Patents

Literature

422 results about "Simethicone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This product is used to relieve symptoms of extra gas caused by air swallowing or certain foods/infant formulas.

Simethicone solid oral dosage form

The present invention provides a composition for forming a compressed solid dosage form that is a free-flowing compressible admixture of simethicone, an adsorbant, and an optional active agent, wherein the weight ratio of simethicone to adsorbent is at least 1:2.22. Also included are solid dosage forms made from a free-flowing compressible admixture of simethicone, an adsorbant, and an optional active agent, wherein the weight ratio of simethicone to adsorbent is at least 1:2.22.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

Silicon rubber cross-linked flame-retardant cable material and its preparation method

ActiveCN102977605AImprove flame retardant performanceExcellent non-flammabilityPlastic/resin/waxes insulatorsInsulated cablesCalcium silicateAntimony trioxide

The invention provides a silicon rubber cross-linked flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of silicon rubber, 20-30 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 15-20 parts of acetylene black, 0.5-1.0 part of dimethyl silicone oil, 0.2-0.5 parts of dicumyl peroxide (DCP), 20-30 parts of high-density polyethylene, 15-25 parts of calcium silicate, 0.5-1.0 part of modified argil, 30-40 parts of precipitated silica, 1-3 parts of a silane coupling agent, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of a vulcanizing agent BP, 2-4 parts of tribasic lead sulfate, 12-15 parts of antimony (III) oxide, and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good corrosion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:佛山市石湾陶瓷工业研究所有限公司

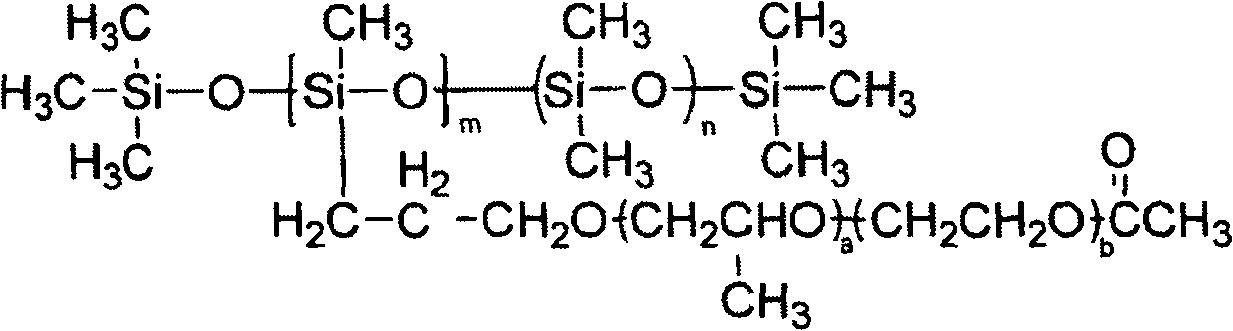

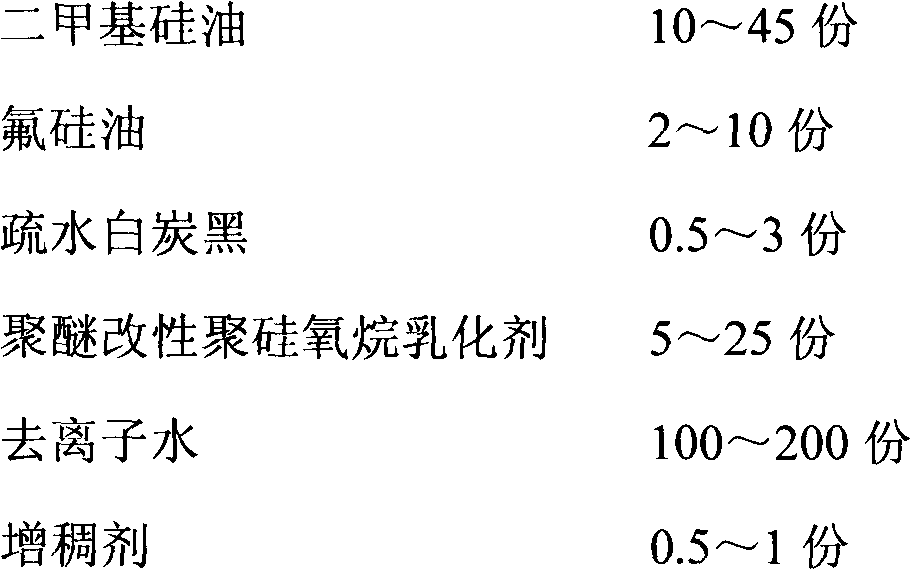

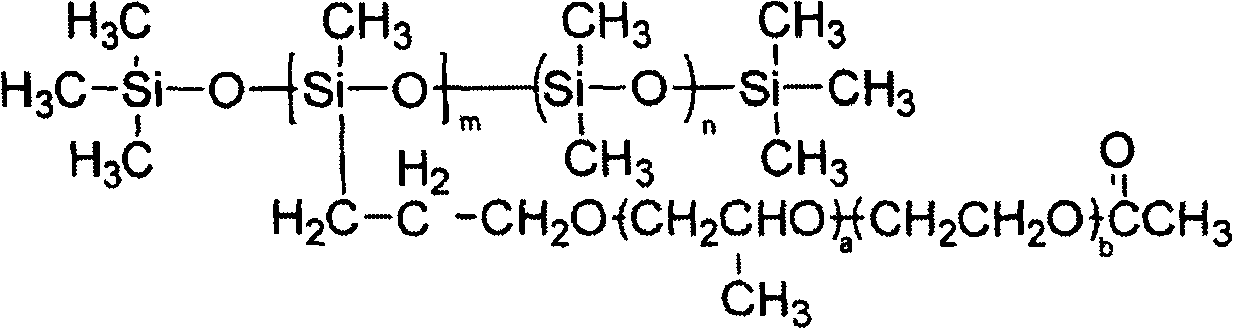

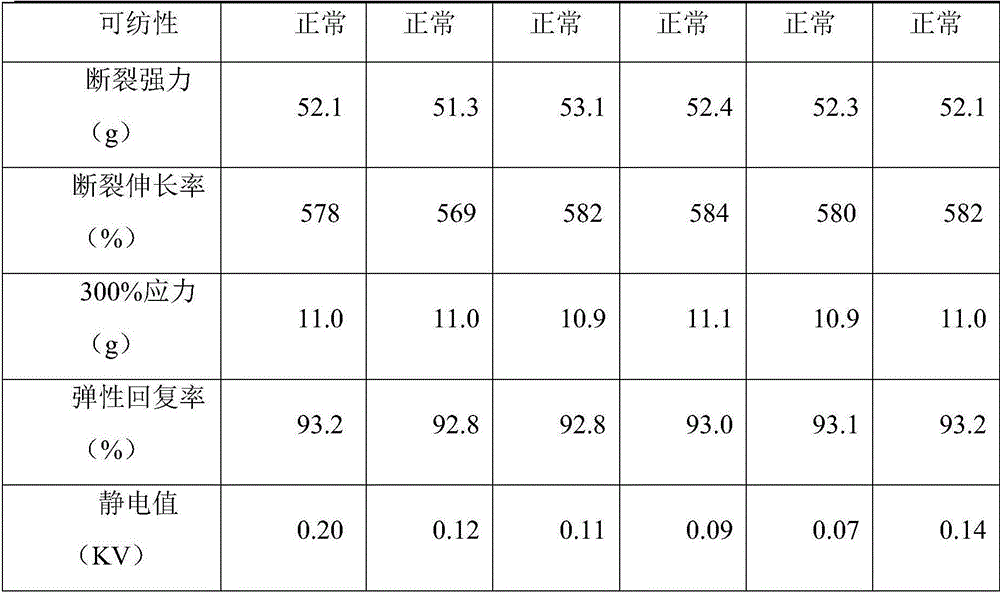

High-efficiency antifoaming agent

InactiveCN102949867AGood anti-foam performanceStrong antifoam performanceFoam dispersion/preventionAdditive ingredientBULK ACTIVE INGREDIENT

The invention relates to a high-efficiency antifoaming agent which comprises the following raw materials based on parts by weight: 10-45 parts of simethicone, 2-10 parts of fluorosilicone oil, 0.5-3 parts of hydrophobic white carbon black, 5-25 parts of polyether-modified polysiloxane emulgator, 100-200 parts of deionized water and 0.5-1 part of thickening agent. The antifoaming agent takes composition of the simethicone and the fluorosilicone oil as a main antifoaming active ingredient; and after the fluorosilicone oil is added, the surface tension of an antifoaming agent system can be reduced, and the antifoaming and foam-inhibiting performances can be improved. According to the polyether-modified polysiloxane emulgator, not only can the antifoaming active ingredients be emulsified, but also the effect enhancing action can be achieved due to the fact that the high-efficiency antifoaming agent further has good antifoaming ingredients. The antifoaming agent is high in antifoaming capacity, long in foam-inhibiting time, wide in application range, capable of being applied to various foam systems, and suitable for antifoaming and foam-inhibiting under severe conditions, i.e. high acid-base, high temperature and the like.

