material is biomass pellets with a water content of 15%. The circulating fluidized bed gas heating furnace 2 is fed with wear-resistant bed materials, and the biomass updraft gasification cogeneration device 1 is gasified to produce biomass gas and biochar. The temperature of the gas is about 250℃, calorific value 1200kcal / Nm 3 The biomass gas is pressurized by the gas booster fan 4 and sent into the circulating fluidized bed gas heating furnace 2 equipped with wear-resistant bed material. The circulating fluidized bed gas heating furnace 2 organizes the mixing and combustion of biomass gas and air to heat the gas to 900°C. The high-temperature gas is sent into the boiler 3, and is combusted with the preheated high-temperature air in the boiler combustion furnace 301. The high-temperature flue gas generated by combustion passes through the heating surface 302, the air preheater 303, and the economizer 304 to recover heat and then discharge it. The NOx content i...

Embodiment 3

[0054] The raw material is straw with a water content of 30%. The circulating fluidized bed gas heating furnace 2 is added with wear-resistant bed materials, and the biomass updraft gasification cogeneration device 1 is gasified to produce biomass gas and biochar. The temperature of the gas is about 140°C. Calorific value 450kcal / Nm 3 The biomass gas is pressurized by the gas booster fan 4 and sent into the circulating fluidized bed gas heating furnace 2 equipped with wear-resistant bed material. The circulating fluidized bed gas heating furnace 2 organizes the mixing and combustion of biomass gas and air, and heats the gas to 500°C. The high-temperature gas is sent into the boiler 3, and is combusted with the preheated high-temperature air in the boiler combustion furnace 301. The high-temperature flue gas generated by combustion passes through the heating surface 302, the air preheater 303, and the economizer 304 to recover heat and then discharge it. The NOx content in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com