Outer burner cap for fuel gas type burner

A technology for an outer fire cover and a burner, which is applied to the field of the outer fire cover, can solve the problems of the fire hole being off or leaving the flame, the flame stability is poor, the flame is not stable enough, etc., and achieves good flame stabilization effect, excellent stability and heating. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

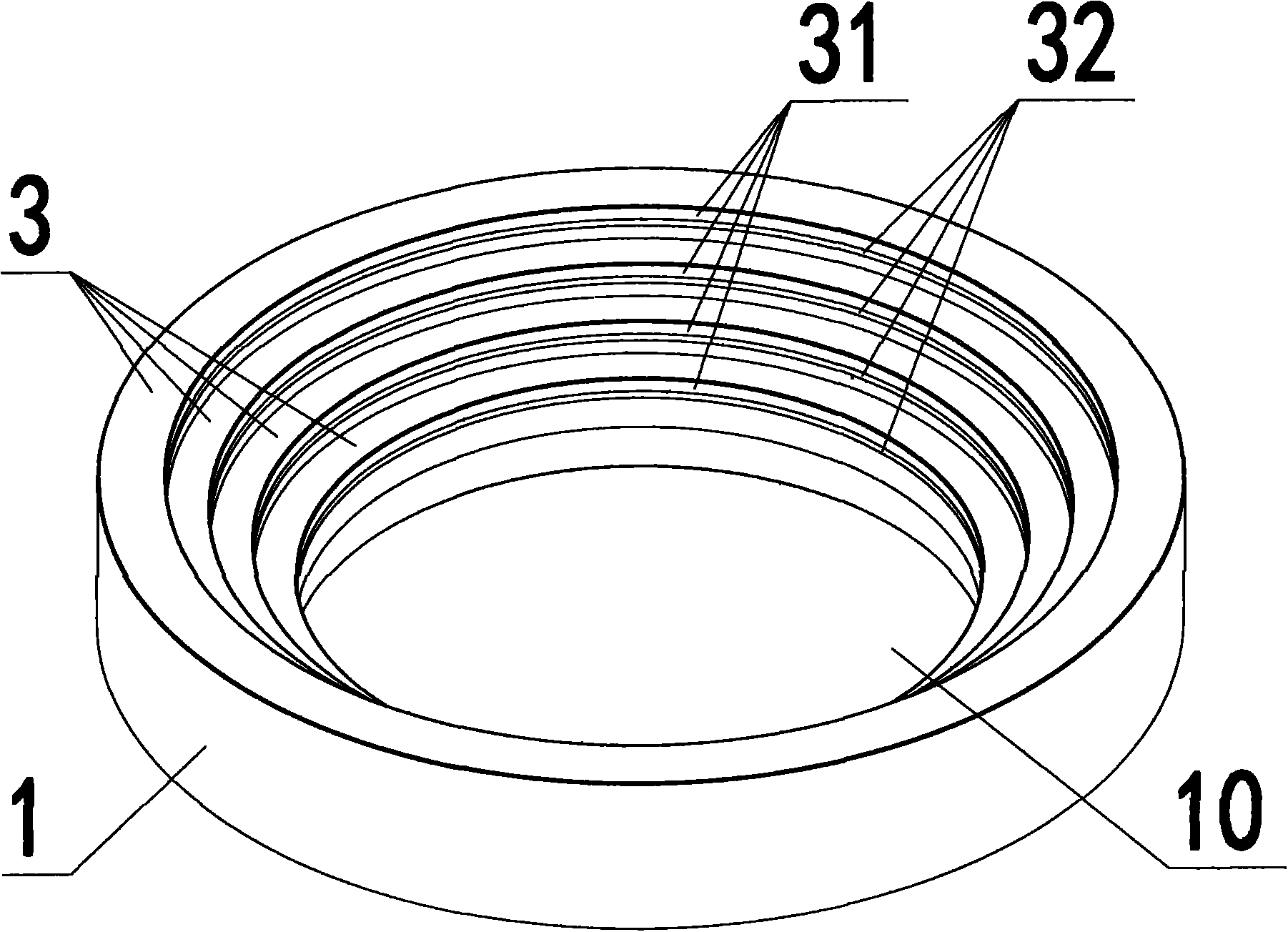

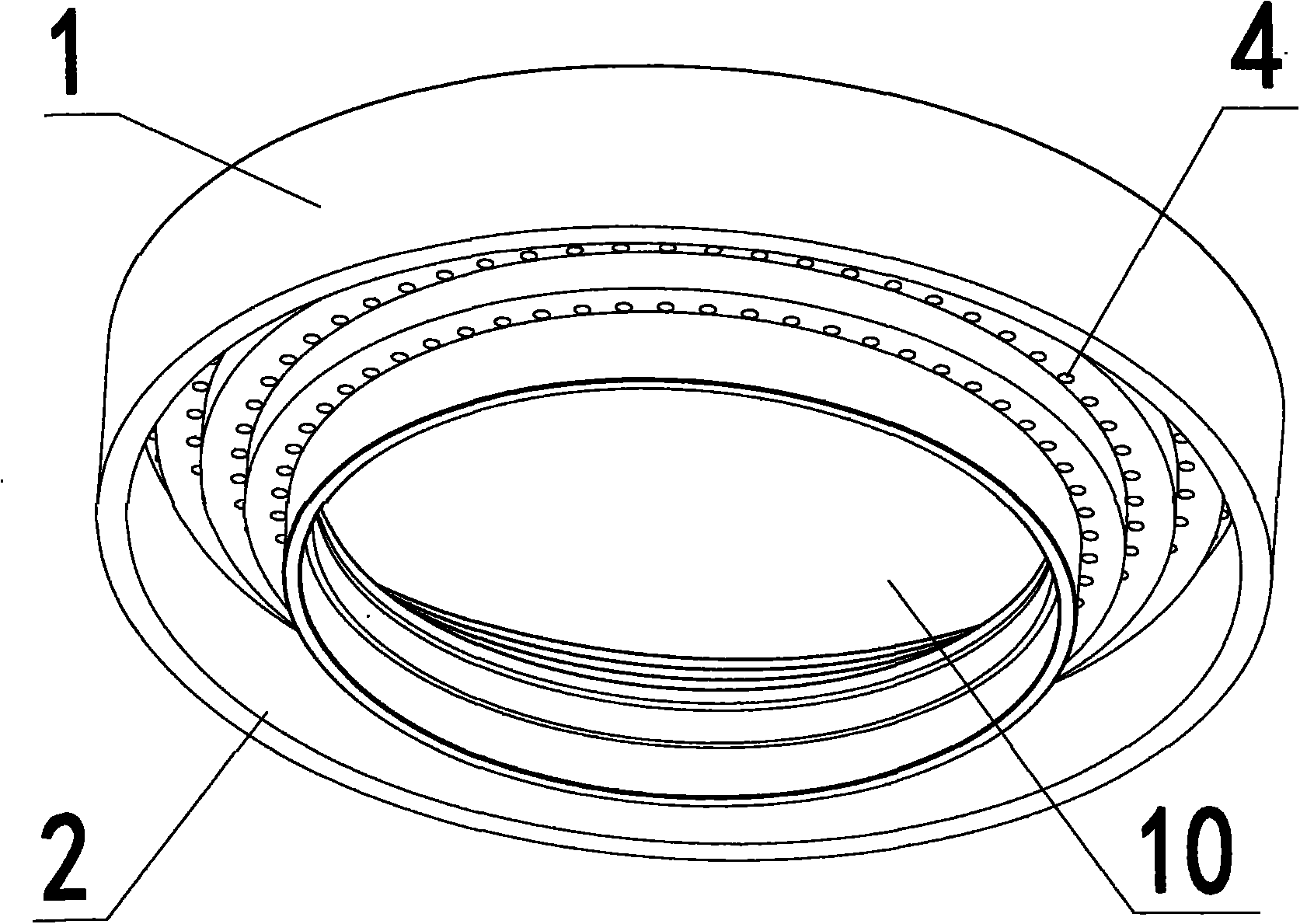