Owner:TIANJIN SCIPHARMACN

Organosilicone defoamer and preparation method thereof

ActiveCN104225965AReduce manufacturing costFast dispersionFoam dispersion/preventionDispersityEmulsion

The invention discloses an organosilicone defoamer and a preparation method of the organosilicone deformer. The defoamer is prepared from the following raw materials in percentage by weight: 10-40% of simethicone (201), 10-25% of high-boiling silicone oil, 1-5% of a thickener, 40-60% of water, 5-25% of an emulgator, and 1-5% of fumed silica, wherein all of the raw materials account for 100%. The preparation process comprises the following steps: (a) weighing the simethicone (201) and the fumed silica in different weight ratios and adding into a reaction kettle, raising the temperature to about 150 DEG C, and stirring for 5-8 hours to prepare a silicon cream; (b) adding the high-boiling silicone oil and the emulgator into the prepared silicon cream, heating to about 40 DEG C, stirring for 30 minutes, then adding the thickener and the deionized water, continuing to stir for 2-4 hours, cooling, discharging, and packaging. The organosilicone defoamer provided by the invention provides a reasonable way to treat byproduct high-boiling residues of the organosilicone, improves the stability and the dispersity of the emulsion, guarantees the storage time, and greatly improves the defoaming capability, and the using temperature range of the materials is relatively wide.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

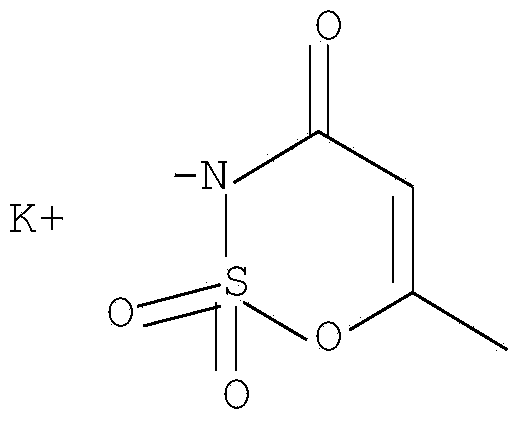

Anti-blocking agent for acesulfame potassium and application method thereof

InactiveCN103960558AAvoid clumpingEasy to processTransportation and packagingMixingFood additiveAnticaking agent

The invention particularly relates an anti-blocking agent for acesulfame potassium and an application method thereof and belongs to the field of food additives. The anti-blocking agent is prepared from the following raw materials by weight percent: 20-60% of sodium polyacrylate solution, 30-70% of surface active agent and 10-20% of simethicone. The application method comprises the following steps: successively adding the sodium polyacrylate solution, the surface active agent and the simethicone at weight ratio into a right amount of water, and then stirring and dissolving, thereby obtaining the anti-blocking agent for acesulfame potassium. When the anti-blocking agent related by the invention is applied, the addition amount of the anti-blocking agent accounts for 0.1wt%-0.5wt% of the acesulfame potassium.

Owner:SOUTHEAST UNIV

Attapulgite composite flame-retardant foaming agent

The invention discloses an attapulgite composite flame-retardant foaming agent. The technical scheme of the attapulgite composite flame-retardant foaming agent has the following key points that the attapulgite composite flame-retardant foaming agent is composed of attapulgite argil powder having an air purifying function, hydrogen peroxide, aluminium hydroxide, sodium polyoxyethylene fatty alcohol ether sulfate, superfine polyvinyl alcohol powder, dimethicone and water, and then the raw materials of the attapulgite composite flame-retardant foaming agent are stirred into a paste, and further stirred into the finished product of the attapulgite composite flame-retardant foaming agent. The attapulgite composite flame-retardant foaming agent is added with water and stirred at a high speed to form porous foamed mud; and the porous foamed mud is capable of quickly isolating a combustible material from air, thereby achieving the purposes of flame retarding and fire extinguishment; the attapulgite composite flame-retardant foaming agent has the effects of flame retarding, heat preservation, heat insulation and sound insulation, and also has the air purification function; and the attapulgite composite flame-retardant foaming agent is suitable for producing flame retarding and fire extinguishing products, light plates, light walls, and sound attenuation and noise reduction products.

Owner:江苏世澳非金属应用科技有限公司

Compositions for prevention and treatement of symptoms of gastrointestinal distress

InactiveUS20070020249A1Preventing gastro-intestinal distressReduce severityBiocidePeptide/protein ingredientsStress conditionsAlcohol sugars

A composition for the treatment or prevention of gastro-intestinal distress associates with the consumption of food products containing sugar alcohols includes at least one enzyme, at least one probiotic organism and simethicone. The composition may be consumed immediately prior to but not more than 20 minutes prior to consuming a sugar alcohol-containing food product in order to reduce the severity of at least one gastro-intestinal stress condition associated with sugar alcohol consumption by at least about 50%.

Owner:DOWNS BERNARD WILLIAM

Medicinal composition containing dimeticone/simethicone

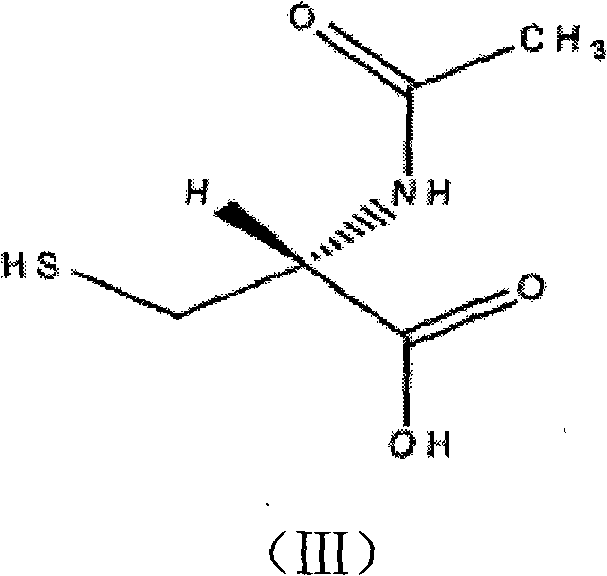

InactiveCN101596181AImprove clarityImprove effectivenessOrganic active ingredientsPharmaceutical non-active ingredientsDiseaseAcetylcysteine

The invention discloses a medicinal composition containing dimeticone / simethicone. The composition is mainly prepared from the following raw material medicaments in portion by weight: 1 to 1,000 portions of acetylcysteine or pharmaceutically acceptable salt thereof, and 1 to 500 portions of the dimeticone / simethicone. The composition can be prepared into various pharmaceutically acceptable preparations; and the composition can be applied to gastrointestinal endoscopy and treatment or an adjuvant drug administered before imaging examination, and compared with the acetylcysteine or the dimeticone or simethicone which is in single use at the same dosage, the composition has stronger defrothing effect, and stronger grume removal effect, so that the composition can effectively improve the visual definition of examination and treatment, reduce misdiagnosis and missed diagnosis, and improve effectiveness of diagnosis and treatment, contributes to early diagnosis discovery of digestive tract diseases, and has wide application prospect.

Owner:重庆健能医药开发有限公司

Antifoaming agent

InactiveCN103127748AFast defoamingEnhanced inhibitory effectFoam dispersion/preventionPotassium iodinePhenol

The invention discloses an antifoaming agent which comprises, by weight, the following raw materials: 1 part to 3 parts of potassium iodide, 2 parts to 5 parts of boric acid, 1 part to 4 parts of sodium bromide, 2 parts to 4 parts of calcium stearate, 4 parts to 8 parts of nonyl phenol polyoxyethylene ether, 2 parts to 6 parts of tetrabutyl phosphorus bromide, 1 part to 5 parts of benzyl triphenyl phosphorus bromide, 3 parts to 6 parts of isoamylene alcohol, 4 parts to 7 parts of tert-amyl chloride, 1 part to 2 parts of trifluoroacetylacetone and 3 parts to 9 parts of simethicone. The antifoaming agent is rapid in antifoaming and good in inhibition performance, and does not affect basic property of a foaming system. Meanwhile, the antifoaming agent is good in diffusivity and permeability, stable in chemical property, free from corrosion, toxicity and adverse side effect and high in safety.

