Elastic flexible glue and preparation method thereof

A soft and elastic technology, applied in the field of elastic materials, can solve the problems of poor high temperature and low temperature resistance, poor quality of toys, insufficient elasticity, etc., and achieve the effects of good adhesion and toughness, reducing density and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

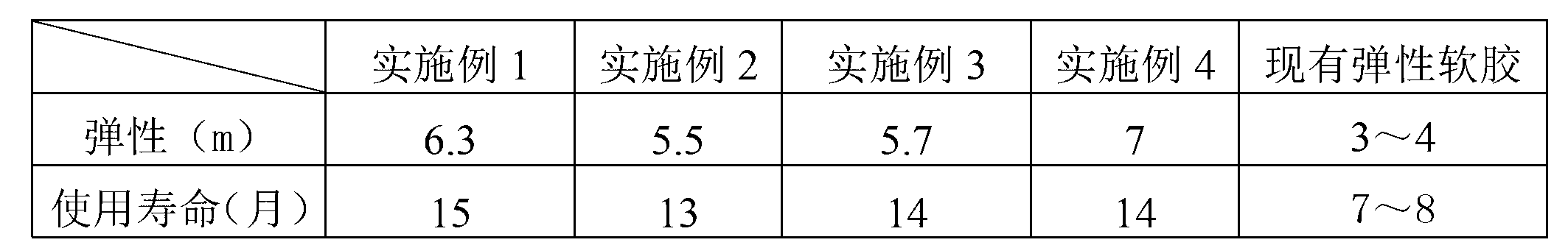

Examples

Embodiment 1

[0043] A kind of elastic soft rubber, the elastic soft rubber is made of the following components by weight percentage:

[0044] Simethicone oil: 21%;

[0045] Ultrafine calcium carbonate: 7%;

[0046] Boric acid: 1%;

[0047] TPR: 25%;

[0049] Silicone resin: 15%;

[0050] Bentonite: 8%;

[0051] Barium carbonate: 3%;

[0052] Linseed oil: 15%;

[0053] Erucamide: 3%.

[0054] The silicone resin is an organic silicon resin with a softening point between 80°C and 160°C.

[0055] The preparation method of this elastic soft glue comprises the following steps:

[0056] (1) Mix simethicone, TPR and linseed oil, and heat the mixture to 100°C, 100°C

[0057] (2) Heat the silicone resin to 160-165°C to melt it, then add it to the mixed liquid in step (1), stir for 2-5 hours, and keep the temperature of the mixed liquid between 100-115°C between. Choose a silicone resin with a softening point between 80 and 160°C. This silicone resin can be com...

Embodiment 2

[0062] A kind of elastic soft rubber, the elastic soft rubber is made of the following components by weight percentage:

[0063] Simethicone oil: 20%;

[0064] Ultrafine calcium carbonate: 7.4%;

[0065] Boric acid: 0.8%;

[0066] TPR: 23%;

[0068] Silicone resin: 16%;

[0069] Bentonite: 8.4%;

[0070] Barium carbonate: 3.2%;

[0071] Linseed oil: 16%;

[0072] Erucamide: 3.3%.

[0073] The silicone resin is an organic silicon resin with a softening point between 80°C and 160°C.

[0074] Preparation method The steps of Example 1 were repeated.

Embodiment 3

[0076] A kind of elastic soft rubber, the elastic soft rubber is made of the following components by weight percentage:

[0077] Simethicone: 22%;

[0078] Ultrafine calcium carbonate: 6.5%;

[0079] Boric acid: 0.9%;

[0080] TPR: 24%;

[0081] Zinc stearate: 2%;

[0082] Silicone: 14%;

[0083] Bentonite: 10%;

[0084] Barium carbonate: 2.8%;

[0085] Linseed oil: 15.2%;

[0086] Erucamide: 2.6%.

[0087] The silicone resin is an organic silicon resin with a softening point between 80°C and 160°C.

[0088] Preparation method The steps of Example 1 were repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com