Patents

Literature

42results about How to "Good bulk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disposable food preparation mats, cutting sheets, placemats, and the like

InactiveUS20060093788A1Decrease liquid permeable propertyGood bulkSynthetic resin layered productsCooking vesselsEngineeringFiber

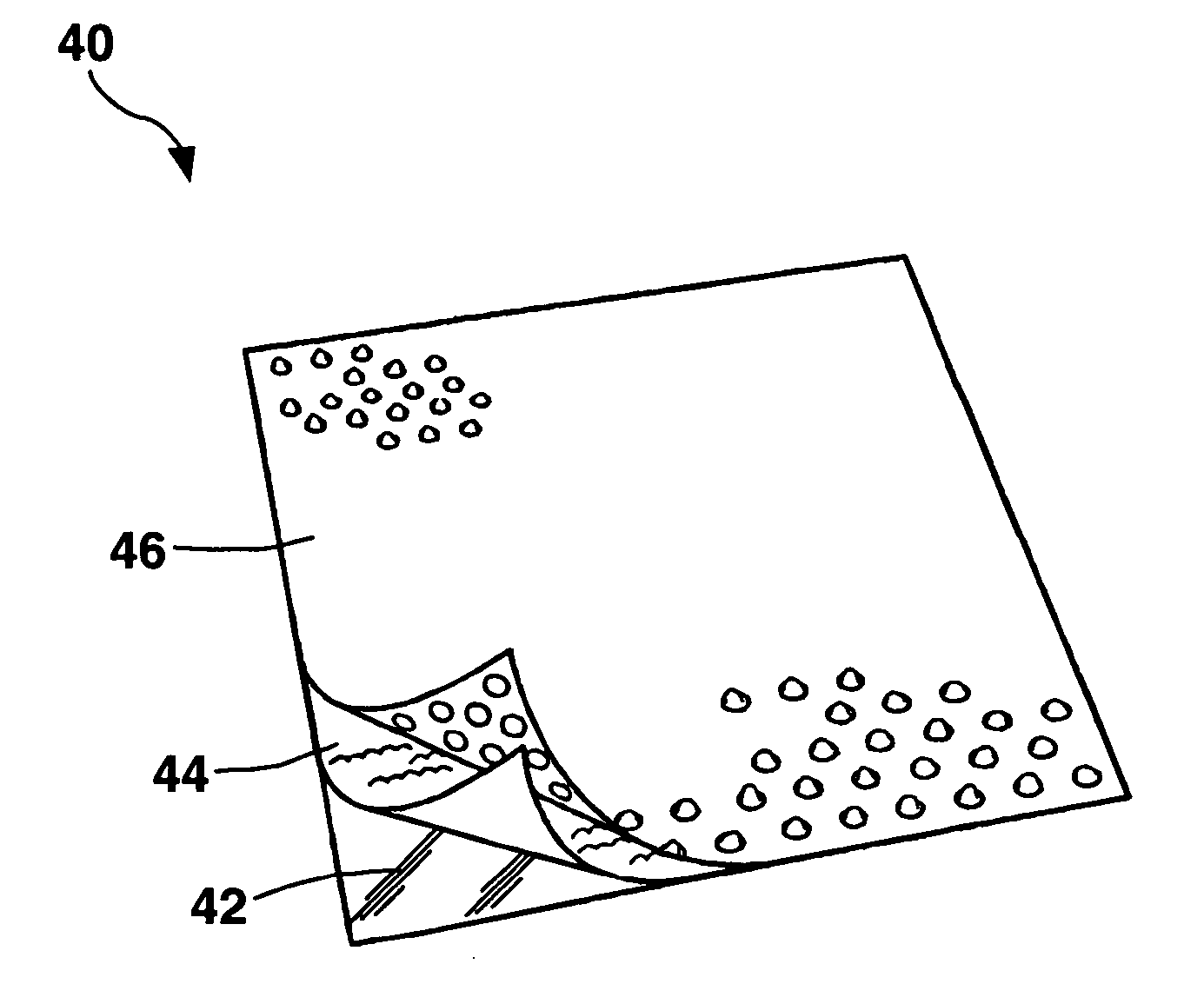

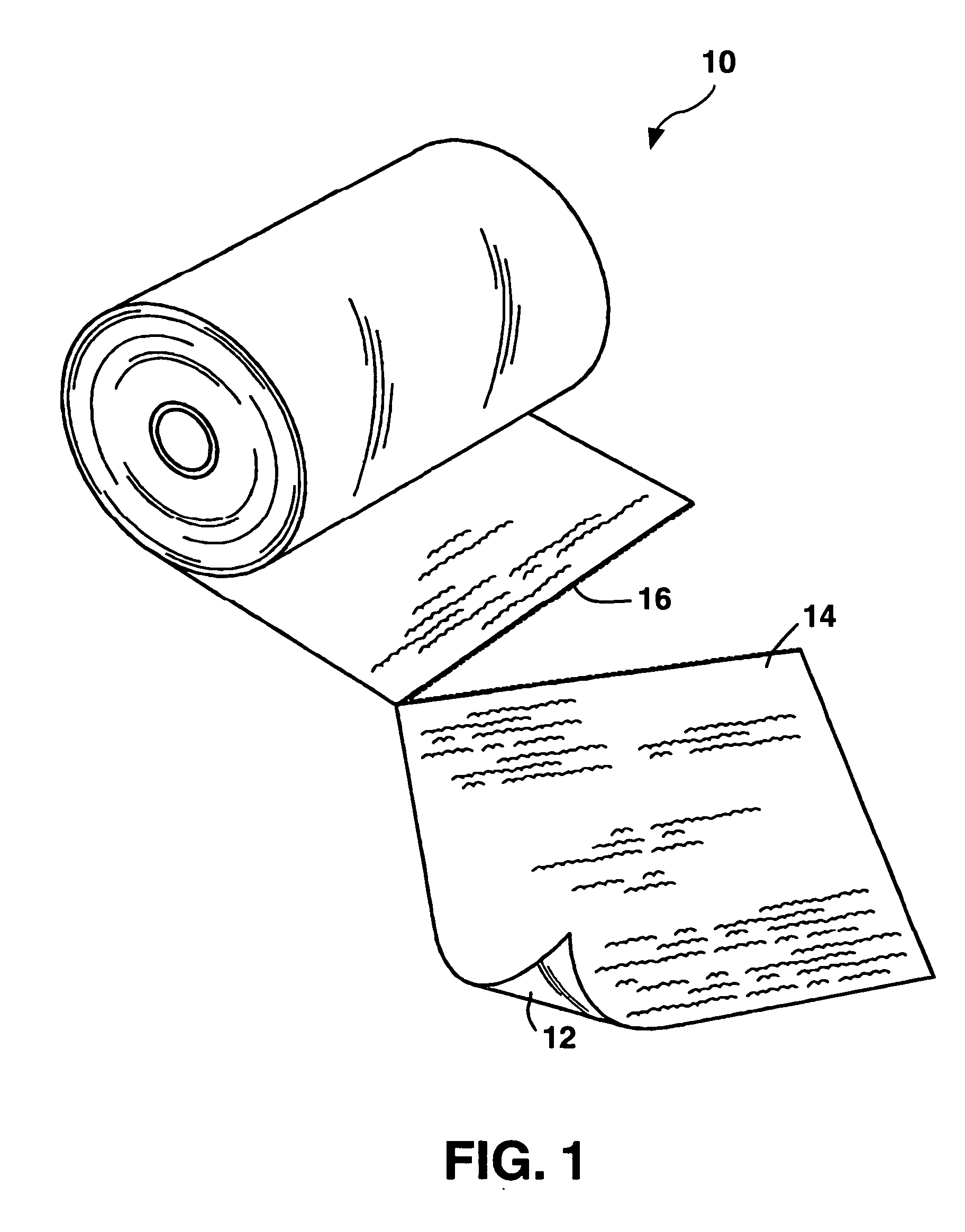

Disposable liquid absorbent mats are described. The mats generally include at least a liquid absorbent layer and a liquid impervious layer. The liquid absorbent layer may be made from a tissue web, a hydroentangled web, an airlaid web, a coform web, and the like. The liquid impervious layer, on the other hand, may comprise a meltspun web, a film, a hydroentangled web, or even a tissue web that has been treated with a sizing agent that renders the web resistant to fluid flow. In one embodiment, the mats can be made so as to have a relatively low caliper so that the mats can be spirally wound into a roll. In other embodiments, however, the mats may be packaged in a stacked arrangement. The mats have various uses and applications. For instance, the mats are well suited for use during food preparation. The mats are well suited to absorbing fluids while preventing the fluids from striking through the product. In some embodiments, the mats are also well suited to serve as an absorbent and cut resistant surface. An added benefit is the addition of a layer of polymer to the bottom side of the film to achieve non-slip feature to an absorbent and cut resistant food prep mat.