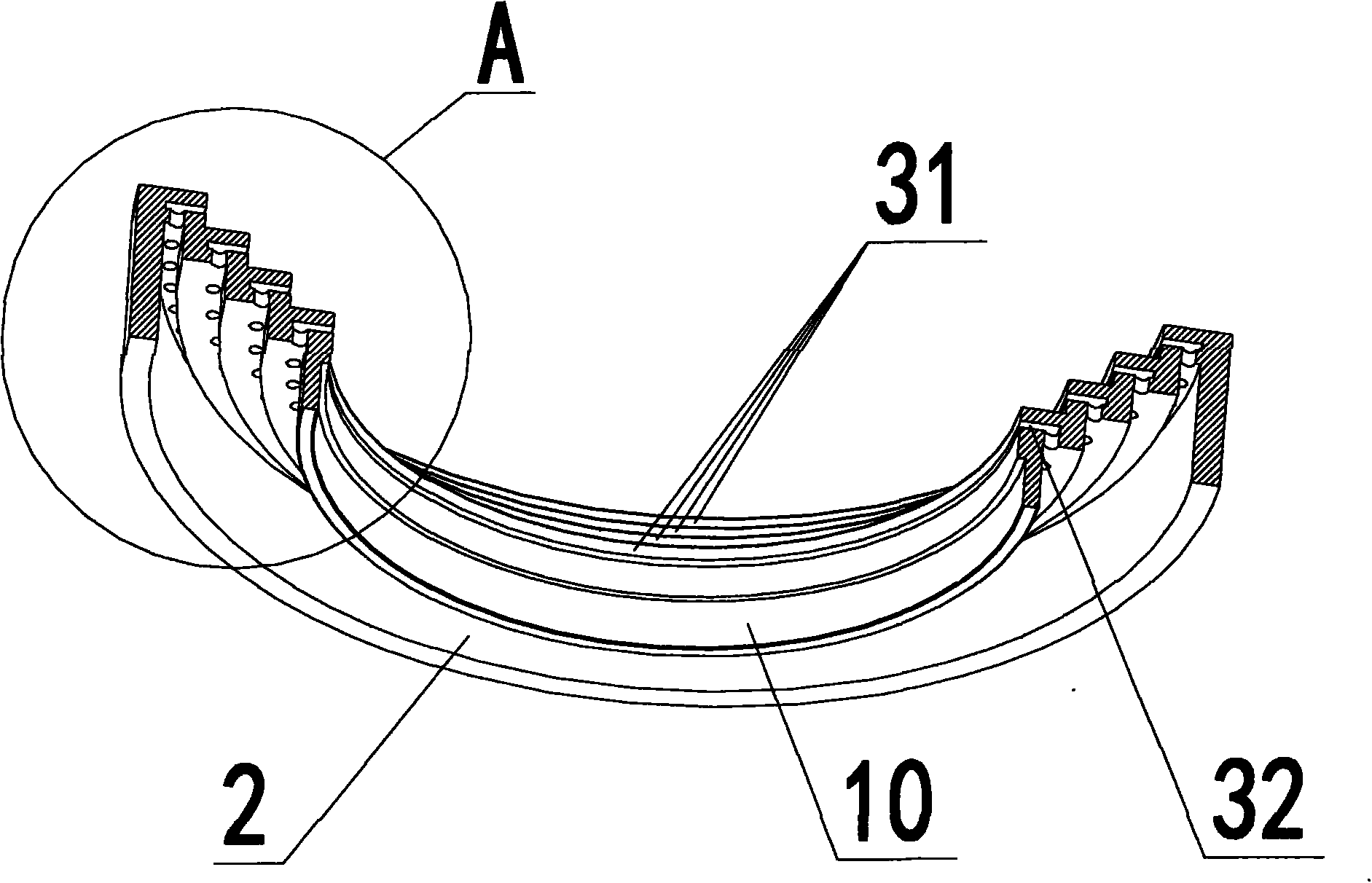

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present embodiment is used for the outer fire cap of gas type burner and comprises the outer fire cap body 1 that has inner hole 10, and the lower side of exterior fire cap body 1 is provided with mixing chamber 2, and the outer fire cap body 1 The inner wall is provided with a plurality of stacked steps 3 that are arranged step by step from the outside to the inside. The stacked steps 3 divide the inner wall of the outer fire cover body 1 into a plurality of side walls 31, and the side walls 31 are provided with annular grooves 32. The lower side of the cover body 1 is provided with a plurality of gas through-hole units respectively corresponding to the annular grooves 32 one-to-one. One end of the gas through hole 4 communicates with the gas mixing chamber 2 respectively, and the other end of the plurality of gas through holes 4 of any one gas through hole unit communicates with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com