Solid antifoaming agent and preparation process thereof

A solid defoamer and preparation process technology, applied in the direction of foam dispersion/prevention, can solve the problems of high packaging cost, increase the cost of filling input, increase the work of workers, etc., reduce packaging and transportation costs, and prevent foam from overturning towers. Accidents, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

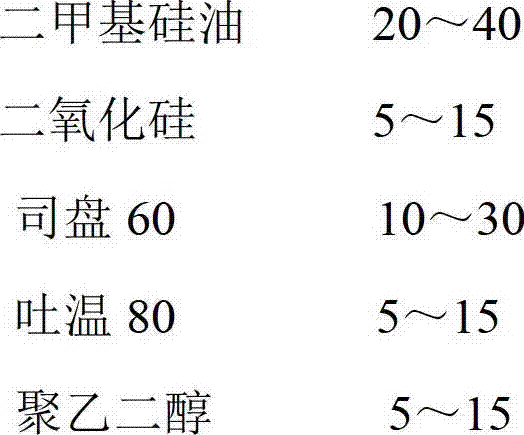

[0033] Solid defoamer, it is made up of the raw material component of following weight portion content:

[0034]

[0035] A kind of preparation technology of solid defoamer, it comprises the following steps:

[0036] (1) Ingredients: Mix the above-mentioned simethicone oil, silicon dioxide, Span 60, Tween 80, polyethylene glycol, and paraffin in the above parts by weight;

[0037] (2) Heating: Put the uniformly mixed materials into the reactor and heat up to 70°C, then keep the temperature constant for 2.5 hours;

[0038] (3) Discharging: discharge all the melted materials and cool them down;

[0039] (4) Molding: Press the cooled material into a round rod shape with a molding machine to obtain a solid defoamer.

Embodiment 2

[0041] Solid defoamer, it is made up of the raw material component of following weight portion content:

[0042]

[0043]

[0044] A kind of preparation technology of solid defoamer, it comprises the following steps:

[0045] (1) Ingredients: Mix the above-mentioned simethicone oil, silicon dioxide, Span 60, Tween 80, polyethylene glycol, and paraffin in the above parts by weight;

[0046] (2) Heating: Put the uniformly mixed materials into the reactor and heat up to 90°C, then keep the temperature constant for 1.5 hours;

[0047] (3) Discharging: discharge all the melted materials and cool them down;

[0048] (4) Molding: Press the cooled material into a round rod shape with a molding machine to obtain a solid defoamer.

Embodiment 3

[0050] Solid defoamer, it is made up of the raw material component of following weight portion content:

[0051]

[0052] A kind of preparation technology of solid defoamer, it comprises the following steps:

[0053] (1) Ingredients: Mix the above-mentioned simethicone oil, silicon dioxide, Span 60, Tween 80, polyethylene glycol, and paraffin in the above parts by weight;

[0054] (2) Heating: Put the uniformly mixed materials into the reactor and heat up to 80°C, then keep the temperature constant for 2 hours;

[0055] (3) Discharging: discharge all the melted materials and cool them down;

[0056] (4) Molding: Press the cooled material into a round rod shape with a molding machine to obtain a solid defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com