Owner:KIMBERLY-CLARK WORLDWIDE INC

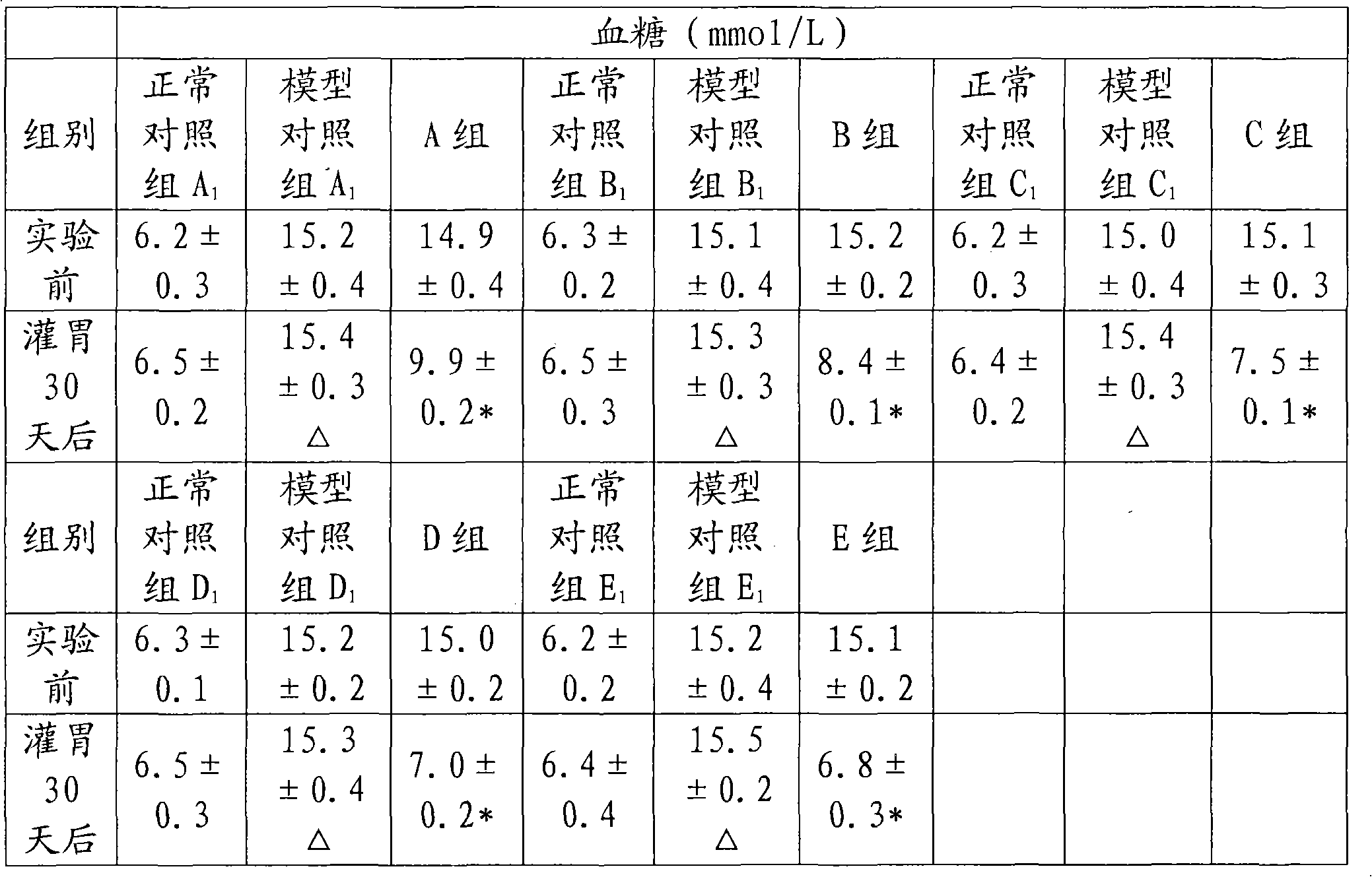

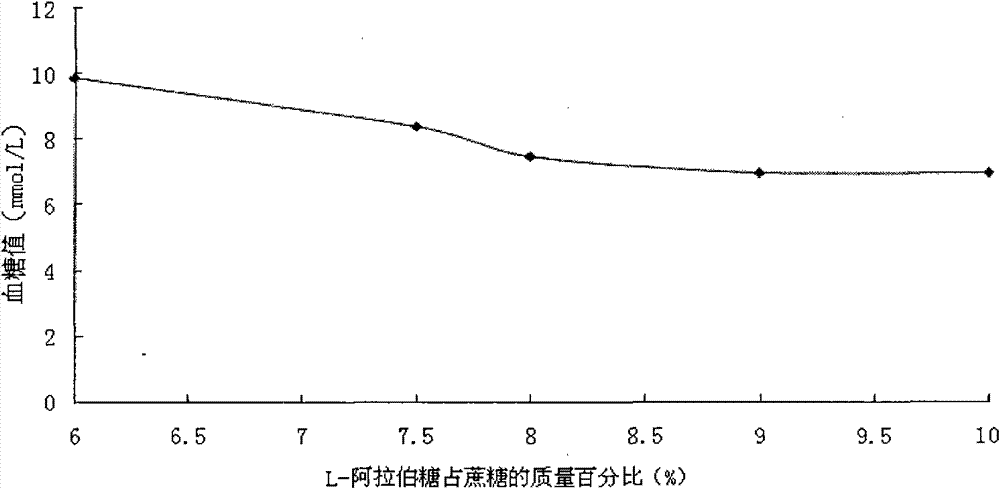

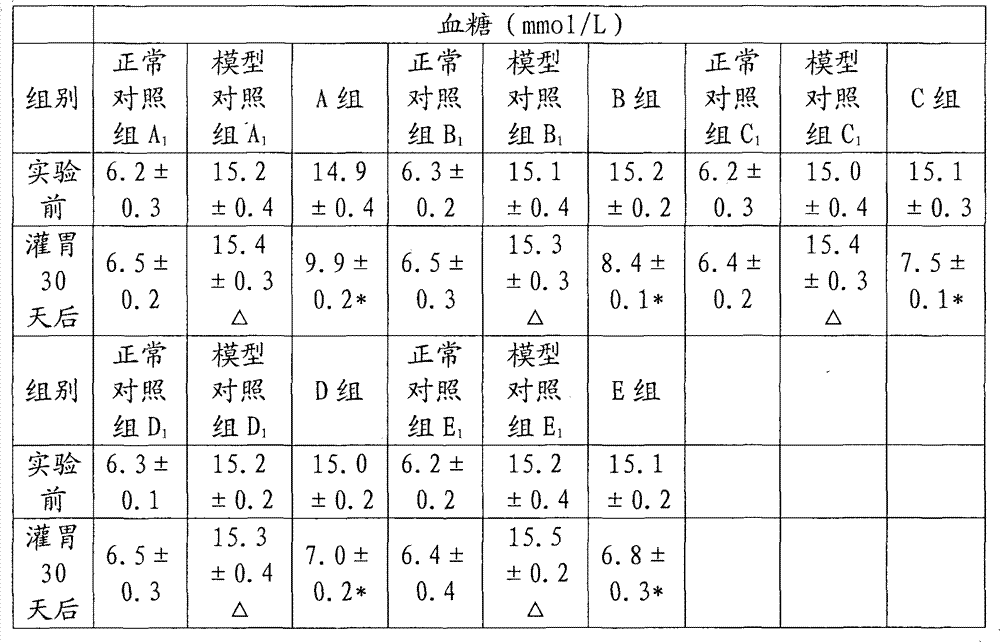

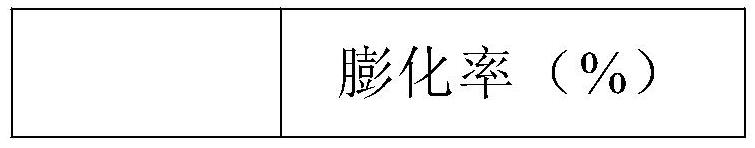

Ice cream

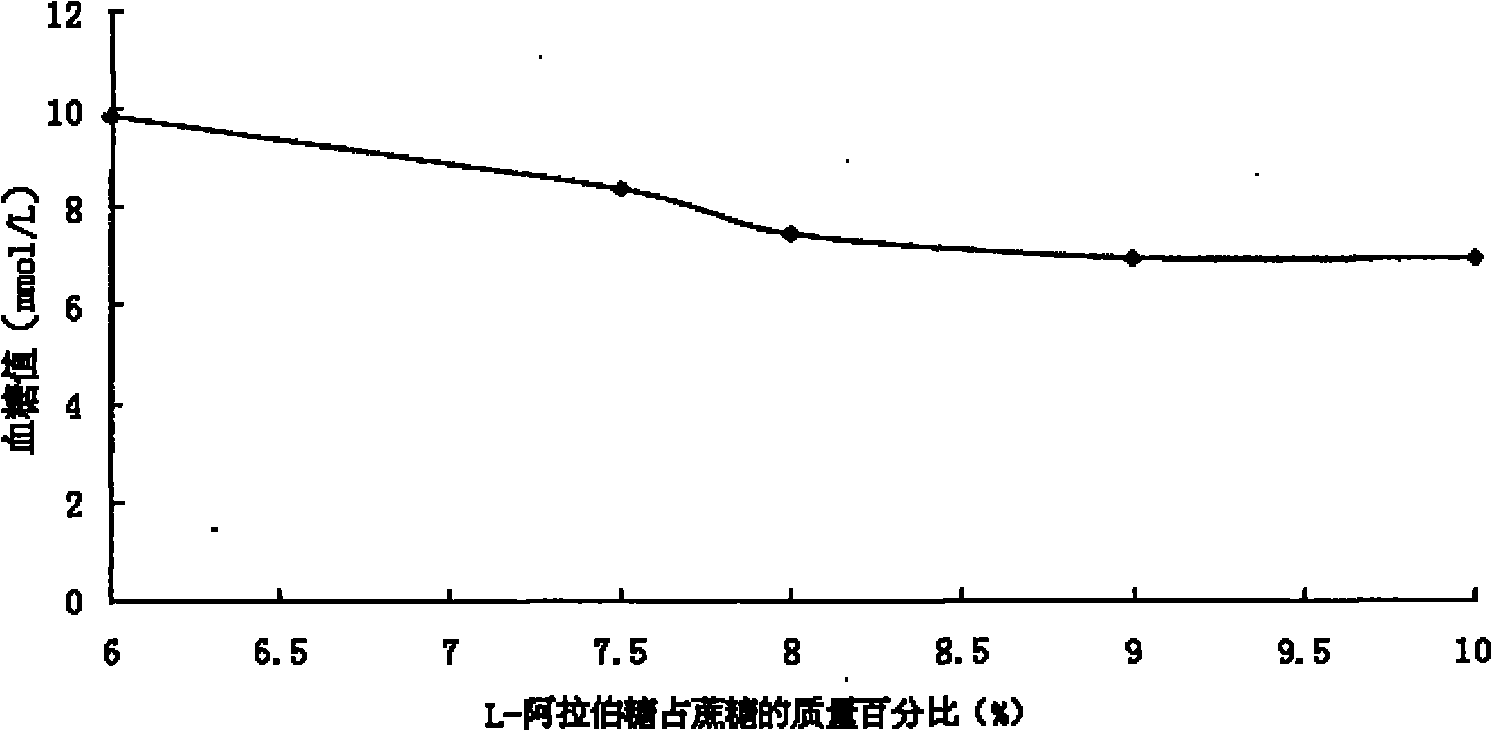

The invention discloses an ice cream which comprises the following substances by mass percent: 0.6-1.35% of L-arabinose, 15-20% of powdered milk, 10-15% of saccharose, 4-8% of single cream, 2-8% of vegetable fat, 0.5-5% of emulsifying agent, 0.1-0.5% of stabilizing agent and balance water. The prepared ice cream has the function of reducing blood sugar level, and the original flavor of the ice cream is not changed.

