Patents

Literature

212results about How to "Lower flame temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

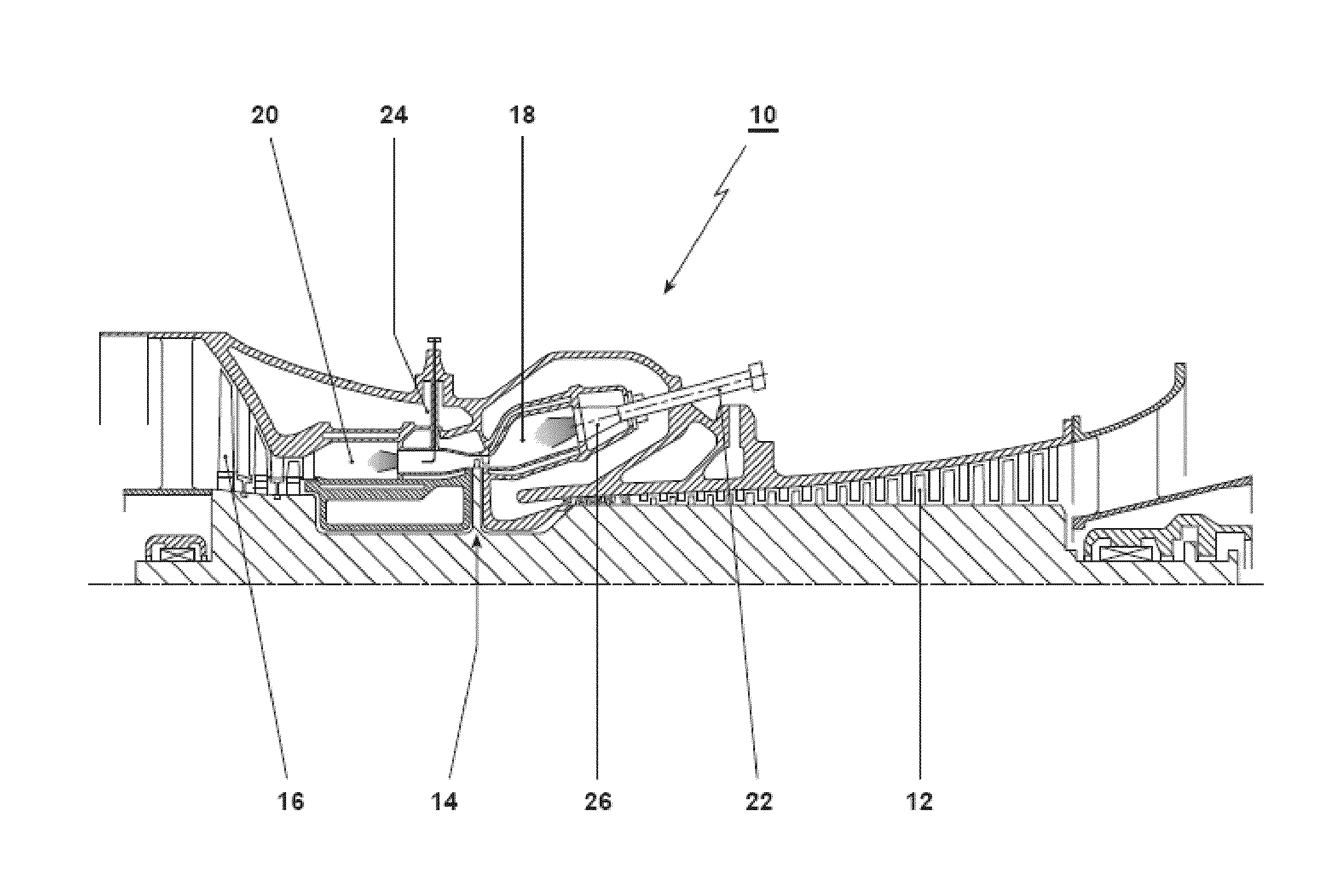

Burner, gas turbine combustor, burner cooling method, and burner modifying method

InactiveUS20070003897A1Reduce flame temperatureImprove reliabilityContinuous combustion chamberGaseous fuel pretreatmentMixed fuelCombustion chamber

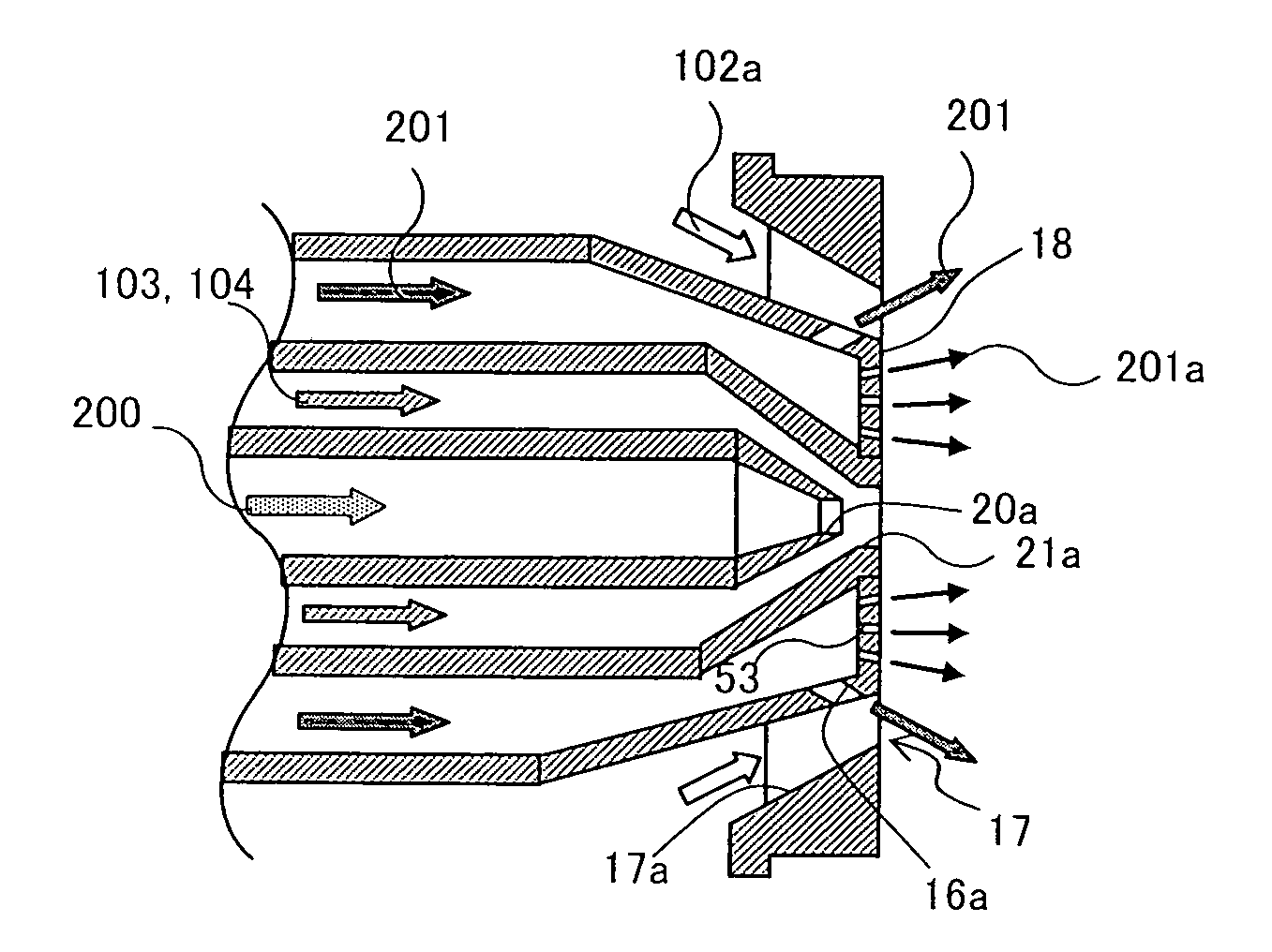

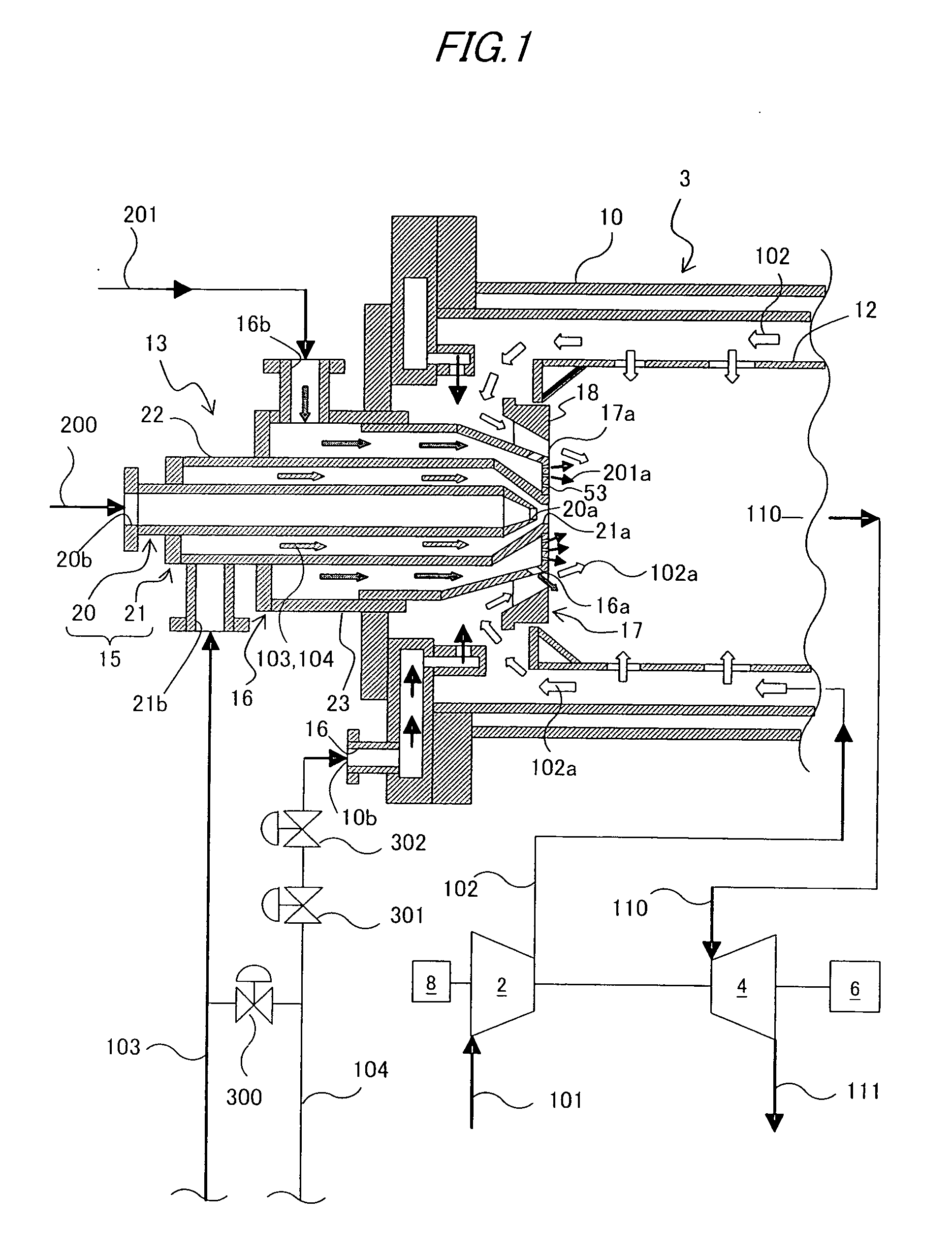

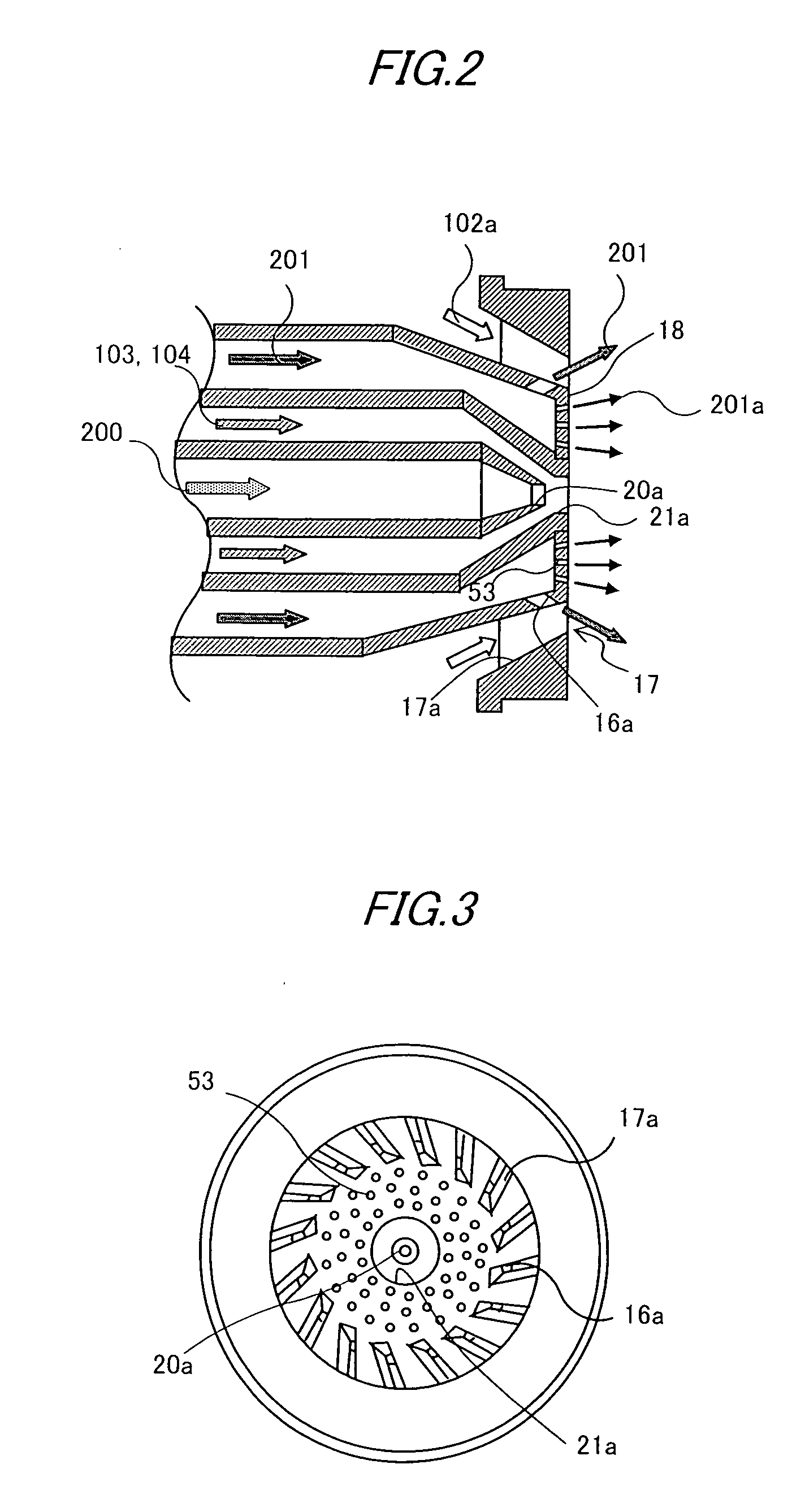

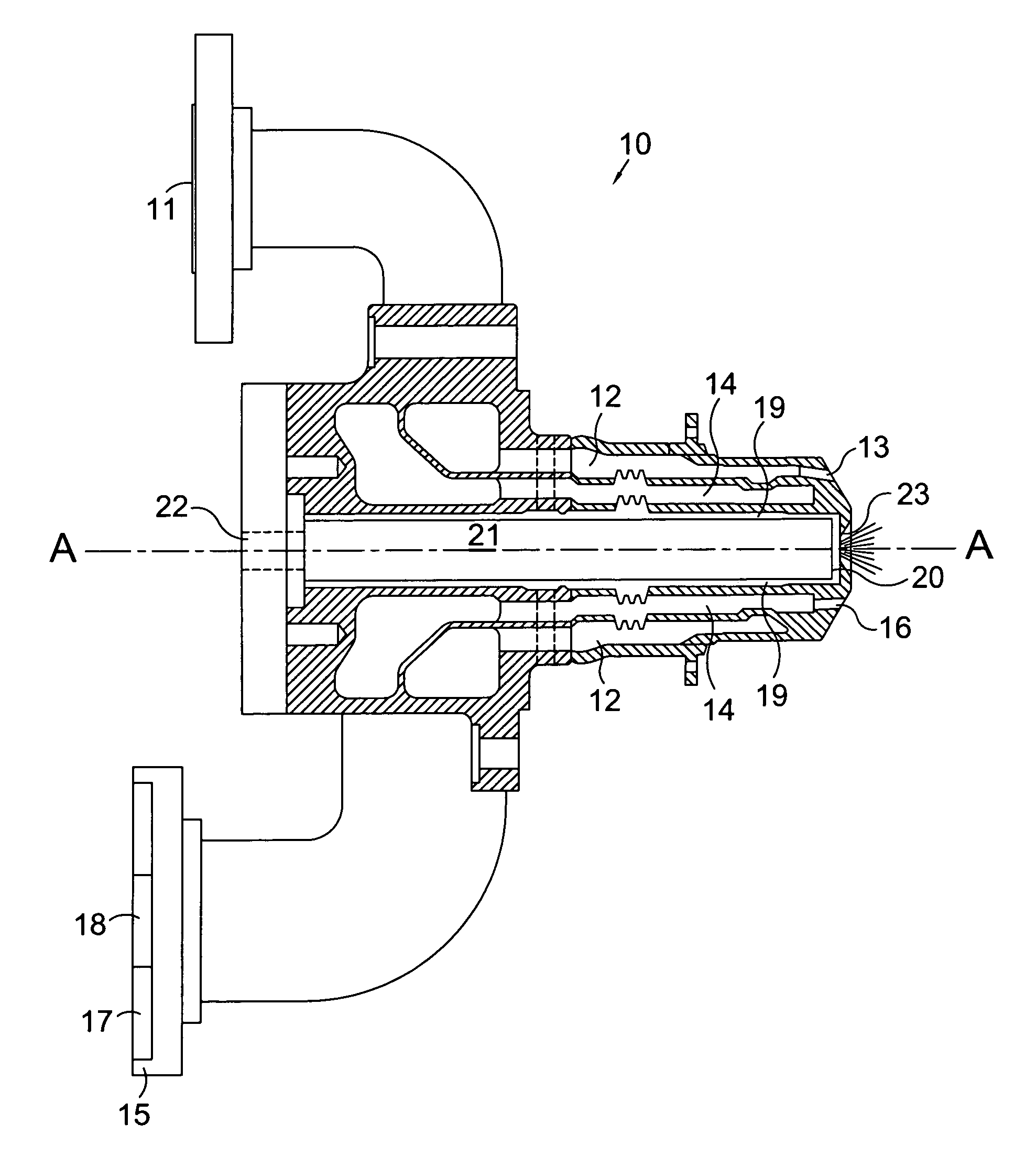

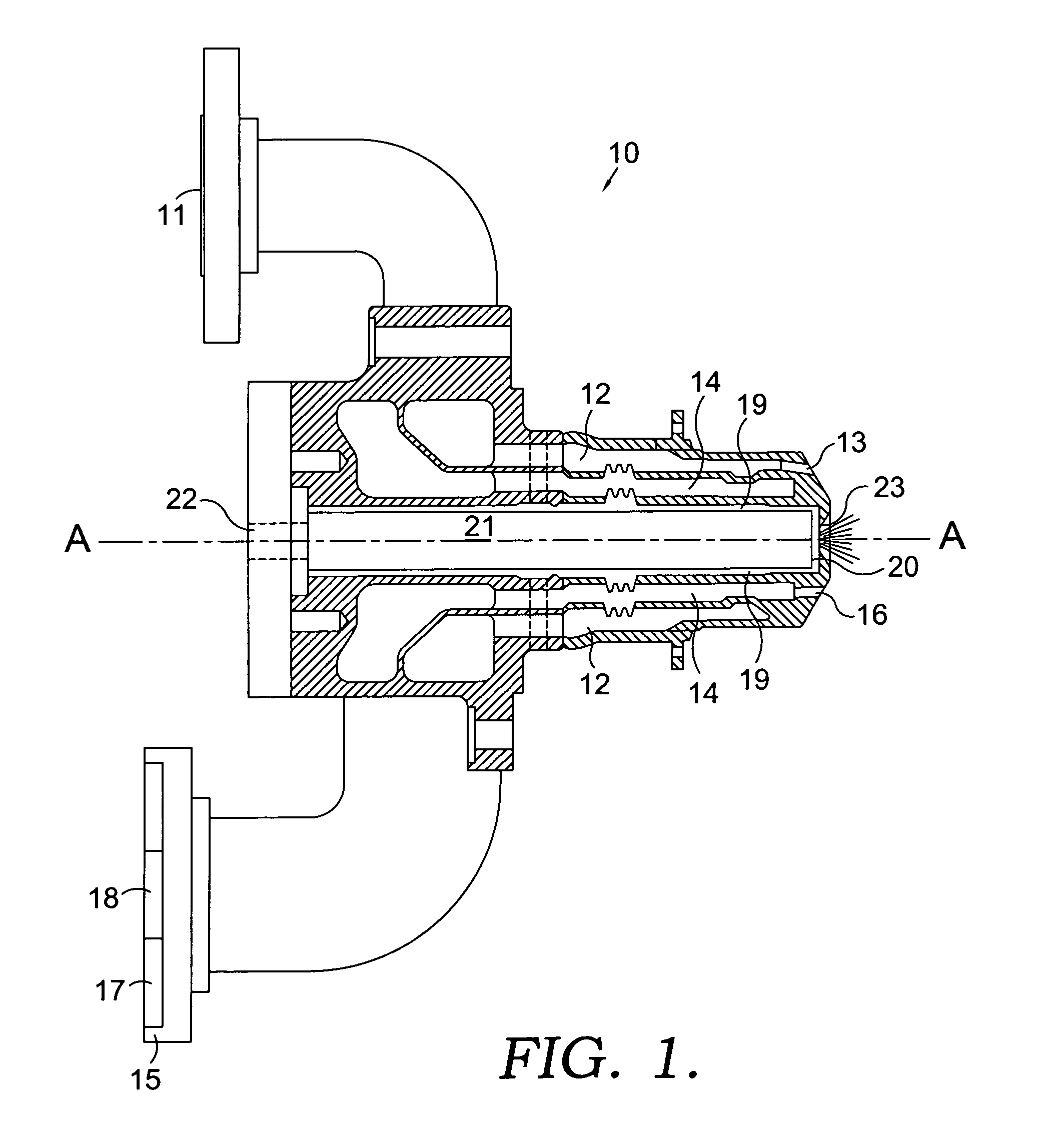

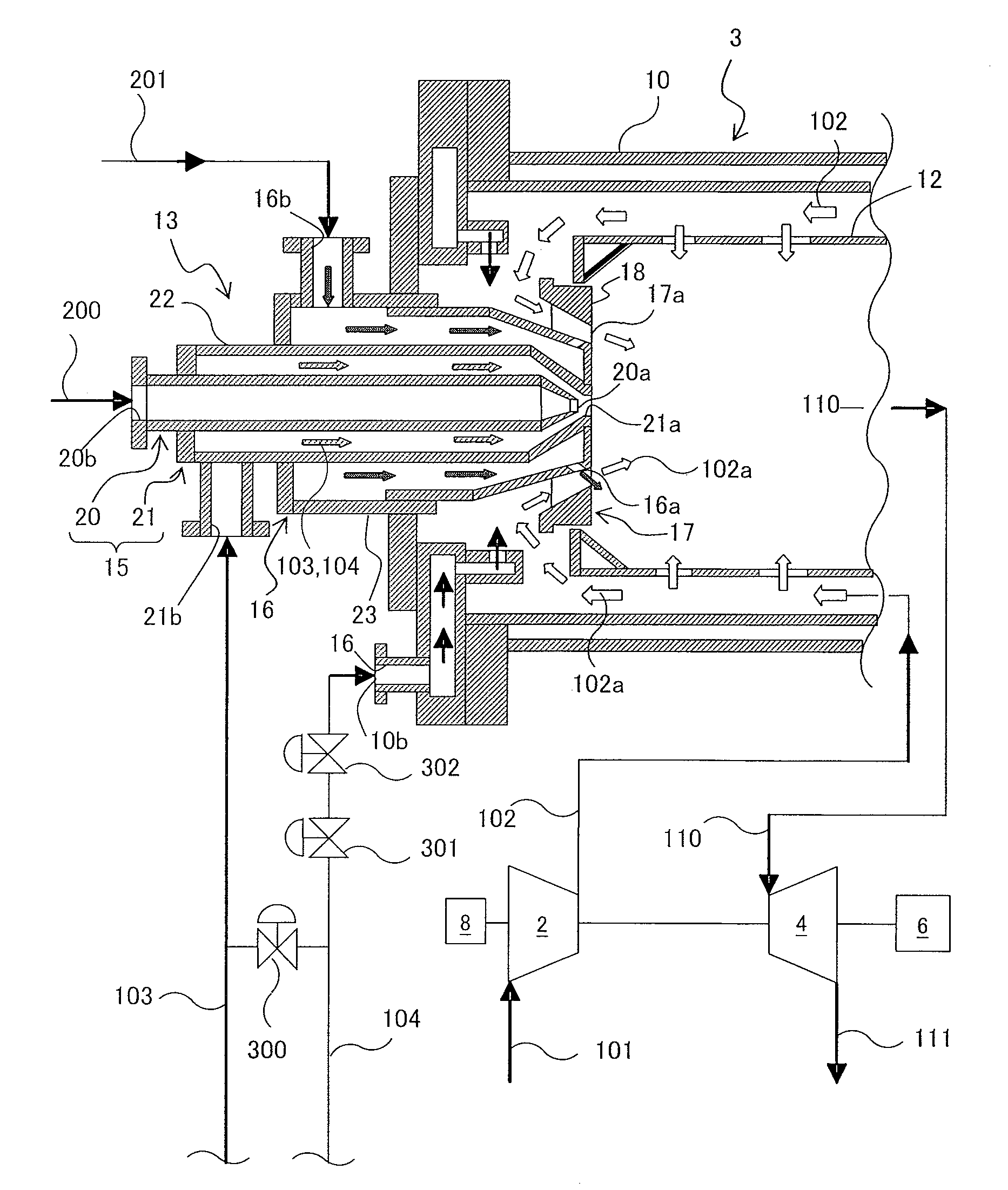

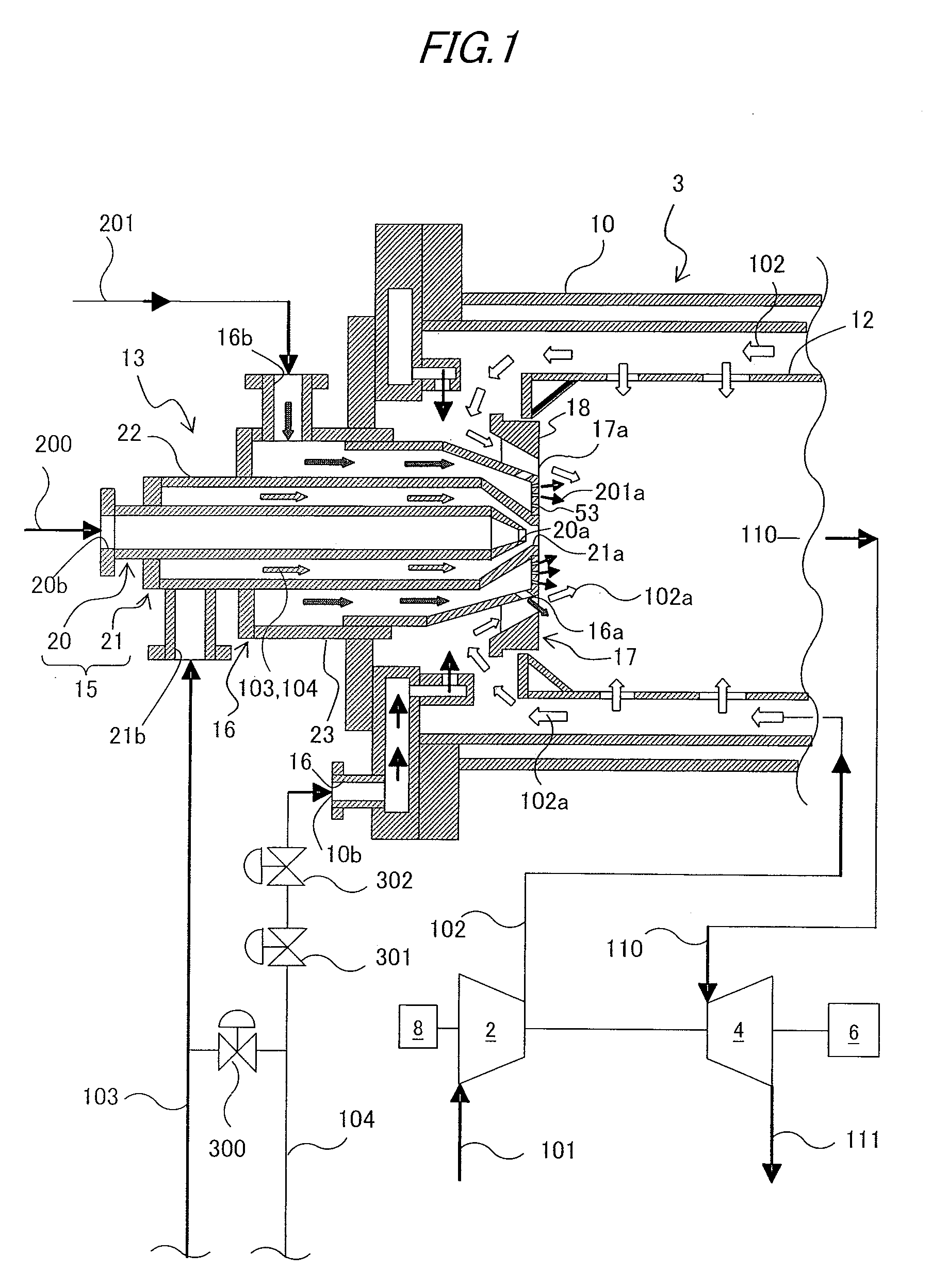

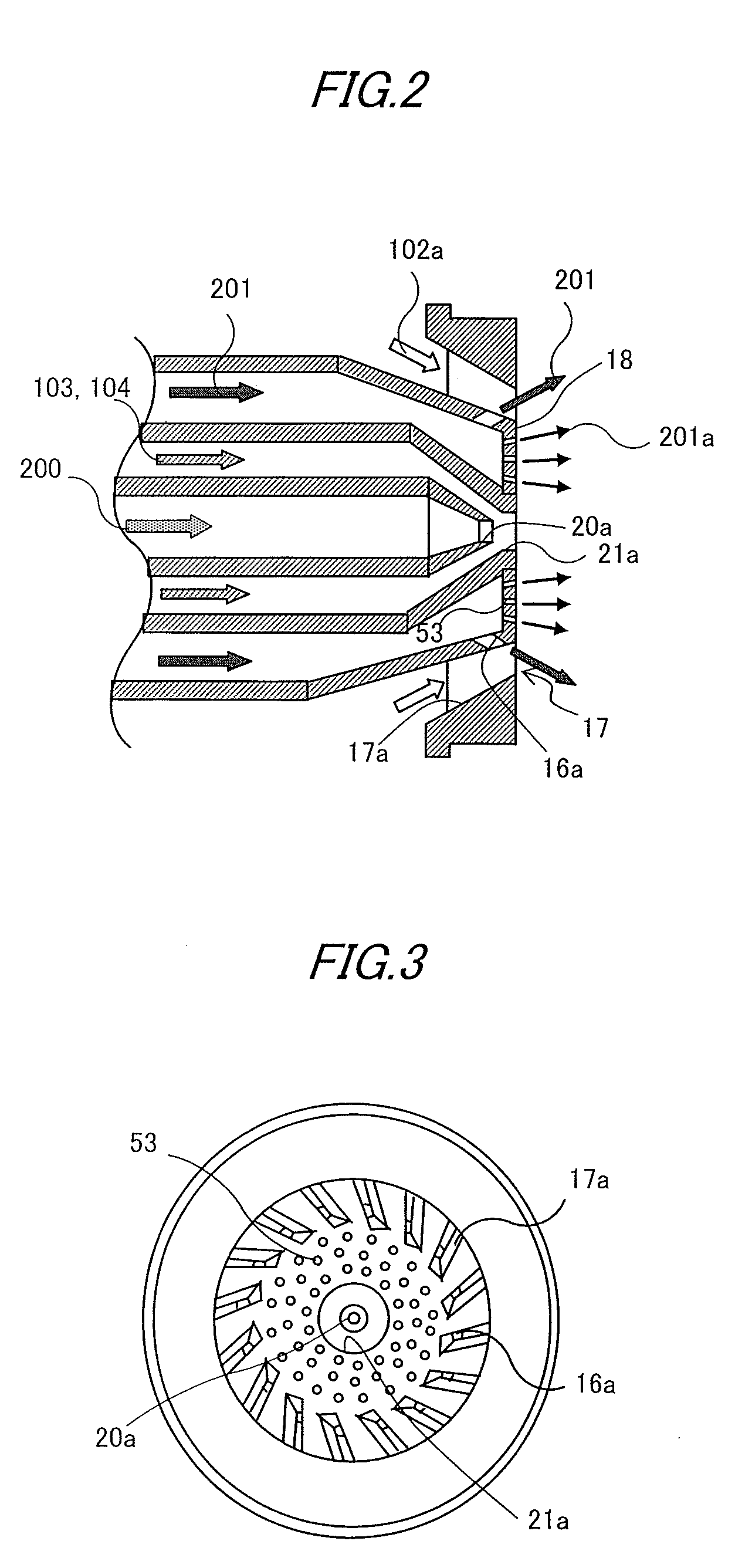

In a burner for injecting mixed gas fuel containing at least one of hydrogen and carbon monoxide into a combustion chamber of a gas turbine combustor, the burner includes a fuel nozzle for startup from which liquid fuel is injected into the combustion chamber, and a mixed fuel nozzle disposed around the fuel nozzle for injecting the mixed gas fuel. An air swirler is disposed at a downstream end of the mixed fuel nozzle and has a plurality of flow passages from which compressed air is injected into the combustion chamber, and the mixed fuel nozzle has injection ports disposed in the inner peripheral side of the flow passages of the air swirler. Cooling holes formed in the nozzle surface and positioned to face the combustion chamber introduce a part of the mixed gas fuel injected from the mixed fuel nozzle into the combustion chamber.