Owner:NANTONG HAISHUN CHEM

Compositions for bowel cleansing and use thereof

The present invention relates to a dry composition for reconstitution in water comprising polyethylene glycol (PEG), optionally sodium sulphate, citric acid, sodium citrate, sodium chloride, potassium chloride, simethicone, effective for bowel cleansing, in particular of colon, prior to diagnostic, surgical or therapeutical procedures, in particular colonoscopy.

Owner:ALFASIGMA SPA

Medical lubricant and preparation method thereof

Owner:GUANGXI XINYE BIOLOGICAL TECH

Powder coating containing modified tree ash and preparation method of powder coating

ActiveCN103013279AImproved surface levelingImprove the decorative effectPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified tree ash and a preparation method of the powder coating. The powder coating consists of the following raw materials: modified epoxy resin, low-density polyethylene resin, phenolic resin, modified tree ash, organosilicone leveling agent, film-forming resin, polydimethylsiloxane, aliphatic amine, silver powder, acrylic resin, ultra-fine calcium carbonate, hexamethylenetetramine, catechol and simethicone. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified tree ash is added in the powder coating, so that the compatibility of the modified epoxy resin, the low-density polyethylene resin and the phenolic resin is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

Oil coke-feeling treatment agent for synthetic leather and preparation method thereof

The invention relates to an oil coke-feeling treatment agent for synthetic leather and a preparation method of the oil coke-feeling treatment agent. The oil coke-feeling treatment agent is a mixture of the following materials in parts by weight: 55 to 65 of nitrocellulose (1 / 4 sec), 95 to 105 of aldehyde-ketone resin, 28 to 32 of silicon dioxide delusterant powder, 9 to 11 of color-change coke-forming wax powder, 9 to 11 of castor oil, 9.5 to 10.5 of dimethyl silicon oil, 9.7 to 10.3 of fluorine-based water repellents, 35 to 45 of dimethyl formamide, 115 to 125 of ethyl acetate and 240 to 250of methylal. The oil coke-feeling treatment agent is prepared by a preparation process comprising the following steps of: firstly uniformly dispersing and then grinding and filtering. The oil coke-feeling treatment agent has a novel formula design. The surface of the leather treated by the oil coke-feeling treatment agent has strong coke feeling and genuine leather feeling and good water resistance, is powdery and delicate, and has excellent glossy and coke feeling and good touch-feeling.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

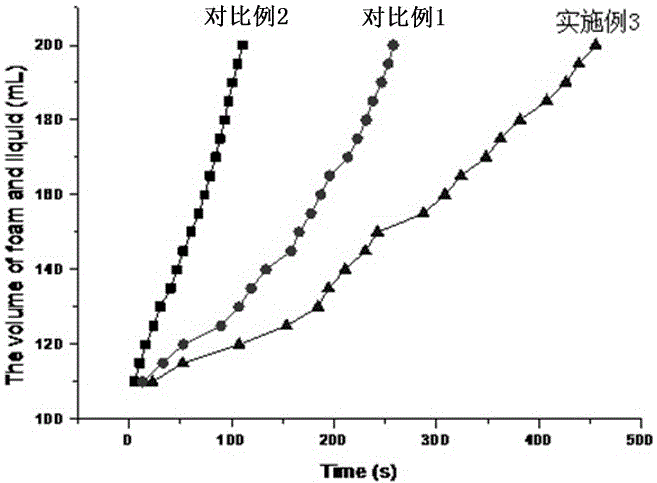

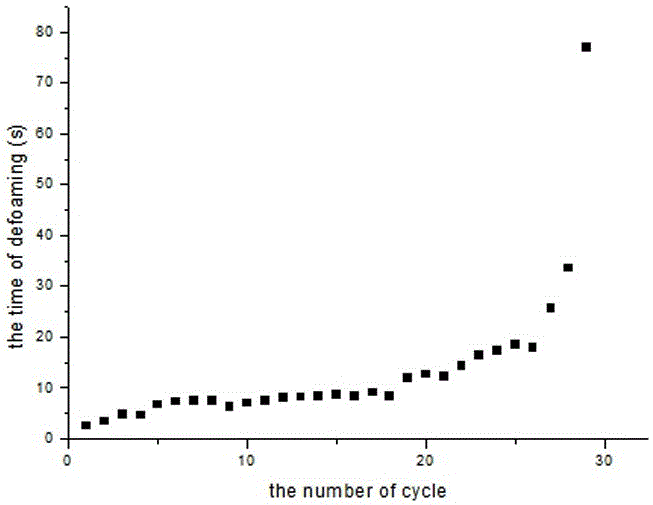

Emulsion-type organosilicone defoamer and preparation method thereof

ActiveCN105688452AImprove bindingLong-lasting defoaming effectFoam dispersion/preventionEmulsionSodium phosphates

The invention discloses an emulsion-type organosilicone defoamer and a preparation method thereof. The preparation method includes: at 90-100 DEG C, using a hydrophobic treatment agent and ammonium dihydrogen phosphate to pre-treat hydrophobic gas-phase white carbon black; bending obtained gas-phase white carbon black with dimethicone at 170-200 DEG C to obtain silicone cream; under action of a compound emulsifier, compounding the silicone cream, fatty alcohol and sodium phosphate to obtain the emulsion-type organosilicone defoamer. The defect that existing emulsion-type organosilicone defoamers are prone to inactivation and poor in foam inhibiting performance is overcome, the organosilicone defoamer obtained has excellent alkali resistance and good continuous application performance, and is high in defoaming speed, foam inhibiting performance and emulsion stability and long in defoaming activity time, and the preparation process is clean and environment-friendly, free of emission of 'three wastes' and suitable for industrial production.

Owner:FUZHOU UNIV

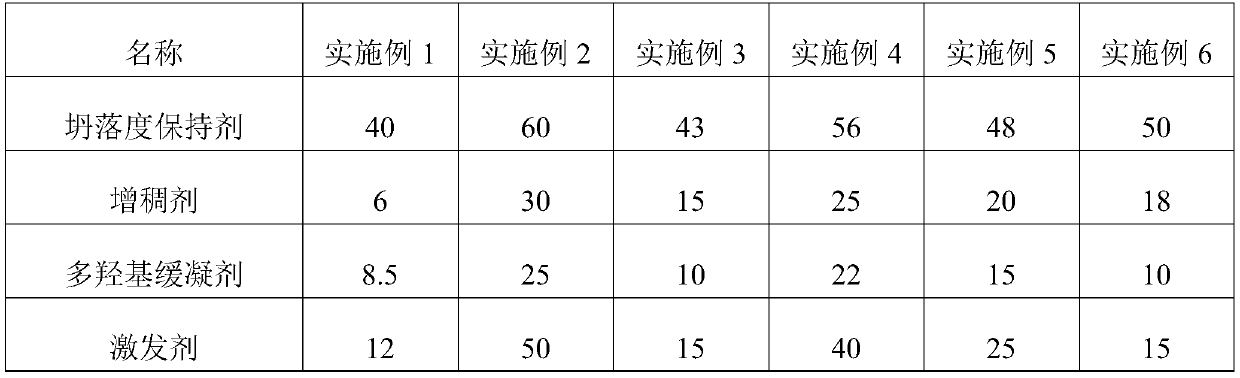

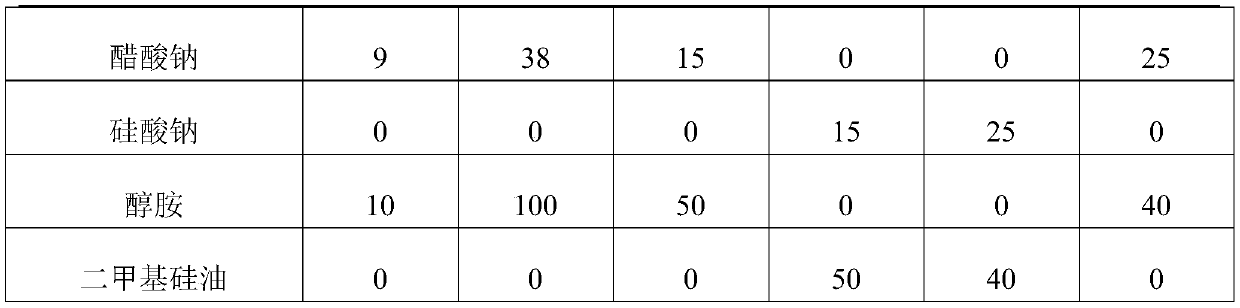

High-slump-loss-resistant synergist and preparation method and application thereof