Owner:SHENGQUAN HEALTANG

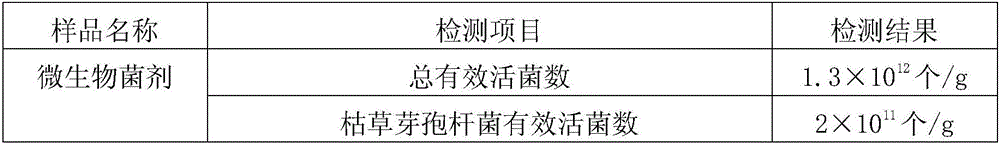

High-concentration microbial inoculum containing polyglutamic acid and preparation method and application of high-concentration microbial inoculum

InactiveCN106495951AImprove colonization rateStay hydratedCalcareous fertilisersMagnesium fertilisersFertilizerChemistry

The invention relates to a high-concentration microbial inoculum containing polyglutamic acid and a preparation method and application of the high-concentration microbial inoculum. The high-concentration microbial inoculum containing polyglutamic acid is prepared from mixed microbial fermentation powder, light calcium carbonate, polyglutamic acid, magnesium sulfate, boric acid and zinc sulfate. Polyglutamic acid is added in the microbial inoculum, since polyglutamic acid contains a large number of super hydrophilic groups, namely, carboxyl groups, therefore, the microbial inoculum can keep the soil moisture, improve the porosity and bulking intensity of the soil, improve the water-retention capacity and fertilizer-rentention capacity of the soil and enhance the phosphorus releasing ability and the potassium releasing ability, and at the same time, the microbial colonization rate can be greatly improved by adding polyglutamic acid in the microbial inoculum.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

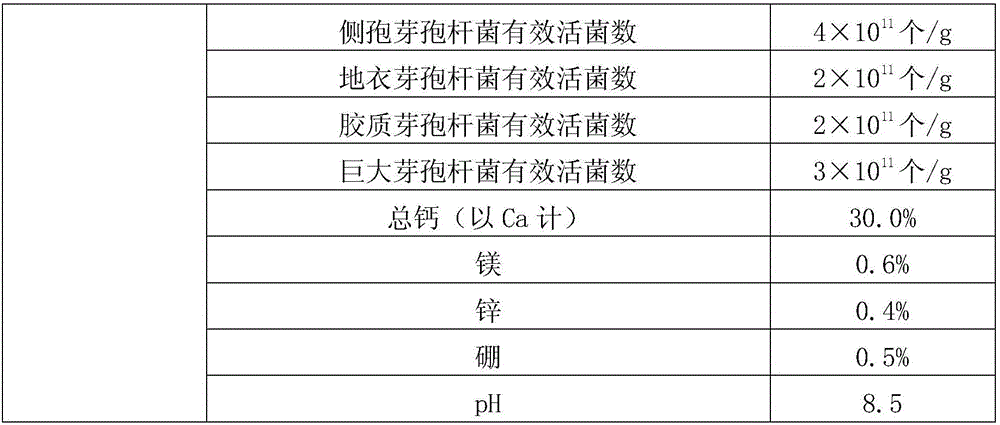

Elastic flexible glue and preparation method thereof

The invention relates to elastic material for preparing elastic and flexible toys, and particularly relates to elastic flexible glue. The elastic flexible glue comprises the following components by weight percentage: simethicone, super fine calcium carbonate, boric acid, TPR (thermal plastic rubber), zinc stearate, silicon resin, bentonite, barium carbonate, linseed oil and erucyl amide. The elastic flexible glue provided by the invention has good elasticity and proper bulking intensity; the surface of the elastic flexible glue is smooth, good in hand feel, adhesive, and tough, and has good aging resistance, high stability and long service life that is from 13 to 15 months; and the elastic and flexible toys made of the elastic flexible glue have high quality, and are playable and durable.

Owner:杜京财

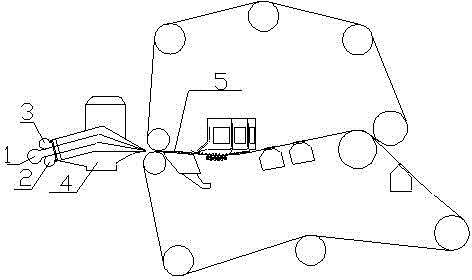

Rewinding roller structure used in toilet paper rewinding machine and rewinding method thereof

InactiveCN101712419ANo deformationGuaranteed reliabilityWebs handlingToilet paperPulp and paper industry

The invention provides a rewinding roller structure used in a toilet paper rewinding machine and a rewinding method thereof. The rewinding roller structure comprises an upper rewinding roller, a lower rewinding roller, a rear rewinding roller and a compression roller which are installed in sequence, wherein the compression roller has the same linear speed with the rear rewinding roller. The rewinding roller structure is characterized in that the compression roller is contacted with the rear rewinding roller in an opening and closing manner duly by the driving of a driving mechanism in the process of the rewinding of the base paper and the base paper being snapped when the upper rewinding roller speeds up. As the invention adopts the structure that the compression roller can be contacted with the rear rewinding roller in an opening and closing manner, the compression roller does not contact with the rear rewinding roller when the patterned toilet paper performs normal rewinding, thus ensuring that the patterned toilet paper is not deformed, leading the finished products thereof to possess good bulking intensity and flexibility, and ensuring good handfeel effect of users; when the upper rewinding roller performs paper snapping by speeding up, the compression roller is compressed with the rear rewinding roller duly, ensuring the accuracy and reliability of the cutting of the toilet paper and the continuity of the work; and the invention is also characterized by simple and smart structure and applicability and reliability.