Owner:HITACHI LTD

Apparatus and method for improving combustion stability

InactiveUS7104069B2Reduce varianceReduce combustion dynamicBurnersContinuous combustion chamberGas turbinesEngineering

A fuel nozzle for use in a gas turbine combustor is provided having the capability of injecting multiple fuel types as well as steam for NOx reduction. Combustion dynamics within a combustor due to the mal-distribution of steam are controlled by the placement of a meterplate at the steam inlet, such that the meterplate reduces steam velocity and increases steam pressure drop. A higher pressure drop reduces the sensitivity of the combustion process to upstream steam supply variations. A method for providing uniform steam flow to a plurality of fuel nozzle assemblies about a gas turbine engine is also disclosed.

Owner:ANSALDO ENERGIA IP UK LTD

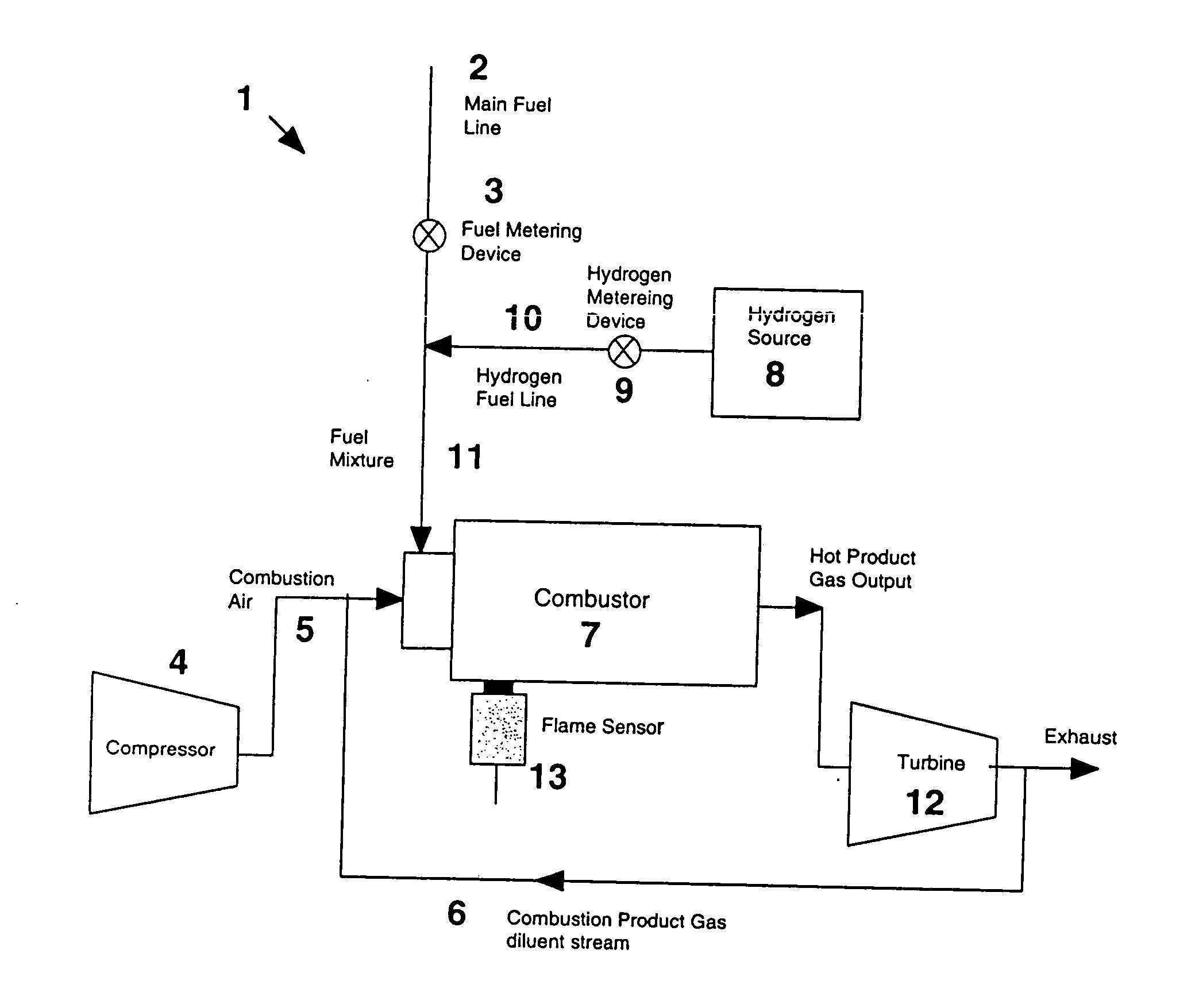

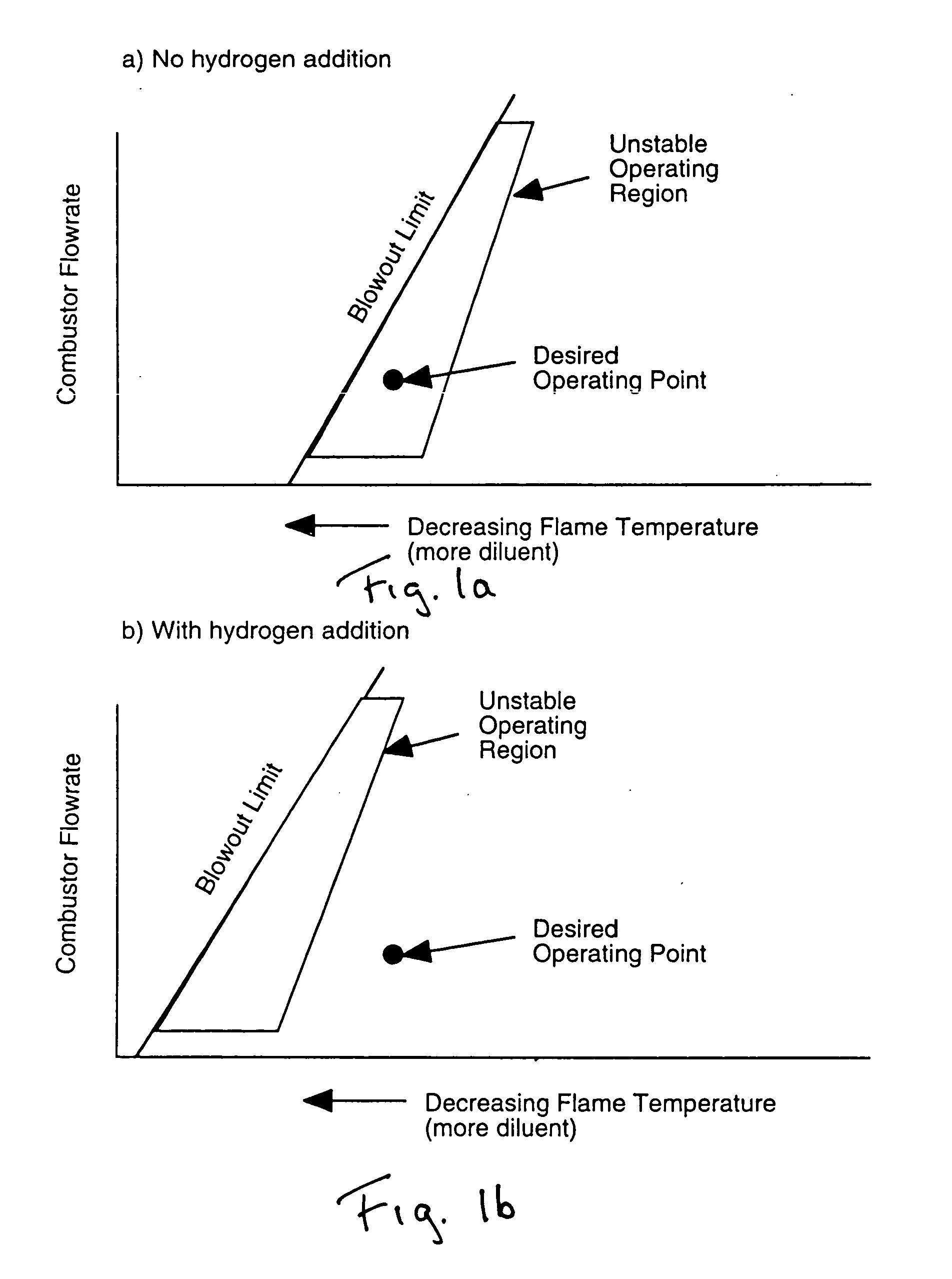

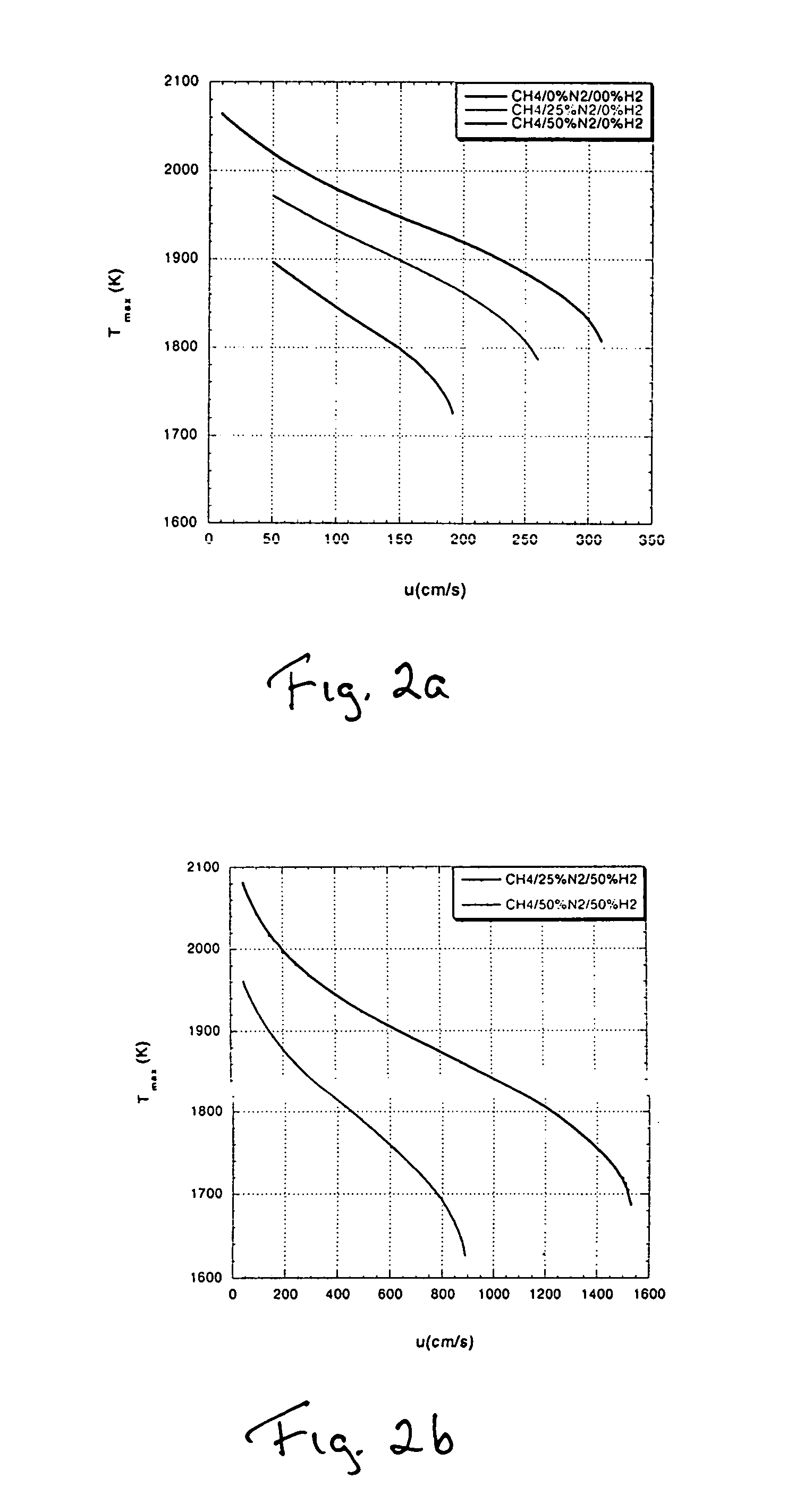

Method for control of NOx emission from combustors using fuel dilution

ActiveUS7162864B1Fast reaction timeLower temperatureInternal combustion piston enginesExhaust apparatusBiomassGas turbines

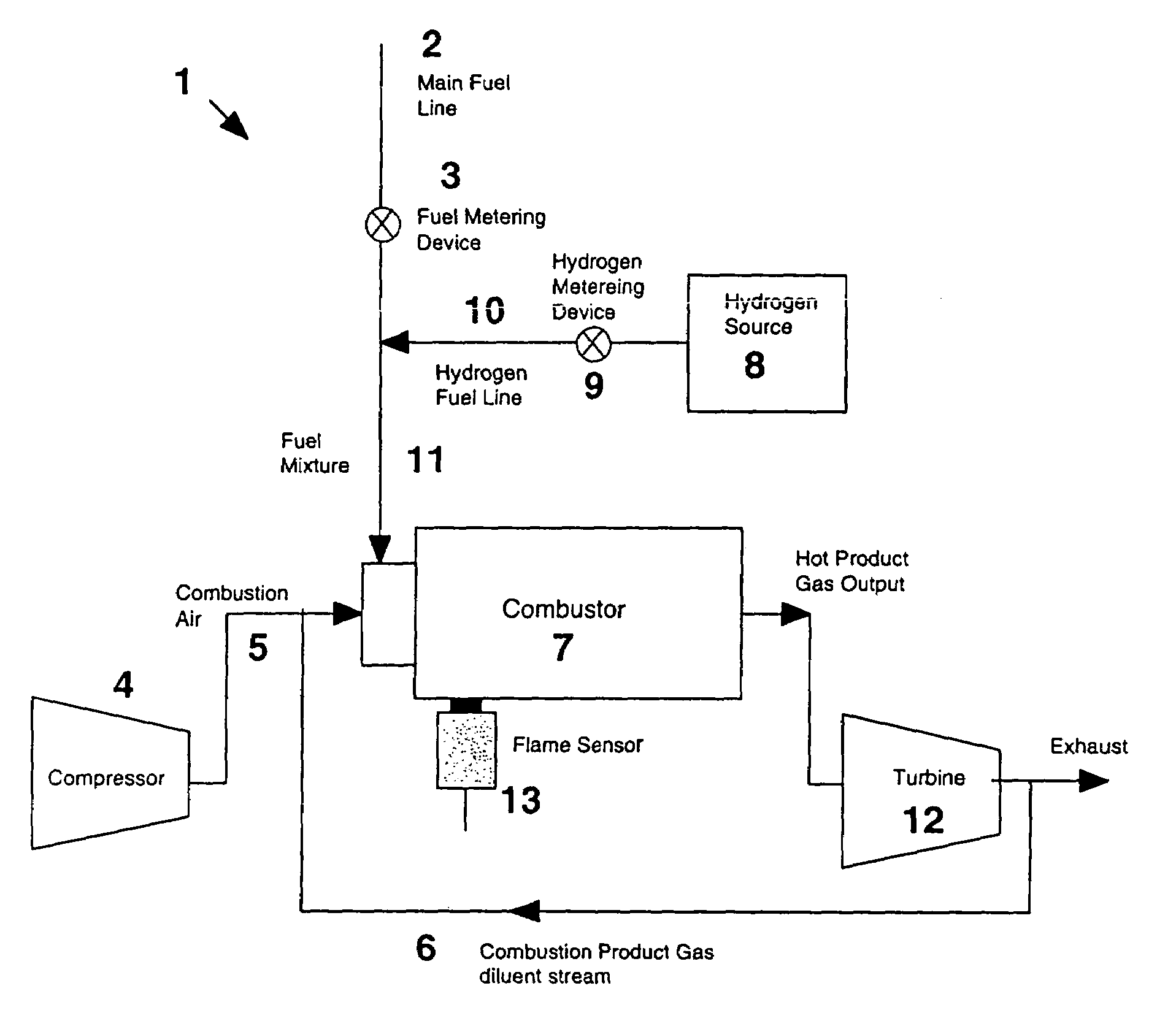

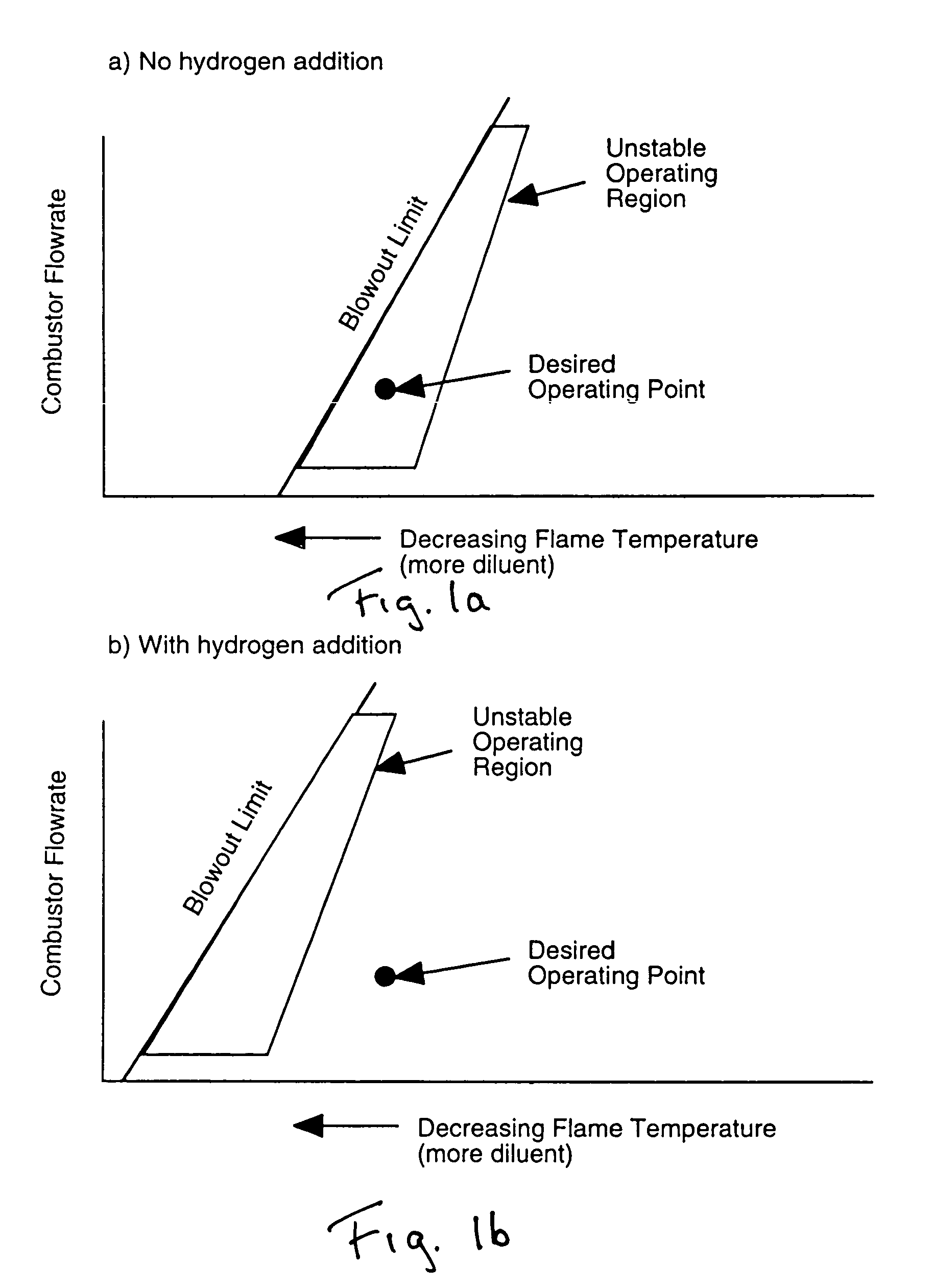

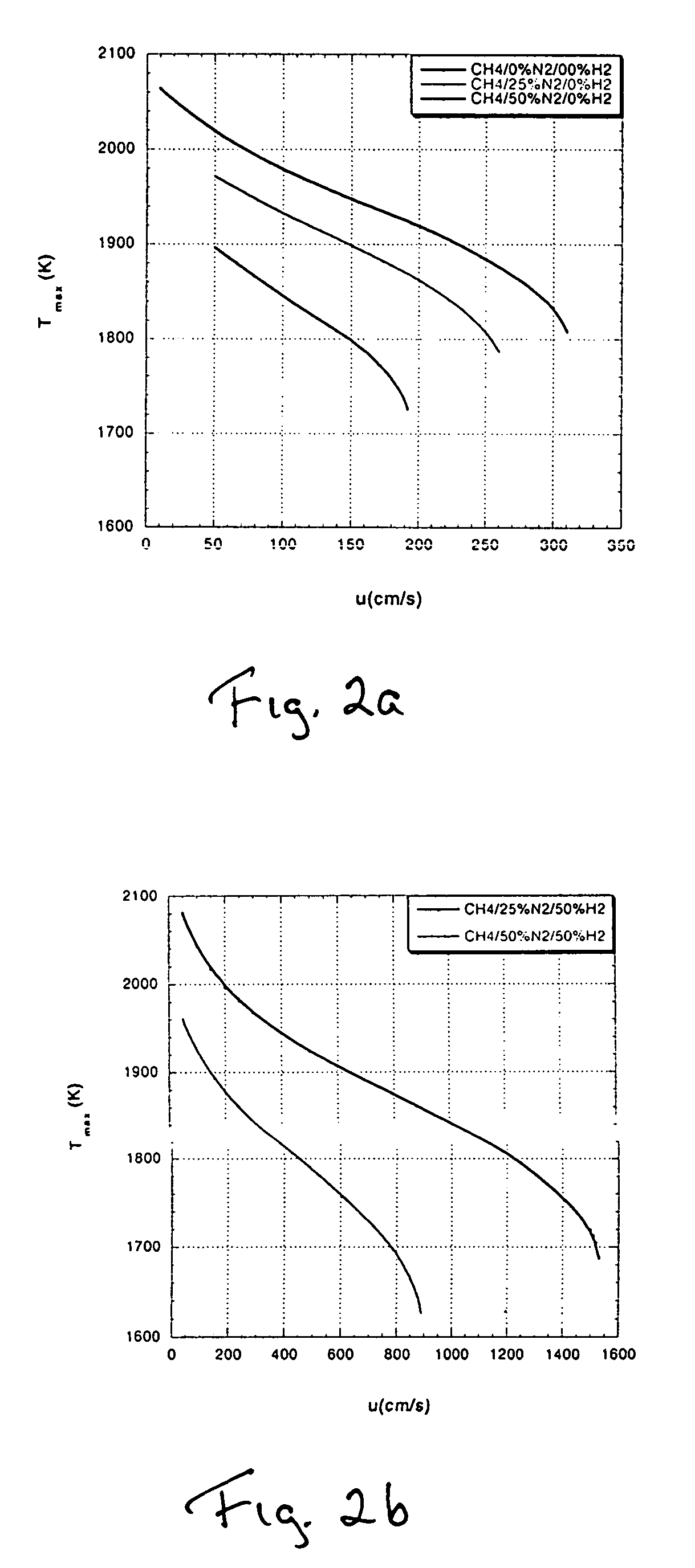

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

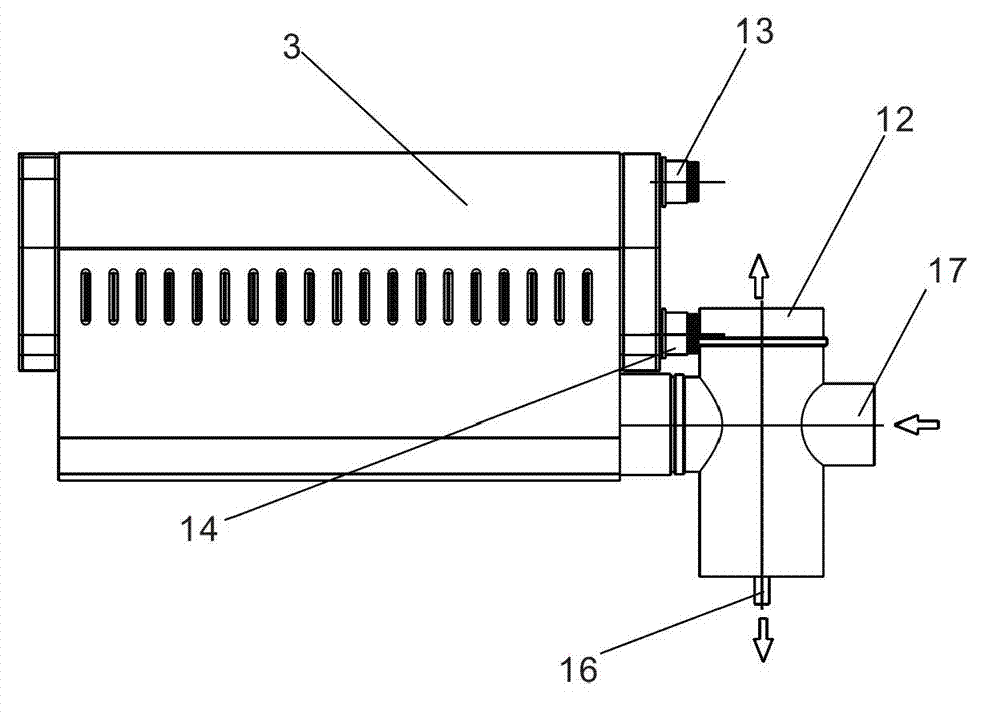

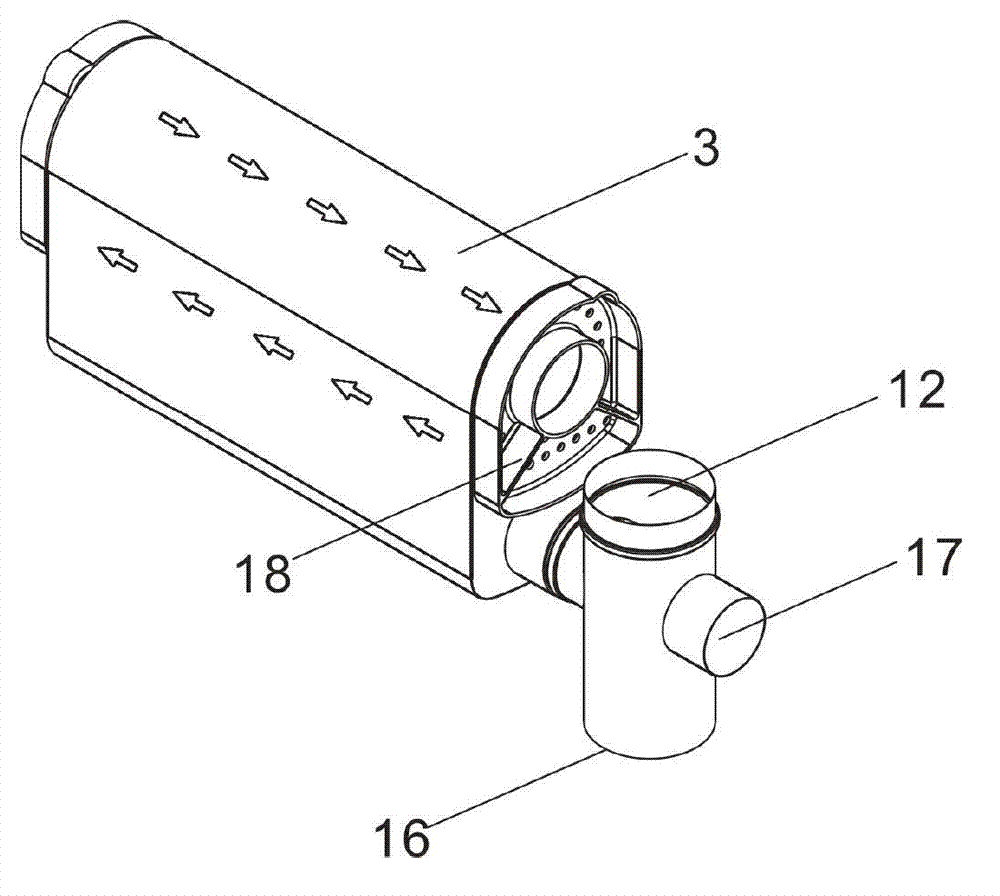

Burner, gas turbine combustor, burner cooling method, and burner modifying method

InactiveUS20130019584A1Improve reliabilityLower flame temperatureContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberInjection port

In a burner for injecting mixed gas fuel containing at least one of hydrogen and carbon monoxide into a combustion chamber of a gas turbine combustor, the burner includes a fuel nozzle for startup from which liquid fuel is injected into the combustion chamber, and a mixed fuel nozzle disposed around the fuel nozzle for injecting the mixed gas fuel. An air swirler is disposed at a downstream end of the mixed fuel nozzle and has a plurality of flow passages from which compressed air is injected into the combustion chamber, and the mixed fuel nozzle has injection ports disposed in the inner peripheral side of the flow passages of the air swirler. Cooling holes formed in the nozzle surface and positioned to face the combustion chamber introduce a part of the mixed gas fuel injected from the mixed fuel nozzle into the combustion chamber.