The invention belongs to the technical field of concrete, and provides a high-slump-loss-resistant synergist, which is prepared from 40 to 60 parts of slump maintainers, 6 to 30 parts of thickening agents, 8.5 to 25 parts of polyhydroxyl retarders, 12 to 50 parts of excitants, 9 to 38 parts of sodium acetate or sodium silicate and 10 to 100 parts of hydramine or simethicone, wherein the slump maintainers are prepared from 300 to 450 parts of polyether, 20 to 45 parts of unsaturated acid, 30 to 80 parts of acrylic ester, 1.1 to 3.8 parts of chain transferring agents and 0.5 to 1.5 parts of reducing agents. A preparation method comprises the following steps of adding polyether into water; performing heating dissolution; then, dripping a material A and a material B; performing reaction for one hour to obtain the slump maintainers; adding water into thickening agents for dissolution; sequentially adding the polyhydroxyl retarders, the excitants, sodium acetate or sodium silicate; after thedissolution, adding hydramine or simethicone; adding the slump maintainers; performing uniform mixing to obtain the high-slump-loss-resistant synergist applied to concrete preparation. By using the technical scheme, the high-slump-loss-resistant synergist solves the problem of fast concrete slump loss in the prior art; meanwhile, the intensity is improved.

Owner:兰州同邦建材有限公司

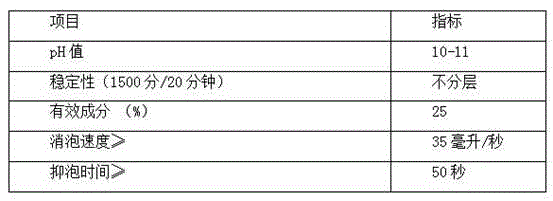

Ultra-strong antistatic spandex spinning oil and preparation method thereof

ActiveCN106521965AExcellent unwinding propertyImprove dispersion stabilityFibre typesGrapheneStearic acid

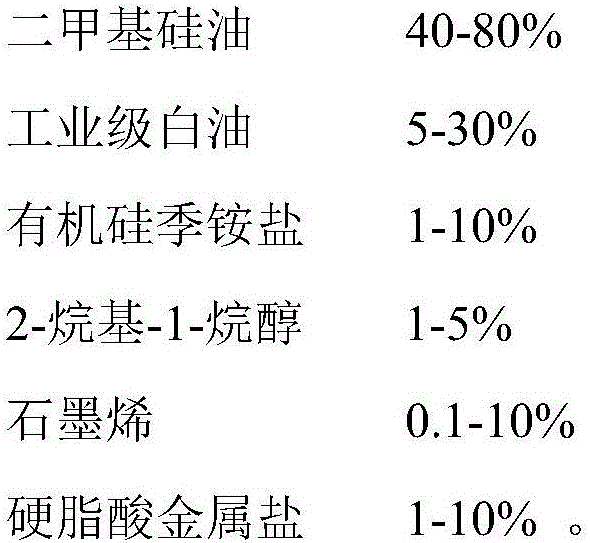

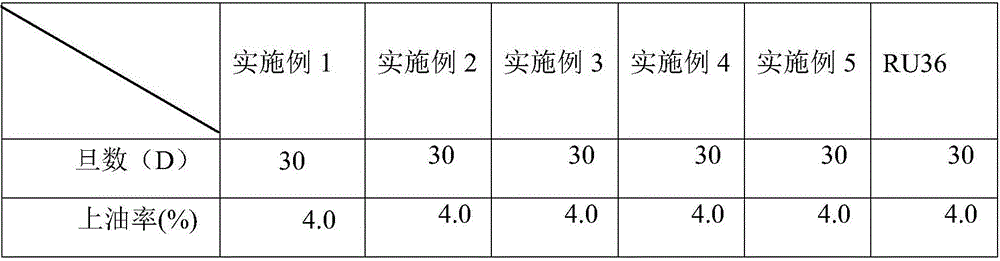

The invention discloses ultra-strong antistatic spandex spinning oil and a preparation method thereof. The ultra-strong antistatic spandex spinning oil is prepared from 40 to 80% mass of polydimethylsiloxane, 5 to 30% mass of white oil, 1 to 10% mass of organosilicon quaternary ammonium salt, 0.1 to 10% mass of metallic stearate and 0.1 to 10% mass of graphene, wherein the percentage content is the mass percentage of the component content to the total oil mass. The novel material ultra-strong antistatic graphene is mixed into the spandex spinning oil, and the prepared spandex spinning cake has good formation, is easy to unwind and has strong antistatic property.

Owner:华峰重庆氨纶有限公司

Defoaming agent for sewage treatment and preparation method thereof

InactiveCN102976429ASolve the problem that the price is expensive, making the cost of sewage treatment highReduce processing costsEnergy based wastewater treatmentWater/sewage treatment by degassingOil and greaseSimethicone

The invention relates to a defoaming agent for sewage treatment and a preparation method of the defoaming agent, belonging to the field of defoaming agent production technology. The defoaming agent comprises the components based on parts by weight: 0.8-1 part of diethanol glyceride, 0.8-1 part of ethylene bis stearamide, 2.4-3.6 parts of heavy liquid paraffin, 40-45 parts of engine oil, 20-25 parts of kerosene, 30-32 parts of dimethyl silicone oil and 1-1.4 parts of white carbon black. The invention solves the problem that in the prior art, organic silicon and polyether type defoaming agents are high in price, so that the sewage treatment cost is high; the defoaming agent provided by the invention has the performances equivalent to those of the existing defoaming agent and even superior to those of the existing defoaming agent, so that the defoaming effect is improved, the defoaming speed is accelerated, and the foam inhibition is prolonged; furthermore, the defoaming agent is good in stability and low in cost, and greatly lowers the sewage treatment cost.

Owner:YIBIN HIEST FIBER +1

Carbon nanotube in situ reinforced LED packaging silica gel and preparation method thereof

InactiveCN103045156AHigh light transmittanceGood adhesionNon-macromolecular adhesive additivesSemiconductor devicesIn situ polymerizationCarbon nanotube

The invention discloses a carbon nanotube in situ reinforced LED packaging silica gel and a preparation method of the carbon nanotube in situ reinforced LED packaging silica gel and relates to an LED packaging silica gel and the preparation method of the LED packaging silica gel. The carbon nanotube in situ reinforced LED packaging silica gel comprises the preparation steps of: 1, carrying out plasma treatment on carbon nanotubes for 1 to 2hours; 2, adding a certain amount of treated carbon nanotubes into an appropriate amount of dimethyl polysiloxane monomer, carrying out in-situ polymerization under the action of an acidic catalyst, after the polymerization is finished, adding an alkaline neutralizing agent to be neutralized in a neutral state, or carrying out water washing to be neutral, and removing residual moisture and obtaining simethicone which is modified by carbon nanotubes and of which the tail end is hydroxyl; and 3, uniformly mixing the product obtained in the step 2 with a crosslinking agent and a catalyst to prepare a potting silica gel which comprises a component A and a component B. With the adoption of the carbon nanotube in situ reinforced LED packaging silica gel, the mechanical property of the silica gel is improved, simultaneously, the silica gel is ensured to have high light transmittance.