Owner:陆德昌

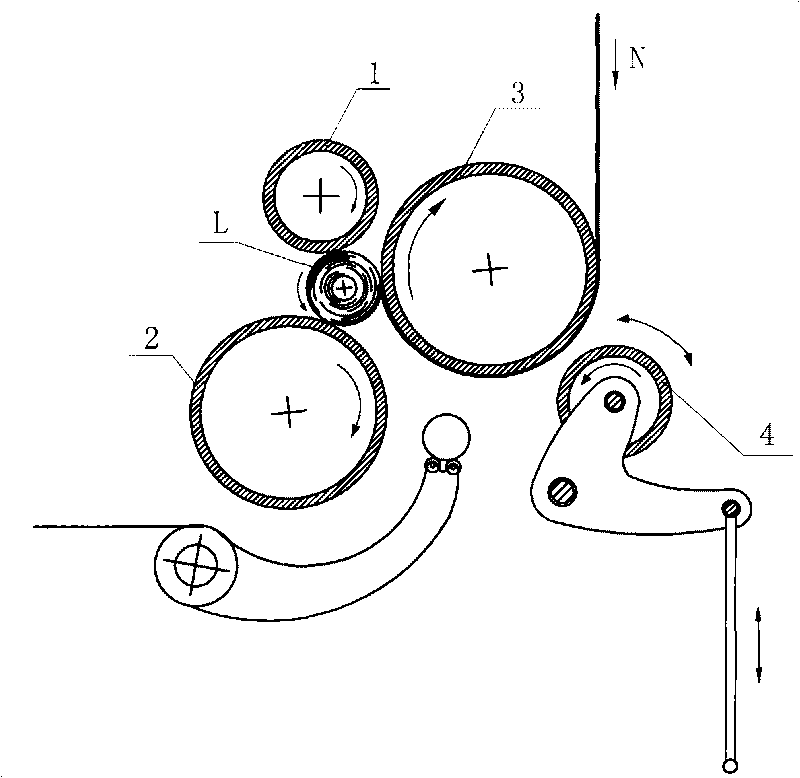

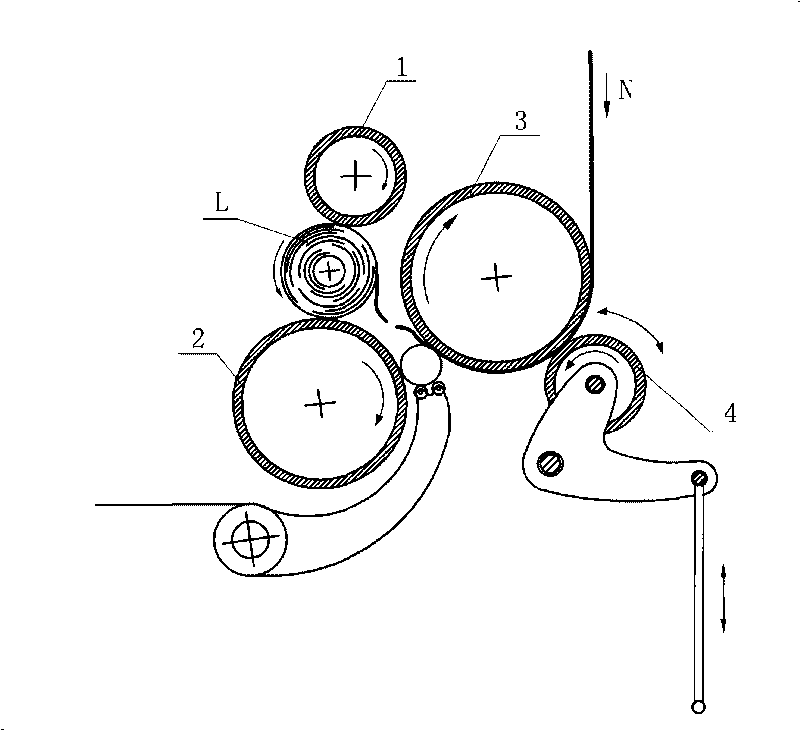

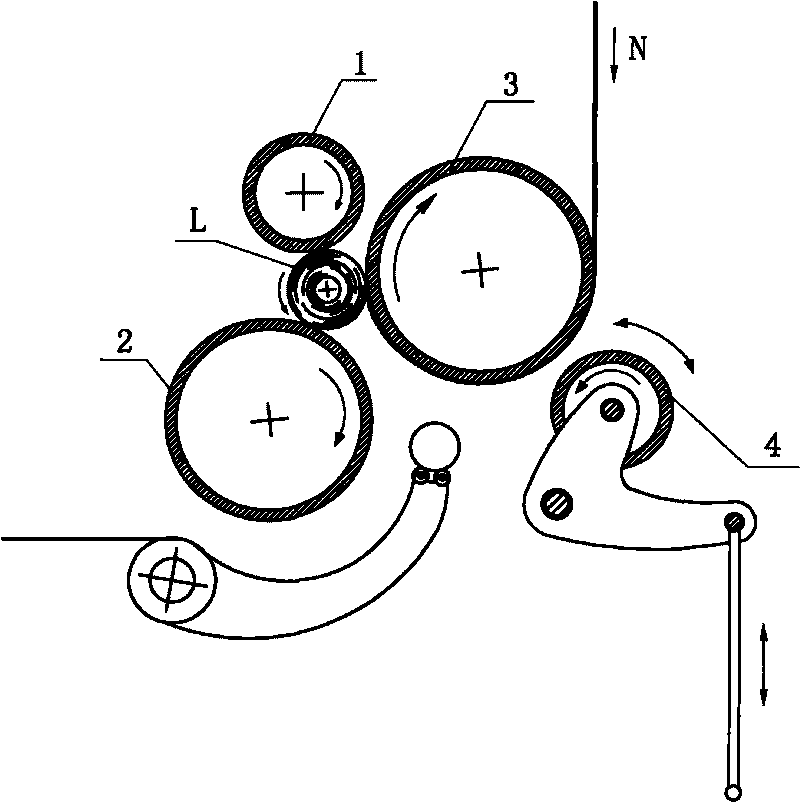

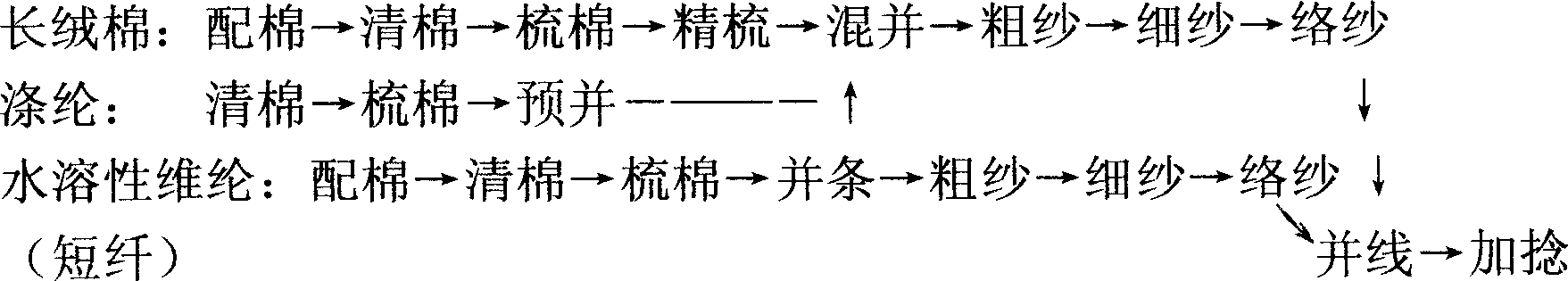

High water-absorption, high moisture-absorption, super-flexible blended tended tender twisted yarn and its production process

The invention discloses a high water absorption, high moisture absorption, supersoft blended weak twist yarn and its production process. The weak twist yarn is characterized by: comprising high moisture absorption polyester and cotton fibers blended into single yarns in a certain proportion, and the blended high moisture absorption The polyester and cotton fibers are merged with water-soluble yarns and twisted, wherein the weight ratio of high moisture-absorbing polyester, cotton fibers, and water-soluble yarns is 1:5-6:1-3. The characteristics of the production process are: firstly, the high moisture absorption polyester and cotton fibers are blended into single yarns, and the water-soluble fibers are purely spun into thinner single yarns, and then the cotton and polyester blended yarns are combined with water-soluble yarns and twisted. A weakly twisted yarn is obtained. Its beneficial effect is: it has the effect of high moisture absorption, high water absorption, super softness, good economy, and the quality and performance of the woven products are improved.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE +1

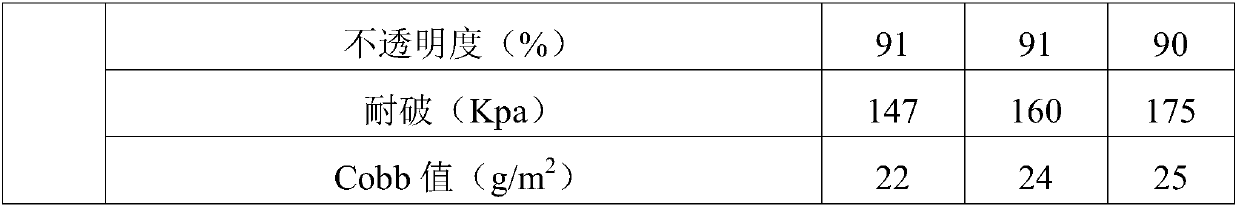

Production method of lightweight paper

InactiveCN109680536AHigh yieldHigh opacityWater-repelling agents additionChemical and mechanical pulp mixtureSulfatePaper manufacturing

The invention discloses a production method of lightweight paper. The production method comprises a wood pulp proportioning step and a mixing step. Needle BCMTP chemimechanical pulp and needle bleached chemical wood pulp are proportioned and pulped; a neutral sizing agent, cationic starch, cationic polyacrylamide and talcum powder are used; then a paper manufacturing process is performed. Importedneedle wood pulp and broadleaf wood bleached sulfate pulp are respectively pulped and blended, and various additives are added; the blend is conveyed into an approaching system for dehydration forming through a wet part and then is further dehydrated through a squeezing part; after pre-drying, semi-dry calendaring and surface sizing are performed, the product is dried through a drying part; the product is baked at low temperature, subjected to soft calendaring finishing and wound. First of all, high bulkiness is achieved, and the flatness and the tensile strength of paper are not affected, sothe production method is suitable for high-speed printing; secondly, no flourescent brightener is contained; compared with common coated paper, offset paper and lightweight paper, the lightweight paper produced according to the method is relatively dark and has a color close to the primary color of wood pulp, so that visual fatigue cannot be caused by long-time reading.

Owner:SHANDONG TIANYANG PAPER

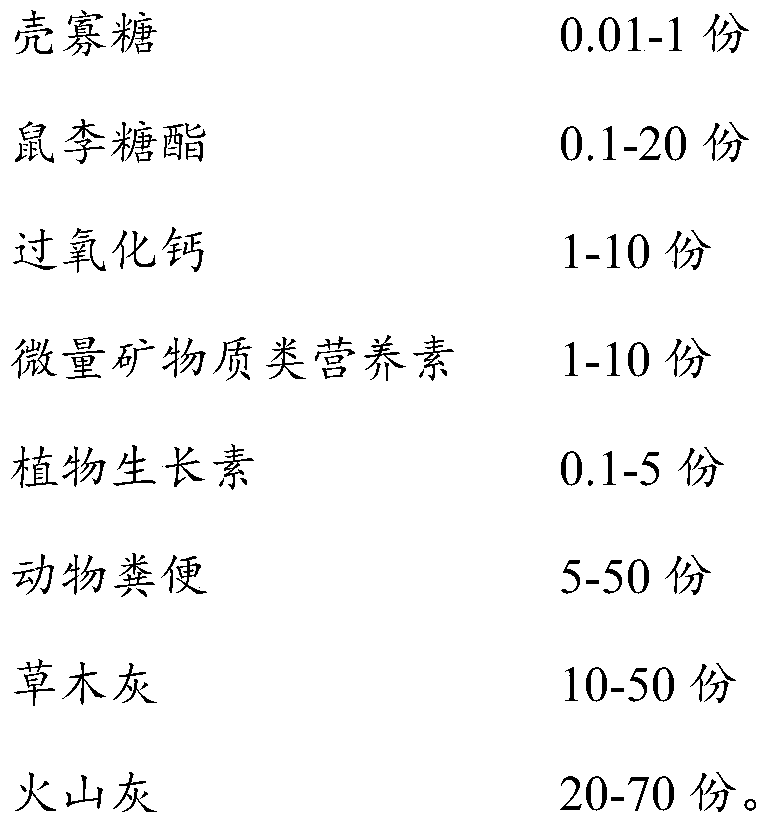

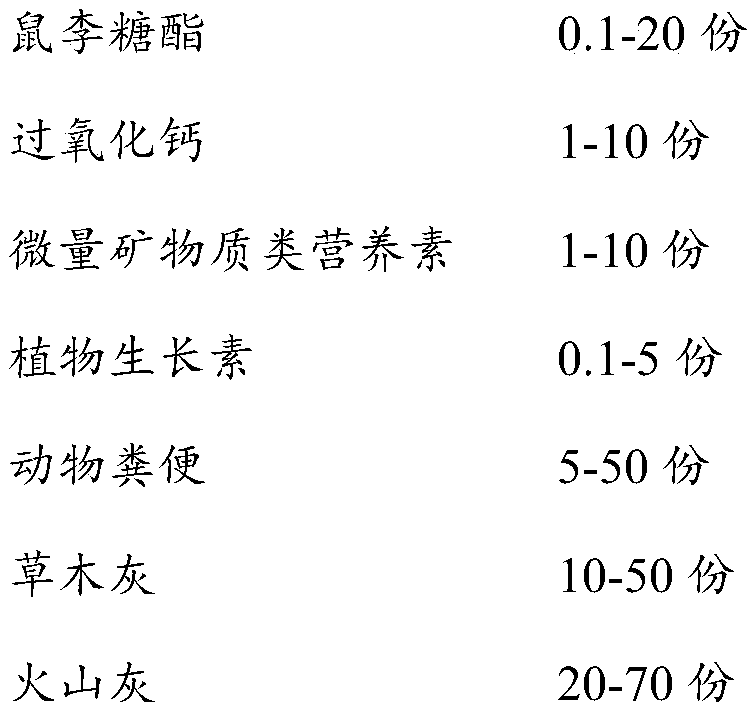

Soil conditioner and preparation method thereof

ActiveCN111303901AStay hydratedImproved structure formation abilityAgriculture tools and machinesOrganic fertilisersEcological environmentEdaphic

The invention belongs to the field of soil improvement, and discloses a soil conditioner. The soil conditioner is mainly composed of chitosan oligosaccharide, rhamnolipid, calcium peroxide, trace mineral nutrients, auxin, animal waste, plant ash and volcanic ash, wherein the polymerization degree of the chitosan oligosaccharide is 5-15, and the molecular weight of the chitosan oligosaccharide is 500-2000 Da. The soil conditioner has the advantages that (1) the bulkiness and porosity of heavy soil can be improved, soil structure forming ability is improved, the soil is activated, and soil hardening is avoided; (2) the soil conditioner can improve the micro-ecological environment of rhizosphere soil of crops, stimulate the development of root systems of the crops and enhance the stress resistance and disease resistance of the crops; (3) the soil conditioner can chelate heavy metal ions in the soil, activates the activity of nutrients in the soil, and facilitates nutrient absorption and utilization of crops; and (4) the soil conditioner can obviously improve crop yield, wherein corn yield can be increased by 9.6% at most, and a disease rate is less than 5%.