Owner:HITACHI LTD

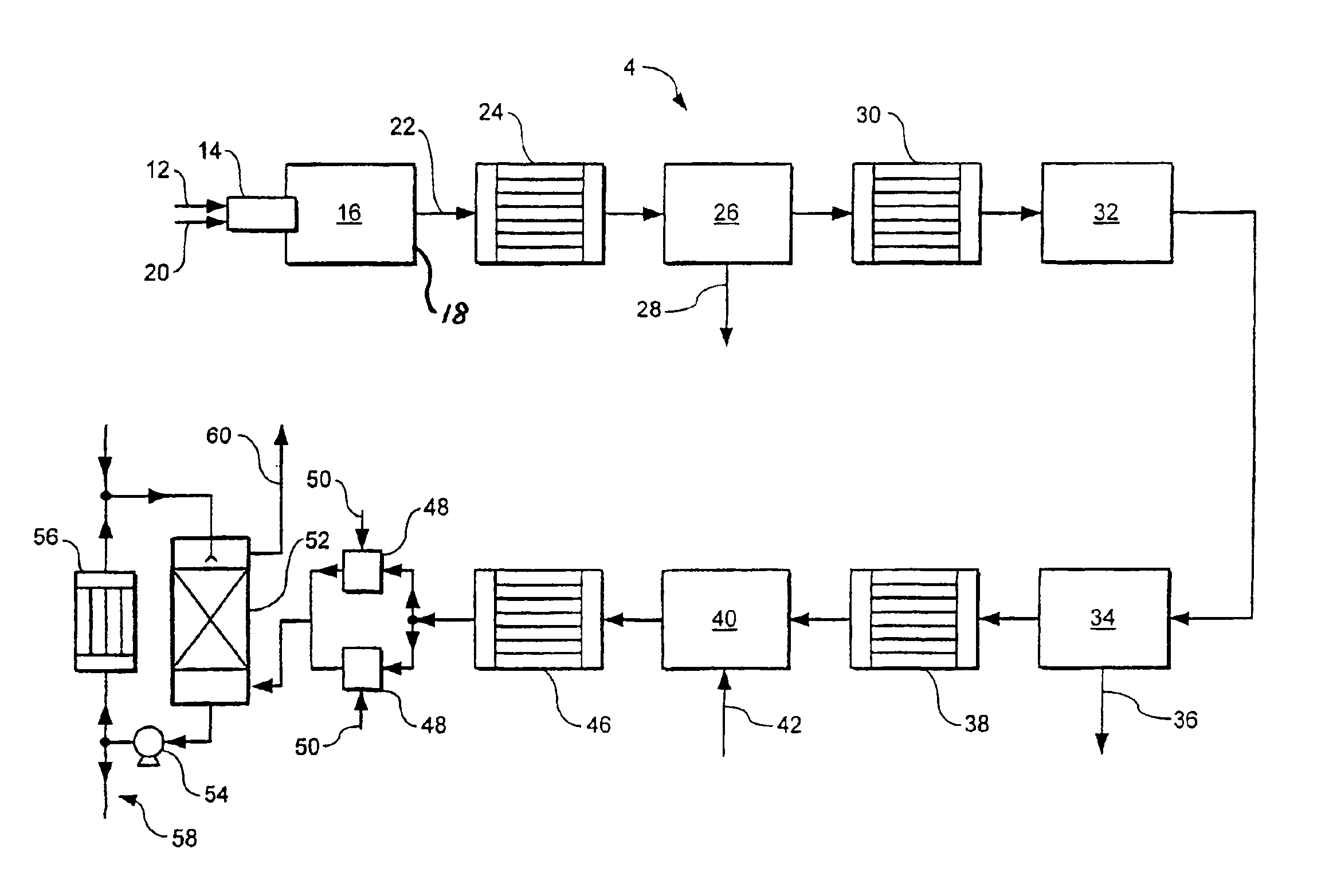

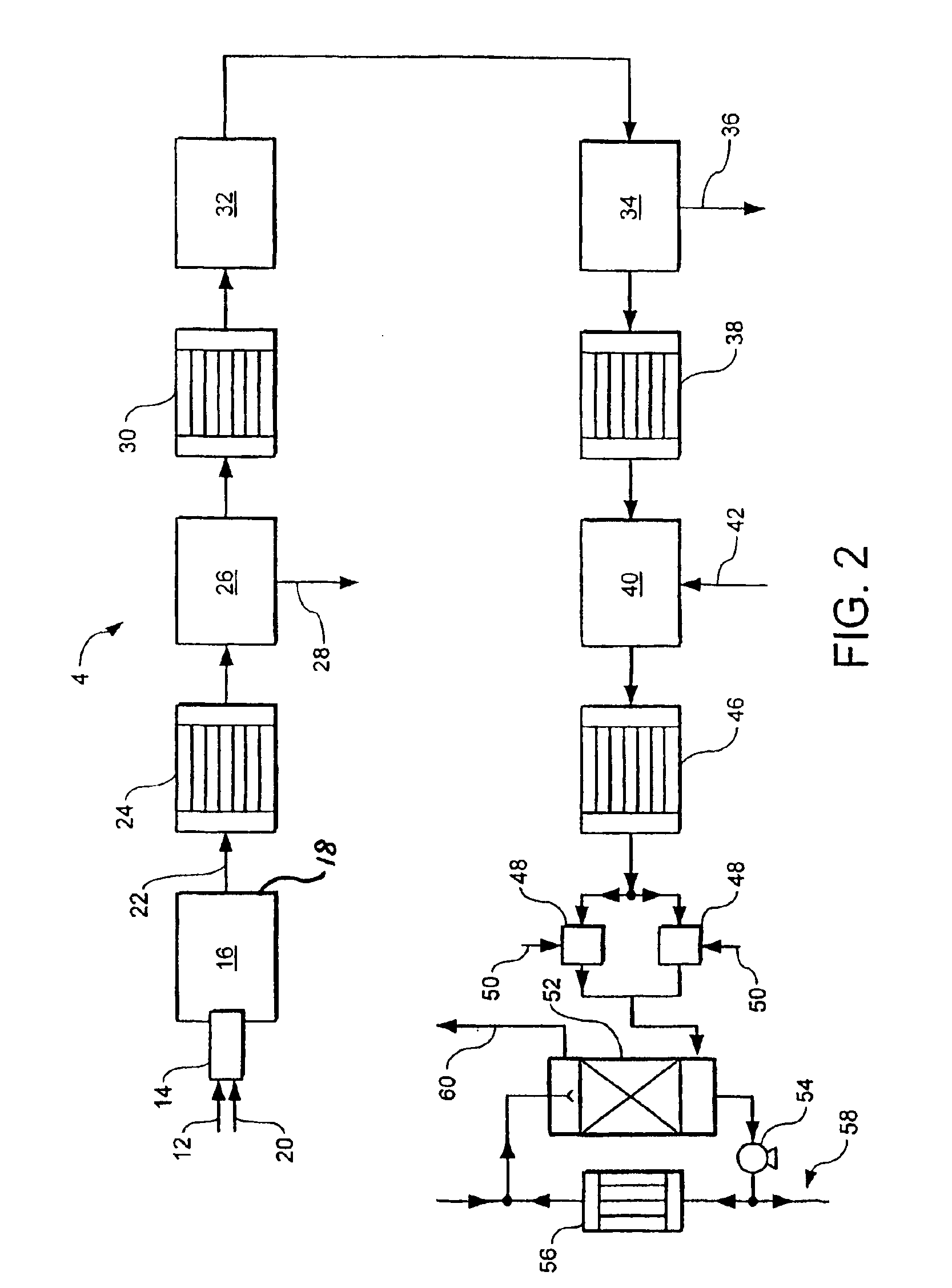

Process and apparatus for recovering sulphur from a gas stream containing hydrogen sulphide

InactiveUS6893620B2Simple treatmentImprove the level ofCombination devicesCyanogen compoundsCombustionWater vapor

Oxygen or oxygen-enriched air is employed to support combustion in furnace (16) of part of the hydrogen sulphide content of a first feed gas stream. Sulphur is extracted from the resulting gas stream in a sulphur condenser (26). Catalyst Claus reaction between hydrogen sulphide and sulphur dioxide in the resulting sulphur vapour depleted gas stream takes place in a catalytic reactor (32). Sulphur is extracted in a further sulphur condenser (34). The resulting sulphur vapour depleted gas stream is passed into a catalytic reduction reactor (40) in which all the residual sulphur dioxide and any sulphur vapour are reduced to hydrogen sulphide. The resulting reduced gas mixture has water vapour extracted there from in a quench tower (52). The resulting water vapour depleted gas stream flows to a Claus plant for further treatment typically together with a second feed gas stream.

Owner:MESSER IND USA INC

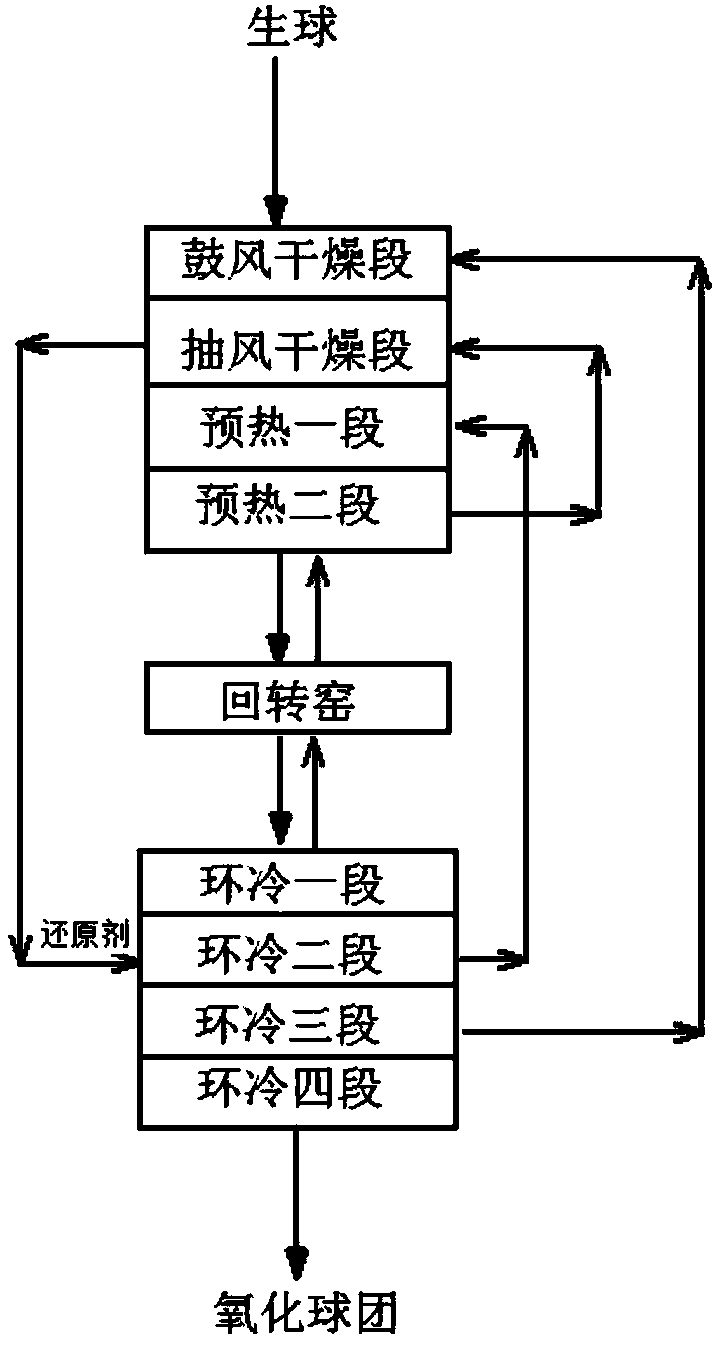

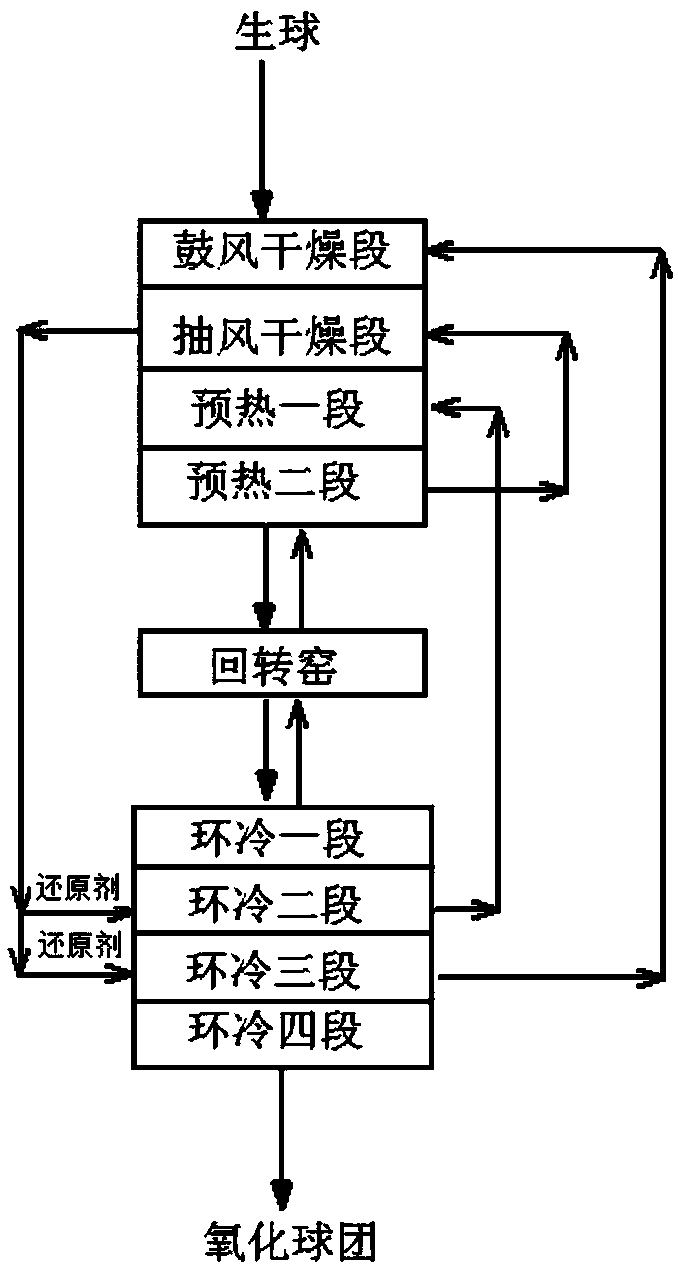

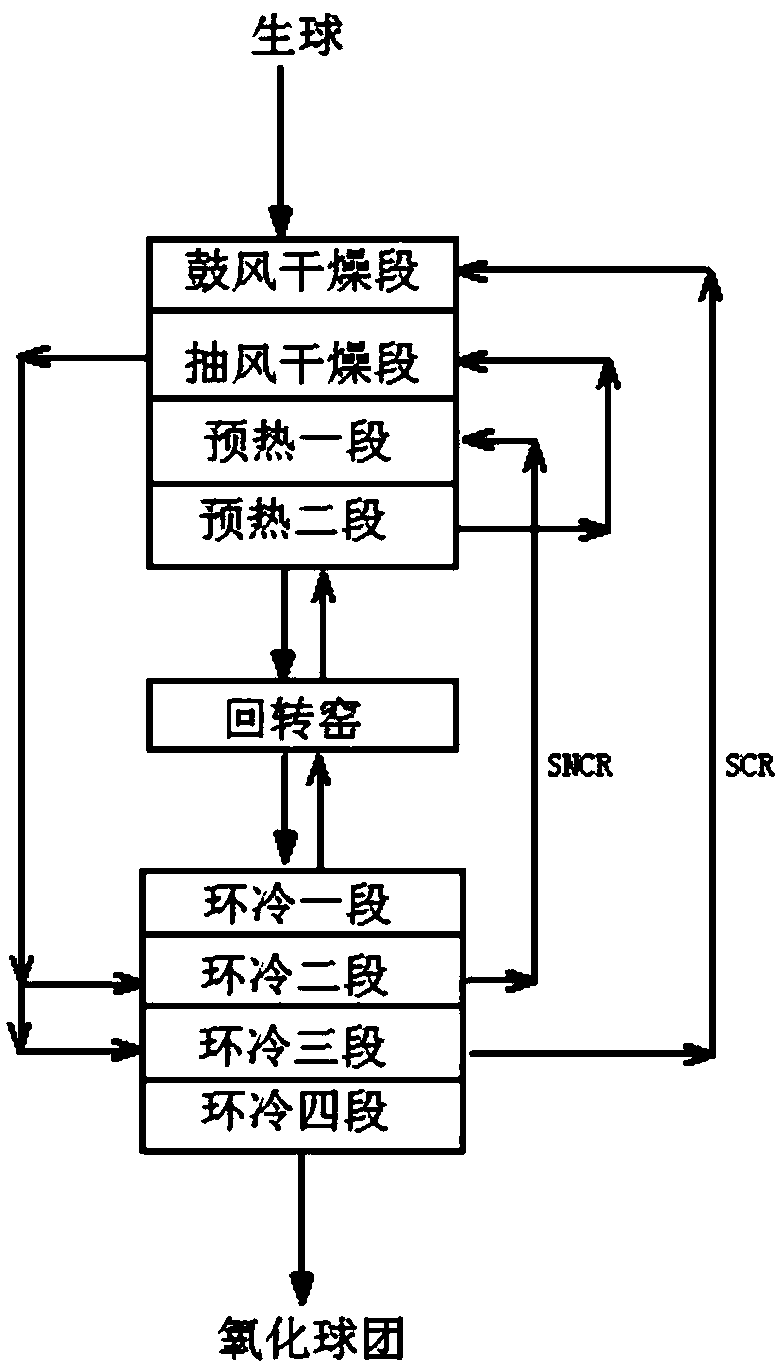

Production process and system of ultralow NOx emission of pellet flue gas

ActiveCN109373767AReduce concentrationReduce contentRotary drum furnacesIncreasing energy efficiencyFlue gasProcess engineering

The invention provides a production process and a system of ultralow NOx emission of pellet flue gas. A set of flue gas circulation system is additionally arranged, the flue gas discharged from an airdraft drying section is taken as cooling air to be further conveyed to an air inlet of an annual cooling two-section, meanwhile, a reducing agent is sprayed at the top located at the annular coolingtwo-section, the reducing agent reacts with NOx in the flue gas subjected to the annular cooling two-section, and SNCR denitration is realized; and or the gas discharged from an air outlet of the annular colling two-section is conveyed to a preheating one-section of a chain grate machine after passing through a SNCR treatment system; the high-temperature characteristic of discharging the flue gasfrom the air draft drying section is utilized, meanwhile, the condition of high-temperature sintering ore in the annual colling two-section is utilized, and the part of the flue gas is treated by adopting the SNCR. By the adoption of the technical means, an enterprise atmospheric pollutant emission limit value on the production pressure of pellet roasting equipment requirements can be reduced to acertain extent, and the process and the system have the characteristics of being decreasd in investment, low in operation cost and remarkable in NOx emission reduction effect.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

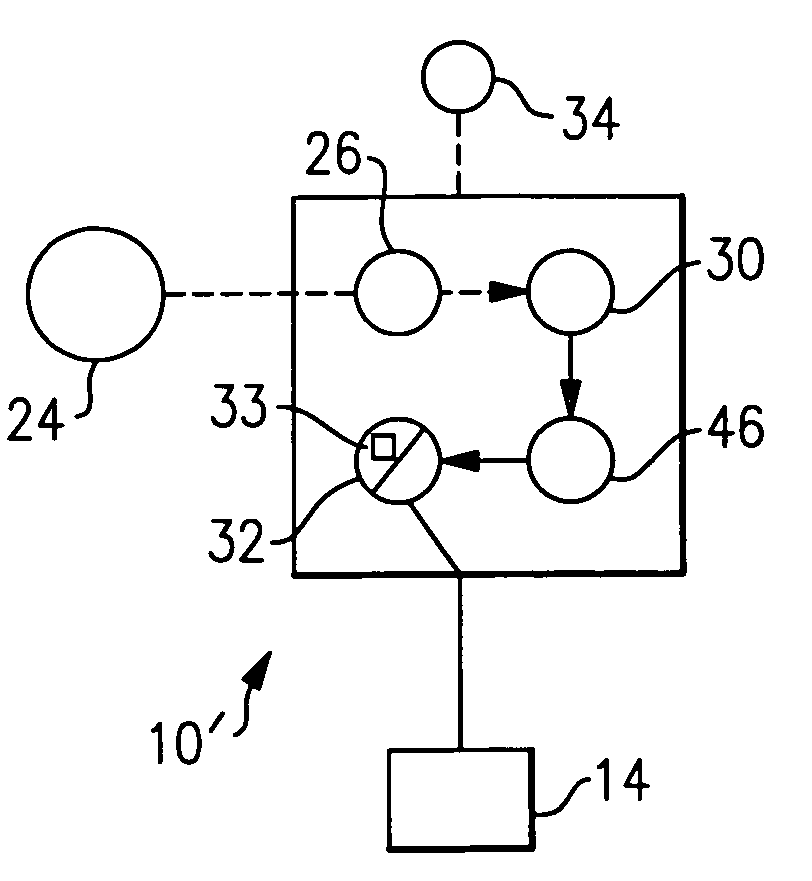

Fuel system and method of reducing emission

InactiveUS7537646B2Emission reductionEasy to operateCombination devicesBurnersEngineeringLiquid fuel

Owner:UNITED TECH CORP

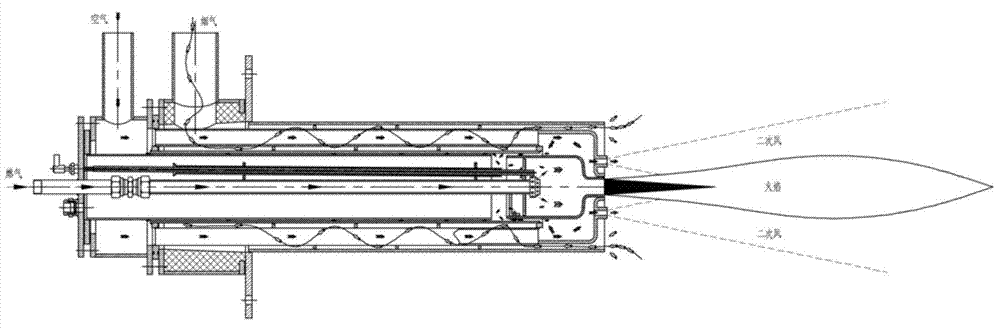

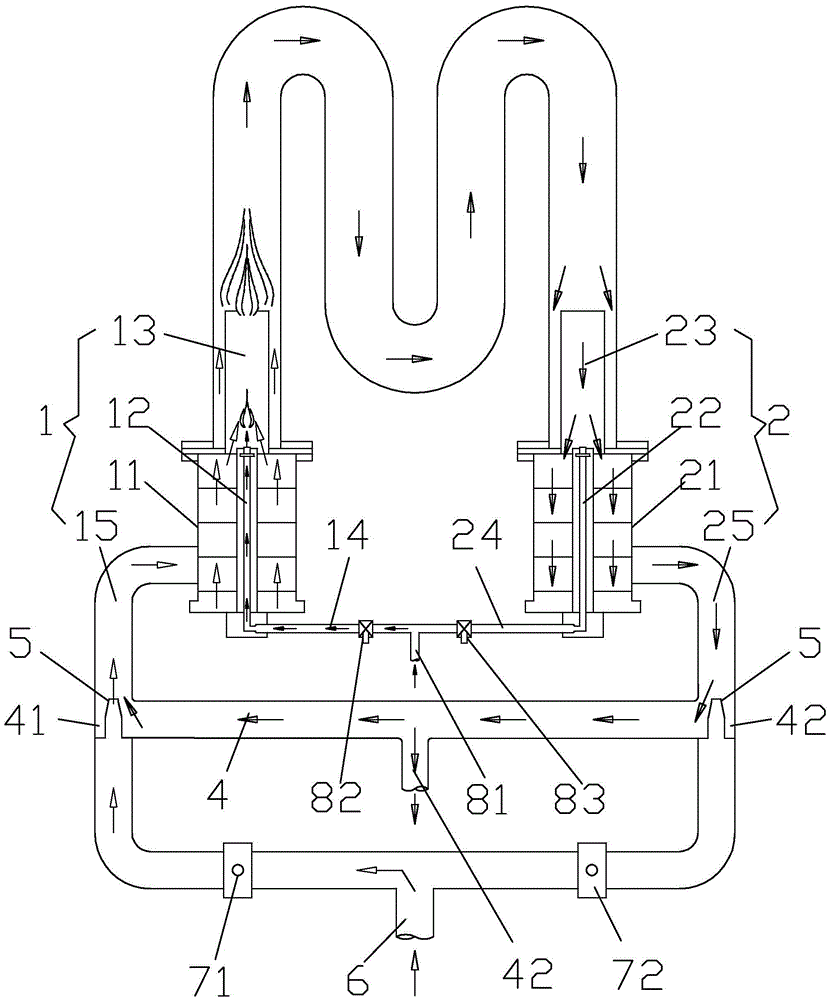

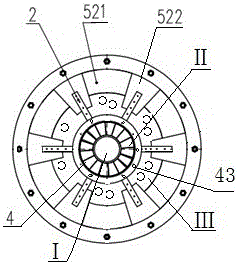

Classified-combustion fuel gas low-nitrogen combustor

ActiveCN105805746AReduce concentrationEmission reductionNon-combustible gases/liquids supplyGaseous fuel burnerCycloneCombustor

The invention discloses a classified-combustion fuel gas low-nitrogen combustor. The classified-combustion fuel gas low-nitrogen combustor comprises first-level fuel spray guns, second-level fuel spray guns, smoke inner circulation injection pipes, a combustion-supporting air channel, a center straight flow air channel, a first-time cyclone air channel, a second-time cyclone air channel and a necking-down type spray port. The center straight flow air channel is arranged in the center of the necking-down type spray port. The first-time cyclone air channel and the second-time cyclone air channel are sequentially arranged on the outer side of the center straight flow air channel. The first-level fuel spray guns are circumferentially and evenly distributed between the first-time cyclone air channel and the second-time cyclone air channel. The smoke inner circulation injection pipes are located on the outermost side in the necking-down type spray port of the combustor, the second-level fuel spray guns stretch into the smoke inner circulation injection pipes, and the smoke inner circulation injection pipes and the second-level fuel spray guns are all evenly distributed on the same reference circle. According to the classified-combustion fuel gas low-nitrogen combustor, the means of fuel classification, air classification, smoke inner circulation and the like are combined, the temperature of a flame high-temperature area is reduced, the mixing time of fuel and air is prolonged, and generation of NOx is effectively restrained.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

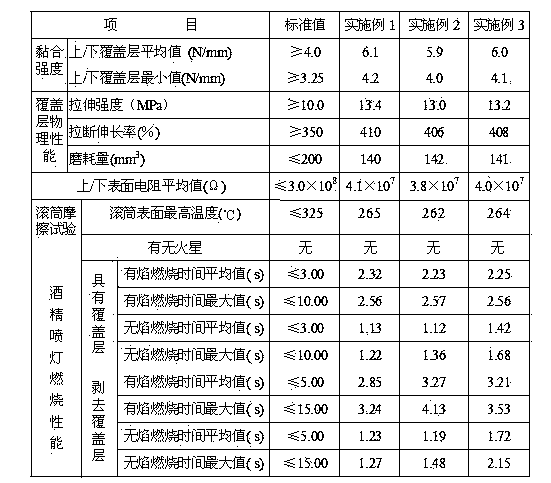

Forced finned straight pipe condensation heat-supply heat exchanger

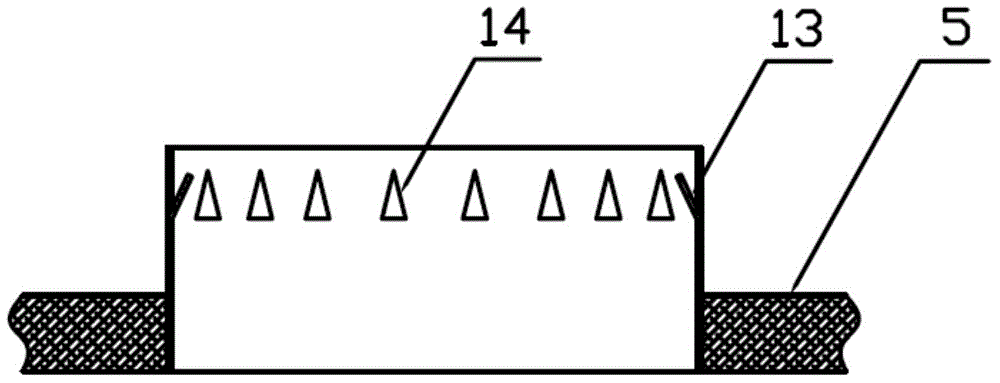

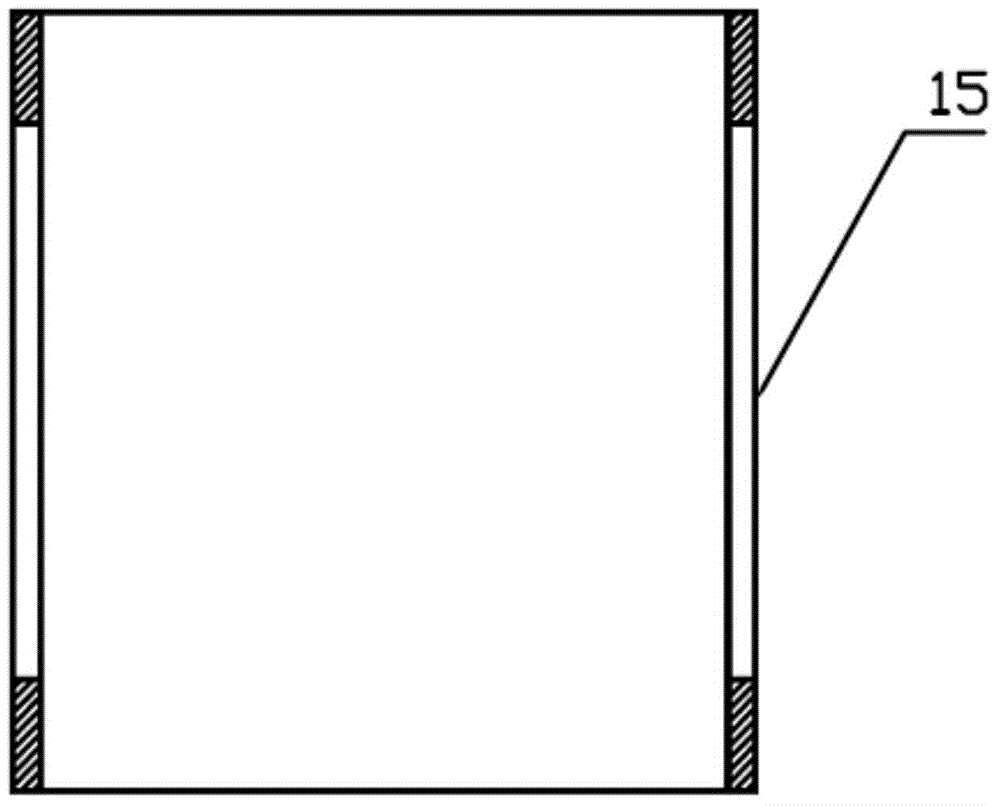

ActiveCN102901221AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersPlate heat exchangerCombustor

The invention discloses a forced finned straight pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor and a plurality of finned straight pipes, wherein the combustor is positioned on the upper part of the shell; the periphery of the combustor is provided with a group of finned straight pipe bundles consisting of a plurality of finned straight pipes which are tightly and uniformly distributed along the circumference; a smoke exhaust pipeline which consists of the shell and a plurality of tightly arranged finned straight pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; two ends of the finned straight pipes are respectively front water main pipes and rear water main pipes; clapboards are arranged in the rear water main pipes; the rear water main pipes are separated into a water inlet area and a water outlet area through the clapboards; and water flow enters part of the finned straight pipes through the water inlet area, reaches the front water main pipes and enters the water outlet area of the rear water main pipes through the other part of the finned straight pipes. The inwards folded finned straight pipes serve as basic elements of the forced finned straight pipe condensation heat-supply heat exchanger, and the heat exchange efficiency is obviously improved.