Owner:HANGZHOU COLORICH CHEM MATERIALS

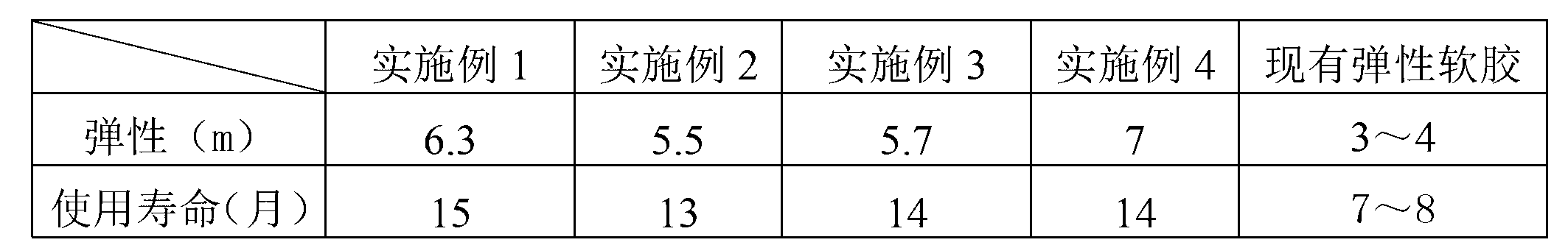

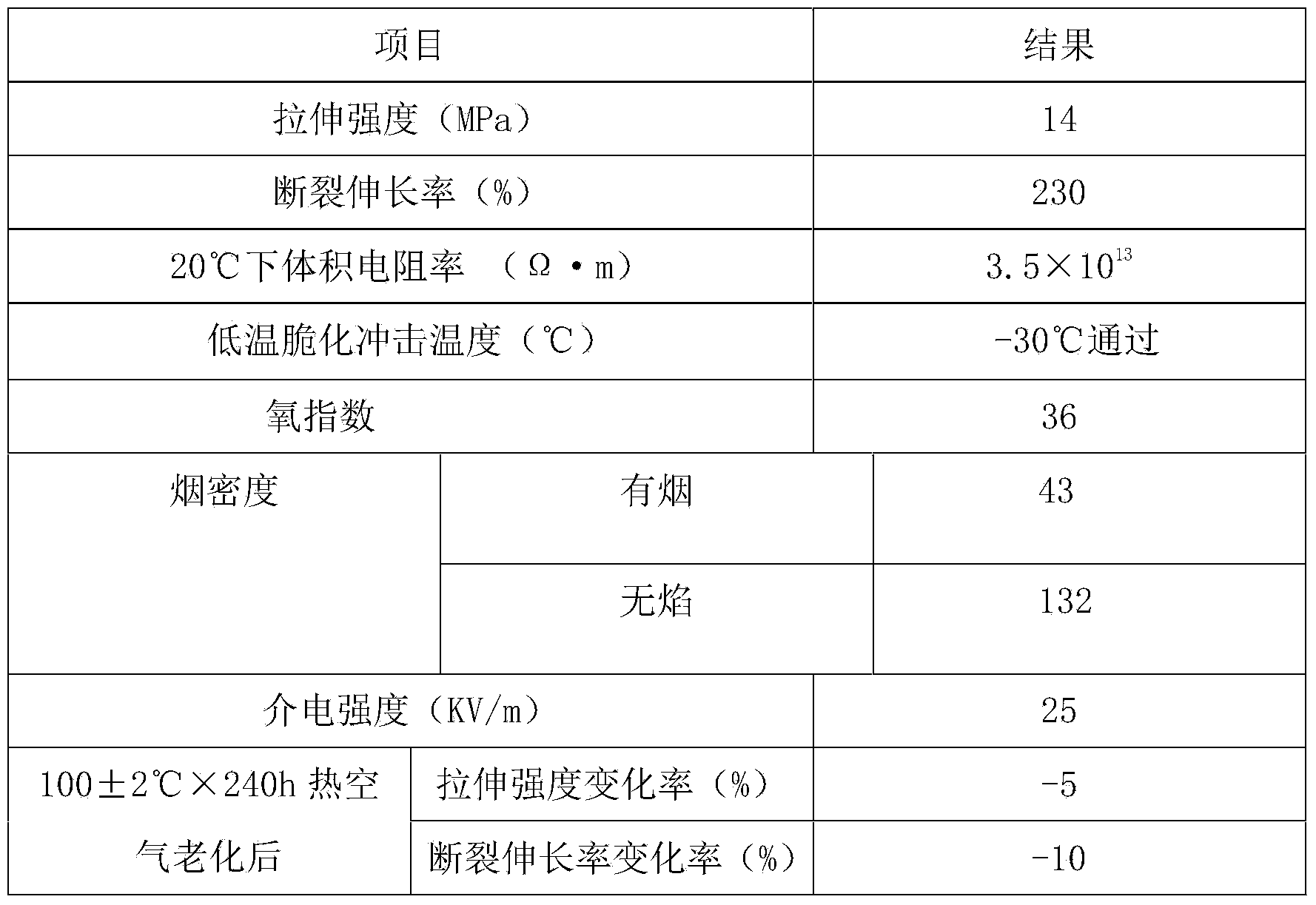

Elastic flexible glue and preparation method thereof

The invention relates to elastic material for preparing elastic and flexible toys, and particularly relates to elastic flexible glue. The elastic flexible glue comprises the following components by weight percentage: simethicone, super fine calcium carbonate, boric acid, TPR (thermal plastic rubber), zinc stearate, silicon resin, bentonite, barium carbonate, linseed oil and erucyl amide. The elastic flexible glue provided by the invention has good elasticity and proper bulking intensity; the surface of the elastic flexible glue is smooth, good in hand feel, adhesive, and tough, and has good aging resistance, high stability and long service life that is from 13 to 15 months; and the elastic and flexible toys made of the elastic flexible glue have high quality, and are playable and durable.

Owner:杜京财

Cleaning agent for rotary machine used for conveying blast furnace gas and coke oven gas

ActiveCN102242020AEasy to cleanNot corrosiveInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium phosphatesCleansing Agents

The invention discloses a cleaning agent for a rotary machine used for conveying blast furnace gas and coke oven gas. The cleaning agent comprises the following components in percentage by mass: 6 to 8 percent of ethoxylated dodecylalcohol, 4 to 5 percent of fatty alcohol-polyoxyethylene ether with 12 to 14 carbon atoms, 11 to 12 percent of nonylphenol polyoxyethylene ether, 15 to 16 percent of sodium dodecyl benzene sulfonate, 7 to 8 percent of sodium hydroxide, 14 to 16 percent of sodium carbonate, 11 to 12 percent of sodium phosphate, 12 to 14 percent of sodium silicate, 7 to 8 percent of sodium tripolyphosphate, 5 to 7 percent of triethanolamine, 1 to 1.5 percent of imidazoline acetate and 0.2 to 0.4 percent of simethicone. The cleaning agent does not corrode equipment and parts, has light environmental pollution, is noninflammable and inexplosive, and is convenient and safe to use.

Owner:XIAN SHAANGU POWER

Rubber material with fire resistance

The invention belongs to the field of rubber, and particularly relates to a rubber material with fire resistance. The fire-resistant rubber material disclosed by the invention comprises the following components in parts by weight: 50-180 parts of chloroprene rubber, 60-180 parts of ethylene propylene terpolymer, 5-12 parts of nano-zinc oxide, 3-5 parts of stearic acid, 10-25 parts of magnesium hydroxide N100, 1-6 parts of aluminum phosphate, 5-12 parts of magnesium silicate, 5-10 parts of sodium silicate, 5-18 parts of mica powder, 5-12 parts of silicon carbide, 1-5 parts of anti-aging agent, 1-10 parts of calcium carbonate, 2-7 parts of hydroxyl silicone oil, 2-6 parts of hydrogen silicon oil, 1-5 parts of white carbon black, 1-5 parts of simethicone, 1-5 parts of dibutyl phthalate, 1-5 parts of N-tertiary butyl-2-benzothiazole sulfonamide and 2-5 parts of 2-thiol based imidazoline. The rubber material has the beneficial effects that the fire-resistant rubber obtained by adopting the formula is good in fire resistance, can play a certain protecting role in a big fire, and can reduce the loss to people caused by the big fire.