Owner:广东牧兴农业科技有限公司

Method for producing carbon-free and thermosensitive body paper by using large proportion of chemithermomechanical pulp

InactiveCN102877354ALow costGood bulkMachine wet endChemical and mechanical pulp mixtureDistribution systemPulp and paper industry

The invention discloses a method for producing a carbon-free and thermosensitive body paper by using large proportion of chemithermomechanical pulp, comprising the working procedures such as sizing, discharging pulp by a pulp flowing box, dewatering by a mesh part, dewatering in a squeezing way, previously drying, coating, carrying out post drying, carrying out press polish, and reeling. The raw materials used by the sizing working procedure are chemithermomechanical pulp and chemical pulp according to the proportion of (6-7.5):(3-3.5), enabling the chemithermomechanical pulp and the chemical pulp subjected to the sizing working procedure to be respectively flowed and transported to different parts of a pulp discharge working procedure of the pulp flowing box, the pulp flowing box in the pulp flowing box sizing working procedure is a three-layer pulp flowing box, the chemical pulp of the sizing working procedure is evenly distributed into an upper-layer pulp distribution system and a lower-layer pulp distribution system of the pulp flowing box, the chemithermomechanical pulp flows to a middle-layer pulp distribution system of the pulp flowing box, and the three-layer pulp flowing out of the pulp flowing box is dewatered by the mesh part. According to the method, not only can the fineness and the smoothness of the surface of a finished paper be guaranteed, but also the paper can not be faded and aged after being stored for a long term.

Owner:HENAN JIANGHE PAPER

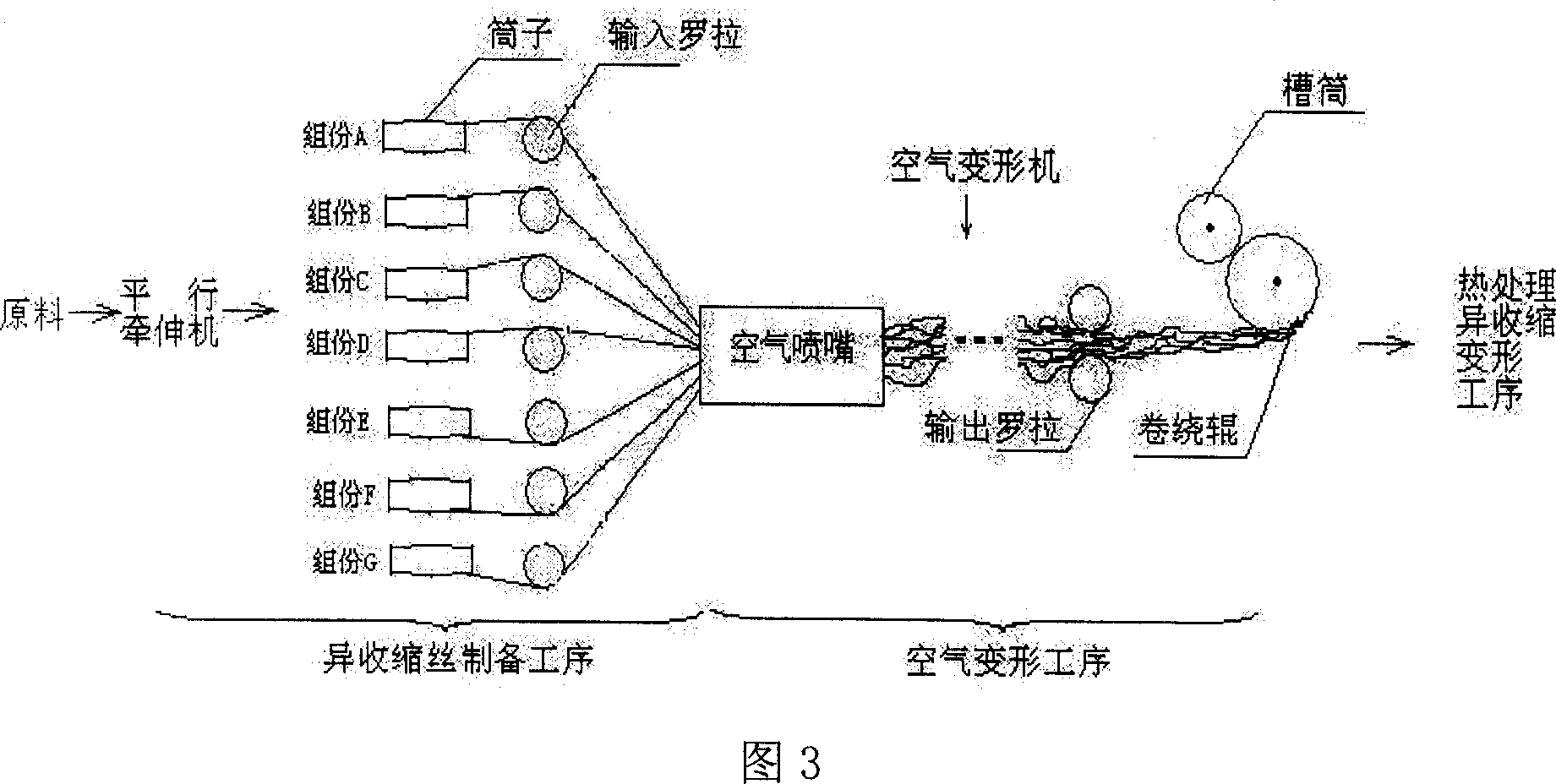

Chinlon 6 filament iso-shrinkage air multi-textured yarn processing method

This invention attribute to spin field, offer a process method of brocade 6 long silk strange shrink air multi- transfiguration yarn. Its trait is that processing method step include material choice, strange shrink silk preparation procedure, air transfiguration procedure, heat manage procedure strange shrink transfiguration procedure. The brocade 6 long silk strange shrink air multi- transfiguration yarn of this invention have many arrangements, wide inside and thin outside, straight inside and thin outside, exquisite yarn configuration, good puff, strong skin type feeling and so on excellences so that apply to spin imitated slap-up worsted.

Owner:DONGHUA UNIV

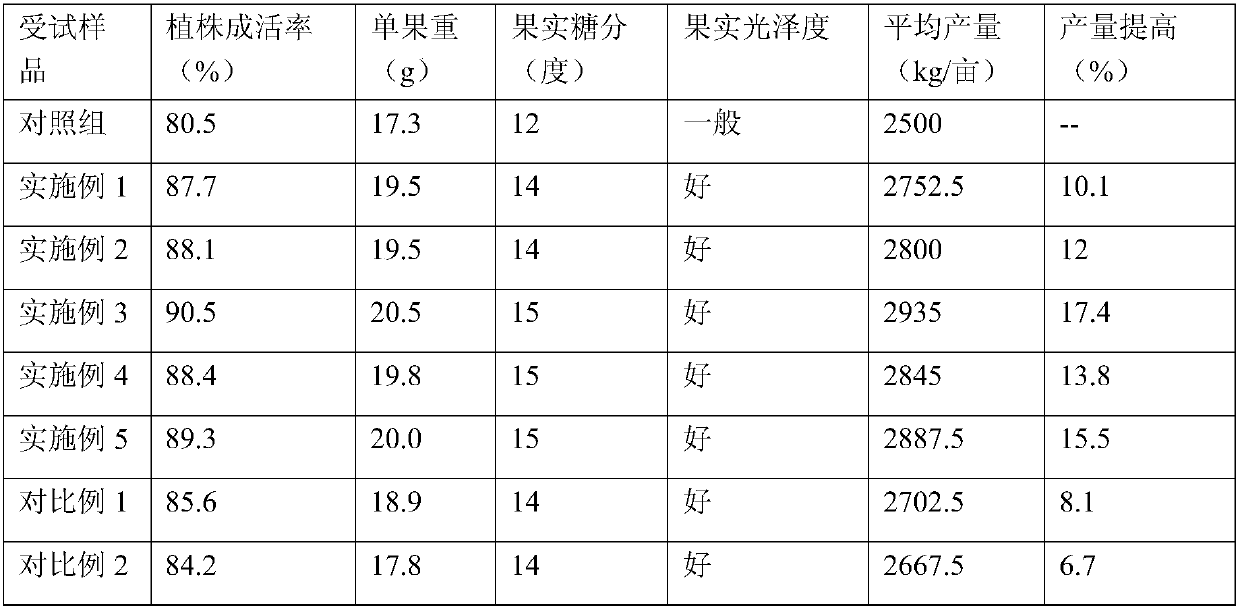

Special compound fertilizer containing LMW (low molecular weight) polyglutamic acid for strawberries and preparation method of special compound fertilizer

InactiveCN109095999APrevent diseaseStay hydratedMagnesium fertilisersDi-calcium phosphate fertilisersManganeseAmmonium Hydrogen Carbonate

The invention discloses special compound fertilizer containing LMW (low molecular weight) polyglutamic acid for strawberries and a preparation method of the special compound fertilizer. According to the method, the special compound fertilizer is prepared from LMW polyglutamic acid fermentation broth, urea, potassium sulfate, calcium hydrogen phosphate, ammonium hydrogen carbonate, magnesium sulfate, borax, zinc sulfate, manganese sulfate, ammonium molybdate, distillers' grains, plant ash and animal waste, and organic fertilizer is prepared from LMW polyglutamic acid cheated medium trace elements, the distillers' grains, the plant ash and the animal waste. The special compound fertilizer for the strawberries is rich in polyglutamic acid, trace elements and organic fertilizer, so that nutriment supply of the strawberry growing process is guaranteed, furthermore, the fertilizer has slow release feature, so that soil fertility can be improved, strawberry yield is greatly increased, meanwhile, the utilization rate of the fertilizer is increased, and the production cost is reduced.

Owner:SHANDONG FREDA BIOTECH

Acrylic fiber with antistatic property and preparation method thereof

InactiveCN109023617ASoft touchGood bulkElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentCarbon nanotubeAcrylic fibre

The invention relates to an acrylic fiber with an antistatic property and a preparation method thereof. According to the special preparation method, 15% of carbon nanotubes, 10% of carbon black and 75% of polyacrylonitrile by mass are mixed and then sequentially subjected to treatment with a pre-drawing machine, pre-drawing of the acrylic fiber, roving, spinning, impregnation, drying, winding andother procedures, and the acrylic fiber produced by means of the preparation method not only has the high antistatic property but also is low in price, unlikely to mildew and be damaged by borers andeasy to preserve and recover after washing and does not fall off from a connecting plate.