Owner:SUZHOU CQ HEAT EXCHANGER

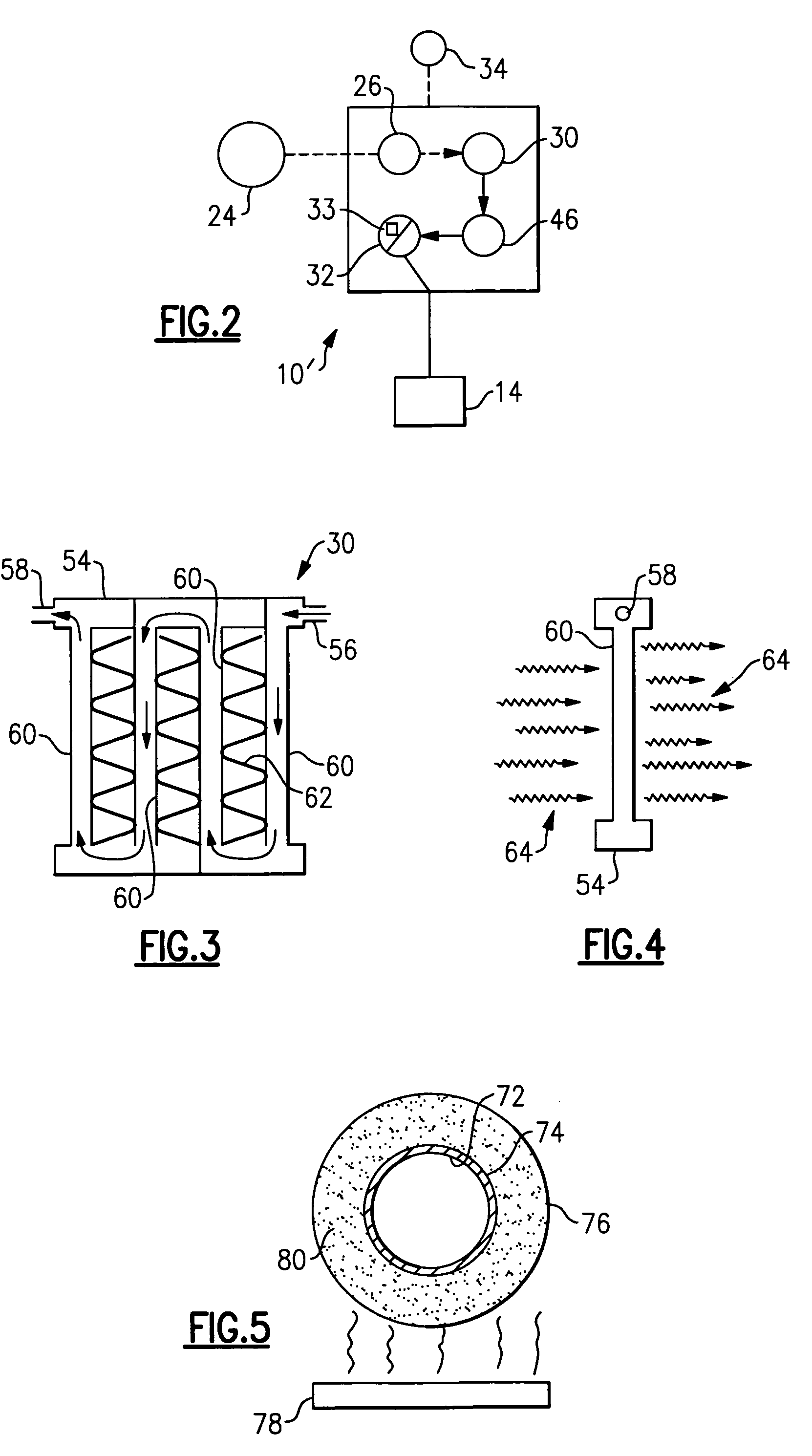

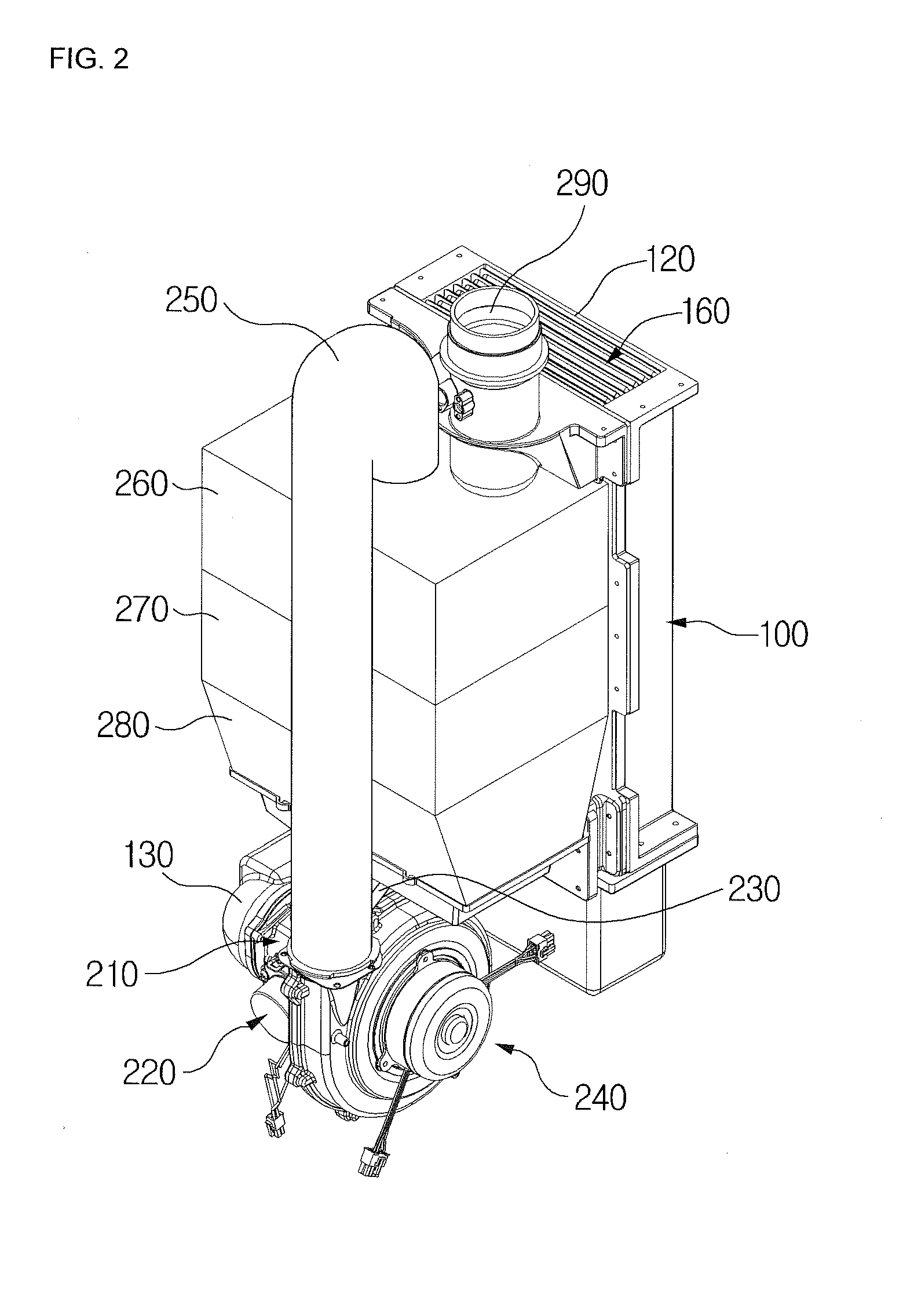

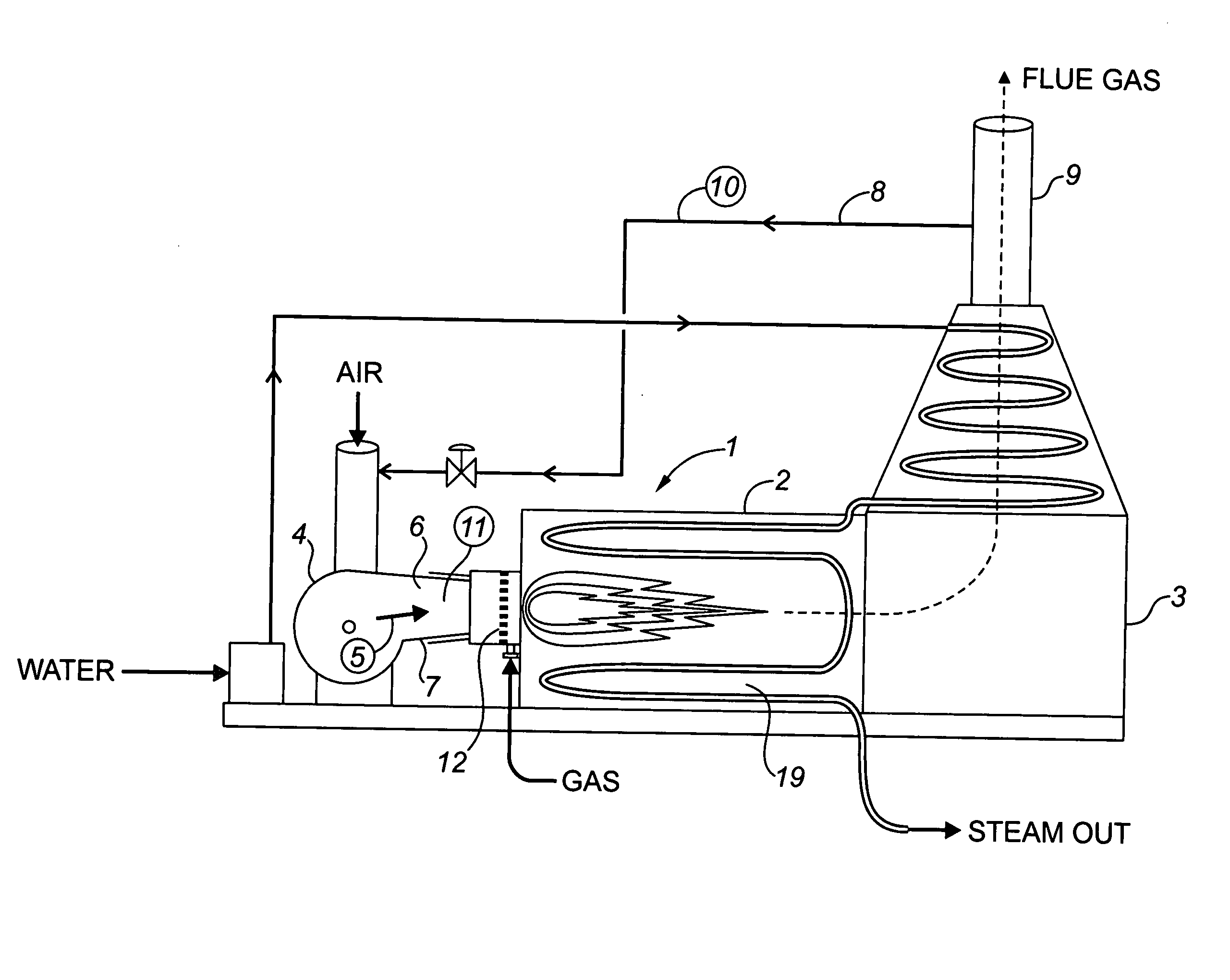

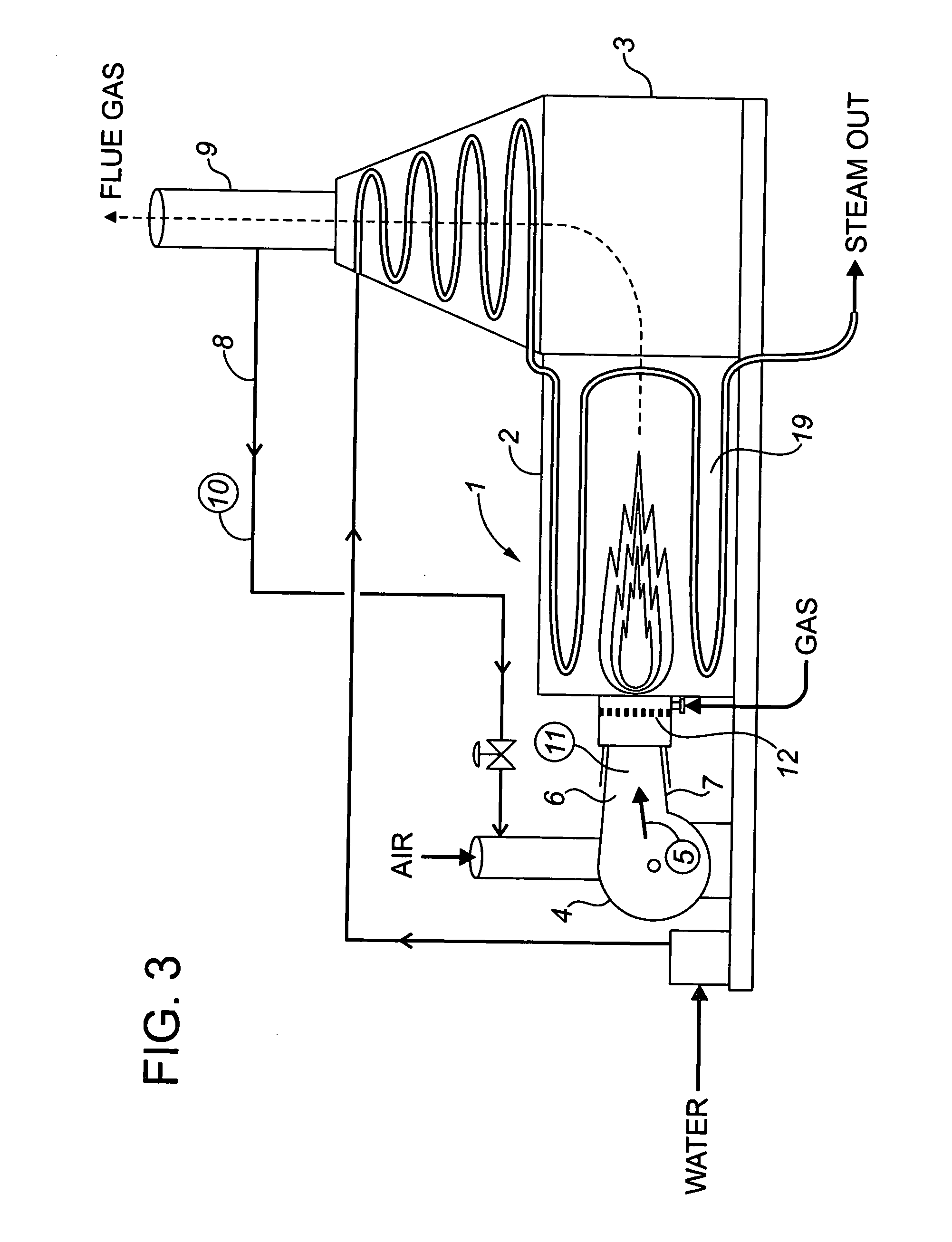

Combustion apparatus having air intake preheater

ActiveUS20150338127A1Reduce combustion loadImprove combustion efficiencyRecuperative heat exchangersIndication apparatusCombustorCombustion chamber

The present invention relates to a combustion apparatus capable of reducing the combustion load of a burner and improving the combustion efficiency thereof. The combustion apparatus includes: a premixing chamber for premixing external air, introduced through an air supply inlet, with a combustion gas; a blower for supplying a mixed air premixed in the premixing chamber toward a burner; a combustion chamber for burning the mixed air by ignition of the burner; a heat exchanger for heat exchange with room heating water by using the combustion heat of the combustion chamber; an exhaust gas discharging part for discharging an exhaust gas having passed through the heat exchanger; and a duct through which the exhaust gas having passed through the exhaust gas discharging part is discharged outside, wherein the combustion apparatus includes an air intake preheater for heat exchange between the exhaust gas discharged to the duct through the exhaust gas discharging part and the air supplied to the premixing chamber through the air supply inlet, the air intake preheater including a channel-forming member in which a plurality of unit plates are stacked with a predetermined interval therebetween to form an exhaust gas channel and an air intake channel therein that are separated from each other, are adjacent to each other, and are alternately arranged.

Owner:KYUNGDONG NAVIEN

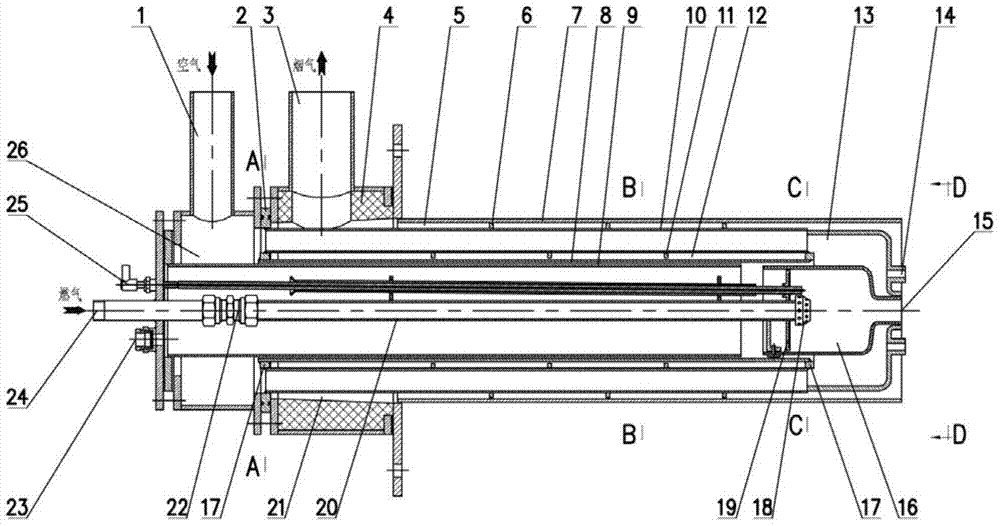

Efficient counter-distributary self-preheating low-NOx combustion device

InactiveCN103939903AIncrease the heat exchange areaReduce concentrationIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invention discloses an efficient counter-distributary self-preheating low-NOx combustion device. The combustion device comprises a gas core tube and a combustion chamber arranged at the front end of the gas core tube. A gas sprayer head of the gas core tube is located in the combustion chamber, and an air outlet air chamber is further arranged outside the combustion chamber in a sleeved mode. The gas core tube is sleeved with an air inner sleeve used for delivering combustion air into the combustion chamber, the air inner sleeve is sleeved with an annular smoke channel, and a plurality of special tubes used for increasing the heat exchange area are arranged in the smoke channel at equal intervals in the axial direction. A plurality of secondary air holes are formed in the air outlet air chamber, secondary air and a mixture after combustion are both sprayed into a hearth at high speed, a large amount of smoke can be induced to flow back, the concentration of fuel and O2 is reduced, the temperature of flames is lowered, and formation of heating power NOx is reduced. Meanwhile, air is distributed to the secondary air holes through the air outlet air chamber and sprayed into the hearth at high speed, and thus the ignition time can be effectively prolonged. The running cost of the combustion device and NOx emission can be reduced, and the combustion device can contribute to energy conservation and environment protection.