Owner:QINGDAO BOYANG BIOTECH

Flame-retardant polyethylene cable material capable of preventing mould

ActiveCN103509228AWith anti-mold functionWeather resistantInsulatorsZinc hydroxideLinear low-density polyethylene

The invention provides a flame-retardant polyethylene cable material capable of preventing mould. The flame-retardant polyethylene cable material is prepared with the following components and raw materials by weight: 50-60 parts of high-density polyethylene, 30-45 parts of linear low-density polyethylene, 10-15 parts of polyester resin, 8-10 parts of organic silicon resin, 2-3 parts of simethicone, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 1-2 parts of barium sulfate, 5-6 parts of dolomite, 6-8 parts of attapulgite, 4-6 parts of celestite, 10-12 parts of zinc hydroxide, 10-15 parts of triammonium phosphate, 10-12 parts of tricresyl phosphate (TCP), 6-8 parts of poly(1,2-propylene glycol adipate), 1-2 parts of sophora flavescens alcohol extract, 0.5-0.6 parts of zanthoxylum oil, 1-2 parts of OBPA (10,10'-oxybisphenoxarsine) mould inhibitor, 1-1.5 parts of PVC (polyvinyl chloride) processing agent ACR-401 (acrylate plastic modifier), and 10-15 parts of modified filler. The cable wire has good antibacterial property, and the characteristics of weather resistance, low smoke, ageing resistance, flame retardation and so on.

Owner:蚌埠尚维知识产权运营有限公司

Preparation method of photoresponsive intelligent gel microspheres for three-dimensional cell culture

InactiveCN103962112AControllable assemblyControllable separabilityAnimal cellsOther chemical processesN dimethylformamideMicrosphere

The invention relates to a preparation method of photoresponsive intelligent gel microspheres for three-dimensional cell culture. The preparation method is characterized by comprising the following steps: dissolving poly(methyl vinyl ether-maleic anhydride) and beta-cyclodextrin into a solvent, namely N,N-dimethylformamide, carrying out heating reaction under the protection of nitrogen, and removing the solvent; adding a mixture water solution of polyethylene glycol 20000 and agarose into the reactant, and vibrating until the reactant is dissolved, so as to prepare a water-phase solution for later use; dropwise adding the water-phase solution into oil-phase simethicone, carrying out heating, stirring, reaction and standing, removing supernate, cleaning microspheres deposited at the bottom of a container, and carrying out vacuum drying, so as to obtain the gel microspheres; putting the gel microspheres into Azo-RGD methane water solution, vibrating for 24 hours under the room temperature, repeatedly rinsing by virtue of deionized water, and drying by virtue of N2. By utilizing the gel microspheres prepared by virtue of the preparation method, growing environments of cells in vivo can be simulated, and the adsorption and controllable separation of the cells on the microspheres can be realized.

Owner:SOUTHEAST UNIV

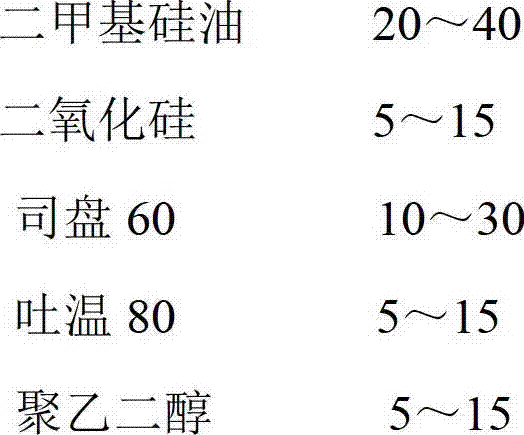

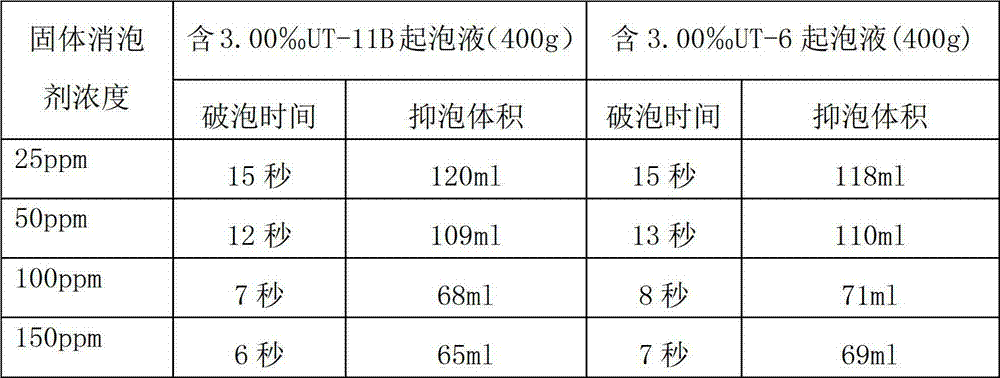

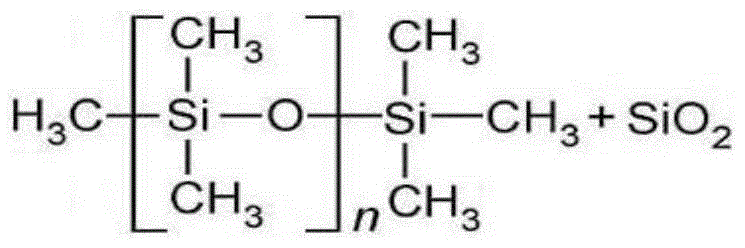

Solid antifoaming agent and preparation process thereof

ActiveCN102921199APrevent tower overturning accidentsAvoid wastingFoam dispersion/preventionParaffin waxPolyethylene glycol

The invention discloses a solid antifoaming agent and a preparation process thereof. The solid antifoaming agent comprises, by weight, 20-40 parts of dimethicone, 5-15 parts of silicon dioxide, 10-30 parts of span-60, 5-15 parts of polysorbate 80, 5-15 parts of polyethylene glycol (PEG) and 10-30 parts of paraffin wax. The preparation process includes the following steps: preparing materials, evenly mixing the dimethicone, the silicon dioxide, the span-60, the polysorbate 80, the PEG and the paraffin wax; heating the evenly mixed materials to 70-90 DEG C and standing for 1.5-2.5 hours at the temperature; discharging, discharging and cooling all the melted materials; and forming, pressing the materials into a round rod shape through a forming machine. The solid antifoaming agent and the preparation process thereof have the advantages that an automatic adjusting function is provided; packaging and transportation costs are reduced; the agent is arranged on a gas piping, so that the production is saved; and the guarantee period is long.

Owner:成都孚吉科技有限责任公司

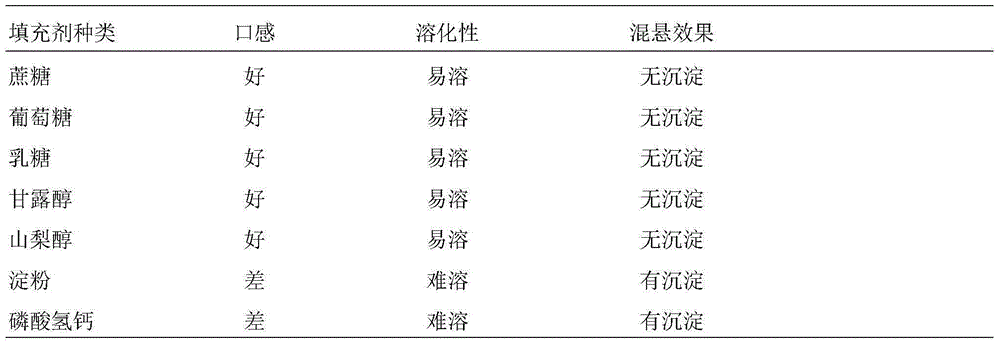

Simethicone dry suspension and preparation method thereof

ActiveCN105055326AQuality improvementGreat tasteDigestive systemSilicon compound active ingredientsDiseaseEmulsion

The invention discloses a simethicone dry suspension and a preparation method thereof. The simethicone dry suspension contains simethicone of 4% in mass percentage and a carrier which is pharmaceutically acceptable. The preparation method is simple and convenient in operation, low in cost and suitable for industrialized production. The simethicone dry suspension has the advantages of good taste, uniform distribution, high dissolubility and stable quality, is more advantageous and convenient than conventional liquid simethicone suspensions and emulsions in aspects of packaging, carrying and transporting, is used for treating diseases like abdominal distension, abdominal discomfort, indigestion and postoperative abdominal distension caused by abdominal gas gathering and has good application prospect.