Owner:江苏三富纤维科技有限公司

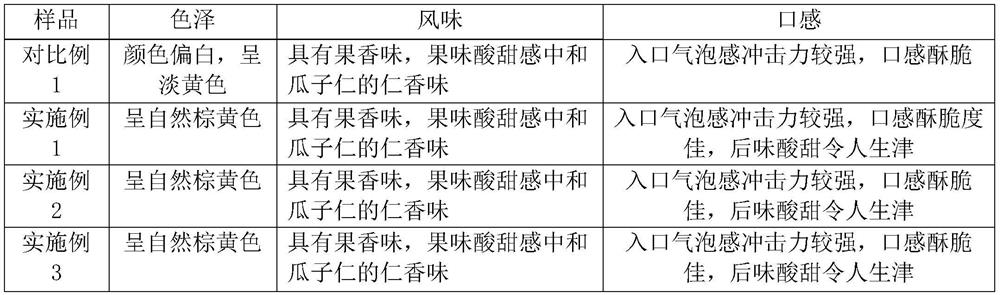

Bubble shelled melon seeds and production method thereof

The invention provides bubble shelled melon seeds and a production method thereof. Compared with the prior art, a technology for performing drying by utilizing the sublimation principle is that a dried substance is quickly frozen at a low temperature to form a compact, loose and porous network structure; then freeze-dried coated shelled melon seeds are uniformly baked by utilizing hot air flow ofa vibration bed, and the shelled melon seeds taste crisper and more delicious in cooperation with a coating flour raw material; and then seasoning powder maintains the stability of the bubble feelingby adopting an embedding technology. Moreover, the fruity flavor and the bubble feeling are combined to be applied to the baked shelled melon seeds for the first time, and then freeze-dried fruits areadded, so that the product is novel and unique in taste, and the popular refreshing taste is dominated.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS +1

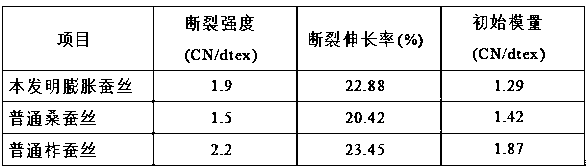

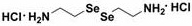

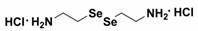

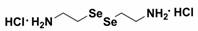

Expanded silk wadding quilt based on mulberry silk and preparation method of expanded silk wadding quilt

The invention discloses an expanded silk wadding quilt based on mulberry silk and a preparation method of the expanded silk wadding quilt. The preparation method comprises the following steps: addinga mixed solution of turmeric extract, acetic acid and carboxymethylcellulose into a degummed silk fiber solution, performing ultrasonic treatment, adding polyurea-formaldehyde and selenocysteine hydrochloride, and performing ultrasonic treatment; preparing perforated silk into silk floss pieces, and impregnating in an aqueous solution of amino polyethylene glycol so as to obtain treated silk flosspieces; putting the treated silk floss pieces into a rotatable closed container filled with a rupture disk, and expanding to obtain expanded wet silk floss pieces; dehydrating the expanded wet silk floss pieces, manually garneting, and drying to obtain expanded silkworm dried silk floss pieces; and combining and sewing the expanded silkworm dried silk floss pieces and treated tussah silk floss pieces, thereby obtaining the expanded silk wadding quilt. The porous expanded silk floss pieces with excellent service performance are successfully prepared, and the expanded silk wadding quilt has excellent antibacterial property and also has positive practical significance.

Owner:NANTONG LOVER APPL +1

Goose down based expanded silk wadding quilt and preparation method thereof

ActiveCN109730496AGood bulkImprove insulation effectUltrasonic/sonic fibre treatmentSilk filament obtainingPolyethylene glycolAqueous solution

The invention discloses a goose down based expanded silk wadding quilt and a preparation method thereof. The preparation method of the goose down based expanded silk wadding quilt comprises the following steps: adding a mixed solution of turmeric extract, vinegar and carboxymethylcellulose to a degummed silk fibroin solution for ultrasonic treatment, and adding polyureaformaldehyde and selenocystamine dihydrochloride for ultrasonic treatment; preparing silk wadding sheets from silk with holes and impregnating the silk wadding sheets in an amino polyethylene glycol aqueous solution to obtain treated silk wadding sheets; putting the treated silk wadding sheets in a rotatable closed container filled with a rupture film for expansion to obtain the expanded wet silk wadding sheets; dehydratingand unloosening the expanded wet silk wadding sheets manually and drying the same to obtain the expanded dry silk wadding sheets; and combining and sewing the expanded dry silk wadding sheets with thetreated goose down to obtain the expanded silk wadding quilt. The porous expanded silk wadding sheets which are excellent in wearability are prepared successfully and have good bacterial resistance,and the preparation method has realistic positive meaning.

Owner:NANTONG LOVER APPL

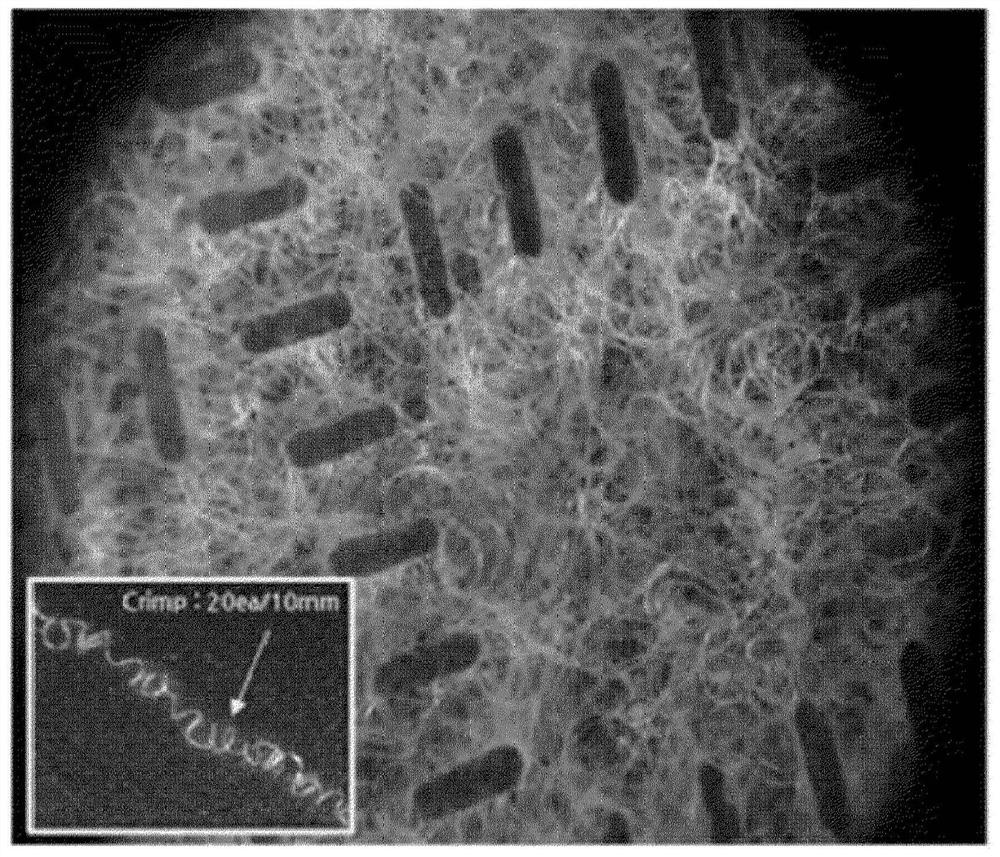

Non-woven fabric of crimped composite fiber and laminate thereof, and article including the laminate

PendingCN112074632AImproved shape stabilityGood flexibilityPersonal carePattern makingFiberPolymer science

There is provided a non-woven fabric of a crimped composite fiber including: a first propylene-based polymer and a second propylene-based polymer, wherein, in the first propylene-based polymer and thesecond propylene-based polymer, a melting point of the first propylene-based polymer is higher than a melting point of the second propylene-based polymer by 30 DEG C or more, a ratio (second polymer / first polymer) of melt flow rates (MFR: measurement temperature 230 DEG C, load 2.16 kg) of the first propylene-based polymer and the second propylene-based polymer is 1.7 or more, and a component ratio represented by a weight ratio of the first propylene-based polymer / the second propylene-based polymer is 50 / 50 to 10 / 90.

Owner:TORAY ADVANCED MATERIALS KOREA

Soybean cake making method

The invention discloses a soybean cake making method and belongs to the technical field of food processing. The method sequentially comprises the following steps: (1) alkaline water making: making alkaline water of which the PH value is 10-11 from rice and white hyacinths bean main stems; (2) raw material pre-treatment: soaking glutinous rice with Chinese honey locust, grinding into glutinous rice flour after air-drying, grinding soybeans into soybean pulp, and then mixing with the glutinous rice flour to make mashed soybean and rice ; (3) steaming: steaming the mashed soybean and rice into a soybean and rice paste; (4) blending: adding dasheen pulp and white sugar into the soybean and rice paste, uniformly agitating and mixing, and controlling the temperature of the soybean and rice paste at 55-65 DEG C; (5) soybean cake making: making into a soybean cake with the thickness of 4-6mm; (6) drying: first performing air-drying on the soybean cake until the water content is 4-6%, transferring into an un-ventilated room until the soybean cake is dried and packaging to obtain the soybean cake. The soybean cake made by the method is white and bouffant and can be stored for 530-550 days after being dried.

Owner:李仙蕊

Ice cream

The invention discloses an ice cream which comprises the following substances by mass percent: 0.6-1.35% of L-arabinose, 15-20% of powdered milk, 10-15% of saccharose, 4-8% of single cream, 2-8% of vegetable fat, 0.5-5% of emulsifying agent, 0.1-0.5% of stabilizing agent and balance water. The prepared ice cream has the function of reducing blood sugar level, and the original flavor of the ice cream is not changed.

Owner:SHENGQUAN HEALTANG CO LTD

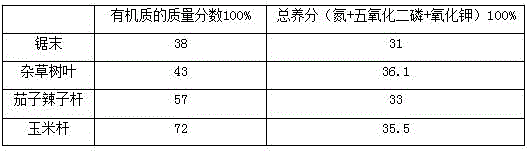

Preparation method of biomass filtering and purifying filter material and use method thereof

ActiveCN106621559AGood bulkMany fine spacesMembrane filtersFiltration separationFiber structureChemistry

The invention discloses a preparation method of a biomass filtering and purifying filter material and a use method thereof. The preparation method comprises the following steps of using crop straw and agricultural and forestry wastes as raw materials; crushing, screening, soaking, cleaning, whitening, loosening, rinsing, whitening, drying, and the like, so as to prepare the biomass filtering and purifying filter material. The biomass filtering and purifying filter material has the advantages that the biomass is whitened and loosened, so that multiple fine gaps in a biomass fiber structure are loose, impurities in a filtering matter are effectively contained, and the flowing drag on the filtering matter is reduced; the filtering property is good; by utilizing the particular physical structure, the corresponding additive is added to act on the filtering matter according to different function requirements of the filtering matter, so that the expected requirement and effect are reached; the biomass filtering and purifying filter material provided by the invention has the characteristics that the application range is wide; and is convenient to be processed into various filtering devices for purifying gas and liquid.