Owner:XI AN JIAOTONG UNIV

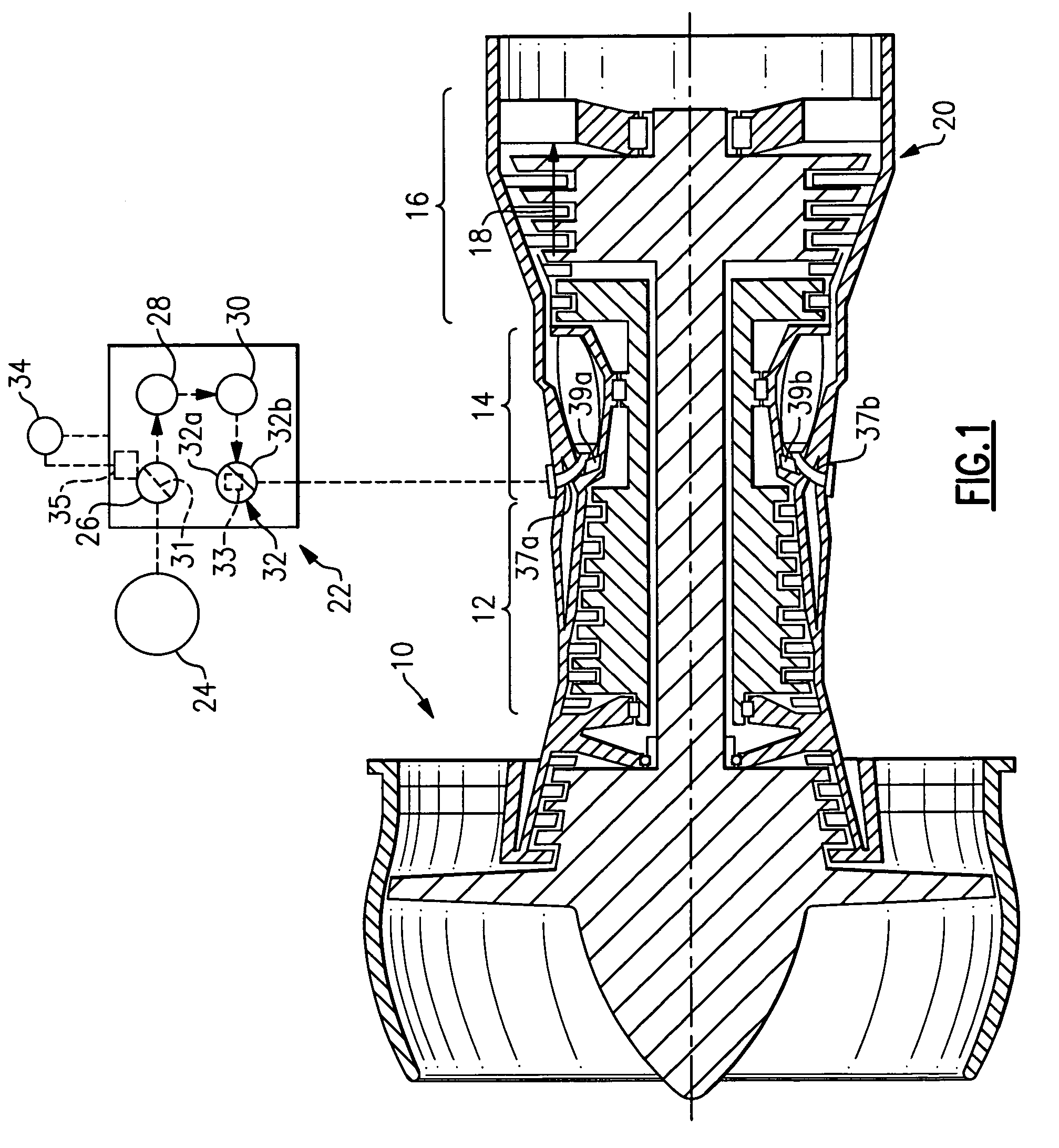

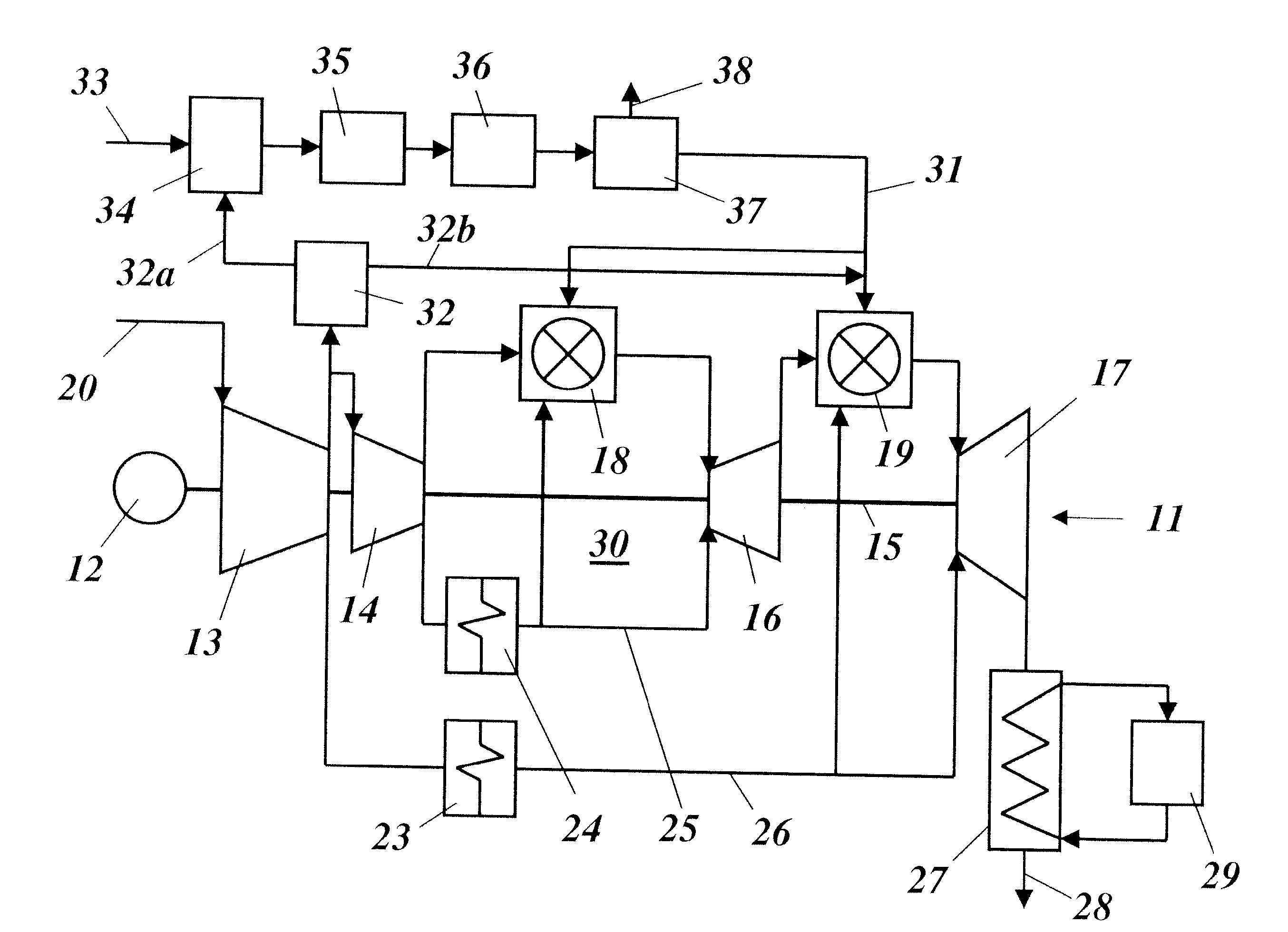

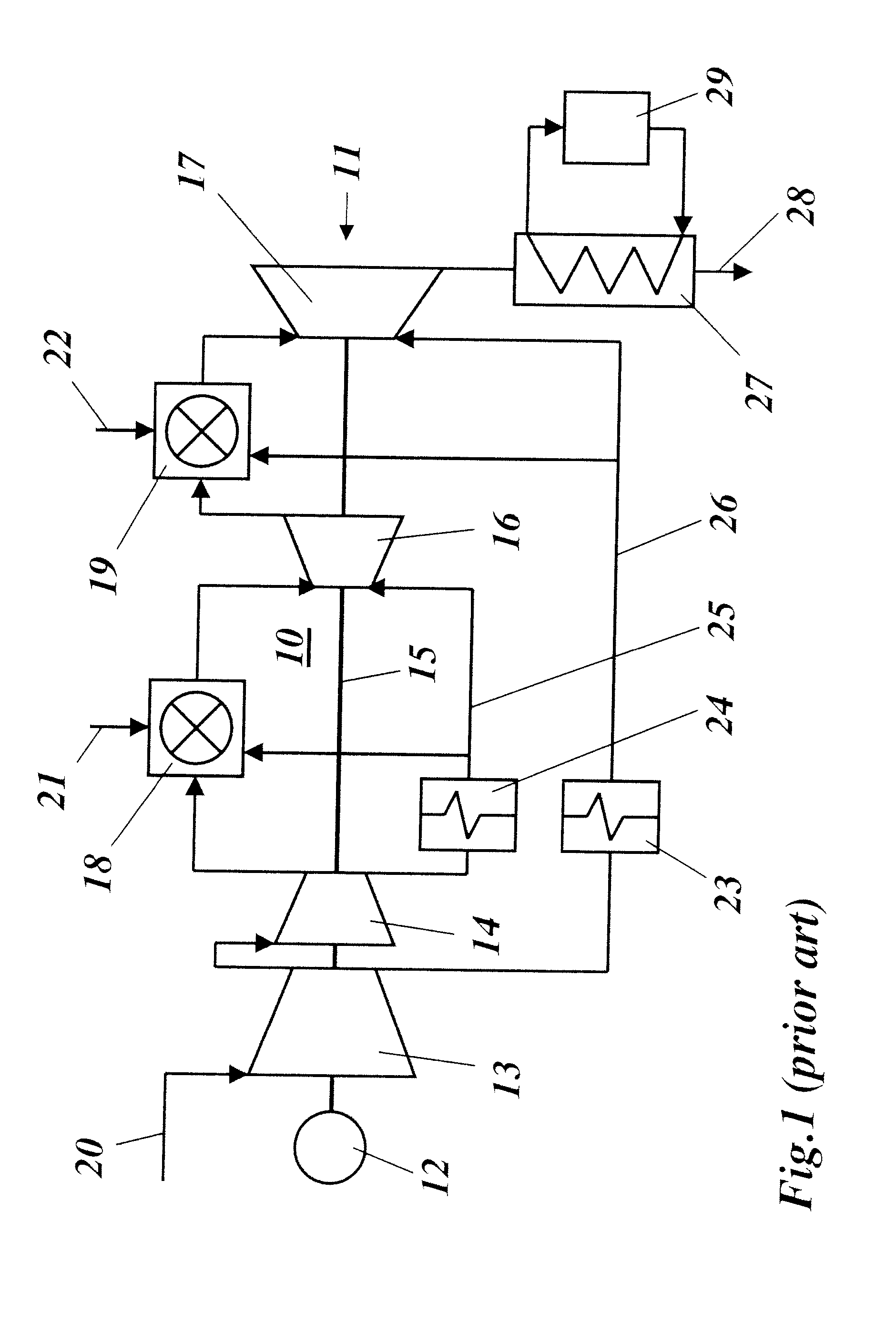

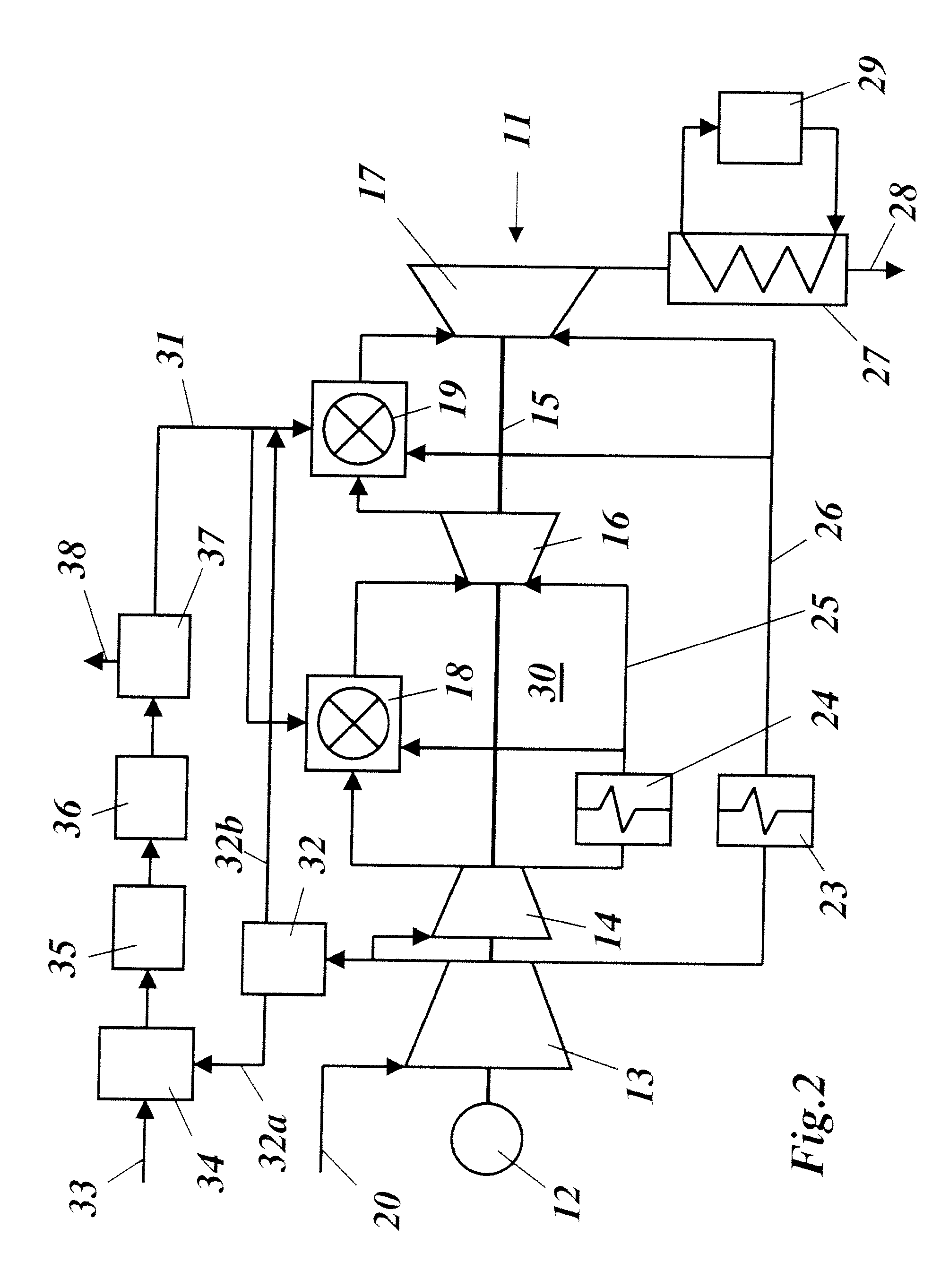

Method for operating a gas turbine

InactiveUS20090260368A1Lower flame temperatureNoticeable loss of output and flexibility of operationSolidificationLiquefactionSyngasCombustor

A method for operating a gas turbine (11), which is used especially in a combined-cycle power plant (30), includes inducting and compressing air by the gas turbine (11), the compressed air is fed to a combustor (18, 19) for the combustion of a syngas which is produced from coal, and the hot gases which result during the combustion are expanded in a subsequent turbine (16, 17), performing work, wherein some of the compressed air is separated into oxygen and nitrogen, and the oxygen is used in a coal gasification plant (34) for producing the syngas. With such a method, a reduction of the NOx emission is achieved without noticeable loss of output and flexibility of operation by a gas turbine (11) with reheating being used, which includes two combustors (18, 19) and two turbines (16, 17), wherein in the first combustor (18) syngas is combusted, using the compressed air, and the resulting hot gases are expanded in the first turbine (16), and wherein in the second combustor syngas is combusted, using the gases which issue from the first turbine (16), and the resulting hot gases are expanded in the second turbine (17), the two combustors (18, 19) are operated with undiluted syngas, and the flame temperature (TF) in the first combustor (18) of the gas turbine (11) is lowered compared with the operation with natural gas (TNG), while the second combustor (19) is operated largely in the normal operation (TNG) which is designed for natural gas.

Owner:GENERAL ELECTRIC TECH GMBH

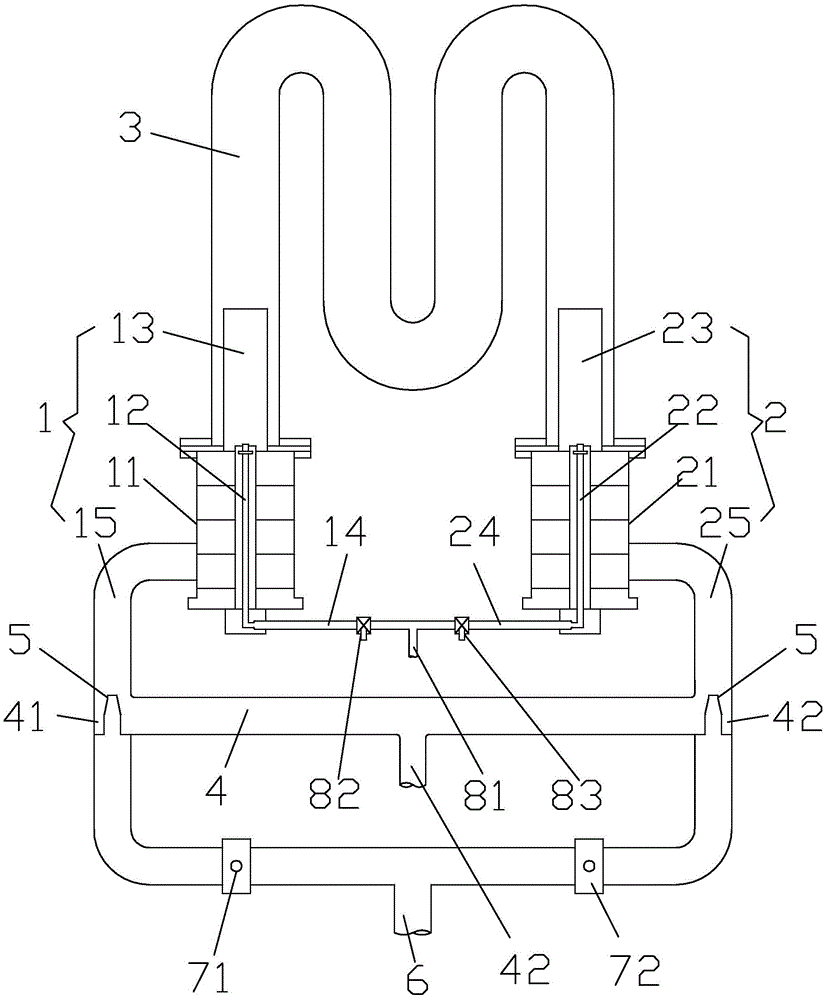

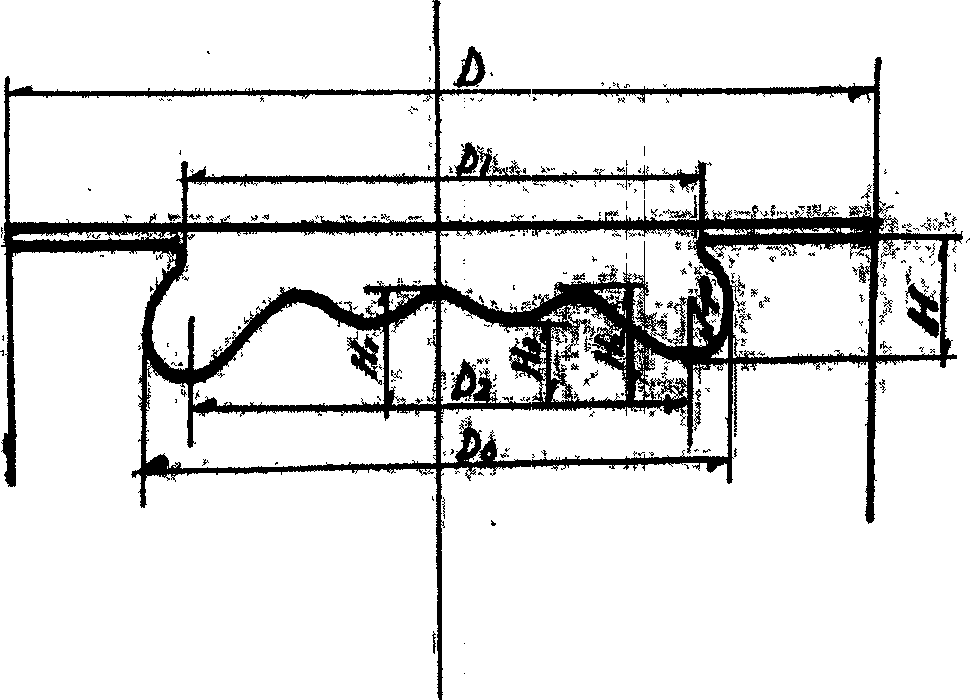

Regenerative radiant tube burner with flue gas recirculation

ActiveCN105465784ARaise the preheat temperatureReduce oxygen contentIndirect carbon-dioxide mitigationGaseous fuel burnerFlue gasEngineering

The invention discloses a regenerative radiant tube burner with flue gas recirculation. The regenerative radiant tube burner comprises a first burner body and a second burner body; the first burner body comprises a first regenerative body, a first burner core penetrating through the first regenerative body and a first air conduit located at the front end of the first burner core, one end of the first burner core is connected with a first gas pipeline, and the first air conduit is connected with a first air pipeline; the second burner body comprises a second regenerative body, a second burner core penetrating through the second regenerative body and a second air conduit located at the front end of the second burner core, one end of the second burner core is connected with a second gas pipeline, and the second air conduit is connected with a second air pipeline; the first air pipeline and the second air pipeline are mutually communicated to form a circulating pipeline which is provided with an air inlet and a flue gas outlet. By means of the regenerative radiant tube burner with flue gas recirculation, the oxygen content of burning supporting air can be decreased, the flame temperature during burning can be decreased, emission of NOx is greatly reduced, and pollution to the atmosphere in the burning process is reduced.

Owner:FOSHAN KEHAO COMBUSTION EQUIP MFG

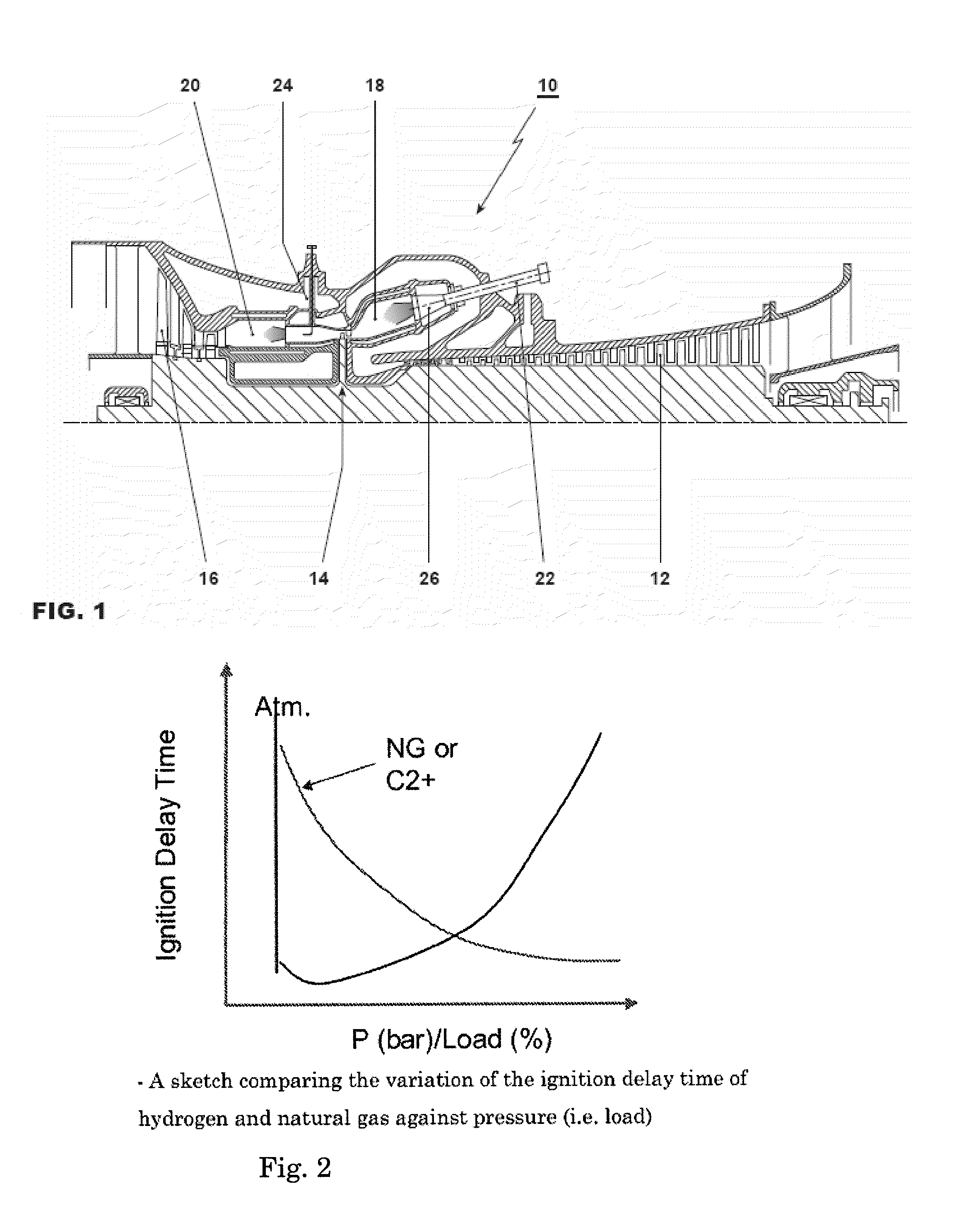

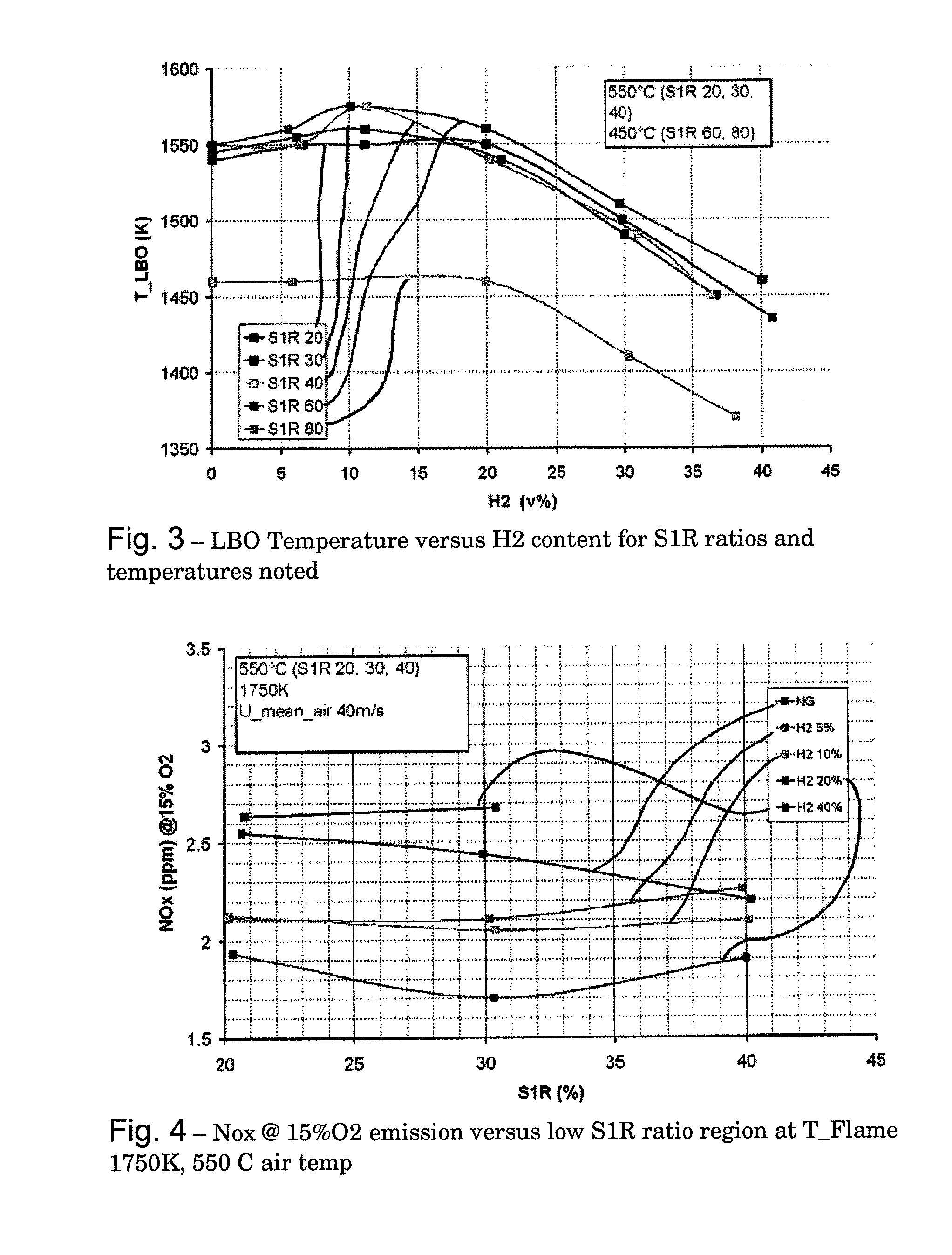

Operating method for hydrogen/natural gas blends within a reheat gas turbine

InactiveUS20130091852A1Improve LBOIncreased stability rangeGas turbine plantsTurbine/propulsion fuel controlHydrogen concentrationModularity

A gas turbine is operated using a varying blend of a first fuel, preferably natural gas, and a second fuel that is hydrogen. The hydrogen concentration is varied depending on operating conditions in order to reduce emissions of CO and NOx, and / or to mitigate LBO. The fuel mixture is varied using a controller based on a combination of factors in a modular operation concept to address different issues according to relevant load limitations. A method of operating a gas turbine according to this modular operational concept is also provided.

Owner:ANSALDO ENERGIA IP UK LTD

Flue gas and air premixing pipe bundle self-cooling low-nitrogen combustion device and combustion method thereof

ActiveCN106594716ALower burn valueLower combustion temperatureFuel supply regulationFluegas recirculationLow nitrogenNitric oxide

The invention discloses a flue gas and air premixing pipe bundle self-cooling low-nitrogen combustion device and a combustion method thereof. The flue gas and air premixing pipe bundle self-cooling low-nitrogen combustion device comprises a gas pipeline, an air blower and a flue gas and air premixing pipe bundle self-cooling low-nitrogen combustor; a flue gas and air mixing device is connected to an air inlet of the air blower; a flue gas and air mixing pipeline is connected to an air outlet of the air blower; a flue gas and air mixing ejector is connected onto the flue gas and air mixing pipeline; an air sleeve is arranged on the low-nitrogen combustor; a main gas jet pipe is arranged in the air sleeve; a circle of flue gas and air mixing cooling pipe bundle is arranged on the periphery of the main gas jet pipe and directly goes deep into a hearth; a burning torch is arranged on the combustor; a flue gas and air mixing inlet is formed in the air sleeve; the rear end of the main gas jet pipe communicates with a big fire gas pipeline provided with a big fire valve and a small fire gas pipeline provided with a small fire valve; and a flame detector is arranged on the end head of the burning torch. The device is applicable to a gas boiler, has the characteristics of simple structure, reasonable design, flame combustion with low nitrogen at low temperature, capability of automatic cooling, accurate control and the like, and ensures lower nitric oxide emission load of the gas boiler.

Owner:王立臣

High thermal conductivity silica brick for coke oven and preparation method thereof

ActiveCN104119081ADense microstructureImprove thermal conductivitySilica particleCarboxymethyl cellulose

The invention relates to a high thermal conductivity silica brick for coke oven and a preparation method thereof. The high thermal conductivity silica brick for a coke oven comprises the following components by weight: 68.0%-82.0% of natural silica particles, 13.0%-26.0% of natural silica powder, 0.5%-2.0% of an additive containing dispersant, 1.5%-5.0% of siliceous non oxide, 1.0%-3.0% of a mineralization agent, and an additional binder in the weight 1.5%-3.0% of the total weight of the previous materials. The additive comprises a dispersant carboxymethyl cellulose (CMC) with granularity less than 0.088 mm and siliceous non-oxide Si with granularity less than 0.043 mm, wherein the content of Si is greater than 96 wt.%. The silica brick provided by the invention has high thermal conductivity and keeps other comprehensive excellent performances of silica brick, and can satisfy the demands of coke oven for longevity, energy saving and high efficient production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

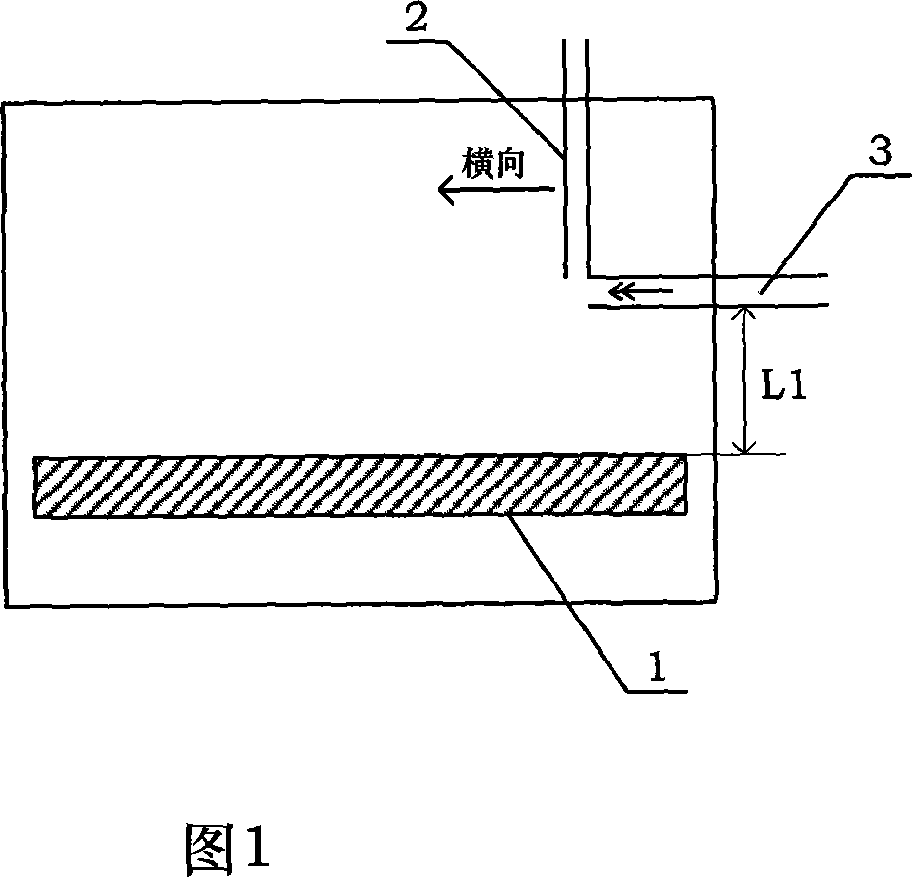

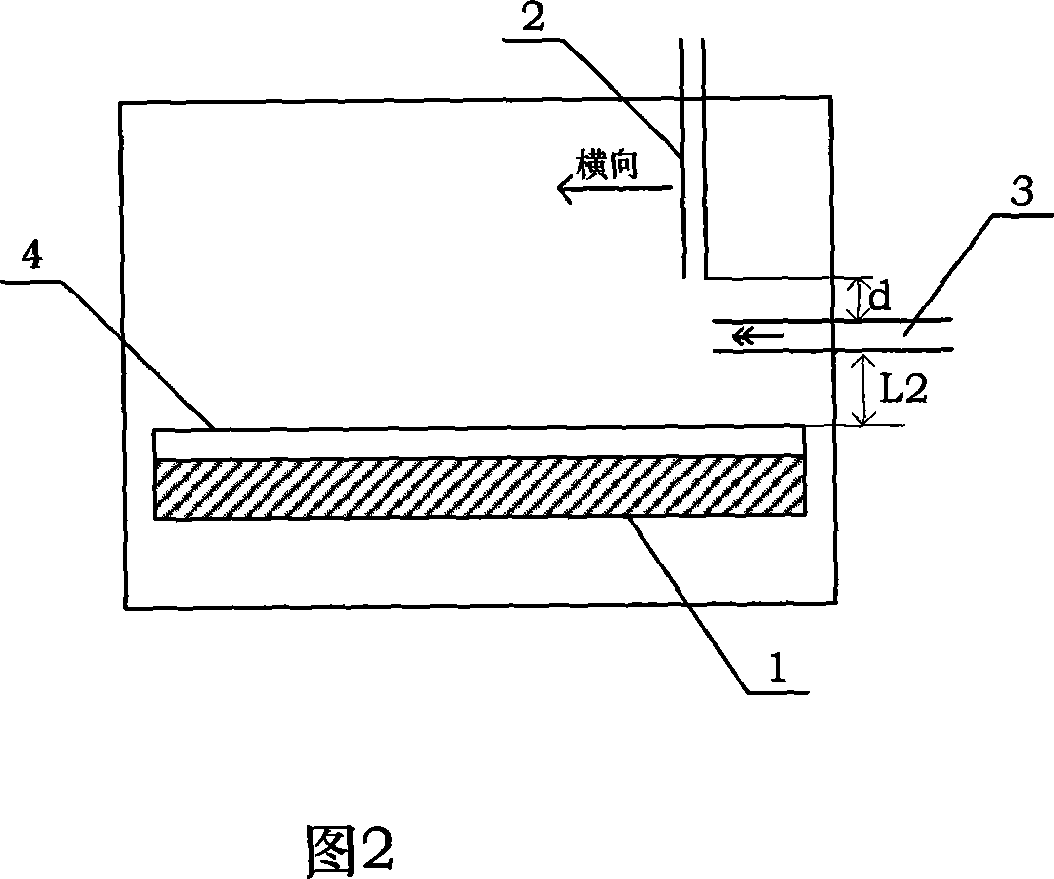

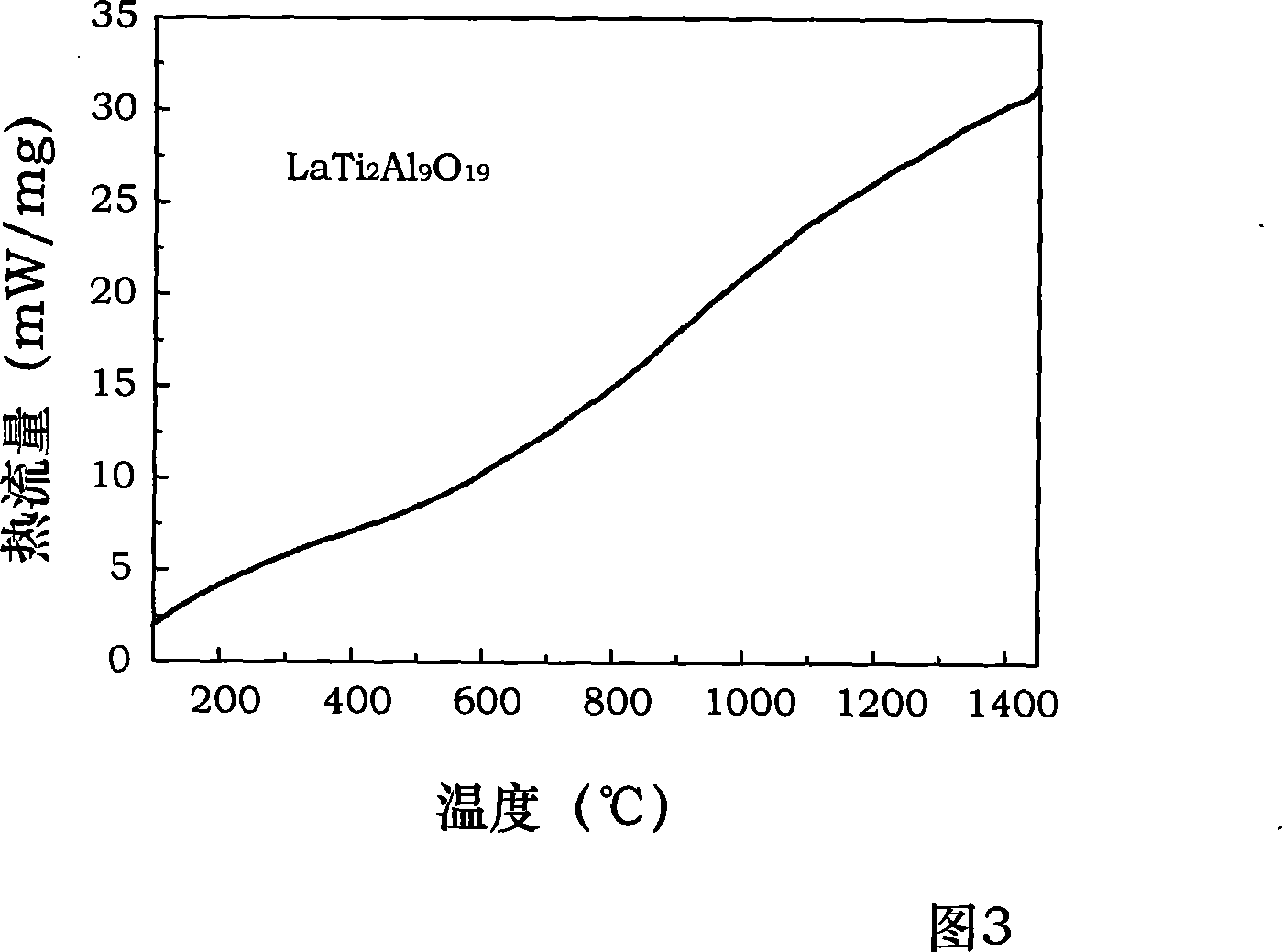

Method for preparing heat barrier coating with column form crystal structure ceramic layer

InactiveCN101078117AAvoid decompositionMaintain high temperature structural stabilityEfficient propulsion technologiesMetallic material coating processesThermal isolationMetallurgy

The invention discloses a thermal barrier coating preparation method with the columnar crystals coating to solve the problem of non-crystal coating and low anti-thermal in normal plasma spraying for the LaTi2Al9O19 ceramic material. It changes the distance and the technique data of the tack coat and ceramic powder channel in the normal plasma spraying process, so the thermal barrier coating of the LaTi2Al9O19 with the stable energetic and the columnar crystal structure. The thermal isolation temperature is 130deg.C-300deg.C and improves the strain limit and anti-thermal character, the hot circle life can reach above 1500 times and improves by 4 times.

