Recycled paper pulp prepared by utilizing waste paperboards

A technology for recycling pulp and waste cardboard, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of bad environmental impact, unreasonable allocation of resources, discarded cartons, etc. The effect of breeding and avoiding decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

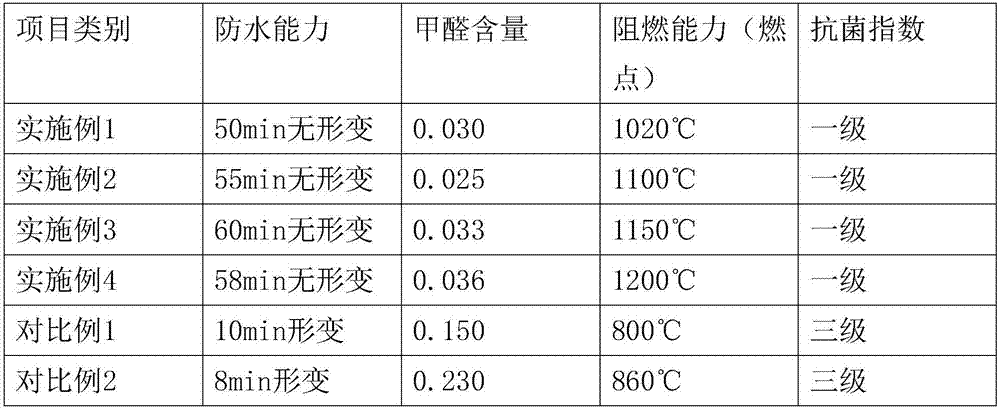

Embodiment 1

[0049] A recycled paper pulp prepared from waste paperboard, comprising the following raw materials in parts by mass:

[0050]300 parts of waste cardboard, 100 parts of bagasse, 1 part of thermal initiator, 1 part of defoamer, 2 parts of oxidizing agent, 10 parts of bentonite, 10 parts of fish bone meal, 2 parts of flour, 2 parts of citric acid, 2 parts of vinasse, 4 parts of solanine, 0.2 parts of additives, 5 parts of flame retardant, 5 parts of waterproofing agent, 50 parts of PVC granules, 5 parts of lime powder, 5 parts of orange peel powder;

[0051] Wherein the auxiliary agent comprises the following components in parts by weight: 0.1 part of thickener; 0.1 part of toughening agent.

[0052] The defoamer is an equal combination of one or more of simethicone, higher alcohol, and polyether-modified silicon;

[0053] Thermal initiator is one or two equivalent combinations in cumene hydroperoxide, tert-butyl hydroperoxide;

[0054] The oxidizing agent comprises the follow...

Embodiment 2

[0072] A recycled paper pulp prepared from waste paperboard, comprising the following raw materials in parts by mass:

[0073] 400 parts of waste cardboard, 120 parts of bagasse, 2 parts of thermal initiator, 2 parts of defoamer, 5 parts of oxidizing agent, 15 parts of bentonite, 20 parts of fish bone meal, 5 parts of flour, 5 parts of citric acid, 5 parts of vinasse, 10 parts of solanine, 0.3 parts of additives, 8 parts of flame retardant, 8 parts of waterproofing agent, 65 parts of PVC granules, 8 parts of lime powder, and 8 parts of orange peel powder;

[0074] Wherein the auxiliary agent comprises the following components in parts by weight: 0.1 part of thickener; 0.2 part of toughening agent.

[0075] The defoamer is an equal combination of one or more of simethicone, higher alcohol, and polyether-modified silicon;

[0076] Thermal initiator is one or two equivalent combinations in cumene hydroperoxide, tert-butyl hydroperoxide;

[0077] The oxidizing agent comprises th...

Embodiment 3

[0095] A recycled paper pulp prepared from waste paperboard, comprising the following raw materials in parts by mass:

[0096] 500 parts of waste cardboard, 150 parts of bagasse, 4 parts of thermal initiator, 4 parts of defoamer, 8 parts of oxidizing agent, 20 parts of bentonite, 30 parts of fish bone meal, 8 parts of flour, 8 parts of citric acid, 8 parts of vinasse, 20 parts of solanine, 0.4 parts of additives, 10 parts of flame retardant, 8 parts of waterproofing agent, 80 parts of PVC granules, 10 parts of lime powder, 10 parts of orange peel powder;

[0097] Wherein the auxiliary agent comprises the following components in parts by weight: 0.2 part of thickener; 0.2 part of toughening agent.

[0098] The defoamer is an equal combination of one or more of simethicone, higher alcohol, and polyether-modified silicon;

[0099] Thermal initiator is one or two equivalent combinations in cumene hydroperoxide, tert-butyl hydroperoxide;

[0100] The oxidizing agent comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com