Owner:李旺达

Drying method of traditional Chinese medicine thick paste

InactiveCN103697665AExcellent quality control indicatorsGood bulkDrying machines with local agitationDrying machines with materials at restEngineeringHeat control

The invention relates to a drying method of traditional Chinese medicine thick paste. The method comprises the steps that traditional Chinese medicine extract to be dried is concentrated into thick paste with relative density of above 1.10; the thick paste is paved into a dry container whose upper part is irradiated by light wave, and the thickness is controlled to be 2mm to 5mm; the container is vacuumized until the vacuum degree is above 0.6MPa; light wave irradiation is started to heat and dry the material for 45 minutes to 180 minutes, and a dry product is obtained. In addition, electric heating or steam heating is added at a lower part, so as to dry the thick paste. Due to the fact that the adopted light wave can directly penetrate through the material, compared with a drying method which adopts electric heating or steam heating, according to the drying method of traditional Chinese medicine thick paste, the drying speed is higher, the heating uniformity is good, the defects of no easiness in microwave heating control and electromagnetic leakage are overcome, a metal structure is allowed to exist in the equipment during work, no-load heating and static heating of the equipment are allowed, particularly the auxiliary electric heating or steam method is added at the lower part, heating is carried out simultaneously up and down, the drying time is obviously shortened, and a significant effect in keeping heat sensitive components and easily oxidized components during a drying process is achieved. The operation and control are simple, and the large-scale production is suitable.

Owner:ZHEJIANG CONBA PHARMA

Nutritious ice cream powder and its production process

ActiveCN107494880BGood bulkStrong fragranceFrozen sweetsFood ingredient functionsBiotechnologyNutrition

The invention discloses nutritional ice cream powder and a production process thereof. According to the production process, the use amounts of L-arabinose and xylitol are regulated, so that the preservation time of the ice cream powder is prolonged, and meanwhile, ice cream prepared from the ice cream powder has relatively good bulking intensity; oleoresin is converted into solid instant powder by virtue of microencapsulated clove oil resin, so that the solid instant powder has good fluidity and dissolubility, has no dreg feel, is high in flavor preservation level and is relatively stable, and the shelf life is prolonged; and by virtue of a reasonable proportion of the components, the ice cream has the characteristics of cool, tastiness, strong fragrance and the like of traditional ice cream and has the functions of promoting digestion and appetite, clearing heat, refresh mind and the like. The production process comprises the following steps: (S1) weighing the raw materials as follows: skim milk powder, L-arabinose, xylitol, white granulated sugar, whey protein powder, yolk powder, a preservation agent, guar gum, clove oil resin and maltodextrin; and (S2) uniformly mixing the raw materials, and carrying out sterilization.

Owner:米开朗食品股份有限公司

Dacron textile fabric for indoor interior-lighting lamp box and manufacturing method of Dacron textile fabric

InactiveCN103266408AGood light transmissionIncrease elasticityFibre typesDuplicating/marking methodsYarnTransmittance

The invention discloses a Dacron textile fabric for an indoor interior-lighting lamp box and a manufacturing method of the Dacron textile fabric. For the Dacron textile fabric, Dacron draw-textured yarns are used as raw materials, the organization structure is GB3:10 12 11 and GB2:10 34 11 or GB3: 10 01 11 and GB2: 10 45 11, and light transmittance is larger than or equal to 20%. The manufacturing method of the Dacron textile fabric includes steps of (1) selecting the Dacron draw-textured yarns as raw materials, and customizing an organization structure cam; (2) knitting warps and fabricating; (3) washing, degreasing and bleaching gray fabric; (4) forming at high temperature of 210 DEG C for 40-50 seconds; and (5) inspecting and reeling to obtain finished products. The Dacron textile fabric is environment-friendly for picture printing, free of color fading, foldable and easy to carry and mount. Light transmittance is higher than 20%, and shapes of light sources can be shaded by the Dacron textile fabric with good density. Further, the Dacron textile fabric is suitable for indoor interior-lighting lamp boxes.