Owner:BEIHANG UNIV

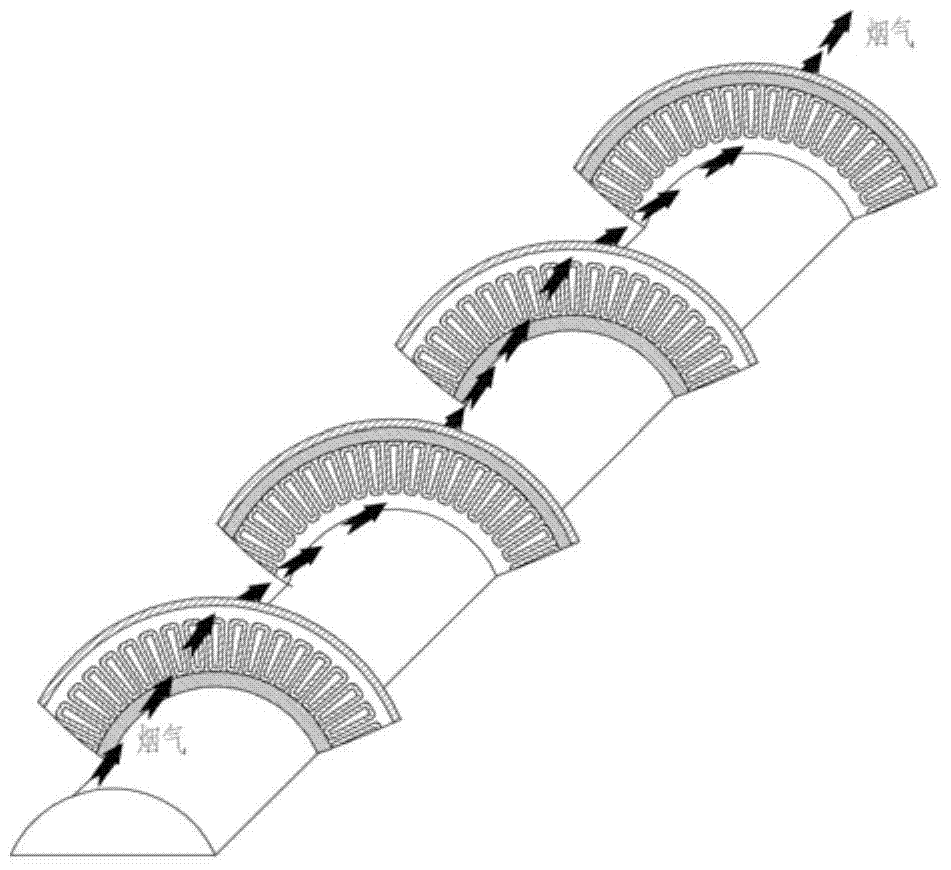

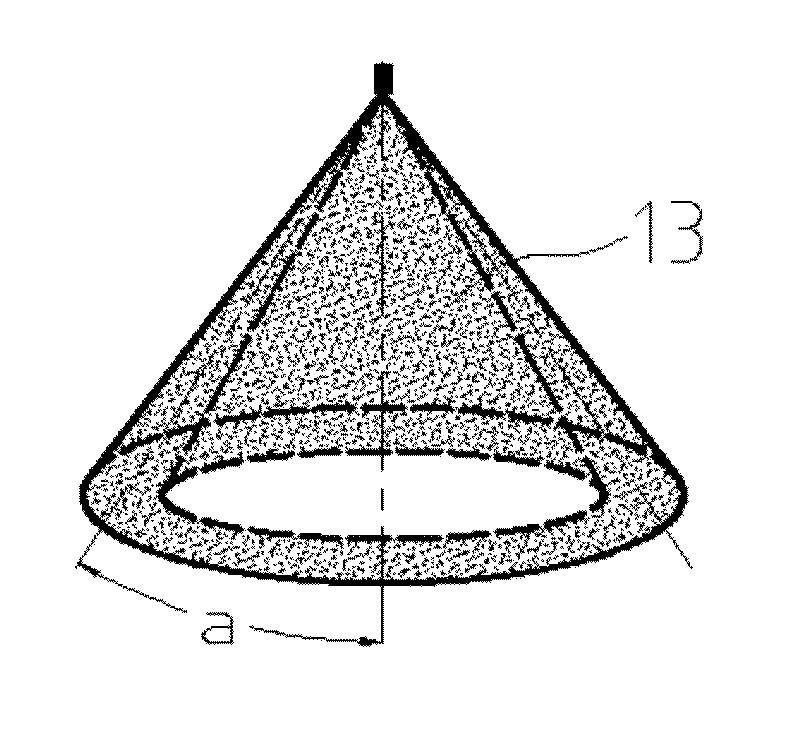

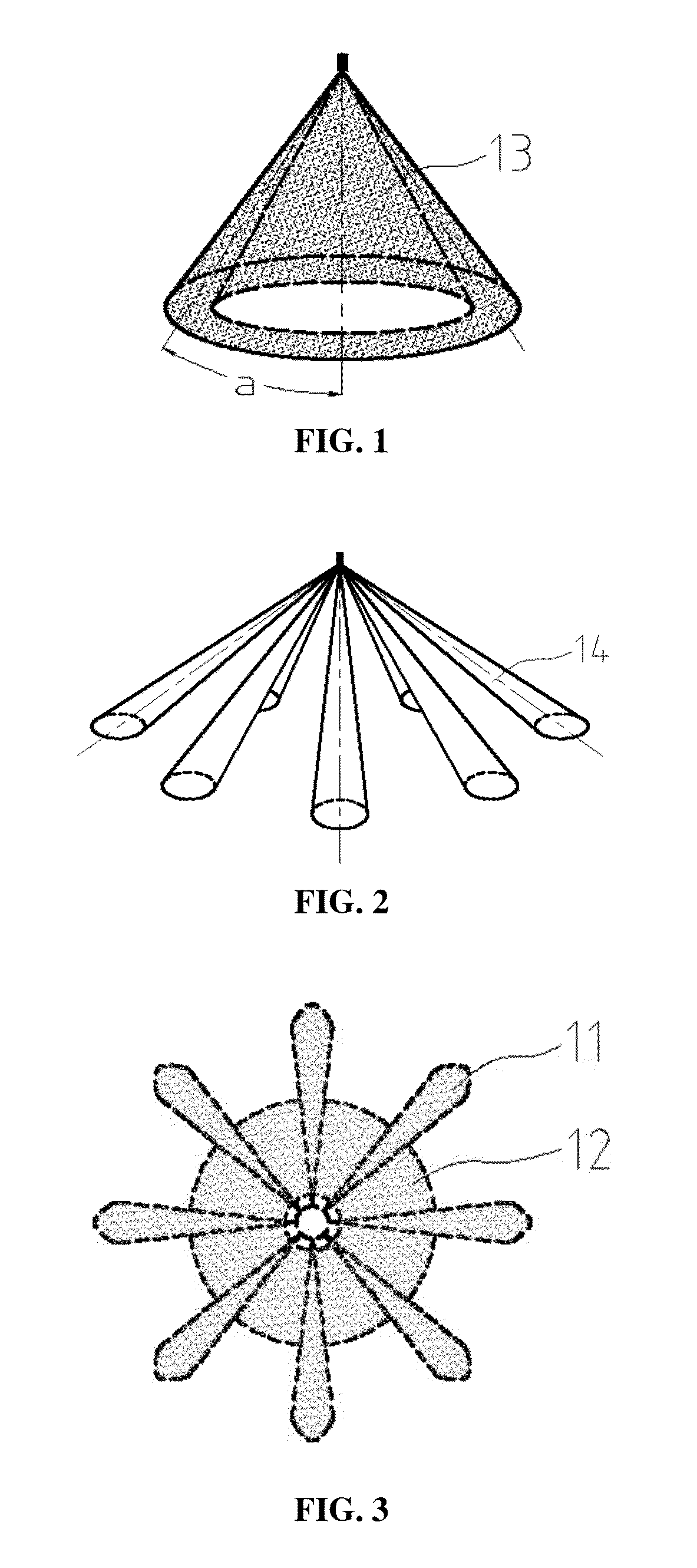

Petal-shaped staged combustion gas low-nitrogen combustor

The invention discloses a petal-shaped staged combustion gas low-nitrogen combustor. The combustor comprises a fuel gas collection tank, a combustion stabilizing disc, a nozzle and a combustion supporting channel; the nozzle is connected to one end of the fuel gas collection tank, and the combustion supporting channel extends to the tail end of the nozzle from an inlet of the fuel gas collection tank; the combustion stabilizing disc is arranged in the nozzle, and a gas chamber is arranged between the combustion stabilizing disc and the inner wall of the nozzle; the air chamber is connected to the fuel gas collection tank through a plurality of fuel conveying pipes, and a plurality of sector-shaped grooves which are evenly formed in the circumferential direction of the nozzle are formed in the tail end of the nozzle; a spray gun is formed in the position, in the circumferential direction of each sector-shaped groove, in each sector-shaped groove, and is connected with the gas chamber to obtain gas; and the combustion stabilizing disc comprises a center channel and a bending blade channel. The low-nitrogen combustor achieves staged combustion, nitric oxides are reduced, the combustion efficiency is not reduced, the current environment-friendly requirement is met, and meanwhile emissions of the nitric oxides are reduced to a greater extent.

Owner:XUZHOU KERONG ENVIRONMENTAL RESOURCES CO LTD +1

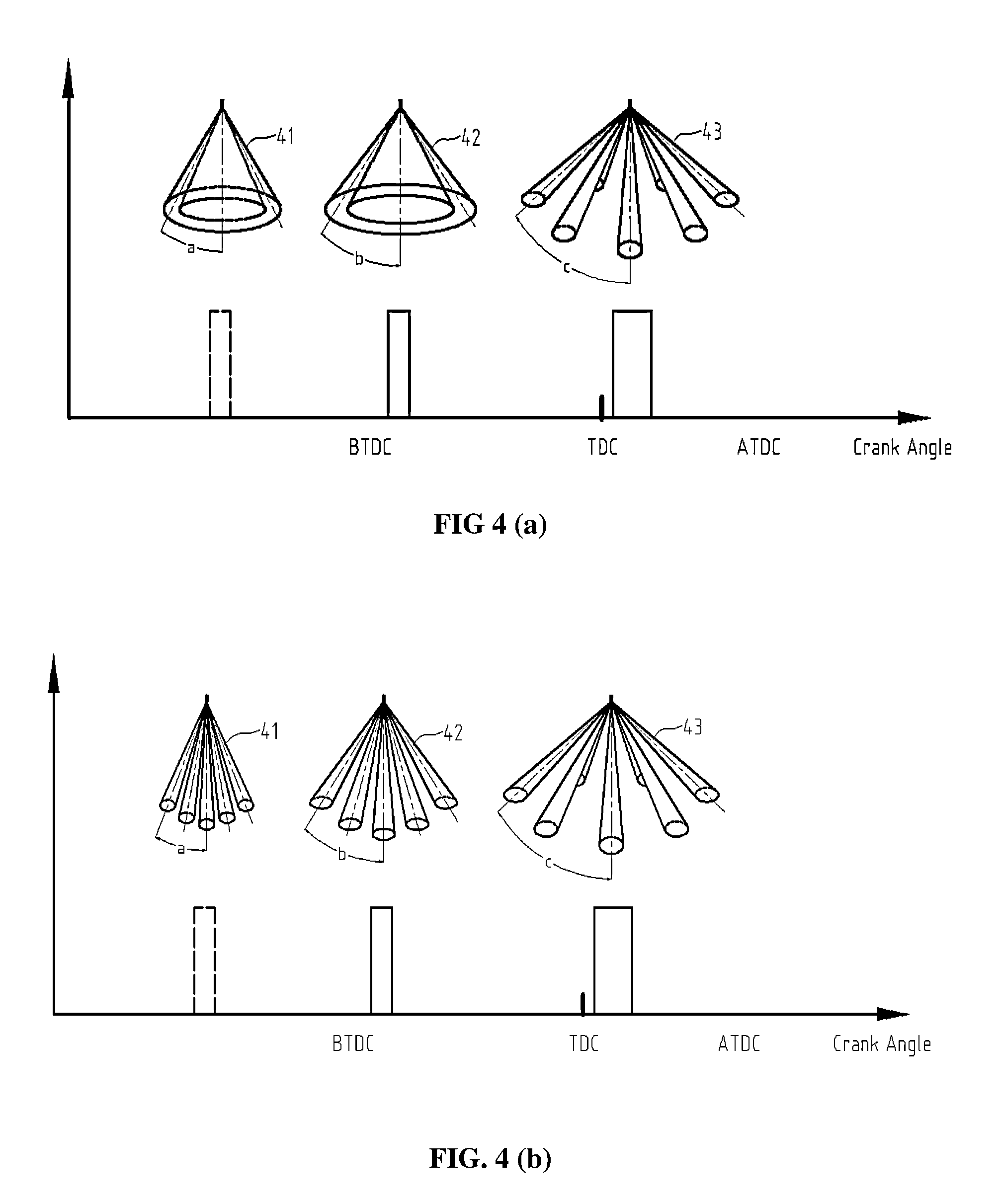

Combustion system and method for self adaption controllable heat premixing direct jet type diesel engine

InactiveCN1587660AReduce generationEffective time controlInternal combustion piston enginesFuel injection apparatusCombustion systemBurn rate

The invention discloses a kind of self-adaptnig, heat-controllable, pre-mixing and direct-spraying diesel engine burning system and its method, which belongs to the field of internal-combustion engine. The stated burning system incldues multi-hole glib talker, multi connection space burning room and inelt track. The stated multi connection space burning room consists of two or more linking space structure, it can control the transmitting way for pre-mixing burning, and when cooperatnig with the fuel spraying and timing oil support, it can effectively control the space-time distribution of combination gas and fire-starting point and burn rate under different operating modes, thus make the burning system be self-adapting and controllable. The burning room can form multi circulations to promote the forming of the homogeneous combination gas. The vortex ratio O of the stated system is 0-2, glib aperture is 50-180 mum, the oil spraying pressure is higher than 800 bar, it can reduce flame temperature notably, carbon smoke, NOX and HC, improve the combustion efficiency.