Owner:SOUTHWEST UNIVERSITY

Active openings agent, reticulated urethane foam material and preparation methods for active openings agent and reticulated urethane foam material

The invention provides an active openings agent. The active openings agent is composed of a compound generated through reaction of dihydric alcohol of oxyalkylene ether with two or more primary hydroxyl group structures or polyhydric alcohols and first acid anhydride, at least one amine compounds, at least one acid or second acid anhydride, a compound containing phosphorus and simethicone. The invention further provides a preparation method for the active openings agent. The invention provides an areticulated urethane foam material which is composed of polyether polyol, deionized water, dichloromethane, stannous octoate, amine catalyst, TDI80 / 20, organosilicon surfactant and an openings agent. The further provides a preparation method for the reticulated urethane foam material. The novel active openings agent is used for preparing the reticulated urethane flexible foam material, the opening performance of the foam material can be improved, the operation tolerance level of the technology is improved, the foam material is prevented from contracting, and safety is high.

Owner:SHANGHAI MAIPU NEW MATERIAL TECH CO LTD

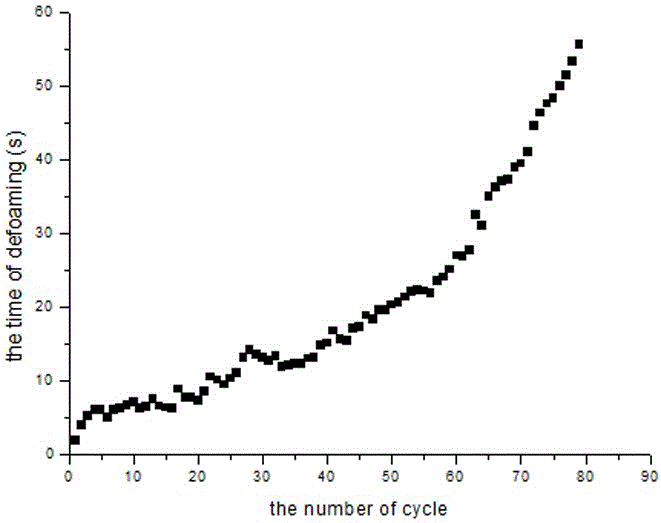

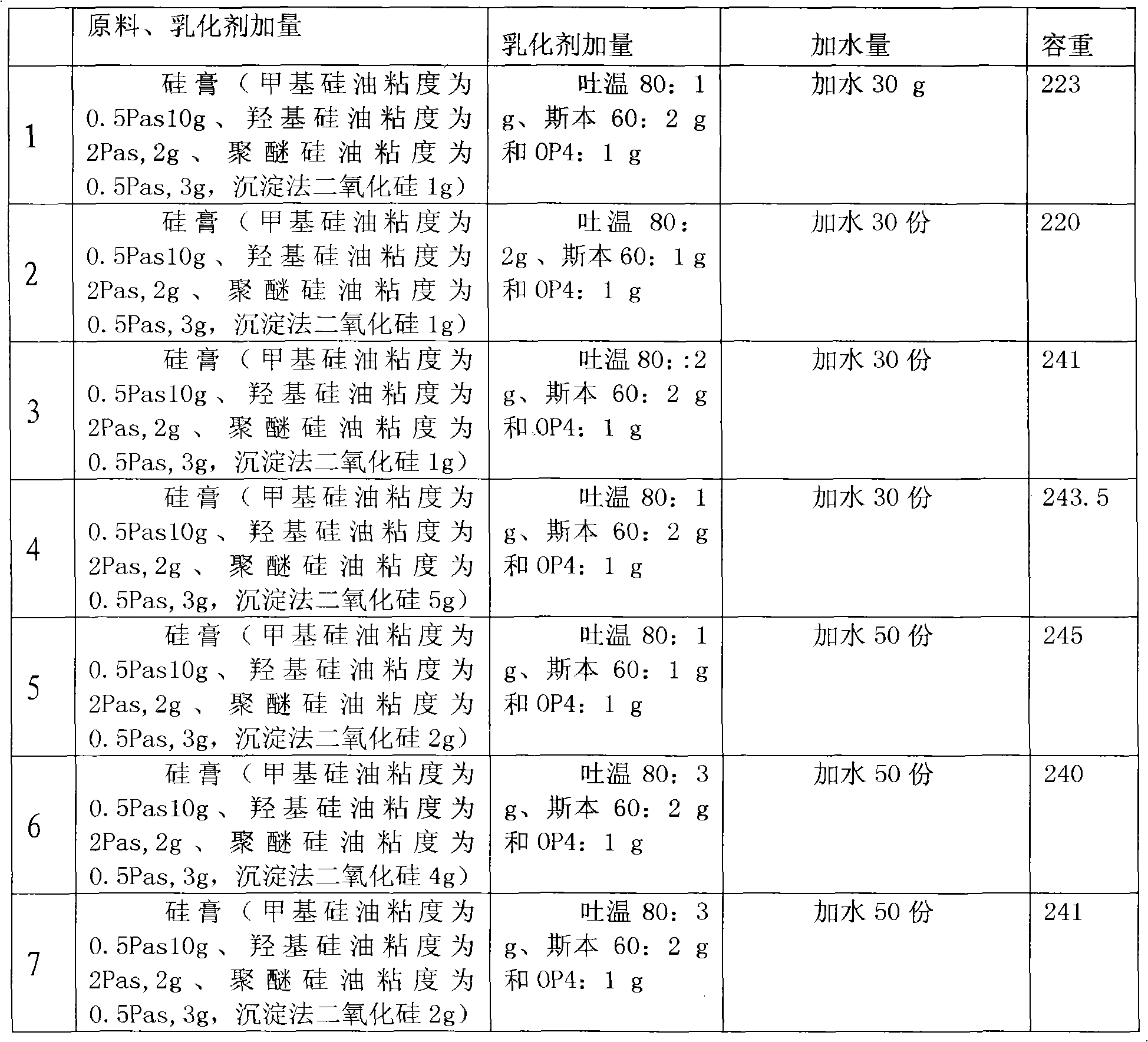

Method for preparing defoamer for cement mortar containing rubber emulsion

The invention relates to an organic silicon defoamer. The organic silicon defoamer comprises the following main materials in part by weight: 10 parts of dimethicone, 2 parts of hydroxyl silicone oil, 3 parts of polyether silicone oil and 1 to 5 parts of precipitated silicon dioxide. The method comprises the following steps of: preparing three kinds of silicone oil and the precipitated silicon dioxide by a three-roller grinding machine at the temperature of between 140 and 200 DEG C to obtain silicon paste; and adding the silicon paste and an emulsifier (1 to 3 parts of Tween 80, 1 to 3 parts of spunray and 1 part of spandex (OP)) into a stirring kettle, adding 30 to 50 parts of water while stirring, and stirring uniformly for half an hour to prepare uniform emulsion serving as the organicsilicon defoamer. The invention has the advantages that the organic silicon defoamer can be used for the preparation and using process of the cement mortar which is used for construction and containsthe rubber emulsion, has high defoaming and foam breaking capacity, can improve the breaking speed of air bubbles and reduce the generation quantity of the air bubbles, and has high compatibility andstability.