Owner:HAINING TIANCHENG WARP KNITTING FABRIC

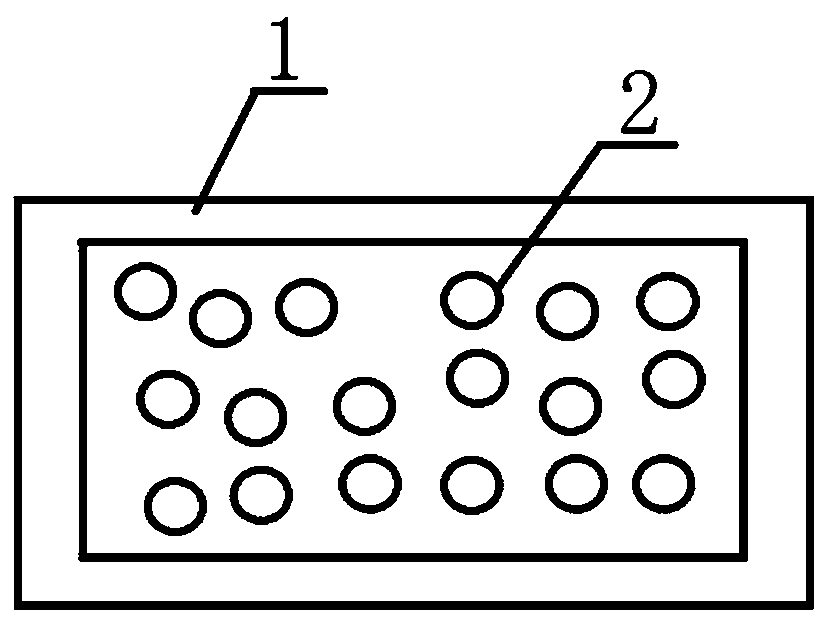

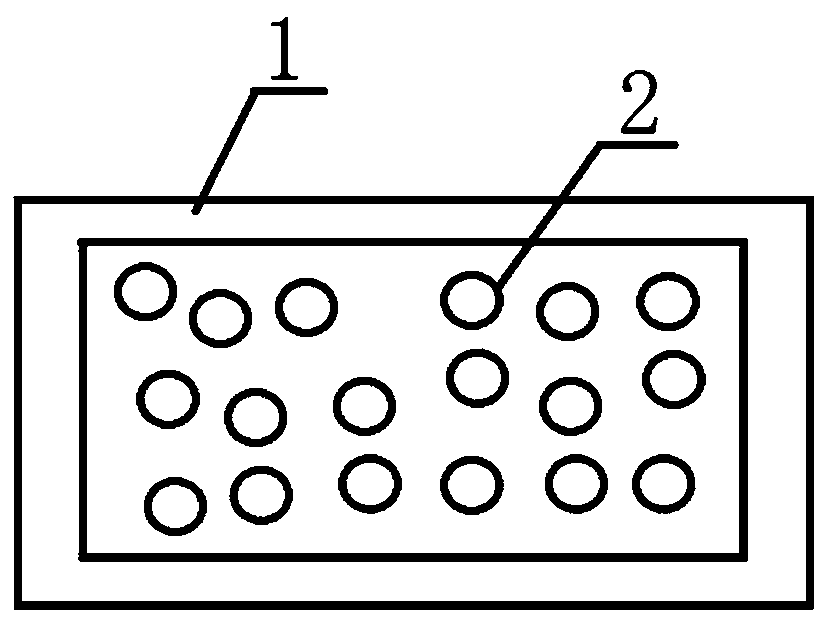

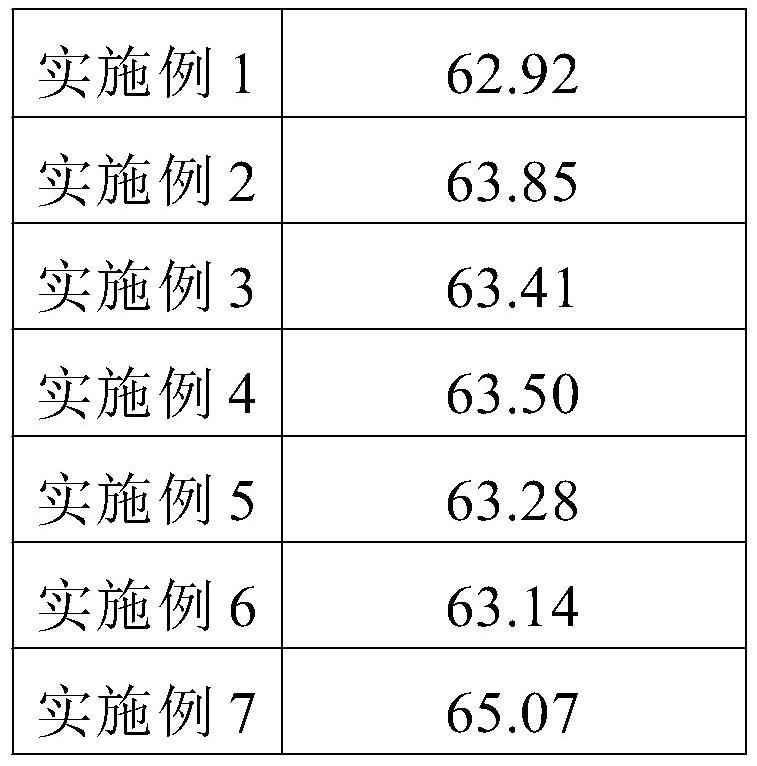

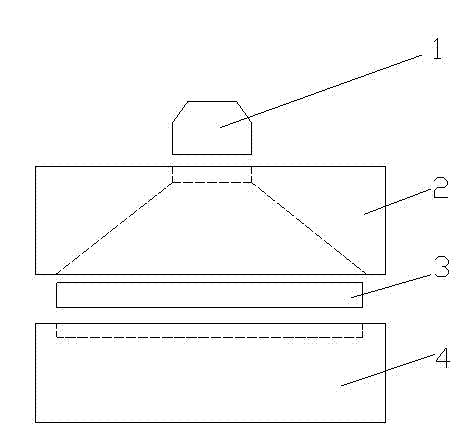

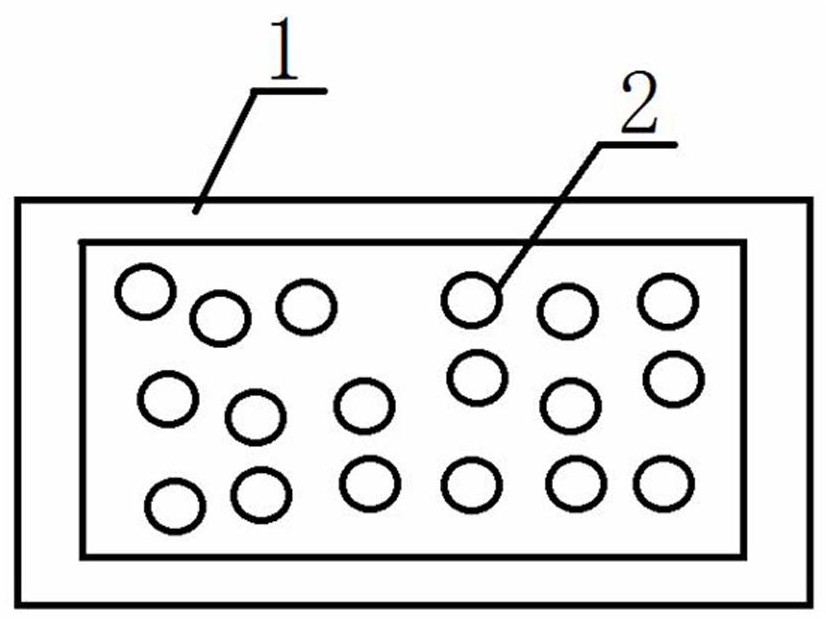

Composite special-shaped spinning device for producing high-brightness high-resilience terylene BCF (Bulked Continuous Filament)

The invention discloses a composite special-shaped spinning device for producing a high-brightness high-resilience terylene BCF (Bulked Continuous Filament). The composite special-shaped spinning device comprises a shell, a filter screen, a spinning plate, a washer and a fastening piece, wherein the spinning plate and the filter screen are fixed in the shell through the fastener; the washer is embedded into the melt inlet of the shell; and the spinning plate is provided with a spinning hole. The composite special-shaped spinning device is characterized in that: the spinning hole is trefoiled; the width of the leaf top of each leaf of a trefoil is smaller than that of each leaf root; both sides of each leaf intersect with each other on an elongation line, so that an included angle is formed; the included angle is 10-11 degrees; and the length of each leaf is 0.8-1.1 millimeters. The spinning device is easy and convenient to clean, assemble and produce, and the product terylene BCF has the advantage of high bulkiness and the characteristic of high brightness. A fabric business carpet has high covering performance, bright color and luster, bright color and high resilience, and a high-grade novel fiber material is provided for the business carpet.

Owner:JIANGSU HAOYI TEXTILE TECH

Ice cream and preparation technology thereof

The invention relates to an ice cream and a preparation technology thereof, and particularly provides the ice cream. The ice cream comprises the following components of 10-30 parts by weight of milk powder, 3-10 parts by weight of cream, 3-6 parts by weight of plant fat, 5-8 parts by weight of cane sugar, 3-6 parts by weight of levulose, 0.3-2 parts by weight of L-arabinose, 0.5-4 parts by weightof xylan, 0.5-2 parts by weight of trehalose, 1-4 parts by weight of an emulsifying agent, 0.5-2 parts by weight of a stabilizing agent and 40-60 parts of water. The ice cream is good in bulkiness, appropriate in sugariness, and smooth in mouth feel rather than greasy, and has favorable market prospects, and industrialized production is easy to realize.

Owner:益家元品实业(厦门)有限公司

Flat belly yarn and preparation method thereof

The invention relates to a flat belly yarn and a preparation method thereof, and the method comprises the steps of mixing cashmere core thread and terylene ornamental thread in a blending ratio of 0.97:1, and then performing the procedures of going through a strip mixing machine-two needle-three needle-flyer frame-spinning machine-automatic spooler-two-for-one twister-reeled yarn in order. According to the invention, the prepared flat belly yarn has the advantages of good bulkiness, hard agglomeration, low price, no mildew, free from insects, and easy preservation; and the yarn can be recovered easily after washing and won't fall off when in touch with a board.

Owner:JURONG RUNLONG TEXTILE CO LTD

Special polyglutamic acid-containing fertilizer for sweet potatoes and preparation method of special polyglutamic acid-containing fertilizer

PendingCN114736079AThe fertilizer making process is simpleFertilization method is simpleSuperphosphatesBio-organic fraction processingPolyaspartic acidRoot growth

The invention provides a special polyglutamic acid-containing fertilizer for sweet potatoes. The special polyglutamic acid-containing fertilizer is prepared from the following raw materials in parts by weight: 0.1-5 parts of polyglutamic acid fermentation liquor, 1-5 parts of polyaspartic acid, 0.1-5 parts of glutathione, 10-25 parts of nitrogen fertilizer, 10-30 parts of phosphate fertilizer, 15-35 parts of potassium fertilizer, 1-15 parts of magnesium fertilizer, 1-10 parts of zinc fertilizer, 0.5-5 parts of manganese fertilizer and 0.5-5 parts of boron fertilizer. The polyglutamic acid-containing special fertilizer for sweet potatoes has the advantages of strong water retention capacity and high chemical fertilizer utilization rate, can enrich nutritional ingredients, promotes crop root growth and protein synthesis, and greatly improves the yield of sweet potatoes when being used for sweet potato planting.

Owner:北京化工大学秦皇岛环渤海生物产业研究院

Preparation method of biological adsorbent for separating sodium cyclamate

InactiveCN111545178AImprove abilitiesHigh selectivityOrganic chemistryOrganic compound preparationFiberSodium cyclamate

The invention discloses a preparation method of a biological adsorbent for separating sodium cyclamate, which is characterized by comprising the following steps: pretreating alginate fibers by using ammonium carbonate and urea to obtain pretreated alginate fibers; then, using mercaptoacetic acid and sodium sulfide for carrying out surface modification on the pre-treated alginate fibers under the sulfuric acid condition to obtain surface-modified alginate fibers; finally, in a reactor, adding 85-88% of deionized water and 7-10% of silver nitrate in percentage by mass, stirring for dissolving, adding 4-6% of surface modified alginate fiber, regulating the pH value to 2-3 with dilute nitric acid, soaking at room temperature for 24 hours, carrying out solid-liquid separation, washing with deionized water, and drying to obtain the biological adsorbent for separating sodium cyclamate. The adsorbing material has the advantages of selective adsorption on sodium cyclamate, good mechanical property, good chemical stability, high adsorption speed, easiness in elution and regeneration capacity.

Owner:UNIV OF JINAN

Expanded silk quilt based on mulberry silk and preparation method thereof

ActiveCN109730497BGood bulkImprove insulation effectPhysical treatmentBlanketCellulosePolymer science

The invention discloses an expanded silk wadding quilt based on mulberry silk and a preparation method of the expanded silk wadding quilt. The preparation method comprises the following steps: addinga mixed solution of turmeric extract, acetic acid and carboxymethylcellulose into a degummed silk fiber solution, performing ultrasonic treatment, adding polyurea-formaldehyde and selenocysteine hydrochloride, and performing ultrasonic treatment; preparing perforated silk into silk floss pieces, and impregnating in an aqueous solution of amino polyethylene glycol so as to obtain treated silk flosspieces; putting the treated silk floss pieces into a rotatable closed container filled with a rupture disk, and expanding to obtain expanded wet silk floss pieces; dehydrating the expanded wet silk floss pieces, manually garneting, and drying to obtain expanded silkworm dried silk floss pieces; and combining and sewing the expanded silkworm dried silk floss pieces and treated tussah silk floss pieces, thereby obtaining the expanded silk wadding quilt. The porous expanded silk floss pieces with excellent service performance are successfully prepared, and the expanded silk wadding quilt has excellent antibacterial property and also has positive practical significance.

Owner:NANTONG LOVER APPL +1

A kind of expanded silk floss sheet and preparation method thereof

ActiveCN109008499BGood bulkImprove insulation effectBiochemical fibre treatmentBlanketFiberCellulose

The invention discloses an expanded silk floss sheet and a preparation method therefor. The method comprises the following steps: (1), performing high-temperature and high-pressure degumming of cleaned silk to obtain degummed fibroin fiber solution; (2), adding the mixed solution of a turmeric extractive, acetic acid and carboxymethylcellulose to degummed fibroin fiber solution, performing the supersonic processing for 2-3 hours, adding polyurea formaldehyde and selenocystamine dihydrochloride, performing supersonic processing for 1-1.5 hours, performing dehydration and drying to obtain processed silk; (3), heating the processed silk under the temperature of 180 DEG C for 30 seconds, and heating the processed silk under the temperature of 210 DEG C for 20 seconds to obtain perforated silk,preparing a silk floss sheet through the perforated silk and then performing the dipping of amino polyethylene glycol aqueous solution to obtain a processed silk floss sheet; (4), putting the processed silk floss sheet into a rotatable sealed container with a blasting membrane for puffing, and performing glue spraying and drying to obtain an expanded silk floss sheet. According to the invention,the porous varicosity oak silk sheet with the good wearability is successfully prepared, and the antibacterial property is good, so the method is of positive realistic significance.

Owner:NANTONG LOVER APPL +1

A preparation method and application method of biomass filtration and purification filter material

ActiveCN106621559BGood bulkMany fine spacesMembrane filtersFiltration separationFiltrationProduct gas

The invention discloses a preparation method of a biomass filtering and purifying filter material and a use method thereof. The preparation method comprises the following steps of using crop straw and agricultural and forestry wastes as raw materials; crushing, screening, soaking, cleaning, whitening, loosening, rinsing, whitening, drying, and the like, so as to prepare the biomass filtering and purifying filter material. The biomass filtering and purifying filter material has the advantages that the biomass is whitened and loosened, so that multiple fine gaps in a biomass fiber structure are loose, impurities in a filtering matter are effectively contained, and the flowing drag on the filtering matter is reduced; the filtering property is good; by utilizing the particular physical structure, the corresponding additive is added to act on the filtering matter according to different function requirements of the filtering matter, so that the expected requirement and effect are reached; the biomass filtering and purifying filter material provided by the invention has the characteristics that the application range is wide; and is convenient to be processed into various filtering devices for purifying gas and liquid.

Owner:李旺达

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com