Owner:侯德洋

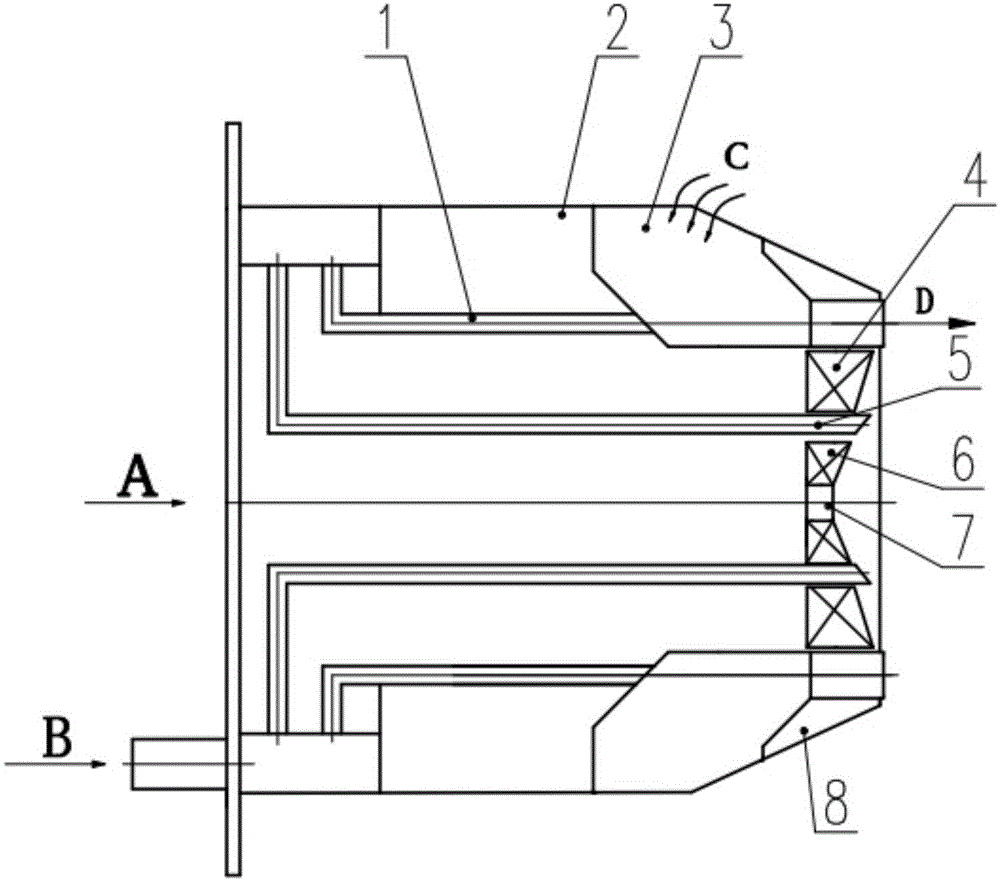

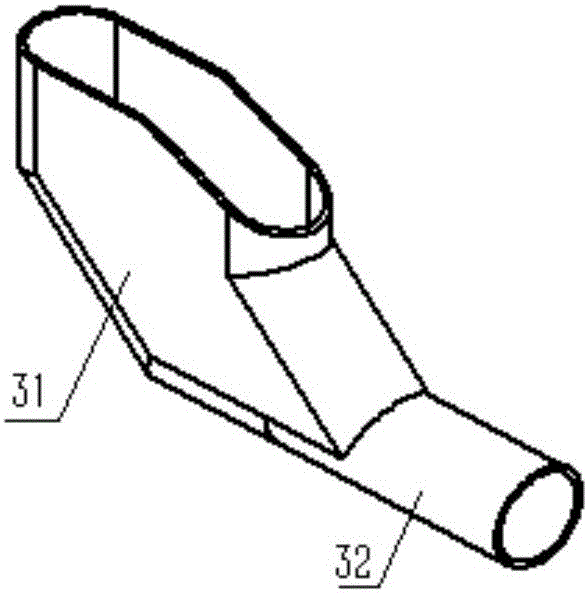

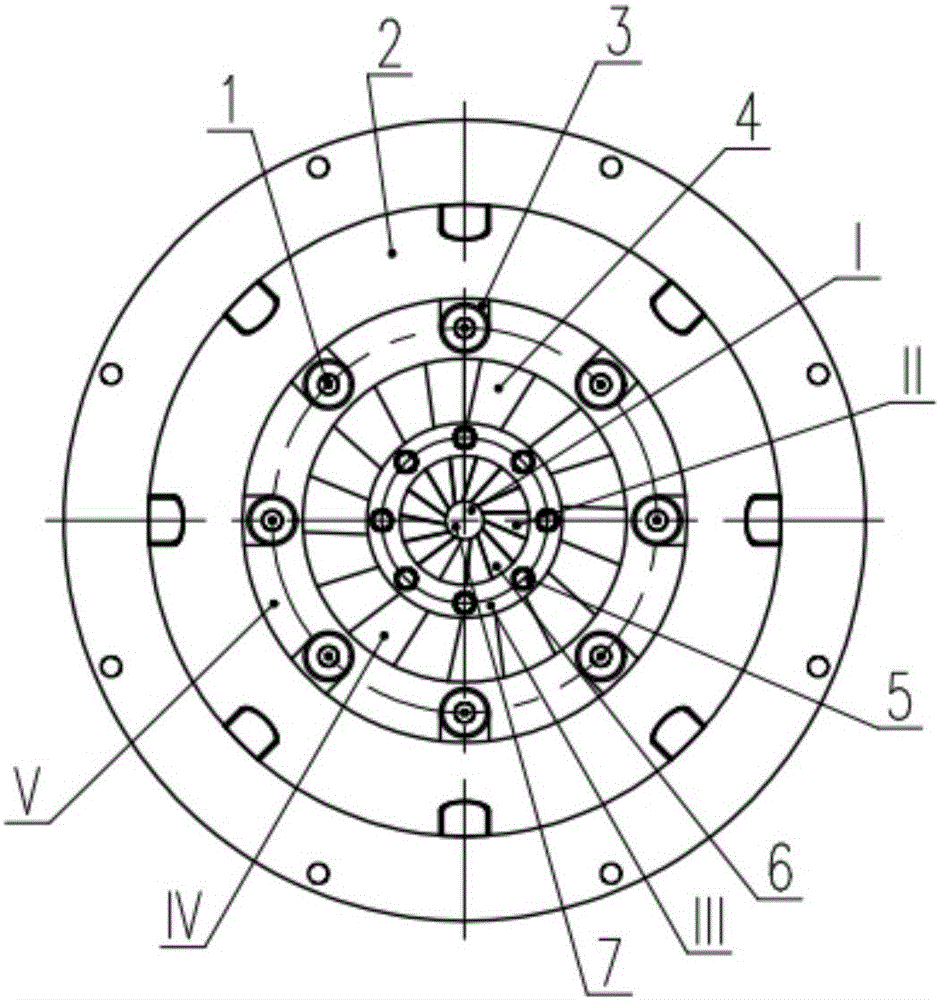

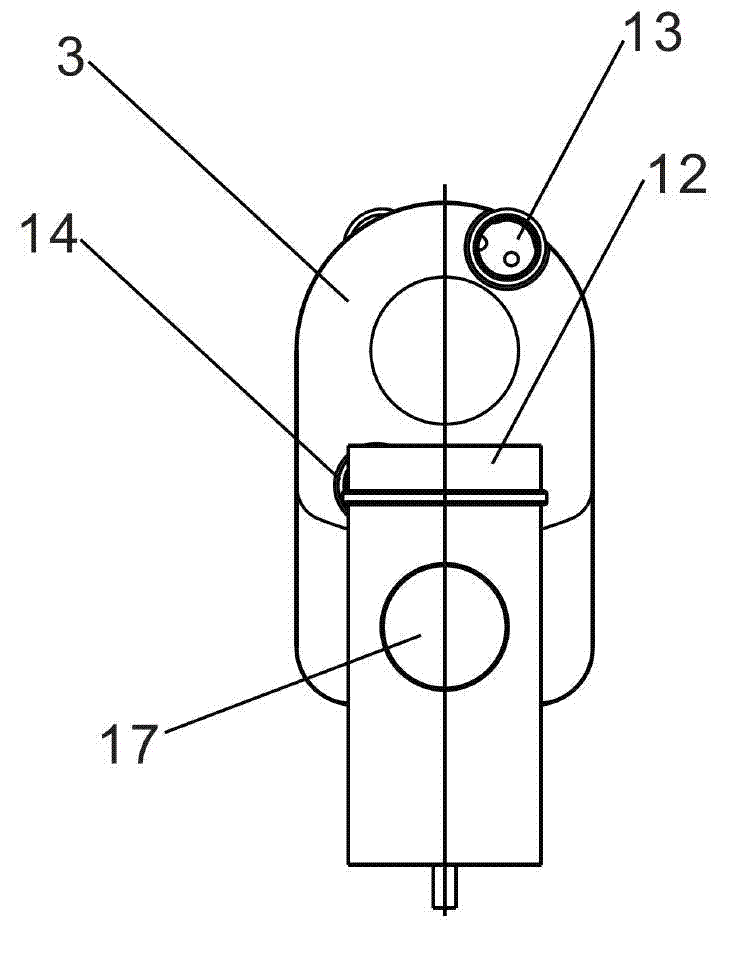

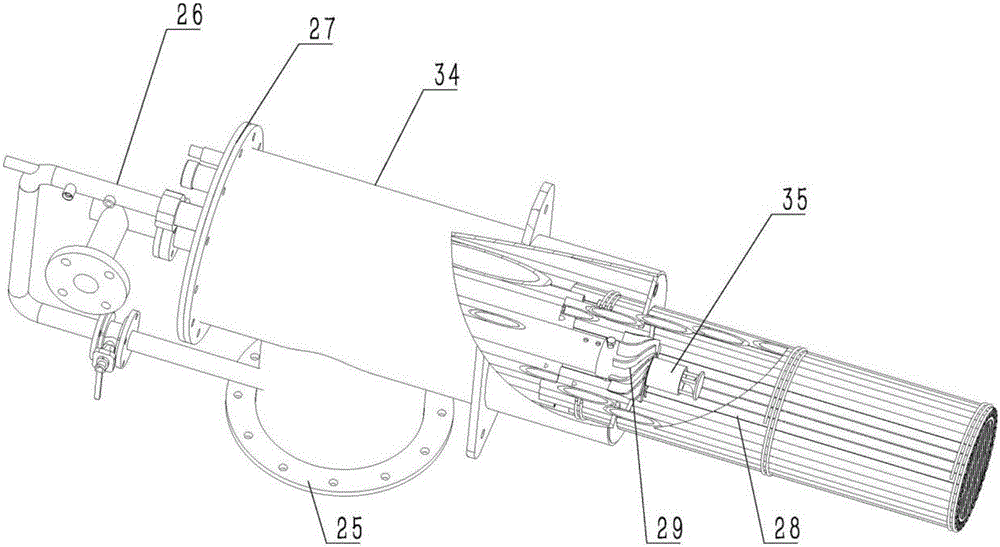

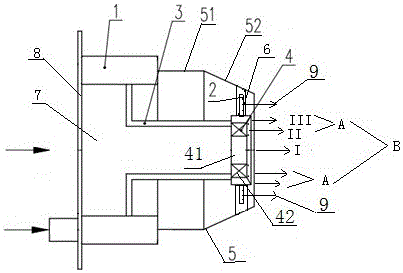

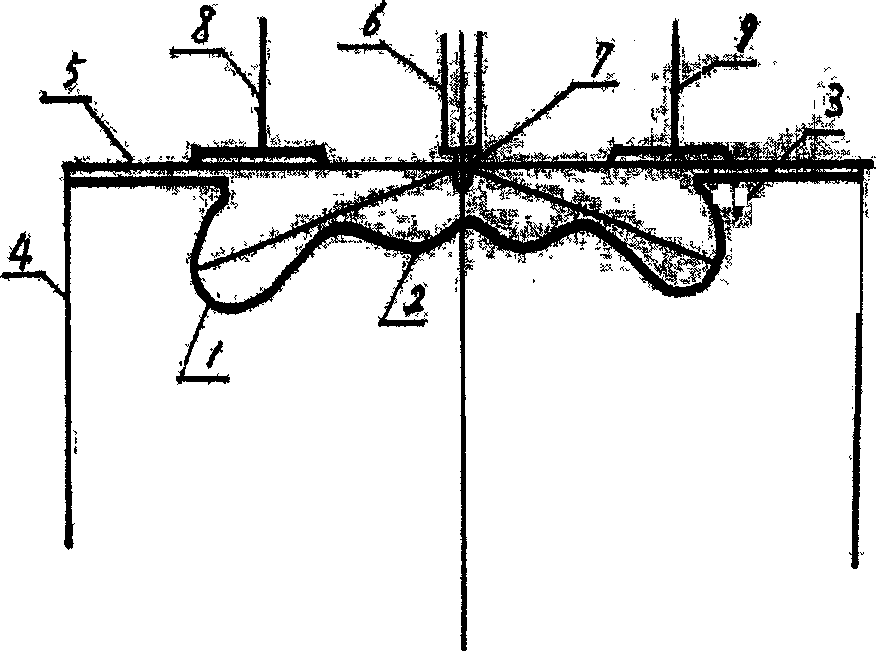

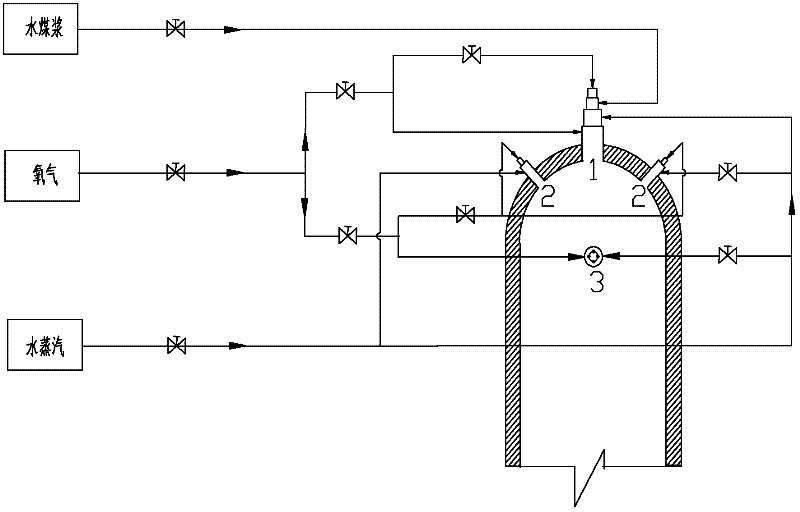

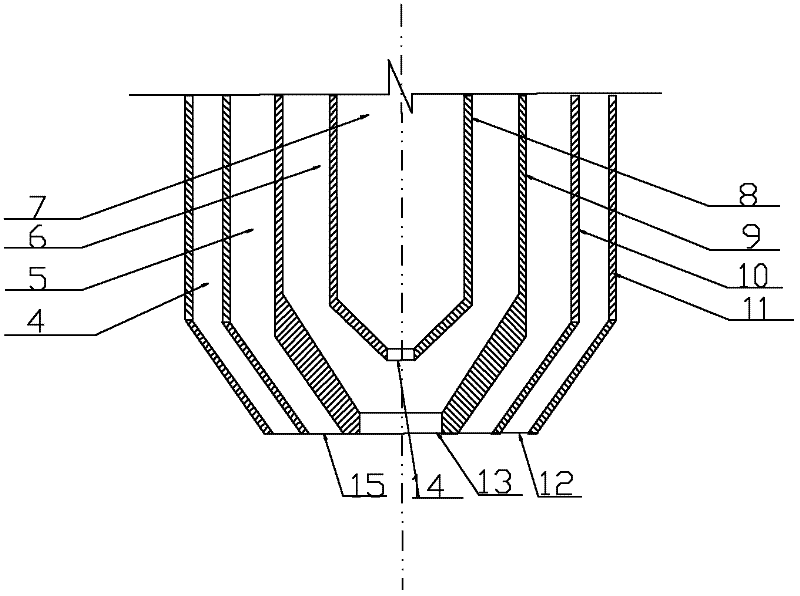

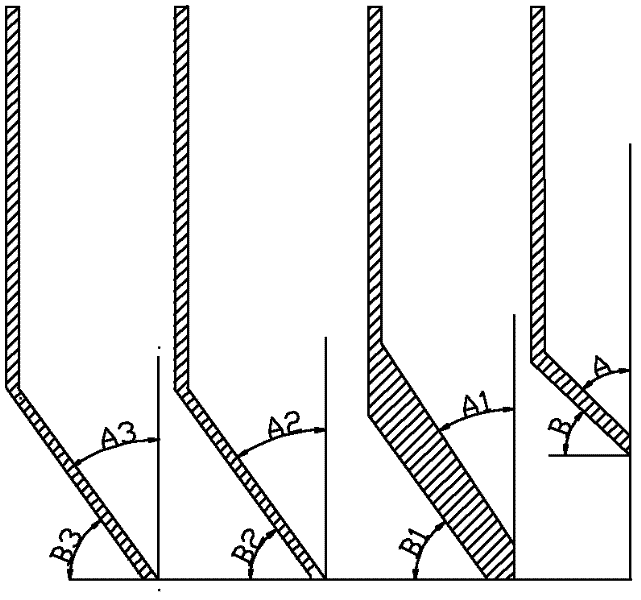

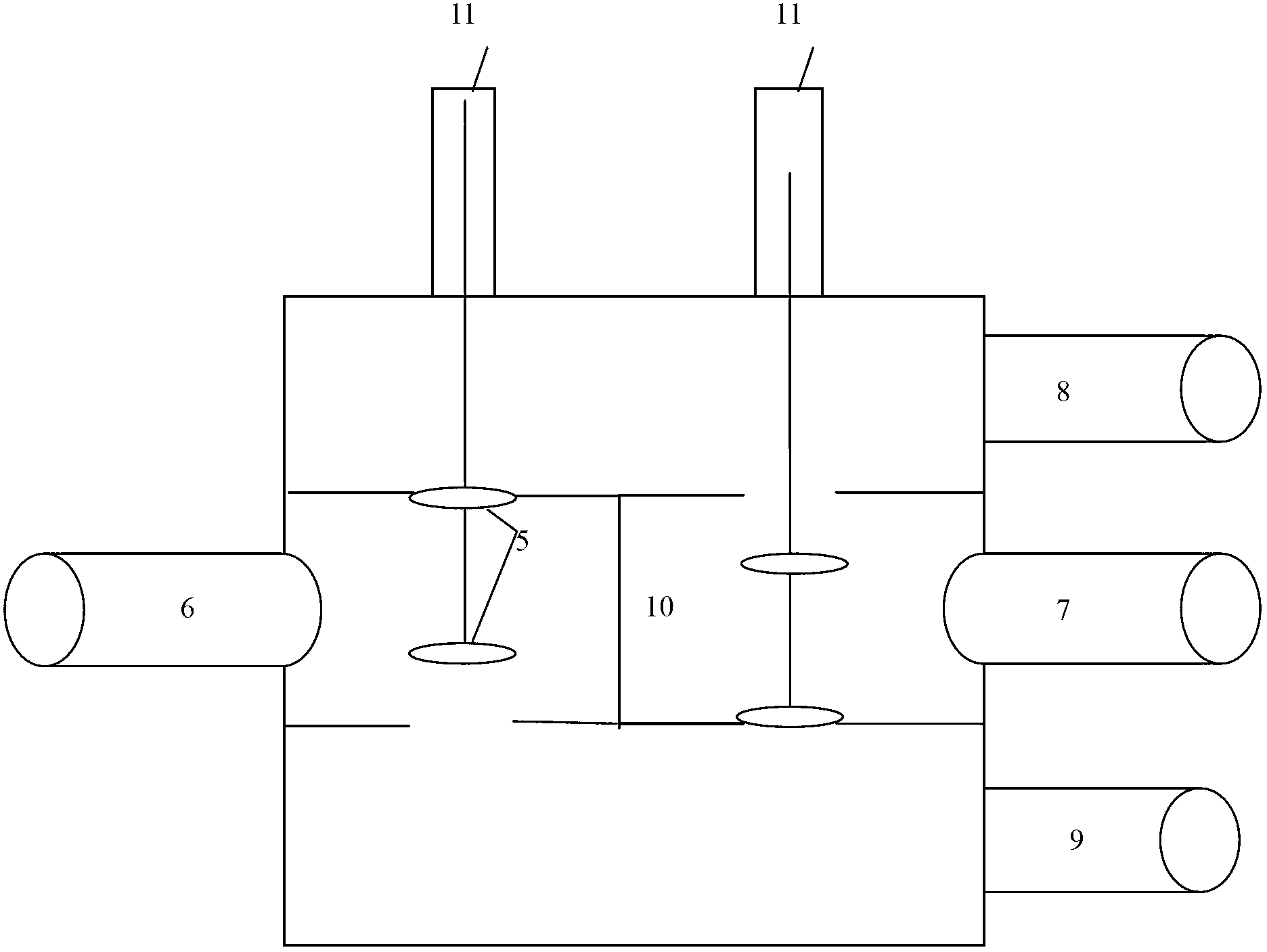

Hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle

InactiveCN102492477AReduce burning intensityLower flame temperatureLiquid spraying apparatusCombined combustion mitigationSlagReaction rate

The invention relates to a hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle which is arranged on a gasification furnace. The hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle comprises a main fuel nozzle which is arranged at the top of a furnace, two steam nozzles which are arranged at the two sides of a furnace arch and two oxygen supply nozzles which are horizontally arranged in a hedging manner, wherein the nozzles are respectively connected with a coal water slurry source, an oxygen source and a steam source, and the openings of the nozzles lead into a hearth of the gasification furnace. According to the invention, an advanced temperature control technology combining a grading oxygen supply temperature control technology and a steam temperature control technology is adopted, combustion intensity and flame temperature in the furnace are effectively reduced, and the aim that ash at the outlet of the gasification chamber is non-fused solid slag; meanwhile, gasification reaction rate and carbon conversion rate are improved, thus gasification solid deslagging on a 'double high' coal type large-scale pressurization entrained bed in China is realized, and the hierarchical oxygen supply and controllable flame coal water slurry entrained bed combined nozzle provided by the invention is especially applicable to industrial application of a high-ash (25-27%) and high-ash-fusing-point (FT is more than 1400 DEG C) coal type large-scale gasification device in China.

Owner:SHANGHAI JIAO TONG UNIV

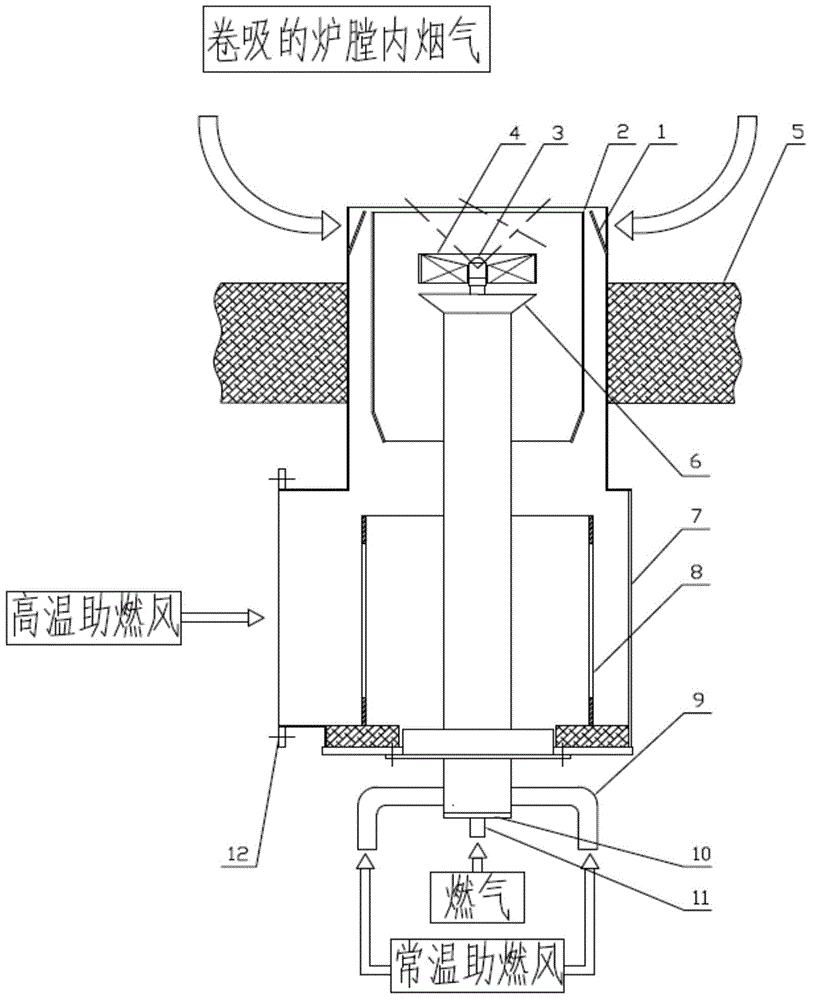

Tail edge backflow dual-classification low-nitrogen-oxygen gas burner

ActiveCN105114951AReduce the temperatureReduce generationIndirect carbon-dioxide mitigationGaseous fuel burnerSpray nozzleLow nitrogen

The invention provides a tail edge backflow dual-classification low-nitrogen-oxygen gas burner which comprises an air box assembly. A smoke backflow fin ring is arranged at the upper end of the air box assembly. A center gas nozzle is arranged in a center air channel in the air box assembly and provided with a rotational flow flame holder. A coaxial air adjusting barrel is installed at the upper portion of the air box assembly. A coaxial cold air barrel is arranged at the lower end of the center gas nozzle. A combustion-supporting air distribution barrel is arranged at the lower portion of the air box assembly. A gas inlet is formed in the center of the bottom of the air box assembly. Constant-temperature combustion-supporting air inlets are formed in the two sides of the gas inlet and a high-temperature combustion-supporting air inlet is formed in one side. Under the same working condition, when the tail edge backflow dual-classification low-nitrogen-oxygen gas burner of the structure is adopted for reaching the standard of CO emission, the content of NOx can be reduced by over 65% compared with that of a conventional burner. When the temperature of combustion-supporting air is 270 DEG C, the emission amount of NOx can be reduced to average 138 mg / Nm<3> from 400 mg / Nm<3>.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

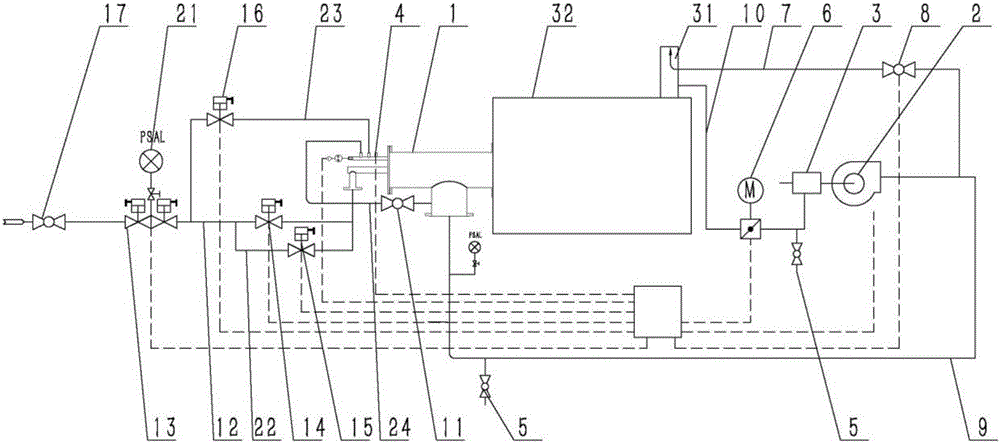

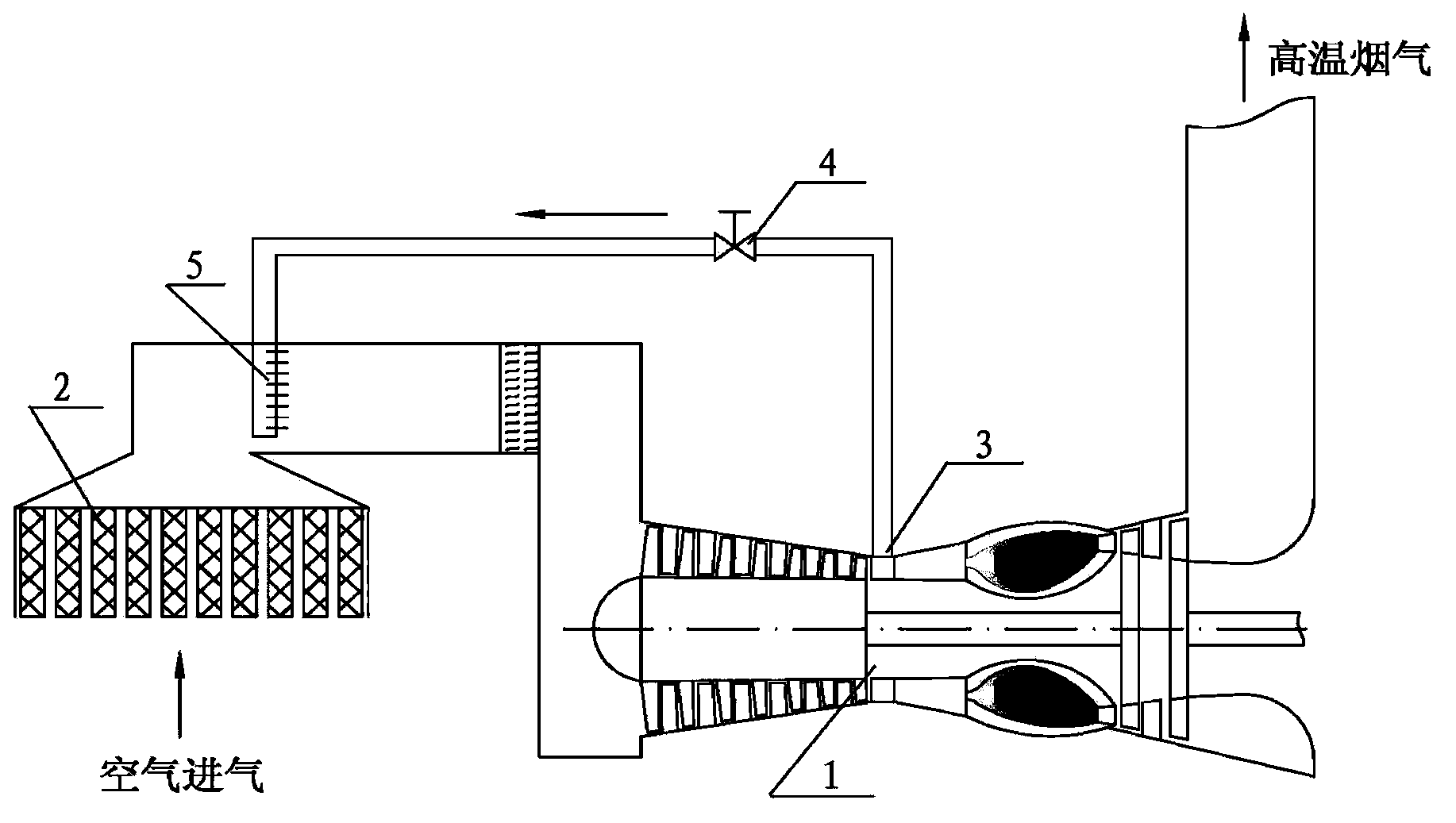

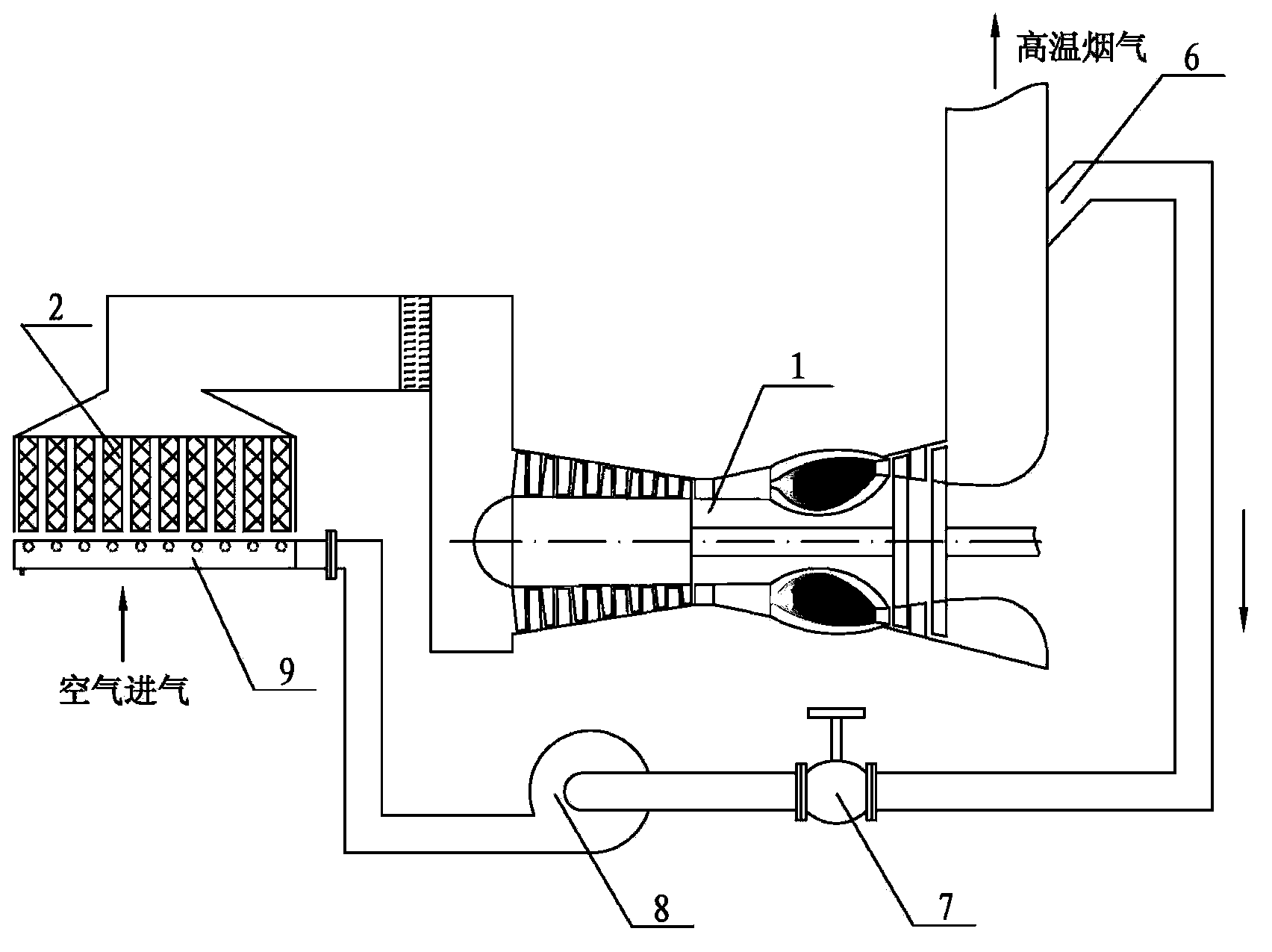

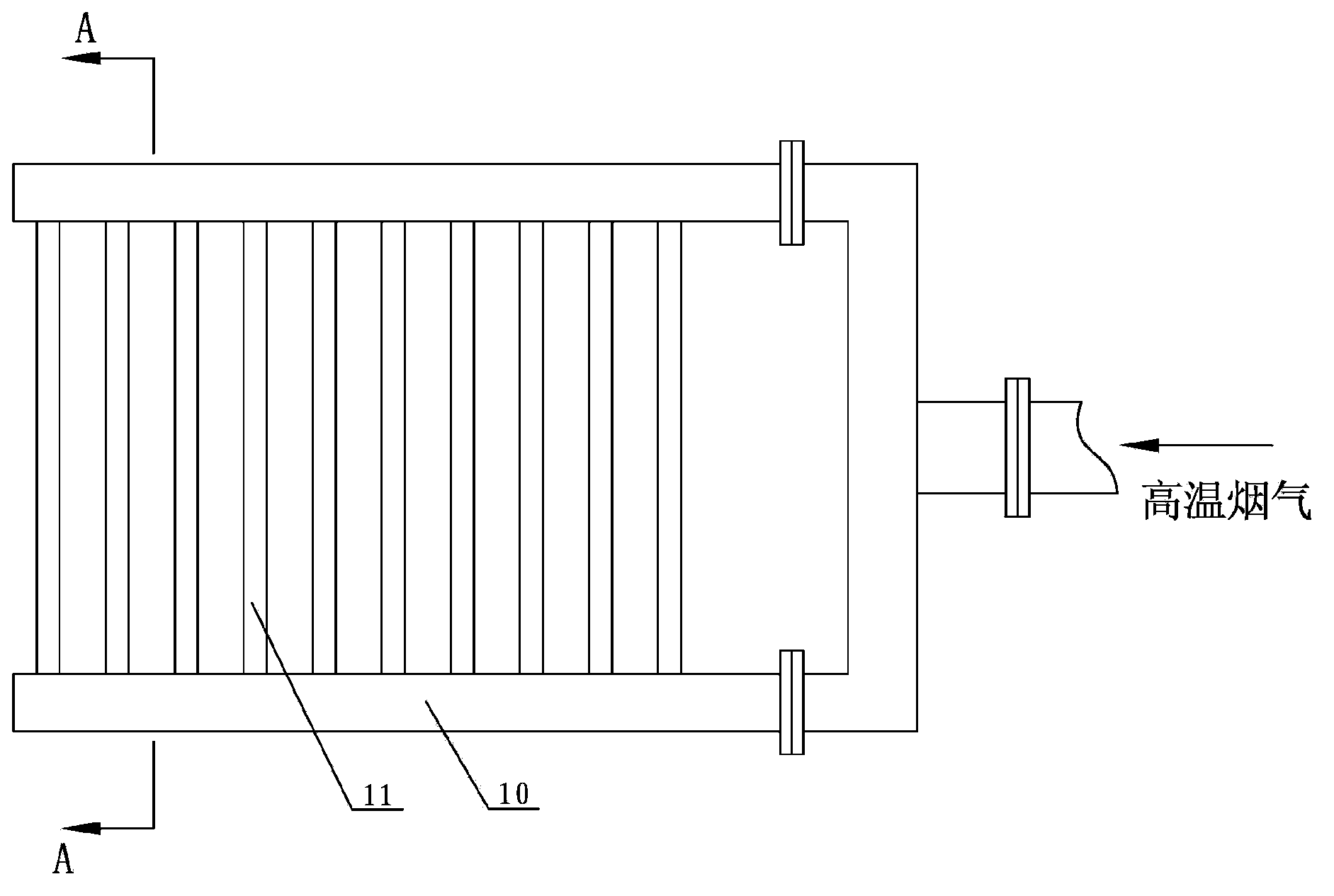

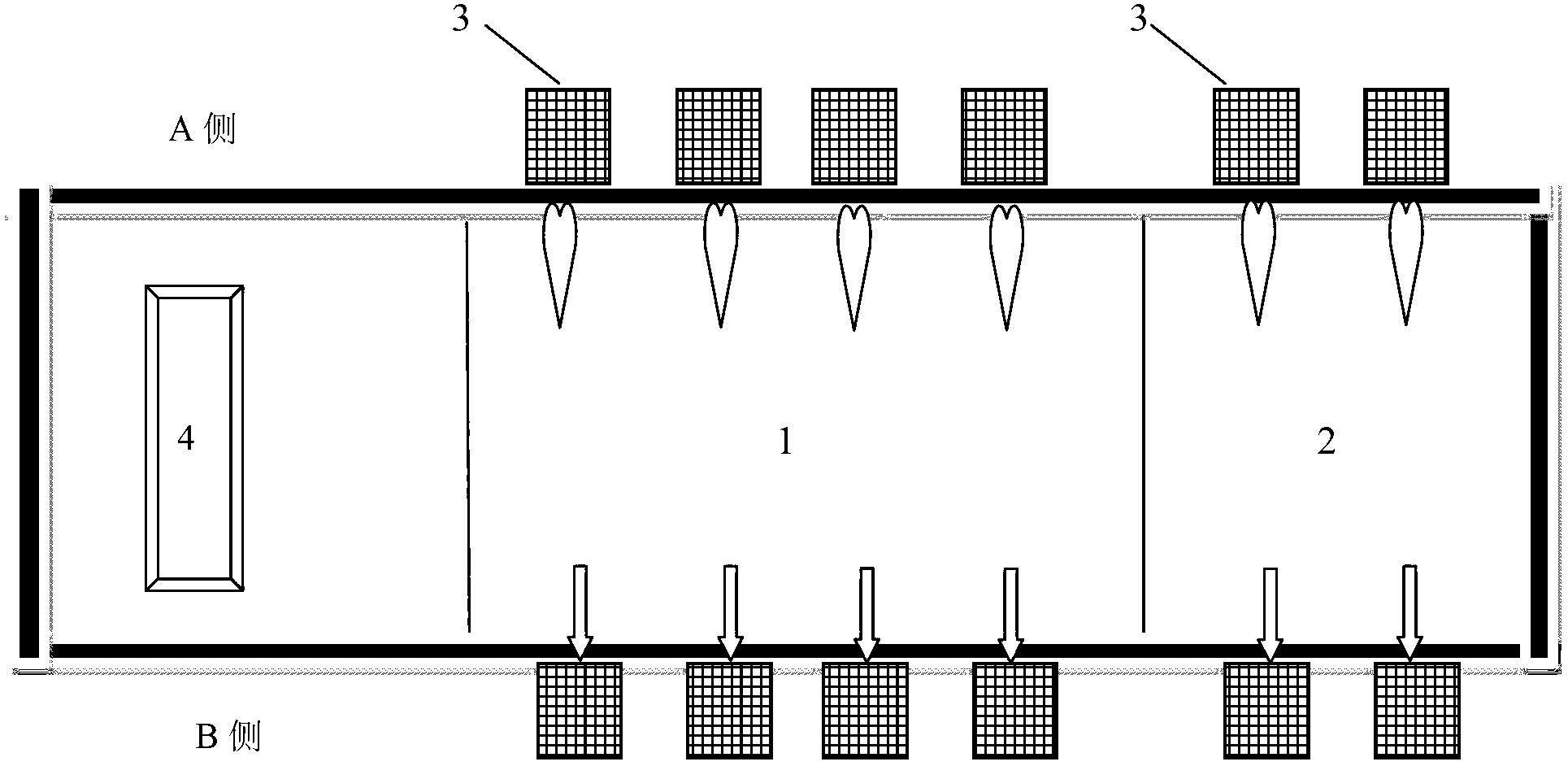

Gas turbine energy saving type incoming gas anti-icing apparatus

ActiveCN103573413AImprove energy savingAvoid frostGas turbine plantsJet propulsion plantsFrostUnit operation

The present invention discloses a gas turbine energy saving type incoming gas anti-icing apparatus, provides improvement on the existing gas turbine air compressor inlet air anti-icing apparatus, and relates to the technical field of non-variable-capacity engines, heat exchange and pipeline systems. The gas turbine energy saving type incoming gas anti-icing apparatus is characterized in that the mixing heating device structure is that multi-row mixing heating alignment pipes (11) are aligned in a parallel manner, both ends of the mixing heating alignment pipes (11) are connected with connection boxes (10), one ends of the connection boxes (10) on both ends of the alignment pipes are communicated to form an n shape, the middle portion of the communication edge of the n-shaped connection box (10) is connected with a wind outlet pipe of an induced fan, the n-shaped connection box and the horizontal plane form downward inclination with an angle of 1-3 DEG along the air flow direction, and the lowest end bottom is provided with a tiny connection box low point drainage hole (12). According to the present invention, gas turbine unit power loss caused by the anti-icing system can be reduced, adverse effects of the anti-icing system on gas turbine unit operation stability can be reduced, and effects of anti-icing, frost prevention and energy saving are provided.

Owner:PIPECHINA SOUTH CHINA CO

Methods for Low Temperature Combustion and Engines Using the Same

InactiveUS20140299105A1Promote combustionEmission reductionElectrical controlInternal combustion piston enginesCombustion chamberBoiling point

This invention discloses a method for low temperature combustion using at least two fuels with low and high boiling points being directly injected into engine combustion chamber separately and sequentially with two different spray patterns, wherein the low boiling point fuel can be quickly vaporized to form a low temperature zone for containing fuel jet combustion of high boiling point fuels. An internal combustion engine using the disclosed low temperature combustion method is also provided.