Owner:DALIAN RES & DESIGN INST OF CHEM IND

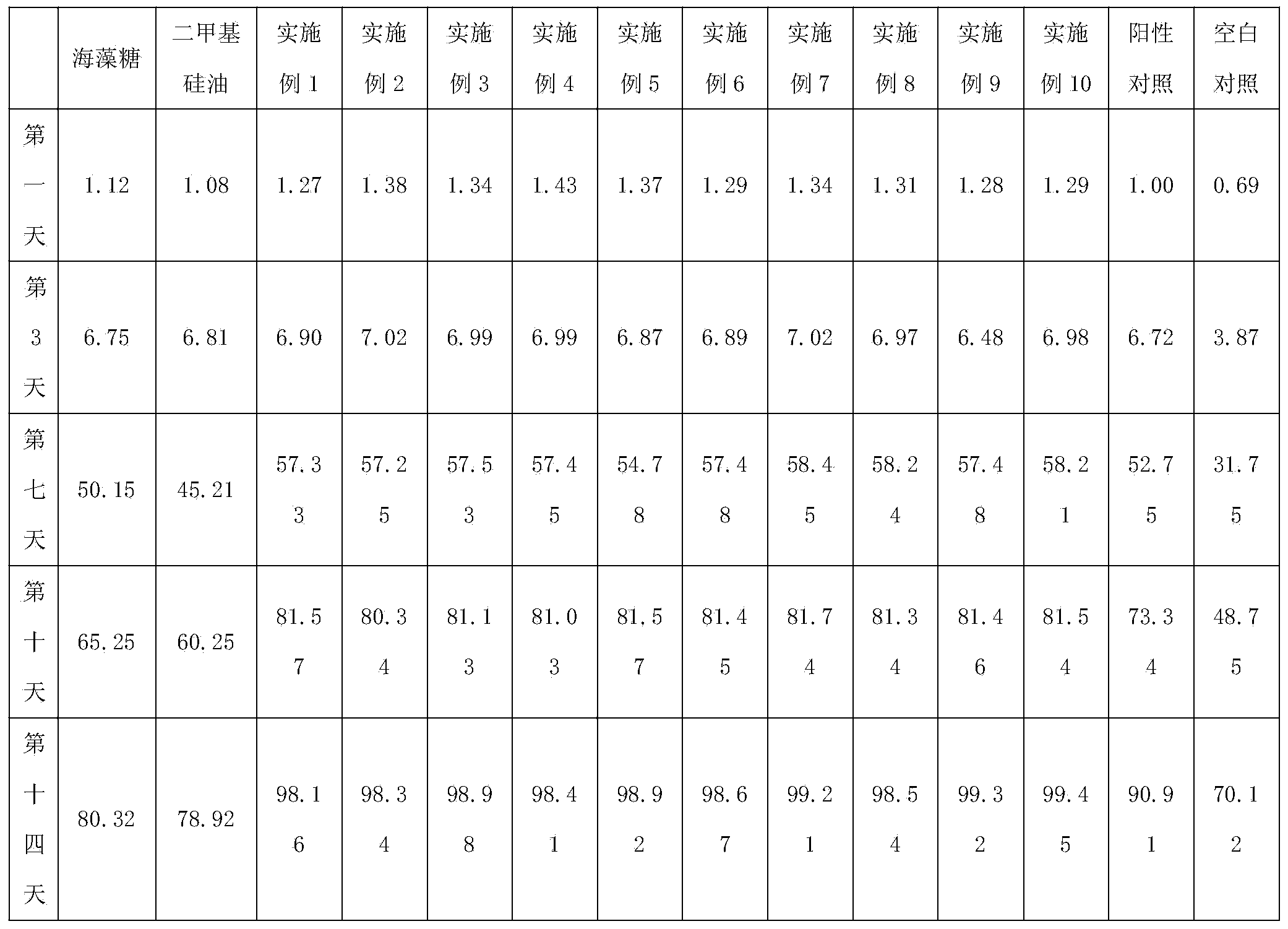

Skin repair gel

ActiveCN104382843ANormal air permeabilityRelieve dry itching, redness, swelling, heat pain and other symptomsOrganic active ingredientsAerosol deliveryMedicineIrritation

The invention discloses skin repair gel. The skin repair gel is prepared from the following components in percentage by weight: 3-8 percent of mycose, 2-20 percent of simethicone, 1-3 percent of an emulsifier, 5-10 percent of a wetting agent and 65-78 percent of purified water. Experiments prove that the gel disclosed by the invention can be used for maintaining normal breathability of the skin, is beneficial for generating beneficial bacteria and high in moisturizing function, provides a good wet healing environment for wounds, quickens the healing of the wounds, causes no irritation to the skin, relieves symptoms such as xerosis, itching, swelling, fever and pain of the wound skin, and is low in cost and convenient to use.

Owner:TIANJIN JIASHITANG SCI & TECH

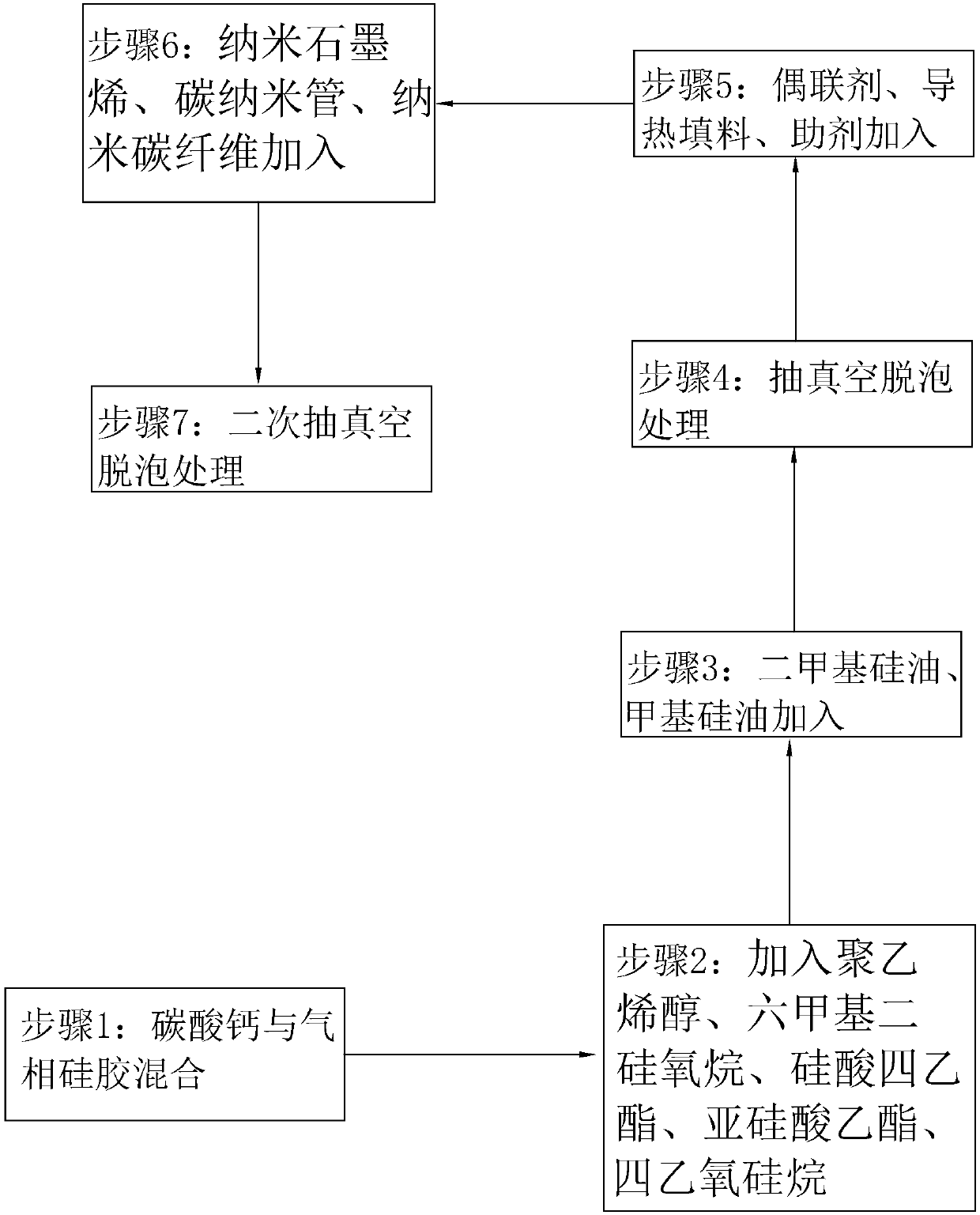

Heat conduction silicone grease as well as processing method and application thereof

InactiveCN107739513AImprove thermal conductivityEasy to useHeat-exchange elementsFilling materialsGas phase

The invention relates to heat conduction silicone grease as well as a processing method and application thereof. The heat conduction silicone grease is prepared from substances of simethicone, heat conduction filling materials, coupling agents, auxiliary agents, methylsilicone oil, gas phase silicone and the like. In the prior art, when the heat conduction silicone grease with high viscosity is used, a surface coating method is generally used, i.e., a thick layer of heat conduction silicone grease coats on the surface of an electronic device; then, a heat radiation fin is adhered onto the heatconduction silicone grease. By using the operation mode, the consumption of the heat conduction silicone grease is great; in addition, pores can be easily generated between the heat radiation fin andthe heat conduction silicone grease. When the heat conduction silicone grease provided by the scheme is used, the heat conduction silicone grease can be dripped into the electronic device; then, theheat radiation sheet can be adhered onto the heat conduction silicon grease by force; the viscosity of the heat conduction silicone grease is low, and the flowability is good, so that during the adhesion on the heat radiation fin by force, the heat conduction silicone grease completely fits the shape of the two opposite sides of the heat radiation fin and the electronic device; the heat radiationeffect reduction due to pore remaining between the heat radiation fin and the electronic device can be avoided.

Owner:苏州柯仕达电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com