Flame-retardant conveying belt covering adhesive for mine and preparation method thereof

A technology of conveyor belt and covering glue, applied in the direction of conveyor, transportation and packaging, can solve the problems affecting the better application of flame retardant conveyor belt, the effect is not obvious, to reduce the occurrence of combustibles, improve rigidity and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

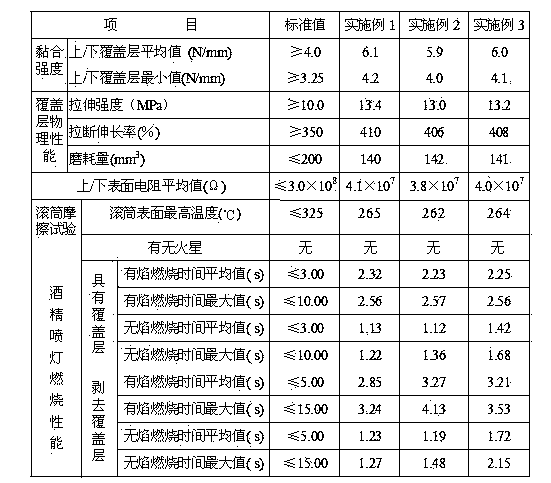

Embodiment 1

[0074] A mine-used flame-retardant conveyor belt covering rubber, the content ratio of its components is as follows:

[0075] Suspension polyvinyl chloride resin-Ⅲ type 100 parts

[0076] Powdered nitrile rubber 15 parts

[0077] Carbon black 1.5 parts

[0078] TCEP 16 copies

[0079] 10 parts triaryl phosphate ester

[0080] Dioctyl phthalate 53 parts

[0081] Chlorinated paraffin - 52% 2 parts

[0082] Nano magnesium hydroxide 14 parts

[0083] 6 parts of antimony trioxide

[0084] 1 part stearic acid

[0085] Barium stearate 0.5 parts

[0086] Stabilizer 1.5 parts

[0087] Antistatic agent 5.5 parts

[0088] Strengthening agent 4 parts

[0089] Light calcium carbonate 15 parts

[0090] The molecular weight of the suspension method polyvinyl chloride resin-III type is 2500-3000.

[0091] The powdered nitrile rubber mentioned above is P830.

[0092] The above-mentioned carbon black is N660.

[0093] The above-...

Embodiment 2

[0109] A special material for covering rubber of mine flame-retardant conveyor belts, the content ratio of its components is:

[0110] Suspension polyvinyl chloride resin-Ⅲ type 80 parts

[0111] Powdered nitrile rubber 8 parts

[0112] Carbon black 0.8 parts

[0113] TCEP 10 copies

[0114] Triaryl phosphate 5 parts

[0115] Dioctyl phthalate 45 parts

[0116] Chlorinated paraffin-52% 1 part

[0117] Nano magnesium hydroxide 8 parts

[0118] 2 parts antimony trioxide

[0119] 0.2 parts of stearic acid

[0120]Barium stearate 0.5 parts

[0121] Stabilizer 1 part

[0122] Antistatic agent 3 parts

[0123] Reinforcing agent 2 parts

[0124] Light calcium carbonate 10 parts

[0125] The molecular weight of the suspension method polyvinyl chloride resin-III type is 2500-3000.

[0126] The powdered nitrile rubber mentioned above is P830.

[0127] The above-mentioned carbon black is N660.

[0128] The above-mentioned...

Embodiment 3

[0144] A special material for covering rubber of mine flame-retardant conveyor belts, the content ratio of its components is:

[0145] Suspension polyvinyl chloride resin-Ⅲ type 120 parts

[0146] Powdered nitrile rubber 20 parts

[0147] Carbon black 2 parts

[0148] 20 copies of TCEP

[0149] 15 parts triaryl phosphate ester

[0150] Dioctyl phthalate 60 parts

[0151] Chlorinated paraffin-52% 4 parts

[0152] Nano magnesium hydroxide 20 parts

[0153] 8 parts antimony trioxide

[0154] 3 parts stearic acid

[0155] Barium stearate 2 parts

[0156] Stabilizer 3 parts

[0157] Antistatic agent 8 parts

[0158] Strengthening agent 6 parts

[0159] Light calcium carbonate 25 parts

[0160] The molecular weight of the suspension method polyvinyl chloride resin-III type is 2500-3000.

[0161] The powdered nitrile rubber mentioned above is P830.

[0162] The above-mentioned carbon black is N660.

[0163] The above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com