Owner:QUANTLOGIC CORP

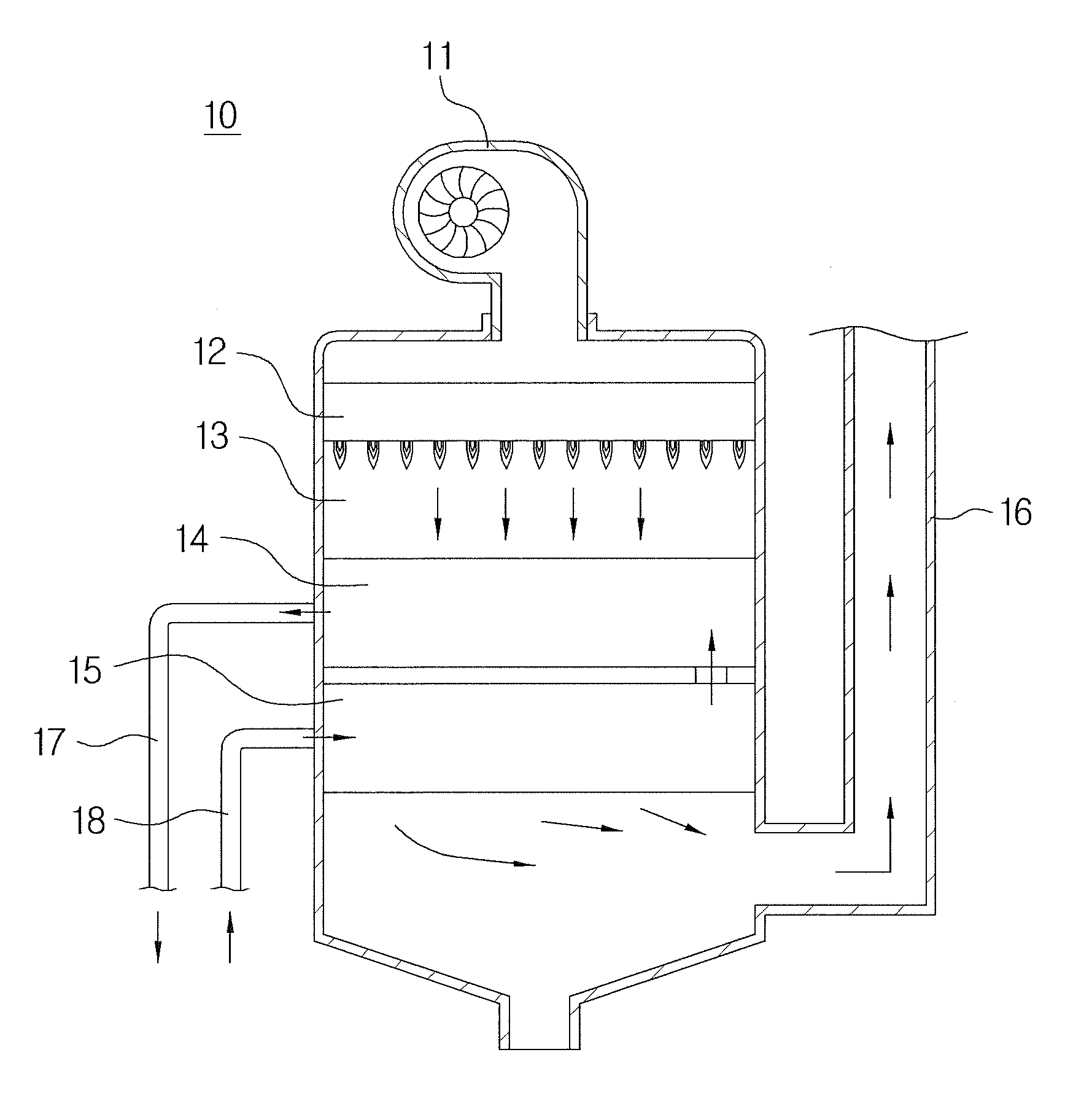

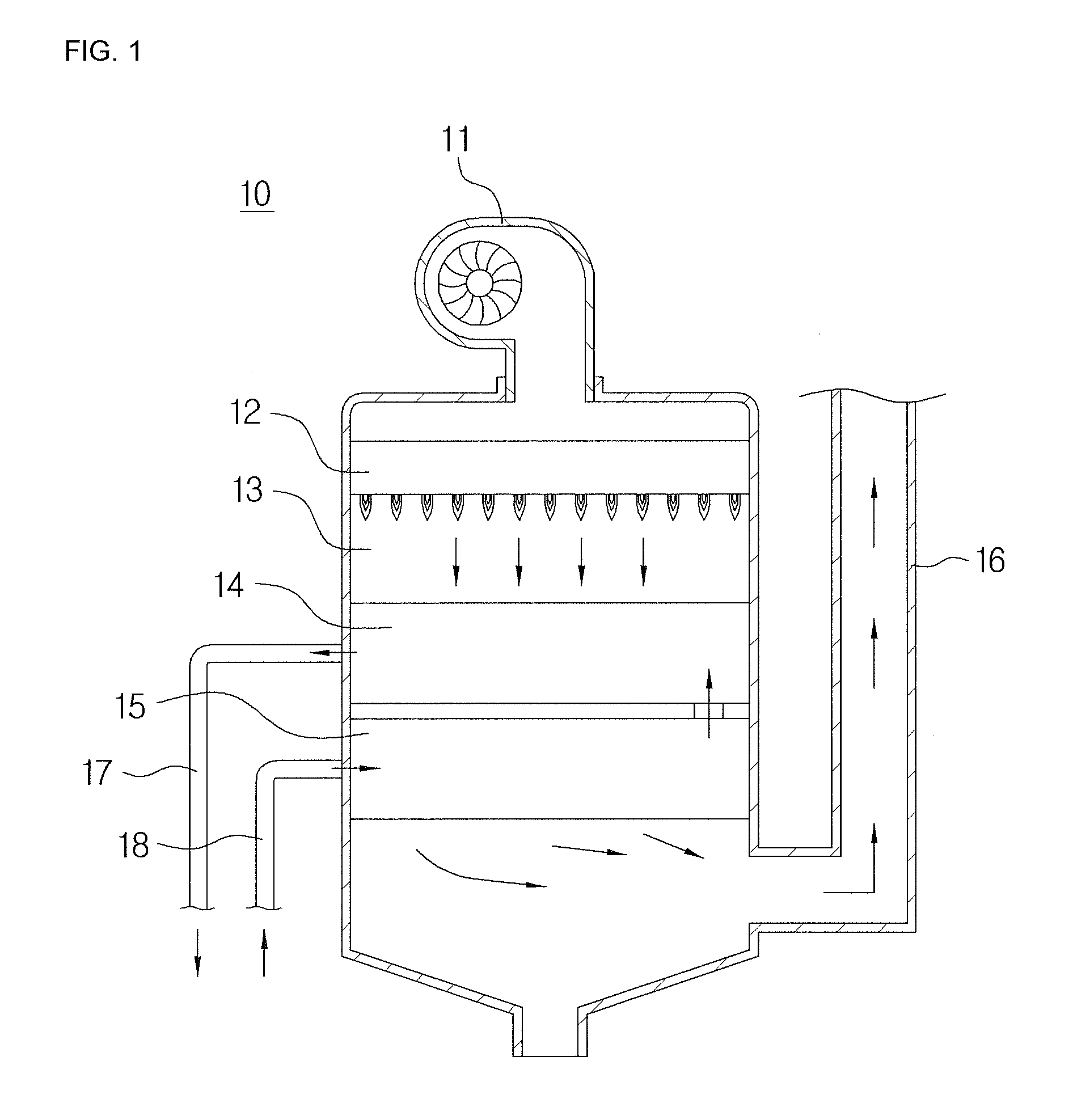

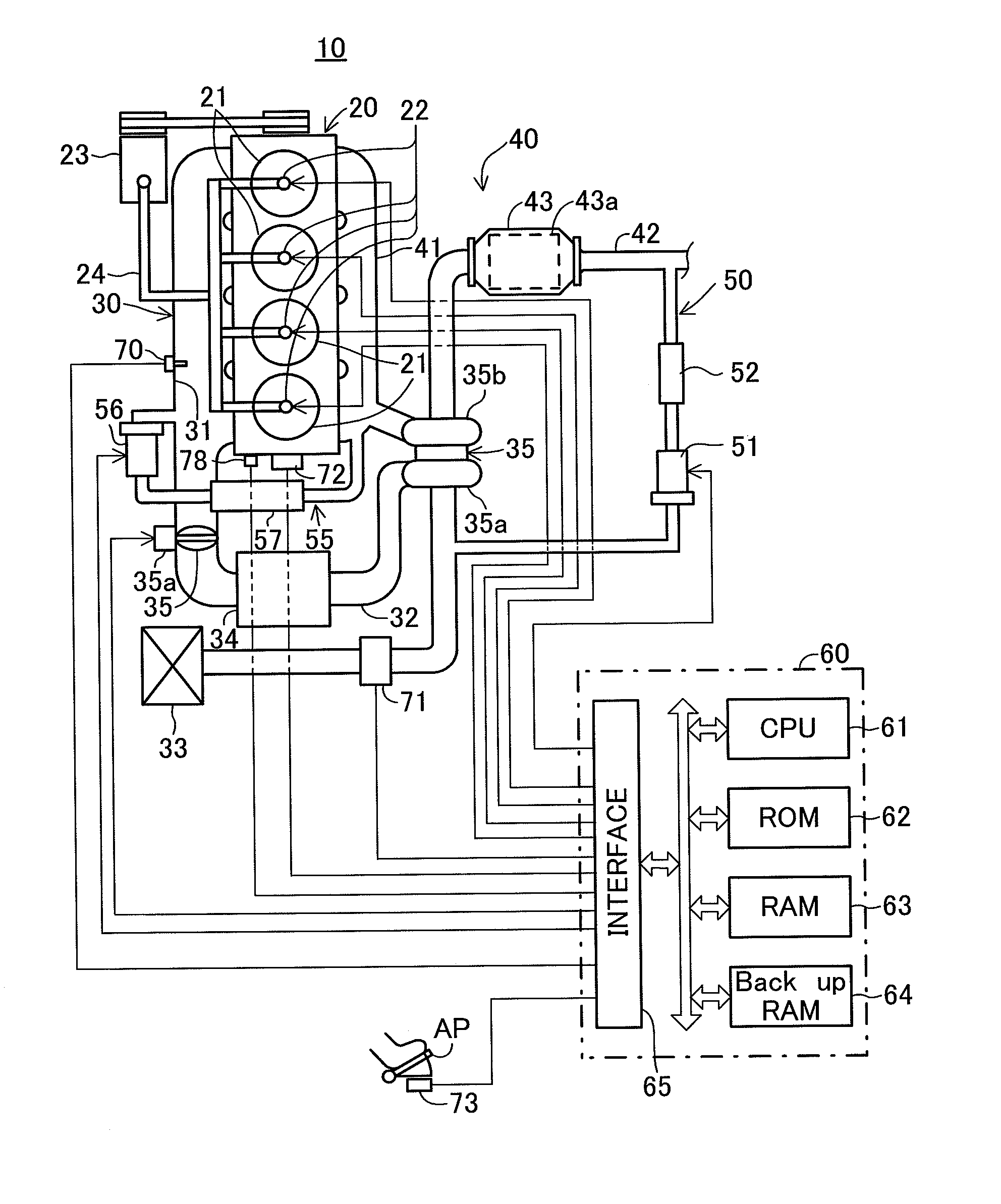

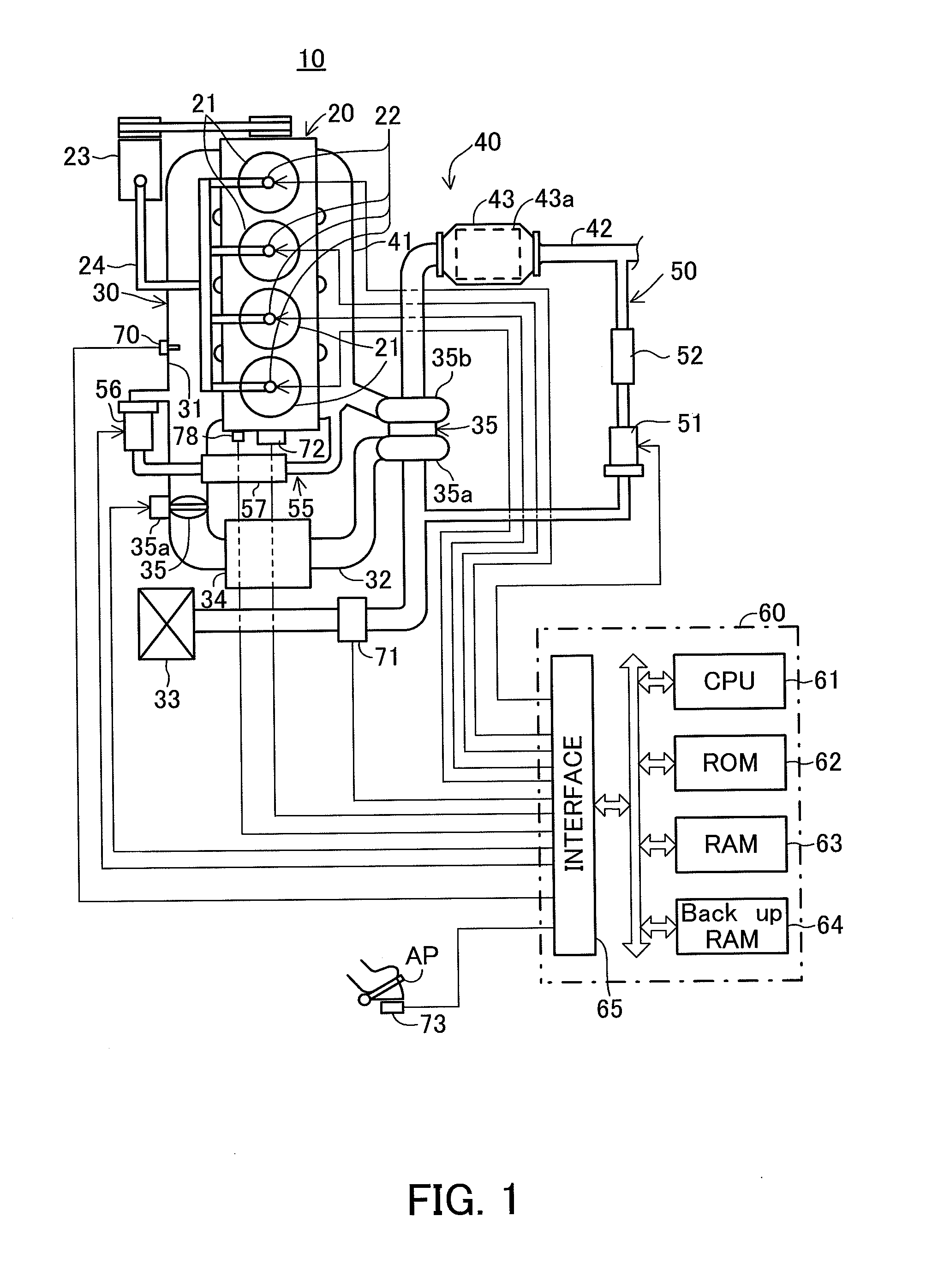

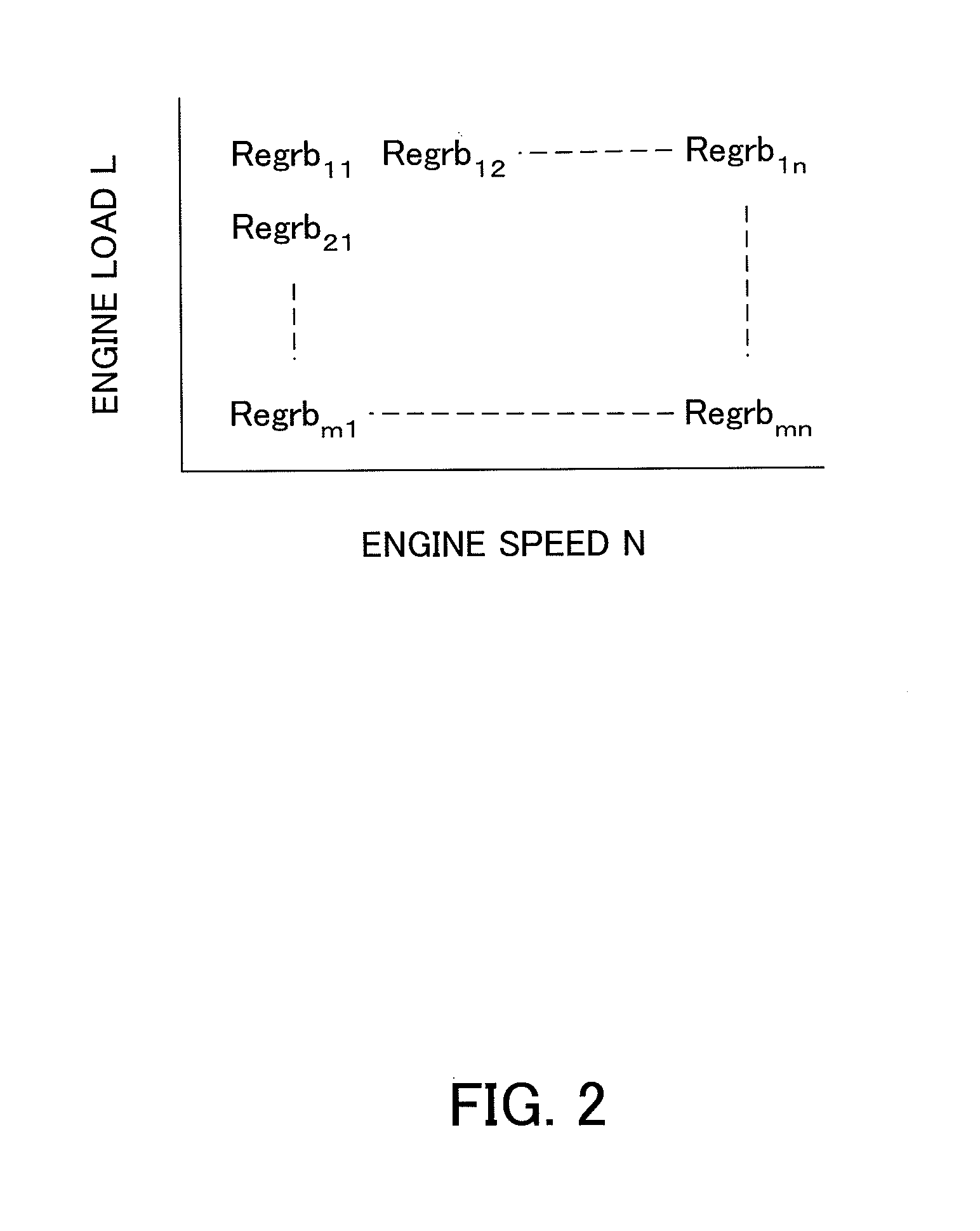

Exhaust gas recirculation device of engine

InactiveUS20110155109A1Lower flame temperaturePrecise proportionElectrical controlNon-fuel substance addition to fuelCombustion chamberExhaust gas recirculation

An exhaust gas recirculation device of an engine (10) of the invention comprises a first exhaust gas recirculation passage (50) for connecting an exhaust passage (40) and an intake passage (30) to each other and introducing into the intake passage an exhaust gas discharged from a combustion chamber (21) to the exhaust passage, and a second exhaust gas recirculation passage (55) for connecting the exhaust passage upstream of a part of the exhaust passage connected to the first exhaust gas recirculation passage and the intake passage downstream of a part of the intake passage connected to the first exhaust gas recirculation passage to each other and introducing into the intake passage the exhaust gas discharged from the combustion chamber to the exhaust passage. The amount of the exhaust gas introduced into the intake passage via the first exhaust gas recirculation passage is controlled to a first target exhaust gas recirculation amount and the amount of the exhaust gas introduced into the intake passage via the second exhaust gas recirculation passage is controlled to a second target exhaust gas recirculation amount. When a temperature of the flame on the combustion of a fuel is lower than or equal to an allowable upper limit flame temperature, a first reference exhaust gas recirculation amount set depending on the operation condition of the engine, is set as the first target exhaust gas recirculation amount and a second reference exhaust gas recirculation amount set depending on the operation condition of the engine, is set as the second target exhaust gas recirculation amount. When the temperature of the flame on the combustion of the fuel is higher than the allowable upper limit flame temperature, one of the first reference exhaust gas recirculation gas amount and an amount smaller than the first reference exhaust gas recirculation gas amount is set as the first target exhaust gas recirculation amount and an amount larger than the reference second exhaust gas recirculation amount is set as the second target exhaust gas recirculation amount.

Owner:TOYOTA JIDOSHA KK

Control method of regenerative burner of regenerative heating furnace

InactiveCN103014312ALow powerAvoid overall overheatingFurnace typesProcess efficiency improvementCombustionEngineering

The invention discloses a control method of a regenerative burner of a regenerative heating furnace The regenerative heating furnace comprises a furnace body comprising a heating section and a soaking section; an auxiliary smoke exhausting pipe is mounted on the furnace body, and regenerative burners for heating billet steel are also distributed on two sides of the furnace body; the regenerative heating furnace also comprises a four-way air reversing valve and a four-way coal gas reversing valve, which are communicated with the furnace body; and in a process of processing special steel, the regenerative burners on the two sides of the furnace body in the heating section are controlled to periodically and reversely burn, the four-way air reversing valve and the four-way coal gas reversing valve are adjusted to simultaneously convey the air and the coal gas to the two sides of the furnace body in the soaking section, the regenerative burners on the two sides of the furnace body in the soaking section are kept in an entire combustion status, and excessive smoke is exhausted through the auxiliary smoke exhausting pipe. The method disclosed by the invention can effectively avoid steel sticking and avoid local overheating and overburning of the billet steel.

Owner:WISDRI WUHAN WIS IND FURNACE

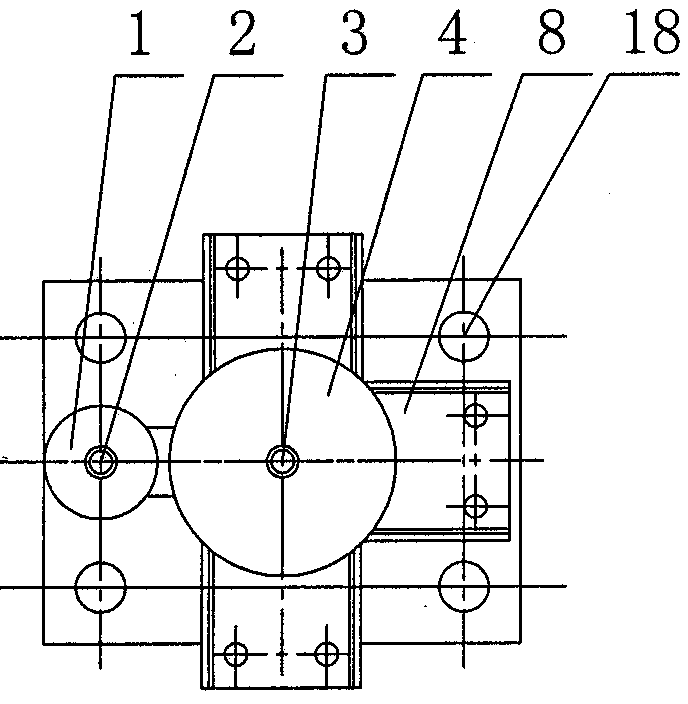

Diffuser plate for boiler burner feed assembly

InactiveUS20070224556A1Lower flame temperatureFluegas recirculationFirebridgesVena contracta diameterCombustion chamber

A diffuser or orifice plate is positioned across the bore of a feed pipe supplying a mixture of pressurized air and recycled flue gas to the combustion chamber of a gas burner associated with a boiler. The diffuser plate comprises inner and outer, radially spaced apart, annular baffles. The baffles define a central opening and an outer series of openings forming an annular array. Part of the gas mixture is accelerated as it passes through the restrictive outer openings and forms an annular stream. Part of the gas mixture passes through the central opening in the form of a lance-like stream. Fuel gas is injected into the annular stream immediately downstream of the diffuser plate. The resulting air / flue gas / fuel gas mixture mixes and adopts an elongated form in the combustion chamber. The burner feed assembly described contributes to maintaining the Ox content in the burner flue gas at a low level such as less than 15 ppm.

Owner:PCL IND SERVICES

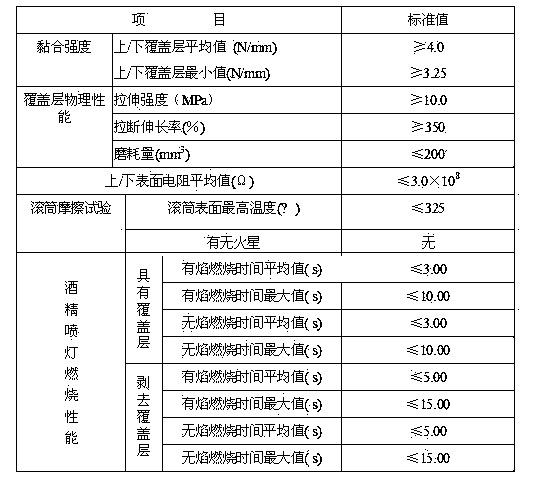

Flame-retardant conveying belt covering adhesive for mine and preparation method thereof

InactiveCN103524914ASpecial Flame RetardancyLower flame temperatureConveyorsChemistryThermal radiation

The invention discloses a flame-retardant conveying belt covering adhesive for a mine and a preparation method thereof. The flame-retardant conveying belt covering adhesive disclosed by the invention is added with nanometer magnesium hydroxide subjected to modification treatment in a preparation process, belongs to an environment-friendly green fire retardant and can play a high-efficiency smoke inhibition role; compared with a similar inorganic flame retardant, the flame-retardant conveying belt covering adhesive disclosed by the invention has a specific cooling technology, can promote the generation of a noncombustible compound and play a heat conduction and heat radiation obstructing role without corroding processing equipment, is low in price and low in production cost, and solves the problems of low extensibility and higher abrasion of the traditional covering adhesive and the problems of abrasion resistance and heat resistance especially through added superfine andalusite powder, thereby greatly prolonging the service life of a conveying belt.

Owner:JIUQUAN RONGTAI RUBBER PROD

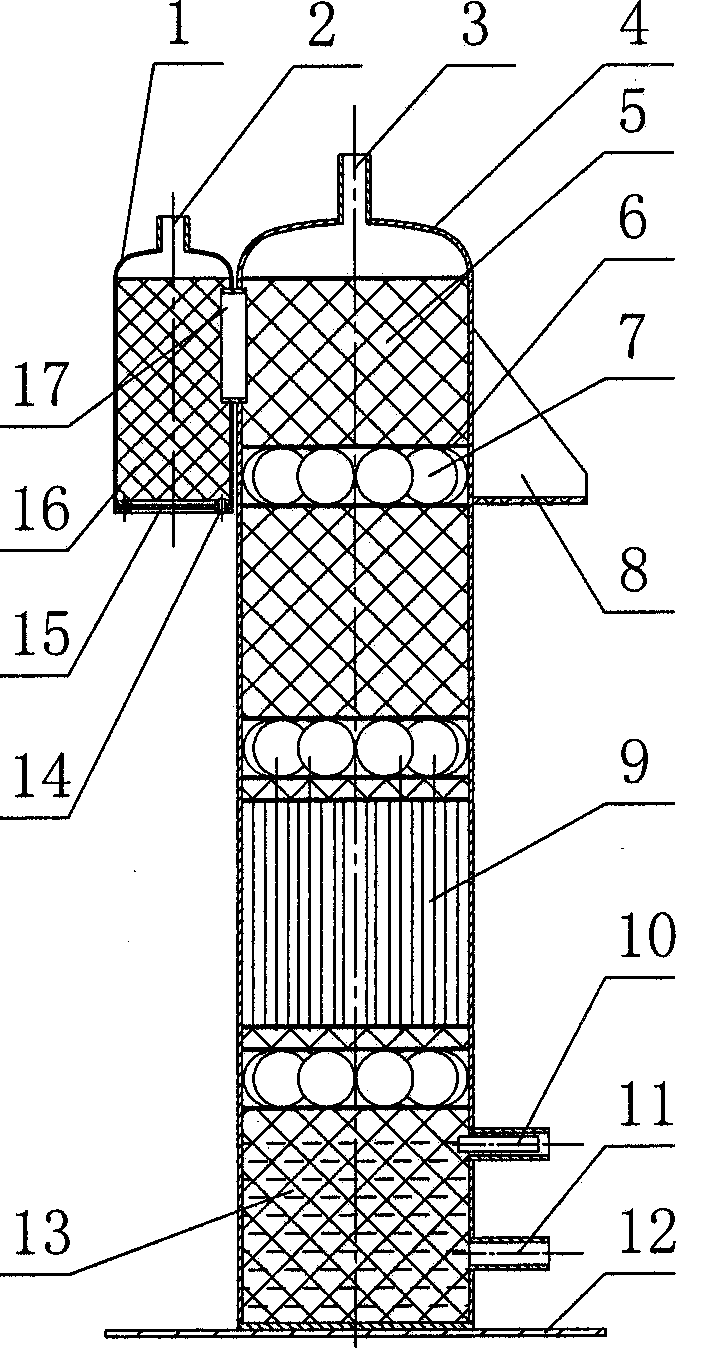

Dry-wet comprehensive flame arrester for hydrogen-oxygen mixed gas

ActiveCN104368100AIt has the function of sealing and preventing fireReasonable structural designFire rescueFlame arresterHydrogen

The invention relates to a dry-wet comprehensive flame arrester for hydrogen-oxygen mixed gas. According to the dry-wet comprehensive flame arrester, the problems that tempering, flash explosion and the like of hydrogen-oxygen mixed gas cannot be prevented in the prior art are solved. The dry-wet comprehensive flame arrester comprises a parent flame arresting tank and a child flame arresting tank which are connected through a communication pipe, as well as a control loop. According to the technical key point, a hydrogen-oxygen mixed gas outlet pipe is arranged at the top of a child flame arresting tank shell, an explosion-proof film and a pressure sensor are arranged at the bottom of the child flame arresting tank shell, and the pressure sensor is connected with the control loop; the interior of a parent flame arresting tank shell is isolated by virtue of stainless steel hole-shaped flame arresting plates and is respectively filled with a flame-arresting filler layer, a stainless steel capillary tube layer and a water seal layer from top to bottom, a safety valve connecting pipe is arranged at the top of the parent flame arresting tank shell, a hydrogen-oxygen mixed gas inlet is formed in the side wall of the water seal layer at the bottom of the parent flame arresting tank shell, and a liquid level sensor connected with the control loop is arranged on the side wall of the water seal layer at the bottom of the parent flame arresting tank shell. The dry-wet comprehensive flame arrester is reasonable in structural design, safe and reliable to use and has the functions of sealing and reverse flame arresting of a dry flame arrester, furthermore, the temperature of flame and the pressure can be reduced by virtue of a water seal and a baffle, and the damage caused by the hydrogen-oxygen mixed gas during tempering, flash explosion and detonation can be effectively prevented.

Owner:刘枫

Method for control of NOX emissions from combustors using fuel dilution

InactiveUS20070031768A1Easy to installLow costInternal combustion piston enginesExhaust apparatusCombustion chamberWater vapor

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

Lip-type oil seal rotating shaft abrasion-resistant antifriction composite coating and preparation method thereof

ActiveCN109023365ADoes not significantly change roughnessAvoid corrosionMolten spray coatingVacuum evaporation coatingCombustionIon beam

The invention relates to a lip-type oil seal rotating shaft abrasion-resistant antifriction composite coating and a preparation method thereof, and belongs to the technical field of material surface treatment. The lip-type oil seal rotating shaft abrasion-resistant antifriction composite coating comprises a rotating shaft base body, a tungsten carbide coating, a tungsten carbide film and a nanocrystalline-mixed tungsten carbide gradient amorphous carbon film, wherein the tungsten carbide coating, the tungsten carbide film and the nanocrystalline-mixed tungsten carbide gradient amorphous carbonfilm are sequentially attached to the rotating shaft base body. The coating has quite good abrasion resistant and antifriction performance. The preparation method of the lip-type oil seal rotating shaft abrasion-resistant antifriction composite coating comprises the following steps that the tungsten carbide coating is sprayed on the surface of the pretreated rotating shaft base body by adopting an air combustion-supporting supersonic flame spraying method; and after the tungsten carbide coating is ground, polished and ion beam cleaned, the tungsten carbide film and the nanocrystalline-mixed tungsten carbide gradient amorphous carbon film are sequentially deposited by adopting ion source assisted magnetron sputtering. The preparation method is simple and reliable, mass production is easy to realize, and environmental pollution is little.

Owner:GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com